Page 1

MVI-ADM

'C' Programmable

'C' Programmable Application

Development Module

February 20, 2013

DEVELOPER'S GUIDE

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2013 ProSoft Technology, Inc., all rights reserved.

MVI-ADM Developer's Guide

February 20, 2013

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com.

Content Disclaimer

This documentation is not intended as a substitute for and is not to be used for determining suitability or reliability of

these products for specific user applications. It is the duty of any such user or integrator to perform the appropriate

and complete risk analysis, evaluation and testing of the products with respect to the relevant specific application or

use thereof. Neither ProSoft Technology nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. Information in this document including illustrations, specifications and

dimensions may contain technical inaccuracies or typographical errors. ProSoft Technology makes no warranty or

representation as to its accuracy and assumes no liability for and reserves the right to correct such inaccuracies or

errors at any time without notice. If you have any suggestions for improvements or amendments or have found errors

in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of ProSoft Technology. All pertinent state, regional, and local safety

regulations must be observed when installing and using this product. For reasons of safety and to help ensure

compliance with documented system data, only the manufacturer should perform repairs to components. When

devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use ProSoft Technology software or approved software with our hardware products may result in injury,

harm, or improper operating results. Failure to observe this information can result in injury or equipment damage.

© 2013 ProSoft Technology. All rights reserved.

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

C Suitable for use in Class I, division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Electrical Ratings

Backplane Current Load: 800 mA @ 5 V DC; 3mA @ 24V DC

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Shock: 30g Operational; 50g non-operational; Vibration: 5 g from 10 to 150 Hz

Relative Humidity 5% to 95% (non-condensing)

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Page 4

CE

EMC-EN61326-1:2006; EN6100-6-4:2007

CSA/cUL

C22.2 No. 213-1987

CSA CB Certified

IEC61010

ATEX

EN60079-0 Category 3, Zone 2

EN60079-15

243333

ME06

ANSI / ISA

ISA 12.12.01 Class I Division 2, GPs A, B, C, D

CSA/cUL

C22.2 No. 213-1987

CSA CB Certified

IEC61010

ATEX

EN60079-0 Category 3, Zone 2

EN60079-15

243333

Markings - MVI56, MVI69, PTQ

Markings - MVI46, MVI71

Warning: This module is not hot-swappable! Always remove power from the rack before inserting or removing this

module, or damage may result to the module, the processor, or other connected devices.

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Page 5

MVI-ADM ♦ 'C' Programmable Contents

'C' Programmable Application Development Module Developer's Guide

Contents

Your Feedback Please ........................................................................................................................ 2

Content Disclaimer .............................................................................................................................. 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 4

1 Introduction 13

1.1 Operating System .................................................................................................... 13

2 Preparing the MVI-ADM Module 15

2.1 Package Contents ................................................................................................... 16

2.2 Recommended Compact Flash (CF) Cards ............................................................ 17

2.3 Jumper Locations and Settings ............................................................................... 18

2.3.1 Setup Jumper .......................................................................................................... 18

2.3.2 Port 1 and Port 2 Jumpers ...................................................................................... 18

2.4 Cable Connections .................................................................................................. 19

2.4.1 RS-232 Configuration/Debug Port .......................................................................... 19

2.4.2 RS-232 Application Port(s) ..................................................................................... 19

2.4.3 RS-422 .................................................................................................................... 22

2.4.4 RS-485 Application Port(s) ...................................................................................... 22

2.4.5 DB9 to RJ45 Adaptor (Cable 14) ............................................................................ 23

3 Understanding the MVI-ADM API 25

3.1 API Libraries ............................................................................................................ 26

3.1.1 Calling Convention .................................................................................................. 26

3.1.2 Header File .............................................................................................................. 26

3.1.3 Sample Code ........................................................................................................... 26

3.1.4 Multi-threading Considerations ............................................................................... 27

3.2 Development Tools ................................................................................................. 28

3.3 Theory of Operation ................................................................................................ 29

3.3.1 ADM API .................................................................................................................. 29

3.4 ADM Functional Blocks ........................................................................................... 30

3.4.1 Database ................................................................................................................. 30

3.4.2 Backplane Communications .................................................................................... 30

3.4.3 Serial Communications ........................................................................................... 53

3.4.4 Main_app.c .............................................................................................................. 53

3.4.5 Debugprt.c ............................................................................................................... 54

3.4.6 MVIcfg.c................................................................................................................... 54

3.4.7 Commdrv.c .............................................................................................................. 56

3.4.8 Using Compact Flash Disks .................................................................................... 58

3.5 ADM API Architecture ............................................................................................. 59

3.6 ADM API Files ......................................................................................................... 60

3.6.1 ADM Interface Structure .......................................................................................... 60

3.7 Backplane API Files ................................................................................................ 64

3.7.1 Backplane API Architecture..................................................................................... 64

ProSoft Technology, Inc. Page 5 of 342

February 20, 2013

Page 6

Contents MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

3.8 Serial API Files ....................................................................................................... 66

3.8.1 Serial API Architecture ............................................................................................ 66

3.9 Side-Connect API Files ........................................................................................... 67

3.9.1 Side-Connect API Architecture ............................................................................... 67

3.9.2 Data Transfer .......................................................................................................... 67

4 Setting Up Your Development Environment 69

4.1 Setting Up Your Compiler ....................................................................................... 70

4.1.1 Configuring Digital Mars C++ 8.49.......................................................................... 70

4.1.2 Configuring Borland C++5.02 ................................................................................. 80

4.2 Setting Up WINIMAGE ........................................................................................... 87

4.3 Installing and Configuring the Module .................................................................... 88

4.3.1 Using Side-Connect (Requires Side-Connect Adapter) (MVI71) ........................... 88

5 Programming the Module 91

5.1 ROM Disk Configuration ......................................................................................... 92

5.1.1 CONFIG.SYS File ................................................................................................... 92

5.1.2 Command Interpreter .............................................................................................. 94

5.1.3 Sample ROM Disk Image ....................................................................................... 95

5.2 Creating a ROM Disk Image ................................................................................... 97

5.2.1 WINIMAGE: Windows Disk Image Builder ............................................................. 97

5.3 MVIUPDAT ............................................................................................................. 99

5.4 MVI System BIOS Setup ...................................................................................... 101

5.5 Debugging Strategies ........................................................................................... 102

6 Creating Ladder Logic 103

6.1 MVI46 Ladder Logic .............................................................................................. 104

6.1.1 Main Routine ......................................................................................................... 104

6.2 MVI56 Ladder Logic .............................................................................................. 105

6.2.1 Main Routine ......................................................................................................... 105

6.2.2 Read Routine ........................................................................................................ 105

6.3 MVI69 Ladder Logic .............................................................................................. 106

6.3.1 Main Routine ......................................................................................................... 106

6.3.2 Read Routine ........................................................................................................ 107

6.3.3 Write Routine ........................................................................................................ 108

6.4 MVI71 Ladder Logic .............................................................................................. 109

6.4.1 Sample Ladder Logic ............................................................................................ 109

6.5 MVI94 Ladder Logic .............................................................................................. 115

6.5.1 Main Routine ......................................................................................................... 115

6.5.2 ADM ...................................................................................................................... 116

7 Application Development Function Library - ADM API 119

7.1 ADM API Functions .............................................................................................. 120

7.2 ADM API Initialization Functions........................................................................... 123

ADM_Open ................................................................................................................................ 123

ADM_Close ............................................................................................................................... 124

7.3 ADM API Debug Port Functions ........................................................................... 125

ADM_ProcessDebug ................................................................................................................. 125

Page 6 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 7

MVI-ADM ♦ 'C' Programmable Contents

'C' Programmable Application Development Module Developer's Guide

ADM_DAWriteSendCtl ............................................................................................................... 126

ADM_DAWriteRecvCtl ............................................................................................................... 127

ADM_DAWriteSendData............................................................................................................ 128

ADM_DAWriteRecvData ............................................................................................................ 129

ADM_ConPrint ........................................................................................................................... 130

ADM_CheckDBPort ................................................................................................................... 131

