Page 1

Model Da-P1

Machine Code:

M187

Field Service Manual

January, 2015

Page 2

Page 3

Important Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the main machine and peripherals, make sure that the

power cord of the main machine is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. Note that some components of the machine and the paper tray unit are supplied with electrical

voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

• To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

Health Safety Conditions

1. Toner and developer is non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Immediately wash eyes with plenty of water. If unsuccessful, get

medical attention.

2. This machine, which uses a high voltage power source, can generate ozone gas. High ozone

density is harmful to human health. Therefore, the machine must be installed in a well-ventilated

room.

Observance of Electrical Safety Standards

1. This machine and its peripherals must be serviced by a customer service representative who has

completed the training course on those models.

2. The NVRAM on the system control board has a lithium battery which can explode if replaced

incorrectly. Replace the NVRAM only with an identical one. The manufacturer recommends

replacing the entire NVRAM. Do not recharge or burn this battery. Used NVRAM must be handled

in accordance with local regulations.

1

Page 4

Handling Toner

• Work carefully when removing paper jams or replacing toner bottles or cartridges to avoid spilling

toner on clothing or the hands.

• If toner is inhaled, immediately gargle with large amounts of cold water and move to a well

ventilated location. If there are signs of irritation or other problems, seek medical attention.

• If toner gets on the skin, wash immediately with soap and cold running water.

• If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there are signs of

irritation or other problems, seek medical attention.

• If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If there are

signs of any problem, seek medical attention.

• If toner spills on clothing, wash the affected area immediately with soap and cold water. Never use

hot water! Hot water can cause toner to set and permanently stain fabric.

• Always store toner and developer supplies such as toner and developer packages, cartridges, and

bottles (including used toner and empty bottles and cartridges) out of the reach of children.

• Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location that is not

exposed to direct sunlight.

• Do not use a vacuum cleaner to remove spilled toner (including used toner). Vacuumed toner may

cause a fire or explosion due to sparks or electrical contact inside the cleaner. However, it is

possible to use a cleaner designed to be dust explosion-proof. If toner is spilled over the floor,

sweep up spilled toner slowly and clean up any remaining toner with a wet cloth.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the organic

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

2

Page 5

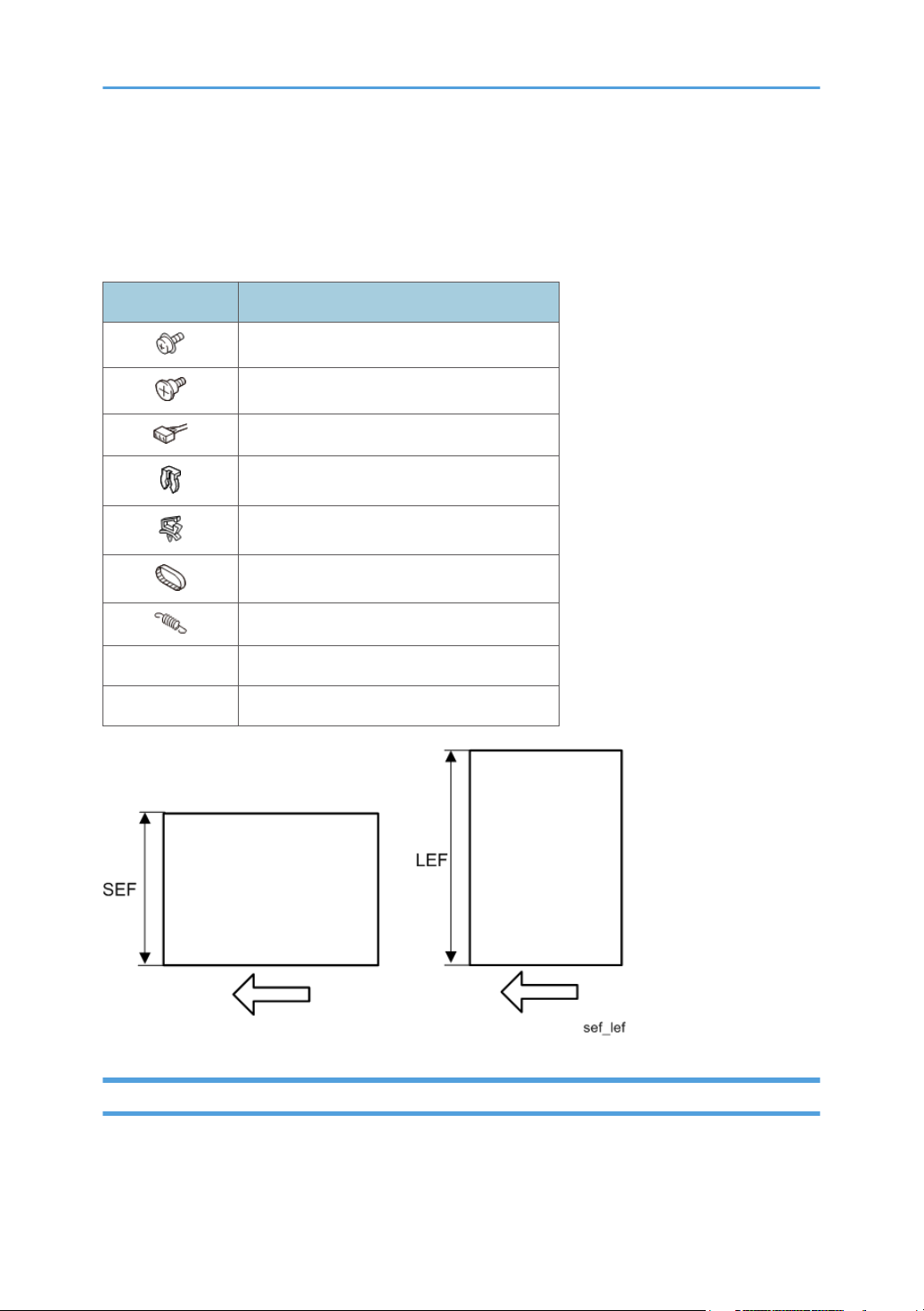

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations

are as follows:

Symbol What is means

Screw

Shoulder screw

Connector

Clip ring

Clamp

Timing belt

Spring

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Adobe, Acrobat, PostScript, PostScript 3, and Reader are either registered trademarks or trademarks of

Adobe Systems Incorporated in the United States and/or other countries.

3

Page 6

Mac OS, OS X, and Safari are trademarks of Apple Inc., registered in the United States and other

countries.

Firefox® is a registered trademark of the Mozilla Foundation.

Java is a registered trademark of Oracle and/or its affiliates.

JAWS® is a registered trademark of Freedom Scientific, Inc., St. Petersburg, Florida and/or other

countries.

Microsoft®, Windows®, Windows Server®, Windows Vista®, and Internet Explorer® are either

registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

Monotype is a registered trademark of Monotype Imaging Inc.

NetWare, IPX, IPX/SPX, NCP, and NDS are either registered trademarks or trademarks of Novell, Inc.

PCL® is a registered trademark of Hewlett-Packard Company.

The proper name of Internet Explorer 6 is Microsoft® Internet Explorer® 6.

The proper name of Internet Explorer 8 is Windows® Internet Explorer® 8.

The proper names of the Windows operating systems are as follows:

• The product names of Windows XP are as follows:

Microsoft® Windows® XP Professional Edition

Microsoft® Windows® XP Home Edition

Microsoft® Windows® XP Media Center Edition

Microsoft® Windows® XP Tablet PC Edition

• The product names of Windows Vista are as follows:

Microsoft® Windows Vista® Ultimate

Microsoft® Windows Vista® Business

Microsoft® Windows Vista® Home Premium

Microsoft® Windows Vista® Home Basic

Microsoft® Windows Vista® Enterprise

• The product names of Windows 7 are as follows:

Microsoft® Windows® 7 Home Premium

Microsoft® Windows® 7 Professional

Microsoft® Windows® 7 Ultimate

Microsoft® Windows® 7 Enterprise

• The product names of Windows 8 are as follows:

Microsoft® Windows® 8

Microsoft® Windows® 8 Pro

4

Page 7

Microsoft® Windows® 8 Enterprise

• The product names of Windows 8.1 are as follows:

Microsoft® Windows® 8.1

Microsoft® Windows® 8.1 Pro

Microsoft® Windows® 8.1 Enterprise

• The product names of Windows Server 2003 are as follows:

Microsoft® Windows Server® 2003 Standard Edition

Microsoft® Windows Server® 2003 Enterprise Edition

• The product names of Windows Server 2003 R2 are as follows:

Microsoft® Windows Server® 2003 R2 Standard Edition

Microsoft® Windows Server® 2003 R2 Enterprise Edition

• The product names of Windows Server 2008 are as follows:

Microsoft® Windows Server® 2008 Standard

Microsoft® Windows Server® 2008 Enterprise

• The product names of Windows Server 2008 R2 are as follows:

Microsoft® Windows Server® 2008 R2 Standard

Microsoft® Windows Server® 2008 R2 Enterprise

• The product names of Windows Server 2012 are as follows:

Microsoft® Windows Server® 2012 Foundation

Microsoft® Windows Server® 2012 Essentials

Microsoft® Windows Server® 2012 Standard

• The product names of Windows Server 2012 R2 are as follows:

Microsoft® Windows Server® 2012 R2 Foundation

Microsoft® Windows Server® 2012 R2 Essentials

Microsoft® Windows Server® 2012 R2 Standard

Other product names used herein are for identification purposes only and might be trademarks of their

respective companies. We disclaim any and all rights to those marks.

