Page 1

MVI56-BAS

ControlLogix Platform

BASIC Module (DB/BAS Compatible)

December 13, 2011

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

MVI56-BAS User Manual

December 13, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

C Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

Avertissement - Risque d'explosion - Avant de déconnecter l'équipement, couper le courant

ou s'assurer que l'emplacement est désigné non dangereux.

D Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Page 4

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Markings

Electrical Ratings

Backplane Current Load: 800 mA @ 5.1 Vdc; 3 mA @ 24 Vdc

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30 g, operational; 50 g, non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity: 5% to 95% with no condensation

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Label Markings

ATEX

II 3 G

EEx nA IIC T6

0°C <= Ta <= 60°C

cULus

E183151

Class I Div 2 Groups A,B,C,D

T6

-30°C <= Ta <= 60°C

Agency Approvals and Certifications

Agency Applicable Standard

RoHS

CE EMC-EN61326-1:2006; EN61000-6-4:2007

ATEX EN60079-15:2003

cULus UL508; UL1604; CSA 22.2 No. 142 & 213

CB Safety CA/10533/CSA

IEC 61010-1 Ed.2; CB 243333-2056722 (2090408)

GOST-R EN 61010

CSA EN 61010

Korea KCC KCC-REM-PFT-MVI56-AFC

243333

ME06

E183151

Page 5

Page 6

Page 7

MVI56-BAS ♦ ControlLogix Platform Contents

BASIC Module (DB/BAS Compatible) User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 4

Markings .............................................................................................................................................. 4

Guide to the MVI56-BAS User Manual 13

1 Start Here 15

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.6.1

System Requirements ............................................................................................. 16

Package Contents ................................................................................................... 17

Setting Jumpers ...................................................................................................... 18

Installing the Module in the Rack ............................................................................ 19

Connecting Your PC to the ControlLogix Processor ............................................... 21

Using the Sample Ladder Logic .............................................................................. 22

Configuring the RSLinx Driver for the PC COM Port .............................................. 22

Downloading the Sample Program to the Processor .............................................. 24

Connecting Your PC to the Module ......................................................................... 25

2 Module Configuration 29

2.1

Installing and Configuring the Module ..................................................................... 29

3 BASIC Programming 33

3.1

3.2

3.3

3.4

The Argument Stack ................................................................................................ 34

Using CALLs ........................................................................................................... 35

Using Strings ........................................................................................................... 36

ControlLogix Processor Interrupt ............................................................................ 37

4 Backplane Data Transfer 39

4.1

4.2

Data Transfer from Output Buffer to CLX Processor .............................................. 40

Data Transfer from CLX Processor to MVI Input Buffer .......................................... 43

5 Using the Program Port (PRT1) 45

5.1

5.2

5.3

5.4

5.4.1

5.4.2

5.4.3

Interfacing the PC and the MVI56-BAS ................................................................... 46

Creating BASIC programs ....................................................................................... 47

EDIT Command ....................................................................................................... 50

Permanently Saving BASIC Programs .................................................................... 51

EPROM File Storage ............................................................................................... 51

Erasing EPROM Programs ..................................................................................... 51

Editing EPROM Programs....................................................................................... 51

ProSoft Technology, Inc. Page 7 of 234

December 13, 2011

Page 8

Contents MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

5.4.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.4.5

5.5.1

5.5.2

5.5.3

5.6.1

5.6.2

5.7.1

5.7.2

Using XRAM and EPROM Programs as Subroutines ............................................ 52

Automatically Executing ROM 1 at Power-up ......................................................... 52

Creating Offline BASIC programs ........................................................................... 53

Downloading BASIC Files From a PC to the MVI56-BAS ...................................... 53

Uploading BASIC files from the MVI56-BAS to a PC ............................................. 56

Loading a BASIC Program ..................................................................................... 58

Module Backup ....................................................................................................... 59

Backup with a Compact Flash Card Reader .......................................................... 59

Backup without a Compact Flash Card Reader ..................................................... 59

Module Restoration ................................................................................................. 61

Restoration with a Compact Flash Card Reader .................................................... 61

Restoration without a Compact flash Card Reader ................................................ 61

Program Copies ...................................................................................................... 63

Running a BASIC Program ..................................................................................... 64

Debugging a BASIC Program ................................................................................. 65

Commenting a BASIC Program .............................................................................. 70

Checking Available and Used RAM Memory .......................................................... 71

Exit a BASIC Program (Ctrl+C) .............................................................................. 72

6 Using ASCII Communications 73

6.1

6.2

6.3

Port Transmit and Receive Buffers ......................................................................... 74

ASCII Data Transfer from MVI56-BAS Serial Port to CLX ..................................... 75

ASCII Data Transfer from CLX to MVI56-BAS Serial Port ..................................... 78

7 Using DF1 Protocol Communications 81

7.1

7.2

7.3

7.4

7.5

7.6

7.7

Operation ................................................................................................................ 82

Communication ....................................................................................................... 83

DF1 Commands ...................................................................................................... 84

Sending a DF1 Read Command ............................................................................. 85

Sending a DF1 Write Command ............................................................................. 87

Receiving a DF1 Write Command .......................................................................... 89

Transmitting a DF1 Packet ..................................................................................... 91

8 Using DH-485 Communications 93

8.1

8.2

8.3

8.4

Data File 98

8.5

8.6

File (CIF) 101

8.6.1

Data Transfer Between the CLX and a Remote SLC DH-485 Data File ................ 94

Writing to a Remote DH-485 SLC Data File (CALL 28).......................................... 95

Reading From a Remote DH-485 SLC Data File (CALL 27) .................................. 97

Data Transfer Between a MVI56-BAS Internal String and a Remote DH-485 SLC

Data Transfer Between the MVI56-BAS and Remote DH-485 Data Files ............. 99

Transfer Data Between the MVI56-BAS Module and a Remote Common Interface

Using the MVI56-BAS Common Interface File (CIF) ............................................ 102

9 BASIC CALLs Syntax 105

9.1

9.1.1

CALL 14: Convert 16-Bit Signed to Float Point ......................................................................... 106

Data Conversion CALLs ....................................................................................... 106

Input CALLs .......................................................................................................... 106

Page 8 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 9

MVI56-BAS ♦ ControlLogix Platform Contents

BASIC Module (DB/BAS Compatible) User Manual

CALL 15: Convert 16-Bit Unsigned to Float Point ..................................................................... 108

CALL 89: CLX Floating Point to BASIC Float Point ................................................................... 109

9.1.2

CALL 24: Convert Floating Point Data to 16-Bit Signed Integer ............................................... 109

CALL 25: Convert Floating Point Data to 16-Bit Binary ............................................................. 111

CALL 88: Convert BASIC Floating Point Data to CLX Floating Point ....................................... 112

9.2

CALL 51: Check CLX Output Image .......................................................................................... 113

CALL 53: Transfer CLX Output Image to BASIC Input Buffer ................................................... 114

CALL 54: Transfer Data from BASIC Output Buffer to CLX Input Image .................................. 115

CALL 55: Check CLX Input Image ............................................................................................. 116

CALL 56: Transfer Data from CLX to BASIC Input Buffer using MSG ...................................... 117

CALL 57: Transfer BASIC Output Buffer to CLX using MSG .................................................... 118

CALL 58: Check CLX MSG ....................................................................................................... 119

CALL 59: Check CLX MSG ....................................................................................................... 120

CALL 75: Check CLX Status ..................................................................................................... 121

CALL 120: Clear Module Input and Output Buffers ................................................................... 122

9.3

CALL 30: Set PRT2 Port Parameters ........................................................................................ 123

CALL 31: Display PRT2 Port Setup ........................................................................................... 124

CALL 35: Get Input Character From PRT2................................................................................ 125

CALL 36: Get Number of Characters in PRT2 Buffer ................................................................ 126

CALL 37: Clear PRT2 Buffers .................................................................................................... 127

CALL 78: Set Program Port Baud Rate ..................................................................................... 128

CALL 94: Display PRT1 Port Setup ........................................................................................... 129

CALL 95: Get Number of Characters in PRT1 Buffer ................................................................ 130

CALL 96: Clear PRT1 Buffers .................................................................................................... 131

CALL 97: Set PRT2 DTR Signal ................................................................................................ 132

CALL 98: Clear PRT2 DTR Signal ............................................................................................. 133

CALL 99: Reset Print Head Pointer ........................................................................................... 134

CALL 105: Reset PRT1 to Default Parameters ......................................................................... 135

CALL 119: Reset PRT2 to Default Parameters ......................................................................... 136

9.4

CALL 40: Set Clock Time .......................................................................................................... 137

CALL 41: Set Calendar Date ..................................................................................................... 138

CALL 42: Set Day of the Week .................................................................................................. 139

CALL 43: Retrieve Date and Time String .................................................................................. 140

CALL 44: Retrieve Date Numeric .............................................................................................. 141

CALL 45: Retrieve Date String .................................................................................................. 142

CALL 46: Retrieve Time Numeric .............................................................................................. 143

CALL 47: Retrieve Day of Week String ..................................................................................... 144

CALL 48: Retrieve Day of Week Numeric ................................................................................. 145

CALL 52: Retrieve Date String .................................................................................................. 146

9.5

CALL 60: Repeating a Character ............................................................................................... 147

CALL 61: Concatenating a String .............................................................................................. 148

CALL 62: Converting from Numeric Format to String Format ................................................... 149

CALL 63: Converting from String Format to Numeric Format ................................................... 150

CALL 64: Finding a String within Another String ....................................................................... 151

CALL 65: Replacing a String in Another String ......................................................................... 152

CALL 66: Inserting a String in Another String ............................................................................ 153

CALL 67: Deleting a String in Another String ............................................................................ 154

