Philips EverFlo Service manual

EverFlo

EverFlo

TM

Oxygen Concentrator

TM

Q Oxygen Concentrator

Service & Technical Refe ren ce M anual

Page 1 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Updated to include Field Communications

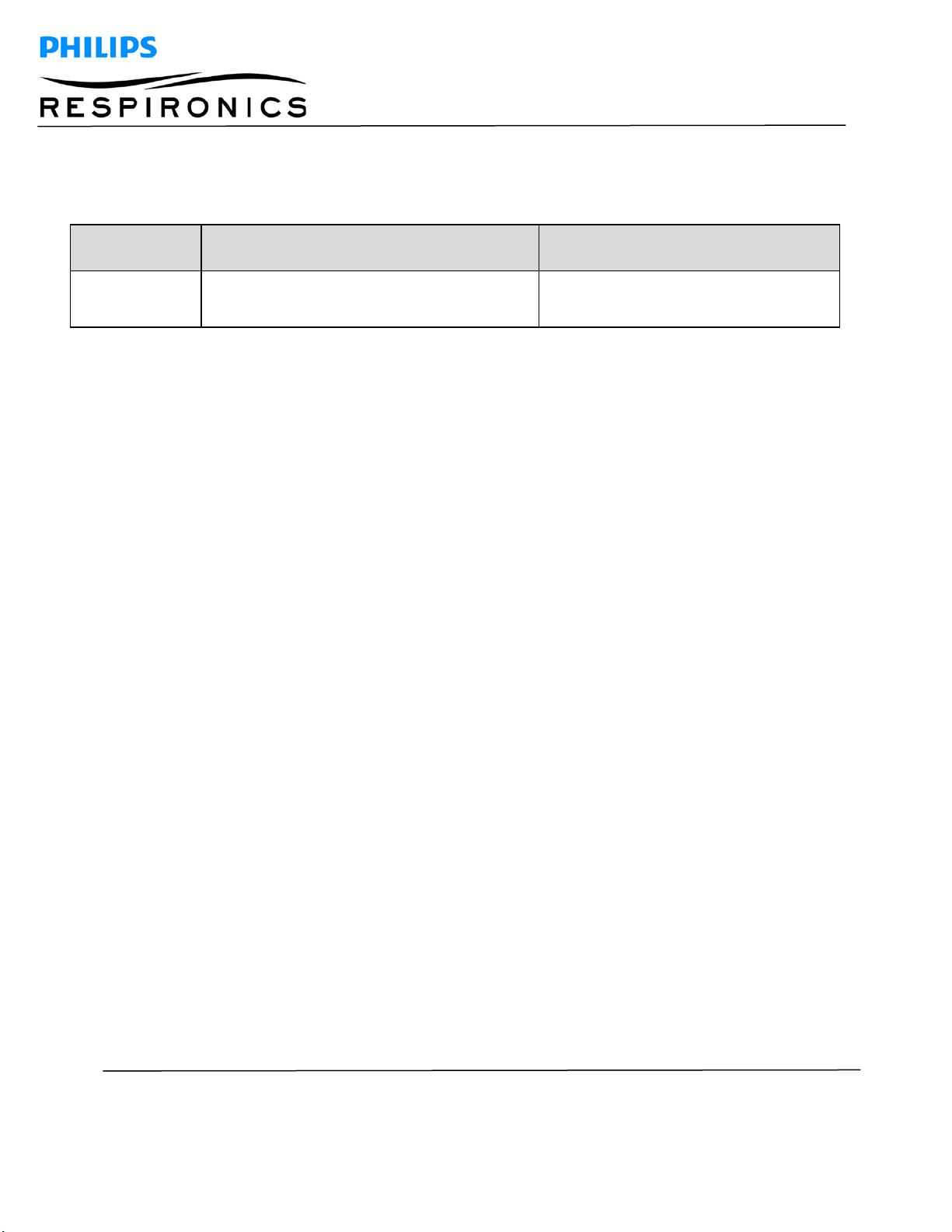

REVISION HISTORY

Revision Description Author

06

Reformatted

K. Carter

Page 2 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Chapter 1. INTRODUCTION ............................................................................................................ 5

1.1 EVERFLO OXYGEN CONCENTRATOR OVERVIEW ............................................................................. 5

1.2 SERVICE NOTICE .................................................................................................................................... 5

1.3 SERVICE TRAINING ................................................................................................................................. 5

1.4 SERVICE/TECHNICAL SUPPORT STATEMENT .................................................................................... 5

Chapter 2. WARNINGS & CAUTIONS ........................................................................................... 6

2.1 WARNINGS ............................................................................................................................................... 6

2.2 CAUTIONS ................................................................................................................................................ 7

Chapter 3. SPECIFICATIONS & CLASSIFICATIONS .................................................................... 8

3.1 SPECIFICATIONS ..................................................................................................................................... 8

Chapter 4. THEORY OF OPERATION .......................................................................................... 10

4.1 PNEUMATIC OPERATION ..................................................................................................................... 10

4.2 ELECTRICAL OPERATION .................................................................................................................... 12

4.3 PCA CONTROLLER OVERVIEW ........................................................................................................... 12

Chapter 5. SYSTEM SETUP ......................................................................................................... 14

5.1 INTRODUCTION ..................................................................................................................................... 14

5.2 SYSTEM SETUP PROCEDURES .......................................................................................................... 14

Chapter 6. MAINTENANCE ........................................................................................................... 16

6.1 DEALER ROUTINE MAINTENANCE ..................................................................................................... 16

6.2 EVERFLO OXYGEN CONCENTRATOR MAINTENANCE RECORD .................................................... 17

6.3 SYSTEM VERIFICATION PROCEDURES ............................................................................................ 18

Chapter 7. TROUBLESHOOTING & ALARMS ............................................................................. 31

7.1 INTRODUCTION ..................................................................................................................................... 31

7.2 INDICATORS & ALARMS ....................................................................................................................... 31

7.3 TROUBLESHOOTING TABLE ................................................................................................................ 32

7.4 SYSTEM PRESSURE TEST TABLE ...................................................................................................... 39

Chapter 8. REPAIR & REPLACEMENT ....................................................................................... 40

8.1 OVERVIEW ............................................................................................................................................. 40

8.2 REPAIR KIT REFERENCE TABLE ......................................................................................................... 41

8.3 FILTER COVER REPLACEMENT .......................................................................................................... 44

8.4 INLET FILTER REPLACEMENT ............................................................................................................ 45

8.5 REAR CABINET/POWER CORD REPLACEMENT ............................................................................... 46

8.6 O2 QUICK COUPLER REPLACEMENT ................................................................................................ 49

Page 3 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

8.7 EVERFLO AND EVERFLO Q PRESSURE REGULATOR ASSEMBLY REPLACEMENT .................... 50

8.8 EVERFLO ULTRAFILL COMPATIBLE PRESSURE REGULATOR ASSEMBLY REPLACEMENT ...... 52

8.9 MAIN PCA REPLACEMENT ................................................................................................................... 55

8.10 SIEVE CANISTER ASSEMBLY REPLACEMENT ............................................................................. 59

8.11 VALVE SOLENOID REPLACEMENT .................................................................................................. 63

8.12 COOLING FAN REPLACEMENT ....................................................................................................... 67

8.13 CAPACITOR REPLACEMENT ........................................................................................................... 69

8.14 COMPRESSOR REPLACEMENT ...................................................................................................... 70

8.15 MICRO-DISK FILTER & TUBING REPLACEMENT ........................................................................... 79

8.16 FLOW METER REPLACEMENT ........................................................................................................ 80

8.17 FRONT CABINET REPLACEMENT ................................................................................................... 81

8.18 RETURNS / PACKAGING ................................................................................................................... 84

8.19 LABELS ................................................................................................................................................ 88

Chapter 9. TESTING ..................................................................................................................... 90

9.1 LONG LIFE FILTER TEST ...................................................................................................................... 90

9.2 EVERFLO SYSTEM FINAL TEST .......................................................................................................... 90

9.3 EVERFLO TEST DATA SHEET ............................................................................................................... 93

Chapter 10. TOOLS AND EQUIPMENT ....................................................................................... 94

10.1 ACCEPTABLE TEST EQUIPMENT .................................................................................................... 95

Chapter 11. SERVICE SOFTWARE ............................................................................................. 96

11.1 EVERFLO SERVICE TOOL ................................................................................................................. 96

Page 4 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

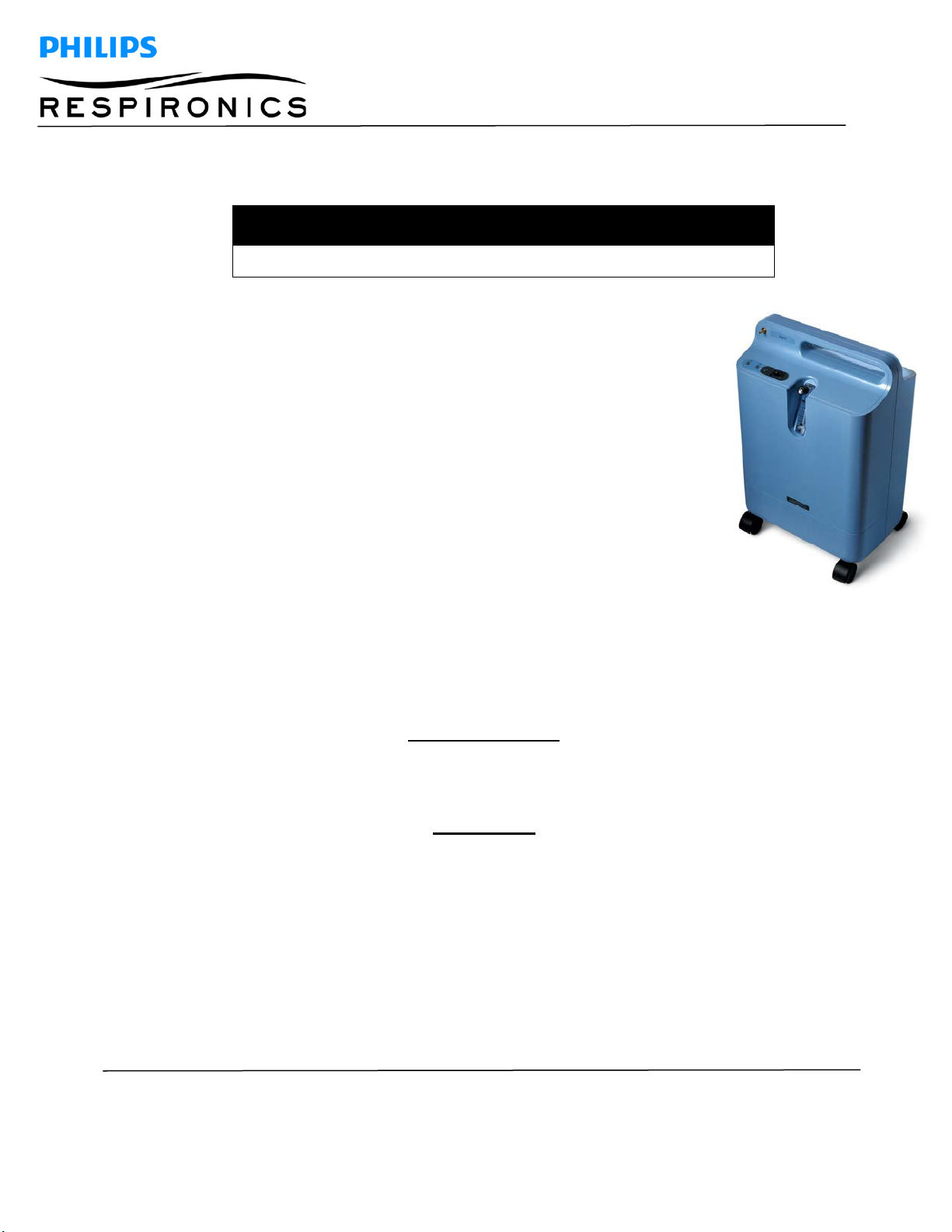

Chapter 1. INTRODUCTION

CAUTION

U.S. federal law restricts this device to sale by or on the order of a physician.

