Page 1

POINT I/O Thermocouple and RTD

Modules

Catalog Numbers 1734-IR2, 1734-IR2E and 1734-IT2I

User Manual

Page 2

2

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://literature.rockwellautomation.com

available from your local Rockwell

) describes

some important differences between solid state equipment and hard-wired

electromechanical devices. Because of this difference, and also because of the wide variety

of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular installation,

Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on

the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission

of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety

considerations.

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, Rockwell Automation, POINT I/O, RSLinx, RSLogix 5000, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1734-UM004F-EN-E - December 2012

Page 3

Summary of Changes

About POINT I/O Modules

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

New and Revised Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Change Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preface

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Module Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Selecting a Module Input Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Communicating with Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Default Data Map for the Thermocouple Input Module

(catalog number 1734-IT2I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Default Data Map for the RTD Input Module

(catalog numbers 1734-IR2, and 1734-IR2E). . . . . . . . . . . . . . . . . 13

Data Format (1734-IT2I, 1734-IR2, and 1734-IR2E modules) . . 14

Use Module Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overrange Alarm (1734-IT2I, 1734-IR2, and

1734-IR2E modules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Underrange Alarm (1734-IT2I, 1734-IR2, and

1734-IR2E modules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Level Alarms (1734-IT2I, 1734-IR2, and

1734-IR2E modules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Open-wire Alarm (1734-IT2I, 1734-IR2, and

1734-IR2E modules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cold Junction Compensation (1734-IT2I module) . . . . . . . . . . . . . . . 16

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2

Install the Module

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preventing Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . 17

Environment and Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install the Mounting Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install the Removable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . 21

Remove a Mounting Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wire the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3

Configure Your Module

iii Publication 1734-UM004F-EN-E - December 2012

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Commissioning a Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 4

iv Table of Contents

Using the RSNetWorx Commissioning Tool. . . . . . . . . . . . . . . . . 26

Use Sequential Auto Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Use Third Party Configuration Software . . . . . . . . . . . . . . . . . . . . 27

Add the Adapter to Your Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Add I/O Modules to Your Network POINTBus. . . . . . . . . . . . . 28

Set the Thermocouple Input Module Parameters Using RSNetWorx 30

Configure Your Thermocouple Input Module. . . . . . . . . . . . . . . . . . . 32

Basic Set-up Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Advanced Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Advanced Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Set the RTD Input Module Parameters Using RSNetWorx . . . . . . . . 37

Configure Your RTD Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Basic Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Advanced Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Basic Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Advanced Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Check I/O Status and View the EDS File . . . . . . . . . . . . . . . . . . . . . . 44

1734-IT2I module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1734-IR2 and 1734-IR2E modules. . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Calibrate Your Module

Troubleshoot the Module

Configure Modules in

RSLogix 5000 Software

Chapter 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

When and How to Calibrate Your Module . . . . . . . . . . . . . . . . . . . . . 47

Calibration Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Tools and Equipment Required to Calibrate

Your Thermocouple Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Calibrate the Thermocouple Input Module . . . . . . . . . . . . . . . . . . . . . 48

Access Calibration Parameters in RSNetWorx . . . . . . . . . . . . . . . 49

Input (mV) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cold Junction Compensation Calibration . . . . . . . . . . . . . . . . . . . 53

Tools and Equipment Required to Calibrate

Your RTD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Calibrate the RTD Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Interpret the Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix A

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Publication 1734-UM004F-EN-E - December 2012

Page 5

Calculate Absolute Accuracy and

Accuracy Drift

Index

Table of Contents v

Understanding Data, Connection, and

Communication Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Configure Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Use the Help Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Working with Dialogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Work with Dialogs for RTD Modules . . . . . . . . . . . . . . . . . . . . . . 65

Work with Dialogs for Thermocouple Modules . . . . . . . . . . . . . . 70

Appendix B

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Calculate with Formulas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Absolute Accuracy Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Accuracy Drift Formula. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Publication 1734-UM004F-EN-E - December 2012

Page 6

vi Table of Contents

Notes:

Publication 1734-UM004F-EN-E - December 2012

Page 7

Summary of Changes

This publication contains new and revised information not in the last release.

New and Revised Information

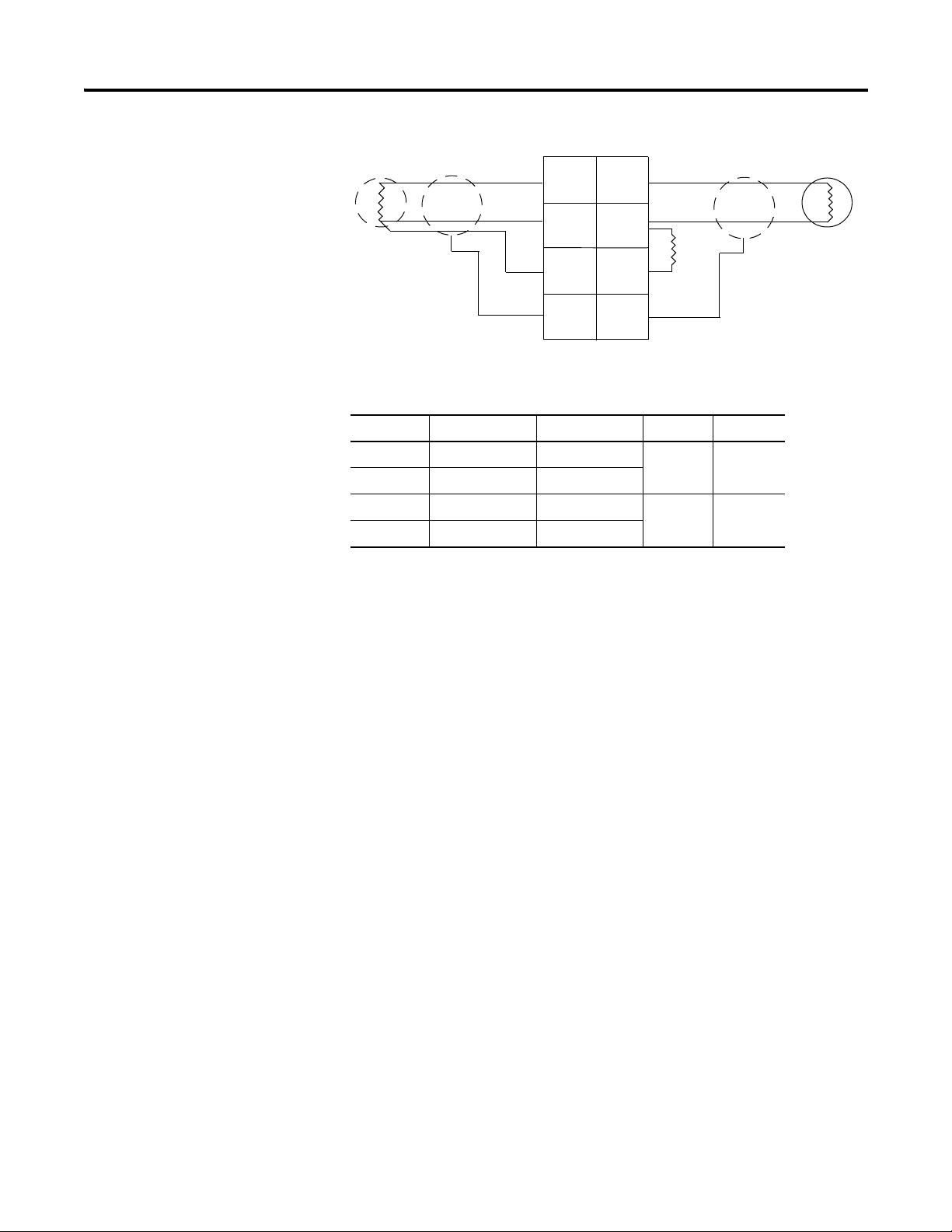

See the table for a summary of the major changes in this manual.

Revised to include Chapter

New Appendix on Absolute Accuracy and Accuracy Drift calculation Appendix B

Change Bars

Change bars (as shown with this paragraph) show the areas in this manual that

differ from previous editions and indicate the addition of new or revised

information.

vii Publication 1734-UM004F-EN-E - December 2012

Page 8

viii Summary of Changes

Notes:

Publication 1734-UM004F-EN-E - December 2012

Page 9

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this Manual

Purpose of this Manual

You must be able to use your selected configuration software to set up and

calibrate these modules. You must have the capability to download and use

files.

We assume you know how to do this in this manual. If you do not, refer to

your software user manuals or online help before attempting to use these

modules.

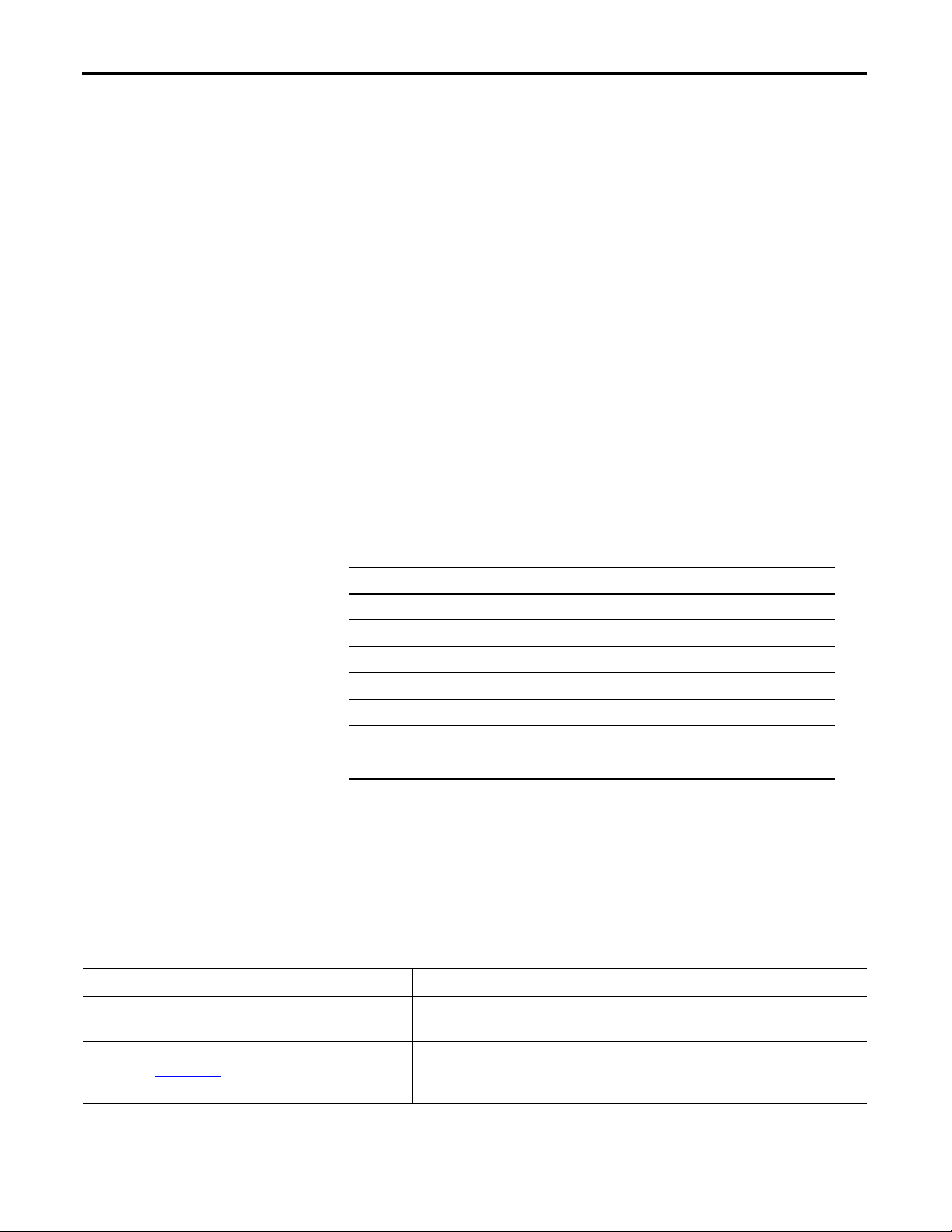

This manual describes how to install, configure and troubleshoot your

Thermocouple and Resistance Termperature Detector (RTD) modules.

