Nissan XTrail T30 2006 User Manual

TRANSFER

D DRIVELINE/AXLE

A

B

SECTION TF

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Rest raint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions .............................................................. 3

Service Notice or Precautions .................................. 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 7

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .......................... ...................... 8

NVH Troubleshooting Chart ..................................... 8

TRANSFER OIL .......................................................... 9

Changing Transfer Oil .............................................. 9

DRAINING ................................ ............. ................ 9

FILLING .............................. ...... ............................. 9

Checking Transfer Oil ............................................... 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

AWD SYSTEM ............ ...... ........................................ 10

Power Transfer Diagram ........................................ 10

System Description ................................................ 10

ELECTRIC CONTROLLED COUPLING ............. 10

AWD CONTROL UNIT ........................................ 10

AWD MODE SWITCH ..........................................11

AWD INDICATOR LAMP AND LOCK INDICA-

TOR LAMP ...........................................................11

AWD WARNING LAMP ........................................11

System Diagram ..................................................... 12

COMPONENTS FUNCTION DESCRIPTION ..... 13

CAN Communication .............................................. 13

SYSTEM DESCRIPTION .................................... 13

TROUBLE DIAGNOSIS ............................................ 14

Fail-Safe Function .................................................. 14

How to Perform Trouble Diagnosis ........................ 14

BASIC CONCEPT ............................................... 14

Location of Electrical Parts .............................. ....... 15

Circuit Diagram ...................................................... 16

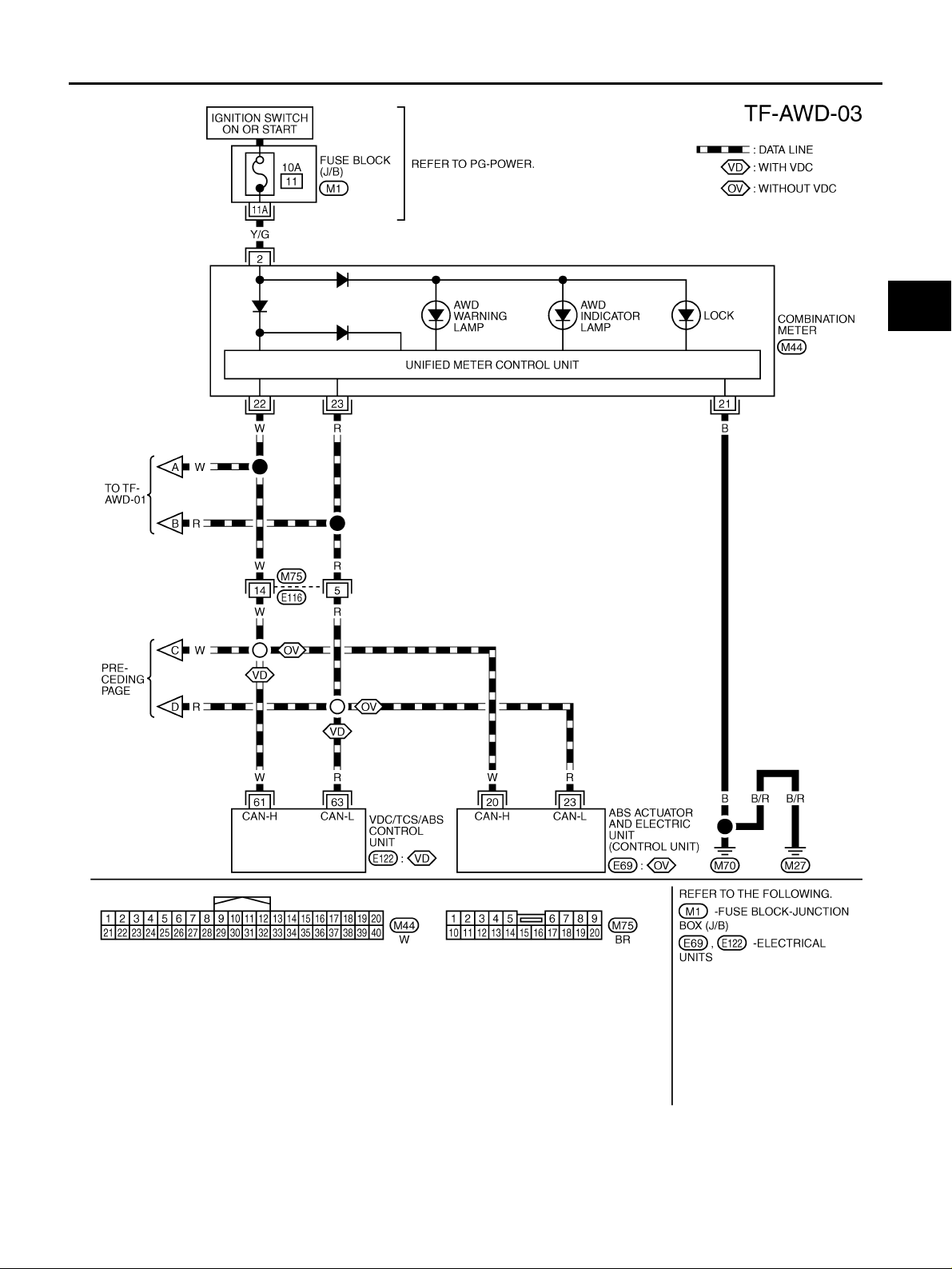

Wiring Diagram — AWD — .................................... 17

Trouble Diagnosis Chart for Symptoms ................. 20

AWD Control Unit Input/Output Signal Reference

TRANSFER

Values ................................................................. ....21

AWD CONTROL UNIT INSPECTION TABLE ..... 21

CONSUL T-II Function (ALL MODE AWD/4WD) ..... 22

FUNCTION .................................. ........................22

CONSULT-II SETTING PROCEDURE ................22

SELF-DIAG RESULTS MODE ............................ 23

DATA MONITOR MODE ......................................24

ACTIVE TEST MODE ......................................... 25

AWD CONTROL UNIT PART NUMBER ............. 25

TROUBLE DIAGNOSIS FOR SYSTEM ... ...... ....... ....26

Power Supply Circuit for AWD Control Unit ............26

CONSUL T-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 26

DIAGNOSTIC PROCEDURE .............................. 26

AWD Control Unit ........ ...... ..................................... 27

DIAGNOSTIC PROCEDURE .............................. 27

ABS System ...........................................................28

DIAGNOSTIC PROCEDURE .............................. 28

AWD Solenoid ...... ....... ...... ....... .............................. 28

CONSUL T-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 28

DIAGNOSTIC PROCEDURE .............................. 29

COMPONENT INSPECTION ...... ........................ 31

AWD Actuator Relay ................. ...... ....... ...... ....... ....32

CONSUL T-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 32

DIAGNOSTIC PROCEDURE .............................. 32

AWD Mode Switch .................... ...... ....... ...... ....... .... 33

CONSUL T-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 33

DIAGNOSTIC PROCEDURE .............................. 33

COMPONENT INSPECTION ...... ........................ 35

Engine Control Signal ..................... ....... ...... ....... ....35

DIAGNOSTIC PROCEDURE .............................. 35

CAN Communication Line ...................................... 36

DIAGNOSTIC PROCEDURE .............................. 36

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 37

AWD Indicator Lamp and LOCK Indicator Lamp Do

Not Turn ON for Approx. 1 Second When Ignition

Switch Is Turned to ON .......................................... 37

C

TF

E

F

G

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

TF-1

DIAGNOSTIC PROCEDURE ....................... ....... 37

AWD Warning Lamp Does Not Turn ON When Igni-

tion Switch Is Turned to ON ....................................38

DIAGNOSTIC PROCEDURE ....................... ....... 38

AWD Warning Lamp Does Not Turn OFF Several

Seconds After Engine Started .................................39

DIAGNOSTIC PROCEDURE ....................... ....... 39

AWD Mode Cannot Be Switched After Engine Is

Started ....................................................................40

DIAGNOSTIC PROCEDURE ....................... ....... 40

Heavy Tight-Corner Braking Symptom Occurs

When Vehicle Is Driven in AUTO Mode and Steering

Wheel Is Turned Fully to Either Side after Engine

Is Started ................................................................41

DIAGNOSTIC PROCEDURE ....................... ....... 41

Vehicle Does Not Enter AWD Mode Even Though

AWD Warning Lamp Turned to OFF .......................42

DIAGNOSTIC PROCEDURE ....................... ....... 42

While Driving, AWD Warning Lamp Flashes Rapidly

(When Flashing in Approx. 1 Minute and Then Turn-

ing OFF) ...... ....... ...... ...... ....... ...... ....... ...... ....... ....... 43

While Driving, AWD Warning Lamp Flashes Slowly

(When Continuing to Flash Until Turning Ignition

Switch OFF) ............................................................43

DIAGNOSTIC PROCEDURE ....................... ....... 43

AWD CONTROL UNIT ..............................................45

Removal and Installation ........................................45

REMOVAL ...........................................................45

INSTALLATION ......................... ............. ..............45

SIDE OIL SEAL .........................................................46

Removal and Installation .........................................46

REMOVAL ........................................................ ....46

INSTALLATION ......... ...........................................46

AIR BREATHER HOSE .............................................47

Components ....................... .................... .................47

Removal and Installation .........................................47

TRANSFER ASSEMBLY ...........................................48

Removal and Installation .........................................48

COMPONENTS ...................................................48

REMOVAL ........................................................ ....48

INSTALLATION ......... ...........................................49

Disassembly and Assembly ............ ....... ...... ....... ....50

COMPONENTS ...................................................50

ASSEMBLY INSPECTION ...................................51

DISASSEMBLY ................................................ ....55

INSPECTION AFTER DISASSEMBLY ..... ....... ....59

SELECTING ADJUSTING SHIMS ............ ....... ....60

ASSEMBLY ...................................................... ....62

SERVICE DATA AND SPECIFICATIONS (SDS) ......67

General Specifications ............................................67

Inspection and Adjustment ......................................67

PRELOAD TORQUE BE FORE DISASSEMB L Y ...67

PRELOAD TORQUE AFTER DISASSEMBLY

AND REASSEMBLY ............................................67

BACKLASH ............... ................................ ...........67

COMPANION FLANGE RUNOUT .......................67

SELECTIVE PARTS ............................................67

Revision: 2006 July 2006 X-Trail

TF-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

ADS0016Z

A

The Supplemental Rest raint System such as “AIR BAG” and “SEAT BELT PR E-TENSIONER”, used along

with a front seat belt, helps to redu ce th e risk or se verit y of i njury to the driv er and front passenge r for ce rtain

types of col lision. Information necessary to service the system safely is includ ed in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid rendering the SRS inopera tive, whi ch could incr ease the risk of pe rsonal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional ac tiv atio n o f the system. For remo va l of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

