Philips EM8E Service Manual

Colour television Chassis

EM8E

AA

E_14780_000.eps

170704

Contents Page Contents Page

1 Technical Specifications, Connections,

and Chassis Overview 2

2 Safety Instructions, Warnings, and Notes 6

3 Directions for Use 8

4 Mechanical Instructions 9

5 Service Modes, Error Codes, and Faultfinding 15

6 Block Diagrams, Testpoint Overview, and

Waveforms (Not Applicable yet)

Wiring Diagram 32” Sharp LCD 21

7 Circuit Diagrams and PWB layouts Diagram PWB

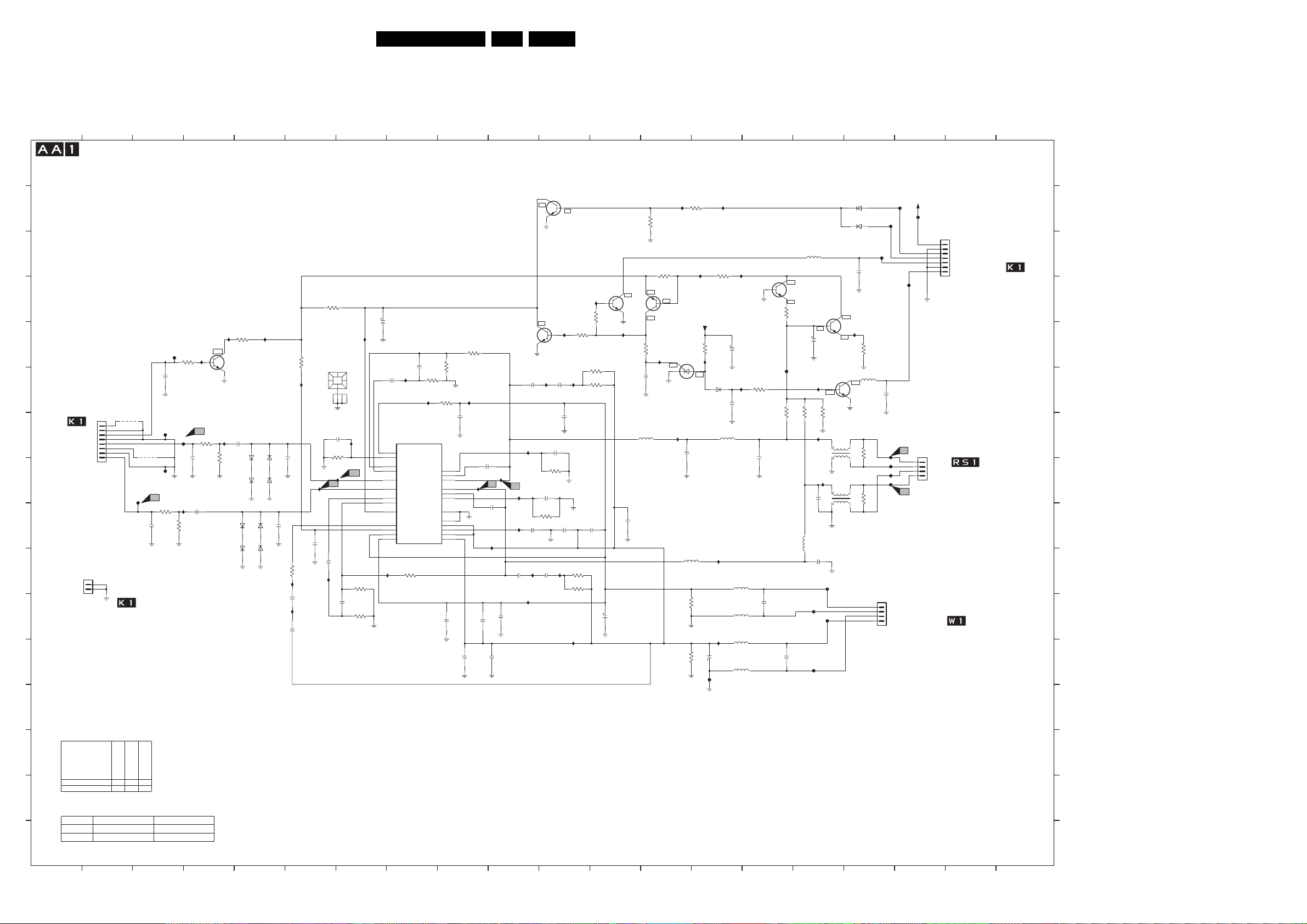

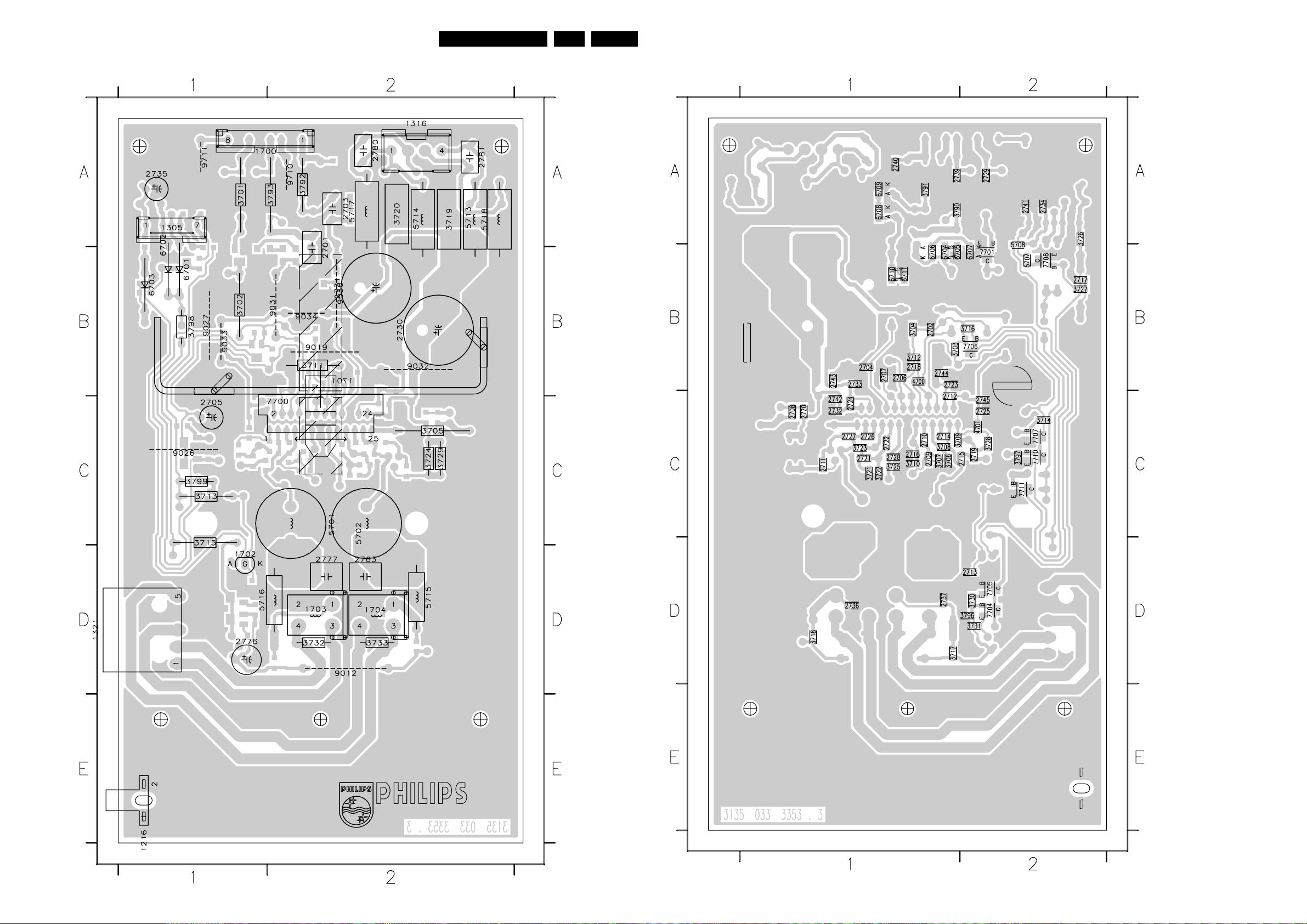

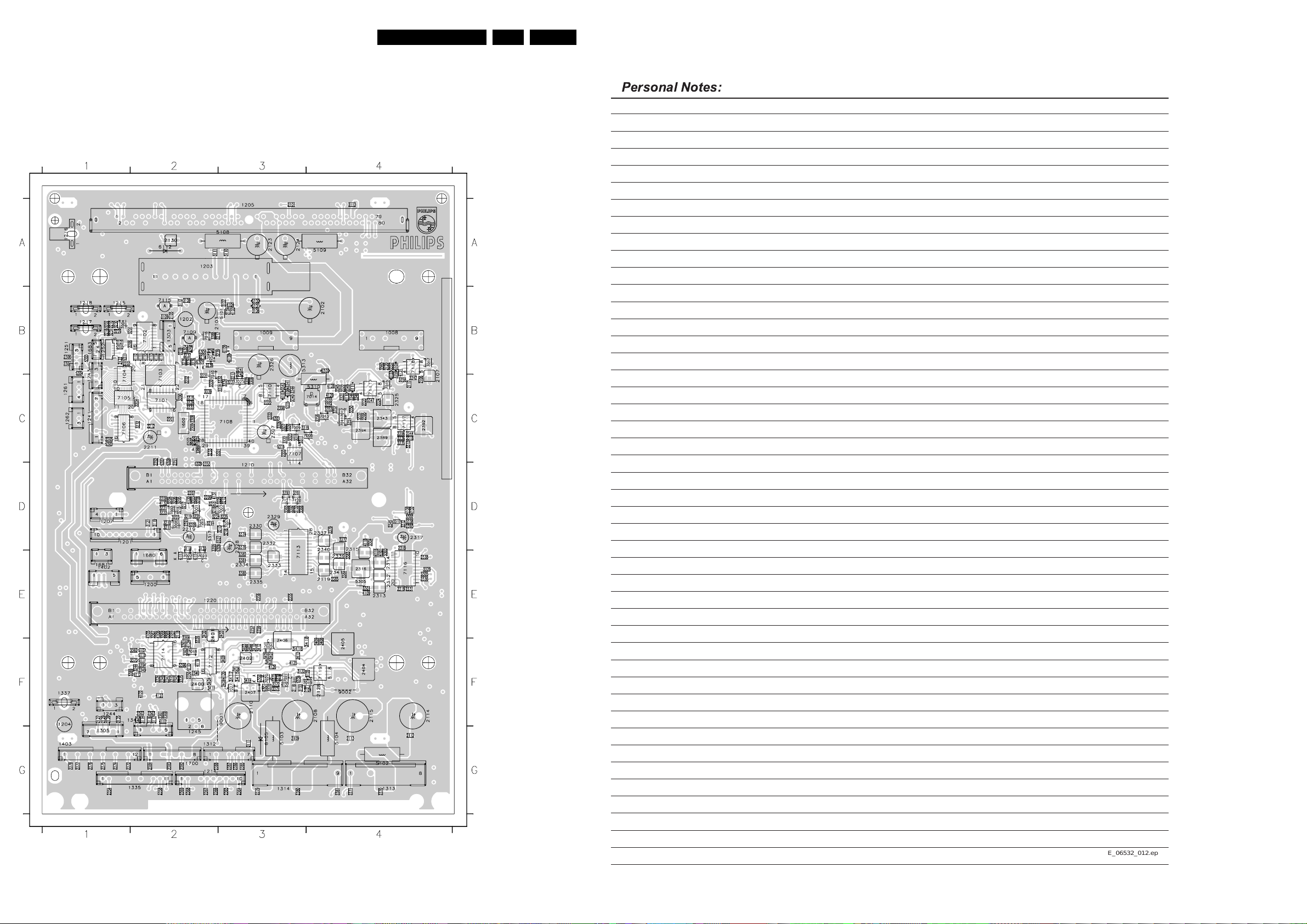

LCoS Audio Amplifier Board (Diagram AA1) 22 23

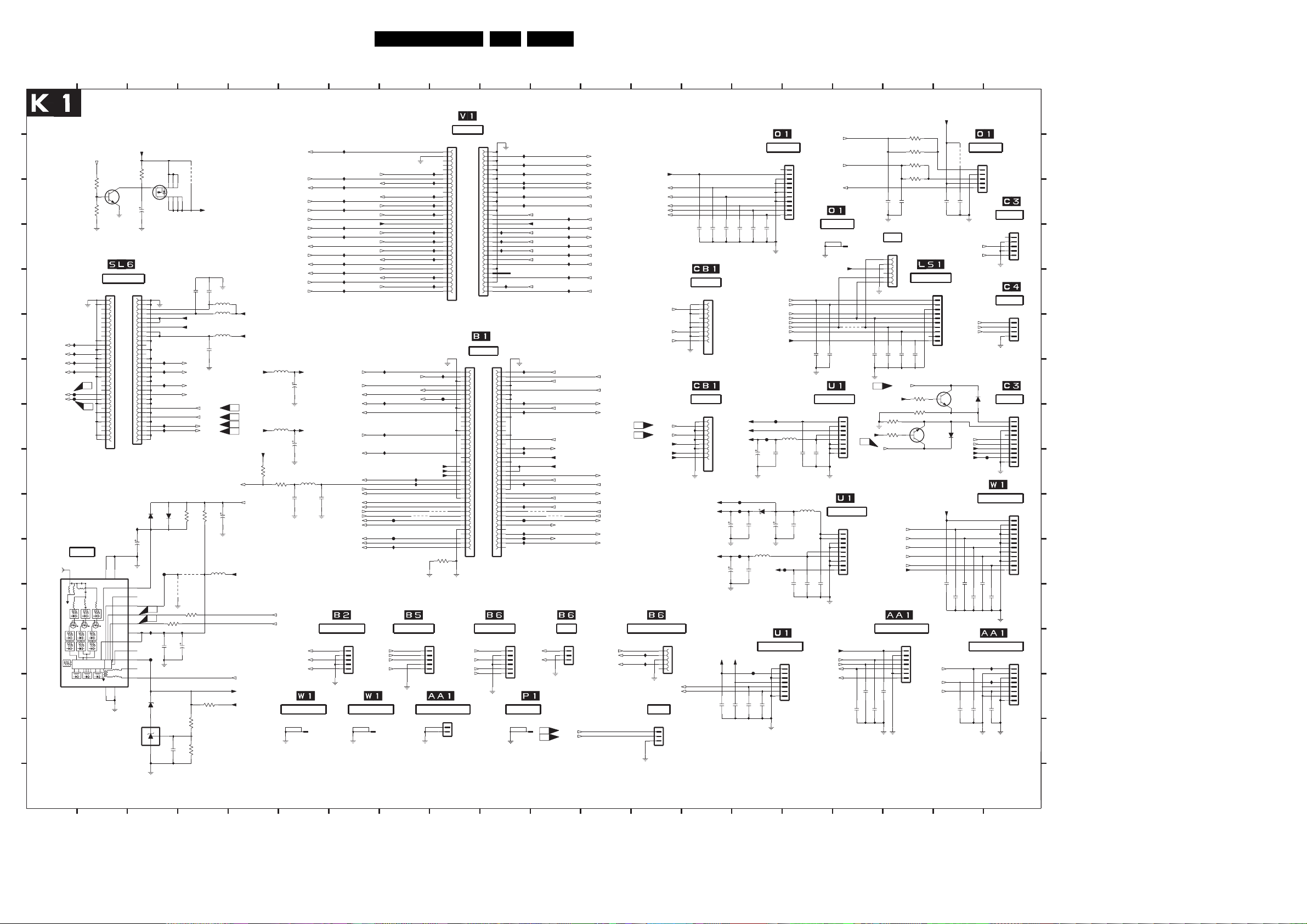

LCoS System Board (Diagram K1) 24 28

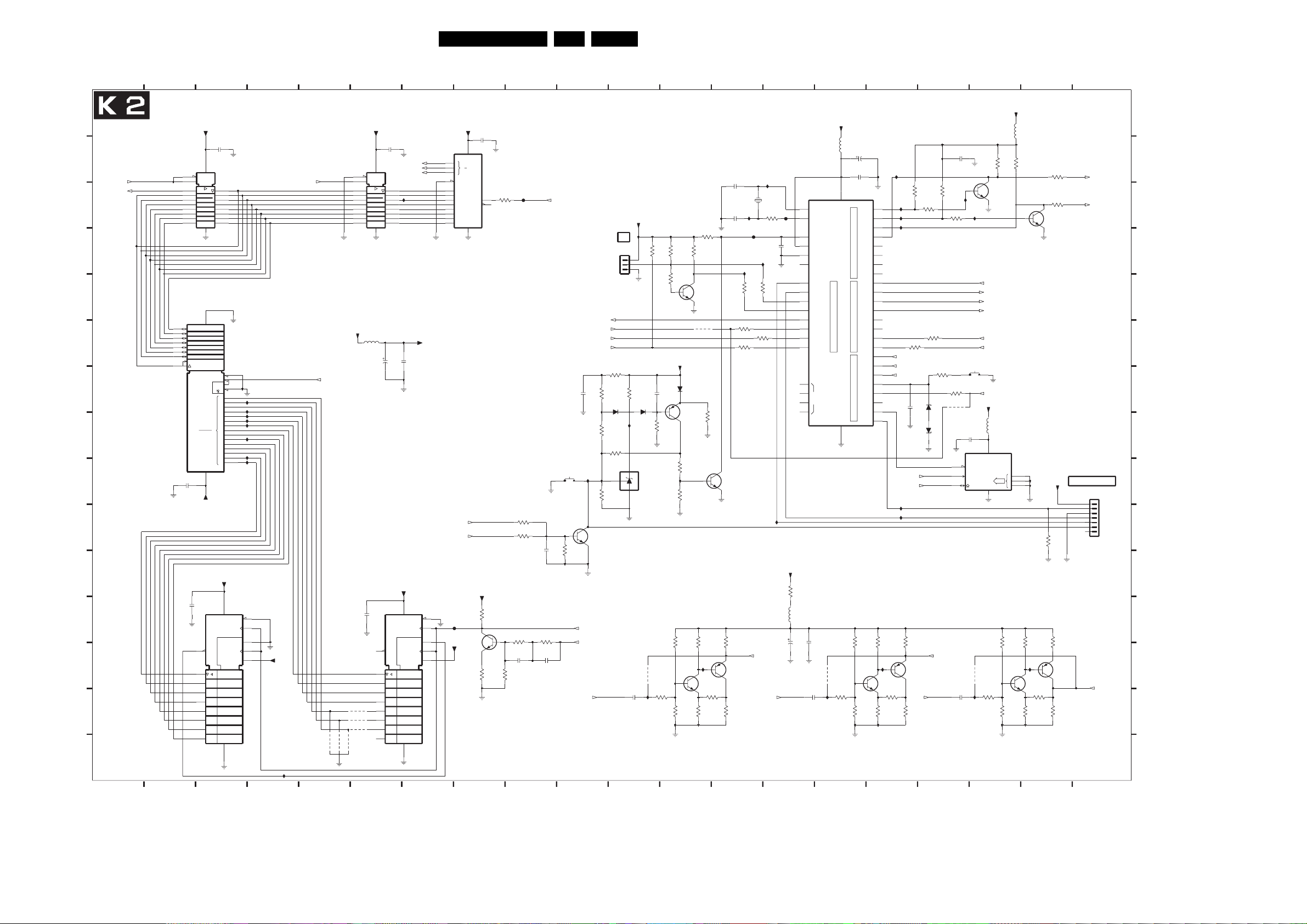

LCoS System Board (Diagram K2) 25 28

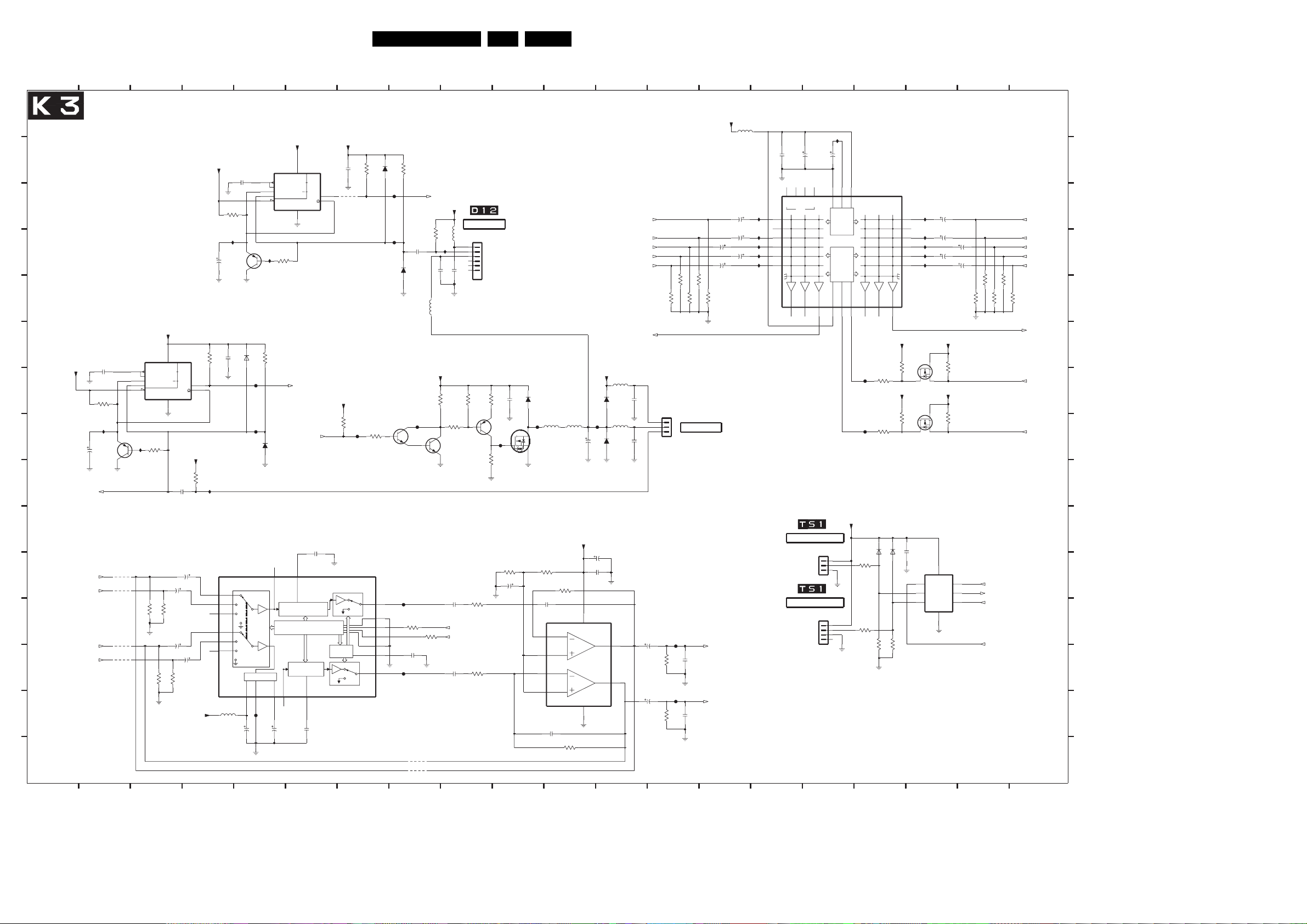

LCoS System Board (Diagram K3) 26 28

LCoS System Board (Diagram K4) 27 28

LED Sensor Panel (Diagram LS) 29 30

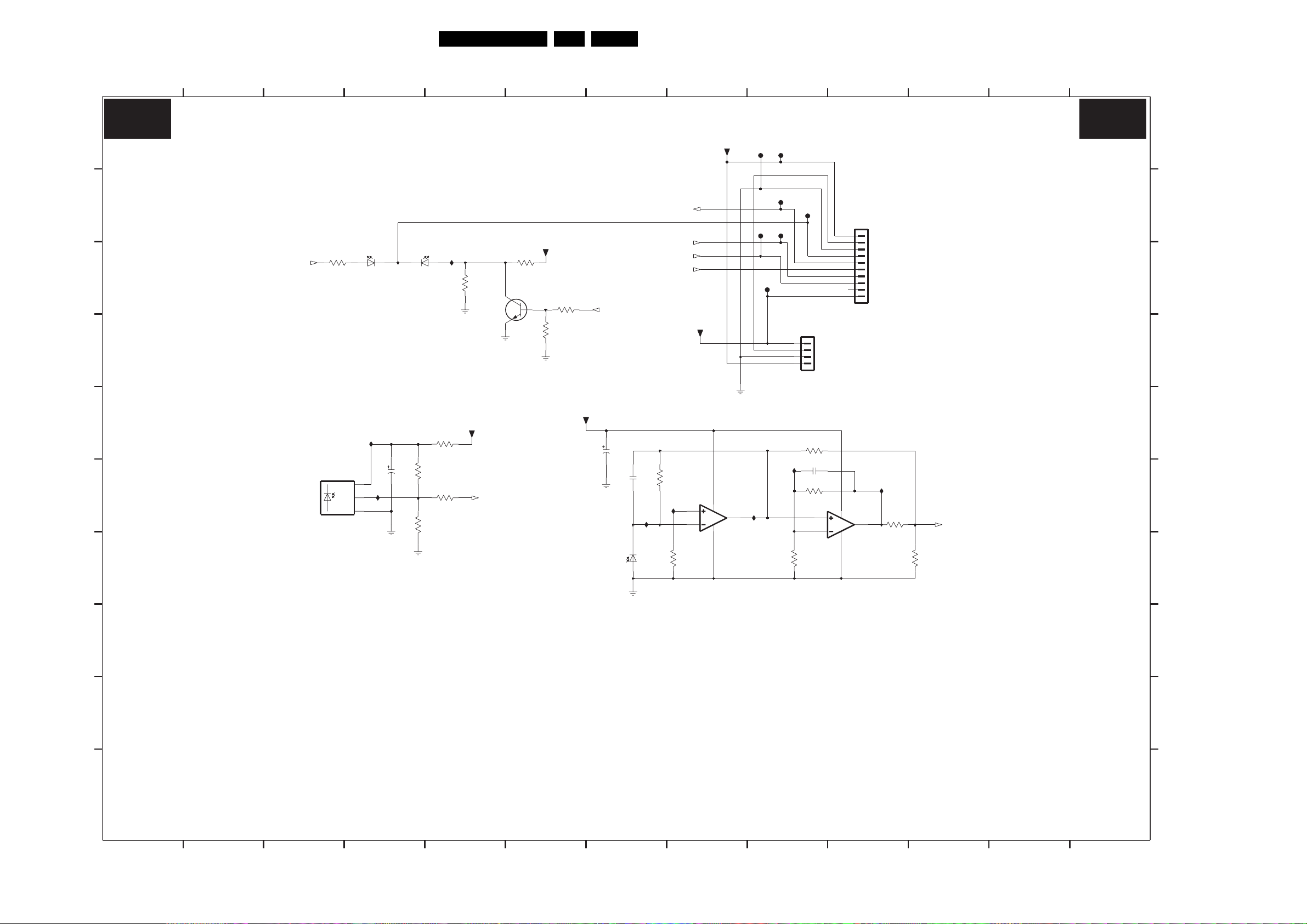

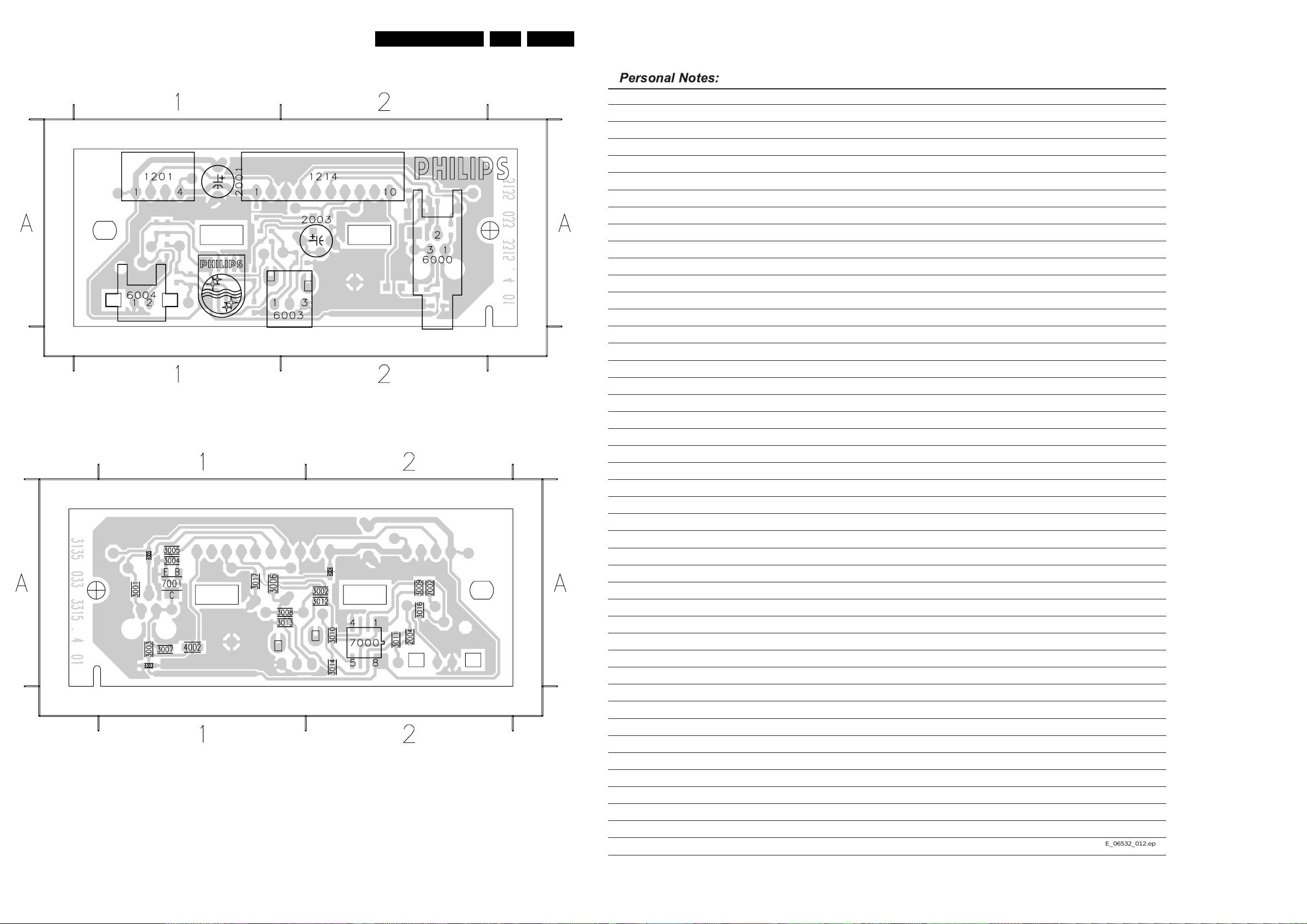

LCoS Side Jack Panel (Diagram O) 31 32

LCoS LED / Keyboard Panel (Diagram P1) 33 34

LCoS MSB: OSD Insertion (Diagram SL1A) 35 (NA)

LCoS MSB: OSD Insertion (Diagram SL1B) 36 (NA)

LCoS MSB: OSD Insertion (Diagram SL1C) 37 (NA)

LCoS MSB: TMDS-TX (Diagram SL2) 38 (NA)

LCoS MSB: Scaler 1 (Diagram SL3A) 39 (NA)

LCoS MSB: Scaler 2 (Diagram SL3B) 40 (NA)

LCoS MSB: Scaler 3 (Diagram SL3C) 41 (NA)

LCoS MSB: LVDS Receiver (Diagram SL3D) 42 (NA)

LCoS MSB: HD Sync Slicer (Diagram SL4A) 43 (NA)

LCoS MSB: HD2 + VGA Input (Diagram SL4B) 44 (NA)

LCoS MSB: HD1 - 2 Selector (Diagram SL4C) 45 (NA)

LCoS MSB: DVI Receiver (Diagram SL5) 46 (NA)

LCoS MSB: DC-Converter (Diagram SL6) 47 (NA)

Thermo Sensor Panel (Diagram TS1) 48 48

LCoS Main Power Board (Diagram U1) 49 50

LCoS SCART Daughter Board (Diagram VDS1) 51 52