7.4 ADM API Database Functions .............................................................................. 132

ADM_DBOpen ........................................................................................................................... 132

ADM_DBClose ........................................................................................................................... 133

ADM_DBZero ............................................................................................................................. 134

ADM_DBGetBit .......................................................................................................................... 135

ADM_DBSetBit .......................................................................................................................... 136

ADM_DBClearBit ....................................................................................................................... 137

ADM_DBGetByte ....................................................................................................................... 138

ADM_DBSetByte ....................................................................................................................... 139

ADM_DBGetWord ...................................................................................................................... 140

ADM_DBSetWord ...................................................................................................................... 141

ADM_DBGetLong ...................................................................................................................... 142

ADM_DBSetLong ....................................................................................................................... 143

ADM_DBGetFloat ...................................................................................................................... 144

ADM_DBSetFloat ....................................................................................................................... 145

ADM_DBGetDFloat .................................................................................................................... 146

ADM_DBSetDFloat .................................................................................................................... 147

ADM_DBGetBuff ........................................................................................................................ 148

ADM_DBSetBuff ........................................................................................................................ 149

ADM_DBGetRegs ...................................................................................................................... 150

ADM_DBSetRegs ...................................................................................................................... 151

ADM_DBGetString ..................................................................................................................... 152

ADM_DBSetString ..................................................................................................................... 153

ADM_DBSwapWord .................................................................................................................. 154

ADM_DBSwapDWord ................................................................................................................ 155

ADM_GetDBCptr ....................................................................................................................... 156

ADM_GetDBIptr ......................................................................................................................... 157

ADM_GetDBInt .......................................................................................................................... 158

ADM_DBChanged ..................................................................................................................... 159

ADM_DBBitChanged ................................................................................................................. 160

ADM_DBOR_Byte ..................................................................................................................... 161

ADM_DBNOR_Byte ................................................................................................................... 162

ADM_DBAND_Byte ................................................................................................................... 163

ADM_DBNAND_Byte................................................................................................................. 164

ADM_DBXOR_Byte ................................................................................................................... 165

ADM_DBXNOR_Byte ................................................................................................................ 166

7.5 ADM API Clock Functions ..................................................................................... 167

ADM_StartTimer ........................................................................................................................ 167

ADM_CheckTimer ...................................................................................................................... 168

7.6 ADM API Backplane Functions ............................................................................. 169

ADM_BtOpen ............................................................................................................................. 169

ADM_BtClose ............................................................................................................................ 170

ADM_BtNext .............................................................................................................................. 171

ADM_ReadBtCfg ....................................................................................................................... 172

ADM_BtFunc .............................................................................................................................. 173

ADM_SetStatus ......................................................................................................................... 174

ADM_SetBtStatus ...................................................................................................................... 175

7.7 ADM LED Functions .............................................................................................. 176

ProSoft Technology, Inc. Page 7 of 342

February 20, 2013

Page 8

Contents MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

ADM_SetLed ............................................................................................................................. 176

7.8 ADM API Flash Functions ..................................................................................... 177

ADM_FileGetString ................................................................................................................... 177

ADM_FileGetInt ......................................................................................................................... 178

ADM_FileGetChar ..................................................................................................................... 179

ADM_GetVal.............................................................................................................................. 180

ADM_GetChar ........................................................................................................................... 181

ADM_GetStr .............................................................................................................................. 182

ADM_SkipToNext ...................................................................................................................... 183

ADM_Getc ................................................................................................................................. 184

7.9 ADM API Miscellaneous Functions....................................................................... 185

ADM_GetVersionInfo ................................................................................................................ 185

ADM_SetConsolePort ............................................................................................................... 186

ADM_SetConsoleSpeed ........................................................................................................... 187

7.10 ADM Side-Connect Functions .............................................................................. 188

ADM_ScOpen ........................................................................................................................... 188

ADM_ScClose ........................................................................................................................... 189

ADM_ReadScFile ...................................................................................................................... 190

ADM_ReadScCfg ...................................................................................................................... 191

ADM_ScScan ............................................................................................................................ 192

7.11 ADM API RAM Functions ..................................................................................... 193

ADM_EEPROM_ReadConfiguration ......................................................................................... 193

ADM_RAM_Find_Section ......................................................................................................... 194

ADM_RAM_GetString ............................................................................................................... 195

ADM_RAM_GetInt ..................................................................................................................... 196

ADM_RAM_GetLong ................................................................................................................. 197

ADM_RAM_GetFloat ................................................................................................................. 198

ADM_RAM_GetDouble ............................................................................................................. 199

ADM_RAM_GetChar ................................................................................................................. 200

8 Backplane API Functions 201

8.1 Backplane API Initialization Functions .................................................................. 203

MVIbp_Open ............................................................................................................................. 203

MVIbp_Close ............................................................................................................................. 204

8.2 Backplane API Configuration Functions ............................................................... 206

MVIbp_GetIOConfig .................................................................................................................. 206

MVIbp_SetIOConfig .................................................................................................................. 208

8.3 Backplane API Synchronization Functions ........................................................... 210

MVIbp_WaitForInputScan ......................................................................................................... 210

MVIbp_WaitForOutputScan ...................................................................................................... 212

8.4 Backplane API Direct I/O Access ......................................................................... 214

MVIbp_ReadOutputImage ......................................................................................................... 214

MVIbp_WriteInputImage ............................................................................................................ 215

8.5 Backplane API Messaging Functions ................................................................... 216

MVIbp_ReceiveMessage .......................................................................................................... 216

MVIbp_SendMessage ............................................................................................................... 218

8.6 Backplane API Miscellaneous Functions .............................................................. 220

MVIbp_GetVersionInfo .............................................................................................................. 220

MVIbp_GetModuleInfo .............................................................................................................. 221

MVIbp_ErrorString ..................................................................................................................... 222

MVIbp_SetUserLED .................................................................................................................. 223

MVIbp_SetModuleStatus ........................................................................................................... 224

Page 8 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 9

MVI-ADM ♦ 'C' Programmable Contents

'C' Programmable Application Development Module Developer's Guide

MVIbp_GetConsoleMode .......................................................................................................... 225

MVIbp_GetSetupMode .............................................................................................................. 226

MVIbp_GetProcessorStatus ...................................................................................................... 227

MVIbp_Sleep ............................................................................................................................. 228

MVIbp_SetConsoleMode ........................................................................................................... 229

8.7 Platform Specific Functions ................................................................................... 230

MVIbp_ReadModuleFile (MVI46) .............................................................................................. 230

MVIbp_WriteModuleFile (MVI46) ............................................................................................... 231

MVIbp_SetModuleInterrupt (MVI46) .......................................................................................... 232

9 Serial Port Library Functions 233

9.1 Serial Port API Initialization Functions .................................................................. 235

MVIsp_Open .............................................................................................................................. 235

MVIsp_OpenAlt .......................................................................................................................... 237

MVIsp_Close .............................................................................................................................. 239

9.2 Serial Port API Configuration Functions ................................................................ 240

MVIsp_Config ............................................................................................................................ 240

MVIsp_SetHandshaking ............................................................................................................ 242

9.3 Serial Port API Status Functions ........................................................................... 243

MVIsp_SetRTS .......................................................................................................................... 243

MVIsp_GetRTS .......................................................................................................................... 244

MVIsp_SetDTR .......................................................................................................................... 245

MVIsp_GetDTR .......................................................................................................................... 246

MVIsp_GetCTS .......................................................................................................................... 247

MVIsp_GetDSR ......................................................................................................................... 248

MVIsp_GetDCD ......................................................................................................................... 249

MVIsp_GetLineStatus ................................................................................................................ 250

9.4 Serial Port API Communications ........................................................................... 251

MVIsp_Putch .............................................................................................................................. 251

MVIsp_Getch ............................................................................................................................. 252

MVIsp_Puts ................................................................................................................................ 253

MVIsp_PutData .......................................................................................................................... 255

MVIsp_Gets ............................................................................................................................... 257

MVIsp_GetData ......................................................................................................................... 259

MVIsp_GetCountUnsent ............................................................................................................ 261

MVIsp_GetCountUnread ........................................................................................................... 262