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

5

Page 8

TABLE OF CONTENTS

Important Safety Notices................................................................................................................................... 1

Important Safety Notices............................................................................................................................... 1

Prevention of Physical Injury................................................................................................................. 1

Health Safety Conditions...................................................................................................................... 1

Observance of Electrical Safety Standards.........................................................................................1

Handling Toner...................................................................................................................................... 2

Safety and Ecological Notes for Disposal................................................................................................... 2

Symbols, Abbreviations and Trademarks.........................................................................................................3

Trademarks..................................................................................................................................................... 3

1. Product Information

Product Overview.............................................................................................................................................15

Component Layout.......................................................................................................................................15

Paper Path.................................................................................................................................................... 16

Drive Layout..................................................................................................................................................17

Machine Codes and Peripheral Configuration............................................................................................. 18

Machine Codes and Peripheral Configuration......................................................................................... 18

Specifications....................................................................................................................................................21

2. Installation

Installation Requirements................................................................................................................................. 23

Environment..................................................................................................................................................23

Machine Space Requirements....................................................................................................................24

Machine Dimensions................................................................................................................................... 24

Power Requirements.................................................................................................................................... 25

Main Machine Installation...............................................................................................................................26

Accessory Check..........................................................................................................................................26

Instructions for the Customers......................................................................................................................26

Moving the Machine................................................................................................................................... 26

Security Settings........................................................................................................................................... 28

Changing an Administrator's Password.............................................................................................28

Configuring SSL/TLS...........................................................................................................................28

Paper Feed Unit TK2010................................................................................................................................ 29

Component Check.......................................................................................................................................29

Installation Procedure..................................................................................................................................29

6

Page 9

USB Device Server Option Type M12...........................................................................................................31

Component Check.......................................................................................................................................31

Interface Board Surface......................................................................................................................31

Installation Procedure..................................................................................................................................32

What Do the LED Indications Mean?................................................................................................ 35

Notes for Energy Save Mode Setting................................................................................................36

IP Address Setting........................................................................................................................................ 36

SD Card Appli Move.......................................................................................................................................39

Overview...................................................................................................................................................... 39

Notes on Using the SD Merge Function.................................................................................................... 39

SD Card Applications..................................................................................................................................40

Move Exec................................................................................................................................................... 40

Undo Exec.................................................................................................................................................... 42

Settings for @Remote Service..........................................................................................................................44

Check points before making @Remote settings.........................................................................................44

Execute the @Remote Settings.................................................................................................................... 44

3. Preventive Maintenance

Preventive Maintenance Tables...................................................................................................................... 49

Preventive Maintenance Tables..................................................................................................................49

Image Quality Standards................................................................................................................................ 50

Image Quality Standards............................................................................................................................50

Paper Transfer Quality Standards.................................................................................................................. 51

Paper Transfer Quality Standards.............................................................................................................. 51

4. Replacement and Adjustment

General Cautions.............................................................................................................................................53

Notes on the Main Power Switch...............................................................................................................53

Characteristics of the Push Switch (DC Switch).................................................................................53

Shutdown Method...............................................................................................................................54

Forced Shutdown................................................................................................................................ 55

Special Tools ................................................................................................................................................... 56

Exterior Covers................................................................................................................................................. 57

Front Cover...................................................................................................................................................57

Left Cover......................................................................................................................................................58

7

Page 10

Right Cover...................................................................................................................................................60

Rear Cover, Rear Lower Cover...................................................................................................................63

By-pass Tray.................................................................................................................................................66

Upper Cover................................................................................................................................................ 67

Operation Panel...........................................................................................................................................68

LED Optics........................................................................................................................................................ 72

LED Unit........................................................................................................................................................ 72

PCDU.................................................................................................................................................................78

PCDU............................................................................................................................................................ 78

Toner Cartridge................................................................................................................................................ 79

Toner Cartridge............................................................................................................................................79

Image Transfer..................................................................................................................................................81

Image Transfer Roller...................................................................................................................................81

Drive Unit.......................................................................................................................................................... 83

Main Motor..................................................................................................................................................83

Exit/Reverse Motor..................................................................................................................................... 84

Registration Clutch....................................................................................................................................... 86

Paper Feed Clutch........................................................................................................................................86

By-pass Feed Clutch.................................................................................................................................... 87

By-pass Bottom Plate Clutch........................................................................................................................89

Drive Unit......................................................................................................................................................89

Gear Unit......................................................................................................................................................89

Toner Supply Clutch.................................................................................................................................... 92

Relay Clutch................................................................................................................................................. 93

Duplex Clutch...............................................................................................................................................94

Junction Gate Solenoid............................................................................................................................... 95

Fusing................................................................................................................................................................ 96

Fusing Unit.................................................................................................................................................... 96

Upper Fusing Unit, Lower Fusing Unit........................................................................................................ 98

Fusing Pressure Roller.................................................................................................................................. 99

Fusing Lamp, Hot Roller............................................................................................................................ 100

Thermostat..................................................................................................................................................104

Thermistor...................................................................................................................................................104

8

Page 11

Hot Roller Stripper.....................................................................................................................................106

Paper Feed..................................................................................................................................................... 107

Paper Feed Tray........................................................................................................................................ 107

Paper Feed Roller......................................................................................................................................107

Friction Roller, Torque Limiter................................................................................................................... 108

Paper End Sensor...................................................................................................................................... 109

By-pass Feed Unit......................................................................................................................................110

By-pass Feed Roller...................................................................................................................................112

By-pass Friction Pad..................................................................................................................................114

By-pass Paper End Sensor........................................................................................................................115

By-pass Bottom Plate HP Sensor.............................................................................................................. 116

Paper Size Detection Switch.....................................................................................................................117

Paper Transport..............................................................................................................................................119

Paper Exit Unit........................................................................................................................................... 119

Paper Exit Sensor.......................................................................................................................................121

Paper Overflow Sensor.............................................................................................................................121

Duplex Reverse Sensor............................................................................................................................. 121

Duplex Entrance Sensor............................................................................................................................123

Registration Roller (Driven).......................................................................................................................123

Registration Roller (Drive)......................................................................................................................... 126

Registration Sensor....................................................................................................................................128

Electrical Components...................................................................................................................................130

Controller Box............................................................................................................................................130

PSU............................................................................................................................................................. 131

Controller Board........................................................................................................................................134

Before replacing the controller board in the model without HDD................................................134

Replacement Procedure................................................................................................................... 134

After installing the controller board.................................................................................................136

NVRAM on the Controller Board.............................................................................................................136

BCU............................................................................................................................................................ 137

EEPROM on the BCU................................................................................................................................138

Toner End Sensor...................................................................................................................................... 139

HVPS...........................................................................................................................................................140

9

Page 12

HVPS with Bracket.....................................................................................................................................140

PCDU Cooling Fan....................................................................................................................................141

PCDU Cooling Fan with Duct................................................................................................................... 141

PSU Cooling Fan....................................................................................................................................... 142

DC Switch.................................................................................................................................................. 142

Front Cover Interlock Switch.....................................................................................................................143

Front Cover Interlock Switch with Bracket...............................................................................................144

Rear Cover Interlock Switch..................................................................................................................... 144

DIMM.........................................................................................................................................................145

Temp Humid Sensor.................................................................................................................................. 147

Envelope Lever Detection Switch............................................................................................................. 147

5. System Maintenance

Service Program Mode.................................................................................................................................149

SP Tables....................................................................................................................................................149

Enabling and Disabling Service Program Mode....................................................................................149

Entering SP Mode.............................................................................................................................149

Exiting SP Mode............................................................................................................................... 149

Types of SP Modes....................................................................................................................................150

Service Mode Lock/Unlock..................................................................................................................... 150

Updating the Firmware..................................................................................................................................151

Overview....................................................................................................................................................151

Type of Firmware.......................................................................................................................................151

Updating Firmware................................................................................................................................... 152

Before You Begin..............................................................................................................................152

Preparation........................................................................................................................................153

Updating Procedure......................................................................................................................... 153

Firmware Update Error.....................................................................................................................156

Recovery after Power Loss............................................................................................................... 156

Handling Firmware Update Errors...........................................................................................................157

Uploading/Downloading NVRAM Data....................................................................................................162

Uploading Content of NVRAM to an SD Card...................................................................................... 162

Downloading an SD Card to NVRAM....................................................................................................163

Capturing Log to SD card............................................................................................................................. 164

10

Page 13

Overview....................................................................................................................................................164

Security of the Operation Log..........................................................................................................165

Retrieving the Debug Logs........................................................................................................................ 165

Procedure for Retrieving the Debug Log.........................................................................................166

Address Book Upload/Download.............................................................................................................. 167

Information List...........................................................................................................................................167

Upload (Backup) to SD Card...................................................................................................................167

Download (Restore) to Machine..............................................................................................................168

Erasing the Backup Data.......................................................................................................................... 168

6. Troubleshooting

Self-Diagnostic Mode................................................................................................................................... 169

Self-Diagnostic Mode at Power On.........................................................................................................169

Service Call.................................................................................................................................................... 170

Summary.................................................................................................................................................... 170

When a Level “D” SC code occurs.................................................................................................170

SC100........................................................................................................................................................171

SC200 (LED Optics)................................................................................................................................. 171

SC300 (Image Processing – 1)............................................................................................................... 173

SC400 (Image Processing – 2)............................................................................................................... 175

SC500 (Paper Feed and Fusing)............................................................................................................. 176

SC600 (Device Communication).............................................................................................................185

SC700 (Peripherals)................................................................................................................................. 196

SC800 (Controller)................................................................................................................................... 197

SC900 (Others).........................................................................................................................................262

Jam Detection.................................................................................................................................................269

Jam Displays.............................................................................................................................................. 269

