Parkside PBSD 600 A1 Translation Of The Original Instructions

BELT SANDER PBSD 600 A1

BELT SANDER

Translation of the original instructions

IAN 298810

BANDSCHLEIFER

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / NI Translation of t he original instructions Page 1

DE / AT / CH Originalbetriebsanleitung Seite 13

A

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Depicted components ......................................................... 2

Package contents ............................................................ 2

Technical data .............................................................. 2

General Power Tool Safety Warnings ................................3

1. Work area safety .......................................................... 3

2. Electrical safety ........................................................... 3

3. Personal safety ............................................................ 4

4. Power tool use and care .................................................... 4

5. Service .................................................................. 5

Appliance-specific safety instructions for grinders ................................... 5

Operation .......................................................5

Tensioning/replacing the abrasive belt ........................................... 5

Adjusting the additional handle ................................................. 5

Flipping up the front cover ..................................................... 6

Attaching/removing a dust extraction unit ......................................... 6

Working procedures ..........................................................7

Use .............................................................7

Switching on and off .........................................................7

Emptying the dust collector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Selecting speed and abrasive belt ............................................... 8

Stationary work ............................................................. 8

Tips and tricks ............................................................... 9

Maintenance and cleaning ..........................................9

Disposal .........................................................9

Kompernass Handels GmbH warranty ..............................10

Service .........................................................11

Importer .......................................................11

Translation of the original Conformity Declaration .....................12

PBSD 600 A1

GB│IE│NI

│

1 ■

BELT SANDER PBSD 600 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

The belt grinder is designed for the dry surface

sanding of wood, plastic, metal and plaster and

painted surfaces (depending on the type of sandpaper used). The appliance may only be used

for dry sanding. Please note that you need to use

appropriate abrasive belts with different grains for

working different materials, and that you may need

to adapt the speed to suit the material. The appliance is not intended for commercial use. Any other

use of or modification to the appliance is deemed

to be improper and carries the risk of serious personal injury. The manufacturer accepts no responsibility for damage(s) attributable to misuse.

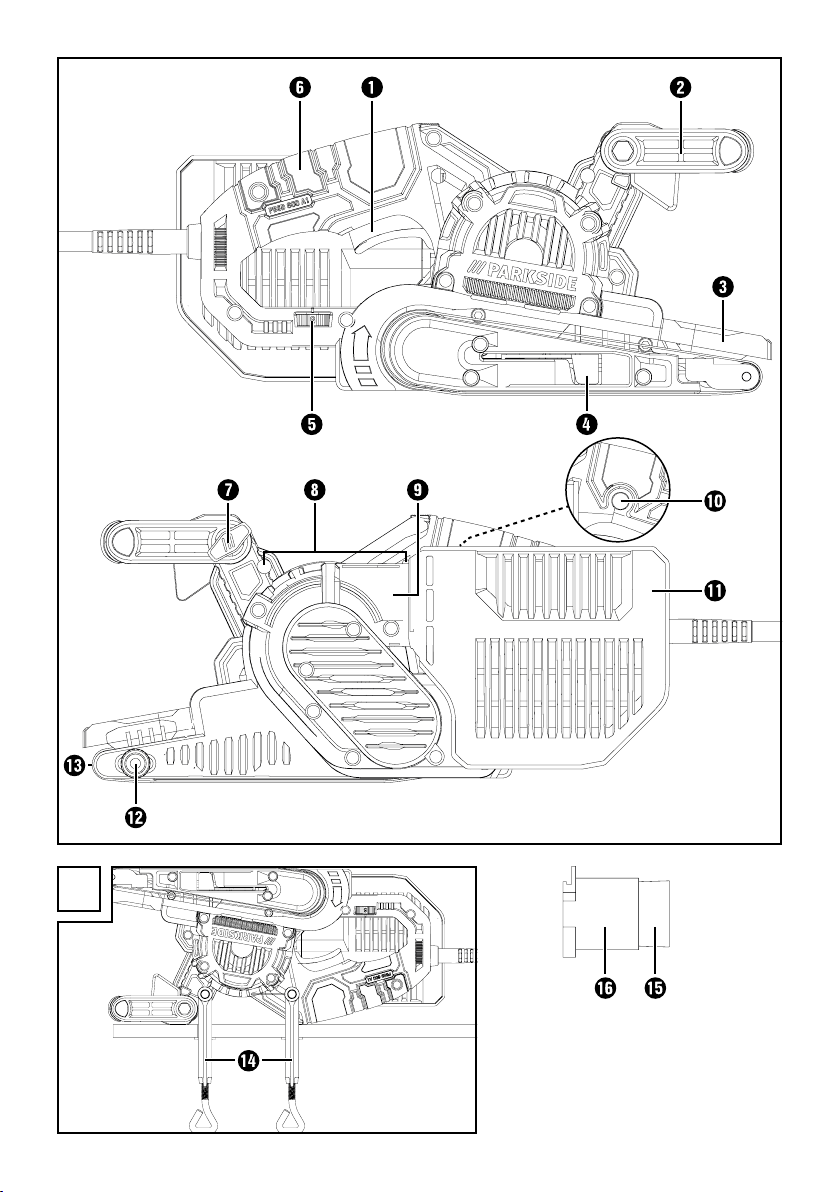

Depicted components

ON/OFF switch

Additional handle (rubberised grip)