CALL 68: Determining the Length of a String ............................................................................ 155

9.6

Output CALLs ........................................................................................................ 109

Backplane CALLs .................................................................................................. 113

Serial Port CALLs .................................................................................................. 123

Wall Clock CALLs .................................................................................................. 137

String CALLs ......................................................................................................... 147

DH-485 CALLs ...................................................................................................... 156

ProSoft Technology, Inc. Page 9 of 234

December 13, 2011

Page 10

Contents MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

CALL 27: Read Remote DH-485 SLC Data File ....................................................................... 156

CALL 28: Write to Remote DH-485 SLC Data File ................................................................... 158

CALL 83: Display DH-485 Port Parameters .............................................................................. 160

CALL 84: Transfer DH-485 Interface File to MVI56-BAS Input Buffer ...................................... 161

CALL 85: Transfer MVI56-BAS Output Buffer to DH-485 Interface File ................................... 162

CALL 86: Check DH-485 Interface File Remote Write Status .................................................. 163

CALL 87: Check DH-485 Interface File Remote Read Status .................................................. 164

CALL 90: Read Remote DH-485 Data File to MVI56-BAS Input Buffer ................................... 165

CALL 91: Write MVI56-BAS Output Buffer to Remote DH-485 Data File ................................. 167

CALL 92: Read Remote DH-485 Common Interface File to MVI56-BAS Input Buffer ............. 169

CALL 93: Write From BAS Output Buffer to Remote DH-485 CIF ............................................ 170

9.7

CALL 108: Enable DF1 Driver to PRT2 .................................................................................... 171

CALL 113: Disable PRT2 DF1 Driver ........................................................................................ 173

CALL 114: Transmit DF1 Packet............................................................................................... 174

CALL 115: Check DF1 XMIT Status ......................................................................................... 175

CALL 117: Get DF1 Packet Length ........................................................................................... 176

9.8

CALL 0: Reset BASIC ............................................................................................................... 176

CALL 16: Enable DF1 Packet Interrupt ..................................................................................... 177

CALL 17: Disable DF1 Packet Interrupt .................................................................................... 178

CALL 20: Enable Processor Interrupt ....................................................................................... 179

CALL 21: Disable Processor Interrupt ....................................................................................... 180

CALL 29: Read/Write To/From Internal String (DF1 or DH-485) .............................................. 181

CALL 70: ROM to RAM Program Transfer ................................................................................ 182

CALL 71: ROM/RAM to ROM Program Transfer ...................................................................... 183

CALL 72: ROM/RAM Return ..................................................................................................... 184

9.9

9.9.1

CALL 22: Transfer Data from a Serial Port to CLX ................................................................... 185

CALL 23: Transfer Data from CLX to a Serial Port ................................................................... 187

9.9.2

CALL 118: Receive DF1 or DH-485 Unsolicited Write .............................................................. 188

9.9.3

CALL 118: Receive DF1 or DH-485 Unsolicited Write .............................................................. 189

CALL 122: Read Remote DF1 PLC Data File ........................................................................... 192

CALL 123: Write Remote DF1 PLC Data File ........................................................................... 194

9.10

CALL 18: Enable ^C Check ....................................................................................................... 196

CALL 19: Disable ^C Check ...................................................................................................... 197

CALL 80: Check Battery Condition ........................................................................................... 198

CALL 81: EPROM Check .......................................................................................................... 199

CALL 109: Print Argument Stack .............................................................................................. 200

9.11

9.11.1

9.11.2

DF1 CALLs ........................................................................................................... 171

BASIC Program Flow Control CALLs ................................................................... 176

Background CALLs ............................................................................................... 185

ASCII Background CALLs .................................................................................... 185

DH-485 Background CALLs ................................................................................. 188

DF1 Background CALLs ....................................................................................... 189

Miscellaneous CALLs ........................................................................................... 196

LED Status Indicators ........................................................................................... 201

Clearing a Fault Condition .................................................................................... 202

Troubleshooting .................................................................................................... 202

10 BASIC-52 Implementation 203

10.1

10.2

10.2.1

10.2.2

Operators and Statements .................................................................................... 204

Control Expressions .............................................................................................. 210

IF-THEN-ELSE ..................................................................................................... 210

DO-UNTIL ............................................................................................................. 210

Page 10 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 11

MVI56-BAS ♦ ControlLogix Platform Contents

BASIC Module (DB/BAS Compatible) User Manual

10.2.3

DO-WHILE ............................................................................................................ 210

10.2.4

FOR-TO- (STEP)-NEXT ........................................................................................ 211

10.2.5

GOTO .................................................................................................................... 211

10.2.6

END ....................................................................................................................... 211

10.2.7

GOSUB.................................................................................................................. 212

11 Reference 213

11.1

11.2

11.3

11.4

11.1.1

11.1.2

11.1.3

11.2.1

11.3.1

11.3.2

11.4.1

11.4.2

11.4.3

Product Specifications ........................................................................................... 214

General Specifications .......................................................................................... 214

Hardware Specifications........................................................................................ 215

Functional Specifications....................................................................................... 216

Functional Overview .............................................................................................. 217

General Concepts ................................................................................................. 217

Cable Connections ................................................................................................ 226

BASIC DH-485 Port ............................................................................................... 227

BASIC PRT1 and PRT2 ........................................................................................ 227

1746-BAS Comparison .......................................................................................... 228

CALLs Not Supported ........................................................................................... 228

New Commands .................................................................................................... 228

Differences ............................................................................................................ 228

12 Support, Service & Warranty 229

Contacting Technical Support ......................................................................................................... 229

Warranty Information ...................................................................................................................... 230

Index 231

ProSoft Technology, Inc. Page 11 of 234

December 13, 2011

Page 12

Contents MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

Page 12 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 13

MVI56-BAS ♦ ControlLogix Platform Guide to the MVI56-BAS User Manual

BASIC Module (DB/BAS Compatible) User Manual

Guide to the MVI56-BAS User Manual

Function

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Support, Service, and

Warranty

Index

Section to Read Details

Start Here (page 15) This section introduces the customer to the

→

Diagnostics and

→

Troubleshooting

Reference (page

→

213)

Product

Specifications (page

214)

Support, Service

→

and Warranty (page

229)

Index

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

This section describes Diagnostic and

Troubleshooting procedures.

These sections contain general references

associated with this product and its

Specifications..

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 13 of 234

December 13, 2011

Page 14

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

Page 14 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 15

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

1 Start Here

In This Chapter

System Requirements ........................................................................... 16

Package Contents ................................................................................. 17

Setting Jumpers .................................................................................... 18

Installing the Module in the Rack ........................................................... 19

Connecting Your PC to the ControlLogix Processor .............................. 21

Using the Sample Ladder Logic ............................................................ 22

Downloading the Sample Program to the Processor ............................. 24

Connecting Your PC to the Module ....................................................... 25

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

BASIC and ControlLogix devices to a power source and to the MVI56-BAS

module’s application port(s)

ProSoft Technology, Inc. Page 15 of 234

December 13, 2011

Page 16

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

1.1 System Requirements

The MVI56-BAS module requires the following minimum hardware and software

components:

Rockwell Automation ControlLogix™ processor, with compatible power

supply and one free slot in the rack, for the MVI56-BAS module. The module

requires 800 mA of available power.

Rockwell Automation RSLogix 5000 programming software version 2.51 or

higher

Rockwell Automation RSLinx communication software

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o

Microsoft Windows XP Professional with Service Pack 1 or 2

o

Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o

Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 × 768 recommended)

CD-ROM drive

ProSoft Configuration Builder, HyperTerminal or other terminal emulator

program.

Note: You can install the module in a local or remote rack. For remote rack installation, the module

requires EtherNet/IP or ControlNet communication with the processor.

Page 16 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 17

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

1.2 Package Contents

The following components are included with your MVI56-BAS module, and are all

required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

Qty. Part Name Part Number Part Description

1 MVI56-BAS Module MVI56-BAS BASIC Module (DB/BAS Compatible)

1 Cable Cable #15, RS232

3 Cable Cable #14, RJ45 to

2 Adapter 1454-9F Two Adapters, DB9 Female to Screw

1 ProSoft Solutions CD Contains sample programs, utilities and

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

For RS232 Connection to the CFG Port

Null Modem

For DB9 Connection to Module’s Port

DB9 Male Adapter

cable

Terminal. For RS422 or RS485

Connections to Port 1 and 2 of the Module

documentation for the MVI56-BAS module.