©

Copyright 2004 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

LCoS 1fH SCART Panel (Diagram VS1) 53 56

LCoS 1fH SCART Panel (Diagram VS2) 54 56

LCoS 1fH SCART Panel (Diagram VS3) 55 56

LCoS Input Power Board (Diagram W1) 57 59

LCoS Input Power Board (Diagram W2) 58 59

8 Alignments 61

9 Circuit Descriptions 67

List of Abbreviations 93

IC Data Sheets (Not Applicable)

10 Spare Parts List 95

11 Revision List 106

Published by JH 0467 TV Service Printed in The Netherlands Subject to modification EN 3122 785 14780

EN 2 EM8E1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1. Technical Specifications

2. Connections

3. Chassis Overview

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

1.1 Technical Specifications

1.1.1 Vision

Display type : Rear projection, LCD

Screen size : 55” (140 cm), 16:9

Resolution (HxV) : 1280 x 720p, WXGA

Viewing angle (HxV) : 160 x 120 deg.

Tuning system : PLL

Colour systems : PAL B/G, D/K, I

: SECAM B/G, D/K, L/L’

Add. systems Ext in : NTSC 3.58, 4.43

: 576i (YPrPb)

: 576p (YPrPb)

: 720p

: 1080i

: SECAM

: VGA (640 x 400)

: VGA (640 x 480)

: WVGA (848 x 480)

: WVGA (852 x 480)

: SVGA (800 x 600)

: XGA (1024 x 768)

: SXGA (1280 x 1024)

Channel selections : 100 presets

: UVSH

Aerial input : 75 ohm, IEC-type

1.1.2 Sound

1.2 Connections

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Side Connections / Top Control

R

AUDIO

L

VIDEO

S-VIDEO

E_14780_011.eps

250604

Figure 1-1 Side I/O connections

-+

VOLUME CHANEL

Figure 1-2 Top Control

Mini Jack: Audio Headphone - Out

Bk -Headphone 32 - 600 ohm / 10 mW ot

MENU

E_14780_012.eps

250604

Sound systems : AV stereo,

: FM/FM B/G (5.5-5.74)

: FM/FM Cz (6.5-6.25)

: NICAM B/G (5.5-5.85)

: NICAM D/K (5.5-5.85)

: NICAM I (6.0-6.52)

: NICAM L (6.5AM-

5.85)

Maximum power : 2 x 25 WRMS (int.)