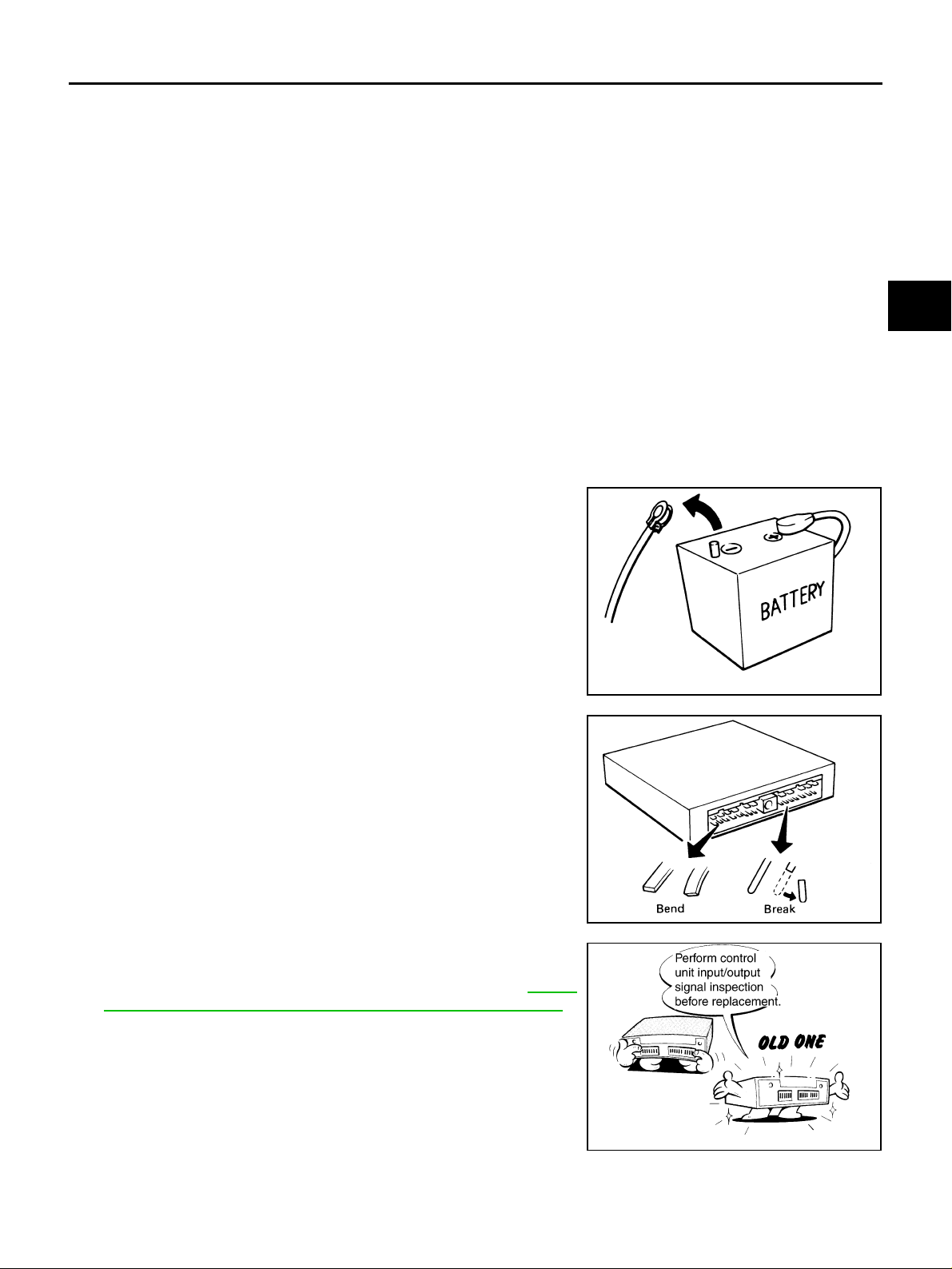

Precautions ADS00170

● Before connecting or disconnecting the AWD control unit

harness connector, turn ignition switch “OFF” and disconnect battery negative cable from batt ery negative terminal.

Because battery voltage is applied to AWD control unit even

if ignition switch is turned “OFF”.

B

C

TF

E

F

G

H

I

● When connecting or disconnecting pin connectors i nto or

from AWD control unit, take care not to damage pin terminals (bend or break).

When connecting pin connectors, make sur e that there are

no bends or breaks on AWD control unit pin terminal.

● Before replacing AWD control unit, perform AWD control

unit input/output signal inspection and make sure whether

AWD control unit functions properly or not. Refer to TF-21,

"AWD Control Unit Input/Output Signal Reference Values" .

SEF289H

SEF291H

SDIA1848E

J

K

L

M

Revision: 2006 July 2006 X-Trail

TF-3

PRECAUTIONS

Service Notice or Precaution s ADS00171

● After overhaul refill the transfer with new transfer oil.

● Check the oil level or replace oil only with the vehicle parked on level surface.

● During removal or installation, keep inside of transfer clear of dust or dirt.

● Replace all tires at the same time. Always use tires of the proper size and the same brand and pattern.

Fitting improper siz e and/or unusual wear tires applies exc essive force to vehicle mechanism and can

cause longitudinal vibration.

● Disassembly should be done in a clean work area.

● Before proceeding with disassembly, thoroughly clean the transfer. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign matter.

● Check for the correct installation status prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of th e parts when applied.

● All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

● Check appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with a new ones if necessary.

● Gaskets, seals, O-rings and lock nuts should be replaced any time when the transfer is dis assembled.

● In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

● Observe the specified torque when assembling.

● Clean and flush the parts sufficiently and blo w-dry them.

● Be carefu l not to damage sliding surface s and mating surfaces.

● Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transfe r.