ProSoft Technology, Inc. Page 17 of 234

December 13, 2011

Page 18

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

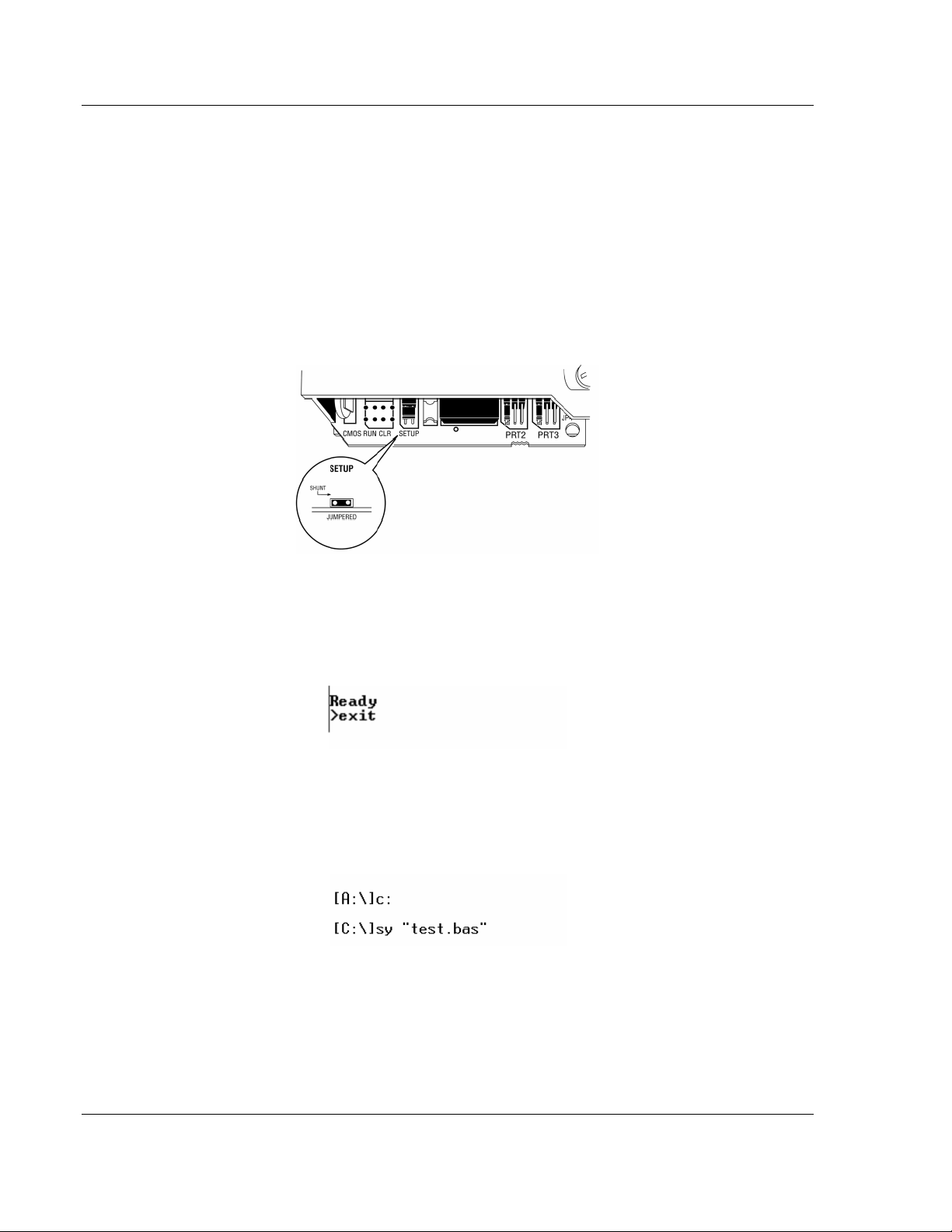

1.3 Setting Jumpers

If you use an interface other than RS-232 (default), you must change the jumper

configuration to select the interface you wish to use. There are three jumpers

located at the bottom of the module.

The following illustration shows the MVI56-BAS jumper configuration:

1 Set the PRT 2 (for application port 1) and PRT 3 (for application port 2)

jumpers select RS232, RS422, or RS485 to match the wiring needed for your

application. The default jumper setting for both application ports is RS-232.

2 The Setup Jumper acts as "write protection" for the module’s flash memory.

In "write protected" mode, the Setup pins are not connected, and the

module’s firmware cannot be overwritten. Do not jumper the Setup pins

together unless you are directed to do so by ProSoft Technical Support.

Page 18 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 19

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

1.4 Installing the Module in the Rack

If you have not already installed and configured your ControlLogix processor and

power supply, please do so before installing the MVI56-BAS module. Refer to

your Rockwell Automation product documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures are in place before installing or servicing the

device.

After you have checked the placement of the jumpers, insert MVI56-BAS into the

ControlLogix chassis. Use the same technique recommended by Rockwell

Automation to remove and install ControlLogix modules.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can occur. This could cause an explosion in hazardous location installations. Verify that power is

removed or the area is non-hazardous before proceeding. Repeated electrical arcing causes

excessive wear to contacts on both the module and its mating connector. Worn contacts may

create electrical resistance that can affect module operation.

1 Turn power OFF.

2 Align the module with the top and bottom guides, and slide it into the rack

until the module is firmly against the backplane connector.

ProSoft Technology, Inc. Page 19 of 234

December 13, 2011

Page 20

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

3 With a firm but steady push, snap the module into place.

4 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

5 Make a note of the slot location. You must identify the slot in which the

module is installed in order for the sample program to work correctly. Slot

numbers are identified on the green circuit board (backplane) of the

ControlLogix rack.

6 Turn power ON.

Note: If you insert the module improperly, the system may stop working, or may behave

unpredictably.

Page 20 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 21

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

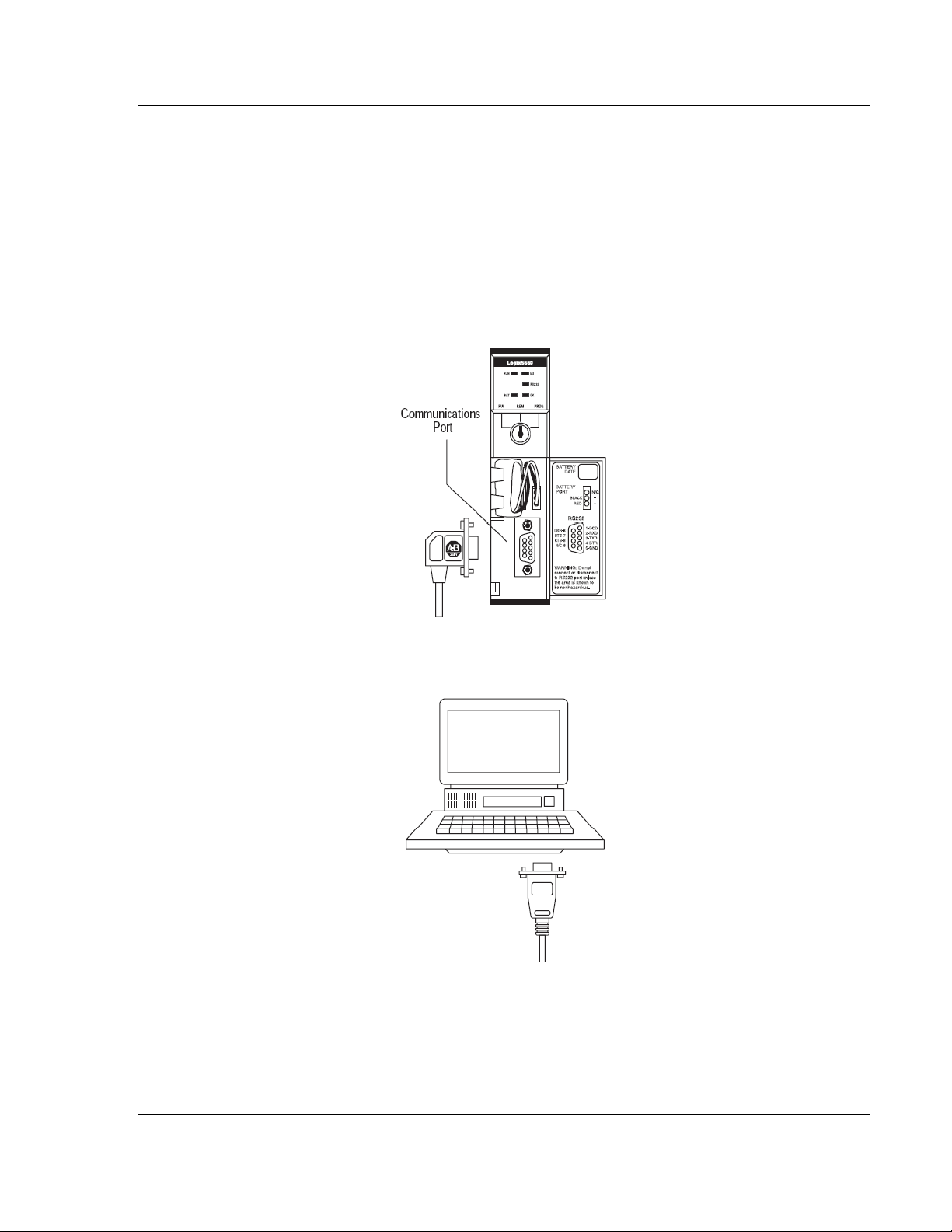

1.5 Connecting Your PC to the ControlLogix Processor

There are several ways to establish communication between your PC and the

ControlLogix processor. The following steps show how to establish

communication through the serial interface. It is not mandatory that you use the

processor's serial interface. You may access the processor through whatever

network interface is available on your system. Refer to your Rockwell Automation

documentation for information on other connection methods.

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

ProSoft Technology, Inc. Page 21 of 234

December 13, 2011

Page 22

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

1.6 Using the Sample Ladder Logic

The sample program for your MVI56-BAS module includes custom tags, data

types, and ladder logic for data I/O and status monitoring. For most applications,

you can run the sample ladder program without modification, or, for advanced

applications, you can incorporate the sample program into your existing

application.

The inRAx Solutions CD provides one or more versions of the sample ladder

logic. The version number appended to the file name corresponds with the

firmware version number of your ControlLogix processor. The firmware version

and sample program version must match.

