Panasonic ER-Q Instruction Manual

INSTRUCTION MANUAL

Static Remover Ultra-compact Fan Ionizer

ER-Q

CMJE-ERQ No.0053-70V

Thank you very much for using Panasonic products. Please read this

Instruction Manual carefully and thoroughly for the correct and optimum use

of this product. Kindly keep this manual in a convenient place for quick

reference.

WARNING

Never use this product with a device for personnel protection.

In case of using devices for personnel protection, use products which meet laws

or standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable

in each region or country.

Do not use this product in places where there may be a danger of fl ammable or

combustible items being present.

Clean the equipment regularly (discharge needles: about once every week, fi lter:

about once a month), otherwise optimum charge removal performance may not be

obtained and fi re or operating problems may occur.

If this product is used in an airtight room, ozone emitted from this product may be

detrimental. Therefore, in order for this product to be used in an airtight room, be

sure to keep the room ventilated.

Do not direct ionized air toward the face. Ozone may cause irritation to places

such as the nose and throat.

Since the tip of the discharge needle is sharp, take suffi cient care in handling the

discharge needle, or injuries may result.

Be sure to ground the frame ground (F.G.) terminal, otherwise electric charge

removal may not be reliable.

Take care not to let any foreign objects get into the fan air inlet, otherwise

accidents or operating problems may occur.

1 OUTLINE

This is a static charge remover which utilizes ion generation by means of corona

discharge.

It has a compact shape, so that it can be positioned either vertically or horizontally.

It is equipped with an automatic stop function which operates when the discharge

needle unit has been removed.

2 PART DESCRIPTION

Ion air outlet

Discharge needle unit

2-M3 screws (depth 10 mm) (Note 2)

Notes: 1) Fan speed control

This is set to MAX fan speed at the time of shipment from the factory.

Use a precision screwdriver (-) to adjust the fan speed.

2) Screw threads exclusive for SUNX mounting brackets. Do not use them in mounting with

other products.

When mounting this product directly to a case or such, fi x it with M3 screws using 2-Φ3.5

mounting holes.

Description of indicators

Discharge indicator (DSC) ... Lights during discharge

3.5

3.5

60

52

Alarm indicator (ALARM) ... Lights when discharge error or discharge checking

65

58

Filter cover

Φ3.7 mm cable

Connector 5559-08P

manufactured by MOLEX

5.5

2-Φ3.5 mm

mounting hole

Alarm indicator

(red)

Discharge indicator

(green)

Power switch

25.419.8

(when ions are being generated)

occurs, blinks when fan error occurs.

Fan speed control

(Note 1)

