Page 1

CNC SYSTEM

OSP-P200M

OSP-P20M

SPECIAL FUNCTION FOR MB-V/MD-V/MU-V SERIES

INSTRUCTION MANUAL

(2nd Edition)

Pub No. 5309-E-R1 (ME61-048-R2) Feb. 2007

Page 2

5309-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from

hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety

devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Installation

(1) Please be noted about a primary power supply as follows.

• Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this

could cause malfunction of the CNC unit.

• If possible, connect the machine to a ground not used by any other equipment. If there is

no choice but to use a common ground, the other equipment must not generate a large

amount of noise (such as an electric welder or electric discharge machine).

(2) Installation Environment

Observe the following points when installing the control enclosure.

• Make sure that the CNC unit will not be subject to direct sunlight.

• Make sure that the control enclosure will not be splashed with chips, water, or oil.

• Make sure that the control enclosure and operation panel are not subject to excessive

vibrations or shock.

• The permissible ambient temperature range for the control enclosure is 5 to 40°C.

• The permissible ambient humidity range for the control enclosure is relative humidity 50%

or less at 40°C (no condensation).

• The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2. Points to Check before Turning on the Power

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

Page 3

3. Precautions Relating to Operation

(1) After turning on the power, carry out inspection and adjustment in accordance with the daily

inspection procedure described in this instruction manual.

(2) Use tools whose dimensions and type are appropriate for the work undertaken and the machine

specifications. Do not use badly worn tools since they can cause accidents.

(3) Do not, for any reason, touch the spindle or tool while spindle indexing is in progress since the

spindle could rotate: this is dangerous.

(4) Check that the workpiece and tool are properly secured.

(5) Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6) Do not remove chips by hand while machining is in progress since this is dangerous. Always

stop the machine first, then remove the chips with a brush or broom.

(7) Do not operate the machine with any of the safety devices removed. Do not operate the

machine with any of the covers removed unless it is necessary to do so.

(8) Always stop the machine before mounting or removing a tool.

5309-E P-(ii)

SAFETY PRECAUTIONS

(9) Do not approach or touch any moving part of the machine while it is operating.

(10) Do not touch any switch or button with wet hands. This is extremely dangerous.

(11) Before using any switch or button on the operation panel, check that it is the one intended.

4. Precautions Relating to the ATC

(1) The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that

a tool could be released and fall in the event of an unforeseen accident, exposing you to

danger: do not touch or approach the ATC mechanism during ATC operation.

(2) Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3) Remove chips adhering to the magazine at appropriate intervals since they can cause

misoperation. Do not use compressed air to remove these chips since it will only push the chips

further in.

(4) If the ATC stops during operation for some reason and it has to be inspected without turning the

power off, do not touch the ATC since it may start moving suddenly.

5. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

Page 4

5309-E P-(iii)

SAFETY PRECAUTIONS

6. Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the

following points when performing maintenance inspections or during checking when trouble has

occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were

and secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

a. Switch the main power disconnect switch OFF before opening the control enclosure door.

b. Even when the main power disconnect switch is OFF, there may some residual charge in

the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted

to perform any work on this unit. Even then, they must observe the following precautions.

• MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c. The control enclosure contains the NC unit, and the NC unit has a printed circuit board

whose memory stores the machining programs, parameters, etc. In order to ensure that the

contents of this memory will be retained even when the power is switched off, the memory

is supplied with power by a battery. Depending on how the printed circuit boards are

handled, the contents of the memory may be destroyed and for this reason only service

personnel should handle these boards.

Page 5

(11) Periodic Inspection of the Control Enclosure

a. Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive

temperature rise inside the control enclosure and increase the reliability of the NC unit.

Inspect the following points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7. General Precautions

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine

operators must wear safety equipment such as safety shoes and goggles.

5309-E P-(iv)

SAFETY PRECAUTIONS

(4) Machine operators must read the instruction manual carefully and make sure of the correct

procedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

Page 6

8. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of

particular importance. Read the instructions marked with these symbols carefully and follow them.

DANGER

indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

5309-E P-(v)

SAFETY PRECAUTIONS

indicates a potentially hazardous situation which, if not avoided, may result in damage to your

property.

SAFETY INSTRUCTIONS

indicates general instructions for safe operation.

Page 7

5309-E P-(i)

INTRODUCTION

INTRODUCTION

Thank you very much for choosing our CNC system. This numerical control system is an expandable CNC

with various features. Major features of the CNC system are described below.

(1) NC operation panels

The following types of NC operation panels are offered to improve the user-friendliness.

• Color CRT operation panels

• Thin color operation panels (horizontal)

• Thin color operation panels (vertical)

One or more of the above types may not be used for some models.

(2) Machining management functions

These functions contribute to the efficient operation of the CNC system and improve the profitability from

small quantity production of multiple items and variable quantity production of variations. Major control

functions are described below.

a. Reduction of setup time

With increase in small-volume production, machining data setting is more frequently needed. The

simplified file operation facilitates such troublesome operation. The documents necessary for setup,

such as work instructions, are displayed on the CNC system to eliminate the necessity of controlling

drawings and further reduce the setup time.

b. Production Status Monitor

The progress and operation status can be checked on a real-time basis on the screen of the CNC

system.

c. Reduction of troubleshooting time

Correct information is quickly available for troubleshooting.

(3) Help functions

When an alarm is raised, press the help key to view the content of the alarm.

This helps take quick action against the alarm.

To operate the CNC system to its maximum performance, thoroughly read and understand this instruction

manual before use.

Keep this instruction manual at hand so that it will be available when you need a help.

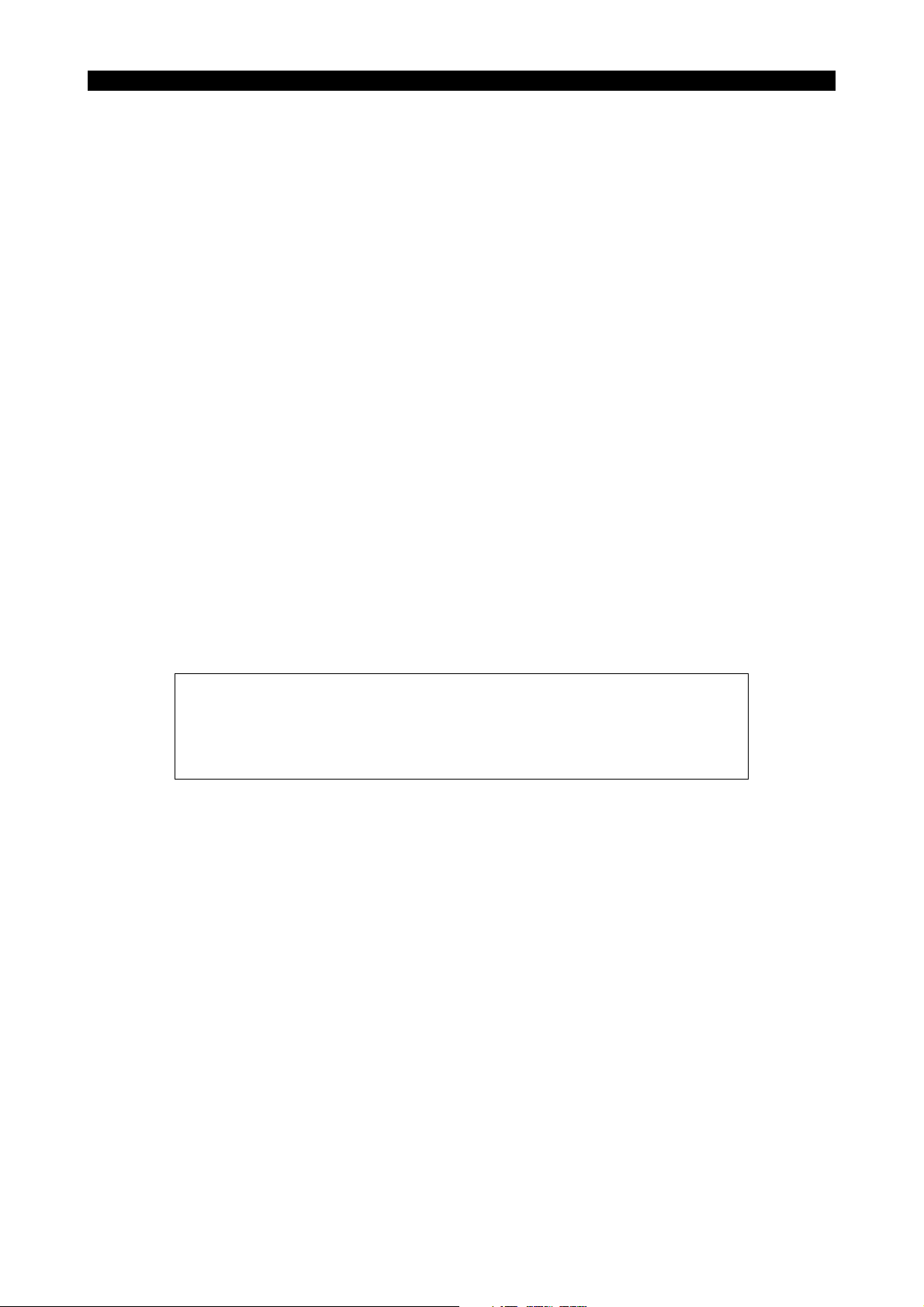

Screens

Different screens are used for different models. Therefore, the

screens used on your CNC system may differ from those shown

in this manual.

Page 8

CONTENTS

SECTION 1 ROBOT/LOADER INTERFACE TYPES

SECTION 2 Chuck (Jig) Control

SECTION 3 Work Sit Confirmation

SECTION 4 OPERATION DOOR AUTO OPEN/CLOSE SPEC

SECTION 5 STACKER CRANE INTERFACE

SECTION 6 DNC-C STACKER CRANE I/F FOR ETHERNET

5309-E P-(i)

CONTENTS

SECTION 7 SEMI-DRY COOLANT UNIT

This instruction manual consists of several specifications for peripheral devices

and systems including those not selected by some users.

For details of each specification, refer to the corresponding materials such as the

final specification.

Page 9

5309-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 ROBOT/LOADER INTERFACE TYPES...................................................1

1. Robot/loader Interface Types ..................................................................................................1

2. Automatic Mode....................................................................................................................... 1

3. NC Operation Interlock ............................................................................................................ 1

4. List of Input and Output Signals............................................................................................... 3

4-1. Inputs from the Robot/loader to the NC ............................................................................ 3

4-2. Outputs from the NC to the Robot/loader ......................................................................... 4

5. Description of Signals.............................................................................................................. 5

5-1. Robot/loader Interface Type B.......................................................................................... 5

5-2. Robot/loader Interface Type C ....................................................................................... 12

6. Interlock ................................................................................................................................. 20

6-1. Axis Interlock .................................................................................................................. 20

6-2. APC Interlock.................................................................................................................. 20

7. Work Condition Display Function........................................................................................... 21

8. Parameters ............................................................................................................................ 22

9. Automatic Power Shutdown................................................................................................... 23

9-1. Effective Conditions........................................................................................................23

9-2. Description of the Function............................................................................................. 24

9-3. Parameters ..................................................................................................................... 25

10.Input/Output Bit ...................................................................................................................... 26

SECTION 2 CHUCK (JIG) CONTROL.......................................................................30

1. No. 1 Chuck (Jig)................................................................................................................... 30

1-1. Clamping Modes............................................................................................................. 30

1-2. Chuck clamp/unclamp commands.................................................................................. 30

1-3. Chuck clamp/unclamp sequences.................................................................................. 33

1-4. "Chuck Open/Closed" limit switches............................................................................... 34

1-5. Work clamp/unclamp timers ........................................................................................... 35

1-6. Timing chart.................................................................................................................... 36

1-7. Interlocking ..................................................................................................................... 37

1-8. Special conditions........................................................................................................... 38

1-9. Status indicators ............................................................................................................. 38

2. Chuck (jig) pressure switching............................................................................................... 39

2-1. No. 1 chuck (jig).............................................................................................................. 39

3. Chuck air blow control ........................................................................................................... 45

3-1. Chuck air blow commands ............................................................................................. 45

3-2. Special cases ................................................................................................................. 45

4. Input/output signals................................................................................................................ 46

Page 10

5309-E P-(ii)

TABLE OF CONTENTS

SECTION 3 WORK SIT CONFIRMATION.................................................................47

1. Work Sit Condition Monitor....................................................................................................47

1-1. M Codes ......................................................................................................................... 47

1-2. Entering the sit condition monitoring mode .................................................................... 47

1-3. Continuous monitoring in work sit condition monitoring mode ....................................... 48

1-4. Exiting the sit condition monitoring mode ....................................................................... 49

1-5. Linking the seating air blow ............................................................................................ 50

1-6. Protection against air outlet clogging matter .................................................................. 50

1-7. Sit condition confirmation timer ...................................................................................... 51

1-8. Robot/loader interface .................................................................................................... 51

1-9. Seating Error LED .......................................................................................................... 52

1-10.Seating Alarm Reset button........................................................................................... 52

1-11.Normally Seated LED .................................................................................................... 52

2. Input/output signals................................................................................................................ 53

SECTION 4 OPERATION DOOR AUTO OPEN/CLOSE SPEC ................................54

1. Automatic Operation Door Functions..................................................................................... 54

1-1. Contents of Functions..................................................................................................... 54

1-2. Timing chart.................................................................................................................... 57

1-3. Door status monitoring ................................................................................................... 58

1-4. Notes .............................................................................................................................. 58

2. Operation door closing operation with both hands ................................................................ 59

2-1. Linking the dual-palm starting and operation door closing sequences........................... 59

2-2. Operation door closing operation with both hands ......................................................... 62

2-3. Ineffective M code commands........................................................................................ 63

3. Prevention of entanglement by automatic operation door ..................................................... 63

3-1. Content of sequence ...................................................................................................... 63

4. Input/output signals................................................................................................................ 64