MVIsp_PurgeDataUnsent .......................................................................................................... 263

MVIsp_PurgeDataUnread .......................................................................................................... 264

9.5 Serial Port API Miscellaneous Functions .............................................................. 265

MVIsp_GetVersionInfo ............................................................................................................... 265

10 CIP Messaging Library Functions 267

10.1 CIP Messaging API Files....................................................................................... 268

10.2 CIP API Architecture ............................................................................................. 269

10.2.1 Backplane Device Driver ....................................................................................... 269

10.3 CIP API Initialization Functions ............................................................................. 270

MVIcip_Open ............................................................................................................................. 270

MVIcip_Close ............................................................................................................................. 271

10.4 CIP Object Registration ......................................................................................... 272

MVIcip_RegisterAssemblyObj ................................................................................................... 272

MVIcip_UnregisterAssemblyObj ................................................................................................ 274

ProSoft Technology, Inc. Page 9 of 342

February 20, 2013

Page 10

Contents MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

10.5 CIPConnect® Data Transfer .................................................................................. 275

MVIcip_WriteConnected ............................................................................................................ 275

MVIcip_ReadConnected ........................................................................................................... 276

10.6 CIP Callback Functions ........................................................................................ 278

connect_proc ............................................................................................................................. 278

service_proc .............................................................................................................................. 282

rxdata_proc................................................................................................................................ 284

fatalfault_proc ............................................................................................................................ 286

flashupdate_proc ....................................................................................................................... 287

resetrequest_proc ..................................................................................................................... 288

10.7 CIP Special Callback Registration ........................................................................ 289

MVIcip_RegisterFatalFaultRtn .................................................................................................. 289

MVIcip_RegisterResetReqRtn .................................................................................................. 290

MVIcip_RegisterFlashUpdateRtn .............................................................................................. 291

10.8 CIP Miscellaneous Functions ............................................................................... 292

MVIcip_GetIdObject .................................................................................................................. 292

MVIcip_GetVersionInfo ............................................................................................................. 293

MVIcip_SetUserLED ................................................................................................................. 294

MVIcip_SetModuleStatus .......................................................................................................... 295

MVIcip_ErrorString .................................................................................................................... 296

MVIcip_GetSetupMode ............................................................................................................. 297

MVIcip_GetConsoleMode ......................................................................................................... 298

MVIcip_Sleep ............................................................................................................................ 299

11 Side-Connect API Library Functions 301

11.1 Initialization ........................................................................................................... 302

11.1.1 PLC Data Table Access ........................................................................................ 302

11.1.2 Synchronization .................................................................................................... 302

11.2 PLC Message Handling ........................................................................................ 303

11.2.1 Block Transfer ....................................................................................................... 303

11.2.2 PLC Status and Control ........................................................................................ 303

11.2.3 Miscellaneous ....................................................................................................... 303

11.3 Side-connect API Initialization Functions ............................................................. 304

MVIsc_Open .............................................................................................................................. 304

MVIsc_Close ............................................................................................................................. 305

11.4 Side-connect API PLC Data Table Access Functions .......................................... 306

MVIsc_GetPLCFileInfo .............................................................................................................. 306

MVIsc_WritePLC ....................................................................................................................... 308

MVIsc_ReadPLC ....................................................................................................................... 310

MVIsc_RMWPLC ...................................................................................................................... 312

11.5 Side-connect API Synchronization Functions ....................................................... 314

MVIsc_WaitForEos .................................................................................................................... 314

11.6 Side-connect API PLC Message Handling Functions .......................................... 315

MVIsc_PLCMsgRead ................................................................................................................ 315

MVIsc_PLCMsgWrite ................................................................................................................ 316

MVIsc_PLCMsgWait ................................................................................................................. 317

11.7 Side-connect API Block Transfer Functions ......................................................... 318

MVIsc_PLCBTRead .................................................................................................................. 318

MVIsc_PLCBTWrite .................................................................................................................. 319

11.8 Side-connect API PLC Status and Control Functions .......................................... 320

MVIsc_GetPLCStatus ............................................................................................................... 320

MVIsc_GetPLCClock ................................................................................................................. 322

Page 10 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 11

MVI-ADM ♦ 'C' Programmable Contents

'C' Programmable Application Development Module Developer's Guide

MVIsc_SyncPLCClock ............................................................................................................... 323

MVIsc_ClearFault ...................................................................................................................... 324

MVIsc_SetPLCMode.................................................................................................................. 325

11.9 Side-connect API Miscellaneous Functions .......................................................... 326

MVIsc_GetVersionInfo ............................................................................................................... 326

MVIsc_ErrorStr .......................................................................................................................... 327

MVIsc_GetLastPcccError........................................................................................................... 328

MVIsc_BCD2BIN ....................................................................................................................... 329

MVIsc_BIN2BCD ....................................................................................................................... 330

12 DOS 6 XL Reference Manual 331

13 Support, Service & Warranty 333

13.1 Contacting Technical Support ............................................................................... 333

13.2 Warranty Information ............................................................................................. 334

Glossary of Terms 335

Index 339

ProSoft Technology, Inc. Page 11 of 342

February 20, 2013

Page 12

Contents MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

Page 12 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 13

MVI-ADM ♦ 'C' Programmable Introduction

In This Chapter

Operating System .................................................................................. 13

'C' Programmable Application Development Module Developer's Guide

1 Introduction

This document provides information needed for development of application

programs for the MVI ADM Serial Communication Module. The MVI suite of

modules is designed to allow devices with a serial port to be accessed by a PLC.

The modules and their corresponding platforms are as follows:

MVI46: 1746 (SLC)

MVI56: 1756 (ControlLogix)

MVI69: 1769 (CompactLogix)

MVI71: 1771 (PLC)

MVI94: 1794 (Flex)

The modules are programmable to accommodate devices with unique serial

protocols.

Included in this document is information about the available software API libraries

and tools, module configuration and programming information, and example code

for both the module and the PLC. This document assumes the reader is familiar

with software development in the 16-bit DOS environment using the 'C'

programming language. This document also assumes that the reader is familiar

with Rockwell Automation programmable controllers and the PLC platform.

1.1 Operating System

The MVI module includes General Software Embedded DOS 6-XL. This

operating system provides DOS compatibility along with real-time multi-tasking

functionality. The operating system is stored in Flash ROM and is loaded by the

BIOS when the module boots.

DOS compatibility allows user applications to be developed using standard DOS

tools, such as Digital Mars C++ and Borland compilers. User programs may be

executed automatically by loading them from either the CONFIG.SYS file or an

AUTOEXEC.BAT file.

Note: DOS programs that try to access the video or keyboard hardware directly will not function

correctly on the MVI module. Only programs that use the standard DOS and BIOS functions to

perform console I/O are compatible.

Refer to the General Software Embedded DOS 6-XL Developer’s Guide

(page 331) on the MVI-ADM CD-ROM for more information.

ProSoft Technology, Inc. Page 13 of 342

February 20, 2013

Page 14

Introduction MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

Page 14 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 15

MVI-ADM ♦ 'C' Programmable Preparing the MVI-ADM Module

In This Chapter

Package Contents ................................................................................. 16

Recommended Compact Flash (CF) Cards .......................................... 17

Jumper Locations and Settings ............................................................. 18

Cable Connections ................................................................................ 19

'C' Programmable Application Development Module Developer's Guide

2 Preparing the MVI-ADM Module

ProSoft Technology, Inc. Page 15 of 342

February 20, 2013

Page 16

Preparing the MVI-ADM Module MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

2.1 Package Contents

Your MVI-ADM package includes:

MVI-ADM Module

ProSoft Technology Solutions CD-ROM (includes all documentation, sample

code, and sample ladder logic).

Null Modem Cable

Config/Debug Port to DB-9 adapter

Page 16 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 17

MVI-ADM ♦ 'C' Programmable Preparing the MVI-ADM Module

'C' Programmable Application Development Module Developer's Guide

2.2 Recommended Compact Flash (CF) Cards

What Compact Flash card does ProSoft recommend using?

Some ProSoft products contain a "Personality Module", or Compact Flash card.