1.1.3 Miscellaneous

Power supply:

- Mains voltage : 220 - 240 VAC

- Mains frequency : 50 / 60 Hz.

Ambient conditions:

- Temperature range : +5 to +40 deg. C

- Maximum humidity : 90 % R.H.

Power consumption

- Normal operation : ca. 270 W

- Standby : < 1 W

Dimensions (WxHxD) : 1437 x 968 x 443 cm

Weight : 40 kg

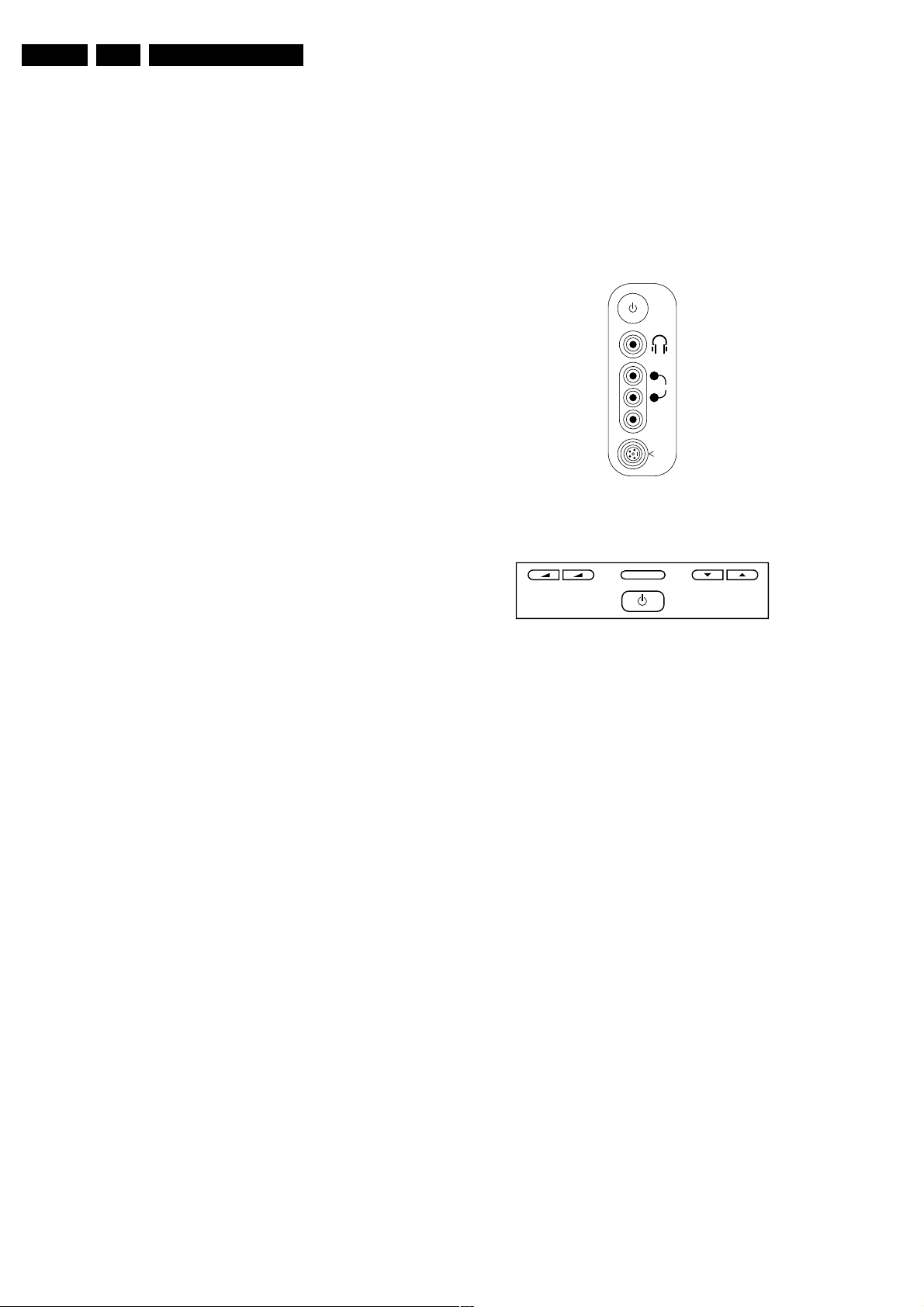

1.2.2 Rear Connections

Cinch: Audio - In, CVBS - In

Re - Audio - R 0.5 VRMS / 10 kohm jq

Wh -Audio - L 0.5 VRMS / 10 kohm jq

Ye -CVBS 1 VPP / 75 ohm jq

Hosiden: SVHS - In

1-Y Ground H

2-C Ground H

3-Y 1 VPP / 75 ohm j

4-C 0.3 VPP / 75 ohm j

Technical Specifications, Connections, and Chassis Overview

External 2: Audio - In/Out, RGB/YUV - In, CVBS - In/Out

EN 3EM8E 1.

C

2

EXT3

R

L

EXT5 EXT4 EXT2 EXT1 SERVICE I

L

R

STANDARD/

HD INPUTS

STANDARD/

HD INPUTS

OUT

MONITOR

SUB

OUT

IN

CENTER

EXT7

EXT6

DVI

R

R

RGB+HV

PrPrPb

L

L

Y

TUNER

Pb

Y

E_14780_010.eps

250604

Figure 1-3 Rear connections

Service Connector (ComPair)

1-SDA-S I2C data (5 V) jk

2-SCL-S I2C clock (5 V) j

3-GND Ground H

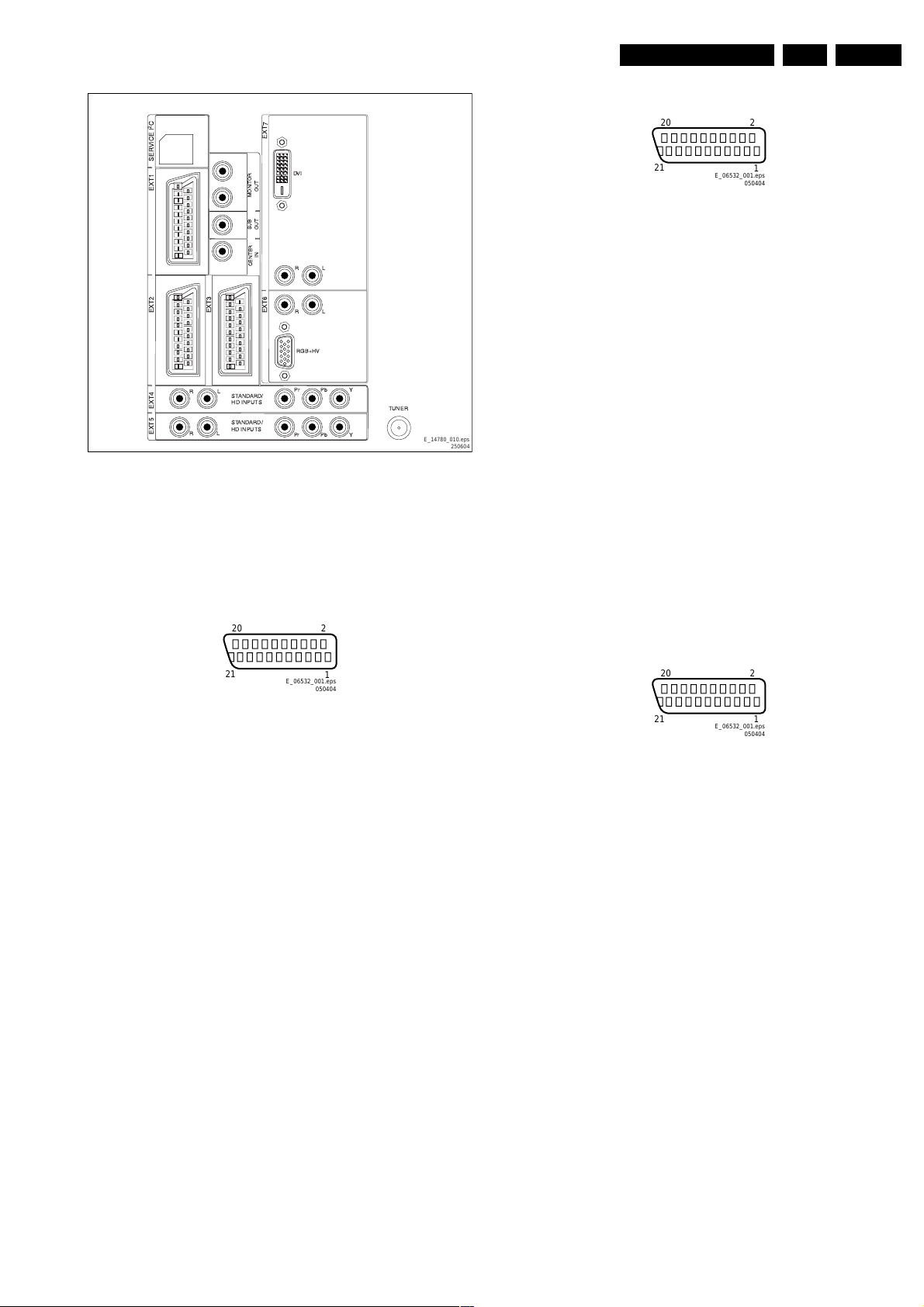

External 1: Audio In/Out, RGB/YUV - In , CVBS - In/Out

20

2

20

21

2

E_06532_001.eps

050404

1

Figure 1-5 SCART connector

1-Audio - R 0.5 VRMS / 1 kohm k

2-Audio - R 0.5 VRMS / 10 kohm j

3-Audio - L 0.5 VRMS / 1 kohm k

4-Audio - gnd Ground H

5-Blue - gnd Ground H

6-Audio - L 0.5 VRMS / 10 kohm j

7-Blue/U - in 0.7 VPP / 75 ohm j

8-CVBS-status 0 - 2 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9-Green - gnd Ground H

10 - Easylink P50 j

11 - Green/Y - in 0.7 VPP / 75 ohm j

12 - n.c.

13 - Red - gnd Ground H

14 - FBL - gnd Ground H

15 - Red/V - in 0.7 VPP / 75 ohm j

16 - Status/FBL 0 - 0.4 V: INT

1 - 3 V: EXT / 75 ohm j

17 - Video Ground H

18 - Video Ground H

19 - CVBS - out 1 VPP / 75 ohm k

20 - CVBS - in 1 VPP / 75 ohm j

21 - Shielding Ground H

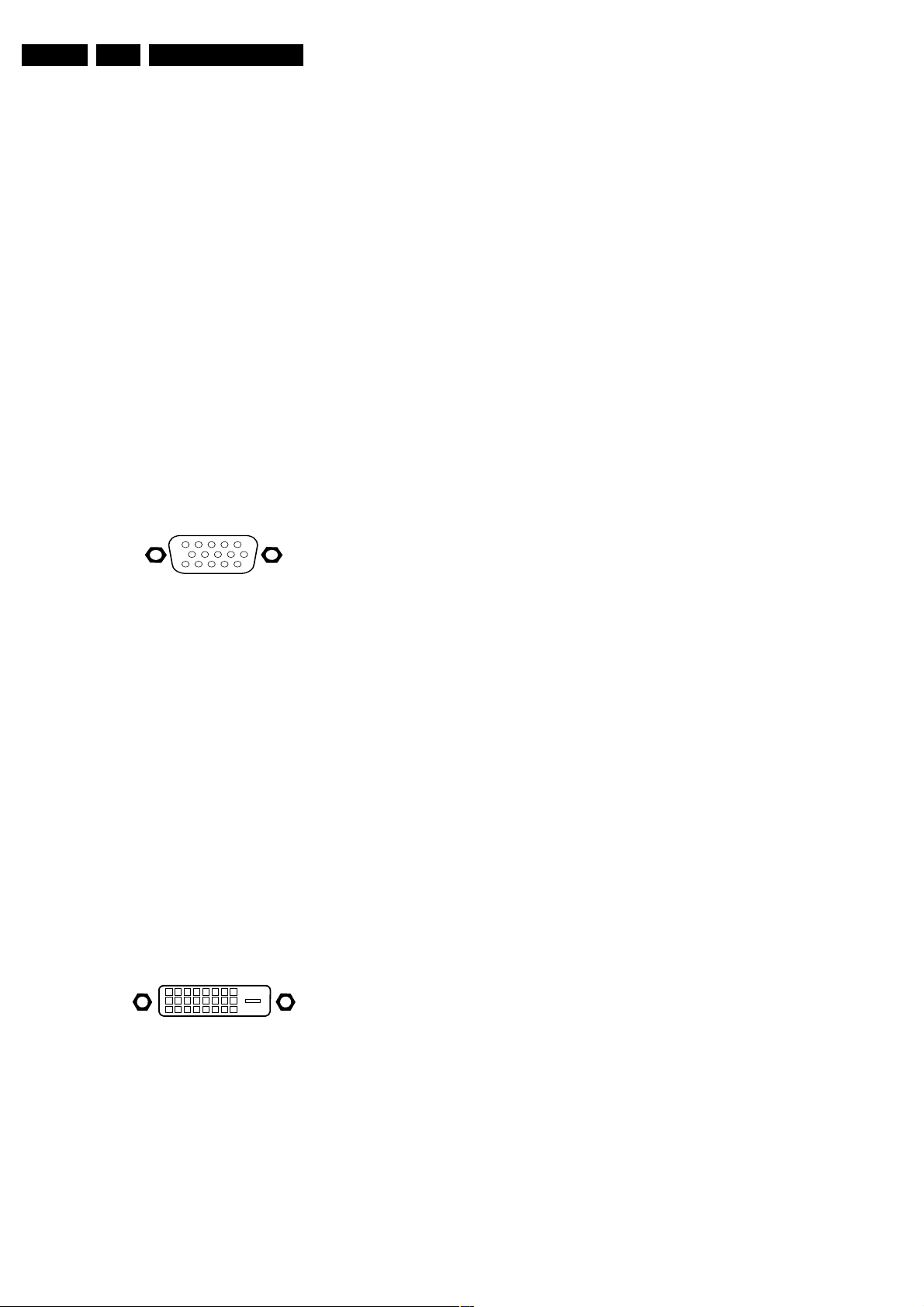

External 3: Audio - In, CVBS - In

21

E_06532_001.eps

050404

1

Figure 1-4 SCART connector

1-Audio - R 0.5 VRMS / 1 kohm k

2-Audio - R 0.5 VRMS / 10 kohm j

3-Audio - L 0.5 VRMS / 1 kohm k

4-Audio - gnd Ground H

5-Blue - gnd Ground H

6-Audio - L 0.5 VRMS / 10 kohm j

7-Blue/U - in 0.7 VPP / 75 ohm j

8-CVBS-status 0 - 2 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9-Green - gnd Ground H

10 - n.c.

11 - Green/Y - in 0.7 VPP / 75 ohm j

12 - n.c.

13 - Red - gnd Ground H

14 - FBL - gnd Ground H

15 - Red/V - in 0.7 VPP / 75 ohm j

16 - Status/FBL 0 - 0.4 V: INT

1 - 3 V: EXT / 75 ohm j

17 - Video Ground H

18 - Video Ground H

19 - CVBS - out 1 VPP / 75 ohm k

20 - CVBS - in 1 VPP / 75 ohm j

21 - Shielding Ground H

20

21

2

E_06532_001.eps

050404

1

Figure 1-6 SCART connector

1-n.c.

2-Audio - R 0.5 VRMS / 10 kohm j

3-n.c.

4-Audio - gnd Ground H

5-Blue - gnd Ground H

6-Audio - L 0.5 VRMS / 10 kohm j

7-n.c.

8-CVBS-status 0 - 2 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9-Green - gnd Ground H

10 - n.c.

11 - n.c.

12 - n.c.

13 - Red - gnd Ground H

14 - FBL - gnd Ground H

15 - n.c.

16 - n.c.

17 - Video Ground H

18 - Video Ground H

19 - n.c.

20 - CVBS - in 1 VPP / 75 ohm j

21 - Shielding Ground H

EN 4 EM8E1.