Jam History.................................................................................................................................................269

Sensor Position Layout.............................................................................................................................. 270

Sensor Position...........................................................................................................................................270

Main Machine.................................................................................................................................. 271

Optional Bank...................................................................................................................................272

Troubleshooting............................................................................................................................................. 273

Test Pattern Printing....................................................................................................................................273

11

Page 14

Image Position Adjustment........................................................................................................................274

Registration Adjustment.............................................................................................................................274

Print Area...........................................................................................................................................274

Adjustment Reference Values...........................................................................................................275

Adjustment Procedure.......................................................................................................................275

Image Problem.......................................................................................................................................... 275

Problem at Regular Intervals............................................................................................................275

When Vertical Banding is Generated.............................................................................................277

When Black Spots are Generated on Print Image.........................................................................277

When Toner Smears Appear on the Backside of the Printouts..................................................... 278

Paper Feed (Skew)....................................................................................................................................279

Recycled or Thin Paper Is Severely Curled after Printing.......................................................................279

Electrical Component Defects.......................................................................................................................280

Electrical Components.............................................................................................................................. 280

Fuses........................................................................................................................................................... 281

BCU....................................................................................................................................................281

PSU.................................................................................................................................................... 283

7. Energy Save

Energy Save................................................................................................................................................... 285

Energy Saver Modes................................................................................................................................ 285

Sleep Mode Setting..........................................................................................................................285

Weekly Timer.................................................................................................................................... 286

Eco Night Mode............................................................................................................................... 286

Fusing Off Mode...............................................................................................................................289

Fusing Heater Off on Stndby........................................................................................................... 290

Return to Stand-by Mode.................................................................................................................290

Recommendation..............................................................................................................................290

Energy Save Effectiveness........................................................................................................................ 291

Paper Save.....................................................................................................................................................293

Effectiveness of Duplex/Combine Function............................................................................................ 293

1. Duplex:..........................................................................................................................................293

2. Combine mode:............................................................................................................................293

3. Duplex + Combine:...................................................................................................................... 294

12

Page 15

Recommendation..............................................................................................................................294