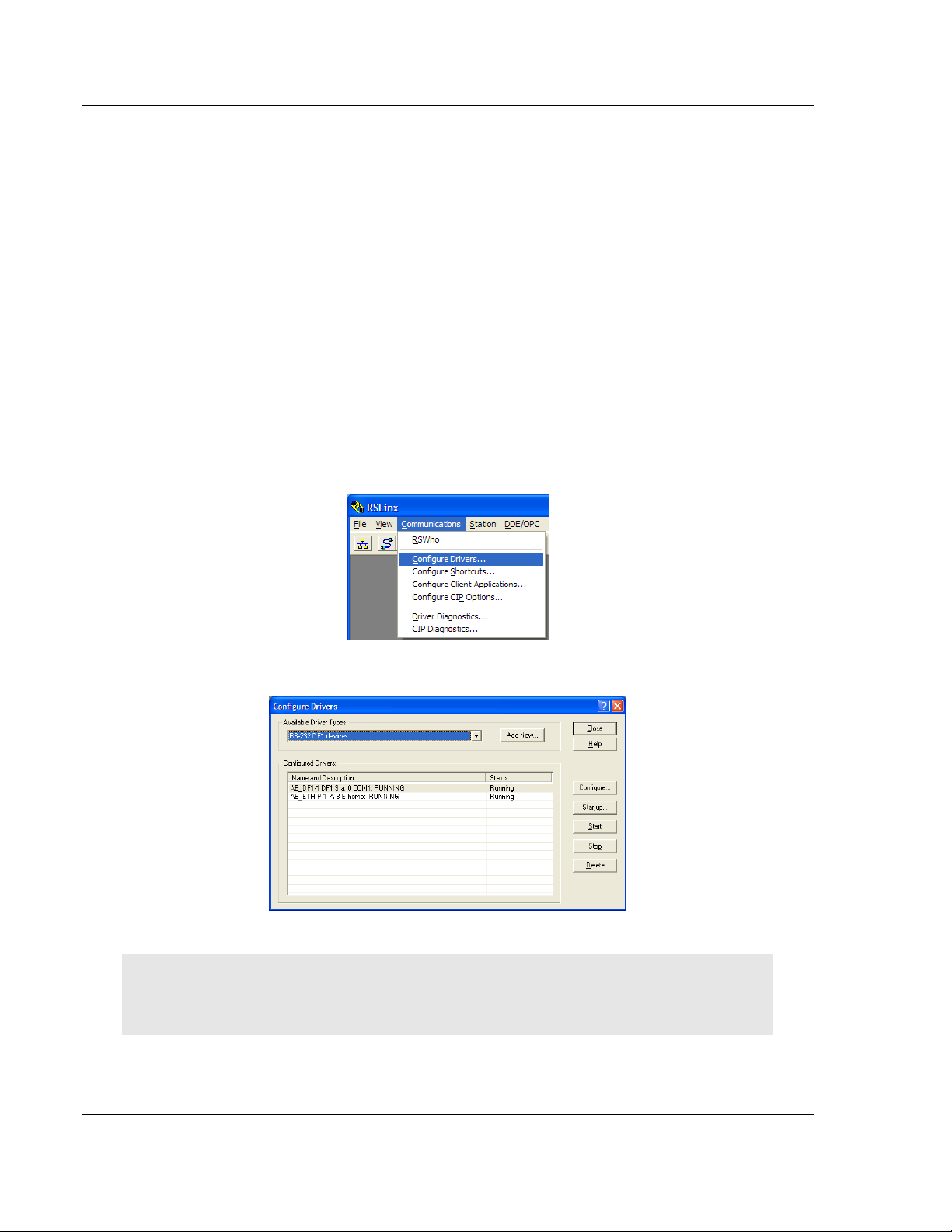

1.6.1 Configuring the RSLinx Driver for the PC COM Port

If RSLogix is unable to establish communication with the processor, follow these

steps.

1 Open RSLinx.

2 Open the C

OMMUNICATIONS

menu, and choose C

ONFIGURE DRIVERS

.

This action opens the Configure Drivers dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the

Available Driver Types list. The recommended driver type to choose for serial communication with

the processor is RS-232 DF1 Devices.

Page 22 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 23

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

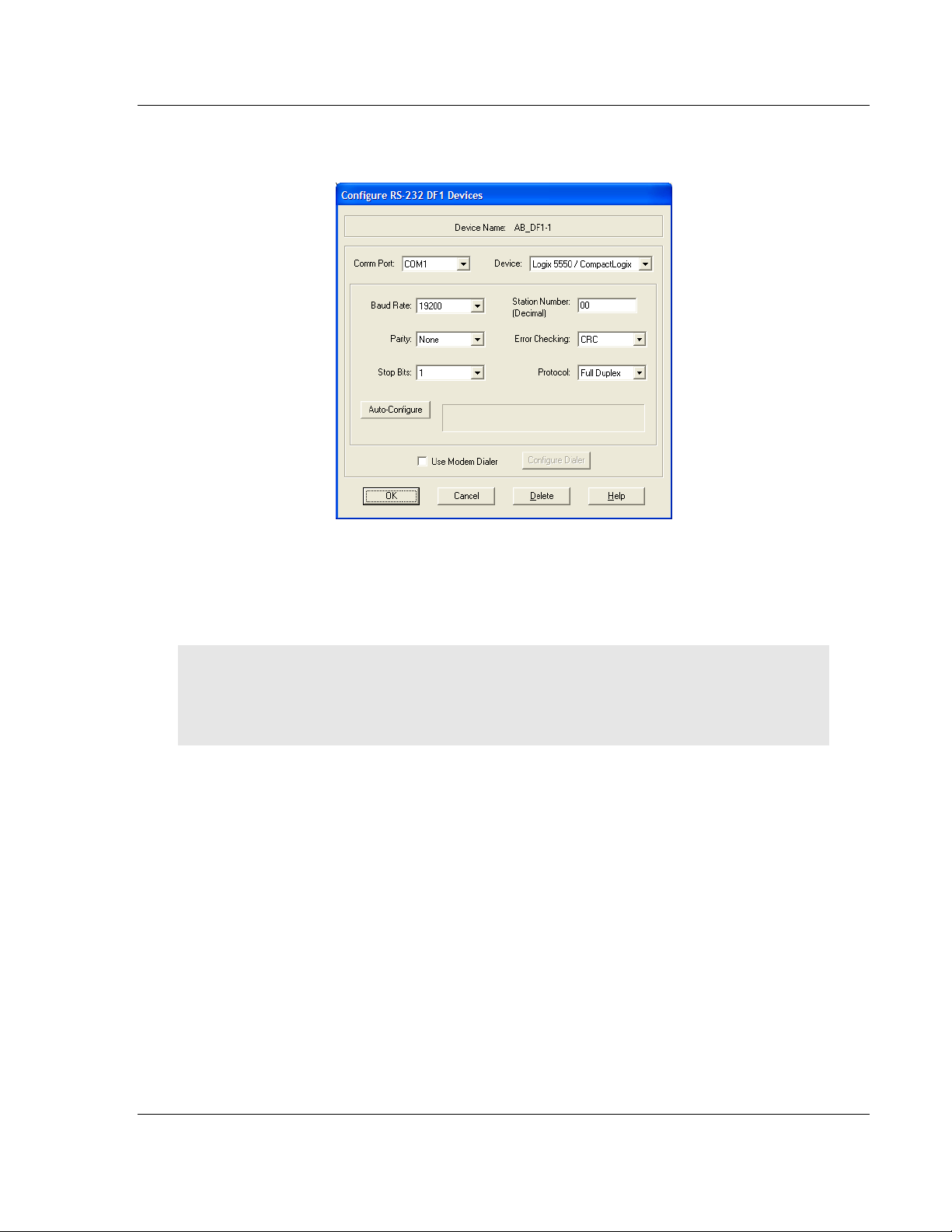

3 Click to select the driver, and then click C

ONFIGURE

. This action opens the

Configure RS-232 DF1 Devices dialog box.

4 Click the A

UTO-CONFIGURE

button. RSLinx will attempt to configure your

serial port to work with the selected driver.

5 When you see the message Auto Configuration Successful, click the OK

button to dismiss the dialog box.

Note: If the auto-configuration procedure fails, verify that the cables are connected correctly

between the processor and the serial port on your computer, and then try again. If you are still

unable to auto-configure the port, refer to your RSLinx documentation for further troubleshooting

steps.