SECTION 5 STACKER CRANE INTERFACE............................................................65

1. Link Mode .............................................................................................................................. 65

2. Description of Input/output Signals ........................................................................................ 65

2-1. Input/output Signals List ................................................................................................. 65

2-2. Detailed Description of Input/output Signals................................................................... 67

3. Pallet Loading/unloading Time Chart..................................................................................... 75

4. M334 (Work Ready) Command............................................................................................. 75

5. NC Operation Interlock .......................................................................................................... 76

6. M Command for Requesting Unloading of Pallet................................................................... 76

7. Specification for Work State Display...................................................................................... 77

8. Optional Input/output Bit Table .............................................................................................. 78

Page 11

5309-E P-(iii)

TABLE OF CONTENTS

SECTION 6 DNC-C STACKER CRANE I/F FOR ETHERNET ..................................79

1. Link Mode .............................................................................................................................. 79

2. Description of Input/output Signals ........................................................................................ 80

2-1. Input/output Signal List ................................................................................................... 80

2-2. Input/output Signal List ................................................................................................... 81

3. NC Operation Interlock .......................................................................................................... 85

4. Optional Input/output Bit Table .............................................................................................. 85

SECTION 7 SEMI-DRY COOLANT UNIT..................................................................86

1. Semi-Dry Coolant .................................................................................................................. 86

1-1. Related Commands........................................................................................................ 86

1-2. M Code Command and RT Command in the Same Block ............................................. 86

1-3. Manual Operation ........................................................................................................... 88

1-4. Temporary Stop of All Coolants...................................................................................... 88

1-5. Linkage with Chip Conveyor ........................................................................................... 89

1-6. Semi-Dry Unit Low Level Alarm...................................................................................... 89

Page 12

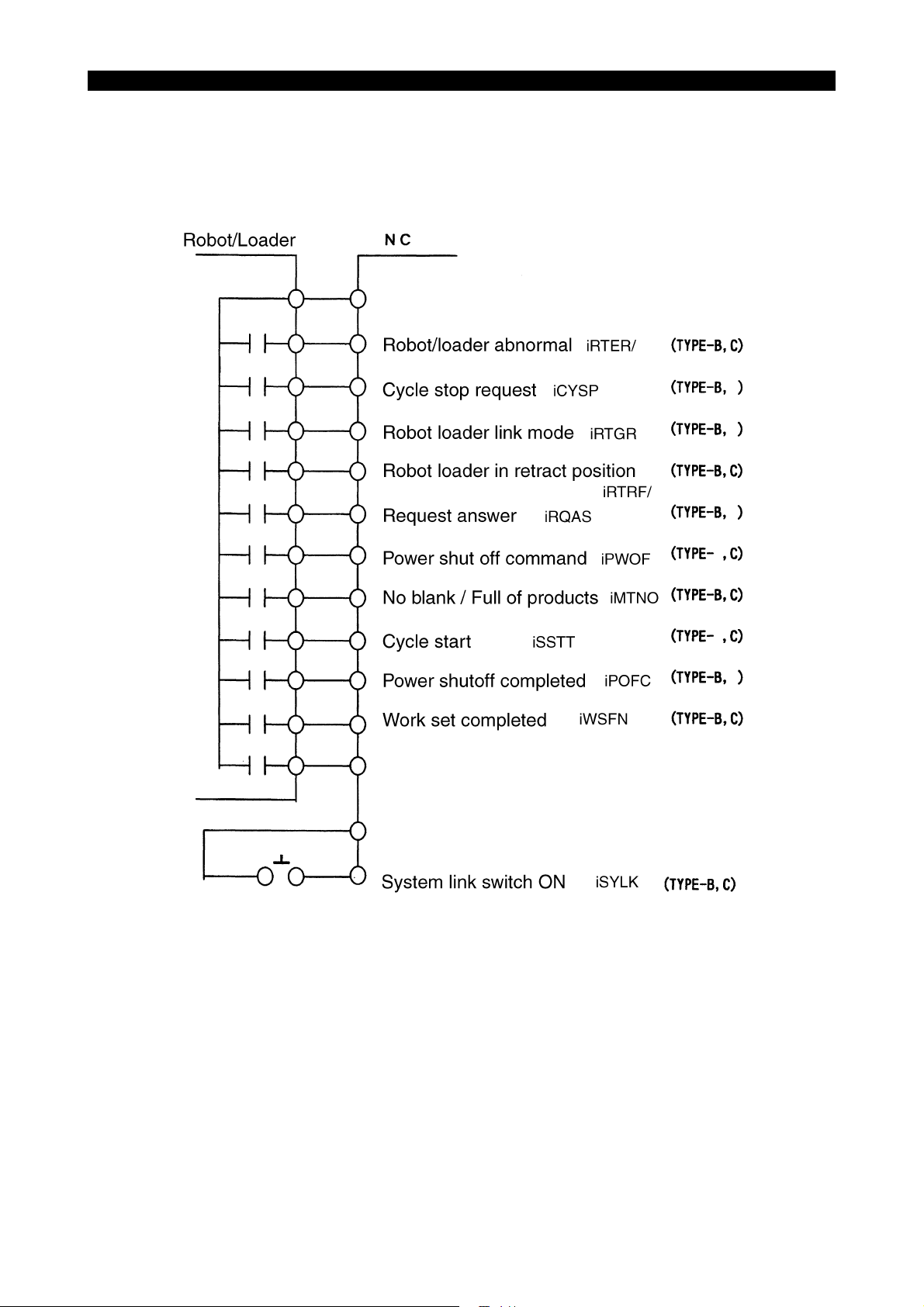

SECTION 1 ROBOT/LOADER INTERFACE TYPES

SECTION 1 ROBOT/LOADER INTERFACE TYPES

1. Robot/loader Interface Types

(1) Robot/loader interface type B

This is an NC-mastered system that controls the robot/loader operations according to commands from the NC.

(2) Robot/loader interface type C

This is a robot/loader-mastered system that controls the NC according to commands from the

robot/loader.

(3) Robot/loader interface type D

The robot/loader interface type D is designed to enable switching between the type B and the

type C.

MC user parameter No. 21 Robot/loader interface type

1 Selects the robot/loader interface type B.

0 .... Robot/loader interface type C

1 .... Robot/loader interface type B

5309-E P-1

2. Automatic Mode

"NC automatic mode" output is turned ON while the "system link switch" is kept ON in automatic

operation mode. The mode when "NC automatic mode" is ON is called "automatic mode.

3. NC Operation Interlock

When the robot/loader interface type C is selected, the operations listed below, which impede the

robot sequence, will be disabled when the "system link switch" is turned ON.

This function is not provided with the robot/loader interface type B.

(1) When the robot/loader interface type C is selected, the following operations will be disabled

when the "system link switch" is turned ON:

• Program selection

• Schedule program selection

• Pointer movements by moving the cursor on the program screen

• Sequence stop

• Program number search

• Schedule program number search

• Return search

• New schedule program registration

Page 13

5309-E P-2

SECTION 1 ROBOT/LOADER INTERFACE TYPES

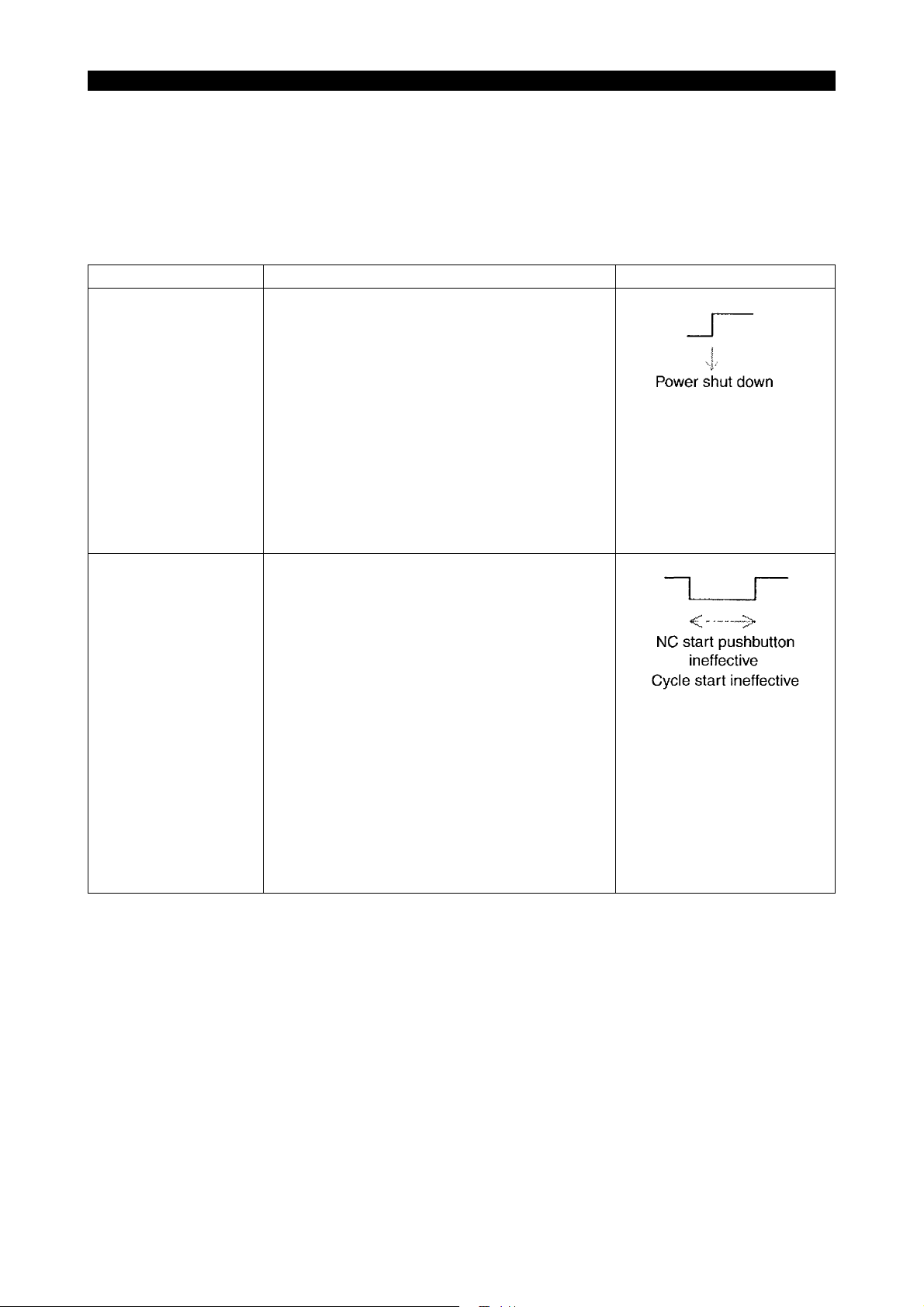

(2) NC start pushbutton invalid

When the robot/loader interface type C is selected, the start pushbutton is invalid with the "system link mode" ON except for restarting after stops by single block ON, program stop or slide

hold.

The following alarm will be displayed when the NC start pushbutton on the panel is pressed

although it is ineffective:

"4720 Alarm D NC start pushbutton ineffective 11"