This section provides an introduction to the EverFlo Oxygen Concentrator as well as contact

and service training information.

1.1 EVERFLO OXYGEN CONCENTRATOR OVERVIEW

The EverFlo Oxygen Concentrator produces concentrated oxygen from room air for delivery

to a patient requiring low flow oxygen therapy. The oxygen from the air is concentrated using

a molecular sieve and a pressure swing adsorption process. The EverFlo Oxygen

Concentrator is not intended to be lif e supporting or life sustaining.

1.2 SERVICE NOTICE

The EverFlo Oxygen Concentrator is designed so that trained Service Technicians can

perform repair and testing procedures. Only trained and qualified personnel should repair

these products using authorized parts.

1.3 SERVICE TRAINING

Philips Respironics offers service training for EverFlo Oxygen Concentrators. Training

includes complete disassembly of the device, troubleshooting subassemblies and

components, repair and replacement of components, setup of test equipment, and necessary testing. For more

information, contact the Respironics Customer Service department @ 1-800-345-6443.

1.4 SERVICE/TECHNICAL SUPPORT STATEMENT

For technical assistance, please contact Philips Respironics Service and Technical Support.

U.S.A. and Canada

Phone: 1-800-345-6443

Fax: 1-800-886-0245

International

Phone: 1-724-387-4000

Fax: 1-724-387-5012

Page 5 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Chapter 2. WARNINGS & CAUTIONS

Warnings and cautions are used throughout this manual to identify possible safety hazards, conditions that may

result in equipment or property damage, and important information that must be considered when performing

service and testing procedures on the EverFlo Oxygen Concentrator. Please read this section carefully before

servicing the EverFlo Oxygen Concentrator. Additional Warning and Cautions can be located in the EverFlo User

Manual.

WARNING

Warnings indicate the possibility of injury to people.

CAUTION

Cautions indicate the possibility of damage to equipment.

2.1 WARNINGS

WARNINGS

•

For proper operation, your concentrator requires unobstructed ventilation. The ventilation ports

are located at the top and bottom of the rear cabinet. Keep the dev ice 6 to 12 (15 to 30 cm)

inches away from walls that c ould im pede adequat e airf low to the device. Always make sure

that these areas are not obstructed by items, wh ich may impede ventilation. Do not place

concentrator in a small closed space.

•

Servicing of this device must be referred to an authorized and trained Respironics home care

provider.

•

Oxygen generated by this concentrator is supplemental and should not be considered life

supporting or life sustaining. In certain circumstances, oxygen therapy can be hazardous; any

user should seek medical advice prior to using this device.

•

Oxygen vigorously accelerates combustion and should be kept away from heat or open flame.

Not suitable for us e in the presenc e of a f lamm able anesthet ic mix ture with air, with oxygen,

or with nitrous oxide.

•

Do not smoke or allo w oth e r s to smoke or have open flames near the concentrator when it is

in use.

•

Do not use oil or grease on the conc entrator or its com ponents as these substanc es, when

combined with oxygen, can greatly increase the potential for a fire hazard and personal injury.

•

Do not use the concentrator if either the plug or power cord is damaged. Do not use extension

cords or electrical adaptors.

•

Do not attempt to clean the concentrator while it is plugged into an electrical outlet.

Page 6 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

•

Avoid handling the molecular sieve material. Respironics recommends the return of the sieve

of the device if allowed within tubing or fittings.

canister assembly to Respironics for any service that involves sieve disposal.

•

Use extreme caution when handling the compressor capacitor as it holds an elec tric al charge

until is it properly discharged.

•

Device operation abo ve or outs id e of the vo ltag e, L PM , temperature, humidity a nd /or altitu de

values specified may decrease oxygen concentration levels.

•

If the EverFlo Ox ygen Co ncentrator has been subj ected to s ub-f reezing tem peratures for an

extended period, it should be allowed to warm up to the stated operating temperatures bef ore

power up. Failure t o do so could resul t in improper perform ance and or alarm conditions until

the device reaches normal operating temperatures.

2.2 CAUTIONS

U.S. federal law restricts this device to sale by or on the order of a physician.

Do not place liquids on or near the device.

WARNINGS

CAUTIONS

If liquid is spilled on the device, turn the power off and unplug from electrical outlet before attempting to

clean up a spill.

When using liquid leak detector, be careful not to allow it to contact electrical parts.

Make sure connections of fittings, tubing, and hoses are secure.

Be cautious when using thread sealants because they can cause extensive damage to the internal parts

Page 7 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Model

Voltage

Operational

Power

Consum

Oxygen

Concentrati

Flow LPM

Sound

Weight

1020000

1039363

31 lbs (14 kg)

1020002BR

31 lbs (14 kg)

1020014

1020015

120 VAC +

10%

350 W

At 120 VAC

<40 dBA

typ

31 lbs (14 kg)

1020006

1039370

33 lbs (15 kg)

1020008

1104000

33 lbs (15 kg)

1020007

1039367

230 VAC +

10%

<300 W

At 230 VAC

<40 dBA

typ

33 lbs (15 kg)

230 VAC +

10%

<300 W

At 230 VAC

<40 dBA

typ

33 lbs (15 kg)

1020004

1020005

220 VAC +

10%

320 W

At 220 VAC

33 lbs (15 kg)

220 VAC +

10%

<300 W

At 220 VAC

33 lbs (15 kg)

230 VAC +

<300 W

33 lbs (15 kg)

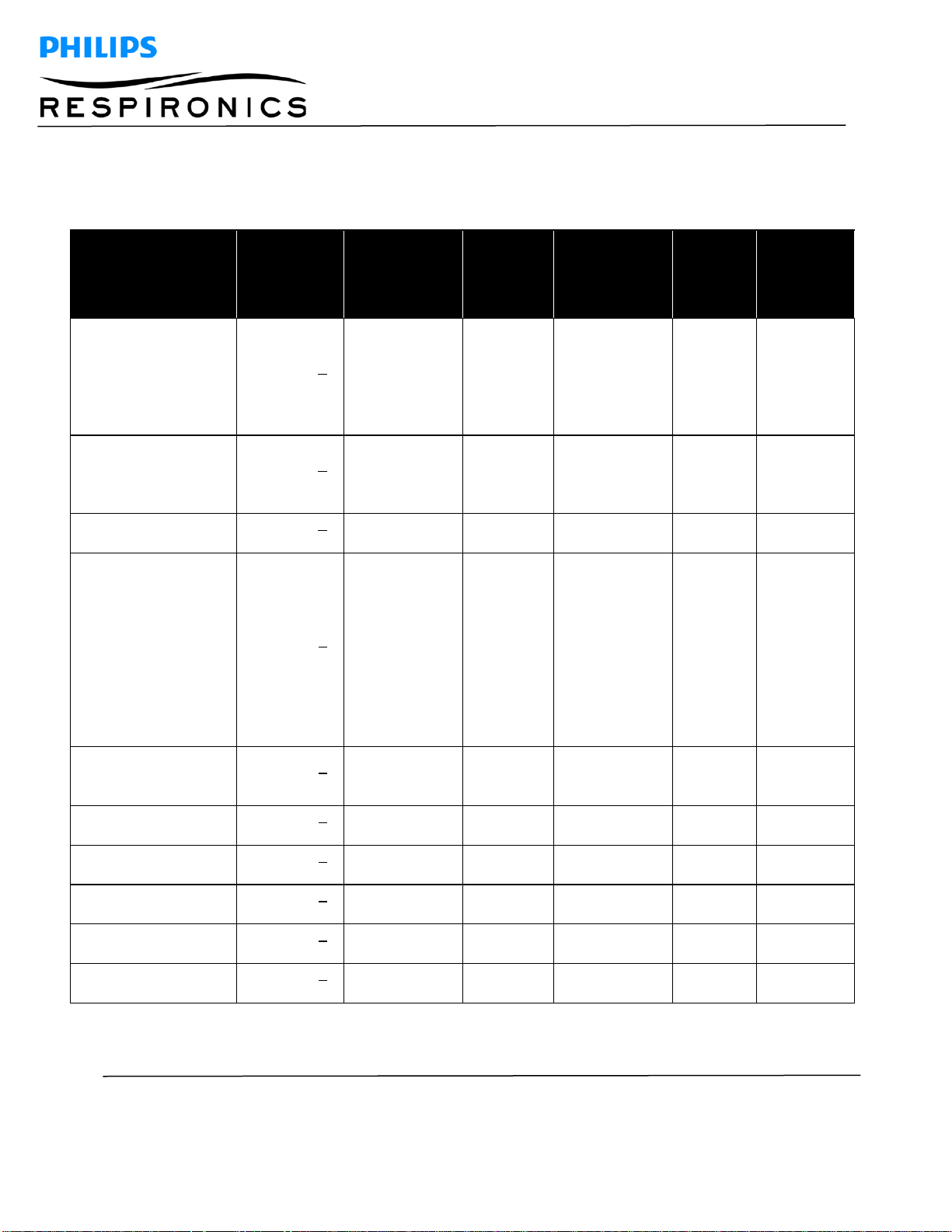

Chapter 3. SPECIFICATIONS & CLASSIFICATIONS

3.1 SPECIFICATIONS

Numbers

1020001

1020002

1020003

1039362

1020003BR

1039364

1039365

1020009

1020010

1020011

1020012

1020016

1020017

1020020

1039366

120 VAC +

10%

120 VAC +

10%

230 VAC +

10%

Power

Frequency

60 Hz

60 Hz

60 Hz

50 Hz

ption

350 W

At 120 VAC

350 W

At 120 VAC

<300 W

At 230 VAC

on Zero to

Level

Maximum

90 - 95.5% 45 dBA typ

90 - 95.5% 43 dBA typ

90 - 95.5%

90 - 95.5% 43 dBA typ

1039368

1125558

1020013

1102443

Page 8 E

230 VAC +

10%

10%

VERFLO

50 Hz

50 Hz

50 Hz

60 Hz

60 Hz

60 Hz

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

<300 W

At 230 VAC

At 230 VAC

87 - 95.5%

87 - 95.5%

90 - 95.5%

90 - 95.5% 45 dBA typ

90 - 95.5% 43 dBA typ

90 - 95.5%

43 dBA typ

43 dBA typ

7,500 to 13,123 ft (2286 to 4000 m) not specified, exceeds specified

All Models

Dimensions 22.8” (58 cm) x 15” (38 cm) x 9.5” (24 cm) (H x W x D)