Revision: 2006 July 2006 X-Trail

TF-4

PREPARATION

PREPARATION PFP:00002

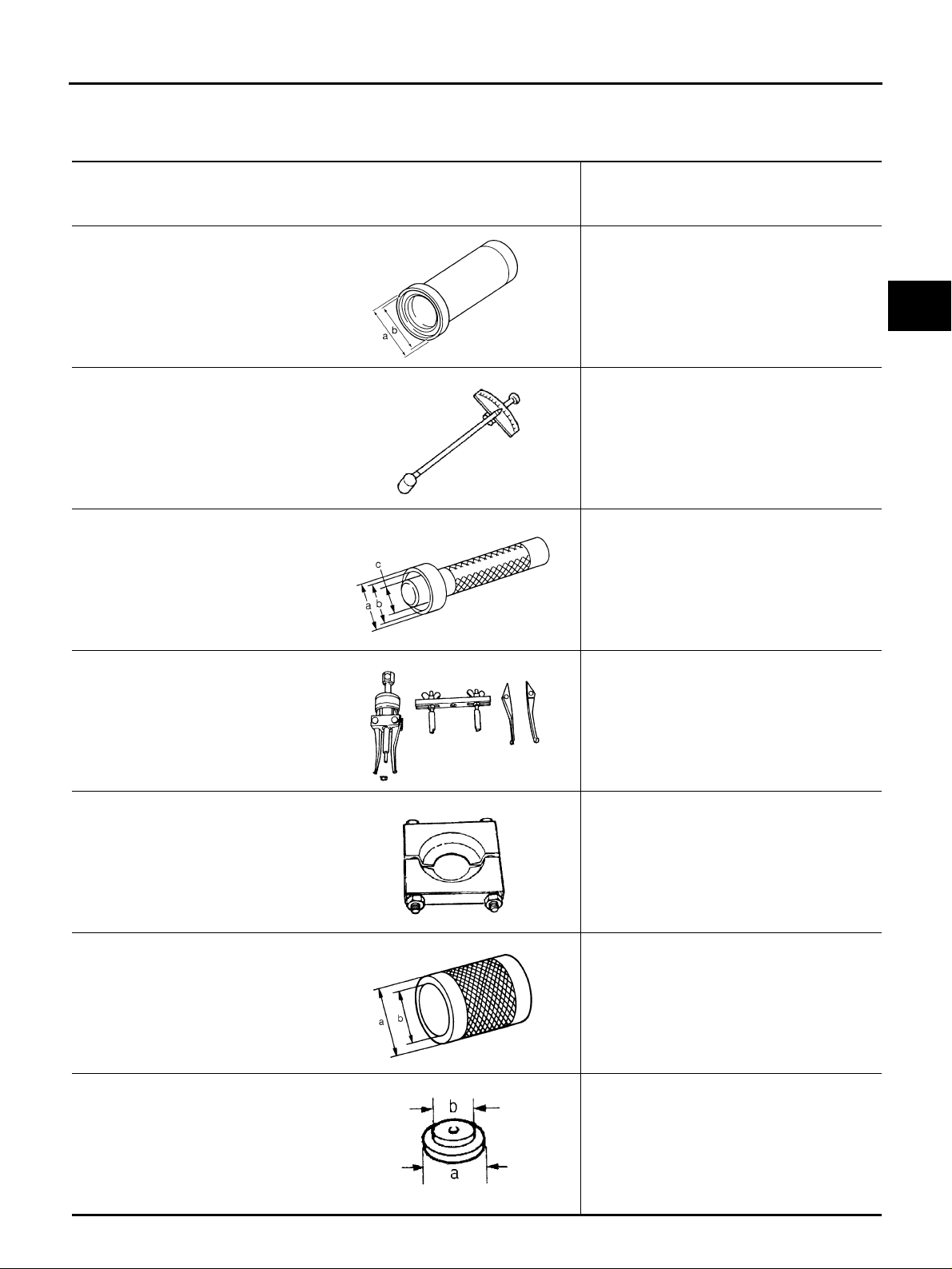

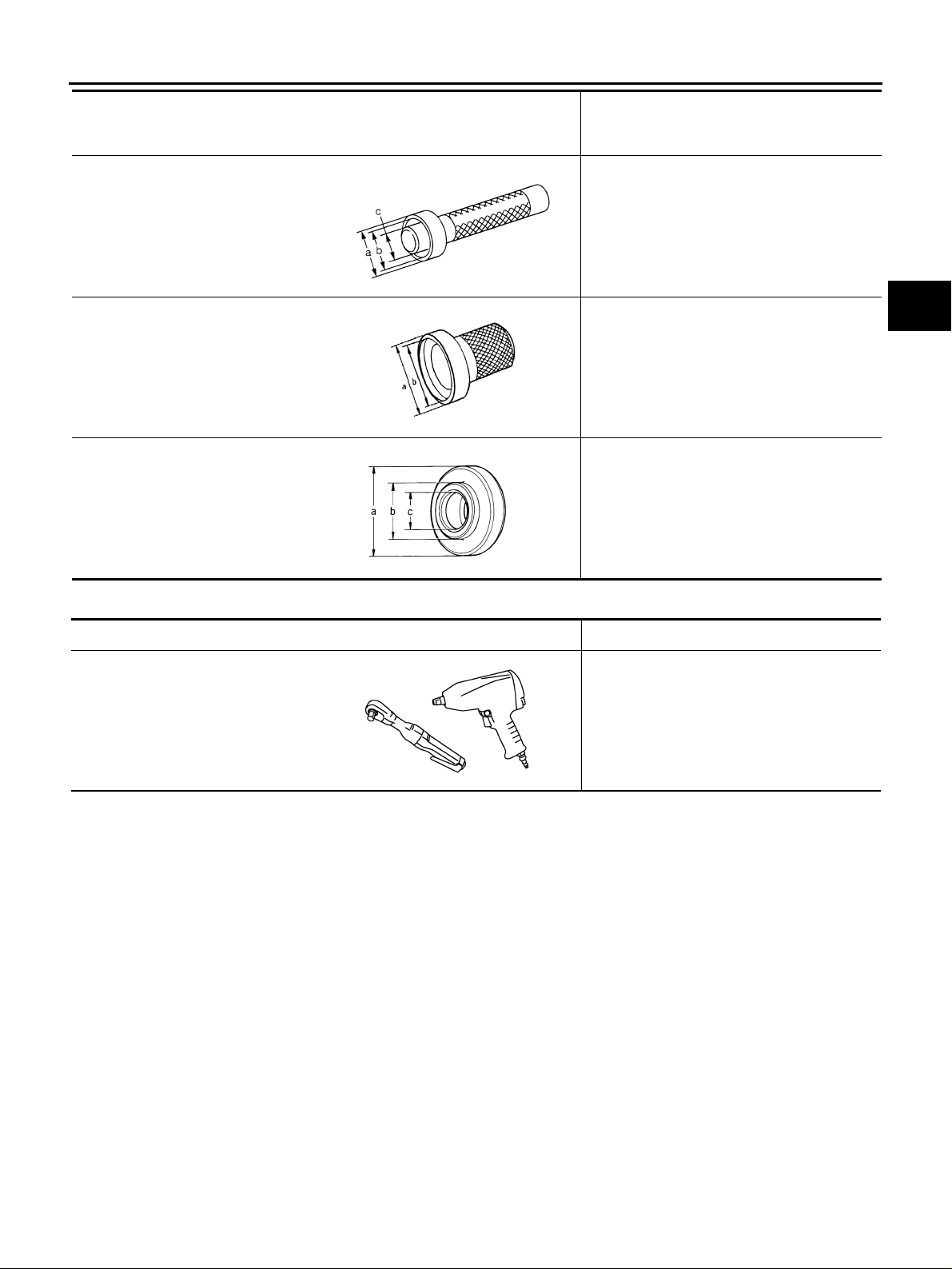

Special Service Tools ADS00173

The actual shapes of Kent-Moore tools may differ from those of spec ial ser vi ce tool s illust rat ed here.

Tool number

(Kent-Moore No.)

Tool name

Description

A

B

KV38101700

(—)

Drift

a: 82 mm (3.23 in) dia.

b: 78 mm (3.07 in) dia.

ST3127S000

(J-25765-A)

Preload gauge

ST33220000

(J-25804-01)

Drift

a: 37 mm (1.46 in) dia.

b: 31 mm (1.22 in) dia.

c: 22 mm (0.87 in) dia.

KV381054S0

(J-34286)

Puller

ZZA1149D

ZZA0503D

ZZA1046D

Installing side oil seal (installing adapter case

oil seal)

Measuring preload torque

Removing drive pinion

● Removing pinion rear bearing outer race

● Removing pinion front bearing outer race

● Removing gear ring oil seal

C

TF

E

F

G

H

I

J

ST30031000

(J-22912-01)

Replacer

ST33200000

(J-26082)

Drift

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

ST33061000

(J-8107-2)

Drift

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

K

ZZA0601D

Removing pinion front bearing inner race

L

M

ZZA0700D

● Removing gear ring bearing inner race

(adapter case side)

● Installing companion flange

ZZA1002D

Removing gear ring bearing inner race

(transfer case side )

ZZA0810D

Revision: 2006 July 2006 X-Trail

TF-5

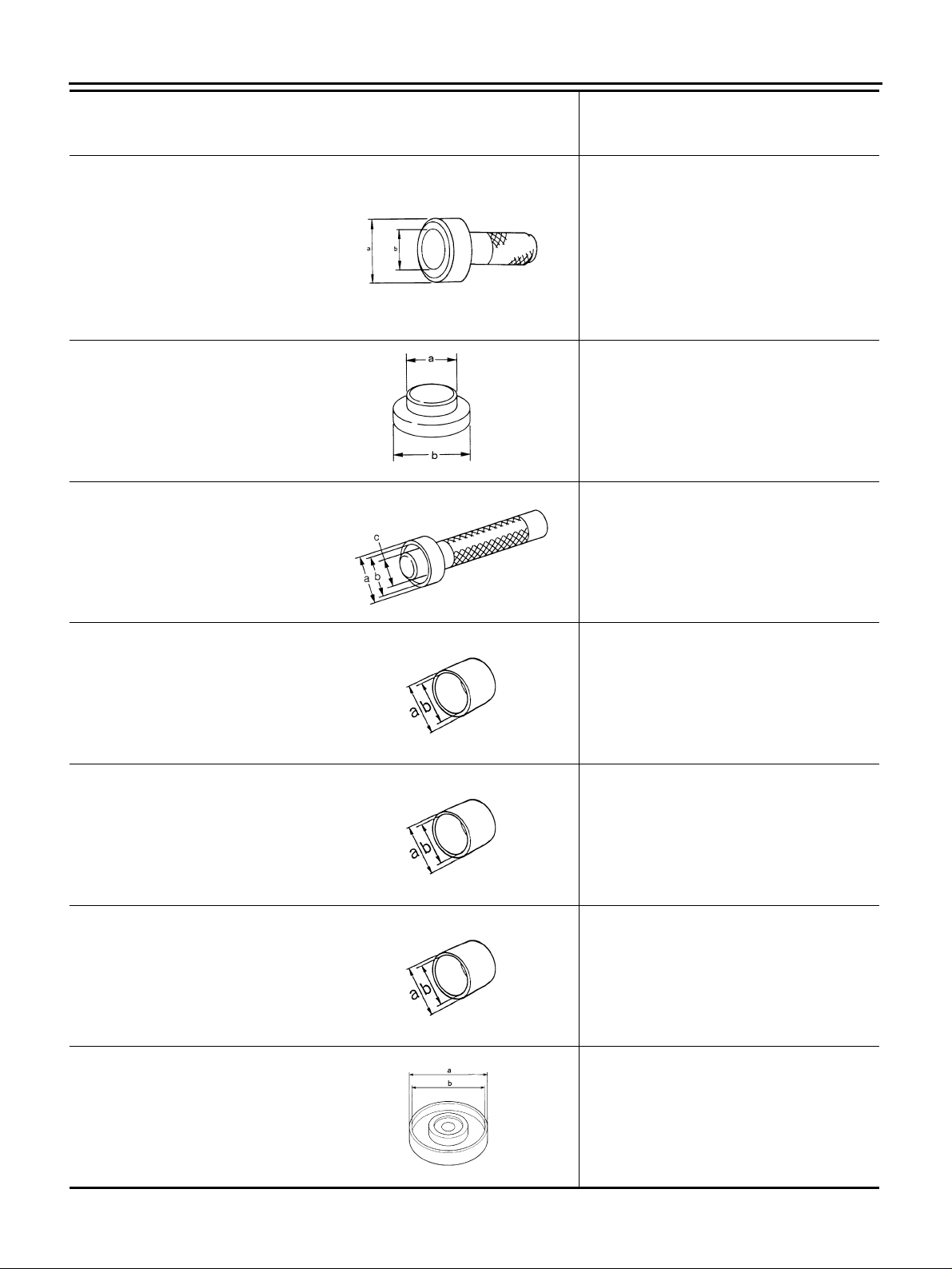

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Description

ST30720000

(J-25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

KV40101840

(—)

Drift

a: 77 mm (3.03 in) dia.

b: 85 mm (3.35 in) dia.

