PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

ORDER NO.

CRT3248

DVD NAVIGATION UNIT

AVIC-88D VD

This service manual should be used together with the manual(s) listed below. For the

parts numbers, adjustments, etc. which are not shown in this manual, refer to the following manual(s).

Model No. Order No. Mech.Module Remarks

AVIC-90DVD/UC CRT2890

CX-954 CRT2670 MS2 DVD Mech. Module : Circuit Description, Mech. Description, Disassembly

/UC

For details, refer to "Important symbols for good services".

K-ZZA. JUNE 2004 printed in Japan

1234

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

A

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

B

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

C

D

E

F

2

1234

AVIC-88DVD/UC

5678

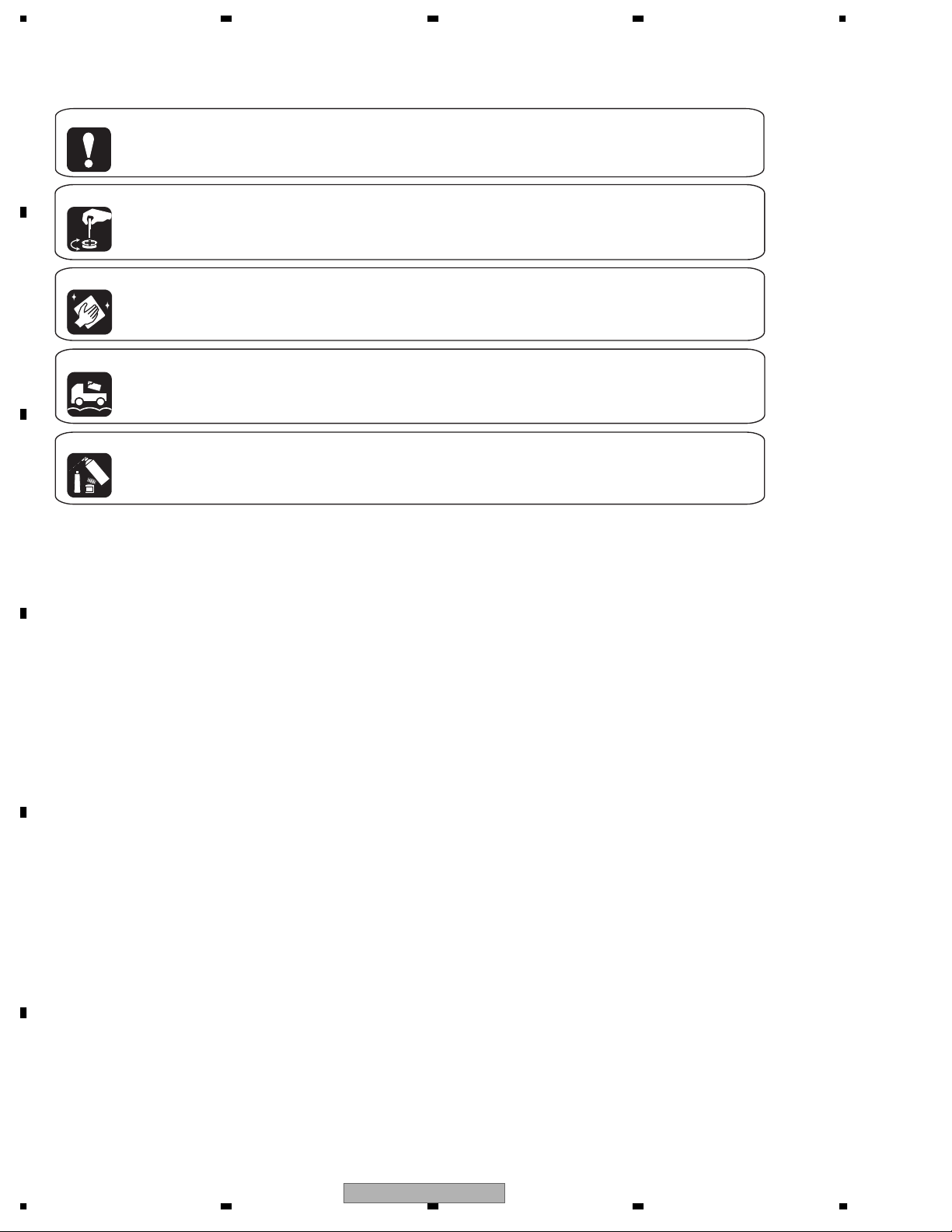

EXPLODED VIEWS AND PARTS LIST

PACKING(Page 6)

-

PACKING SECTION PARTS LIST

Mark No. Description AVIC-90DVD/UC AVIC-88DVD/UC

1-1 Owner’s Manual CRB1798 CRB1975

1-2 Owner’s Manual/PA/FRE CRB1783 CRB1977(Owner’s Manual/POC/FRE)

1-3 Owner’s Manual CRB1796 CRB1974

1-4 Owner’s Manual/PA/FRE CRB1797 CRB1976(Owner’s Manual/POC/FRE)

1-5 Installation Manual CRD3650 Not used

1-6 Owner’s Manual CRD3661 CRD3914(Installation Manual)

2 Cord Assy CDE7062 CDE7725

3 Accessory Assy CEA2913 CEA4467

8 Accessory Assy CEA2536 CEA4299(Connector Assy)

9 Polyethylene Bag CEG1011 * E36-615

10 Battery CEX1021 Not used

12 Sheet CNM6370 Not used

13 Holder CNS5606 Not used

17 Screw Assy CEA2896 CEA4465

19 Screw CMZ50P060FMC CMZ50P060FTC

* : Non spare part

A

B

23 Carton CHG4738 CHG5266

25 Contain Box CHL4738 CHL5266

31 Remote Control Assy CXB9118 Not used

34 DVD-ROM CPJ1143 CPJ1161

35 Screw Assy CEA2938 CEA4466

36 Screw(M6x16) CBA1295 CBA1795

* 37 Polyethylene Bag E36-613 CNM4338(Polyethylene Sheet)

38 Remote Control Assy Not used CXC3646

38

C

D

E

56

AVIC-88DVD/UC

F

7

8

3

1234

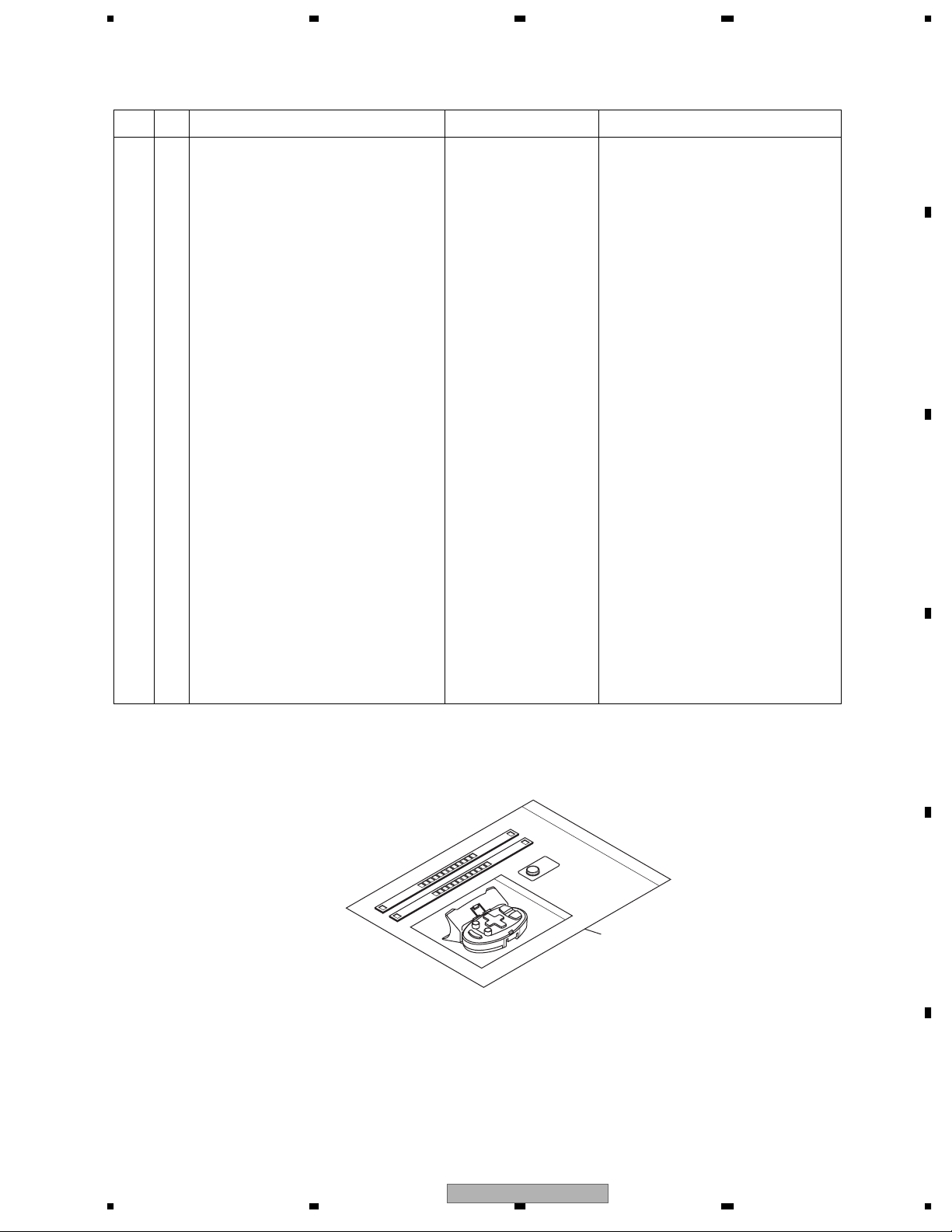

EXTERIOR(Page 12)

-

EXTERIOR SECTION PARTS LIST

Mark No. Description AVIC-90DVD/UC AVIC-88DVD/UC

A

1 Screw BMZ20P025FMC BMZ20P025FTC

2 Screw BMZ26P040FMC BMZ26P040FTC

23 CC Unit CWM8391 CWM9059

36 Screw IMS26P030FMC IMS26P030FTC

37 Main Unit CWM8484 CWM9642

73 GPS Unit CWX2591 CWX2925

79 Screw BPZ20P050FMC BPZ20P050FTC

B

83 Grille Assy CXB9890 CXC3631(Grille Unit)

90 Door Unit CXB7566 CXC3674

91 DVD Mechanism Module(MS2) CXK6160 CXK6121

96 Cord Assy CDE7062 CDE7725

103 Grille Unit GXX1229 GXX1246

104 Door Unit GXX1223 GXX1247

C

D

REMOTE CONTROL ASSY(Page 16)