Oxygen Purity Alarms

Operating Temperature

Storage and Transport Temperature

Low Oxygen at 82% purity (For OPI models only), Very Low Oxygen

at < 70%

55o F to 90o F (13o C to 32o C)

29o F to 160o F (-34o C to 71o C)

Relative Humidity 15 to 95%, noncondensing

Outlet Pressure 5 to 7 psi (0.34 to 0.48 Bar)

0 to 7,500 ft (0 to 2,286 m) meets specifications

Operating Altitude

operating altitude

Maximum Flow at 0 & 7 kPa Outlet Pressure 5 LPM (3 LPM During trans fill operation)

Pressure Relief Valve 49 to 55 psi (338 to 378 kPa)

Each EverFlo unit is measured in the factory with an Oxygen Analyzer that measures oxygen concentration with an

accuracy specification of +/- .1 %. When

the Oxygen Concentration for an EverFlo Oxygen Concentrator, you may receive

using an Oxygen Analyzer with an accuracy specification of +/- 2 % to test

inaccurate readings below the

acceptable pass criteria for the device. This 2% offset should be taken in to consideration when determining if the

EverFlo is

measurement of the oxygen purity. As an example, a unit could be

Analyzer to measure 91.1%. If this same unit is then measured with a +/- 2% Oxygen Analyzer, the reading could

functioning properly. A more accurate Oxygen Analyzer may also be used for a more precise

measured in the factory with the +/- 1% Oxygen

display a result of 89.1%. With the +/- 2% Oxygen Analyzer, it may inaccurately look like the unit falls below the 90-

95.5% specification, when in fact the unit is within specification.

Refer to User Manual (1041063) for classification, standards compliance, and EMC requirements.

Page 9 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Chapter 4. THEORY OF OPERATION

This section describes the theory of operation for the EverFlo Oxygen Concentrator.

4.1 PNEUMATIC OPERATION

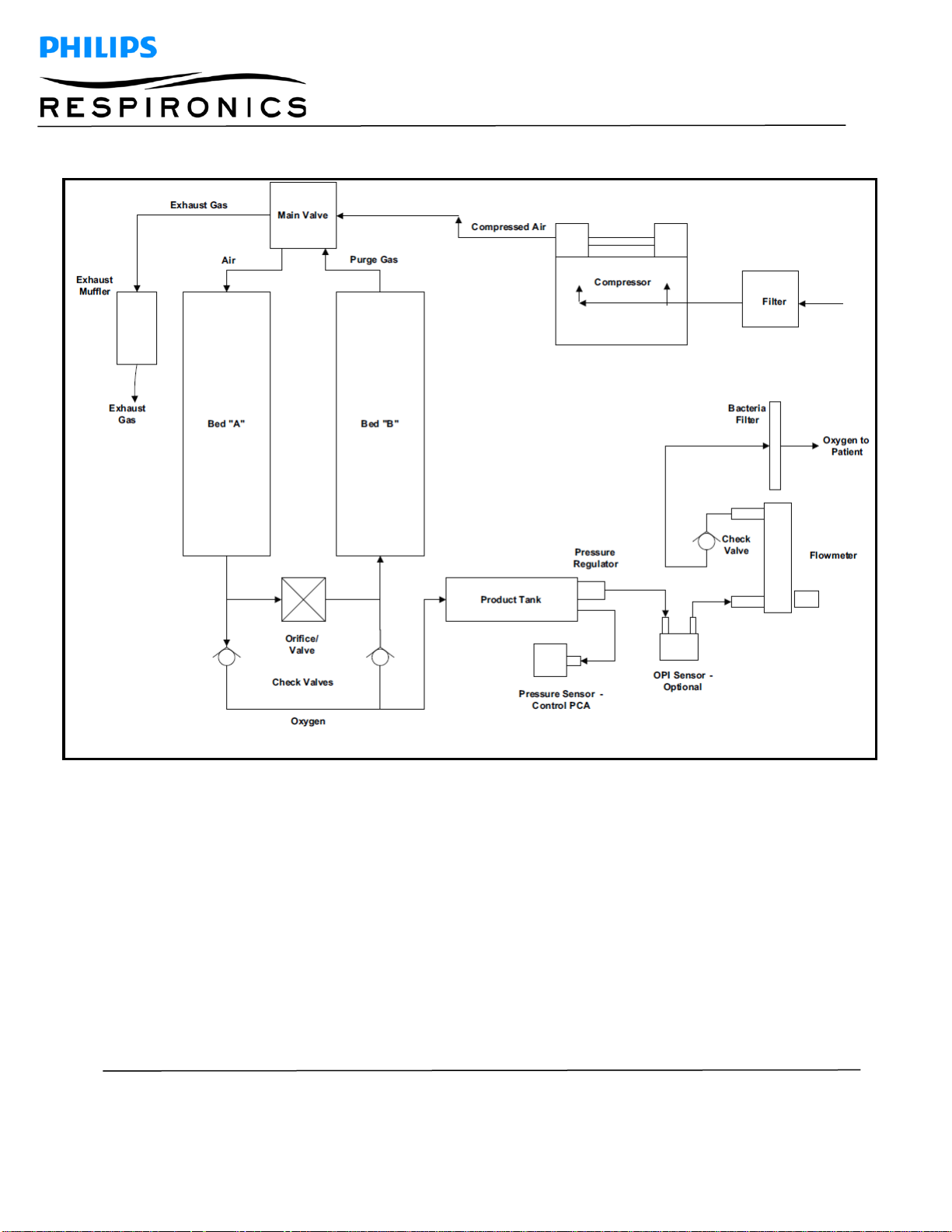

Refer to Figure 4-1 while reading the following discussion.

The room air is drawn into the unit through the air inlet filter by the compressor. The compressed air is routed to

the sieve beds through an electronically controlled Solenoid Valve Assembly. The Solenoid Valve alternates the

airflow to a pair of sieve beds that allows Oxygen production. The Solenoid Valve Assembly also alternates the

flow through the sieve beds to allow purging of the Nitrogen molecules from the sieve beds.

At startup, the valve/sol eno id is de-energized allowing compressed air to flow through both sieve beds until the

pressure sensor builds up to switching pressure. At switching pressure, a 12-volt signal is received at the

valve/solenoid closing off the input and allowing the compressed air to cycle through one of the sieve beds. As

the air is cycled through one of the sieve beds, the molecular sieve material traps the Nitrogen molecules from

the air and allows the Oxygen enriched air to flow through the sieve bed.

At 5 liters of flow, approximately 1/3 of the Oxygen enriched air enters the product tank and the other 2/3 of the

Oxygen enriched air is passed through an orifice in the sieve bed to purge the trapped Nitrogen molecules from

the sieve bed, allowing the sieve material to be ready for Oxygen production during the next cycle.

The concentrated Oxygen is stored in the product tank. The product tank is continuously filled with concentrated

Oxygen and the output from the product tank is regulated at 5.5 psig nominal. The product tank pressure is

continuously monitored using a pressure sensor. The stored Oxygen is delivered to the patient through a

pressure regulator, an externally adjustable flow meter and a microbial filter.

In the beginning, the 230V units, had an orifice built into the purge valve. The

electronically controlled purge valve controls the Oxygen flow timing from one sieve

bed to the other based on the flow meter setting.

Page 10 E

VERFLO

NOTE

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Figure 4-1: Pneumatic Block Diagram (Non-O2 Piloted)

Page 11 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

4.2 ELECTRICAL OPERATION

The EverFlo Concentrator is a medical device, which produces concentrated oxygen from room air for delivery to

a patient. It uses a molecular sieve and a pressure swing adsorption process to concentrate oxygen from air. The

device consists of filters, a compressor, a sieve canister module, a set of valves, a microprocessor-based

electronic controller PCA, a flow meter and a cooling fan – all contained within a plastic enclosure.

The EverFlo Embedded Software

valves used to generate the oxygen, measures/monitors the pressure & oxygen levels, drives the Elapsed Time

counter (Hour meter), reports exception conditions to the User via visual and audible indicators and provides

diagnostic information to a Host computer via an RS232 communications interface.

—via the microprocessor contained on the PCA Controller—controls the sieve

4.3 PCA CONTROLLER OVERVIEW

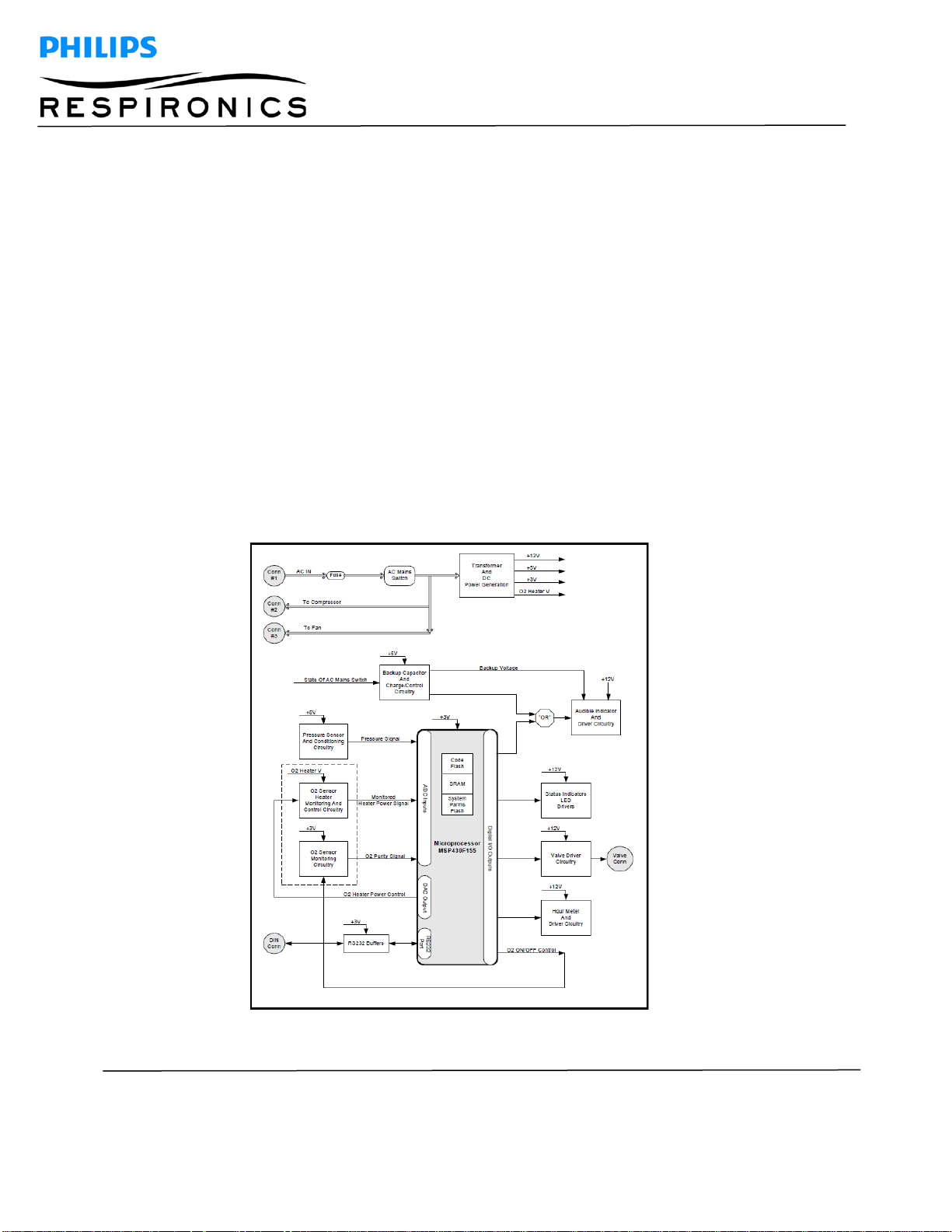

All the electric / electronic functions of the EverFlo Concentrator reside on the PCA Controller. A block diagram of

the PCA controller is provided in Figure A. The reader is urged to continually refer to this diagram when reading

the remaining sections of this document.