Page 14

SECTION 1 ROBOT/LOADER INTERFACE TYPES

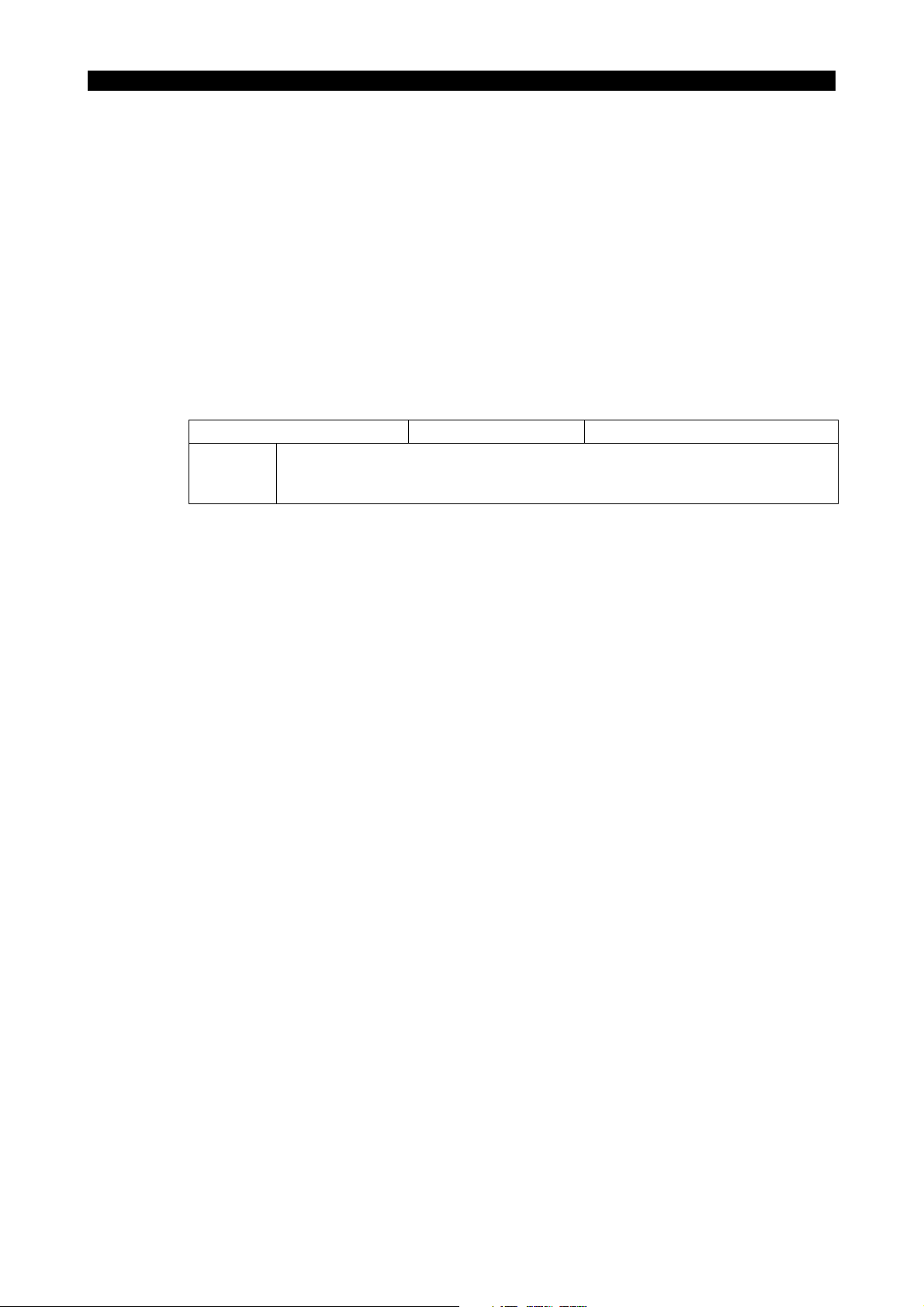

4. List of Input and Output Signals

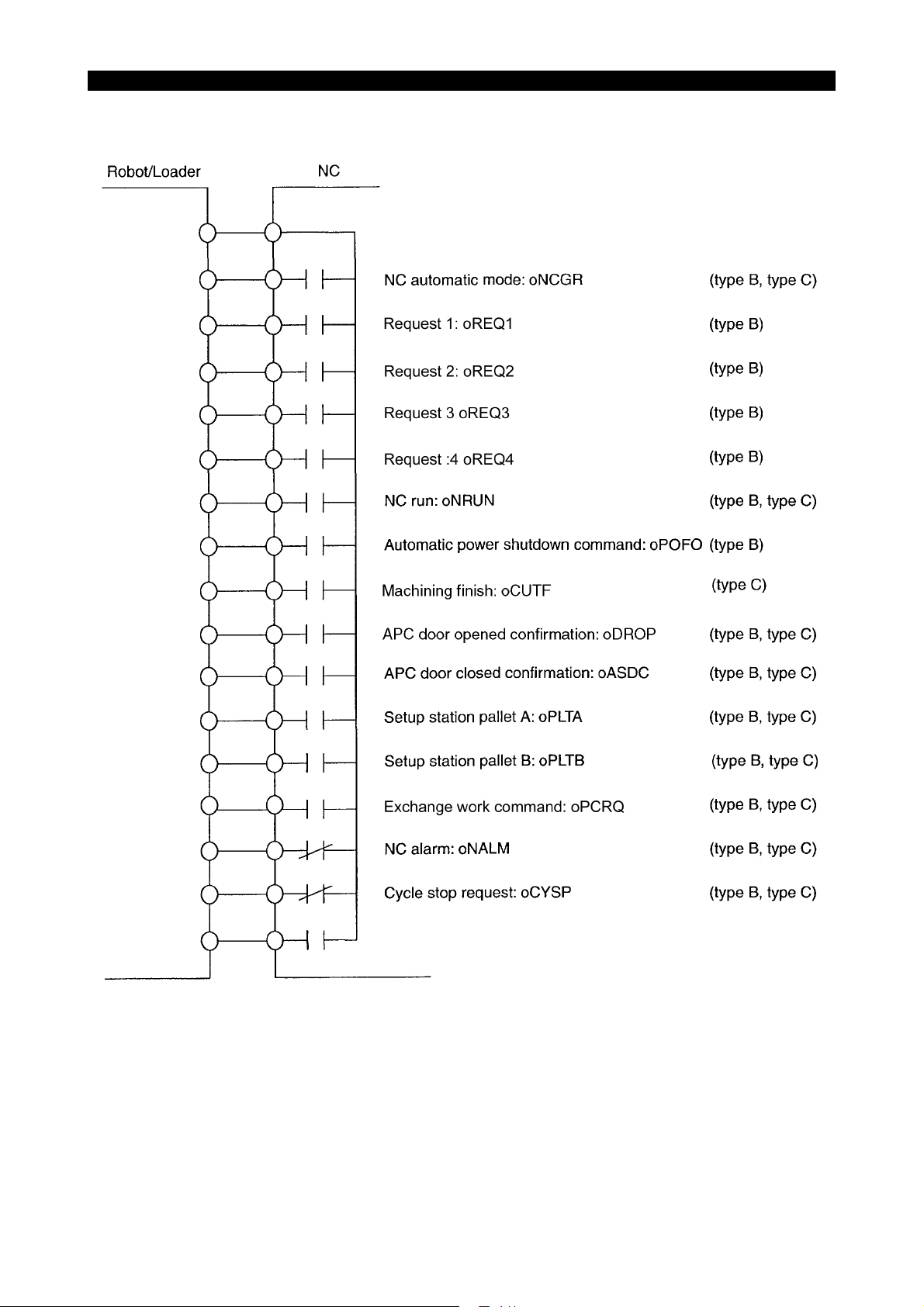

4-1. Inputs from the Robot/loader to the NC

5309-E P-3

ME61048R0200300040001

Page 15

SECTION 1 ROBOT/LOADER INTERFACE TYPES

4-2. Outputs from the NC to the Robot/loader

5309-E P-4

ME61048R0200300050001

Page 16

SECTION 1 ROBOT/LOADER INTERFACE TYPES

5. Description of Signals

5-1. Robot/loader Interface Type B

5-1-1. Inputs from the Robot/loader to the NC (Type B)

Signal name Description Signal level

Robot/loader abnormal

(iRTER/)

Robot/loader at retract

position

(iRTRF/)

Either of the following alarms occurs when the

"system link switch" is turned ON and this signal is

turned OFF.

The alarm level is changeable with the appropriate parameter.

"8. Robot alarm is made alarm-C." of MC user

parameter ROBOT/LOADER I/F

"0": "1709 Alarm A external"

"1": "3718 Alarm C external"

However, this signal will not be monitored during

warm-up program start wait or during NC operation by warm-up program start.

The NC start pushbutton on the panel and the

"cycle start" command become ineffective when

the "system link switch" is turned ON and this signal is turned OFF.

5309-E P-5

The following alarm occurs when the NC start

pushbutton on the panel is pressed or the "cycle

start" signal is turned ON although NC start is ineffective.

The alarm remains displayed while the NC start

pushbutton on the panel is held down or the "cycle

start" signal is kept ON.

"4720 Alarm DNC start ineffective 12"

However, the above interlock becomes ineffective

when "2. Cycle start: STANDBY POS. I/L is made

ineffective" of MC user parameter ROBOT/

LOADER I/F is set to "1."

Page 17

SECTION 1 ROBOT/LOADER INTERFACE TYPES

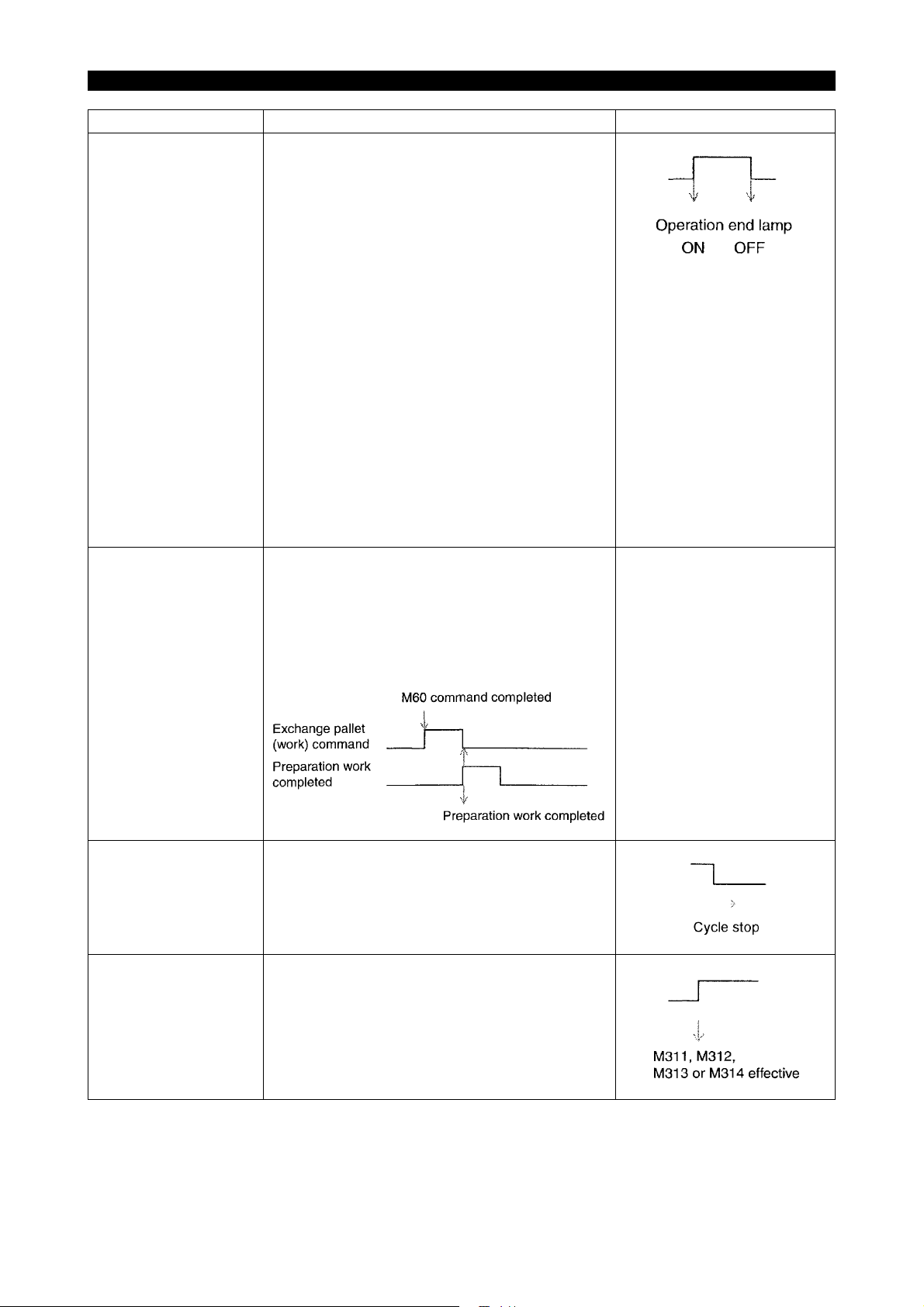

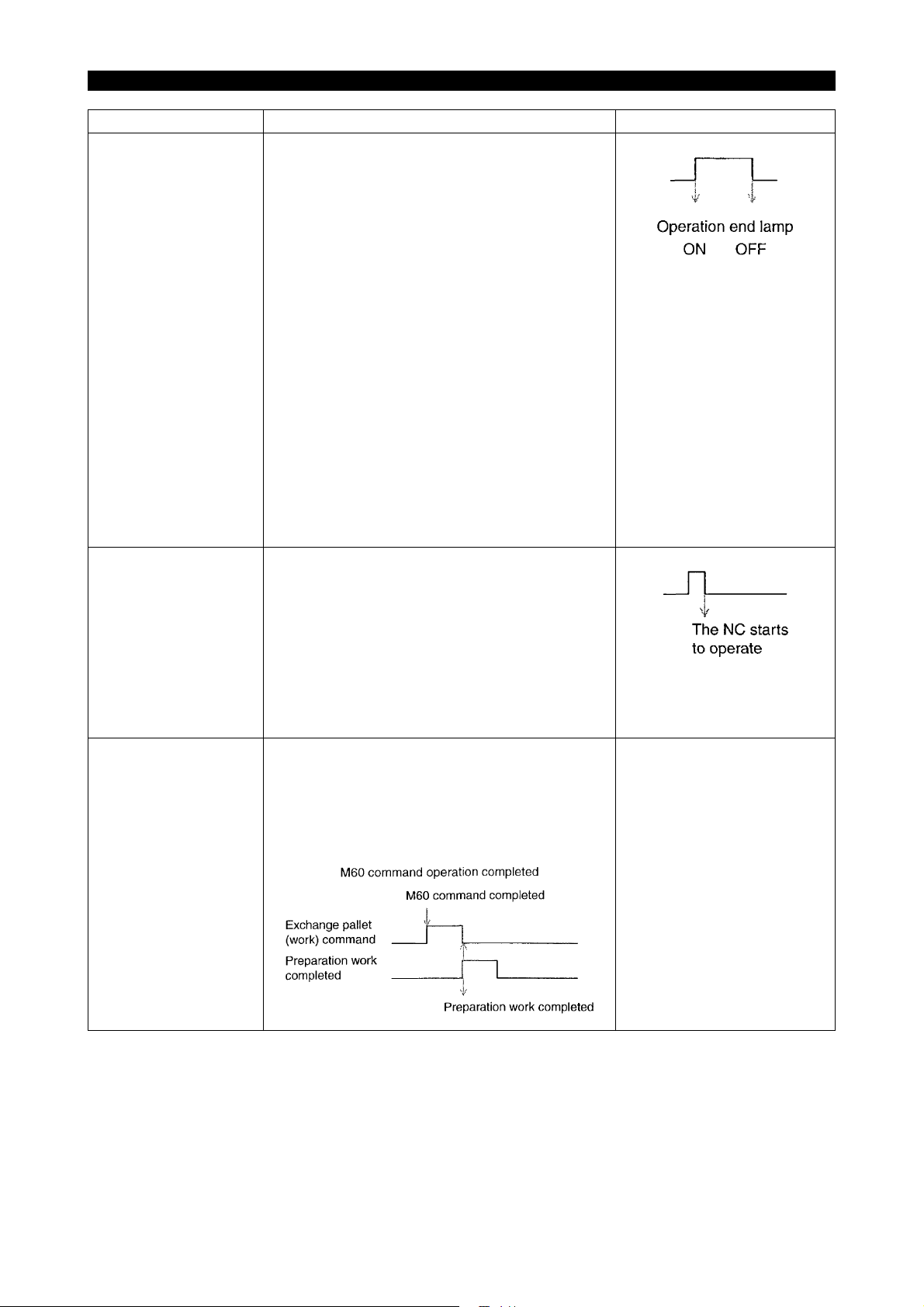

Signal name Description Signal level

No material/full-work

(iMTNO)

Preparation work completed

(iWSFN)

The operation end lamp lights while the "system

link switch" is kept ON, the operation end lamp is

effective (described below), and this signal is kept

ON.