ST33230000

(J-25805-01)

Drift

a: 51 mm (2.01 in) dia.

b: 41 mm (1.61 in) dia.

c: 28.5 mm (1.122 in) dia.

ST27863000

(—)

Drift

a: 74.5 mm (2.933 in) dia.

b: 62.5 mm (2.461 in) dia.

ZZA0811D

ZZA0881D

ZZA1046D

● Installing gear ring bearing outer race

(transfer case side)

● Installing gear ring bearing inner race

(transfer case side)

● Installing gear ring bearing inner race

(adapter case side)

● Installing gear ring bearing outer race

(adapter case side)

● Installing transfer case oil seal

Installing gear ring bearing outer race

(transfer case side)

Installing gear ring oil seal

Installing gear ring bearing inner race

(transfer case side)

KV40101630

(J-35870)

Drift

a: 68 mm (2.68 in) dia.

b: 60 mm (2.36 in) dia.

KV38102510

(—)

Drift

a: 71 mm (2.80 in) dia.

b: 65 mm (2.56 in) dia.

KV40105230

(—)

Drift

a: 92 mm (3.62 in) dia.

b: 86 mm (3.39 in) dia.

ZZA1003D

Installing gear ring bearing inner race

(transfer case side)

ZZA1003D

Installing gear ring bearing inner race

(adapter case side)

ZZA1003D

Installing gear ring bearing outer race

(adapter case side)

ZZA1141D

Revision: 2006 July 2006 X-Trail

TF-6

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

KV38100300

(J-25523)

Drift

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia.

ST33400001

(J-26082)

Drift

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST30901000

(J-26010-01)

Drift

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia.

ZZA1046D

ZZA0814D

ZZA0978D

Description

Installing pinion rear bearing outer race

● Installing pinion front bearing outer race

● Installing pinion sleeve oil seal

● Installing pinion front bearing outer race

● Installing pinion front bearing inner race

A

B

C

TF

E

F

G

H

Commercial Service Tools ADS00189

Tool name Description

Power tool Loosening nuts and bolts

PBIC0190E

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

TF-7

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003 NVH Troubleshooting Chart ADS00174

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

Reference page

SUSPECTED PARTS

(Possible cause)

Symptom

TF-9

TRANSFER OIL (Level low)

Noise 1 2 3 3

Transfer oil leakage 3 1 2 2 2

TRANSFER OIL (Wrong)

TRANSFER OIL (Level too high)

TF-50

LIQUID GASKET (Damaged)

TF-50

O-RING (Worn or damaged)

TF-50

OIL SEAL (Worn or damaged)

TF-59

GEAR (Worn or damaged)

TF-59

BEARING (Worn or damaged)

Revision: 2006 July 2006 X-Trail

TF-8

TRANSFER OIL

TRANSFER OIL PFP:KLD30

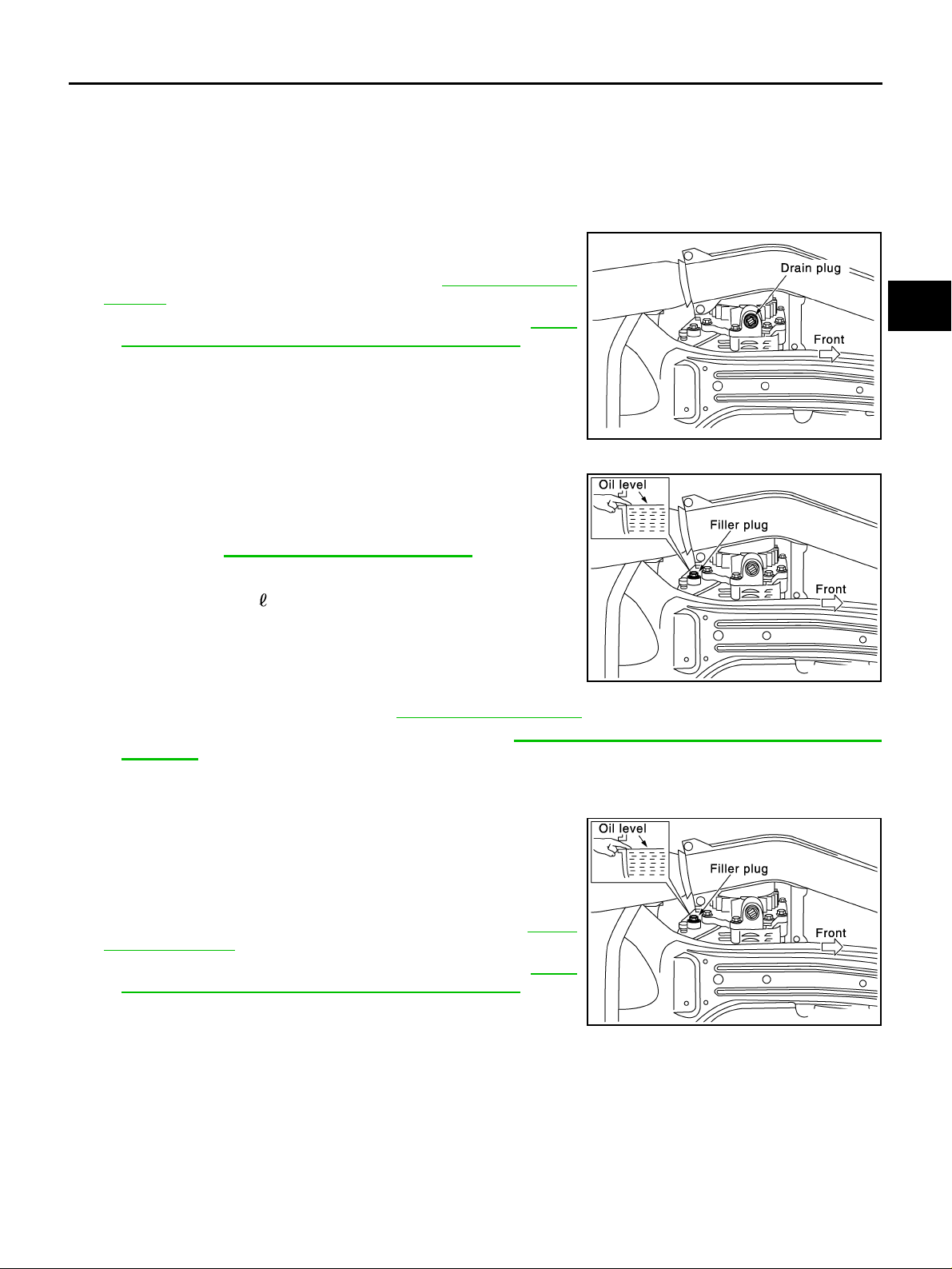

Changing Transfer Oil ADS00175

DRAINING

CAUTION:

When draining oil, protect exhaust tube with cover.

1. Run vehicle to warm up transfer body suffici ently.

2. Stop engine, and remove drain plug to drain transfer oil.

3. Apply sealant to drain plug. Install drain plug on transfer and

tighten to the specified torque. Refer to TF-50, "

NENTS" .

● Use Genuine Silicone RT V or equivalent. Refer to GI-47,

"Recommended Chemical Products and Sealants" .

COMPO-

A

B

C

TF

E

SDIA0512E

FILLING

1. Remove filler plug and add gear oil until oil level reaches the

specified limit near filler plug mounting hole.

Oil grade and Viscosi ty:

Refer to MA-10, "

Fluids and Lubricants" .

Oil capacity:

Approx. 0.31 (5/8 US pt, 1/2 lmp pt)

CAUTION:

Carefully fill oil. (Fill up for approx. 3 minutes)

2. Leave vehicle for 3 minutes, and check oil level again.

SDIA0513E

3. Apply sealant to filler plug. Install filler plug on transfer and

tighten to the specified torq ue . Refe r to TF-50, "

● Use Genuine Silicone RTV or equivalent. Refer to GI-47, "Recommended Chemical Products and

COMPONENTS" .

Sealants" .

Checking Transfer Oil ADS00176

OIL LEAKAGE AND OIL LEVEL

1. Check oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Do not start engine while checking oil level.

2. Before installing filler plug, apply sealant. Install filler plug on

transfer and tighten to the specified torque. Refer to TF-50,

"COMPONENTS" .

● Use Genuine Silicone RT V or equivalent. Refer to GI-47,

"Recommended Chemical Products and Sealants" .

