Panasonic ER-VS01 Installation Manual

INSTRUCTION MANUAL

Static Remover

Ionizer㨯Spot type

ER-VS01

Thank you very much for using SUNX products. Please read this Instruction

Manual carefully and thoroughly for the correct and optimum use of this product.

Kindly keep this manual in a convenient place for quick reference.

٨

This product is to remove static electricity for industrial use. Never use this product for medical equipment etc. relating to maintenance/supervision of human life or body, for prevention of accidents which damage a human life or properties, or for safety

maintenance.

٨

Since the tip of the discharge needle is pointed, take sufficient

care in handling the discharge needle, or injuries may result.

Do not use this product near or around surroundings containing

٨

any dangerous materials, such as combustible material and

flammable material.

The discharge needle gathers dust after a long period of use. In

٨

WARNING

1

OUTLINE

٨

This product is a compact, corona discharge type electrostatic charge removal device.

٨

This product neutralizes electrostatic charge from charged objects quickly

and effectively.

This product removes dust stuck to charged objects due to static electricity,

٨

and keeps such objects free from electrostatic dust.

2

CAUTIONS

٨

Make sure to use the DC power supply insulated by an isolation transformer

etc. for this product. If an auto-transformer etc. (single winding transformer) is

used, this product or the power supply may get damaged due to short-circuit.

٨

If the air supplied to this product is ON/OFF by a solenoid valve etc., turn the main

power on/off simultaneously. [Discharge halt (DSC OFF) input should be used]

٨

If corona discharge is done without supplying air, the amount of ozone generation increases remarkably.

Do not use during the initial transient time (0.5 sec.) after the power supply

٨

is switched on.

If the power supply is switched on immediately after being switched off, fault

٨

output may be generated. After the power supply is switched off, keep an

interval of 1 sec. or more, before switching it on again.

٨

Do not use this product beyond its rated specifications. Doing so can cause

product breakdown, non-function, or damage. Further, it will also cause a

marked reduction in product life.

٨

Never disassemble, repair, modify, or misuse this product, as it can cause

accident or malfunction.

٨

Do not throw this product in fire. There is a danger of it exploding, or generating poisonous gas.

Since this product emits ozone into the atmosphere, circulate the air if it is

٨

foul-smelling. If ozone stays for long period, metals etc. may oxidize/decay.

Further, do not try to confirm the foul-smelling ozone by drawing your face

near the nozzle outlet. There is a danger of hurting your nose, throat, etc.

If this product is used immediately after storage in a high-humidity environ-

٨

ment, its ion balance may remain lost. Therefore, before use, leave this

product in the atmosphere with a temperature of +25 or so and a relative

humidity of 30% RH for over 8 hours.

Do not use this product in steamy or dusty places and in places where water

٨

splashes or spatter flies when welding.

Make sure that the power supply is off while wiring and inspection. Other-

٨

wise, there is a danger of accident, electric shock or malfunction.

After wiring, reconfirm the wiring connections before switching on the power

٨

supply.

Take care that wrong wiring will damage the product.

٨

Verify that the supply voltage variation is within the rating.

٨

٨

If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

٨

In case a surge is generated in the used power supply, connect a surge absorber to the supply and absorb the surge.

Do not run the wires together with high-voltage lines or power lines or put

٨

them in the same raceway. This can cause malfunction due to induction.

Confirm the wiring and piping state before supplying power or air. Wrong wir-

٨

ing and piping may cause malfunction.

Use air (dried clean air) for the fluid. Fluid other than air (dried clean air) or

٨

that containing corrosive gas may cause accident or malfunction.

order to prevent accident or product malfunction, clean up the discharge needle, periodically once every two weeks or so, or this

product will be unable to exert the charge removal performance.

٨

Be sure to ground the main body of this product via ground terminal

to ensure electric shock prevention and reliable charge removal.

Since the discharge needle is live with high voltage, never touch

٨

the discharge needle, or an electric shock may result.

