OSP-U100L/U10L/

E100L/E10L/P200L/P20L

GAUGING SYSTEMS

INSTRUCTION MANUAL

(2nd Edition) -APPLICATION-

Pub No. 5327-E-R1 (LE61-129-R2) Feb. 2007

5327-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from

hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety

devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Installation

(1) Please be noted about a primary power supply as follows.

• Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this

could cause malfunction of the CNC unit.

• If possible, connect the machine to a ground not used by any other equipment. If there is

no choice but to use a common ground, the other equipment must not generate a large

amount of noise (such as an electric welder or electric discharge machine).

(2) Installation Environment

Observe the following points when installing the control enclosure.

• Make sure that the CNC unit will not be subject to direct sunlight.

• Make sure that the control enclosure will not be splashed with chips, water, or oil.

• Make sure that the control enclosure and operation panel are not subject to excessive

vibrations or shock.

• The permissible ambient temperature range for the control enclosure is 5 to 40°C.

• The permissible ambient humidity range for the control enclosure is relative humidity 50%

or less at 40°C (no condensation).

• The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2. Points to Check before Turning on the Power

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

5327-E P-(ii)

SAFETY PRECAUTIONS

3. Precautions Relating to Manual/Continuous Operation

(1) Follow the instruction manual during operation.

(2) Do not operate the machine with the front cover, chuck cover, or another protective cover

removed.

(3) Close the front cover before starting the machine.

(4) When machining the initial workpiece, check for machine operations, run the machine under no

load to check for interference among components, cut the workpiece in the single block mode,

and then start continuous operation.

(5) Ensure your safety before rotating the spindle or moving a machine part.

(6) Do not touch chips or workpiece while the spindle is rotating.

(7) Do not stop a rotating part with hand or another means.

(8) Check that the condition of hydraulic chuck jaws as mounted, operating pressure, and

maximum permissible revolving speed.

(9) Check the condition and location of the cutting tool as mounted.

(10) Check the tool offset value.

(11) Check the zero offset value.

(12) Check that the SPINDLE OVERRIDE and FEEDRATE OVERRIDE dials on the NC operation

panel are set to 100%.

(13) When moving the turret, check the software limits for X- and Z-axes or the locations of limit

switch dogs to prevent interference with the chuck and tailstock.

(14) Check the location of the turret.

(15) Check the location of the tailstock.

(16) Cut workpieces with a transmitted power and torque within the permissible range.

(17) Chuck each workpiece firmly.

(18) Check that the coolant nozzle is properly located.

4. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

5327-E P-(iii)

SAFETY PRECAUTIONS

5. Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the

following points when performing maitenance inspections or during checking when trouble has

occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were

and secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

a. Switch the main power disconnect switch OFF before opening the control enclosure door.

b. Even when the main power disconnect switch is OFF, there may some residual charge in

the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted

to perform any work on this unit. Even then, they must observe the following precautions.

• MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c. The control enclosure contains the NC unit, and the NC unit has a printed circuit board

whose memory stores the machining programs, parameters, etc. In order to ensure that the

contents of this memory will be retained even when the power is switched off, the memory

is supplied with power by a battery. Depending on how the printed circuit boards are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

(11) Periodic Inspection of the Control Enclosure

a. Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive

temperature rise inside the control enclosure and increase the reliability of the NC unit.

Inspect the following points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

6. General Precautions

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine

operators must wear safety equipment such as safety shoes and goggles.

5327-E P-(iv)

SAFETY PRECAUTIONS

(4) Machine operators must read the instruction manual carefully and make sure of the correct

procedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

7. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of

particular importance. Read the instructions marked with these symbols carefully and follow them.

DANGER

indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

5327-E P-(v)

SAFETY PRECAUTIONS

indicates a potentially hazardous situation which, if not avoided, may result in damage to your

property.

SAFETY INSTRUCTIONS

indicates general instructions for safe operation.

5327-E P-(i)

INTRODUCTION

INTRODUCTION

Thank you very much for purchasing our numerical control unit OSP-E100L/E10L.

Before using this NC unit (hereafter simply called NC), thoroughly read this programming manual (hereafter

called this manual) in order to ensure correct use.

This manual explains how to use and maintain the NC so that it will deliver its full performance and maintain

accuracy over a long term.

You must pay particular attention to the cautions given in this manual, read them carefully, and make sure you

fully understand them before operating the NC.

Display Screens

The NC display screens vary with the selected NC specifications.

The screens shown in this manual, therefore, may not exactly the same with

those displayed on your NC.

5327-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB) .................................1

1. Notes for Using Gauging MSB................................................................................................. 1

1-1. Notes ................................................................................................................................ 1

1-2. Control Statements........................................................................................................... 3

2. Touch Setter Gauging and Touch Sensor Gauging................................................................. 8

2-1. Overview........................................................................................................................... 8

2-2. Variable Tables................................................................................................................. 8

2-3. Print ................................................................................................................................ 17

2-4. Program.......................................................................................................................... 21

2-5. Flow Charts .................................................................................................................... 24

2-6. Program List ................................................................................................................... 60

3. Touch Sensor Gauging (Automatic Zero Offset Function)..................................................... 75

3-1. General Description of MSB ........................................................................................... 75

3-2. Variable Tables............................................................................................................... 75

3-3. Program.......................................................................................................................... 79

4. Automatic C-axis Zero Offset Function.................................................................................. 82

4-1. General Description of MSB ........................................................................................... 82

4-2. Variable Tables............................................................................................................... 82

4-3. Programs ........................................................................................................................ 86

5. Y-axis Gauging Function ..................................................................................................... 107

5-1. Outline of MSB ............................................................................................................. 107

5-2. Variables Table.............................................................................................................107

5-3. Programs ...................................................................................................................... 110

6. Automatic Gauging System Using Five Level Signals (BCD System)................................. 135

6-1. General Description of MSB ......................................................................................... 135

6-2. Variable Tables.............................................................................................................136

6-3. Program........................................................................................................................ 140

7. Automatic Gauging System Using Five Level Signals......................................................... 146

7-1. General Description of MSB ......................................................................................... 146

7-2. Variable Tables.............................................................................................................146

7-3. Program........................................................................................................................ 151

8. Automatic Gauging System by Seven Level Signals........................................................... 157

8-1. General Description of MSB ......................................................................................... 157

8-2. Variable Tables.............................................................................................................157

8-3. Program........................................................................................................................ 162

9. CEJ MATIC Gauging MSB .................................................................................................. 168

9-1. CEJ MATIC Gauging Subprograms ............................................................................. 168

9-2. Common Variables ....................................................................................................... 168

9-3. System Variables.......................................................................................................... 168

9-4. Program........................................................................................................................ 169

10.MSB for Post-process Gauging Using RS-232C ................................................................. 172

5327-E P-(ii)

TABLE OF CONTENTS

10-1.Gauging Subprogram .................................................................................................. 172

10-2.System Variables......................................................................................................... 172

10-3.Common Variables ...................................................................................................... 172

10-4.Program....................................................................................................................... 173

5327-E P-1

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING

(MSB)

1. Notes for Using Gauging MSB

1-1. Notes

General notes for using maker subprograms (MSB) for gauging are presented below.

1-1-1. NOEX Command

In the single block mode, sequences preceded by NOEX are excluded in single block operation.

This speeds up internal processing for checking and correcting the program in single block

operation.

When specifying the NOEX command, the restrictions stated below apply.

• NOEX cannot be specified before axis movement commands.

NOEX G00 Z100......................×

• NOEX cannot be specified before an IF statement.

NOEX IF [AA EQ 0] N004........×

• NOEX cannot be specified before a GOTO statement.

NOEX GOTO N004..................×

• NOEX cannot be specified before a sequence number/label.

NOEX can be specified after a sequence number/label.

NOEX N001 V1 = 100..............×

N001 NOEX V1 = 100.............{

• NOEX cannot be specified before a CALL statement.

NOEX CALL OWMXA...............×

In modes other than the single block mode, NOEX has no influence on the execution of a program.

If NOEX is specified in a variable setting sequence, the execution time is shortened since the

sequence is excluded from single block processing. The operation itself does not vary regardless of

whether or not NOEX is specified.