Technical Specifications, Connections, and Chassis Overview

Cinch: Audio Centre - In

Gn -Centre 0.5 VRMS / 10 kohm jq

Cinch: Audio Subwoofer - Out

Bk -Subwoofer 0.5 VRMS / 1 kohm kq

Cinch: Audio Monitor - Out

Rd -Audio - R 0.5 VRMS / 1 kohm kq

Wh -Audio - L 0.5 VRMS / 1 kohm kq

External 4 (Cinch): YPbPr - In (2fH)

Gn -Y 0.7 VRMS / 10 kohm kq

Bu -Pb 0.7 VRMS / 10 kohm kq

Rd -Pr 0.7 VRMS / 10 kohm kq

Rd -Audio - R 0.5 VRMS / 10 kohm kq

Wh -Audio - L 0.5 VRMS / 10 kohm kq

External 5 (Cinch): YPbPr - In (2fH)

Gn -Y 0.7 VRMS / 10 kohm kq

Bu -Pb 0.7 VRMS / 10 kohm kq

Rd -Pr 0.7 VRMS / 10 kohm kq

Rd -Audio - R 0.5 VRMS / 10 kohm kq

Wh -Audio - L 0.5 VRMS / 10 kohm kq

External 6: VGA - In

1

6

11

5

10

15

E_06532_002.eps

050404

11 - Ground GND H

12 - n.c.

13 - n.c.

14 - +5V

15 - Ground GND H

16 - + 5V Hot Plug

17 - RX0- j

18 - RX0+ j

19 - Ground GND H

20 - n.c.

21 - n.c.

22 - Ground GND H

23 - RXC+ j

24 - RXC- j

C5 - Ground GND H

External 7 (Cinch): DVI Audio - In

Rd - Audio - R 0.5 VRMS / 10 kohm jq

Wh -Audio - L 0.5 VRMS / 10 kohm jq

Aerial - In

-IEC-type Coax, 75 ohm D

Figure 1-7 VGA Connector

1-Red 0.7 VPP / 75 ohm j

2-Green 0.7 VPP / 75 ohm j

3-Blue 0.7 VPP / 75 ohm j

4-TXD k

5- Ground H

6-Red Ground H

7-Green Ground H

8-Blue Ground H

9-RC k

10 - Ground H

11 - RXD j

12 - DDC_SDA j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL j

External 6 (Cinch): VGA Audio - In

Rd -Audio - R 0.5 VRMS / 10 kohm jq

Wh -Audio - L 0.5 VRMS / 10 kohm jq

External 7: DVI-D: In

18

916

17

24

E_06532_003.eps

C5

050404

Figure 1-8 DVI-D connector

1-RX2- j

2-RX2+ j

3-Ground GND H

4- n.c.

5- n.c.

6-SCL_DVI k

7-SDA_DVI jk

8- n.c.

9-RX1- j

10 - RX1+ j

Technical Specifications, Connections, and Chassis Overview

1.3 Chassis Overview

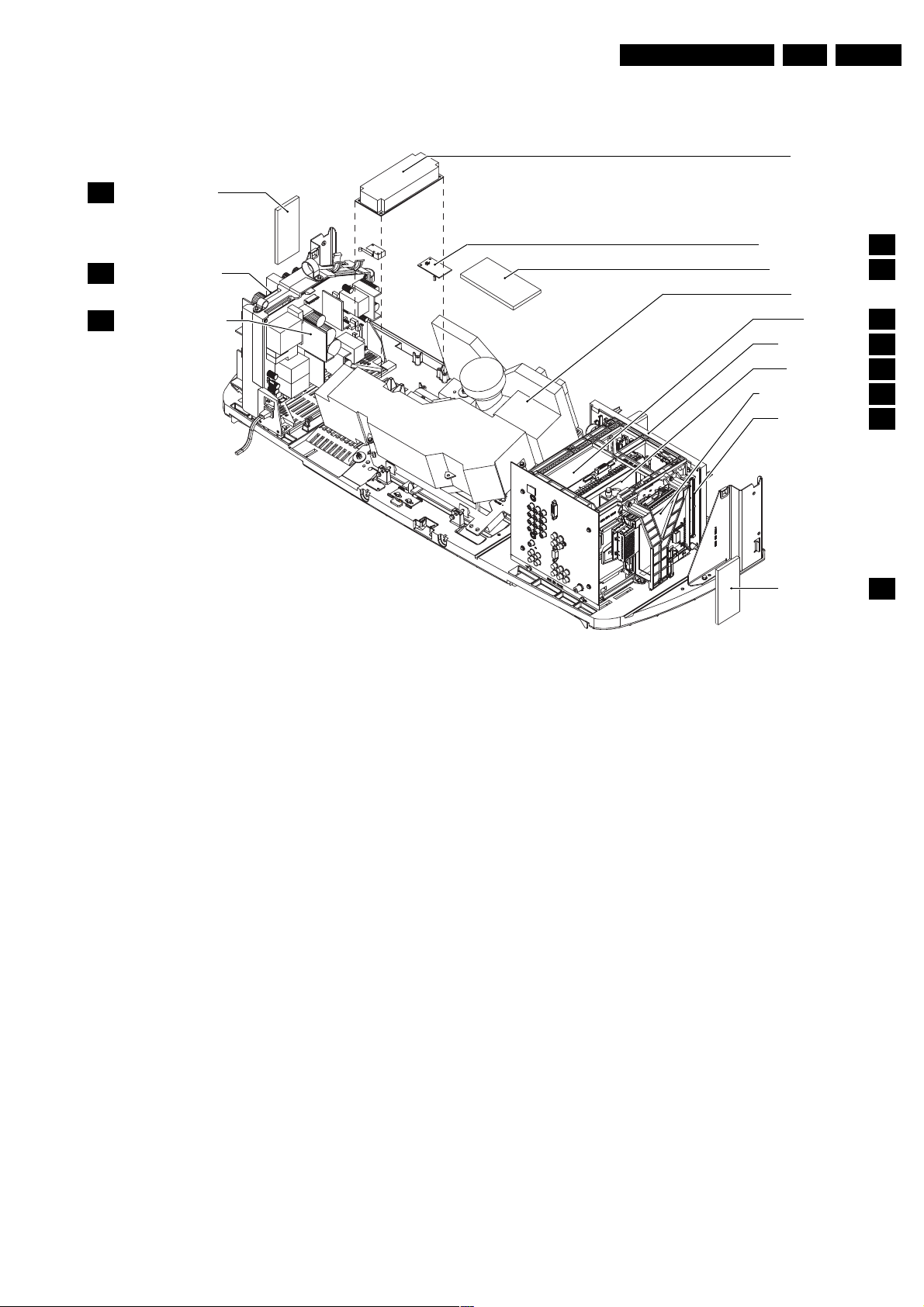

LED SENSOR PANEL

LS

EN 5EM8E 1.

LAMP SUPPLY

MAIN POWER BOARD

U

POWER INPUT BOARD

W

Figure 1-9 PWB location

TEMP SENSOR BOARD

KEYBOARD PANEL

LIGHT ENGINE

JACK PANEL

AUDIO AMPLIFIER

SCALER BOARD

SMALL SIGNAL BOARD

SYSTEM BOARD

SIDE JACK PANEL

E_14780_013.eps

TS

P

VS

AA

SL

B

K

O

190704

EN 6 EM8E2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

2.1 Safety Instructions

Safety regulations require that during a repair:

• Connect the set to the mains via an isolation transformer

(> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the strain relief of the mains cord for proper function.

• Check the electrical DC resistance between the mains plug

and the secondary side (only for sets which have a mains

isolated power supply):

1. Unplug the mains cord and connect a wire between the

two pins of the mains plug.

2. Set the mains switch to the "on" position (keep the

mains cord unplugged!).

3. Measure the resistance value between the pins of the

mains plug and the metal shielding of the tuner or the

aerial connection on the set. The reading should be

between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the mains plug.

• Check the cabinet for defects, to avoid touching of any

inner parts by the customer.

2.2 Warnings

voltages in the power supply section both in normal

operation (G) and in standby (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

E_06532_006.eps

240604

Figure 2-1 Dolby PL Symbol

2.3.2 Schematic Notes

• All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10-6),

nano-farads (n= x10-9), or pico-farads (p= x10-12).

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

2.3.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device Removal

As is the case with any component that, it is essential when

removing an (LF)BGA, the board, tracks, solder lands, or

surrounding components are not damaged. To remove an

(LF)BGA, the board must be uniformly heated to a temperature

close to the reflow soldering temperature. A uniform

temperature reduces the chance of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has shown to result in

problems during re-soldering.

Safety Instructions, Warnings, and Notes

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

To reflow the solder, apply a temperature profile according to

the IC data sheet. So as not to damage neighbouring

components, it may be necessary to reduce some

temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL:

http://www.atyourservice.ce.philips.com (needs

subscription). After login, select “Magazine”, then go to

“Workshop Information”. Here you will find Information on how

to deal with BGA-ICs.

2.3.4 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions - reactions that are best avoided. Before reaching

into a powered TV set, it is best to test the high voltage

insulation. It is easy to do, and is a good service precaution.

EN 7EM8E 2.

EN 8 EM8E3.

3. Directions for Use

You can download this information from the following website:

http://www.philips.com/support

Directions for Use

4. Mechanical Instructions

Mechanical Instructions

EN 9EM8E 4.

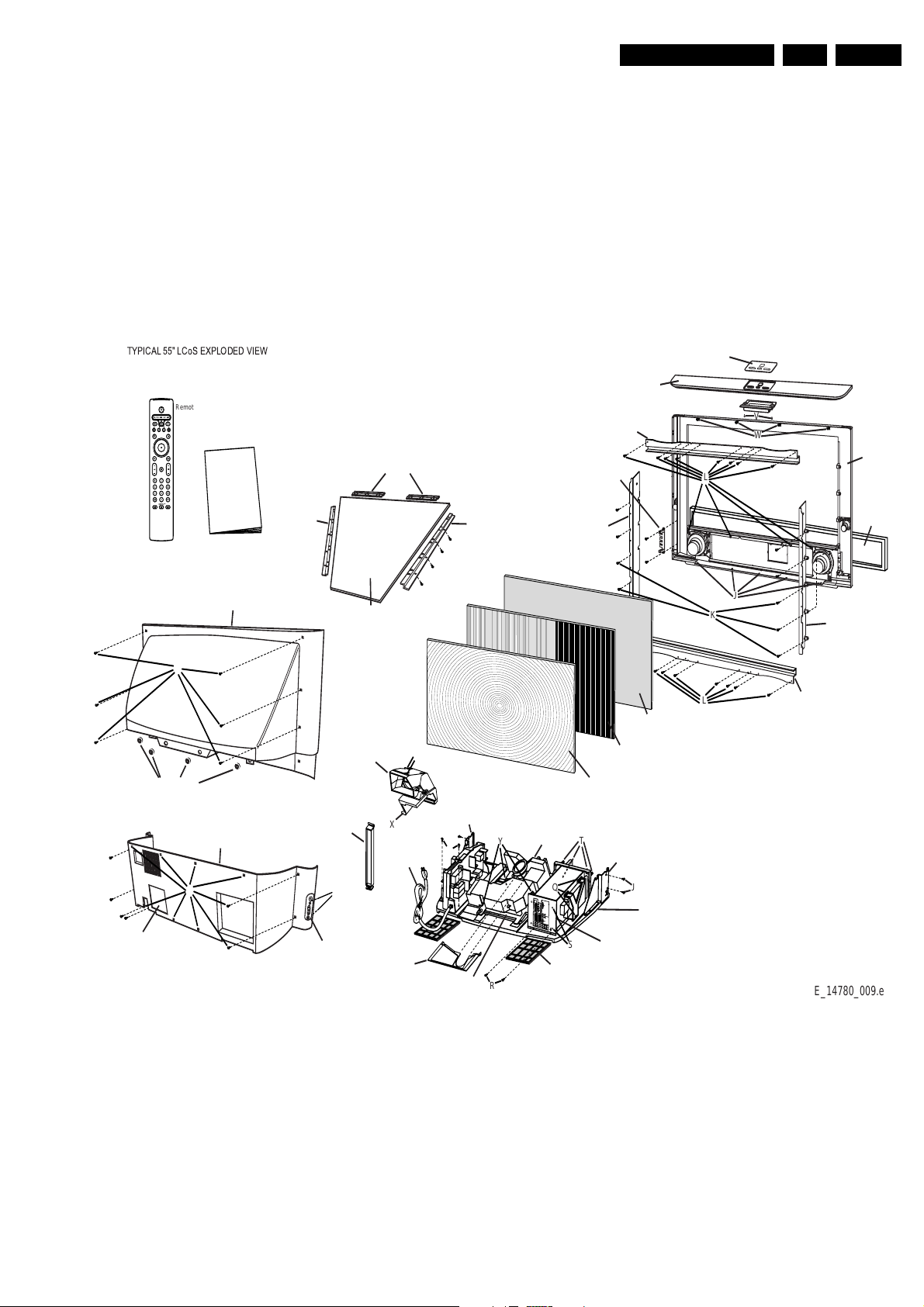

Index of this chapter:

1. Dust Filter

2. Rear Covers

3. Mirror

4. Top Control

5. Speakers

6. Screen Assembly

7. Side Jack Panel

8. Small Signal Package

9. Large Signal Package

10. LED/Sensor Panel

11. Lamp Replacement

Remote Control

N

¨

¨

¨

¨

DFU

Owner's Manual

Item 0034

Back Cover,

(Upper)

Item 0080

Support,

Mirror,

(Left)

Item 0021

Mirror

Item 0078

Support,

Mirror,

(Top)

Item 0079

Support,

Mirror,

(Right)

12. Light Engine Replacement

13. Re-assembly

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

• Use Torx T10 and T20 screwdrivers to dismantle the set.

Item 0066

Overlay,

Control Housing

L

J

K

V

W

Item 0076

Rail, Screen,

(Vertical Right)

Item 0030

Front,

Cabinet

Item 0039

Baffle,

Speakers

Rail, Screen,

(Horizontal)

Item 0132

Frame, LED

Sensor Board

Item 0075

Rail, Screen,

(Vertical Left)

Item 0077

Item 0032

Cap,

(Top)

Item 0096

Door,

Lamp Access

C

Item 0144 & 0145

Cap Mounting

A

Item 0036

Back Cover,

(Lower)

Item 0093

Support,

Back

B

Item 0127

Side Jacks for

Mains Knob

Item 0150

Fan Assembly

Item 8190 (UK/HK)

Item 8191 (Europe)

D

Item 0090

Bracket,

X

Mains Cord

Item 0023

Light

Shield

Left Interconnect

N

Item 0018

Bracket,

Light Engine

R

Figure 4-1 Exploded view

Item 0077

L

Item 0022

Screen,

Protector

Item 0019

Screen,

Lenticular

Item 0020

Lens,

Fresnel

Item 0017

Xion-1

Light Engine

Y

Q

Item 0098

Assembly Filter

(2 Required)

T

S

Item 0091

Bracket,

Right Interconnect

Item 0067

Label,

Rear Jack Scart

J

Item 0038

Base,

Cabinet

Rail, Screen,

(Horizontal)

E_14780_009.eps

240604

EN 10 EM8E4.

Mechanical Instructions

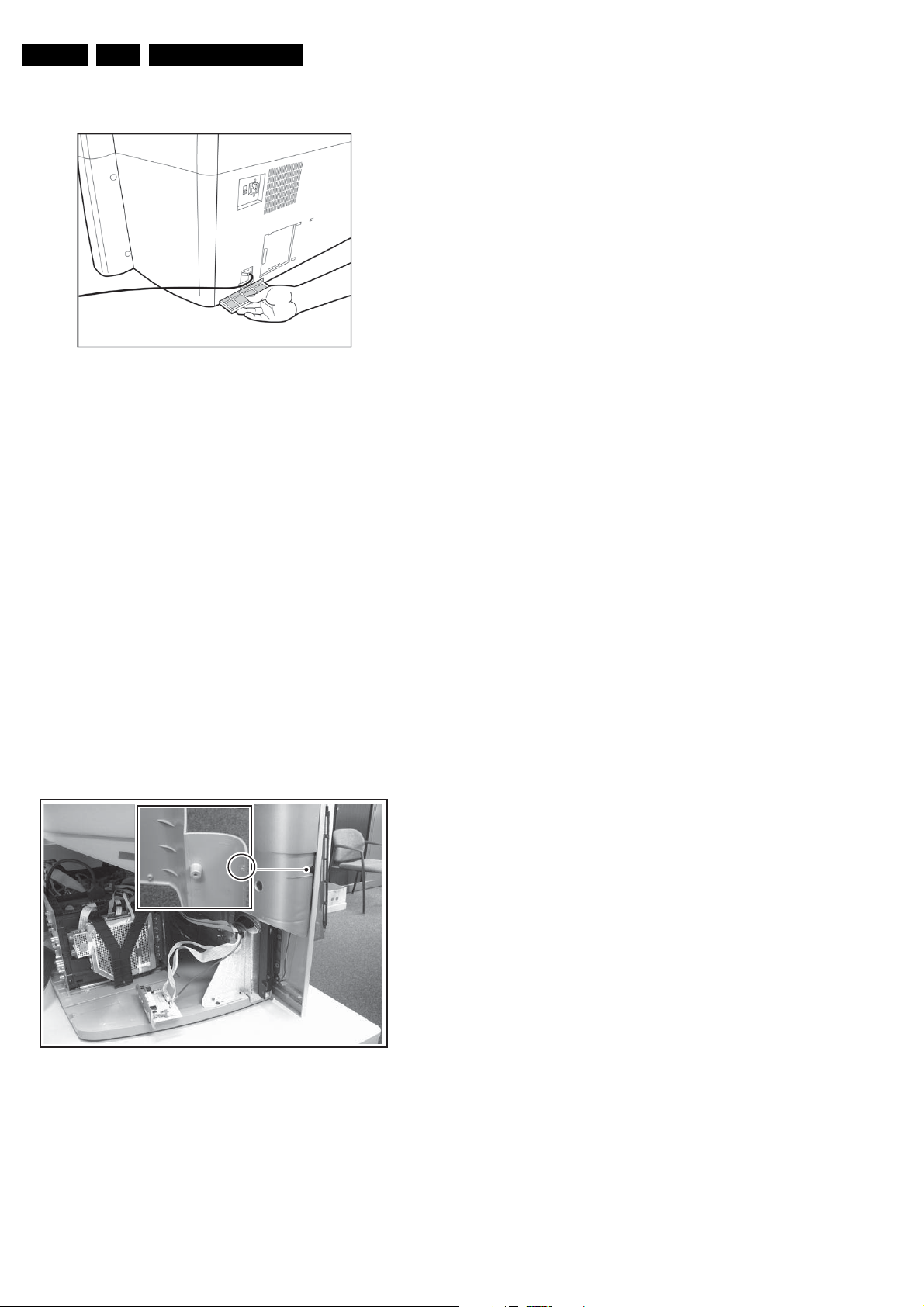

4.1 Dust Filter (Item 0098)

E_14780_071.eps

Figure 4-2 Dust filter removal

One dust filter is located under the Power Cord another one

under the Small Signal Package, to prevent dust buildup in the

set.