If this product is used in an airtight room, ozone emitted from this

٨

product may be detrimental. Therefore, in order for this product to

be used in an airtight room, be sure to keep the room ventilated.

Since the ion air contains ozone, do not aim this product at anyone.

٨

٨

Do not use air containing foreign particles, such as, carbon dust or dust, water or oil. Since those may cause electric shock or malfunction, take appropriate measures, such as, installing an air-filter or an air-drier, etc.

When maintenance, checkup or cleaning are carried out, make sure to cut

٨

the air supply completely and confirm that the inside the product and the

tubes became atmospheric pressure in advance. The remained air pressure

may cause accident or malfunction.

Do not use this product for a purpose other than charge removal.

٨

This product is CE-conformed under the EMC Directive. The immunity adopt-

٨

ed by this product should be conformable to EN 61000-6-2. In order for such

immunity to be conformable to this standard, all wires connected to this product should be limited in length to less than 10m.

When this product is no longer usable or required, carry out the appropriate

٨

disposal process meant for industrial waste.

3

SPECIFICATIONS

Item

Charge removal time

Ion balance r15V or less (Note 1)

Ozone generation

Applicable fluid Air (dried clean air) (Note 3)

Supplied air flow

Air pressure range

Supply voltage 24V DCr10%

Current consumption

Discharge method

Discharge output voltage

Check output

(CHECK)

Error output

(ERROR)

Discharge halt input

(DSC OFF) (Note 6)

Reset input

(RESET)

Ambient temp./humidity

Cable Cable with a connector, 0.5m long

Material

Weight 120g approx.

Accessory

Notes: 1)

Type

Model No.

500 /min (ANR) or less (Note 4)

NPN open-collector transistor

Maximum sink current㧦50mA

Applied voltage㧦30V DC or less (between check output and 0V)

Residual voltage㧦1V or less (at 50mA sink current)

Output operation

Short-circuit protection

Output operation

Short-circuit protection

Power

Discharge

Check

Indicators

Error

A typical sample (measured on a sample left in the atmosphere at a relative humidity of 65%

RH for 24 hours) applied with a power voltage of 24V, a distance of 100mm from the front

surface of the airflow inlet and a pressure of 0.25MPa while the shower nozzle is in use.

2)

A typical sample applied with a power voltage of 24V, a distance of 300mm from the front

surface of the air flow inlet and a pressure of 0.25MPa while the shower nozzle is in use.

3)

The air is dried (dew point: equivalent of -20) and filtered (mesh-size: equivalent of 0.01Ǵm) air.

4)

The applicable pressure range depends on the nozzle to be used.

5)

When the power is ON, or the discharge halt input is activated, the check output may

operate transitively, however, the charge removal capability remains the same.

In case of using the check output to halt the device or give an alarm etc., use a sequence

controller that processes with 5 sec., or more, output.

6)

"DSC" stands for "DISCHARGE".

ON when a dirt or wear etc. of the discharge needle is detected, OFF when operation is normal (Note 5)

NPN open-collector transistor

Maximum sink current㧦50mA

Applied voltage㧦30V DC or less (between error output and 0V)

Residual voltage㧦1V or less (at 50mA sink current)

OFF when abnormal discharge is detected, ON when operation is normal (Note 5)

Discharge halt: short-circuit with 0V

In the state that operation is stopped due to an error detection, open

0V of the power supply from short-circuit state to cancel ERROR.

Orange LED (lights up when a dirt or wear etc. of the discharge needle is detected)

Enclosure: PPS, Cover: Stainless steel, Discharge needle: Tungsten

[Manufactured by Molex: Housing (5557-08R), Terminal (5556T)]

Discharge allowed (operation start): Open

Green LED (lights up when the power is ON)

Green LED (lights up when discharging)

Red LED (lights up when error is detected)

0to+55/35 to 65% RH (No dew condensation)

Spot type

ER-VS01

1 sec. or less (Note 1)

0.03ppm or less (Note 2)

0.05 to 0.7MPa (Note 4)

70mAorless

High frequency AC method

2,000V approx.