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

1-1-2. Judging Local Variable Definition Using IF Statement

N2 IF Local-variable-name N3

5327-E P-2

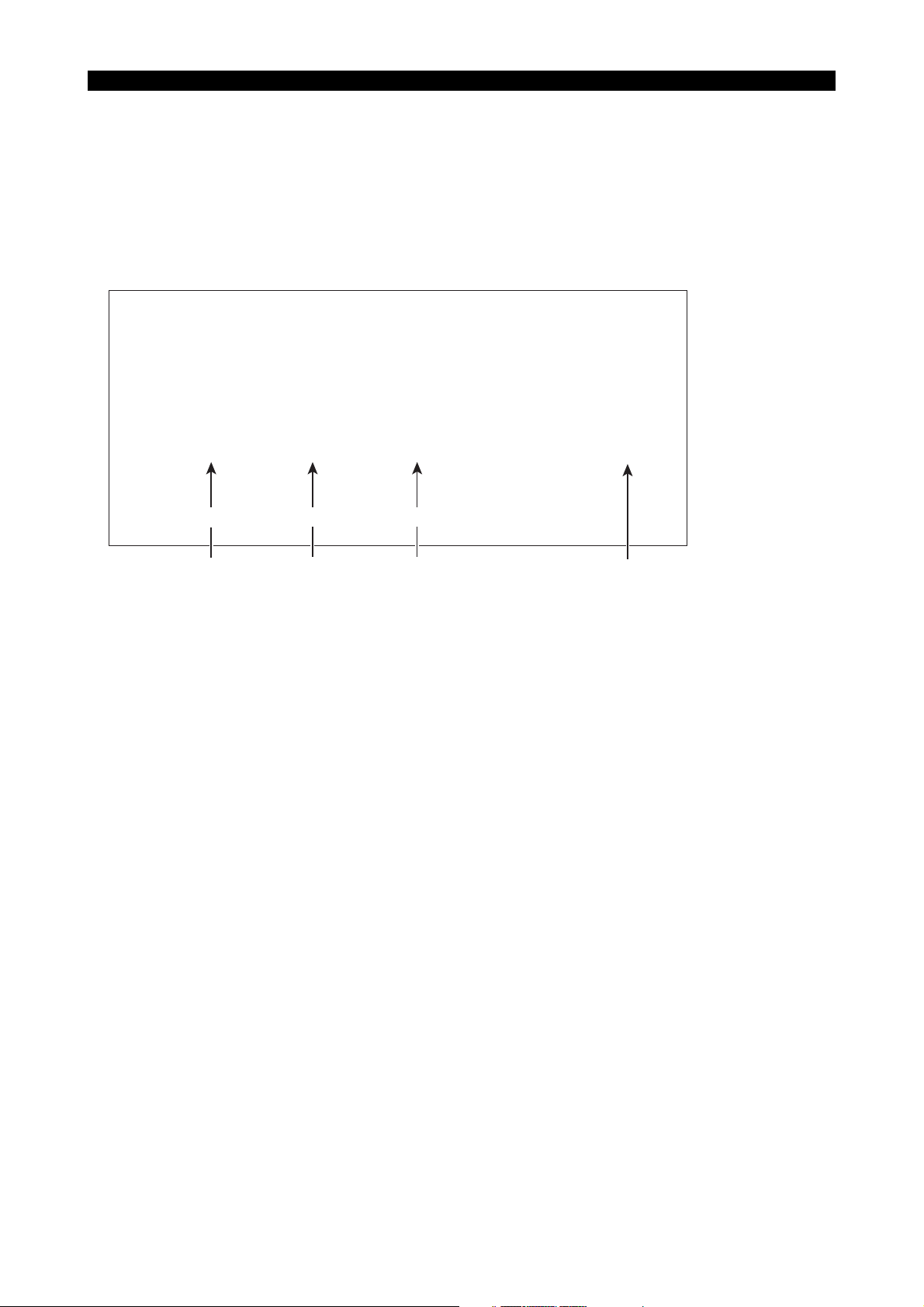

(1)

(2)

(3) (4)

LE61129R0200700030001

(1) Specify the sequence name of this block.

(2) This indicates that this sequence is the IF statement sequence.

(3) Specify the local variable name whose defined/undefined status is to be checked. Note that a

local variable name may not be enclosed by brackets ([ ]).

(4) Specify the sequence name of the destination block to which the program jumps if the specified

local variable has been defined.

The IF statement judges whether or not the specified local variable has been defined and causes a

jump to the N3 block if it has been defined.

If it has not been defined, the next block is executed.

Example:N1000 IF ABC N2000

If local variable ABC has been defined, the program jumps to the N2000 block.

If not, the program proceeds to the next block.

1-1-3. Calculating the Measured Value (Sensor Contact Point, Program Coordinate

System) (Gauging in the Z-axis Direction)

Measured value = VSKPZ [*] - VZOFZ - VZSHZ - VETFZ (* = 1 or 2)

After the execution of the G30 gauging cycle, the coordinate value of the contact point (in the

machine coordinate system) is set at VSKPZ.

X

Z

Machine zero

Contact point VSKPZ [*]

Measured

Zero offset

Zero shift

value

Tool offset value

value

LE61129R0200700040001

Measured value - Target value (MSP):

The difference between the “measured value” and the “target value (MSP)” is calculated as the

amount of variation and judgment is carried out based on this amount of variation.

[Supplement]

The coordinate value of the contact point is set at either variable VSKPZ [1] or VSKPZ [2]. In the

touch setter gauging cycle, the contact point coordinate value is set at VSKPZ [2]. In the touch

sensor gauging cycle (master ring gauging cycle, work gauging cycle), it is set at VSKPZ [1]. This

is also true for VSKPX [1] and VSKPX [2].

1-2. Control Statements

In gauging programs, the following control statements are used:

(1) GOTO statement

(2) IF statement

(3) CALL statement

(4) RTS statement

These control statements are all entered at the beginning of a block or immediately after the

“sequence name” which comes first in a block. They must be followed by a space or a tab code. If

no space or tab code is entered following a control statement, an alarm occurs.

However, note that since a left bracket “[“ is specified following IF statement, no space or tab code is

required after an IF instruction.

Example:

5327-E P-3

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

N1001 GOTO N2000

Enter a space or a tab code

NLAP1 GOTO NLAP2

LE61129R0200700050001

Specify either a space or a tab code immediately after an element consisting of two or more

consecutive address characters such as a sequence name or control code.

[Supplement]

A sequence name means a code that is used to identify a block in a program. It consists of four

alphanumeric digits following address N.

Sequence names can be expressed in two ways: [N] [4-digit number] and [N] [Alphabet] [3-digit

alphanumerics]

In this manual, sequence names include both of these two types of expression.

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

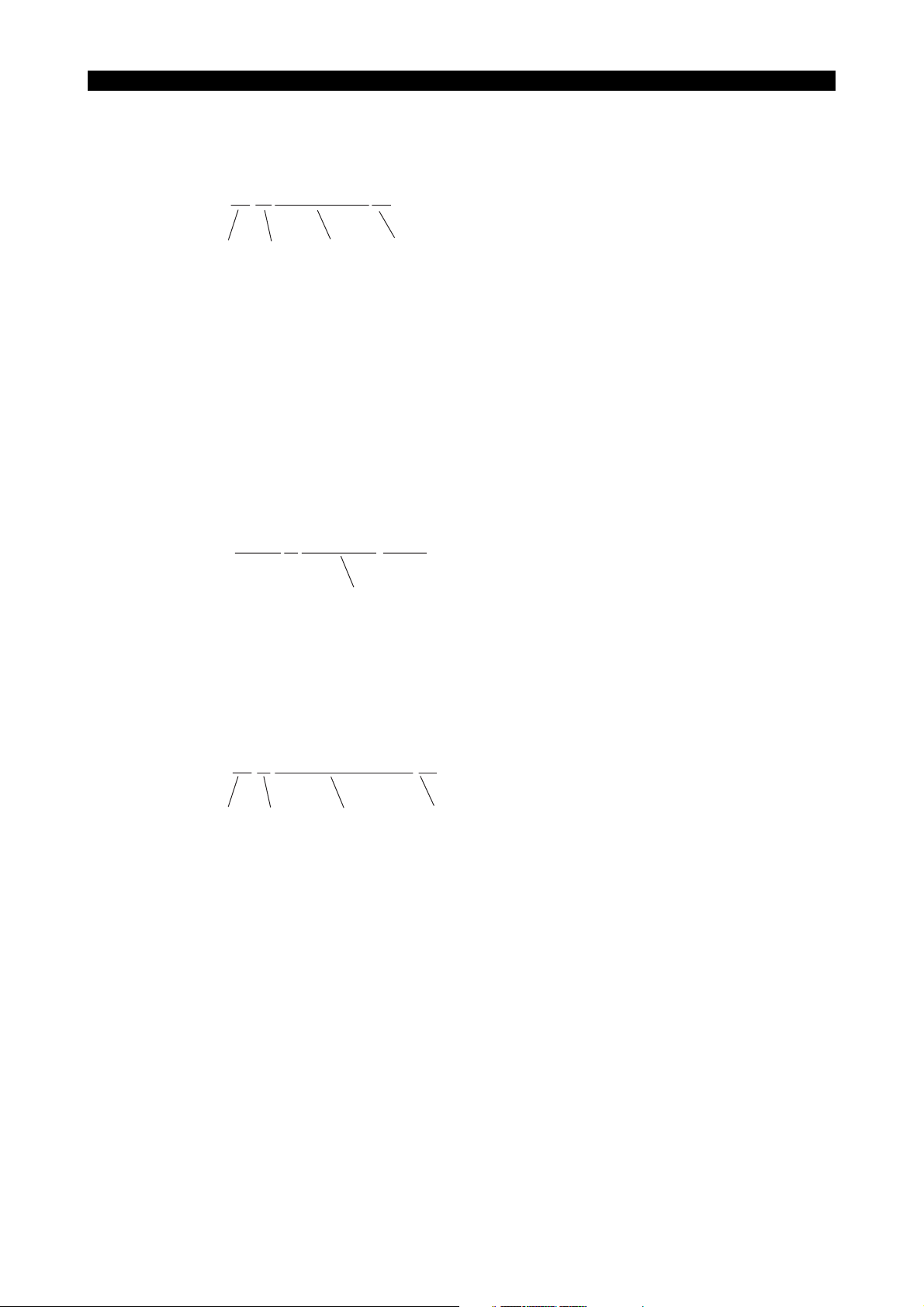

1-2-1. GOTO Statement (Unconditional Branch)

(1) Programming format

N0 GOTO N1

5327-E P-4

(a)

(b)

(c)

(a) Sequence name of this block. The sequence name may be omitted.

(b) Indicates a GOTO statement.

(c) Sequence name of the destination of branching. A branch destination sequence name

must always be specified.

LE61129R0200700060001

[Supplement]

The branch destination sequence name “N1” must be present in the same block where the control

statement (GOTO) is specified.

(2) Function

Program branches to the specified block (N1) unconditionally.

With a two-saddle model, branching from the turret A side program to the turret B side program

or from the turret B side program to the turret A side program is not allowed.