MC user parameter

"0" is set at INDICATING LAMP (8. Operation end

lamp is made effect):

Operation end lamp is ineffective.

"1" is set at INDICATING LAMP (8. Operation end

lamp is made effect):

Operation end lamp is effective.

"5. Operation end lamp does not light on by M02/

M30" MC user parameter of ROBOT/LOADER I/F

"0":

The standard operation end lamp function also

becomes effective.

"1":

The standard operation end lamp function

becomes ineffective when the "system link switch"

is turned ON.

The "exchange pallet (work) command" is turned

OFF and work preparation is completed when this

signal is turned ON.

Note: The work preparation completed status will

be retained even if the NC is reset or the power is

turned ON or OFF.

[Time chart]

See the left figure.

5309-E P-6

Cycle stop request

(iCYSP)

Robot automatic mode

(iRTGR)

The NC stops the ongoing cycle when this signal

is turned OFF in "automatic mode."

Request 1, 2, 3 or 4 becomes effective when this

signal is turned ON in "automatic mode."

If M311, M312, M313 or M314 is issued when this

signal is OFF, nothing will take place, and an

answer will be given back immediately.

Page 18

SECTION 1 ROBOT/LOADER INTERFACE TYPES

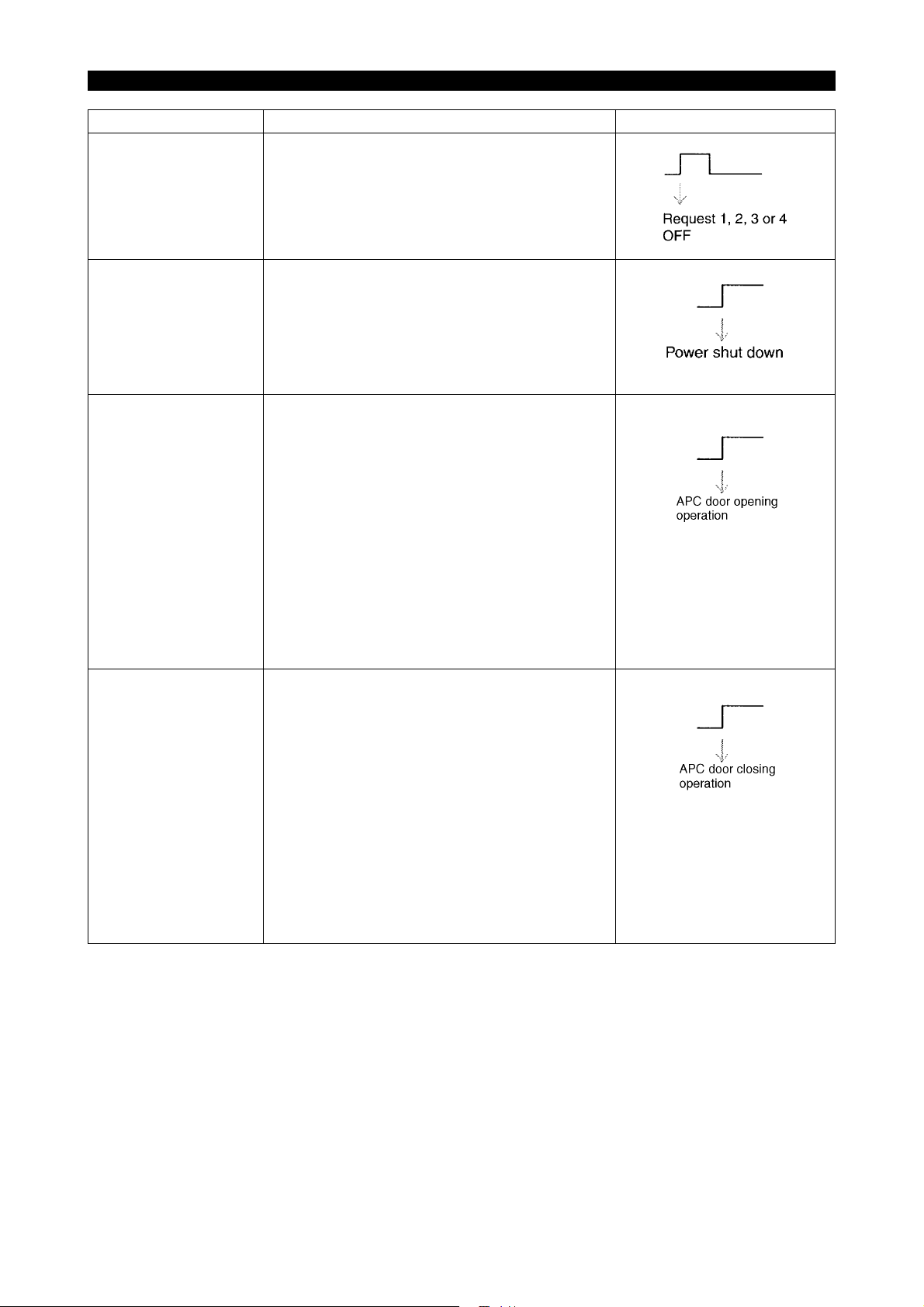

Signal name Description Signal level

Request answer

(iRQAS)

The request output signal (request 1, 2, 3 or 4) is

turned OFF when this signal is turned ON in

"automatic mode."

Turn OFF this signal when the request output signal is turned OFF.

5309-E P-7

Automatic power shutdown completed

(iPOFC)

APC door open command

(iDROC)

APC door close command

(iDRCS)

The power will be shut down automatically when

this signal is turned ON with the "automatic power

shutdown command" output to the robot/loader in

"automatic mode."

For further information, see "Automatic Power

Shutdown Function".

On the machine without APC, the operation door

opens with this signal ON. This signal, however,

becomes ineffective under the following conditions:

• No link mode is established.

• The signal "Robot/loader retract position

iRTRF" is OFF.

(The robot/loader interface is ineffective when

"1" is set at the parameter 4. "DOOR MOVE:

STANDBY POS. I/L IS MADE INEFFECTIVE"

in the MC USER PARAMETER, ROBOTLOADER I/F).

• The machine is equipped with APC.

On the machine without APC, the operation door

closes with this signal ON. This signal, however,

becomes ineffective under the following conditions:

• No link mode is established.

• The signal "Robot/loader retract position

iRTRF" is OFF.

(The robot/loader interface is ineffective when

"1" is set at the parameter 4. "DOOR MOVE:

STANDBY POS. I/L IS MADE INEFFECTIVE"

in the MC USER PARAMETER, ROBOTLOADER I/F).

• The machine is equipped with APC.

Page 19

SECTION 1 ROBOT/LOADER INTERFACE TYPES

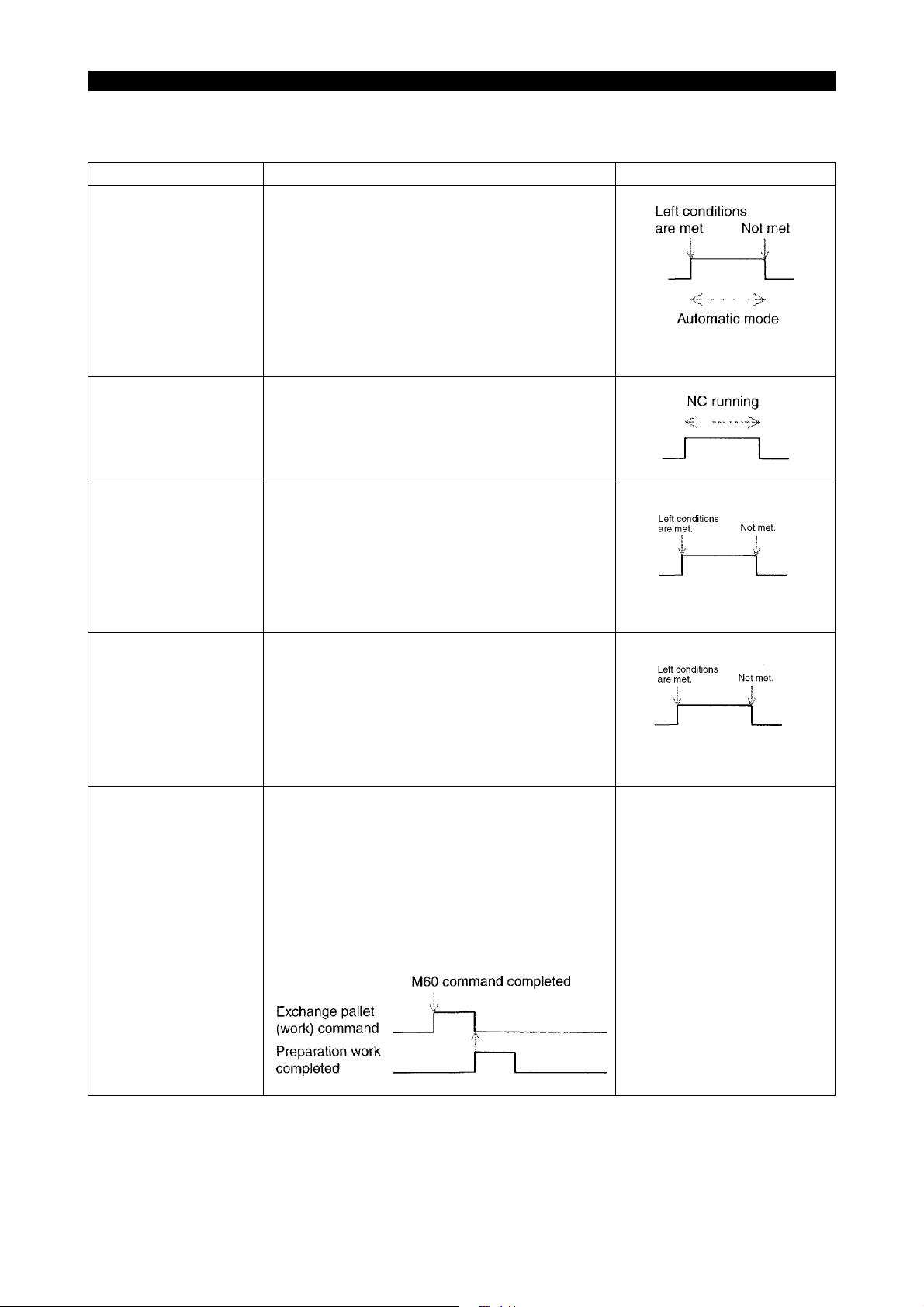

5-1-2. Outputs from the NC to the Robot/loader (Type B)

Signal name Description Signal level

NC automatic mode

(oNCGR)

NC run

(oNRUN)

This signal is turned ON when the following conditions are met:

• Automatic operation mode

• "System link switch" ON

However, this signal will not be turned ON during

warm-up program start wait or during NC operation by warm-up program start.

This signal remains ON during NC operation.

5309-E P-8

A-pallet is outside of

M/C

(oPLTA)

B-pallet is outside of

M/C

(oPLTB)

Exchange pallet (work)

command

(oPCRQ)

This signal comes ON when all the following conditions are met:

• Pallet B mode is ON.

• Pallet A mode is ON when "1" is set at "B pal-

let in M/C side, when APC Seq. No.1" of the

machine user parameter CHUCK, SIT CONFIRMATION, TAILSOTCK.

This signal comes ON when all the following conditions are met:

• Pallet A mode is ON.

• Pallet B mode is ON when "1" is set at "B pal-

let in M/C side, when APC Seq. No.1" of the

machine user parameter CHUCK, SIT CONFIRMATION, TAILSOTCK.

This signal is turned ON upon completion of the

M60 command operation in automatic mode.

This signal is turned OFF with the "preparation

work completed" signal turned ON.

This signal will be retained even if the NC is reset

or the power is turned ON or OFF.

APC sequence No.

APC sequence No.

See the time chart shown on

the left.

