Nissan XTrail T30 2006 User Manual

BODY, LOCK & SECURITY SYSTEM

I BODY

A

B

SECTION BL

BODY, LOCK & SECURITY SY STEM

CONTENTS

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restr aint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 4

Precautions for Work ................................................ 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 6

Work Flow ................................................................ 6

CUSTOMER INTERVIEW ..................................... 6

DUPLICATE THE NOISE AND TEST DRIVE ....... 7

CHECK RELATED SERVICE BULLETINS .. ......... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 7

REP AIR THE CAUSE ........................................... 7

CONFIRM THE REPAIR ....................................... 8

Generic Squeak and Rattle Troubleshooting ........... 8

INSTRUMENT PANEL .......................................... 8

CENTER CONSOLE ............................................. 8

DOORS .............................. ................................... 8

TRUNK ............................... ................................... 9

SUNROOF/HEADLINING ..................................... 9

SEATS ................................................................... 9

UNDERHOOD .................... ............. ............. ......... 9

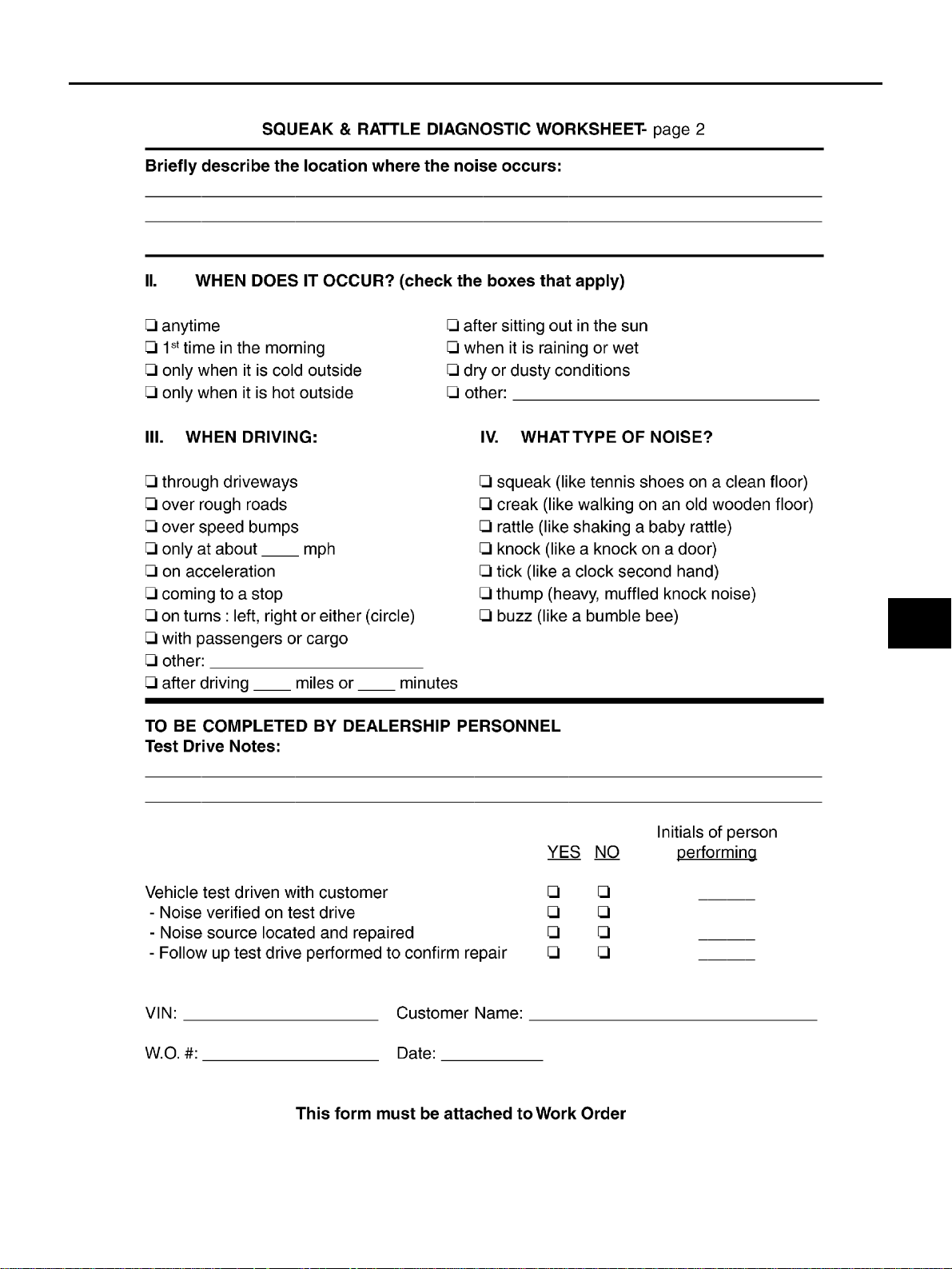

Diagnostic Worksheet ............................................ 10

HOOD ....................................................................... 12

Fitting Adjustment .................................................. 12

LONGITUDINAL AND LATERAL CLEARANCE

ADJUSTMENT ................... ................................. 12

FRONT END HEIGHT ADJUSTMENT ............... 13

SURFACE HEIGHT ADJUSTMENT ................... 14

Removal and Installation of Hood Assembly .......... 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