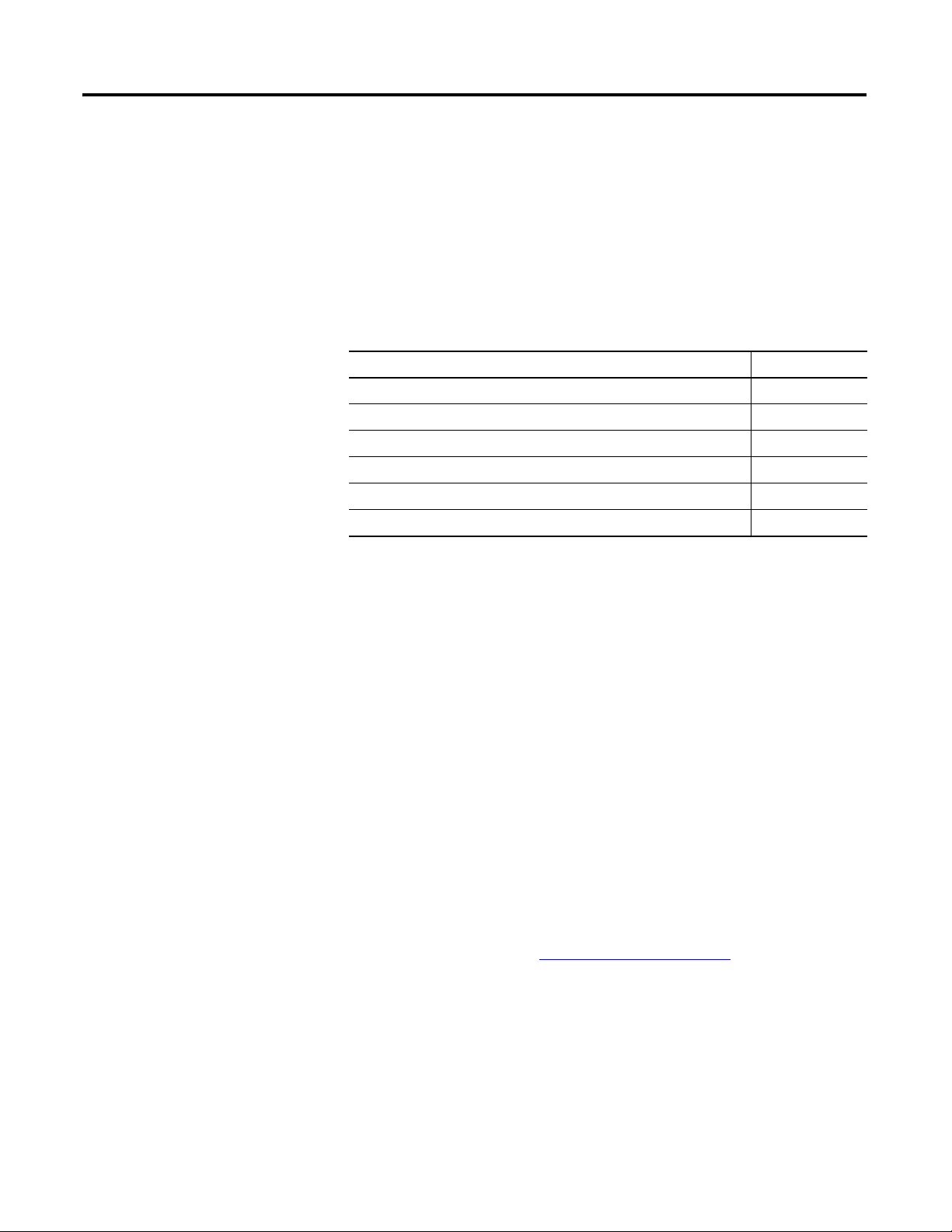

For Information About See

About POINT I/O Modules Chapter 1

Install the Module Chapter 2

Configure Your Module Chapter 3

Calibrate Your Module Chapter 4

Troubleshoot the Module Chapter 5

Configure Modules in RSLogix 5000 Software Appendix A

Calculate Absolute Accuracy and Accuracy Drift Appendix B

Related Documentation

The following documents contain additional information concerning Rockwell

Automation products. To obtain a copy, contact your local

Rockwell Automation office or distributor.

Resource Description

POINT I/O RTD and Thermocouple Input Module

Installation Instructions, publication 1734-IN011

Analog Input Modules Installation Instructions,

publication 1734-IN024

ix Publication 1734-UM004F-EN-E - December 2012

Information about specification and safety approval concerning 1734-IT2I,

1734-IR2, and 1734-IR2E modules.

Information about how to install the 1734-IE2C, Series C, POINT I/O Current

Input Analog Module, 1734-IE2V, Series C, POINT I/O Voltage Input Analog

Module, and POINT I/O 2 Current and 2 Voltage Input Analog Module.

Page 10

x

Resource Description

Analog Output Modules Installation Instructions,

publication 1734-IN002

Cold Junction Wiring Base Assembly Installation

Instruction, publication 1734-IN583

DeviceNet Communication Interface Installation

Instructions, publication 1734-IN057

Expansion Power Supply Installation Instructions,

publication 1734-IN058

Field Potential Distributor Installation Instructions,

publication 1734-IN059

POINT I/O Selection Guide, publication 1734-SG001

Protected Output Modules Installation Instructions,

publication 1734-IN056

Relay Output Modules Installation Instructions,

publication 1734-IN055

Sink Input Modules Installation Instructions, publication

1734-IN051

Source Output Modules Installation Instructions,

publication 1734-IN052

.

Information about how to install 1734-OE2C and 1734-OE2V, Series C Point I/O

Current and Voltage Output Analog Modules.

Information about how to install the POINT I/O Cold Junction Compensation

Wiring Base Assembly.

Information about how to install the 1734-PDN Series B POINT I/O DeviceNet

Communication Interface Module.

Information about how to installthe 1734-EP24DC, Series B POINT I/O 24V DC

Expansion Power Supply.

Information about how to install the 1734-FPD, Series B POINT I/O Field

Potential Distributor Module.

A description and overview of the 1734 and 1734D series POINT I/O modules

and compatible control platforms. Also includes an overview of how to specify

a POINT I/O system.

Information about how to install 1734-OB2E, -OB4E and -OB8E Series C POINT

I/O Protected Output Modules.

Information about how to install 1734-OW2 and 1734-OW4, Series C POINT I/O

2 or 4 Relay Output Modules.

Information about how to install 1734-IB2, 1734-IB4, 1734-IB8, Series C POINT

I/O Input Modules.

Information about how to install 1734-IV2, -IV4 and -IV8 Series C POINT I/O

Source Input Modules.

Very High Speed Counter Modules Installation

Instructions, publication 1734-IN003

Wiring Base Assembly Installation Instructions,

publication 1734-IN511

Wiring Base Assembly Installation Instructions,

publication 1734-IN013

Common Techniques Used in this Manual

Information about how to install 1734-VHSC5 and 1734-VHSC24, Series C

POINT I/O 5V DC and 24V DC Very High Speed Counter Modules.

Information about how to install 1734-TB and -TBS POINT I/O Wiring Base

Assemblies.

Information about how to install 1734-TB3 and -TB3S POINT I/O Wiring Base

Assemblies.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

Publication 1734-UM004F-EN-E - December 2012

Page 11

About POINT I/O Modules

Chapter

1

Overview

Module Features

Read this chapter to familiarize yourself with configurable features on the

1734-IT2I, 1734-IR2, and 1734-IR2E modules. The following table lists where

to find specific information in this chapter.

Topic Page

Module Features 1

Selecting a Module Input Type 2

Communicating with Your Module 2

Use Module Alarms 5

Cold Junction Compensation (1734-IT2I module) 6

Chapter Summary 6

The module features include:

Input type

•Sensor type

• Data formats

• Preset temperature selection

•Fault mode

• Overrange alarms

•Underrange alarms

• Fault alarms

You must use your programming software, like Rockwell Automation

RSNetWorx, to configure these features. See this chapter for a brief

description of each module feature. Use the online help included with your

programming software to perform specific configuration. You can find the

EDS files for this module at www.ab.com/networks/eds/.

1 Publication 1734-UM004F-EN-E - December 2012

Page 12

2 About POINT I/O Modules

Selecting a Module Input Type

The 1734-IT2I module consists of two isolated millivolt inputs (+70 mV).

Configure the module to do the linearization necessary for thermocouple

inputs. See the table for a list of supported thermocouple input types.

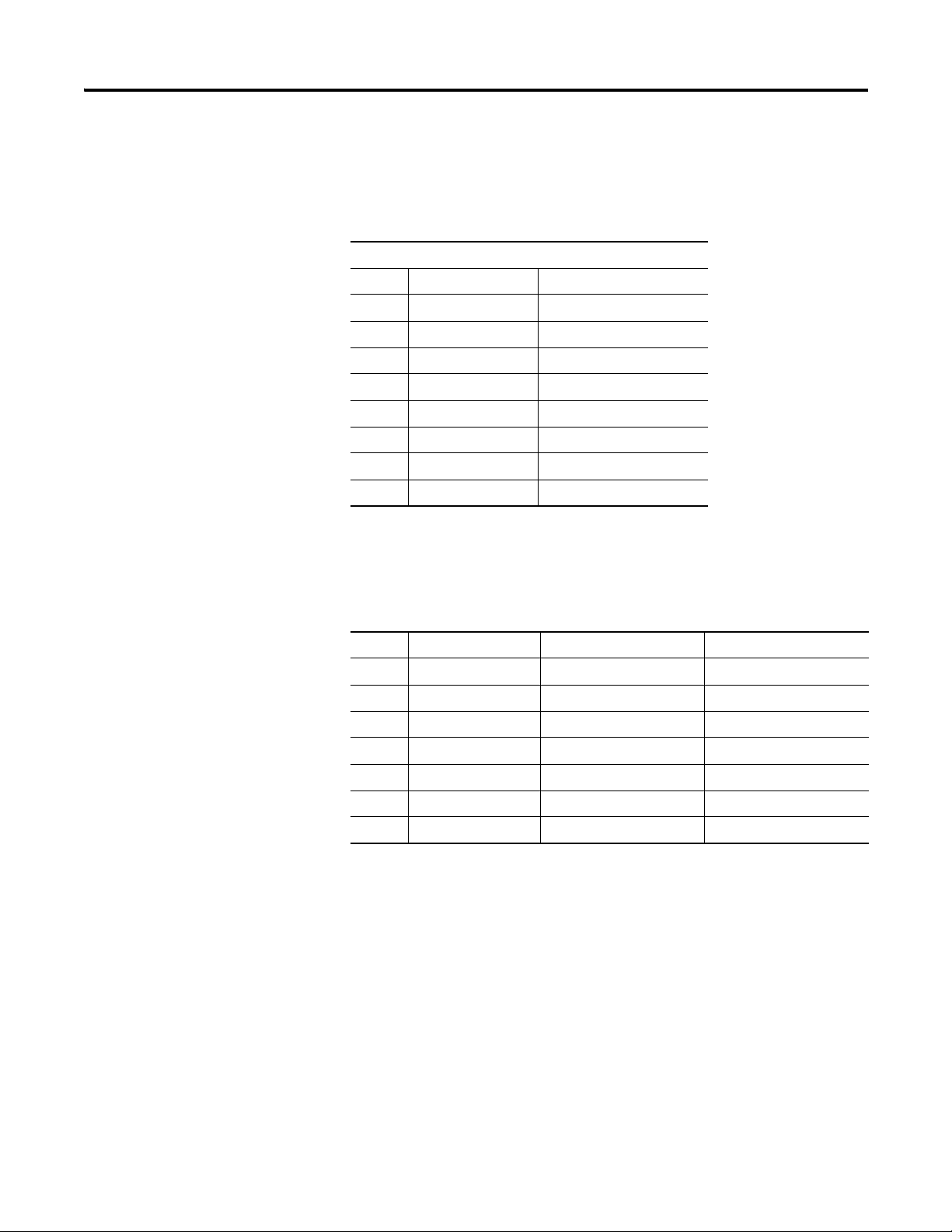

Supported Sensor Types – Thermocouple

mV (default) -70...+70 mV

B 572...3272 °F (300...1800 °C)

C 32...4199 °F (0...2315 °C)

E -418...+1832 °F (-250...+1000 °C)

J -346...+2192 °F (-210...+1200 °C)

K -418...+2502 °F (-250...+1372 °C)

N -418...+2372 °F (-250...+1300 °C)

R 32...3214 °F (0...1768 °C)

S 32...3214 °F (0...1768 °C)

T -418...+752 °F (-250...+400 °C)

The 1734-IR2 consists of two RTD inputs (0...600 W). Configure the module

to do the linearization necessary for RTD inputs. See the table for a list of

supported input types.

