Page 1

O PERAT O R’S

M ANUAL

Medium Duty Models

Cla ss Pa ys

Page 2

1

7

13

18

44

56

57

113

221

222

227

Page 3

Introduction

INTRODUCTION

How to Use This Manual

This Operator's Manual contains useful information for the

safe and efficient operation of your Medium Duty vehicle. It

also provides information on maintaining your vehicle in the

best condition, with an outline for performing safety checks

and basic preventive maintenance inspections.

We have tried to present the information you'll need to learn

about your vehicle's functions, controls, and operation as

clearly as possible. We hope you'll find this manual easy to

use. There will be times when you need to take this manual

out of your Peterbilt vehicle. When you do, please be sure to

return it to the cab when you are finished using it. That way it

will be there when you need it the ne xt time or when y ou pass

the vehicle on to the next user.

Your Medium Duty may not have all the features or options

mentioned in this manual. Therefore, you should pay careful

attention to the instructions that pertain to just your vehicle. In

Medium Duty

(R10/06) Y53-6008 – 1 –

addition, if your vehicle is equipped with special equipment or

options not discussed in this manual, consult your dealer or

the manufacturer of the equipment.

All information contained in this manual is based on the latest

production information available at the time of publication.

Peterbilt Motors Company reserves the right to make

changes at any time without notice.

Safety Signals

A number of alerting messages are in this manual. Please

read and follow them. They are there for your protection and

information. These messages can help you avoid injury to

yourself and your passengers, and can help prevent costly

damage to the vehicle.

Key symbols and “signal words” are used to indicate what

kind of message is going to follow. Pay special attention to

instructions prefaced by symbols and the signal words

“WARNING”, “CAUTION”, and “NOTE”. Please do not ignore

any of these alerts.

Page 4

Introduction

WARNING

When you see this word, the message that follo ws is

especially vital. It signals a potentially hazardous

situation which, if not avoided, could result in an

injury or death. This message will tell you what the

hazard is, what can happen if you don't heed the

warning, and how to avoid it.

WARNING! Never carry additional fuel containers in the vehicle. Such containers, full or empty,

may leak, explode or cause a fire in the event of

a collision.

CAUTION

Signals a potentially hazardous situation which, if

not avoided, could result in property or vehicle damage.

CAUTION: Continuing to operate your vehicle

with insufficient oil pressure will cause serious

engine damage.

Example:

Example:

NOTE

Provides general information: for example, the note

could warn you on how to av oid damaging y our vehicle or how to drive the vehicle more efficiently.

Example:

NOTE: Pumping the accelerator will not assist in

starting the engine.

Please take the time to read these messages when

you see them, and remember:

WARNING!

Something that could seriously injure you.

CAUTION:

Something that could cause property or vehicle damage.

NOTE:

Useful information.

– 2 – Y53-6008

Medium Duty (R10/06)

Page 5

Introduction

Vehicle Safety

Make sure your Medium Duty is in top working condition

before heading out on the road—it is the responsible driver's

duty to do so. Inspect the vehicle according to the “

Check List”, page 13.

WARNING! Do not drink and drive. Your reflexes,

perceptions, and judgment can be affected by

even a small amount of alcohol. You could have

a serious—or even fatal accident—if you drive

after drinking. Please do not drink and drive or

ride with a driver who has been drinking.

Please remember, this manual is not a training manual. It

cannot tell you everything you need to know about driving

your Peterbilt vehicle. For that you need a good training program or truck driving school. If you have not been trained, get

the proper training before you drive. Only qualified drivers

should drive this vehicle.

Every new P eterbilt vehicle is designed to conform to all Federal Motor Vehicle Safety Standards applicable at the time of

manufacture. However, even with these safety features, continued safe and reliable operation depends greatly upon regular vehicle maintenance. The vehicle must be operated

within the range of its mechanical capabilities and the limits

Driver's

of its load ratings. (See the tire and rim weight ratings information on the Vehicle Certification Label on the driver's door

frame.) This vehicle is not approved for off-road operation.

How to Find What You Want

There are several tools built into this manual to help you find

what you need quickly and easily. First is the Contents.

Located at the front of the manual, this lists the main subjects

covered and gives page numbers where you can find these

subjects. Use the Contents to find information on a large subject like “Operating the Transmission.”

Cross-references also help you get the in f ormation you need.

If some other part of the manual contains further information

on the subject you are reading about, a cross-reference will

refer you to another page, for example: “See page 46

more information on Safety Restraint Belts.”

Finally, you will find a helpful Index at the back of the manual,

listing subjects alphabetically. For example, if you want information on brakes, just look under “Brakes” in the Index. You

will find the pages where brakes or related topics are discussed.

, for

Medium Duty

(R10/06) Y53-6008 – 3 –

Page 6

Introduction

A Special Word About Repairs

This is not a repair or workshop manual. Your Peterbilt

Dealer's Service Center is the b est place to have your

Medium Duty repaired. You can find Peterbilt dealers all over

the country with the equipme nt and trained personnel to

quickly get you back on the road—and to keep you there.

Your Medium Duty is a complex machine. Anyone attempting

repairs on it needs good mechanical training, proper specifications, and proper tools. If you are sure you meet these

qualifications, then you can probably perform some repairs

yourself. But if you are not an ex perienced mechanic, or do

not have the right equipment or training, please leave the

repairs to an authorized service facility. They are the ones

equipped to do the job safely and correctly.

WARNING! Do not attempt repair work without

sufficient training, service manuals, and the

proper tools. You could be injured, or you could

make your vehicle unsafe. Do only those tasks

you are fully qualified to do.

Shop Manuals

If you do decide to do complex repair work, you will need the

Medium Duty Maintenance Manual. It contains service procedures, parts information, and supporting material on major

components in your vehicle, such as Suspensions, Drivelines, Axles, and the Heater/Air Conditioner.

Listed below are manuals available from your Peterbilt

Dealer. (There is a charge for these manuals.) Please provide the Chassis Serial Number when ordering, to be sure

you get the correct manuals for your vehicle.

Medium Duty Maintenance Manual

detailed service procedures specifically co mpiled for the

components on your vehicle, including: ele ctrical information,

maintenance, disassembly, assembly, repairs, overhaul, and

troubleshooting procedures. The information contained in

this manual is the same used by Peterbilt dealers.

Medium Duty Master Parts Catalog

parts lists with drawings and exploded views for Medium

Duty series vehicles.

. This manual includes

. Contains illustrated

– 4 – Y53-6008

Medium Duty (R10/06)

Page 7

Introduction

Medium Duty Body Builders' Manual. Contains general

guidelines on mechanical and electrical modifications

required by your dealer to add bodies, accessories, and special equipment to straight-truck configurations.

WARNING! Modifying your vehicle can make it

unsafe. Some modifications can affect your

vehicle's electrical sy stem, stability, or other

important functions. Before modifying your

vehicle, check with your dealer to make sure it

can be done safely.

Preventive Maintenance Section

The Preventive Maintenance section (pages 116 – 226) in

this manual contains general service information for the operator, such as: lubrication points, making adjustments, and

other helpful service information. This is summary information only, used for general maintenance of major components

installed on your Medium Duty. For detailed service information see your Medium Duty Maintenance Manual.

When it comes time for major service work, your Peterbilt

Dealer or Authorized Service Center will need vehicle and

component information. To help you gather this vehicle infor-

mation, see “

tion” on page 226. This section explains vehicle identification

and provides space to record model and serial numbers of

major components installed on your vehicle.

Consumer Information and Vehicle Identifica-

Additional Sources of Information

Installed Equipment — Operator's Manuals

Major component suppliers to Peterbilt also supply operation

manuals specific to their products. Additional manuals and

other pieces of literature are included in the glove compartment literature set. Look for information on products such as

the engine, driver’ s seat, transmission, axles, tires , and radio.

If you are missing these pieces of literature, ask y our P eterbilt

Dealer for copies.

Truck Driver's Handbook

Your set of glove compartment literature also contains a copy

of the Truck Driver's Handbook, published by the American

Trucking Association (ATA). Refer to it for important information on driving your Medium Duty.

Medium Duty

(R10/06) Y53-6008 – 5 –

Page 8

Introduction

Other Sources

Another place to learn more about trucking is from local truck

driving schools. Contact one near you to learn about courses

they offer.

Federal and state agencies such as the department of licensing also have information you can ask for. The Interstate

Commerce Commission can give you information about regulations governing transportation across state lines. Regulations that differ from state to state can be found at various

agencies in state governments.

– 6 – Y53-6008

Medium Duty (R10/06)

Page 9

Operating Instructions Start–Up

OPERATING INSTRUCTIONS

START–UP

Introduction

The following section covers start-up procedures for getting

your Medium Duty ready for the road.

Door Lock and Keys

Doors can be locked from the inside by using the loc k button.