13

Page 16

14

Page 17

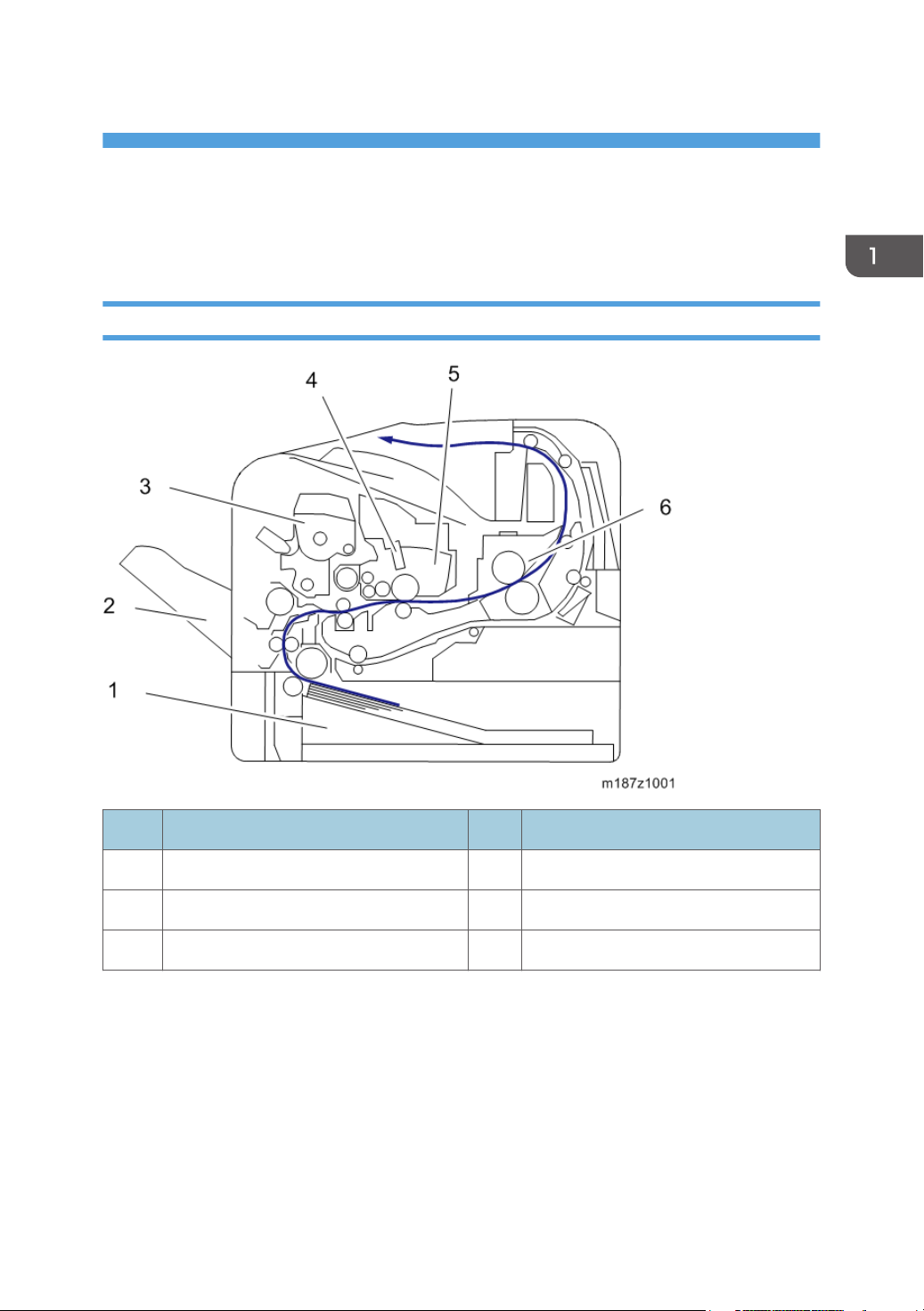

1. Product Information

Product Overview

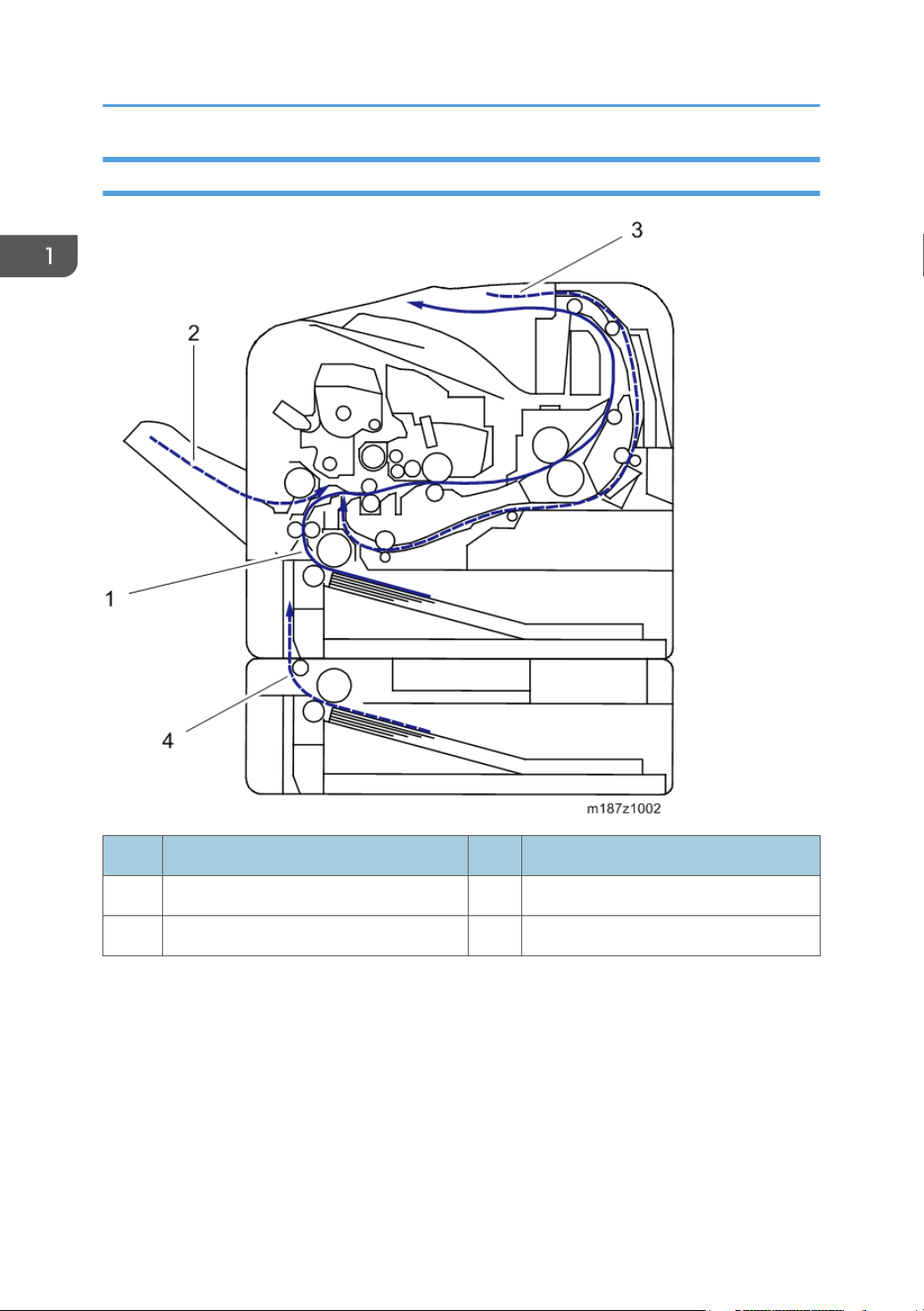

Component Layout

No. Description No. Description

1 Paper Feed Unit 4 LED Head

2 By-pass Tray 5 PCDU

3 Toner Cartridge 6 Fusing Unit

15

Page 18

1. Product Information

Paper Path

16

No. Description No. Description

1 Main Machine Paper Feed Path 3 Duplex Paper Feed Path

2 By-pass Paper Feed Path 4 Optional Tray Paper Feed Path

Page 19

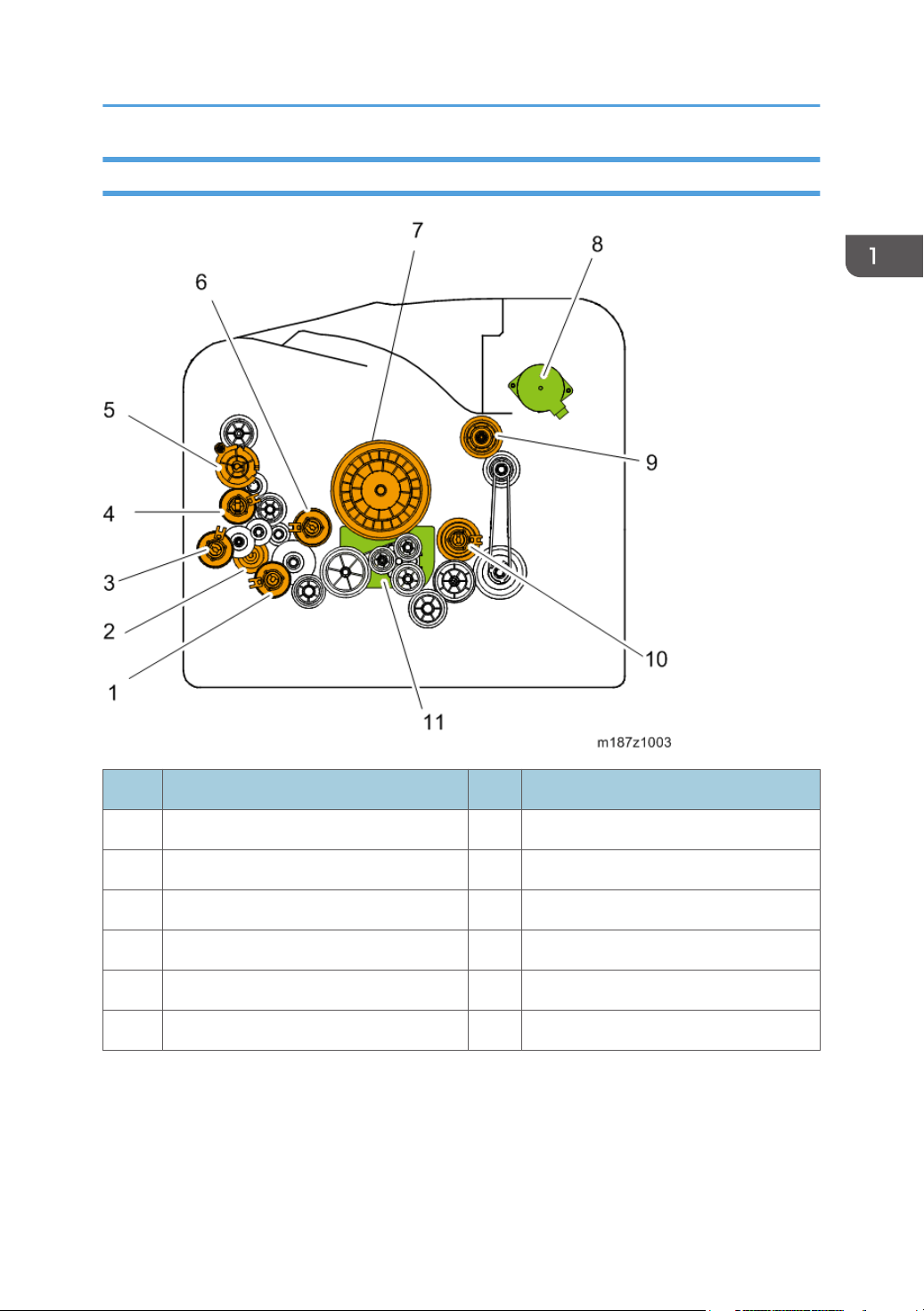

Drive Layout

Product Overview

No. Description No. Description

1 Paper feed clutch 7 Drum Gear

2 Replay Clutch 8 Exit/Reverse Motor

3 By-pass Bottom Plate Clutch 9 Fusing Drive Gear

4 By-pass Feed Clutch 10 Duplex Clutch

5 Toner Supply Clutch 11 Main Motor

6 Registration Clutch

17

Page 20

1. Product Information

Machine Codes and Peripheral Configuration

Machine Codes and Peripheral Configuration

Main Frame

Item Machine Code Remarks

M187-17 (NA) NEW

SP 6430DN

External Options

No. Item Machine Code Remarks

M187-27 (EU/AA) NEW

M187-21 (CHN) NEW

1 Paper Feed Unit TK2010 M456-17 NEW

Internal Options

IPDS Unit Type P4 M444-50 (NA)

18

Item Machine Code Remarks

M444-51 (EU)

M444-52 (AA/CHN)

Page 21

Item Machine Code Remarks

XPS Direct Print Option Type P4 M444-49

VM CARD Type W *1 M417-19 (NA)

M417-20 (EU)

M417-21 (AA/CHN)

Memory Unit Type N M417-03

SD card for NetWare printing Type P4 M444-55

Hard Disk Drive Option Type P4 M444-42

IEEE802.11 Interface Unit Type O M417-06 (NA)

USB Device Server Option Type M12 D3A7-28 (NA)

D3A7-29 (EU/AA/CHN)

Machine Codes and Peripheral Configuration

IEEE1284 Interface Board Type A B679-17

*1: To install this, Memory Unit Type N and Hard Disk Drive Option Type P4 must first be installed.

Consumables for M187

Item Machine Code Remarks Yield

Print Cartridge SP 6430A M915-17 (NA)

Print Cartridge SP 6430E M915-27 (EU)

Print Cartridge SP 6430S M915-20 (AA)

10,000 pages

(ISO)

Print Cartridge SP 6430C M915-21 (CHN)

NEW

Drum Unit SP 6430

25,000 pages

M919-17

(3P/J)

Maintenance Kit SP 6430 M920-17 (NA)

M920-27 (EU)

90,000 pages

(3P/J)

19

Page 22

1. Product Information

• (ISO): The number of printable pages is based on pages that are compliant with ISO/IEC 19752

with the image density set as the factory default. ISO/IEC 19752 is an international standard for

measurement of printable pages, set by the International Organization for Standardization.

• (6%, 3P/J): A4/Letter 6% test chart, 3 pages/job.

• (3P/J): A4/Letter, 3 pages/job.

20

Page 23

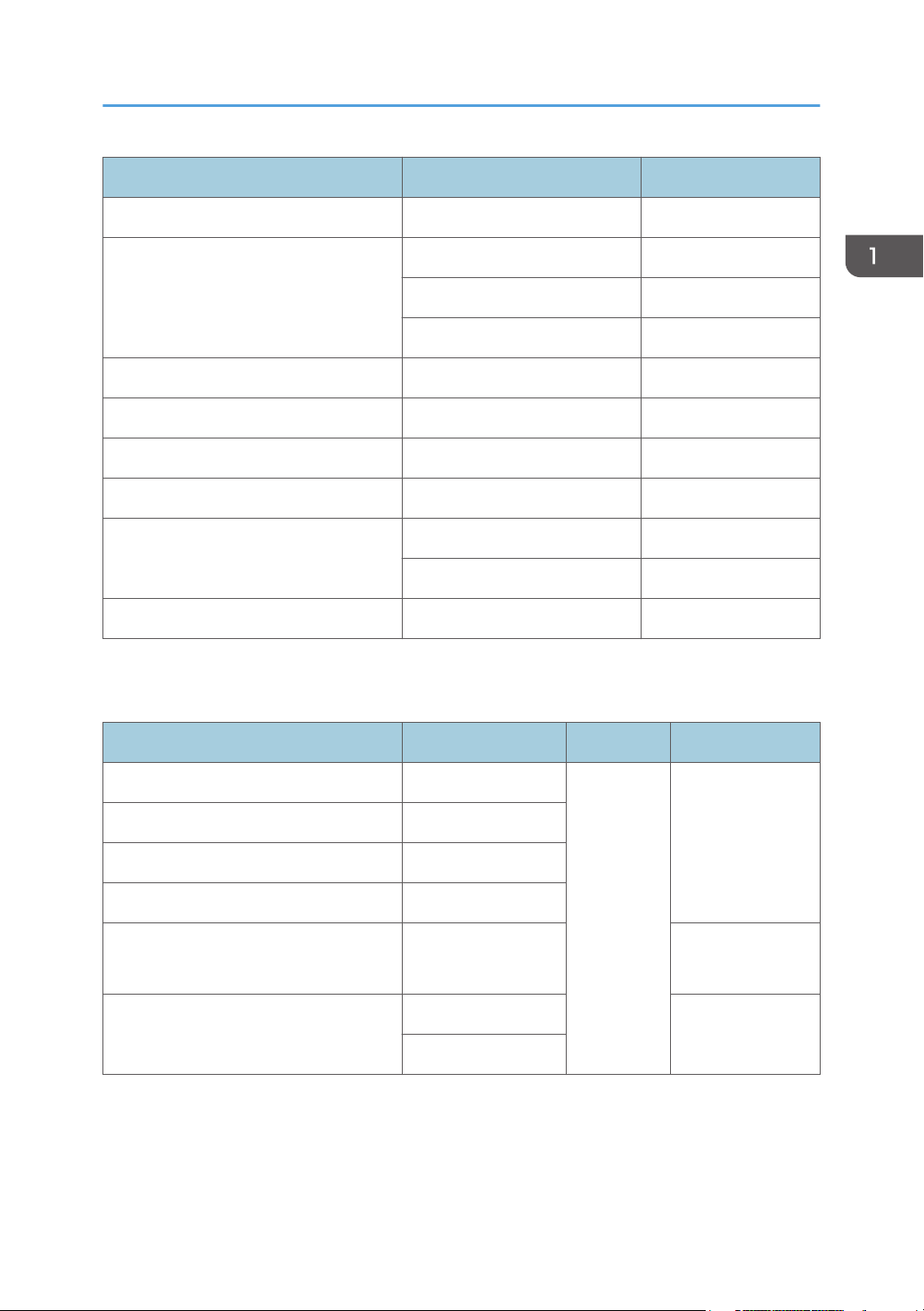

Specifications

See "Appendices" for the following information:

• General Specifications

• Supported Paper Sizes

• Software Accessories

• Optional Equipment

Specifications

21

Page 24

1. Product Information

22

Page 25

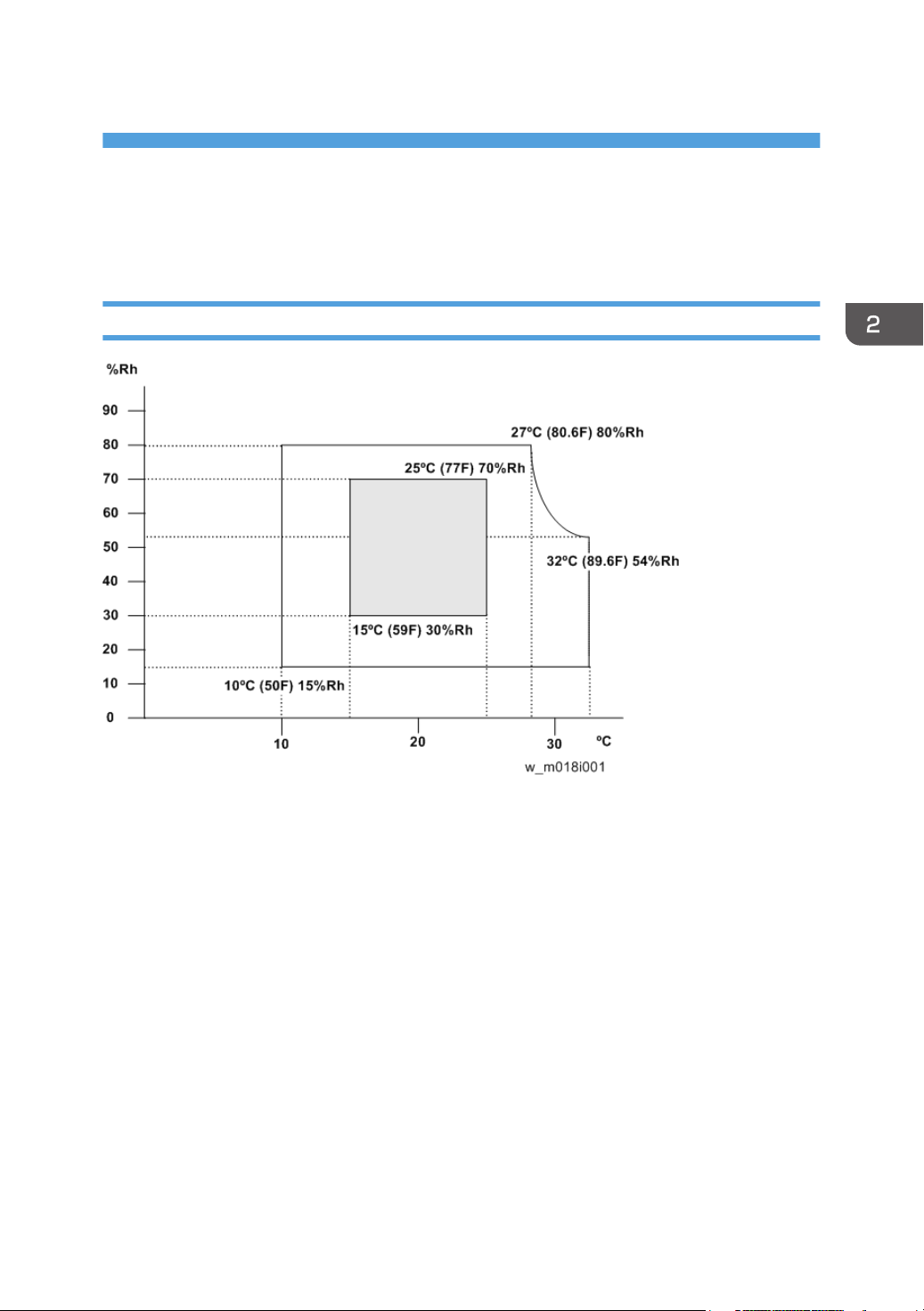

2. Installation

Installation Requirements

Environment

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1,500 lux (do not expose to direct sunlight)

4. Ventilation: More than 3 times/hr/person

5. Do not install the machine at locations over 2,000 m (6,562 ft.) above sea level.

23

Page 26

2. Installation

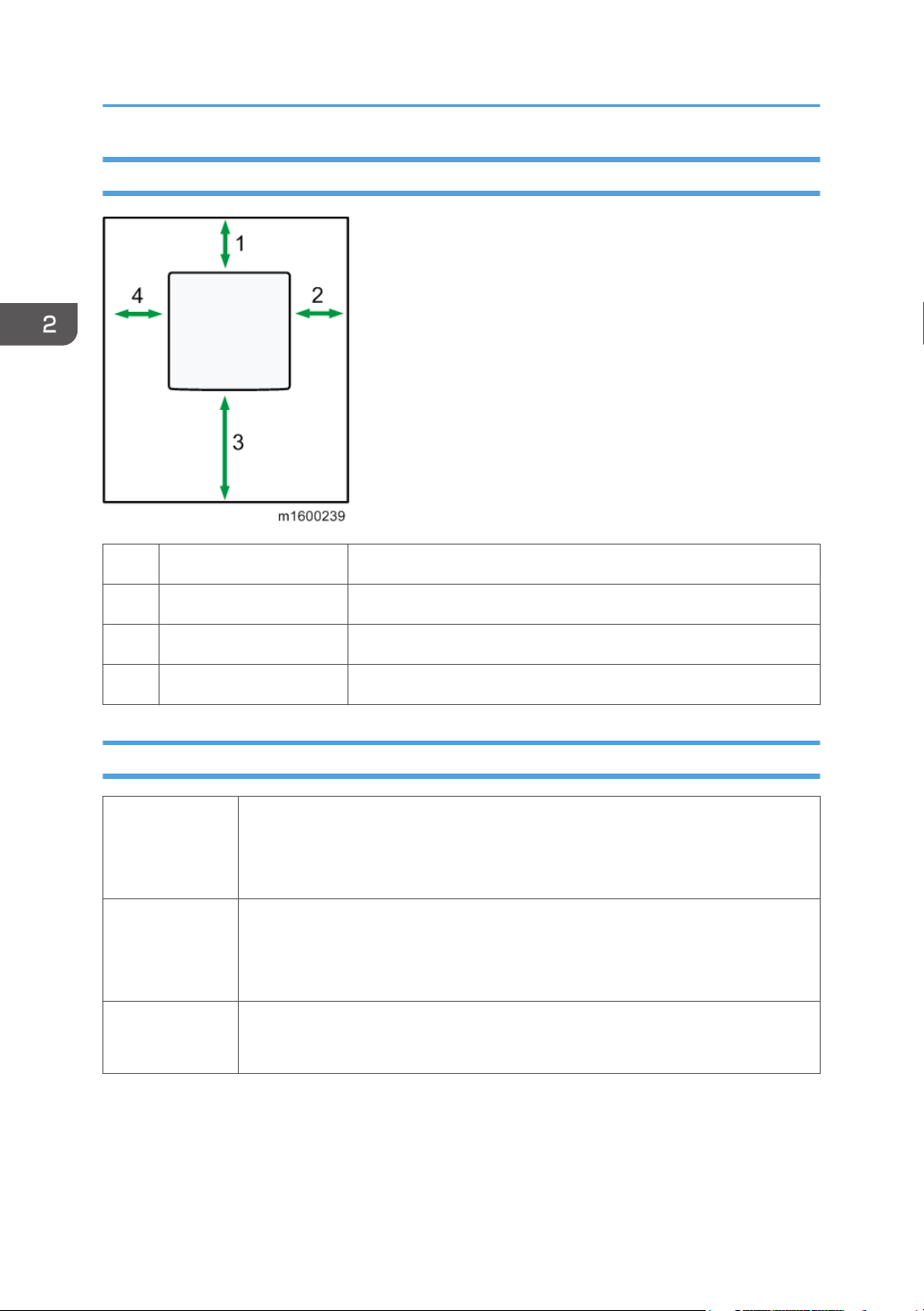

Machine Space Requirements

1 Rear Over 20 cm (7.9 inches)

2 Right Over 10 cm (3.9 inches)

3 Front Over 55 cm (21.7 inches)

4 Left Over 10 cm (3.9 inches)

Machine Dimensions

• Printer only: 459 mm (18.07 inches)