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

1-2-2. IF Statement (Conditional Branch)

(1) Programming format

N0 IF [Qualification] N1

5327-E P-5

(a)

(b)

(c) (d)

(a) Sequence name of this block. The sequence name may be omitted.

(b) Indicates an IF statement.

(c) There are two qualification states resulting from the comparison operation: "true" and "false."

The qualification must be enclosed by brackets ([ ]).

(d) The sequence name of the destination of branching that occurs if the result of qualification is

"true". The branch destination sequence name must always be specified.

LE61129R0200700070001

(2) Function

The program jumps to the specified block if the result of [qualification] is true.

If the result if false, the next block is executed.

Example:

N1000 IF [V1 EQ 10] N2000

This stands for "EQUAL".

LE61129R0200700070002

In the example program above, if “10” is set for variable V1 (V1 = 10), the program jumps to the

N2000 block. In other cases, the next block is executed.

(3) Evaluation of defined or undefined local variables by IF statement

N2 IF Local-variable name N3

(a)

(b)

(c) (d)

(a) Sequence name of this block.

(b) Indicates an IF statement.

(c) Local variable name whose defined/not defined status is to be evaluated. A variable name

may not be enclosed by brackets ([ ]).

(d) Sequence name of the destination of branching that occurs if the specified local variable

has been defined.

Whether the specified local variable has been defined or not is judged; if it has been

defined, the program jumps to the N3 block.

If it has not been defined, the next block is executed.

LE61129R0200700070003

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Example:

:

N1000 IF ABC N2000

:

:

N2000

In the example program above, if local variable ABC has been defined, the program jumps to

the N2000 block.

If it has not been defined, the next block is executed.

1-2-3. CALL Statement (Program Call)

(1) Programming format

N0 CALL O1 Q1 Variable-setting-part

5327-E P-6

LE61129R0200700070004

(a)

(b)

(d)

(c) (e)

(a) Sequence name of this block. The sequence name may be omitted.

(b) Indicates a CALL statement.

(c) Program name of the subprogram to be called. The program name must always be specified.

(d) The number of times the called subprogram should be repeated. The programmable range of

this repetition is from 1 to 9999. If the Q word is omitted, "Q1" is assumed.

(e) Set variables that are used in the subprogram to be called.

LE61129R0200700080001

(2) Function

The CALL statement calls and executes the specified subprogram (O1).

If variables are set in “variable setting set”, the specified variables are all registered.

Example: N1000 CALL O1234 XP1=150 ZP1=100

Calls and executes subprogram O1234 and registers variables XP1 and ZP1.

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

1-2-4. RTS Statement (Subprogram End Code)

(1) Programming format

N0 RST

(b)

(a)

(a) Sequence name of this block. The sequence name may be omitted.

(b) Indicates the end of the subprogram (RTS statement).

(2) Function

The RTS statement must always be specified at the end of a subprogram.

When this block is executed, the called subprogram ends and the program returns to the block

next to the CALL statement block.

Variables registered by the execution of the CALL statement and those registered in the called

subprogram are discarded.

Example:

5327-E P-7

LE61129R0200700090001

Main program

N1000 CALL O1234 XP1=150

ZP1=100

N1001 G00 X Z

:

:

:

Subprogram

O1234

N001 G00 X=XP1 Z=ZP1

N002

:

:

N050 RTS

:

LE61129R0200700090002

When N1000 in the main program is executed, program execution jumps to O1234 in the

subprogram and that subprogram is executed. After that, when the RTS statement in N050 is

executed, program execution jumps to the N1001 block and the blocks in the main program are

executed from N1001.

Variables XP1 and ZP1 are discarded.

program sequence

N1000 O1234

→

→→

N001 N050

→

N1001

LE61129R0200700090003

The sequence name specified as the jump destination must be present in the same

subprogram.

Designation of G13 and G14 is not allowed in a subprogram.

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

2. Touch Setter Gauging and Touch Sensor Gauging

2-1. Overview

2-1-1. General Description of MSB

This section covers the list, flow chart, variable table and other information relating to the touch

setter M/A and touch sensor gauging function, taking the following maker subprogram (MSB) as an

example.

LMSA300A.MSB

The name of the gauging control software is expressed as indicated below.

LMS*????.MSB

*: Indicates the content of the gauging software.

????: Indicates the gauging software version.

In this manual, the gauging control software is represented by “MSB”.

MSBs largely differ from other control software in their contents.

Other control software is used to control signals from the machine and also input/output of part

programs and/or user’s commands.

In contrast, MSBs have the same format as part programs, and they may be considered to be

control software that executes gauging cycles instead of an operator.

In the explanation below, LMSA300A.MSB (tool nose gauging using a touch sensor) is used as an

example. A variety of MSBs exist in addition to this program and the internal specification is specific

to the individual programs. However, the basic programming format, variables to be used, etc. are

common to all MSBs.

5327-E P-8

2-2. Variable Tables

The variables used in MSBs are explained in this section.

(1) Common variables (different from common variables V1 to V200 used for parameter setting)

(2) System variables 1 (used for reading and correcting various types of data)

(3) System variables 2 (used for transmitting data between turret A and turret)

(4) System variables 3 (used as counter for gauging functions)

(5) System variables 4 (used for screen display)

(6) Input/output variables (used for input/output)

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

2-2-1. Common Variables (VS01 to VS32)

Differing from common variables (V1 to V200) used for parameter setting, common variables VS01

to VS32 are not displayed on the screen.

5327-E P-9

Variable

No.

VS01 Tool offset number For printer output VS17 Not used

VS02 Target value For printer output VS18

VS03

VS04

VS05 Offset value (new) For printer output VS21

VS06 Result of judgment For printer output VS22

VS07 Not used VS23 Tool number Work gauging

VS08 Not used VS24

VS09 Not used VS25

VS10 Not used VS26 NG processing flag

VS11

VS12 Not used VS28

VS13 Not used VS29 Target point

VS14 Not used VS30 Compensation data

VS15

VS16 Not used VS32 Result of judgment

Function Remark

Gauging (measured)

value

Offset value

(previous)

Absplite value of

amount of varition

Gauging cycle

starting point X (Z)

coordinate value

For printer output VS19

For printer output VS20

Work/touch setter

gauging

Master ring/work/

touch setter gauging

Variable

No.

VS27

VS31

Function Remark

Absolute value of

judgment result

Sensor input number

(1 or 2)

Touch setter gauging

cycle start condition

judgment (=1:

Gauging)

Diameter gauging,

diameter gauging

value

Diameter gauging,

upper diameter

gauging value

Diameter gauging,

OD/ID judgment flag

(=0: OD, =1: ID)

NG double-contact

flag

Gauging direction

judgment flag (=0: Xaxis, =1: Z-axis)

Tool offset read-out,

tool breakage

detection cycle

judgment flag (=0:

Read-out cycle, =1:

Tool breakage

detection cycle)

Gauging (measured)

value

Work/touch setter

gauging

Master ring/work/

touch setter gauging

Touch setter

gauging

Work gauging

Work gauging

Work gauging

Work/touch setter

gauging

Touch setter

gauging

Work/touch setter

gauging

Touch setter

gauging

Master ring/work/

touch setter gauging

Work/touch setter

gauging

Master ring/work/

touch setter gauging

Work/touch setter

gauging

5327-E P-10

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

(1) Common variables V1 to V200 used for setting parameters are used in common for turrets A

and B. On the other hand, the common variables VS01 to VS32 indicated above are turret

dependent.

That is, turrets A and B have an independent VS01, for example, and the VS01 for turret A must

be specified and called out from turret A, while the VS01 for turret B must be specified and

called out from turret B.

(2) Note that these common variables (VS01 to VS32) will be used in other MSBs in addition to the

gauging cycle discussed here. Therefore, if these common variables are used as variables

transferred between subprograms, numerical values might be changed during the transfer.

When these common variables are used, their processing must end within the same

subprogram.

G13

N1 NOEX VS01=100

Variables used in common in G13 side program

N2 NOEX VS02=10 VS03=20

N3 CALL OSUB1

Within a subprogram, they can be used as desired.

N4

N5

N6

N7 CALL OSUB2

N8

Do not use common variables for transferring

numerical values from OSUB1 to OSUB2.

N9

N10

G14

N1 NOEX VS01=100 VS02=50

N2 CALL OSUB1

N3

N4

* Not used for transferring numerical values

N5

N6 NOEX VS01=100 VS03=60

N7 CALL OSUB3

N8

N9

M02

When calling more than one subprogram from a subprogram,

pay attention to the transfer of variables between

subprograms.

Variables used in common in G14 side program

LE61129R0200700120001

2-2-2. System Variables

System variables 1 are used in in-process gauging operations.

They have numerical values automatically determined by the CNC and are used for reading, writing,

and altering various types of data.

* The subscript expression is the numerical value that can be specified following a variable name in

the format [*].