ProSoft Technology, Inc. Page 23 of 234

December 13, 2011

Page 24

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

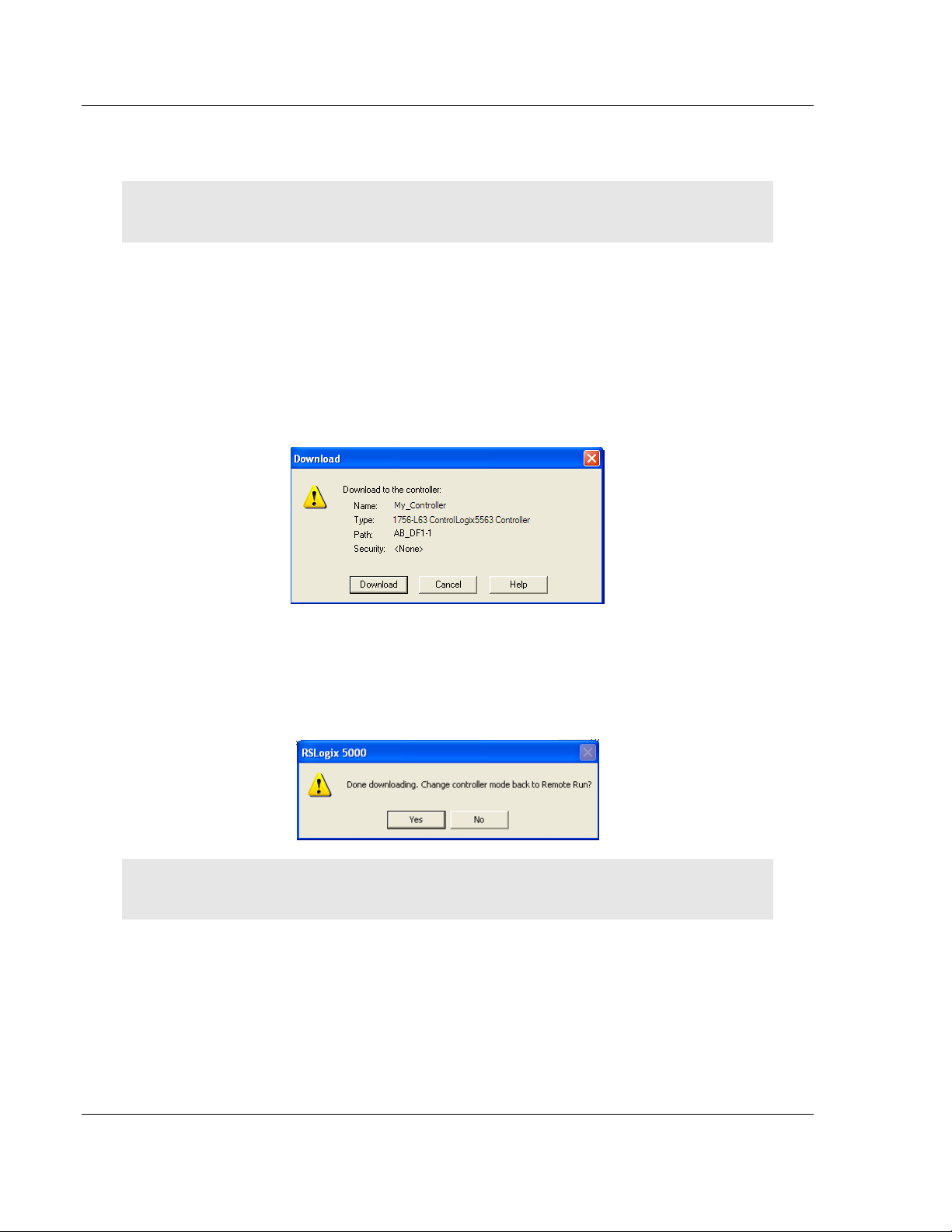

1.7 Downloading the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix processor must be in the REM or PROG

position.

1 If you are not already online with the processor, open the Communications

menu, and then choose D

communication with the processor. You do not have to download through the

processor's serial port, as shown here. You may download through any

available network connection.

2 When communication is established, RSLogix 5000 will open a confirmation

dialog box. Click the D

processor.

OWNLOAD.

OWNLOAD

RSLogix 5000 will establish

button to transfer the sample program to the

3 RSLogix 5000 will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix 5000 will open another

confirmation dialog box. If the key switch is in the REM position, click OK to

switch the processor from PROGRAM mode to RUN mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

Page 24 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 25

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

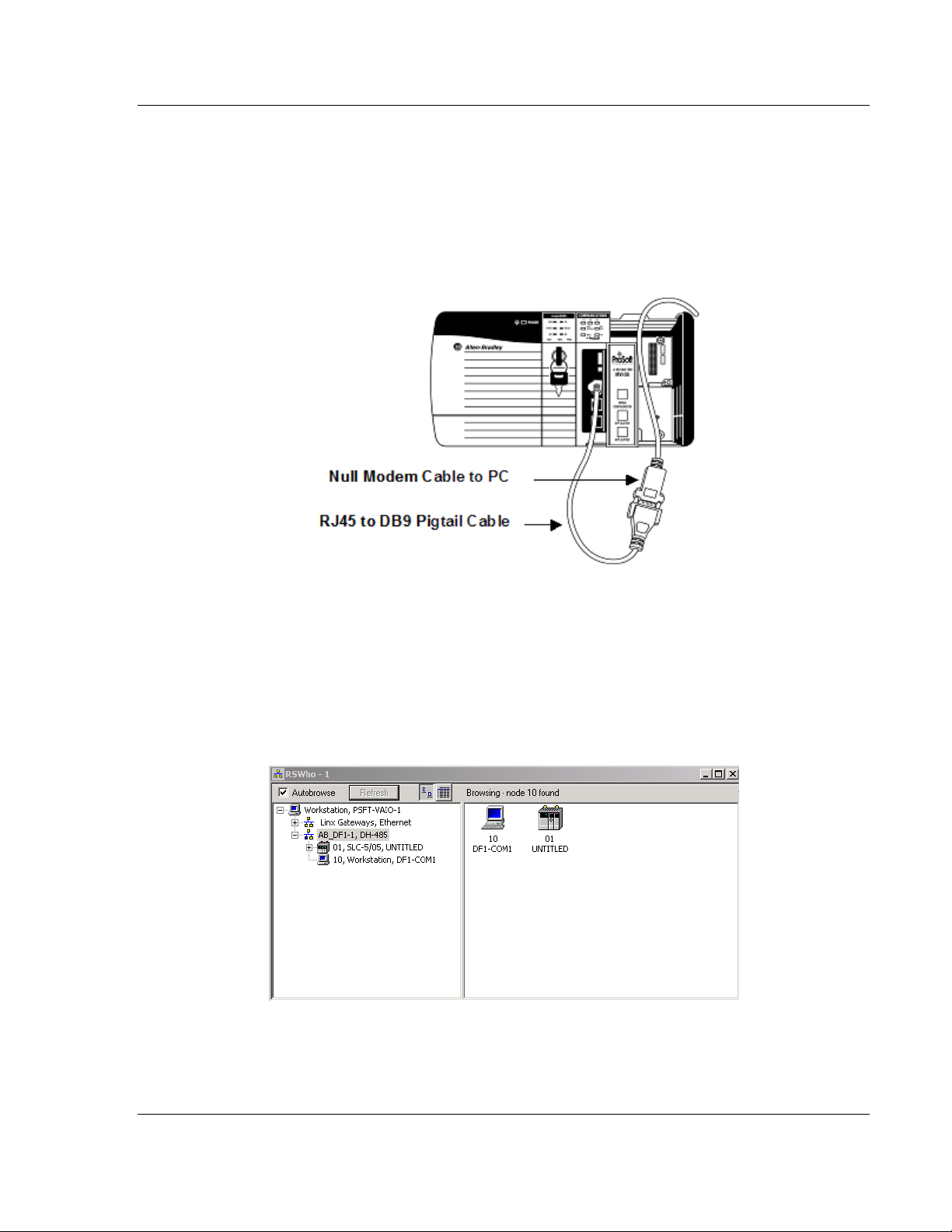

1.8 Connecting Your PC to the Module

With the module securely mounted, connect your PC to the

Configuration/Debug port using an RJ45-DB-9 Serial Adapter Cable and a Null

Modem Cable.

1 Attach both cables as shown.

2 Insert the RJ45 cable connector into the Config/Debug port of the module.

3 Attach the other end to the serial port on your PC.

The communication port driver in RSLinx can occasionally prevent other

applications from using the PC’s COM port. If you are not able to connect to the

module’s configuration/debug port using ProSoft Configuration Builder (PCB),

HyperTerminal or another terminal emulator, follow these steps to disable the

RSLinx driver.

1 Open RSLinx and go to C

OMMUNICATIONS

> RSWHO.

2 Make sure that you are not actively browsing using the driver that you wish to

stop. The following shows an actively browsed network.

ProSoft Technology, Inc. Page 25 of 234

December 13, 2011

Page 26

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

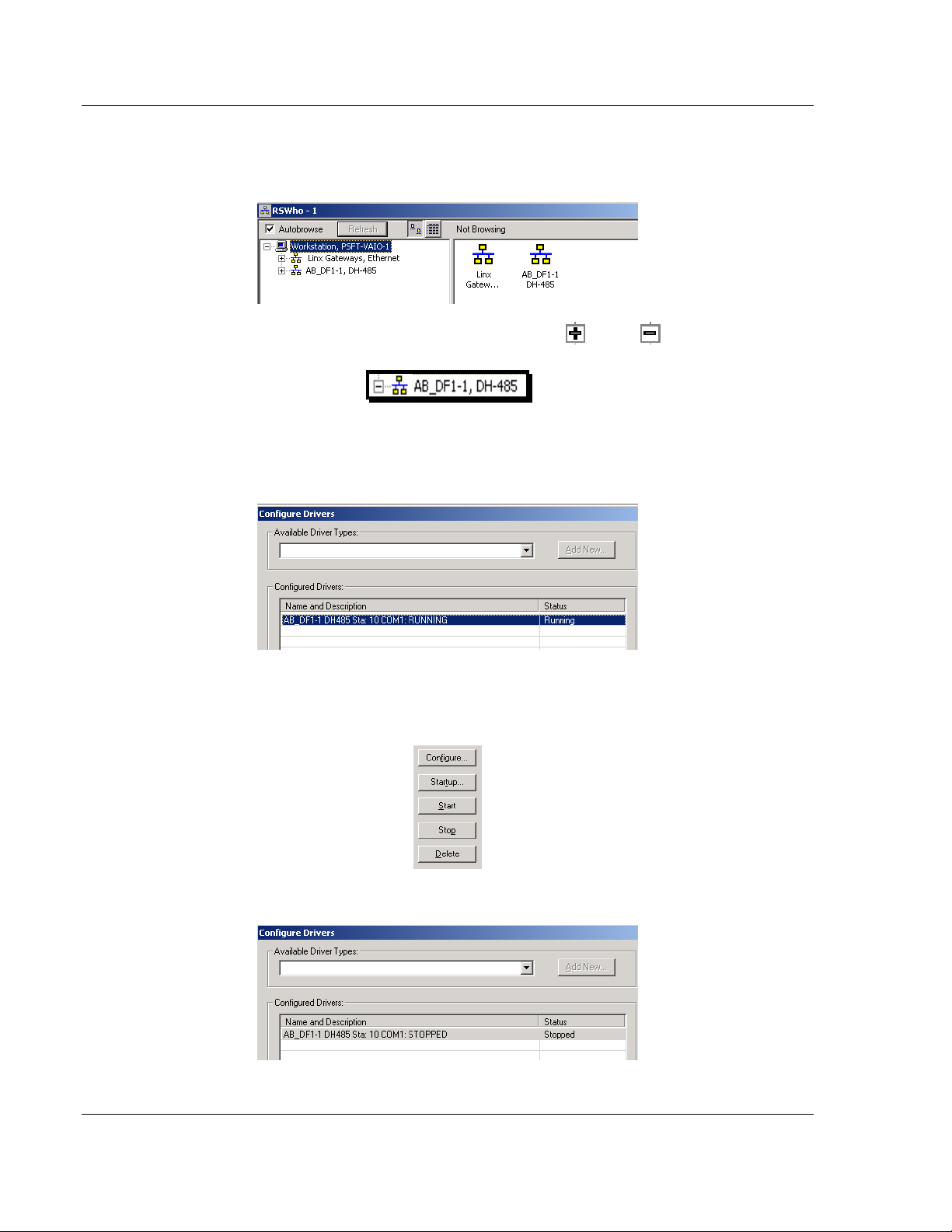

3 Notice how the DF1 driver is opened, and the driver is looking for a processor

on Node 1. If the network is being browsed, then you will not be able to stop

this driver. To stop the driver your RSWho screen should look like this:

Branches are displayed or hidden by clicking on the or the icons.