Under certain conditions, if this filter becomes dirty, the set

could overheat and shut down.

This item can be replaced by the customer.

290604

• It may be necessary to press on the sides of the upper back

where it “snaps” into place at the front cabinet to get it to

release.

• When replacing the Upper Cabinet Rear, care should be

used to properly route the cable for theTop Control

assembly.

• When re-installing the Upper Cabinet Rear, care should be

taken to correctly position the Light Shield that is attached

to the Upper Cabinet Rear.

1. Remove (8) T20 Torx screws (C).

2. Remove (2) T20 Torx screws (D) attaching the Fan Motor

Assembly to the Upper Rear Cover.

3. Remove (4) T20 Torx screws (E) attaching the small signal

cable assembly harness to the Upper Cabinet Rear (not

shown).

4.3 Mirror (Item 0021)

1. Remove both Lower and Upper Rear Covers.

2. Remove both the Left and Right Vertical mirror support

brackets (items 0079 and 0080).

3. Remove both Horizontal Mirror support brackets and

remove the mirror (items 0078).

Note: Care should be taken NOT to place fingerprints or

smudges on the mirror.

4.2 Rear Covers

4.2.1 Lower Rear Cover (item 0036)

1. Make sure all power-, audio-, video-, coax-, and SCART

cables are unplugged.

2. Remove all fixation screws (A) from the Rear Cover (lower

part only).

3. Pull the Rear Cover a few inches away from the set. Note:

It is clamped at the upper left and right side. Therefore you

must e.g. insert a thin metal plate (do not use a

screwdriver!) to release this clamp (see figure “Rear cover

clamp”).

4. Now, unplug the Side Jack panel (B).

5. Remove the Rear Cover and set it aside.

4.4 Top Control (Item 1032)

1. Remove (2) T20 Torx screws (V) holding the Keyboard and

cover to the cabinet cap.

2. Remove (2) T6 Torx screws holding the circuit board to the

control bracket.

3. Release (4) plastic clips holding the circuit board to the

control bracket and lift the PWB from the bracket.

4. Disconnect connector 1201 and ground clip 1202.

4.5 Speakers

4.5.1 Woofer (Item 5213)

1. Remove Lower Rear Cover item 0034.

2. Remove (2) T20 Torx screws (R) to allow the small signal

assembly to slide to the rear.

3. Remove (2) T20 Torx screws (N) to allow the power

assembly to slide to the rear.

4. Remove (4) T20 Torx screws from the speakers and

disconnect the speaker wires.

4.5.2 Tweeter (Item 5214)

1. Remove both the Lower and Upper Rear Covers.

2. Remove (2) T20 Torx screws and disconnect the speaker

wires.

Figure 4-3 Rear cover clamp

4.2.2 Upper Rear Cover (Item 0034)

Notes:

• The Lower Rear Cover must be removed before removing

the Upper Rear Cover.

• The Upper Rear Cover holds the Mirror.

E_14780_001.eps

240604

4.5.3 Speaker Baffle (Item 0039)

Note: There are no adjustments that require the removal of the

speaker baffle.

Caution: Do NOT reposition the light engine to gain access to

the speaker baffle tabs.

1. Remove the Lower Rear Cover.

2. Carefully release the (20) plastic tabs holding the speaker

baffle in place.

Mechanical Instructions

EN 11EM8E 4.

4.6 Screen Assembly (Item 0030)

1. Remove the Lower and Upper Rear Covers.

2. Remove (4) T20 Torx screws (W) and remove the Top Cap

with Customer Control Assembly (0032).

3. Disconnect the Tweeter speaker wiring.

4. Remove (9) T20 Torx screws (J).

5. Lay lens assembly on flat clean surface.

6. Remove (12) T20 Torx screws (K) from vertical side rails

Item 0075 and 0076.

7. Remove (16) T20 Torx screws (L) from horizontal screen

rails Item 0077.

4.7 Side Jack Panel (Item 0127)

• Make sure all cables of the Side Jack panel are unplugged.

• Remove the two mounting screws.

• Unlock the clamps, which secure the panel, and remove

the Side Jack panel.

4.8 Small Signal Package

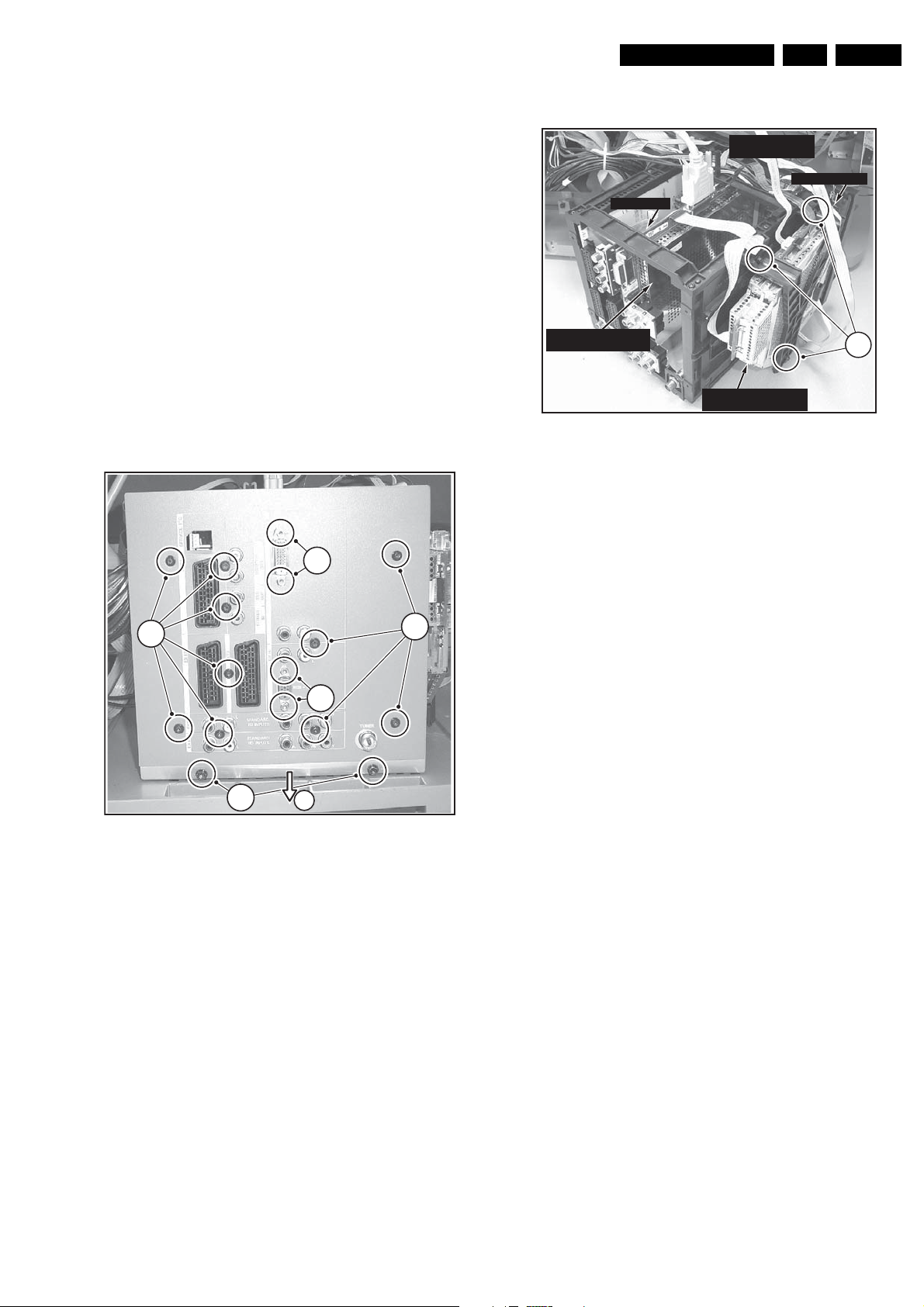

3

4.8.2 Jack Panel

AUDIO AMPLIFIER

(at the rear)

SYSTEM BOARD

JACK PANEL

MAIN SCALER BOARD

(MSB)

SMALL SIGNAL BOARD

(SSB)

Figure 4-5 Boards of the Small Signal Package

Pull out the Jack panel from the Small Signal Package,

unplugging it from the System Board connector.

See Figure “Boards of the Small Signal Package”.

Note: For measurements it is sometimes necessary to place

the Jack Panel in a service position. In this case it is necessary

to use the specific “Extending card” (4835 310 57605)

1

E_14780_002.eps

240604

2

3

1a

1b

Figure 4-4 Small Signal Package

1. Remove the two package mounting screws (1a).

1. Slide the Small Signal Package forward (1b).

4.8.1 Cover Plate

1. Remove all Cover Plate mounting screws (2). See Figure

“Small Signal Package”.

2. Use a 5 mm socket screwdriver to remove the four

connector distance bolts (3). See Figure “Small Signal

Package”.

3. Remove the Cover Plate.

2

E_14780_005.eps

240604

4.8.3 Main Scaler Board (MSB)

1. Disconnect the DVI connector and all cables from the top

of the MSB.

2. Pull out the MSB from the Small Signal package,

unplugging it from the System Board connector.

3. Remove both cover shields from the MSB.

See Figure “Boards of the Small Signal Package”.

Note: For measurements it is sometimes necessary to place

the MSB in a service position. In this case it is necessary to use

the specific “Extending card”, including two cables (4835 310

57605).

4.8.4 Small Signal Board (SSB)

1. Disconnect all cables from the SSB.

2. Remove the three mounting screws (1) from the SSB

bracket. See Figure “Boards of the Small Signal package”.

3. Carefully pull out the SSB, unplugging it from the System

Board connector.

4. Remove all shieldings from the SSB.

Note: For measurements sometimes it is necessary to place

the SSB in a service position. In this case it is necessary to use

the specific “Repair kit board” (order nr. 9965 000 14526)

4.8.5 Audio Amplifier Board

The Audio Amplifier is located at the rear of the System Board.

1. Disconnect all cables from the Audio Amplifier board.

2. Remove the four mounting board screws.

3. Remove the board.

EN 12 EM8E4.

Mechanical Instructions

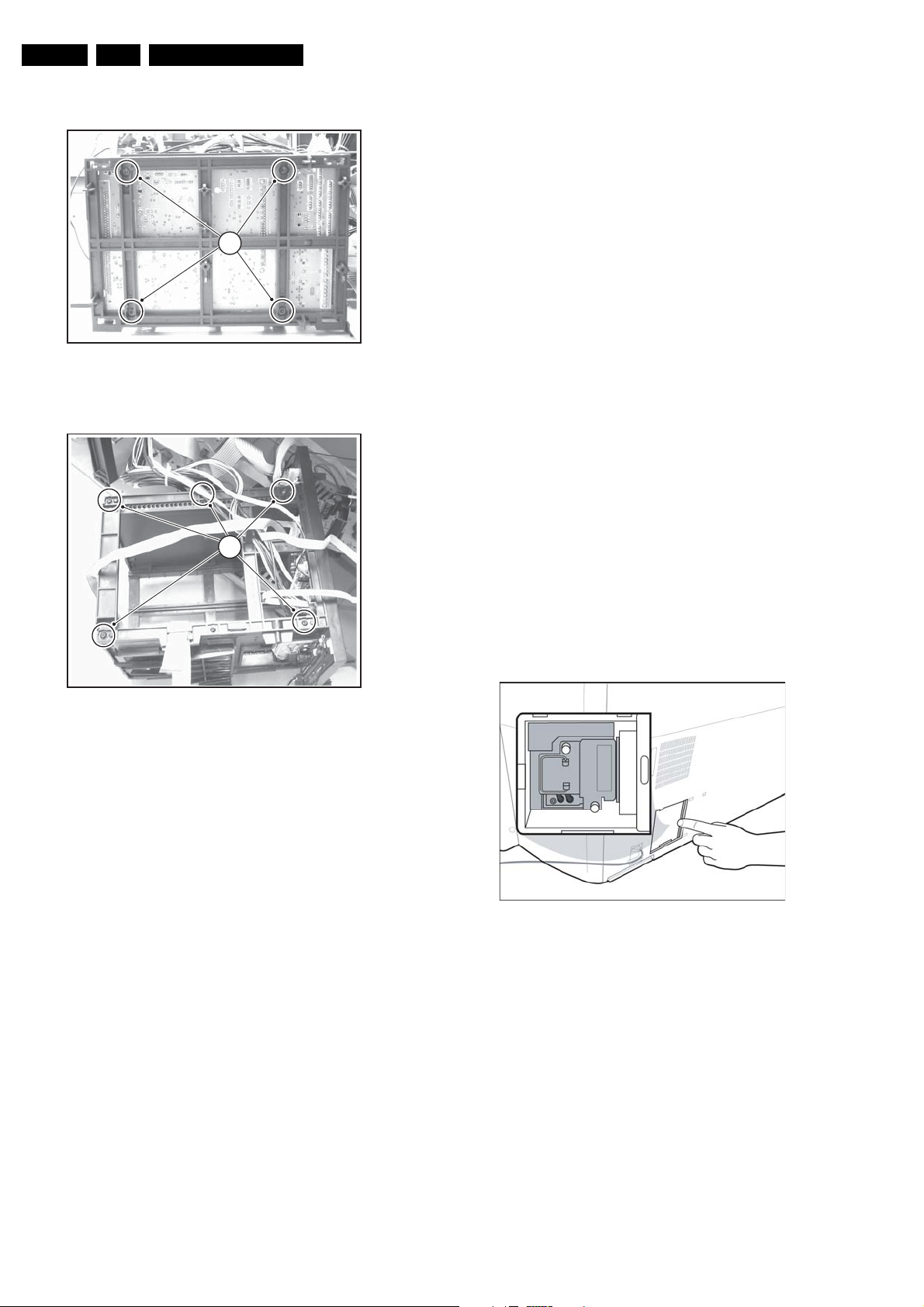

4.8.6 System Board

Figure 4-6 Rear side of the Small Signal Package

4.9.1 Main Power Board

1. Remove the six board mounting screws (1).

2. Disconnect all cables from the Main Power board.

3. Unlock the clamp, which secures the board at the topside,

and remove the Main Power board.

4.9.2 Input Power Board

1

1. Remove the six board mounting screws.

2. Disconnect all cables from the Input Power Board.

3. Unlock the clamps, which secure the board at the topside,

and remove the Input Power Board.

4.10 LED/Sensor Panel (Item 0132)

E_14780_003.eps

240604

1. Remove the two Sensor panel mounting screws.

2. Remove the Sensor panel bracket.

3. Disconnect all cables from the Sensor panel. Unlock the

two clamps, which secure the panel, and remove the

Sensor panel.

