User Manual

POINT Guard I/O Safety Modules

Catalog Numbers 1734-IB8S, 1734-OB8S, 1734-IE4S

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, GuardLogix, Guardmaster, POINT Guard I/O, Rockwell Automation, Rockwell Software, RSNetWorx, SmartGuard, and Studio 5000 are trademarks of Ro ckwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

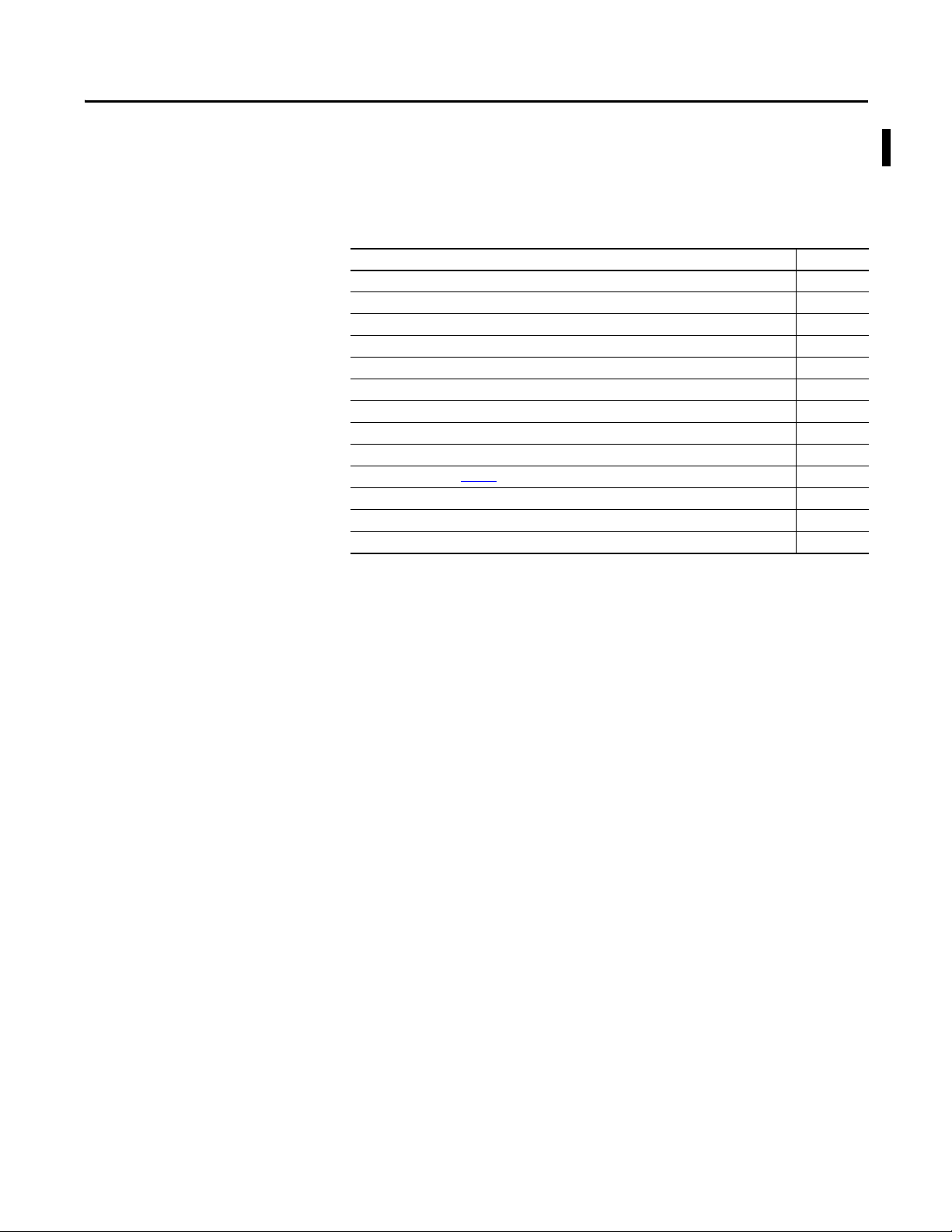

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pa ge

Added information on accessing Release Notes. 12

Added information on single -channel operation to the list of 1734-IB8S module features 18

Updated Single-channel Mode Normal Operation and Fault Detection figure. 26

Updated Dual-channel, Equivalent Normal Operation and Fault Detection figure. 28

Updated Complementary, Normal Operation and Fault Detection figure. 29

Updated Dual-channel Setting figure. 39

Added information on placing Series B modules. 48

Updated European Hazardous Location Approval information. 52

Added guidance for using the 1734-IE4S module's sensor power supply. 58

Correc ted the Cla ss ID in Ta bl e 15

Updated Appendix C: Specifications 161

Added specification for Sensor Supply Undercurrent Fault. 166

Added Safety Data for Series B modules to Appendix C. 173

Safety Analog Input Module (1734-IE4S) 158

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 3

Summary of Changes

Notes:

4 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

POINT Guard I/O Overview

Table of Contents

Preface

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Access Product Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 1

Understand Suitability for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing and Replacing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

POINT Guard I/O Modules in CIP Safety Systems. . . . . . . . . . . . . . . . . 17

1734-IB8S Digital Input Module Features. . . . . . . . . . . . . . . . . . . . . . 18

1734-OB8S Safety Digital Output Module Features. . . . . . . . . . . . . 18

1734-IE4S Safety Analog Input Module Features . . . . . . . . . . . . . . . 19

Programming Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CIP Safety Architectures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Safety Application Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety Inputs, Safety Outputs, and

Safety Data

Chapter 2

Safe States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

POINT Guard Digital I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

POINT Guard I/O Analog Input Module. . . . . . . . . . . . . . . . . . . . . . 24

Safety Inputs (1734-IB8S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Using a Test Output with a Safety Input . . . . . . . . . . . . . . . . . . . . . . . 24

Single-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dual-channel Mode and Discrepancy Time. . . . . . . . . . . . . . . . . . . . . 27

Dual-channel, Equivalent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dual-channels, Complementary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Safety Input Fault Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Input Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Safety Analog Inputs (1734-IE4S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Input Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Digital Input Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sensor Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Channel Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Using a Single-channel Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dual-channel Equivalent Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Tachometer Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Safety Outputs (1734-OB8S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Safety Output with Test Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Dual-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Safety Output Fault Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Muting Lamp Operation (1734-IB8S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 5

Table of Contents

Guidelines for Placing Power Supplies

and Modules in a System

Install the Module

I/O Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Digital I/O Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Analog I/O Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 3

Choosing a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power Supply Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Example 1: Isolating Field Power Segments . . . . . . . . . . . . . . . . . . . . . 47

Example 2: POINT Guard I/O Used with AC I/O Modules . . . . . 47

Placing Series A Digital and Analog Modules . . . . . . . . . . . . . . . . . . . . . . . 48

Placing Series B Digital Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 4

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

European Hazardous Location Approval . . . . . . . . . . . . . . . . . . . . . . . 52

North American Hazardous Location Approval. . . . . . . . . . . . . . . . . 53

Environment and Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Preventing Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

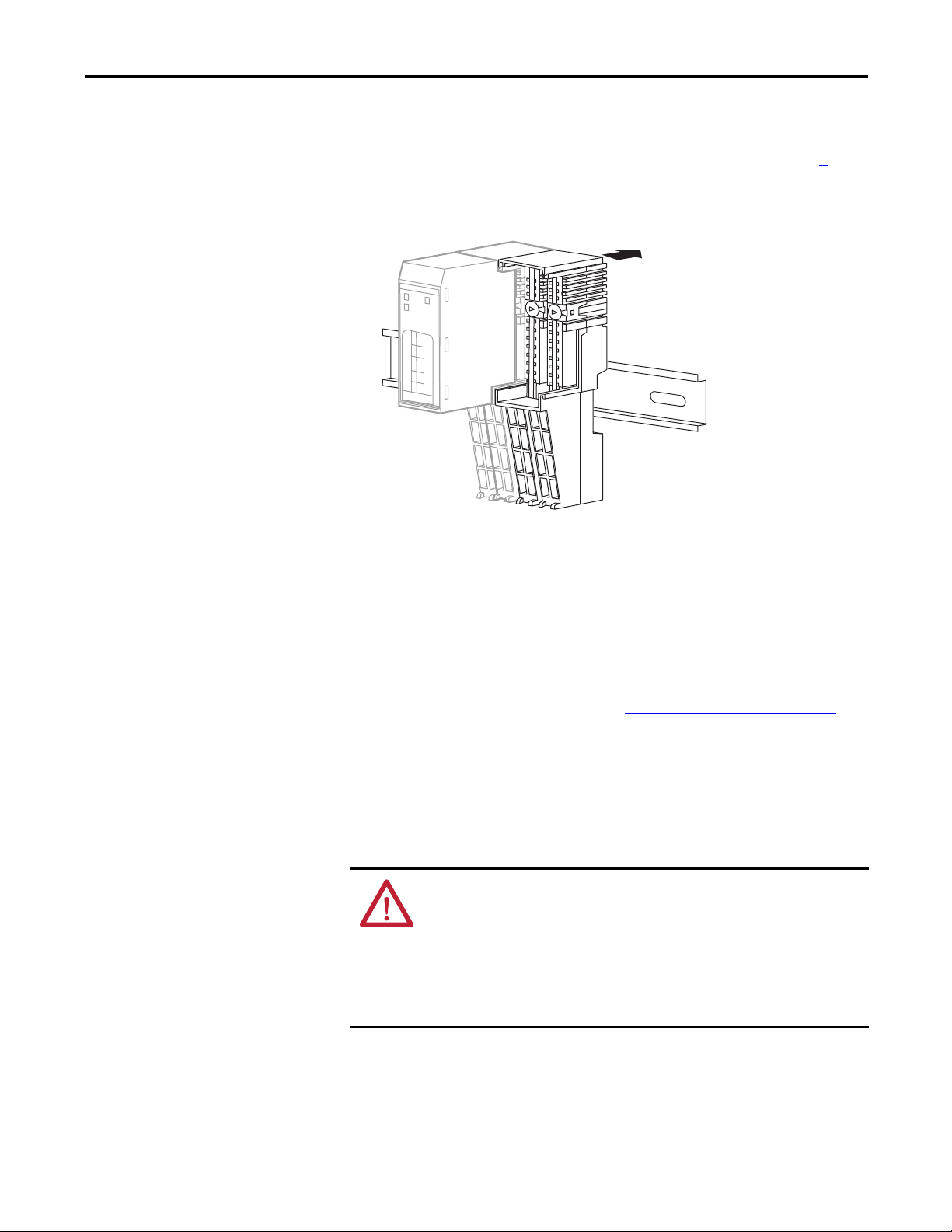

Mount the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Install the Mounting Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connect the Module to the Mounting Base . . . . . . . . . . . . . . . . . . . . . 55

Connect the Removable Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . 56

Remove a Mounting Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Wire Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

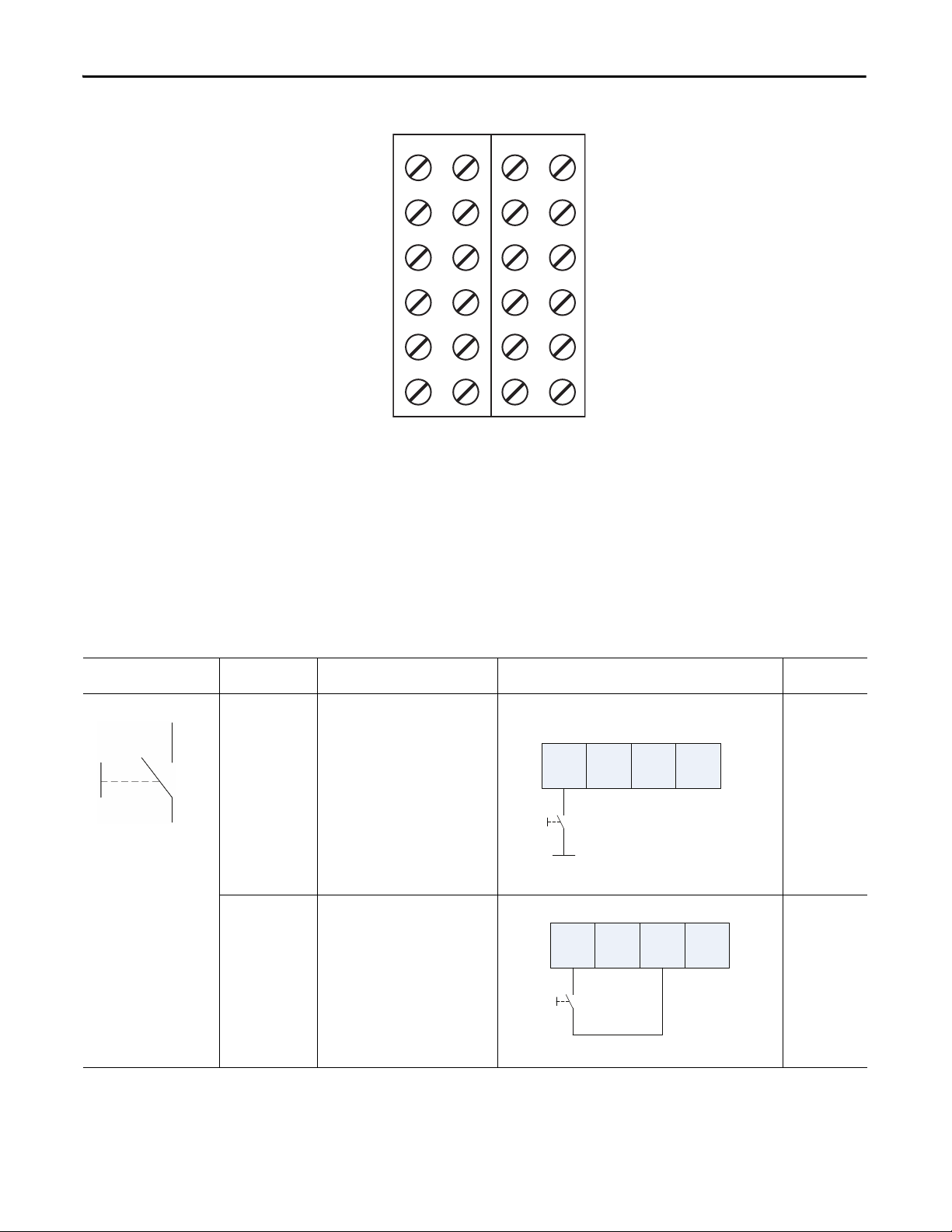

Terminal Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connection Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