ProSoft recommends using an industrial grade Compact Flash card for best

performance and durability. The following cards have been tested with ProSoft’s

modules, and are the only cards recommended for use. These cards can be

ordered through ProSoft, or can be purchased by the customer.

Approved ST-Micro cards:

32M = SMC032AFC6E

64M = SMC064AFF6E

128M = SMC128AFF6E

Approved Silicon Systems cards:

256M = SSD-C25MI-3012

512M = SSD-C51MI-3012

2G = SSD-C02GI-3012

4G = SSD-C04GI-3012

ProSoft Technology, Inc. Page 17 of 342

February 20, 2013

Page 18

Preparing the MVI-ADM Module MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

2.3 Jumper Locations and Settings

Each module has three jumpers:

Setup

Port 1

Port 2 (Not available on MVI94)

2.3.1 Setup Jumper

The Setup jumper, located at the bottom of the module, should have the two pins

jumpered when programming the module. After programming is complete, the

jumper should be removed.

2.3.2 Port 1 and Port 2 Jumpers

These jumpers, located at the bottom of the module, configure the port settings

to RS-232, RS-422, or RS-485. By default, the jumpers for both ports are set to

RS-232. These jumpers must be set properly before using the module.

Page 18 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 19

MVI-ADM ♦ 'C' Programmable Preparing the MVI-ADM Module

'C' Programmable Application Development Module Developer's Guide

2.4 Cable Connections

The application ports on the MVI-ADM module support RS-232, RS-422, and RS485 interfaces. Please inspect the module to ensure that the jumpers are set

correctly to correspond with the type of interface you are using.

Note: When using RS-232 with radio modem applications, some radios or modems require

hardware handshaking (control and monitoring of modem signal lines). Enable this in the

configuration of the module by setting the UseCTS parameter to 1.

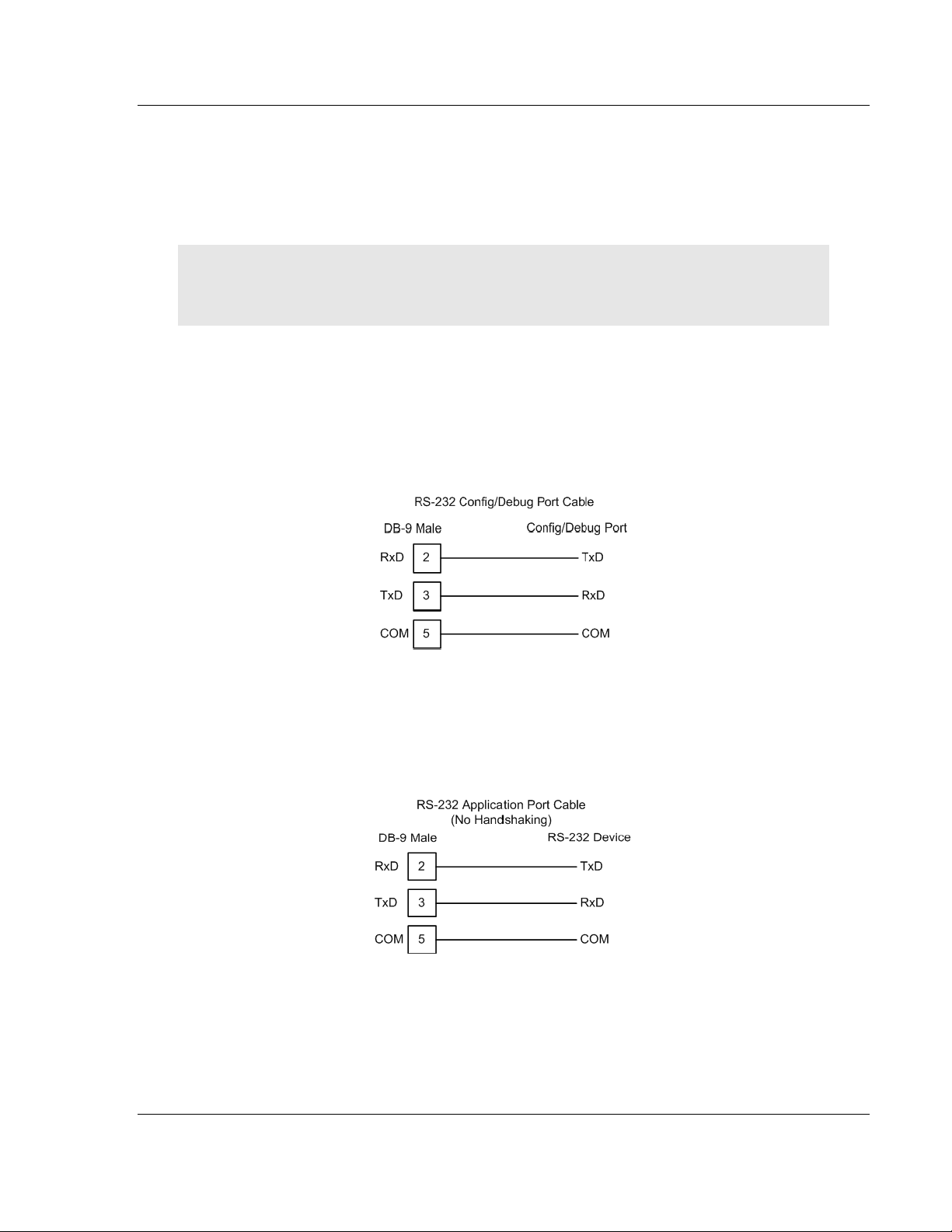

2.4.1 RS-232 Configuration/Debug Port

This port is physically an RJ45 connection. An RJ45 to DB-9 adapter cable is

included with the module. This port permits a PC based terminal emulation

program to view configuration and status data in the module and to control the

module. The cable for communications on this port is shown in the following

diagram:

2.4.2 RS-232 Application Port(s)

When the RS-232 interface is selected, the use of hardware handshaking

(control and monitoring of modem signal lines) is user definable. If no hardware

handshaking will be used, here are the cable pinouts to connect to the port.

ProSoft Technology, Inc. Page 19 of 342

February 20, 2013

Page 20

Preparing the MVI-ADM Module MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