Width

Depth

Height

• With an optional hard disk cover: 475 mm (18.70 inches)

• With Intake louver: 464 mm (18.27 inches)

• 392 mm (15.4 inches)

• With paper feed tray handle: 412 mm (16.22 inches)

• With controller screw: 396.4 mm (15.61 inches)

• Printer Only: 347.5 mm (13.68 inches)

• With optional paper feed trays (TK2010×3): 719.5 mm (28.33 inches)

24

Page 27

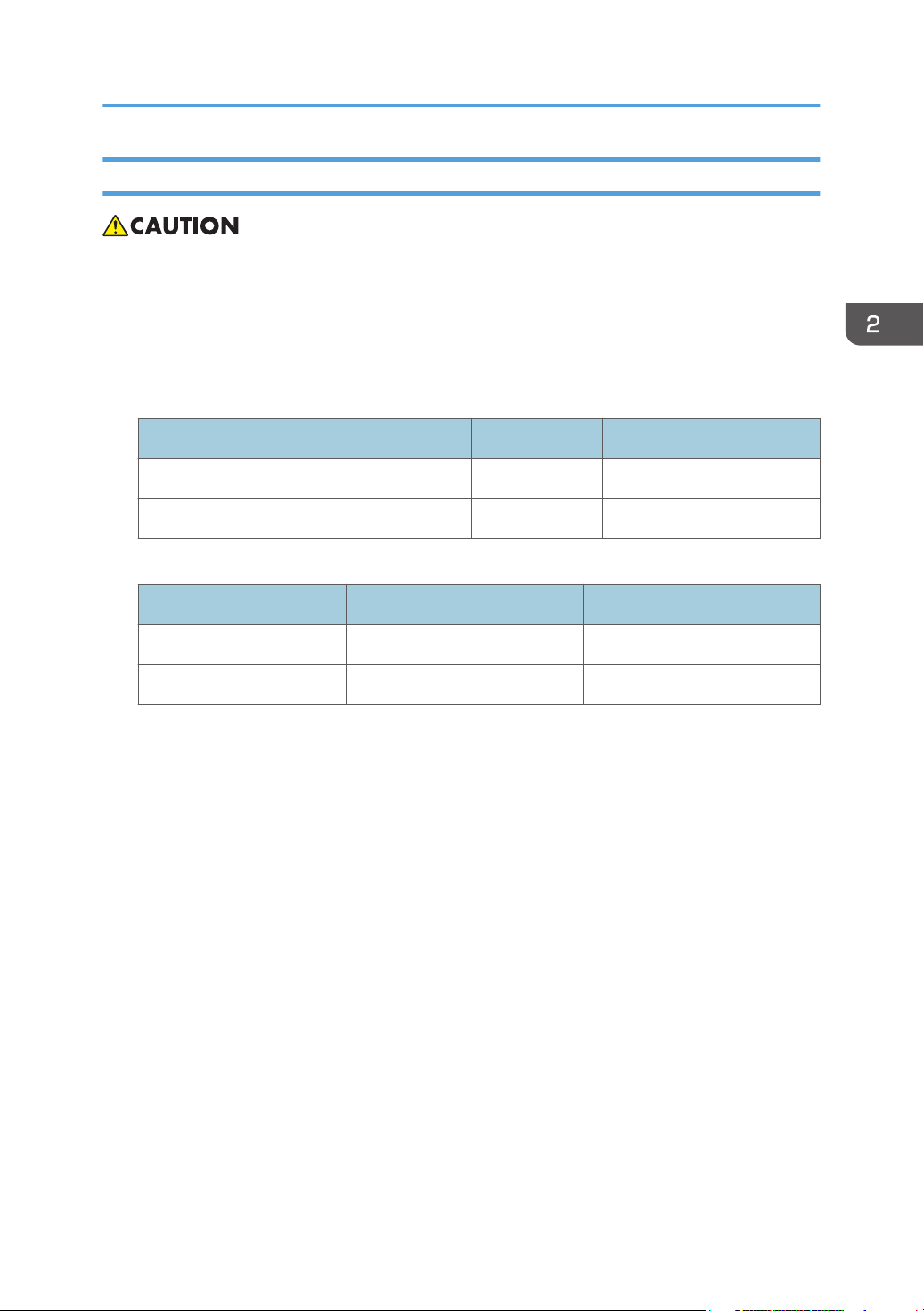

Power Requirements

• Make sure that the plug is firmly inserted in the outlet.

• Avoid multi-wiring.

• Be sure to ground the machine.

• Never place anything on the power cord.

1. Input voltage level:

Destination Power supply voltage Frequency Rated current consumption

NA 120 V to 127 V 60 Hz More than 10 A

EU/AP/CHN 220 V to 240V 50 Hz/60 Hz 5.3 A

2. Permissible voltage fluctuation:

Destination For printing images For operating

Installation Requirements

NA +8.66 / -10% +8.66 / -15%

EU/AP/CHN ±10% ±15%

25

Page 28

2. Installation

Main Machine Installation

• The M187 models are for installation by users.

Accessory Check

Description Q’ty

Power cord 1

Instructions for the Customers

Provide instructions on the following matters to customers. For detailed procedures, see the user

manuals.

• Operating the printer function

• Installing consumables and loading paper

• Operating the main power switch

• Removing jammed paper

• Registering/changing/deleting data in the address book

• Providing precautions on use

• Connecting to computers (such as configuring the port setting)

• Giving a brief outline of the tabs in the drivers

Moving the Machine

• It is dangerous to handle the power cord plug with wet hands. Doing so could result in electric

shock.

• Unplug the power cord from the wall outlet before you move the machine. While moving the

machine, take care that the power cord is not damaged under the machine. Failing to take these

precautions could result in fire or electric shock.

26

Page 29

Main Machine Installation

• If you have to move the machine when the optional paper tray unit is attached, do not push on the

main unit's top section. Doing so can cause the optional paper tray unit to detach, possibly resulting

in injury.

• When disconnecting the power cord from the wall outlet, always pull the plug, not the cord. Pulling

the cord can damage the power cord. Use of damaged power cords could result in fire or electric

shock.

• The machine weighs approximately 22.5 kg (49.6 lb.). When moving the machine, use the inset

grips on both sides, and lift slowly in pairs. The machine will break or cause injury if dropped.

• Do not hold the control panel while moving the machine. Doing so may damage the control panel,

cause a malfunction, or result in injury.

• Be careful when moving the machine. Take the following precautions:

• Close all covers and trays, including the front cover and by-pass tray.

• If optional paper feed units are attached, remove them from the machine and move them

separately.

• Keep the machine level and carry it carefully, taking care not to jolt or tip it. Rough handling may

cause a malfunction or damage the hard disk or memory, resulting in loss of stored files.

1. Be sure to check the following:

The main power switch is turned off.

The power cord is unplugged from the wall outlet.

The interface cable is unplugged from the machine.

2. If any external options are attached, remove them.

3. Lift the machine using the inset grips on both sides of the machine. And then move it

horizontally to the place where you want to use it.

4. If you removed options, reattach them.

• Be sure to move the machine horizontally. To prevent toner from scattering, move the machine

slowly.

27

Page 30

2. Installation

Security Settings

Changing an Administrator's Password

You will be prompted to enter the password when logging in to the printer. No password is set by

default. We strongly recommend you to change the factory default password immediately to prevent

information leakage and unauthorized operations by others.

• For details, see the user manuals. User manual "Security Guide".

Configuring SSL/TLS

To prevent unauthorized viewing, analysis or modification of the data during its transmission, enable

SSL/TLS as required.

• For details, see the user manuals. User manual "Security Guide".

28

Page 31

Paper Feed Unit TK2010

Paper Feed Unit TK2010

• When lifting the machine, use the inset grips on both sides. The machine could break or cause an

injury if dropped.

Component Check

To attach two lower paper trays at the same time, first stack them one upon the other, and then attach

them as a single tray.

Check the quantity and condition of the accessories against the following list.

Paper Feed Unit TK2010 (500 Sheets M456)

No. Description Q’ty

1 Installation Procedure 1

2

Manufacturer Information / Authorized Representative Information

(Paper)

Installation Procedure

• Turn off the main power switch of the copier and unplug the power cord before you start the

installation procedure.

• To attach two lower paper trays at the same time, first stack them one upon the other, and then

attach them as a single unit.

1. Remove the packaging from the lower paper tray.

2. Lift the machine slowly using the inset grips on both sides, and then position it

immediately above the lower paper tray.

1

29

Page 32

2. Installation

3. There are three upright pins on the optional lower paper tray. Align them with the holes

on the underside of the machine, and then carefully lower the machine.

4. Plug in the power cord, and then turn on the machine.

5. Print the configuration page to confirm that the tray was attached correctly.

• Check "Attached Equipment" on the configuration page. If the tray is attached correctly, "Tray 2",

"Tray 3", and "Tray 4" appear.

30

Page 33

USB Device Server Option Type M12

USB Device Server Option Type M12

Component Check

No Items Q’ty

1 Interface board 1

2 USB connector 1

3 Ferrite cores 2

• An Ethernet cable, which is not packed with this option, is required.

Interface Board Surface

No. Item Description

1 Switch Used to reset to the factory settings.

31

Page 34

2. Installation

No. Item Description

2 Ethernet port Used to connect the Ethernet cable.

3 USB port

Used to connect this option to the main machine.

Do not use with other options.

Installation Procedure

• When you install this option to the main machine for the first time, the interface board must be

connected directly to your PC to set up the IP address and other network settings.

