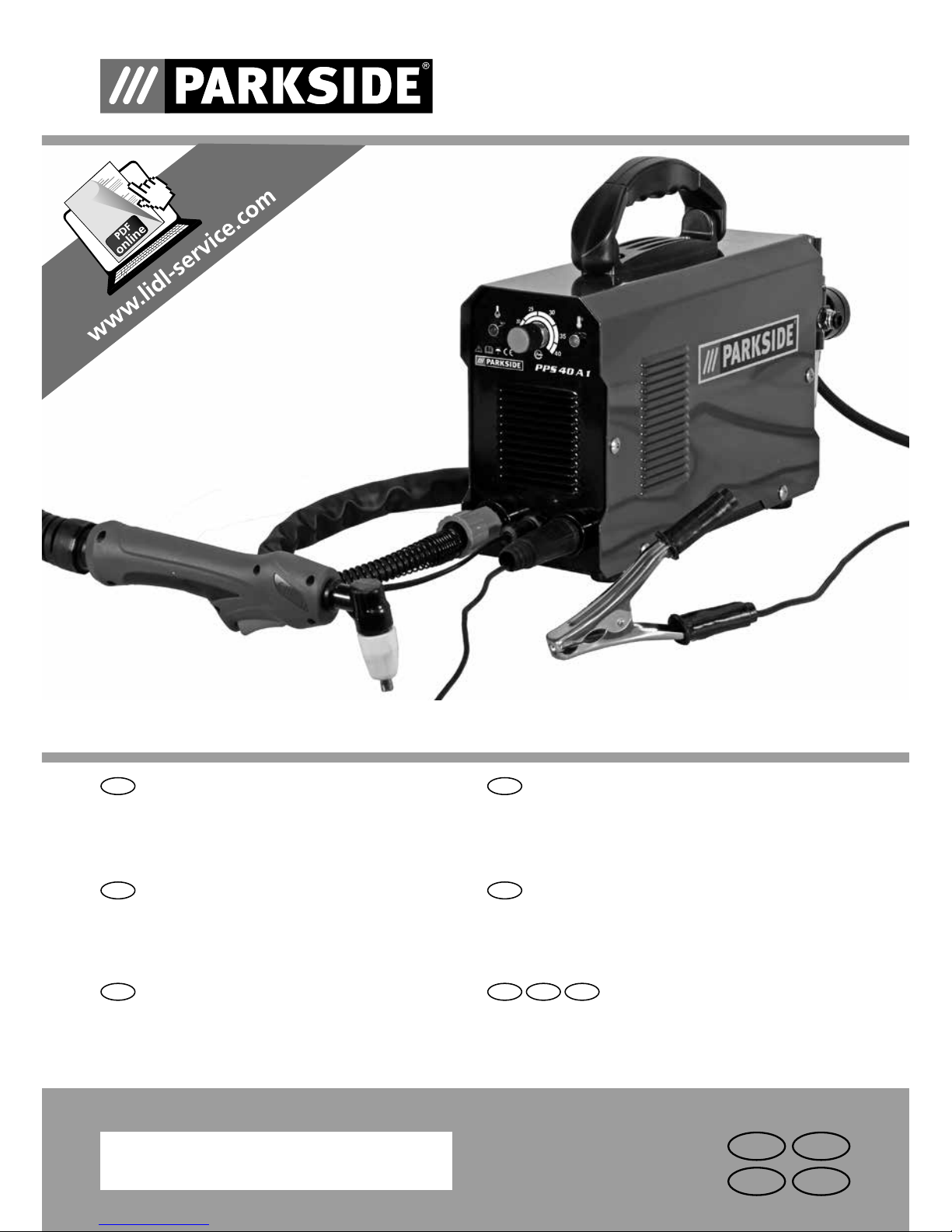

Parkside PPS 40 A1 Operation And Safety Notes

PLASMA CUTTER PPS 40 A1

PLASMA CUTTER PLAZMAVÁGÓ

Last Information Update

Operation and Safety Notes

Kezelési és biztonsági hivatkozások

Az eredeti használati utasítás fordítása

GB HU

PLAZEMSKI REZALNIK PLAZMOVÁ ŘEZAČKA

Navodila za upravljanje in varnostna opozorila

Prevod originalnega navodila za uporabo

Návod k obsluze a bezpečnostní pokyny

Originální návod k obsluze

SI CZ

PLAZMOVÁ REZAČKA PLASMASCHNEIDER

Návod na obsluhu a bezpečnostné upozornenia

Originálny návod na obsluhu

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

SK DE AT CH

SI

SK

HU

CZ

IAN 307722

GB

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

HU

Olvasás előtt hajtsa ki az ábrát tartalmazó oldalt, és ezután ismerje meg a készülék

mindegyik funkcióját.

SI

Pred branjem odprite stran s slikami in se nato seznanite z vsemi funkcijami naprave.

CZ

Než začnete číst tento návod k obsluze, rozložte stránku s obrázky a seznamte se se

všemi funkcemi zařízení.

SK

Prv než začnete čítať tento návod, rozložte si stranu s obrázkami a potom sa oboznámte

so všetkými funkciami zariadenia.