5327-E P-11

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Variable

Name

VSIOX

VSIOZ

VSKPX

VSKPZ

VETFX Presently used tool offset data (X-axis) -99999.999 to 99999.999

VETFZ Presently used tool offset data (Z-axis) -99999.999 to 99999.999

VETON Presently used tool offset number 1 to 32

VETLN Presently used tool number 1 to 12

VRNGX

VRNGZ

VSNX

VSNZ

VGRSL Tool number selected within a tool group 0 to 12 1 to 12

VGRID

VTLNG

VTLOA Offset number (group 1) 0 to 32 1 to 12

VTLGN Group number the tool belongs to 0 to 12 1 to 12

VTLSN Tool life - preset count number 0 to 9999 1 to 12

VTLCN Actual machined number 0 to 9999 1 to 12

VTLST Tool life - preset time 0 to 359999 1 to 12

VTLCT Actual cutting time 0 to 359999 1 to 12

VTLSA Tool life - preset wear amount 0 to 999.999 1 to 12

VTLCA Actual tool wear amount 0 to 99999.999 1 to 12

VTLLF Flag indicating the tool life status 0 to 1 1 to 12

VTLOB Offset number (group 2) 0 to 32 1 to 12

VTLOC Offset number (group 3) 0 to 32 1 to 12

VZOFX X-axis zero offset data -99999.999 to 99999.999

VZOFZ Z-axis zero offset data -99999.999 to 99999.999

VZSHX X-axis zero shift data -99999.999 to 99999.999

Actual position of X-axis

(program coordinate system)

Actual position of Z-axis

(program coordinate system)

Sensor contact position of X-axis

(machine coordinate system)

Sensor contact position of Z-axis

(machine coordinate system)

Master ring position (X-axis)

(program coordinate system)

Master ring position (Z-axis)

(program coordinate system)

Sensor position (X-axis)

(machine coordinate system)

Sensor position (Z-axis)

(machine coordinate system)

Flag indicating an occurrence of automatic

indexing in a tool group

Flag indicating the result in a gauging cycle was

NG

Function Min - Max. - Values

-99999.999 to 99999.999

-99999.999 to 99999.999

-99999.999 to 99999.999 1 to 2

-99999.999 to 99999.999 1 to 2

-99999.999 to 99999.999

-99999.999 to 99999.999

-99999.999 to 99999.999 1 to 2

-99999.999 to 99999.999 1 to 2

0 to 1 1 to 12

0 to 1 1 to 12

Subscript

Expression

5327-E P-12

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Variable

Name

VZSHZ Z-axis zero shift data -99999.999 to 99999.999

VTOFX Tool offset data (X-axis) -99999.999 to 99999.999 1 to 32

VTOFZ Tool offset data (Z-axis) -99999.999 to 99999.999 1 to 32

Setting for OPTIONAL PARAMETER (GAUGING)

VSKFA

VSKFB

VNSRX Nose radius compensation data (X-axis) -99999.999 to 99999.999 1 to 32

VNSRZ Nose radius compensation data (Z-axis) -99999.999 to 99999.999 1 to 32

Feedrate in gauging cycle 2 (Feedrate for the first

contact detection in double-contact gauging cycle)

Setting for OPTIONAL PARAMETER (GAUGING)

Feedrate in gauging cycle 1

(Feedrate for the second contact detection in a

double-contact gauging cycle; feedrate for the

contact detection in a single-contact gauging

cycle)

Function Min - Max. - Values

1 to 500

1 to 500

Subscript

Expression

2-2-3. System Variables 2

System variables 2 are used for transferring data between turret A and turret B. They cannot be

displayed on the screen.

They are used in common for the two turrets.

Variable

Name

VMDT [1] Compensation data Master ring gauging

VMDT [2] Target value Work gauging

VMDT [3] Gauging (measured value) Work gauging

VMDT [4] Judgment Work gauging

VMDT [5] Compensation data Work gauging

Tool life management specification flag

VMDT [6]

VMDT [7] Diameter gauging, upper diameter gauging value

VMDT [8] Diameter gauging, lower diameter gauging value

VMDT [9] Diameter gauging, diameter gauging value

VMDT [10] Not used

VMDT [11] Not used

VMDT [12] Not used

The system variables for data transfer, indicated above, may be used in programs other than

gauging subprograms.

They can be used in the same manner as parameter setting common variables.

(=1: Specification supported, =0: Specification not

supported)

Function Remarks

Tool nose gauging,

Work gauging

2-2-4. System Variables 3

System variables 3 are used as counters for gauging cycles.

They are used for counting the specified events and also for setting the intervals between gauging

cycle executions.

They are used in common for turret A and turret B.

5327-E P-13

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Variable

Name

Function

Variable

Name

Function

VMCN [1] Master ring gauging cycle ON preset value Setting VMCN [17] Not used

VMCN [2] Master ring gauging cycle ON counter Counter VMCN [18] Not used

VMCN [3] Work gauging cycle ON preset value Setting VMCN [19] Not used

VMCN [4] Work gauging cycle ON counter Counter VMCN [20] Not used

VMCN [5] Read-out cycle ON preset value Setting VMCN [21] Not used

VMCN [6] Read-out cycle ON counter Counter VMCN [22] Not used

VMCN [7] Tool breakage detection cycle ON preset value Setting VMCN [23] Not used

VMCN [8] Tool breakage detection cycle ON counter Counter VMCN [24] Not used

VMCN [9] Not used VMCN [25] Not used

VMCN [10] Not used VMCN [26] Not used

VMCN [11] Not used VMCN [27] Not used

VMCN [12] Not used VMCN [28] Not used

VMCN [13] Not used VMCN [29] Not used

VMCN [14] Not used VMCN [30] Not used

VMCN [15] Not used VMCN [31] Not used

VMCN [16] Not used VMCN [32] Not used

Subprogram OCNCK is used for automatically incrementing a counter; when the counter data

reaches the preset value, it is cleared.

When the setting is “0”, the corresponding counter does not operate.

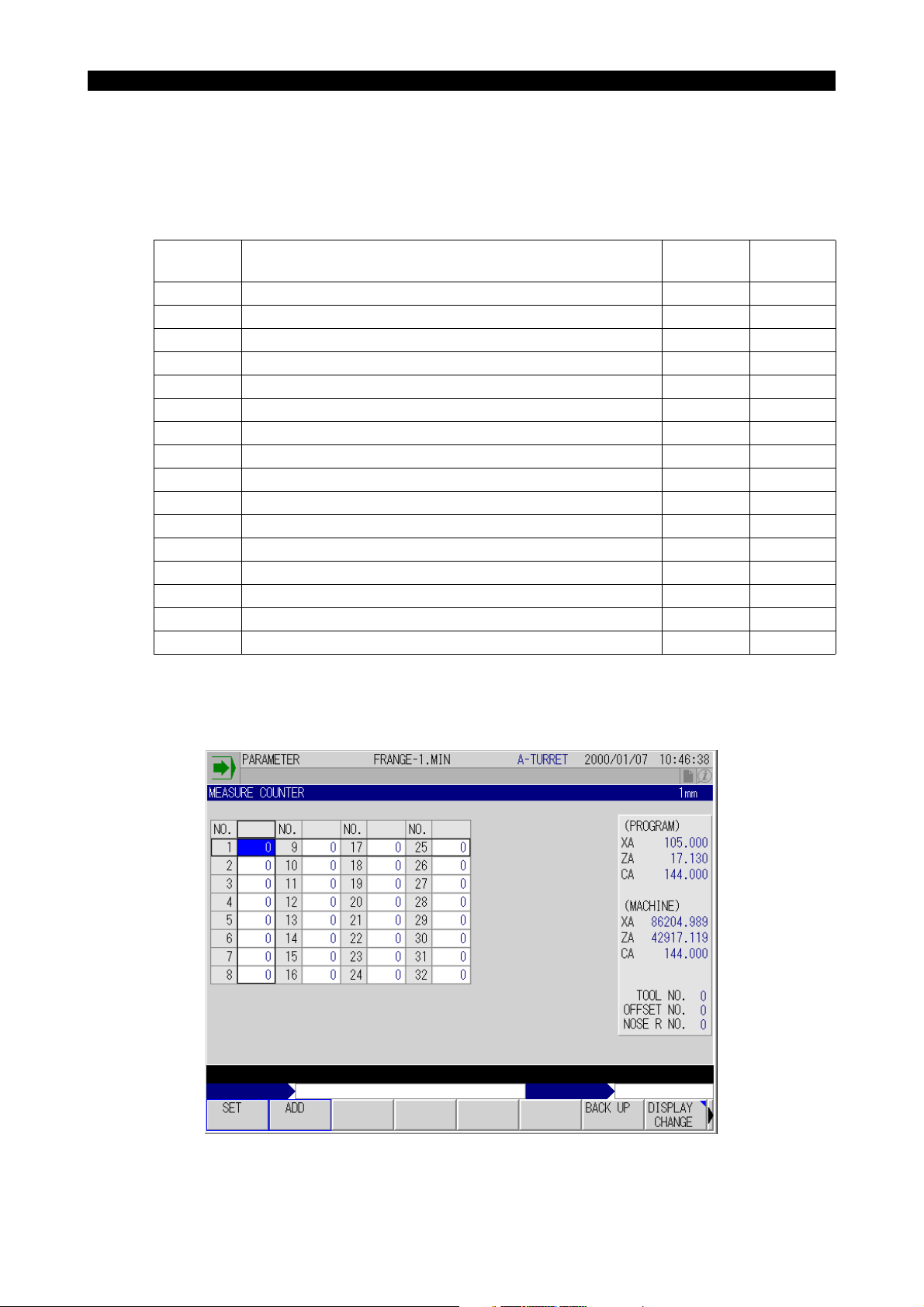

System variables VMCN[1] to VMCN[32] correspond to counters No. 1 to No. 32, respectively.

LE61129R0200700150001

System variables not assigned specific functions may be used and displayed in the same manner as

common variables.

Note that the range of numerical values that can be handled by these parameters is 0 to 9999

(positive integer).

2-2-5. System Variables 4

System variables 4 are used for display.

When a numerical value is set for the system variables indicated below, the set numerical value is

displayed at the specified field in the display screen.

They are independent for each of the turrets.