29

33

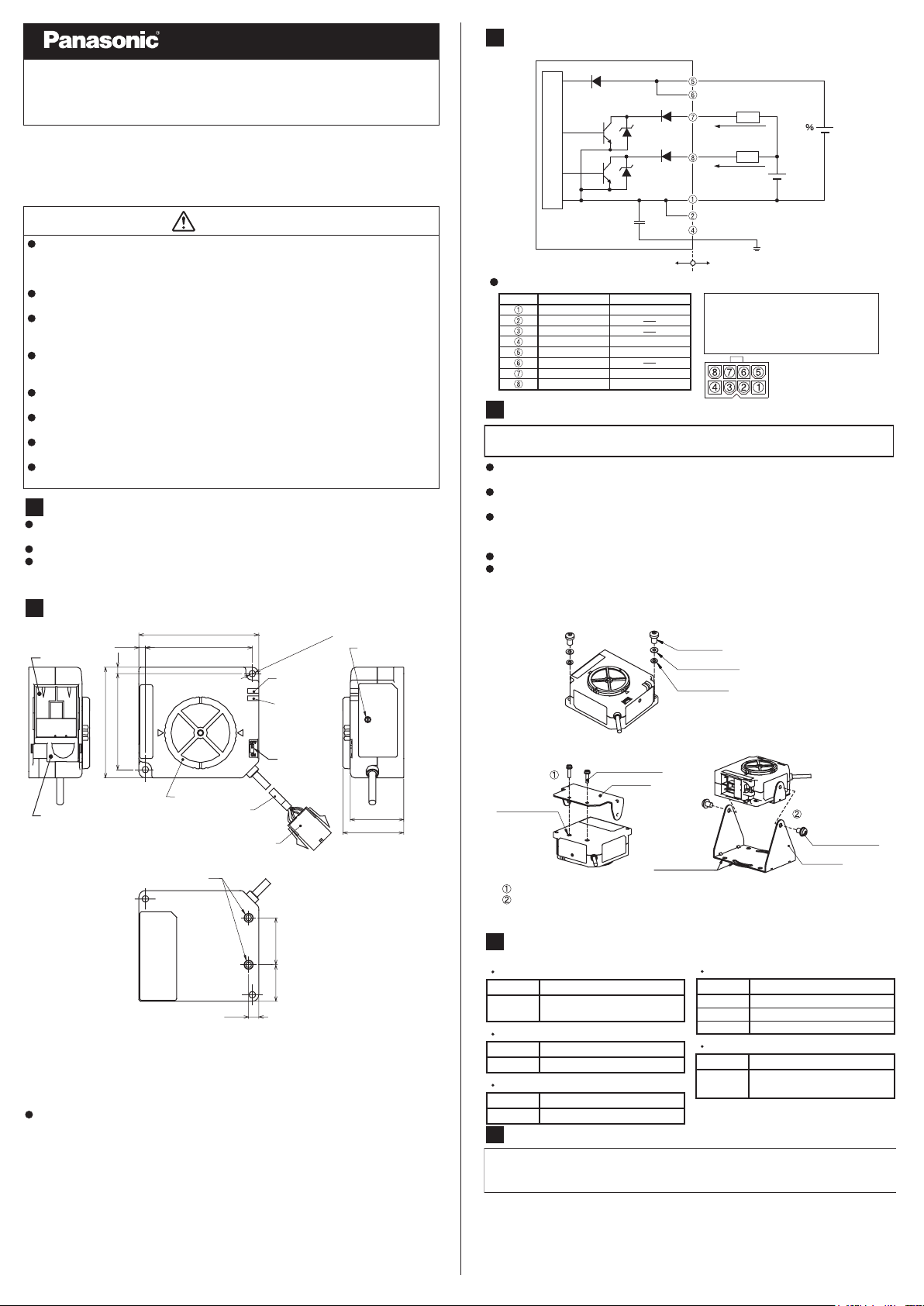

3 INPUT AND OUTPUT CIRCUIT DIAGRAM

D

1

Tr

1

ZD

Main circuit

Tr

2

1

ZD

2

Internal circuits

Connector pin layout diagram

Terminal name Lead wire color

Terminal no.

0 V

COM (-)

N.C. (Not used)

F.G.

24 V

COM(+)