DE AT CH

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie

sich anschließend mit allen Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

HU Kezelési és biztonsági hivatkozások Oldal 25

SI Navodila za upravljanje in varnostna opozorila Stran 45

CZ Návod k obsluze a bezpečnostní pokyny Strana 65

SK Návod na obsluhu a bezpečnostné upozornenia Strana 85

DE / AT / CH Montage-, Bedienungs- und Sicherheitshinweise Seite 105

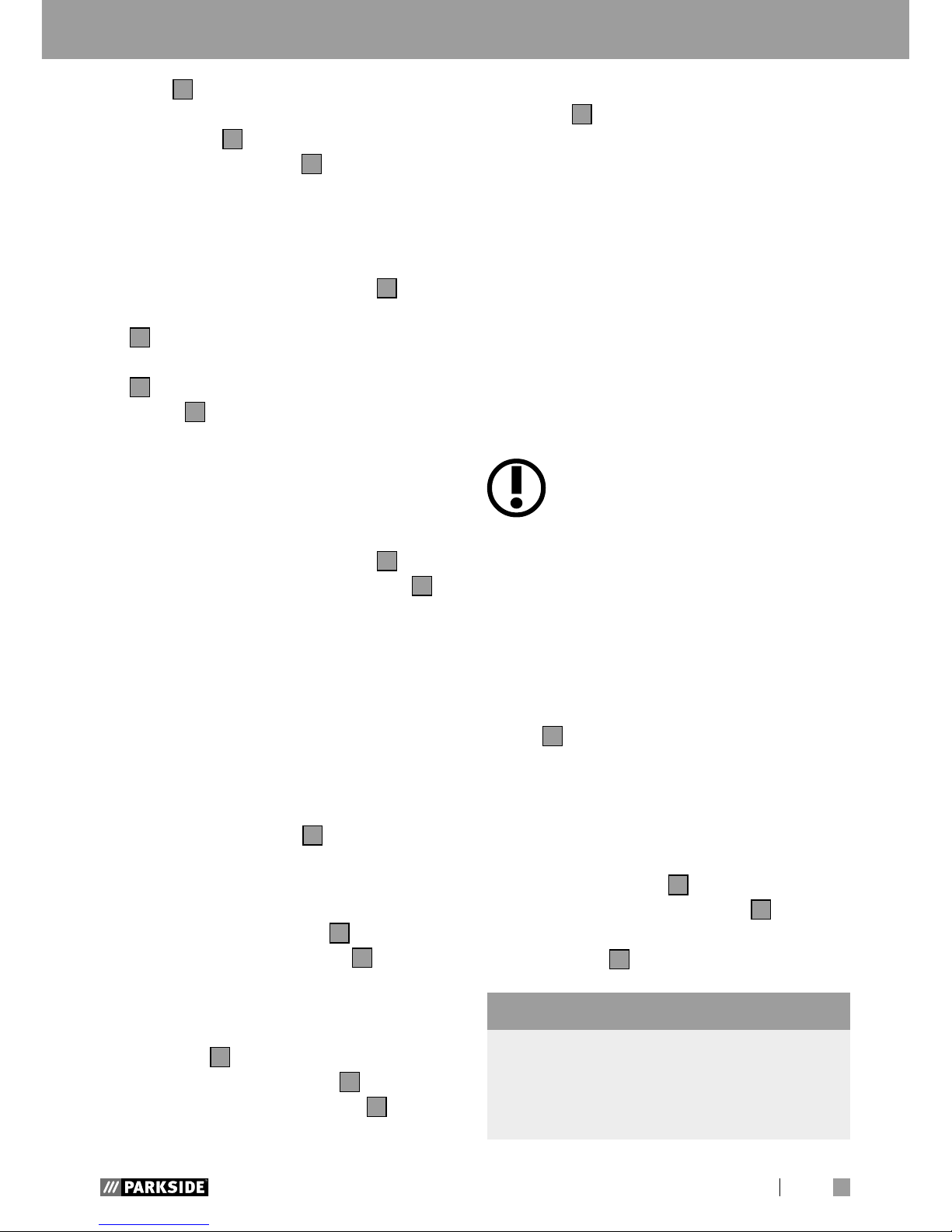

1 2

2

14 9

11

4

7

12

5

8

8a

35678 4

6

10

13

8b 8c

A

B

C D

8c

8c

22

8e8d

8d

8b

8

8a

8b

8c

E F G

16

15

21 21 21

21

17

16

18

2

20

19

H

J K L

I

5

GB

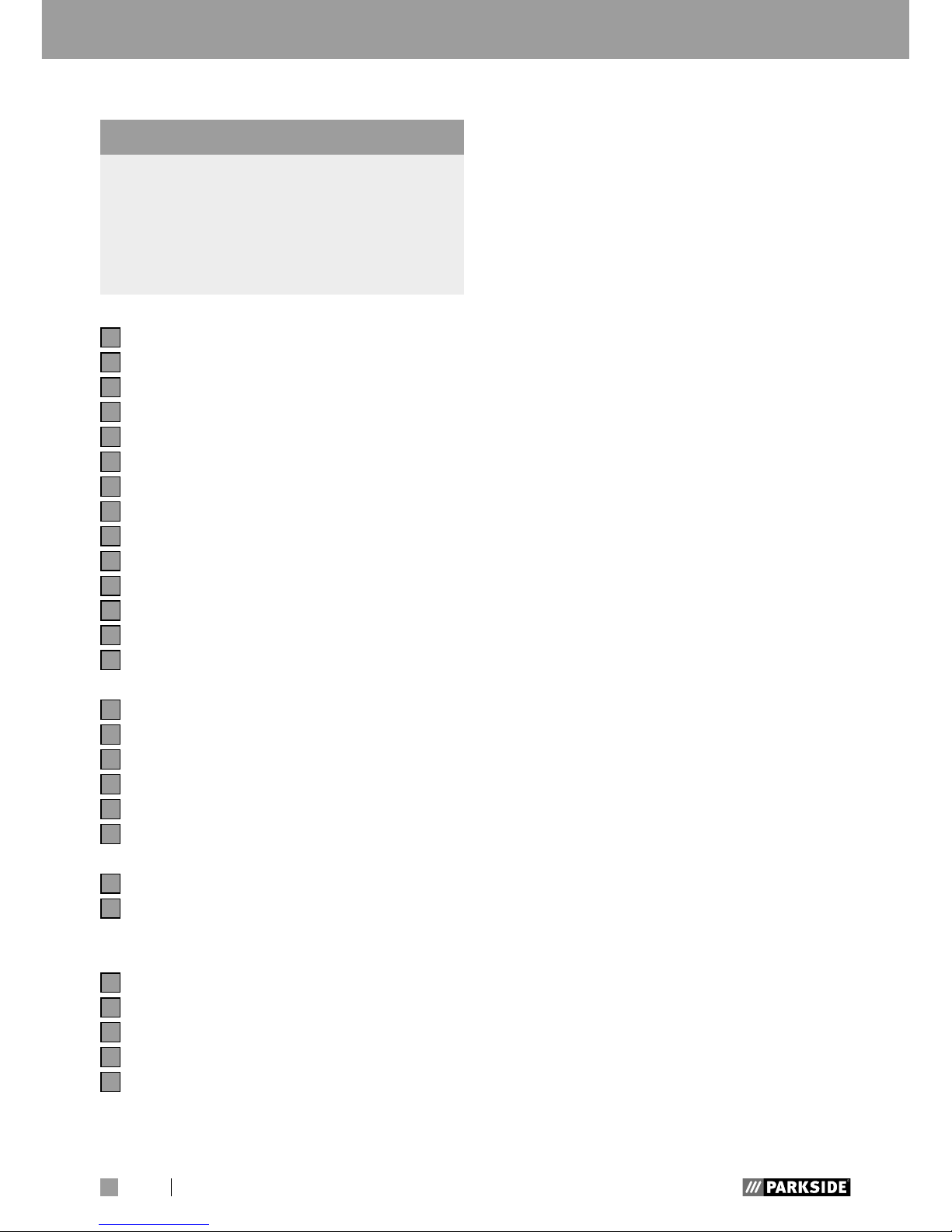

Table of contents

Table of pictograms used ............................................................................... Page 6

Introduction ........................................................................................................... Page 7

Intended use ............................................................................................................... Page 7

Equipment .................................................................................................................. Page 7

Technical specifications ................................................................................................ Page 8

Package contents ......................................................................................................... Page 8

Safety instructions .............................................................................................. Page 8

General plasma explanations...................................................................... Page 13

Before use .............................................................................................................. Page 14

Installation environment ................................................................................................ Page 14

Connecting compressed air........................................................................................... Page 14

Connecting the cutting torch .......................................................................................... Page 15

Connecting the ground cable ........................................................................................ Page 15

Using the device .................................................................................................. Page 15

Operation................................................................................................................... Page 15

Plasma cutting types ..................................................................................................... Page 16

Troubleshooting ................................................................................................... Page 17

Maintenance and care ..................................................................................... Page 19

Maintaining the burner ................................................................................................. Page 19

Maintenance ............................................................................................................... Page 20

Storage ...................................................................................................................... Page 20

Warranty and service information ............................................................ Page 20

Warranty conditions .................................................................................................... Page 20

Extent of warranty ....................................................................................................... Page 20

Processing of warranty claims ....................................................................................... Page 21

Information about recycling and disposal ............................................. Page 21

Original EC Declaration of Conformity ..................................................... Page 22

