Omron E5 R DATASHEET

s

y

ge

n

d

s

t

Refer to the E5 R datasheet (H122) for more information.

3

C

p

e

Co

od

g

d

C

d

s

,

D

g

s

)

)

.

:

Digital Controller for Control Applications

A

ph

r

R

96

m

(

)

R

m

(

)

C

01

:

.

n

y

n

,

n

9

s

OMRO

.

p

s

8

OMRO

C

3

.

8

OMRO

.

,

e

E

g

g

g

a

8

)

r

s

p

g

o

ol

p

g

o

ol

o

ol

SP

o

ol

-

)

t

)

s

p

g

g

ol

t

t

)

)

)

t

)

t

)

p

s

p

g

g

ol

o

ol

S

p

o

ol

t

)

p

s

o

ol

o

ol

g

l

t

)

p

s

l

s

-

)

)

t

)

l

s

R

Requiring Rapid Response and High Resolution.

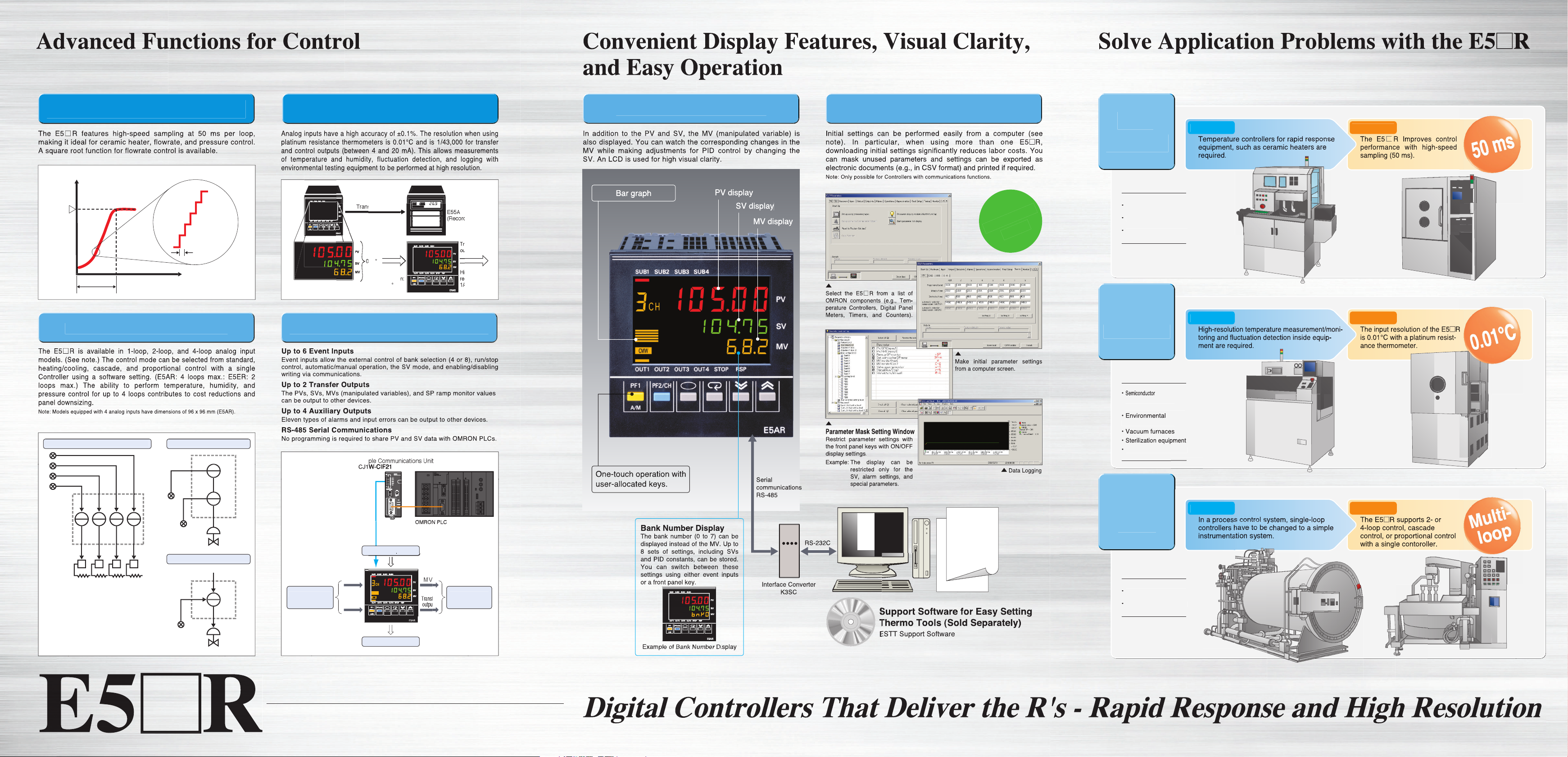

The E5 R samples at 50 ms per loop for use with high-speed

response equipment, such as ceramic heaters. Measurements,

fluctuation detection, and logging for environmental testing equipment

are performed at a high resolution of 0.01°C.