Incorporated

Incorporated

Connector for wiring: 1 set

٨Options

Nozzle and Holder

For details of the nozzle and holder, refer to the instruction manual enclosed

with the nozzle.

AC adapter Discharge unit

Model No.

ER-VAPS

4

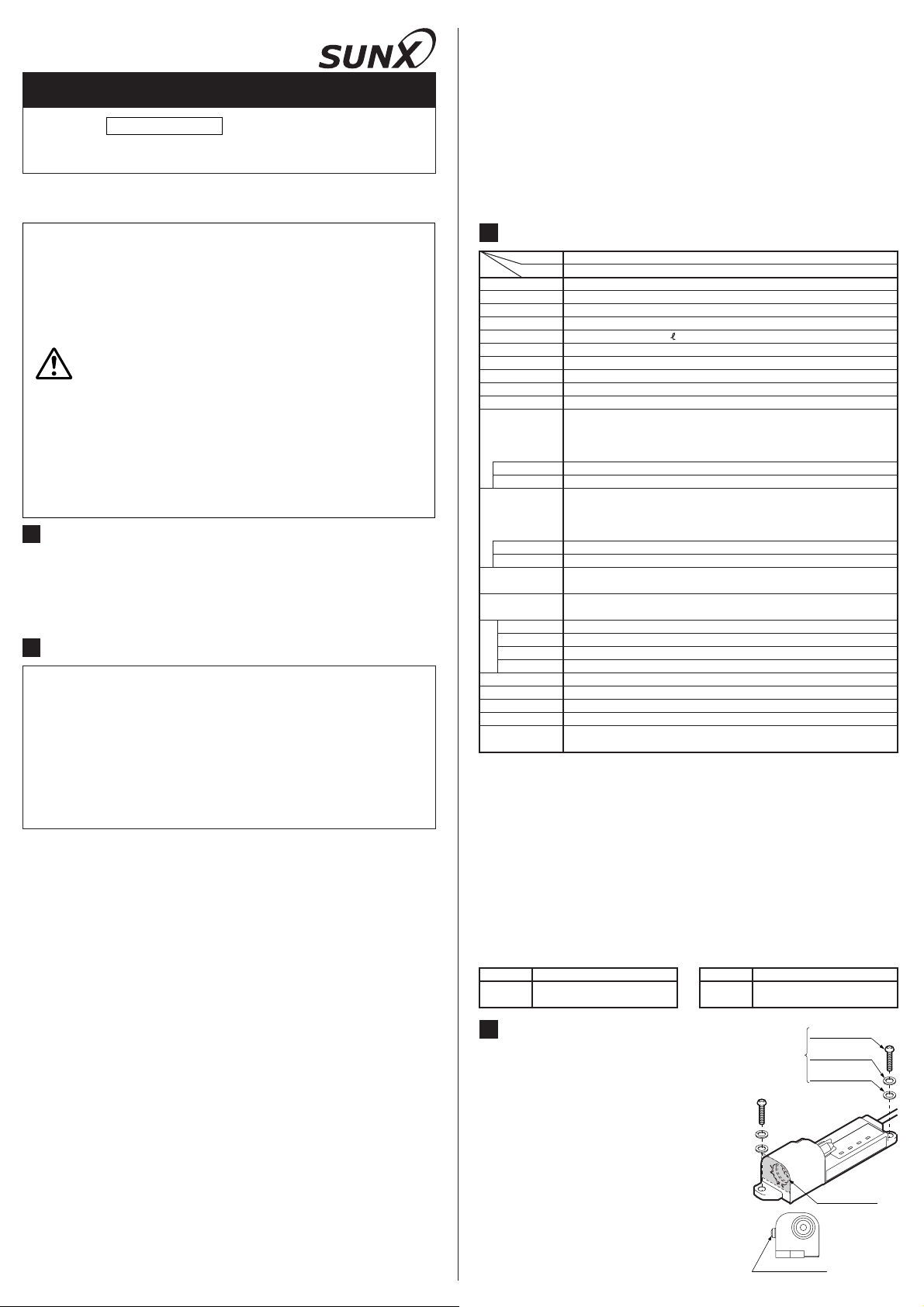

MOUNTING

٨

When this product is mounted on a housing,

use M4 screws. (please arrange separately.)