6

GB

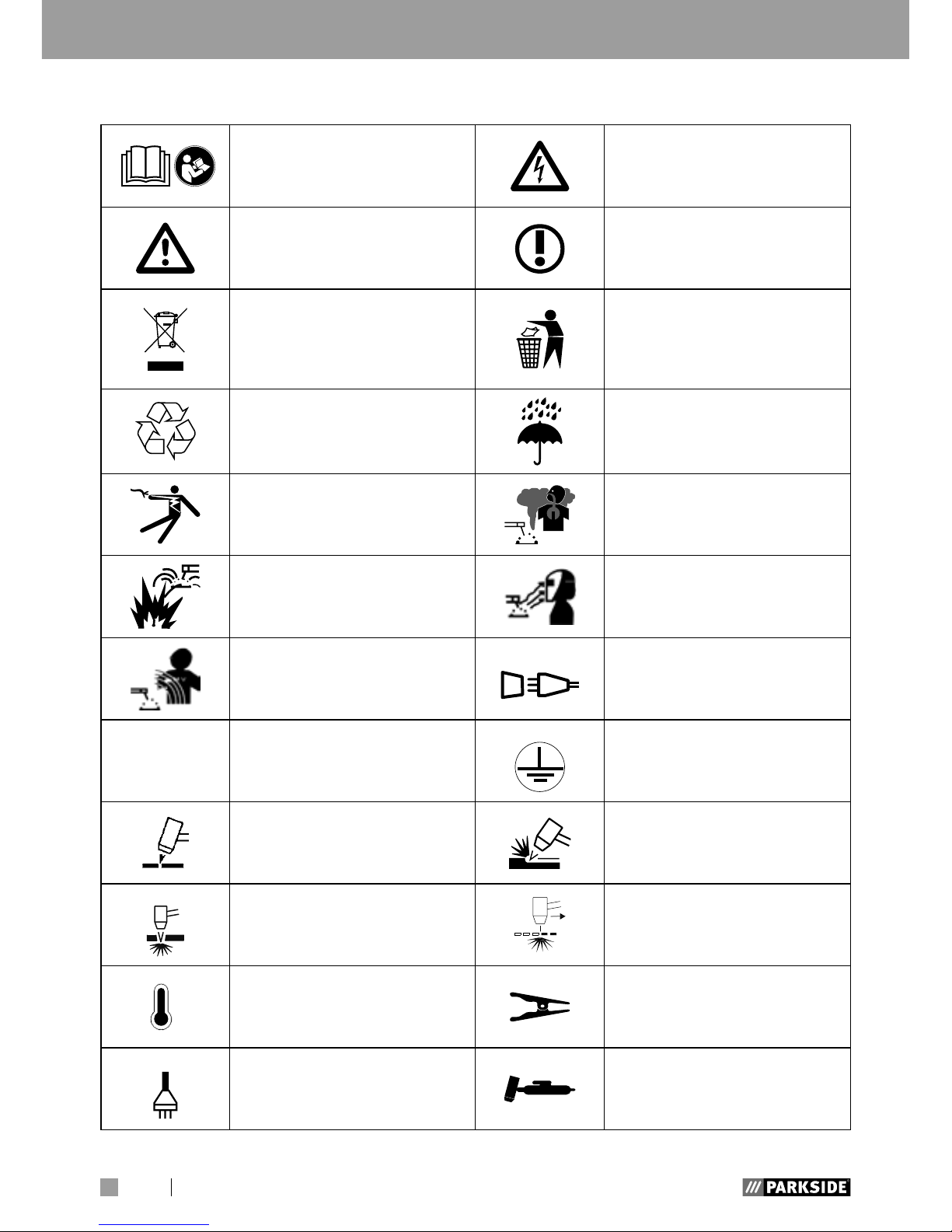

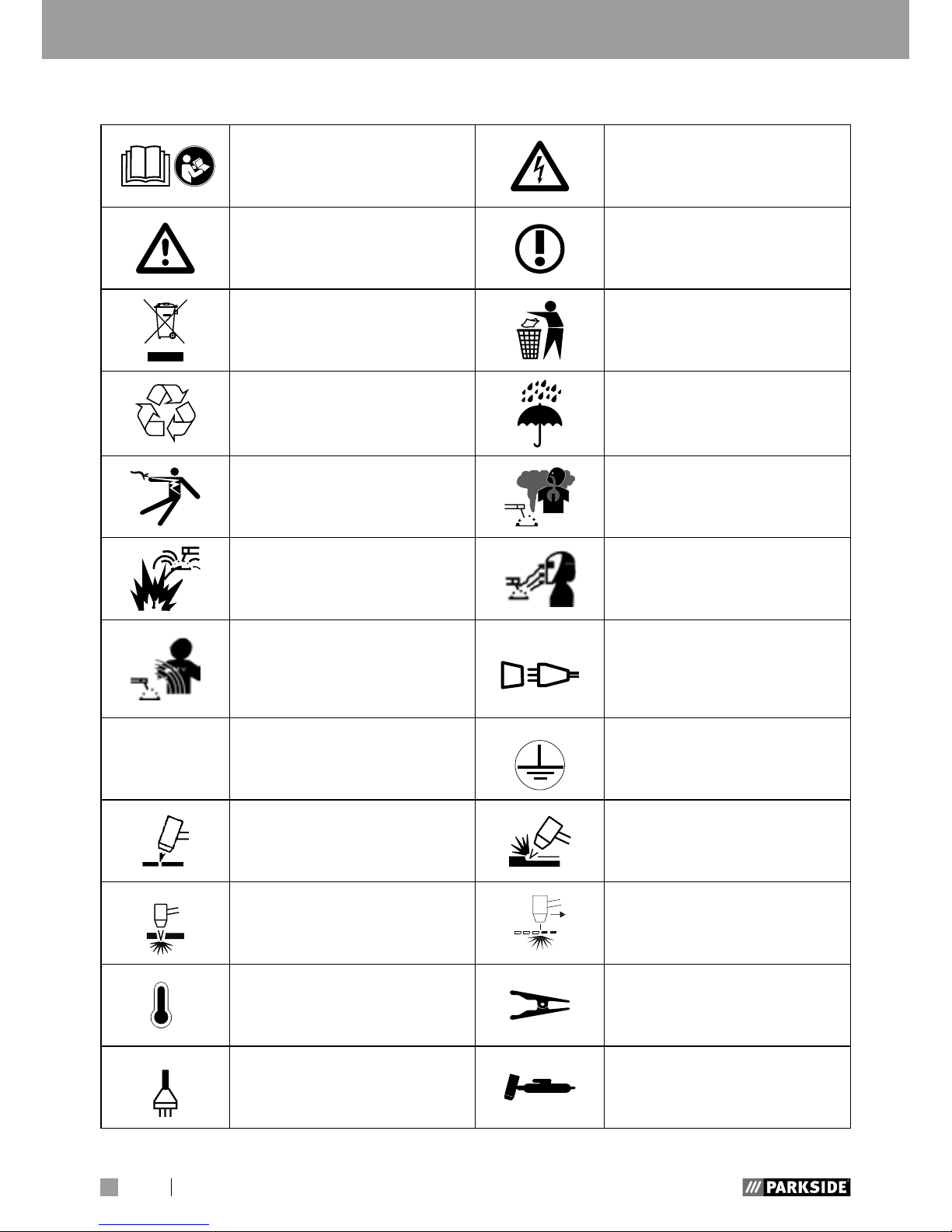

Table of pictograms used

• Table of pictograms used

Caution!

Read the operating

instructions!

Caution!

Risk of electric shock!

Warning: Potential hazards! Important note!

Do not dispose of any

electrical devices in

domestic waste!

Dispose of packaging

properly. Do not dispose of

the appliance in household

waste!

Made from recycling

material.

Never use the device in the

open or when it’s raining!

Electric shock from the

welding electrode can

be fatal!

Inhalation of welding fumes

can endanger your health!

Welding sparks can cause

an explosion or fire!

Arc beams can damage

your eyes and injure your

skin!

Electromagnetic fields

can disrupt the function of

cardiac pacemakers!

AC–mains connection.

H Insulation class.

Terminal for the external

(grounding) equipment

conductor.

Cutting with the plasma

cutter.

Gouging tool.

Cutting metal plates. Cutting expanded metal.

Indicator lamp – thermal

sensor.

Connection – ground

terminal - plug.

Indicator lamp – mains

connection.

Connection –

plasma burner - plug

Plasma burner - power plug.

7

GB

Plasma cutter PPS 40 A1

• Introduction

Congratulations! You have

purchased one of our high-quality

products. Please familiarise yourself

with the product before setup or first use.

Please also read the safety instructions

carefully. This product must be set up or used

only by people who have been trained to

do so.

Keep out of the reach of children!

PLEASE NOTE!

fThe use of the term ‘product’

or ‘device’ in the following text refers

to the plasma cutter named in these

operating instructions.

• Intended use

The device is intended for compressed-air

plasma cutting of all electrically conductive

metals. Observing the safety instructions

and assembly instructions and operating

information in the instructions for use is also

a component of intended use.

It is imperative to adhere to the applicable

accident prevention regulations. The device

must not be used:

in insufficiently ventilated rooms,

in moist or wet environments,

in explosive environments,

to defrost pipes,

in close proximity to people

with cardiac pacemakers and

in close proximity to easily

flammable materials.

Use the product only as described and

only for the specific applications as stated.

Keep these instructions in a safe place.

Ensure you hand over all documentation

when passing the product on to anyone else.

Any use that differs to the intended use as

stated above is prohibited and potentially

dangerous. Damage or injury caused by

misuse or disregarding the above warning

is not covered by the warranty or any

liability on the part of the manufacturer.

RESIDUAL RISK

Even if you operate the device as intended,

there will be residual risks.

Following hazards may occur in conjunction

with the construction and design of this plasma

cutter:

Eye injuries due to glare,

Touching hot parts of the device

or workpiece (burn injury),

In case of improper protection risk

of accident and fire through sparks

and slag particles,

Harmful emissions from smoke and gases

if there is a lack of air or if closed rooms

are insufficiently extracted.

Reduce the residual risk by carefully using

the device as intended and observing all

instruction.

• Equipment

PLEASE NOTE!

f After unpacking the product, please

check that all of the package contents

are present and that the device is in

perfect condition. Do not use the device

if it is defective.