The R in E5 R represents the two areas where this Digital Controller

excels - Rapid response and high Resolution.

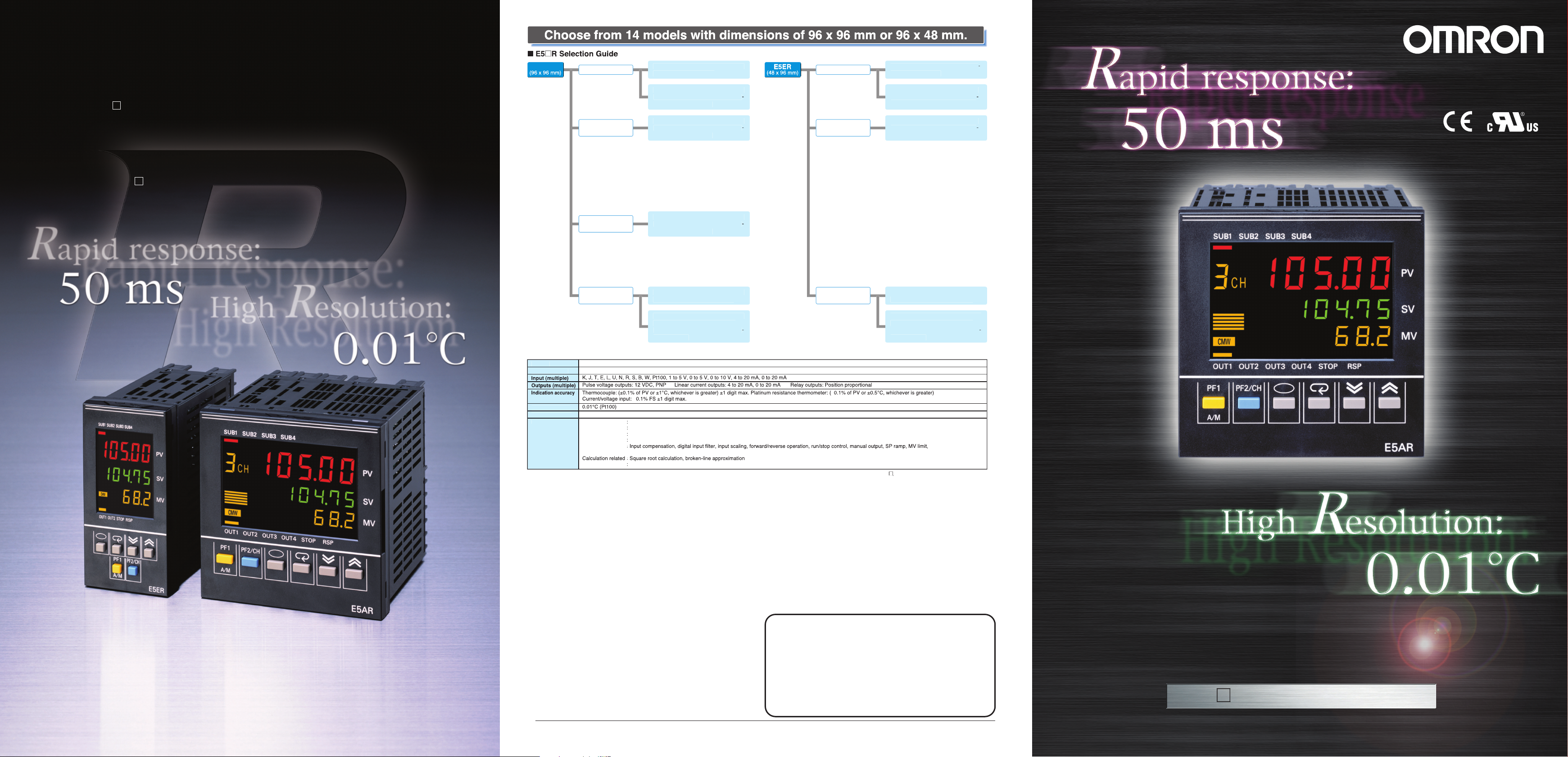

E5A

Basic model

1 loop for standard

control/1 loo

heatin

c

and cooling

ntr

for

-loo

model

2 loops for standard

control/2 loo

heatin

c

1 loop for cascade

c

1 loop for standard

control with remote

1 loop for proportional

c

and cooling

ntr

ntr

ntr

s for

4-loo

model

4 loops for standard

c

ntr

2 loops for standard

c

ntr

2 loops for heating and

contro

coolin

osition-proportiona

ntrol model

1 loop for position

roportional control

4 alarm outputs, 2 event inputs, 2

outputs (control/transfer

4 alarm outputs, 6 event inputs,

RS-485 communications, 4 ou

uts (control/transfer

4 alarm outputs, 4 event inputs,

RS-485 communications, 4 ou

uts (control/transfer

4 alarm outputs, 4 event inputs,

RS-485 communications, 4 ou

uts (control/transfer

4 alarm ouputs, 4 event inputs,

2 relay ouputs (open, closed

4 alarm outputs, 4 event inputs,

2 relay outputs (open, closed

RS-485 communications, 1 ou

ut (transfer

Basic model

1 loop for standard

control/1 loo

heatin

contr

for

and coolin

2-loo

model

2 loops for standard

control/1 loo

heatin

contr

1 loop for cascade

c

1 loop for standard

control with remote

1 loo

c

and coolin

ntr

for proportional

ntr

for

osition-proportiona

ntrol model

1 loop for position

roportional control

4 alarm outputs, 2 event inputs, 2 ou

uts (control/transfer)