1. Turn off the main power switch, and unplug the power cord from the wall socket.

2. Remove the interface slot cover. ( ×2)

32

Page 35

3. Insert the interface board into the interface slot [A] ( ×2).

4. Insert the USB connector into the USB port on this option.

USB Device Server Option Type M12

5. Insert the other side of the USB connector into the USB port B on the main machine.

• The machine shape and/or USB port location differs depending on the machine.

33

Page 36

2. Installation

6. Mount the ferrite cores on the Ethernet cable, while looping the cable at 3 cm (approx.

1.2 inch) [A] from the each end of the cable.

34

Page 37

USB Device Server Option Type M12

RTB 14

Step added

RTB 14

Steps added

7. Insert the Ethernet cable into the Ethernet board on this option.

8. Insert the other end of the Ethernet cable to a PC for network setting.

9. Plug the power cord into the wall socket and turn on the main power switch.

• Do not unplug the USB connector while the machine is recognizing this option. It may take

between 30 seconds to 1 minute to finish recognizing it (the LEDs by the connector light up

when finished; see below). If unplugged, connect the cable again.

What Do the LED Indications Mean?

When this option is properly installed and recognized by the main machine, the LED indicators light up

under the following conditions.

35

Page 38

2. Installation

RTB 14

Replace this

procedure

No. Light Color Lights Up When:

1 Green and Yellow 1000BASE-T operates

2 Green 10BASE-T operates

3 Yellow 100BASE-TX operates

Notes for Energy Save Mode Setting

If the machine that has this option enters into the energy save mode, you cannot print because there will

be a communication error. Follow the instructions below to set the machine to disable entering into the

energy save mode.

1. Press [Features Settings] on the operation panel.

2. Press [Administrator Tools] in [System Settings].

3. Press [Energy Saver Mode to Disable Print Server].

4. Press [Disable Mode].

5. Press [OK].

6. Press [Features Settings].

IP Address Setting

This section describes how to set an IP address on this option manually. Note that you can set an IP

address which is not only on the same network segment but also on a different network segment to share

a single printer with devices in multiple networks.

• You cannot change the IP address for this option from the operation panel of the main machine.

The setting must be done from a web browser on your PC.

• The network setting of this option is initially assigned as follows:

IP address: 192.168.100.100 / Subnet mask: 255.255.255.0

• The network setting of your PC must be in the same network segment to change the network setting

of this option.

1. Make a note of the current network settings of your PC.

2. Change the IP address on your PC to [192.168.100.xxx (*0 - 255)].

3. Change the subnet mask on your PC to [255.255.255.0].

36

4. Open a web browser.

5. Type [http://192.168.100.100/] in the address bar.

Page 39

6. Press the Enter key.

• The setting screen for this option appears.

7. Click [Network Setting].

USB Device Server Option Type M12

8. Type [root] in the user name textbox and click [OK].

9. Input [IP Address], [Subnet Mask] and [Default Gateway].

10. Set other items if needed.

11. Press [Set].

12. Close the web browser.

37

Page 40

2. Installation

13. Disconnect the Ethernet cable from the PC.

14. Connect the Ethernet cable to a network device (e.g. switching hub).

15. Set the IP address of this option in the printer driver that you use.

38

Page 41

SD Card Appli Move

SD Card Appli Move

Overview

Since there are only two SD card slots (one of them is a service slot), three or more SD card applications

cannot be used simultaneously.

However, if multiple SD card applications are merged, three or more SD card options can be used.

This function is referred to as the “SD card merge function.”

The “SD card merge function” is a function which enables the use of three or more functions within the

capacity of two SD cards by physically transferring the function of one SD card to other SD cards (all SD

card options can be stored in two SD cards).

However, SD card applications are under license, therefore, since an SD card license after merge is

transferred to the target SD card, it cannot be used even if it is moved to the target machine.

Also, a process to prevent illegal copying is performed.

The service program "SD Card Appli Move" (SP5-873) lets you move application programs from one

SD card to another SD card.

Notes on Using the SD Merge Function

• The data necessary for authentication is transferred with the application program from an SD card

to another SD card. Authentication fails if you try to use the SD card after you move the application

program from one card to another card.

• Do not use the SD card if it has been used before for other purposes. Normal operation is not

guaranteed when such an SD card is used.

• An SD card, which becomes empty after moving the data in it to another card, cannot be reused.

• After moving the data in an SD card to another card so that the source card becomes empty, keep

the empty card in place by, for example, affixing it near the SD card slot with adhesive tape. This is

done for the following reasons:

• The SD card can be the only proof that the user is licensed to use the application program.

• You may need to check the SD card and its data to solve a problem in the future.

39

Page 42

2. Installation

SD Card Applications

SD Card Option

IPDS Unit Type P1 128M Yes Yes Available for use in

SD card for NetWare printing

Type P1

XPS Direct Print Option Type

P1

Browser Unit Type P1 128M Yes Yes

VM Card Type W 512M No Yes Available for use

• Both Slots 1 and 2 are vacant when the machine is shipped from the factory.

• VM Card Type W cannot be moved to another SD card.

Card Size

Capacity

128M Yes Yes

128M Yes Yes

Movable to

another SD

card

Target SD

card

Remarks

Slot 1 (Upper) and

Slot 2 (Lower)

only in Slot 1

(Upper)

Move Exec

The menu "Move Exec" (SP5-873-001) lets you move application programs from the original SD card

to another SD card.

• Do not turn ON the write protect switch of the system SD card or application SD card on the

machine. If the write protect switch is ON, a download error (e.g. Error Code 44) occurs during a

firmware upgrade or application merge.

1. Turn the main power switch off.

40

Page 43

SD Card Appli Move

2. SD card slot cover [A].

3. Make sure that a target SD card is in SD Card Slot 1 [A]. The application program is

moved to this SD card.

4. Insert the source SD card with the application program in SD Card Slot 2 [B]. The

application program is copied from this source SD card.

5. Turn the main power switch on.

6. Start the SP mode.

7. Select SP5-873-001 "Move Exec".

8. Follow the messages shown on the operation panel.

9. Turn the main power switch off.

10. Remove the source SD card from SD Card Slot 2 [B].

11. Attach the SD card slot cover.

41

Page 44

2. Installation

12. Turn the main power switch on.

13. Check that the application programs run normally.

Undo Exec

"Undo Exec" (SP5-873-002) lets you move back application programs from an SD card in SD Card

Slot 1 (upper) to the original SD card in SD Card Slot 2 (lower). You can use this program when, for

example, you have mistakenly copied some programs by using Move Exec (SP5-873-001).

• Do not turn ON the write protect switch of the system SD card or application SD card on the

machine. If the write protect switch is ON, a download error (e.g. Error Code 44) occurs during a

firmware upgrade or application merge.

1. Turn the main power switch off.

2. SD card slot cover [A].

42

Page 45

3. Insert the integrated SD card in Slot 1 [A].

4. Insert the SD card which became empty after integration in Slot 2 [B].

SD Card Appli Move

5. Turn the main power switch on.

6. Start the SP mode.

7. Select SP5-873-002 "Undo Exec."

8. Follow the messages shown on the operation panel.

9. Exit the SP mode.

10. Remove the SD card from SD Card Slot 2 [B].

11. Turn the main power switch off.

12. Attach the SD card slot cover.

13. Turn the main power switch on.

14. Check that the application has been deleted.

43

Page 46

2. Installation

Settings for @Remote Service

• Prepare and check the following check points before you visit the customer site. For details, ask the

@Remote key person.

Check points before making @Remote settings

1. The setting of SP5-816-201 in the mainframe must be "0".

2. Print the SMC with SP5-990-002 and then check if a device ID2 (SP5-811-003) must be

correctly programmed.

• 6 spaces must be put between the 3-digit prefix and the following 8-digit number (e.g.

xxx______xxxxxxxx).

3. The following settings must be correctly programmed.

4. If a proxy server is available, configure the following SP settings.

• Use Proxy (SP5-816-062) Set to "1: Enable".

• Proxy server IP address (SP5-816-063)

• Proxy server Port number (SP5-816-064)

• Proxy User ID (SP5-816-065)

• Proxy Password (SP5-816-066)

5. Get a Request Number.

Execute the @Remote Settings

1. Enter the SP mode.

2. Input the Request number which you have obtained from @Remote Center GUI, and then

enter [OK] with SP5-816-202.

3. Confirm the Request number, and then click [EXECUTE] with SP5-816-203.

4. Check the confirmation result with SP5-816-204.

Value Meaning Solution/ Workaround

0 Succeeded -

Communication error (proxy

3

enabled)

Check the network condition.

44

Page 47

Settings for @Remote Service

Value Meaning Solution/ Workaround

Communication error (proxy

4

disabled)

Check the network condition.

5 Proxy error (authentication error) Check Proxy user name and password.

6 Communication error Check the network condition.

8 Other error See "SP5-816-208 Error Codes" below this.

Request number confirmation

9

executing

Processing… Please wait.

11 Already registered -

12 Parameter error -

20 Dial-up authentication error

21 Answer tone detection error

22 Carrier detection error

23 Invalid setting value (modem)

* These errors occur only in the modems that

support @Remote.

24 Low power supply current

25 unplugged modem

26 Busy line

5. Make sure that the screen displays the Location Information with SP5-816-205 only when

it has been input at the Center GUI.

6. Click [EXECUTE] to execute the registration with SP5-816-206.

7. Check the registration result with SP5-816-207.

Value Meaning Solution/ Workaround

0 Succeeded -

2 Already registered Check the registration status.

Communication error (proxy

3

enabled)

Check the network condition.

Communication error (proxy

4

disabled)

Check the network condition.