Introduction

8

GB

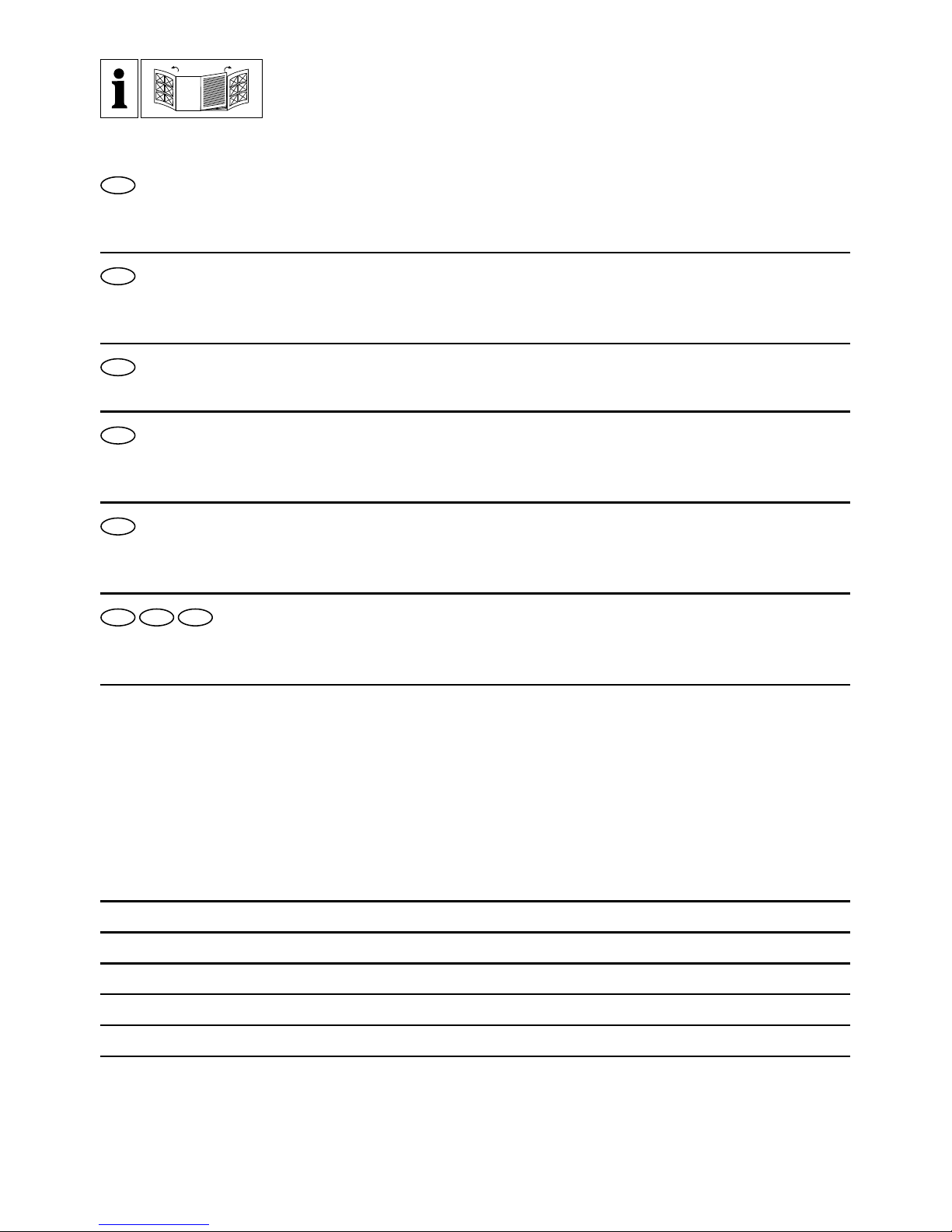

1

Plasma cutter

2

Handle

3

Mains plug

4

Ground terminal

5

Ground terminal plug

6

Plasma burner - power plug

7

Plasma burner - plug

8

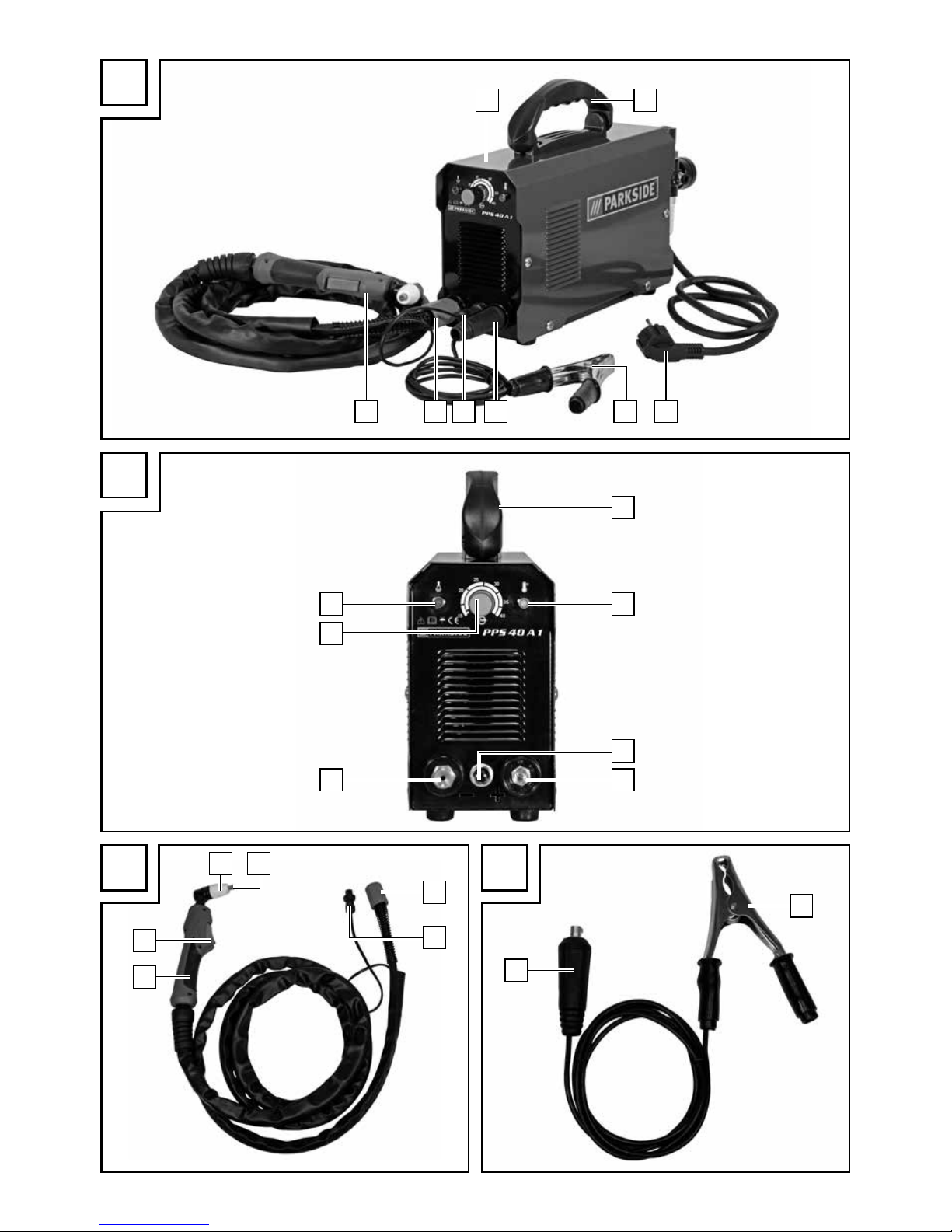

Plasma burner

8a

Plasma burner button

8b

Nozzle clamping sleeve

8c

Nozzles

8d

Electrode

8e

Diffuser

9

Overheat protection indicator lamp

10

Plasma burner - power socket

11

Ground terminal - connection socket

12

Plasma burner - connection socket

13

Current controller

14

Mains indicator lamp

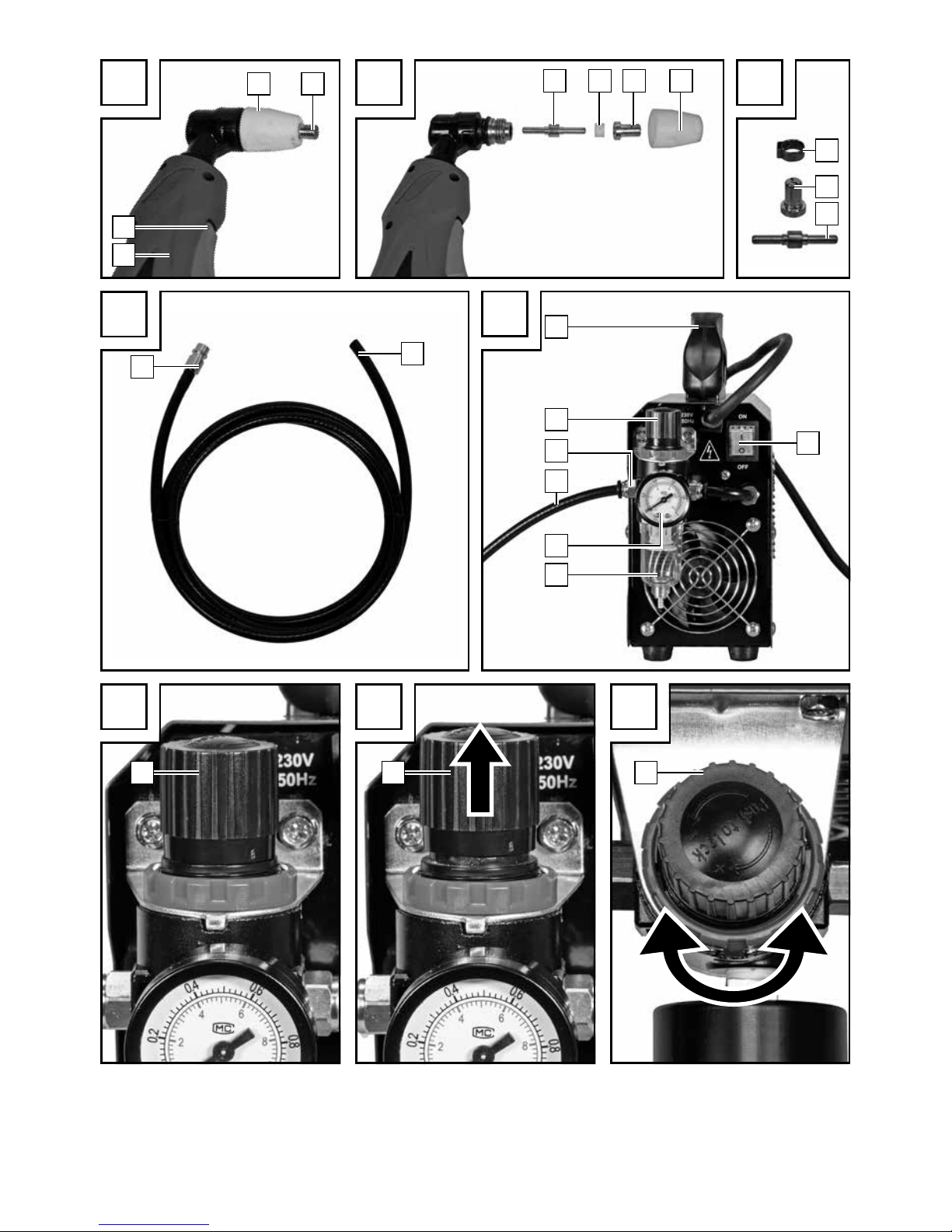

15

Quick connector compressed air hose

16

Compressed air hose

17

On/off - switch

I switched on

O switched off

18

Condensation water tank

19

Manometer

20

Compressed air connection

21

Rotary knob to regulate the pressure

22

Hose clamp

• Technical specifications

Output: 15 - 40 A

Input: 230 V~ 50 Hz

Weight: approx. 5.2 kg

Dimensions 341 × 113 x 237 mm

Insulation class: H

Duty Cycle: 35 % at 40 A (25 °C)

20 % at 40 A (40 °C)

‘Real’ cutting

capacity: 0.1 mm – 12 mm

(depending on the material)

Copper:1 - 4 mm

Stainless steel: 1 - 8 mm

Aluminium:1 - 8 mm

Iron: 1 - 10 mm

Steel: 1 - 12 mm

Working

pressure: 4 - 4.5 bar

(4 bar preset)

• Package contents

1 plasma cutter

1 ground cable with terminal

1 cutting cable incl. cutting torch

1 compressed air hose with Quick-Connect

2 hose clamps

2 nozzles

3 electrodes (1 pre-assembled)

1 set of operating instructions

3 burner sleeves (1 pre-assembled)

• Safety instructions

WARNING!

f Please read through the

operating instructions

carefully before use.

Familiarise yourself with the

device, its proper use and

the safety notes based on

these operating instructions.

These form part of the

product and must be

available at all times.

Introduction / Safety instructions

9

GB

WARNING!

f RISK OF SERIOUS

INJURY OR DEATH

FOR INFANTS AND

CHILDREN!

Never leave children

unsupervised near packaging

material. There is a risk of

suffocation

.

This device may be used by

children aged 16 years and

older, and by persons with

reduced physical, sensory

or mental capacities, or a lack

of experience and knowledge,

if they are supervised or have

been instructed on how to

use the device safely and

understand the dangers that

may arise when using it.

Do not allow children to play

with the device. Cleaning and

day-to-day maintenance must

not be performed by children

without supervision.

Repairs and/or maintenance

work must only be carried

out by qualified electricians.

Only use the weld cable

provided in the scope of

delivery.

During operation, the device

should not be positioned

directly on the wall, covered

or jammed between other

devices so that sufficient air

can be absorbed through

the ventilation slats. Make

sure the device is correctly

connected to the supply

voltage. Avoid any form of

tensile stress of the power

cable. Disconnect the plug

from the socket prior to setting up the device in another

location.

If the device is not in

operation, always switch it

off by pressing the ON/OFF

switch. Place the electrode

holder on an insulated surface

and only remove it from the

holder after allowing it to cool

down for 15 minutes.

Hot metal and sparks are blown

off from the cutting arch.

Flying sparks, hot metal as well

as hot objects and hot device

equipment can cause fires or

burns. Check the working

environment and make sure

the workplace is suitable prior

to using the device.

Remove all flammable materials

within 10 m of the plasma

cutter. If this is not possible,

cover the objects meticulously

using suitable covers.

Safety instructions

10

GB

Do not make cuts where flying

sparks could come into contact

with flammable material.

Protect yourself and others from

flying sparks and hot metal.

Please be careful because

sparks and hot materials can

easily fall through small gaps

and openings while cutting

and land on adjacent areas.

Please be aware that

cutting on a ceiling, floor

or a partition can cause

a fire on the opposite side

that is not visible.

Connect the cable as practical

as possible with a socket

situated close to the workplace

to prevent the power cable

from being spread across the

whole room and located on

unknown ground which could

cause an electric shock, sparks

or fire outbreak.

Do not use the plasma cutter

to defrost frozen tubes.

Risk of electric shock:

WARNING!

f Electric shock from the

welding electrode can

be fatal.

Do not use the plasma cutter

when it is raining or snowing.

Wear dry insulating gloves.

Do not touch the electrodes

with bare hands.

Do not wear wet or damaged

gloves.

Protect yourself from electric

shock with insulation against

the workpiece.

Do not open the device

housing.

Danger from welding

fumes:

Inhalation of welding fumes

can endanger health.

Do not keep your head in the

fumes.

Use the equipment in open

areas.

Use extractors to remove the

fumes.

Danger from welding

sparks:

Welding sparks can cause

an explosion or fire.