Removal and Installation of Hood Lock Control ..... 16

REMOVAL ........................................................... 16

INSTALLATION ................................................... 17

Hood Lock Control Inspection ................................ 17

FRONT FENDER ......................................................18

Removal and Installation ........................................ 18

REMOVAL ...........................................................18

INSTALLATION ...................................................18

DOOR ............................. ...........................................19

Fitting Adjustment ...................................................19

FRONT DOOR .................................................... 19

REAR DOOR ..... ....... ...... ....... ...... ....... ...... ....... ....19

STRIKER ADJUSTMENT ....................................19

Removal and Installation of Front Door .................. 20

REMOVAL ...........................................................20

INSTALLATION ...................................................20

Removal and Installation of Rear Door ...................20

REMOVAL ...........................................................21

INSTALLATION ...................................................21

Door Weatherstrip ..................................................22

REMOVAL ...........................................................22

INSTALLATION ...................................................22

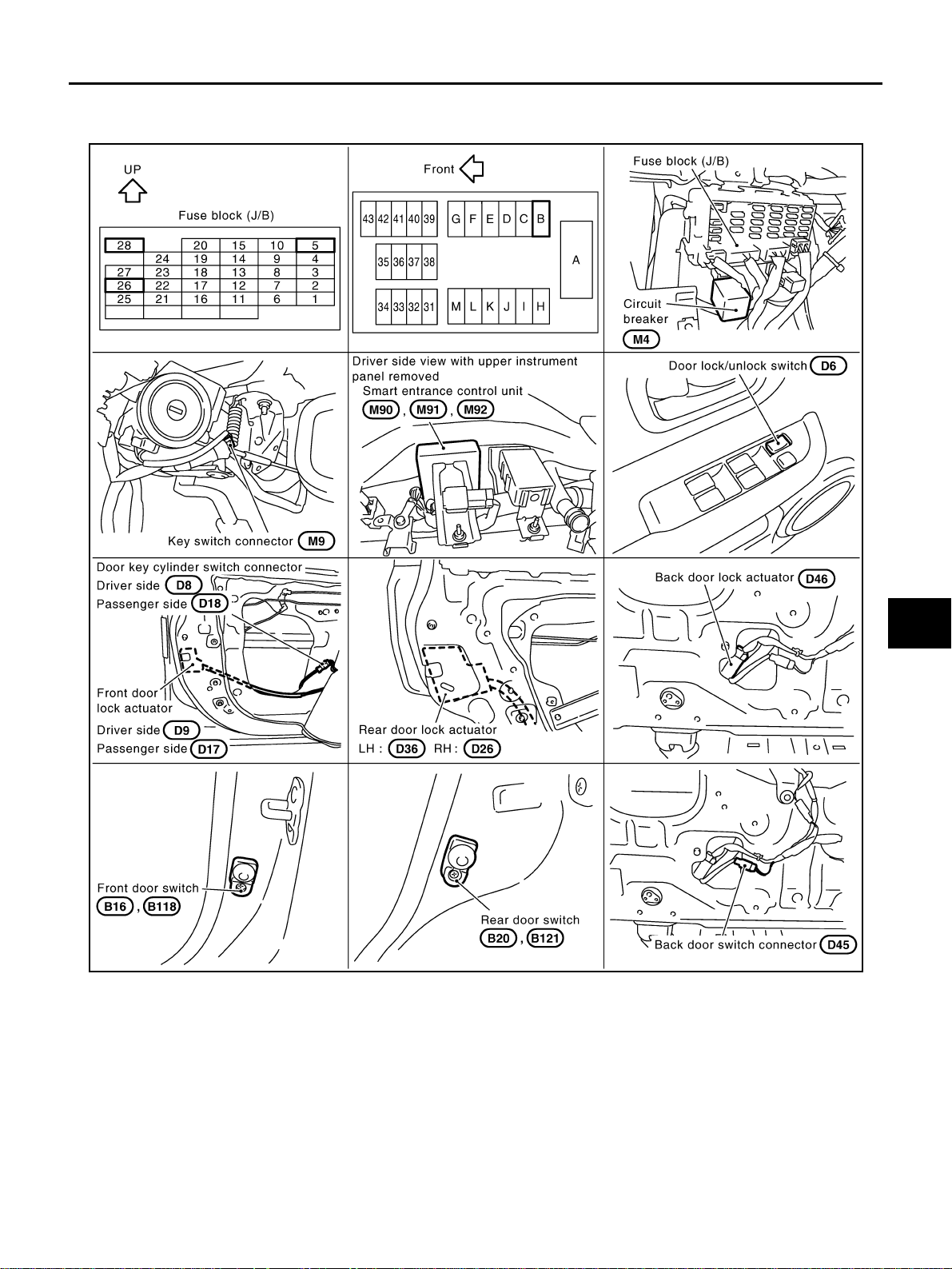

POWER DOOR LOCK SYSTEM ..............................23

Component Parts and Harness Connector Location ...23

System Description .................................................23

OPERATION ........................................................23

DOOR LOCK/UNLOCK SWITCH (POWER WIN-

DOW MAIN SWITCH) OPERATION ...................24

DOOR LOCK/UNLOCK SWITCH (PASSENGER