The PCA controller can be sub-divided into 2 major sections:

1.

Power distribution and DC voltage generation.

2.

Monitoring / Control / User Interface.

Page 12 E

Figure 4-2: EverFlo PCA Controller Block Diagram

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

4.3.1 POWER

The AC mains power, via the line cord, is brought onto the PCA and the “switched” AC is distributed to the

Compressor, the Cooling Fan and to the AC to DC conversion module. The DC voltages that are generated are

used to power the remaining circuitry.

The PCA contains a 1 Farad “super capacitor” which is used to sound the Audible Indicator when the AC mains

power is absent AND the mains switch is in the ON position. The purpose is to alert the User to the fact that

there has been a loss of AC mains power (that is, an AC mains power failure, a plug removal, a blown fuse). The

circuitry functions as follows:

1.

During normal operation, the capacitor is energized (charged) using the +5 VDC. The capacitor

reaches full charge after approximately ½ hour of system on-time.

2.

The mains switch has a 2nd set of contacts that are used to determine whether the switch is open

or closed. If the switch is closed (in the ON position) and the microprocessor is not functional (no

DC power), then the backup circuitry is such that it will turn on the Audible Indicator, using the

“super cap” as its energy source.

The “super cap” is capable of sounding the Audible Indicator for a period of greater than 8 minutes, given that it

is fully charged.

4.3.2 MICROPROCESSOR AND ASSOCIATED CIRCUITRY

The remainder of the PCA controller electronics is centered around the MSP430F155 microprocessor. The

microprocessor is the only processing element contained in the EverFlo concentrator. In addition to the

microprocessor, the “remaining circuitry” consists of sensors, LEDS, a piezo Audible Indicator, amplifiers / signal

conditioners, communication buffers and discrete components.

The embedded software, in conjunction with the microprocessor and its associated hardware, is used to control

the sieve valves, measure/monitor the pressure & oxygen levels, control the oxygen sensor, drive the Hour

meter, reports exception conditions to the User via visual and audible indicators and provide diagnostic

information to a Host computer via an RS232 communications interface.

Page 13 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Chapter 5. SYSTEM SETUP

NOTE

Please refer to the appropriate User Manual for additional information.

5.1 INTRODUCTION

This section provides information regarding setup and operation of the EverFlo Oxygen Concentrator as needed

for servicing, repairing, and testing the device.

5.2 SYSTEM SETUP PROCEDURES

1.

Select a location that allows the concentrator to draw in room air without being restricted. Make

sure that the device is at least 6 to 12 inches (15 to 30 cm) away from walls, furniture, and

especially curtains that could impede adequate airflow to the device. Do not place the device

near any heat source.

2.

Plug the EverFlo Oxygen Concentrator into an electrical outlet.

3.

If you are NOT using a humidifier, connect the cannula to the EverFlo Oxygen Outlet Port, as

shown below. Proceed to step 4.

4.

If you are using a humidifier follow these steps:

a.

Open the filter door on the back of the device.

b.

Remove the humidifier connector tube from the back of the filter door and replace the filter

door.

c.

Fill the humidifier with water following the manufacturer’s instructions.

d.

Mount the filled humidifier on the top of the EverFlo device inside the velcro strap.

e.

Tighten the velcro strap around the bottle and secure it so it is held firmly in place.

f.

Connect the humidifier connector tube (that you retrieved from the filter door) to the Oxygen

Outlet Port.

g.

Connect the other end of the humidifier connector tube to the top of the humidifier with the

elbow in the tubing facing the front.

h.

Connect your cannula to the humidifier bottle according to the humidifier bottle manufacturer’s

specifications.

Page 14 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

5.

Press the power switch to the On [I] position. Initially, all the LEDS will illuminate and the audible

alert will sound for a few seconds. After that time, only the green LED should rema in lit. You can

begin breathing from the device immediately even though it typically takes 10 minutes to reach

oxygen purity specifications. The device normally takes 10 minutes to reach oxygen purity

specifications.

6.

Adjust the flow to the proper setting by turning the knob on the top of the flow meter until the ball is

centered on the line marking the specific flow rate.

7.

Be sure oxygen is flowing through the cannula. If it is not, refer to the Troubleshooting section of

this manual.

8.

When you are not using the oxygen concentrator, press the power switch to the Off [O] position.

Page 15 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Chapter 6. MAINTENANCE

6.1 DEALER ROUTINE MAINTENANCE

This section describes scheduled and routine maintenance procedures. Normal routine maintenance involves

periodic checking, cleaning, and or replacing the following items as necessary:

•

Inlet Filter

•

Micro-Disk Filter

•

Cabinet cleaning

•

LPM flow setting to the prescribed level

•

Oxygen concentration level

Routine maintenance is very important in prolonging dependability and in reducing costly repairs. Long-term

maintenance and regular checking of the filters helps assure the efficient operation of the unit.

6.1.1 FILTERS

Respironics recommends checking and replacing the Inlet Filter every two (2) years. Respironics also

recommends checking and replacing the Micro-Disk filter as necessary.

6.1.2 CABINET

Commensurate with hospital or homecare policies, Respironics recommends cleaning the cabinet and

inspecting for damage as necessary. Ensure that the small holes on the Inlet Filter door are unobstructed. Refer

to the Tools and Equipment section for approved cleaning solution.

6.1.3 FLOW SETTING

Commensurate with hospital or homecare policies, Respironics recommends verifying the patient flow setting as

necessary.

6.1.4 OXYGEN CONCENTRATION VERIFICATION

Commensurate with hospital or homecare policies, Respironics recommends verifying the oxygen concentration

level per homecare provider's policies as necessary. Refer to the Testing section for more detailed instructions

on how to check the oxygen concentration level.

6.1.5 COMPRESSOR

Respironics does not require routine maintenance or recommend field service of the EverFlo Oxygen

Concentrator compressor. The compressor may require replacement when:

•

The system pressure is not within specifications and there are no leaks detected.

•

The compressor bearings have worn to a point that make the compressor noticeably louder.

6.1.6 HUMIDIFIER CONNECTOR TUBE AND CONNECTOR

Commensurate with hospital or homecare policies, Respironics recommends disinfecting the tube and

connector using 70% isopropyl alcohol.

Page 16 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

(Record at Each Check)

(Clean & Replace as Necessary)

(Clean and Inspect as Necessary)

(Check Setting)

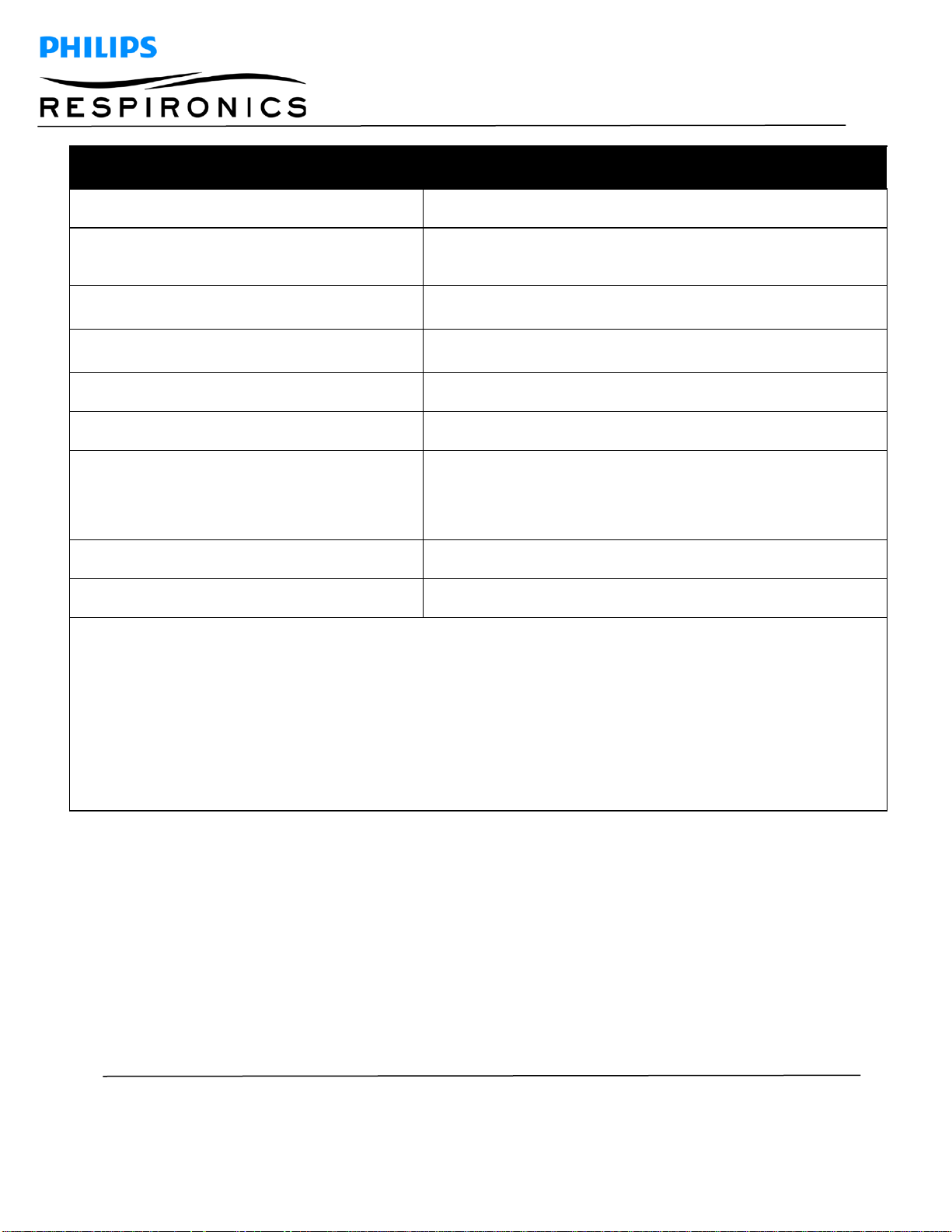

6.2 EVERFLO OXYGEN CONCENTRATOR MAINTENANCE RECORD

MODEL NUMBER SERIAL NUMBER

DATE PURCHASED

FILTERS

DATE/HOURS/LPM

Inlet Micro-Disk

CABINET

FLOW SETTING

OXYGEN

CONCENTRATION

(Check Level)

Page 17 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

NOTE

6.3 SYSTEM VERIFICATION PROCEDURES

The following procedures may be performed at any time to ensure that the EverFlo Concentrator is functioning

properly.