Communicating with Your Module

Supportted Sensor Types – RTD

100 Pt α = 0.00385 Euro -328...1598 °F (-200...+870 °C)

200 Pt α = 0.00385 Euro -328...1166 °F (-200...+630 °C)

100 Pt α = 0.003916 U.S. -328...1166 °F (-200...+630 °C)

200 Pt α = 0.003916 U.S. -328...1166 °F (-200...+630 °C)

10 Cu α = 0.00427 -328...500 °F (-200...+260 °C)

100 Ni α = 0.00618 -76...+482 °F (-60...+250 °C)

120 Ni α = 0.00618 -76...+482 °F (-60...+250 °C)

120 Ni α = 0.00672 -76...+482 °F (-60...+250 °C)

The 1734-IR2E consists of two RTD inputs (0...200 W). Configure the module

to do the linearization necessary for RTD inputs. See the table for a list of

supported input types.

I/O messages are sent to (consumed) and received from (produced) the

POINT I/O modules. These messages are mapped into the processor’s

memory. The Thermocouple input module produces 8 bytes of input data

(scanner Rx) and fault status data. It does not consume I/O data (scanner Tx).

Publication 1734-UM004F-EN-E - December 2012

The RTD input module produces 6 bytes of input data (scanner Rx) and fault

status data. It does not consume I/O data (scanner Tx).

Page 13

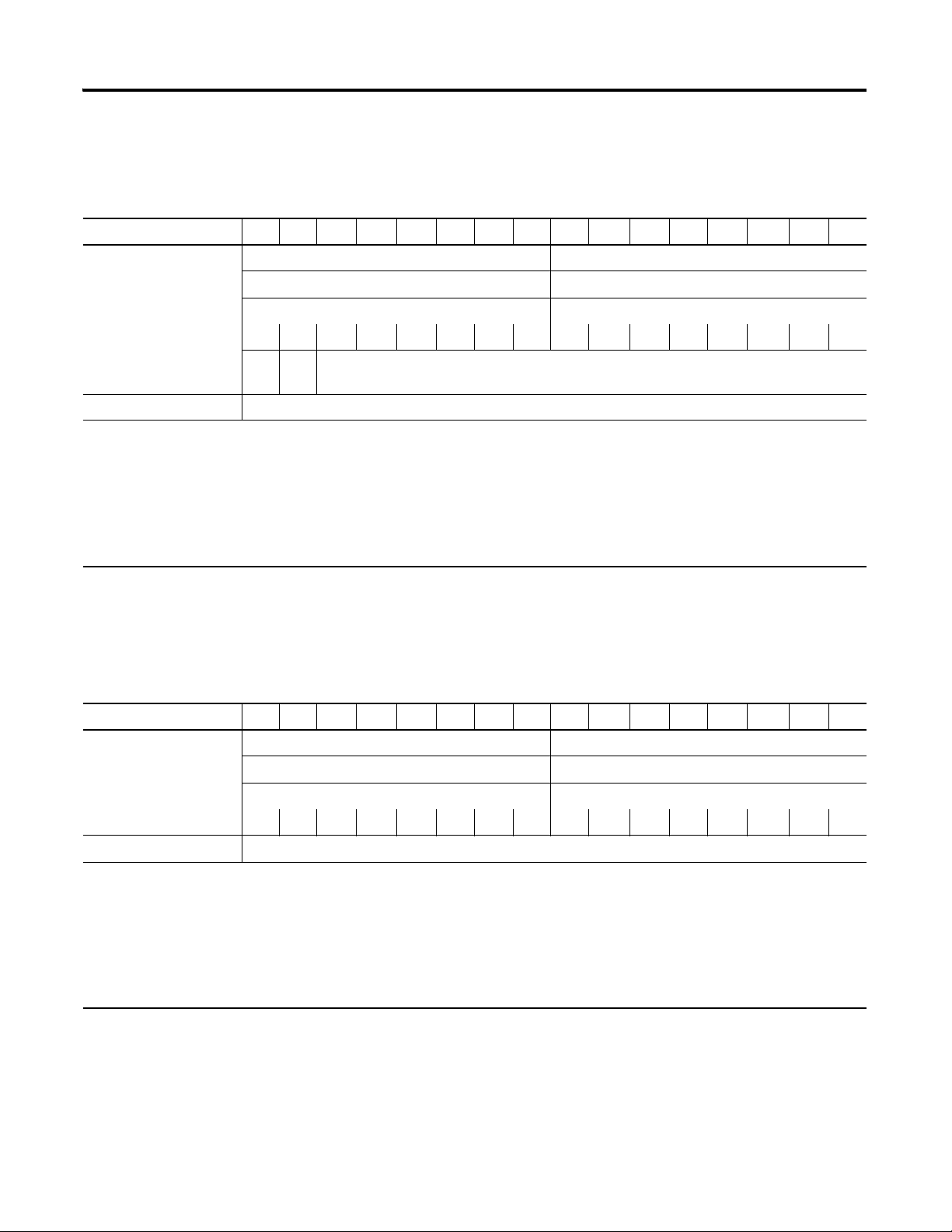

Default Data Map for the Thermocouple Input Module (catalog number 1734-IT2I)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Produces (scanner Rx) Input Channel 0 - High Byte Input Channel 0 - Low Byte

Input Channel 1 - High Byte Input Channel 1 - Low Byte

Status Byte for Channel 1 Status Byte for Channel 0

OR UR HHA LLA HA LA CM CF OR UR HHA LLA HA LA CM CF

OR UR Cold Junction Temperature

(Selectable: Channel 0, Channel 1, or Average of both Channel 0 and 1)

Consumes (scanner Tx) No consumed data

Where: OR = Overrange; 0 = no error, 1 = fault (value went above selected range)

UR = Underrange; 0 = no error, 1 = fault (value went below selected range)

HHA = High/High Alarm; 0 = no error, 1 = fault (value went below setpoint

LLA = Low/Low Alarm; 0 = no error, 1 = fault (value went below setpoint

HA = High Alarm; 0 = no error, 1 = fault (value went below setpoint

LA = Low Alarm; 0 = no error, 1 = fault (value went below setpoint)

CM = Calibration Mode; 0 = normal, 1 = calibration mode

CF = Channel Fault status; 0 = no error, 1 = fault

About POINT I/O Modules 3

Default Data Map for the RTD Input Module (catalog numbers 1734-IR2, and 1734-IR2E)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Produces (scanner Rx) Input Channel 0 - High Byte Input Channel 0 - Low Byte

Input Channel 1 - High Byte Input Channel 1 - Low Byte

Status Byte for Channel 1 Status Byte for Channel 0

OR UR HHA LLA HA LA CM CF OR UR HHA LLA HA LA CM CF

Consumes (scanner Tx) No consumed data

Where: OR = Overrange; 0 = no error, 1 = fault (value went above selected range)

UR = Underrange; 0 = no error, 1 = fault (value went below selected range)

HHA = High/High Alarm; 0 = no error, 1 = fault (value went below setpoint)

LLA = Low/Low Alarm; 0 = no error, 1 = fault (value went below setpoint)

HA = High Alarm; 0 = no error, 1 = fault (value went below setpoint)

LA = Low Alarm; 0 = no error, 1 = fault (value went below setpoint)

CM = Calibration Mode; 0 = normal, 1 = calibration mode

CF = Channel Fault status; 0 = no error, 1 = fault

Publication 1734-UM004F-EN-E - December 2012

Page 14

4 About POINT I/O Modules

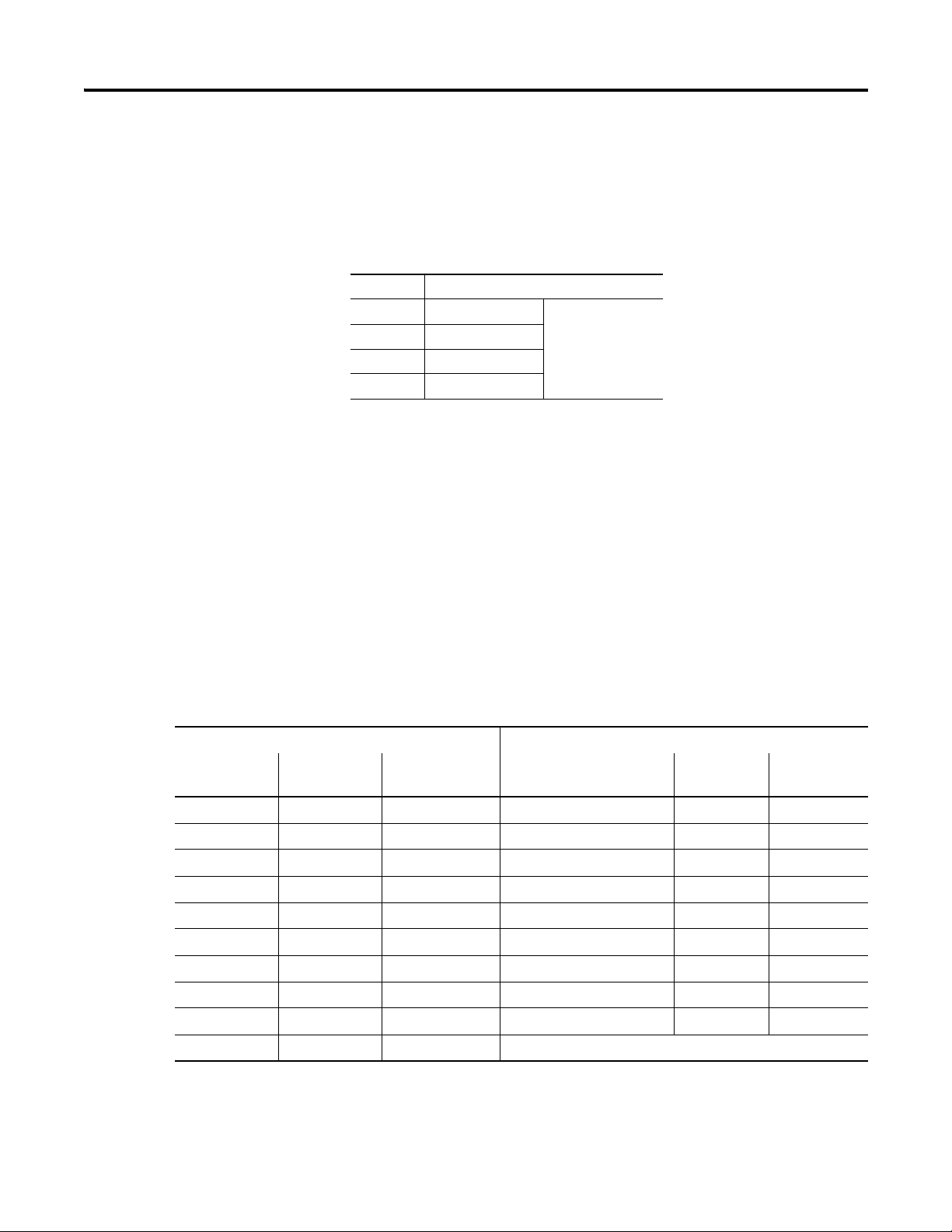

Data Format (1734-IT2I, 1734-IR2, and 1734-IR2E modules)

You must choose a module data format in your user program. Select the

format. These are four predefined scales and one custom scale.

Data Formats

mV Custom Scale

⋅ C Celsius Predefined Scale

⋅ F Fahrenheit

⋅ KKelvin

⋅ R Rankine

°C, F, °R, and °K returns data in tenths of a degree (250 implies 25.0 °).

For the 1734-IR2E,

(250 implies 2.50

⋅ C, ⋅ F, ⋅ R, and ⋅ K returns data in hundreths of a degree

⋅ ). If scaling is set to 10,000 and 20,000, the module returns

hundredths of an ohm (12345 implies 123.45).

For the 1734-IR2, if using ohms, the default data returned is in tenths of ohms

(1234 implies 123.4 Ω).

For the 1734-IT2, if using mV, the default data is returned in hundredths of a

mV, or tens of a μV (3500 implies 35.00

⋅ ).

If the input scale is custom scale, you can specify scaling points as shown in

the table.