Close the door then push the button down to lock. Doors

automatically unlock when you open them from inside, and

can be locked from the outside with the key only.

As standard equipment, two keys are provided for the doors

and ignition. When necessary, additional locks and keys are

provided for storage compartments.

Medium Duty

(R10/06) Y53-6008 – 7 –

WARNING! To help lessen the chance and/or

severity of personal injury in case of an accident, always lock the doors while driving. Along

with using the lap shoulder belts properly, locking the doors helps prevent occupants from

being thrown from the vehicle.

To lock or unlock the doors from outside the cab:

• Insert the key in the door lock.

• Turn the key toward the rear door frame to lock; forward

to unlock.

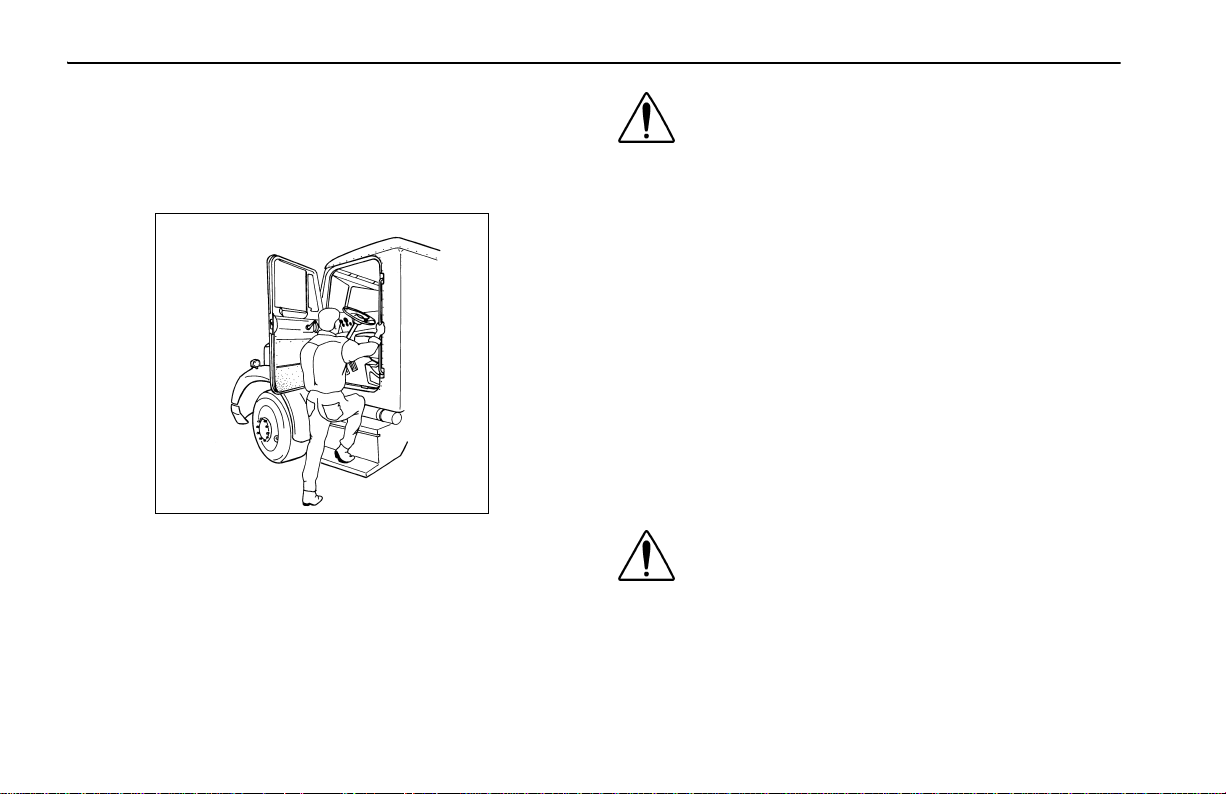

Cab and Frame Access

The following cab and frame entry/exit procedure recommendations were prepared with personal safety f oremost in mind.

WARNING! Do not jump out of the cab or get into

the cab without proper caution. You could slip or

fall, possibly suffering a serious injury. You

could slip and fall if the steps are wet or icy, or if

you step in fuel, oil, or grease.

Page 10

Start–Up Operating Instructions

To help avoid personal injury due to a slip or fall:

• Use three points of contact (two feet, one hand or one

foot, two hands) to grip the steps or handholds whenev er

possible and look where you are going.

02611

• Use even more care when steps and handholds (or footwear) are wet, coated with ice, snow, mud, oil, fuel, or

grease.

WARNING! Do not step on vehicle components

without antiskid surfaces or use components

not designed for entry-and-exit use. You could

fall and injure yourself if y ou step ont o a slippery

surface. For example:

•Do not step onto the surface of a fuel tank. A

fuel tank is not a step. The tank surface can get

very slippery, and you might not be able to prevent a fall. Use only the steps and handholds

provided, not chain hooks, quarter fenders, etc.

•Do not climb onto and off the deck plate—use

steps and grab handle provided. If there is no

deck plate, or if proper steps and grab handles

are not provided, do not climb onto the area

behind the cab.

•Keep steps clean. Clean any fuel, oil, or grease

off the steps before entering the cab or accessing the deck plate.

WARNING! Always reinstall the battery compartment cover (step) before entering the cab. Without the battery cover you could slip and fall,

resulting in possible injury to yourself.

– 8 – Y53-6008

Medium Duty (R10/06)

Page 11

Operating Instructions Start–Up

NOTE: Any alteration (adding bulkheads, headache

racks, tool boxes, etc.) behind the cab tha t affects

the utilization of grab handles, deck plates, or frame

access steps installed by Peterbilt should comply

with Federal Motor Carrier Safety Regulation 399.

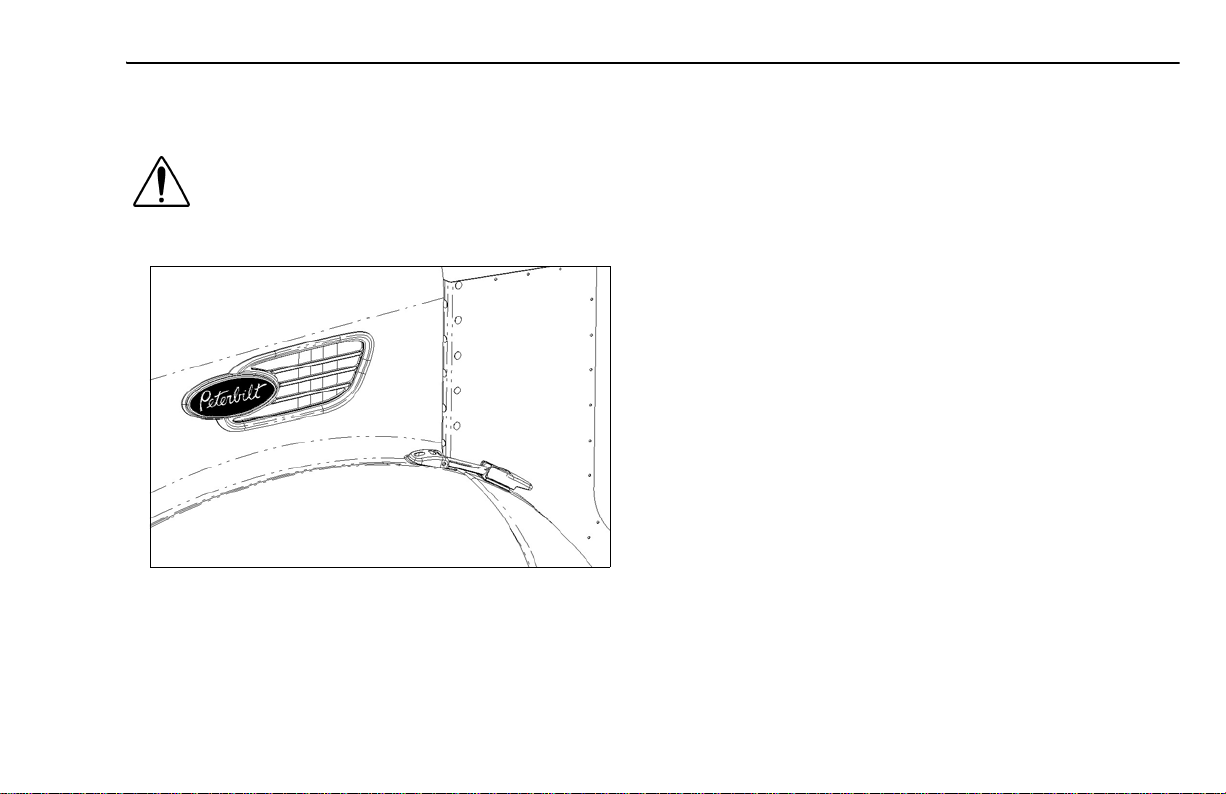

Hood Hold Downs and Tilt

The hood is locked in its closed position by an exter nal latch

on each side. These latches serve as hold downs and keep

the hood from opening unexpectedly.