6.3.1 SYSTEM SELF TEST AND S TART UP TEST

6.3.2 POWER LOSS ALARM TEST

1.

Connect the power cord to the proper power source.

2.

Turn on the unit by moving the power switch to the ON (I) position and verify the following:

•

All LEDs light up and the audible alarm sounds for two seconds.

•

The unit starts to run.

•

The red and yellow LED lights go off and the audible alarm stops.

•

The green LED stays on.

1.

Test the power loss alarm as follows:

a.

Connect the device to a proper power source.

a.

Let the device warm up for two minutes to charge the capacitor.

b.

Disconnect the device from the power source and move the power switch to the On (I) position

and verify an audible alarm sounds continuously.

c.

The alarm should have sufficient power to sound for 10 minutes. Verify that the EverFlo

Device alarms.

d.

If the audible alarm does not sound, replace the Main PCA.

6.3.3 OUTLET/REGULATED PRESSURE TEST

1.

Power up the unit and allow it to run for at least two minutes to stabilize.

2.

Set the flow meter to 5 LPM (1 LPM for units equipped with pediatric flow meters).

If using the Concentrator tool kit (H647), be sure to remove the DISS outlet fitting

from the tubing before proceeding to step 3.

Page 18 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

3.

Connect the pressure gauge from the tool kit to the outlet barb. The flow ball should drop to 0.0

LPM.

NOTE

Be sure to hold the pressure gauge in a vertical position.

4.

If the outlet pressure does not fall between 5.0 and 7.0 psig, perform steps 5 through 14. If the

pressure does fall between 5.0 and 7.0 psig, remove pressure gauge, the test is now complete.

5.

Turn the unit off.

6.

Remove the pressure gauge from the outlet barb.

7.

Remove the front and rear cabinets.

Page 19 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

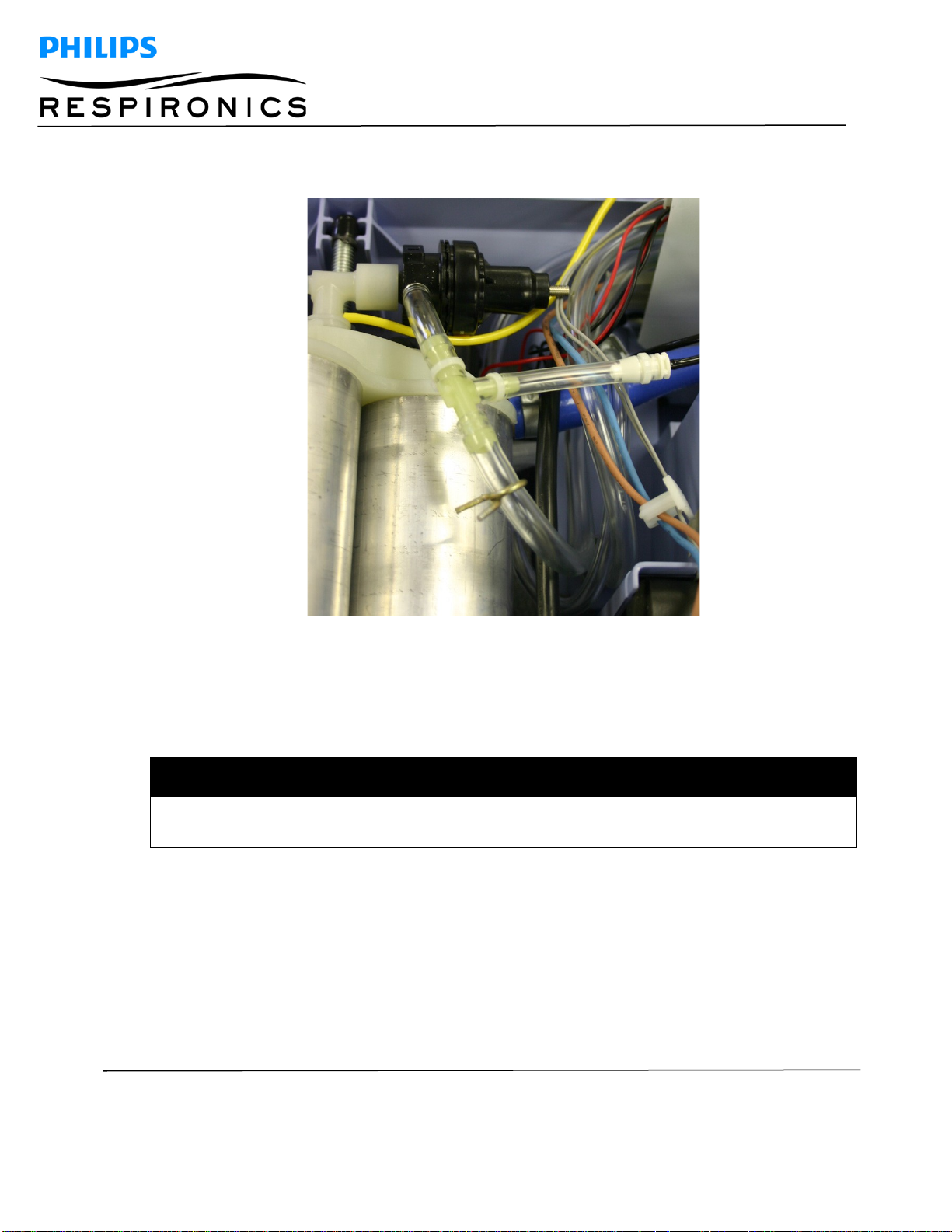

NOTE

8.

Insert a “T” from the tool kit in between the regulator and the clear oxygen tubing and connect the

pressure gauge.

9.

Turn the device on and set the flow meter to 5 LPM (1 LPM for units equipped with pediatric

flow meters).

10.

With the gauge held in a vertical position, verify that the regulated pressure is at 5.5 ± 0.25 psig.

11.

If the regulated pressure needs adjusted, place a 3/32” Allen wrench in the adjusting screw on the

end of the regulator.

If the regulated pressure is low, turn the wrench clockwise to increase the regulated pressure. If the

regulated pressure is high, turn the wrench counter-clockwise.

12.

Disconnect the pressure ga uge and “T ” fitting.

13.

Reconnect the clear oxygen tubing to the pressure regulator.

14.

Install the front and rear cabinets.

Page 20 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

NOTE

6.3.4 SYSTEM PRESSURE TEST

The system pressure test is used to verify the proper operation of the EverFlo Compressor and Sieve Canister

Assemblies.

If pressures are not within the normal operating pressure, it does not necessarily indicate an issue

with the concentrator. T he F ina l Test located in the Testing Chapter of this manual is the only test

to be used when deter mining a k nown good E verFlo Concentrator from a Concentrator requir ing

repair.

1.

Run the unit with the front and rear cabinets in place for a minimum of ten minutes.

2.

Set the flow to 5 LPM (1 LPM for units equipped with pediatric flow meters).

3.

Turn off the Everflo Oxygen Concentrator.

4.

Remove the front and rear cabinets from the unit.

5.

Disconnect the yello w pressure tubing from the f itting on th e PCA. Using the pres s ur e gau ge, “T”

fitting, and pressure tubing supplied with the Concentrator tool kit, connect to the Pressure

Regulator as shown below.

6.

Turn the unit on and allow the unit to cycle for at least two (2) minutes to stabilize.

7.

Hold the pressure gauge in a vertical position.

8.

Verify press ures a gains t the tab le below. This table is a ref erence gui deli ne for s ystem press ures

and troubleshooting. If a value is measured outside of these ranges, it may not mean the unit has

a fault. If the Outlet Pressu re and Out let Oxygen values are w ithin tolera nces, and the u nit is not

alarming, the unit should be considered acceptable.