[Time chart]

Page 20

SECTION 1 ROBOT/LOADER INTERFACE TYPES

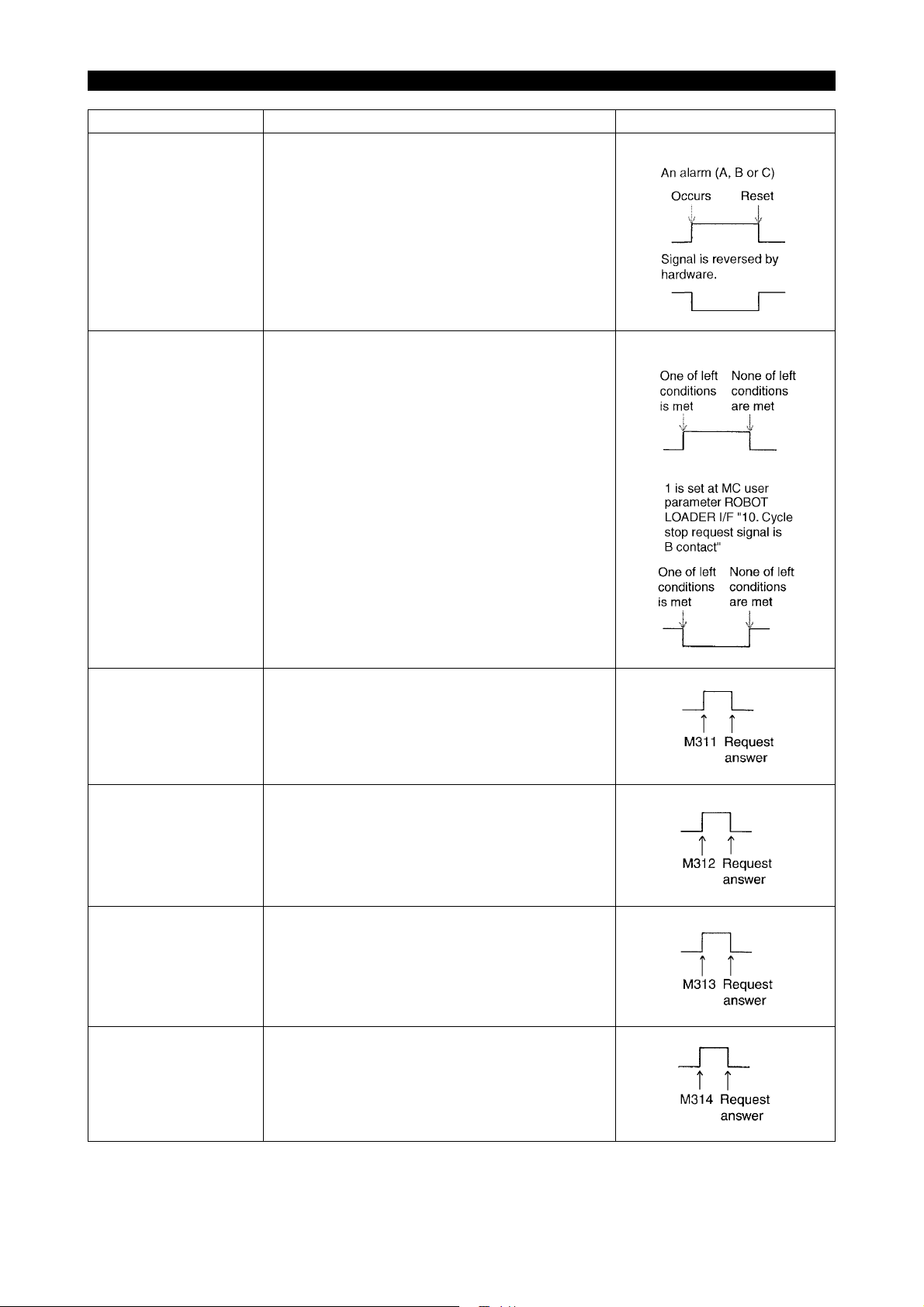

Signal name Description Signal level

NC alarm

(oNALM)

This signal is usually OFF, but will be turned ON

when an alarm (A, B or C) occurs. NC reset will

turned OFF the signal again.

The signal will be reversed into a B contact by

hardware.

An alarm (A, B or C)

5309-E P-9

Cycle stop request

(oCYSP)

Request 1

(M311)

oREQ1

Request 2

(M312)

oREQ2

This signal is turned ON in one of the following

cases. The signal is turned OFF in other cases:

• When the count of the NC work counter is full.

• When the tool can no longer serve.

• When the "no material/full-work" signal is

turned ON with the "system link switch"

turned ON.

Whenever "1" is set at the MC user parameter

ROBOT LOADER I/F "10. Cycle stop request signal is B contact", this signal is turned ON. However, it will be turned OFF in one of the above

cases. (B contact output)

This signal is turned ON with the M311 command

when the "robot automatic mode" signal is turned

ON in "automatic mode."

An answer will be given back with the request

answer signal turned ON, and this signal will be

turned OFF.

Same as request 1, except that the M command is

M312.

Request 3

(M313)

oREQ3

Request 4

(M314)

oREQ4

Same as request 1, except that the M command is

M313.

Same as request 1, except that the M command is

M314.

Page 21

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Signal name Description Signal level

Automatic power shutdown command

oPOFO

This signal is turned ON after the time set by “6.

Power shutdown time” of MC user parameter

POWER SAVE/SHUTDOWN passes away if all of

the following conditions are met when the automatic power shutdown effective parameter (“3.

‘Automatic Power Shutdown’ is made effective” of

MC user parameter POWER SAVE/SHUTDOWN)

or automatic power shutdown ON/OFF switch is

turned ON in "automatic mode":

• Single block OFF in automatic operation

mode

• During existence of the machining cycle com-

pleted signal or alarm A, B or C

When "Automatic power shutdown MC alone" (“9.

Automatic power shutdown MC alone” of MC user

parameter ROBOT LOADER I/F) is "1", this signal

will not be output, and the power to the machine

will be shut down.

5309-E P-10

For further information, see "SECTION 7 WORK

SET ST AUTO DOOR SPEC."

Page 22

SECTION 1 ROBOT/LOADER INTERFACE TYPES

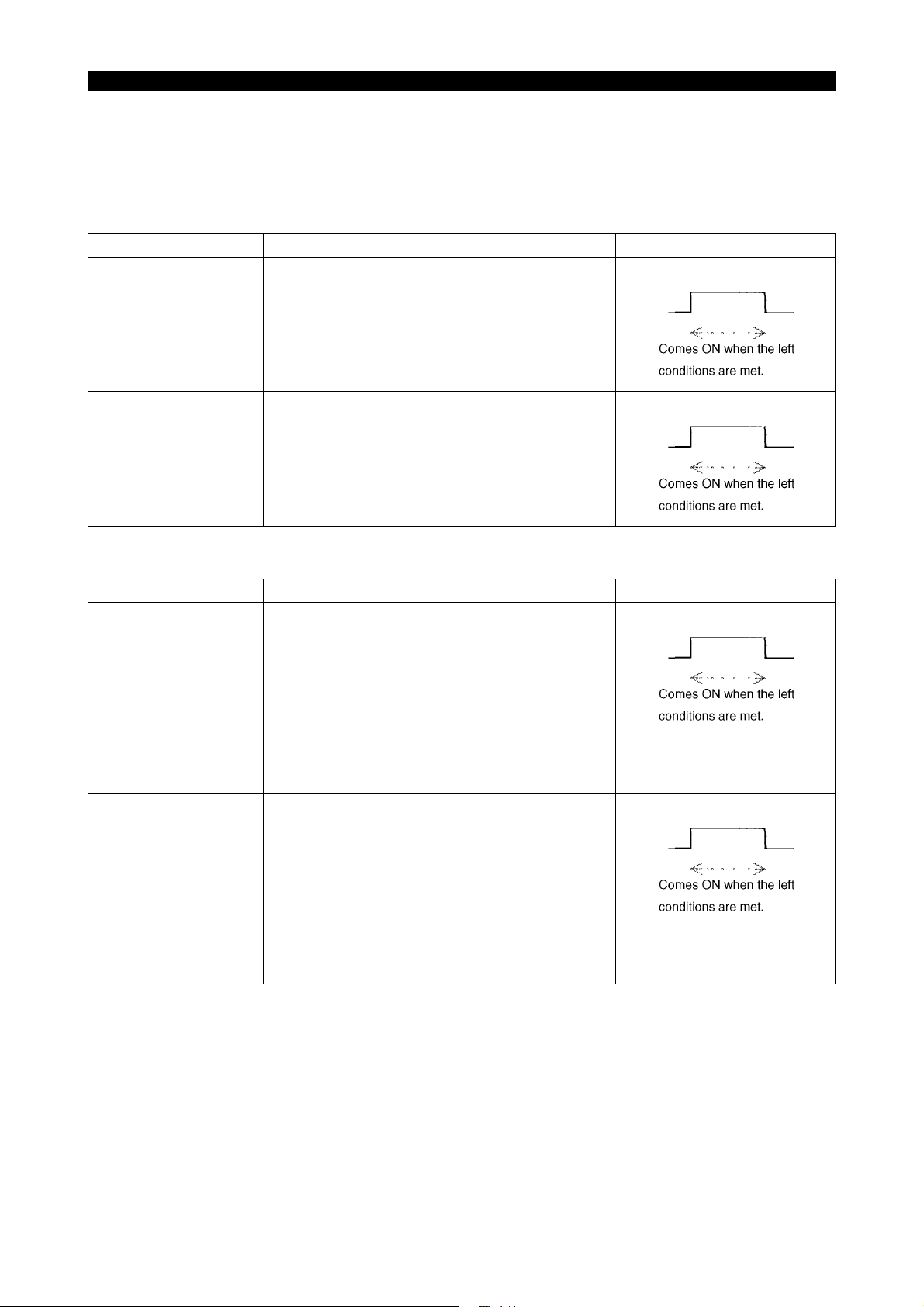

The conditions for outputting the operation door open/close confirmation signals vary with the specifications as described below:

a. With the operation door auto open/close spec

For details regarding the operation door auto open/close spec, refer to "Section 4 Operation

Door Auto Open/Close Spec".

Signal name Description Signal level

Operation door open

(oDROP)

This signal comes ON when the following conditions are met:

• Operation door open output ON

• Operation door open confirmation ON

• Operation door close confirmation OFF

Operation door close

(oDRCP)

This signal comes ON when the following conditions are met:

• Operation door close output ON

• Operation door close confirmation ON

• Operation door open confirmation OFF

5309-E P-11

b. Without the operation auto door spec

Signal name Description Signal level

Operation door open

(oDROP)

This signal comes ON when the following conditions are met:

• Operation door open confirmation ON *

• Operation door close confirmation OFF

* Without the operation door auto open/close, The

signal "Operation door open confirmation" is provided as option.

Operation door close

(oDRCP)

This signal comes ON when following conditions

are met:

• Front door open confirmation ON

• Front door close confirmation OFF*

* Without the operation door auto open/close

spec, The signal "Operation door close confirmation" is provided as option.

Page 23

SECTION 1 ROBOT/LOADER INTERFACE TYPES

5-2. Robot/loader Interface Type C

5-2-1. Inputs from the Robot/loader to the NC (Type C)

Signal name Description Signal level

Robot/loader abnormal

(iRTER/)

Robot/loader at retract

position

(iRTRF/)

Either of the following alarms occurs when the

"system link switch" is turned ON and this signal is

turned OFF. The alarm level is changeable with

the appropriate parameter.

"8. Robot alarm is made alarm C." of MC user

parameter ROBOT LOADER I/F

"0": "1709 Alarm A external"

"1": "3718 Alarm C external"

However, this signal will not be monitored during

warm-up program start wait or during NC operation by warm-up program start.

The NC start pushbutton on the panel and the

"cycle start" command become ineffective when

the "system link switch" is turned ON and this signal is turned OFF.

5309-E P-12

The following alarm occurs when the NC start

pushbutton on the panel is pressed or the "cycle

start" signal is turned ON although NC start is ineffective.

The alarm remains displayed while the NC start

pushbutton on the panel is held down or the "cycle

start" signal is kept ON.

"4720 Alarm D NC start ineffective 12"

However, the above interlock becomes ineffective

when "2. Cycle start: STANDBY POS. I/L is made

ineffective" of MC user parameter ROBOT

LOADER I/F is "1".

Page 24

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Signal name Description Signal level

Automatic power shutdown command

(iPWOF)

The power is automatically shut down after the

time set by "6. Automatic power shutdown timer"

of MC user parameter POWER SAVE/SHUTDOWN passes away if all of the following conditions are met when this signal is turned ON in

"automatic mode":

• Single block OFF in automatic operation

mode

• During existence of the machining cycle com-

pleted signal or alarm A, B or C

This signal is not affected by the automatic power

shutdown effective switch ("3. 'Automatic Power

Shutdown' is made effective" of MC user parameter POWER SAVE/SHUTDOWN) or automatic

power shutdown ON/OFF switch.

When "6. Automatic Power shutdown switch is

made effective" of MC user parameter ROBOT

LOADER I/F is "1", this function becomes effective only when the automatic power shutdown

effective switch ("3. 'Automatic Power Shutdown'

is made effective" of MC user parameter POWER

SAVE/SHUTDOWN) is set to "1" or the automatic

power shutdown ON/OFF switch is set to automatic power shutdown ON.

When "4. Alarm is added as a requirement for

Shutdown" of MC user parameter POWER SAVE/

SHUTDOWN is "0", the occurrence of an alarm A

or B is not included in the automatic power shutdown conditions.

5309-E P-13

For further information, see "SECTION 7 WORK

SET ST AUTO DOOR SPEC."

Page 25

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Signal name Description Signal level

No material/full-work

(iMTNO)

Cycle start

(iSSTT)

The operation end lamp lights while the "system

link switch" is kept ON, the operation end lamp is

effective (described below), and this signal is kept

ON.

MC user parameter

"0" is set at INDICATING LAMP, "8. Operation end

lamp is made effect":

Operation end lamp is ineffective.

"1" is set at INDICATING LAMP, "8. Operation end

lamp is made effect":

Operation end lamp is effective.

MC user parameter

"5. Operation end lamp does not light on by M02/

M30" of ROBOT LOADER I/F

"0":

The standard operation end lamp function also

becomes effective.

"1":

The standard operation end lamp function

becomes ineffective when the "system link switch"

is turned ON.

The NC starts to operate on the falling edge of this

signal when all of the following conditions are met:

5309-E P-14

Preparation work completed

(iWSFN)

• "Automatic mode"

• "Robot/loader at retract position" ON

(The "robot/loader at retract position interlock

be-comes ineffective when "2. Cycle start:

STANDBY POS. I/L is made ineffective" of

MC user parameter ROBOT LOADER I/F is

"1".)

The "exchange pallet (work) command" is turned

OFF and work preparation is completed when this

signal is turned ON.

Note: The work preparation completed status will

be retained even if the NC is reset or the power is

turned ON or OFF.

See the figure shown on the

left.

Page 26

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Signal name Description Signal level

APC door open command

(iDROC)

The APC door opens when this signal comes ON.

However, the door does not open in any of the following cases:

• The link mode is not established.

• The APC door opening M command is being

executed.

• The APC cycle is being conducted or the

APC is not in the start position.

• An alarm A is occurring.

• The power save mode is established.

• Machine lock is ON.

• The robot/loader retract position signal

iRETRF_b is OFF.