CAUTION: If you do not latch the hood securely,

it could open during operation and cause vehicle damage. Be sure to latch the hood securely

before moving the vehicle.

WARNING! A pivoting hood could hurt someone

or be damaged itself. Before opening or closing

the hood, be sure there are no people or objects

in the way.

To open the hood, unlatch both of the hood hold downs.

UNLATCHED

Medium Duty

(R10/06) Y53-6008 – 9 –

Page 12

Start–Up Operating Instructions

Put one hand on the hood handle (just above the Peterbilt

emblem), one foot on the bumper, and one foot on the

ground. Tilt the hood forward until you hear it “lock”.

02609-1, -2

WARNING! If the hood falls, anyone under it

could be injured. Always make sure the lock is

engaged to keep your hood open any time anyone gets under the hood for any reason. Never

work under the hood unless the hood safety lock

is engaged.

To close the hood, you must first releas e the hood safety

lock.

WARNING! Before closing the hood, be sure the

area is clear—no people or objects are in the

way.

CAUTION: To avoid hood damage when closing

the hood, firmly squeeze the handle to release

the hold-open lock.

HOOD HOLD-OPEN

RELEASE HANDLE

– 10 – Y53-6008

Medium Duty (R10/06)

Page 13

Operating Instructions Start–Up

After lowering the hood, latch the hood closed with the hold

downs.

WARNING! If the hood is not latched securely, it

could open during operation and cause an accident. Be sure the hood is latched securely

before moving the vehicle.

LATCHED

Safe Vehicle Operation

For your safety, as well as those around you, be a responsible driver:

• If you drink, do not drive.

• Do not drive if you are tired, ill, or under emotional stress.

Much has gone into the manufacturing of your Medium Duty,

including advanced engineering techniques, rigid quality control, and demanding inspections. These manufacturing processes will be enhanced by you—the safe driver—who:

• knows and understands how to operate the vehicle and

all its controls

• maintains the vehicle properly

• uses driving skills wisely

For more information, refer to Department of Transportation

Regulation 392.7, which states that interstat e commercial

motor vehicles are not to be driven unless the driver is sure

that certain parts and accessories are in working order.

Medium Duty

(R10/06) Y53-6008 – 11 –

Page 14

Start–Up Operating Instructions

WARNING! Do not drink and drive. Your reflexes,

perceptions, and judgment can be affected by

even a small amount of alcohol. You could have

a serious—even fatal—accident if you drive after

drinking. Please do not drink and drive or ride

with a driver who’s been drinking.

•The use of alcohol, drugs, and certain medications will seriously impair perception, reactions,

and driving ability. These circumstances can

substantially increase the risk of an accident

and serious personal injury.

Vehicle Loading

Compare your vehicle's load capacity with the total load you

are carrying. If ad justments need to be made, make them—

do not drive an overloaded vehicle. If you are overloaded or

your load has shifted, your vehicle may be unsafe to drive.

WARNING! Do not exceed the specified load rating. Overloading can result in loss o f vehicle

control and serious personal injury, either by

causing component failures or by affecting vehicle handling. Exceeding load ratings can also

shorten the service life of the vehicle.

•The components of your vehicle are designed

to provide satisfactory service if the vehicle is

not loaded in excess of either the gross vehicle

weight rating (GVWR), or the maximum front an d

rear gross axle weight ratings (GAWRs). (Axle

weight ratings are listed on the driver's door

edge.)

Here are some definitions of weight you should know:

GVWR:

MAXIMUM WEIGHT your vehicle is allowed to carry, including the weight of the empty vehicle, loading platform, occupants, fuel, and any load. Never exceed the GVWR of your

vehicle.

GCW:

Weight (GCW), of your vehicle and its load: tractor, plus

trailer(s), plus cargo.

is the Gross Vehicle Weight Rating. This is the

is the actual combined weight, or Gross Combination

– 12 – Y53-6008

Medium Duty (R10/06)

Page 15

Operating Instructions Start–Up

GAWR: is the Gross Axle Weight Rating. This is the total

weight that one axle is designed to transmit to the ground.

You will find this number listed on the driver's door edge.

Load Distribution: be sure any load you carry is distributed

so that no axle has to support more than its GAWR.

WARNING! An unevenly distributed load or a

load too heavy over one axle can affect the braking and handling of your vehicle, which could

result in an accident. Even if your load is under

the legal limits, be sure it is distributed evenly.

Emergency Equipment

It is good practice to carry an emergency equipment kit in

your vehicle. One da y, if you hav e a roadside emergency, you

will be glad the following items are with you:

• window scraper

• snow brush

• container or bag of sand or salt

• emergency light

•small shovel

• first aid kit

• fire extinguisher

Driver's Check List

To keep your Medium Duty in top shape and maintain a high

level of safety for you, your passengers, and your load, make

a thorough inspection every day before you drive. You will

save maintenance time later, and the safety checks could

help prevent a serious accident. Please remember, too, that

the Federal law requires a pre-trip inspection and so do commercial trucking companies.

You are not expected to become a professional mechanic.

The purpose of your inspections is to find anything that might

interfere with the safe and efficient transportation of yourself,

any passengers, and your load. If you do find something

wrong and cannot fix it yourself, have an Authorized Service

Center or qualified mechanic repair your vehicle right away.

The following operations are to be perfor med by the driver.

Performing these checks and following the maintenance procedures in this manual will help keep your Medium Duty running properly.

Approaching Your Vehicle

• Check the overall appearance and condition. Are windows, mirrors, and lights clean and unobstructed?

Medium Duty

(R10/06) Y53-6008 – 13 –

Page 16

Start–Up Operating Instructions

• Check beneath the vehicle. Are th ere signs of fuel, oil, or

water leaks?

• Check for damaged, loose, or missing parts. Are there

parts showing signs of excessive wear or lack of lubrication? Have a qualified mechanic examine any questionable items and repair them without delay.

• Check your load. Is it secured properly?

Daily Checks

NOTE: The following items (Engine Compartment, Chassis and Cab, and Prestart Checks)

should be checked daily, as a minimum. They

are in addition to, not in place of, federal motor

Carrier Safety Regulations. These regulations

may be purchased by writing to:

Superintendent of Documents

U.S. Government Printing Office

Washington, DC 20402

Engine Compartment Checks — Daily

1. Engine Fluid Levels—add more if necessary.

• Engine oil

• Coolant (check while engine is cold)

• Power steering fluid level

• If your truck has hydraulic brakes, check the fluid

level in the master cylinder reservoir. See page 154

for more information.

2. Engine Belt—check tension and condition of belts. This

is important to ensure proper air compressor and engine

operation.

• Measure the belt tension at the longest span of the

belt. See page 142

ing belt tension.

NOTE: Deflection should be one belt thickness for each foot distance between the

pulley centers.

• If breaks or tears are found, the belt should be

replaced before operating the vehicle.

3. Fuel Filter/Water Separator Draining—check and drain.

Depending on the fuel storage facility, more frequent

draining may be required.

4. Windshield washer reservoir fluid level—fill if necessary.

5. Hood closed before entering cab. Is it latched properly?

Chassis and Cab Checks — Daily

Before entering the cab and operating the vehicle, check the

following equipment for proper maintenance:

for further information on check-

– 14 – Y53-6008

Medium Duty (R10/06)

Page 17

Operating Instructions Start–Up

1. Lights—do headlights, turn signals, emergency flashers,

and exterior lamps function and are they clean and

adjusted properly?

2. Windows and Mirrors—are they clean and adjusted

properly?

3. Tires and Wheels—are they inflated properly? Are all

wheel cap nuts in place and torqued properly—tighten if

necessary. Check front wheel bearing oil levels. Inspect

all tires and wheels for damage—correct if found.

4. Suspension—check for loose or missing fasteners.

Check damage to springs or other suspension parts.

5. Brake Components—check lines, linkages, chambers,

and brake operation.

6. If your truck has hydraulic brakes, check:

• the brake system for leaks

• hydraulic lines for cracks or kinks

• calipers for leaks

7. Air System—are there leaks?

• Air Tanks—drain water from all air tanks. Make sure

the drain cocks are closed. This procedure is also

required for air suspension tanks equipped with

automatic drain valves.

• See page 72

System.”

for further details on “Using the Brake

8. Steps and Handholds—check for worn surfaces and

loose or missing fasteners.

9. Fluid Tanks—check underneath the vehicle for signs of

fluid leaks. If any are found, correct before operating the

vehicle.

10. Fuel Tank Caps—are they secure?

WARNING! Diesel fuel in the presence of an ignition source (such as a cigarette) could cause an

explosion. You could be seriously injured. A

mixture of gasoline or alcohol with diesel fuel

increases this risk of explosion.