1734-IT2I Thermocouple Input Module 1734-IR2 RTD Input Module

Thermocouple

Ty pe

mV 0 mV 70mV Ohms 100 Ω 500 Ω

Type B 212 °F (100 °C) 1832 °F (1000 °C) 100 Ω Ptα = 0.00385 Euro 32 °F (0 °C) 932 °F (500 °C)

Type C 32 °F (0 °C) 4199 °F (2315 °C) 200 Ω Ptα = 0.00385 Euro 32 °F (0 °C) 932 °F (500 °C)

Type E 32 °F (0 °C) 1832 °F (1000 °C) 100 Ω Ptα = 0.003916 U.S. 32 °F (0 °C) 932 °F (500 °C)

Type J 32 °F (0 °C) 1832 °F (1000 °C) 200 Ω Ptα = 0.003916 U.S. 32 °F (0 °C) 932 °F (500 °C)

Type K 32 °F (0 °C) 1832 °F (1000 °C) 10 Ω Cuα = 0.00427 32 °F (0 °C) 482 °F (250 °C)

Low Scaling

Endpoint

High Scaling

Endpoint

RTD Type Low Scaling

Endpoint

High Scaling

Endpoint

Type N 32 °F (0 °C) 1832 °F (1000 °C) 100 Ω Niα = 0.00618 32 °F (0 °C) 482 °F (250 °C)

Type R 32 °F (0 °C) 1832 °F (1000 °C) 120 Ω Niα = 0.00672 32 °F (0 °C) 482 °F (250 °C)

Type S 32 °F (0 °C) 1832 °F (1000 °C) 120 Ω Niα = 0.00618 32 °F (0 °C) 482 °F (250 °C)

Type T 32 °F (0 °C) 212 °F (100 °C)

Publication 1734-UM004F-EN-E - December 2012

Page 15

1734-IR2E RTD Input Module

About POINT I/O Modules 5

Use Module Alarms

RTD Type Low Scaling

Endpoint

O hms 100 Ω 200 Ω

100 Ω Ptα = 0.00385 Euro 32 °F (0 °C) 572 °F (300 °C)

POINT I/O modules are capable of generating the following alarms.

•Overrange

•Underrange

• Level (low-low, low, high, high-high)

• Cold-junction Compensation (CJC) Fault (1734-IT2 only)

•Open-wire Detection

High Scaling

Endpoint

Overrange Alarm (1734-IT2I, 1734-IR2, and 1734-IR2E modules)

The channel overrange alarm is set if the input is greater than the maximum

temperature (thermocouple or RTD range dependent), millivolt (+75 mV) or

resistance (600 Ω) range value, or above the maximum range of the

thermocouple or RTD.

The cold junction compensator has its own overrange alarm. If the CJC

temperature goes above 70 ⋅ C, the overrange alarm is set.

Underrange Alarm (1734-IT2I, 1734-IR2, and 1734-IR2E modules)

The channel underrange alarm is set if the input is less than the minimum

temperature (thermocouple or RTD range dependent), millivolt (-75 mV) or

resistance (10 Ω) range value, or below the minimum range of the

thermocouple or RTD.

The cold junction compensator has its own underrange alarm. If the CJC

temperature goes below 0 ⋅ C, the underrange alarm is set.

Level Alarms (1734-IT2I, 1734-IR2, and 1734-IR2E modules)

The following level alarms are available.

•Low

Publication 1734-UM004F-EN-E - December 2012

Page 16

6 About POINT I/O Modules

• Low-Low

•High

•High-High

When the channel input goes below a low alarm or above a high alarm, a bit is

set in the data table. All Alarm Status bits can be read individually or by

reading the Channel Status Byte (Bits 2...5 for channel 0; bits 10...13 for

channel 1).

You can configure each channel alarm individually.

Open-wire Alarm (1734-IT2I, 1734-IR2, and 1734-IR2E modules)

The module has the ability to check for a broken or detached wire. In any

mode, if a broken/detached lead is detected, the data value is forced to

maximum and the overrange alarm is set. Once the alarm is issued, it remains

active as long as the input signal is faulted.

Cold Junction Compensation (1734-IT2I module)

Chapter Summary

When using thermocouples, cold junction compensation is required at the

termination of the thermocouple wire. Accomplish a cold junction in the

following ways:

• Enter an estimated temperature.

• Use a 1734-TBCJC mounting base (recommended).

• Use external cold junction compensators.

Entering an estimated temperature is the least accurate way for CJC

compensation. Using the compensation built-into the 1734-TBCJC provides

the easiest and most accurate way.

An open CJC causes the CJC input to point to the maximum temperature

value for the selected input type. This causes an alarm to be set. Once the

alarm is issued, it remains active as long as the input signal is faulted (above

maximum).

In this chapter you were given an overview of the 1734 family of modules. The

next chapter walks you through installing your module.

Publication 1734-UM004F-EN-E - December 2012

Page 17

Install the Module

ATTENTION

Chapter

2

Overview

Read this chapter for information about how to install and wire RTD and

thermocouple modules. The following table lists where to find specific

information in this chapter.

Topic Page

Install the Mounting Base 8

Install an I/O Module 10

Install the Removable Terminal Block 12

Remove a Mounting Base 13

Wire the Modules 14

Chapter Summary 16

The RTD module uses a 1734-TB or 1734-TBS mounting base assembly with

1734-RTB removable terminal block (RTB) for RTD wiring.

The thermocouple module uses a 1734-TBCJC mounting base assembly with

1734-CJCRTB removable terminal block with built-in cold junction

compensation for thermocouple inputs.

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can

cause internal damage and affect normal operation. Follow

these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate static-safe

packaging.

7 Publication 1734-UM004F-EN-E - December 2012

Page 18

8 Install the Module

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II

applications (as defined in IEC publication 60664-1), at

altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated

disturbance.

This equipment is supplied as open-type equipment. It

must be mounted within an enclosure that is suitably

designed for those specific environmental conditions that

will be present and appropriately designed to prevent

personal injury resulting from accessibility to live parts.

The interior of the enclosure must be accessible only by

the use of a tool. Subsequent sections of this publication

may contain additional information regarding specific

enclosure type ratings that are required to comply with

certain product safety certifications.

Install the Mounting Base

See NEMA Standards publication 250 and IEC publication

60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure. Also,

see the appropriate sections in this publication, as well as

the Allen-Bradley publication 1770-4.1

Automation Wiring and Grounding Guidelines, for

additional installation requirements pertaining to this

equipment.

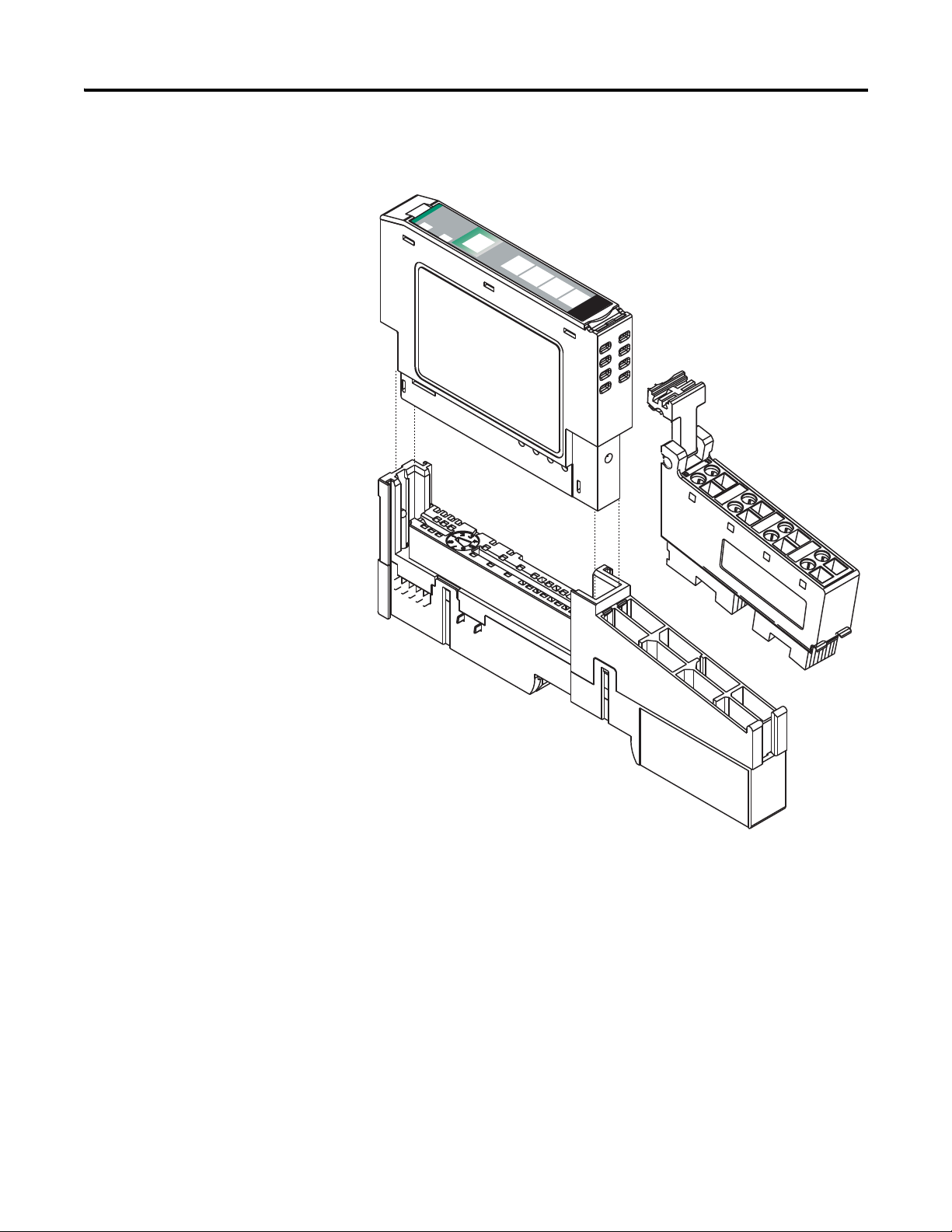

The wiring base assembly (1734-TB or 1734-TBS) consists of the following:

• Mounting base, catalog number 1734-MB

• Removable terminal block, catalog number 1734-RTB or 1734-RTBS

The wiring base assembly (1734-TBCJC) consists of the following:

• Mounting base, catalog number 1734-MB

• Removable terminal block, catalog number 1734-RTBCJC

, Industrial

Publication 1734-UM004F-EN-E - December 2012

Page 19

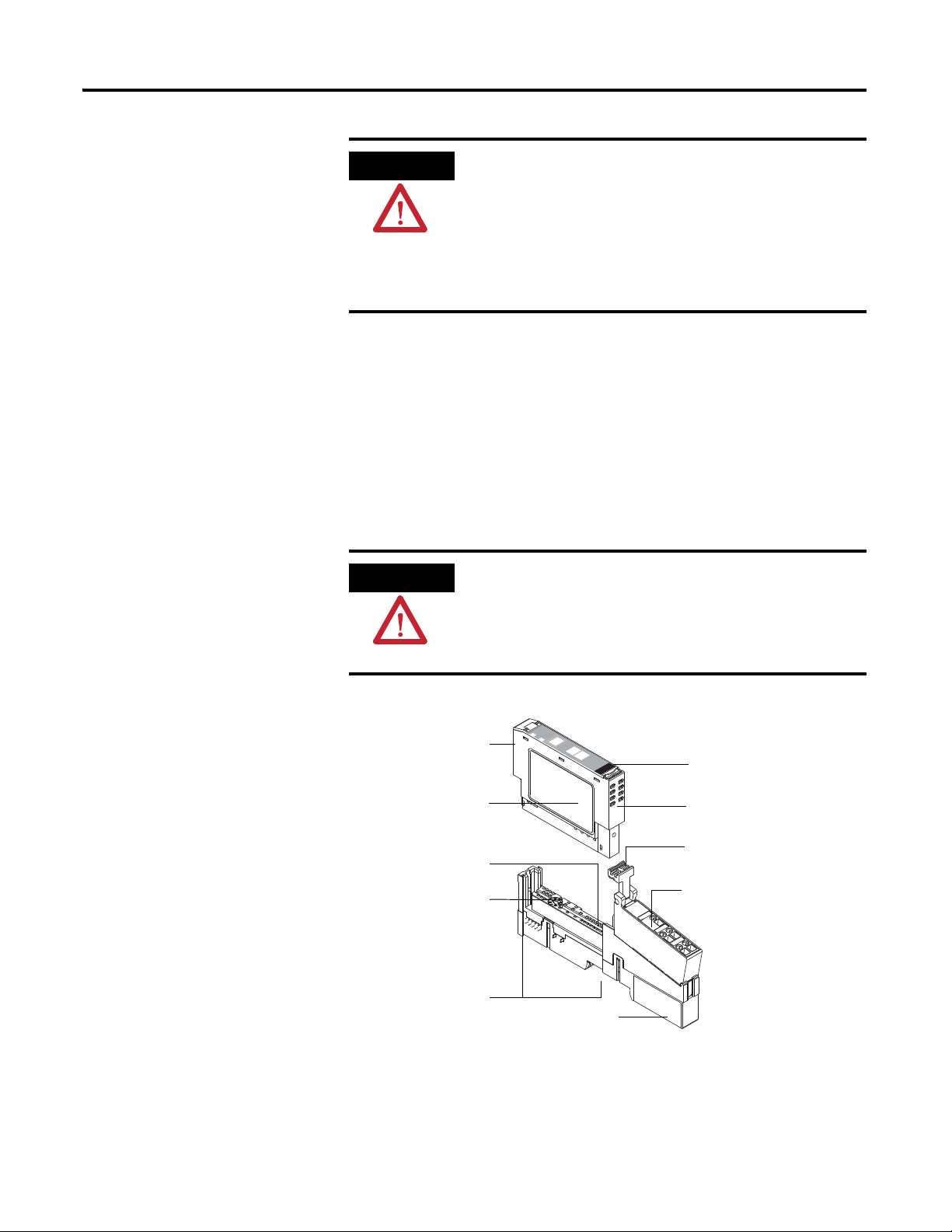

Install the Module 9

ATTENTION

ATTENTION

Therm

ocou

ple

Input

Module

Status

Network

Status

N

O

D

E

:

0

1

1

7

3

4

IT

2

I

Removable terminal

block (1734-RTBCJC)

Insertable

I/O module

RTB Removal

Handle

Slide-in writable label

Interlocking

side pieces

Mechanical keying

(orange)

Module wiring

diagram

DIN rail locking

screw (orange)

Module locking

mechanism

Mounting base

46008

POINT I/O is grounded through the DIN rail to chassis ground.

Use zinc-plated, yellow-chromated steel DIN rail to assure

proper grounding. The use of DIN rail materials (such as

aluminum and plastic) that can corrode, oxidize, or are poor

conductors can result in improper or intermittent grounding.

Secure DIN rail to mounting surface approximately every

200 mm (7.8 in.).

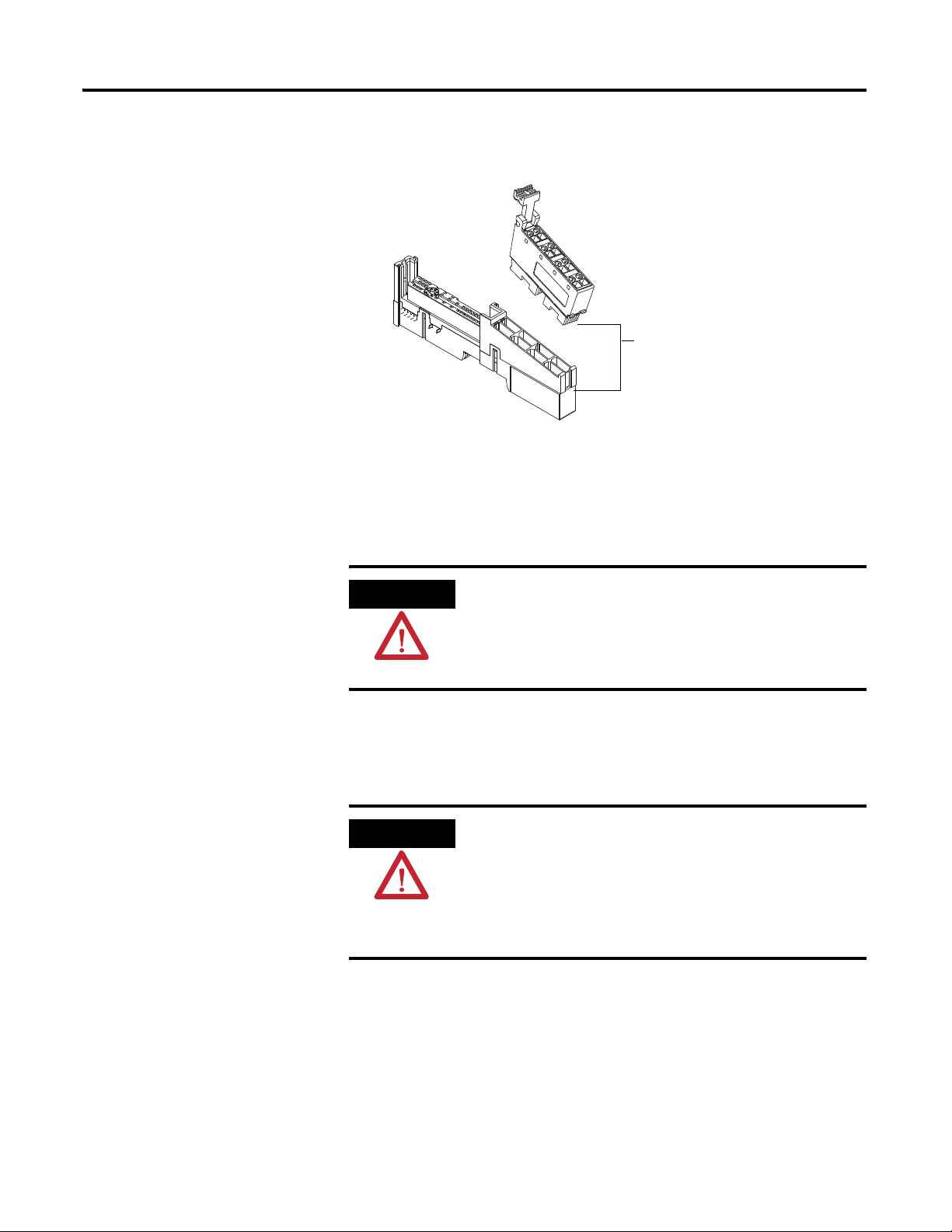

You can install the assembly, or just the mounting base.

Follow this procedure to install the mounting base/wiring base assembly on

the DIN rail.

1. Position the mounting base (wiring base) assembly vertically above the

installed units (adapter, power supply, or existing module).

2. Slide the mounting base down so that the interlocking side pieces

engage the adjacent module or adapter.

Do not discard the end cap shipped with an adapter or

communication interface. Use this end cap to cover the exposed

interconnections on the last mounting base on the DIN rail.

Failure to do so could result in equipment damage or injury from

electric shock.

1734-IT2I shown

Publication 1734-UM004F-EN-E - December 2012

Page 20

10 Install the Module

46003

WARNING

3. Press firmly to seat the mounting base on the DIN rail.

The mounting base snaps into place.

Module

Status

Network

Status

N

ODE:

24VDC

Source

Output

0

1

2

3

1734

OB4E

4. Repeat this procedure for the next mounting base assembly.

Install an I/O Module

Install the module before or after base installation. Make sure you correctly

keyed the mounting base before installing the module into the mounting base.

In addition, make sure you positioned the mounting base locking screw

horizontal, referenced to the base.

When you insert or remove the module while backplane power

is on, an electrical arc can occur. This could cause an explosion

in hazardous location installations.

Be sure that power is removed or the area is nonhazardous

before proceeding. Repeated electrical arcing causes excessive

wear to contacts on both the module and its mating connector.

Worn contacts may create electrical resistance that can affect

module operation.

1. Using a bladed screwdriver, rotate the keyswitch on the mounting base

clockwise till the number required for the type of module you are

installing aligns with the notch in the base.

Publication 1734-UM004F-EN-E - December 2012

Page 21

Install the Module 11

4

5

6

7

8

1

2

3

Turn the keyswitch to align

the number with the notch.

Notch

(position 6 shown)

Make sure the DIN rail locking

screw is in the horizontal position.

1734-RTD - Position 6

1734-IT2I - Position 6

2. Make certain the DIN rail locking screw is in the horizontal position,

noting that you cannot insert the module if the locking mechanism is

unlocked.

Publication 1734-UM004F-EN-E - December 2012

Page 22

12 Install the Module

24VD

C

Source

Output

Module

Status

Netw

ork

Status

1734

OB4E

NODE:

0

1

2

3

44012

3. Insert the module straight down into the mounting base and press to

secure, locking the module into place.

Install the Removable Terminal Block

A removable terminal block comes with your mounting base assembly. To

remove, pull up on the RTB handle to remove the base and replace, as

necessary, without removing any of the wiring. To reinsert the removable

terminal block, proceed as follows.

Publication 1734-UM004F-EN-E - December 2012

Page 23

Install the Module 13

WARNING

Hook the RTB end into the

mounting base end, and

rotate until it locks into place.

WARNING

1. Insert the RTB end opposite the handle into the base unit, which has a

curved section that engages with the mounting base.

2. Rotate the terminal block into the mounting base until it locks itself in

place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

Remove a Mounting Base

When you connect or disconnect the removable terminal block

(RTB) with field-side power applied, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

To remove a mounting base, you must remove any installed module, and

remove the removable terminal block (if wired).

When you connect or disconnect the removable terminal block

(RTB) with field-side power applied, an electrical arc can occur.

This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous

before proceeding.

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the removable terminal block.

3. Press in on the module lock on the top of the module, and pull up on

the I/O module to remove from the base.

Publication 1734-UM004F-EN-E - December 2012

Page 24

14 Install the Module

WARNING

43923

Module status

Network status

Status of input 0

Status of input 1

0+

Shield

0-

1+

1-

4. Remove the module to the right of the base you are removing, noting

that the interlocking portion of the base sits under the adjacent module.

5. Use a small-bladed screwdriver to rotate the orange DIN rail locking

screw on the mounting base to a vertical position. releasing the locking

mechanism.

6. Lift the mounting base straight up to remove.

Wire the Modules

To wire the thermocouple input modules, refer to the figures.

If you connect or disconnect wiring while the field-side power

is on, an electrical arc can occur. This could cause an explosion

in hazardous location installations. Be sure that power is

removed or the area is nonhazardous before proceeding.

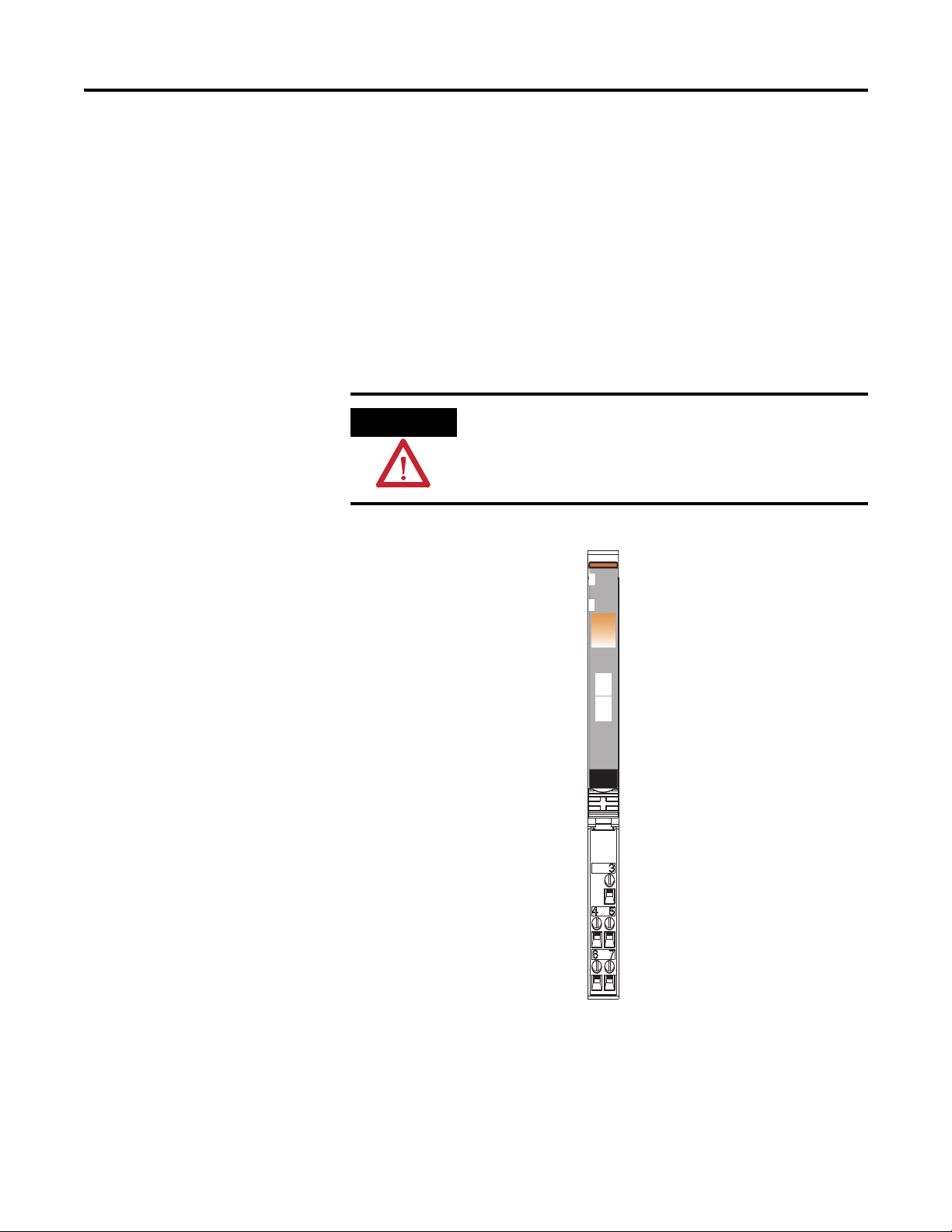

1734-IT2I Module Overview

Module

Status

Network

Status

NODE:

Thermocouple

Input

0

1

1734

IT2

Publication 1734-UM004F-EN-E - December 2012

Page 25

Wiring Diagram

Shield

0+

0-

1-

1+

3

5

7

4

6

Thermocouple 0

Thermocouple 1

0+ = Input channel 0 High

0- = Input channel 0 Low

1+ = Input channel 1 High

1- = Input channel 1 Low

Shld = Shield

46000

Module Status

Network Status

Status of Input 0

Status of Input 1

Input 0/A HIgh Input

Input 0/B Low Input

RET 0

Shield

Input 1/A High Input

Input 1/B Low Input

Shield

RET 1

Input Channel Power Limits

Channel Input High Input Low Shield

0+ 4 3

0- 5

1+ 6 3

1- 7

Power is provided by the internal power bus.

Install the Module 15

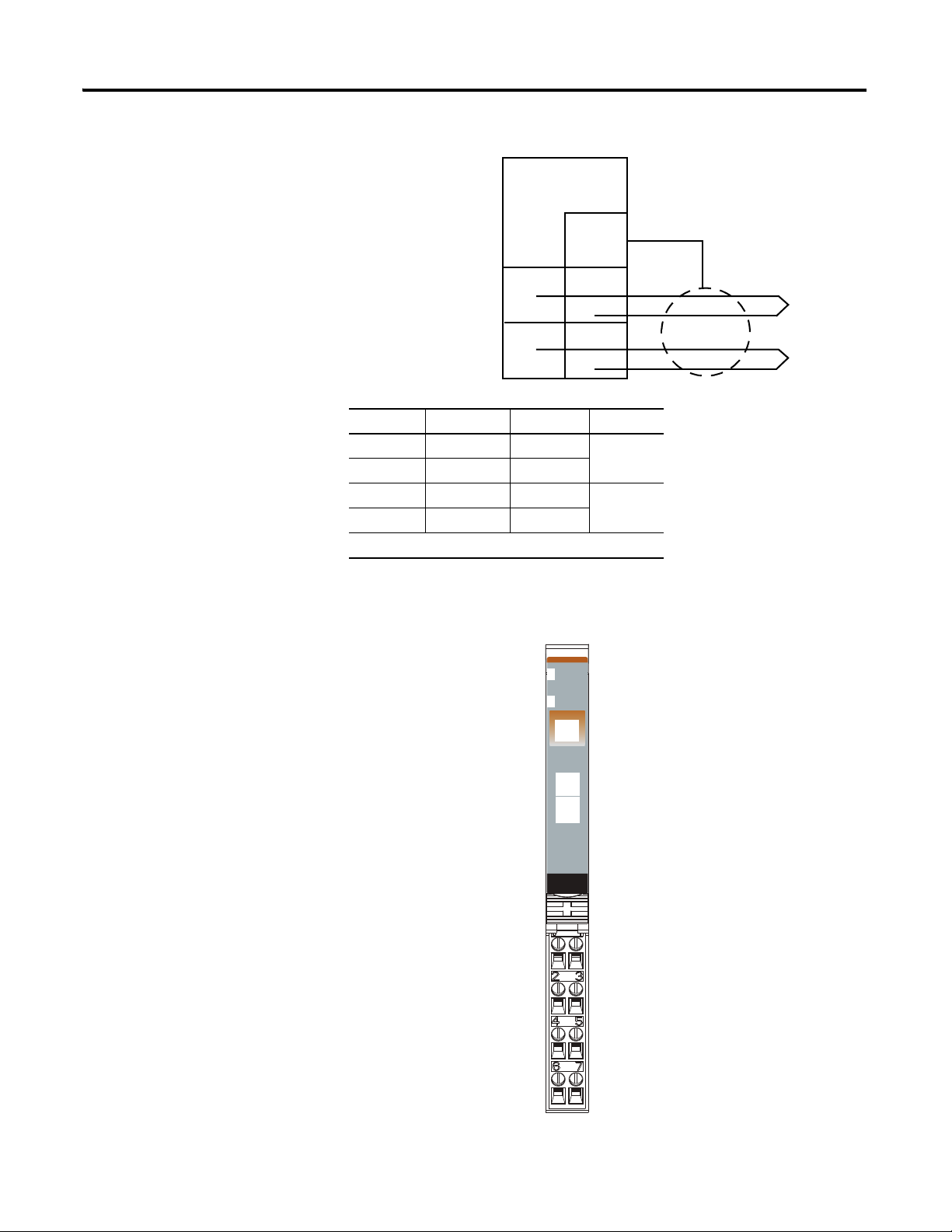

To wire RTD modules, refer to the figures.

1734-IR2, 1734-IR2E Module Overview

Module

Status

Network

Status

NODE:

RTD

Input

0

1

1734

IR2

Publication 1734-UM004F-EN-E - December 2012

Page 26

16 Install the Module

In 0/A In 1/A

In 1/BIn 0/B

RET 0 RET 1

ShieldShield

3-wire

RTD

In = Input channel

RET = Sensor return

Shield = Sensor cable shield

3

5

0

1

2

4

2-wire

RTD

6

7

When using 2-wire RTDs,

Insert 1 Ω resistor IN/B to

RET.

1 Ω

resistor

Wiring Diagram

Input Channel Power Limits

Channel High Signal (+) Low Signal (-) Return Shield

In 0/A 0 4 6

In 0/B 2

In 1.A 1 5 7

Chapter Summary

In 1/B 3

This chapter explained how to install and wire the modules. The next chapter

describes how to configure your POINT I/O Thermocouple and RTD

Modules.

Publication 1734-UM004F-EN-E - December 2012

Page 27

Configure Your Module

Chapter

3

Overview

Configuration Overview

This chapter describes how to configure your thermocouple input module

with RSNetWorx.

Topic Page

Configuration Overview 17

Commissioning a Node 17

Add the Adapter to Your Network 19

Set the Thermocouple Input Module Parameters

Using RSNetWorx

Configure Your Thermocouple Input Module 24

Set the RTD Input Module Parameters Using

RSNetWorx

Configure Your RTD Input Module 31

Check I/O Status and View the EDS File 36

Chapter Summary 37

Configuring POINT I/O modules is as easy as point and click. RSNetWorx

lets you identify the network and configure the I/O modules

with Electronic Data Sheet (EDS) files - just point to the field and click your

selection.

22

29

To obtain EDS files for use in configuration, go to

http://www.ab.com/networks/eds

In this chapter, you learn how to do the following.

• Add the adapter to the system.

• Commission individual modules in the system.

• Set the individual modules parameters.

Commissioning a Node

17 Publication 1734-UM004F-EN-E - December 2012

Here are the methods for commissioning nodes.

• Use the RSNetWorx commissioning pull-down dialog.

• Use the Sequential Auto Addressing feature.

• Use third-party configuration software.

.

Page 28

18 Configure Your Module

IMPORTANT

ATTENTION

Using the RSNetWorx Commissioning Tool

Use the RSNetWorx commissioning tool to commission devices (set the node

address and the data rate parameters) that are:

• connected to a DeviceNet network.

• connected via a point-to-point connection.

The node commissioning tool works through RSLinx; RSNetWorx does not

have to be online when performing the operation.

Before you can add any device to a DeviceNet network, it must be

commissioned. This means that a node address and a data rate must be

programmed into the device. Some devices are precommissioned, meaning a

node address (usually set to 63) and a data rate (usually set to 500 Kbps) are

programmed into the device at the factory prior to shipment. Other devices

muse be commissioned in the field. Once a device is commissioned and

attached to a network, you can use the RSNetWorx for DeviceNet node

commissioning tool to edit the node address and data rate that were set

previously.

Exercise caution while editing node addresses when on a

network. When you apply a new node address, it immediately

overwrites the node address data in the device currently

specified. If you decide to reassign node addresses, you should

first determine the order you use so that all the devices still

have unique node addresses when you are finished.

For example, if two of the devices on your network are a photoelectric sensor

and a hand controller, and you accidentally change the node address of the

hand controller to be the same as that of the photoelectric sensor, then the

photoelectric sensor no longer has a unique address, which means that it is not

be able to provide data to the scanner. If you cannot access a device because

you have used its node address for another device, you have to remove it from

the network, recommission it, then reinstall it on the network.

Do not change the data rate of devices while they are

connected to a network. Erratic operation may result. We

recommend that if you need to change the data rate of a device,

you should remove it from the network, establish a

point-to-point connection between the PC, which hosts the

RSNetWorx for DeviceNet software, and the target device,

recommission it, and then, reconnect it to the network.

Publication 1734-UM004F-EN-E - December 2012

Page 29

Configure Your Module 19

IMPORTANT

Use Sequential Auto Addressing

Sequential Auto Addressing (SAA) reassigns the node address of every module

to the right of the one you select. Each module changes its node address to

one greater than its neighbor.

Make sure the node address of the selected module is the

desired value before issuing the SAA command.

When this command is set, each module to the right gets a new address one

greater than its neighbor. The addressing ripples through a line of POINT I/O

modules, assigning a node number to each module installed in a mounting

base.

Perform this procedure to Auto Address a line of POINT I/O modules.

1. Set the address of the first module you want to address.

Add the Adapter to Your Network

2. Set the Auto Address command to Sequential Address.

3. All modules in line reset with new sequential addresses.

An example is if 5 POINT I/O modules are in a line, and the address of the

first module is 10. After the Sequential Address command is sent to the first

module, the node address of the line is: 10, 11, 12, 13, and 14.

Use Third Party Configuration Software

When using third party configuration software, simply load the EDS files into

the software and follow the designer’s instructions.

You can use the RSNetWorx for DeviceNet software, or some other

configuration tool for DeviceNet, to configure your module. If the EDS files

are not in your software, you can get them at

http://www.ab.com/networks/eds/

You can configure the module while it is:

.

• online.

• offline.

Publication 1734-UM004F-EN-E - December 2012

Page 30

20 Configure Your Module

1. Click here to expand the list of

communication adapters.

2. Double-click here to choose the

scanner. You can also click and

drag the scanner name onto

the network.

Make sure you choose the

1734-ADN POINT I/O Scanner.

The scanner appears

on the network.

1. Click here to expand the list of

Specialty modules.

2. Double-click the catalog number

to choose the module. You can

also click and drag the module

name onto the network.

This chapter shows configuration in the online mode. Configuration dialogs

appear similar in both modes. The primary difference is that if you make

changes offline, you must go online before the configuration changes take

effect.

Perform this procedure to add a communication device.

1. Start the RSNetWorx for DeviceNet software.

2. Add the communication adapter as shown in the figure.

In this case, the chosen device was a 1770-KFD RS232 Interface.

Publication 1734-UM004F-EN-E - December 2012

Add I/O Modules to Your Network POINTBus

After you add the communication device, you must add the POINT I/O

modules connected to the scanner on the POINTBus.

Add modules as shown in the figure.

Page 31

Configure Your Module 21

1. Go to the Tools pull-down menu.

2. Select Node Commissioning.

3. Click Browse.

4. Select the module to change.

5. The node commissioning dialog

returns. It displays the node number

and data rate.

6. Change the node number and

Apply, noting that the dialog then

identifies the new setting.