Keep flammable substances

away from the welding

location.

Do not use the plasma cutter

near flammable substances.

Welding sparks can cause fires.

Keep a fire extinguisher close

by and an observer should

be present to be able to use

it immediately.

Safety instructions

11

GB

Do not weld on drums or any

other closed containers.

Danger from arc beams:

Arc beams can damage your

eyes and injure your skin.

Wear a hat and safety

goggles.

Wear hearing protection and

high, closed shirt collars.

Wear welding safety helmets

and filter sizes in perfect

condition.

Wear complete body

protection.

Danger from

electromagnetic fields:

Welding current generates

electromagnetic fields.

Do not use if you have

a medical implant.

Never wrap the welding

cable around your body.

Guide welding cables

together.

z Welding shield-specific

safety instructions

With the help of a bright light

source (e.g. lighter) examine

the proper functioning of the

welding shield prior to starting

with any welding work.

Weld spatters can damage the

protective screen. Immediately

replace damaged or scratched

protective screens.

Immediately replace damaged

or highly contaminated

or splattered components.

The device must only be

operated by people over the

age of 16.

Please familiarise yourself with

the welding safety instructions.

To that end, you must also

observe the safety instructions

of your plasma cutter.

Always wear a welding

helmet while welding. If it is

not used, you could sustain

severe lesions to the retina.

Always wear protective clothing

during welding operations.

Never use the welding shield

without the protective screen

because this could damage

the optical unit. There is a risk

of damage to the eyes!

Regularly replace the protective

screen to ensure good visibility

and fatigue-proof work

.

z Small and moist rooms

Insulating mats and pads

must be used when working

in small, moist or hot rooms.

Furthermore, leather gauntlet

gloves or other insulating

Safety instructions

12

GB

materials must be worn to

insulate the body against

ground.

When using plasma cutters

under electrically dangerous

conditions, e.g. tight spaces

made of electrically conductive

walls (boiler, pipes, etc.),

in wet rooms (soaking of work

clothes), the output voltage

of the plasma cutter must

be greater than 48 volt

when idling (effective value).

The plasma cutter may be

used in these cases due to the

output voltage.

z Protective clothing

At work, the welder must

protect his/her whole body

by using appropriate

clothing and face protection

against radiations and burns.

The following steps must be

observed:

– Wear protective clothing

prior to welding work.

– Wear gloves.

– Open windows to guarantee

air supply.

– Wear safety goggles.

Gauntlet gloves made of a

suitable material (leather) must

be worn on both hands. They

must be in perfect condition.

A suitable apron must be

worn to protect clothing

from flying sparks and burns.

When specific work, e.g.

overhead welding, is required,

a protective suit must be worn

and, if necessary, even head

protection.

z Protection against rays

and burns

A ‘Caution! Do not stand in

the flames!’ warning sign to

indicate an eye hazard must

be visible at the workplace.

The workplaces must be

shielded so that the persons

in the vicinity are protected.

Unauthorised persons must be

kept away from welding work.

The walls in the immediate

vicinity of fixed workplaces

should neither be bright

coloured or shiny. Windows

up to head height must be

protected to prevent rays

from penetrating or reflecting

through them, e.g. by using

suitable paint.

z EMC Device Classification

According to standard

IEC 60974-10, it has to do

Safety instructions

13

GB

with a plasma cutter with class A

electromagnetic compatibility.

Thus, it meets the appropriate

requirements in the industrial and

residential area. In residential

areas, it can be connected to

the public low-voltage supply

network.

Even if the plasma cutter complies

with the emission level as per the

standard, the plasma cutter can

still result in electromagnetic

disturbances in sensitive systems

and devices.

The operator is responsible for

malfunctions that occur through

the arc while welding and must

take suitable protective measures.

In doing so, the operator must

consider the following:

Power cables, control, signal

and telecommunication lines

Computer and other

microprocessor controlled

devices.

Television, radio and other

playback devices

Electronic and electrical safety

equipment

Persons with cardiac

pacemakers or hearing aids

Measurement and calibration

devices

Noise immunity of other

devices in the vicinity

The time of day at which the

welding work is performed.

The following is recommended

to reduce possible interference

radiation:

The plasma cutter must be

regularly maintained and kept

in a good condition

Welding cables should be

completely unwound and

installed parallel on the floor,

if possible

Devices and systems at risk

of interference radiation must

be removed from the welding

area if possible, or shielded.

• General plasma explanations

Plasma cutters are operated by

pushing pressurised gas,

e.g. air, through a small pipe.

In the centre of the pipe, there

is a negatively charged electrode

that is directly above the nozzle.

The vortex ring controls the speed

at which the plasma can rotate.

If you supply the negative

electrode with current and make

the tip of the nozzle touch the

metal, this connection creates

a closed, electrical circuit.

Safety instructions / General plasma explanations

14

GB

A powerful spark occurs between

the electrode and the metal.

While the gas flows into the pipe,

the spark heats up the gas until

it has reached the plasma

condition. This reaction causes

a current from the controlled

plasma with a temperature of

16,649 ºC or more that moves at

speed of 6.096 m/sec and the

metal transforms into steam and

molten discharge. The plasma

itself conducts electrical current.

The working circuit that allows

the arc to occur remains as

long as current is supplied to

the electrode and the plasma

remains in contact with the metal

to be processed.

The cutting nozzle has two types

of channels. These channels

generate a constant flow of

protective gas around the cutting

area. The pressure of the gas

flow controls the radius of the

plasma jet.

PLEASE NOTE!

fThis machine is only designed to use

compressed air as ‘gas’.

• Before use

• Installation environment

Make sure that working area is sufficiently

ventilated. If the device is used without

sufficient cooling, the power-on time reduces

and it can result in overheating.

Additional protection can be required for

this purpose:

The device must be free-standing with

a distance of at least 0.5 m all around.

Ventilation slots must not be blocked

or covered.

The device must not be used as a storage

place and tools or other items must not

be placed on the device.

It must be operated in a dry and well

ventilated working environment.

• Connecting compressed air

PLEASE NOTE!

fThis device is designed for operating

pressure of up to 6.3 bar. Please bear

in mind that the pressure can lower

while setting the air pressure.

Thus, in a hose length measuring

10 m and an internal diameter of 9 mm

it drops by approx. 0.6 bar.

The compressed air must be filtered,

lubricated and regulated.

Connect the compressed air hose

16

on

the back of the plasma cutter

1

to the

compressed air connection

20

. To do so,

insert the side of the compressed air hose

16

into the compressed air connection

20

of the plasma cutter 1 without a quick

connector.

The pressure can be set via the knob 21

on the condensate separator. (see Fig. J - L

)

In order to release the compressed air

General plasma explanations / Before use

15

GB

hose 16, you must press the locking

mechanism of the compressed air

connection

20

and pull out the

compressed air hose

16

.

• Connecting the cutting torch

Insert the plasma burner - plug 7 into

the plasma burner – connection socket

12

and tighten the union nut hand-tight.

Insert the plasma burner – power plug

6

into the plasma burner – power

socket

10

and tighten the union nut

hand-tight.

• Connecting the ground cable

Connect the ground terminal plug 5 with

the ground terminal connection socket

11

.

Make sure that the connecting shaft is first

connected and then turned. This does not

require force!

• Using the device

• Operation

1. Set the plasma cutter 1 up in a dry and

well ventilated area.

2. Position the machine in the vicinity of the

workpiece.

3. Press the on / off switch

17

.

4. Clamp the ground terminal

4

to the

workpiece to be cut and make sure that

there is a good electrical contact.

5. Set the cutting current on the current

controller

13

.

6. Position the plasma cutter

8

on the

workpiece so that the nozzle

8c

is free

and that a blowback of the molten metal

is not possible. Press the plasma burner

button

8a

. The transmitted cutting arch

is ignited on the edge of the sheet in this

manner.

7. Start cutting slowly and then increase the

speed in order to achieve the desired

cutting quality.

8. The speed must be regulated so that

a good cutting capacity can be

achieved. The plasma air creates

a straight arch (stainless steel, aluminium)

or a 5° arch of approach (soft steel).

9. While cutting make sure the nozzle is

always in contact with the workpiece.

To cut in the manual cutting mode,

pull the overlying burner across

the workpiece while maintaining

a constant speed. To achieve the perfect cut,

it is important for the material thickness to

comply with the correct cutting speed. If the

cutting speed is too low, the cutting edge

will be blunt due to the severe heat input.

The optimal cutting speed is achieved once

the cutting jet is slightly inclined towards

the rear while cutting. If the plasma burner

button

8a

is released, the plasma jet goes

out and the power source switches off.

The gas continues to flow for approx.

5 seconds in order to cool the burner.

The same process is followed when the

workpiece is pulled out with the plasma

burner button pressed

8a

. During the gas

post-flow time, the plasma cutter

1

must

not be switched off to avoid damaging the

plasma burner

8

as a result of overheating.

ATTENTION!

fThe device must be left on for approx.

2-3 minutes once the cutting work has

been completed. The cooler cools the

electronics.

Before use / Using the device

16

GB

• Plasma cutting types

Drag cutting

Hold the tip of the pistol low over the

workpiece and press the pistol switch.

Now move the pistol tip until there is contact

with the workpiece and the cutting arch

is fixed in position. Once the cutting arch

has been generated, move the pistol in the

desired direction. Makes sure that the pistol

tip is slightly angled and that contact with

the workpiece is maintained. This working

method is called drag cutting. Avoid quick

movements. Sparks falling off the top of the

workpiece is an indication of moving too

quickly. Move the pistol at a speed in which

the spark accumulation is concentrated on

the bottom side of the workpiece. Ensure

the material is completely separated prior to

continuing with this process. Set the necessary drag speed.

Distance cutting

In some cases, it is beneficial to cut while

holding the tip of the pistol at a height

of 1.5 mm to 3 mm above the workpiece.

This reduces the quantity of material that

is blown back into the tip. This makes it

possible to penetrate thicker material

strengths. Distance cutting should be used

if penetration or furrow work is carried out.

Furthermore, the ‘distance’ working technique can be used when you need to cut

sheet metal to minimise the risk of material

splashing back which could damage the tip.