F

G

H

I

J

K

L

M

SDIA0513E

Revision: 2006 July 2006 X-Trail

TF-9

AWD SYSTEM

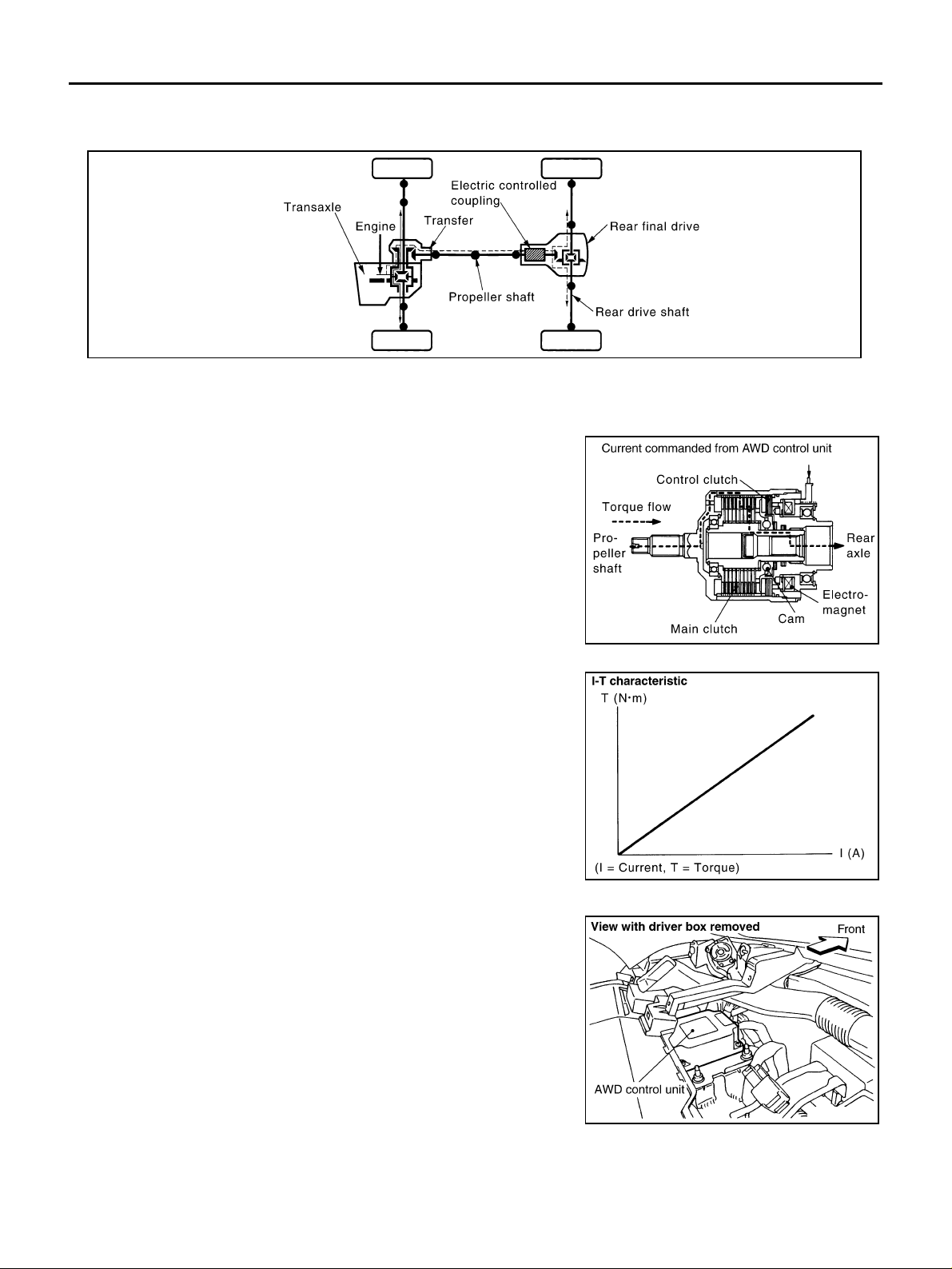

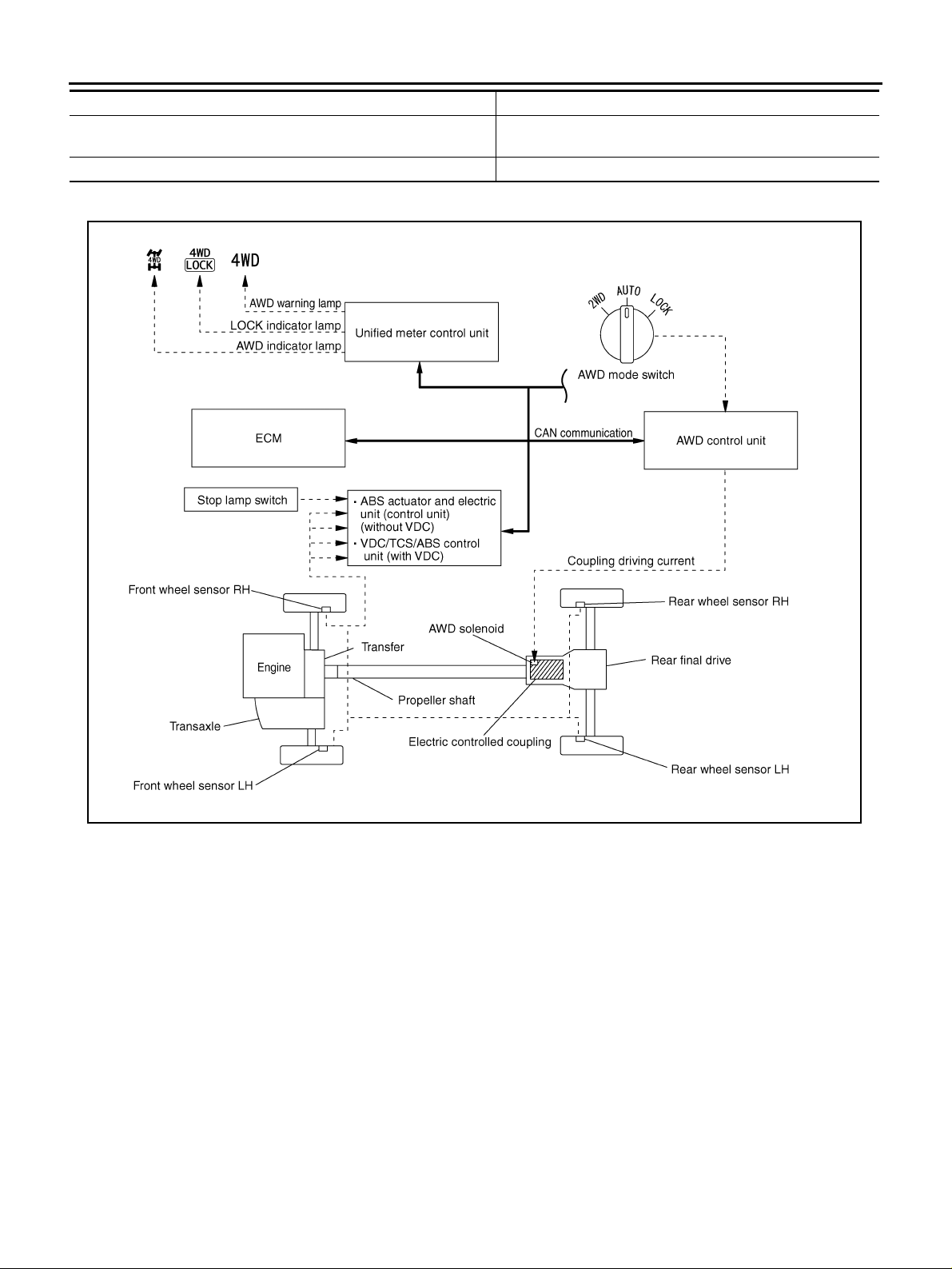

AWD SYSTEM PFP:41650 Power Transfer Diagram ADS00177

SDIA1607E

System Description ADS00178

ELECTRIC CONTROLLED COUPLING

Operation Principle

1. The AWD control unit supplies comm and current to t he electric

controlled coupling (AWD solenoid).

2. The control clu tch is engaged by th e electromagnet an d torque

is detected in control clutch.

3. The cam operates in response to the control clutch torque and

applies pressure to the main clutch.

4. The main clutch transmits torque to front wheels according to

pressing power.

● Transmission torque to the rear wheels is determined accord-

ing to command cu rrent.

AWD CONTROL UNIT

● AWD control unit controls distribution of drive power between

front-wheel drive (100:0 ) and AWD (50:50) cond ition s accord ing

to the signals from the sensors.

● Self-diagnosis results can be read with CONSULT-II.

SDIA2501E

SDIA1844E

SDIA2502E

Revision: 2006 July 2006 X-Trail

TF-10

AWD SYSTEM

AWD MODE SWITCH

AUTO Mode

● Electronic control allows optimal distribution o f torque to front/rear wheels to match road conditions.

● AWD mode makes possible stable driving, with no wheel spin, on snowy roads or other slippery surfaces.

● On roads which d o n ot r eq ui re AWD, AUTO mode co ntr i bu tes to i mp rov ed f uel ec on omy b y d ri vi ng in c on -

ditions close to fron t-wh ee l dr iv e.

● Sensor inputs determ ine the ve hicle's tu rning con dition, an d tight co rnering/ brakin g are contro lled by dis-

tributing optimum torque to the rear wheels.

LOCK Mode

● Front/rear wheel torque distribution is fixed, ensuring stable driving when climbing slopes.

● AWD cont ro l u ni t wi ll s w itch au to ma ti cal ly to AUTO mode if vehicle speed inc r ease s. If vehi cl e s pe ed then

decreases, the vehicle automatically returns to direct 4-wheel driving conditions.

● LOCK mode will change to AUTO mode automatically, when the vehicle speed exceeds approx. 30 km/h

(19 MPH). The LOCK indicator light keeps illuminating.

NOTE:

If there is a significant difference in pressure or wear between tires, full vehicle performance is not available.

LOCK mode may be prohibited, or speeds at which LOCK mode is enabled may be restricted detecting tire

conditions.

A

B

C

TF

E

F

2WD Mode

Vehicle is in front-wheel drive.

NOTE:

● If front whee ls are sli pping in 2 WD mode , do not s witch to AU TO or LOC K. Th is ca n ca use difficult ie s for

the system.

● Even if the AWD mode switch is in 2WD mode, the AWD control unit occasiona l ly autom at i call y ch an ge to

AUTO mode de pe ndin g on th e dri vi ng con di tio n ( Fo r exa mp le ; De pre ssi ng th e ac cel er at io n fir m ly ). T hi s is

not malfunction. However, AWD indicator lamp dose not illuminate.