-

REMOTE CONTROL ASSY SECTION PARTS LIST

Mark No. Description AVIC-90DVD/UC AVIC-88DVD/UC

E

1 Remote Control Assy CXB9118 Not used

2 Cover CZN5432 Not used

3 Scroll Stick CZA5047 Not used

4 3D View Stick CZA5085 Not used

5 Cover Not used CZN5497

F

5

4

1234

AVIC-88DVD/UC

5678

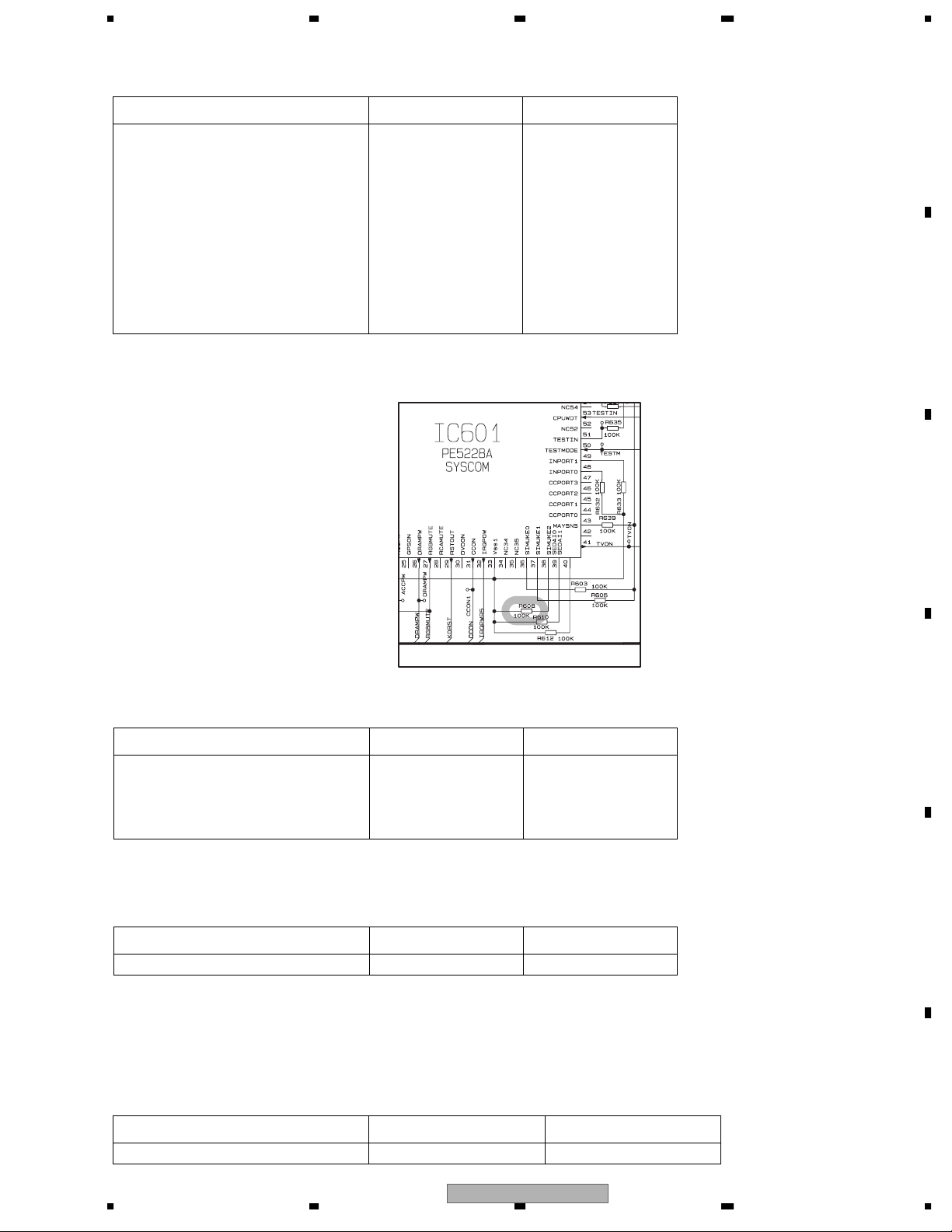

ELECTRICAL PARTS LIST(Page 110)

MAIN UNIT

Circuit Symbol and No. AVIC-90DVD/UC AVIC-88DVD/UC

IC571 IC S-81250SGUP S-812C50AUA-C3E

IC631 IC S-8423AFS S-8424AABFT

D1841 Diode MA110 MA111

FU1801 Fuse 2A CEK1190 CEK1257

FU1802, 1804 Fuse 4A CEK1199 CEK1260

FU1850, 3251 Fuse 1A CEK1191 CEK1254

GY572 Sensor CSX1052 CSX1050

R607 RS1/16S104J Not used

R608 Not used RS1/16S104J

Page 31 7-B

A

B

C

CC UNIT

Circuit Symbol and No. AVIC-90DVD/UC AVIC-88DVD/UC

IC110 IC PD6403B PD6444B

IC111 IC PD6404B PD6445B

FU801 Fuse 4A CEK1199 CEK1260

FU802, 803 Fuse 2.5A CEK1209 CEK1258

GPS UNIT

Circuit Symbol and No. AVIC-90DVD/UC AVIC-88DVD/UC

IC502 IC PD6362B PD6452A

ADJUSTMENT

USING THE TEST DISC(Page 166)

AVIC-90DVD/UC AVIC-88DVD/UC

TEST DISC GGV1059(CNDK-LT0102) GGV1132(S-57364)

D

E

F

56

AVIC-88DVD/UC

7

8

5

N

1234

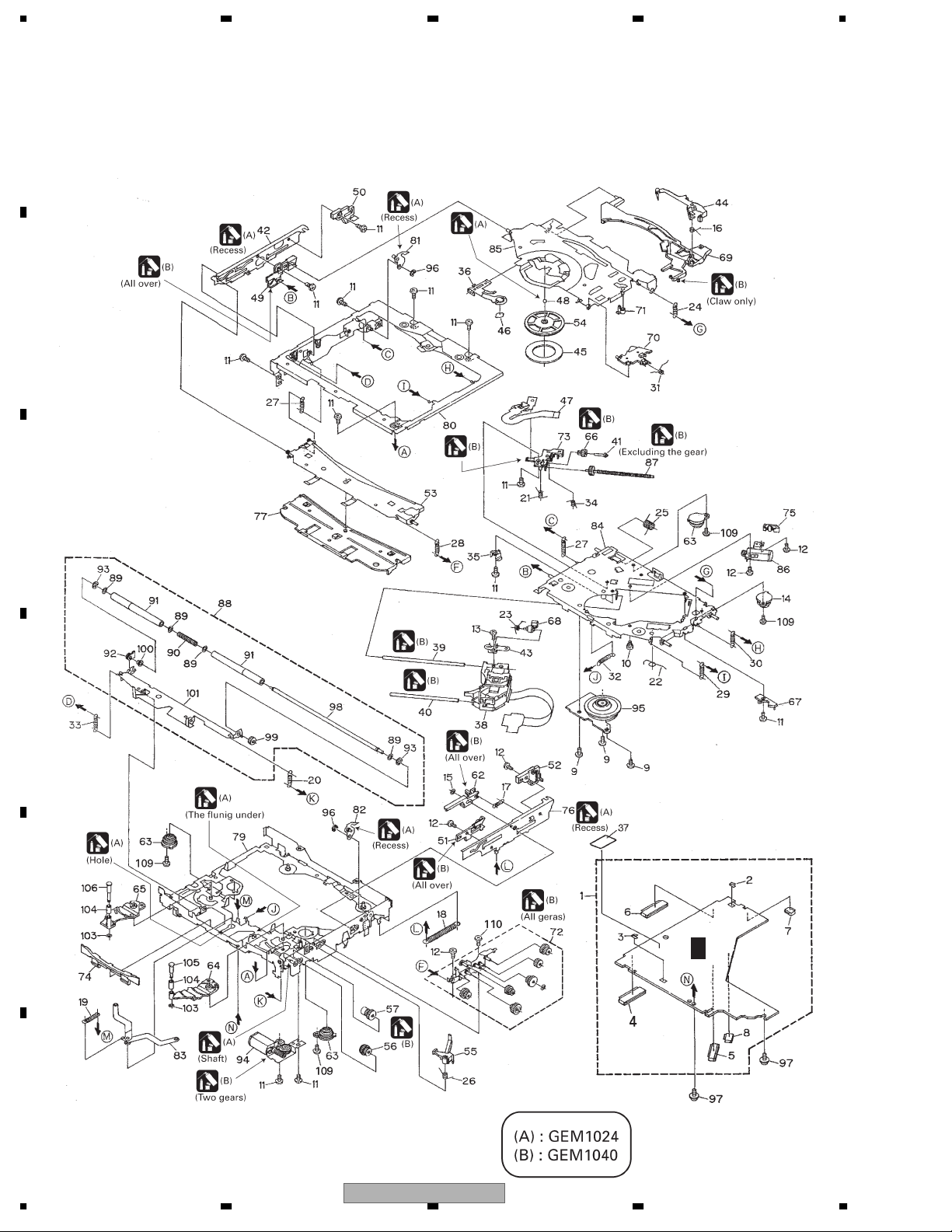

EXPLODED VIEWS AND PARTS LIST

OTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

A

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lobricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

"

DVD MECHANISM MODULE

B

C

D

E

F

G

F

6

1234

AVIC-88DVD/UC

5678

DVD MECHANISM MODULE SECTION PARTS LIST

Mark No. Description Part No.

1 DVD Core Unit R CWX2576

2 Terminal(CN1703) CKF1065

3 Terminal(CN1705) CKF1065

4 Connector(CN1401) CKS4052

5 Connector(CN1100) CKS3749

6 Connector(CN1701) CKS4052

7 Connector(CN1700) CKS4374

8 Connector(CN1300) CKS4507

9 Screw(M2x3) CBA1486

10 Screw CBA1535

11 Screw(M2x2.2) CBA1547

12 Screw(M2x2.2) CBA1548

13 Screw(M1.4x2) CBA1549

14 Damper CNV6927

15 Washer CBF1038

16 Spring CBH2394

17 Spring CBH2395

18 Spring CBH2396

19 Spring CBH2397

20 Spring CBH2622

21 Spring CBH2399

22 Spring CBH2400

23 Spring CBH2401

24 Spring CBH2402

25 Spring CBH2403

26 Spring CBH2404

27 Spring CBH2405

28 Spring CBH2406

29 Spring CBH2407

30 Spring CBH2408

31 Spring CBH2410

32 Spring CBH2411

33 Spring CBH2413

34 Spring CBH2414

35 Spring CBL1499

36 Spring CBL1500

37 Sheet CNM7590

38 Pickup Unit(DP4)(Service) CXX1530

39 Shaft CLA3878

40 Shaft CLA3879

41 Shaft CLA3881

42 Lever CNC8988

43 Bracket CNC8992

44 Arm CNC8994

45 Sheet CNM8149

46 Sheet CNM6884

47 PCB CNP5971

48 Ball CNR1189

49 Guide CNV6352

50 Guide CNV6353

51 Guide CNV6354

52 Guide CNV6355

53 Guide CNV6356

54 Clamper CNV6357

No. Description Part No.