Check output

Error output

Blue

Green

Brown

Orange

Black

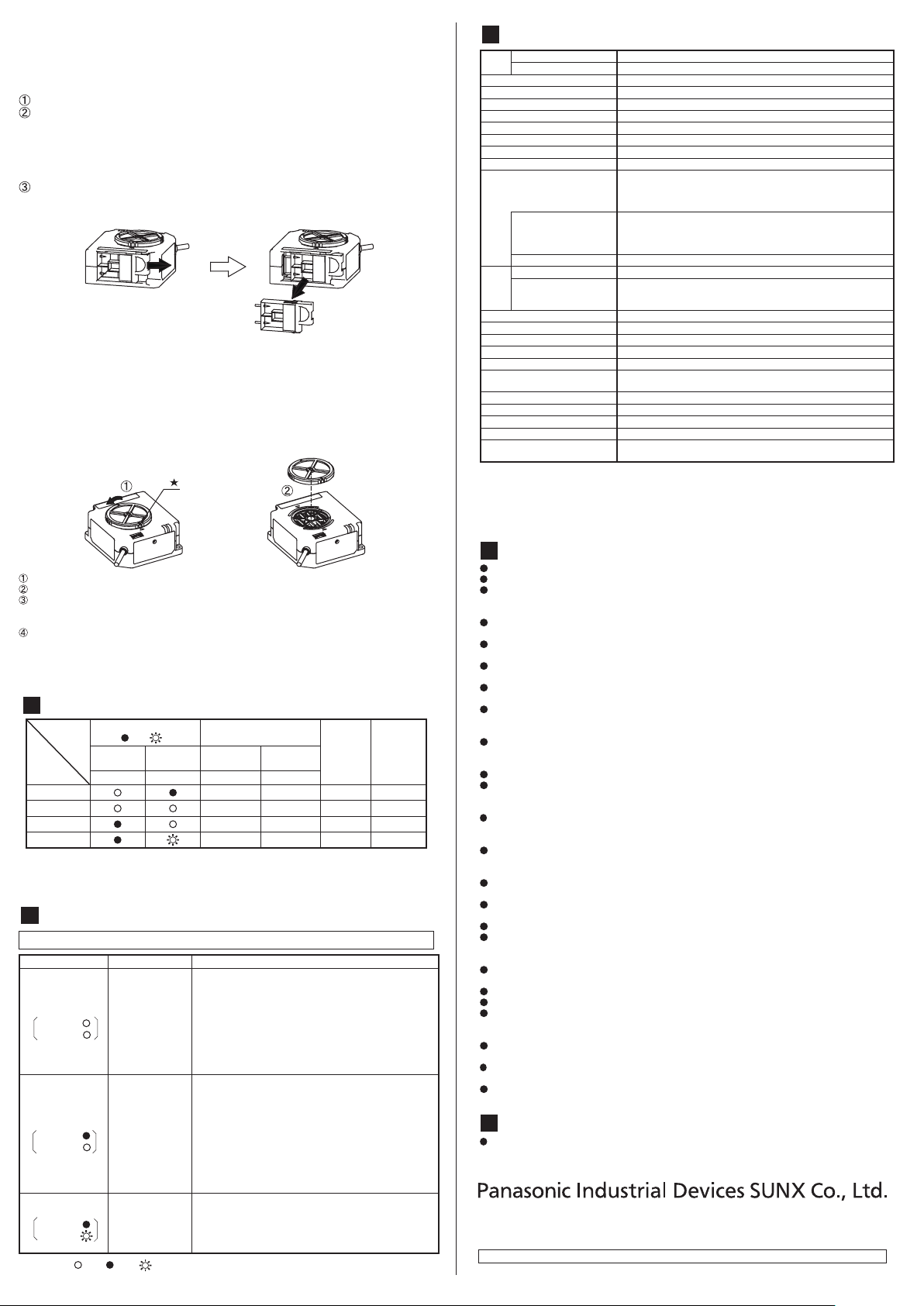

4 MOUNTING

●

Be sure to turn off the power before carrying out angle adjustment for this

product, otherwise accidents or problems with operation may occur.

If installing this product directly to the enclosure, use M3 screws. (M3 screws

should be arranged separately.)

If using the ER-QMS1 (optional mounting bracket), use the screws provided with

the mounting bracket.

If using SUNX mounting bracket or screws other than the ER-QMS1, do not use

screws which are longer than 10 mm, otherwise they may cause damage to

internal parts when fastened.

Tightening torques are 0.5 N・m for M3 screws and 1.2 N・m or less for M4 screws.

If using several of these products alongside each other, leave a space of 50 mm

or more between each product, otherwise product performance may be adversely

affected.

[If installing this product directly to the enclosure]

[If using the

2-M3 screw

(depth 10 mm)

5

AC adapter

Model No. Details

ER-VAPS1

Replacement discharge needle unit

Model No. Details

ER-QANT

Replacement air filter

Model No. Details

ER-QFX5

6

●

●

●

ER-QMS1

Install bracket 1 to the main unit with the M3 screws.

Install bracket 2 to the main unit with the M4 sems screws, and then use the M4 screw

mounting holes to install to the enclosure.

* The M3 and M4 screws are included with the ER-QMS1.

(optional mounting bracket)]

M3 sems screw

Bracket 1

OPTIONS

IN: 100 to 240 V AC, 50/60 Hz, 40 VA

OUT: 24 V DC, 750 mA

Unit with tungsten needles

5-piece air filter set

CARE AND MAINTENANCE

Be sure to turn off the power before carrying out cleaning and maintenance.

The discharge needle has a sharp point, so be very careful when cleaning the

needle.

After long periods of use, dirt may adhere to the discharge needles, the area

around them and the filter. If these areas are not cleaned, charge removal

performance will drop and accidents or problems with operation may occur.

Therefore they should be periodically cleaned (discharge needles: about once

every week, fi lter: about once a month).

(Brown) +24 V

COM (+)

D

2

(Orange) Check output

D

3

(Black) Error output

(Blue) 0 V

M3 screw

Spring washer

Flat washer

M4 screw

mounting hole

ER-QMS1

Load

50 mA MAX

Load

50 mA MAX

COM(-)

(Green) F.G.

User’s circuits

D1: Power supply reverse connection

protection diode

D

, D3: Output protection diodes

2

ZD

, ZD2:

1

Tr1, Tr2: NPN output transistors

Front view

24 V DC

±10

30 V

DC MAX

Surge voltage absorption Zener diodes

M4 sems screw

Bracket 2

Cable with connectors

Model No. Details

ER-QCC2

ER-QCC5

Cable length 2 m

Cable length 5 m

Mounting bracket

Model No. Details

Mounting bracket for air

direction adjustment

●

The discharge needles are consumable parts. If the discharging performance is not

restored after the discharge needles have been cleaned, it is recommended that

you replace the whole discharge needle unit (option). It is recommended that you

replace the discharge needle unit after about 10,000 hours of operation.