4 When you have verified that the driver is not being browsed, go to

C

OMMUNICATIONS

> C

ONFIGURE DRIVERS

.

You may see something like this:

5 If you see the status as running, you will not be able to use this COM port for

anything other than communication to the processor. To stop the driver press

the S

TOP

button on the side of the window:

6 After you have stopped the driver you will see the following.

Page 26 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 27

MVI56-BAS ♦ ControlLogix Platform Start Here

BASIC Module (DB/BAS Compatible) User Manual

7 You may now use the COM port to connect to the Config/Debug port of the

module.

Note: You may need to shut down and restart your PC before it will allow you to stop the driver

(usually only on Windows NT machines). If you have followed all of the above steps, and it will not

stop the driver, then make sure you do not have RSLogix open. If RSLogix is open, you will not be

able to stop the DF1 driver. If RSLogix is not open, and you still cannot stop the driver, then reboot

your PC.

ProSoft Technology, Inc. Page 27 of 234

December 13, 2011

Page 28

Start Here MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

Page 28 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 29

MVI56-BAS ♦ ControlLogix Platform Module Configuration

BASIC Module (DB/BAS Compatible) User Manual

2 Module Configuration

In This Chapter

Installing and Configuring the Module ................................................... 29

This section contains the setup procedure, data, and ladder logic for successful

application of the MVI56-BAS module. Each step in the setup procedure is

defined in order to simplify the use of the module.

2.1 Installing and Configuring the Module

This chapter describes how to install and configure the module to work with your

application. The configuration process consists of the following steps.

1 Use RSLogix 5000 to identify the module to the processor and add the

module to a project.

Note: The RSLogix 5000 software should be in "off-line" mode to add the module to a project.

Although some newer versions of RSLogix 5000 may allow new modules to be added while in

"online" mode, it is always considered safer to add new modules off-line and test the new

configuration in a test system before putting the modified program online.

2 Modify the example ladder logic to meet the needs of your application, and

download the ladder logic to the processor. Example ladder logic files are

provided on the CD-ROM.

Note: If you are installing this module in an existing application, you can copy the necessary

elements from the example ladder logic into your application.

The rest of this chapter describes these steps in more detail.

ProSoft Technology, Inc. Page 29 of 234

December 13, 2011

Page 30

Module Configuration MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

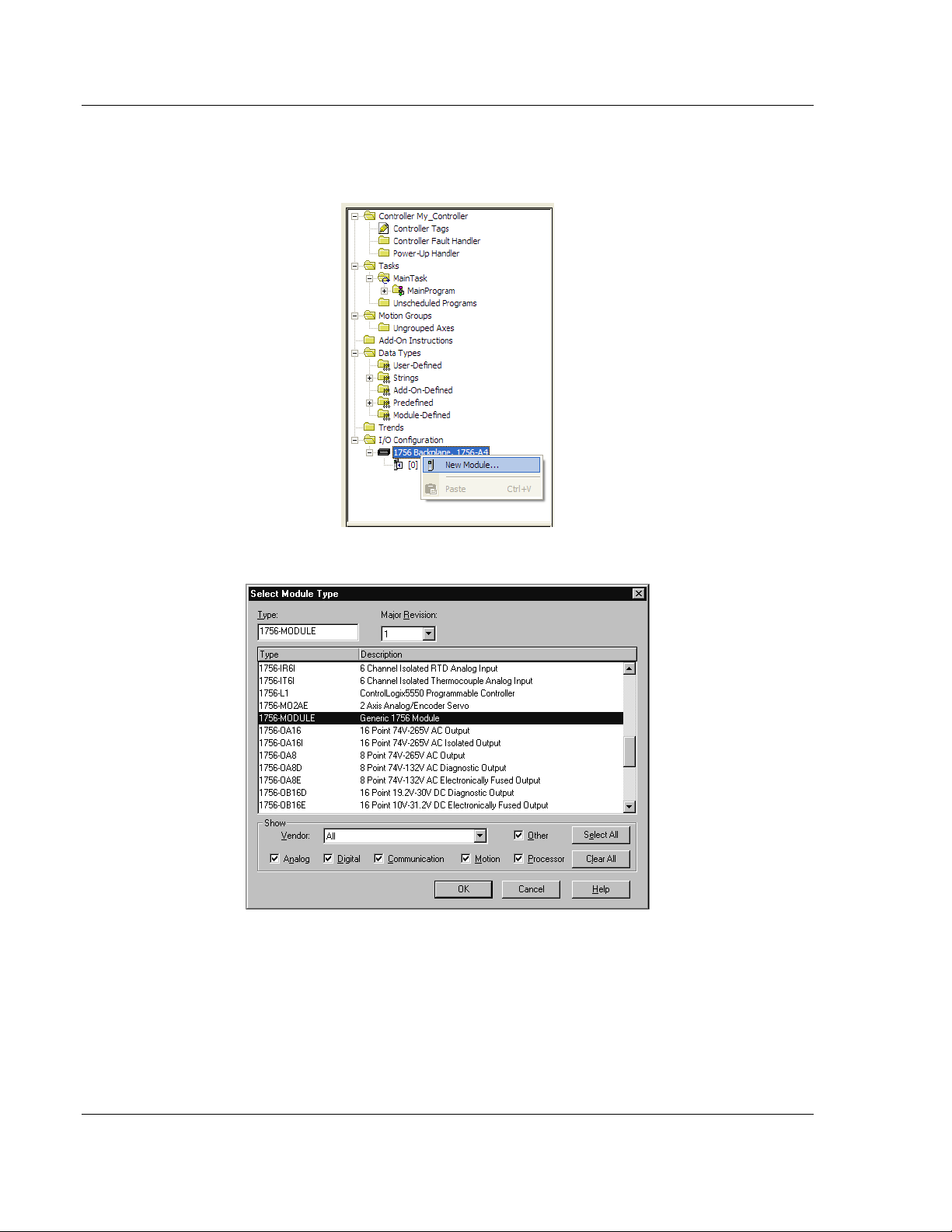

First, define the module to the system. Right-click the mouse button on the I/O

Configuration option in the Controller Organization window to display a pop-up

menu. Select the New Module option from the I/O Configuration menu.

This action opens the following dialog box.

Page 30 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 31

MVI56-BAS ♦ ControlLogix Platform Module Configuration

BASIC Module (DB/BAS Compatible) User Manual

Select the 1756-Module (Generic 1756 Module) from the list and click OK. The

following dialog box is displayed.

Fill in the dialog box as shown adjusting the Name, Description and Slot options

for your application. You must select the Comm Format as Data - INT in the

dialog box. Failure to set the Assembly Instance and Size values correctly will

result in a module that will not communicate over the backplane of the

ControlLogix rack. Click Next to display the next dialog box.

Select the Request Packet Interval value for scanning the I/O on the module.

This value represents the minimum frequency that the module will handle

scheduled events. This value should not be set to less than 1 millisecond. Values

between 1 and 10 milliseconds should work with most applications.

ProSoft Technology, Inc. Page 31 of 234

December 13, 2011

Page 32

Module Configuration MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

After completing the module setup, the Controller Organization window will

display the module’s presence. The data required for the module will be defined

to the application, and objects will be allocated in the Controller Tags data area.

An example of the Controller Organization window is shown below.

Download the new application to the controller and place the processor in run

mode. If all the configuration parameters are set, the module’s Application LED

(APP LED) should remain off and the backplane activity LED (BP ACT) should

blink rapidly. Refer to Diagnostics and Troubleshooting if you encounter errors.

Attach a computer or terminal to PRT1 on the module and look at the status of

the module using the Configuration/Debug Menu in the module.

Page 32 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 33

MVI56-BAS ♦ ControlLogix Platform BASIC Programming

BASIC Module (DB/BAS Compatible) User Manual

3 BASIC Programming

In This Chapter

The Argument Stack .............................................................................. 34

Using CALLs ......................................................................................... 35

Using Strings ......................................................................................... 36

ControlLogix Processor Interrupt ........................................................... 37

This section presents an overview of the BASIC-52 implementation for the

MVI56-BAS. It provides the information necessary to write a BASIC program for

the MVI56-BAS.

ProSoft Technology, Inc. Page 33 of 234

December 13, 2011

Page 34

BASIC Programming MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

3.1 The Argument Stack

The results of all BASIC expressions or operations are stored in the argument

stack. The argument stack holds up to 20 values.