•Do not remove a fuel tank cap near an open

flame.

•Use only the fuel and/or additives recommended for your engine.

•See page 114

11. Trailer Connections (Tractor)—are they secure and the

lines clear? If they are not being used, are they stored

properly?

• Is the trailer spare wheel secure and inflated?

• Is the landing gear up and the handle secured?

12. Check the fifth wheel. Is the kingpin locked?

• Is the sliding fifth wheel locked?

for more information.

Medium Duty

(R10/06) Y53-6008 – 15 –

Page 18

Start–Up Operating Instructions

Prestart — Daily

1. Seat—adjust the seat for easy reach of controls.

2. If your vehicle is equipped with an adjustable steering

column, adjust the steering wheel to a comfortable position.

3. Mirrors—check and readjust mirrors if necessary.

4. Lights—turn ignition key to the IGN & ACC position and

check for warning lights and buzzer. Check operation of

turn signals and emergency lights.

5. Instruments—check all instruments.

6. Windshield—check operation of windshield wipers and

washers.

7. Horn—check operation of horn.

8. Check fire extinguisher charge and road emergency kit.

9. Fuel—check fuel. Is there enough fuel?

10. Seat Belts—fasten and adjust safety restraint belts

Weekly Operations

1. Battery—check battery and terminals.

2. Wheel Cap Nuts—are they all in place and torqued properly—tighten if necessary. See “

Page 173.

3. Other Controls and Wiring—check for condition and

adjustment.

4. Steering Components—check pitman arm, draglink, and

power steering hoses, etc., for loose, broken, or missing

parts.

5. Other Engine Compartment Checks

• Check condition and fastening of engine belt, hoses ,

clamps, and radiator.

• Check the air cleaner, muffler, and exhaust pipes.

Are they tight and secure?

• After Engine Warm-up

– Automatic Transmission—check fluid level in the

automatic transmission oil (if equipped).

Wheel Cap Nut Torque,”

– 16 – Y53-6008

Medium Duty (R10/06)

Page 19

Operating Instructions Start–Up

1

3

02599A

14

5

6

2

15

4

10

9

11

8

7

12

DASH INSTRUMENT PANEL

1 Headlight 6 Oil Pressure 11 Voltmeter (option)

2 Clearance Lights 7 Water Temperature 12 Air Pressure

3 Windshield Washer/Wiper 8 Speedometer 13 Transmission Temperature (option)

4 Panel Lights 9 Air Cleaner Restriction/Filter (option) 14 Warning Lamp Cluster

5 Tachometer 10 Fuel 15 Ignition Switch

13

02595-1A

Medium Duty

(R10/06) Y53-6008 – 17 –

Page 20

Instruments and Controls Operating Instructions

INSTRUMENTS AND CONTROLS

Introduction

Your Medium Duty dashboard is shown on the opposite

page.

The dash includes standard gauges and switches. Your vehicle may come with all or some of the switches and gauges

discussed here. The location of switches on the dash will

vary depending on the options ordered and how your vehicle

was configured.

For your convenience, all gauges and their corresponding

page numbers are listed here, see “

to the page listed to learn what each gauge does and how it

should be used.

Index of Gauges”. Refer

Instrument Index

Table 1 Index of Gauges

GAUGE REFERENCE PAGE

Tachometer 22

Engine Oil Pressure 25

Engine Coolant Temperature 23

Speedometer 21

Air Cleaner Restriction (option) 30

Fuel Level 28

Voltmeter (option) 29

Air System Pressure 26

Transmission Temperature (option) 29

Warning Lights and Buzzer

Many vehicle systems are linked to the instruments on your

instrument panel. Warning lights (in each instrument) may

indicate something is wrong with one of the many vehicle

systems. Check the lights frequently, and respond properly

as soon as a light or buzzer comes on.

– 18 – Y53-6008

Medium Duty (R10/06)

Page 21

Operating Instructions Instruments and Controls

WARNING LAMP MODULE

Medium Duty

HIGH

BEAM

FIFTH

WHEEL

LOAD

LIGHT

STOP

ENGINE

CHECK

ENGINE

CRUISE

CONTROL

DIFF

LOCK

SPOT

LIGHT

WAIT

TO

START

ENGINE

OIL

BRAKE

AIR

MIRROR

HEAT

LOW

WATER

WATER

FAN

ABS

VEHICLE WITH AIR BRAKES

CHECK

TRANS

OIL

!

BRAKE

MIRROR

HEAT

LOW

WATER

WATER

ENGINE

FAN

HIGH

BEAM

FIFTH

WHEEL

LOAD

LIGHT

STOP

ENGINE

CHECK

ENGINE

CRUISE

CONTROL

PARK

RANGE

SPOT

LIGHT

INHIBIT

P

VEHICLE WITH HYDRAULIC BRAKES

(R10/06) Y53-6008 – 19 –

Page 22

Instruments and Controls Operating Instructions

Self Test

When you turn on your ignition, the following warning lights

will turn on for 3 - 5 seconds, as a test to let you know they

are working.

Diff Lock Trailer ABS

Water Temp Left Turn

Mirror Heat Load Light

Brake Air (or Brake *) High Beam

Fifth Wheel Right Turn

Oil Pressure Engine Fan

ABS Park *

* Vehicle with hydraulic brakes only

WARNING! Do not ignore a warning light or

buzzer. These signals tell you some thing is

wrong with your vehicle. It could be a failure in an

important system, such as the brakes, which

could lead to an accident. Have the appropriate

system checked immediately.

The buzzer will sound continuously as long as:

• Engine temperature is above the specified range

• Air pressure to the service brakes is low

• Engine oil pressure is low

• There is a problem in the hydraulic brake system

If the buzzer sounds while driving, or if a light comes on, do

the following:

1. Slow down carefully.

2. Move a safe distance off the road and stop.

3. Set the parking brake. (See Pages 68

mission shifting and parking brake information.)

4. If the engine is overheating do not turn it off, see page

23; otherwise, for other conditions turn the engine OFF.

5. Turn on the emergency flasher and use other warning

devices to alert other motorists.

and 74 for trans-

– 20 – Y53-6008

Medium Duty (R10/06)

Page 23

Operating Instructions Instruments and Controls

WARNING! Do not operate the vehicle if the

BRAKE warning lamp illuminates or the buzzer

sounds. The vehicle should not be oper ated until

the system is repaired. Failure to respond to a

brake warning (lamp or buzzer) could result in an

accident and/or severe injury.

Speedometer and Odometer

The speedometer indicates the vehicle speed in miles per

hour (MPH) and in kilometers per hour (km/h).

The odometer records the distance traveled by the vehicle,

either in miles or kilometers, depending on which unit is

installed in the vehicle.

Speedometer (MPH-km/h)

02587

Medium Duty

(R10/06) Y53-6008 – 21 –

Page 24

Instruments and Controls Operating Instructions

Tachometer

The vehicle's tachometer measures the engine speed in revolutions–per–minute (rpm). Watching the tachometer is

important to driving efficiently. It will let you match driving

speed and gear selection to the operating range of your

engine. If the engine speed gets too high, you can select a

higher gear to lower the rpm's. If the engine speed drops too

low, you can select a lower gear to raise the rpms. See page

99 for further instructions on driving techniques and using the

HOURMETER

(OPTION)

Tachometer

02586

tachometer.

• To avoid engine damage, do not let the pointer exceed

maximum governed speed.

• When driving downhill, shift to a lower gear and use the

service brake, keeping the engine speed below the maximum governed speed.

The hour meter (option) records the time in hours the engine

is operating.

– 22 – Y53-6008

Medium Duty (R10/06)

Page 25

Operating Instructions Instruments and Controls

Coolant (Water) Temperature Gauge

The water temperature gauge shows the temperature of the

engine coolant. Under normal operating conditions the water

temperature gauge should register between 165 and 205°F

(74 and 90°C). Under certain conditions, somewhat higher

temperatures may be acceptable. The maximum allowable

temperature is 210°F (99°C) with the cooling system pressurized, except for cer tain special engines. Check the engine

manual to be sure.

02580

Water Temperature Gauge

Engine Overheating

The cooling system may ov erheat if the coolant level is below

normal or if there is sudden loss of coolant, such as a split

hose. The system may also temporarily overheat during

severe operating conditions such as:

• Climbing a long hill on a hot day

• Stopping after high–speed driving

If the Engine Coolant Temperature (“WATER”) warning light

comes on and the audible alarm sounds showing an overheat condition, or if you have an y other re ason to suspect the

engine may be overheating, DON'T TURN OFF THE

ENGINE unless the “LOW WATER” warning light also comes

on, indicating a loss of coolant. Instead, follow these steps:

A. Reduce engine speed or stop. When stopped, place the

transmission in Neutral and set the parking brake. See

Pages 68

and 74 for transmission shifting and parking

brake information.