(This interlock signal is ignored when "1" is

set at "4. Door move: STANDBY POS. I/L is

made ineffective" of the machine user parameter ROBOT LOADER I/F).

5309-E P-15

APC door close command

(iDRCS)

For details, refer to SECTION 7 "WORK SET ST

AUTO DOOR SPEC."

The APC door opens when this signal comes ON.

However, the door does not open in any of the following cases:

• The link mode is not established.

• The APC door opening M command is being

executed.

• The APC cycle is being conducted or the

APC is not in the start position.

• An alarm A is occurring.

• The power save mode is established.

• Machine lock is ON.

• The robot/loader retract position signal

iRETRF_b is OFF.

(This interlock signal is ignored when "1" is

set at "4. Door move: STANDBY POS. I/L is

made ineffective" of the machine user parameter ROBOT LOADER I/F).

For details, refer to SECTION 7 "WORK SET ST

AUTO DOOR SPEC."

Page 27

SECTION 1 ROBOT/LOADER INTERFACE TYPES

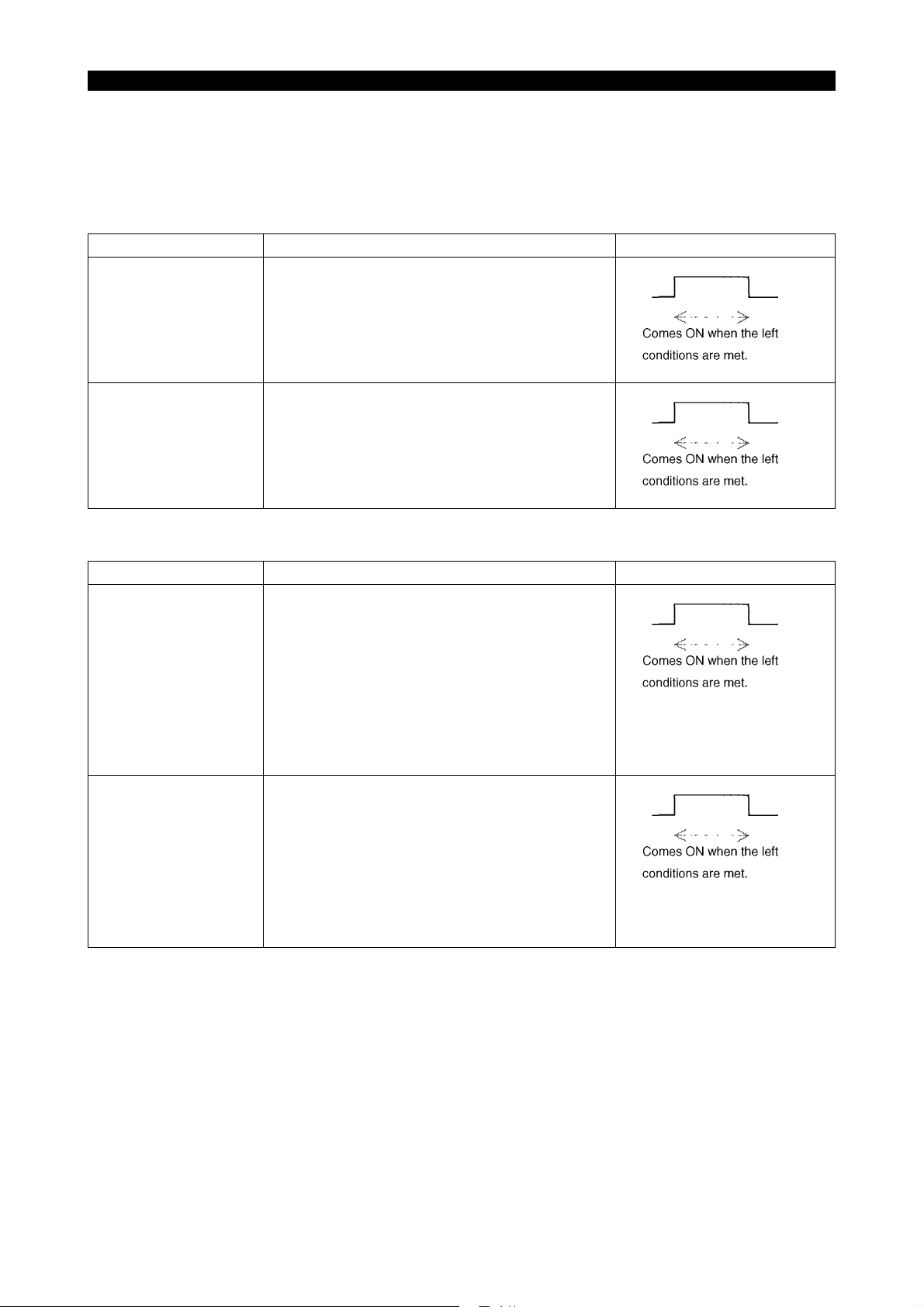

5-2-2. Outputs from the NC to the Robot/loader (Type C)

Signal name Description Signal level

NC automatic mode

(oNCGR)

NC running

(oNRUN)

This signal is turned ON when the following conditions are met:

• Automatic operation mode

• "System link switch" ON

However, this signal will not be turned ON during

warm-up program start wait or during NC operation by warm-up program start.

This signal remains ON during NC operation.

5309-E P-16

Machining cycle completed

(oCFUTF)

This signal is turned ON upon completion of NC

machining (at the end of M02, M30 or schedule

program).

This signal is turned OFF on the rising edge of the

cycle star switch and NC run signal.

This signal will be retained even if the NC is reset

or the power is turned ON or OFF.

This signal does not come ON with M02 or M30

by warm-up program start. This signal does not go

OFF by warm-up program start because it is not

regarded as NC running.

[Machining time chart]

See the time chart shown on

the left.

A-pallet is outside of

M/C

(oPLTA)

This signal comes ON when all the following conditions are met:

• Pallet B mode is ON.

• Pallet A mode is ON when "1" is set at "B pal-

let in M/C side, when APC Seq. No.1" of the

machine user parameter CHUCK, SIT CONFIRMATION, TAILSOTCK.

APC sequence No.

Page 28

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Signal name Description Signal level

B-pallet is outside of

M/C

(oPLTB)

This signal comes ON when all the following conditions are met:

• Pallet A mode is ON.

APC sequence No.

• Pallet B mode is ON when "1" is set at "B pal-

let in M/C side, when APC Seq. No.1" of the

machine user parameter CHUCK, SIT CONFIRMATION, TAILSOTCK.

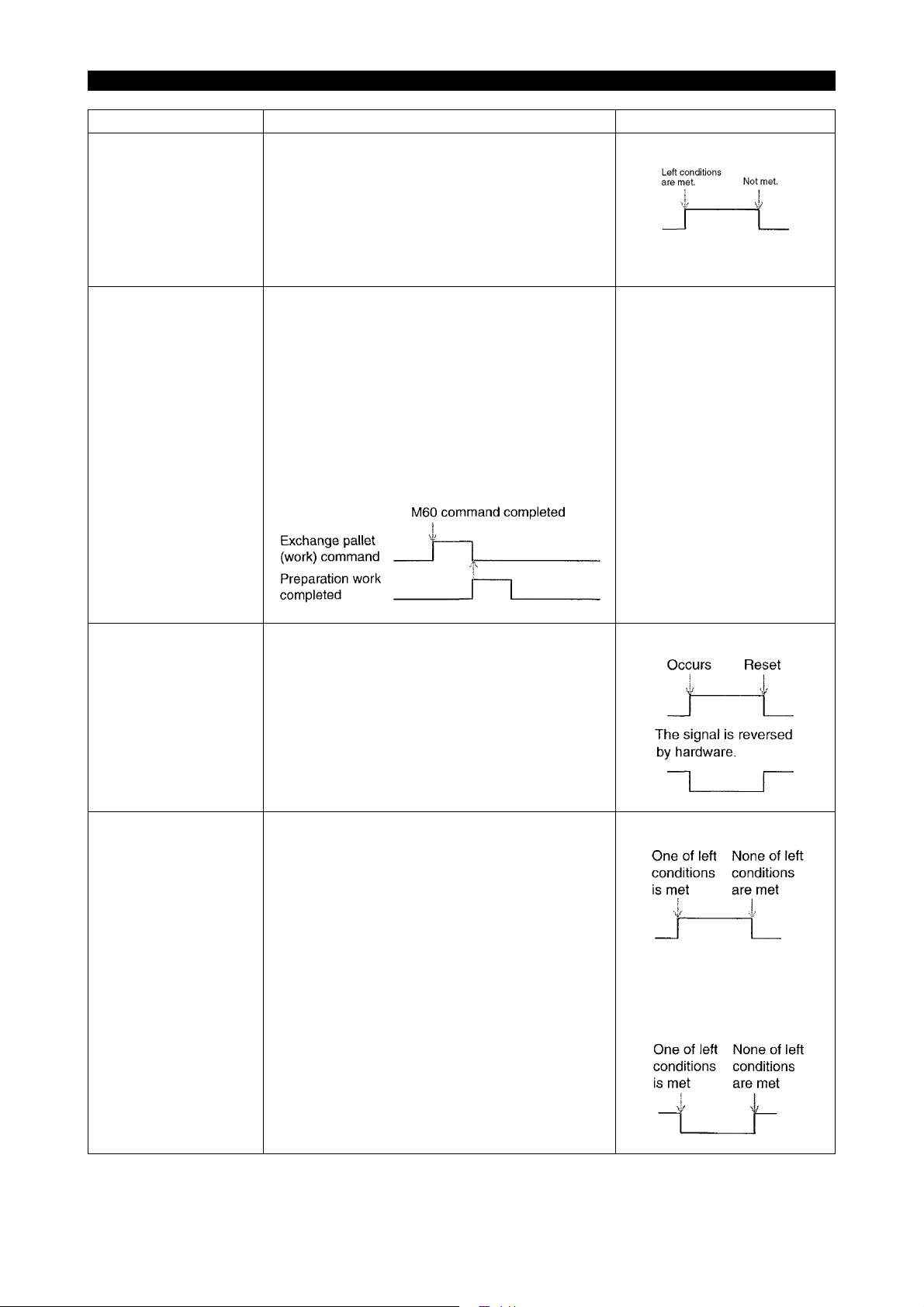

Exchange pallet (work)

command

(oPCRQ)

This signal is turned ON upon completion of the

M60 command operation in automatic mode. This

signal is turned OFF with the "preparation work

completed" signal turned ON.

This signal will be retained even if the NC is reset

or the power is turned ON or OFF.

This signal will be turned OFF in a mode other

than automatic mode.

[Time chart]

See the time chart shown on

the left.

5309-E P-17

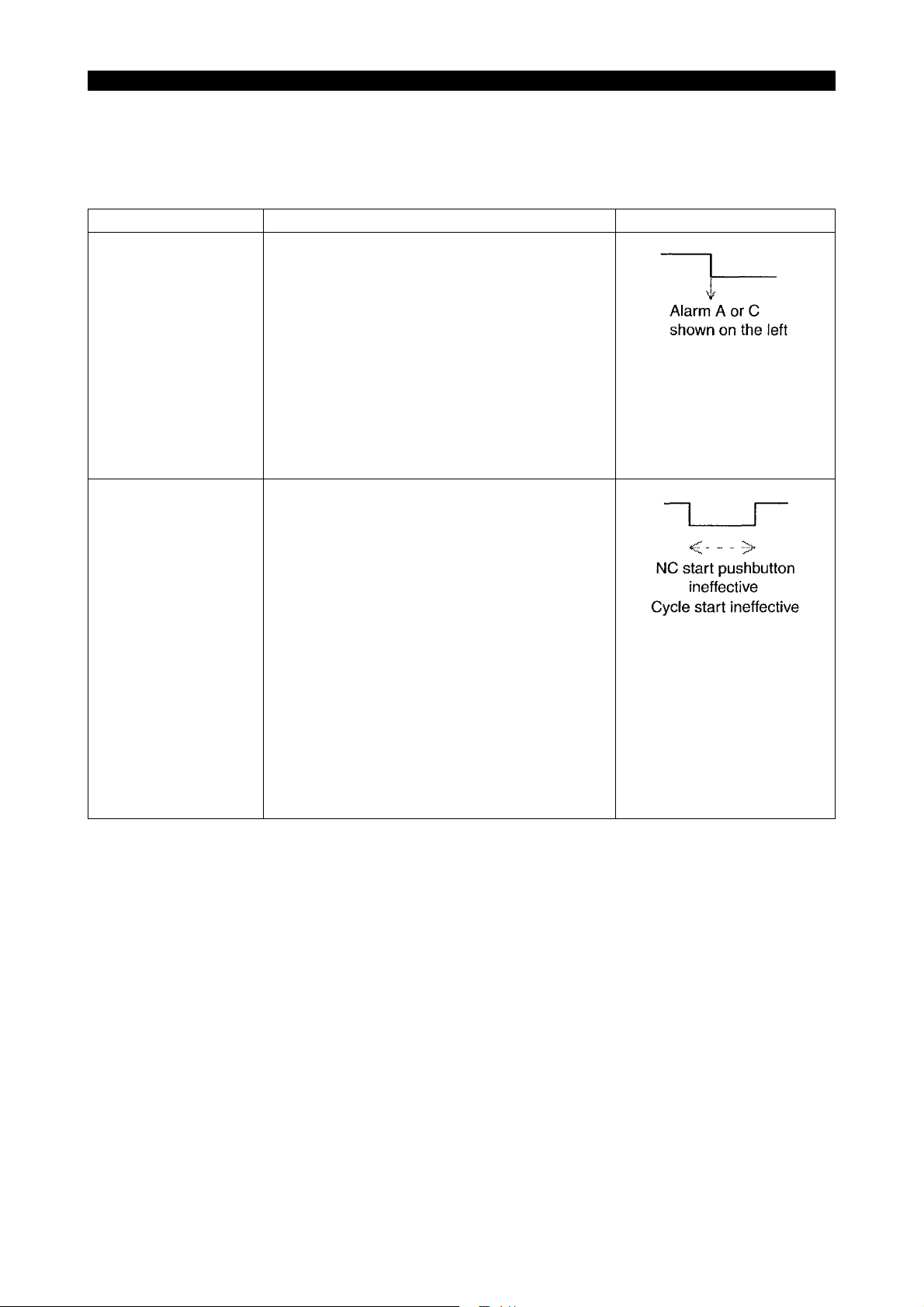

NC alarm

(oNALM)

Cycle stop request

(oCYSP)

This signal is usually OFF, but will be turned ON

when an alarm (A, B or C) occurs. NC reset will

turn OFF the signal again.