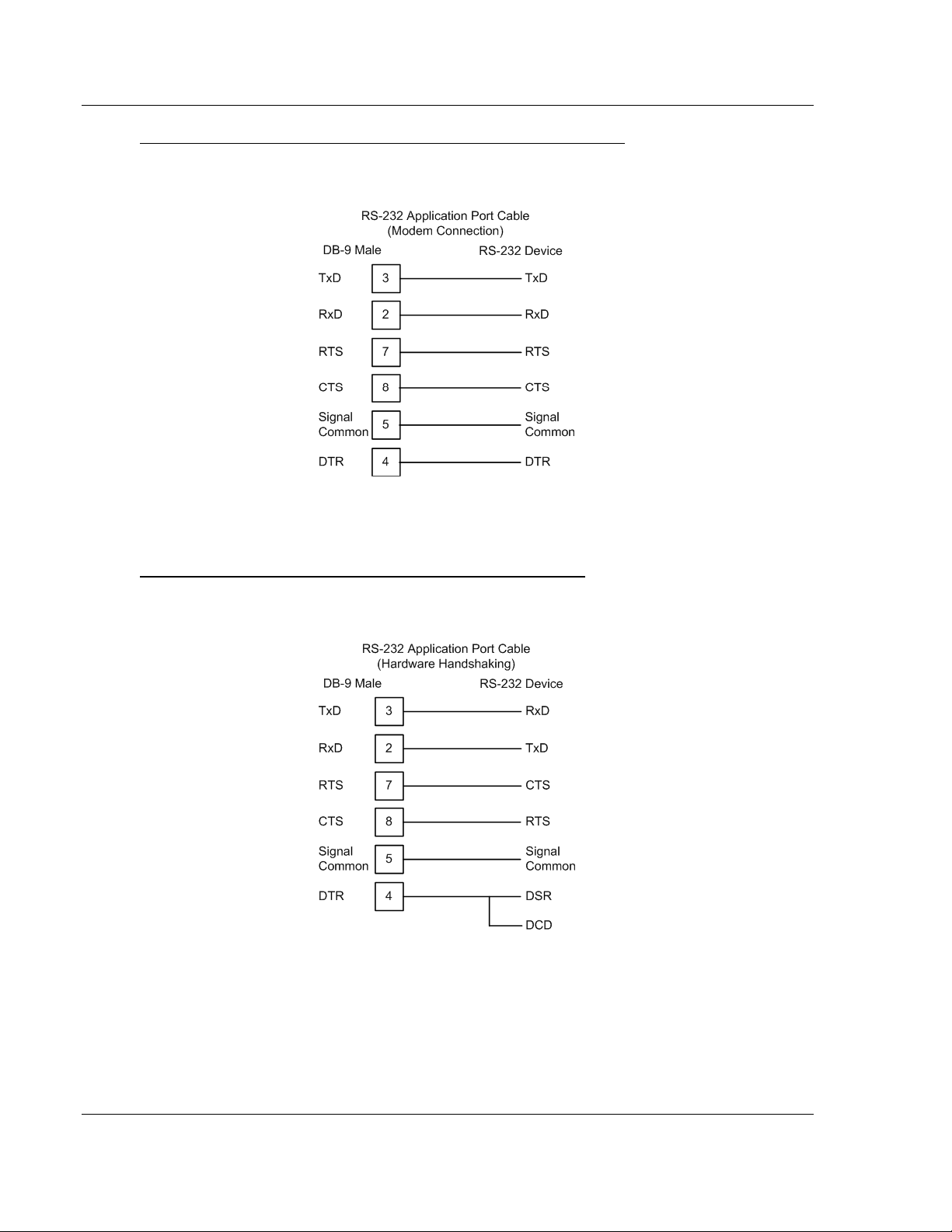

RS-232: Modem Connection (Hardware Handshaking Required)

This type of connection is required between the module and a modem or other

communication device.

The "Use CTS Line" parameter for the port configuration should be set to 'Y' for

most modem applications.

RS-232: Null Modem Connection (Hardware Handshaking)

This type of connection is used when the device connected to the module

requires hardware handshaking (control and monitoring of modem signal lines).

Page 20 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 21

MVI-ADM ♦ 'C' Programmable Preparing the MVI-ADM Module

'C' Programmable Application Development Module Developer's Guide

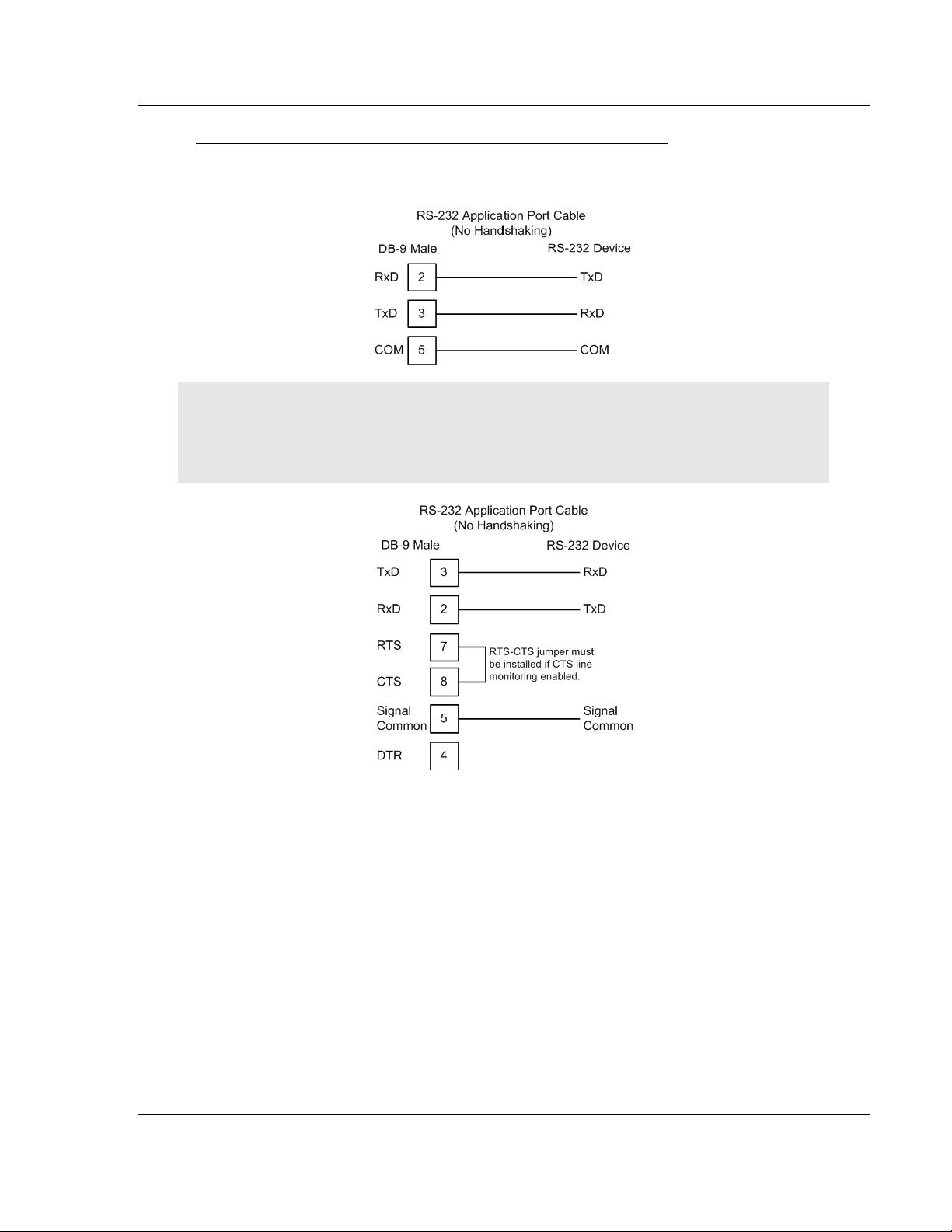

RS-232: Null Modem Connection (No Hardware Handshaking)

This type of connection can be used to connect the module to a computer or field

device communication port.

Note: For most null modem connections where hardware handshaking is not required, the Use

CTS Line parameter should be set to N and no jumper will be required between Pins 7 (RTS) and 8

(CTS) on the connector. If the port is configured with the Use CTS Line set to Y, then a jumper is

required between the RTS and the CTS lines on the port connection.

ProSoft Technology, Inc. Page 21 of 342

February 20, 2013

Page 22

Preparing the MVI-ADM Module MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