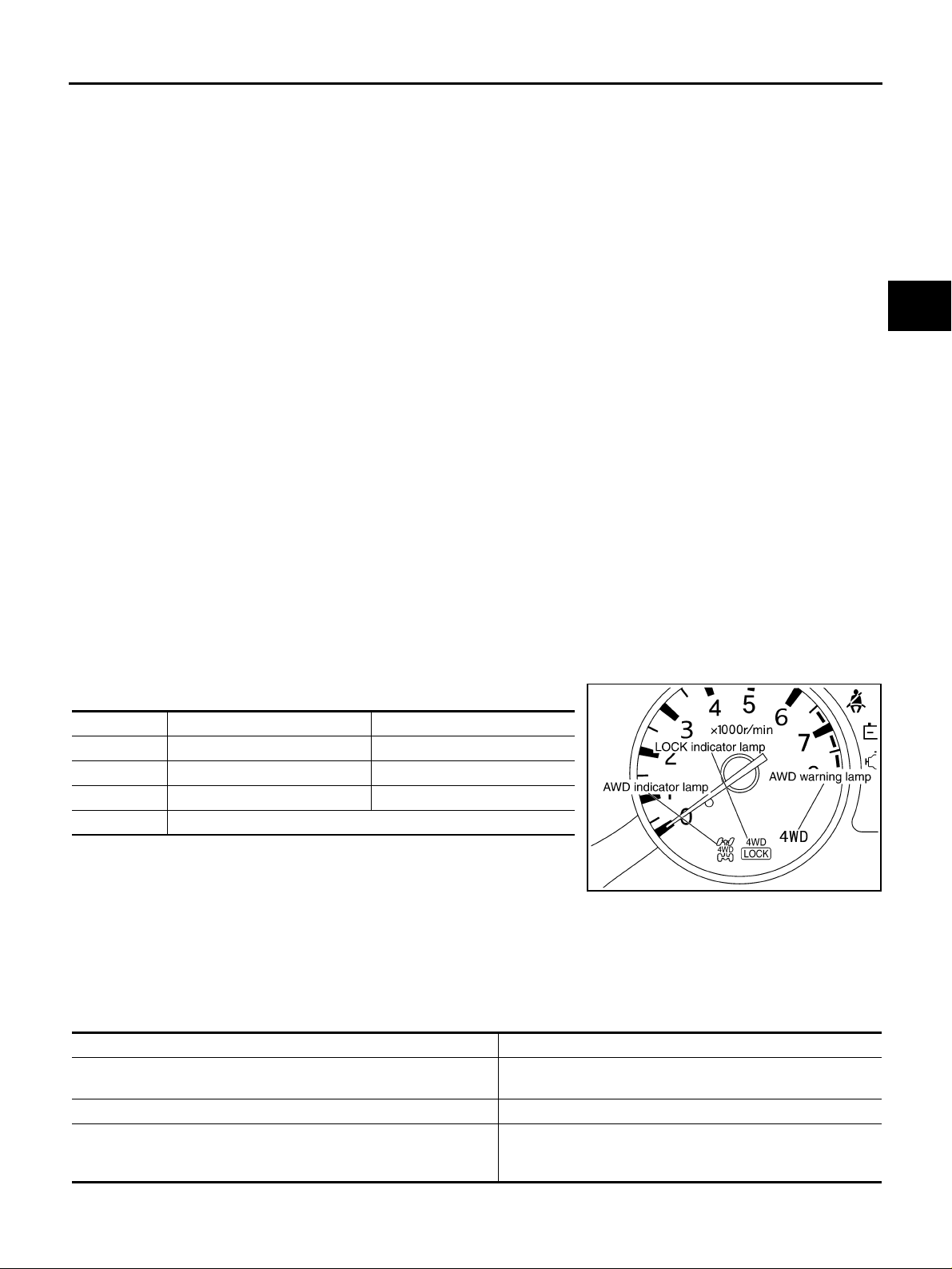

AWD INDICATOR LAMP AND LOCK INDICATOR LAMP

The following is the indications of indicator lamp.

Condition AWD indicator lamp LOCK indicator lamp

AUTO mode ON OFF

LOCK mode ON ON

2WD mode OFF OFF

Lamp check Turns ON for approx. 1 second when ignition switch is turned ON.

SDIA2503E

AWD WARNING LAMP

Turns ON when there is a malfu nction in AWD system. It indicate s that the vehicle is in fail-safe mode and

changes to front-wheel driv e or shifting dri v ing force-AWD (Rear-wheels still have some driving to rque).

Also turns ON when ignition switch is turned ON, for purpose of lamp check.

Turns OFF approximately for 1 second aft er the engine starts if system is normal.

G

H

I

J

K

L

M

AWD Warni ng Lamp Indication

Condition AWD warning lamp

Lamp check

AWD system malfunction ON

Protection function is activated due to he avy l oad t o electri c con-

trolled coupling. (AWD system is not malfunctioning and AWD system

changes to 2WD mode.)

Revision: 2006 July 2006 X-Trail

TF-11

Turns ON when ignition switch is turned ON. Turns OFF

approx. 1 seconds after engine start.

Rapid flashing: 2 times/second

(Flashing in approx. 1 minute and then turning OFF.)

AWD SYSTEM

Condition AWD warning lamp

Large difference in diameter of front/rear tires

Other than above (system normal) OFF

(Continuing to flash until turning ignition switch OFF)

Slow flashing: 1 time/2 seconds

System Diagram ADS00179

SDIA2504E

Revision: 2006 July 2006 X-Trail

TF-12

AWD SYSTEM

COMPONENTS FUNCTION DESCRIPTION

Component parts Function

● Controls driving force distribution by signals from each sensor and switches from front wheel driv-

AWD control unit

Wheel sensors Detects wheel speed.

AWD solenoid Controls electric controlled coupling by operation signal from AWD control unit.

Electric controlled coupling Transmits driving force to rear final drive.

AWD mode switch Able to select from 2WD, AUTO or LOCK mode.

AWD warning lamp

AWD indicator lamp Indicates operation with optimal distributio n of torq ue to fron t/re ar wheels.

LOCK indicator lamp Indicates that AWD system is under direct 4-wheel driving mode.

ABS actuator and electric unit

(control unit) (without VDC) or

VDC/TCS/ABS control unit

(with VDC)

ECM

Unified meter control unit Transmits conditions of parking brake switch via CAN communication to AWD control unit.

ing mode (100:0) to AWD mode (50:50).

● 2WD mode is available by fail-safe function if malfunction is detected in electrical system .

● Illuminates if malfunction is detected in electrical system of AWD system.

● There is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

● There are 2 blinks in 1 second if load is still applied to driving parts.

Transmits the following signals via CAN communication to AWD control unit.

● Vehicle speed signal

● Stop lamp switch signal (brake signal)

Transmits the following signals via CAN communication to AWD control unit.

● Accelerator pedal position signal

● Engine speed signal

A

B

C

TF

E

F

G

H

CAN Communication ADS0017A

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent error detection ability. Many electronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during opera tion (not independent). In CA N communication, cont rol units are connected with 2

communicatio n lines ( CAN H lin e, CAN L li ne) all owi ng a high ra te of in forma tion tr ans missi on wit h less wir ing.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer to LAN-21, "

CAN Communication Unit" .

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

TF-13

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS PFP:00004 Fail-Safe Function ADS0017B

● If any malfunction occu rs in AWD electrical system , and control unit de tects the malfun ction, AWD warn-

ing lamp on combination meter turns ON to indicate system malfunction.

● When AWD warning lamp is ON, vehicle changes to front-wheel drive or shifting driving force-AWD (Rear-

wheels still have some drivin g torque).

How to Perform Trouble Diagnosis ADS0017C

BASIC CONCEPT

● To perform troub le diagn osis, it is th e most im portant to ha ve unde rstanding ab out vehic le syste ms (con-

trol and mechanism) thoroughly.

● It is also important to clarify cus tome r comp laints be fore in spec -

tion.

First of all, reproduce symptoms, and understand them fully.

Ask customer about his/her complaints carefully. In some case s,

it will be necessary to check symptoms by driving vehicle with

customer.

CAUTION:

Customers are not profes sional. It is dangerous to m ake a n

easy guess like "maybe the customer means that...," or

"maybe the customer mentions this sym ptom ".

SEF233G

● It is essential to check symptoms right from the beginning in

order to repair malfunctions completely.

For intermittent malfunctions, reproduce symptoms based on

interview with customer and past examples. Do not perform

inspection on ad hoc basis. Most intermittent malfunctions are

caused by poor contacts. In this case, it will be effective to shake

suspected harness or connector by ha nd. When repairing wit hout any symptom diagnosis, you cannot judge if malfunctions

have actually been eliminated.

● After completing diagnosis, always erase diagnostic memory.

Refer to TF-24, "

● For intermittent malfunctions, move harness or harness connec-

How to Erase Self-Diagnosis Resu lts" .

tor by hand. Then check for poor contact or reproduced open circuit.