Page 21 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

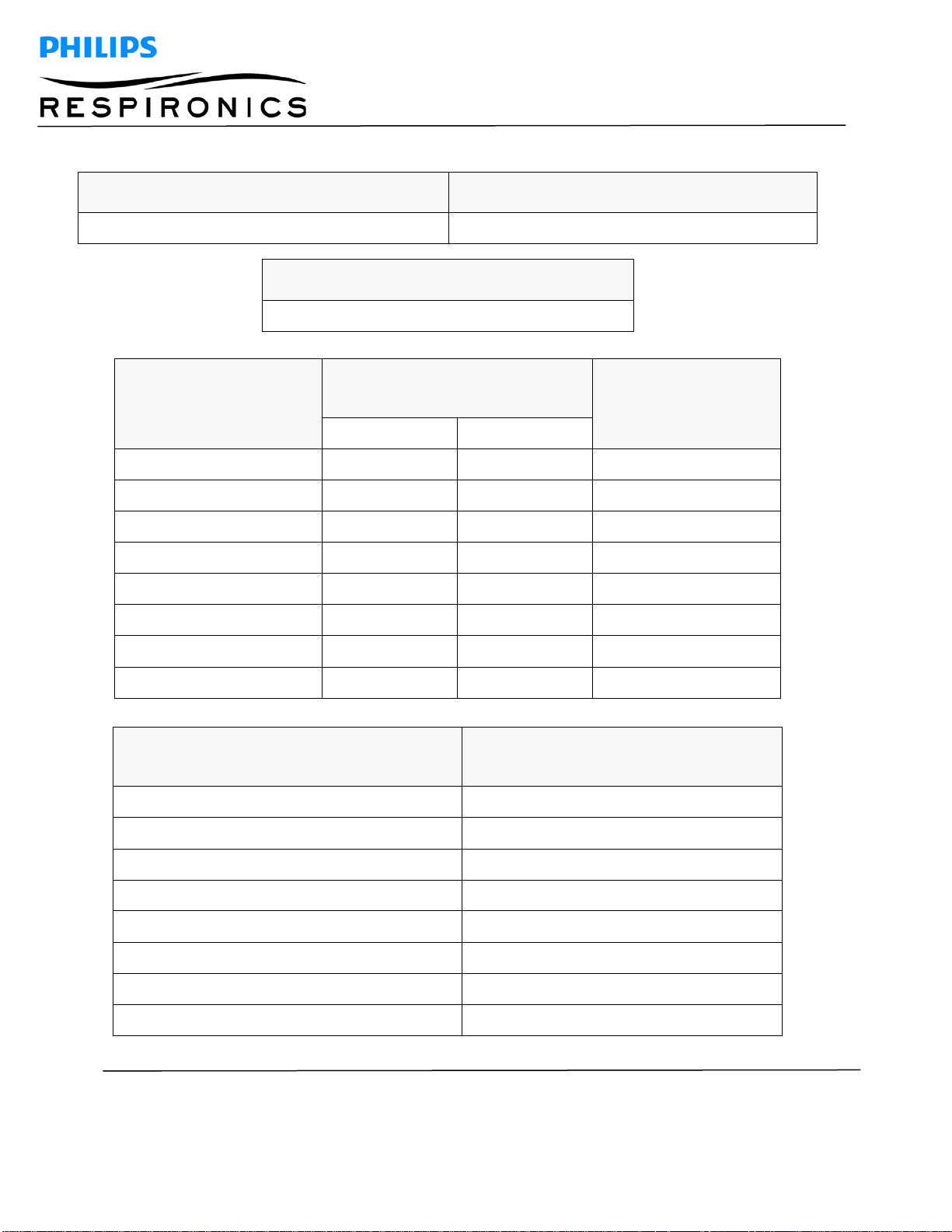

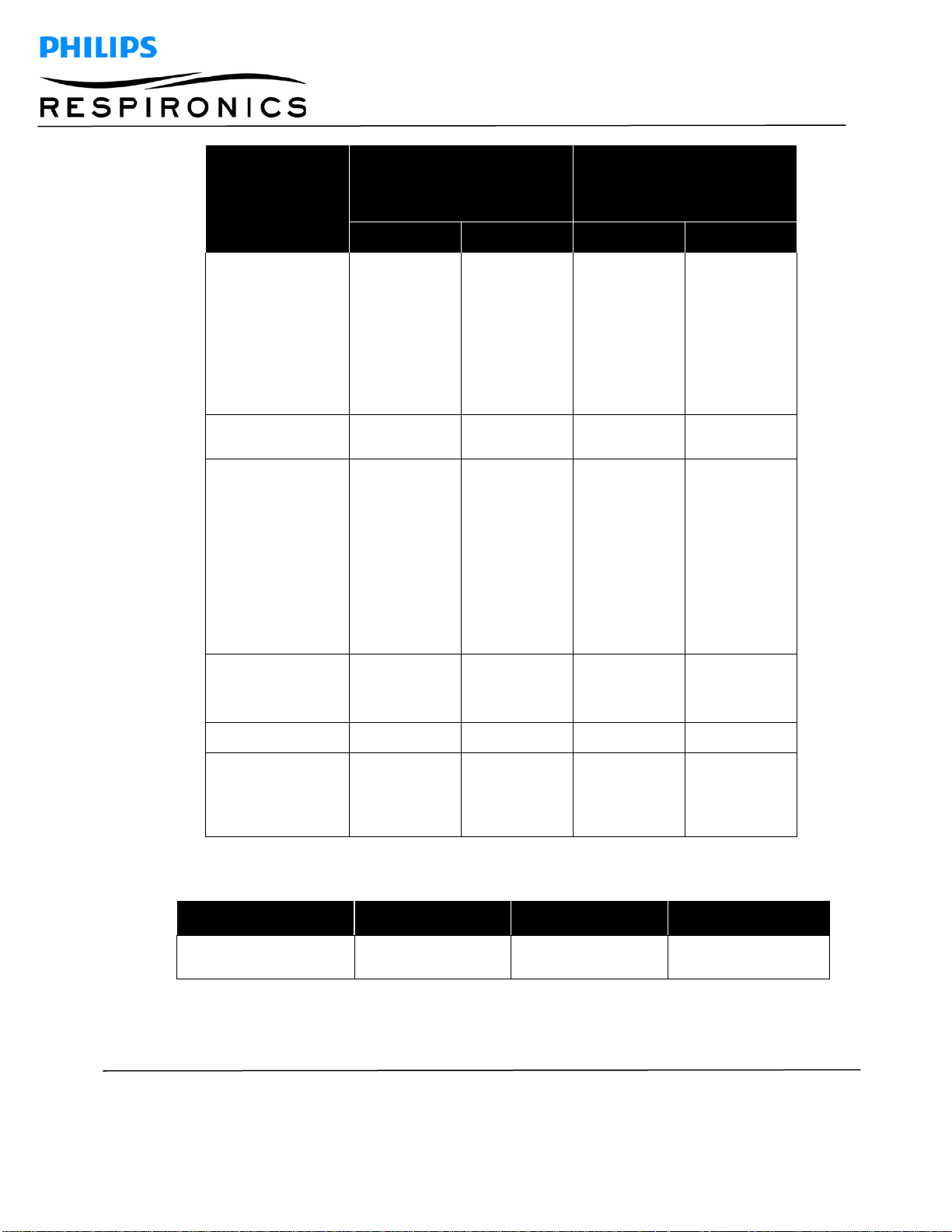

EverFlo

Normal Pressure for

Normal Pressure for

Min

Max

Min

Max

1020000

NA NA 15 27

1020004

NA NA NA NA

1020006

16 24 14 25

1020007

12 22 12 23

1020013

NA NA 11 22

1020014

NA NA 14 24

CYCLE 1

CYCLE 2

CYCLE 3

CYCLE 4

Model

1020001

1020002

1020003

1020002BR

1020003BR

1039362

1039363

1020005

1020009

1020010

1020011

1020012

1020016

1020017

1039366

1039368

1039370

units equipped with

Purge Valves

units without Purge

Valves

1020008

1039367

1020015

1039364

1039365

9.

Record the peak pressure for four cycles.

Page 22 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

NOTE

10.

Confirm that all peaks are within one (1) psig of each other.

If the four cycles are not within specification, refer to the troubleshooting section of the service manual.

11.

Turn off the EverFlo Concentrator and disconnect the pressure gauge, “T” fitting, and tubing.

Reconnect the yellow tubing to the Pressure Regulator Adaptor located on the top of the Sieve

Canister Assembly.

12.

Install the front and rear cabinets.

6.3.5 OXYGEN OUTPUT TEST

1.

Power up the concentrator and allow it to run for a minimum of 15 minutes.

2.

Connect a calibrated oxygen analyzer to the outlet fitting of the concentrator.

3.

Set the flow to 5 LPM (1 LPM for units equipped with pediatric flow meters).

4.

Verify the oxygen reading is as follows:

Page 23 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

1020000, 1020001,

> 90%

1020007, 1020008,

> 87%

NOTE

MODEL NUMBER OXYGEN PURITY

1020002, 1020003,

1020002BR, 1020003BR

1020004, 1020005,

1020006, 1020009,

1020010, 1020011,

1020012, 1020013,

1020014, 1020015,

1020016, 1020017,

1039362, 1039363

1039364, 1039365

1039366, 1039368,

1039370

1039367

6.3.6 MAIN PCA OXYGEN VERIFICATION (OPI UNITS ONLY)

This procedure verifies that the Main PCA is operating properly.

1.

Plug the unit into a power outlet.

2.

Turn the device on, set the flow to 5.0 LPM, and let it run for 10 minutes.

3.

If either the yellow or red LED illuminates after 10 minutes, perform the oxygen output test with a

calibrated oxygen analyzer. If the red LED illuminates, the audible alarm should also sound at the

same time.

The oxygen analyzer used in the following steps must be calibrated to meet the

manufacturer’s specifications.

If the device is alarming and the oxygen concentration is measured at 82% or higher, check the device for leaks.

If no leaks are found then replace the Main PCA.