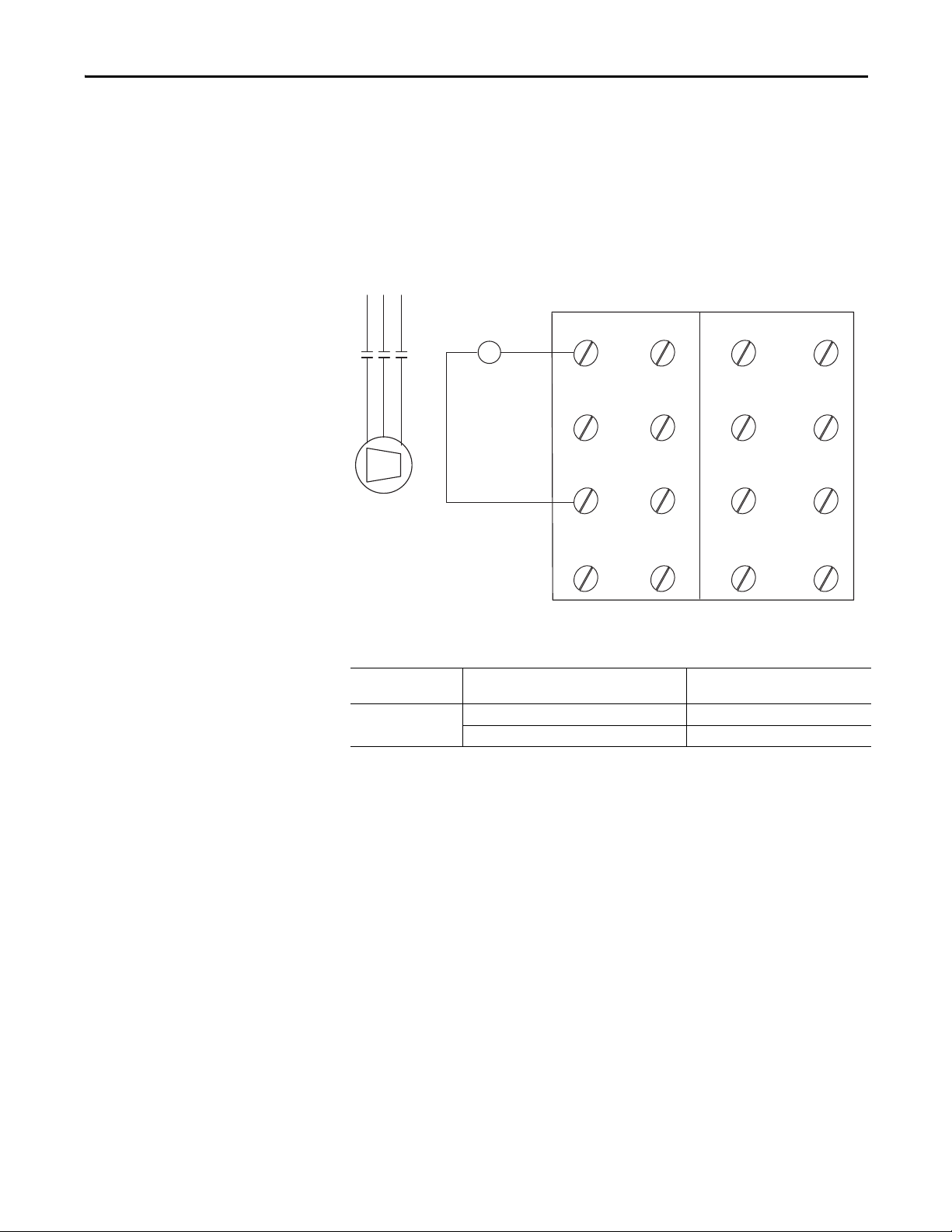

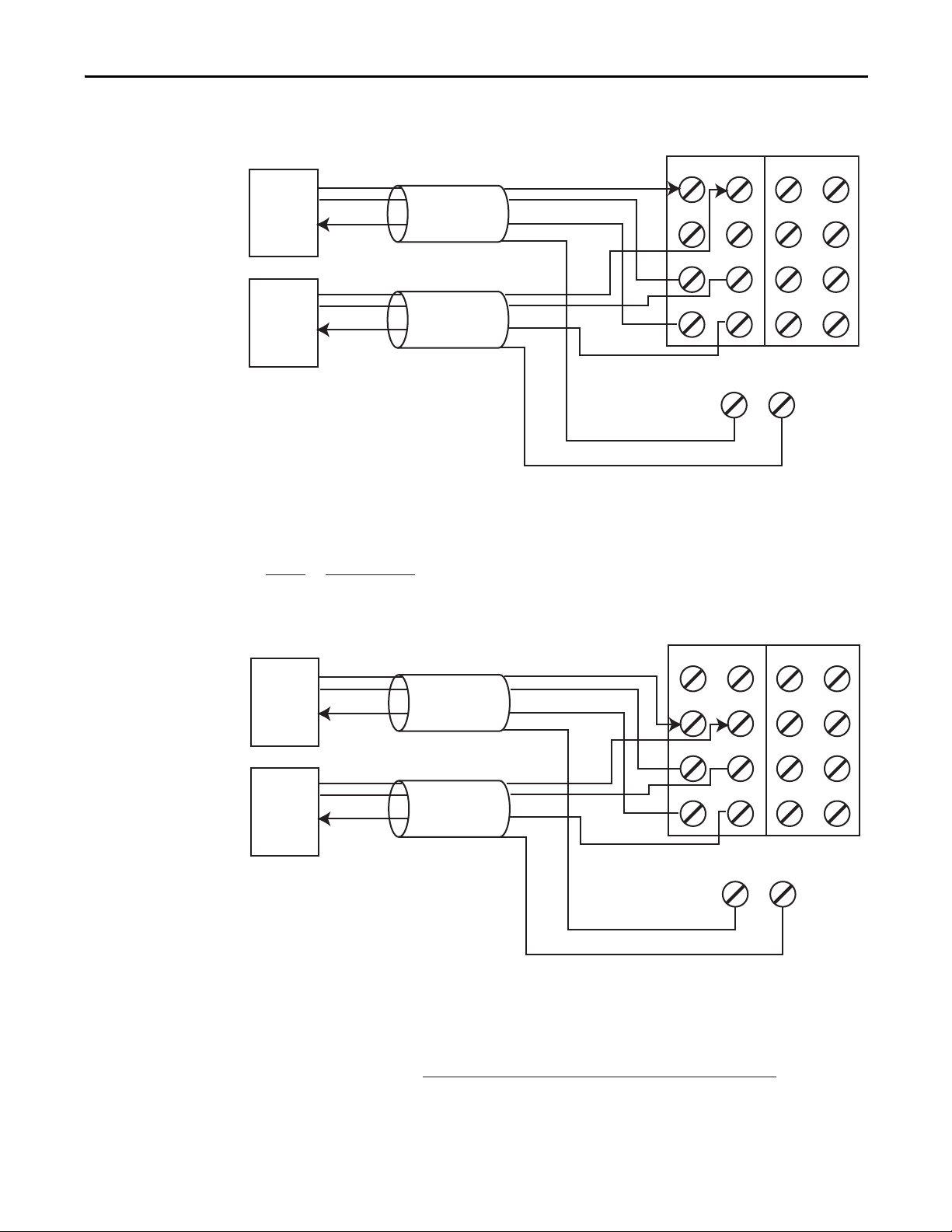

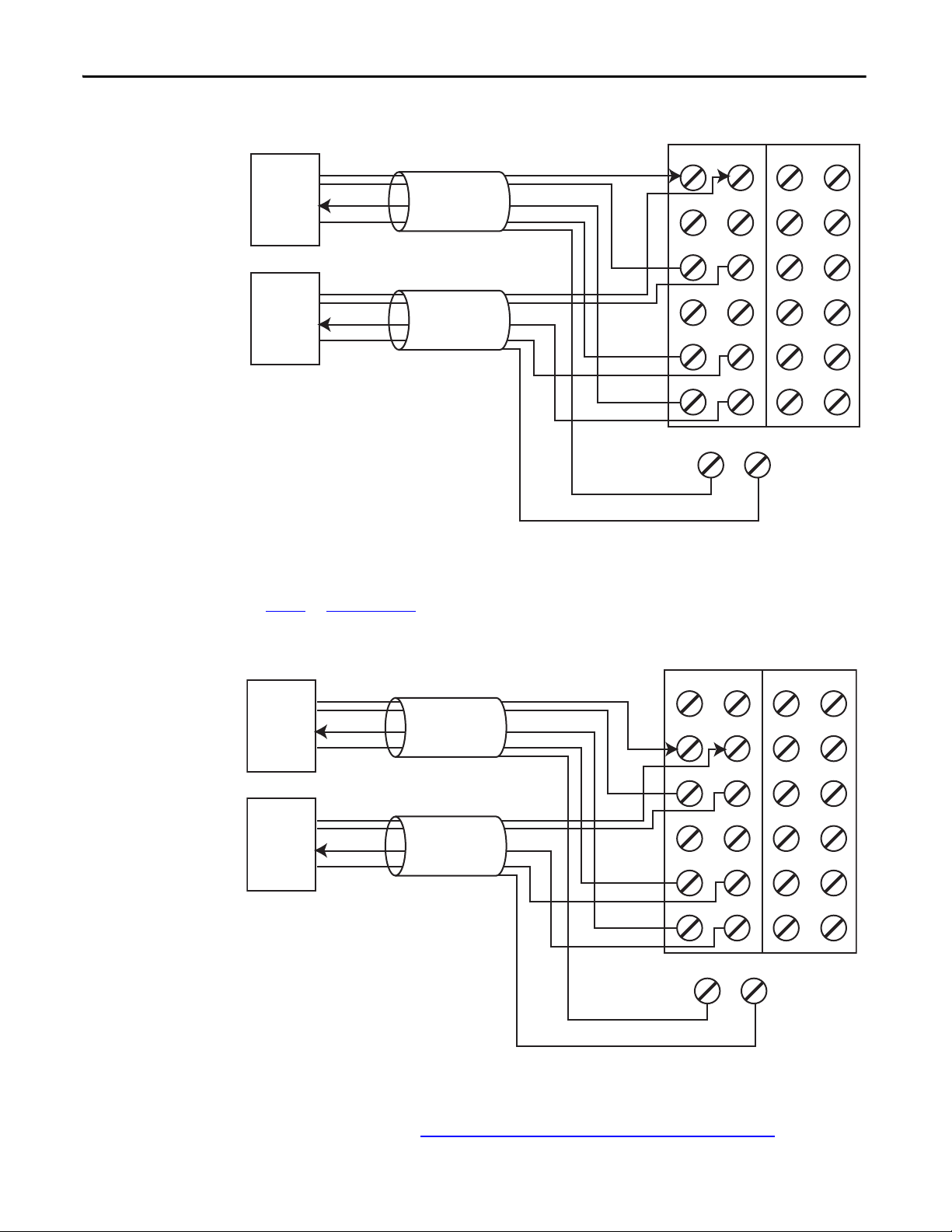

Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Emergency Stop Dual-channel Devices . . . . . . . . . . . . . . . . . . . . . . . . . 62

Single-channel Safety Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Dual-channel Safety Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Safety Analog Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 5

Configure the Module in a GuardLogix

Controller System

6 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Setting Up the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Add and Configure the Ethernet Bridge Module . . . . . . . . . . . . . . . . . . . . 74

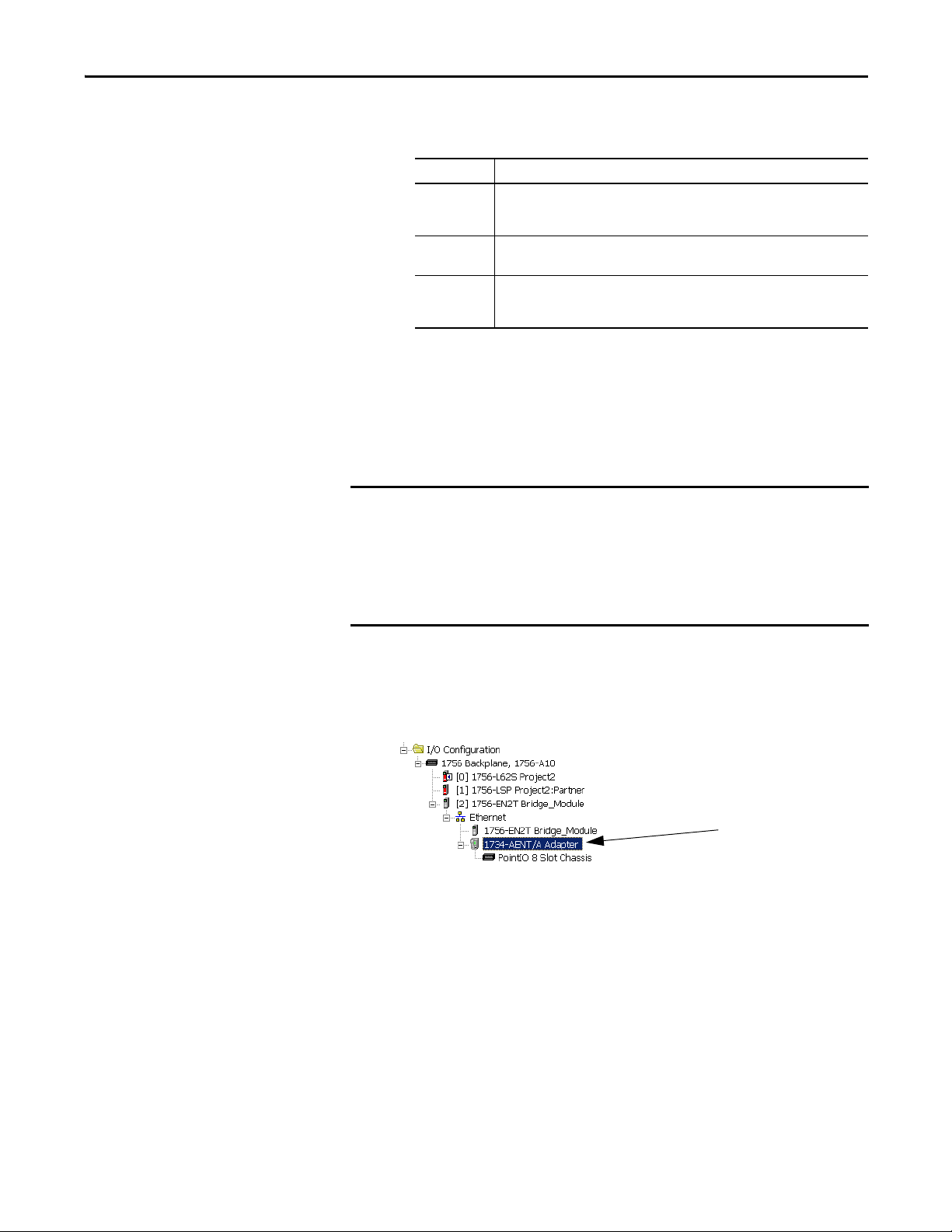

Add and Configure the 1734 Ethernet Adapter . . . . . . . . . . . . . . . . . . . . . 75

Add and Configure Safety Digital Input Modules . . . . . . . . . . . . . . . . . . . 77

Add the Safety Digital Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configure the Safety Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Configure the Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Add and Configure Safety Digital Output Modules . . . . . . . . . . . . . . . . . 86

Add the Safety Digital Output Module . . . . . . . . . . . . . . . . . . . . . . . . . 86

Configure the Safety Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . 90

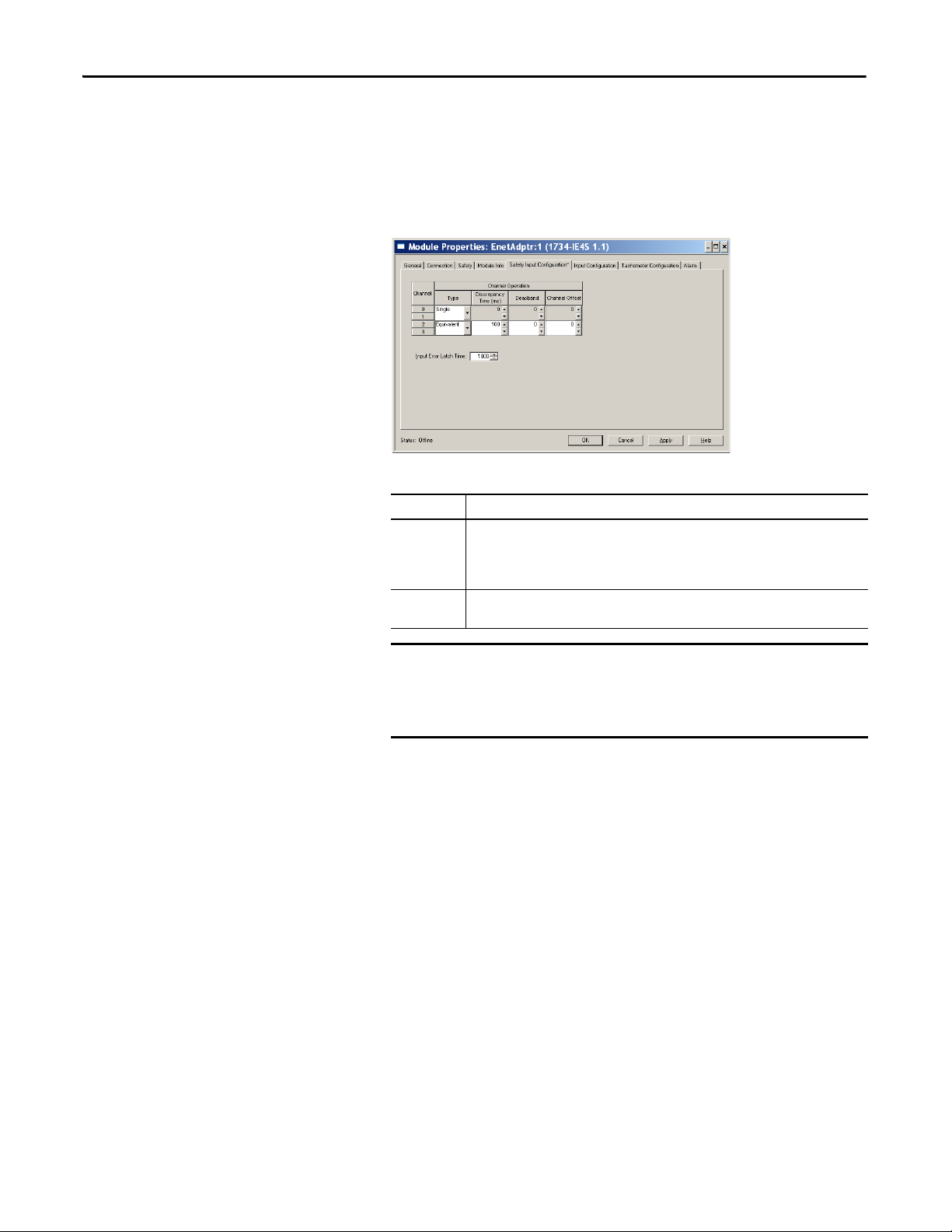

Add and Configure Safety Analog Input Modules . . . . . . . . . . . . . . . . . . . 91

Add the Safety Analog Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Configure the Safety Analog Input Channel Operation . . . . . . . . . . 94

Configure the Safety Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table of Contents

Configure Safety Analog Input Alarms (optional) . . . . . . . . . . . . . . . 96

Configure Tachometer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Values and States of Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Configure Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Configuration Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Saving and Downloading the Module Configuration. . . . . . . . . . . . . . . 104

Using ControlFLASH Software to Update POINT Guard I/O

Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 6

Configure the Module for a

SmartGuard Controller

Configuring Safety Connections

between a GuardLogix Controller and

POINT Guard I/O Modules on a

DeviceNet Network

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Set the Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Auto-addressing with a 1734-PDN Adapter . . . . . . . . . . . . . . . . . . . . . . . 108

Set Up Your DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Configure the POINT Guard I/O Modules . . . . . . . . . . . . . . . . . . . . . . . 110

Configure Digital Safety Inputs and Test Outputs . . . . . . . . . . . . . 110

Configure Digital Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Configure Safety Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Configure the SmartGuard Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Set Up the Input and Output Connections . . . . . . . . . . . . . . . . . . . . 119

Complete the Set Up of the SmartGuard Controller . . . . . . . . . . . 123

Save and Download Module Configuration . . . . . . . . . . . . . . . . . . . . . . . 124

Chapter 7

Configure the Module in RSNetWorx for DeviceNet Software . . . . . 125

Add the POINT Guard I/O Module to the Controller Project . . . . . 126

Complete the Safety Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Download the DeviceNet Network Configuration. . . . . . . . . . . . . . . . . 131

Verify Your DeviceNet Safety Configuration . . . . . . . . . . . . . . . . . . . . . . 131

Determine If Devices Can Be Verified. . . . . . . . . . . . . . . . . . . . . . . . . 132

Select Devices to Verify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Review the Safety Device Verification Reports . . . . . . . . . . . . . . . . . 134

Lock Safety Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Replacing POINT Guard I/O Modules

Chapter 8

The Safety Network Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Manually Setting the Safety Network Number. . . . . . . . . . . . . . . . . . . . . 138

Resetting a Module to Out-of-box Condition . . . . . . . . . . . . . . . . . . . . . 139

By Using the Logix Designer Application. . . . . . . . . . . . . . . . . . . . . . 139

By Using RSNetWorx for DeviceNet Software . . . . . . . . . . . . . . . . 140

Replacing a Module in a GuardLogix System on an EtherNet/IP

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Replacement with ‘Configure Only When No Safety Signature

Exists’ Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Replacement with ‘Configure Always’ Enabled. . . . . . . . . . . . . . . . . 145

Replacing a Module When Using a SmartGuard or GuardLogix

Controller on a DeviceNet Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 7

Table of Contents

Appendix A

Indicators

Get I/O Diagnostic Status from

Modules in Logix Systems

Specifications

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Network Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Configuration Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1734-IE4S Sensor Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1734-IE4S Safety Analog Input Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1734-IB8S Safety Input Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1734-OB8S Safety Output Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Appendix B

Message Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Configure the Message Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Class, Instance, and Attribute Data for I/O Modules . . . . . . . . . . . . . . . 157

Appendix C

Technical Specifications for Series A Modules . . . . . . . . . . . . . . . . . . . . . 161

Safety Digital Input Module Specifications. . . . . . . . . . . . . . . . . . . . . 161

Safety Digital Output Module Specifications. . . . . . . . . . . . . . . . . . . 163

Safety Analog Input Module Specifications . . . . . . . . . . . . . . . . . . . . 164

Technical Specifications for Series B Modules. . . . . . . . . . . . . . . . . . . . . . 173

Safety Digital Input Module Specifications. . . . . . . . . . . . . . . . . . . . . 173

Safety Digital Output Module Specifications. . . . . . . . . . . . . . . . . . . 176

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Legislations and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Safety Data

Configuration Parameters

I/O Assemblies

Appendix D

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Series A Safety Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Series B Safety Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Appendix E

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Appendix F

Input Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Output Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Analog Input Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Configuration Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Using Data from Modules Configured via the Generic Profile. . . . . . . 200

8 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Appendix G

Table of Contents

History of Changes

Index

1734-UM013I-EN-P, May 2013 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1734-UM013H-EN-P, August 2012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1734-UM013G-EN-P, August 2012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1734-UM013F-EN-P, June 2012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1734-UM013E-EN-P, March 2012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

1734-UM013D-EN-P, September 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . 202

1734-UM013C-EN-P, August 2010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

1734-UM013B-EN-P, June 2009. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

1734-UM013A-EN-P, February 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 9

Table of Contents

10 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Preface

Thoroughly read and understand this manual before installing and operating a

system using POINT Guard I/O™ modules.