Perforation

To drill through, place the tip approx.

3.2 mm above the workpiece. Hold the

pistol at a slight angle to guide the sparks

away from the pistol tip and your body.

Press the plasma burner button

8a

and lower

the tip of the pistol until there is a main

cutting arch and sparks begin to form. Test

the perforation on a test object that is no

longer needed and once there are no

problems start drilling through at the

previously defined cutting line on your

workpiece. Check the pistol for wear and

tear, cracks or exposed cable pieces.

Replace or repair them prior to using the

device. A badly worn pistol tip/nozzle

contributes to the reduction of speed, voltage

and unclean separation. An indication of a

badly worn pistol tip/nozzle is an extended

or oversized nozzle opening. The external

electrode must not be recessed by more

than 3.2 mm. Replace it if the wear is

greater than the specified dimensions.

If the protective cap is difficult to tighten,

check the thread.

Using the device

17

GB

Troubleshooting

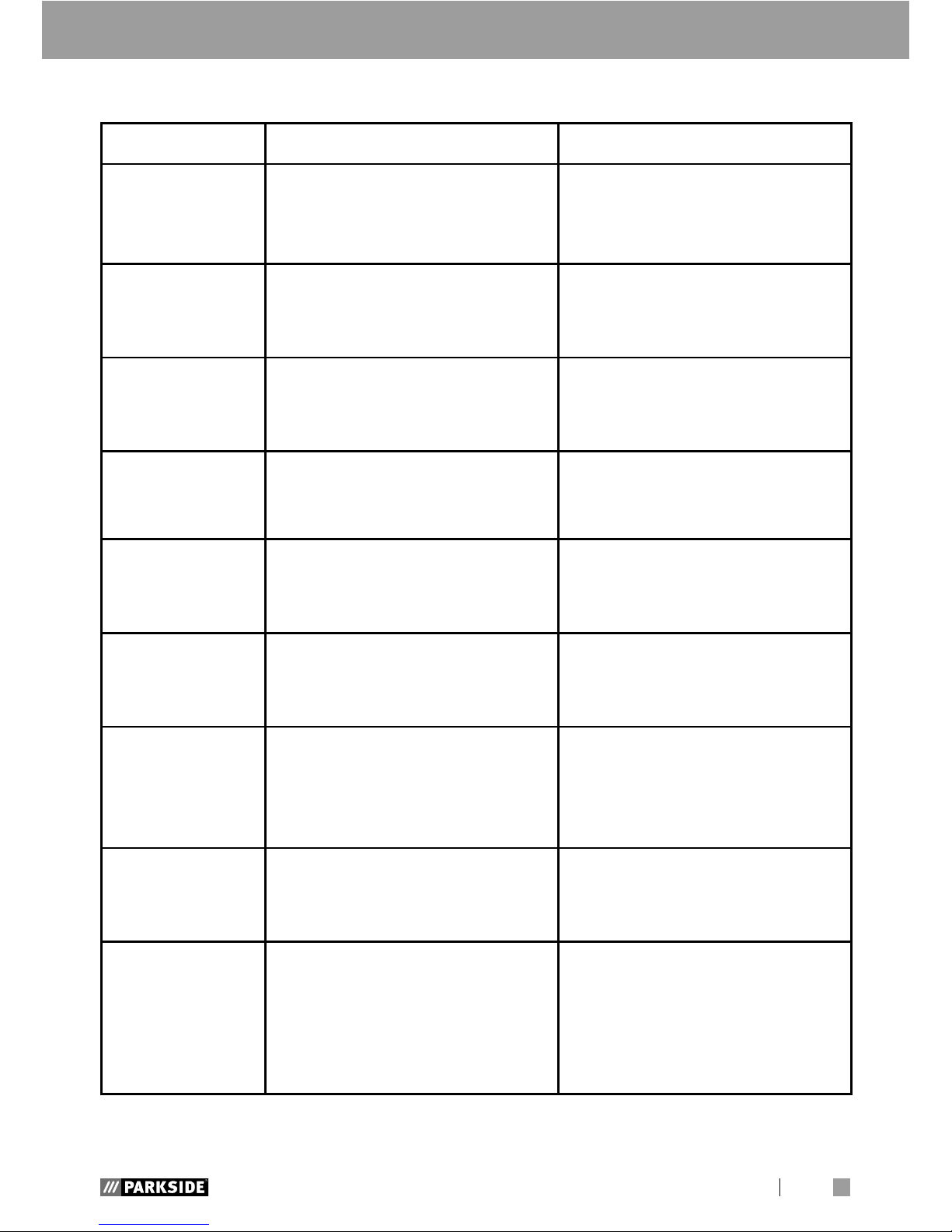

Faults Cause of fault Troubleshooting

Indicator lamp

does not lit up?

No electrical connection.

ON/OFF switch set to off.

Check power cable.

Set switch to ON.

Ventilator does

not work?

Power line interrupted.

Power line ventilator faulty.

Ventilator faulty.

Check power line.

Warning lamp

switches on?

Overheating protection

switched on.

Input voltage too high.

Allow device to cool down.

Input voltage according

to type plate.

No output

current?

Machine faulty.

Overvoltage protection

activated.

Machine must be repaired.

Allow device to cool down.

Output current

does not

decrease?

Input voltage too low.

Connection cable cross-section

too low.

Observe input voltage

according to type plate.

Air current cannot

be regulated?

Compressed air hose

damaged or faulty.

Valve/manometer fails.

New connection of the hose.

HF-arc is not

created?

The burner switch is faulty.

Soldering point on the burner

switch or plug loosened.

Valve/manometer fails.

Renew electrode.

Bad ignition? Burner wear parts damaged

or worn.

Check HF spark gap.

Change wear parts.

Set spark gap.

Pistol is not ready

for operation?

Current switch is switched off.

Air transmission is restricted.

Workpiece is not connected to

the ground terminal.

Switch the current switch to

‘on’.

Another indication of this is

a green flame. Check the air

supply.

Check the connection.

• Troubleshooting

18

GB

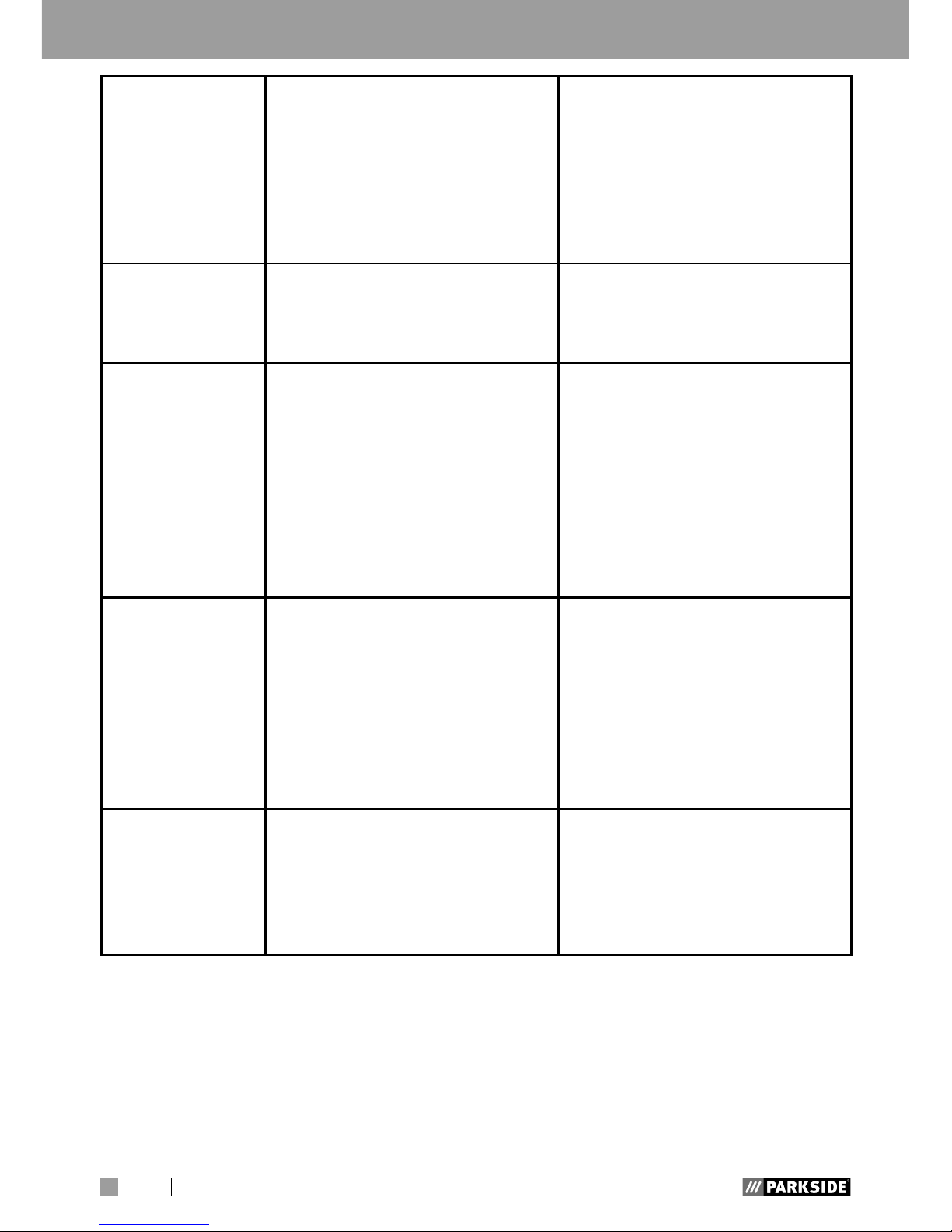

Troubleshooting

Sparks fly

upwards,

instead of down

through the

material?

Plasma pistol does not

penetrate the material.

Pistol too far away from

the material.

Apparently material was

not grounded properly.

Lifting speed is too quick.

Increase the current.

Reduce the distance between

the pistol and material.

Check the connection

for correct grounding.

Reduce the speed.

Initial cut but not

completely drilled

through?

Potential connection problem. Check all connections.

Slag formation

on interfaces?

Tool/material creates heat.

Cutting speed too low

or current too high.