Page 24 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

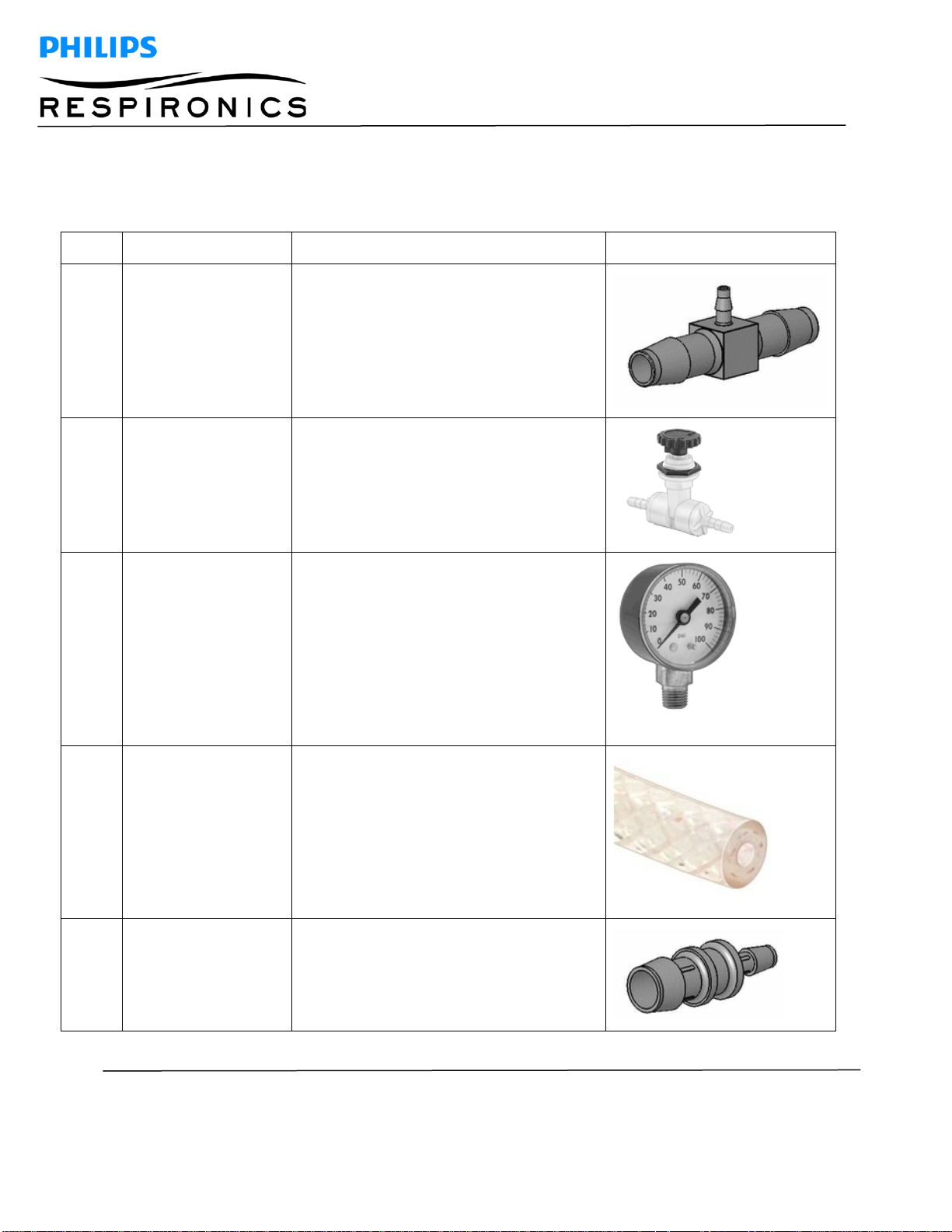

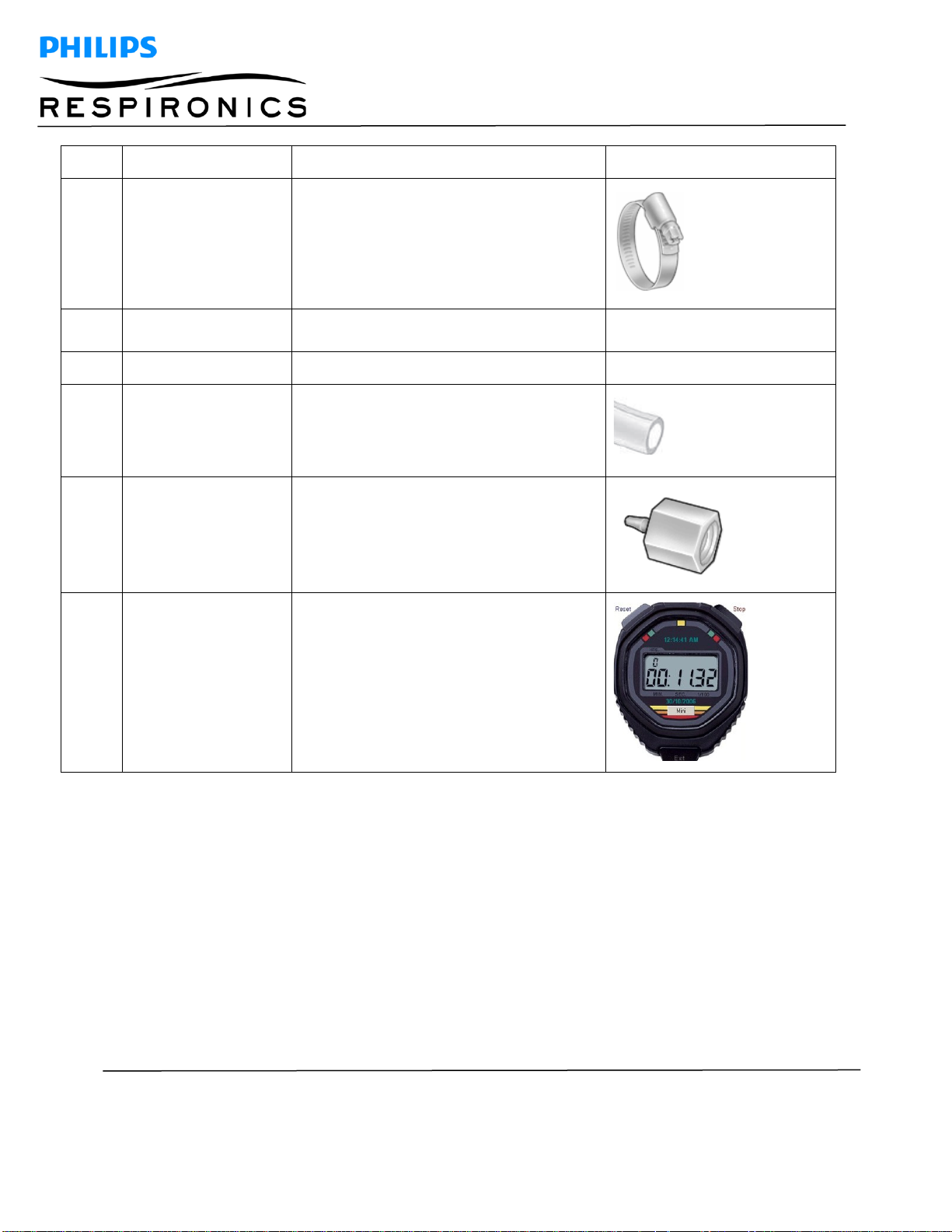

Item

Reference Part No.

Description

Picture

1

McMaster-Carr: Qty 1

White Polypropylene Barbed Tube Fitting

2

McMaster-Carr: Qty 1

Compact Plastic Needle Valve 3/8" Barb X

3

McMaster-Carr: Qty

Multipurpose Gauge +/-2% Mid-Scale

4

McMaster-Carr: Qty

High Pressure Tubing, 1/8” ID, 3/8” OD,

5

McMaster-Carr: Qty 1

Durable Nylon Single-Barbed Tube Fitting

6.3.7 COMPRESSOR TEST

This procedure verifies if the Compressor is working properly.

EQUIPMENT REQUIRED FOR OPTION 1

of Part #: 5121K851

of Part #: 7781K33

of 1 of Part #:

4089K13

Reducing Tee for 3/8" X 1/8" X 3/8" Tube

ID

3/8" Barb Connections

Accuracy 2" Dial, 1/4" NPT Male Bottom, 0

- 60 PSI

of 1 of Part #:

5439K19

of Part #: 2974K278

(Same as 5463K653)

Page 25 E

1/8” Wall

Reducing Coupling for 1" X 1/2" Tube ID

White

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Item

Reference Part No.

Description

Picture

6

7

8

TSI Flow Meter, Qty 1

9

High-Pressure Tygothane Polyurethane

10

11

Hose Clamp, Qty 5 Clamping range of 1/4”

to 5/8”

18” Patient Tubing, Qty 1

Tubing Clear, 3/8" ID, 1/2" OD, 1/8" Wall.

10’L

FDA White Nylon Single Barbed Tube

Fitting Adapter for 1/8” Tube ID X ¼” FNPT

Page 26 E

Stopwatch

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

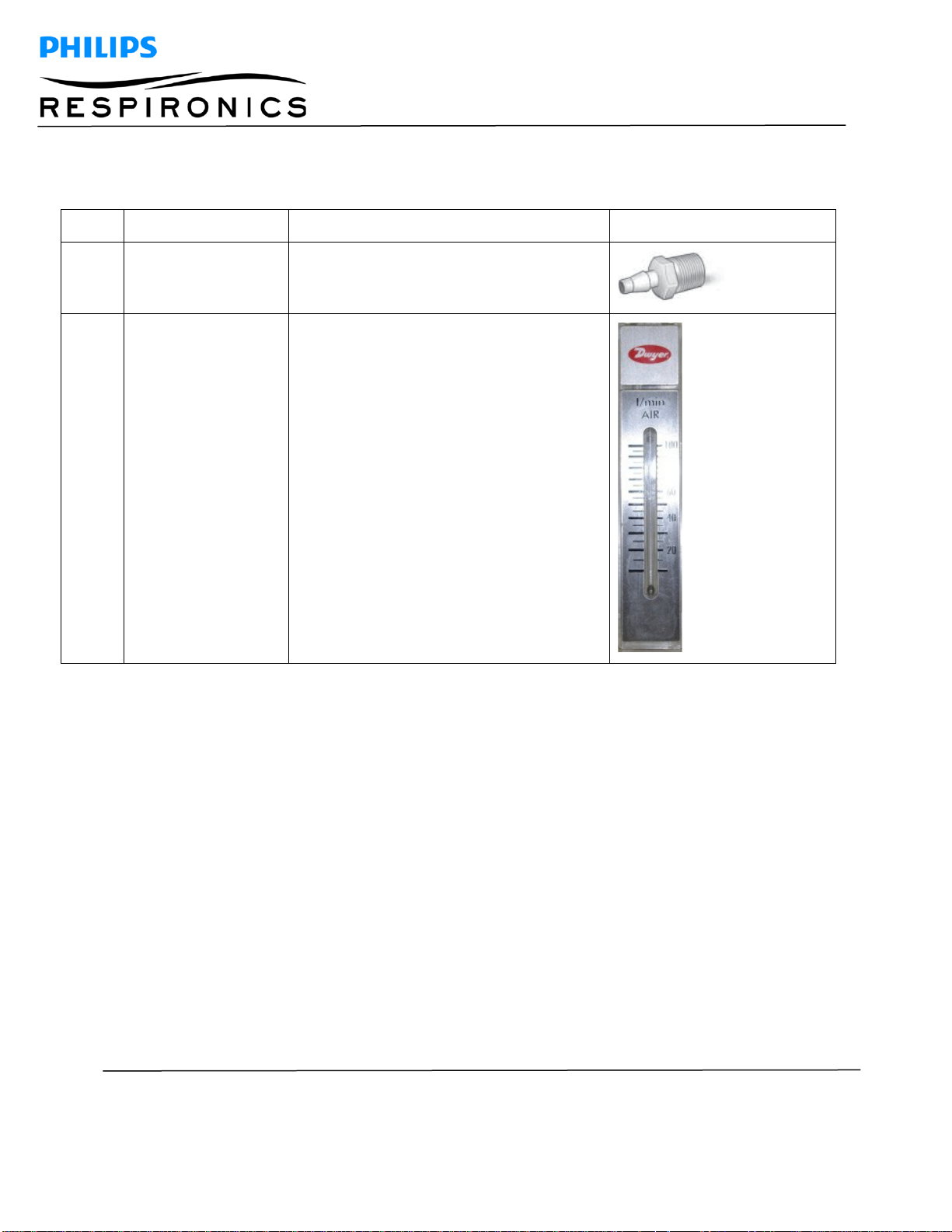

ID

Reference Part No.

Description

Picture

1

2

EQUIPMENT REQUIRED FOR OPTION 2

Items 1-4, 6, 9, and 10 as detailed above with the addition of the following items:

Male Tube Adapter 1/8” NPT x 3/8” Barb,

McMaster-Carr: Part # 5372K116

Flow Meter, Dwyer Instruments Part # RMA25

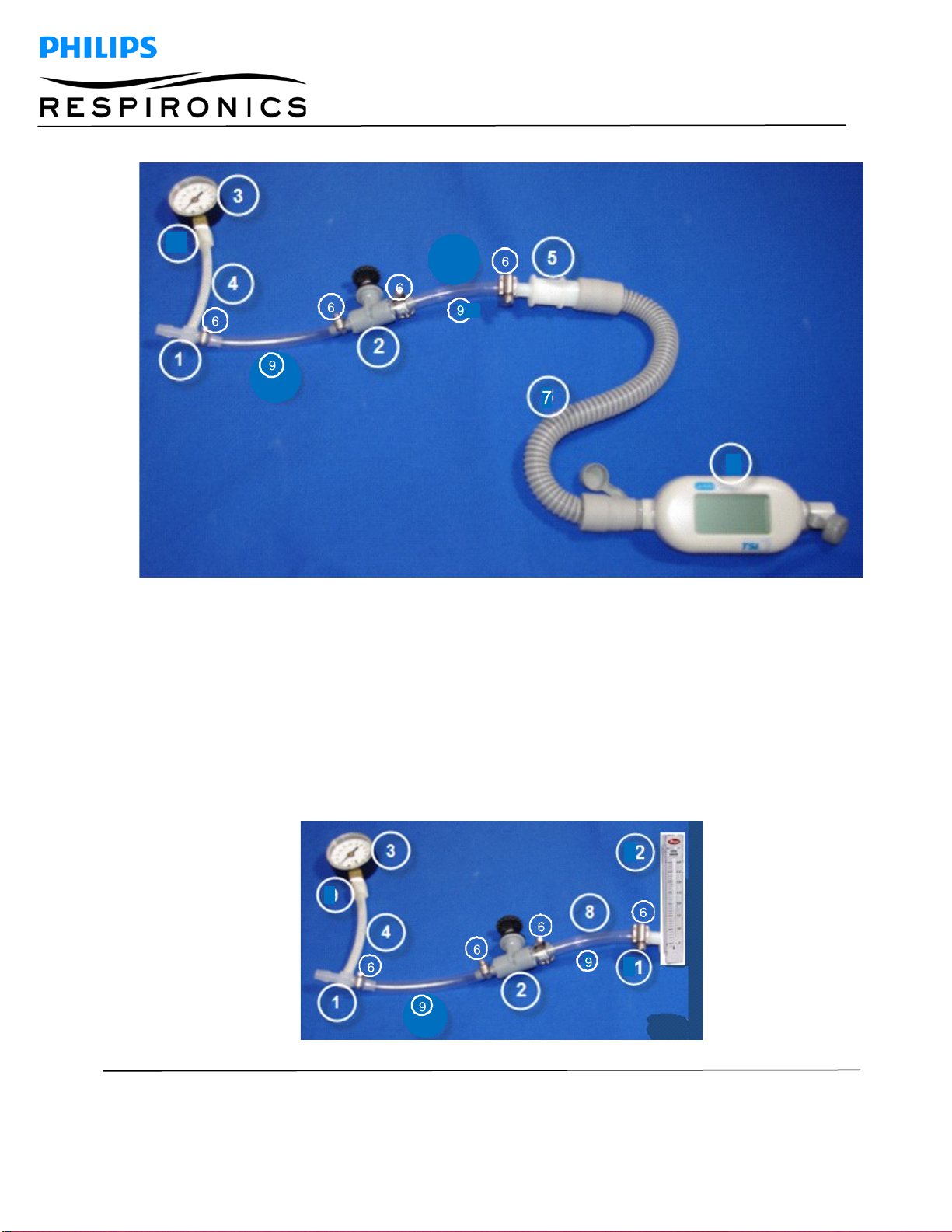

ASSEMBLY INSTRUCTIONS FOR EQUIPMENT OPTION 1

1. Connect the compressor blue outlet tube to Barbed Tube Fitting Reducing Tee (#1) and secure with a

hose clamp (#6).

2. Thread the Barbed Tubing Fitting Adapter (#10) to the gauge (#3) using Teflon tape.

3. Connect the Tubing Fitting Adapter (#10) to the Reducing Tee (#1) using the High Pressure Tubing (#4).

4. Install the High Pressure Clear Tubing (#9) to the Reducing Tee (#1) and the Needle Va lve (#2) and

secure with hose clamps (#6).

5. Install the High Pressure Clear Tubing (#9) to the Needle Valve (#2) and the Single Barbed Tube Fitting

(#5) and secure with hose clamps (#6).

6. Install the 18” Patient Tubing (#7) to the Single Barbed Tube Fitting (#5) and the TSI Flow Meter (#8).

7. Install the power adapter to the TSI Flow Meter (#8) and plug into a 120 VAC/60 Hz outlet.

Page 27 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

1

1

1

10

8

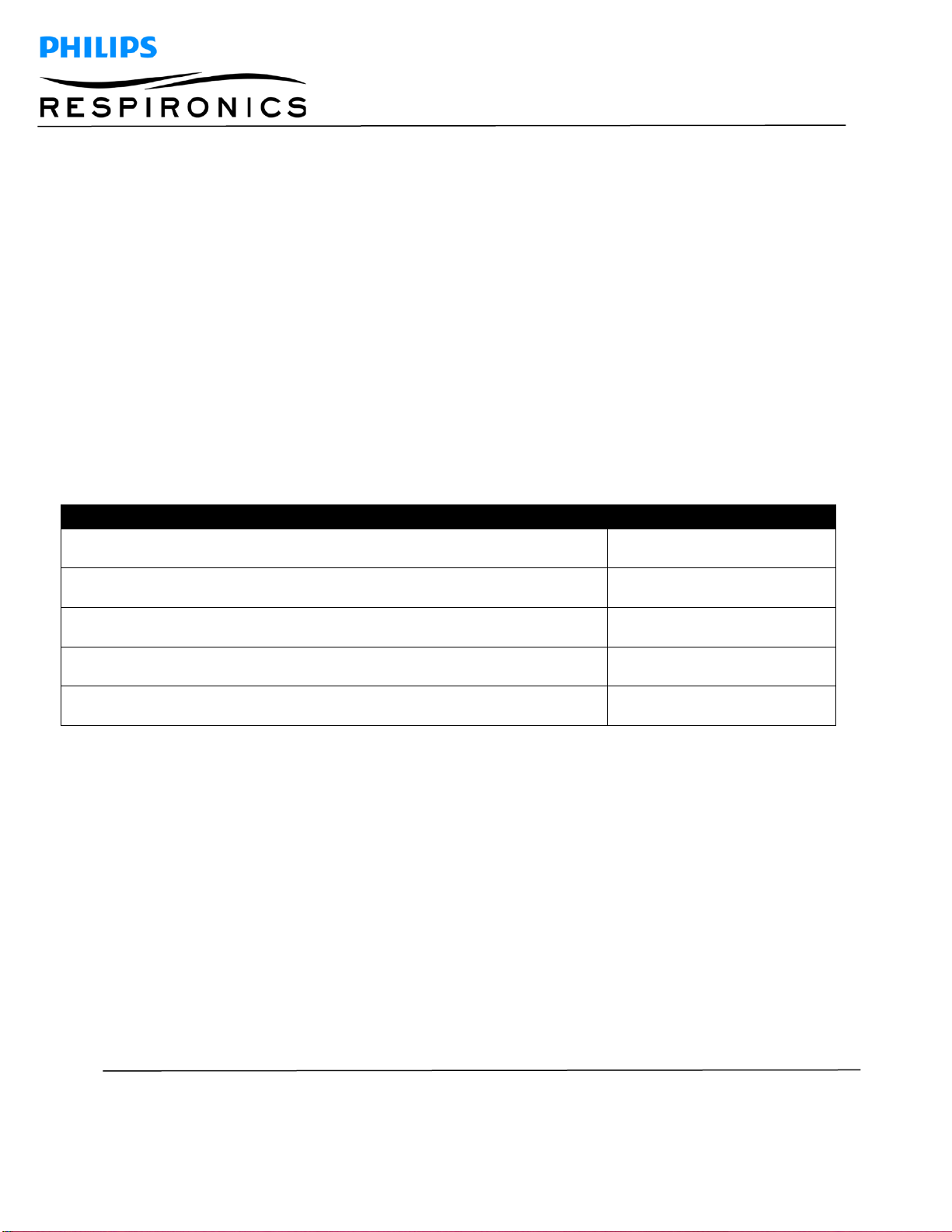

ASSEMBLY INSTRUCTIONS FOR EQUIPMENT OPTION 2

1.

Connect the compressor blue outlet tube to Barbed Tube Fitting Reducing Tee (#1) and secure

with a hose clamp (#6).

2.

Thread the Barbed Tubing Fitting Adapter (#10) to the gauge (3) using Teflon tape.

3.

Connect the Tubing Fitting Adapter (#10) to the Reducing Tee (#1) using the High Pressure Tubing

(#4).

4.

Install the High Pressure Clear Tubing (#9) to the Reducing Tee (#1) and the Needle Valve (#2)

and secure with hose clamps (#6).

5.

Install the High Pressure Clear Tubing (#9) to the Needle Valve (#2)

6.

Install the 1/8” Male Tube Adapter (#12) to the Flow Meter (#13) using Teflon tape.

7.

Install the High Pressure Clear Tubing (#9) to the 3/8” Male Tube Adapter (#12) and secure with

a hose clamp (#6).

Page 28 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

ASSEMBLY INSTRUCTIONS FOR EQUIPMENT OPTION 3

Option 3 is only available in SCMS (equipment not shown above).

1. Attach the TSI flow meter to the inlet filter.

2. Attach the grommet to the inlet adapter.

3. Inset the pipe nipple into a length of hose. (@ 7” in length)

4. Attach the hose to the Compact Plastic Needle Valve 3/8" Barb X 3/8" Barb Connections.

5. Join a short length of hose to the white polypropylene barbed tube.

6. Connect the pressure gage to the tee fitting on the barbed tube.

7. Attach a length of blue hose (30” in length) from the barb fitting to a brass fitting.

This is the test end of the device for testing the compressors for flow and pressure.

8. Insert an inline muffler to help collect any sieve material in the test line.

9. Use clamps to secure the fittings together.

PROCEDURE

1. Follow the procedures detailed in the EverFlo Service Manual for the removal of the following

components:

a. Filter Cover

b. Inlet Filter

c. Rear Cabinet

Page 29 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Compressor Table

E

.38 C

-120V (

1098014

1122381)

≤ 63.0 LPM indicates a “FAIL”

EverFlo Compressor-120V .44 (

1098014

1122381)

≤ 69.0 LPM indicates a “FAIL”.

PRI Compressor model 1082141 (115, 60Hz and .38 stroke)

≤ 56.0LPM indicates a “FAIL”.

PRI Compressor model 1082142 (115, 60Hz and .44 stroke)

≤ 65.0 LPM indicates a “FAIL”.

GSE compressor (115, 60Hz and .45 stroke)

≤ 68.0 LPM indicates a “FAIL”.

2. Remove the blue hose running from the Compressor to the Sieve Canister Assembly by carefully cutting

the one-eared clamp.

3. Connect the Compressor blue outlet tube to the Test Fixture’s Barbed Tube Fitting Reducing Tee.

4. Install the Inlet Filter to the Compressor’s Inlet Boot.

5. If using Test Fixture Option 1, turn ON the flow meter.

6. Ensure is Compact Plastic Needle Valve is fully open.

7. Turn ON the EverFlo power switch.

8. Start the stopwatch.

9. Adjust Compact Plastic Needle Valve to achieve 20 psi pressure. (turning clockwise to increase pressure

and turning counter-clockwise to decrease pressure)

10. When time reaches 1 minute, observe and record LPM reading from Flow Meter.

11. Stop the stopwatch.

12. A reading ≥ 69 LPM indicates a “PASS” for the 0.44 compressor, a reading < 69 LPM indicates a “FAIL”.

13. A reading ≥ 63 LPM indicates a “PASS” for the 0.38 compressor, a reading of < 63 LPM indicates a

“FAIL”

14. If the Compressor failed, replace the compressor as per the Service Manual Compressor Replacement

instruction.

15. If the Compressor passed, continue to troubleshoot as per the System Verification Procedures in the

Service Manual.

VERFLO

OMPRESSOR

MODEL

MODEL

OR

OR

Page 30 E

VERFLO

TM

SERVICE & TECHNICAL INFORMATION 1039055, VER. 06

Loading...

Loading...