Mark

55 Arm CNV6358

56 Gear CNV6361

57 Gear CNV6362

58-61 •••••

62 Rack CNV6367

63 Damper CNV6368

64 Arm CNV6369

65 Arm CNV6370

66 Gear CNV6372

67 Holder CNV6374

68 Rack CNV6376

69 Arm CNV6377

70 Arm CNV6378

71 Arm CNV6379

72 Gear Unit CXB5959

73 Holder CNV6383

74 Guide CNV6384

75 Holder CNV6385

76 Lever Unit CXB5943

77 Holder Unit CXB5944

78 •••••

79 Frame Unit CXB5948

80 Frame Unit CXB5949

81 Arm Unit CXB5950

82 Arm Unit CXB5951

83 Arm Unit CXB5952

84 Chassis Unit CXB5953

85 Arm Unit CXB5954

86 Motor Unit(CRG)(M2) CXC4218

87 Screw Unit CXB5957

88 Roller Unit CXB5958

89 Washer CBF1060

90 Spring CBH2170

91 Roller CNV6068

92 Holder CNV6210

93 Washer YE20FTC

94 Motor Unit(LOAD)(M1) CXC1187

95 Motor Unit(SPDL)(M3) CXB6218

96 Washer YE15FTC

97 Screw IMS20P030FTC

* 98 Shaft CLA3877

* 99 Gear CNV6359

* 100 Caller CNV6382

* 101 Arm Unit CXB5945

102 •••••

103 Washer CBF1087

104 Roller CNV6928

105 Shaft CLA4180

106 Shaft CLA4181

107,108•••••

109 Screw (M2x3.5) CBA1560

110 Screw (M2x2.2) CBA1419

A

B

C

D

E

F

56

AVIC-88DVD/UC

7

8

7

1234

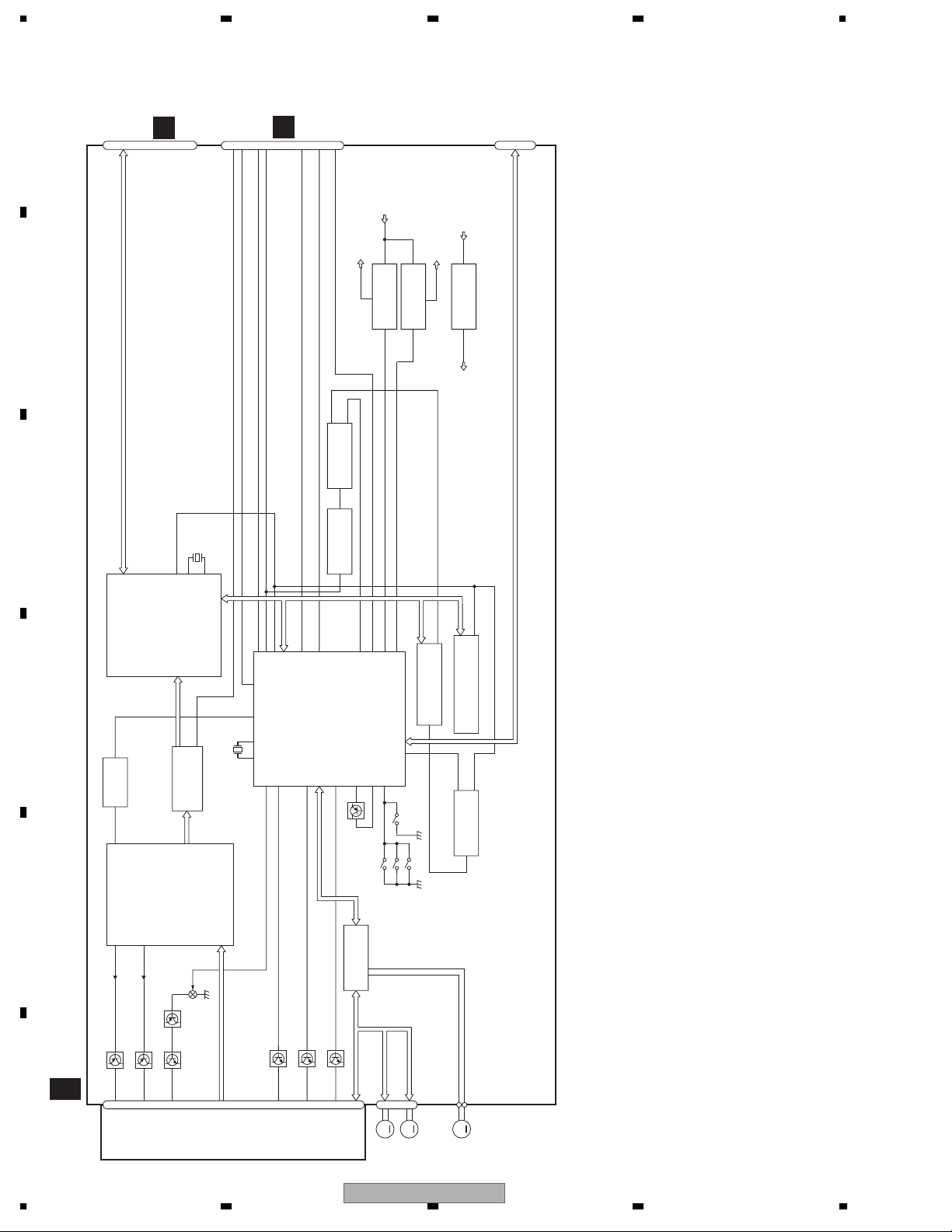

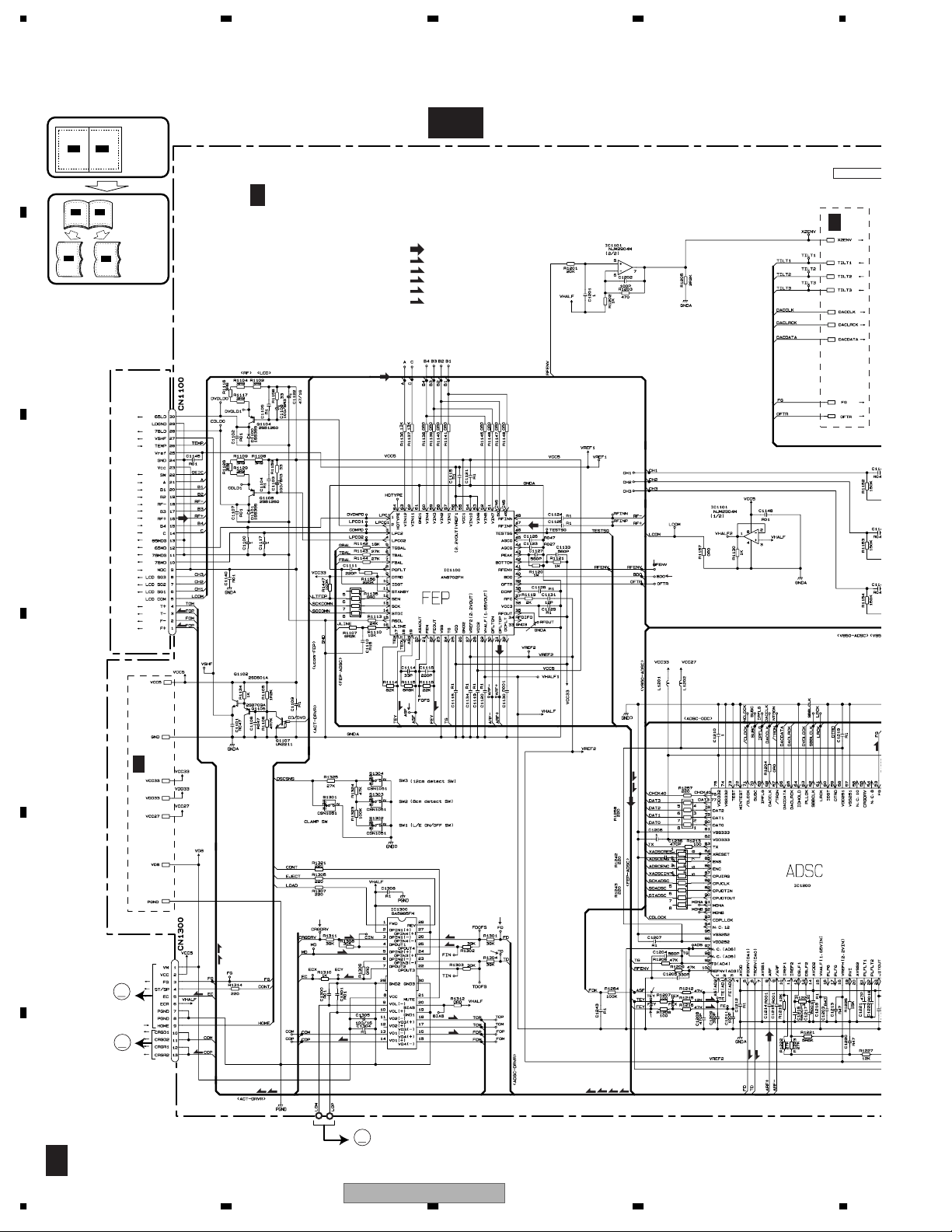

BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

BLOCK DIAGRAM

EMPH

33

XRESET

16

CN3251

A

22

20

AMUTE

TMODE

21

EJSNS

CN1700

VD5

A

CN1401

E

37

AOUT0

CN1701

26

DISCDET

CN2

VCC27

2

4

B

4

IC 1804

BA00BC0WFP

1

1

2

IC 1802

BA033SFP

1

VCC33

4

4

IC 1801

BA05SFP

2

VD63 VCC5

CTS,DTR,RXPC,TXPC,VPP,SICOMN,SOCOMN,SCKCOMN

IC 1705

TC7SH32FU

C

X1500

33MHz

59

100

101

XWR

ODC

IC 1400

MNZS25BDAUB

D

97

59

114

XWR

EMPH

XRESET

DISCDET

X2ENV

66

5MHz

X1700

X2 X1

62 63 78 105

TILT1

ADSC

IC 1101

NJM2904M

57

IC 1200

MN677061ZYUB

FBAL

TBAL,

GBAL,

94

CD/DVD

23

A0-17,D0-15

25

TMODE

CPU

IC 1700

TILT2

36

IC 1703

TC7SH04FU

243

88

AMUTE

PE5324C

TILT3

33

718379

Q1700

74

107

XCSSRAM

AVRE F

EJSNS

ADENA

116

VCONTA

DSCSNS

117

VCONTB

XUWR

S1301

6

SRAM

IC 1701

M5M5V216ATP-70HI

17

96

CLAMP SW

FLASH MEMORY

2

11

IC 1702

PD6378D

1

IC 1704

TC7SH08FU

4

FEP

IC 1100

4

AN8702FH

LPC02

Q1107

Q1105

E

LPC01 RFENV

241

12cm detect SW

10

IC 1300

BA5985FM

DRIVER BLOCK

9

S1303

S1304

8cm detect SW

LOP

LOM

S1302

L/E ON/OFF SW

DVD CORE UNIT R

Q1109

Q1110

Q1104

Q1108

F

G

65LD

CN1100

F

8

Q1102

27

PICKUP

UNIT

A,B1-4,C,RF+,RF-

(DP4)

(SERVICE)