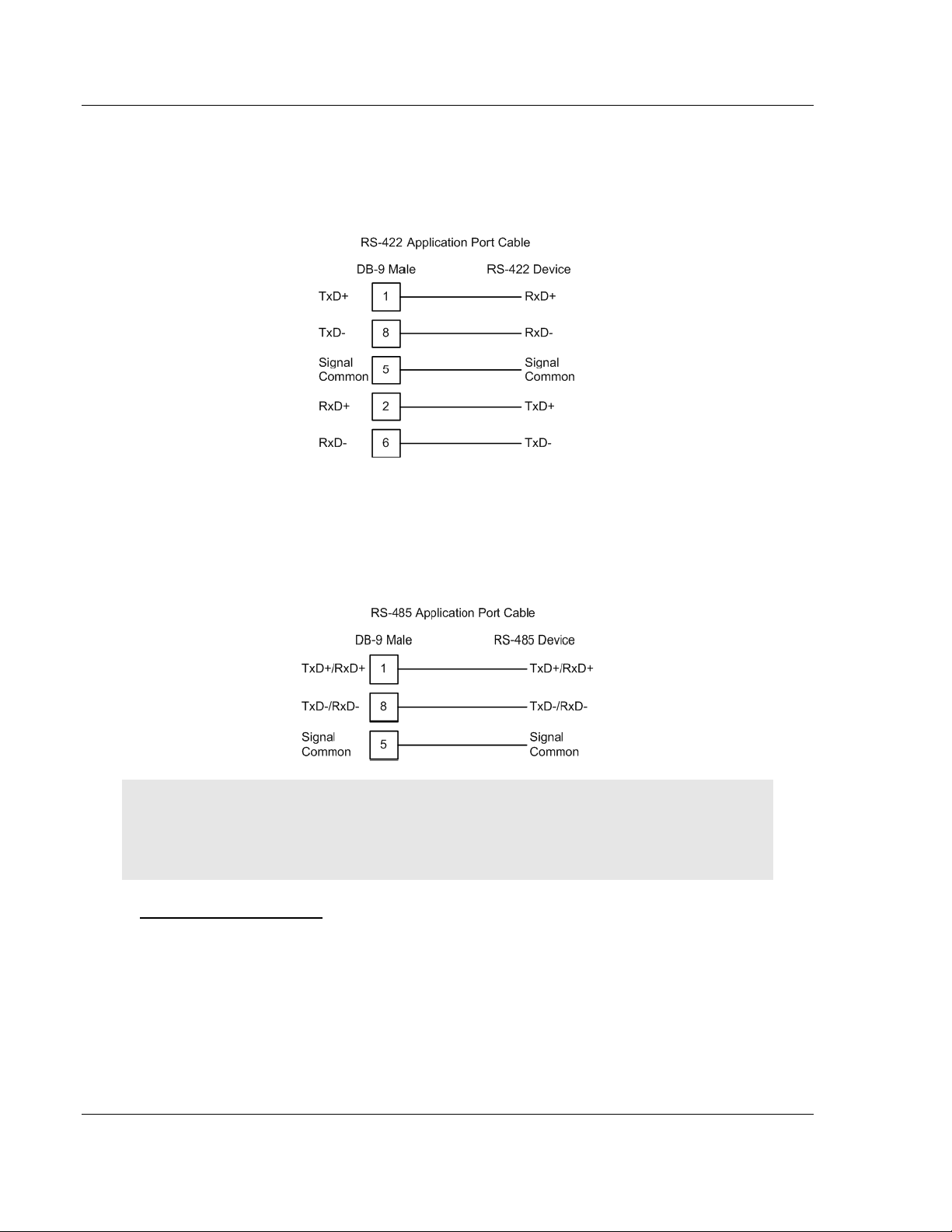

2.4.3 RS-422

The RS-422 interface requires a single four or five wire cable. The Common

connection is optional, depending on the RS-422 network devices used. The

cable required for this interface is shown below:

2.4.4 RS-485 Application Port(s)

The RS-485 interface requires a single two or three wire cable. The Common

connection is optional, depending on the RS-485 network devices used. The

cable required for this interface is shown below:

Note: Terminating resistors are generally not required on the RS-485 network, unless you are

experiencing communication problems that can be attributed to signal echoes or reflections. In

these cases, installing a 120-ohm terminating resistor between pins 1 and 8 on the module

connector end of the RS-485 line may improve communication quality.

RS-485 and RS-422 Tip

If communication in the RS-422 or RS-485 mode does not work at first, despite

all attempts, try switching termination polarities. Some manufacturers interpret +

and -, or A and B, polarities differently.

Page 22 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 23

MVI-ADM ♦ 'C' Programmable Preparing the MVI-ADM Module

'C' Programmable Application Development Module Developer's Guide

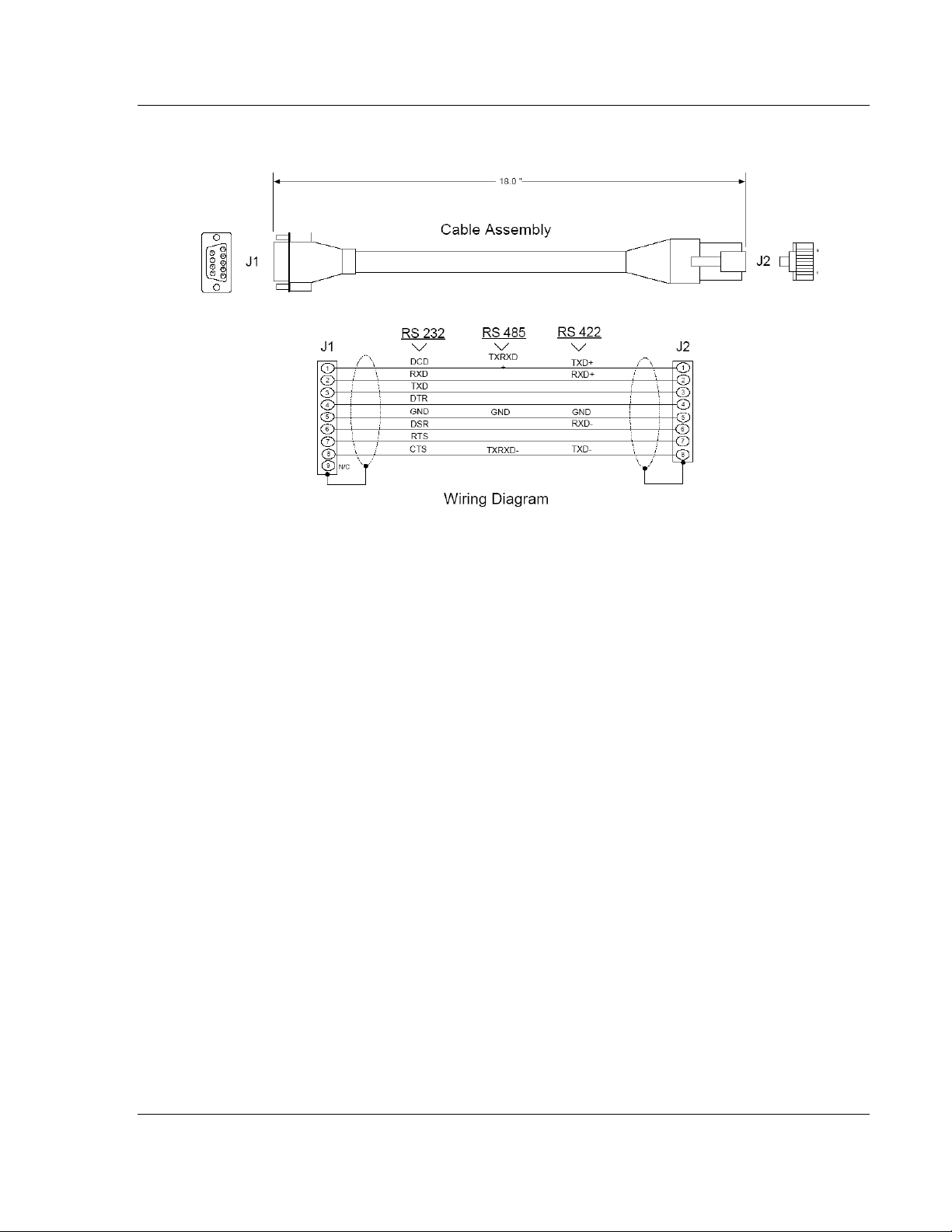

2.4.5 DB9 to RJ45 Adaptor (Cable 14)

ProSoft Technology, Inc. Page 23 of 342

February 20, 2013

Page 24

Preparing the MVI-ADM Module MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

Page 24 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 25

MVI-ADM ♦ 'C' Programmable Understanding the MVI-ADM API

In This Chapter

API Libraries .......................................................................................... 26

Development Tools ............................................................................... 28

Theory of Operation .............................................................................. 29

ADM Functional Blocks ......................................................................... 30

ADM API Architecture............................................................................ 59

ADM API Files ....................................................................................... 60

Backplane API Files .............................................................................. 64

Serial API Files ...................................................................................... 66

Side-Connect API Files ......................................................................... 67

'C' Programmable Application Development Module Developer's Guide

3 Understanding the MVI-ADM API

The MVI ADM API Suite allows software developers to access the PLC

backplane and serial ports without needing detailed knowledge of the module’s

hardware design. The MVI ADM API Suite consists of three distinct components:

the Serial Port API, the MVI Backplane/CIP API and the ADM API.

The MVI Backplane API provides access to the processor

The Serial Port API provides access to the serial ports

The ADM API provides functions designed to ease development.

In addition to the MVI Backplane API, MVI71 also provides the MVI Side-

Connect API as an alternative interface.