B. Check to ensure that the oil pressure gauge reads nor-

mal.

C. Increase the engine speed to about one–half of full oper-

ating speed, or 1100 to 1200 rpm, maximum.

Medium Duty

(R10/06) Y53-6008 – 23 –

Page 26

Instruments and Controls Operating Instructions

D . Return the engine speed to normal idle after two or three

minutes.

E. Monitor the engine temperature. After the temperature

returns to normal, allow the engine to idle 3 to 5 minutes

before shutting it off. This allows the engine to cool gradually and uniformly.

• If the overheating came from severe operating conditions, the temperature should have cooled by this

time.

FILL

02604

Coolant Expansion Tank

F. Check the level of coolant in the coolant expansion tank

(engine compartment, right side.)

WARNING! Removing the radiator fill cap while

the engine is hot can be dangerous. Never

remove the caps of the expansion tank while the

engine is still hot; you could be badly burned.

•Scalding steam and fluid under pressure may

escape and cause serious personal injuries.

•Wait until the coolant temperature is below

122°F (50°C).

•Protect your face, hands, and arms by covering

the cap with a large, thick rag to protect against

escaping fluid and steam.

WARNING! Carefully and slowly turn cap one

turn to allow excess pressure to escape, then

push down and turn for final removal.

G. See page 143

for instructions on checking and filling the

coolant expansion tank.

– 24 – Y53-6008

Medium Duty (R10/06)

Page 27

Operating Instructions Instruments and Controls

WARNING! To reduce the chance of personal

injury and/or vehicle damage due to engine

overheating, never leave the engine idling without an alert driver present. If the engine should

overheat, as indicated by the engine coolant

temperature light, immediate action is required

to correct the condition. Continued unattended

operation of the engine, even for a short time,

may result in serious engine damage or a fire.

For further details on engine operation, see the Engine Operation and Maintenance Manual in the glove compartment of

your vehicle.

Engine Oil Pressure Gauge

It is important to maintain oil p ressure within acceptable limits. If oil pressure drops below the minimum psi a Red Warning Lamp on the oil pressure gauge and the Stop Engine

Warning Lamp will come ON.

For further information on engine oil and normal operating

pressures, see the Engine Operation and Maintenance Man-

ual.

Medium Duty

(R10/06) Y53-6008 – 25 –

02585

Engine Oil Pressure Gauge

CAUTION: Continuing to operate your vehicle

with insufficient oil pressure will cause serious

engine damage.

• If the oil pressure fails to rise within 10 seconds after the

engine starts, stop the engine and determine the cause.

• Check the engine manufacturer's manual for the correct

oil pressure ranges for your vehic le's engine.

• If the oil pressure suddenly drops, or the audible alarm

and engine oil pressure warning light come on while driving, do the following:

1. Slow down carefully.

2. Move a safe distance off the road and stop.

Page 28

Instruments and Controls Operating Instructions

3. Place the transmission in park and set the parking

brake. (See Pages 68

and 74 for transmission

shifting and parking brake information.)

4. Turn OFF the engine.

5. Turn ON the emergency flasher and use other

FRONT

SECONDARY

SERVICE

CIRCUIT

(WHITE)

warning devices to alert other motorists.

6. Wait a few minutes to allow oil to drain into the

engine oil pan, and then check the oil level. (See

page 139

7. Add oil if necessary. If the problem persists, contact an Authorized Service Center.

For further information on operating your engine properly,

see page 58

for details on checking oil level.)

.

02581

Dual Air Pressure Gauge (Air Reservoir)

REAR

PRIMARY

SERVICE

CIRCUIT

(ORANGE)

If the pressure in either or both circuits is too low for normal

Dual Air Pressure Gauge (Air Reservoir)

The dual air pressure gauge indicates the amount of air pressure in the brake system in pounds per square inch (psi). The

WHITE pointer shows the front (secondary service) reservoir

air pressure, and the ORANGE pointer indicates pressure in

the rear (primary service) reservoir.

brake operation (below 64 psi), a warning light in the panel

will glow and the audible alarm will sound.

WARNING! If the light and alarm do not turn off

at start-up, do not try to drive the vehicle until

the problem is found and fixed.

– 26 – Y53-6008

Medium Duty (R10/06)

Page 29

Operating Instructions Instruments and Controls

WARNING! If the air pressure falls below 60 psi

(414 kPa) the spring brakes may stop the vehicle

abruptly, which could result in an accident and/

or injuries. Observe the warning light in the

panel. If it comes on, do not continue to drive the

vehicle until it has been properly repaired or serviced.

WARNING! The air pressure warning light and

the audible alarm indicate a dangerous situation: there is not enough air pressure in the reservoirs for repeated braking and the brake

system has failed. Without the use of your service brakes, your spring brakes could suddenly

apply. This could cause a wheel lock-up, loss of

control, or over-take by following vehicles. You

could be in an accident and severely injured.

•Bring the vehicle to a safe stop right awa y, while

you still have control of the vehicle.

Air Loss Emergency Procedure

1. Slow down carefully.

2. Move a safe distance off the road and stop.

3. Place the transmission in park and set the parking brake.

(See Pages 68

ing brake information.)

4. Turn OFF the engine.

5. Turn ON the emergency flasher (See “

Flasher Switch” on page 55) and use other warning

devices to alert other motorists.

and 74 for transmission shifting and park-

Emergency

Medium Duty

(R10/06) Y53-6008 – 27 –

Page 30

Instruments and Controls Operating Instructions

Fuel Gauge

The fuel gauge shows the approximate amount of fuel in the

fuel tanks. Besides empty and full, the gauge also indicates

1/4, 1/2 and 3/4 of total fuel capacity.

02584

Fuel Gauge

Your truck has one main fuel tank and up to four optional

tanks. The fuel gauge shows the total amount of fuel. It is a

good idea to keep fuel tanks at least half–full; otherwise,

water that condenses in an empty tank will contaminate the

fuel and could damage the engine.

WARNING! Do not carry additional fuel containers in your vehicle. Fuel container s, eit her full or

empty, may leak, explode, and cause or feed a

fire. Do not carry extra fuel containe rs, even

empty ones are dangerous.

WARNING! Do not remove a fuel tank cap near

an open flame. Hot fuel vapors are combustible

and can cause an explosion or fire resulting in

injury or death.

See page 114

for more information.

– 28 – Y53-6008

Medium Duty (R10/06)

Page 31

Operating Instructions Instruments and Controls

Voltmeter (option)

The voltmeter shows the voltage your vehicle's electrical system is putting out. Normally, it should show 10 to 16 volts. If

voltage drops, have the electrical system checked.

02582

Voltmeter

Transmission Temperature Gauge (option)

Your vehicle may be equipped with a transmission temperature gauge. It indicates the temperature of the oil in your

transmission. Watch this gauge to know when your tr ansmission is overheating. If it is, have it checked by an Authorized

Service Center.

02579

Transmission Temperature Gauge

CAUTION: Maximum allowable transmission

temperature may vary, depending upon your

transmission and type of lubricant. Check your

transmission Owner's Manual.

Medium Duty

(R10/06) Y53-6008 – 29 –

Page 32

Instruments and Controls Operating Instructions

CAUTION: Do not continue to operate with the

Air Filter Restriction Gauge reading 25 in. (start

of red area). It could lead to damage to the

RED

CAUTION

AREA

engine. Inspect the filter and replace if necessary.

Holes in the paper element render an air cleaner useless and

may cause the Air Filter Restriction Gauge to give a false

reading, even if the element is clogged. Replace the element

if it is damaged. See page 167

for information on Air Filter

Replacement.

02583

Air Filter Restriction Indicator

Headlight Switch

The headlights are controlled by a toggle

Air Filter Restriction Indicator (option)

This gauge indicates the condition of the engine air cleaner

and is measured by inches of water . A clean filter should register 7 in. of water and a filter whose life is over will register

approximately 25 in.

For High Beam operation see page 54

switch on the left instrument panel. See

page 17

. When the headlights are ON, the

dash lights, side, and tail lamps are also

on.

.

– 30 – Y53-6008

Medium Duty (R10/06)

Page 33

Operating Instructions Instruments and Controls

Daytime Running Lights (option)

On vehicles equipped with the Daytime Running Light (DRL)

system, the low beam headlights are turned ON automatically at reduced brightness (to conserve headlamp life).

Three controls (or conditions) will affect whether the system

is ON or OFF:

• headlight switch

• engine on

• parking brake

If the headlight switch is turned OFF, the DRL system

engages automatically after the engine starts and you

release the parking brake. If the headlight switch is ON, the

DRL system is overridden, and headlights operate normally.

WARNING! Do not use daytime running lights

(DRL) during periods of darkness or reduced

visibility. Do not use DRL as a substitute for

headlights or other lights during operations that

require lighting of your vehicle. Doing so could

lead to an injury accident.