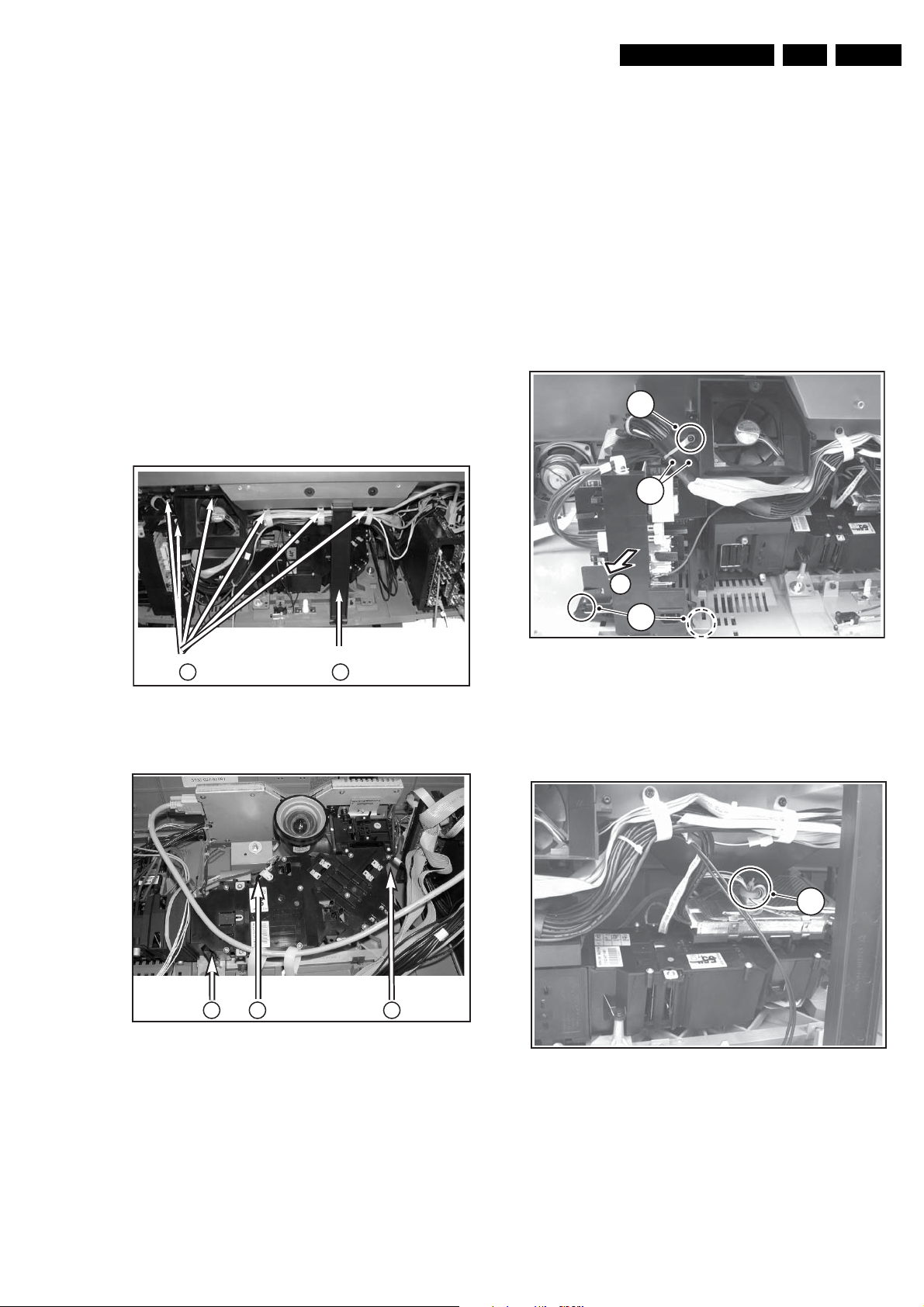

4.11 Lamp Replacement

Caution: The light source lamp produces extreme heat. Allow

a cool-down period before touching or replacing the lamp

1

assembly.

Notes:

• The lamp is easy accesible via the sliding door in the lower

rear cover.

• For protection, the lamp circuit contains a “normally closed”

switch. Therefore, the lamp will not operate with the lamp

access door in the open position.

• There are no tools required for this procedure.

E_14780_004.eps

Figure 4-7 Top side of the Small Signal Package

Note: The Audio, Jack, Scaler, and SSB panels should be

removed prior to removal of the system board.

1. Disconnect all cables from the System Board.

2. Disconnect the Arial-In cable.

3. Remove the four mounting screws at the rear side of the

Small Signal package (1). See Figure “Rear side of the

Small SignalPpackage”.

4. Remove the six mounting screws at the top side of the

Small Signal package (1). See Figure “Top side of the

Small Signal Package”.

5. Remove the six mounting screws from the bottom side of

the Small Signal Package (1). See Figure “Top side of the

Small Signal Package”.

6. Remove the two side panels from the Small Signal

Package.

7. Unlock the clamp, which secures the board at the bottom

side, and remove the System Board.

4.9 Large Signal Package

1. Remove the two Large Signal Package mounting screws

(1). See figure “Cable dressing part 1: PSU” further on.

2. Slide the package out of the set (2). Note: It may be

necessary to release some of the cable holders first.

240604

E_14780_072.eps

290604

Figure 4-8 Lamp replacement

To replace the lamp assembly:

1. Slide the Lamp Access Door on the rear of the unit to the

right.

2. Unscrew the two silver thumbscrews holding the assembly

in place.

3. Slide the old lamp assembly out by crisping the “metal

handle” and pulling straight out.

4. Install the replacement lamp assembly by pushing into

place and tightening the thumbscrews.

5. Slide the Lamp Access Door to the left to close (the unit will

not operate with this door open).

Mechanical Instructions

EN 13EM8E 4.

4.12 Light Engine Replacement

Notes:

• The LCoS Light Engine comes pre-adjusted. No

adjustment for focus should be required. In rare cases, the

set may require a minor focus touch up (see chapter

“Alignments”).

• Due to screw placement, to replace the Light Engine, it is

necessary to remove the upper rear cover before

beginning the replacement. Use care with the routing of the

wiring for the Customer Keypad when replacing the upperback. Also, note mounting direction of the Upper-back

support bracket for proper re-installation.

Caution:

• Do not remove the three “silver” nuts and washers, as

these hold the Light Engine support bracket and are

critical adjustment points for focus and picture alignment.

• The Light Engine has an operating voltage of

approximately 1,000 volts. Always use caution when

working in the vicinity of the Light Engine while the unit is

in operation.

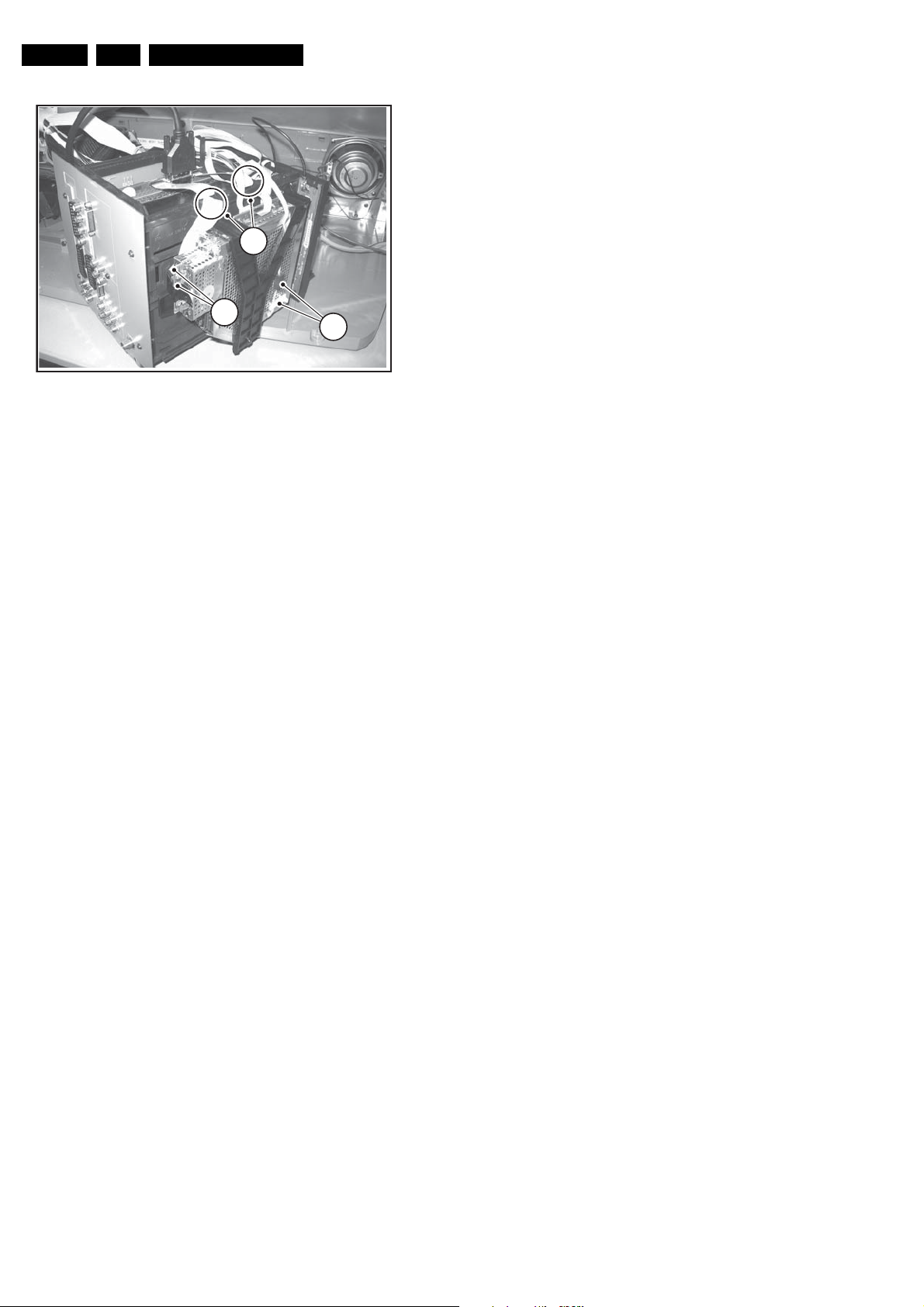

4.13 Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Note: While re-assembling the set, make sure that:

• All cables are placed and connected in their original

position (see next figures).

• All cables are routed such that contact with any PWB is

prevented.

• All cables are dressed away from the Lamp Power Supply

(located behind the lamp assy).

• All "grounding" wires are re-connected (Side I/O, Audio

Amplifier, System Board, and PSU).

4.13.1 Cable Dressing

3

4

Remove the screws shown.

1 2

Remove the bracing bar

Figure 4-9 Light engine removal (part 1)

4 4 4

Figure 4-10 Light engine removal (part 2)

E_14780_081.eps

050704

E_14780_082.eps

050704

2

1

E_14780_006.eps

240604

Figure 4-11 Cable dressing part 1: PSU

• Screw mounted cable tie to the fan assy (3).

• Be sure that the wires between the fan assy and the PSU

(4) are fitted with double insulation (heat shrink sleeve).

5

E_14780_007.eps

240604

1. First, disassemble the fan assy and the cable tree (1).

2. Then, remove the bracing bar (2).

3. Next, take out the screws (“C”, see exploded view) and

remove the top cover

4. Remove the three “black” T-10 Torx screws (3) located in

the vicinity of each of the three “silver” nuts and washers.

5. Re-install the Light Engine in reverse order

Figure 4-12 Cable dressing part 2: Light Engine

• Attach the ferrite to the shield (5) with a cable tie .

EN 14 EM8E4.

Mechanical Instructions

8

7

6

E_14780_008.eps

240604

Figure 4-13 Cable dressing part 3: SSP

• Route the flat foil cable through the clip and through the

ferrite (6).

• Be sure that a ferrite (2422 549 00125) is mounted on the

flat foil cable near the PWB connector (7). The flat foil cable

must be secured with tape at this side (the tape must

overlap both sides of the SSB shielding).

• Both flat foil cables from the SSB to the Scaler board must

be routed through the strain reliefs (8) on the bracket.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

EN 15EM8E 5.

Index of this chapter

1. Test Conditions

2. Service Modes

3. Error Codes

4. ComPair

5. The “Blinking LED” Procedure

6. Fault Finding

5.1 Test Conditions

The chassis is equipped with test points, printed on the circuit

board assemblies. They refer to the diagram letters. The

numbering is in a logical sequence for diagnostics. Always start

diagnosing (within a functional block), in the sequence of the

relevant test points for that block.

Perform measurements under the following conditions:

• Service Default Mode (SDM).

• Video: colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between a Philips Customer Care Centre (P3C) and a

customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements below) and the TV

chassis. It offers the ability of structured troubleshooting, test

pattern generation, error code reading, software version

readout, and software upgrading.

Minimum requirements: a Pentium processor, Windows 95/

98, and a CD-ROM drive.

5.2.1 Service Default Mode (SDM)

Upon entry into the Service default mode, the letters “SDM” will

be displayed at the upper right corner of the screen.

Special SDM functions

Access to Normal user menu

Press the “MENU” button on the remote control to switch from

the SDM to the normal user menu (with the SDM mode still

active in the background).

How to exit

To exit the Service default mode, enter zero “0” twice.

Note: To save the error codes, “unplug” the AC power cord

without turning the set "off".

5.2.2 Service Alignment Mode (SAM)

Purpose

The Service alignment mode (SAM) is used to align the set

and/or adjust the option settings and to display/clear the error

code buffer values.

How to activate SAM

Use one of the following methods:

• Via a standard RC transmitter: key in the code “062596”

directly followed by the “OSD [i+]” button. After activating

SAM with this method a service warning will appear on the

screen, you can continue by pressing any digit key on the

RC.

• Short for a moment the two solder pads on the SSP with

the indication "SAM". Depending on the software version,

it is possible that a service warning will appear. You can

continue by pressing any digit key on the RC.

• Use the DST-emulation feature of ComPair.

• Press the ALIGN button on the DST while the set is in the

normal operation

After activating this mode, “SAM” will appear in the upper right

corner of the screen.

Introduction

The Service default mode (SDM) is a technical aid for the

service technician. The Service default mode (SDM)

establishes fixed, repeatable settings of customer controls,

which allow consistent measurements to be made. The SDM

also initiates the blinking LED procedure and, if necessary,

overrides the 5V protection.

The following functions are turned OFF while in SDM:

• Timer

• Sleep timer

The following functions are disabled during SDM (and enabled

after leaving SDM):

• Parental lock

• Blue mute

• Hospitality mode

• No-ident timer (normally the set is automatically switched

off when no video signal (IDENT) is received for 15

minutes).

All other controls operate normally.

How to enter

To enter the Service alignment mode (SAM), press the

following key sequence on the standard remote control

transmitter: 0-6-2-5-9-6-[MENU]. Do not allow the display to

“time out” while entering the key sequence.

• DEFECTIVE MODULE: Displays “Unknown” if no defective module is found.

Contents of SAM

• OPERATION HOURS (Run Timer). Displays the

accumulated total of operational hours (in hexadecimal

format).

• SW VERSION INFO (example):

– ROM VERSION. Displays the date of the software and

the software version of the ROM

(e.g.: EM8EU1_1.0_01234 = AAABBC_X.Y_NNNNN).

• AAA= the chassis name.

• BB= the region: EU= Europe, AP= Asia Pacific

PAL/Multi, AN= Asia Pacific NTSC, US= USA, LT=

LATAM.

• C= the language cluster number.

• X.Y= the software version, where X is the main

version number (different numbers are not

compatible with one another) and Y is the sub

version number (a higher number is always

compatible with a lower number).

• NNNNN= last five digits of 12nc code software.

– SW VERSION MAIN SCALER: Displays the software

version of the MSP.

– SW VERSION EPLD. Displays the software version of

the EPLD.

– SW VERSION GDE: Displays the software version of

the System Board.

• ERRORS (10 errors possible): Displays the 10 most

recent errors. The most recent error is displayed at the

upper left.

EN 16 EM8E5.

Service Modes, Error Codes, and Fault Finding

• RESET ERROR BUFFER: Pressing the “OK” or RIGHT

cursor clears the error buffer and the “Errors” level shows

“No Errors.”

• ALIGNMENTS: Allows access to 6 alignment menus.

General, Luminance Delay, MSB, GDE-Video, GDE-NVM,

and Gamma.

• DEALER OPTIONS: Allows access to dealer “Personal

Options” menu.

• SERVICE OPTIONS: Allows access to 6 service option

menus. Dual Screen, Video repro, Source Select, Audio

repro, Miscellaneous, Opt. No.

• INITIALISE NVM: Not Accessible (only after replacing the

NVM).

• STORE OPTIONS: Select “OK” to save previously

changed selections.

• FUNCTIONAL TEST: Finds module Errors and places the

Error code in the “Errors” register and shows the module

name at the “Defective Module” level. If this test finds no

faults, the ERROR buffer is set to “No Errors” and the

“Defective Module” level shows “NONE.”

• BROADCAST INFO. The purpose of this menu is to debug

the broadcast, NOT the TV. The menu gives an overview

of what is received on the current preset related to Time

extraction, CNI codes, and NexTView transmission.

Following items are displayed:

– Preset. Shows the preset number.

– Local. Local date and time from the selected preset.

– UTC (Coordinated Universal Time). Extracted from the

selected preset.

– LTO (Local Time Offset). Extracted from the selected

preset.

– CNI (Country and Network Identification). Extracted

from the current preset (displayed as a four digit

hexadecimal number. The CNI number identifies the

broadcaster.

– NexTView service (optional). This item gives

information about the type of NexTView service that is

available for the current preset. The possible strings

are:

1. NexTView provider.

2. NexTView data available from preset xx (where xx

is the preset number).

3. No NexTView data available.

– CNI Linking (optional). 'Link' refers to the connection

between the broadcasted NexTView programme

information and the preset number. The possible

strings are:

1. Data available for preset xx xx xx (where xx xx xx

is a list off all presets for which a CNI link is

available).