Always observe the following guidelines when using a module, noting that in this

manual we use safety administrator to mean a person qualified, authorized, and

responsible to secure safety in the design, installation, operation, maintenance,

and disposal of the ‘machine’.

• Keep this manual in a safe place where personnel can refer to it when

necessary.

• Use the module properly according to the installation environment,

performance ratings, and functions of the machine.

Studio 5000 Environment

See Understand Suitability for Use on page 15

page 17.

Product specifications and accessories can change at any time. Consult with your

Rockwell Automation representative to confirm specifications of purchased

product. Dimensions and weights are nominal and are not for manufacturing

purposes, even when tolerances are shown.

Consult your Rockwell Automation representative if you have any questions or

comments. Also refer to the related documentation, listed in the page 13

necessary.

The Studio 5000® Automation Engineering & Design Environment combines

engineering and design elements into a common environment. The first element

is the Studio 5000 Logix Designer™ application. The Logix Designer application

is the rebranding of RSLogix™ 5000 software and will continue to be the product

to program Logix5000™ controllers for discrete, process, batch, motion, safety,

and drive-based solutions.

and Safety Precautions on

, as

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all of the elements of

their control system.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 11

Preface

Terminology

Ter m Me ans

Connection Logical communication channel for communication between nodes. Connections are maintained and controlled between masters and slaves.

EDS Electronic data sheet, a template used in RSNetWorx software to display the configuration parameters, I/O data profile, and connection-type support for a

given I/O module. RSNetWorx software uses these simple text files to identify products and commission them on a network.

ODVA Open DeviceNet Vendor Association, a nonprofit association of vendors established for the promotion of CIP networks.

PFD Probability of failure on demand, the average probability of a system to fail to perform its design function on demand.

PFH Probability of failure per hour, the probability of a system to have a dangerous failure occur per hour.

Proof test Periodic test performed to detect failures in a safety-related system so that, if necessary, the system can be restored to an as-new condition or as close as

practical to this condition.

SNN Safety network number, which uniquely identifies a network across all networks in the safety system. You are responsible for assigning a unique number

for each safety network or safety sub-net within a system.

Standard Devices or portions of devices that do not participate in the safety function.

Access Product Release Notes

Refer to this table for the meaning of common terms.

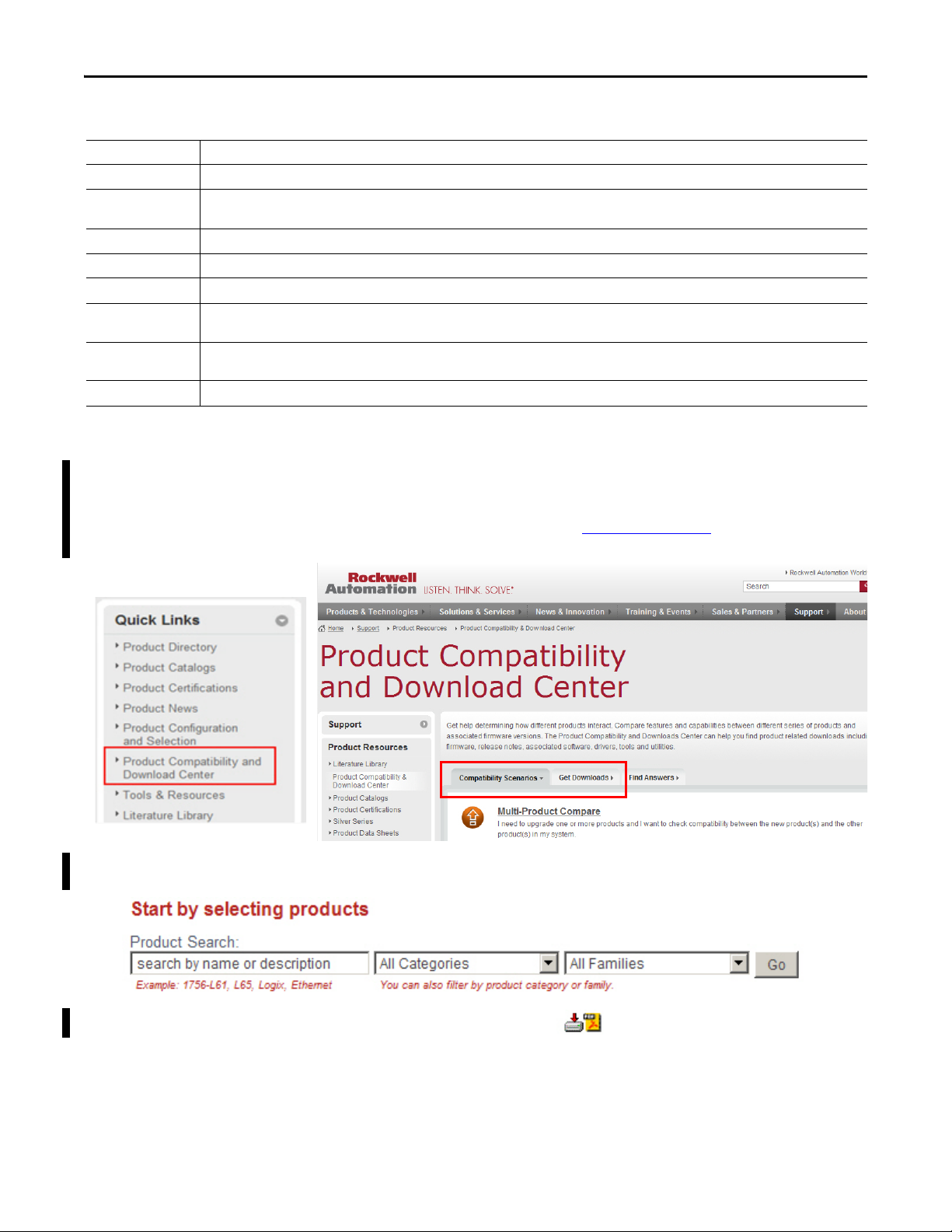

Product release notes are available online within the Product Compatibility and

Download Center.

1. From the Quick Links list on http://www.ab.com

, choose Product

Compatibility and Download Center.

2. From the Compatibility Scenarios tab or the Get Downloads tab, search

for and choose your product.

3. Click the download icon to access product release notes.

12 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Preface

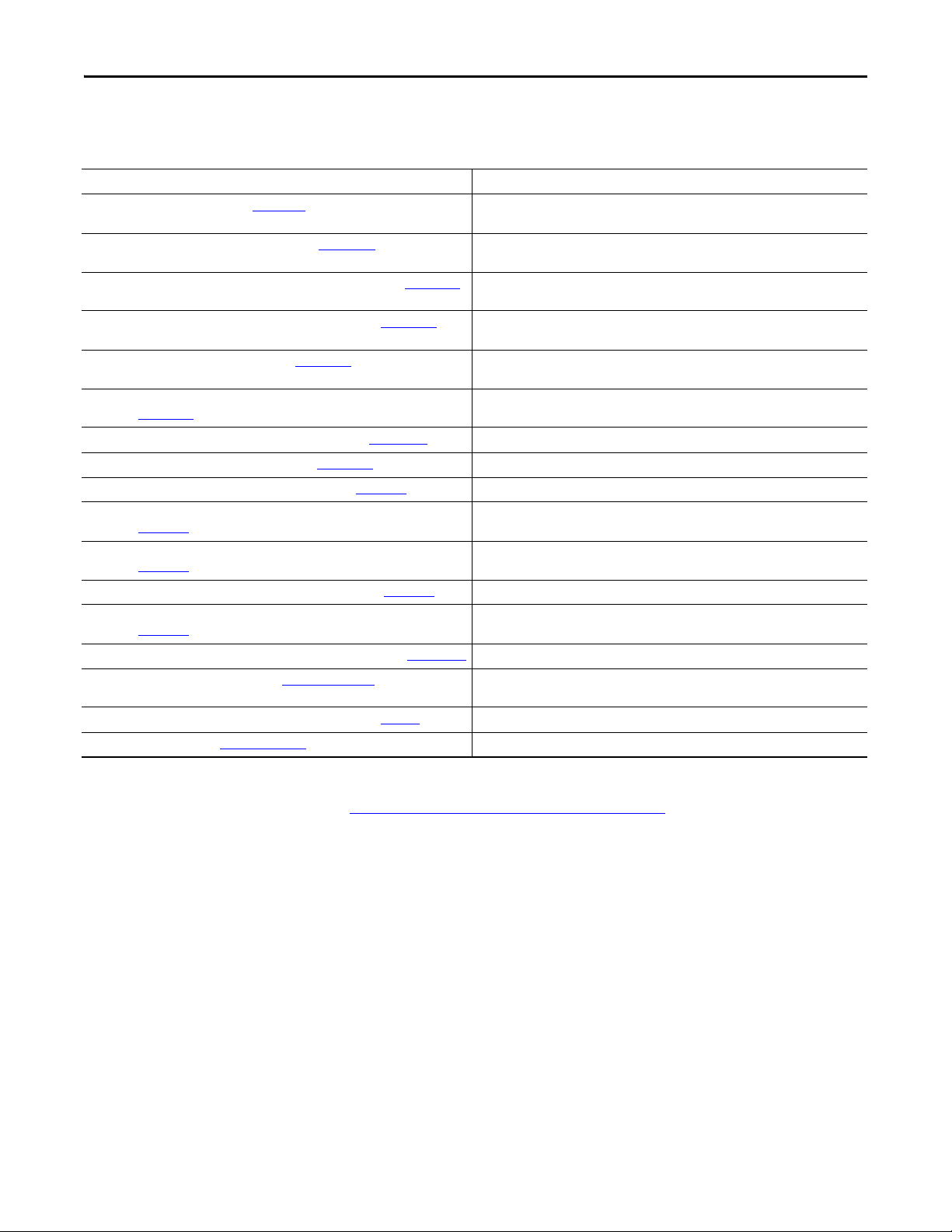

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

POINT I/O Selection Guide, publication 1734-SG001 Provides selection information for POINT I/O™ modules. Additional publication references

GuardLogix 5570 Controllers User Manual, publication 1756-UM022 Provides information on how to install, configure, program, and use GuardLogix 5570

GuardLogix 5570 Controller Systems Safety Reference Manual, publication 1756-RM099

GuardLogix Controller Systems Safety Reference Manual, publication 1756-RM093 Provides information on safety system requirements and describes the GuardLogix®

GuardLogix Controllers User Manual, publication 1756-UM020 Provides information on how to install, configure, program, and use GuardLogix

GuardLogix Safety Application Instructions Safety Reference Manual,

publication 1756-RM095

SmartGuard 600 Controllers Safety Reference Manual, publication 1752-RM001 Describes SmartGuard 600-specific safety requirements and controller features.

SmartGuard 600 Controllers User Manual, publication1752-UM001 Describes how to configure, operate, and troubleshoot the controller.

Field Potential Distributor Installation Instructions, publication 1734-IN059

POINT I/O 24V DC Expansion Power Supply Installation Instructions,

publication 1734-IN058

POINT I/O 120/240V AC Expansion Power Supply Installation Instructions,

publication 1734-IN017

POINT I/O Wiring Base Assembly Installation Instructions, publication 1734-IN511

POINT I/O One-piece Wiring Base Assembly Installation Instructions,

publication 1734-IN028

DeviceNet Modules in Logix5000 Control Systems User Manual, publication DNET-UM004 Provides information on how to connect the controller to the network.

ODVA Media Planning and Installation Guide, http://www.odva.org

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details.

Describes the required media components and how to plan for and install these required

are listed as well.

controllers in Studio 5000 Logix Designer projects.

Provides information on safety application requirements for GuardLogix 5570 controllers

in Studio 5000™ Logix Designer projects.

controller system.

controllers in RSLogix 5000 projects.

Provides reference information describing the GuardLogix Safety Application Instruction

Set.

Provides installation information on 1734-FPD distributors.

Provides installation information on 1734-EP24DC power supplies.

Provides installation information on 1734-EPAC power supplies.

Provides installation information on 1734-TB and 1734-TBS assemblies.

Provides installation information on 1734-TOP, 1734-TOPS, 1734-TOP3, and 1734-TOP3S

assemblies.

components.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 13

Preface

Notes:

14 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Chapter 1

POINT Guard I/O Overview

Top ic Pag e

Understand Suitability for Use 15

Safety Precautions 17

POINT Guard I/O Modules in CIP Safety Systems 17

Safety Application Requirements 21

Use the POINT Guard I/O safety modules in the POINT I/O platform to

distribute safety I/O on a safety-control network that meets the requirements up

to and including SIL CL3, and PLe, Cat. 4 as defined in IEC 61508, IEC 61511,

IEC 62061, and ISO 13849-1. POINT Guard I/O modules may be used with

1756 GuardLogix, 1768 Compact GuardLogix, or SmartGuard 600 controllers.

Understand Suitability for Use

You can configure the modules for use on DeviceNet networks by using the

network configuration tool, RSNetWorx™ for DeviceNet software. For EtherNet

networks, use the GuardLogix programming tool, the Logix Designer

application.

Rockwell Automation is not responsible for conformity with any standards,

codes, or regulations that apply to the combination of the products in your

application or use of the product. See Legislations and Standards

more information.

Take all necessary steps to determine the suitability of the products for the

systems, machine, and equipment with which it is used.

Know and observe all prohibitions of use applicable to these products.

Use this equipment within its specified ratings.

Never use these products for an application involving serious risk to life or

property without making sure that the system as a whole was designed to address

the risks and that the Rockwell Automation products are properly rated and

installed for the intended use within the overall equipment or system.

on page 179 for

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 15

Chapter 1 POINT Guard I/O Overview

TIP

Verify that the POINT Guard I/O firmware revision is correct prior to

commissioning the safety system. Firmware information for safety I/O modules

is available at

http://www.rockwellautomation.com/products/certification/safety

.

Field power must be applied to the 1734-IE4S module when updating

firmware.

Verify that a safety administrator conducts a risk assessment on the machine and

determines module suitability before installation.

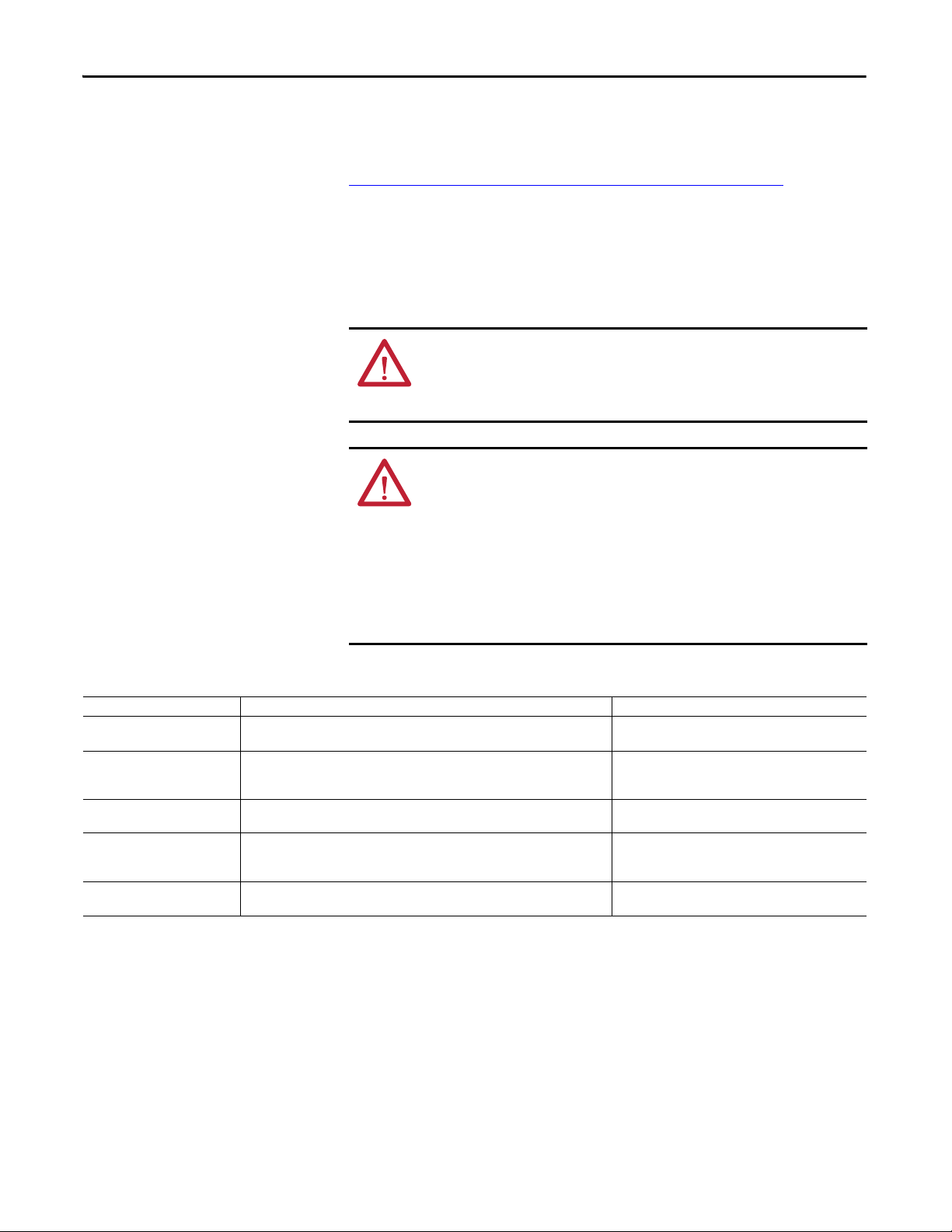

ATTENTION: Personnel responsible for the application of safety-related

programmable electronic systems (PES) shall be aware of the safety

requirements in the application of the system and shall be trained in using the

system.