LCDSG1

78LD

30

VSHF

28

1234

Q1111

LCDSG2

6

LCDSG3

7

EC,CONT

FOP,FOM,TOP,TOM

CN1300

8

M

MOTOR

SPINDLE

AVIC-88DVD/UC

COP,COM

M

MOTOR

CARRIAGE

M

MOTOR

LOADING

5678

A

B

C

D

E

56

AVIC-88DVD/UC

F

7

8

9

1234

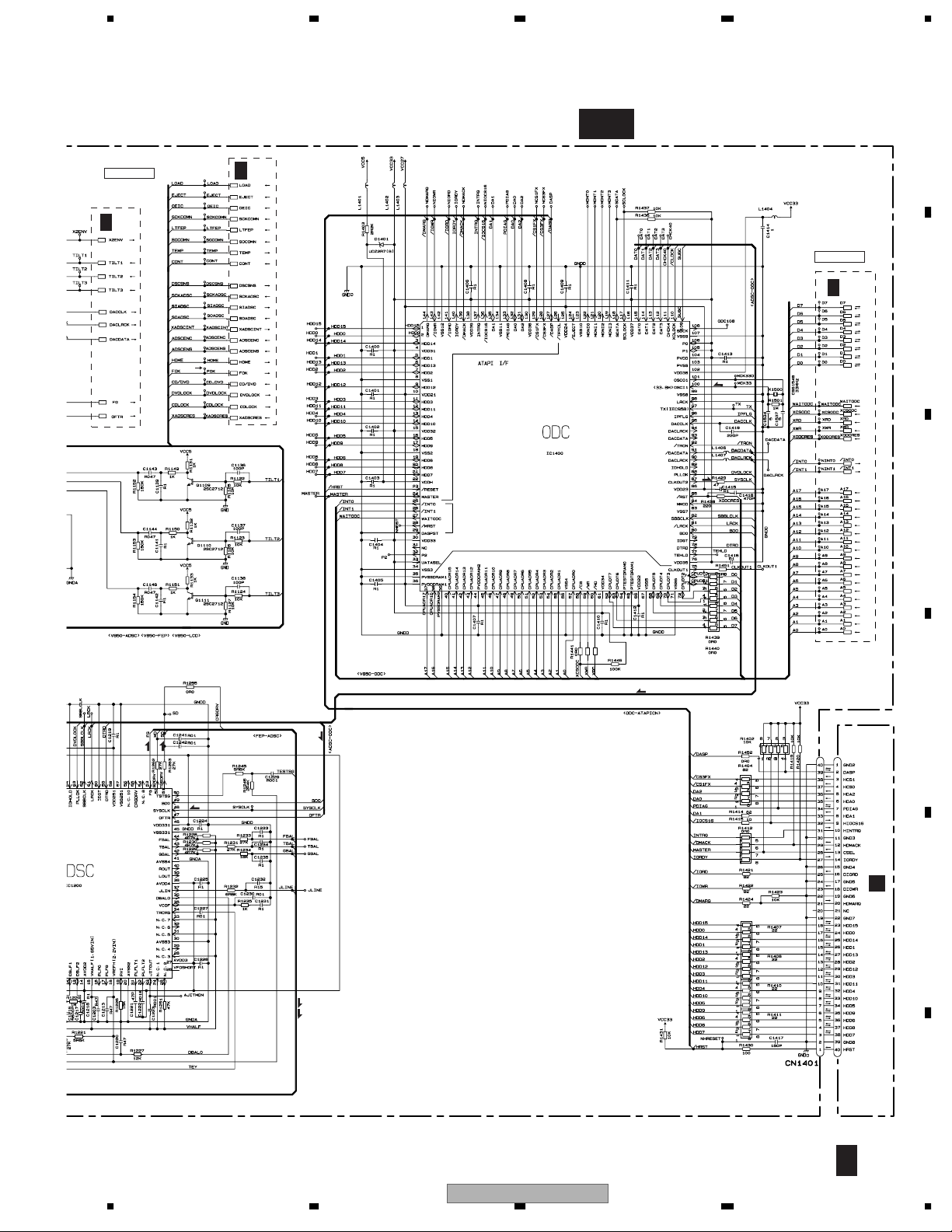

DVD MECHANISM MODULE(1/2)(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A

Large size

A-b

A-b

SCH diagram

Guide page

Detailed page

G

DVD CORE UNIT R(FRONT END)

F

1/2

A-a A-b

A-a

A-a

B

GF-a

RF SIGNAL

F

FOCUS SERVO LINE

T

TRACKING SERVO LINE

C

CARRIAGE SERVO LINE

S

SPINDLE SERVO LINE

CLK

CLOCK LINE

1/2

SERVO-CPU I/F

G

F

2/2

RF AMP BLOCK

2.2V

C

1.65V

PICKUP UNIT(DP4)(SERVICE)

T

F

5.0V

POWER SUPPLY

T

2

5.0V

3.3V

8

2.2V

1.65V

F

3

0

SERVO CONTROLLER BLOCK

D

S

G

F

2/2

8.0V

DISC DETECT SWITCH

T

F

POWER SUPPLY

3.3V

2.7V

MN677061ZYUB

E

F

T

M2

M

SPINDLE

MOTOR

CXC4218

M3

M

CARRIAGE

MOTOR

CXB5955

S

C

S

F

G

F

1/2

10

1234

9

C

S

S

T

C

POWER SUPPLY

8.0V

C

DRIVER BLOCK

M1

M

LOADING

MOTOR

CXC1187

F

AVIC-88DVD/UC

4

F

T

7

6

T

F

1

F

T

S

T

T

C

F

F

7

5678

A

GF-b

1/2

SERVO-CPU I/F

G

F

2/2

G

F

2/2

OPTICAL DISC CONTROLLER BLOCK

ODC-CPU I/F

G

F

2/2

B

5

POWER SUPPLY

3.3V

2.7V

MNZS25BDAUB

I/F

SYSTEM

CONTROLLER

SYSTEM CONTROLLER I/F

CLK

CLK

C

R1442 220

R1443 220

ROLLER BLOCK

WER SUPPLY

3.3V

2.7V

CLK

C

S

CLK

CLK

ATAPI I/F

D

1/6 CN2

7061ZYUB

E

E

C

S

56

AVIC-88DVD/UC

F

G

F

1/2

7

8

11

SERVO CONTROLLER BLOCK

1234

A

B

C

GF-b

1/2

SERVO-CPU I/F

2/2

F

G

1

1.65V

3

2.2V

0

2

1.65V

2.2V

8

GF-b

A-a

GF-a

RF SIGNAL

FOCUS SERVO LINE

TRACKING SERVO LINE

CARRIAGE SERVO LINE

SPINDLE SERVO LINE

C

S

CLOCK LINE

CLK

RF AMP BLOCK

5.0V

3.3V

POWER SUPPLY

D

T

F

DVD CORE UNIT R(FRONT END)

E

1/2

F

G

F

T

5.0V

F

GF-a

12

PICKUP UNIT(DP4)(SERVICE)

1/2

AVIC-88DVD/UC

1234

P

5678

C

S

A

8

2.2V

SERVO CONTROLLER BLOCK

F

T

1.65V

3.3V

2.7V

POWER SUPPLY

MN677061ZYUB

6

3

GF-b

1/2

T

F

F

T

1

C

S

T

T

F

F

B

C

4

7

GF-b

F

T

F

F

T

A-a

GF-a

D

2

T

8.0V

POWER SUPPLY

DRIVER BLOCK

M1

M

MOTOR

CXC1187

C

DISC DETECT SWITCH

F

5.0V

8.0V

9

S

S

T

F

S

C

C

S

C

LOADING

E

2/2

F

G

M3

M2

M

MOTOR

SPINDLE

56

AVIC-88DVD/UC

CXC4218

7

M

MOTOR

CXB5955

CARRIAGE

GF-a

8

1/2

F

13

1234

A

ODC-CPU I/F

B

C

GF-b

GF-a

OPTICAL DISC CONTROLLER BLOCK

2/2

F

G

CLK

CLK

CLK

R1443 220

R1442 220

3.3V

2.7V

POWER SUPPLY

MNZS25BDAUB

SYSTEM CONTROLLER I/F

I/F

CONTROLLER

SYSTEM

D

E

2/2

F

G

5

F

GF-b

1/2

14

2/2

SERVO-CPU I/F

F

G

1

2

AVIC-88DVD/UC

1234

5678

1/6 CN2

E

A

B

ATAPI I/F

CLK

R1443 220

R1442 220

C

GF-b

GF-a

D

CLK

C

S

E

CLK

C

S

ER BLOCK

PLY

YUB

AVIC-88DVD/UC

56

F

3

GF-b

1/2

7

8

15

1234

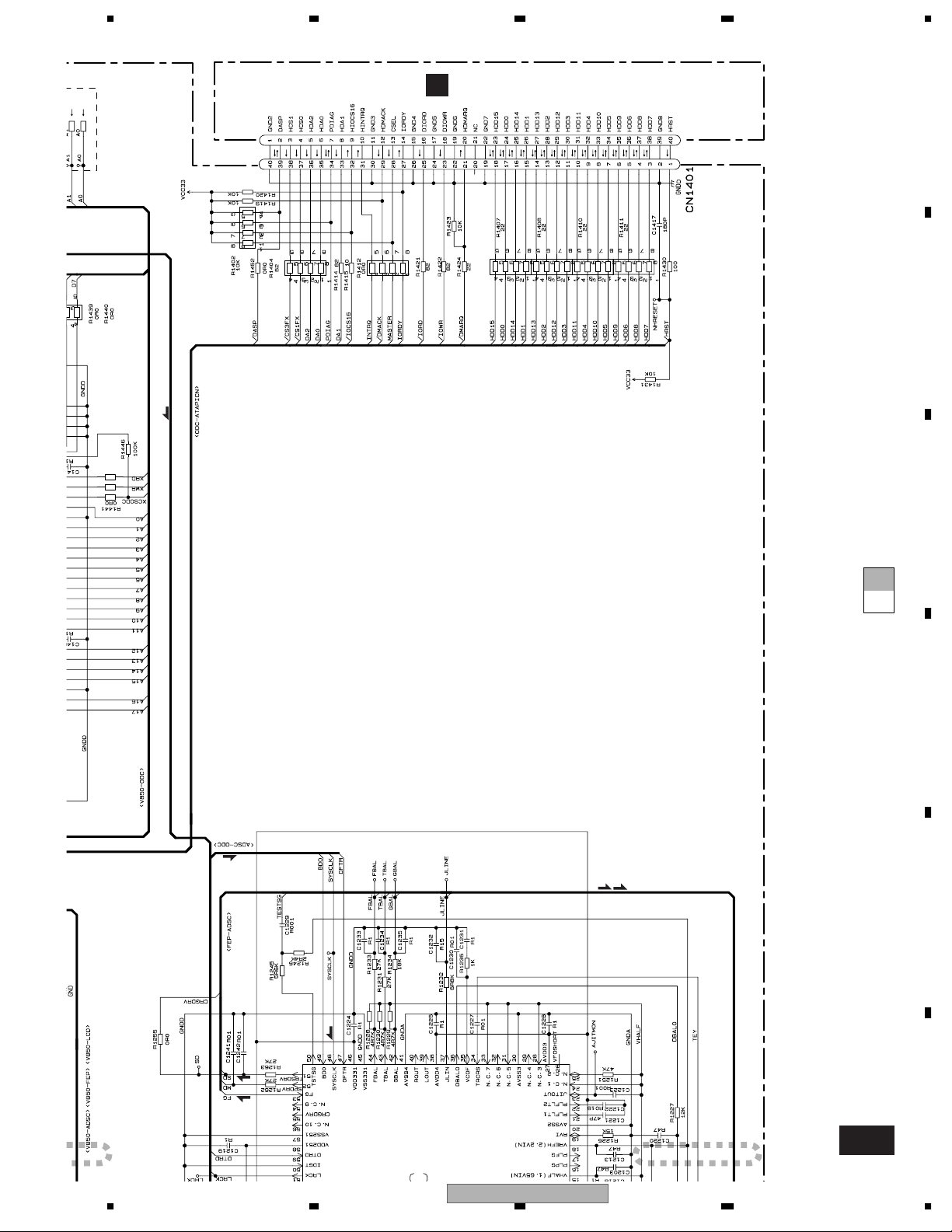

DVD MECHANISM MODULE(2/2)

A

B

4/5 CN3251

A

1/2

F

G

C

PD6378D

1/2

F

3.3V

G

SERVO-CPU I/F

1/2

F

G

1/2

F

G

2.7V

D

POWER SUPPLY

E

1/2

6.3V(5.0V)