2. 'Automatic link' or ' Manual link', depending on

what is read from the broadcast and from the CNI

table in the NVM. 'Automatic' means that the link

has been made based on broadcasted information,

without user-interaction. 'Manual' means that the

user has established this link by selecting a preset

in the pop-up menu that you get after setting a

reminder/recording/lock/watch in EPG. Erase a

wrong 'Manual link' by entering the Manual

Installation menu and (without changing anything)

activate 'Store'.

3. Nothing is shown.

How to navigate

• Use the Cursor UP/DOWN keys to select Menu items. The

selected option will be highlighted. When not all menu

options fit on the screen, press the Cursor UP/DOWN or

LEFT/RIGHT keys on the remote transmitter, to display the

next/previous menu.

• With the cursor LEFT/RIGHT keys, it is possible to:

– activate/deactivate the selected menu (e.g.

ALIGNMENTS/GENERAL)

– change the value of the selected menu item (e.g.

TUNER AGC)

– activate the selected submenu (e.g. TEST PATTERN)

How to exit

Press the “MENU” button, enter zero “0” twice, or switch the set

off with the power button.

Note: To save the error codes, “unplug” the AC power cord

without turning the set off.

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer. The service technician can than ask the

customer to activate the CSM, in order to identify the status of

the set. Now, the service technician can judge the severity of

the complaint. In many cases, he can advise the customer how

to solve the problem, or he can decide if it is necessary to visit

the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

How to activate CSM

Use one of the following methods:

• Press the “MUTE” button on the RC-transmitter

simultaneously with the “MENU” button on the TV (top

control) for at least 4 seconds.

• Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter, you can navigate through the menus.

Contents of CSM

CUSTOMER SERVICE MENU 1

• SW VERSION. Displays the built-in software version of the

SSB micrprocessor. In case of field problems related to

software, software can be upgraded. You will find details of

the software versions in the chapter “Software Survey” of

the “Product Survey - Colour Television” publication. This

publication is generated four times a year.

• SW VERSION MAIN. Displays the built-in software

version for the Main Scaler Board.

• SW VERSION EPLD. SW VERSION MAIN. Displays the

built-in software version of the EPLD.

• SW VERSION GDE. SW VERSION MAIN. Displays the

built-in software version of the System Board.

• LIGHT ENG SW VERSION.SW VERSION MAIN.

Displays the built-in software version of the LE.

• LIGHT ENG HW VERSION. Displays the hardware

version of the LE.

• MANUFACTURER’S ID. Each Manufacturer that uses this

Light Engine got an ID number assigned to them. This

number shown in CSM is used to verify that a light engine

for one mfgr did not get mixed up with another mfgr. Size is

up to 5 characters

• PRODUCT ID. This is the product ID, basically the

identification number for the given manufacturer, which

light engine product is hooked up. It will tell if the engine is

a Xion engine, or a Venus engine. For 2k4 based LCoS

products, this means it will always see a XIon ID. For 2k5

with Jaguar, this may be Xion or Venus. Size is up to 5

characters.

• ENGINE DRB SERIAL. The serial number of the DRive

module Board, the electronics of the light engine. Size is up

to 10 characters.

• ENGINE OPTICS SERIAL. This is the serial number of the

optics assemly of the light engine. The big black plastic part

containing the prisms, mirrors, etc. Size is up to 10

characters

Service Modes, Error Codes, and Fault Finding

EN 17EM8E 5.

CUSTOMER SERVICE MENU 2

• LAMP LIFETIME COUNTER. This is the count of hours

since the time the lamp lifetime reset was pressed. This

reset is available to the customer. Range is 0 to 32,767.

• LAMP EXPECTED. This is the setting the customer chose

as the type of lamp he is using, and then the number of

hours based on that type of lamp. (e.g. customer selects

lamp type X, and this is converted into hours) . Range is 0

to 32,767.

• ENGINE LIFETIME. This is the total number of hours the

engine itself has been run with the lamp “on”. This is

important for later service as the Light Engine can be

swapped from final TV to TV. Range is 0 to 32,767.

• POLARIZE LIFETIME. This is the total number of hours

that the polarizer within this light engine has been active.

Again, important because engines can be swapped, or

polarizers repaired and replaced in an existing engine.

Range is 0 to 32,767.

• PANEL LIFETIME. This is the total number of hours that

the LCoS Panel itself within this light engine has been

active. Again, important because engines can be swapped,

or panels repaired and replaced in an existing engine.

Range is 0 to 32,767.

• SET TYPE. This information is very helpful for a help desk/

workshop as reference for further diagnosis. In this way, it

is not necessary for the customer to look at the rear of the

TV-set.

• CODE 1. Gives the latest five errors of the error buffer. As

soon as the built-in diagnose software has detected an

error the buffer is adapted. The last occurred error is

displayed on the left most position. Each error code is

displayed as a 3-digit number. When less than 10 errors

occur, the rest of the buffer is empty (000). See also

paragraph Error Codes for a description.

• CODE 2. Gives the first five errors of the error buffer. See

also paragraph Error Codes for a description.

• VOLUME. Gives the last status of the volume as set by the

customer. The value can vary from 0 (volume is minimum)

to 100 (volume is maximum). Volume values can be

changed via the volume key on the RC-transmitter.

CUSTOMER SERVICE MENU 3

• BRIGHTNESS. Gives the last status of the brightness as

set by the customer. The value can vary from 0 (brightness

is minimum) to 100 (brightness is maximum). Brightness

values can be changed via the “CURSOR LEFT” and

“CURSOR RIGHT” keys on the RC-transmitter after

pressing the “MENU” button and selecting “PICTURE” and

“BRIGHTNESS”.

• CONTRAST. Gives the last status of the contrast as set by

the customer. The value can vary from 0 (contrast is

minimum) to 100 (contrast is maximum). Contrast values

can be changed via “CURSOR LEFT” and “CURSOR

RIGHT” keys on the RC-transmitter after pressing the

“MENU” button and selecting “PICTURE” and

“CONTRAST”.

• COLOUR. Gives the last status of the colour saturation, as

set by the customer. The value can vary from 0 (colour is

minimum) to 100 (colour is maximum). Colour values can

be changed via “CURSOR LEFT” and “CURSOR RIGHT”

keys on the RC-transmitter after pressing the “MENU”

button and selecting “PICTURE” and “COLOUR”.

• HUE. Only relevant for NTSC-signals (e.g. NTSC DVD

discs)

• SHARPNESS. Gives the sharpness value. The value can

vary from 0 (sharpness is minimum) to 7 (sharpness is

maximum). In case of bad antenna signals, a too high

value of the sharpness can result in a noisy picture.

Sharpness values can be changed via the “CURSOR

LEFT” and “CURSOR RIGHT” keys on the RC-transmitter

after pressing the “MENU” button and selecting “PICTURE”

and “SHARPNESS”.

• HEADPHONE VOLUME. Gives the last status of the head

phone volume, as set by the customer. The value can vary

from 0 (volume is minimum) to 100 (volume is maximum).

Head phone volume values can be changed via the

“CURSOR LEFT” and “CURSOR RIGHT” keys on the RCtransmitter after pressing the “MENU” button and selecting

“SOUND” and “HEADPHONE VOLUME”.

• TUNER FREQUENCY. Indicates the frequency the

selected transmitter is tuned to. The tuner frequency can

be changed via the “CURSOR LEFT” and “CURSOR

RIGHT” keys for fine tune after opening the installation

menu and selecting “INSTALL” and “MANUAL INSTALL”.

• DIGITAL OPTION. Gives the selected digital mode,

“PROGRESSIVE SCAN”, “MOVIE PLUS” or “PIXEL

PLUS”. Change via “MENU”, “PICTURE”, “DIGITAL

OPTIONS”.

• TV SYSTEM. Gives information about the video system of

the selected transmitter.

– BG: PAL BG signal received.

– DK: PAL DK signal received.

– I: PAL I signal received.

– L/La: SECAM L/La signals received.

– M: NTSC M signal received with video carrier on 38.9

MHz.

• DNR. Gives the selected DNR setting (Dynamic Noise

Reduction), “OFF”, “MINIMUM”, “MEDIUM”, or

“MAXIMUM”. Change via “MENU”, “PICTURE”, “DNR”

CUSTOMER SERVICE MENU 4

• NOISE FIGURE. Gives the noise ratio for the selected

transmitter. This value can vary from 0 (good signal) to 127

(average signal) and to 255 (bad signal). For some

software versions, the noise figure will only be valid when

“Active Control” is set to “medium” or “maximum”.

• SOURCE. Indicates which source is used and the video/

audio signal quality of the selected source. (Example:

Tuner, Video/NICAM) Source: “TUNER”, “EXT1”, “EXT2”,

“EXT3”, “EXT4”, “SIDE”, “AV1”, “AV2”, “AV3” or “AV4”.

Video signal quality: “VIDEO”, “S-VIDEO”, “RGB 1FH”,

“YPBPR 1FH 480P”, “YPBPR 1FH 576P”, “YPBPR 1FH

1080I”, “YPBPR 2FH 480P”, “YPBPR 2FH 576P”, “YPBPR

2FH 1080I”, “RGB 2FH 480P”, “RGB 2FH 576P” or “RGB

2FH 1080I”. Audio signal quality: “STEREO”, “SPDIF 1”,

“SPDIF 2”, or “SPDIF”.

• AUDIO SYSTEM. Gives information about the audio

system of the selected transmitter: “ANALOGUE MONO”,

“ANALOGUE STEREO”, “PCM 2/0”, “DD 1/0”, “DD 2/0

LtRt”, “DD 2/0 L0R0”, “DD 2/1”, “DD 2/2”, “DD 3/0”, “DD 3/

1”, “DD 3/2”, “DD 1+1”, “MPEG 1/0”, “MPEG 2/0”, “MPEG

2/0 LtRt”, “MPEG 2/1”, “MPEG 2/2”, “MPEG 3/0”, “MPEG

3/1”, “MPEG 3/2”, “MPEG 1+1” or “MPEG 2+2”.

• TUNED BIT. Gives information about the tuning method of

the stored pre-set. If a channel is found via “automatic

installation”, you will see the value “YES”. When you

change this (automatically found) frequency via “fine tune”

adjustment (installation menu - manual installation), the

displayed value will change to “NO”. Therefore, when you

see the value “NO” in this line, it is an indication that the

received channel is a non-standard signal (e.g. of a VCR).

• ON TIMER. Indicates if the “On Timer” is set “ON” or “OFF”

and if the timer is “ON” also displays start time, start day

and program number. Change via “MENU”, “TV”,

“FEATURES”, and “ON TIMER”.

• PRESET LOCK. Indicates if the selected preset has a child

lock: “LOCKED” or “UNLOCKED”. Change via “MENU”,

“TV”, “FEATURES”, “CHILD LOCK”, and “CUSTOM

LOCK”.

• CHILD LOCK. Indicates the last status of the general child

lock: “UNLOCK”, “LOCK”, or “CUSTOM LOCK”. Change

via “MENU”, “TV”, “FEATURES”, “CHILD LOCK”, and

“LOCK”.

• AGE LOCK. Indicates the last status of the EPG rating for

child lock: “OFF”, “4 YEARS”, “6 YEARS”, “8 YEARS”, “10

YEARS”, “12 YEARS”, “14 YEARS” or “16 YEARS”. This is

only displayed if child lock is set to “CUSTOM LOCK”

• LOCK AFTER. Indicates at what time the child lock is set:

“OFF” or e.g. “18:45” (lock time). This is only displayed if

child lock is set to “CUSTOM LOCK”

EN 18 EM8E5.

Service Modes, Error Codes, and Fault Finding

• CATEGORY LOCK. Indicates the last status of the EPG

theme child lock: “MOVIES”, “NEWS”, “SHOWS”,

“SPORTS”, “CHILDREN”, “MUSIC”, “CULTURE”, or

“SERIES”. This is only displayed if child lock is set to

“CUSTOM LOCK”. It is possible that more than one value

is shown.

CUSTOMER SERVICE MENU 5

• PROGRAM CATEGORY. Indicates the theme of the

selected transmitter: “MOVIES”, “NEWS”, “SHOWS”,

“SPORTS”, “CHILDREN”, “MUSIC”, “CULTURE”, or

“SERIES”.

• SW CODE 1.

• SW CODE 2.

• TV RATINGS LOCK. Only applicable for US.

• MOVIE RATINGS LOCK. Only applicable for US.

• V-CHIP TV STATUS. Only applicable for US.

• V-CHIP MOVIE STATUS. Only applicable for US.

• OPTION S 1. Gives the option codes of option group 1 as

set in SAM (Service Alignment Mode).

• OPTION S 2. Gives the option codes of option group 2 as

set in SAM (Service Alignment Mode).

• LAMP SERVICE COUNTER.

CUSTOMER SERVICE MENU 6

• BULB REPLACED INST. 1 - 5. These each should be

zero, unless a customer has replaced his bulb. This will

show the last 5 run time hours of the set, where the

customer has pressed the lamp replaced menu item to

“yes”. Multiples are kept as a customer may errantly press

the button, and these numbers, along with the lifetime of

the engine, can be used in warranty claim questions as to

whether a lamp has been replaced by customer or by

service, or not. Or if a kid has pressed it just to see what it

would do, etc. Range is 0 to 65,535.

SW EVENT - LOG

This item contains 'software event logging' information that can

be delivered to the Philips development centre on special

request.

How to exit CSM

Use one of the following methods:

• After you press a key on the RC-transmitter (with exception

of the “CHANNEL”, “VOLUME” and digit (0-9) keys), or

• After you switch the TV-set “OFF” with the mains switch.

5.3 ComPair

5.3.1 Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the European DST (service remote control),

which allows faster and more accurate diagnostics. ComPair

has three big advantages:

• ComPair helps you to quickly get an understanding on how

to repair the chassis in a short time by guiding you

systematically through the repair procedures.

• ComPair allows very detailed diagnostics (on I2C level)

and is therefore capable of accurately indicating problem

areas. You do not have to know anything about I2C

commands yourself because ComPair takes care of this.

• ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

the SearchMan electronic manual of the defective chassis,

schematics and PWBs are only a mouse click away.

5.3.2 Specifications

ComPair consists of a Windows based faultfinding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

or RS232 cable.

For this chassis, the ComPair interface box and the TV

communicate via a bi-directional service cable via the service

connector.

The ComPair faultfinding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in two ways:

• Automatic (by communication with the television): ComPair

can automatically read out the contents of the entire error

buffer. Diagnosis is done on I2C level. ComPair can access

the I2C bus of the television. ComPair can send and

receive I2C commands to the micro controller of the

television. In this way, it is possible for ComPair to

communicate (read and write) to devices on the I2C

busses of the TV-set.

• Manually (by asking questions to you): Automatic

diagnosis is only possible if the micro controller of the

television is working correctly and only to a certain extends.

When this is not the case, ComPair will guide you through

the faultfinding tree by asking you questions (e.g. Does the

screen give a picture? Click on the correct answer: YES /

NO) and showing you examples (e.g. Measure test-point I7

and click on the correct oscillogram you see on the

oscilloscope). You can answer by clicking on a link (e.g.

text or a waveform picture) that will bring you to the next

step in the faultfinding process.

By a combination of automatic diagnostics and an interactive

question / answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

Beside fault finding, ComPair provides some additional

features like:

• Up- or downloading of pre-sets.

• Managing of pre-set lists.

• Emulation of the Dealer Service Tool (DST).

• If both ComPair and SearchMan (Electronic Service

Manual) are installed, all the schematics and the PWBs of

the set are available by clicking on the appropriate

hyperlink.

Example: Measure the DC-voltage on capacitor C2568

(Schematic/Panel) at the Mono-carrier.

– Click on the “Panel” hyperlink to automatically show

the PWB with a highlighted capacitor C2568.

– Click on the “Schematic” hyperlink to automatically

show the position of the highlighted capacitor.