The tightening torque should be 2N㨯m or less.

If more than 2 units are mounted closely, keep

٨

Description

IN: 100 to 120V AC, 50/60Hz, 40VA

OUT: 24V DC, 750mA

Model No.

ER-VANT

Description

Unit with Tungsten needle

(1 set)

M4 pan-head screw

Please arrange

separately

Spring lock-washer

Plain washer

5mm, or more, distance between them. Otherwise, the capability may be affected.

Make sure to ground this product. If the

٨

grounding is not proper, the charge removal

capability is reduced. (Direct earth or power

supply common earth)

If AC adopter is used, be sure to connect the

٨

ground terminal to the power supply common

Protective film

earth.

Ground terminal

٨٨This product cannot be used by its own. Be sure to fit the optional

nozzle for use of this product.

9#40+0)

٨ Since a protective film is affixed on the

For the details of the optional nozzle, refer to the instruction

manual enclosed with the nozzle.

ER-VS01

nozzle fitting part, be sure to remove it

before fitting the nozzle (optional). The

tightening torque should be 6N㨯m or less.

5

PIPING

٨

The outer diameter of the air-tube to fit to the air inlet portion of this product

Convex

part

Attachment

Resin tube

Shower nozzle (ER-VAS) (optional)

(Enclosed with nozzle)

Protective film

should be Ǿ6mm.

٨

Make sure that clean air (air containing no-water, no-oil and no dust) should

be supplied.

Since the pressure will drop when the air piping from the main pressure sup-

٨

ply is extended or pneumatic-components (e.g., needle valve, spin core, mini

filter) are added, keep an eye on the pressure supply to the ionizer making

sure it isn't in short supply. For the pneumatic- components, select those that

can accommodate the air supply flow rate.

6

I/O CIRCUIT DIAGRAMS

Terminal connecter No.

Color code

(Brown) +V

D

COM (+)

Tr1

Tr2

Sensor circuit

Ground

terminal

Internal circuit Users' circuit

Symbols... D: Reverse supply polarity protection diode

*1

Non-voltage contact or NPN open-collector transistor

Discharge halt input

Z

D1, ZD2:

Surge absorption zener diode

1,Tr2:

Tr

NPN

Low (0V): Discharge halt

High (Open): Discharge allowed (Operation starts)

Reset input

In the state that operation is stopped due to an error detection, open 0V of the

power supply from short-circuit state to cancel ERROR

٨ Connector pin arrangement

(Front view)

7

INPUT SIGNAL CONDITIONS

(Orange) Check output

Z

D1

(Black) Error output

Z

D2

(Pink) Discharge halt input

(Violet) Reset input

(Blue) 0V

COM (-)

output transistor

Terminal No.

Load

50mA max.

*1 *1

or

Ԙ

ԙ

Discharge halt input

Ԛ

ԛ

Ԝ

ԝ

Ԟ

ԟ

Load

50mA max.

㧗

㧙

Terminal Color code

0V

COM

Reset input

24V

COM

Check output

Error output

Blue

㧙

Pink

Violet

Brown

㧙

Orange

Black

٨ Conditions for the discharge halt input and the reset input are as follows.

Discharge halt input

0.5 sec.

DSC OFF

(Low input)

Note: Repeat control with 'DSC OFF' input

should be 1Hz or less.