5327-E P-14

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Variable

Name

ID master ring gauging, Upper surface gauging

VIMDX [1]

VIMDX [2]

VIMDX [3]

VIMDX [4]

VIMDX [5]

VIMDX [6]

VIMDX [7]

VIMDX [8]

VIMDX [9] Not used Display available

VIMDX [10] Not used Display available

VIMDX [11] Spare

VIMDX [12] Spare

value

OD master ring gauging, X gauging value

ID master ring gauging, Lower surface gauging

value

Zero offset, Compensation data in the X-axis

direction (amount of variation)

Work gauging, Gauging (measured) value in the Xaxis direction

Touch setter gauging, Gauging (measured) value

in the X-axis direction

Tool offset, Compensation data in the X-axis

direction (amount of variation)

Diameter gauging, Upper diameter gauging

(measured) value in the X-axis direction

Diameter gauging, Lower diameter gauging

(measured) value in the X-axis direction

Function Remarks

Master ring gauging

Master ring gauging

Master ring gauging

Work gauging

Touch setter gauging

Work/touch setter

gauging

Work gauging

Work gauging

No display with standard

specification

No display with standard

specification

5327-E P-15

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Variable

Name

VIMDZ [1]

Master ring gauging, Gauging (measured) value in

the Z-axis direction

Function Remarks

Master ring gauging

VIMDZ [2] Not used Display available

VIMDZ [3]

VIMDZ [4]

VIMDZ [5]

VIMDZ [6]

Zero offset, Gauging (measured) value in the -Z

direction

Work gauging, Gauging (measured) value in the Zaxis direction

Touch setter gauging, Gauging (measured) value

in the Z-axis direction

Tool offset, Compensation data in the Z-axis

direction (amount of variation)

Master ring gauging

Work gauging

Touch setter gauging

Work/touch setter

gauging

VIMDZ [7] Not used Display available

VIMDZ [8] Not used Display available

VIMDZ [9] Not used Display available

VIMDZ [10] Not used Display available

VIMDZ [11] Spare

VIMDZ[12] Spare

No display with standard

specification

No display with standard

specification

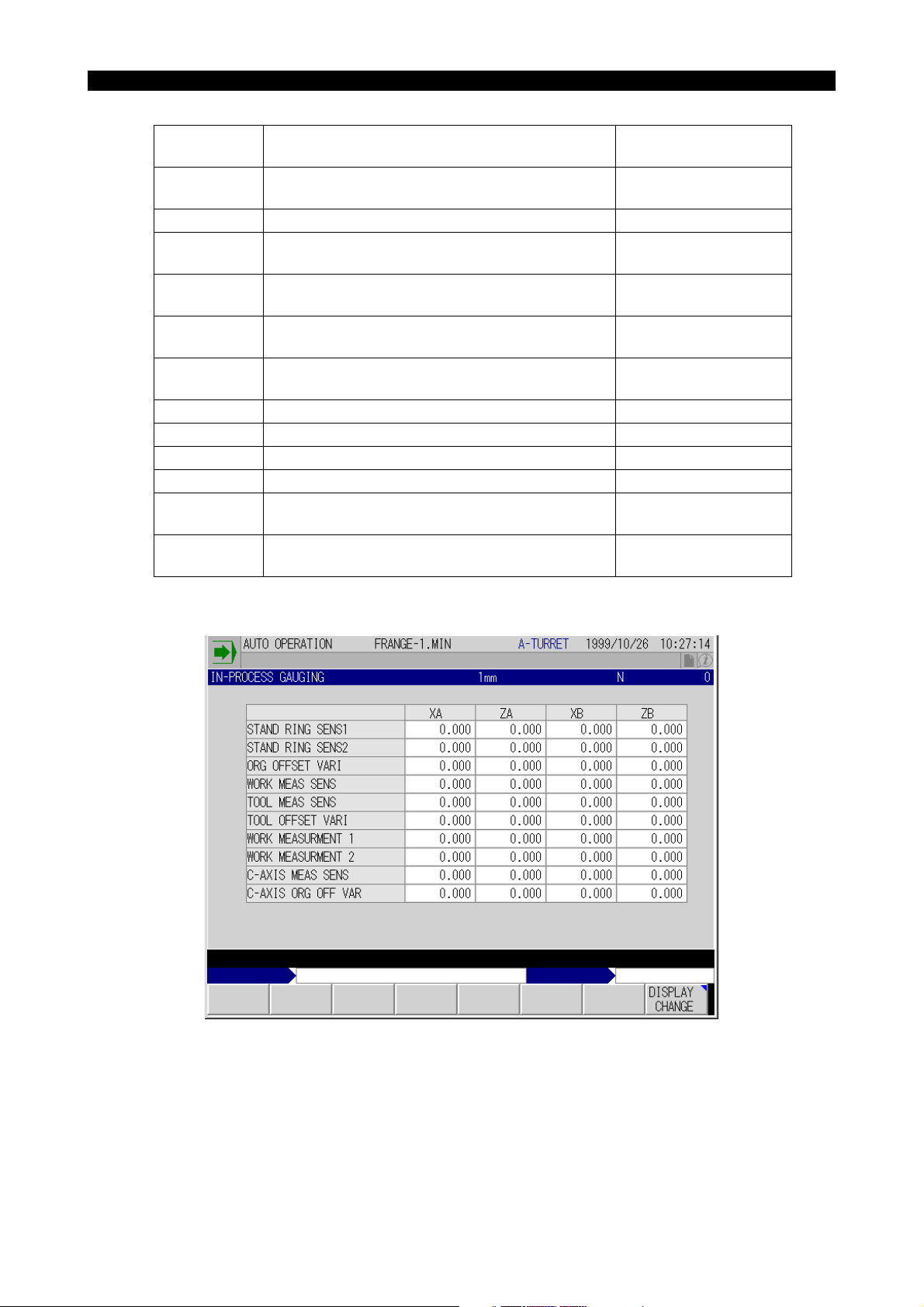

The data is displayed by selecting the IN-PROCESS GAUGING screen in the operation mode

(automatic, MDI, manual).

LE61129R0200700160001

The data set for VIMDX [*] and VIMDZ [*] (*: 1 to 10) is displayed on the screen shown above.

For VIMDX [*] and VIMDZ [*] (*: 11 and 12), data is not displayed with the standard specification.

The data input at the turret A side is displayed in the XA and ZA columns and the data input at the

turret B side is displayed in the XB and ZB columns.

Variables VIMDX [*] and VIMDZ [*] (*: 11, 12), which are not displayed on the screen, can be used

as variables.

2-2-6. Input/Output Variables

These variables are used to input and output signals to and from the MSB.

VDOUT is used for outputs and VDIN is used for inputs. The subscript determines the contents of

the inputs and outputs.

Output Variables

5327-E P-16

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Variable

Name

VDOUT [1] = 1:+NG indicating lamp is turned ON.

VDOUT [2] = 1:+OK indicating lamp is turned ON.

VDOUT [3] = 1:OK indicating lamp is turned ON.

VDOUT [4] = 1:-OK indication lamp is turned ON.

VDOUT [5] = 1:-NG indicating lamp is turned ON.

VDOUT [9] = 0:All judgment indicating lamps are turned OFF.

VDOUT [991] = ####: Outputs “ALARM C user reserve code ####”.

VDOUT [992] = ####: Outputs “ALARM B user reserve code ####”

VDOUT [993] = ####: Outputs “ALARM A user reserve code ####”.

Function

Special Input/Output Variables

The inputs and outputs of the input/output variables indicated below correspond to each other and

when the output variable is set ON (=1), the corresponding input is also set ON.

Variable

Name

VDOUT [31] = 1:The master ring gauging cycle ON lamp is turned on and “1” is set for VDIN [31].

VDOUT [32] = 1:The work gauging cycle ON lamp is turned on and “1” is set for VDIN [32].

VDOUT [33] = 1:The trial-cut gauging cycle ON lamp is turned on and “1” is set for VDIN [33].

VDOUT [34] = 1:The touch setter gauging cycle ON lamp is turned on and “1” is set for VDIN [34].

VDOUT [35]

VDIN [31]

VDIN [32] = 1:The work gauging cycle is turned ON. This is not checked within a subprogram.

VDIN [33]

VDIN [34]

VDIN [35]

= 1:The touch setter breakage detection cycle ON lamp is turned on and “1” is set

for VDIN [35].

= 1:The master ring gauging cycle is turned ON. This is checked within a

subprogram.

= 1:The trial-cut gauging cycle is turned ON. This is not checked within a

subprogram.

= 1:The touch setter gauging cycle is turned ON. This is checked within a

subprogram.

= 1:The touch setter breakage detection cycle is turned ON. This is checked within

a subprogram.

Function

2-3. Print

The print (PRNT) command can be used when the gauging data print function is selected.

When PRNT* (*: 1 to 14) is specified, the measured data is output to the printer.

The number to be specified with the PRNT command is fixed for each type of data to be output.

5327-E P-17

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Command

No.

PRNT 1 Work gauging cycle; turret A, X-axis

PRNT 2 Work gauging cycle; turret A, Z-axis

PRNT 3 Work gauging cycle; turret B, X-axis

PRNT 4 Work gauging cycle; turret B, Z-axis

PRNT 5 Master ring gauging cycle; turret A, X-axis

PRNT 6 Master ring gauging cycle; turret A, Z-axis

PRNT 7 Master ring gauging cycle; turret B, X-axis

PRNT 8 Master ring gauging cycle; turret B, Z-axis

PRNT 9 Touch setter gauging cycle; X-axis; data of the designated turret

PRNT 10 Touch setter gauging cycle; Z-axis; data of the designated turret

PRNT 11 Work gauging cycle; X-axis; data of the designated turret

PRNT 12 Work gauging cycle; Z-axis data of the designated turret

PRNT 13 Master ring gauging cycle; X-axis; data of the designated turret

PRNT 14 Master ring gauging cycle; Z-axis; data of the designated turret

2-3-1. Print Out Data

Set the measured data at the corresponding common variables (VS01 to VS06).