In order to insert a value in the top of the argument stack, the

must be used.

In order to retrieve the value from the top of the argument stack, a

must be used. It will remove the current value from the top of the argument stack

moving the following value in its place.

For example, entering in the program port command line:

>PUSH 1

>PUSH 2

>PUSH 3

>POP A

>POP B

>POP C

>PRINT A

3

>PRINT B

2

>PRINT C

1

Use CALL 109 to print the first 9 values in the argument stack to aid in

troubleshooting.

For example:

>PUSH 1

>PUSH 2

>PUSH 3

>CALL 109

000 1

001 2

002 3

Argument Stack Pointer is 3

PUSH

command

POP

command

Page 34 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 35

MVI56-BAS ♦ ControlLogix Platform BASIC Programming

BASIC Module (DB/BAS Compatible) User Manual

3.2 Using CALLs

There are several pre-defined functions in BASIC referred to as CALLs. Each

CALL can have zero or more input parameters and return zero more output

values. The module uses the argument stack to read the input parameters and

write the output results. The input parameters and the output result(s) are both

located in the argument stack.

functions that require input and output variables.

For example, if a CALL function requires 3 input parameters and returns 2 output

values, it should be used in a BASIC program in the following way:

PUSH 4

PUSH 2

PUSH 4

CALL [CALLNUMBER]

POP D

POP E

The variables D and E will store the 2 output values returned by this CALL. The

BASIC CALLs Syntax section provides information about each call supported by

the MVI56-BAS.

PUSH

and

POP

commands are used with CALL

ProSoft Technology, Inc. Page 35 of 234

December 13, 2011

Page 36

BASIC Programming MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

3.3 Using Strings

Strings are a group of characters that can be accessed in a BASIC program or

command line by the following syntax:

$(num)

Where num varies between 0 and 254.

Before using strings, you must allocate enough memory using the

command:

STRING(A,B)

Where:

A = total number of bytes for the all strings

B = maximum number of bytes for each string

The MVI56-BAS requires an extra byte for each string and an additional

overhead byte.

Example:

10 STRING 307, 50

20 $(0) = "TEST 1"

30 $(1) = "TEST 2"

40 $(2) = "TEST 3"

50 $(3) = "TEST 4"

60 $(4) = "TEST 5"

70 $(5) = "TEST 6"

The

STRING

for each string and one byte overall.

There are several BASIC CALLs that allow string manipulation. Refer to String

CALLs (page 147).

command allocated space for 6 strings (50 bytes each) plus one byte

STRING

Page 36 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 37

MVI56-BAS ♦ ControlLogix Platform BASIC Programming

BASIC Module (DB/BAS Compatible) User Manual

3.4 ControlLogix Processor Interrupt

The MVI56-BAS allows the ControlLogix to interrupt the current BASIC program

using CALL 20 (Enable Processor Interrupt). When word 0 bit 15 in the output

image (Local:x:O:Data[0].15) toggles from OFF to ON, the program jumps to the

line number specified by the CALL 20 parameter.

Use the

being interrupted.

The following BASIC program shows how to use CALL 20:

10 PUSH 50: REM JUMPS TO LINE NUMBER 50

20 CALL 20

30 GOTO 30

35 PRINT "LINE 35"

40 PRINT "LINE 40"

50 PRINT "LINE 50"

60 PRINT "LINE 60"

70 RETI

80 END

While the program is running, the following ladder logic is executed:

RETI

command in order to return to the point the program was before

The result is:

LINE 50

LINE 60

To disable the processor interrupt, use CALL 21 (Disable Processor Interrupt).

This routine has no arguments and does not return any value.

Refer to BASIC CALLs Syntax (page 105) for more information about CALLs 20

and 21.

ProSoft Technology, Inc. Page 37 of 234

December 13, 2011

Page 38

BASIC Programming MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

Page 38 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 39

MVI56-BAS ♦ ControlLogix Platform Backplane Data Transfer

BASIC Module (DB/BAS Compatible) User Manual

4 Backplane Data Transfer

In This Chapter

Data Transfer from Output Buffer to CLX Processor ............................. 40

Data Transfer from CLX Processor to MVI Input Buffer ........................ 43

This section describes how to transfer data between the MVI56-BAS and the

ControlLogix processor.

ProSoft Technology, Inc. Page 39 of 234

December 13, 2011

Page 40

Backplane Data Transfer MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

4.1 Data Transfer from Output Buffer to CLX Processor

The MVI56-BAS module output buffer can be used to transfer data to the

ControlLogix processor.

The first step is to move data to the output buffer using CALLs 24 and 25. These

CALLs convert BASIC floating point data into integer values truncating the

fractional part. The result is stored in the output buffer between addresses 0 and

231.

After the data has been moved to the output buffer, there are 2 ways to transfer it

to the ControlLogix; writing to the CLX input image file (CALL 54) or using MSG

instructions (CALL 57).

The following illustration shows how to transfer data between the MVI56-BAS

output buffer and the ControlLogix processor.

The output buffer is divided into areas depending on the destination of the data

transferred. The output buffer addressing is shown in the following table.

Address Definition

0 to 39 DH-485 Common Interface File - data read by other devices

40 to 99 Reserved

100 to 199 Data read by the CLX using MSG instruction

200 to 231

Data transferred to the CLX Input Image file

CALL 54 transfers words 200 to 207 (8 words) from the module output buffer to

the CLX input image (Local:x:I.Data[ ]). No ladder logic is required to perform the

data transfer.

Page 40 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 41

MVI56-BAS ♦ ControlLogix Platform Backplane Data Transfer

BASIC Module (DB/BAS Compatible) User Manual

Note: The upper three bits in Word 200 are reserved and cannot be modified.

The lower thirteen bits can be used. The upper three bits provide module status

information to the ControlLogix, Where

Address Definition

bit 0 Modifiable

bit 1 Modifiable

bit 2 Modifiable

bit 3 Modifiable

bit 4 Modifiable

bit 5 Modifiable

bit 6 Modifiable

bit 7 Modifiable

bit 8 Modifiable

bit 9 Modifiable

bit 10 Modifiable

bit 11 Modifiable

bit 12 Modifiable

bit 13 Battery status bit (0-battery good 1 -low voltage)

bit 14 Reserved

bit 15 MVI56-BAS program mode (0-run mode , 1-command)

CALL 57 will transfer data from the MVI56-BAS output buffer to a CLX data file

using a Class 3 Message. In order to accomplish this, ladder logic is required

The following BASIC program transfers data to the output buffer using CALL 24

and executes CALL 57:

1 REM CALL 57

10 FOR I=100 TO 149

30 PUSH 200-I: REM VALUE TO BE TRANSFERRED

40 PUSH I: REM ADDRESS IN OUTPUT BUFFER

50 CALL 24

60 NEXT I

70 PUSH 50: REM NUMBER OF WORDS TO BE TRANSFERRED

80 CALL 57:

90 POP S: REM CALL 57 RESULT

130 END

ProSoft Technology, Inc. Page 41 of 234

December 13, 2011

Page 42

Backplane Data Transfer MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

Following CALL 57 execution, the ladder logic should perform a MSG instruction

in order to read the data setup by CALL 57. The MSG instruction should be

configured as shown in the following example:

The following ladder logic can be used to read the data:

Page 42 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 43

MVI56-BAS ♦ ControlLogix Platform Backplane Data Transfer

BASIC Module (DB/BAS Compatible) User Manual

4.2 Data Transfer from CLX Processor to MVI Input Buffer

The following BASIC CALLs 14, 15, 53 and 56 are covered in this section. Refer

to BASIC CALLs Syntax (page 105) for detailed syntax information about these

CALLs.

The MVI56-BAS input buffer can receive data transferred from the CLX

processor through the backplane using CALLs 56 or 53. The input buffer data

can be read using CALLs 14 and 15.

The data transfer from the CLX to the MVI56-BAS input buffer is shown in the

following diagram:

The input buffer is divided into areas depending on the source of the data

transferred. The input buffer addressing is shown in the following table.

Address Definition

0 to 39 DH-485 Common Interface File - data written by other devices

40 to 99 Reserved

100 to 199 Data transferred from the CLX using Message instruction

200 to 231 Data transferred from the CLX Output Image file

CALL 53 transfers 8 words from the CLX output image file to the MVI56-BAS

input buffer.

The following example BASIC code uses CALL 53 to transfer data from the CLX

output image file to the input buffer. After that, it uses CALL 14 to read the data

from the MVI56-BAS input buffer and prints it to PRT1.

10 CALL 53

20 POP X: REM CALL 53 status code

30 FOR I = 200 TO 207

ProSoft Technology, Inc. Page 43 of 234

December 13, 2011

Page 44

Backplane Data Transfer MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

40 PUSH I: REM INPUT BUFFER ADDRESS

50 CALL 14

60 POP Y: REM INPUT BUFFER VALUE AT ADDRESS I

65 X = I - 200

70 PRINT "VALUE AT [", X, "] = ", Y

80 NEXT I

90 END

CALL 56 transfers up to 100 words from a CLX data file to the MVI56-BAS input

buffer using Class 3 message instructions.

Ladder logic must execute a MSG instruction prior to CALL 56 execution in order

to move the data to a temporary buffer. The MSG should have the following

parameters:

The following ladder logic writes the data that will be read by CALL56.

After the ladder logic execution, a CALL 56 can be performed in order to transfer

the data to the MVI56-BAS input buffer.