ATT EN TI ON : Use only appropriate components or devices complying with

relevant safety standards corresponding to the required safety category and

safety integrity level.

• Conformity to requirements of the safety category and safety integrity level

must be determined for the entire system.

• We recommend you consult a certification body regarding assessment of

conformity to the required safety integrity level or safety category.

You are responsible for confirming compliance with the applicable standards for

the entire system.

Table 1 - Requirements for Controlling Devices

Device Requirement Allen-Bradley Bulletin Safety Components

Emergency stop switches Use approved devices with direct opening mechanisms complying with IEC/EN 60947-

Door interlocking switches,

limit switches

Safety sensors Use approved devices complying with the relevant product standards, regulations, and

Relays with forcibly- guided

contacts, contac tors

Other devices Evaluate whether devices used are appropriate to satisfy the requirements of safety

5-1.

Use approved devices with direct opening mechanisms complying with IEC/EN 60947-

5-1 and capable of switching microloads of

24V DC, 3 mA.

rules in the country where used.

Use approved devices with forcibly-guided contacts complying with EN 50205. For

feedback purposes, use devices with contacts capable of switching micro loads of

24V DC, 3 mA.

category levels.

Bulletin 800F, 800T

Bulletin 440K, 440G, 440H for interlock switch

Bulletin 440P, 802T for limit switch

Any Guardmaster product

Bulletin 700S, 100S

-

16 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

POINT Guard I/O Overview Chapter 1

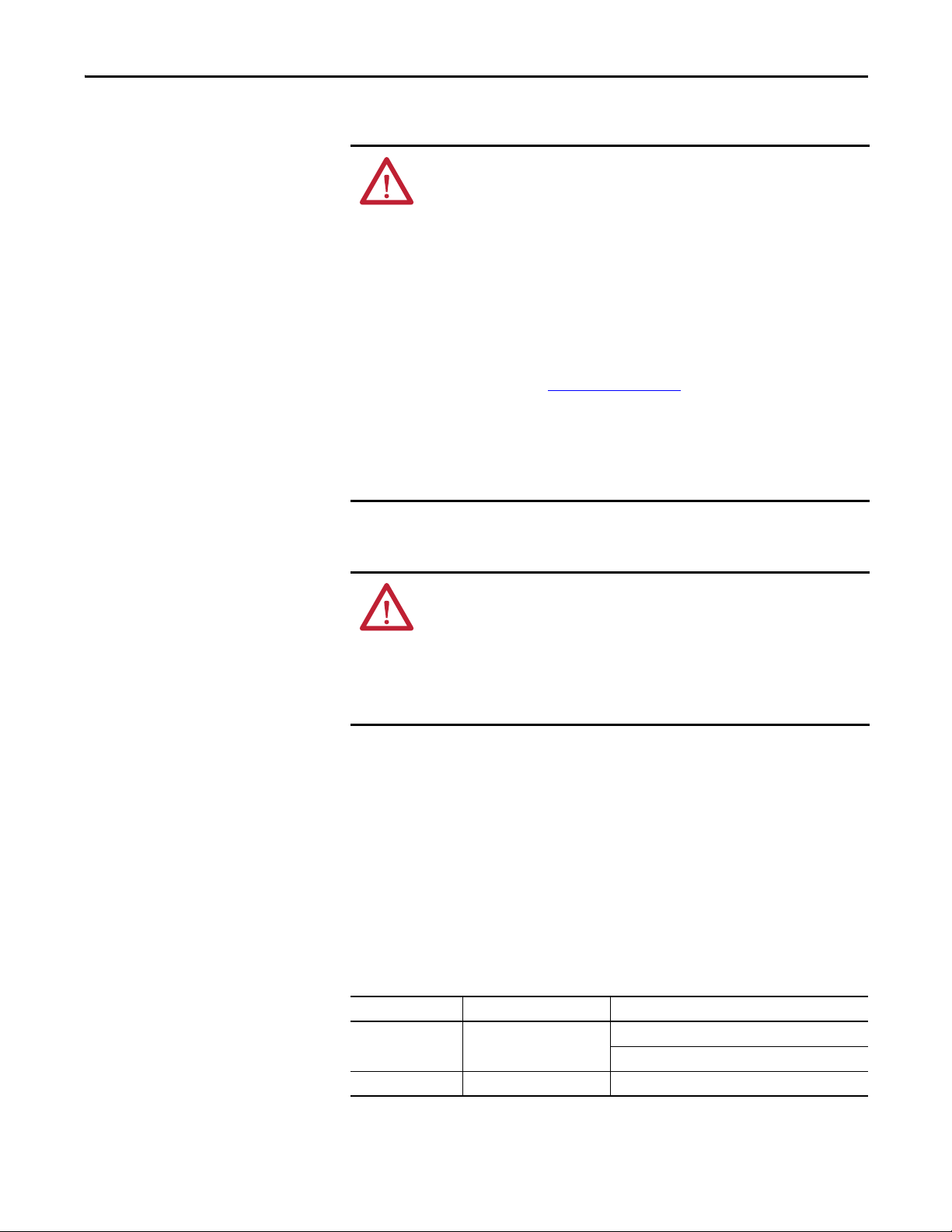

Safety Precautions

Observe these precautions for proper use of POINT Guard I/O modules.

ATTENTION: As serious injury may occur due to loss of required safety function,

follow these safety precautions.

• Never use test outputs as safety outputs. Test outputs are not safety outputs.

• Do not use Ethernet, DeviceNet, or ControlNet standard I/O data or explicit

message data as safety data.

• Do not use LED status indicators on the I/O modules for safety operations.

• Do not connect loads beyond the rated value to the safety outputs.

• Apply properly specified voltages to the module. Applying inappropriate

voltages may cause the module to fail to perform it’s specified function, which

could lead to loss of safety functions or damage to the module.

• Wire the POINT Guard I/O modules properly following the wiring requirements

and guidelines in Wire Modules

on page 58.

• Set unique network node addresses before connecting devices to the network.

• Perform testing to confirm that device wiring, configuration, and operation is

correct before starting system operation.

• Do not disassemble, repair, or modify the module. This may result in loss of

safety functions.

Installing and Replacing Modules

POINT Guard I/O Modules in CIP Safety Systems

ATTENTION:

• Clear previous configuration data before connecting devices to the network or

connecting input or output power to the device.

• Configure the replacement device properly and confirm that it operates

correctly.

• After installation of the module, a safety administrator must confirm the

installation and conduct trial operation and maintenance.

When cleaning modules, do not use the following:

• Thinner

• Benzene

• Acetone

POINT Guard I/O modules are used in the POINT I/O platform and

implement CIP Safety protocol extensions over EtherNet/IP and DeviceNet

networks to communicate safety messages. POINT Guard I/O modules connect

to EtherNet/IP or DeviceNet networks via these network adapters.

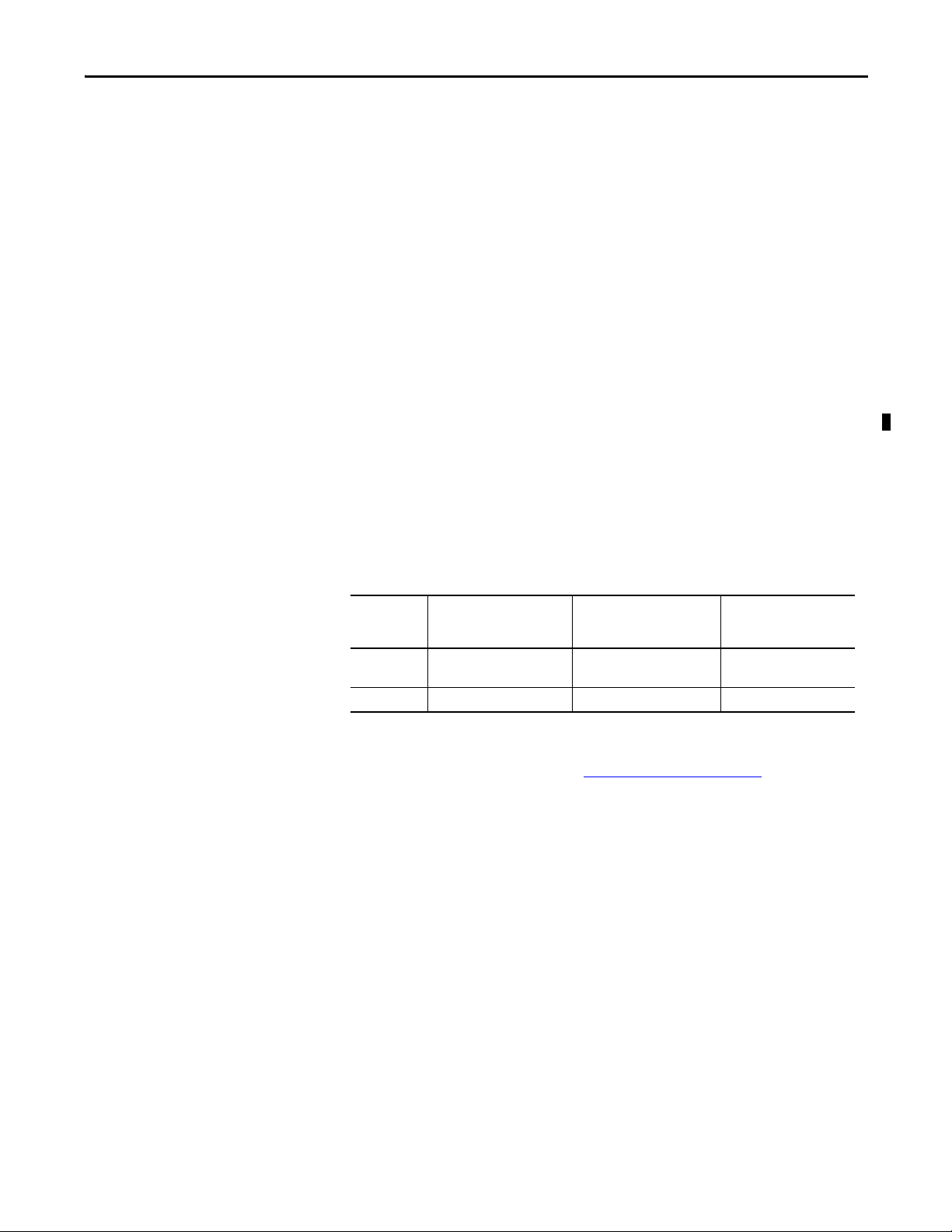

Table 2 - Network Adapters

Network System Adapter

EtherNet/IP GuardLogix 1734-AENT (firmware revision 3 or later)

DeviceNet SmartGuard or GuardLogix 1734-PDN

(1)

1734-AENTR

(1) Not compatible with 1734-ADN, 1734-ADNX, 1734-APB, or 1734-ACNR adapters.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 17

Chapter 1 POINT Guard I/O Overview

Distributed I/O communication for safety I/O data is performed through safety

connections supporting CIP Safety over an EtherNet/IP or DeviceNet network.

Data processing is performed in the safety controller. The status and fault

diagnostics of POINT Guard I/O modules are monitored by a controller.

In addition to I/O state data, the modules include status data for monitoring I/O

faults within each circuit.

The configuration information of the modules can be protected by a password.

1734-IB8S Digital Input Module Features

• Safety digital inputs

– Safety devices, such as emergency stop push buttons, gate switches, and

safety light curtains, can be connected.

– Dual-channel mode evaluates consistency between two input signals

(channels), which allows use of the module for safety Category 3 and 4

and in applications rated up to and including Performance Level e/

SIL CL3.

– Single-channel mode evaluates one input signal (channel), which allows

use of the module for safety Category 2 and in applications rated up to

and including Performance Level d/SIL CL 2.

– You can configure a discrepancy time to control how long two channels

are allowed to be discrepant before a fault is declared.

– An external wiring short-circuit check is possible when inputs are wired

in combination with test outputs. The module must be wired in

combination with test outputs when this function is used.

– Independently adjustable on and off delays are available per channel.

• Test outputs (digital input modules only)

– Separate test outputs are provided for short-circuit detection of a safety

input (or inputs).

– Power (24V) can be supplied to devices, such as safety sensors.

– Test outputs can be configured as standard outputs.

– Specific test outputs can be used for broken-wire detection of a muting

lamp.

1734-OB8S Safety Digital Output Module Features

• Solid-state outputs

• Dual-channel mode provides redundant control by using two output

signals (channels), which allows use of the module for safety Category 3

and 4, and applications rated up to and including Performance Level e/

SIL CL3.

• Safety outputs can be pulse-tested to detect field wiring short circuits to

24V DC.

18 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

POINT Guard I/O Overview Chapter 1

1734-IE4S Safety Analog Input Module Features

• Connection of up to four voltage or current sensors.

• Sensor power outputs are individually current-limited and monitored.

• Measurement of process variables, such as temperature, pressure, or flow

rate.

• Seven configurable input ranges

(±10V, ±5V, 0…5V, 0…10V, 4…20 mA, 0…20 mA, Tachometer).

• Tachometer mode converts 24V DC switching signals into pulses per

second.

• Single-channel or dual-channel for SIL 3-rated safety devices and

applications.

• Dual-channel mode evaluates the consistency between two input signals

(channels), which allows use of the module in applications rated up to and

including SIL CL3/PLe/Cat. 4.

• You can configure a discrepancy time to control how long two channels are

allowed to be discrepant before a fault is declared.

Programming Requirements

Use the minimum software versions listed here.

Cat. No. Studio 5000 Environment

1734-IB8S,

1734-OB8S

1734-IE4S 21 18

(1) This version or later.

(2) If you are using digital POINT Guard I/O modules with the analog POINT Guard I/O module, you need to update the add-on

profiles to version 2.02.004 or later for the modules to be compatible with version 18 or later of RSLogix 5000 software and the

Studio 5000 environment. To find add-on profiles, go to http://www.rockwellautomation.com/support

(3) Dual-channel Analog ( DCA) safety application instruction is available in RSLogix 5000 software, version 20 or later and Studio

5000 environment, version 21 and later.

(1)

Versi on

21 17

RSLogix 5000 Software

(1)

Vers ion

(EtherNet/IP Network)

(2)

(3)

RSNetWorx for DeviceNet

Software Version

(DeviceNet Network)

9

10

.

(1)

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 19

Chapter 1 POINT Guard I/O Overview

Safety Communication

GuardLogix

Control ler

CompactBlock

Guard I/O™

POINT Guard I/O and POINT I/O

Standard Communication

Stratix Switch

GuardLogix

Control ler

Guard I/O

POINT Guard I/O and POINT I/O

Safety Communication

Standard Communication

SmartGuard

Control ler

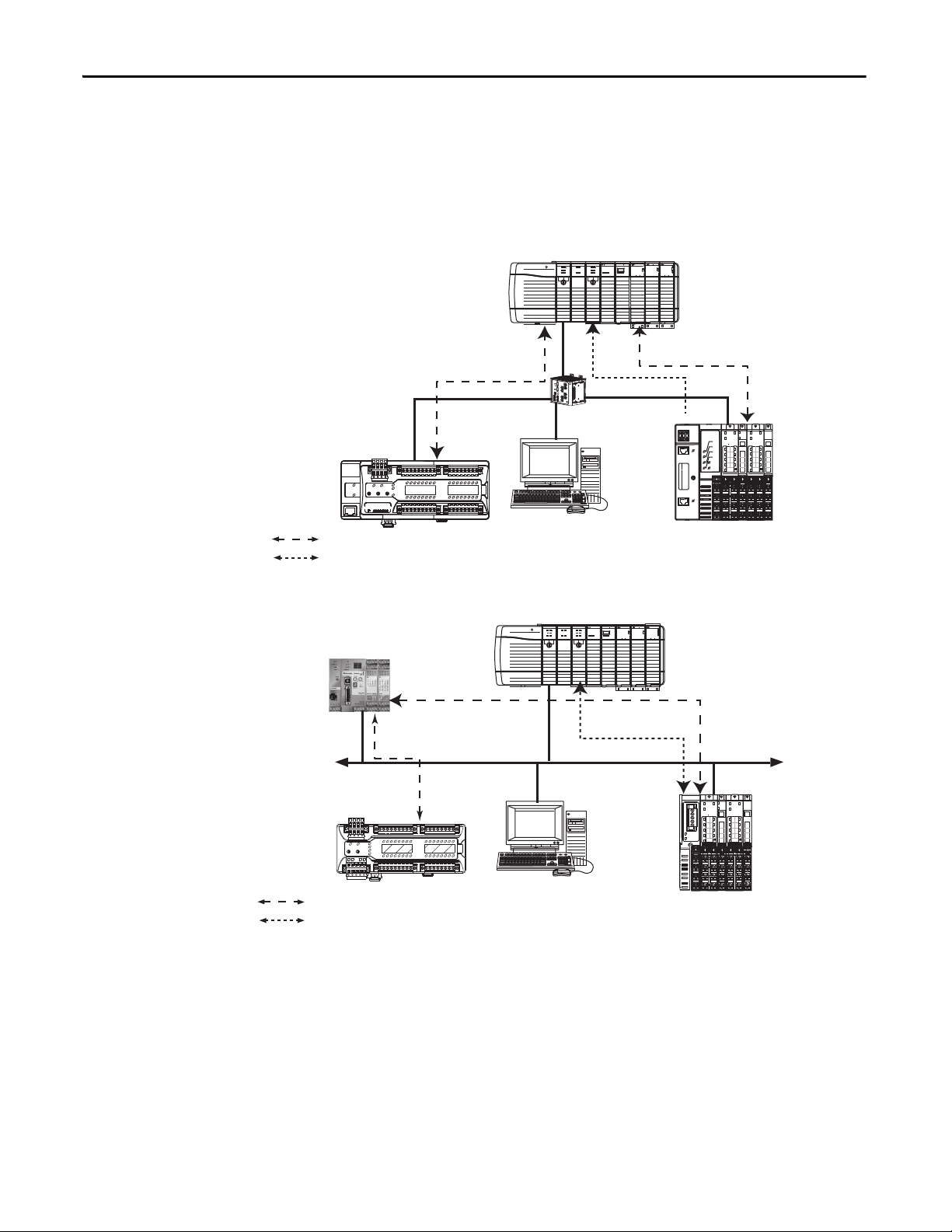

CIP Safety Architectures

Use POINT Guard I/O modules in EtherNet/IP or DeviceNet safety

architectures. Safety controllers control the safety outputs. Safety or standard

PLC controllers can control the standard outputs.