Individual parts of the pistol

are worn.

Allow the material to cool

down and then continue

cutting.

Increase the speed and/or

reduce the current until the

slag has been reduced to

a minimum.

Check and replace worn

parts.

Arc stops during

cutting?

Cutting speed too low.

Pistol is held too high and too

far away from the material.

Individual parts of the pistol

are worn.

Workpiece no longer

connected to the grounding

cable.

Increase the cutting speed until

the problem no longer exists.

Lower the pistol to the

recommended height.

Check and replace worn

parts.

Check the connections.

Insufficient

penetration?

Cutting speed too fast.

Pistol is not straight.

Metal is too thick.

Individual parts of the pistol

are worn.

Slow down the working

speed.

Adjust the inclination.

Several cycles necessary.

Check and replace worn

parts.

19

GB

Troubleshooting / Maintenance and care

• Maintenance and care

• Maintaining the burner

The parts displayed in Figure F are the

electrode

8d

, diffuser 8e and the nozzle

8c

. They can be replaced once the

nozzle clamping sleeve

8b

has been

unscrewed.

The electrode

8d

must be replaced

if there is a crater of approximately

1.5 mm depth in the centre.

ATTENTION!

fTo unscrew the electrode, do not apply

irregular pressure, gradually increase

pressure until the thread is released.

The new electrode must be screwed into

its bracket and blocked but not tightened

up to the stop.

The nozzle

8c

must be placed if the

central bore is damaged or if it has

expanded in comparison to a drilling of

a new nozzle. If the electrode

8d

or the

nozzle

8c

are replaced too late, this can

result in an overheating of the parts. This

can reduce the lift cycle of the diffuser 8e.

Once replaced, make sure the nozzle

clamping sleeve

8b

is tightened

sufficiently.

ATTENTION!

fThe nozzle clamp sleeve 8b must only

be screwed on to the burner

8

once

it has been equipped with the electrode

8d

, diffuser 8e and nozzle 8c.

fIf these parts are missing,

the device may malfunction

and it may create a hazard

for the operating personnel.

Consumables

wear quickly?

Performance was

overstretched.

Arc control time exceeded.

Incorrect pistol assembly.

Insufficient air supply,

pressure too low.

Faulty air compressor.

Material too thick, increase

the angle to avoid material

from being blown back into

the tip.

Do not control the arc for

more than 5 seconds.

You can also start with contact

between the pistol and metal

or with a 3.2 mm distance

to the metal.

See paragraph titled

‘Pistol set up’.

Check the air filter,

increase the air pressure.

Check the performance of the

air compressor and make sure

the inlet pressure is at least

100 PSI.

20

GB

• Maintenance

PLEASE NOTE!

fThe plasma cutter must be regularly

maintained for perfect function and

comply with the safety requirements.

Improper and wrong operation may

cause failures and damage to the

device.

Switch off the main power supply and

the main switch of the device prior to

carrying out maintenance or repair work

on the plasma cutter.

Regularly clean the outside of the plasma

cutter. Use compressed air, cotton waste

or a brush to remove dirt and dust.

• Storage

If you will not be using the device for

a while, protect it from dust by storing

it in a clean and dry place.

• Warranty and service

information

Warranty from Creative

Marketing & Consulting GmbH

We give you a warranty on this device of

3 years from the date of purchase. In the

event of product defects, you have legal

rights against the retailer of this product.

Your statutory rights are not affected in any

way by our warranty conditions, which are

described below.

• Warranty conditions

The warranty period begins on the date of

purchase. Please retain the original sales

receipt. This document is required as your

proof of purchase.

Should this product show any defect in

materials or manufacture within 3 years

from the date of purchase, we will repair

or replace it – at our discretion – free of

charge. This warranty service requires that

you retain proof of purchase (sales receipt)

for the defective device for the three year

period and that you briefly explain in writing

what the fault entails and when it occurred.

If the defect is covered by our warranty,

we will repair and return your product

or send you a replacement. The original

warranty period is not extended when

a device is repair or replaced.

• Extent of warranty

This device has been manufactured

according to strict quality guidelines and

carefully inspected before delivery.

The warranty applies to material and

manufacturing defects only. This warranty

does not cover product parts that are subject

to normal wear and tear and can therefore

be regarded as consumables, nor does

it cover damage to fragile parts such as

switches, rechargeable batteries or parts

made from glass.

This warranty is voided if the product

becomes damaged or is improperly used or

maintained. For proper use of the product,

all of the instructions given in the operating

Maintenance and care / Warranty and service information

21

GB

instructions must be followed precisely.

If the operating instructions advise you or

warn you against certain uses or actions,

these must be avoided in all circumstances.

The product is for consumer use only and

is not intended for commercial or trade use.

The warranty becomes void in the event

of misuse and improper use, use of force,

and any work on the device that has not

been carried out by our authorised service

branch.

• Processing of warranty

claims

To ensure prompt processing of your claim,

please follow the instructions given below.

Please retain your proof of purchase and

quote the product number (e.g. the EAN

code) in all correspondence.

The product number can be found on the

type plate, an engraving, the cover page

of your instructions (bottom left), or the

sticker on the back or underside of the

device. In the event of malfunctions or other

defects, please first contact our service

department below by phone or email.

If your product is found to be defective,

you can then send your product with proof

of purchase (till receipt) and a statement

describing what the fault involves and when

it occurred free of charge to the service

address given.

Please note:

On www.lidl-service.com you can

download this and several other

manuals, product videos and

software.

How to contact us:

GB

Name: C. M. C. GmbH

Website: www.cmc-creative.de

E-mail:

service.gb@cmc-creative.de

Phone: 0-808-189-0652

Registered office: Germany

IAN 307722

Please note that the following address is not

a service address. Please first contact the

service point given above.

C.M.C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

GERMANY

• Information about recycling

and disposal

Don’t throw away – recycle

Please return this device, accessories

and packaging

to your local recycling depot.

According to European Directive

2012/19/ EU, used electrical devices

must be collected separately for

environmentally compatible recycling

or recovery.Please return this device to

an approved waste management company

or use your municipal waste collection

service. Please ensure you comply with

local regulations. If you have any questions,

please contact your local authority or waste

management company.

Warranty and service ... / Information about recycling and disposal

22

GB

• Original EC Declaration

of Conformity

We,

C.M.C. GmbH

Responsible for documentation:

Alexander Hoffmann

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

hereby take sole responsibility for declaring

that the product

Plasma cutter PPS 40 A1

IAN: 307722

Year of manufacture: 04/19

Art. no.: 2163

Model: PPS 40 A1

meets the basic safety requirements

as specified in the European Directives

EC Guideline on Electromagnetic

Compatibility

2014 / 30 / EU

Machinery Directive

2006 / 42 / EC

and the amendments to these Directives.

The manufacturer will be solely responsible for

the creation of the declaration of conformity.

The object of the declaration described

above meets the requirements of Directive

2011/65/EU of the European Parliament

and of the Council of 8 June 2011 on the

restriction of the use of certain hazardous

substances in electrical and electronic

equipment.

This conformity assessment is based on the

following harmonised standards:

EN 60974-1:2012

EN 60974-10:2007

EN 55011:2009+A1:2010

EN 61000-3-11:2000

EN 61000-3-12:2011

St. Ingbert, 15/10/2018

On behalf of M. Sc. Alexander Hoffmann

– Quality Assurance –

Original EC Declaration of Conformity

23

GB

24

GB

25

HU

Tartalomjegyzék

A használt piktogramok táblázata ........................................................................... Oldal 26

Bevezetés............................................................................................................................. Oldal 27

Rendeltetésszerű használat .................................................................................................. Oldal 27

Felszereltség ......................................................................................................................... Oldal 28

Műszaki adatok ...................................................................................................................... Oldal 28

Szállítási terjedelem .............................................................................................................. Oldal 28

Biztonsági tudnivalók .................................................................................................... Oldal 29

Plazmával kapcsolatos általános magyarázatok.............................................. Oldal 34

Üzembe helyezés előtt................................................................................................... Oldal 35

Felállítási környezet ............................................................................................................... Oldal 35

A sűrített levegő csatlakoztatása ........................................................................................... Oldal 35

A vágóégő csatlakoztatása .................................................................................................... Oldal 35

A testkábel csatlakoztatása ................................................................................................... Oldal 35

Üzembe helyezés ............................................................................................................. Oldal 35

Kezelés .................................................................................................................................. Oldal 35

Plazmavágási módok ............................................................................................................ Oldal 36

Hibaelhárítás ...................................................................................................................... Oldal 37

Karbantartás és ápolás ................................................................................................. Oldal 39

Az égő karbantartása ............................................................................................................ Oldal 39

Karbantartás .......................................................................................................................... Oldal 40

Tárolás ................................................................................................................................... Oldal 40

Garanciával és szervizeléssel kapcsolatos tudnivalók................................. Oldal 40

Garanciális feltételek ............................................................................................................. Oldal 40

A garancia terjedelme ............................................................................................................ Oldal 41

Eljárás garanciális esetben .................................................................................................... Oldal 41

Környezettel kapcsolatos tudnivalók és ártalmatlanítási adatok ............ Oldal 42

Eredeti EK megfelelőségi nyilatkozat .................................................................... Oldal 42

Hu jótállási tájékoztató .................................................................................................. Oldal 43

26

HU

A használt piktogramok táblázata

• A használt piktogramok táblázata

Vigyázat!

Olvassa el az üzemeltetési

útmutatót!

Vigyázat! Veszély

elektromos áramütés miatt!

Figyelem, lehetséges

veszélyek!

Fontos tudnivaló!

Ne dobja az elektromos

készülékeket a háztartási

szemét közé!

Környezetbarát módon

ártalmatlanítsa a csomago-

lást és a készüléket!

Újrahasznosítható

anyagokból készült.

Ne használja a készüléket

szabadban és esőben!

A hegesztőelektróda általi

áramütés halálos lehet!

A hegesztési füstök

belélegzése veszélyeztetheti az egészséget!

A hegesztési szikrák

robbanást vagy tüzet

okozhatnak!

Az ívfénysugarak

károsíthatják a szemet,

és megsérthetik a bőrt.