4 alarm outputs, 2 event inputs,

RS-485 communications, 4 ou

uts (control/transfer

4 alarm outputs, 4 event inputs,

RS-485 communications, 2 ou

uts (control/transfer

P

4 alarm outputs, 4 event inputs,

relay outputs (open, closed

4 alarm outputs, no event input,

relay outputs (open, closed

RS-485 communications, 1 ou

ut (transfer

E5E

48 x 96 x 95m

W x H x D

dvanced & So

Specification

Displa

Supply volta

Input resolutio

Sampling perio

Function

7-segment LCD with backligh

100 to 240 VAC, 24 VAC/VD

50 ms per loo

Control typ

ntrol meth

Tunin

Setting relate

ontrol relate

Communication

Standard, heating/cooling, position proportional

ON/OFF

Autotunin

SV limits, parameter protection, 8 bank

MV rate-of-change limit, MV when stopped, MV for error, SV tracking, special control (cascade, proportional

RS-485 (CompoWay/F or MODBUS

Display colors: Red, green, and orangeNumber of digits per display line: 5Number of display lines:

1 digit max

2-PI

OMRON Corporatio

Industrial Automation Compan

Measuring and Control Divisio

Shiokoji Horikawa, Shimogyo-ku

Kyoto, 600-8530 Japa

Tel: (81)75-344-7080/Fax: (81)75-344-718

Regional Headquarter

N EUROPE B.V

Wegalaan 67-69, NL-2132 JD Hoofddor

The Netherland

Tel: (31)2356-81-300/Fax: (31)2356-81-38

N ELECTRONICS LL

E5A

x 96 x 95m

W x H x D

isticated Digital Controlle

1 East Commerce Drive, Schaumburg, IL 6017

U.S.A

Tel: (1)847-843-7900/Fax: (1)847-843-856

N ASIA PACIFIC PTE. LTD

83 Clemenceau Avenue,

#11-01, UE Square

239920 Singapor

Tel: (65)6835-3011/Fax: (65)6835-2711

OMRON CHINA CO., LTD. BEIJING OFFIC

Room 1028, Office Building,

Capital Times Square,

Beijin

No. 88 West Chan

, 100031 Chin

Beijin

Tel: (86)10-8391-3005/Fax: (86)10-8391-368

'an Road,

at. No. H121-E1-

Authorized Distributor

Note: Specifications subject to change without notice

Advanced Digital Controlle

Rapid Response & High Resolution

rinted in Japan

403-1.5M (0403) (O

High-speed Samplin

g

s

s

g

s

e

.

t

t

01

t

)

0

01

r

s

3

3

g

g

r

y

R

R

R

R

g

SP

)

y.

A

s

)

r

s

)

)

eso

on

-

p

s

t

t

t

s

t

t

s

g)

t

t

on

on

on

s

e

s

Easy Initial

Setu

p

Stable control in high-speed response applications.

at 50 m

Resolution of 0.01°C with

latinum Resistance Thermometer

LCD with 3 Lines of 5 Digit

Easy Setting with

Thermo Tools Support Softwar

Rapid

Response

Application

roblem

luti

High-speed

samplin

50 m

Tim

High-speed response:

Only a few seconds are required to reach the set value

4 Loops in a Single Controlle

Control 4 Loops with a Single ControllerCascade Control with a Sin

E5A

E5E

le Controller

fer outpu

er

Analog

inpu

.

High

resolutio

.

nsfer/control

tpu

h

olution:

3,00

A Variety of I/O to Control with PLC

Sim

Bonding equipmen

Evaporation equipmen

Coil winding equipmen

igh

R

luti

Application

manufacturing equipment

(exposure and air conditionin

testing equipmen

Food processing equipmen

roblem

luti

E5AR onl

PV

V

V

Proportional Control with a Sin

roportional settin

E5A

E5E

le Controlle

ultipoint analog input

(4 inputs: IN1 to IN4

RS-485

(CompoWay/F

V and SV data

can be shared easil

R

CS/CJ Series, CQM1, or CPM2

Auxiliary output (alarms, etc.

Multipoint analog output

e

(4 outputs: OUT1 to OUT 4

arameter

Multi

loo

Application

Sterilization equipmen

Food processing equipmen

roblem

luti

Loading...

Loading...