F

G

DVD CORE UNIT R(BACK END)

2/2

F

G

F

16

F

G

2/2

1234

1/2

F

G

AVIC-88DVD/UC

3.3V

5678

A

B

PE5324C

POWER SUPPLY 3.3V

CLOCK FREQUENCY 5MHz

C

D

MICRO COMPUTER BLOCK

E

3.3V

56

AVIC-88DVD/UC

F

G

F

2/2

7

8

17

1234

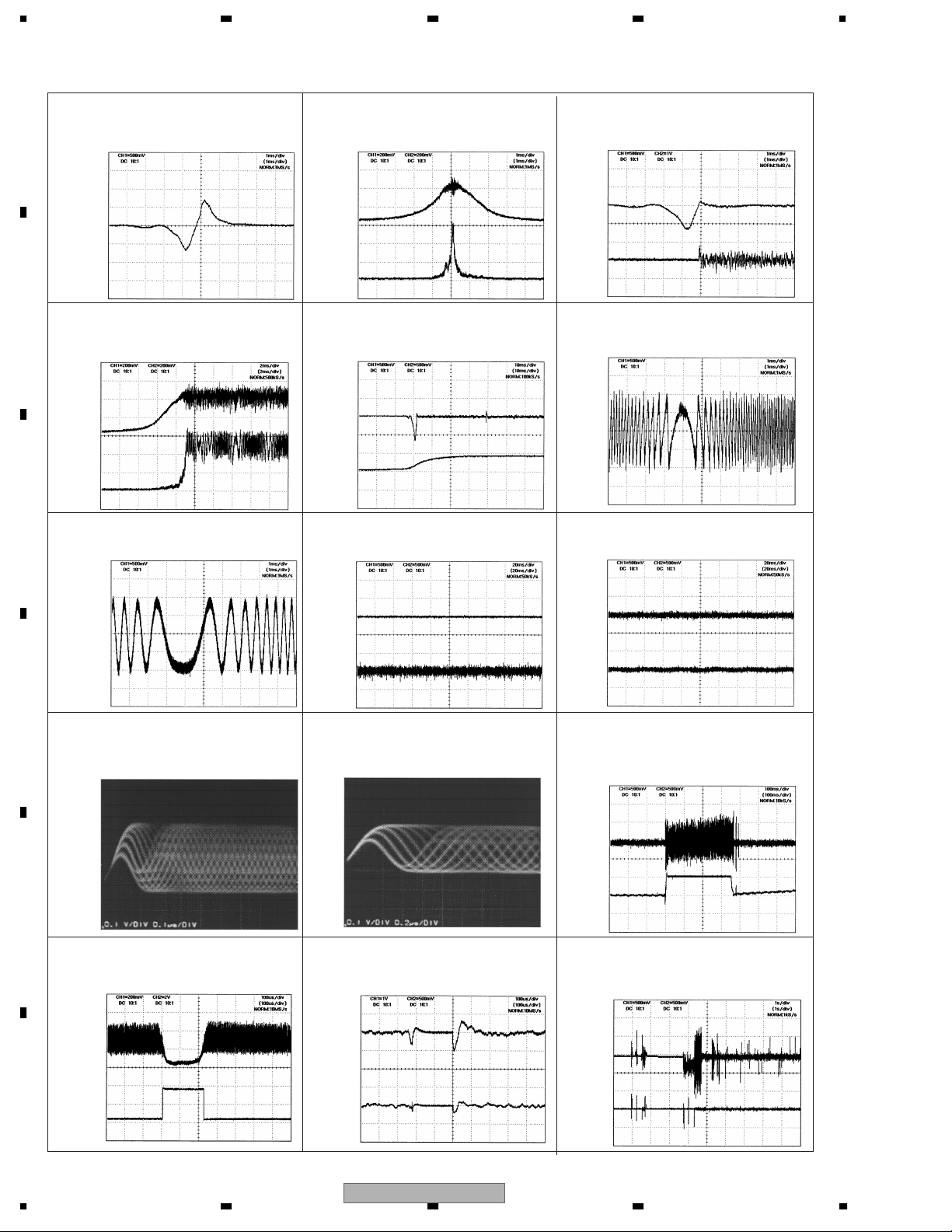

- Waveforms

1 FEY 500mV/div. 1ms/div.

A

B

C

Focus search

VHALF→

2 CH1: ASF

3 CH1: RFENV

200mV/div. 2ms/div.

Focus close

VHALF→

VHALF→

6 CH1: TEY 500mV/div. 1ms/div.

Focus close(CD)

Note:1. The encircled number denote measuring pointes in the circuit diagram.

2.

Reference voltage VHALF : 1.65V

2 CH1: ASF

3 CH2: RFENV

Focus search

VHALF→

VHALF→

1 CH1: FEY

5 CH2: FOK

200ms/div. 1ms/div.

500mV/div. 10ms/div.

1 CH1: FEY 500mV/div. 1ms/div.

4 CH2: FD 1V/div. 1ms/div.

Focus close

VHALF→

VHALF→

6 CH1: TEY 500mV/div. 1ms/div.

Focus close(DVD)

Focus close

VHALF→

VHALF→

1 CH1: FEY

4 CH2: FD

Play

500mV/div.20ms/div.

VHALF→

6 CH1: TEY

7 CH2: TD

Play

500mV/div.20ms/div.

VHALF→

D

8 CH1: RFOUT 0.1V/div. 0.1µs/div.

Play(DVD surroundings on inside)

E

8 CH1: RFOUT 200mV/div. 100µs/div.

0 CH2: BDO 2V/div. 100µs/div.

Black dot

VHALF→

VHALF→

VHALF→

8 CH1: RFOUT 0.1V/div. 0.2µs/div.

Play(CD)

4 CH1: FD 1V/div. 100µs/div.

7 CH2: TD 500mV/div. 100µs/div.

Black dot

VHALF→

VHALF→

VHALF→

6 CH1: TEY

500mV/di v. 100ms/div .

9 CH2: CRGDRV

Surroundings on inside->

surroundings on outside

VHALF→

VHALF→

6 CH1: TEY

1 CH2: FEY

500mV/div.1s/div.

EDC1 mode set up(DVD)

VHALF→

VHALF→

F

18

1234

VHALF→

VHALF→

AVIC-88DVD/UC

5678

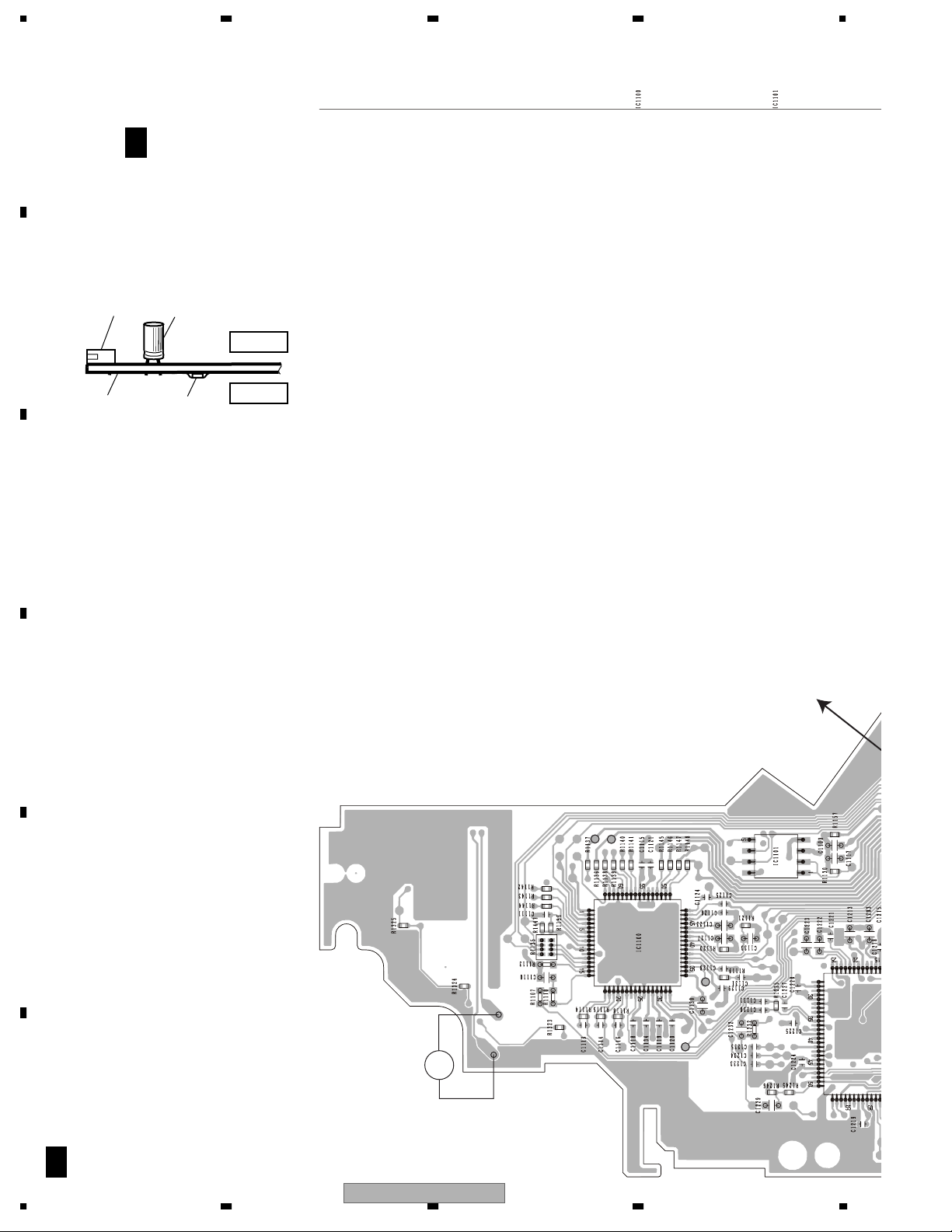

PU UNIT(REFERENCE)

A

SHORT

LAND

F1/2

G

CN1100

B

C

D

56

AVIC-88DVD/UC

E

F

7

8

19

1234

PCB CONNECTION DIAGRAM

DVD CORE UNIT R

A

DVD CORE UNIT R

F

G

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

B

C

Connector

P.C.Board

Capacitor

Chip Part

SIDE A

SIDE B

IC,Q

D

A

C

E

RFOUT

M1

F

VHALF1

(DP4)

(SERVICE)

PICKUP UNIT

20

G

F

AVIC-88DVD/UC

1234

5678

M3

GND1

SIDE A

A

CN3251

A

B

C

(SERVICE)

M2

D

VREF1

E

56

AVIC-88DVD/UC

CN2

E

F

F

G

7

8

21

1234

DVD CORE UNIT R

F

A

B

G

C

D

E

L/E ON/OFF

F

F

G

22

1234

AVIC-88DVD/UC

5678

IC,Q

SIDE B

A

B

C

12cm DETECT

8cm DETECT

D

CLAMP

E

F

56

AVIC-88DVD/UC

F

G

7

8

23

1234

ELECTRICAL PARTS LIST

NOTE:

A

• Parts whose parts numbers are omitted are subject to being not supplied.

• The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

Circuit Symbol and No. Part No.