[Cleaning and replacement procedure for discharge needle unit]

Follow the procedure given below to remove the discharge needle unit from the main unit.

Use a cotton swab or similar moistened in alcohol to clean the discharge needles

and the areas around them.

If the needles are particularly dirty, use a brush (such as a toothbrush) moistened

with alcohol to rub them clean, and then use a cotton swab to wipe them.

A commercially-available ultrasonic cleaner can also be used for cleaning. (Immerse

the discharge needle unit into the cleaning tank to clean them.)

Insert the tabs of the discharge needle unit into the two slots in the main unit, slide

the discharge needle unit sideways to install it to the main unit until a click is heard.

[Discharge needle unit removal procedure]

1

1 Hook your finger into the slot in the

discharge needle unit and slide the

unit in the direction shown in the

illustration until a click is heard.

2 After this, you can pull the

discharge needle unit toward you

to remove it.

* Do not touch the interior of the main unit when removing and installing the discharge

needle unit, otherwise accidents or problems with operation may occur.

* Do not apply any more force than is necessary when removing and installing the

discharge needle unit, otherwise the discharge needle unit may become damaged.

2

[Fan fi lter cleaning and replacement procedure]

Install and use a fi lter depending on the operating environment.

Turn the filter cover in the direction shown in the illustration to align the * marks.

Remove the filter cover and the filter from the ER-Q main unit.

Remove the filter from the filter cover, and remove any dust and dirt adhering to the filter. If the

filter is extremely dirty, wash it in water. If washing the filter in water, let it dry thoroughly before

using it again.

Install the filter and the filter cover to the ER-Q main unit.

* If the filter is used while it is still wet, accidents or problems with operation may occur.

* If the filter cannot be cleaned, replace it.

* Be careful not to let any foreign objects get inside the main unit when removing and installing the

filter.

7 OPERATION MATRIX

Indicator

(O: Lit, : Off, : Blinking)

Discharge

(DSC)

Normal OFFONONON

Discharge check

Discharge error

Fan error

Green RedNormal open

Alarm

(ALARM)

* Once an error has been detected, the error status will be maintained until the power

is turned off and back on again.

* Eliminate the cause of the error before turning the power back on again.

* If the cause of the error has not been eliminated, the error will occur again.

Output

Check Error

Normal closed

ON ON ON ON

OFFOFF OFF OFF

OFFOFF OFF OFF

Discharge

operation

operation

Fan

8 TROUBLESHOOTING

●

Be sure to turn off the power before checking the discharge unit or the fan unit.

Problem Probable cause Remedy

Dirty discharge

Discharge check

Discharge

Alarm

Discharge error

Discharge

Alarm

Fan error

Discharge

Alarm

* Indicators (

needle

Wear

Condensation

F.G. not

connected

Foreign object

obstruction

Condensation

F.G. not

connected

Fan intake

covered

Filter blocked

Foreign object

obstruction

: Lit, : Off, : Blinking)

Check that the power supply voltage is within theusable

・

range.

Turn off the power and check that the tips of thedischarge

・

needles are not worn or dirty and that the discharge

needle unit is correctly installed to the main unit.

If the alarm indicator remains lit even after the discharge

・

needles have been cleaned, check for any dirt around

the discharge needles also.

Check that the F.G. terminal is securely connected to the round.

・

Check that the power supply voltage is within the usable

・

range.

There may be an abnormal discharge. Turn off the

・

power and check that the discharge needles are not

dirty or broken and that the discharge needle unit is

correctly installed to the main unit.

If the alarm indicator remains lit even after the discharge

・

needles have been cleaned, check for any dirt and

foreign objects around the discharge needles also.

Check that the F.G. terminal is securely connected to the ground.

・

Turn off the power and check if the fi lter is blocked.

・

Check if there are any foreign objects inside the product.

・

9 SPECIFICATIONS

Type Fan type ionizer

Item

Model No. ER-Q

Charge removal time 1.5 sec. approx. (Note 1)

Ion balance ±10 V or less (Note 1)

Power supply voltage 24 V DC ±10 %

Power consumption 200 mA or less

Discharge method High-frequency AC method

Discharge output voltage ±2 kV approx.

Max. fan speed 6.4 m/s (Note 1)

Max. fan volume 0.2 m

Output

(CHECK, ALARM)

Output operation

Short-circuit protection Incorporated

DSC Green LED (Lights up during normal discharge)

ALARM

Indicators

Ozone generation amount 0.02 ppm or less (Note 1)

Pollution leve

Ambient temperature

Ambient humidity

Operating altitude 2,000m or less (Note 3)

Vibration resistance

Over-voltage category I

Material Enclosure: PBT Discharge needle: Tungsten

Grounding methodC (capacitor) grounding

Weight 110g approx. (main unit only)

Accessories

Notes: 1) Representative value at 100 mm from directly in front of fan outlet, maximum fan speed

10

This product has been developed / produced for industrial use only.