7. Click Close to continue.

4

2

3

1

5

6

IMPORTANT

The out-of-the-box node setting for 1734 modules is 63. You can change the

setting by using the node commissioning tool. The node commissioning tool is

available either online or offline.

If you commission a node online, you must power down your

system before the change takes place.

Publication 1734-UM004F-EN-E - December 2012

Page 32

22 Configure Your Module

IMPORTANT

1. Right-click the module.

2. Click Properties to configure.

You can also left-click the module or name.

These are the tabs you click to

view the options.

Set the Thermocouple Input

After adding the module to the network, you must configure the modules for

use.

Module Parameters Using

RSNetWorx

Configure the modules as shown in the figure.

You see a dialog with a series of tabs. Each tab provides options view or edit.

The tabs are shown in the following figure.

This chapter shows configuration in the online mode. Changes

set in this mode take effect when you download to the

individual module.

Publication 1734-UM004F-EN-E - December 2012

Refer to these dialogs for an explanation of features.

Page 33

The module name appears here.

Type a description here.

The module address appears

here. (This field is read-only.)

This dialog also shows the

module’s device identity.

These fields are read-only.

At any point, you can click here to

finish changing configuration

parameters.

IMPORTANT: If configuration

changes are made in

offline mode they do

not take effect until

the system goes

online.

Click the Device parameters tab to

get to the dialog for setting the

parameters.

This dialog appears after clicking the

Device parameters tab. If you want

the existing parameters uploaded

from the module, select Upload.

The following dialog then shows the

existing parameters set on the

module.

Use this pull-down menu to edit or view

the parameters. Available choices are:

POINTBus

Status

Configuration

Configure Your Module 23

Setting Parameters

Publication 1734-UM004F-EN-E - December 2012

Page 34

24 Configure Your Module

IMPORTANT

Configure Your Thermocouple Input Module

Configuration can be divided into two categories: Basic Set-up Parameters and

Advanced Setup Parameters.

Basic Set-up Parameters

The basic parameters you need to set for the thermocouple module consist of:

• Temperature units - Select how the input is linearized:

– mV/Custom Scale (default)

– Celsius

– Fahrenheit

– Kelvin

– Rankine

• Thermocouple type - Choose the type of sensor for this input. The

module performs the linearization of the selected type.

– mV (No Linearization)

– Type B

– Type C

– Type E

– Type J

– Type K

– Type N

– Type R

– Type S

– Type T

• Cold Junction Enable - This bit enables or disables the cold junction

linearization. If enabled, the proper cold junction compensation value is

applied to the selected thermocouple. If disabled, the data (CJ

Temperature) is still available but not applied to the input. If the Cold

Junction Compensation Removable Terminal Block is not available, this

parameter should be set to disabled. A cold junction value can be added

using the Cold Junction Offset parameter.

• Cold Junction Produced Data - Selects how the Cold Junction Data is

returned in the Produced IO message. The last two bytes of the

produced message contain one of the following.

– None (zeros)

– Channel 0 (default)

– Channel 1 - Average of both channels

The Over/Under Range status is also included in the last two

bytes, along with the cold junction value.

Publication 1734-UM004F-EN-E - December 2012

Page 35

Configure Your Module 25

Advanced Setup Parameters

Advanced parameters you can set for the thermocouple module consist of:

• Notch filter - Select the Notch Filter for the analog to digital converter.

At higher frequencies, faster sample rates are possible

– 50 Hz

– 60 Hz (default)

– 100 Hz

– 120 Hz

– 200 Hz

– 240 Hz

– 300 Hz

– 400 Hz

– 480 Hz

If the filter value is changed, the module may require calibration to meet

specifications.

• Digital filter - A digital filter is available on this module. You set a time

constant which is used in the equation:

Yn = Yn-1 + (dt / (dt + TA) * (Xn-Yn-1)

Where: Yn = new data

Yn-1 = old data

dt = Channel Update Rate in milliseconds

T

= digital filter time constant

A

Xn = present unfiltered data

TA can be an integer from 0 to 10,000 ms. If set to 0, the filter is

disabled.

• Cold Junction Offset - If you do not use a 1734-RTBCJC removable

terminal block, enter an estimate for the junction temperature here.

Enter the value in hundreths of degrees Celsius, even if another scale is

selected (2500 implies 25.00 °C).

• Enable alarms latch - If enabled, alarms for this channel latch

FAULTED until a Latch Reset command is received.

The alarms effected are:

– Input Status

– Low and High level

– Range

• Disable alarms - If Alarms are Disabled, all alarms for this channel show

No FAULT. This is useful for unused channels.

Publication 1734-UM004F-EN-E - December 2012

Page 36

26 Configure Your Module

To configure your module,

select Configuration and

modify the parameters as

desired for your application.

When complete, download to

your module by clicking the

Download to Device button.

You can download each

change as you make it using

“Single,” or download all your

changes using “All.” If you

press the “Apply” button, only

the selected parameter is

downloaded to the module.

Click here when finished.

• Level alarms - low-low, low, high, and high-high - any value from

-32,768...+32,767 can be entered.

• Scaling - Values returned when input is at low scale value or high scale

value. The low and high scale points are different for each sensor input:

Thermocouple Scaling limits

Thermocouple

Ty pe

mV 0 mV 70 mV

Type B 212 °F (100 °C) 1832 °F (1000 °C)

Type C 32 °F (0 °C) 4199 °F (2315 °C)

Type E 32 °F (0 °C) 1832 °F (1000 °C)

Type J 32 °F (0 °C) 1832 °F (1000 °C)

Type K 32 °F (0 °C) 1832 °F (1000 °C)

Type N 32 °F (0 °C) 1832 °F (1000 °C)

Type R 32 °F (0 °C) 1832 °F (1000 °C)

Low Scaling

Endpoint

High Scaling

Endpoint

Publication 1734-UM004F-EN-E - December 2012

Type S 32 °F (0 °C) 1832 °F (1000 °C)

Type T 32 °F (0 °C) 212 °F (100 °C)

To configure your module, select Configuration as shown in the figure.

Configure a module

Use the procedures in the figures that show basic setup and advanced setup,

noting that you complete steps 1-5 during basic setup, then continue with steps

6-10 during advanced setup.

Page 37

1. Select the

temperature scale.

2. Then select the type

of thermocouple:

B

C

E

J

K

N

R

S

T or mV

3. Select cold junction

compensation if desired.

4. Select how the cold

junction data is returned in the produced I/O

message. Select None, channel 0, channel

1, or the average of both channels.

5. Download to the device.

Configure Your Module 27

Basic Setup

Publication 1734-UM004F-EN-E - December 2012

Page 38

28 Configure Your Module

6. Select the notch filter

desired (60 Hz to

480 Hz).

7. Select the digital filter

(select as necessary)

8. Enable or disable the

latching alarms.

9. Enable or disable the

alarms.

10. Apply and download to

the device.

Advanced Setup

Publication 1734-UM004F-EN-E - December 2012

Page 39

Configure Your Module 29

IMPORTANT

1. Right-click the module.

2. Click Properties to

configure.

You can also left click the module or name.

Click these tabs to view the

options.

Set the RTD Input Module Parameters Using RSNetWorx

After adding the module to the network, you must configure the modules for

use.

This chapter shows configuration in the online mode. Changes

set in this mode take effect when you download to the

individual module.

Configure the modules as shown.

You see a dialog with a series of tabs. Each tab provides options to view or

edit. Refer to the figure to see the tabs.

Refer to these dialogs for an explanation of features.

Publication 1734-UM004F-EN-E - December 2012

Page 40

30 Configure Your Module

The module name appears here.

Type a description here.

The module address appears

here. (This field is read-only.)

This dialog also shows the

module’s device identity.

These fields are read-only.

At any point, click here to finish changing

configuration parameters.

If configuration changes are made in offlin

mode, they do not take effect until the

system goes online.

Click the Device parameters tab to

get to the dialog for setting the

parameters.

This dialog appears after you click

the Device parameters tab. If you

want the existing parameters

uploaded from the module, select

Upload. The following dialog then

shows the existing parameters set

on the module.

Use this pull-down menu to edit or view the

parameters. Available choices are:

POINTBus

Status

Configuration

Setting Parameters

Publication 1734-UM004F-EN-E - December 2012

Page 41

Configure Your Module 31

Configure Your RTD Input Module

Configuration is divided into basic and advanced parameters.

Basic Setup Parameters

The basic parameters you need to set for the RTD module consist of:

• Temperature units – Use the Temperature Scale parameter to select a

predefined scale or a custom scale. Custom Scale allows you to enter the

scaling endpoint values. If using Ohms RTD Type, ignore this

parameter. Predefined Scales include: Celsius(C), Fahrenheit(F),

Kelvin(K), and Rankine(R).

Scaling Endpoints for Custom Scale (low & high):

RTD Module Scaling Limits

RTD Type Low Scaling

Endpoint

Ohms 100 Ω 500 Ω

100 Ω Ptα = 0.00385 Euro 32 °F (0 °C) 932 °F (500 °C)

200 Ω Ptα = 0.00385 Euro 32 °F (0 °C) 932 °F (500 °C)

100 Ω Ptα = 0.003916 U.S. 32 °F (0 °C) 932 °F (500 °C)

200 Ω Ptα = 0.003916 U.S. 32 °F (0 °C) 932 °F (500 °C)

High Scaling

Endpoint

10 Ω Cuα = 0.00427 32 °F (0 °C) 482 °F (250 °C)

100 Ω Niα = 0.00618 32 °F (0 °C) 482 °F (250 °C)

120 Ω Niα = 0.00672 32 °F (0 °C) 482 °F (250 °C)

120 Ω Niα = 0.00618 32 °F (0 °C) 482 °F (250 °C)

RTD Type (1734-IR2E) Low Scaling

Endpoint

Ohms 100 Ω 200 Ω

100 Ω Ptα = 0.00385 Euro 32 °F (0 °C) 572 °F (300 °C)

High Scaling

Endpoint

• RTD type – Select the RTD type that the input uses. Valid types are

shown in the table.

• Copper RTD Offset – If using the copper RTD, this is the error of the

Copper RTD (10

250 in hundredths of Ohms (such as 361 = 3.61

Ω Cu427) in Ohms. Enter a value between -250 and

Ω). This value is added

to the input reading before linearization.

Publication 1734-UM004F-EN-E - December 2012

Page 42

32 Configure Your Module

Advanced Setup Parameters

Advanced parameters you can set for the RTD module consist of:

• Notch filter – Select the Notch Filter for the analog to digital converter.

At higher frequencies, faster sample rates are possible

– 50 Hz

– 60 Hz (default)

– 100 Hz

– 120 Hz

– 200 Hz

– 240 Hz

– 300 Hz

– 400 Hz

– 480 Hz

If the filter value is changed, the module may require calibration to meet

specifications.

• Digital filter – A digital filter is available on this module. You set a time

constant that is used in the equation:

Yn = Yn-1 + (dt / (dt + TA) * (Xn-Yn-1)

Where: Yn = new data

Yn-1 = old data

dt = Channel Update Rate in milliseconds

T

= digital filter time constant

A

Xn = present unfiltered data

TA can be an integer from 0 to 10,000 ms. If set to 0, the filter is

disabled.

• Enable alarms latch – If enabled, alarms for this channel latch

FAULTED until a Latch Reset command is received.

The alarms effected are:

– Input Status

– Low and High level

– Range

• Disable alarms – If Alarms are Disabled, all alarms for this channel

show No FAULT. This is useful for unused channels.

• Level alarms – low-low, low, high, and high-high.

Publication 1734-UM004F-EN-E - December 2012

Page 43

Configure Your Module 33

1. To configure your RTD module,

select Configuration and

modify the parameters as

desired for your application.

2. When complete, download to

your module by clicking the

Download to Device button.

You can download each

change as you make it using

Single, or download all your

changes using All. If you press

the Apply button, only the

selected parameter

downloads to the module.