1 REM CALL 56

10 PUSH 10

20 CALL 56

30 POP X

40 PRINT X

Page 44 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 45

MVI56-BAS ♦ ControlLogix Platform Using the Program Port (PRT1)

BASIC Module (DB/BAS Compatible) User Manual

5 Using the Program Port (PRT1)

In This Chapter

Interfacing the PC and the MVI56-BAS ................................................. 46

Creating BASIC programs ..................................................................... 47

EDIT Command ..................................................................................... 50

Permanently Saving BASIC Programs .................................................. 51

Creating Offline BASIC programs .......................................................... 53

Module Backup ...................................................................................... 59

Module Restoration ............................................................................... 61

Program Copies .................................................................................... 63

Running a BASIC Program .................................................................... 64

Debugging a BASIC Program ................................................................ 65

Commenting a BASIC Program ............................................................. 70

Checking Available and Used RAM Memory ......................................... 71

Exit a BASIC Program (Ctrl+C) ............................................................. 72

The present section discusses important points while using the MVI56-BAS

program port such as creating, editing, and transferring a BASIC program to the

module. The program port by default is PRT1 (the middle port).

This section only describes PRT1 as the program port.

ProSoft Technology, Inc. Page 45 of 234

December 13, 2011

Page 46

Using the Program Port (PRT1) MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

5.1 Interfacing the PC and the MVI56-BAS

The software required on your personal computer to interface with the

configuration/debugger port is operating system dependent. Tested software

includes the following:

DOS ProComm and several other terminal emulation programs

Windows 3.1 Terminal

Windows 95/98/2000/XP HyperTerminal

Windows NT HyperTerminal

Linux Minicom

Any ASCII terminal emulation software application provided with your operating

system should work as long as it can be configured as follows for all MVI56-BAS

ports:

Baud Rate 19,200

Parity None

Data Bits 8

Stop Bits 1

Software Handshaking XON/XOFF

The following steps are required to interface with the configuration/debugger port:

1 Connect your computer to the module’s port using a Null Modem cable.

2 Start the terminal emulation program on your computer and configure the

communication parameters.

If there is no response from the module, look at the communication setup and the

cable. In addition, make sure you are connected to the correct port on your

computer and the module.

Page 46 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 47

MVI56-BAS ♦ ControlLogix Platform Using the Program Port (PRT1)

BASIC Module (DB/BAS Compatible) User Manual

5.2 Creating BASIC programs

Creating a BASIC program is simple. First, hit the enter key a couple of times.

You should see the following response each time you hit the enter key:

Ready

>

If you do not get the above response, it is possible that the module is already

running a BASIC program. To stop a program that is already running, hit the 'C'

while simultaneously holding the control key down. The short symbol for this key

stroke combination is ^C. If you still do not get a response, check the module

power, check the serial cable, and check port connections.

After you get the Ready prompt, type in the BASIC command:

print "Hello World!"

followed by and enter key. The BAS module should respond with the following:

Ready

>print "Hello World!"

Hello World!

Ready

>

You just typed in a PRINT command. Practically any BASIC statement can also

be used as a command. For example:

Ready

>for i=0 to 5:p. i:next i

0

1

2

3

4

5

Ready

>

Note that the "p." is short hand for "PRINT".

The above approach can be used for debugging a program, but there are a few

problems writing a program this way. First, there is no permanent copy of the

program saved in memory. That is, the program disappears as soon as it is

executed. Second, you cannot write a program any longer than one line in length.

Third, someone has to be there to write the program each time it is executed.

You can write a program which is permanently saved and executes whenever

you want by adding line numbers at the beginning of each line. The program is

executed in the order matching the line number. For example:

Ready

>10 for i = 0 to 5

Ready

>20 p. i

Ready

>30 next i

Ready

>40 end

Ready

>list

ProSoft Technology, Inc. Page 47 of 234

December 13, 2011

Page 48

Using the Program Port (PRT1) MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

10 FOR I = 0 TO 5

20 PRINT I

30 NEXT I

40 END

Ready

>

The LIST command allows you to see what you have done so far.

You can now execute the program using the RUN command:

Ready

>run

0

1

2

3

4

5

Ready

>

If you want to add a line in the middle of your program, select an unused line

number between the line numbers where you want to insert the line, and type in

the new line:

Ready

>list

10 FOR I = 0 TO 5

20 PRINT I

30 NEXT I

40 END

Ready

>25 p. "Hello World"

Ready

>list

10 FOR I = 0 TO 5

20 PRINT I

25 PRINT "Hello World"

30 NEXT I

40 END

Ready

>

If you want to remove a line from the program, type in that line number:

Ready

>list

10 FOR I = 0 TO 5

20 PRINT I

25 PRINT "Hello World"

30 NEXT I

40 END

Ready

>20

Ready

>list

10 FOR I = 0 TO 5

25 PRINT "Hello World"

30 NEXT I

Page 48 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 49

MVI56-BAS ♦ ControlLogix Platform Using the Program Port (PRT1)

BASIC Module (DB/BAS Compatible) User Manual

40 END

Ready

>run

Hello World

Hello World

Hello World

Hello World

Hello World

Hello World

Ready

>

ProSoft Technology, Inc. Page 49 of 234

December 13, 2011

Page 50

Using the Program Port (PRT1) MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

5.3 EDIT Command

Sometimes you may have typed in a long line and made a mistake in the middle.

You fear that you may make more mistakes if you attempt to re-type the entire

line. To solve this dilemma, use the EDIT command. To edit a line, type EDIT

followed by that line number. For example "EDIT 100".

The EDIT command will respond by printing the entire line to the screen with the

cursor at the beginning of the line. At this point, EDIT has several sub-commands

that must be explained.

EDIT Sub-command Description

<space> Hitting the space key will cause the cursor to move to the right.

<backspace> Hitting the backspace key will cause the cursor to move to the left.

Any character Hitting any character will replace the character above the cursor with the

^A ^A toggles between insert mode and non-insert mode. When you first

^D ^D will delete the character above the cursor.

<enter> The enter key will cause the line to be re-typed as it exists after the

^C Typing ^C will exit EDIT mode without saving any changes.

^X Typing ^X will exit EDIT mode and save all changes.

new character.

enter the EDIT command, you are in non-insert mode. Typing a ^A will

erase the line from the cursor to the end. At this point, you can type in

any text which you want to insert into the line. When you type ^A again,

the part of the line which was erased when you first hit ^A will reappear,

and you will exit insert mode.

edits.

Page 50 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 51

MVI56-BAS ♦ ControlLogix Platform Using the Program Port (PRT1)

BASIC Module (DB/BAS Compatible) User Manual

5.4 Permanently Saving BASIC Programs

There are two ways to permanently save a BASIC program. The first method has

already been shown. When you type the program into the module, it is

permanently saved to a file on the Compact Flash drive called "XRAM.BAS". If

you want to save more than one program, you can use the PROG command.

Refer to the Using ROM Storage section for more information. The PROG

command copies the program from the "XRAM.BAS" file to another file called

"EPROM.BAS". The "EPROM.BAS" file differs from the "XRAM.BAS" file in two

important points. First, up to 255 programs can be saved in "EPROM.BAS". The

programs are stored as ROM 1, ROM 2 , ROM 3, and so on. Second, you cannot

modify a program stored in "EPROM.BAS". All you can do is ERASE the last

program stored in "EPROM.BAS".

5.4.1 EPROM File Storage

When you want to store a XRAM program in EPROM, you type the PROG

command. The programs are stored sequentially starting with ROM 1.

Executing a Program in EPROM

If you want to execute a program in EPROM, use the ROM command. ROM

without a number moves the BASIC pointer to point to ROM 1. If you want to

select another program stored in EPROM, type ROM followed by the number of

the program you wish to execute.

Note that the ROM command only changes the BASIC program pointer. It does

not automatically execute the program. You can use the RUN command to

execute the program.

If you want to select another EPROM program and execute that program, you

can use the RROM (RUN ROM) command followed by the number of EPROM

program you wish to execute (that is, RROM 3).

5.4.2 Erasing EPROM Programs

If you want to remove EPROM programs, you can use the ERASE command.

The ERASE command removes the last program in EPROM. You cannot remove

a program at the beginning or in the middle of the EPROM programs.

5.4.3 Editing EPROM Programs

You cannot modify programs stored in EPROM. If you must modify a program in

EPROM, you can use ROM to change the pointer to the program that needs

modification. Then you can XFER that program to XRAM. Then you change the

BASIC program pointer back to XRAM using the RAM command. Now the

program has been moved to XRAM, and the BASIC pointer is pointing to XRAM,

so the program can be edited.

ProSoft Technology, Inc. Page 51 of 234

December 13, 2011

Page 52

Using the Program Port (PRT1) MVI56-BAS ♦ ControlLogix Platform

User Manual BASIC Module (DB/BAS Compatible)

5.4.4 Using XRAM and EPROM Programs as Subroutines

The BASIC programs are limited to the size of program that you can squeeze

into XRAM. However, you can create larger programs by using CALLs 70, 71,

and 72. These three CALLs allow you to use XRAM and EPROM programs as

subroutines.

5.4.5 Automatically Executing ROM 1 at Power-up

If the setup jumper is off, then the program in XRAM will automatically be

executed at power-up. You can change the module to automatically execute

ROM 1 at power-up by using the PROG2 command. The PROG2 will have the

same effect at power-up as someone typing RROM 1 (or ROM 1, RUN). If at a

later time you want to stop executing ROM 1 at power-up, use PROG0 to clear

the effect of PROG2.

Page 52 of 234 ProSoft Technology, Inc.

December 13, 2011

Page 53

MVI56-BAS ♦ ControlLogix Platform Using the Program Port (PRT1)

BASIC Module (DB/BAS Compatible) User Manual

5.5 Creating Offline BASIC programs

You can use a regular ASCII editor such as Notepad, Wordpad (Windows) or

EDIT.EXE (DOS) in order to edit and save offline BASIC programs.

When saving programs, choose a name starting with a letter and containing no