The signal will be reversed into a B contact by

hardware. The signal is reversed by hardware.

This signal is turned ON in one of the following

cases.

The signal will be turned OFF in none of the following cases:

• When the count of the NC work counter is full.

• When the tool can no longer serve.

• When the "no material/full-work" signal is

turned ON with the "system link switch"

turned ON.

Whenever "10. Cycle stop request signal is B contact" of MC user parameter ROBOT LOADER I/F

is "1", this signal is turned ON. However, it will be

turned OFF in one of the above cases. (B contact

output)

An alarm (A, B or C)

"1" is set at MC user parameter ROBOT LOADER I/F"10.

Cycle stop request signal is B

contact".

Page 29

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Signal name Description Signal level

Work condition 1

oREQ1

Work condition 2

oREQ2

Work condition 3

oREQ3

Work condition 4

oREQ4

This signal comes ON when M311 is issued

(immediate answer).

This signal goes OFF at the rising edge of the

cycle start signal or NC running signal. (The OFF

conditions are the same with those of the machining end signal.)

This signal remains effective after NC reset or

power ON/OFF.

This signal comes ON when M312 is issued

(immediate answer).

This signal goes OFF at the rising edge of the

cycle start signal or NC running signal. (The OFF

conditions are the same with those of the machining end signal.)

This signal remains effective after NC reset or

power ON/OFF.

This signal comes ON when M313 is issued

(immediate answer).

This signal goes OFF at the rising edge of the

cycle start signal or NC running signal. (The OFF

conditions are the same with those of the machining end signal.)

This signal remains effective after NC reset or

power ON/OFF.

This signal comes ON when M314 is issued

(immediate answer).

This signal goes OFF at the rising edge of the

cycle start signal or NC running signal. (The OFF

conditions are the same with those of the machining end signal.)

This signal remains effective after NC reset or

power ON/OFF.

5309-E P-18

Page 30

SECTION 1 ROBOT/LOADER INTERFACE TYPES

The conditions for outputting the APC door open/close confirmation signals vary with the specifications as described below:

a. With the work set ST auto door spec

For details regarding the specifications for the setup station door auto open/close, refer to "Section 7 Work Set ST Auto Door Spec"

Signal name Description Signal level

APC door open

(oDROP)

This signal comes ON when the following conditions are met:

• APC door open output ON

• APC door open confirmation ON

• APC door close confirmation OFF

5309-E P-19

APC door close

(oDRCP)

This signal comes ON when the following conditions are met:

• APC door close output ON

• APC door close confirmation ON

• APC door open confirmation OFF

b. Without the work set ST auto door spec

Signal name Description Signal level

APC door open

(oDROP)

This signal comes ON when the following conditions are met:

• APC door open confirmation ON *

• APC door close confirmation OFF

* Without work set ST auto spec, the APC door

open confirmation is provided as an optional

specification.

APC door close

(oDRCP)

This signal comes ON when following conditions

are met:

• APC door open confirmation ON *

• This signal comes ON when APC door close

confirmation is ON.

* Without work set ST auto spec, the APC door

open confirmation is provided as an optional

specification.

Page 31

6. Interlock

6-1. Axis Interlock

This interlock function disables movement of X, Y, and Z-axes when the system link switch is ON

and the robot/loader retract position signal is OFF.

However, this interlock is ignored when "1" is set at "3. Axis move: STANDBY POS. I/L is made ineffective" of the machine user parameter ROBOT LOADER I/F.

* For the machine with APC, the X, Y, Z-axis can be moved even if the robot/loader retract position

signal is OFF.

6-2. APC Interlock

(1) The following alarm occurs when the APC is in operation (during a cycle), the "system link

switch" is turned ON, and the robot/loader at retract position signal is turned OFF:

"1744 Alarm A Robot/loader at retract position 10"

However, the above interlock will be ignored when "3. Axis move: STANDBY POS. I/L is made

ineffective" of MC user parameter ROBOT LOADER I/F is "1".

5309-E P-20

SECTION 1 ROBOT/LOADER INTERFACE TYPES

(2) When the "system link switch" is turned ON and the robot/loader at retract position signal is

turned OFF during execution of the M60 command, the APC cycle does not begin, and the

above-mentioned alarm occurs.

However, the above interlock will be ignored when "3. Axis move: STANDBY POS. I/L is made

ineffective" of MC user parameter ROBOT LOADER I/F is "1".

Page 32

SECTION 1 ROBOT/LOADER INTERFACE TYPES

7. Work Condition Display Function

When the indication of work condition display spec is provided for the ROBOT LOADER I/F type C,

"1" is set at the following parameter.

Machine user parameter ROBOT LOADER I/F

13 Indication of work condition is made effective.

0 ... Indication of work condition ineffective

1 ... Indication of work condition effective

If "1" is set at the above parameter of ROBOT/LOADER I/F type C, the following signals become

effective.

• Work condition 1 (oREQ1)

• Work condition 2 (oREQ2)

• Work condition 3 (oREQ3)

• Work condition 4 (oREQ4)

Note

The robot loader I/F type B request 1 (oREQ1) to request 4 (oREQ4) signals are used (shared).

However, their ON/OFF conditions and M command answer conditions are different.

5309-E P-21

Note

This specification is ineffective for ROBOT LOADER I/F type B. For the robot loader I/F type B, the

existing request 1 (oREQ1) to 4 (oREQ4) can be selected.

Specifications: For details of the specifications, refer to 5-2-2. Output from the NC to Robot/Loader

(Type C).

Page 33

8. Parameters

5309-E P-22

SECTION 1 ROBOT/LOADER INTERFACE TYPES

ME61048R0200300130001

Page 34

SECTION 1 ROBOT/LOADER INTERFACE TYPES

9. Automatic Power Shutdown

9-1. Effective Conditions

Any of the following states is called an "automatic power shutdown ON state".

(1) Robot/loader interface type C

a. In "automatic mode"

When the "automatic power shutdown command iPWOF" is input from the robot/loader.

[Supplement]

This function is not affected by the automatic power shutdown effective parameter ("3. 'Automatic

Power Shutdown' is made effective" of MC user parameter POWER SAVE/SHUTDOWN) or automatic power shutdown ON/OFF switch.

When "6. Automatic Power shutdown Switch is made effective" of MC user parameter ROBOT

LOADER I/F is "1", this function becomes effective only when the automatic power shutdown

effective parameter ("3. 'Automatic Power Shutdown' is made effective" of MC user parameter

POWER SAVE/SHUTDOWN) is "1" or the automatic power shutdown ON/OFF switch is set to

automatic power shutdown ON (iPOFF)

5309-E P-23

b. In a mode other than "automatic mode"

When the automatic power shutdown effective parameter ("3. 'Automatic Power Shutdown'

is made effective" of MC user parameter POWER SAVE/SHUTDOWN) is "1" or the automatic power shutdown ON/OFF switch is set to automatic power shutdown ON (iPOFF).

(2) Robot/loader interface type B

a. In "automatic mode" when automatic power shutdown robot/loader interlocking is desig-

nated:

When "automatic power shutdown completed iPOFC" is input from the robot/loader while

the "automatic power shutdown command iPOFO" is output to the robot/loader.

* Automatic power shutdown robot/loader interlocking designation:

When the automatic power shutdown MC alone designation parameter ("9. Automatic

power shutdown MC alone" of MC user parameter ROBOT LOADER I/F) is "0".

The "automatic power shutdown command iPOFO" will be output in the power shutdown

state described in 8-2. Description of the Function when the automatic power shutdown

effective parameter ("3. 'Automatic Power Shutdown' is made effective" of MC user parameter POWER SAVE/SHUTDOWN) is "1" or the automatic power shutdown ON/OFF switch

is set to automatic power shutdown ON (iPOFF) in "automatic mode" with automatic power

shutdown robot/loader interlocking designated.

b. In a case other than automatic power shutdown MC alone designation or "automatic mode"

When the automatic power shutdown effective parameter ("3. 'Automatic Power Shutdown'

is made effective" of MC user parameter POWER SAVE/SHUTDOWN) is "1" or the automatic power shutdown ON/OFF switch is set to automatic power shutdown ON (iPOFF).

Page 35

9-2. Description of the Function

In "automatic operation mode" and "single block OFF" with "automatic power shutdown ON," the

power will be shut down automatically after the duration of one of the following states reaches the

time set by 6 "automatic power shutdown timer" of MC user parameter POWER SAVE/SHUTDOWN:

(1) Schedule end during schedule program selection.

(2) After program end (M2 or M30) execution is completed except during schedule program selec-

tion.

(3) When an alarm A, B or C occurs.

(This function is effective only when 4 "Alarm is added as a requirement for Shutdown" of MC

user parameter POWER SAVE/SHUTDOWN is "1".)

- When an alarm A occurs and the setting of the automatic power shutdown timer is 30 seconds or less, the power will be shut down 30 seconds after the alarm A occurs.

- When an alarm B occurs, the main spindle will come to a stop 10 seconds after it is confirmed that the all-axis in-position signal is ON, and the power will be shut down after the

time of the automatic power shutdown timer passes away.

However, if the setting of the automatic power shutdown timer is 30 seconds or less, the

power will be shut down 30 seconds after the main spindle comes to a stop.

- When an alarm C occurs, the power will be shut down after the time of the automatic power

shutdown timer passes away following turning OFF of NC run during schedule program

selection. This function does not become activated in cases except during schedule program selection.

5309-E P-24

SECTION 1 ROBOT/LOADER INTERFACE TYPES

MC user parameter No. 2 Power save/power shutdown

4 Alarm is added as a requirement for Shutdown.

6 Automatic power shutdown timer

Command: Setting, addition

Initial value: 0

Minimum value: 10

Maximum value: 3600

Unit: Second

(4) Other conditions

Auto power shutoff is disabled during file operation.

If auto power shutoff command is issued during file operation, the NC activates the following

alarm and waits until the file operation ends. Then, the NC releases the alarm and executes

auto power shutoff.

"4706 Alarm DAuto power shut-off impossible"

Page 36

9-3. Parameters

5309-E P-25

SECTION 1 ROBOT/LOADER INTERFACE TYPES

ME61048R0200300160001

Page 37

10. Input/Output Bit

The following screen allows you to check the input states of various switches mounted in the

machine and output states of the lamps, relays, and solenoid valves.

Both input and output states are displayed in reverse video, indicating that their signals are ON. For

the other input/output signals and the method of using I/O monitors, refer to OSP-P200M MD-H/MAH series Maintenance Manual.

Procedure :

1 Press the (DIAGNOSE) key among the vertical function keys at the right end of the

screen.

5309-E P-26

SECTION 1 ROBOT/LOADER INTERFACE TYPES

ME61048R0200300170001

Page 38

5309-E P-27

SECTION 1 ROBOT/LOADER INTERFACE TYPES

2 Press the (I/O MONITOR) key in the diagnosis menu. The I/O monitor starts up.

ME61048R0200300170002

Page 39

3 The following I/O monitor screen appears.

5309-E P-28

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Data layout change (vertical, horizontal)

Screen change between logical and physical

Displays the Slave station display screen.

Displays the Search screen.

In the status display of bit data, the active bit (ON) is expressed with a red circle.

Data type (Selectable from

among bit, 2 Byte and 4 Byte)

ME61048R0200300170003

Page 40

SECTION 1 ROBOT/LOADER INTERFACE TYPES

Input bit

Addr Bit Label Comment

0025 01 iRTER_b Robot-IF alarm

0025 02 iCYSP Robot-IF cycle stop request

0025 03 iRTGR Robot-IF ROBOT LINK ON

0025 04 iRTRF_b Robot-IF retract position

0025 05 iRQAS Robot-IF request answer

0025 06 iPWOF Robot-IF auto shout doun request

0025 07 iMTNO Robot-IF No work/ Full work

0025 08 iSSTT Robot-IF cycle start command

0025 09 iPOFC Robot-IF auto shout down FIN

0025 10 iWSFN Robot-IF work set FIN

0025 14 iDROC Robot-IF auto door open command

0025 15 iDRCS Robot-IF auto door close command

0016 15 iSYLK Robot-IF SYSTEM LINK ON

Output bit

5309-E P-29

Addr Bit Label Comment

0529 0 oNCGR Robot-IF NC system link mode

0529 01 oNRUN Robot-IF NC run status

0529 02 oPOFO Robot-IF auto power shot down command

0529 03 oCUTF Robot-IF program end

0529 05 oPLTA Robot-IF A-pallet is outside of M/C

0529 06 oPLTB Robot-IF B-pallet is outside of M/C

0529 07 oPCRQ Robot-IF pallet change request

0529 08 oNALM Robot-IF NC alarm status

0529 09 oCYSP Robot-IF cycle stop request

0529 11 oREQ1 Robot-IF request 1

0529 12 oREQ2 Robot-IF request 2

0529 13 oREQ3 Robot-IF request 3

0529 14 oREQ4 Robot-IF request 4

0525 14 oDROP Robot-IF auto door open confirm

0525 15 oDRCP Robot-IF auto door close confirm

Page 41

SECTION 2 CHUCK (JIG) CONTROL

SECTION 2 CHUCK (JIG) CONTROL

1. No. 1 Chuck (Jig)

1-1. Clamping Modes

The chuck clamps the outer or inner diameter of the workpiece.