Items indicated by “{” are printed.

Function

Output

Variable

VS01

VS02 Target value {{{

VS03 Measured value {{{

VS04 Offset data before compensation {{ ×

VS05 Offset data after compensation {{ ×

VS06

Tool offset number whose tool offset data is

corrected

Result of judgment: 0 for ±OK, ±1 for OK, ±2 for

±NG

Function

Master

Ring

Gauging

× {{

× {{

Work

Gauging

Touch

Setter

Gauging

2-3-2. Print Format

Output format is indicated below.

Master ring gauging cycle

5327-E P-18

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

(1)

* * * MASTER RING GAUGING * * *

A.MIN A-TURRET X-AXIS

COMMAND

ACTUAL LAST-DATA NEW-DATA JUDGE

50.000 50.050 1568.000 1568.050 +OK

1997.8.28 THURSDAY 16:18:20

(2) (3) (4) (5)

(1) Name of file in which gauging cycle has been called

(2) Data set at VS02 (0 for turret B)

(3) Data set at VS03 (0 for turret B)

(4) Data set at VS04

(5) Data set at VS05

A-TURRET X-AXIS for PRNT5 (PRNT13 for turret A)

A-TURRET Z-AXIS for PRNT6 (PRNT14 for turret A)

B-TURRET X-AXIS for PRNT7 (PRNT13 for turret B)

B-TURRET Z-AXIS for PRNT8 (PRNT14 for turret B)

LE61129R0200700200001

In the printout of the data for turret B, the data for COMMAND and ACTUAL are both “0”.

This is because the actual gauging cycle is carried out by turret A and the data for turret B tools is

corrected using these data.

For the measured value in the X-axis direction in the ID master ring gauging cycle, the target value

with the amount of variation added is output to facilitate checking of the amount of variation.

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Work gauging cycle

PRNT1 (PRNT11 on turret A)A-TURRET X-AXIS

PRNT2 (PRNT12 on turret A)A-TURRET Z-AXIS

PRNT3 (PRNT11 on turret B)B-TURRET X-AXIS

PRNT4 (PRNT12 on turret B)B-TURRET Z-AXIS

* * * WORK GAUGING * * *

B.MIN A-TURRET X-AXIS

TOFF.NO. COMMAND ACTUAL LAST-DATA NEW-DATA JUDGE

7 50.000 50.050 10.000 9.950 +OK

1997.8.28 THURSDAY 16:18:20

5327-E P-19

(1) (2) (3) (4) (5)

(1) Data set at VS01

(2) Data set at VS02

(3) Data set at VS03

(4) Data set at VS04

(5) Data set at VS05

(6) Data set at VS06

Set any of 0, ±1 and ±2 for VS06, the variable for judgment.

The output is as indicated below according to this setting.

Setting Output Result

0OK

+1 +OK

+2 +NG

-1 -OK

-2 -NG

(6)

LE61129R0200700200002

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Touch setter gauging cycle

Turret A

•

PRNT9..........A-TURRET X-AXIS

PRNT10.........A-TURRET Z-AXIS

• Turret B

PRNT9...........B-TURRET X-AXIS

PRNT10.........B-TURRET Z-AXIS

* * * TOUCH SETTER GAUGING * * *

B.MIN A-TURRET X-AXIS

TOFF.NO. COMMAND ACTUAL JUDGE

8 50.000 50.050 +OK

5327-E P-20

1997.3.24 THURSDAY 17:25:31

(1) (2) (3) (4)

(1) Data set at VS01

(2) Data set at VS02

(3) Data set at VS03

(4) Data set at VS06

(The judgment result is displayed in the same manner as in the work gauging cycle.)

LE61129R0200700200003

2-4. Program

2-4-1. Table of Subprograms

The subprograms and their functions are briefly described below.

5327-E P-21

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Subprogram No.

(1) ORGIA

(2) ORGOA

(3) ORNGB

(25) OZTM

(4) OWMXA

(5) OWMZA

(6) OWXBA

(7) OWZBA

(8) OWXBB

(9) OWZBB

(10) OWXZ

(12) OTNSL

(14) OMSSF

Subprogram

Name

Function

Master ring gauging ID: To be called from turret A

If called while the chuck is closed, an alarm occurs.

Master ring gauging OD: To be called from turret A

Used for correcting the zero offset data of the X- and Z-axis for turret A.

Master ring gauging - processing at turret B: To be called from turret B

Used for correcting the zero offset data of the X- and Z-axis for turret B

based on the data for turret A.

Judgment cycle for master ring gauging cycle

To be called within a gauging subprogram

The result of measurement is classified into five levels: OK, ±OK and

±NG.

Work gauging - Turret A in the X-axis direction: To be called from turret A

Measures the dimension of a workpiece machined by a tool on turret A in

the X-axis direction and corrects the X offset data.

Work gauging - Turret A in the Z-axis direction: To be called from turret A

Measures the dimension of a workpiece machined by a tool on turret A in

the Z-axis direction and corrects the Z offset data.

Work gauging - Turret B in the X-axis direction: To be called from turret A

Measures the dimension of a workpiece machined by a tool on turret B in

the X-axis direction

For turret B, OWXBB must be called.

Work gauging - Turret B in the Z-axis direction: To be called from turret A

Measures the dimension of a workpiece machined by a tool on turret B in

the Z-axis direction

For turret B, OWZBB must be called.

Work gauging - Turret B in the X-axis direction: To be called from turret B

To be called from turret B when OWXBA is called at turret A.

Based on the data measured at turret A, the X direction tool offset data is

corrected for tools on turret B.

Work gauging - Turret B in the Z-axis direction: To be called from turret B

To be called from turret B when OWZBA is called at turret A.

Based on the data measured at turret A, the Z direction tool offset data is

corrected for tools on turret B.

Work gauging - processing of measured data: To be called within the

gauging cycle subprogram

Measured data is processed according to the result of judgment.

Checks ATG and AOG commands, and selects the tool number and tool

offset number.

To be called within a subprogram. Determines whether the tool life

management function is used or not. An alarm occurs if an ATG or AOG

command is not correct.

Cancels the gauging cycle START conditions: To be called from both

turrets A and B

Turns off all gauging cycle START conditions.

5327-E P-22

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Subprogram No.

(15) OTRCK

(16) OTST

(13) OCNCK

(17) OTLLS

(18) OTFRD

(19) OTMXZ

(20) OSKPX

(21) OSKPZ Executes the same processing as OSKPX in the direction of Z-axis.

(22) OSPCX

(23) OSPCZ Executes the same processing as OSPCX in the Z-axis direction.

(24) OT1ME Executes a 0.1 sec dwell.

(11) OWTM

(26) ODOAA

(27) ODIAA

Subprogram

Name

Function

Checks conditions for starting the trial-cut gauging cycle: To be called

from both turrets A and B

Turns ON the conditions for starting the trial-cut gauging cycle when

automatic tool indexing is conducted by the tool life management

function.

Checks conditions for starting the touch setter gauging cycle: To be called

in the block before the tool gauging cycle block.

Turns ON the conditions for starting the touch setter gauging cycle when

they are turned on by the counter or when automatic tool indexing has

been executed by the tool life management function.

Counter for checking the gauging cycle START conditions: To be called

from either turret A or turret B.

Compares the value set at the gauging cycle counter with the counter

data and turns on the gauging cycle START conditions if the counter data

has reached the preset value.

Touch setter gauging - tool breakage detection cycle: To be called from

the turret on which the tool to be measured is set.

Checks chipping or breakage of the tool both in the X- and Z-axis

directions.

Touch setter gauging - tool offset data read-out cycle: To be called from

the turret on which the tool to be measured is set.

Checks the wear amount of the tool both in the X- and Z-axis direction and

corrects the tool offset data.

Touch setter gauging cycle - processing cycle: To be called from OTFRD

or OTLLS.

Executes a gauging cycle by calling OWTM and processes the obtained

data.

Executes an actual gauging cycle in the X-axis direction with the gauging

cycle start command (G30). This subprogram also determines whether

the cycle programmed is the “single-contact” cycle or the “double-contact”

cycle. This determination is based on whether argument APPS

(argument that specifies the second approach point in the double-contact

gauging cycle) is specified or not. This subprogram is called from a

gauging cycle subprogram.

Converts the coordinate value of the X-axis direction sensor “touch” point,

which is read in terms of the machine coordinate system, into the

coordinate value in the program coordinate system.

Work gauging/Touch setter gauging - Measuring and judgment cycle: To

be called from a gauging subprogram

The result of actual measurement is classified into five levels: OK, ±OK

and ±NG.

Diameter gauging - OD by turret A: To be called from turret A

Measures the dimension (OD in the X-axis direction) of the workpiece

machined by a tool on turret A and corrects the X-axis tool offset data.

Diameter gauging - ID by turret A: To be called from turret A

Measures the dimension (ID in the X-axis direction) of the workpiece

machined by a tool on turret A and corrects the X-axis tool offset data.

5327-E P-23

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Subprogram No.

(28) ODOBA

(29) ODIBA

(30) ODMBB

(31) ODWTM

(32) OTGNM Obtains the maximum value of the tool group No.

(33) OSNCA

(34) OSNMZ

(35) OSNMX

Subprogram

Name

Function

Diameter gauging - OD by turret B: To be called from turret B

Measures the dimension (OD in the X-axis direction) of the workpiece

machined by a tool on turret B.

For turret B, ODMBB must be called.

Diameter gauging - ID by turret B: To be called from turret B

Measures the dimension (ID in the X-axis direction) of the workpiece

machined by a tool on turret B.

For turret B, ODMBB must be called.

Diameter gauging - Turret B: To be called from turret B

Based on the data measured at turret A, the tool offset data on turret B is

corrected.