Figure 1 - POINT Guard I/O Modules in EtherNet/IP Safety Architecture

Figure 2 - POINT Guard I/O Modules in DeviceNet Safety Architectures

20 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

POINT Guard I/O Overview Chapter 1

Safety Application Requirements

POINT Guard I/O modules are certified for use in safety applications up to and

including Performance Level e (PLe/Cat. 4) and Safety Integrity Level 3

(SIL CL3) in which the de-energized state is the safe state. Safety application

requirements include evaluating probability of failure rates (PFD and PFH),

system reaction time settings, and functional verification tests that fulfill SIL 3

criteria.

Creating, recording, and verifying the safety signature is also a required part of

the safety application development process. Safety signatures are created by the

safety controller. The safety signature consists of an identification number, date,

and time that uniquely identifies the safety portion of a project. This includes all

safety logic, data, and safety I/O configuration.

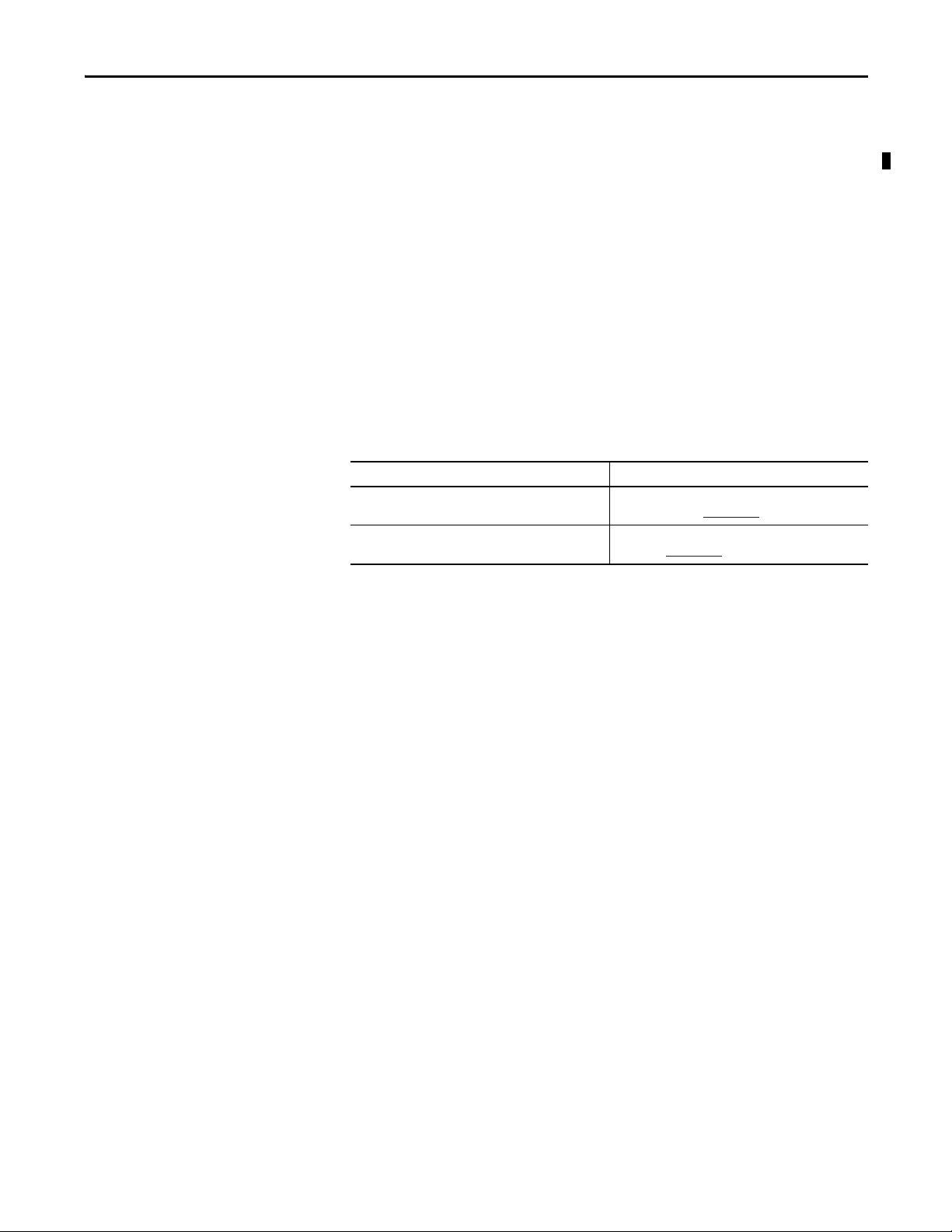

For safety system requirements, including information on the safety network

number (SNN), verifying the safety signature, functional verification test

intervals, system reaction time, and PFD/PFH calculations, refer to the following

publications.

For safety requirements in Refer to

GuardLogix controller systems GuardLogix 5570 Controller Systems Safety Reference

Manual, publication 1756-RM099

SmartGuard 600 controller systems SmartGuard 600 Controllers Safety Reference Manual,

publication 1752-RM001

You must read, understand, and fulfill the requirements detailed in these

publications prior to operating a safety system that uses POINT Guard I/O

modules.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 21

Chapter 1 POINT Guard I/O Overview

Notes:

22 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Chapter 2

Output OFF

Input

Inputs to Network OFFNetworks

Safety

Status

44076

Safety Inputs, Safety Outputs, and Safety Data

Top ic Pag e

Safe States 23

Safety Inputs (1734-IB8S) 24

Safety Analog Inputs (1734-IE4S) 31

Safety Outputs (1734-OB8S) 39

I/O Status Data 42

Safe States

POINT Guard Digital I/O Modules

ATTENTION:

• The safe state of the outputs is defined as the off state.

• The safe state of the module and its data is defined as the off state.

• Use the POINT Guard I/O module only in applications where the off state is the

safe state.

These are the safe states of the digital POINT Guard I/O modules:

• Safety outputs: OFF

• Safety input data to network: OFF (single channel and

dual-channel equivalent)

• Safety input data to network: OFF/ON for input channels n/n+1

(dual-channel complimentary)

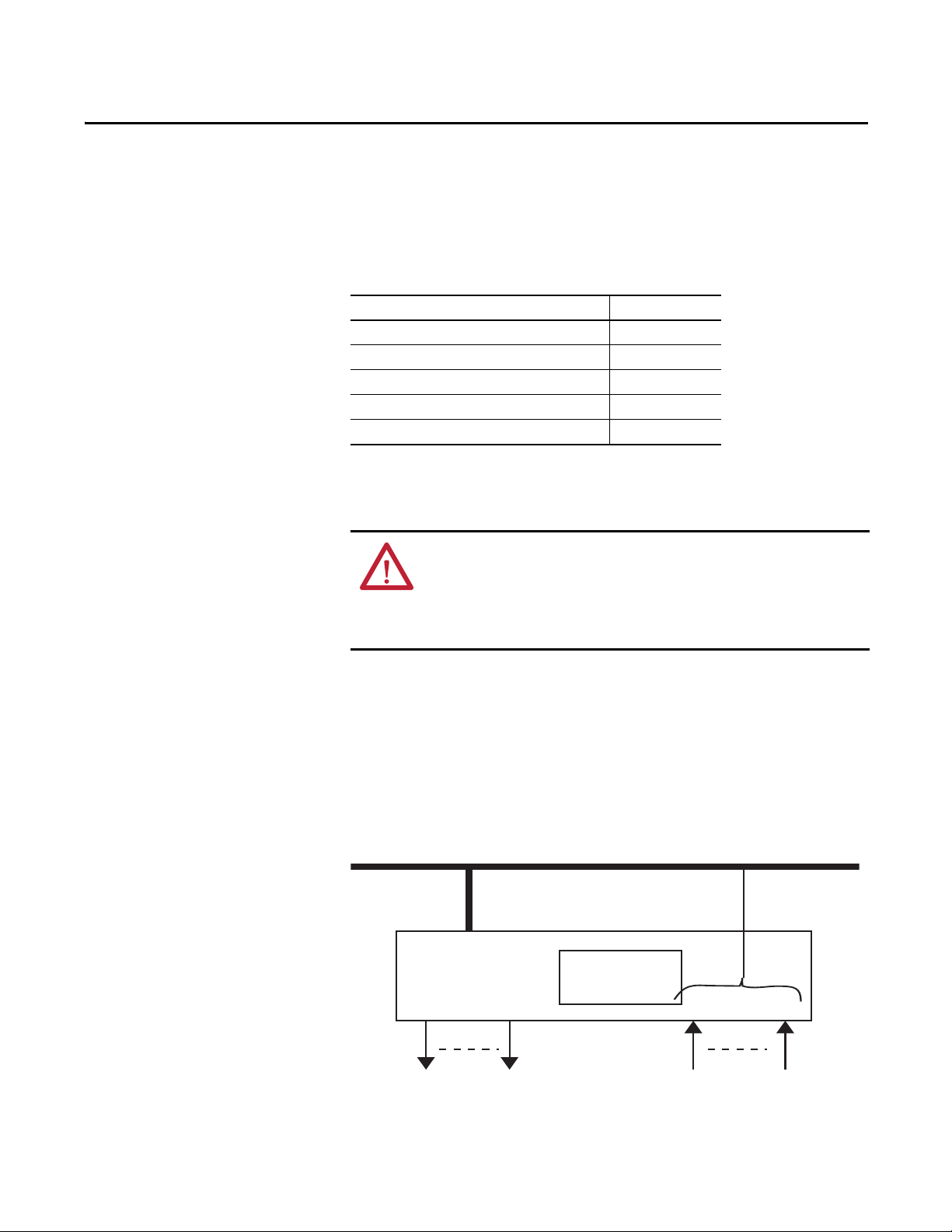

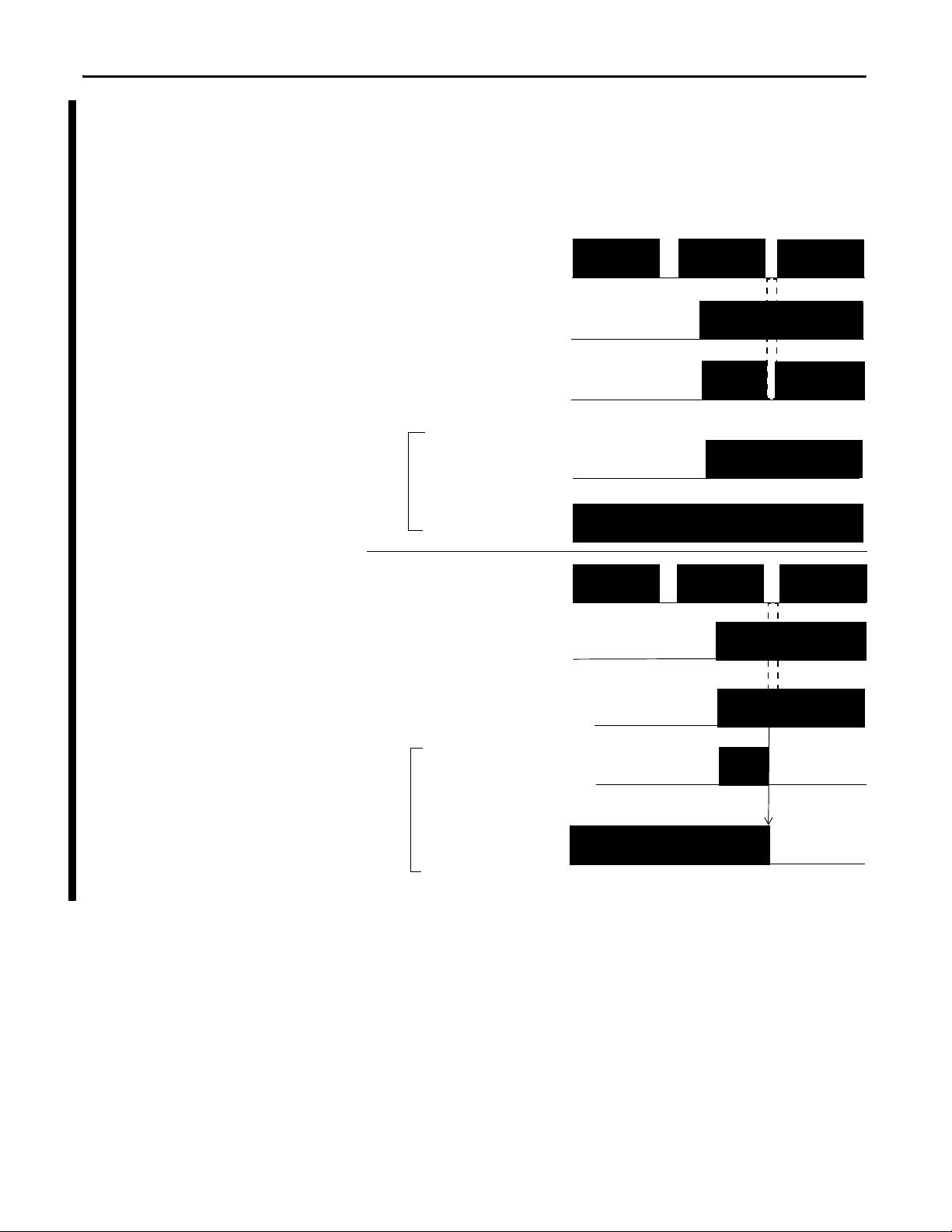

Figure 3 - Safety Status

The module is designed for use in applications where the safe state is the off state.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 23

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

TIP

Where:

T0 = Test Output 0 T1M = Test Output 1 with Muting

T2 = Test Output 2 T3M = Test Output 3 with Muting

I0…I7 = Safety Inputs

Safety Input

Ter m in a l

External

Contac t

POINT Guard I/O Analog Input Module

These are the safe states of the POINT Guard I/O analog input module:

• Safety input data to network in single-channel configuration: 0 (OFF)

• Safety input data to network in dual-channel equivalent configuration:

– If a diagnostic fault occurs, the signal for the faulted channel is set to 0

(OFF).

– If a dual-channel discrepancy fault occurs, the dual-channel inputs

continue to report actual input signals.

Safety Inputs (1734-IB8S)

Safety inputs are used to monitor safety input devices.

Using a Test Output with a Safety Input

A test output can be used in combination with a safety input for short circuit,

cross-channel, and open-circuit fault detection. Configure the test output as a

pulse test source and associate it to a specific safety input.

The test output can also be configured as a power supply to source 24V DC

to an external device, for example, a light curtain.