B

F

G

Unit Number:CWX2576

Unit Name:DVD Core Unit R

MISCELLANEOUS

IC 1100 IC AN8702FH

IC 1101 IC NJM2904M

IC 1200 IC MN677061ZYUB

IC 1300 IC BA5985FM

IC 1400 IC MNZS25BDAUB

C

IC 1700 IC PE5324C

IC 1701 IC M5M5V216ATP-70HI

IC 1702 IC PD6378D

IC 1703 IC TC7SH04FU

IC 1704 IC TC7SH08FU

IC 1705 IC TC7SH32FU

IC 1801 IC BA05SFP

IC 1802 IC BA033SFP

IC 1804 IC BA00BC0WFP

Q 1102 Transistor 2SD601A

D

Q 1104 Transistor 2SB1260

Q 1105 Transistor 2SB709A

Q 1107 Transistor UN2211

Q 1108 Transistor 2SB1260

Q 1109 Chip T r ansistor 2SC2712

Q 1110 Chip T r ansistor 2SC2712

Q 1111 Chip T r ansistor 2SC2712

Q 1700 Transistor DTA123JK

D 1100 Diode 1SS355

D 1101 Diode 1SS355

D 1401 Diode UDZ2R7(B)

E

D 1800 Diode S2G-6600

D 1801 Diode S2G-6600

D 1802 Diode S2G-6600

D 1803 Diode S2G-6600

L 1201 Inductor CTF1295

L 1202 Inductor CTF1295

L 1401 Inductor CTF1399

L 1402 Inductor CTF1399

L 1403 Inductor CTF1395

L 1404 Inductor CTF1410

L 1406 Inductor CTF1410

F

L 1407 Inductor CTF1410

L 1700 Inductor CTF1395

L 1701 Inductor CTF1399

24

1234

Circuit Symbol and No. Part No.

L 1702 Inductor CTF1473

L 1704 Inductor CTF1410

L 1705 Inductor CTF1470

L 1706 Inductor CTF1470

L 1707 Inductor CTF1470

L 1708 Inductor CTF1470

L 1709 Inductor CTF1470

L 1710 Inductor CTF1470

L 1711 Inductor CTF1470

L 1712 Inductor CTF1470

L 1713 Inductor CTF1470

L 1714 Inductor CTF1470

L 1715 Inductor CTF1470

L 1720 Inductor CTF1410

X 1500 Radiator 33.8688MHz CSS1548

X 1700 Ceramic Resonator 4.97MHz CSS1547

S 1301 Spring Switch(CLAMP) CSN1051

S 1302 Spring Switch(L/E ON/OFF) CSN1051

S 1303 Spring Switch(8cm DETECT) CSN1051

S 1304 Spring Switch(12cm DETECT)CSN1051

RESISTORS

R 1102 RS1/16SS3R9J

R 1104 RS1/16SS3R9J

R 1105 RS1/16SS122J

R 1106 RS1/16SS472J

R 1107 RS1/16S6201D

R 1108 RS1/16SS3R9J

R 1109 RS1/16SS3R9J

R 1110 RS1/16S1002D

R 1113 RS1/16S2402D

R 1114 RS1/16SS823J

R 1115 RS1/16SS682J

R 1116 RS1/16SS3R9J

R 1117 RS1/16SS3R9J

R 1118 RS1/16SS223J

R 1119 RS1/16SS202J

R 1120 RS1/16SS105J

R 1121 RS1/16SS105J

R 1122 RS1/16SS103J

R 1123 RS1/16SS103J

R 1124 RS1/16SS103J

R 1125 RS1/16SS103J

R 1126 RS1/16SS103J

R 1127 RS1/16SS103J

R 1128 RS1/16SS3R9J

R 1129 RS1/16SS3R9J

R 1130 RS1/16SS102J

R 1131 RS1/16SS102J

AVIC-88DVD/UC

5678

Circuit Symbol and No. Part No.

R 1132 RS1/16SS102J

R 1133 RS1/16SS102J

R 1134 RS1/16SS102J

R 1135 RAB4CQ0R0J

R 1136 RS1/16SS133J

R 1137 RS1/16SS133J

R 1138 RS1/16SS0R0J

R 1139 RS1/16SS0R0J

Circuit Symbol and No. Part No.

R 1255 RS1/16SS0R0J

R 1257 RS1/16S221J

R 1258 RAB4CQ221J

R 1262 RS1/16SS273J

R 1263 RS1/16SS273J

R 1264 RS1/16SS104J

R 1301 RS1/16S3902D

R 1302 RS1/16S3902D

A

R 1140 RS1/16SS0R0J

R 1141 RS1/16SS0R0J

R 1142 RS1/16SS183J

R 1143 RS1/16SS273J

R 1144 RS1/16SS273J

R 1145 RS1/16SS0R0J

R 1146 RS1/16SS0R0J

R 1147 RS1/16SS0R0J

R 1148 RS1/16SS0R0J

R 1149 RS1/16SS102J

R 1150 RS1/16SS102J

R 1151 RS1/16SS102J

R 1152 RS1/16SS154J

R 1153 RS1/16SS154J

R 1154 RS1/16SS154J

R 1156 RS1/16SS224J

R 1157 RS1/16SS0R0J

R 1158 RS1/16SS330J

R 1159 RS1/16SS330J

R 1201 RS1/16SS203J

R 1202 RS1/16SS102J

R 1203 RS1/16SS471J

R 1204 RS1/16S0R0J

R 1205 RS1/16SS222J

R 1206 RS1/16SS473J

R 1303 RS1/16S3002D

R 1304 RS1/16S3902D

R 1305 RS1/16SS221J

R 1306 RS1/16SS0R0J

R 1307 RS1/16SS221J

R 1308 RS1/16S3002D

R 1310 RS1/16SS102J

R 1311 RS1/16S3902D

R 1312 RS1/16S0R0J

R 1314 RS1/16SS221J

R 1321 RS1/16SS221J

R 1323 RS1/16SS104J

R 1324 RS1/16SS473J

R 1325 RS1/16SS273J

R 1402 RAB4CQ103J

R 1403 RS1/16SS222J

R 1404 RAB4CQ820J

R 1407 RAB4CQ220J

R 1408 RAB4CQ220J

R 1410 RAB4CQ220J

R 1411 RAB4CQ220J

R 1412 RAB4CQ0R0J

R 1414 RS1/16SS820J

R 1415 RS1/16SS100J

R 1419 RS1/16SS103J

B

C

R 1207 RS1/16SS101J

R 1208 RS1/16SS101J

R 1209 RS1/16SS473J

R 1212 RS1/16SS473J

R 1213 RS1/16SS101J

R 1215 RS1/16SS123J

R 1216 RS1/16SS473J

R 1219 RS1/16SS123J

R 1220 RS1/16SS105J

R 1221 RS1/16SS562J

R 1222 RS1/16SS273J

R 1223 RS1/16SS273J

R 1226 RS1/16SS153J

R 1227 RS1/16SS123J

R 1228 RS1/16SS472J

R 1229 RS1/16SS472J

R 1230 RS1/16SS472J

R 1231 RS1/16SS273J

R 1232 RS1/16S6801D

R 1233 RS1/16SS273J

R 1234 RS1/16SS183J

R 1235 RS1/16SS102J

R 1242 RAB4CQ221J

R 1243 RAB4CQ221J

R 1245 RS1/16SS562J

R 1420 RS1/16SS103J

R 1421 RS1/16SS820J

R 1422 RS1/16SS820J

R 1423 RS1/16SS103J

R 1424 RS1/16SS220J

R 1429 RS1/16S470J

R 1430 RS1/16SS101J

R 1431 RS1/16SS103J

R 1436 RS1/16SS103J

R 1437 RS1/16SS103J

R 1438 RS1/16SS221J

R 1439 RAB4CQ0R0J

R 1440 RAB4CQ0R0J

R 1441 RS1/16SS0R0J

R 1442 RS1/16SS221J

R 1443 RS1/16SS221J

R 1446 RS1/16SS104J

R 1447 RS1/16SS104J

R 1451 RS1/16S0R0J

R 1452 RS1/16SS0R0J

R 1501 RS1/16SS105J

R 1701 RN1/16SE1502D

R 1702 RS1/16SS0R0J

R 1703 RS1/16SS221J

R 1704 RS1/16SS104J

D

E

F

R 1246 RS1/16SS242J

R 1251 RS1/16SS473J

56

R 1705 RS1/16SS103J

R 1706 RS1/16SS103J

AVIC-88DVD/UC

7

8

25

1234

Circuit Symbol and No. Part No.

R 1707 RS1/16SS104J

R 1708 RS1/16SS0R0J

R 1709 RS1/16SS104J

A

R 1710 RS1/16SS473J

R 1711 RS1/16SS221J

R 1712 RS1/16SS104J

R 1713 RS1/16SS104J

R 1714 RS1/16SS104J

R 1715 RS1/16SS472J

R 1716 RS1/16SS104J

R 1717 RS1/16SS473J

R 1718 RS1/16SS104J

R 1719 RS1/16SS104J

B

R 1720 RS1/16SS473J

R 1721 RS1/16SS104J

R 1722 RS1/16SS104J

R 1723 RS1/16SS473J

R 1724 RS1/16SS221J

R 1726 RS1/16SS104J

R 1727 RS1/16SS103J

R 1728 RS1/16SS104J

R 1729 RS1/16SS104J

R 1730 RS1/16SS473J

R 1731 RS1/16SS221J

C

R 1732 RS1/16SS221J

R 1733 RS1/16SS104J

R 1734 RS1/16SS104J

R 1735 RS1/16SS222J

R 1736 RS1/16SS221J

R 1737 RS1/16SS221J

R 1738 RS1/16SS104J

R 1739 RS1/16SS103J

R 1740 RS1/16SS103J

R 1742 RS1/16SS104J

R 1747 RS1/16SS222J

D

R 1748 RS1/16SS473J

R 1749 RS1/16SS104J

R 1750 RS1/16SS472J

R 1751 RS1/16SS103J

R 1752 RS1/16SS104J

R 1756 RS1/16SS473J

R 1757 RS1/16SS472J

R 1762 RS1/16SS104J

R 1763 RS1/16SS104J

R 1764 RS1/16SS104J

R 1766 RS1/16SS104J

E

R 1771 RS1/16SS104J

R 1772 RS1/16SS104J

R 1773 RS1/16SS104J

R 1774 RS1/16SS473J

R 1775 RS1/16SS221J

R 1776 RS1/16SS104J

R 1777 RS1/16SS104J

R 1801 RS1/16S3902D

R 1802 RS1/16S3302D

R 1808 RS1/16SS102J

R 1809 RS1/16SS102J

F

R 1810 RS1/16S0R0J

CAPACITORS

26

1234

AVIC-88DVD/UC

Circuit Symbol and No. Part No.