SEF234G

Revision: 2006 July 2006 X-Trail

TF-14

TROUBLE DIAGNOSIS

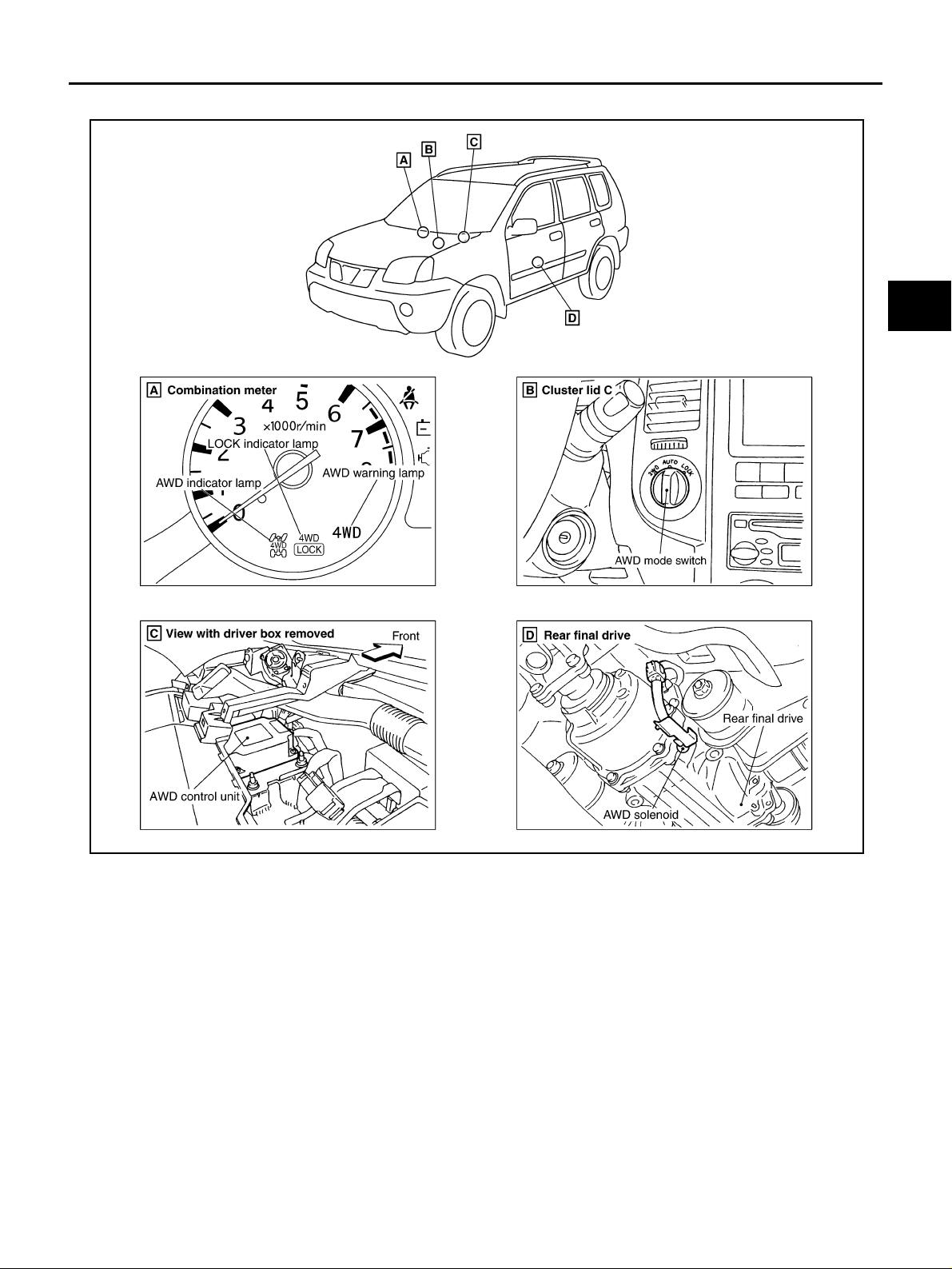

Location of Electrical Parts ADS0017D

A

B

C

TF

E

F

G

SDIA2506E

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

TF-15

TROUBLE DIAGNOSIS

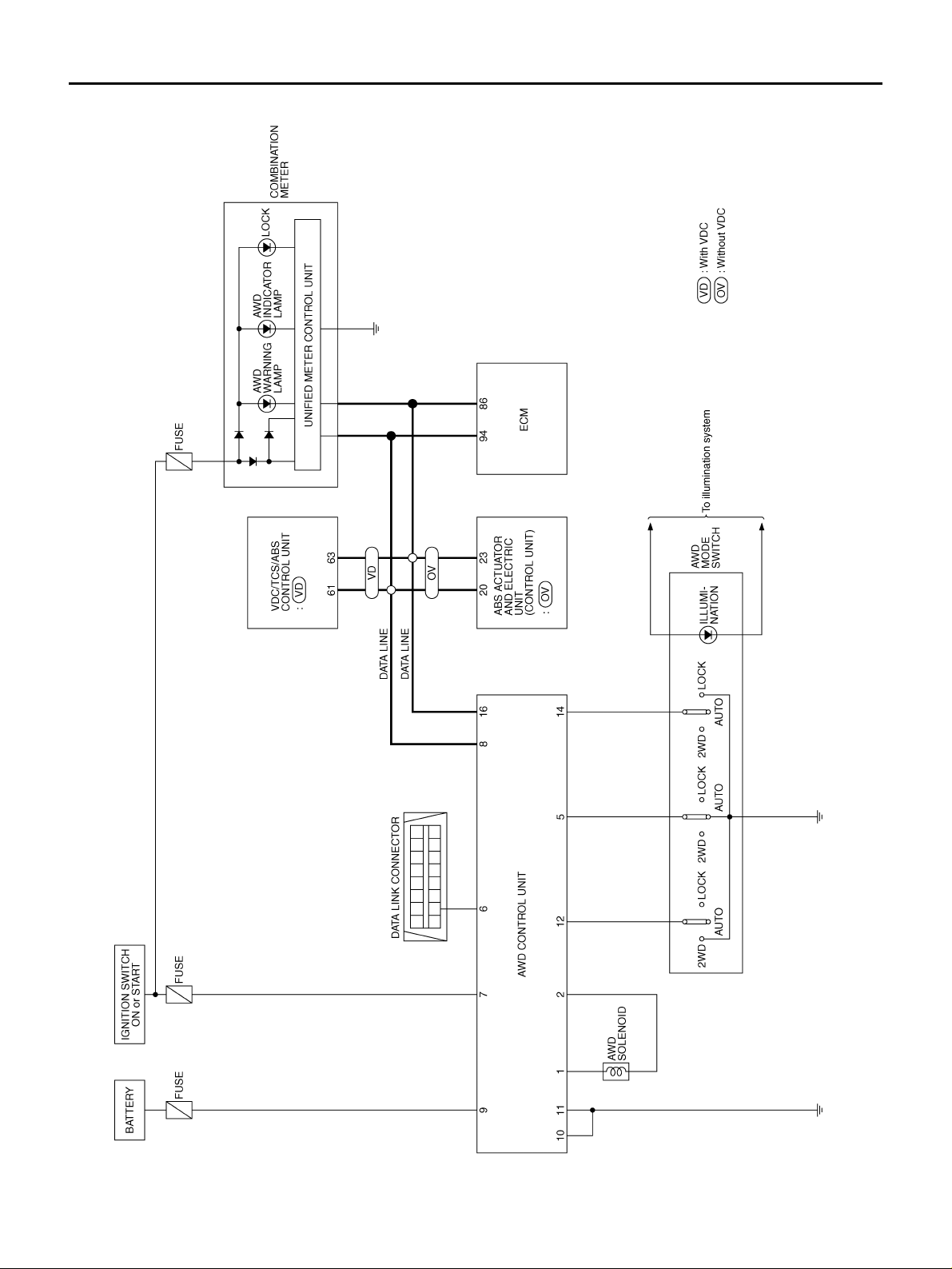

Circuit Diagram ADS0017E

TDWB0001E

Revision: 2006 July 2006 X-Trail

TF-16

TROUBLE DIAGNOSIS

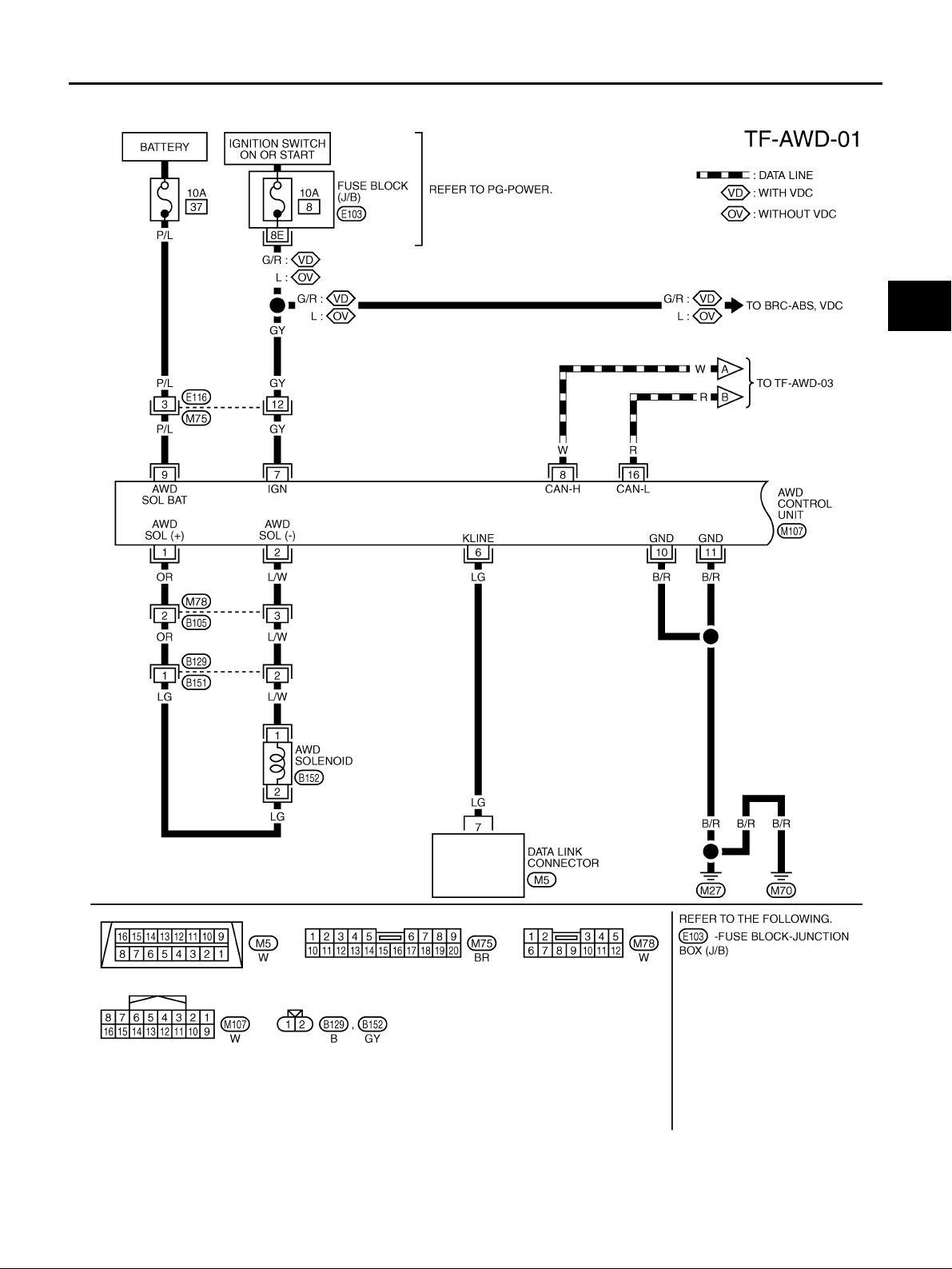

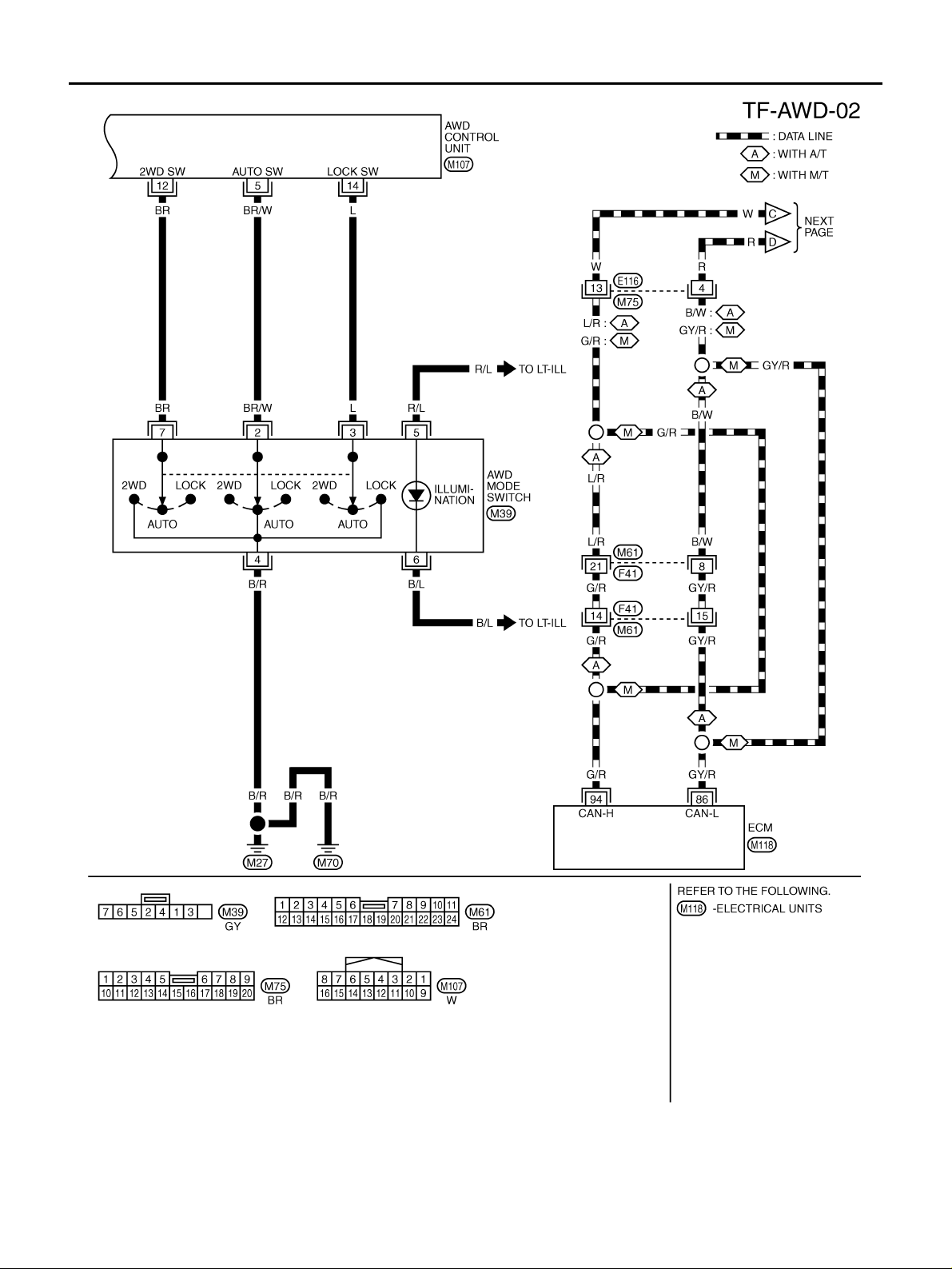

Wiring Diagram — AWD — ADS0017F

A

B

C

TF

E

F

G

H

K

M

I

J

L

TDWB0002E

Revision: 2006 July 2006 X-Trail

TF-17

TROUBLE DIAGNOSIS

TDWB0053E

Revision: 2006 July 2006 X-Trail

TF-18

TROUBLE DIAGNOSIS

A

B

C

TF

E

F

G

H

K

M

I

J

L

TDWB0004E

Revision: 2006 July 2006 X-Trail

TF-19

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart for Symptoms ADS0017G

If AWD warning lamp turns ON, perform self-diagnosi s. Refer to TF-23, "SE LF-DIAG RESULTS MODE" .

Symptom Condition Check item Reference page

AWD indicator lamp and LOCK indicator

lamp do not turn ON for approx. 1 second

when ignition switch is turned to ON.

Ignition switch: ON

(AWD indicator lamp and LOCK indicator

lamp check)

AWD warning lamp does not turn ON when

ignition switch is turned to ON.

Ignition switch: ON

(AWD warning lamp check)

AWD warning lamp does not turn OFF several seconds after engine started.

AWD mode cannot be switched after engine

is started.

Heavy tight-corner braking symptom occurs

when vehicle is driven in AUTO mode and

steering wheel is turned fully to either side

after engine is started. (See NOTE.)

Engine ru nning

Engine ru nning

● While driving

● AUTO mode

● Steering wheel is

turned fully to either

sides

Vehicle speed: 10 km/h

(6 MPH) or less

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF.

Vehicle speed: 10 km/h

(6 MPH) or more

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/second

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turning ignition switch OFF)

Slow flashing: 1 time/2 seconds

● While driving

● AUTO mode and

LOCK mode

● While driving

● Vehicle speed: 20 km/h

(12 MPH) or m o re

NOTE:

● Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode. This is not malfunction.

● Heavy tight-corner braking symptom oc curs when vehicle is driven in the following conditions: LOCK mode, steering

wheel is turned fully to either side, and accelerator pedal w as depr essed.

CAN communication line

Power supply and ground for AWD con-

trol unit

Unified meter control unit

CAN communication line

Unified meter control unit

CAN communication line

Power supply and ground for AWD control unit

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