Applications for the MVI ADM module may be developed using industry-standard

DOS programming tools and the appropriate API components.

This section provides general information pertaining to application development

for the MVI ADM module.

ProSoft Technology, Inc. Page 25 of 342

February 20, 2013

Page 26

Understanding the MVI-ADM API MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

3.1 API Libraries

Each API provides a library of function calls. The library supports any

programming language that is compatible with the Pascal calling convention.

Each API library is a static object code library that must be linked with the

application to create the executable program. It is distributed as a 16-bit large

model OMF library, compatible with Digital Mars C++ or Borland development

tools.

Note: The following compiler versions are intended to be compatible with the MVI module API:

Digital Mars C++ 8.49

Borland C++ V5.02

More compilers will be added to the list as the API is tested for compatibility with them.

3.1.1 Calling Convention

The API library functions are specified using the 'C' programming language

syntax. To allow applications to be developed in other industry-standard

programming languages, the standard Pascal calling convention is used for all

application interface functions.

3.1.2 Header File

A header file is provided along with each library. This header file contains API

function declarations, data structure definitions, and miscellaneous constant

definitions. The header file is in standard 'C' format.

3.1.3 Sample Code

A sample application is provided to illustrate the usage of the API functions. Full

source for the sample application is provided. The sample application may be

compiled using Digital Mars C++ or Borland C++.

Important: The sample code and libraries in the 1756-MVI-Samples folder are not compatible with,

and are not supported for, the Digital Mars compiler.

Page 26 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 27

MVI-ADM ♦ 'C' Programmable Understanding the MVI-ADM API

'C' Programmable Application Development Module Developer's Guide

3.1.4 Multi-threading Considerations

The DOS 6-XL operating system supports the development of multi-threaded

applications.

Note: The multi-threading library kernel.lib in the DOS folder on the distribution CD-ROM is

compiler-specific to Borland C++ 5.02. It is not compatible with Digital Mars C++ 8.49. ProSoft

Technology, Inc. does not support multi-threading with Digital Mars C++ 8.49.

Note: The ADM DOS 6-XL operating system has a system tick of 5 milliseconds. Therefore, thread

scheduling and timer servicing occur at 5ms intervals. Refer to the DOS 6-XL Developer’s Guide

on the distribution CD-ROM for more information.

Multi-threading is also supported by the API.

DOS and cipapi libraries have been tested and are thread-safe for use in

multi-threaded applications.

MVIbp and MVIsp libraries are safe to use in multi-threaded applications with

the following precautions: If you call the same MVIbp or MVIsp function from

multiple threads, you will need to protect it, to prevent task switches during

the function's execution. The same is true for different MVIbp or MVIsp

functions that share the same resources (for example, two different functions

that access the same read or write buffer).

WARNING: ADM and ADMNET libraries are not thread-safe. ProSoft Technology, Inc. does not

support the use of ADM and ADMNET libraries in multi-threaded applications.

ProSoft Technology, Inc. Page 27 of 342

February 20, 2013

Page 28

Understanding the MVI-ADM API MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

3.2 Development Tools

An application that is developed for the MVI ADM module must be executed from

the module’s Flash ROM disk. Tools are provided with the API to build the disk

image and download it to the module’s Config/Debug port.

Page 28 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 29

MVI-ADM ♦ 'C' Programmable Understanding the MVI-ADM API

'C' Programmable Application Development Module Developer's Guide

3.3 Theory of Operation

3.3.1 ADM API

The ADM API is one component of the MVI ADM API Suite. The ADM API

provides a simple module level interface that is portable between members of the

MVI Family. This is useful when developing an application that implements a

serial protocol for a particular device, such as a scale or bar code reader. After

an application has been developed, it can be be used on any of the MVI family

modules.

ProSoft Technology, Inc. Page 29 of 342

February 20, 2013

Page 30

Understanding the MVI-ADM API MVI-ADM ♦ 'C' Programmable

Developer's Guide 'C' Programmable Application Development Module

3.4 ADM Functional Blocks

3.4.1 Database

The database functions of the ADM API allow the creation of a database in

memory to store data to be accessed via the backplane interface and the

application ports. The database consists of word registers that can be accessed

as bits, bytes, words, longs, floats or doubles. Functions are provided for reading

and writing the data in the various data types. The database serves as a holding

area for exchanging data with the processor on the backplane, and with a foreign

device attached to the application port. Data transferred into the module from the

processor can be requested via the serial port. Conversely, data written into the

module database by the foreign device can be transferred to the processor over

the backplane.

3.4.2 Backplane Communications

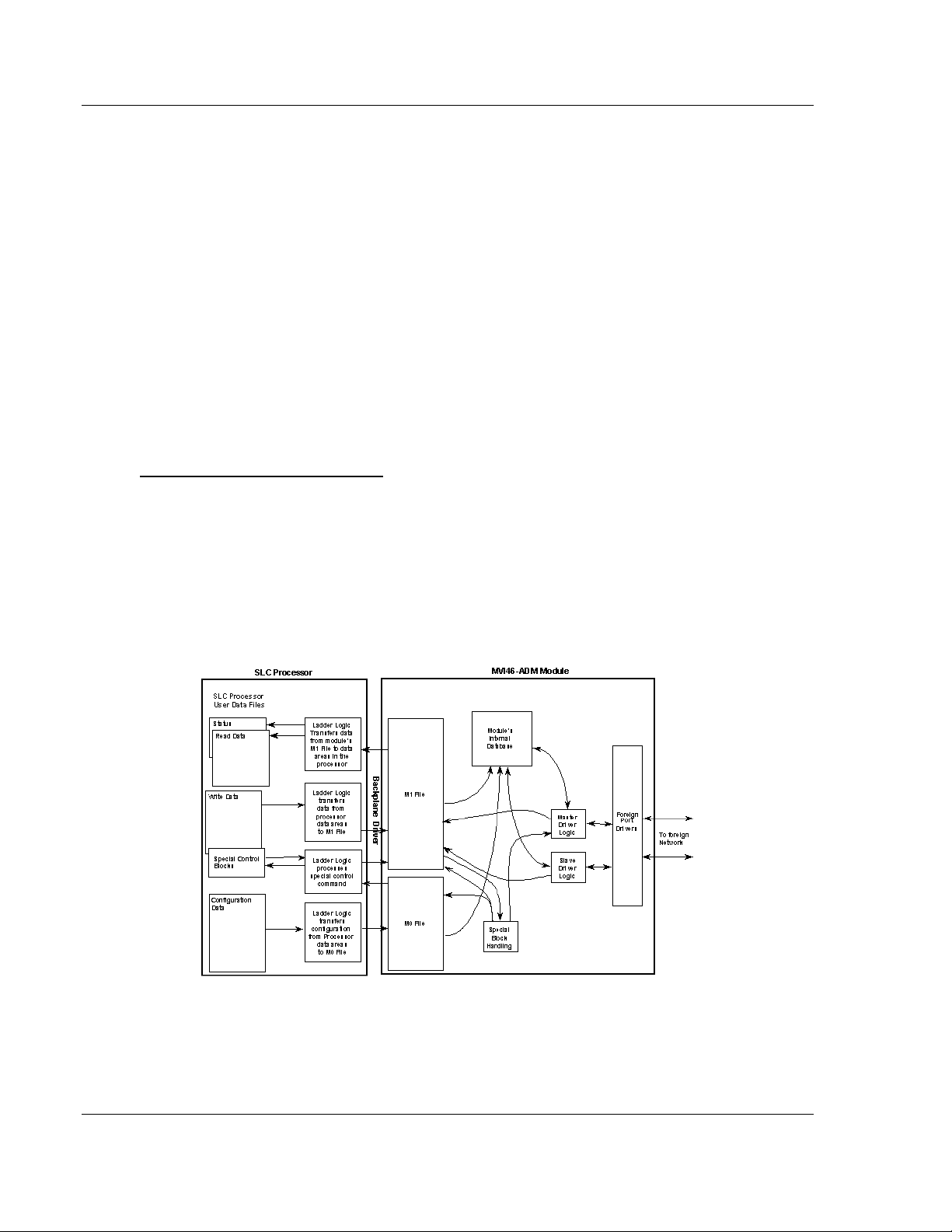

MVI46 Backplane Data Transfer

The MVI46-ADM module communicates directly over the backplane. All data for

the module is contained in the module's M1 file. Data is moved between the

module and the SLC processor across the backplane using the module's M-files.