C 1100 CKSR YB105K10

C 1101 CKSR YB473K25

C 1102 CKSSYB103K16

C 1103 CSZSR101M6R3

C 1104 CKSSYB104K10

C 1105 CKSSYB104K10

C 1106 CKSR YB473K25

C 1107 CKSSYB103K16

C 1108 CSZSR101M6R3

C 1109 CKSSYB104K10

C 1110 CKSR YB154K10

C 1111 CCSSCH221J25

C 1114 CCSSCH330J50

C 1115 CKSSYB104K10

C 1116 CCSSCH221J25

C 1117 CKSR YB105K10

C 1118 CKSSYB104K10

C 1119 CKSSYB104K10

C 1120 CKSSYB104K10

C 1121 CKSSYB104K10

C 1122 CSZSC470M16

C 1123 CKSR YB273K25

C 1124 CKSSYB104K10

C 1125 CKSSYB104K10

C 1126 CKSSYB473K10

C 1127 CCSRCH561J50

C 1128 CKSSYB104K10

C 1129 CKSSYB104K10

C 1130 CCSRCH102J50

C 1131 CCSSCH120J50

C 1133 CCSRCH561J50

C 1134 CKSSYB104K10

C 1136 CCSSCH101J50

C 1137 CCSSCH101J50

C 1138 CCSSCH101J50

C 1139 CKSSYB104K10

C 1140 CKSSYB103K16

C 1141 CKSSYB104K10

C 1142 CKSSYB104K10

C 1143 CKSSYB473K10

C 1144 CKSSYB473K10

C 1145 CKSSYB103K16

C 1146 CKSSYB473K10

C 1148 CKSSYB103K16

C 1201 CKSR YB105K10

C 1202 CCSSCH101J50

C 1203 CKSR YB474K10

C 1204 CCSRCH561J50

C 1205 CCSRCH331J50

C 1206 CKSR YB105K10

C 1207 CKSSYB104K10

C 1208 CCSRCH471J50

C 1209 CCSRCH391J50

C 1210 CKSR YB105K10

C 1211 CCSSCH101J50

C 1212 CKSSYB104K10

C 1213 CKSR YB474K10

C 1214 CCSRCH102J50

C 1215 CCSRCH102J50

C 1216 CKSSYB562K25

5678

Circuit Symbol and No. Part No.

Circuit Symbol and No. Part No.

C 1217 CCSRCH102J50

C 1218 CKSSYB104K10

C 1219 CKSSYB104K10

C 1220 CKSR YB474K10

C 1221 CCSSCH470J50

C 1222 CKSR YB183K25

C 1223 CCSRCH102J50

C 1224 CKSSYB104K10

C 1225 CKSSYB104K10

C 1227 CKSSYB103K16

C 1228 CKSSYB104K10

C 1229 CCSRCH102J50

C 1230 CKSSYB103K16

C 1231 CKSSYB104K10

C 1232 CKSR YB154K10

C 1233 CKSSYB104K10

C 1234 CKSSYB104K10

C 1235 CKSSYB104K10

C 1236 CKSSYB471K50

C 1241 CKSSYB103K16

C 1242 CKSSYB103K16

C 1243 CKSSYB104K10

C 1300 CKSSYB103K16

C 1301 CKSSYB103K16

C 1304 CKSR YB104K16

C 1305 CEV101M16

C 1308 CKSSYB104K10

C 1400 CKSSYB104K10

C 1401 CKSSYB104K10

C 1402 CKSSYB104K10

C 1711 CKSSYB104K10

C 1712 CKSSYB103K16

C 1714 CKSYB106K6R3

C 1715 CKSSYB104K10

C 1719 CKSSYB471K50

C 1720 CKSSYB103K16

C 1721 CKSSYB104K10

C 1722 CKSSYB103K16

C 1728 CKSSYB104K10

C 1729 CKSSYB104K10

C 1730 CKSSYB104K10

C 1753 CKSR YB104K16

C 1801 CKSR YB474K10

C 1802 CKSR YB474K10

C 1803 CKSR YB474K10

C 1804 22µF/6.3V CCH1300

C 1805 22µF/6.3V CCH1300

C 1808 CSZSC101M10

C 1810 CCSRCH102J50

C 1812 CSZSC101M10

Miscellaneous Parts List

Pickup Unit(DP4)(Service) CXX1530

M 1 Motor Unit(LOADING) CXC1187

M 2 Motor Unit(CARRIAGE) CXC4218

M 3 Motor Unit(SPINDLE) CXB6218

A

B

C

C 1403 CKSSYB104K10

C 1404 CKSSYB104K10

C 1405 CKSSYB104K10

C 1406 CKSSYB104K10

C 1407 CKSSYB104K10

C 1408 CKSSYB104K10

C 1409 CKSSYB104K10

C 1410 CKSSYB104K10

C 1411 CKSSYB104K10

C 1412 CKSSYB104K10

C 1413 CKSSYB104K10

C 1414 CKSR YB105K10

C 1415 CKSSYB104K10

C 1416 CKSSYB104K10

C 1417 CCSSCH181J25

C 1418 CKSSYB471K50

C 1419 CCSSCH221J25

C 1534 CCSSCH5R0C50

C 1537 CCSSCH5R0C50

C 1700 CKSSYB104K10

C 1701 CKSSYB104K10

C 1702 CKSSYB104K10

C 1703 CKSSYB104K10

C 1704 CKSSYB104K10

C 1705 CKSSYB104K10

D

E

C 1706 CKSSYB104K10

C 1707 CKSR YB105K10

C 1708 CKSSYB104K10

C 1709 CKSSYB104K10

C 1710 CKSSYB104K10

56

AVIC-88DVD/UC

F

7

8

27

1234

ADJUSTMENT

DVD ADJUSTMENT

Cautions for servicing

A

This product uses 5V and 3.3V as standard voltages.

The electrical potential that is the reference for signals,

is not GND, but VREF (approximately 2.2V) and VHALF

(approximately 1.65V).

During product adjustments, if the reference voltage is

mistakenly taken as GND, and a grounding contact is

made, not only would it be impossible to measure the

accurate electrical potential, but also the servo motor

would malfunction, resulting in the application of a

strong impact on the pick up. The following precautionary measures should be strictly adhered to, in order to

B

avoid such problems.

The reference voltage and GND should not be confused

when using the minus probe of a measurement device.

When an oscilloscope is being used special care should

be taken to make sure that the reference voltage is not

connected to the probe of ch1 (on the minus side),

while the probe of ch2 (on the minus side), is connected

to GND. Further, since the body frame of most measurement devices have the same electrical potential as

the minus side of the probe, the body frame of the measurement device should be set to floating ground.

C

If the reference voltage is connected to GND by mistake, turn the regulator OFF immediatel y, or turn the

power OFF.

• Remove the filters and wires used for measurements

only after the regulator has been turned OFF.

• After the power supply is turned on, regulator ON the

following adjustment and measurement are promptly

done.

• Whenever the product is in the test mode, the software

will not take any protective action. For this reason,

special care should be taken to make sure that no

mechanical or electrical shock could be applied to the

product when taking measurements in the test mode.

• Whenever the EJECT key is pressed to eject the disk,

no other keys, other than the EJECT key, should be

pressed until the disk eject action has been completed.

• Press the EJECT key only after the disk has stopped

completely.

• If the product hangs up turn the power OFF immediately.

• Laser didoes may be damaged, if the volume switch for

the laser power adjustment of the pick up unit, is turned.

• Test mode starting procedure

The test mode can be selected from the navigation

test mode.

Please use the " remote control unit of the product

accessory" after the test mode starts.

D

E

F

28

1234

AVIC-88DVD/UC

5678

- Front-End test mode flow chart

FE offset coefficient

TE offset coefficient

AS offset coefficient

ENV offset coefficient

TG offset coefficient

DBALt coefficient

FE MAX level

FE MIN level

AS MAX level

ENV MAX level

FE normalization feature

Spindle gain coefficient

TBAL Coefficient

GBAL Coefficient

TE normalization feature

FBAL Coefficient

Focus Gain Coefficient

Tracking Gain Coefficient

AS normalization adjustment feature

Test mode In

Start test mode

Note 1: At this stage select the media type. Various settings are carried out

according to the media selection made here.

Note 2: While measurements are being taken, only the operation, for which

Set source to DVD

the measurement is being taken, is allowed.

Note 3: Reproduction (play) speed is selectable from: DVD x 1CAV ↔ x 1CLV,

TEST

CD x 2CLV ↔x 1CLV

123

FE

test mode

0000 0000

1

Power On

EDC1

mode

2~5 EJECT

Disc T ype

EDC2

mode

Power off condition

Eject

(Note 1)

0FFF 00000FFF 0000

1X00 0000

81

Power Off CRG +

Focus close

adjustment

1FFF 0000

1A00 0000

1100 0000

0X00 0000

2

Focus Search

2

Focus Search

Stop

34

CRG — LD_ON

81234

Power Off CRG +

T.Bal and

other

Focus Jump

CRG —

adjustments

2FFF 0000

8134

3000 0000

Power Off CRG —

Tracking close

Layer L0:2000 0000

Layer L1:2100 0000

CRG +

Operation while key is being pushed.

2B00 0000 2C00 0000

Operation while key is being pushed.

Focus close condition 2

adjustment

3FFF 0000

4000 0000

4X00 0000

812 5 6 73, 4

Power Off

Error Rate

measurement

(Note 2)

Error Rate

Focus Gain Coefficient

Tracking Gain Coefficient

AS normalization adjustment feature

3B00 0000

Reproduction

speed switching

(Note 3)

DVD x CAV

orCD x 2CLV:

4X00 0000

DVD x 1CAV

orCD x 1CLV:

4X00 0000

Layer L0:4X00 0000

Layer L1:4X00 0000

*Please refer to the next page for the

method of specfying ID.

Operation while key is being pushed.Operation while key is being pushed.

3C00 0000

Focus Jump

ID Search Tracking

4A00 0000

1~4

ID

specification

ID display

5

ID

Search Start

2 : DVD, single-layer

3 : DVD, dual-layer

4 : CD

5 : CD-RW

Power on condition

5

6

CRG_HOME

F-close and F-search cannot be executed, unless LD-ON is set.

[If F-close isn't executed within 9 seconds after LD-ON,

it switches to LD-OFF automatically. And even if F-search is executed

within 9 seconds after LD-ON, it also switches to LD-OFF

.]

Focus close condition 1

Tracking close condition

T. Jump

+/—

Jump+:

3

4B00 0000

Track number

specification

Track

number

display

4

Open

The track number designation is selected

from the track numbers already prepared

for selection.

Switching to cyclic operation is made at step

4, 3, and the decision is finalized (entered)

in step For CD: Tracks 1, 4, 10, 11 and 32.

For DVD: Tracks 1, 4, 10, 11, 32, 64 and 100.

Jump start

A

B

C

D

E

56

AVIC-88DVD/UC

F

7

8

29

1234

EDC1

mode

0000 0000 0000 0000

A

12 12

Layer 0

selected

0000 0000

1003 0000

Layer 1

selected

0100 0000

1103 0000

1~4

ID

designation

Layer0:10** ****

Layer1:11** ****

** ****: ID specification value

5

B

EDC1 start

Layer0:20** ****

Layer1:21** ****

** ****: Present ID value

1~4

designation

5

EDC2

mode

Layer 0

selected

0000 0000

1003 0000

ID

EDC2 start

Layer 1

selected

0100 0000

1103 0000

Layer0:10** ****

Layer1:11** ****

** ****: ID specification value

Layer0:20** ****

Layer1:21** ****

** ****: Present ID value

Method for designating an ID address:

C

• A number of digits are determined through commands 1 and 2. Numerical UP/DOWN operations are performed

through commands 3 and 4. The decision is finalized (entered) with command 5.