Figure 4 - Example Use of a POINT Guard I/O Input Module

I0 I1 I4 I5

0

I2 I3 I6 I7

2

COM COM COM COM

4

TO T1M T2 T3M

6

1

3

5

7

0

2

4

6

1

3

5

7

24 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

X

OUT

Y

On

Off

External Contact

Short-circuit between Input Signal Lines and Power

Supply (positive side)

External Contact

Short-circuit between Input Signal Lines

44079

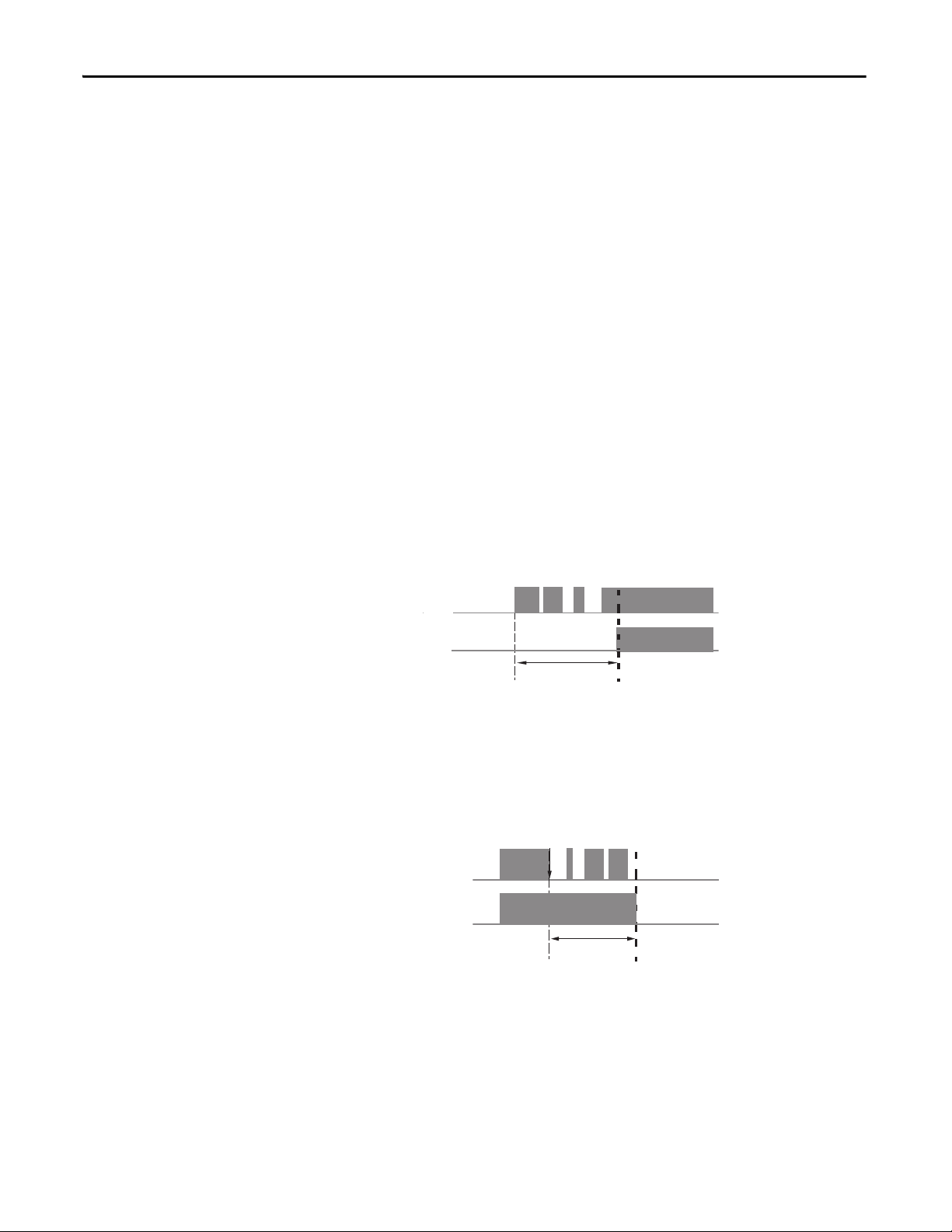

Figure 5 - Test Pulse in a Cycle

For the 1734-IB8S module, the pulse width (X) is typically 525 μs; the pulse

period (Y) is typically 144 ms.

When the external input contact is closed, a test pulse is output from the test

output terminal to diagnose the field wiring and input circuitry. By using this

function, short-circuits between inputs and 24V power, and between input signal

lines and open circuits can be detected.

Figure 6 - Short-circuit between Input Signal Lines

24V

IN+

COM

T0

24V

0V

IN0

T1

IN1

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 25

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

24V

0V

Tes t O utp ut 0

Input Terminal 0

External Device

Faul t De tect ed

ON

OFF

ON

OFF

ON

OFF

ON

OFF

24V

0V

ON

OFF

Safety Input 0

Status

Fault Detection

ON

OFF

ON

OFF

ON

OFF

Safety Input 0

Status

Safety Input 0

Data

Safety Input 0

Data

Input Terminal 0

Normal Operation

External Device

Tes t O utp ut 0

Safety

I/O

Network

Data Sent

to the

Control ler

Safety

I/O

Network

Data Sent

to the

Control ler

Single-channel Mode

If an error is detected, safety input data and safety input status turn off.

Figure 7 - Normal Operation and Fault Detection (not to scale)

26 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

IMPORTANT

IMPORTANT

Dual-channel Mode and Discrepancy Time

To support dual-channel safety devices, the consistency between signals on two

channels can be evaluated. Either equivalent or complementary can be selected.

If the length of a discrepancy between the channels exceeds the configured

discrepancy time (0…65,530 ms in increments of 10 ms), the safety input data

and the individual-safety input status turn off for both channels. In Dual-channel

Complimentary mode, the safety input data goes to off/on for input channels

n/n+1 respectively as described in Ta b l e 3

The dual-channel function is used with two consecutive inputs that are paired

together, starting at an even input number, such as inputs 0 and 1, 2 and 3,

and so on.

If you are using the safety application instructions with a GuardLogix

controller, set the module’s inputs to Single (default). Do not use the modules’

dual-channel mode as this functionality is provided by the safety application

instructions.

.

This table shows the relation between input terminal states and controller input

data and status.

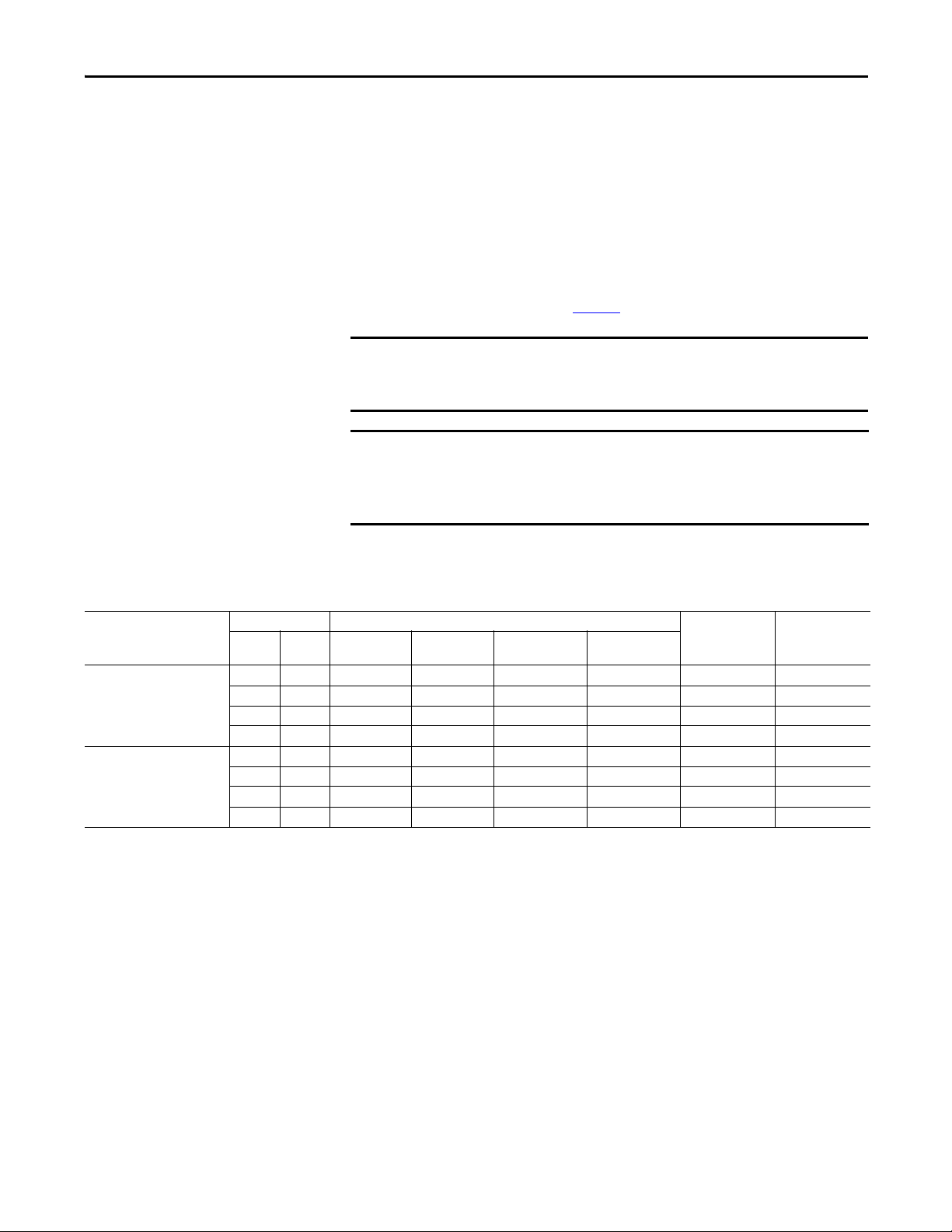

Table 3 - Terminal Input Status and Controller I/O Data

Dual-channel Mode Input Terminal Controller Input Data and Status Dual-channel

IN0 IN1 Safety

Input 0 Data

Dual-channels, Equivalent OFF OFF OFF OFF ON ON OFF Normal

OFF ON OFF OFF OFF OFF OFF Fault

ON OFF OFF OFF OFF OFF OFF Fault

ON ON ON ON ON ON ON Normal

Dual-channels, Complementary OFF OFF OFF ON OFF OFF OFF Fault

OFF ON OFF ON ON ON OFF Normal

ON OFF ON OFF ON ON ON Normal

ON ON OFF ON OFF OFF OFF Fault

Safety

Input 1 Data

Safety

Input 0 Status

Safety

Input 1 Status

Resultant

Data

Dual-channel

Resultant

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 27

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

ON

OFF

IN0

Safety Input 0

Data

IN1

Faul t Dete cted

Discrepancy Time

Safety

I/O

Network

Data Sent

to the

Control ler

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

IN0

Safety Input 0, 1

Status

IN1

Fault Detection

ON

OFF

ON

OFF

ON

OFF

Discrepancy Time

Safety Input 0, 1

Status

Safety Input 1

Data

Safety Input 1

Data

Safety Input 0

Data

Normal Operation

Safety

I/O

Network

Data Sent

to the

Contro ller

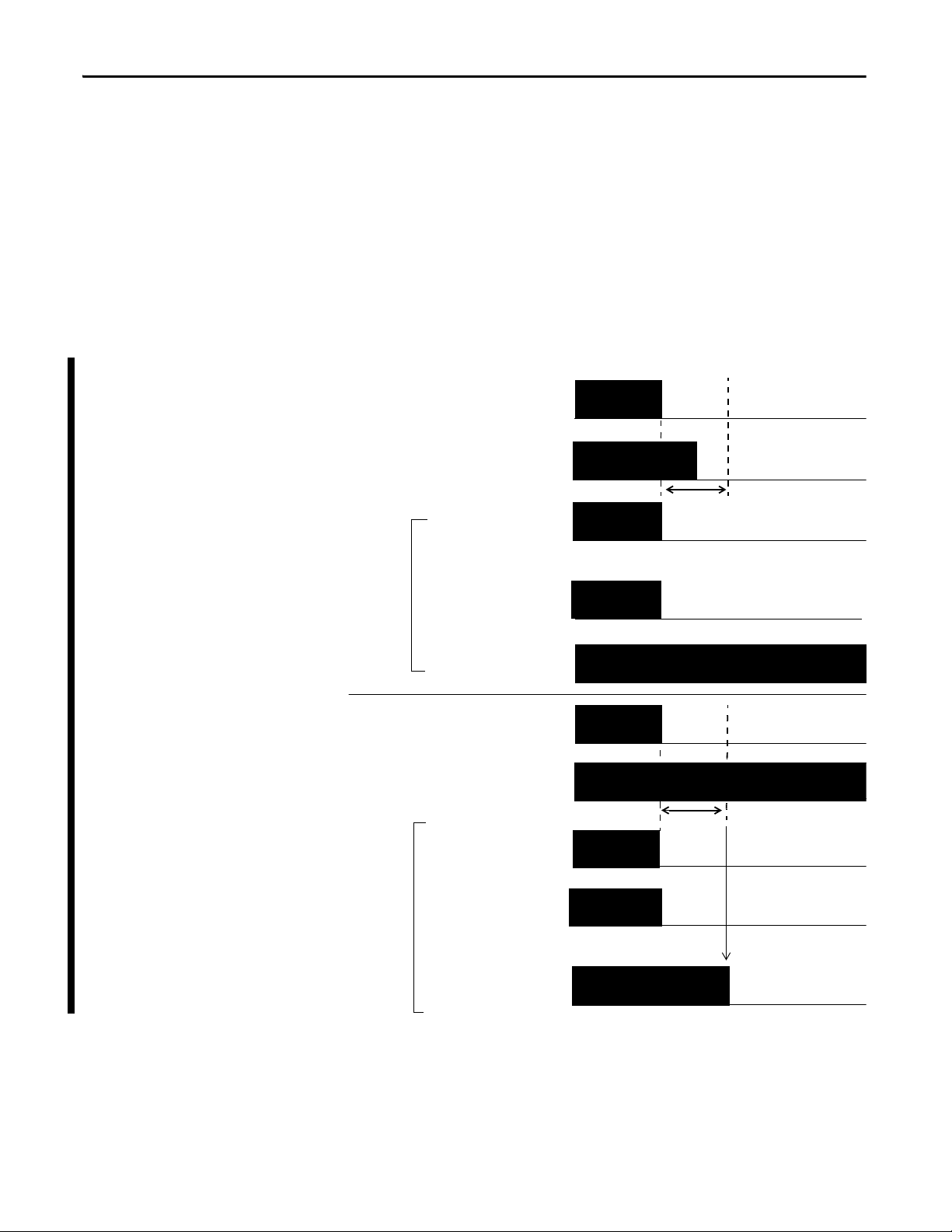

Dual-channel, Equivalent

In Equivalent mode, both inputs of a pair should be in the same (equivalent)

state. When a transition occurs in one channel of the pair prior to the transition

of the second channel of the pair, a discrepancy occurs. If the second channel

transitions to the appropriate state prior to the discrepancy time elapsing, the

inputs are considered equivalent. If the second transition does not occur before

the discrepancy time elapses, the channels will fault. In the fault state, the input

and status for both channels are set low (OFF). When configured as an

equivalent dual pair, the data bits for both channels will always be sent to the

controller as equivalent, both high or both low.

Figure 8 - Equivalent, Normal Operation and Fault Detection (not to scale)

28 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

ON

OFF

IN0

Safety Input 0

Data

IN1

Faul t Dete cted

Discrepancy Time

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

IN0

Safety Input 0, 1

Status

IN1

Fault Detect ion

ON

OFF

ON

OFF

ON

OFF

Discrepancy Time

Safety Input 0, 1

Status

Safety Input 1

Data

Safety Input 1

Data

Safety Input 0

Data

Normal

Operation

Safety

I/O

Network

Data Sent

to the

Control ler

Safety

I/O

Network

Data Sent

to the

Control ler

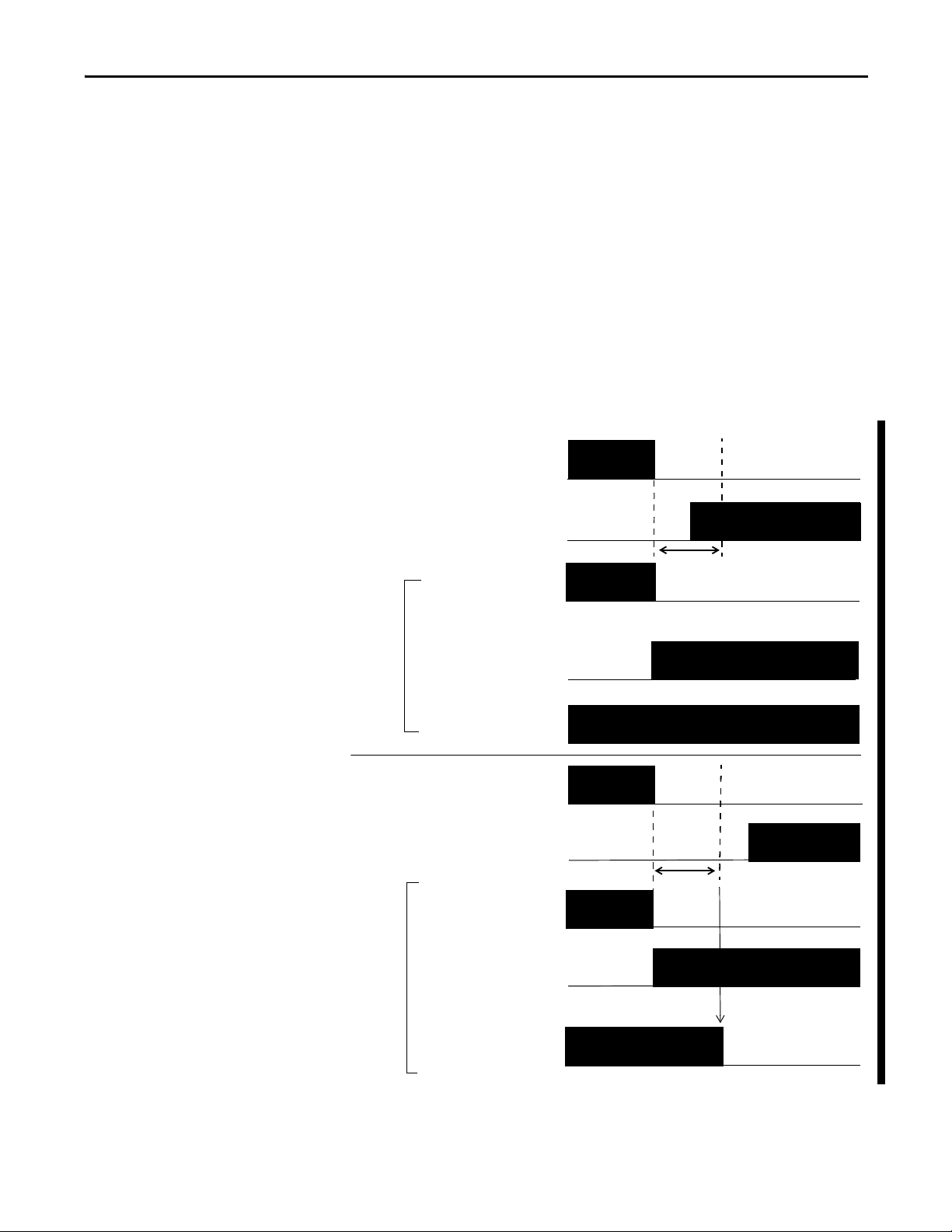

Dual-channels, Complementary

In Complementary mode, the inputs of a pair should be in the opposite

(complementary) state. When a transition occurs in one channel of the pair prior

to the transition of the second channel of the pair, a discrepancy occurs. If the

second channel transitions to the appropriate state prior to the discrepancy time

elapsing, the inputs are considered complementary.

If the second transition does not occur before the discrepancy time elapses, the

channels will fault. The fault state of complementary inputs is the

even-numbered input turned off and the odd-numbered input turned ON.