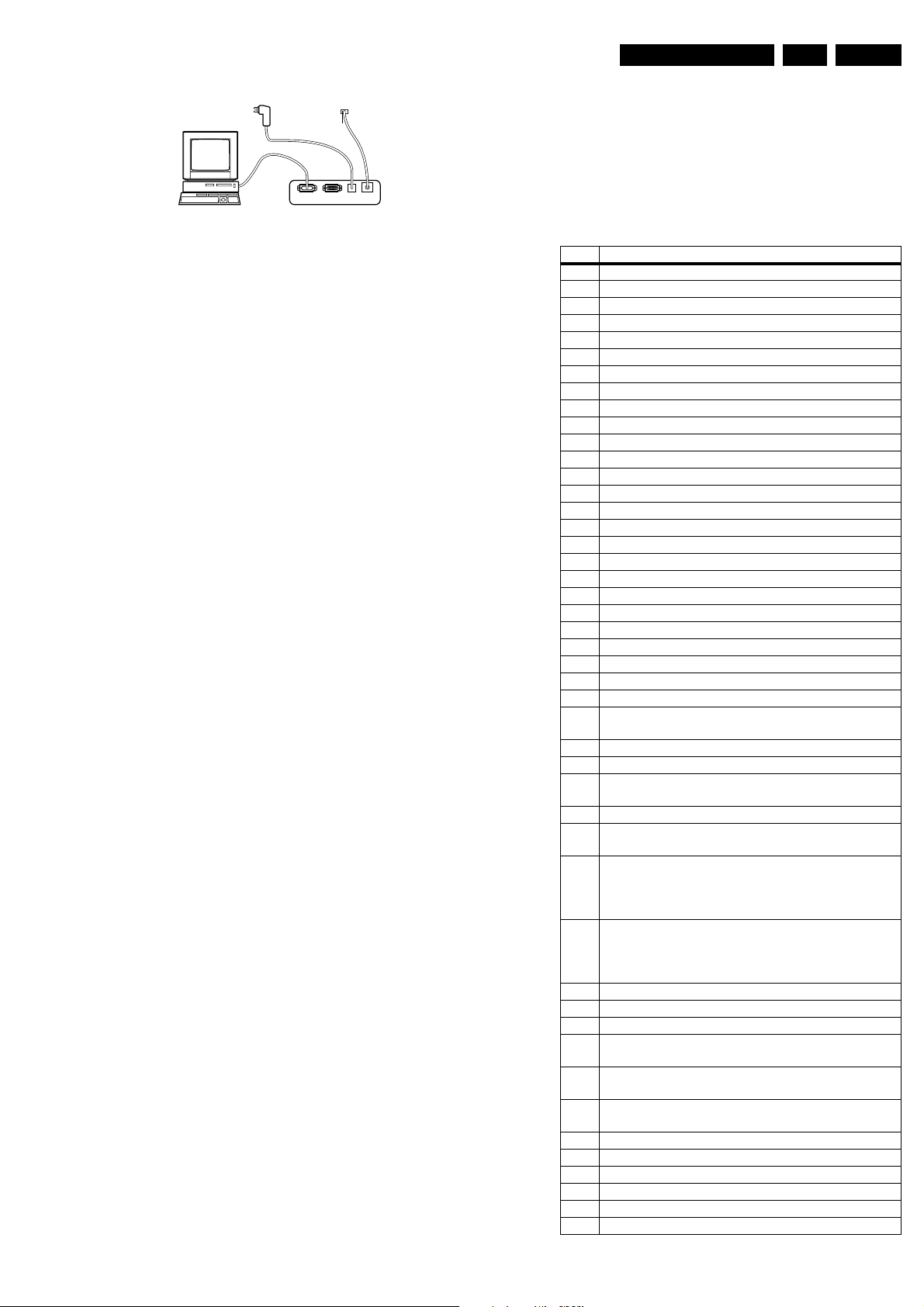

5.3.3 How To Connect

1. First, install the ComPair Browser software (see the Quick

Reference Card for installation instructions).

2. Connect the RS232 interface cable between a free serial

(COM) port of your PC and the PC connector (marked with

“PC”) of the ComPair interface.

3. Connect the mains adapter to the supply connector

(marked with “POWER 9V DC”) of the ComPair interface.

4. Switch the ComPair interface “OFF”.

5. Switch the television set “OFF” with the mains switch.

6. Connect the ComPair interface cable between the

connector on the rear side of the ComPair interface

(marked with “I2C”) and the ComPair connector at the rear

side of the TV.

7. Plug the mains adapter in a mains outlet, and switch the

interface “ON”. The green and red LEDs light up together.

The red LED extinguishes after approx. 1 second while the

green LED remains lit.

8. Start the ComPair program and read the “Introduction”

chapter.

Service Modes, Error Codes, and Fault Finding

Note: A fault in the protection detection circuitry can also lead

to a protection.

TO SERVICE

CONNECTOR

PC VCR I2CPower

9V DC

E_06532_008.eps

190204

Error codes "01", "02", "03", and "04" are protection codes, and

in this case the supplies of some circuits will be switched "off".

Also in protection, the LED will blink the number of times

equivalent to the most recent error code.

Table 5-1 Error codes

EN 19EM8E 5.

Figure 5-1 ComPair Interface connection

5.3.4 How To Order

ComPair order codes (EU/AP/LATAM):

• Starter kit ComPair32/SearchMan32 software and

ComPair interface (excl. transformer): 3122 785 90450.

• ComPair interface (excluding transformer): 4822 727

21631.

• Starter kit ComPair32 software (registration version): 3122

785 60040.

• Starter kit SearchMan32 software: 3122 785 60050.

• ComPair32 CD (update): 3122 785 60070 (year 2002,

3122 785 60110 (year 2003).

• SearchMan32 CD (update): 3122 785 60080 (year 2002),

3122 785 60120 (2003), 3122 785 60130 (2004).

• ComPair interface cable: 3122 785 90004.

• ComPair firmware upgrade IC: 3122 785 90510 (only

useful for TV-sets with flashable software).

• Transformer (non-UK): 4822 727 21632.

• Transformer UK: 4822 727 21633.

Note: If you encounter any problems, contact your local

support desk.

5.4 Error Codes

5.4.1 Introduction

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from the left to

the right. When an error occurs, which is not yet in the error

code buffer, the error code will appear at the left side and all

other errors shift one position to the right.

5.4.2 How to clear the Error Buffer

Use one of the following methods:

• Activate “Reset Error Buffer” in SAM menu

• If the content of the error buffer was not changed for 50+

hours, it resets automatically.

By leaving SDM or SAM via the power switch, the error buffer

will not be reset.

Examples:

ERROR: 000 000 000 : No errors detected

ERROR: 036 000 000 : Error code 036 is the last and only

detected error

ERROR: 018 036 000 : Error code 036 was first detected and

error code 018 is the last detected (newest) error

The contents of the error buffer can also be displayed by using

of the “blinking LED” procedure, if no picture is available. See

the chapter “The blinking LED procedure “below.

5.4.3 Error Code Definition

In case of non-intermittent faults, clear the error buffer before

you begin the repair. Make sure “old” error codes are not

present. If possible, check the entire content of the error

buffers. In some situations an error code is only the result of

another error code (and not the actual cause).

Error Description

1 (1) NVM (M24C32)

2 HFB protection

3 Picnic (SAA4978)

4 5VProtection

5 8V Protection

6 (2) Slow I2C bus blocked

8 HIP I/O-video processing (TDA9320)

9 Wireless Expander (PCF8574)

12 Topic (LT P Peaking) (TDA9178)

13 Tuner Protection

14 ITT Sound Processor (MSP3411/3412/3452)

15 3D Combfilter protection (mPD64083)

16 Feature Box Protection (FBX)

17 I/O Expander HD Interface (M62320P)

18 Fast I2C bus blocked

19 Auto Scavem DAC (TDA8444)

21 PIP I/O Expander (M62320P)

22 PIP BOCMA (TDA888X)

23 PIP Tuner

24 PIP Muppet (SAB9081)

25 PIP V-Chip (Z86130)

26 Falconic (SAA4992)

27 Eagle device

28 Back Current loop

32 Flash Ram (EPG)

36 Light engine shutdown Protection Error

37 Light engine shutdown protection. Spontaneous

blinking 37-37-37.

38 Lamp Failure.

39 Light engine polarizer fan failure, protection error.

41 Shutdown protection error, spontaneous blinking 41-

41-41. GDE not responding

42 Not protection error. GDE NVM error

43 Fan Fault. Not protection error. Shut down if error

exists continuously for 2 minutes

44 Ambient Temperature Warning. Not protection error.

Message should be displayed for 6 seconds and every

15 minutes as long as temp is above ambient temp.

warning

45 High temperature alert. Not protection error. Shut

down message should be displayed and system

should enter standby after 1 minute if the temperature

exceeds this limit.

46 Audio fault (audio board). N ot protection error.

47 Audio fault (audio board). N ot protection error.

48 Thermo cutoff SW. Protection error

49 Engine Fault Lamp Off. Unexpected Lamp Off.

System should enter into standby.

51 Main scaler not working. Communication via EPLD is

ok, scaler not responding. Not a protection error.

52 NVM error MSB Pixelworks (local error number

MSB=3),

53 Video switch. Local error number MSB=4

54 Audio switch (local error number MSB=5) (TEA6422D)

55 EPLD (local error number MSB=6)

56 ADC error (local error number MSB=7) (AD9888)

57 MSB I2C error. Not protection error

59 Reserved error codes for NAFTA Digital TV

EN 20 EM8E5.

Service Modes, Error Codes, and Fault Finding

(1) This error should start the Blinking LED procedure when it

occurs.

(2) This error has the highest priority, so if other errors occur

simultaneously, this should go first.

5.5 The Blinking LED Procedure

NOTE: Perform this procedure without any signal applied.

This is necessary because making any adjustment, such as

lowering the volume, will render the Blinking LED procedure

inoperative.

The contents of the error buffer can also be made visible

through the “blinking LED” procedure. This is especially useful

when there is no picture.

When the SDM is entered, the LED will blink the number of

times, equal to the value of any error codes.

The ON/OFF indicator turning orange for 500 ms precedes all

error code sequences (there is a possibility of up to 10).

After the 500 ms delay, the ON/OFF indicator will turn green for

1500 ms before the first code begins. If an error code is smaller

than 10, the ON/OFF indicator will rapidly flash orange 1-9

times to indicate the code (EXP. Six rapid flashes indicates an

error code of 6.)

There will be a delay, green light, of approximately 3 seconds

between codes.

For error codes of 10 and higher, the ON/OFF indicator will

slowly flash orange the correct number of times to indicate the

first digit, and then will rapidly flash orange the correct number

of times to indicate the second digit (EXP. Three slow orange

flashes followed by 6 rapid orange flashes indicate an error

code of 36.)

When all error-codes are displayed, the sequence is finished

and the ON/OFF indicator turns green for 3 seconds. At this

point the sequence will begin again as indicated by the ON/

OFF indicator turning orange for 500 ms.

approximately 3.3 V. This voltage can be measured on Pin 36

of 1205.

When the set is turned "On", the OTC will pull the Standby Line

Low. The relay on the Input Power board will then turn "On",

providing RAW_DC voltage to the Main Power board via Pin 1

of 1311. If 5 V is present on Pin 11 of 1403, Pin 1 and 3 of 1460,

and Pins 1 and 2 of 1410, the Standby line on Pin 9 of 1403 is

Low, RAW_DC should be present on Pin 1 of 1311. If it is not,

the Input Power board should be repaired or replaced.

When the RAW_DC voltage is applied to the Main Power

board, +36 V should appear on Pin 4 of 1312.

Additional voltage are 5 V on Pins 3, 4 and 5 of 1313, +9 V on

Pins 1 and 2 of 1314, +3.3 V on Pins 5 and 6 of 1314, and +12

V on 1314.

Operating voltages are applied to the Light Engine on

connector 1315.

5.6.2 Troubleshooting Audio Problems

The Audio Power supply is located on the Input Power board.

A positive 25 V should be present on Pin 1 of 1316 and a minus

25 V on Pin 4. An audio signal should be present on Pins 1 and

4 of 1700. The SOUND_ENABLE line should be High to switch

the Audio Amplifier "On".

5.6.3 Troubleshooting Video Problems

The 1fH signals from the SCART panel or Side Jack panel are

fed to the SSB for processing. The signal is fed to the Scaler

board in a digital format via 1401. (Figure 75) After processing,

the signal is fed to the Light Engine via connector 1200. The

SSB can be bypassed by selecting the inputs on the Scaler

board.

Table 5-2 Example of the blinking LED procedure

Error code position 1 2 3 4 5

Error buffer: 018 006 036 0 0

After entering SDM: The sequence will begin with 1 long blink

of 500 ms, then pause 1500 ms, then slowly blink once followed

by 8 rapid blinks (indicating error code 18), next the LED will

pause for 3 seconds followed by 6 rapid blinks (indicating error

code 6), next the LED will pause for 3 seconds, then slowly

blink 3 times followed by 6 rapid blinks (indicating error code

36), then pause 3 seconds ending the sequence in this

example. If there were error codes in positions 4 and 5, those

sequences would also be given.

5.6 Fault Finding

5.6.1 Troubleshooting a Dead Set

If the status lamp is Red, the 5 V supply is present and the OTC

is working. If the indicator LED is "Off", the Standby Supply may

not be working. The Standby Supply is located on the Main

Power Board. This voltage can be measured on Pin 2 of

connector 1312.

This voltage is then fed to the Input Power board on 1403, Pin

1. The 5 V Standby voltage is also fed to the Side Jack Panel

via Pin 4 of 1344. It is then fed back to the System board on Pin

5 of 1344 and then to the Input Power board on Pin 11 of 1403.

If the voltage on Pin 5 of 1344 is High, the +5V_STBY_SW

voltage is switched "On" and fed to the SSB via Pin 40 of

connector 1205.

The ON/OFF LED voltage is fed to the System board via Pin 77

of 1205. It is then fed to the LED Sensor Panel via Pin 5 of

1214. In the Standby mode, the Standby line will be

Block Diagrams, Testpoint Overview, and Waveforms

6. Block Diagrams, Testpoint Overview, and Waveforms

Not applicable yet

EN 21EM8E 6.

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

LCoS Audio Amplifier Board

EN 22EM8E 7.

1

A

B

C

D

E

F

TO SYSTEM

BOARD

(1700)

G

SOUND_ENABLE

H

I

J

K

L

M

N

3135_037_11411_01 X

RESERVED

O

Ref Des

P

9710 NOT USED

9711 NOT USED

3135 033 3353.3

1

2

3

47

LCOS AUDIO AMPLIFIER BOARD

I713

3702

6K8

5V2

5V2

I711

3701

10K

2739

100R

7701

0V

BC847B

A1

I707

2701

3793

100R

47n

2703

330n

330n

3790

100R

6708

6709

4

1700

B8B-EH-A

9711

8

NOT USED

7

6

5

4

AUDIO_R

3

2

1

AUDIO_L

1216

1

2

F702

TO SYSTEM

BOARD

E

N

A

U

F

R

T

O

A

P

E

X

NOT USED

3135_037_11411_01 RESERVED

2

9710

A2

2740

n

o

t

_

u

s

e

d

X

F700

100n

2729

F701

F703

3792

100R

47n

3791

319803690010

319803690010

3

F708

I750

5

I714

6704

6706

BAS316

BAS316

6705

6707

BAS316

BAS316

6710

2704

BAS316

6711

BAS316 BAS316

BAS316

NOTES

1. CAPACITANCE VALUES ARE IN F

m= MILI u= MICRO n= NANO p= PICO f= FEMT

2. RESISTANCE VALUES ARE IN OHMS:

R= OHM K= KILO M= MEGA G= GIGA T= TERA

3. SAFETY TRIANGLE REPRESENTS PCEC REPLA

4. FOR VALUE SEE TABLE.

*

5

6

3703

33K

10K

3704

I710

100n

2702

100n

10R

3705

I704

220n

2708

I702

220n

2720

1701

HEATSINK

123

2718

27p

3712

10K

I708

I712

A4

100n

2706

470p

2722

I751

2721

ARADS:

6

I709

4

I738

A3

3721

470p

2705

-23V1

26V

0V

0V

0V

5V1

-14V2

5V3

24V6

24V6

5K6

3722

68K

O

CEMENT PART ONLY.

7

8

2u2 50V

470p

2709

2710

I717

470p

I718

7700

TDA7490

14

CURREF

8

OSC

7

FEED1

9

FEED2

10

IN1

0V

18

IN2

17

0V

FEED3

19

0V

FEED4

6

STBY-MUTE

25

VREG

-VCCSIGNSUB

12

+5V

4

-VCCPOW1

+VCCPOW1

22

-VCCPOW2

+VCCPOW2

I715

3723

56K

8

913

3708

56K

5K6

3706

3707

68K

I719

3711

120K

220n

2723

0V

11

T1

5

9V2

BOOT1

3

0V

OUT1

OUT2

BOOT2

T2

NC1

GND

-5V

I732

0V

23

9V3

21

15

0V

20

13

1

-24V6

-5V4

16

-24V6

2

24

-24V6

2743

220n

220n

2732

9

10

BC847B

I736

2714

33n

I731

A6

A5

I739

2726

33n

I705

I703

2727

1n0

I742

2733

220n

220n

2724

2742

220n

10

11

7710

BC847B

5V1

5V1

0V

0V

7711

4V9

BC847B

4V9

I720

5V1

5V1

7707

0V6

I721

2719

2715

1n0

1n0

2716

330p

3710

22K

2728

330p

3725

22K

2707

100n

I746

I747

2711

1n0

3799

3714

I756

47K

3728

220R

I722

3709

220R

2744

220n

2712

2725

220n

220n

3724

220R

3729

220R

I723

BC857B

0V6

47K

2731

7706

I726

3713

2713

5701

68u

2745

220n

2m2

12

I757

3K3

3797

3716

47K

5V2

5V2

5V2

5V2

V06

V06

100R

I728

V06

V06

100n

I724

1311

1702

BT169B

2777

1412

I758

3798

3K3

I725

3715

47K

+5V

3K3

2735

3726

I727

4V7

4V7

6703

1N4148

2717

5716

680n

I743

5702

68u

1K0

3720

I735

1K0

2m2

2730

3719

F719

14

15 18

I730

10u 50V

I755

3727

47K

100p

10n

2737

5714

1u0

2780

5717

5713

5718