3. Click here when finished.

• Scaling – Values returned when input is at low scale value or high scale

value. The low and high scale points are different for each sensor input:

RTD Module Scaling Limits

RTD Type Low Scaling

Endpoint

High Scaling

Endpoint

O hms 100 Ω 500 Ω

100 Ω Pt α = 0.00385 Euro 32 °F (0 °C) 932 °F (500 °C)

200 Ω Pt α = 0.00385 Euro 32 °F (0 °C) 932 °F (500 °C)

100 Ω Pt α = 0.003916 U.S. 32 °F (0 °C) 932 °F (500 °C)

200 Ω Pt α = 0.003916 U.S. 32 °F (0 °C) 932 °F (500 °C)

10 Ω Cu α = 0.00427 32 °F (0 °C) 482 °F (250 °C)

100 Ω Ni α = 0.00618 32 °F (0 °C) 482 °F (250 °C)

120 Ω Ni α = 0.00672 32 °F (0 °C) 482 °F (250 °C)

120 Ω Ni α = 0.00618 32 °F (0 °C) 482 °F (250 °C)

RTD Type (1734-IR2E) Low Scaling

Endpoint

High Scaling

Endpoint

O hms 100 Ω 200 Ω

100 Ω Pt α = 0.00385 Euro 32 °F (0 °C) 572 °F (300 °C)

To configure your RTD module, select Configuration as shown in the figure.

Use the procedures in the figures that show basic setup and advanced setup,

noting that you complete steps 1 and 2 during basic setup, then continue with

steps 3…13 during advanced setup.

Publication 1734-UM004F-EN-E - December 2012

Page 44

34 Configure Your Module

1. Select the type of RTD

you are using for

channel 0. Repeat for

channel 1.

2. Then select the scale

for channel 0. Repeat

for channel 1.

This is the error of Copper RTD (10

Ω

Cu427) in O hms. Enter value between

-250 and 250 in hundredths of Ohms

(such as 361 = 3.61

Ω). If you are using a

copper RTD, this value is added to the

input reading before linearization.

Basic Setup

Publication 1734-UM004F-EN-E - December 2012

Page 45

3. Select the digital filter desired.

(Range is 0...10.000 ms.)

6. Select the notch filter.

4. Enable or disable the latching

alarms.

5. Enable or disable the alarms.

7. Apply and download to the device.

Configure Your Module 35

Advanced Setup

Publication 1734-UM004F-EN-E - December 2012

Page 46

36 Configure Your Module

1. Click the I/O Defaults tab to

display the default

characteristics for this module.

This dialog shows the

input/output defaults for the

four modes:

Strobe

Polled

Change of state and

Cyclic

3. Click View File to view

the actual EDS file

(shown).

2. Click the EDS File tab to display the

statistics of the EDS file used to

configure this module.

You can view the actual

EDS file or edit the file.

Check I/O Status and View the EDS File

View the I/O defaults setup and the EDS file by clicking the appropriate tab.

1734-IT2I module

Publication 1734-UM004F-EN-E - December 2012

Page 47

1734-IR2 and 1734-IR2E modules

3. Click View File to

view the actual

EDS file (shown).

2. Click the EDS File tab to display

the statistics of the EDS file used

to configure this module.

1. Click the I/O Defaults tab to display

the default characteristics for this

module.

This dialog shows the

input/output defaults for the

four modes:

Strobe

Polled

Change of state and

Cyclic

Configure Your Module 37

Chapter Summary

This chapter explained how to configure the modules. The next chapter walks

you through how to calibrate your POINT I/O Thermocouple and RTD

Modules.

Publication 1734-UM004F-EN-E - December 2012

Page 48

38 Configure Your Module

Publication 1734-UM004F-EN-E - December 2012

Page 49

Calibrate Your Module

Chapter

4

Overview

When and How to Calibrate

Use this chapter to calibrate the thermocouple/mV module or the RTD input

module. Refer to the table for a summary of what is covered.

Your module is shipped to you already calibrated. If a calibration check is

required, the module must be in a POINT I/O system.

Your Module

Perform module calibration periodically, based on your application. Module

calibration may also be required to remove module error due to aging of

components in your system.

Task Pag e

When and How to Calibrate Your Module 39 Calibration Method 39 Tools and Equipment Required to Calibrate Your Thermocouple Module 39 Calibrate the Thermocouple Input Module 40 Input (mV) Calibration 42 Cold Junction Compensation Calibration 45 Tools and Equipment Required to Calibrate Your RTD Module 48 Calibrate the RTD Input Module 48

Calibration Method

Tools and Equipment

Perform calibration through the I/O configuration software, such as

RSNetWorx and EDS files. If the EDS files are not in your software, get them

online at www.ab.com/networks/eds/

To calibrate your thermocouple module, you need the following tools and

equipment.

.

Required to Calibrate

Your Thermocouple Module

39 Publication 1734-UM004F-EN-E - December 2012

Tool or Equipment Description

Precision Resistors High precision resistors:

1000 Ω, 0.05%, 5 ppm/

3000 Ω, 0.05%, 5 ppm/

or

Calibrated resistor Decade Box, 0.05%

Precision Voltage Source +100 mV, 1 mV resolution - accuracy +

o

C

o

C

3 μV or better

Page 50

40 Calibrate Your Module

IMPORTANT

01 01 01 01 010101

DeviceNet Input

Precision

Voltage

Source

Channel 0

Connect to 4 and 5

Channel 1

Connect to 6 and 7

1734-IT2I

1734-PDN

Shield

0+

0-

1-

1+

Thermocouple 0

Thermocouple 1

Precision Voltage

Source

0+

1+

1734-RTB

CJC

1734-RTB

Precision resistors

0+

1+

0 -

1-

46001

45999

46011

Calibrate the Thermocouple

To calibrate your thermocouple input module, connect the module in a

DeviceNet system similar to that shown in the figure.

Input Module

Module Connection

Apply power to the power supply and module for at least 10

minutes before calibrating the module.

Delete all I/O connections by removing the module from its

master's scan list and inhibiting the module in RSLogix. When

there is no connection present the Network Status Indicator

should flash green.

Publication 1734-UM004F-EN-E - December 2012

Page 51

Calibrate Your Module 41

ATTENTION

Click Device Parameters to

view the parameters.

Access Calibration Parameters in RSNetWorx

1. Double-click the icon of the module to be calibrated to bring up the

General Parameter dialog.

2. Click Device parameters.

The EDS editor may ask you if you want to upload the configuration

from the device.

3. If you do not see the EDS editor dialog, proceed with the next step;

otherwise, from the EDS editor dialog, click Upload.

The dialog box layout varies depending on the version of

RSNetWorx software you are using.

Publication 1734-UM004F-EN-E - December 2012

Page 52

42 Calibrate Your Module

This is the Groups pull-down.

IMPORTANT

4. From the Device Parameters dialog, select Calibration at the Groups

pull-down.

Input (mV) Calibration

Before calibrating the module you need to select the sensor type and download

it to the module.

Perform the following procedure from the Device Parameters dialog.

Apply power to the power supply and module for at least 10

minutes before calibrating the module.

Delete all I/O connections by removing the module from its

master's scan list and inhibiting the module in RSLogix. When

there is no connection present the Network Status Indicator

should flash green.

Publication 1734-UM004F-EN-E - December 2012

Page 53

Calibrate Your Module 43

For input calibration, choose:

Input Channel 0,

Input Channel 1, or

Both Channels.

1. From the Configuration tab, set the Thermocouple Type to mV (no

linearization) for the channel(s) to be calibrated and download to the

module.

2. Open the Device Parameter tab and click Calibration Channel Select to

bring up your channel selections.

3. Select a channel (0 or 1), or select Both Channels.

4. Click Download to Device.

Publication 1734-UM004F-EN-E - December 2012

Page 54

44 Calibrate Your Module

IMPORTANT

Select Accept Low Input and

download to the device.

5. Click Calibration Command, and select Begin Calibration.

6. Click the Download to Device button.

The status indicator of a channel in calibration mode flashes green. The

status indicator of a channel not in calibration turns off.

7. Apply 0.00 mV to the input, referring to the wiring diagram in this

section.

Calibration in millivolts allows the sensor calibration to be

independent of CJC. The cold junction compensation is not

active for the mV input regardless of the CJC setting. The

module must have the exact voltage at its input terminals.

Thermocouple wire or a voltage source that simulates a TC

voltage should not be used.

8. Click Accept Low Input.

Publication 1734-UM004F-EN-E - December 2012

9. Click the Download to Device button.

The status indicator(s) for the channel(s) being calibrated blink(s) green.

Page 55

10. Set the source to 70 mV.

Select Cold Junction 0, Cold

Junction 1, or Both Cold Junction.

Module terminal voltage must be exact.

11. Click Accept High Input.

12. Click the Download to Device button.

Calibrate Your Module 45

Input calibration is now complete. The status indicator should be solid green

(normal) or blinking red (no load). The channel can now be configured to the

type of input desired for normal operation. If an error occurred during

calibration, select Abort Calibration in the Calibration Command parameter to

restore the previous calibration values, and try again.

Cold Junction Compensation Calibration

Perform this procedure from the Device Parameters dialog.

1. Click Calibration Channel Select and select one channel, or both

channels at once.

Publication 1734-UM004F-EN-E - December 2012

Page 56

46 Calibrate Your Module

Click calibration

command and select

Begin CJC calibration.

Then download to the

module.

2. Click Calibration Command and select Begin CJC Calibration.

3. Click the Download to Device button.

4. Using a 1734-RTB removable terminal block, apply 1000 Ω to the

selected CJC channel, referring to the wiring diagram in this section.

5. Select Accept Low CJC and download to the device.

6. Using a 1734-RTB removable terminal block, apply 3000 Ω to the

selected CJC channel.

Publication 1734-UM004F-EN-E - December 2012

Page 57

Calibrate Your Module 47

When the calibration is

accepted by the module, it

sets the Bad Cal Status bit

for the channel to Good

Calibration, as shown

here.

7. Select Accept High CJC and download to the device.

8. If RSNetWorx reports a communication error, or if an error occurred

during this calibration, abort calibration and try again.

Calibration is done as soon as High and Low calibration for the selected

channels is done successfully.

Repeat above steps to calibrate the other channel if you chose to

calibrate only one channel at a time. Both high and low inputs must be

accepted in order for the module to finish calibration.

Calibration is now complete.

If the module does not accept calibration (status indicator still blinking), click

Calibration Command and select Abort Calibration, apply, and start over.

Publication 1734-UM004F-EN-E - December 2012

Page 58

48 Calibrate Your Module

IMPORTANT

01 0101 01 010101

DeviceNet Input

100 Ω for Low;

500 Ω for High

Channel 0

Connect to 0 and 2

Decade

Resistance Box

(0.05% or better)

Channel 1

Connect to 1 and 3

1734-IR21734-PDN

Channel 0

Channel 1

45998

45999

100 Ω for Low;

500 Ω for High

1 Ω resistor

1 Ω resistor

Tools and Equipment Required to Calibrate Your RTD Module

Calibrate the RTD Input Module

To calibrate your RTD module, you need the following tools and equipment.

Tool or Equipment Description

Precision Resistors High precision resistors:

100 Ω, 0.04%, 5 ppm/ oC

500 Ω, 0.03%, 5 ppm/ oC - for 1734-IR2 module

200 Ω, 0.03%, 5 ppm/ oC - for 1734-IR2E module

or

Calibrated resistor Decade Box, 0.05%

Precision Voltage Source +100 mV, 1 mV resolution - accuracy +

3 μV or better

To calibrate your RTD input module, connect the module to a DeviceNet

system similar to that shown in the figure and perform the following

procedures.

Apply power to the power supply and module for at least 10

minutes before calibrating the module.

Module Calibration

Publication 1734-UM004F-EN-E - December 2012

1. Double-click the icon to bring up the General Parameter dialog.

Page 59

Calibrate Your Module 49

Click Device Parameters to

view the parameters.

Select the desired channel,

or select “Both Channels.”

2. Click Device Parameters to view the parameters.

The EDS editor may ask you if you want to upload the configuration

from the device.

3. From the EDS editor, if it asks you about uploading the configuration

from the device, click Upload; otherwise, proceed to the next step.

4. From the Device Parameters dialog, click Calibration Channel Select to

bring up your channel selections, and select a channel, or select both.

Publication 1734-UM004F-EN-E - December 2012

Page 60

50 Calibrate Your Module

This is the Groups pull-down menu.

Select Begin Calibration on the

calibration command pull-down

menu.

5. From the Device Parameters dialog, select Calibration at the Groups

pull-down.

6. Click Calibration Command and select Begin Calibration.

Publication 1734-UM004F-EN-E - December 2012

7. Click the Download to Device button.

Both channel status indicators turn off.

8. From the General Parameters dialog, click the Download to Device

button.

9. Using a 0.05 % accurate resistance box, apply 100.00 Ω to the input,

assuming that you have selected Ohms as the RTD type for the channel

being calibrated.

Page 61

Calibrate Your Module 51

10. From the General Parameters dialog, click Accept Low Calibration.