Measuring and judgment cycle for diameter gauging: To be called from a

gauging subprogram

The result of actual measurement is classified into five levels: OK, ±OK

and ±NG.

Touch setter gauging for correcting the sensor position.

This subprogram measures and compensates the sensor position.

Touch setter gauging called by OSNCA.

This subprogram measures and corrects the sensor position in the Z-axis

direction.

Touch setter gauging called by OSNCA.

This subprogram measures and corrects the sensor position in the X-axis

direction.

2-5. Flow Charts

2-5-1. Master Ring Gauging

Master ring ID gauging cycle

This subprogram is called from turret A

ORGIA

5327-E P-24

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

VRSTT=0

YES

M100

VDIN[31]=0

NO

Is chuck NO.1 open?

YES

XSTP=VSIOX

ZSTP=VSIOZ

VDIN[1255]AND32≠32

NA1

YES

GOO X=-[TOFX[TOF1]-VTOFX[TOF2]/2

Z=ZP1

T=TLN*100+TOF1 M155

NA2

Z=ZP2

VS29=VRNGX

VS19=1

NO

Waiting for

synchronization

with turret B

YES

NO

3C

Storing the start position

Moving the sensor to P2

Setting the gauging target value

(X-coordinate of ring upper face)

Determining the sensor input number

Sequence restart OFF?

Gauging cycle is not ON

3B

NO

GOO X=-[[VTOFX[TOF1]+VTWOX[TOF1]]

-[VTOFX[TOF2]+VTWOX[TOF2]]]/2

Z=ZP1 T=TLN*100+TOF1 M155

Bringing the sensor to

the center of master ring

TLN: tool number only

OSKPX

VIMDX[1]=VS31

VDIN[1255]AND32≠32

YESNA3

GOO X=[TOFX[TOF1]-VTOFX[TOF2]]/2

T=TOF2

NA4

Calling the X-direction gauging subprogram

CRT display (measured value 1)

2A

NO

Setting the sensor offset

value at TOF2

GOO X=[[VTOFX[TOF1]+VTWOX[TOF1]]

-[VTOFX[TOF2]+VTWOX[TOF2]]]/2

T=TOF2

LE61129R0200700220001

2A

5327-E P-25

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

VS29=-VRNGX

OSKPX

VIMDX[2]=VS31

VS32=[VIMDX[1]+VS31]/2

VS27=0

OZTM

VIMDX[3]=VS32

VS02=VRNGX

VS03=VIMDX[3]+VS02

VS04=VZOFX

VS06=VS30

VZOFX=VZOFX+VIMDX[3]

VS05=VZOFX

PRNT 13

VMDT[1]=-VIMDX[3]

Setting the gauging target value

(X-coordinate of ring lower face)

Calling the X-direction gauging subprogram

Measured value 2

Variation in zero offset X

Judging the gauging result

Compensation data in X direction

Target value 2

Measured value

Previous zero offset value

Result of judgment

Zero offset in X direction

New zero offset value

Print command

Setting the variation at the system variable common to

turrets A and B (to transfer the variation to turret B)

M100

G00 Z=ZP3

X=XP3 T=TOF1

VS29=VRNGZ

OSKPZ

3A

Waiting for synchronization with turret B

Moving the sensor to P3

Setting the sensor offset value at TOF1

Setting the target value (Z-coordinate of master ring)

Calling the Z - direction gauging subprogram

LE61129R0200700220002

3A

5327-E P-26

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

VMIRZ=0

NO

YES

Do machine coordinate system

and program coordinate system

have the same Z-axis direction?

VS31=-VS31

NA5

CRT display

VIMDZ[1]=VS31

VS32=VS31-VRNGZ

Measured value

Variation

VS27=1

OZTM

Judging the gauging result

VIMDZ[3]=VS32

VS06=VS30

Setting the

printing data

VS02=VRNGZ

VS03=VS31

VS04=VZOFZ

Target value

Measured value

Previous zero offset value

VZOFZ=VS04+VIMDZ[3]

VS05=VZOFZ

PRNT 14

Print command

VMDT[1]=VIMDZ[3]

M100

VDIN[1255]AND32≠32

Waiting for synchronization with turret B

Zero offset in Z direction

New zero offset value

Setting the variation at the system variable

common to turrets A and B

(to transfer the variation to turret B)

NO

NA6 YES

G00 X=-[TOFX[TOF1]-VTOFX[TOF2]]/2 G00 X=[[VTOFX[TOF1]+VTWOX[TOF1]]

-[VTOFX[TOF2]+VTWOX[TOF2]]]/2

NA7

NA8

3C

VMDT[1]=0

VDOUT[992]=1100

Alarm B

chuck is

not closed

3B

Z=ZP1

X=XSTP Z=ZSTP M154

NA9

M100

Terminating the gauging cycle after synchronization with turret B

NA10

RTS

Retracting the sensor to the start point

M154: air blow OFF

LE61129R0200700220003

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Master ring OD gauging cycle

This subprogram is called from turret A.

ORGOA

5327-E P-27

VRSTT=0

YES

M100

VDIN[31]=0

Waiting for synchronization

with turret B

NO

YES

NO

Storing the

start position

XSTP=VSIOX

ZSTP=VSIOZ

G00 X=XP1 Z=ZP1 T=TLN*100+TOF M155

X=XP2 Z=ZP2

Z=ZP3

VS29=VRNGX

VS19=1

OSKPX

VIMDX[1]=VS31

Moving the sensor to P2

Setting the gauging target value (X-coordinate of ring upper face)

Determining the sensor input number

Calling the X-direction gauging subprogram

Measured value

Sequence restart OFF?

Gauging cycle is not ON

3B

Setting the

printing data

VS32=VS31-VRNGX

VS27=0

OZTM

VIMDX[2]=0

VIMDX[3]=VS32

VS02=VRNGX

VS03=VS31

VS04=VZOFX

VS06=VS30

2A

CRT display (variation)

Target value

Measured value

Previous zero offset

LE61129R0200700220004

2A

5327-E P-28

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

CRT display

VZOFX=VZOFX+VIMDX[3]

VS05=VZOFX

PRNT 13

Print command

VMDT[1]=-VIMDX[3]

M100

G00 Z=ZP2

Waiting for synchronization with turret B

Moving the sensor to P2

X=XP3

VS29=VRNGZ

OSKPZ

VMIRZ=0

Setting the target value (Z-coordinate of master ring)

Calling the Z-direction gauging subprogram

YES

NO

VS31=-VS31

NB2

VIMDZ[1]=VS31

VS32=VS31-VRNGZ

VS27=1

Zero offset in X direction

New zero offset

Setting the variation at the system variable common to

turrets A and B (to transfer the variation to turret B)

Do machine coordinate and program coordinate

system have the same Z-axis direction?

Measured value

Variation

Setting the printing

data

VZOFZ=VZOFZ+VIMDZ[3]

VS05=VZOFZ

OZTM

VIMDZ[3]=VS32

VS02=VRNGZ

VS03=VS31

VS04=VZOFZ

VS06=VS30

3A

Target value

Measured value

Previous zero offset

LE61129R0200700220005

3A

5327-E P-29

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

PRNT 14

VMDT[1]=VIMDZ[3]

M100

G00 X=XP2

X=XP1 Z=ZP1

X=XSTP Z=ZSTP M154

M100

Print command

Setting the variation at the system variable common to

turrets A and B (to transfer the variation to turret B)

Waiting for synchronization with turret B

Moving the sensor to P2

Retracting the sensor to P1

Retracting the sensor to the start point

M154: air blow OFF

Terminating the gauging cycle after

synchronization with turret B

NB1

RTS

Master ring gauging cycle

This subprogram is called from turret B.

ORNGB

NO

VRSTT=0

YES

M100

Sequence restart OFF?

Waiting for synchronization with turret A

3B

LE61129R0200700220006

YES

VDIN[31]=0

M100

VS04=VZOFX

VZOFX=VS04+VMDT[1]

VS05=VZOFX

VIMDX[3]=VMDT[1]

PRNT 13

M100

VS04=VZOFZ

VZOFZ=VS04+VMDT[1]

VS05=VZOFZ

VIMDZ[3]=VMDT[1]

PRNT 14

M100

RTS

Gauging cycle is not ON

NO

Waiting for completion of Z-direction gauging on turret A

Setting the previous zero offset X (for printing)

Zero offset in X-direction on turret B

Setting the new zero offset X (for printing)

Setting the variation in X-direction displayed on CRT at the system

variable common to turrets A and B (gauging result obtained on turret A)

Print command

Waiting for completion of Z - direction gauging on turret A

Setting the previous zero offset Z (for printing)

Zero offset in Z-direction on turret B

Setting the new zero offset Z (for printing)

Setting the variation in Z-direction displayed on CRT at the system

variable common to turrets A and B (gauging result obtained on turret A)

Print command

Terminating the gauging cycle after synchronization with turret A

NC1

LE61129R0200700220007

2-5-2. Work Gauging

Work gauging cycle (Turret A, in the X/Z-axis direction)

This subprogram is called from turret A.

Setting the flag for judging

the gauging direction

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

OWMXA OWMZA

VS27=0 VS27=1

Gauging in

X direction

ND1

M155

Air blow ON

5327-E P-30

Gauging in Z direction

NO

VRSTT=0

Sequence restart OFF?