Panel Lights

The Panel Lights knob lets you vary the

brightness of your instrument panel lights.

The knob is located on the left instrument

panel. See page 17

.

To Operate the Panel Lights:

Turn on either the headlights, clearance lights, or fog/driving

lights.

To brighten the instrument panel lights, tur n the knob clockwise (to the right).

To dim the instrument lights or to turn them off, turn the knob

counterclockwise (to the left).

ID and Clearance Lights

A toggle switch controls the amber lights on

top of your cab , plus any additional lights that

were installed on the front, sides, and rear of

your vehicle. The switch is located on the left instrument

panel, and is labeled CL LPS. See page 17

.

Medium Duty

(R10/06) Y53-6008 – 31 –

Page 34

Instruments and Controls Operating Instructions

Windshield Wipers/Washer

NOTE: The ignition key must be turned to ACC or

IGN & ACC for the wiper/washer switch to operate.

A five-position windshield wiper switch controls the wipers

and washer. To turn ON the wipers, turn the knob clockwise.

• For intermittent operation turn to the 1st and 2nd positions; for continuous operation advance to the 3rd and

4th positions.

• The final option activates the washer cycle. To wash the

windshield, push knob IN and release. Hold knob IN to

extend washing cycle. After one to three wipes (depending on how long you hold the switch in) the wipers will

shut off automatically.

The windshield washer tank is located inside the engine

compartment below the radiator expansion tank. See

“

Washer Reservoir” on page 201. Check the windshield

washing fluid level weekly. If necessary, fill to top.

CAUTION: If the electric pump is operated for a

long period (more than 15 seconds) with a dry

reservoir, the pump rotor may be damaged.

PUSH IN

FOR

WASHER

Windshield wipers/washer switch

POSITION MODE

0OFF

1 Intermittent Range: long delay

2 Intermittent Range: Short delay

3 Low Speed

4 High Speed

Wiper/washer (push in)

0

1

2

3

4

– 32 – Y53-6008

Medium Duty (R10/06)

Page 35

Operating Instructions Instruments and Controls

WARNING! Do not drive with worn or dirty wiper

blades. They can reduce visibility, making driving hazardous. Clean the blades regularly to

remove road film and wax build-up. Use an alcohol-based cleaning solution and a lint-free cloth,

and wipe along the blades.

WINDSHIELD

WASHER FLUID

TANK

02391

Windshield Washer Fluid Tank

Clean all inside and outside windows regularly. Use an alcohol-based cleaning solution and wipe dry with e ither a lintfree or a chamois cloth. Avoid running the wiper blades over

a dry windshield to prevent scratching the glass. Spray on

washer fluid first. A scratched windshield will reduce visibility.

Ignition Key Switch

The engine ignition key switch (located to the left of the steering column) has four positions: ACC (Accessories), OFF, IGN

& ACC, and IGN & START.

OFF: In this position all accessories are OFF (except those

listed below) and you can remove the key.

• The following lights and accessories have power when

the key is in the OFF position:

- brake lights - marker lamps

- cigarette lighter - headlights

- tail lights - radio station memory

- horn - instrument lights

- emergency hazard flasher

- dome and courtesy lamps (on doors)

- auxiliary Power/Body or Trailer

NOTE: In the OFF position, fuel is cut off by a solenoid valve located on the left side of the engine,

near the ejection pump.

ACC (Accessory): With the key in this position you can play

the radio, defrost mirrors (if equipped with mirror heat) or use

other accessories.

Medium Duty

(R10/06) Y53-6008 – 33 –

Page 36

Instruments and Controls Operating Instructions

IGN & ACC: In this position, all circuits are energized. Panel

warning lights will light and the buzzer will sound until (1) the

engine is started, (2) nor mal oil operating pressure is

reached, and (3) air brake system pressure is above 64 psi

(441 kPa). In this position, the ignition key cannot be

removed.

IGN & START: Turn the key to this position to start your

engine: it energizes the starter and retracts the solenoid

valve to allow fuel supply to the engine. See page 59

for

details on starting the engine.

Parking Brake

Before you leave the cab, apply all parking brakes.

- for vehicles with air brakes:

1. Apply all parking brakes. Pull out the Yellow Parking

Brake Control knob (1) located on the dash. In tractors,

the Red (octagon-shaped) Trailer Air Supply Control

knob (2) will automatically pop out.

38//

72$33/<

3$5.,1*

%5$.(

386+72

5(/($6(

02391-1

Full Truck Parking Brake Valve

WARNING! Do not leave the cab without applying the parking brake. The truck could roll and

cause an injury accident. Always apply the parking brake before you leave the cab.

– 34 – Y53-6008

Medium Duty (R10/06)

Page 37

Operating Instructions Instruments and Controls

Using the Brake System” on page 72 for more informa-

See “

(2) Trailer Air Supply

Control (Red)

(1) Parking Brake Control

(Yellow)

tion.

- for vehicles with hydraulic brakes:

The parking brake consists of a driveline drum brake actuated by a lever and cable. The hand lever, mounted on the

vehicle's cab floor, pulls or releases the cable controlling the

brake. Pulling upward on the parking brake lever pulls the

02394

Combination (Tractor/Trailer) Parking Brake Control Valves

cable and expands the driveline brak e shoes outward against

the driveline brake drum.

The driveline brake is disengaged by pushing the handle

2. Shift the transmission into its PARK position. (See Pages

and 74 for transmission shifting and parking brake

68

information.)

3. Turn the key to OFF.

4. Remove the key.

downward to its lowest position.

NOTE: Failure to fully release the parking brake can

cause the brakes to overheat.

CAUTION: Unless it is an emergency, do not pull

upward on the parking brake lever while the

WARNING! Do not pull out the parking brake

valve while the vehicle is moving. Stopping with

the parking brake controls can cause a sudden

wheel lock-up, loss of control, or over-take by

vehicle is moving. Attempting to stop with the

parking brake could cause damage to the drive-

line, transmission, or the parking brake mecha-

nism itself.

following vehicles. You could be severely

injured.

Medium Duty

(R10/06) Y53-6008 – 35 –

Page 38

Instruments and Controls Operating Instructions

Using the Parking Brake

1. Come to a complete stop.

PARKING BRAKE LEVER

ENGAGE

DISENGAGE

2. Apply the parking brake. Pull upward on the parking

brake lever until it reaches an over (top) center position. (The PARK light on the dash will come on.)

NOTE: Ensure the lever is over center. The light will

come on prior to brake being fully applied.

CONTROL

STOP

ENGINE

CHECK

ENGINE

CRUISE

P

PARK

SPOT

LIGHT

PARKING BRAKE INDICATOR

3. Shift the transmission into NEUTRAL position:

4. Turn the key OFF.

5. Remove the key.

6. If you are parked on a grade, always block the

wheels.

– 36 – Y53-6008

Medium Duty (R10/06)

Page 39

Operating Instructions Instruments and Controls

Cruise Control Switch

02901

WARNING! Do not operate the cruise control

when operating on road surfaces with poor

traction (wet, icy, or snow covered roads) or in

heavy traffic. Accelerations caused by the normal operation of the cruise control could cause

you to lose control of the vehicle resulting in an

injury accident.

The master switch turns the cruise control ON or OFF.

The second switch allows you to SET the desired speed

or RESUME the desired speed after the cruise control

function has been interrupted.

See page 65 for instructions on how to use the cruise control.

Hand Throttle Control

Your vehicle may be equipped with a hand throttle. It is

located on the floor, to the left of the driver's seat. It can be

especially helpful in cold weather to keep your engine running above idle speed when you leav e the v ehicle briefly. See

page 64

for more information on idling your engine safely.

WARNING! Do not use the hand throttle control

for cruise control or to control your road speed.

It could cause an accident and you could be

seriously injured. Always disengage the hand

throttle before driving the vehicle.

Medium Duty

(R10/06) Y53-6008 – 37 –

Page 40

Heating and Air Conditioning Operating Instructions

)5(6+

5(&,5&

$&

212))

HEATING AND AIR CONDITIONING

Introduction

WARNING! Do not drive with your visibility

reduced by fog, condensation, or frost on the

windshield. Your view may be obscured, which

could result in an injury accident. For clear visibility and safe driving it is extremely important

for you to follow the instructions on the use of

the ventilation/heating and defogging/defrosting

system. If in doubt, consult your dealer. Maximum heating output and fast defrosting can be

obtained only after the engine has reached operating temperature.

Internal air circulation control is provided by three sets of

outlets:

• Front outlets on the dashboard panel, with directional

louvers

• Floor outlets under the dashboard

• Window defrost vents on the dashboard

A

E

B

Heater and Air Conditioner Controls

WARNING! Excessive heat may cause the pressurized components of the air conditioning system to explode. Never weld, solder, steam clean,

or use a blow torch near any part of the air conditioning system.