AWD mode switch

CAN communication line

Unified meter control unit

CAN communication line

AWD mode switch

Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (Mechanical engagement of clutch is not possible.)

Operating condition of parking brake

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (Mechanical engagement of clutch is not possible.)

Protection function is activated due to

heavy load to electric controlled coupling. (AWD system is not malfunctioning.)

Tire size is different between front and

rear of vehicle.

TF-37

TF-38

TF-39

TF-40

TF-41

TF-42

TF-43

TF-43

Revision: 2006 July 2006 X-Trail

TF-20

TROUBLE DIAGNOSIS

A WD Control Unit Input/Output Signal Reference Values ADS0017H

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Monitor item [Unit] Content Condition Display value

Vehicle stopped 0.00 km/h (0.00 mph)

FR RH SENSOR [km/h] or [mph]

FR LH SENSOR [km/h] or [mph]

RR RH SENSOR [km/h] or [mph]

RR LH SENSOR [km/h] or [mph]

BATTERY VOLT [V]

THRTL POS SEN [%] Throttle opening condition

ETS SOLENOID [A]

STOP LAMP SW [ON/OFF]

ENG SPEED SIG [RUN/STOP] Condition of engine running

ETS ACTUATOR [ON/OFF]

4WD WARN LAMP [ON/OFF] AWD warning lamp condition

4WD MODE SW [2WD/AUTO/

LOCK]

Wheel speed (Front wheel

right)

Wheel speed (Front wheel

left)

Wheel speed (Rear wheel

right)

Wheel speed (Rear wheel

left)

Power supply voltage for

AWD control unit

Monitored value of current at

AWD solenoid

Condition of brake pedal

operation

Operating condition of AWD

actuator relay (integrated in

AWD control unit)

Input condition from AWD

mode switch

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Ignition switch: ON Battery voltage

When depressing accelerator peda l

(Value rises gradually in response to

throttle position.)

2WD Approx. 0.000A

Engine speed

: At idle

Engine speed

: 3,000 rpm or more constant

Brake pedal: Depressed ON

Brake pedal: Released OFF

Engine stopped

(Engine speed: Less than 400 rpm)

Engine running

(Engine speed: 400 rpm or more)

Engine stopped (Ignition

switch: ON)

Engine running ON

AWD warning lamp: ON ON

AWD warning lamp: OFF OFF

AWD mode switch

AUTO Approx. 0.000A

LOCK Approx. 0.000A

2WD Approx. 0.000A

AUTO Approx. 0.000 - 1.500A*

LOCK Approx. 2.800A

2WD 2WD

AUTO AUTO

LOCK LOCK

Approximately equal to

the indication on speedometer (Inside of ±10%)

Approximately equal to

the indication on speedometer (Inside of ±10%)

Approximately equal to

the indication on speedometer (Inside of ±10%)

Approximately equal to

the indication on speedometer (Inside of ±10%)

0 - 100%

STOP

RUN

OFF

A

B

C

TF

E

F

G

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

TF-21

Loading...

Loading...