SIDE) OPERATION ............................................. 24

DOOR KEY CYLINDER SWITCH OPERATION ...24

KEY REMINDER SYSTEM .................................25

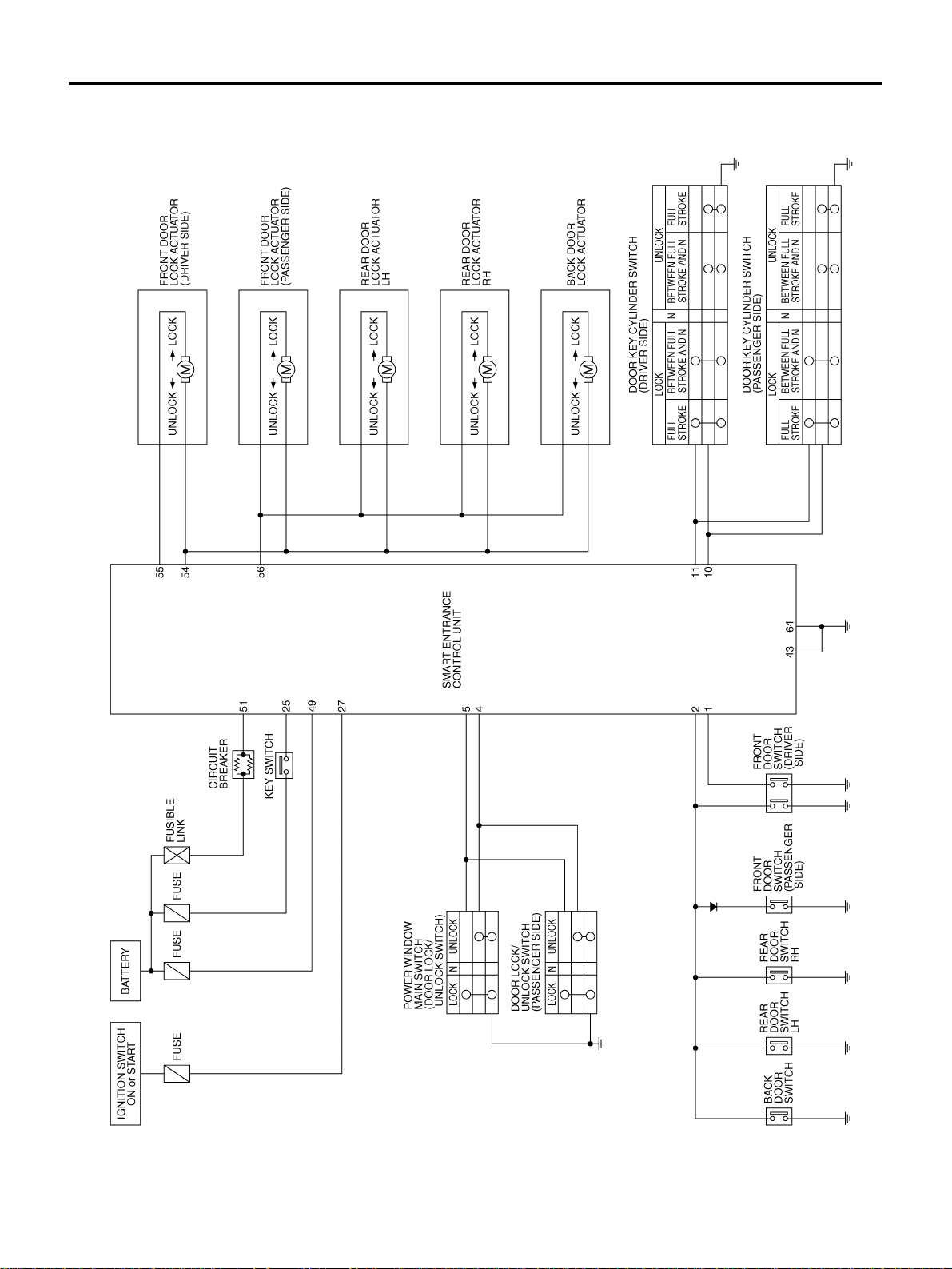

Schematic .................... ....................................... ....26

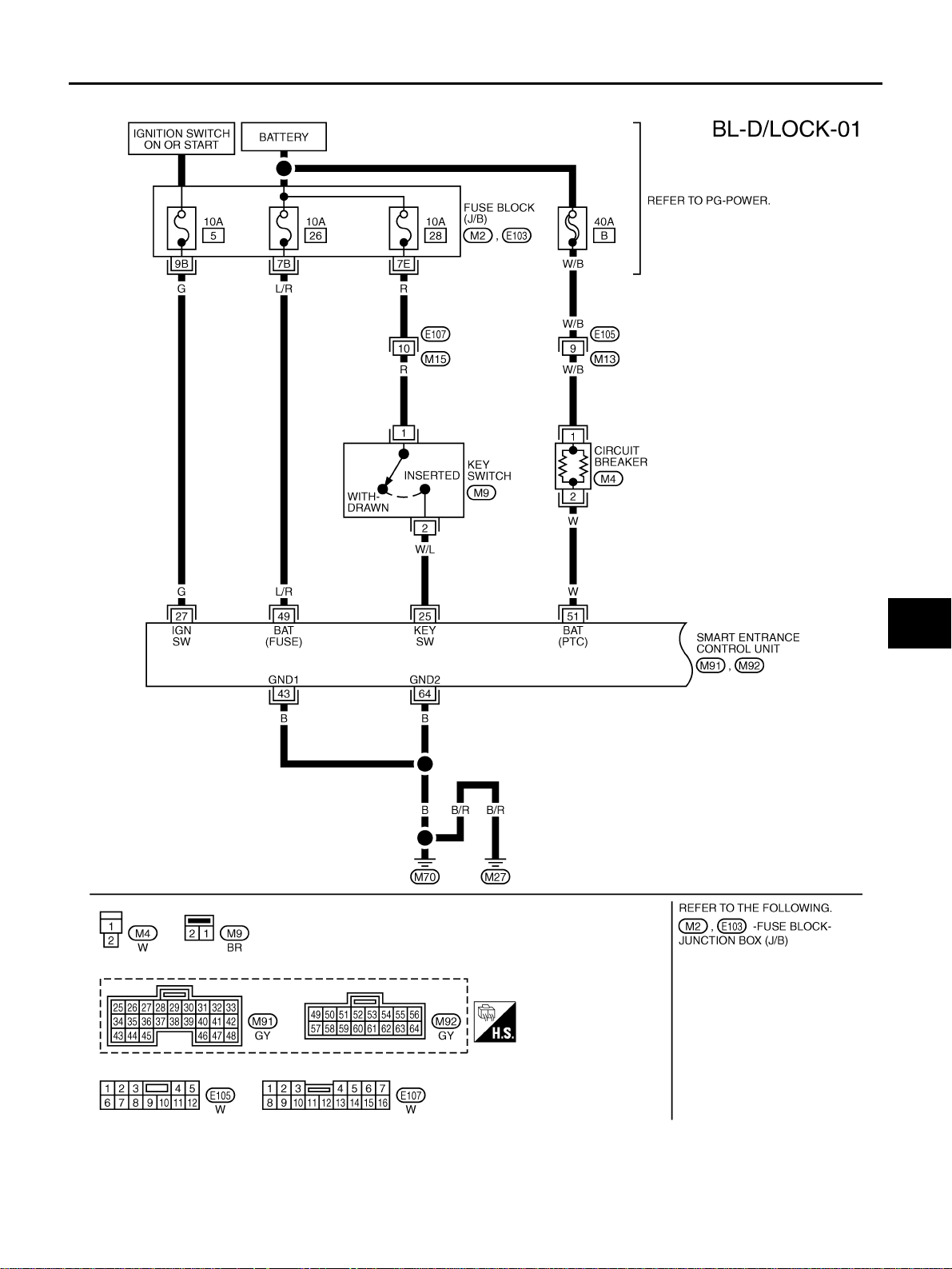

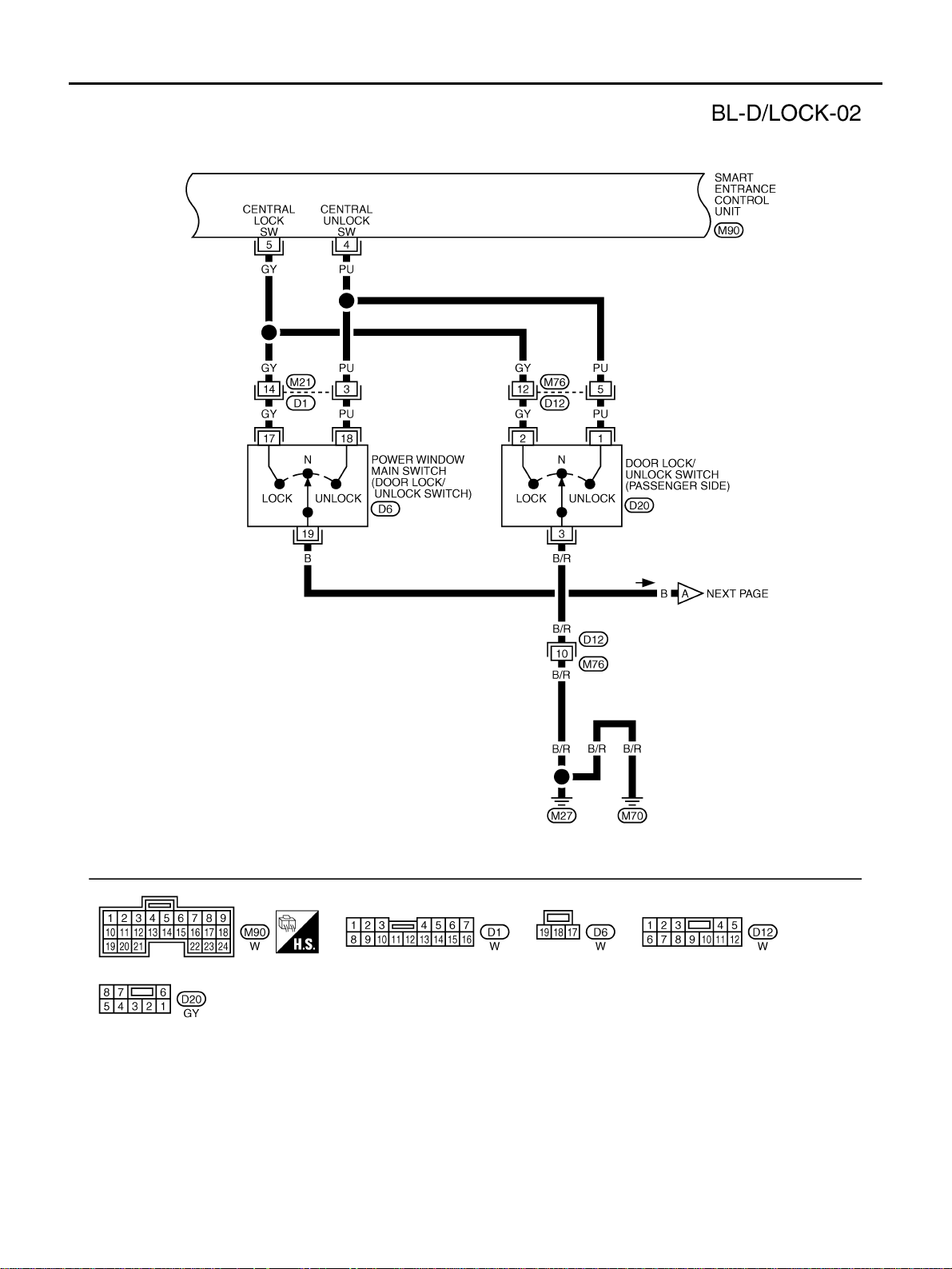

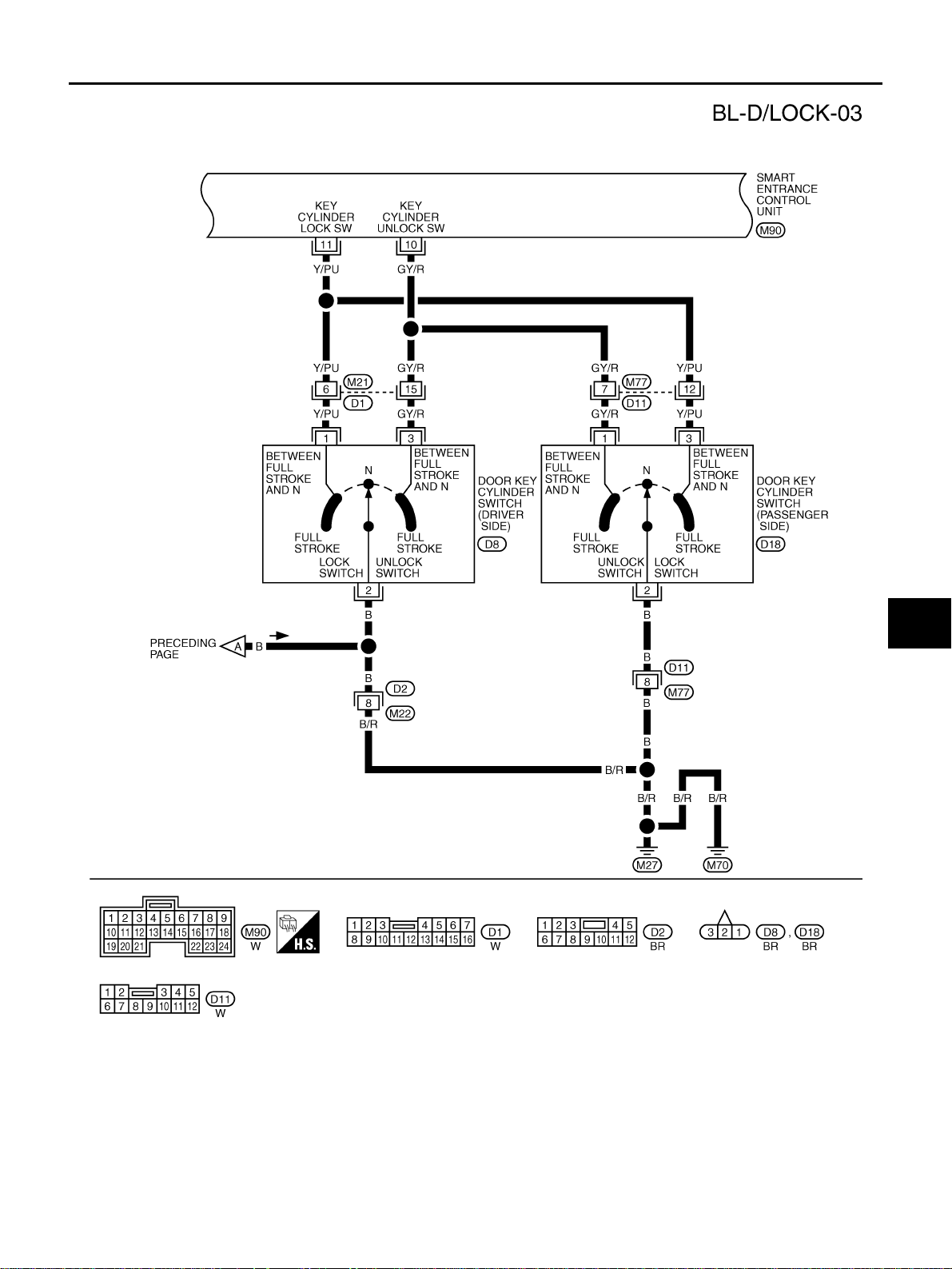

Wiring Diagram — D/LOCK — ...............................27

T erminal and Reference Value for Smart Entrance

Control Unit .............................................................32

Symptom Chart .......................................................33

Smart Entrance Control Unit Power Supply and

Ground Circuit Check ............................................. 33

Power Window Main Switch (Door Lock/Unlock

Switch) Check .........................................................34

Door Lock/Unlock Switch (Passenger Side) Check ...35

Door Key Cylinder Switch (Driver Side) Check ......36