•If a refrigerant leak develops in the presence of

excessive heat or an open flame, hazardous

gases may be generated. These gases may

cause unconsciousness or death. If you become

C

D

02593

– 38 – Y53-6008

Medium Duty (R10/06)

Page 41

Operating Instructions Heating and Air Conditioning

aware of a refrigerant leak on your vehic le, have y our

system serviced immediately and observe the following precautions:

– Stay away from the hot engine until the exhaust

manifold has cooled.

– Do not permit any open flame in the area. Even a

match or a cigarette lighter may generate a hazardous quantity of poisonous gas.

– Do not smoke in the area. Inhaling gaseous

refrigerant through a cigarette may cause violent

illness.

WARNING! Ne ver idle y our vehicle for prolonged

periods of time if you sense that exhaust fumes

are entering the cab. Investigate the cause of the

fumes and correct it as soon as possible. If the

vehicle must be driven under these conditions,

drive only with the windows slightly open. Failure to repair the source of the exhaust fumes

may lead to personal harm.

NOTE: Keep the engine exhaust system and the

vehicle’s cab ventilation system properly maintained. It is recommended that the vehicle’s

exhaust system and cab be inspected:

• By a competent technician every 15,000 miles.

• Whenever a change is noticed in the sound of the

exhaust system.

• Whenever the exhaust system, underbody, cab or

sleeper is damaged.

NOTE: To allow for proper operations of the vehicle

ventilation system, keep the inlet grille at the base

of the windshield clear of snow, ice, leaves, and

other obstructions at all times.

WARNING! Do not stay in the vehicle with the

engine running or idling for more than 10 minutes with the vehicle’s Heater and A/C ventilation system in RECIRC or at LOW FAN SPEED.

Even with the ventilation system ON, running

the engine while parked or stopped for prolonged periods of time is not recommended.

Controls

The heater and air conditioning control unit is mounted in the

center dash console, below the radio. The standard control

unit has four controls to regulate air flow and temperature in

Medium Duty

(R10/06) Y53-6008 – 39 –

Page 42

Heating and Air Conditioning Operating Instructions

the cab: fan speed switch (A), air directional control switch

(B), air temperature switch (C), and air circulating mode

switch (D). With optional air conditioning, a fifth switch (E) is

used.

Fan Speed Control

The fan speed rotary switch (A) allows you to select one of

four blower speeds (1-4).

Air Direction Control

The air direction rotary switch (B) controls the air movement

within the cab. Fiv e modes direct the air flo w to the three sets

of air outlets: front panel, floor, and window defrost:

1.Front Panel only

2.Panel and Floor (Bi-level)

3.Floor only

4.Defrost and Floor (Bi-level)

5.Defrost only

Temperature Control

The temperature rotary switch (C) allows you to adjust and

maintain a comfortable internal cab temperature.

Air Circulation Control

The air circulation rocker switch (D) allows you to select

FRESH air from outside the cab or recirculate (RECIRC) air

from within the cab.

Air Conditioner Control

The optional air conditioner is engaged with this rocker

switch (E).

Heating

To heat the cab: select the desired air direction and circulat ing mode (B and D) and set the temperature knob (C) to hot

(red position on the control). Adjust the fan speed (A) as

desired.

– 40 – Y53-6008

Medium Duty (R10/06)

Page 43

Operating Instructions Heating and Air Conditioning

CAUTION: During extreme cold weather, do not

blow hot air onto cold windshields. This could

crack the glass. Turn the air direction lever to

Defrost and adjust the fan speed accordingly

while the engine warms. If the engine is already

warm, move the temperature selector to Cool,

then gradually increase the temperature when

you see that the windshield is starting to warm

up.

Defogging

NOTE: The air conditioning system is active when

the Defrost mode is selected.

To defog the windshield: select air direction mode 4 or 5 and

turn the fan speed switch (A) to high. Set the temperature

knob (C) to hot (red position on the control). The air conditioner (if equipped) is automatically activated to remov e moisture from the cab. After the windshield is clear, adjust the

controls as desired.

HEAT ING A/C CONTROL

CONTROLS

Fan Speed (A) High (4) Adjust High (4) Adjust High (4) Adjust

Air Direction

Mode (B) Panel

Temperature (C) Warm Adjust Cool Adjust Warm Adjust

Air Circulation

Mode (D)

Air Conditioner -

AC (E)

HEATING COOLING DEFOGGING

MAX NML MAX NML MAX NML

Panel

or BiLevel

(2)

Adjust Adjust

(1)

Recirc Fresh Record Fresh Recirc Fresh

OFF OFF ON ON — —

Defrost

(5)

Defrost

or Bi-

Level (4)

Cooling

To cool the cab: turn on the air cond itioner (if equipped)

(switch E), set the temperature knob (C) to cool (blue side),

and the fan (A) to high until the cab becomes cool—adjust as

desired.

For Efficient Cooling:

1. Ensure all heater/air conditioner controls are off.

2. Start the engine. Allow time for warm–up.

Medium Duty

(R10/06) Y53-6008 – 41 –

Page 44

Heating and Air Conditioning Operating Instructions

NOTE: A cold compressor can cause refrigerant to

liquefy and warp the valve plates or cause a hydr aulic lock. Warm the engine before starting the air conditioner.

3. Set the air conditioner for maximum cooling.

4. Close all windows.

5. Idle the engine between 1000 and 1500 rpm and turn the

fan switch to High.

6. After the cab temperature cools to a comfortable level,

adjust the fan speed and other controls to keep the

desired condition.

If the air conditioner does not cool the air, have the

unit checked at an Authorized Service Center.

NOTE: When the air conditioner isn't in regular use,

operate it for at least 15 minutes at least once a

month or every 5,000 miles (8,000 km), whichever

comes first. This will lubricate the seals in the air

conditioning system.

– 42 – Y53-6008

Medium Duty (R10/06)

Page 45

Operating Instructions Accessories

ACCESSORIES

Radio

As an option, your vehicle has either an AM/FM Stereo

Receiver or an AM/FM Stereo/Cassette Player.

For instructions on how to operate your particular radio, see

the manufacturer's Radio Operating Instructions in the glove

compartment.

Cigarette Lighter

NOTE: The cigarette lighter will operate with the

ignition key in either the OFF, ACC (accessory), or

IGN/ACC position.

To operate, push in on the knob end of the lighter. After a f e w

moments, the lighter will automatically pop out, glowing hot

and ready to use. After use, insert the lighter back into the

socket without pushing all the way in.

The socket of the cigarette lighter may be used to operate 12

volt, 15 ampere appliances, such as a hand spotlight or small

vacuum cleaner.

WARNING! Do not exceed the voltage/amperage

capacity of the cigarette lighter. It could re sult i n

a fire. Follow all warnings and instructions in the

operator's manual for the appliance you are

using.

Ashtray

To open, pull on the upper side of the panel. To close, push

against the panel.

WARNING! Do not place paper or other combustible substances in an ashtray. It could cause a

fire. Keep all burnable materials besides smoking materials, out of the ashtray.

Air Operated Horn (Option)

Your Medium Duty may be equipped with an air horn. To

operate, pull on the lanyard extending from the overhead

header panel. Your vehicle also has an electric horn. See

page 56

.

Medium Duty

(R10/06) Y53-6008 – 43 –

Page 46

Accessories Operating Instructions

Glove Compartment

A glove compartment is provided to store important docu ments, the vehicle literature set (including this Operator's

Manual) and other related materials. You can open it by

pushing the knob on the front.

• To close, push the cover up and press to latch it.

• You can lock and unlock the glove compartment door

with your ignition key; turn it clockwise to lock and counterclockwise to unlock.

WARNING! Do not drive with the glove compartment open, it can be dangerous. In an accident

or sudden stop, you or a passenger could be

thrown against the cover and be injured. To

reduce the risk of personal injury during an accident or sudden stop, keep the glove compartment closed when the vehicle is in motion.

WARNING! Do not carry loose objects in your

cab, it can be dangerous. In a sudden stop, or

even going over a bump in the road, they could

fly through the air and strike y ou or a passenger.

You could be injured or even killed. Secure all

loose objects in the cab before moving the vehicle.

Dome Light

The dome light is automatically activated when you open the

door. To turn the dome light on when you are inside the cab,

turn the headlight switch counter–clockwise until it clicks and

the light comes on.

– 44 – Y53-6008

Medium Duty (R10/06)

Page 47

Operating Instructions Seats

SEATS

Introduction

This section covers the operation and safe use of your

Medium Duty seats. For further information on features and

adjustment of the seat, see the manufacturer's literature

included with the vehicle.

Seat Adjustment

WARNING! Do not adjust the driver's seat while

the vehicle is moving. A sudden or unexpected

seat movement can cause the driver to lose control of the vehicle. Make all adjustments to the

seat while the vehicle is stopped.