Front cover

Clamping lever for abrasive belt

Belt speed adjusting wheel

Handle (rubberised grip)

Screw for adjusting the handle

Recesses for screw clamps

Connection for dust collector

Locking button for ON/OFF switch

Dust collector

Adjustment screw for belt tracking

Abrasive belt

Screw clamp

Reducer

Dust extraction adapter

Package contents

1 belt sander PBSD 600 A1

1 abrasive belt for wood (grain 80)

1 dust collector

1 dust extraction adapter and reducer (for external

dust extraction)

2 screw clamps

1 set of operating instructions

Technical data

Rated voltage: 230 V ∼50 Hz

(AC)

Rated power

consumption: 600 W

Idling belt speed: 170–250 m/min

Rated idling speed:

Abrasive belt: 75 x 457 mm

Protection class: II /

Noise emission value:

Noise measurement value determined in accordance with EN 60745. The A-rated noise level of

the power tool is typically as follows:

Sound pressure level: L

Uncertainty: K

Sound power level: L

Uncertainty: K

Wear hearing protection!

Total vibration value:

Total vibration value (vector total of three directions) determined in accordance with EN 60745:

Grinding with the grinding disc: a

Uncertainty K = 1.5 m/s

n0 360–560 rpm

(double insulation)

= 91 dB (A)

pA

= 3 dB

pA

= 102 dB (A)

WA

= 3 dB

WA

= 4.2 m/s

h

2

2

■ 2 │ GB

│IE│

NI

PBSD 600 A1

NOTE

► The vibration level specified in these instruc-

tions has been measured in accordance

with the standardised measuring procedure

specified in EN 60745 and can be used to

make equipment comparisons. The specified

vibration emission value can also be used to

make an initial exposure estimate. The vibration emission value varies in accordance with

the use of the power tool and may be higher

than the value specified in these instructions

in some cases. Regular use of the power tool

in this way may cause the user to underestimate the vibration.

WARNING!

► Try to keep the vibration loads as low as

possible. Measures to reduce the vibration

load are, e.g. wearing gloves and limiting

the working time. This applies to all states of

operation (e.g. times when the power tool is

switched off and times where the power tool

is switched on but running without load).

General Power Tool

Safety Warnings

WARNING!

► Read all safety warnings and all instruc-

tions. Failure to follow the warnings and

instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmos-

pheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

PBSD 600 A1

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

GB│IE│NI

│

3 ■

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are dan-

gerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

■ 4 │ GB

│IE│

NI

PBSD 600 A1

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Appliance-specific safety instructions

for grinders

■ Hold the appliance by the insulated handles

as the abrasive belt can come into contact

with its own power cable. Damage to a live

wire may make exposed metal parts of the

power tool live and could give the operator an

electric shock.

WARNING!

■ Dusts from materials such as leaded paint,

some types of wood and metal can be harmful to your health.

■ Contact with or inhalation of these dusts can

represent a health hazard for the person

operating the appliance and other people in

the vicinity.

■ Wear safety goggles and a protective dust

mask!