Note that if faulted, both channel status bits are set low. When configured as a

complementary dual-channel pair, the data bits for both channels will always be

sent to the controller in complementary, or opposite states.

Figure 9 - Complementary, Normal Operation and Fault Detection (not to scale)

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 29

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

44094

On-delay

ON

OFF

ON

OFF

Input Signal

Safety Input

Network Data

44095

Safety Input

Network Data

Off-delay

Input Signal

ON

OFF

ON

OFF

Safety Input Fault Recovery

If an error is detected, the safety input data remains in the OFF state. Follow this

procedure to activate the safety input data again.

1. Remove the cause of the error.

2. Place the safety input (or safety inputs) into the safe state.

3. Allow the input-error latch time to elapse.

After these steps are completed, the I/O indicator (red) turns off.

The input data is now active.

Input Delays

On-delay—An input signal is treated as Logic 0 during the on-delay time

(0…126 ms, in increments of 6 ms) after the input contact’s rising edge. The

input turns on only if the input contact remains on after the on-delay time has

elapsed. This helps prevent rapid changes of the input data due to

contact bounce.

Figure 10 - On-delay

Off-delay—An input signal is treated as Logic 1 during the off-delay time

(0…126 ms, in increments of 6 ms) after the input contact’s falling edge.

The input turns off only if the input contact remains off after the off delay time

has elapsed. This helps prevent rapid changes of the input data due to contact

bounce.

Figure 11 - Off-delay

30 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

IMPORTANT

IMPORTANT

EXAMPLE

Safety Analog Inputs (1734-IE4S)

Safety analog-input channels can be configured for current, voltage, or

tachometer inputs, and for input type: single-channel or dual-channel equivalent.

If you are using the module with a GuardLogix controller, set the module’s

inputs to Single (default). Do not use the modules’ dual-channel equivalent

mode with the GuardLogix dual channel safety application instructions, as

dual-channel functionality is provided by the GuardLogix instructions.

Input Range

You configure the module for the following voltage or current input ranges, or for

tachometer inputs.

• ±10V

• ±5V

• 0…5V

• 0…10V

• 4…20 mA

• 0…20 mA

• Tachometer (1…1000 Hz)

When ±10V and ±5V ranges are selected, you must make sure that a

broken-wire condition is not a safety hazard. A broken wire causes the analog

value to transition to 0, which is within the valid input range. Therefore, status

bits will not indicate the broken-wire condition.

Scaling

The module converts input signals to the engineering units specified when you

configure the module. You set the High Engineering value and the Low

Engineering value to which the module scales the input signal before sending the

data to the controller’s application program.

The module is configured as follows:

• Input Range = 0…10V

• Low Engineering value = 0

• High Engineering value = 10,000

If the incoming signal is 1V, the data is 1000.

If the incoming signal is 5.5V, the data is 5500.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 31

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

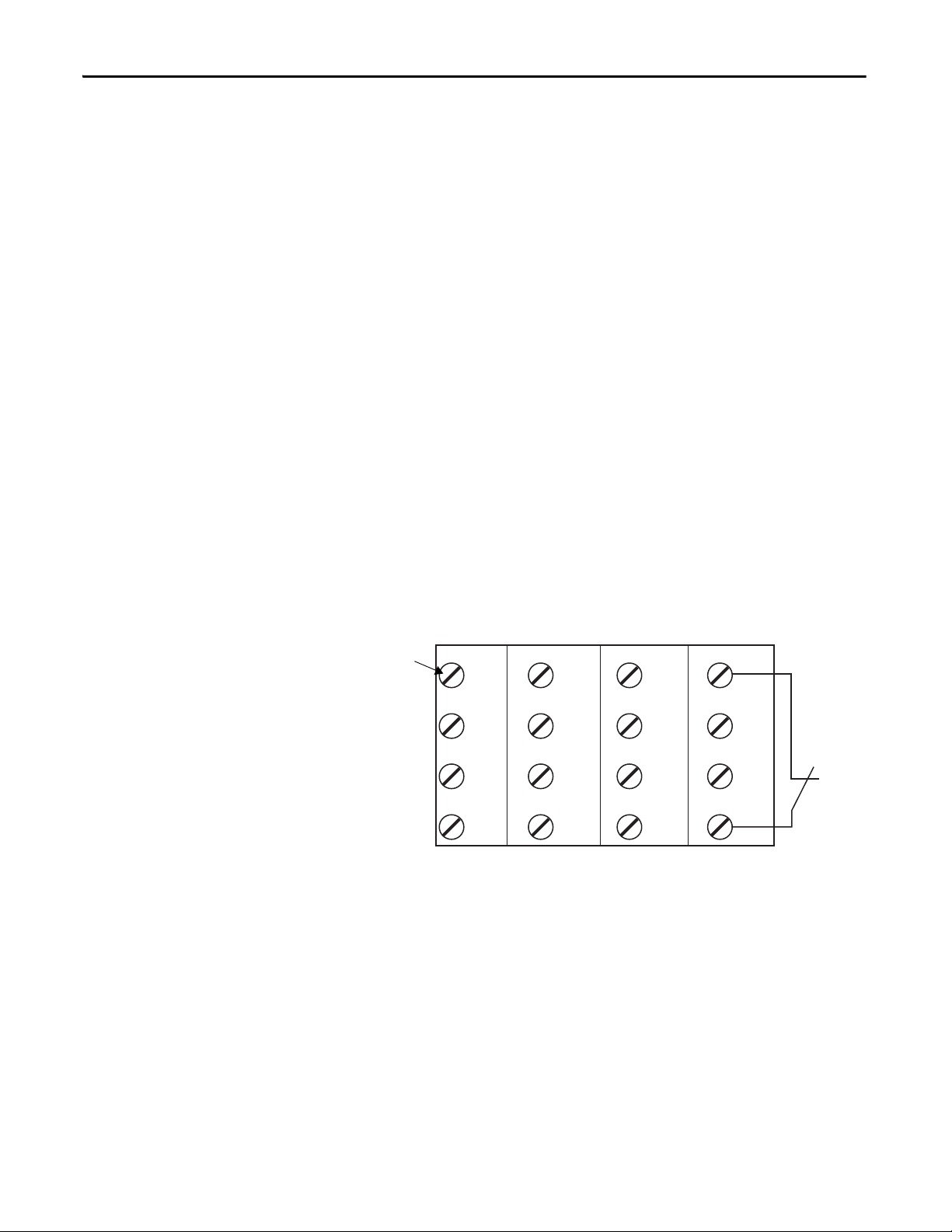

Configurable Digital Filter Settings

N = 1 Hz, 5 Hz, 10 Hz, or 50 Hz

Anti-alias Filter

10 Hz

1 pole 1 pole 1 pole 1 pole 1 pole

NNNN

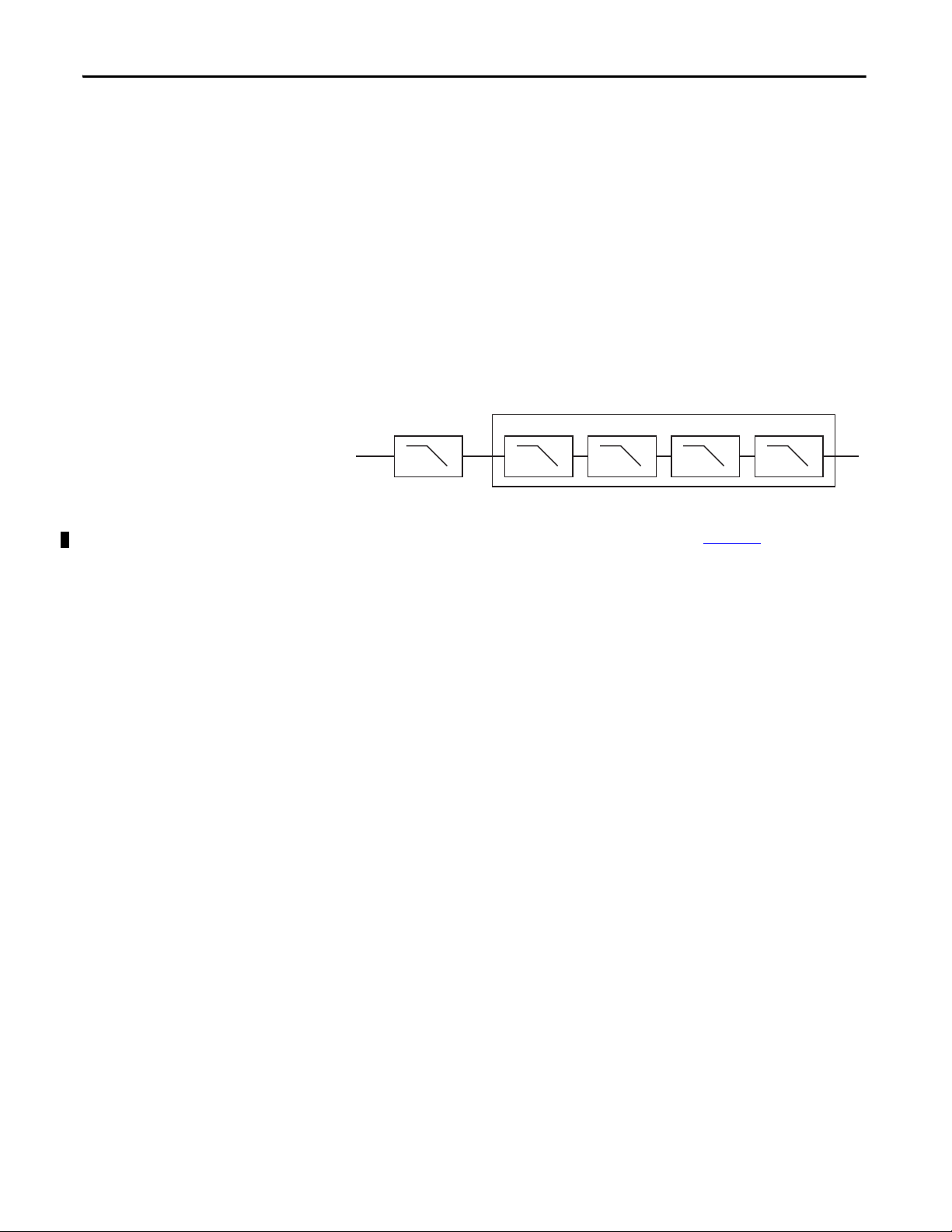

Digital Input Filter

A single-pole, anti-aliasing filter of 10Hz is followed by a four-pole digital filter.

Choose from the following available corner frequencies.

• 1 Hz

• 5 Hz

• 10 Hz

• 50 Hz

The default input filter setting is 1Hz.

Figure 12 - Filter Operation

The filter setting affects the module’s step response. See the technical

specifications for the 1734-IE4S module, beginning on page 164

.

For the analog input modes, the input filter settings set the low-pass filter to filter

out noise that may be present on the signal. In Tachometer mode, the input filter

removes noise that may be present on the calculated frequency, effectively

changing how rapidly the tachometer frequency changes to provide a value with

less jitter.

Sensor Power Supply

You can configure the module to supply power to the connected sensors, or you

can supply power to the sensors from an external power supply. To comply with

UL restrictions, field power and connected devices must be powered by a single,

Class 2-complaint power supply.

We recommend that you configure the module to supply power to the sensors

because this lets the module detect if a sensor loses power, if the sensor is drawing

too much power, or if there is a short in the power wiring to the sensor.

At powerup or after a reconfiguration, each sensor power supply is tested by

being turned on for 500 ms.

32 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

TIP

IMPORTANT

TIP

When a channel is configured for module sensor power, a sensor power

diagnostic is executed on that channel at powerup to make sure that the sensors

are not drawing over- or under-current and that channel-to-channel shorts are

not present.

When a sensor power over-current condition occurs, it may take as much as 15

seconds longer than the configured latch time for channel status to recover

after the over-current condition is cleared.

If you use an external power supply, you must monitor the system for the

following:

• The supply voltage must be within the sensors’ operating range.

• The sensors’ current draw must not be over- or under-current, which could

indicate a problem with the components of the sensor.

• Channel-to-channel shorts must be detected, if they occur.

Channel Offset

You can configure an offset when differences in the sensors nominal input signals

would otherwise exceed the desired discrepancy deadband. Use the Channel

Offset if you are using two sensors of different types to measure the same variable;

that is, sensors from two different vendors that may not give exactly the same data

value for a given temperature or pressure. Use the Channel Offset to bring the

data values back together. You can also use the Channel Offset with two identical

sensors that are physically offset from each other.

The channel offset is applied before the channel discrepancy is evaluated.

The Channel Offset is applied only during the evaluation of discrepancy between

two channels configured for Dual Channel and is not applied to any of the Process

Alarms. Therefore, if you are using two sensors to measure the same process

variable, and these sensors read different values, you may need to set the Process

Alarms to different values based on the sensor readings.

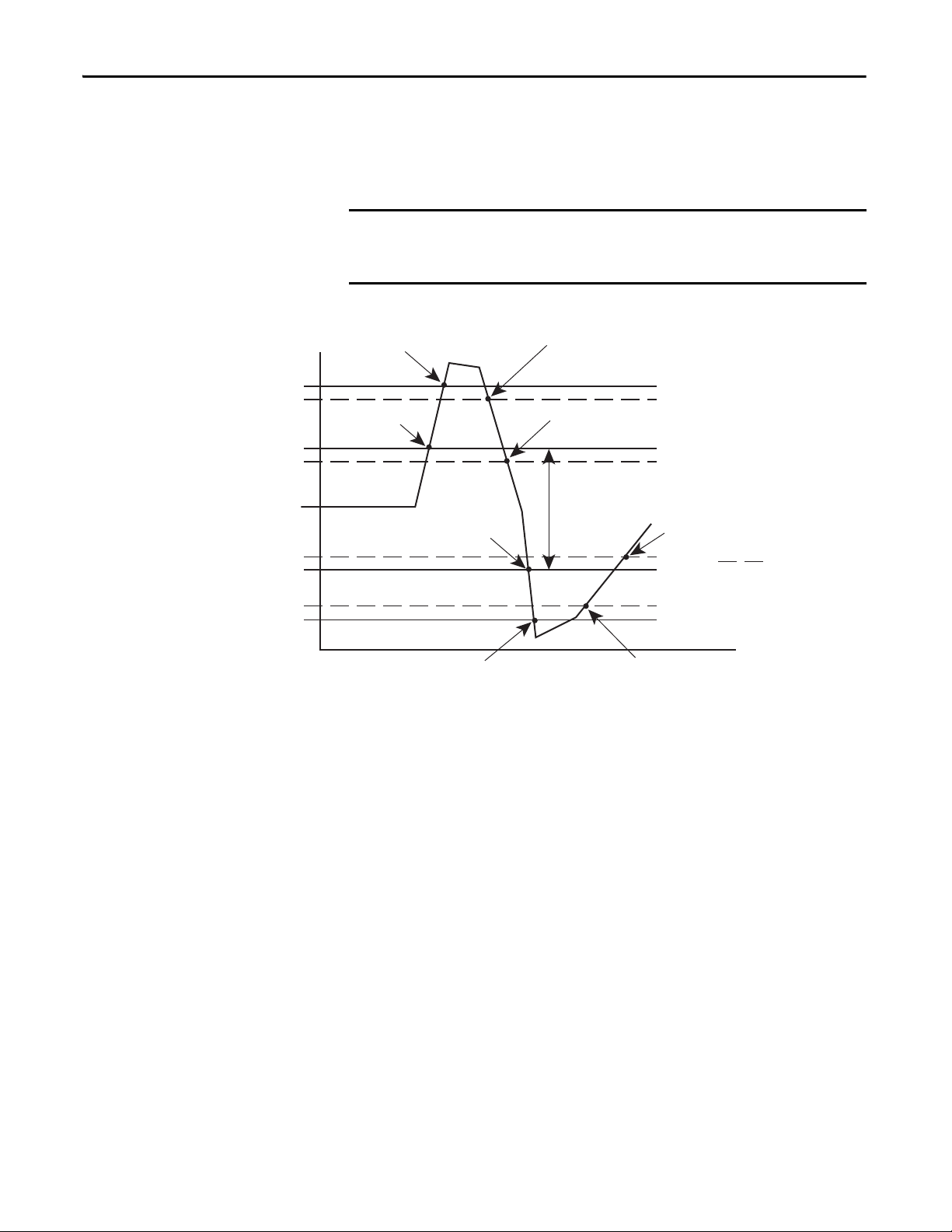

Process Alarms

Process alarms alert you when an analog input value has exceeded the configured

high or low limits for each channel. Process alarms are set at four configurable

trigger points.

• High High alarm

• High alarm

• Low alarm

• Low Low alarm

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 33

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

IMPORTANT

High High alarm turns OFF. High alarm remains ON.

High High alarm turns ON. High alarm remains ON.

High alarm turns

ON.

High alarm turns OFF.

Normal input

range

Low alarm turns

ON.

Low alarm turn s

OFF.

Low Low alarm turns OFF. Low alarm remains ON.

Low Low alarm turns ON. Low alarm remains ON.

Alarm deadbands

High High Alarm

High Alarm

Low Low Alarm

Low Alar m

You can configure a tolerance range, called a deadband, to work with process

alarms. This deadband lets the process alarm status bit remain set, despite the

alarm condition disappearing, as long as the data remains within the deadband of

the process alarm.

If you are using the safety application instructions with a GuardLogix

controller, do not use the module’s process alarms. Instead, perform analog

range checking in your application logic.

Figure 13 - Alarms

Using a Single-channel Sensor

You must address the following requirements to meet SIL 3 with a single-channel

sensor.

• The module’s ±10V and ±5V analog input modes must not be used for

SIL 3 with a single-channel sensor because 0V falls within the valid input

range. Therefore, a stuck at ground fault cannot be detected.

• In a single-channel sensor system, you must use other methods to make

34 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

• If you are using a 3-wire sensor, you must verify its behavior to make sure

sure a channel-to-channel short cannot occur because these faults cannot

be detected.

that if it loses its ground connection, the signal is 0 (safe state) at the

module input when the fault occurs.