Az elektromágneses

mezők megzavarhatják

a szívritmus-szabályozók

működését!

AC hálózati csatlakozó.

H Szigetelési osztály.

Kapocs a külső (földelő)

védővezetékhez.

Vágás a plazmavágóval. Fugavésés.

Fémlemezek vágása. Expandált fém vágása.

Hőmérséklet-gyelő

ellenőrzőlámpája.

Testkapocs dugasz

csatlakozója.

Hálózati csatlakozás

ellenőrzőlámpája.

Plazmaégő dugasz

csatlakozója

Plazmaégő áramdugasza.

27

HU

PPS 40 A1 plazmavágó

• Bevezetés

Gratulálunk! Kiváló minőségű

termék mellett döntött. A termékkel

még az első üzembe helyezés előtt

ismerkedjen meg. Figyelmesen olvassa el

a biztonsági utasításokat. A termék üzembe

helyezését csak oktatásban részesített

személy végezheti.

A BERENDEZÉS NE KERÜLJÖN

GYERMEKEK KEZÉBE!

TUDNIVALÓ!

fAz alábbi szövegben a „termék” vagy

„készülék” kifejezés a jelen kezelési

útmutatóban leírt plazmavágóra

vonatkozik.

• Rendeltetésszerű használat

A készülék minden elektromosan vesetőképes fém sűrített levegős plazmavágására

alkalmas. A rendeltetésszerű használat

részét képezi a biztonsági tudnivalók,

valamint a szerelési útmutató és a kezelési

útmutatóban található üzemeltetési tudnivalók gyelembevétele is.

A legszigorúbban be kell tartani az

érvényes baleset-megelőzési előírásokat.

Nem szabad használni a készüléket:

nem elegendően szellőztetett

helyiségekben,

vizes vagy nedves környezetben,

robbanásveszélyes környezetben,

csövek kiolvasztására,

szívritmus-szabályozót viselő emberek

közelében és

könnyen lobbanó anyagok közelében.

Csak a leírtak szerint, a rendeltetésszerű

használatnak megfelelően használja

a terméket. Őrizze meg ezt az útmutatót.

Ha átadja a terméket egy harmadik fél

számára, mellékelje az összes dokumentu-

mot. Minden rendeltetésszerű használattól

eltérő alkalmazás tilos, és adott esetben

veszélyes lehet. A garancia nem vonatko-

zik az útmutató be nem tartásából vagy

a nem rendeltetésszerű használatból eredő

károkra, és a gyártó céget nem terheli

felelősség ilyen esetben.

FENNMARADÓ KOCKÁZAT

Fennmaradó kockázatok mindig vannak,

még akkor is, ha a készüléket az előírásoknak megfelelően kezeli.

A következő veszélyek léphetnek fel a jelen

plazmavágó felépítésével és kivitelével

összefüggésben:

szem sérülése vakítás miatt,

a készülék vagy a munkadarab

forró részeinek megérintése

(égési sérülések),

szakszerűtlen biztosítás esetén

baleset- és tűzveszély a szétrepülő

szikrák vagy salakdarabok miatt,

füstök és gázok egészségre káros kibo-

csátása levegőhiány, ill. zárt terekben

a nem elegendő elszívás miatt.

Csökkentse a fennmaradó kockázatokat

azzal, hogy a készüléket gondosan, és

az előírásoknak megfelelően használja,

valamint minden utasítást betart.

Bevezetés

28

HU

• Felszereltség

TUDNIVALÓ!

f A kicsomagolást követően azonnal

ellenőrizze, hogy nem hiányzik semmi a csomagból, valamint a készülék

kifogástalan állapotú-e. Ha a készülék

hibás, ne használja.

1

Plazmavágó

2

Hordfogantyú

3

Hálózati dugasz

4

Testkapocs

5

Testkapocs dugasza

6

Plazmaégő áramdugasza

7

Plazmaégő dugasza

8

Plazmaégő

8a

Plazmaégő gombja

8b

Fúvókaszorító hüvely

8c

Fúvókák

8d

Elektróda

8e

Diúzor

9

Túlmelegedés elleni védelem

ellenőrzőlámpája

10

Plazmaégő áram-csatlakozóaljzata

11

Testkapocs csatlakozóaljzata

12

Plazmaégő csatlakozóaljzata

13

Áramszabályozó

14

Hálózat ellenőrzőlámpája

15

Sűrített levegő tömlőjének

gyorscsatlakozója

16

Sűrített levegő tömlője

17

BE/KI kapcsoló

I jelentése: bekapcsolva

O jelentése: kikapcsolva

18

Kondenzvíz tartálya

19

Nyomásmérő

20

Sűrített levegő csatlakozója

21

Nyomásszabályozó forgatógomb

22

Tömlőbilincs

• Műszaki adatok

Teljesítmény: 15 – 40 A

Bemenet: 230 V~ 50 Hz

Súly: kb. 5,2 kg

Méretek: 341 x 113 x 237 mm

Szigetelési osztály: H

Bekapcsolási

időtartam: 35% 40 A mellett

(25 °C)

20% 40 A mellett

(40 °C)

„Valóságos”

vágásteljesítmény: 0,1 mm – 12 mm

(anyagtól függően)

vörösréz: 1 – 4 mm

rozsdamentes acél:

1 – 8 mm

alumínium:1 – 8 mm

vas: 1 – 10 mm

acél: 1 – 12 mm

Munkanyomás: 4 – 4,5 bar

(4 bar előre beállítva)

• Szállítási terjedelem

1 plazmavágó

1 testkábel kapoccsal

1 vágókábel vágóégővel

1 sűrített levegős tömlő gyorscsatlakozóval

2 tömlőbilincs

2 fúvóka

3 elektróda (1 előszerelt)

1 kezelési útmutató

3 égőtakaró (1 előszerelt)

Bevezetés

29

HU

• Biztonsági tudnivalók

FIGYELMEZTETÉS!

f Kérjük, hogy a használat

előtt alaposan olvassa el

gondosan a kezelési útmu-

tatót. A kezelési útmutató

segítségével ismerje meg

a készüléket, annak megfelelő használatát, valamint

a biztonsági utasításokat.

Az útmutató a készülék

része, és mindig kéznél kell

lennie!

FIGYELMEZTETÉS!

f KISGYERMEKEK

ÉS GYERMEKEKRE

LESELKEDŐ ÉLET- ÉS

BALESETVESZÉLY!

Soha ne hagyja felügyelet

nélkül a gyermekeket

a csomagolóanyaggal.

Fennáll a fulladás veszélye.

Ezt a készüléket 16 évnél

idősebb gyermek, valamint

csökkent zikai, érzékszervi

vagy mentális képességekkel

bíró vagy tapasztalat vagy

tudás hiányában szenvedő

személyek csak akkor hasz-

nálhatják, ha felügyelet alatt

állnak, vagy a készülék

biztonságos használatáról

kioktatást kaptak, és a készülék használatából adódó

veszélyeket megértették.

Gyermekek nem játszhatnak

a készülékkel. A tisztítást és

a felhasználói karbantartást

gyermekek felügyelet nélkül

nem végezhetik.

Bízza a javítási és/vagy

karbantartási munkák elvég-

zését minősített elektromos

szakemberekre.

Csak a szállítási terjedelem

részét képező hegesztővezetékeket használja.

Üzemelés közben lehetőség

szerint ne álljon a készülék

közvetlenül a fal mellett,

ne legyen letakarva, és ne

legyen beszorítva más készülékek közé, hogy mindig

elegendő levegő jusson át

a szellőzőréseken. Győződjön

meg arról, hogy a készülék

helyesen csatlakozik a hálózati feszültséghez. Kerülje

a hálózati vezeték húzóterhelését. Húzza ki a készülék

dugaszát az aljzatból, mielőtt

más helyen állítaná fel

a készüléket.

Mindig kapcsolja ki a készü-

léket a BE/KI kapcsolóval,

ha nem használja azt.

Tegye szigetelt alátétre az

Biztonsági tudnivalók

30

HU

elektródatartót, és csak

15 percnyi lehűlés után húzza

ki az elektródákat a tartójukból

.

Forró fémet és szikrákat fújhat el

a vágóív. Ezek a szálló szikrák,

a forró fém, valamint a forró

munkadarabok és a készülék

forró részei tüzet vagy égési

sérüléseket okozhatnak.

Ellenőrizze a munkakörnyezetet,

és gondoskodjon alkalmas mun-

kahelyről a készülék használata

előtt.

Távolítson el minden éghető

anyagot a plazmavágó 10 m

sugarú környezetéből. Ha ez

nem lehetséges, akkor takarja

le ezeket a tárgyakat alkalmas

takaróval.

Ne vágjon olyan helyen, ahol

a szétrepülő szikrák éghető

anyagra eshetnek.

Védje saját magát és másokat

a szétrepülő szikrákkal és

a forró fémmel szemben.

Legyen óvatos, mert a szikrák

és a forró anyagok vágáskor

a réseken és nyílásokon

keresztül könnyen eljuthatnak

a szomszédos területekre.

Legyen tudatában annak,

hogy a mennyezeten, a tala-

jon vagy a köztes területen

végzett vágás tüzet okozhat

a szemben fekvő, nem látható

oldalon.

Csatlakoztassa a munkaká-

belt a munkahelyéhez

a lehető legközelebb eső

dugaszolóaljzatához, hogy

ne nyúljon át az áramkábel

a teljes helységen, és esetleg

olyan, ismeretlen hely felett

haladjon, ahol elektromos

áramütést, szikrázást vagy

tüzet okozhat.

Ne használja a plazmavágót

megfagyott vezetékek

kiolvasztására.

Veszély elektromos áramütés

miatt:

FIGYELMEZTETÉS!

f A hegesztőelektróda miatti

elektromos áramütés halálos

lehet.

Ha használja a plazmavágót

hóban vagy esőben.

Hordjon száraz, szigetelt

kesztyűt.

Ne fogja meg csupasz kézzel

az elektródát.

Na hordjon nedves vagy

károsodott kesztyűt.

Védje magát áramütés ellen

a munkadarab elszigetelésével.

Ne nyissa ki a készülék házát.

Biztonsági tudnivalók

Loading...

Loading...