Operation

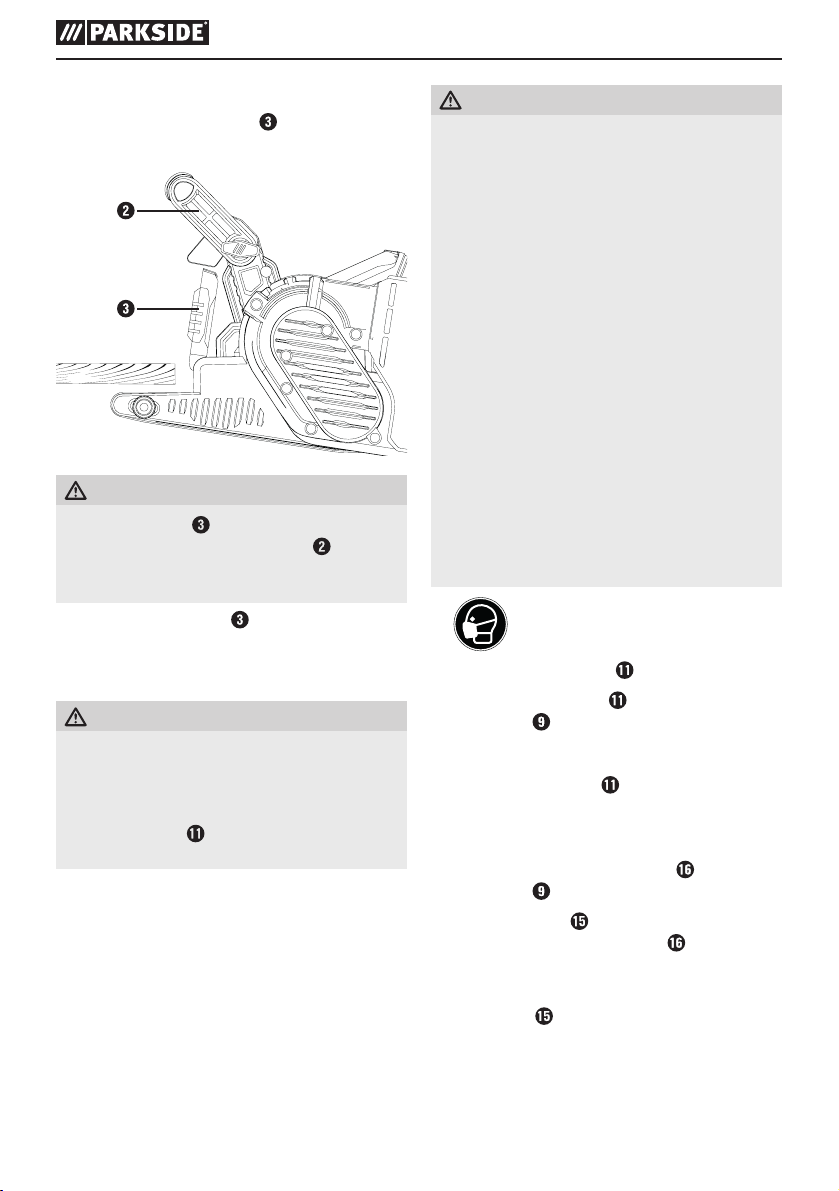

Tensioning/replacing the abrasive

belt

WARNING! RISK OF INJURY

■ Always remove the power plug from the wall

socket before carrying out any work on the

belt grinder.

1. Loosen the clamping device for the abrasive

belt by swivelling the clamping lever

the way out. The abrasive belt can now be

removed.

2. Now fit a new abrasive belt

belt to work on a different material or to use a

different grain size.

IMPORTANT: The direction of the arrows on

the inside of the abrasive belt and on the

appliance housing must match.

3. Push the clamping lever

position.

Manually adjusting the abrasive belt

If the belt tracking is not centred when you switch

on the appliance, you may need to manually adjust it.

♦ To do this, turn the adjusting screw

front roller until the abrasive belt is running

centred.

IMPORTANT: It is important to ensure that

the abrasive belt does not rub against the

housing. Check the belt tracking regularly and

adjust it with the adjusting screw if required .

back into its initial

all

or swap the

:

on the

PBSD 600 A1

Adjusting the additional handle

You can position the additional handle in several

different positions.

♦ To reposition the additional handle

screw .

♦ Move the additional handle

position.

♦ Retighten the screw

.

GB│IE│NI

undo the

to the required

│

5 ■

Flipping up the front cover

You can flip up the front cover to grind in hard-toreach areas (see illustration).

WARNING!

► The front cover

upwards if the additional handle is also

positioned upwards (see section "Adjusting

the additional handle").

♦ Flip up the front cover

can only be flipped

.

Attaching/removing a dust extraction unit

WARNING! RISK OF EXPLOSION!

■ If there is an explosive dust/air mixture, you

must use a specially designed extraction

appliance. RISK OF FIRE DUE TO FLYING

SPARKS! Do not use dust extraction systems

(dust collector

grinding metals.

■ Materials containing asbestos must not be pro-

cessed. Asbestos is a known carcinogen.

or vacuum cleaner) when

WARNING! RISK OF FIRE!

■ When working with power tools which

have a dust collector or can be connected

to a vacuum cleaner via a vacuum cleaner

adapter, there is a risk of fire! In unfavourable

conditions, e.g. when sparks are flying while

sanding metal or metal residues in wood,

wood dust in the dust collector (or the bag

of the vacuum cleaner) can spontaneously

ignite. This is a particular risk if the wood

dust is mixed with paint residues or other

chemicals and the workpiece has become hot

after being worked for a long time. Therefore,

do not allow the workpiece to overheat and

always empty the dust box or the dust bag

of the vacuum cleaner before taking a break

from work.

■ Ensure that your workplace is adequately

ventilated.

■ Observe the regulations applicable in

your country regarding the materials to be

worked.

■

Fitting the dust collector

♦ Push the dust collector

connection from above.

Dismantling/removing the dust collector:

♦ Pull the dust collector

Connecting a dust extraction adapter and

reducer for an external extraction appliance:

♦ Push the dust extraction adapter

connection .

♦ Push the reducer

adapter into the adapter fitting .

♦ Push the hose from a suitable dust extraction ap-

pliance (e.g. a workshop vacuum cleaner) onto

the reducer

Wear a dust mask.

:

onto the dust collector

off upwards.

onto the

for the dust extraction

for external vacuum extraction.

■ 6 │ GB

│IE│

NI

PBSD 600 A1

Loading...

Loading...