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

IMPORTANT

High High Alarm

High Alarm

Low Low A larm

Low Alar m

Channel A

Channel B

Discrepancy Time = 250 ms

Faul t Pre sent

Input Status

Deadband

Difference between Channel A and Channel B

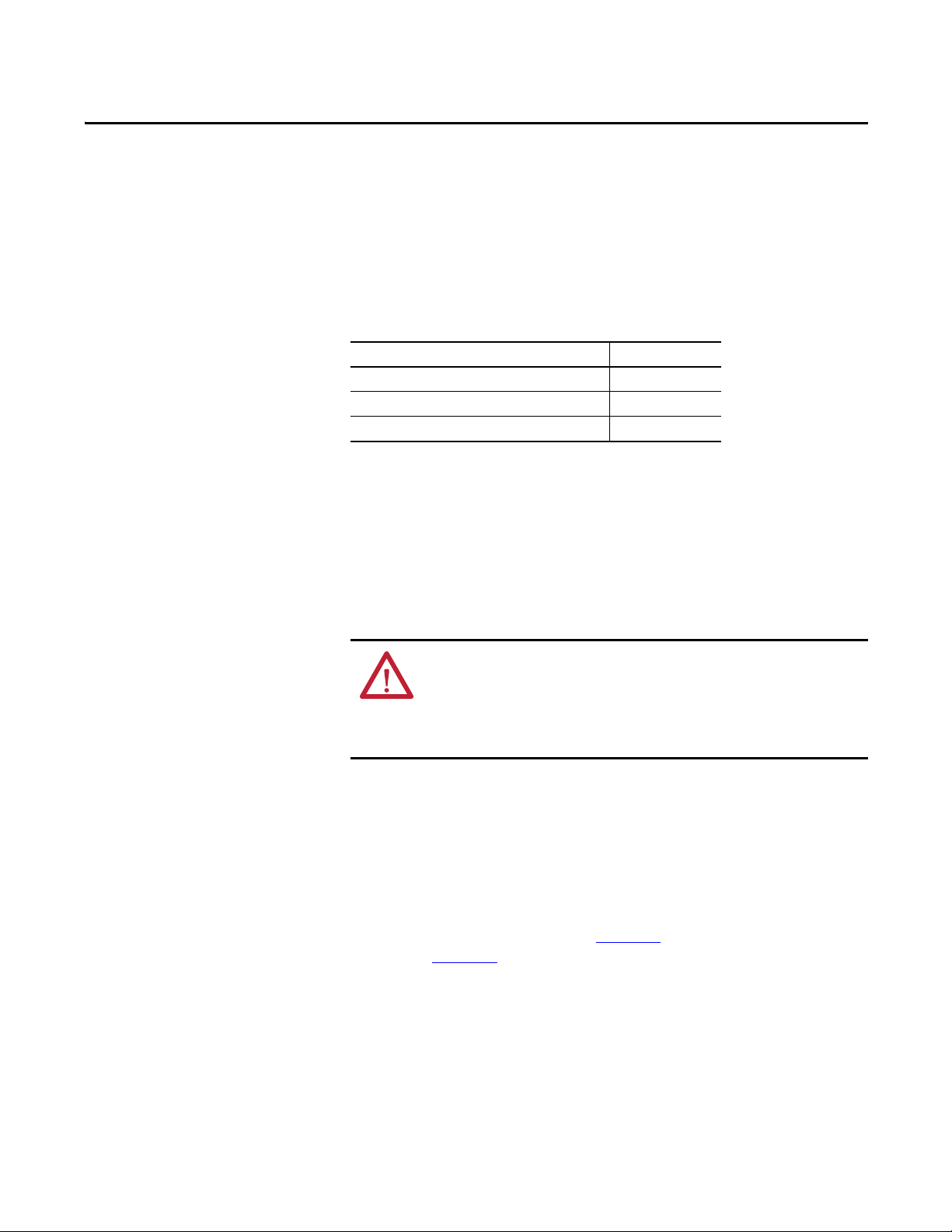

Dual-channel Equivalent Mode

If you are using the module with a GuardLogix controller, set the module’s

inputs to Single (default). Do not use the modules’ dual-channel mode as this

functionality is provided by the GuardLogix safety application instructions.

The 1734-IE4S module supports Dual-channel Equivalent mode. In

Dual-channel Equivalent mode, the values of both inputs of a pair must be within

a configured tolerance range (discrepancy deadband). If the difference between

the channel values exceeds the deadband for longer than the configured

discrepancy time, a discrepancy fault is declared. When a dual-channel

discrepancy fault occurs, the input status values for both channels are set low

(off ) and the actual input values are reported. The fault is cleared when the

difference between the channel’s values falls back within the discrepancy

deadband tolerance range for the discrepancy time.

Figure 14

illustrates module operation in dual-channel equivalent mode. At A,

the difference between the channel values exceeds the discrepancy deadband

tolerance range and the discrepancy timer starts. When the timer expires at B, a

dual-channel discrepancy fault occurs and the inputs status bits are set low. At C,

the values fall back within the discrepancy deadband and the discrepancy timer

starts again. When the timer expires at D, and the values are still within the

discrepancy deadband, the fault is cleared. At E, the difference between the

channels exceeds the discrepancy deadband and the discrepancy timer starts. A

discrepancy fault occurs again at F, when the timer expires and the difference

between the channel values remains greater than the discrepancy deadband.

Figure 14 - Timing Diagram

250 ms

1

0

1

250 ms

250 ms

0

A B C

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 35

D

E F

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

IMPORTANT

Low pulses are offset.

Sensor 1

Sensor 2

Low pulses occur at the same time, causing a fault.

Sensor 1

Sensor 2

Tachometer Mode

In Tachometer mode, the module measures digital pulses between 0 and 24V

DC and converts them into a frequency or pulses per second. Therefore, you can

use 24V DC proximity sensors or 5V DC encoders, for example. The

Tachometer function does not sense direction, so using a differential encoder will

not yield direction data. Tachometer mode could be used, for example, to

measure rotational speed of an axis connected to a gear.

Tachometer mode can operate as SIL 2 single-channel. SIL 3 is achievable by

using two sensors, the dual-low detection parameter, and user program logic.

Safety reaction time is dependent on the signal frequency.

When using two sensors in a dual-channel configuration, position the sensors

to make sure the low pulses occur at different times. If you have configured the

module for dual low detection and both sensors are low at the same time, a

fault will be declared.

Figure 15 - Sensor Pulses in Dual-channel Configuration

Signal Measurement

The edge-to-edge time of the pulse determines the frequency of the signal in

pulses per second. The frequency range is 1 Hz…1 kHz.

In Tachometer mode, you define how the signal is measured, either on the falling

(non-inverted) or rising (inverted) edge. For NPN-style sensors (sensor sinks),

use falling edge. For PNP-style sensors (sensor sources), use rising edge.

36 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Depending on your application, you may need to install an appropriately-sized

pull-up resistor for falling-edge signal measurements or a pull-down resistor for

rising-edge signal measurements.

Figure 16 - Pulse Trains

Ideal Pulse Train

Falling and rising edges

are well-defined.

Rising edges are not

well-defined.

Falling e dges are no t

well-defined.

Falling Edge Rising Edge

Pull-down resistor helps define falling edges.

Pull-up resistor helps define rising edges.

Falling edge measurement

Rising edge measurement

Off and On Signal Levels

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

You configure the Off and On levels, in 1V increments, for the signal. When

selecting these levels, you should assume a tolerance of at least ±0.5V. For

example, if you set the On Level to 10V, you can expect the module to recognize a

signal between 9.5 and 10.5V as On. While the module’s accuracy when

measuring the analog signal is very good, Tachometer mode emphasizes a wider

voltage range and speed to be able to measure pulse widths accurately.

Also consider the variance of the voltage output from your sensor when making

the On and Off Level settings. If possible, we recommend selecting On Levels

that are 2V below and Off Levels that are 2V above the actual thresholds of your

device’s expected output voltage level.

Determining Frequency in Pulses per Second

The edge-to-edge time of either the falling or rising edge of the pulse determines

the frequency in pulses per second.

A single pulse, by itself, does not generate a non-zero frequency. To report a

frequency of 1 Hz, two falling or rising edge pulses must be detected within 1

second. The module reports 0 Hz until 1 Hz is detected. For example, if a falling

or rising edge is not detected for 1.02 seconds after the previous edge, the module

reports 0 Hz.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 37

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

A B C

1 kHz

1 Hz

Frequenc y = 0

Actual values are

repor ted.

Monitor frequency via an

alternate method.

Overfrequency

condition can be

cleared.

Frequency = 1 Hz

Overfrequency bit is set to 0.

Frequency = 1000 Hz

Overfrequency Bit Operation

When the frequency exceeds 1 kHz, the module reports a data value of 1 kHz,

sets the Overfrequency status bit to 0, and latches it. While the Overfrequency

bit is set to 0, you must use an alternate method to monitor the frequency of the

system because the value reported by the module is latched at 1 kHz. Once you

have verified that the frequency is lower than 1 kHz, you may reset the

Overfrequency condition by setting the Reset Tach bit, which lets the module

begin measuring the frequency of field pulses again.

If you set the Reset Tach bit while the frequency is still above 1 kHz, the

Tachometer Overfrequency bit transitions to 1 (within range) momentarily.

However, as soon as the module begins measuring pulses, it will detect another

overfrequency condition and immediately set the Tachometer Overfrequency bit

to 0 again. The Reset Tach bit is edge-sensitive.

ATT EN TI ON : Before resetting the Overfrequency condition, you must use

another method to verify that the actual frequency is lower than 1 kHz.

See Output Assemblies

Overfrequency bit.

Figure 17 - Overfrequency Operation

In Figure 17, the module reports a frequency of 0 Hz until the frequency of the

system reaches 1 Hz at A, when the module begins reporting the actual value. At

B, the frequency exceeds 1 kHz, the Overfrequency bit is set to 0, and the module

continues to report a data value of 1 kHz. Between B and C, you must monitor

the frequency by an alternate method because the value reported by the module

may not be accurate. After C, the Overfrequency condition can be cleared,

provided you have used an alternate method to verify that the actual frequency is

below 1 kHz.

on page 192 for more information on resetting the

38 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

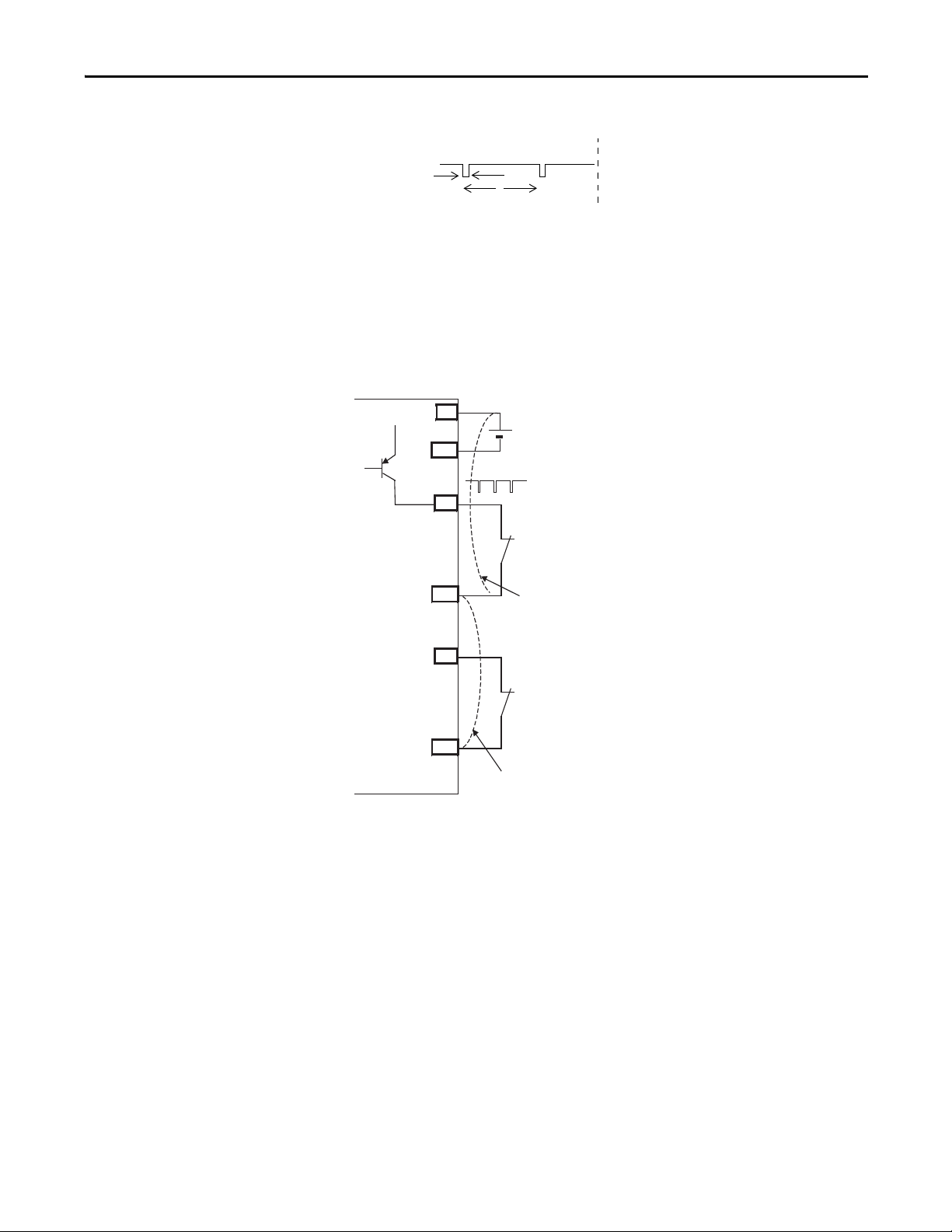

IMPORTANT

44096

X

Y

OUT

On

Off

ON

OFF

OUT0

Safety Output

0, 1

Status

OUT0

OUT1

OUT1

Safety Output

0, 1

Status

Fault Detection

Error

Detected

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Normal Oper ation

Safety

I/O

Network

Data Sent

to the

Controller

Safety

I/O

Network

Data Sent

to the

Controller

Safety Outputs (1734-OB8S)

Read this section for information about safety outputs.

Safety Output with Test Pulse

When the safety output is on, the safety output can be configured to pulse test

the safety output channel. By using this function, you can continuously test the

safety output’s ability to remove power from the module’s output terminals. If an

error is detected, the safety output data and individual safety output status turn

off.

Figure 18 - Test Pulse in a Cycle

For the 1734-OB8S module, the pulse width (X) is typically 475 μs; the pulse

period (Y) is typically 575 ms.

To prevent the test pulse from causing the connected device to malfunction,

pay careful attention to the input response time of the output device.

Dual-channel Mode

When the data of both channels is in the on state, and neither channel has a fault,

the outputs are turned on. The status is normal. If a fault is detected on one

channel, the safety output data and individual safety output status turn off for

both channels.

Figure 19 - Dual-channel Setting (not to scale)

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 39

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

IMPORTANT

TIP

Safety Output Fault Recovery

If a fault is detected, the safety outputs are switched off and remain in the off

state. Follow this procedure to activate the safety output data again.

1. Remove the cause of the error.

2. Command the safety output (or safety outputs) into the safe state.

3. Allow the output-error latch time to elapse.

After these steps are completed, the I/O indicator (red) turns off.

The output data can now be controlled.

Stuck high faults require a module power reset to clear the error.

Muting Lamp Operation (1734-IB8S)

Beginning with firmware revision 1.002, the operation of the muting status bits

for the test outputs T1 and T3 has changed. Test outputs T1 and T3 are

controlled by your PLC processor program to illuminate a muting lamp. Muting

lamp status is monitored with a test that runs periodically during every test

interval to detect a burned-out lamp. The test runs repeatedly when the test

output is commanded on. The figure below explains how muting lamp operation,

status, and fault detection are monitored.

The lamp test interval is 3 seconds. Two consecutive failed lamp tests are

required to declare a burned-out lamp condition. The lamp test may not run

immediately after the test output is energized. It starts at the next 3-second

interval. To allow time for two consecutive test intervals, program a minimum

Test Output On Time of 6 seconds.

40 Rockwell Automation Publication 1734-UM013J-EN-P - July 2014

Figure 20 - Muting Lamp Timing Diagram

IMPORTANT

Safety Inputs, Safety Outputs, and Safety Data Chapter 2

Ta b l e 4 shows the expected behavior of the muting status for test outputs T1 and

T3. Keep these points in mind as well:

• When power is applied to the 1734-IB8S module, and T1 or T3 remains

commanded off, the muting status defaults to on.

This bit operation is designed to help prevent erroneous muting

instruction faults from the GuardLogix controller. This bit status may not

be the true indication of a burned-out lamp.

Before checking the state of the corresponding muting status, be sure the test

output is commanded on. Once the test output is commanded on, a maximum

time of 6 seconds is required for the module to detect a burned-out lamp.

Rockwell Automation Publication 1734-UM013J-EN-P - July 2014 41

Chapter 2 Safety Inputs, Safety Outputs, and Safety Data

• If a muting lamp circuit is open when power is applied to the module, the

condition is detected when the test output is commanded on.

• When a lamp burns out and is replaced, the fault (muting status bit)

returns to the normal condition, independent of the state of the test

output.

Table 4 - Muting Status Bit Operation

I/O Status Data

Tes t Outp ut

Commanded

State

ON Bad (open circuit) 0 Repair lamp.

ON Good 1 Normal condition. Lamp is operating properly.

OFF Bad (open c ircuit) 0 If lamp remains OFF after T1/ T3 output cycled, repair lamp.

OFF Good 1 Normal co ndition.

Lamp Condition Muting

Status

Bit

Description

In addition to I/O data, the module provides status data for monitoring the I/O

circuits. The status includes diagnostic data that can be read by the controllers

with 1 = ON/Normal and 0 = OFF/Fault/Alarm.

Digital I/O Status Data

The following data is monitored:

• Individual Point Input Status

• Combined Input Status

• Individual Point Output Status

• Combined Output Status

• Individual Test Output Status

• Individual Output Monitor (actual ON/OFF state of the outputs)

Individual Point status indicates whether each safety input, safety output, or test

output is normal (normal: ON, faulted: OFF). For fatal errors, communication