YES

VDOUT[9]=0

VS25=0

VS29=MSP

VS19=1

OTNSL

Judgment indicator lamp OFF

Flag for NG double-touch gauging

Setting the gauging target point

Determining the sensor input number

Determining whether the tool life management function

is used or not, checking ATG and AOG commands, and

selecting the tool number and the tool offset number

VS17=0

OWTM

Executing the gauging cycle and judging the

measured data

VMDT[2]=MSP

VMDT[3]=VS31

VMDT[4]=VS30

VMDT[5]=VS32

YES

X direction Z direction

VS27=0

Target point

Measured value

Judgment

Compensation data

NO ND4

VDIN[1255]AND32≠32 VDIN[1255]AND32≠32

NO NO

ND2 YES ND5 YES

VIMDX[4]=VS31

VS04=VTOFX[VS01]

VIMDX[4]=VS31

VS04=VTWOX[VS01]

VIMDZ[4]=VS31

VS04=VTOFZ[VS01]

ND3 ND6

OWXZ

Calling the subprogram for

processing measured data

VIMDX[6]=-VMDT[5] VIMDZ[6]=-VMDT[5]

PRNT 11

Print command

Variation in tool

offset

ND7

M154

Air blow OFF

RTS

VIMDZ[4]=VS31

VS04=VTWOZ[VS01]

OWXZ

PRNT 12

LE61129R0200700230001

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Work gauging cycle (Turret A, in the X/Z-axis direction)

This subprogram is called from turret A.

5327-E P-31

Setting the flag for judging

by Turret B in Z Direction

(Called from Turret A)

NO

VMDT[2]=MSP

VMDT[3]=VS31

VMDT[4]=VS30

VMDT[5]=VS32

VS18=ABS[VS30]

Is the result

±NG?

OK or ±OK

OWXBA

VS27=0 VS27=1

Gauging in

X direction

OWZBA

NE1

M155

VRSTT=0

Air blow ON

Sequence restart OFF?

YES

M100

M100

VDOUT[9]=0

VS25=0

VS29=MSP

Starting the gauging cycle in synchronization with turret B

Waiting for the tool offset number to be selected on turret B

Judgment indicator lamp OFF

Flag for NG double-touch gauging

Setting the gauging target point

VS17=0

VS19=1

OWTM

Determining the sensor input number

Executing the gauging cycle and judging the measured data

Target point Setting the left values at the system

Measured value variables common to turrets A and B

Judgment (to transfer the values to turret B)

Compensation data

Using the absolute value of the result for the subsequent

processing executed after synchronization

VS18=2

NE2

M100

YES ±NG

NO

Ignoring NG YES

Starting the gauging data

processing on turret B

VMDT[6]=0

VDIN[21]=1

NE3

M100

Waiting for the data processing on turret B

Gauging in Z direction

Tool life management function OFF?

YES

NO

NG ignore button ON?

NO

M100

M154

RTS

Waiting for synchronization when the result is ±NG

NE4

Air blow OFF

M100 code (waiting for synchronization) is issued to turret B only twice

when the result is NG through it is issued three times when the result is OK.

This is to prevent the turret A from finishing the gauging subprogram and

executing the next sequence before the alarm occurs on turret B. If NG is

ignored (no alarm occurs), however, M100 is issued three times as in the

case where the result is OK or ±OK.

LE61129R0200700230002

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

j

Work gauging cycle (Turret B, in the X/Z-axis direction)

This subprogram is called from turret A in combination with OWXBA or OWZBA.

5327-E P-32

OWZBB

Gauging in Z direction

Setting the flag for

udging the gauging

direction

NO

OWXBB

VS27=0 VS27=1

Gauging in

X direction

NF1

VRSTT=0

Sequence restart OFF?

YES

M100

OTNSL

Determining whether the tool life management function is

used or not, checking ATG and AOG commands, and

selecting the tool number and the tool offset number

M100

M100

VS27=0

X direction

VIMDX[4]=VMDT[3]

VS04=VTOFX[VS01]

OWXZ

Starting the gauging cycle by turret A

Waiting for completion of the turret A gauging cycle

NO

YES

Z direction

NF2

VIMD4[4]=VMDT[3]

VS04=VTOFZ[VS01]

OWXZ

Calling the gauging data

CRT display

Setting the measured value

(gauging result on turret A)

through the system variable

common to turrets A and B

Previous tool offset (for printing)

processing subprogram

VIMDX[6]=-VMDT[5] VIMDZ[6]=-VMDT[5]

CRT display

Setting the variation in tool offset

(gauging result on turret A)

PRNT 11

NF3

M100

Waiting for synchronization with turret A

PRNT 12

through the system variable

common to turrets A and B

M100

RTS

Waiting for synchronization when the result is NG

NF4

LE61129R0200700230003

5327-E P-33

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Work gauging cycle (Measured data processing, screen output, printer output)

OWXZ

VS02=VMDT[2]

VS03=VMDT[3]

VS06=VMDT[4]

VS18=ABS[VS06]

YES

VS18=1

VS05=VS04

VMDT[5]=0

VS18=2

±OK

processing

1

NG3

VS02 to VS06: variables used for output to the printer

Target value

Measured value

Result of judgment

Using the absolute value of the result to determine the processing

to be executed

NO (OK processing, ±NG processing)

Printing the new offset data (previous data if the result is ±NG or OK)

Setting the variation at the system variable common to turrets A and B

(variation is 0 if the result is ±NG or OK)

YES(±NG)

NO

No action is

taken when the

result is OK

VMDT[6]=0

NG1

VS06>=0

NO (Tool life management)

VDIN[21]=1

YES

NO(-NG)

YES(+NG)

M154 M154

VDOUT[992]=1001+VS27*2

Alarm No.1001 for X-direction gauging (VS27=0)

Alarm No.1003 for Z-direction gauging (VS27=1)

VDOUT[992]=1000+VS27*2

Alarm No.1000 for X-direction gauging (VS27=0)

Alarm No.1002 for Z-direction gauging (VS27=1)

YES (NG ignored)

NO

Setting the NG flag at

the tool life management

table without causing

any alarm

VTLNG[VS23]=1

VDIN[1255]AND32≠32

NG5 YES

VS27=0

NO NO

NG6 YES NG4 YES

VTOFX[VS01]=VTOFX[VS01]

-VMDT[5]

VS05=VTOFX[VS01]

VTOFZ[VS01]=VTOFZ[VS01]

-VMDT[5]

VS05=VTOFZ[VS01]

NG7

Tool life management function OFF?

VMDT[6]=0

NO

TRCT

TRCT specified?

YES

TRCT=1

Addition of compensation data ignored?

NO

VTLCA[VS23]=VTLCA[VS23]

+ABS[VMDT[5]]

NG9

RTS

NO

Adding the compensation data

to the accumulated wear in the

tool life management table C

VS27=0

VTWOX[VS01]=VTWOX[VS01]

-VMDT[5]

VS05=VTWOX[VS01]

YES

NO

YES

VTWOZ[VS01]=VTWOZ[VS01]

-VMDT[5]

VS05=VTWOZ[VS01]

1

LE61129R0200700230004

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

Work gauging data judgment cycle

5327-E P-34

NG double-touch

gauging?

YES

1

Judgment

indicator lamp

ON

OWTM

NH1

VS25=1

VS27=0

NO

NH2

YES

OSKPX

Calling the X-direction

gauging and judging

subprogram

OSKPZ

Calling the Z-direction

gauging and judging

subprogram

Is the turret-B program for touch setter IA gauging unused?

VS17=0

YES

NO

VS27=1

Gauging in X direction?

YES

NH3A

NO

VS32=VS29-VS31 VS32=VS31-VS29

NH3B

VS11=ABS[VS32]

Using the absolute value of the variation for the subsequent

judgment

VIMDX[12]=VS11

VIMDZ[12]=DNG

±NG?

VIMDX[12]

>VIMDZ[12]

NO

VIMDZ[12]=DOK

YES

APPS

NO

YES

VIMDX[12]

>VIMDZ[12]

VS25=0

NH4

NO

VS32>0

+NG

YES YES

VDOUT[1]=1

VS30=2

NO

NH5

-NG

VDOUT[5]=1

VS30=-2

NH7

VS32>0

+OK

VDOUT[2]=1

VS30=1

NH9

RTS

The touch sensor gauging may be performed simultaneously on turret A

and turret B(though work gauging is performed only on turret A), and so

the target value, measured value, ,judgment, and compensation data are

set at the common variables prepared separately for turrets A and B. For

work gauging, these values are set at the variables common to turrets A

and B to transfer the data from turret A to turret B.

1

Regarding that the sensor

has touched the work twice

Variation = Measured value

- Target value

NH6

±OK?

NO

YES

+OK?

NO

NH8

-OK

VDOUT[4]=1

VS30=-1

OK

VDOUT[3]=1

VS30=0

LE61129R0200700230005

Tool offset number indexing

OTNSL

VS01=0

NO

ATG

YES

AOG

YES

N14

VMDT[6]=1

N12

VMDT[6]=0

NO

5327-E P-35

SECTION 1 MAKER SUBPROGRAMS FOR GAUGING (MSB)

OTNSL: subprogram for checking ATG and AOG

command values and selecting tool offset number

VS01: variable used to output the tool offset number to

the printer

Tool offset number?

Is ATG (tool group number) specified?

NO

N13 YES

VS01=TOFN

TOFN

N17

OTGNM

Setting the maximum tool group number at VS07

Is ATG command value within allowable range?

0<ATG<VS07

NO

YES

VS23=VGRSL[ATG]

VS23=0

AOG=1

Are tools registered in the specified tool group?

AOG=2

AOG=3

NONONO

YES YES YES

VS01=VTLOA[VS23] VS01=VTLOB[VS23] VS01=VTLOC[VS23]

VS01=0

Tool offset number unregistered?

YES

N18

NO

VDOUT[992]=1008

N19

RTS

M154

M126

When both ATG and AOG are specified, data is processed assuming the tool life

management specification. If one of the commands is omitted, the tool offset number