OSD display

Error Code List

Error status from

DVD micurocomputer Contents Display

0X50 Mecha. error No dislay

0X40 No disc No dislay

0X30 The temperature is abnormal Thermal Protection in Motion

0X20 Read error Error-02-XX

D

0XE2 Non-playable disc NON-PLAYABLE DISC

0X90

0XFF Undefined error Error-FF

Error code of read error(Part of XX)

Error Code Contents Display

0X99 Data cannot read Please condirm the disc

0X80 The address cannot be found Please condirm the disc

E

0X90 Focus error Please condirm the disc

0X91 Spindle lock NG DVD is stopping because mechanism detected abnormality

0X92 Carrige home NG DVD is stopping because mechanism detected abnormality

0X93 FOK error Please condirm the disc

0X94 ID/Subcode cannot be read Please condirm the disc

0X95 High spindle rotation Please condirm the disc

0X96 Row spindle rotation DVD is stopping because mechanism detected abnormality

0X98 TOC cannot be found Please condirm the disc

0X9A AV chip error DVD is stopping because mechanism detected abnormality

0X9B RecaveryNG(BE) DVD is stopping because mechanism detected abnormality

Drrerent region disc

DFFERENT REGION DISC

F

30

1234

AVIC-88DVD/UC

5678

- Skew adjustment

If any of the following replacements have been performed on the system, adjustments for pick up, must be conducted:

1. Pick up unit replacement

2. Spindle motor replacement

3. Carriage chassis replacement

4. Pick up unit main shaft replacement

5. Pick up unit sub-shaft replacement

Measurement device and tools : Oscilloscope

Allen key wrench

40-pin flexible extension

Adhesive material(GEM1033)

Screw rock(GYL1001)

Disk used : GGV1018

Measurement reference : GND1

Measurement point : RFOUT

A

B

C

Skew adjustment connection diagram

• DVD Core Unit R

IC1100

RFOUT

GND1

D

OSCILLOSCOPE

E

56

AVIC-88DVD/UC

F

7

8

31

1234

-4

Symptoms that can occur if proper adjustments are not made: Error rate reaches 10 (10 or less under normal condi-

-3

tions).

The RF jitter becomes more pronounced - the RF waveform becomes deformed.

Retraction of the tracking and the servo motor, become unstable.

A

Cautions for performing adjustments: Do not look directly into the laser beam for any prolonged periods of time.

Procedure:

1. Replace the cable, connecting the product's main unit and the DVD mechanical module, with a 40-pin extended flexible cable (GGD1170), and turn the DVD mechanical module upside down, in order to proceed with pick-up unit adjustments.

2. Remove adhesive materials from the pick-up unit, using tweezers.

(Note) Make sure that adhesive material fragments are not scattered while removing the adhesive from the unit. Be

also very careful not to exert excessive force on the actuator.

3. Connect the unit to an oscilloscope, referring to the connection diagram.

4. Turn the product power ON, and load the disk for adjustments (GGV1018).

5. Set the disk type to single-layer DVD in the front-end test mode, turn the power ON and then move the pick-up to

B

the middle radius.

6. LD ON.

7. Close in the focus(Do not carry out 'T.Bal adjustment' and 'Tracking close'.)

8. Maximize the level by slightly turning the skew adjustment screw A, while looking at the RF waveform level on the

oscilloscope.

Next, maximize the level by turning the skew adjustment screw B, slightly. Repeat this procedure three times and

adjust the unit to attain a maximum level.

9. Turn the power OFF in the test mode, and eject the disk after verifying that it has stopped spinning.

10. Apply adhesive and screw lock materials, to the locations specified in the pick-up diagram (shown below).

Apply the adhesive material to secure the resin components on the pick-up chassis.

Apply the screw lock material to secure the screws on the pick-up chassis.

Do not apply any of these materials to the pick-up section or mechanical sections, which are not specified.

C

Keep the unit away from vibration or shock until the materials securely fix the components and screws in place.

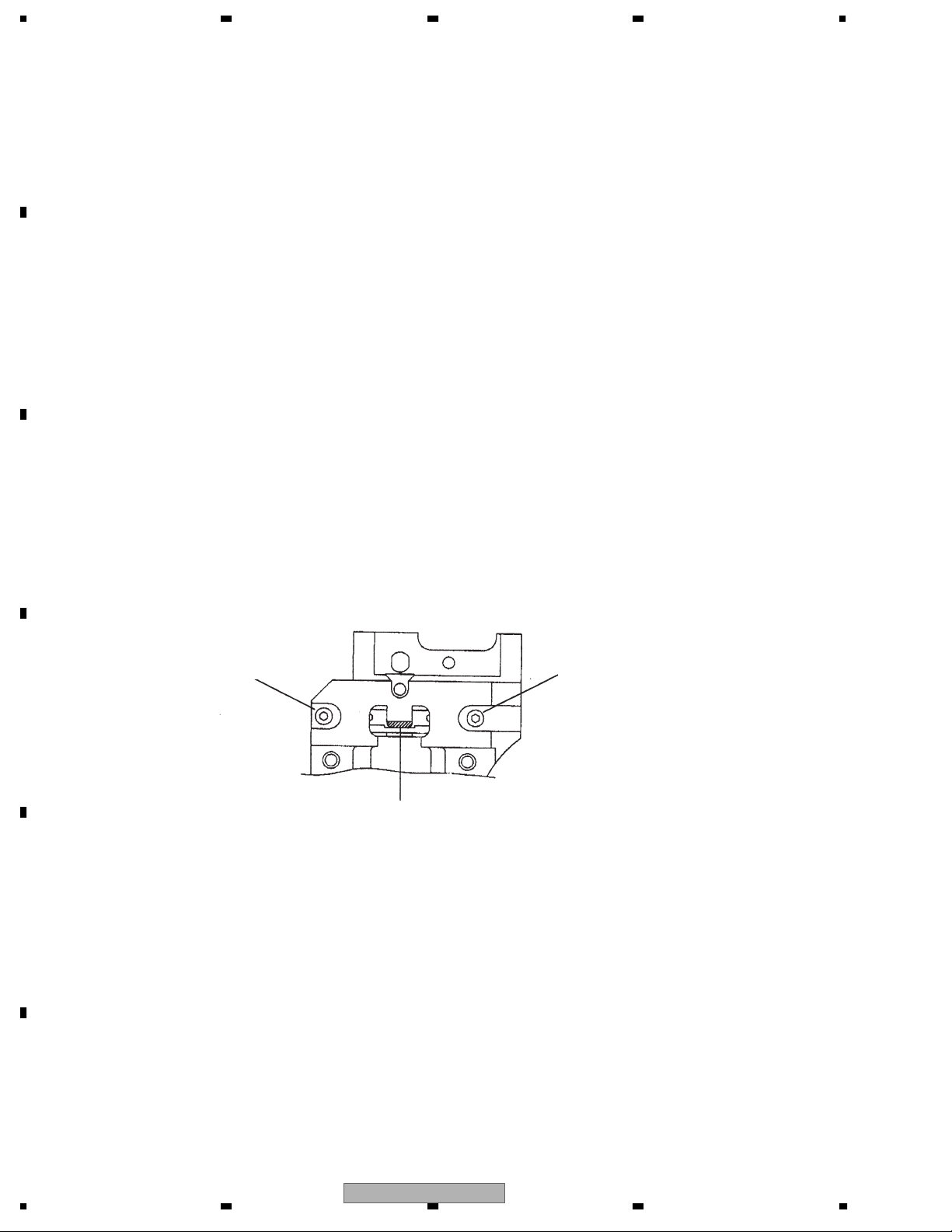

PU diagram

Skew adjustment screw A

Screw rock(GYL1001)

D

Adhesive material

(GEM1033)

E

Skew adjustment screw B

Screw rock(GYL1001)

F

32

1234

AVIC-88DVD/UC

5678

GENERAL INFORMATION

DIAGNOSIS

DISASSEMBLY

- Handling the mechanical module

1. The mechanical module should be handled by holding

the upper frame and main frame of the mechanical module.

2. The front section of the upper frame is not very sturdy,

so this section should not be held too firmly (see fig.1).

A

B

- Removing the DVD Core Unit R

1. Bring the mechanism to a locked position (disk load

standby position).

2. Turn the mechanical module upside down.

3. Set the pick-up flexible cable to a shorted position on

the land end (the other is auxiliary), and turn the SW

knob in the direction opposite to OP (see fig.2).

4. Remove the pick-up flexible cable and the CRG flexible

cable from the connector. Remove the solder on the

lead wires of the load motor.

5. Remove screws at two locations, and remove the DVD

Core Unit R (lift the board in the direction of the white

arrow shown in fig.3, and remove it out diagonally).

Do not hold onto this area.

Auxiliary

land

DVD Core Unit R

Fig.1

Short

C

Fig.2

D

Fig.3

- Removing the PU unit (see fig.4)

1. Lift the pick-up rack to the center of the axis of the rack,

turn it 90 degrees first, then press on it lightly, and fix it

in place temporarily.

2. Remove the screw that keeps the main shaft clamp

spring in place, and remove the main shaft clamp

spring.

3. Remove the PU unit with the main shaft attached.

AVIC-88DVD/UC

56

Main shaft

clamp spring

PU rack

CRG motor

7

PU unit

Main shaft

Fig.4

8

E

F

33

A

1234

IC

*PE5324C

XAVINT, XADSCINT,

B

XADSCRES, XAVRES,

LOCKDET, CRGSENS,

TILT1/TILT, TILT3/CLOCK,

XODCRES, AVREFOFF

C

OPENSENS, EJECTSENS,

CRGADIN, FOK, RFENV,

NMI

RESERVED, CTS

DTR

EDCF, TMODE,

LTFEP

OFTR

SOCOMN

SICOMN

SCKCOMN

SLVSTS

HSTCMD

LTDA C

TXPC

RXPC

SOADSC

SIADSC

SCKADSC

LCDRFOFF

TILT2/BIAS

DISCSENS, TEMP

AVREF

AVSS

IRQPWR

INTC

RPU

SIO

UART0/CSI0

UART1/CSI1

UART2

CSI2

PWM0

PWM1

ADC

ROM

256k

BYTE

RAM

10k

BYTE

PC

32bit

Ballel Sifter

System

Register

General

Register

(32bit X 32)

CPU

Multiplier

(32 X 32 64)

ALU

PORT

BCU

Instruction

Queue

MEMC

DRAMC

ROMC

DMAC

System

Controller

CG

AMUTE

BMUTE

XCSAVW, XCSSRAM

XCSFLSH, BUSISO

RESERVED, XCSAVR

DISCDET

XCSODC

FS44_48

DACINPUT

EJECT

XLBE

XUBE

XUCHKENT

VERENT

CD/DVD

XRD

LOAD

XUWR

XLWR

MCKENA

WAITODC

A0-A20

D0-D15

EMPH, DISCSET,

VCONTA, VCONTB

XODCINT1, XODCINT0,

CDLOCK, FG

ADSCENS, ADSCENC,

CONT, OEIC

CKSEL

CLKOUT

X1

X2

CVDD

CVSS

MODE0-MODE2

XRESET

VDD

VSS

D

IC's marked * are MOS type.

Be careful in handling them because they are very

E

F

34

1234

AVIC-88DVD/UC

liable to be damaged by electrostatic induction.

*PD6378D

5678

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

we

reset

NC

NC

RY/by

NC

A17

A7

A6

A5

A4

A3

A2

A1

A16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A-1,A0-A17 : Address output

DQ0-DQ15 : Data input/output

ce : Chip enable input

oe : Output enable output

we : Write enable output

reset : Connect to VCC

RY/by : Not used

byte : Connect to VCC

VCC : Supply voltage

VSS : GND

NC : Not used

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

byte

VSS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

VCC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

oe

VSS

ce

A0

A

B

C

D

E

F

56

AVIC-88DVD/UC

7

8

35

Loading...

Loading...