Do not use this product for any purpose other than charge removal and dust removal.

Do not use t his product in enviroments which are outside the specification range,

otherwise operating problems or damage may occur. In addition, the operating life of the

product may become signifi cantly reduced.

Never disassemble, repair or m odify this product, otherwise operating problems or

accidents may occur.

Do not dispose of this product by burning it, otherwise it may explode or toxic fumes may

be generated.

This product generates ozone, so be sure to provide adequate ventilation if using it in a

confi ned space.

Do not run the wires together with high-voltage lines or power lines or put them in the

same raceway. This can cause malfunction due to induction.

Be sure to turn off the air and the power supply before carrying out any cable connection

or inspection work. If this is not done, operating problems, damage or electric shocks

may occur.

After connecting the cables, check that the connections are correct before turning on

the power. If the cables are connected incorrectly, operating problems or accidents may

occur.

Verify that the supply voltage variation is within the rating.

It takes approximately 2 seconds after the power is turned on before the fan operation

stabilizes. To ensure proper charge removal performance, do not use the product until

suffi cient time has elapsed.

Do not turn the power back on immediately after it has been turned off, otherwise operating

problems or accidents may o ccur. In addition, the operating life of t he product may become

signifi cantly reduced. Wait at least 2 seconds before turning the power back on again.

When using as a CSA and UL compliant product, use a CLASS 2 CSA/UL certified

power supply, or a CSA/UL certifi ed power supply that has been evaluated as a Limited

Power Source as specifi ed in CAN/CSA-C22.2NO.60950-1/UL60950-1.

Do not use any cables which have any damage (such as splitting or cracking), otherwise

operating problems or accidents may occur.

Avoid using the product in places where there are high levels of steam or dust in the air

or where it might be directly exposed to water, oil or welding spatter.

Avoid use at an elevation higher than 2000m, and outdoor use.

Do not touch the discharge needle with hard objects such as tools. If the discharge

needle becomes broken, it will not provide suffi cient charge removal performance, and

moreover operating problems or accidents may occur.

Avoid using the product while the fi lter is blocked, otherwise accidents or problems with

operation may occur.

Clean and replace the fi lter at periodic intervals.

Always be sure to turn off the power before replacing the fi lter.

Secure the main unit properly when setting up. If the main unit is not correctly secured

or if it is subjected to intermittent vibrations or impacts, accidents or problems with

operation may occur.

Do not place any objects which may obstruct air fl ow within 20 mm the front of the fan air

intake, otherwise accidents or problems with operation may occur.

Use cables with a cross-section of 0.15 mm2 or more and a length of less than

30 m. Furthermore, keep the cables as short as possible to avoid the possibility of interference.

If this product ceases functioning or is no longer required, dispose of it according to

appropriate local waste disposal regulations.

11

This product complies with CSA and UL standards, and has been certifi ed by TUV SUD.

http://panasonic.net/id/pidsx/global

Overseas Sales Division (Head Offi ce)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

About our sale network, please visit our website.

PRINTED IN JAPAN© Panasonic Industrial Devices SUNX Co., Ltd. 2016

l2

with fi lter not installed.

2) Discharge check: Drop in discharging status detected.

Discharge error: Abnormal discharge detected.

Fan error: Fan operating problem detected.

3) Do not use or store the device in an environment where the air pressure is higher than the

atmospheric pressure at an altitude of 0 meters.

CAUTIONS

CSA/UL compliant product

NPN transistor/open collector

• Max. sink current: 50 mA

Applied voltage: 30 V DC or less (between output terminal and 0 V)

•

• Residual voltage: 1 V or less (at input current of 50 mA)

Check: On when discharge check (Note 2) detected

Off at all other times

Error: Off when discharge error or fan error (Note 2) detected

On at all other times

Red LED (Lights up during discharge checking and when

discharge error (Note 1) detected, blinks when fan error (Note 1)

detected)

0 to + 50°C (No dew condensation) / Storage temperature: -10 to + 65°C

35 to 65% RH (No dew condensation) / Storage temperature: 35 to 65% RH

10 to 150 Hz frequency, 0.75 mm amplitude in X, Y and Z

directions for two hours each

Wiring connector: 1 set

[Manufactured by MOLEX: Housing (5557-08P), Terminal (5556T)

3

/min

]

Loading...

Loading...