• After adjusting the seat and before driving off,

always check to be sure that the seat is firmly

latched in position.

Standard Driver's Seat

The standard driver's seat can be adjusted forward and rearward. These movements are each controlled by levers

located on the FRONT of the seat.

Driver's Seat with Air Suspension (Option)

WARNING! Before driving or riding in the vehicle, be sure that there is adequate head clearance at maximum upward travel of seat. Serious

injury may occur if head clearance is not adequate.

CHUGGER-SNUBBER

LOCK-OUT FEATURE

Move handle down to

unlock

FRONT CUSHION

HEIGHT

Lift and pull forward

to raise position

FORE & AFT ISOLATOR

Move to left and slide

seat to desired position

BACKREST TILT

Rotate knob for

infinite selection of

SEAT RIDE HEIGHT

LUMBAR ADJUSTMENT

Push switch up to inflate

Push down to deflate

Peterbilt Ultraride II Highback Air Seat

settings

03017

Medium Duty

(R10/06) Y53-6008 – 45 –

Page 48

Seats Operating Instructions

Safety Restraint Belts

The right and left seats are equipped with 3-point lap/shoulder belts; the center seat has a 2-point seat belt. Safety belts

have proven to be the single most effective means available

for reducing the potential for either serious injury or death in

motor vehicle accidents. Therefore, read and follow these

instructions and always observe user warnings pertaining to

safety belts.

0917A

Unbelted Person in Crash

WARNING! Do not drive vehicle without your

seat belt and your riders’ belts fastened. Riding

without a safety belt which is properly fastened

can lead to increased injury or death in an accident. Unbelted riders could be thrown into the

windshield or other parts of the cab or could be

thrown out of the cab. They could strike another

person. Injuries can be much worse when riders

are unbelted. Always fasten your seat belt and

be sure anyone riding with you does the same.

Lap/Shoulder Belt

The combination lap-shoulder belt is equipped with a locking

mechanism. The system adjusts automatically to a person's

size and movements as long as the pull on the belt is slow.

Hard braking or a collision locks the belt. The belt will also

lock when driving up or down a steep hill or in a sharp curve.

To fasten the belt:

1. Grasp the belt tongue.

2. Pull the belt in a continuous slow motion across your

chest and lap.

– 46 – Y53-6008

Medium Duty (R10/06)

Page 49

Operating Instructions Seats

• Belts should fit snugly across the pelvis and chest.

Make sure any slack is wound up on the retractor.

To unfasten the belt:

Push in the release button on the buckle. The belt will spring

out of the buckle.

• To release a locked belt, lean back to take the body pressure off of the belt.

• To store a lap-shoulder belt, allow the belt to wind up on

the retractor by guiding the belt tongue until the belt

comes to a stop.

01888

Proper Safety Belt Adjustment

3. Insert the belt tongue into the buckle on the inboard side

of the seat.

4. Push down until the tongue locks securely (with an audible click). Pull on the belt to check for proper fastening.

• Pull the shoulder section to make sure the belt fits

snugly across the chest.

• The shoulder belt must be positioned over the shoulder—it must never rest against the neck.

Medium Duty

(R10/06) Y53-6008 – 47 –

Your combination lap-shoulder belt may need adjustment.

Adjust safety belts properly.

• The lap belt should be worn as low and tight on the hips

as possible. Make sure any slack is taken up by the belt

mechanism.

• The shoulder belt should fit snugly across your body. It

should be positioned midway over the shoulder (nearer

to the door); it should never rest against your neck.

Page 50

Seats Operating Instructions

Lap Belt Shoulder Belt

Too High

on Hips

Correct

Safety Restraint Belts

Incorrect

Correct (over arm)

• Be sure, also, that your belt is not too loose. A loose belt

could allow you to slide under it in an accident, and that

could bring the belt up around your abdomen.

• Do not twist the belt in the process of putting it on. A

twisted belt will not work as well to protect you.

WARNING! Always wear your seat belt low over

your pelvic bones.

– 48 – Y53-6008

Incorrect (under arm)

Incorrect (twisted)

• You can be seriously injured if your belt is buckled

too high. In a crash, it would apply force to your

abdomen, not your pelvic bones. This can result in

serious internal injuries.

• Do not drive with your seat belt loose. A seat belt

that is too loose can allow you to fall too far forward,

possibly causing head and neck injuries. You could

strike the wheel or the windshield. Adjust your belt

so that there is no more than 1 in. (25mm) of slack.

Medium Duty (R10/06)

Page 51

Operating Instructions Seats

WARNING! Do not wear the shoulder belt under

your arm or otherwise out of position. In a crash

your body would move too far forward, increasing the chance of head and neck injury. Also, the

belt would apply too much force to the ribs,

which are not as strong as your shoulder bones,

and could cause you to suffer internal injuries.

Wear the shoulder belt over your shoulder (see

Safety Restraint Belts” on page 46).

“

WARNING! Do not twist the belt in the process of

putting it on. A twisted belt will not work as well

to protect you. In a crash, the full width of the

belt would not be protecting you. A twisted belt

could cut into your body and cause serious injuries. Straighten the belt before buckling it. If you

are unable to wear it without twisting it, have

your dealer or service person repair it as soon

as possible.

Safety Restraint Tips

NOTE: Per FMCSR 392.60 - Unauthorized Persons

Not to be Transpor ted. Federal law prohibits the

transportation of persons in commercial vehicles

unless they are specifically authorized in writing by

the motor carrier. See the cited FMCSR for a complete description of the regulation and exemptions.

• Any authorized person riding in your vehicle should wea r

a seat belt. A responsible operator sees to it that everyone in the vehicle rides safely—and that means with a

seat belt.

• Do not strap in more than one person with each belt.

• Do not wear a belt over rigid or breakab le objects in or on

your clothing, such as eye glasses, pens, keys, etc., as

these may cause injury in an accident.

• Several layers of heavy clothing may interfere with

proper positioning of belts and reduce the overall effectiveness of the system.

• Keep belt buckles free of any obstruction that may prevent secure locking.

• Damaged or worn belts, subjected to excessive stretch

forces from crashes, cuts or tears, or normal wear, must

be replaced—they may not protect you if you have an

accident.

• If belts show damage to any part of assembly, such as

webbing, bindings, buckles or retractors, they must be

replaced.

• Do not allow safety belts to become damaged by getting

caught in door or seat hardware, or rubbing against

sharp objects.

Medium Duty

(R10/06) Y53-6008 – 49 –

Page 52

Seats Operating Instructions

• The belts must be kept clean or the retractors may not

work properly.

• Never bleach or dye seat belts: chemicals can weaken

them. Do, however, keep them clean by following the

care label on the belts. Let them dry completely before

allowing them to retract.

• Make sure the belt of the unoccupied passenger seat is

fully wound up on its retractor, so that the belt tongue is

in its stowed position. This reduces the possibility of the

tongue becoming a striking object in case of a sudden

stop.

• Do not modify or disassemble the seat belts in your vehicle. They will not be avail able to keep you and your passengers safe.

• If any seat belt is not working properly, see an Authorized

Service Center for repair or replacement.

WARNING! Before driving or riding in a vehicle,

ensure that there is adequate head clearance at

maximum upward travel of seat. Shorten the

tether belt as necessary to provide adequate

head clearance. Serious injury may occur if head

clearance is not adequate.

Tether Belts

Tether belts are installed on suspension seats. They help

secure the seat to the floor to restrain it in case of a sudden

stop or an accident.

Fixed Tethers

If your Medium Duty has been equipped with fixed length

tethers, no manual adjustment is required. The same inspection and replacement guidelines should be used as stated on

page 197

.

WARNING! Do not remove, modify, or replace

the tether belt system with a different tether system. A failed or missing tether belt could allow

the seat base to fully extend in the event of an

accident leading to greater injuries or death.

WARNING! F ailure to adjust tether belts pr operl y

can cause excessive movement of the seat in an

accident. This could lead to greater injuries to

you. T ether belts should be adjusted so that they

are taut when the seat is in its most upward and

forward position.

– 50 – Y53-6008

Medium Duty (R10/06)

Page 53

Operating Instructions Seats

Tether Adjustment

• Make sure that the tether belt is attached to the cab floor

and seat frame. It should be routed through the buckle

on each side.

• Often the attachments are made using a split-type hook.

Make sure both halves of the hook are around the

anchor bracket.

• To lengthen the tether, turn the buckle to a right angle to

the webbing. Then pull the buckle. To shorten the tether,

pull on the strap.

Komfort–Lok® Latch

Your Peterbilt contains a feature designed to eliminate cinching and provide improved safety and comfort. Cinching is the

condition where a belt becomes continually tighter around

you during a rough, bouncy ride. The need for this feature