45

Page 48

2. Installation

Value Meaning Solution/ Workaround

5 Proxy error (Authentication error) Check Proxy user name and password.

8 Other error See "SP5-816-208 Error Codes" below this.

Request number confirmation

9

executing

Processing… Please wait.

11 Already registered -

12 Parameter error -

20 Dial-up authentication error

21 Answer tone detection error

22 Carrier detection error

23 Invalid setting value (modem)

* These errors occur only in the modems that

support @Remote.

24 Low power supply current

25 unplugged modem

26 Busy line

46

Page 49

8. Exit the SP mode.

SP5-816-208 Error Codes

Cause Code Meaning Solution/ Workaround

Settings for @Remote Service

Operation Error,

Incorrect Setting

-12002Inquiry, registration attempted

without acquiring Request No.

-12003Attempted registration without

execution of a confirmation and

no previous registration.

-12004Attempted setting with illegal

entries for certification and ID2.

-12005@Remote communication is

prohibited. The device has an

Embedded RC gate-related

problem.

-12006A confirmation request was made

after the confirmation had been

already completed.

-12007The request number used at

registration was different from the

one used at confirmation.

Obtain a Request Number

before attempting the Inquiry

or Registration.

Perform Confirmation before

attempting the Registration.

Check ID2 of the mainframe.

Make sure that "Remote

Service" in User Tools is set to

"Do not prohibit".

Execute registration.

Check Request No.

-1200

Update certification failed

8

because mainframe was in use.

-12009The ID2 in the NVRAM does not

match the ID2 in the individual

certification.

-12010The certification area is not

initialized.

Check the mainframe

condition. If the mainframe is

in use, try again later.

Check ID2 of the mainframe.

Initialize the certification

area.

47

Page 50

2. Installation

Cause Code Meaning Solution/ Workaround

-2385 Other error

-2387 Not supported at the Service

Center

-2389 Database out of service

-2390 Program out of service

Error Caused by

Response from

GW URL

-2391

Two registrations for the same

mainframe

Check the registration

condition of the mainframe

-2392 Parameter error

-2393 External RCG not managed

-2394 Mainframe not managed

-2395 Box ID for external RCG is illegal.

-2396

-2397 Incorrect ID2 format

Mainframe ID for external RCG is

illegal.

Check the ID2 of the

mainframe.

-2398 Incorrect request number format Check the Request No.

48

Page 51

3. Preventive Maintenance

Preventive Maintenance Tables

Preventive Maintenance Tables

See "Appendices" for the following information:

• Preventive Maintenance Items

49

Page 52

3. Preventive Maintenance

Image Quality Standards

Image Quality Standards

Engine

Item Specification Remarks

Leading edge: 4.2 mm (1/6 inches)

Assured Image Area

Magnification Error ±0.75% or less

Perpendicularity ±0.7 mm / 100 mm DLT: 1.75/200 mm or less

Linearity ±0.25 mm / 100 mm

Parallelism ±1.8 mm or less DLT: ±2.0 mm or less

• To check whether the problem is with the image or is due to another issue, print the test pattern.

Left/Right: 4.2 mm (1/6 inches)

Trailing edge: 4.2 mm (1/6 inches)

50

Page 53

Paper Transfer Quality Standards

Paper Transfer Quality Standards

Engines

Item Specification Remarks

Single Side:

Main Scan: 0 ± 2.0 mm

Sub Scan: 0 ± 1.5 mm

Margin position

Back of the paper when performing duplex

printing:

Main Scan: 0 ± 2.0 mm

Sub Scan: 0 ± 1.5 mm

Single Side:

Paper Transfer Quality Standards

± 1.2 mm / 200 mm or less (B5 SEF or

more)

± 1.0 mm / 100 mm or less (Less than B5

Skew

Curling after fusing

These standards are determined using standard paper under standard conditions.

Values may vary depending on environmental conditions such as temperature, humidity, use of used

paper, etc.

SEF)

Duplex:

±1.0 mm/100 mm or less (B5 SEF or more)

±1.5 mm/100 mm or less (Less than B5

SEF)

25 mm or less from leading and trailing

edges

60 mm or less (* applicable for printed

forms over 90 kg in weight)

In an office environment

51

Page 54

3. Preventive Maintenance

52

Page 55

4. Replacement and Adjustment

General Cautions

Notes on the Main Power Switch

The main power button of this machine has been changed to a push-button switch (push button) from the

conventional rocker switch. The push switch has characteristics and specifications different from the

rocker switch. Care must be taken when replacing and adjusting parts.

Characteristics of the Push Switch (DC Switch)

Power is supplied to the machine even when the main power switch is turned OFF.

The push switch in this machine uses DC (direct current). Therefore, if the AC power cord is

connected to an electrical outlet, power is supplied to the controller board, the operation unit and

other modules even when the main power is turned OFF. When replacing the controller board and

the operation unit in this state, not only these boards, it will damage other electrical components.

So, when performing maintenance work such as replacing parts, in addition to turning off the main

power with the push switch, always unplug the AC power cord.

When you disconnect the power cord from the AC wall outlet, inside the machine there is still

residual charge.

When you disconnect the power cord from the AC wall outlet, inside the machine for a while there

is still residual charge. Therefore, if you remove boards in this state, it can cause a blown fuse or

memory failure.

-- How to remove the residual charge inside the machine--

After you unplug the power cord from the AC wall outlet, in order to remove the residual charge

from inside the machine, be sure to press the main power switch. Thus, the charge remaining in the

machine is released, and it is possible to remove boards.

When you reconnect the AC power cord into an AC wall outlet, the machine will start

automatically.

In order to remove the residual charge, push the main power switch while you disconnect the AC

power cord. At that time, the power ON flag inside the machine is set. Therefore, after you finish

work on the machine and reconnect the power cord to the AC, even if you do not press the main

power switch, the machine will start automatically and the moving parts will begin to move. When

working on moving parts, be careful that fingers or clothes do not get caught.

53

Page 56

4. Replacement and Adjustment

• Automatic restart deals with cases when you accidentally unplugged the AC power cord or

unexpected power outages. By keeping the power flag ON, after the resumption of power, the

machine will start up automatically.

In rare cases, when you reconnect the AC power cord to a power outlet, the machine does not start

automatically. In this case, the machine has not failed. The cause is due to the timing of releasing the

residual charge. If you press the main power switch while the residual charge was already released, the

power ON flag will not be set. At this time, start the machine manually by pressing the main power

switch.

Shutdown Method

1. Press the main power switch [A] on the left side of the machine.

After the shutdown process, the main power is turned off automatically.

When the shutdown is complete

Operation panel LED: Off

2. Take out the power cord.

3. Wait 3 minutes (this is the time required if you will remove the rear cover and access the

interior of the machine, to take out the controller board for example).

Note: If some LEDs on any of the boards are blinking or lit, current is still flowing.

How to start from shutdown

To start the machine, press the main power switch. However, if you press the main power switch

between the beginning and the end of a shutdown, the machine will not start.

54

Page 57

General Cautions

Forced Shutdown

In case normal shutdown does not complete for some reason, the machine has a forced shutdown

function.

To make a forced shutdown, press and hold the main power switch for 6 seconds.

In general, do not use the forced shutdown.

• Forced shutdown may damage the hard disk and memory, and can cause damage to the machine.

Use a forced shutdown only if it is unavoidable.

55

Page 58

4. Replacement and Adjustment

Special Tools

Part Number Description Q’ty

B6455010 SD Card 128MB 1

B6455020 SD Card 1GB 1

• A PC (Personal Computer) is required for creating the Encryption key file on an SD card when

replacing the controller board for a model in which HDD encryption has been enabled.

56

Page 59

Exterior Covers

Front Cover

1. Paper Feed Tray (page 107)

2. By-pass tray (page 66)

3. Push the release button to open the front cover [A].

Exterior Covers

4. Hanging wire [A]

57

Page 60

4. Replacement and Adjustment

5. Release the hinges at both ends, and detach the front cover [A].

• To remove the front cover, lift the left hinge first to release while raising the front cover

upwards.

• The left hinge is C-cut.

Left Cover

• There is a tab on the back of the left cover. Refer to the picture below.

58

Page 61

1. Open the front cover [A].

2. Two screws securing the front side of the left cover [A] ( ×2)

Exterior Covers

3. Open the rear cover [A].

59

Page 62

4. Replacement and Adjustment

4. Two screws securing the rear side of the left cover [B] ( ×2)

5. One screw to detach the left cover ( ×1)

60

Right Cover

• There is a tab on the back of the right cover. Refer to the picture below.

Page 63

1. Open the front cover [A].

Exterior Covers

61

Page 64

4. Replacement and Adjustment

2. Two screws securing the front side of the right cover [A] ( ×2)

3. Open the rear cover [A].

4. Two screws securing the rear side of the right cover [B] ( ×2)

62

5. Right cover [A] ( ×1)

Page 65

6. Memory cover [B]

Rear Cover, Rear Lower Cover

1. Left cover (page 58)

Exterior Covers

2. Right cover (page 60)

3. Open the rear cover [A].

63

Page 66

4. Replacement and Adjustment

4. Screw ( ×1)

5. Release the stopper [A].

64

Page 67

6. Release the hinges at both ends to detach the rear cover [A].

Exterior Covers

• To release the hinges, push the left hinge inside with your finger while holding the rear cover

[A] open at angle of approx. 10°. The right hinge is removed spontaneously when the left

hinge is released.

7. Rear lower cover [A] (

×4)

65

Page 68

4. Replacement and Adjustment

By-pass Tray

1. Open the by-pass tray [A].

2. Release the hinges at both ends.

66