The SLC scan rate and the communication load on the module determine the

update frequency of the M-files. The COP instruction can be used to move data

between user data files and the module's M1 file.

The following illustration shows the data transfer method used to move data

between the SLC processor, the MVI46-ADM module and the foreign network.

All data transferred between the module and the processor over the backplane is

through the M0 and M1 files. Ladder logic must be written in the SLC processor

to interface the M-file data with data defined in the user-defined data files in the

SLC.

Page 30 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 31

MVI-ADM ♦ 'C' Programmable Understanding the MVI-ADM API

Block Range

Descriptions

9000

Configuration request from module

9001

Configuration ready from controller

9997

Write configuration to controller

9998

Warm-boot control block

9999

Cold-boot control block

'C' Programmable Application Development Module Developer's Guide

All data used by the module is stored in its internal database. The following

illustration shows the layout of the database:

User data contained in this database is continuously read from the M1 file. The

configuration data is only updated in the M1 file after each configuration request

by the module to the SLC. All data in the M1 file is available to devices on the

foreign networks. This permits data to be transferred from these devices to the

SLC using the user data area. Additionally, remote devices can alter the

module's configuration, read the status data and issue control commands. Block

identification codes define specific functions to the module.

The block identification codes used by the module are listed below:

Each block has a defined structure depending on the data content and the

function of the data transfer as defined in the following topics.

Normal Data Transfer

This version of the module provides for direct access to the data in the module.

All data related to the module is stored in the module’s M1 file. To read data from

the module, use the COP instruction to copy data from the module’s M1 file to a

user data file. To write data to the module, use the COP instruction to copy data

from a user file to the module’s M1 file. Registers 0 to 4999 should be used for

user data. All other registers are reserved for other module functions.

ProSoft Technology, Inc. Page 31 of 342

February 20, 2013

Page 32

Understanding the MVI-ADM API MVI-ADM ♦ 'C' Programmable

M0 Offset

Description

Length

0

9001

1

1 to 6

Backplane Set Up

6

7 to 15

Port 1 Configuration

9

16 to 24

Port 2 Configuration

9

M0 Offset

Description

Length

0

9997

1

1 to 6

Backplane Set Up

6

7 to 15

Port 1 Configuration

9

16 to 24

Port 2 Configuration

9

Developer's Guide 'C' Programmable Application Development Module

Configuration Data Transfer Block (9000)

When the module performs a restart operation, it will request configuration

information from the SLC processor. This data is transferred to the module in a

specially formatted write block in the M0 file. The module will poll for this

information by placing the value 9000 in word 0 of the M0 file. The ladder logic

must construct the requested block in order to configure the module. The format

of the block for configuration is given in the following section.

Module Configuration Data Block (9001)

This block sends configuration information from the processor to the module. The

data is transferred in a block with an identification code of 9001. The structure of

the block is displayed below:

If there are any errors in the configuration, the bit associated with the error will be

set in one of the two configuration error words. The error must be corrected

before the module starts operating.

Special Function Blocks

Special Function blocks are special blocks used to control the module or request

special data from the module. The current version of the software supports three

special function blocks: write configuration, warm boot and cold boot.

Write Configuration Block (9997)

This block is sent from the processor, and causes the module to write its current

configuration back to the processor. This function is used when the module’s

configuration has been altered remotely using database write operations. The

write block contains a value of 9997 in the first word. The module will respond

with a block containing the module configuration data. Ladder logic must handle

the receipt of the block. The block transferred from the module is as follows:

Page 32 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 33

MVI-ADM ♦ 'C' Programmable Understanding the MVI-ADM API

M1 Offset

Description

Length

7800

9997

1

M1 Offset

Description

Length

7800

9998

1

M1 Offset

Description

Length

7800

9999

1

'C' Programmable Application Development Module Developer's Guide

Ladder logic must process this block of information and place the data received

in the correct data files in the . The processor requests this block of information

using the following write block:

Warm Boot Block (9998)

This block is sent from the SLC processor to the module when the module is

required to perform a warm-boot (software reset) operation. This block is

commonly sent to the module any time configuration data modifications are made

in the configuration data area. This will cause the module to read the new

configuration information and to restart. The following table describes the format

of the control block.

Cold Boot Block (9999)

This block is sent from the SLC processor to the module when the module is

required to perform the cold boot (hardware reset) operation. This block is sent to

the module when a hardware problem is detected by the ladder logic that

requires a hardware reset. The following table describes the format of the control

block.

MVI56 Backplane Data Transfer

The MVI56-ADM module communicates directly over the backplane. Data is

paged between the module and the ControlLogix processor across the backplane

using the module's input and output images. The update frequency of the images

is determined by the scheduled scan rate defined by the user for the module, and

by the communication load on the module. Typical updates are in the range of 2

to 10 milliseconds.

This bi-directional transference of data is accomplished by the module filling in

data in the module's input image to send to the processor. Data in the input

image is placed in the Controller Tags in the processor by the ladder logic. The

input image for the module is set to 250 words. This large data area permits fast

throughput of data between the module and the processor.

The processor inserts data to the module's output image to transfer to the

module. The module's program extracts the data and places it in the module's

internal database. The output image for the module is set to 248 words. This

large data area permits fast throughput of data from the processor to the module.

ProSoft Technology, Inc. Page 33 of 342

February 20, 2013

Page 34

Understanding the MVI-ADM API MVI-ADM ♦ 'C' Programmable

5000 registers for user data

0

Register Data

4999

2000 words of configuration and

status data

5000

Status and Config

6999

Developer's Guide 'C' Programmable Application Development Module

The following illustration shows the data transfer method used to move data

between the ControlLogix processor, the MVI56-ADM module and the foreign

device.

All data transferred between the module and the processor over the backplane is

through the input and output images. Ladder logic must be written in the

ControlLogix processor to interface the input and output image data with data

defined in the Controller Tags.

All data used by the module is stored in its internal database. The following

illustration shows the layout of the database:

Module’s Internal Database Structure

Data contained in this database is paged through the input and output images by

coordination of the ControlLogix ladder logic and the MVI56-ADM module's

program. Up to 248 words of data can be transferred from the module to the

processor at a time. Up to 247 words of data can be transferred from the

processor to the module. Each image has a defined structure depending on the

data content and the function of the data transfer.

Page 34 of 342 ProSoft Technology, Inc.

February 20, 2013

Page 35

MVI-ADM ♦ 'C' Programmable Understanding the MVI-ADM API

Offset

Description

Length

0

Write Block ID

1

1 to 200

Write Data

200

201 to 247

Spare

47

Offset

Description

Length

0

Reserved

1

1

Write Block ID

1

2 to 201

Read Data

200

202

Program Scan Counter

1

203 to 204

Product Code

2

205 to 206

Product Version

2

207 to 208

Operating System

2

209 to 210

Run Number

2

211 to 212

Not Used

2

213 to 219

Port 1 Error Status

7

220 to 226

Port 2 Error Status

7

227 to 232

Data Transfer Status

6

233

Port 1 Current Error/Index

1

234

Port 1 Last Error/Index

1

235

Port 2 Current Error/Index

1

236

Port 2 Last Error/Index

1

237 to 248

Spare

12

249

Read Block ID

1

'C' Programmable Application Development Module Developer's Guide

Normal Data Transfer

Normal data transfer includes the paging of the user data found in the module’s

internal database in registers 0 to 4999 and the status data. These data are

transferred through read (input image) and write (output image) blocks. The

structure and function of each block is discussed in the following topics.

Block Request from the Processor to the Module

These blocks of data transfer information from the processor to the module. The

following table describes the structure of the output image.

The Write Block ID is an index value used to determine the location in the

module’s database where the data will be placed. Each transfer can move up to

200 words (block offsets 1 to 200) of data.

Block Response from the Module to the Processor