Open

Low

or more

Reset input

RESET

(Start-up input)

Open

Low

10ms

or more

10ms

or more

24V DC

r10%

8

OPERATION MATRIX

Indicators ( 㧦Lights upޔ㧦OFF)

Discharge

Power

Green Green Orange

Normal

Check

Error

Discharge halt input

Reset input

'DSC OFF' input in the 'ERROR' state is invalid (since the 'ERROR' state is prioritized).

Notes: 1)

'RESET' input is enabled even when in the 'DSC OFF' input state, and 'DSC 'OFF' input

2)

remains unaffected by 'RESET' input.

'RESET' input in the 'ERROR' state resumes the 'ERROR' state unless the cause of the

3)

error has been eliminated.

9

MAINTENANCE

Check

(Maintained)(Maintained)

Error

Output

Check

N.O. N.C.Red

OFF

ON

OFF

OFF

(Maintained)

Error

ON

ON

OFF

ON

ON

٨٨Before checking the high-voltage part, be sure to turn off the

power supply, or you may get an electric shock.

WARNING

٨

Since the removal discharge effect will deteriorate if dirt is stuck to the tip of

Since the tip of the discharge needle is pointed, take sufficient

care when cleaning. There is a danger of injury.

the discharge needle, clean the discharge needle periodically.

٨

The maintenance required depends on the environment of use. As a reference, the maintenance should be done once in two weeks.

The discharge needle is a part having a product life time. It is recommended

٨

that the needle should be replaced, as a reference, after 10,000 hours in

use. When replacing it, replace the whole unit.

Procedure of cleaning and replacing the discharge needle

Ԙ

Confirm that the power supply is off.

ԙ

Unscrew the discharge needle counter-

Discharge needle unit

clockwise.

Remove the dirt on and around the dis-

Ԛ

charge needle with a cotton bud soaked in

alcohol.

After cleaning, screw the needle clockwise to fit. The tightening torque

ԛ

should be 0.3N㨯m or less.

10

TROUBLE SHOOTING

Make sure that the power supply is off while checking the highvoltage part. Otherwise, you may get an electric shock.

WARNING

Symptom Remedy

Check indicator

(orange)