OD clamping ...The chuck clamps the workpiece as it closes and unclamps as it opens.

ID clamping ...The check clamps the workpiece as it opens and unclamps as it closes.

The clamping modes can be switched using the following parameter.

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

1 The chuck clamps the inner diameter of the workpiece.

0...The chuck clamps the outer diameter of the workpiece.

1...The chuck clamps the inner diameter of the workpiece.

1-2. Chuck clamp/unclamp commands

5309-E P-30

The chuck clamp/unclamp commands include pushbutton input, M code and robot/loader commands.

(1) Pushbutton input commands

Press the Chuck Clamp button to clamp.

Press the Chuck Unclamp button to unclamp.

Conditions for executing the commands:

All of the following conditions should be met to execute the commands.

• The System Link switch is off (in case of the robot/loader interface).

• The NC is not active.

Note that the pushbutton input commands are only effective when the M code Chuck

Clamp/Unclamp Pushbuttons Validate command (M35) has been given.

(The M code Pushbuttons Validate command is cancelled by the M02/M03 command

or by pressing the RESET (or MODE REST) button).

• Alarm A has not been pending, the power not saved, and the machine not locked.

• The spindle is at rest.

This condition only applies to the Chuck Unclamp command.

• The operation door is closed.

Chuck Clamp command: Effective when the following parameter has been set to "1."

MC UNSER PARAMETER No.15-3 CHUCK, SIT CONFIRMATION, TAILSTOCK

25 The Work Clamp PB is ineffective when the door is open.

0...The Work Clamp PB is effective even when the door is open.

1...The Work Clamp PB is ineffective when the door is open.

Page 42

5309-E P-31

SECTION 2 CHUCK (JIG) CONTROL

Chuck Unclamp command: Effective when the following parameter has been set to

"1."

MC UNSER PARAMETER No.15-5 CHUCK, SIT CONFIRMATION, TAILSTOCK

57 The Work Unclamp PB is ineffective when the door is open.

0...The Work Unclamp PB is effective even when the door is open.

1...The Work Unclamp PB is ineffective when the door is open.

Note: This does not depend on the NC operation mode.

[Single Chuck Clamp/Unclamp PB mode]

The single chuck clamp/unclamp PB mode is made effective using the following

parameter.

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

11 Chuck clamp/unclamp PB 1 button spec

0...Two chuck clamp/unclamp pushbuttons

1...A single chuck clamp/unclamp PB

If the Chuck Clamp pushbutton is pressed when the Chuck Unclamp command has

been given, the chuck clamps the workpiece. If it is pressed when the Chuck Clamp

command has been given, the chuck unclamps the workpiece.

If the Chuck Clamp PB is pressed when the workpiece is being clamped, the chuck

stops clamping and starts unclamping. Similarly, if the Chuck Clamp PB is pressed

when the workpiece is being unclamped, the chuck stops unclamping and starts

clamping.

Chuck Clamp PB

Chuck Clamp signal

Chuck Unclamp signal

ME61048R0200400020001

Page 43

SECTION 2 CHUCK (JIG) CONTROL

(2) M code commands

M code Content

M148 Clamps with No. 1 chuck (jig).

M149 Unclamps with No. 1 chuck (jig).

• The Chuck Clamp command is answered back when the workpiece is completely clamped

(further described later).

• The Chuck Unclamp command is answered back when the workpiece is completely

unclamped (further described below).

• The Answer Ignore command is enabled when the operating time reduction mode has

been selected.

M149 M301.......Answered back without confirming the completion of clamping.

:

M302................Answered with confirmation.

M148 M301.......Answered back without confirming the completion of unclamping.

:

M302................Answered with confirmation.

5309-E P-32

• The M149 command, if given during the spindle revolution, does not unclamp the work-

piece and permits the STM to continue running.

The following diagnosis message appears if the chuck is interlocked as mentioned above.

"15203 Spindle has not stopped."

Note that this message only appears when the STM is permitted by the M149 command to

continue running.

(3) Robot/loader commands (in case of robot/loader interface)

The robot/loader commands are effective in the "linked" mode.

The workpiece is clamped when "Chuck Clamp command iCHCL" turns on.

The workpiece is unclamped when "Chuck Unclamp command iCHUC" turns on.

This does not apply under the following conditions.

• Alarm A is pending.

• The power has been saved.

• The machine has been locked.

• The workpiece is being clamped or unclamped according to an M code command.

• The spindle is revolving (for the Chuck Unclamp command only).

If the "Chuck Clamp" command turns off before the workpiece is completely clamped, the chuck

continues to clamp until the "Chuck Unclamp" command turns on.

If the "Chuck Unclamp" command turns off before the workpiece is completely unclamped, the

chuck continues to unclamp until the "Chuck Clamp" command turns on.

Page 44

1-3. Chuck clamp/unclamp sequences

(1) OD clamping

• The Chuck Clamp command turns the Chuck Open SOL off and the Chuck Close SOL on.

The workpiece is considered completely clamped after the "Chuck Open" limit switch turns

off and the "Chuck Close" limit switch on and the work clamp timer (described later) counts

up.

Note that the workpiece is not considered completely clamped if the "Chuck Close" limit

switch remains off for 0.5 second or longer after the workpiece is completely clamped.

• The Chuck Unclamp command turns the Chuck Close SOL off and the Chuck Open SOL

on.

The workpiece is considered completely unclamped after the "Chuck Closed" limit switch

turns off and the "Chuck Open" limit switch on and the work unclamp timer (described later)

counts up.

(2) ID clamping

• The Chuck Clamp command turns the Chuck Close SOL off and the Chuck Open SOL on.

The workpiece is considered completely clamped after the "Chuck Closed" limit switch

turns off and the "Chuck Open" limit switch on and the work clamp timer (described later)

counts up.

Note that the workpiece is not considered completely clamped if the "Chuck Open" limit

switch remains off for 0.5 second or longer after the workpiece is completely clamped.

5309-E P-33

SECTION 2 CHUCK (JIG) CONTROL

• The Chuck Unclamp command turns the Chuck Open SOL off and the Chuck Close SOL

on.

The workpiece is considered completely clamped after the "Chuck Open" limit switch turns

off and the "Chuck Closed" limit switch turns on and the work unclamp timer (described

later) counts up.

Page 45

1-4. "Chuck Open/Closed" limit switches

The presence of the chuck open/close confirmation LS can be switched using the following parameter.

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

4 The 'Chuck Closed' limit switch is made ineffective

0...Makes "Chuck Closed" limit switch effective.

1...Makes "Check Closed" limit switch ineffective.

Note

If only the "Chuck Closed" LS is ineffective, the "Chuck Open" LS is checked in the chuck clamp/

unclamp sequences of 4) but the "Chuck Closed" LS is not.

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

5 The 'Chuck Open' limit switch is made ineffective

0...Makes "Chuck Open" limit switch effective.

1...Makes "Chuck Open" limit switch ineffective.

5309-E P-34

SECTION 2 CHUCK (JIG) CONTROL

Note

If only the "Chuck Open" LS is ineffective, the "Chuck Close" LS is checked in the chuck clamp/

unclamp sequences of 4) but the "Chuck Open" LS is not.

If both of the aforementioned parameters are set to "1" (both the "Chuck Closed" and "Chuck Open"

limit switches are ineffective), the sequence completes after the relevant SOL remains on for the

time preset by the timer after issue of the Chuck Clamp/Unclamp command.

It is more specifically described below.

(1) OD clamping

• The Chuck Clamp command turns the Chuck Open SOL off and the Chuck Close SOL on.

The workpiece is considered completely clamped after the work clamp timer (described

later) counts up.

• The Chuck Unclamp command turns the Chuck Close SOL off and the Chuck Open SOL

on. The workpiece is considered completely unclamped after the work unclamp timer

(described later) counts up.

(2) ID clamping

• The Chuck Clamp command turns the Chuck Close SOL off and the Chuck Open SOL on.

The workpiece is considered completely clamped after the work clamp timer (described

later) counts up.

• The Chuck Unclamp command turns the Chuck Open SOL off and the Chuck Close SOL

on. The workpiece is considered completely unclamped after the work unclamp timer

(described later) counts up.

Page 46

1-5. Work clamp/unclamp timers

The work clamp/unclamp timers can be preset using the following parameters.

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

6 Work clamp timer

Commands: Set and Add

Default: 0

Min. value: 0

Max. value: 6000

Programmable unit: 10ms

7 Work unclamp timer

Commands: Set and Add

Default: 0

Min. value: 0

Max. value: 6000

Programmalble unit: 10 ms

5309-E P-35

SECTION 2 CHUCK (JIG) CONTROL

Page 47

1-6. Timing chart

5309-E P-36

SECTION 2 CHUCK (JIG) CONTROL

Note: Chuck Clamp LS/SOL For OD clamping: Chuck Close LS/SOL

For ID clamping: Chuck Close LS/SOL

Chuck Unclamp LS/SOL For OD clamping: Chuck Open LS/SOL

For ID clamping: Chuck Close LS/SOL

ME61048R0200400060001

Page 48

1-7. Interlocking

(1) Interlocking for inhibiting cutting feed

Cutting feed is inhibited when the workpiece has not been completely clamped.

Interlocking for cutting feed inhibition can be overridden using the following parameter.

(With the following parameter set to "1," cutting feed is permitted even when the workpiece has

not been completely clamped.)

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

2 Even if the chuck opens, cutting feed remains executable.

The following diagnosis message appears when the aforementioned interlocking is active.

"15202 Chuck close LS in not ON."

"15204 Fixture clamp confirmation LS is not ON."

Note that this message only appears during NC operation or cutting process.

(2) Interlocking for spindle revolution inhibition

Spindle revolution is permitted when the workpiece has not been completely clamped.

Interlocking for spindle revolution inhibition can be activated using the following parameter.

(With the following parameter set to "1," spindle revolution is inhibited even when the workpiece

has not been completely clamped.)

Note that the spindle can be indexed even when the interlocking for spindle revolution inhibition

is active.

MC UNSER PARAMETER No.15-1 CHUCK, SIT CONFIRMATION, TAILSTOCK

3 Spindle revolution is inhibited when the chuck opens.

5309-E P-37

SECTION 2 CHUCK (JIG) CONTROL

0...Makes cutting feed executable even when the chuck is open.

1...Makes cutting feed inexecutable when the chuck is open.

Or, for some models:

0...Inhibits spindle revolution when the chuck is open.

1...Permits spindle revolution when the chuck is open.

The following diagnosis message appears when the aforementioned interlocking is active.

"15202 Chuck close LS is not ON"

Or, for some models:

"15421 Fixture clamping is not completed."

With the interlocking for spindle revolution inhibition active, the following alarm message

appears when the workpiece becomes no longer completely clamped during spindle revolution.

"1707 Alarm A Spindle rotation interlock 3C36"

Or, for some models:

"1707 Alarm A Spindle rotation interlock 3C3D"

Page 49

1-8. Special conditions

• Each SOL remains off when alarm A has been pending or the power saved.

(The statuses are retained if the system is reset with RESET or RESET MODE.)

If alarm A is released, the power saving mode exited, or the system powered on, the system

returns to the status where alarm A has not been raised, the power saving mode not entered, or

the system not powered off.

• With the following parameter set to "1," the SOL does not turn off even with alarm A pending or

in the power saving mode.

MC UNSER PARAMETER No.15 CHUCK, SIT CONFIRMATION, TAILSTOCK

23 Even if alarm A is pending or in the power saving mode, chuck SOL remains on.

0...Turns SOL off with alarm A pending or in the power saving mode.

1...Keeps SOL on with alarm A pending or in the power saving mode.

1-9. Status indicators

The Chuck Clamp LED lights while the workpiece is clamped.

The Chuck Unclamp LED lights while the workpiece is unclamped.

5309-E P-38

SECTION 2 CHUCK (JIG) CONTROL

Page 50

2. Chuck (jig) pressure switching

2-1. No. 1 chuck (jig)

(1) Outline

The clamping pressure for the first chuck (jig) can be switched between high and low levels.

• If the Chuck Clamp command is given using the pushbutton or code M148 or from the

robot/loader with the workpiece unclamped, the workpiece is clamped at the high pressure.

• Giving the M148 command with the workpiece clamped at the low pressure changes the

pressure from the low to the high level.

Giving the Chuck Clamp command using the pushbutton or from the robot/loader with the

workpiece clamped at the low pressure does not changes the pressure.

• Giving the Chuck Unclamp command using the pushbutton or code M149 or from the

robot/loader also gives the high pressure command.

• An M code command for low pressure clamping (M385) has been added. The Chuck

Clamp command accompanies the low pressure command.

5309-E P-39

SECTION 2 CHUCK (JIG) CONTROL

Purpose: A higher clamping force may deform the workpice and consequently affects the

machining accuracy. Using the high pressure for rough grinding and the low pressure for finishing improves the machining accuracy.

(2) Conditions for supporting the function

The chuck pressure switching function is supported when the fixture control is effective and the

following parameter set to "1."

Machine user parameter No.15-3 CHUCK, SIT CONFIRMATION, TAILSTOCK

27 High/low chuck pressure is made switchable.

0...Chuck pressure is not switchable.

1...Check pressure is switchable.

Page 51

(3) Pressure switching commands

a. High Pressure Clamp Command

Giving the Chuck Clamp command using the pushbutton or code M149 or from the robot/

loader also gives the high pressure command.

(1) High Pressure Clamp command with workpiece unclamped

If the Chuck Clamp command is given using the pushbutton or code M148 or

from the robot/loader with the workpiece unclamped, the workpiece is clamped

at the high pressure.

(2) High Pressure Clamp command with workpiece clamped at low pressure

Giving the M148 command with the workpiece clamped at the low pressure

changes the pressure from the low to the high level.

Giving the Chuck Clamp command using the pushbutton or from the robot/

loader with the workpiece clamped at the low pressure does not changes the

pressure.