lights up

Error indicator

(red) lights

up

Doesn't go back to

normal state by reset

11

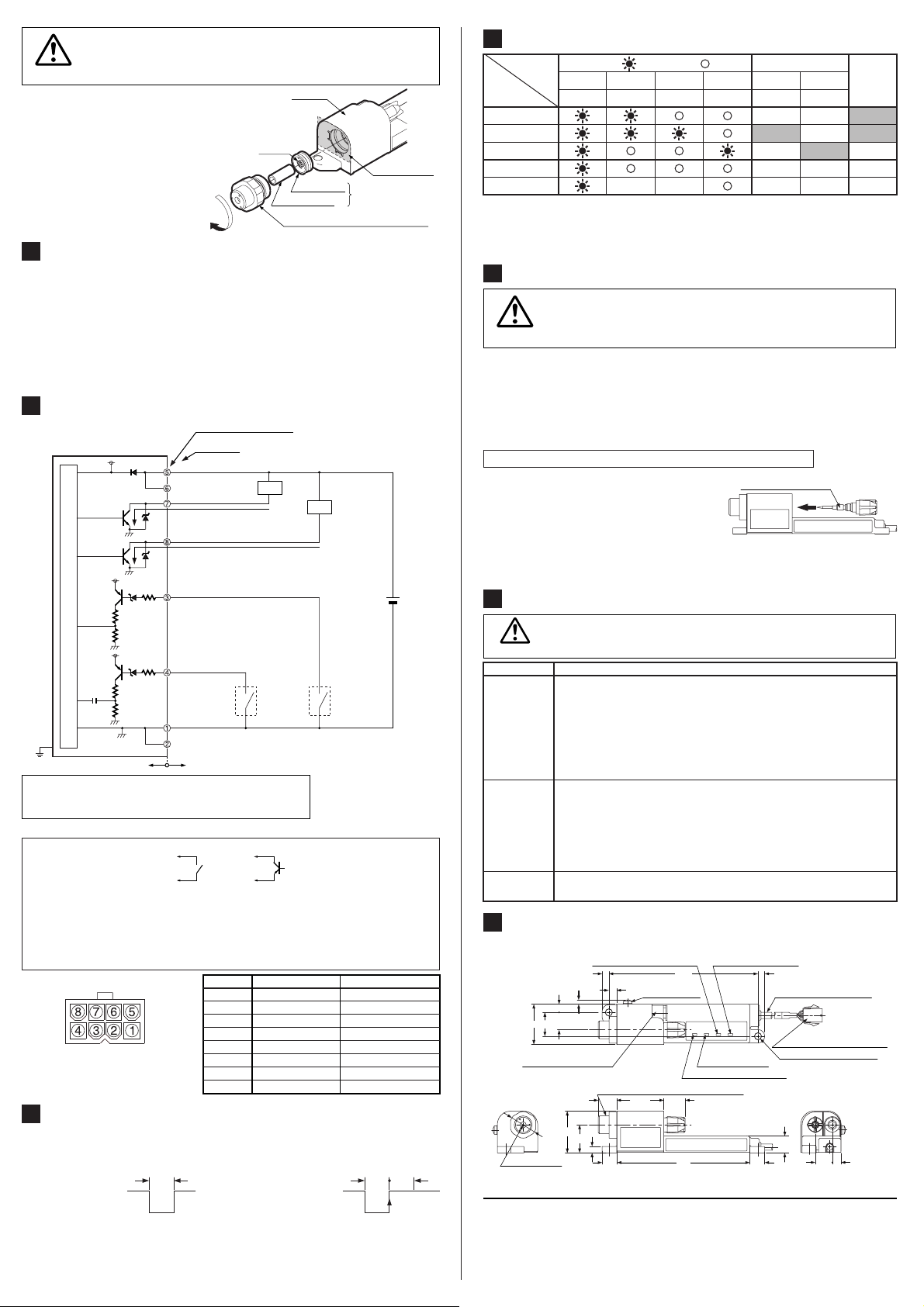

DIMENSIONS (Unit: mm)

Make sure that the power voltage is within the tolerance as per specifications.

Check the tip of the discharge needle for chip and contamination, and make

sure that the discharge needle unit is mounted normally on the main body.

If the CHECK indicator (orange) lights up even after cleaning the

discharge needle, also check the nozzle part for contamination.

Make sure that the nozzle assembly (including the attachment and

the resin tube) is mounted properly.

Make sure that the air pressure is within the applicable range as per specifications.

Make sure that the power voltage is within the tolerance as per specifications.

Abnormal discharge is possible.

Turn off the power supply, check the tip of the discharge needle for chip and

contamination, and make sure that the discharge needle unit is mounted

normally on the main body. Also, check the inside of the nozzle for foreign

objects, and make sure that the nozzle is mounted and installed properly.

Make sure that the ground terminal is connected completely.

Make sure that the cause of the error has been eliminated.

٨ Mounting drawing with shower nozzle (optional)

Error indicator (Red)Check indicator (Orange)

2.8

5.5

11.7

27

16

PCC6-M8M manufactured by PISCO

Shower nozzle (ER-VAS) (optional)

28

4.3

18.8

Ǿ17.8

Airflow outlet

10 1089

SUNX Limited

100

Ground terminal

5.2

(M3)

Power indicator (Green)

31.712.3 14.3

Discharge indicator

(Green)

(4.5)4.5

Ǿ4.2 cable 0.5m (gray)

5559-08P manufactured

by Molex 5559-08P

2-Ǿ4.5 mounting holes

11.3

http://www.sunx.co.jp/

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN

Discharge

through

needle

ON

ON

OFF

OFF

(Allowed)

5.811.4

Loading...

Loading...