Door Key Cylinder Switch (Passenger Side) Circuit

C

D

E

F

G

H

BL

J

K

L

M

Revision: 2006 July 2006 X-Trail

BL-1

Check .....................................................................37

Front Door Lock Actuator (Driver Side) Check .......38

Front Door Lock Actuator (Passenger Side) Check ...39

Rear Door Lock Actuator LH Check .......................40

Rear Door Lock Actuator RH Check .......................40

Back Door Lock Actuator Check .............................41

Front Door Switch (Driver Side) Check ...................42

All Door Switch Check ............................................42

Key Switch Check ...................................................44

MULTI-REMOTE CONTROL SYSTEM .....................45

Component Parts and Harness Connector Location ...45

System Description .................................................45

INPUTS ............................................................... 45

OPERATED PROCEDURE ................................. 46

Schematic ................. .............................................. 48

Wiring Diagram — MULTI — ..................................49

T erminal and Reference Value for Smart Entrance

Control Unit .............................................................55

Symptom Chart .......................................................56

Remote Controller Battery Check ...........................57

ACC Switch Circuit Check ......................................57

Power Supply and Ground Circuit Check ...............57

Front Door Switch (Driver Side) Circuit Check .......59

All Door Switch Circuit Check .................................59

Key Switch Circuit Check ....................................... 60

Hazard Reminder Check ........................................61

Horn Reminder Check ............................................ 62

Interior Room Lamp Operation Check ....................62

ID Code Entry Procedure .......................................63

KEY FOB ID SET UP ..........................................63

Key Fob Battery Replacement ................................64

FRONT DOOR LOCK ............................................... 65

Component Parts Location .....................................65

Inspection and Adjustment .....................................65

OUT SIDE HANDLE ROD ADJUSTMENT ..........65

Removal and Installation ........................................65

REMOVAL ...........................................................65

INSTALLATION ....................................................66

Disassembly and Assembly ....................................67

DISASSEMBLY ...................................................67

ASSEMBLY .........................................................67

REAR DOOR LOCK .............................. ...... ....... .......68

Component Parts Location .....................................68

Inspection and Adjustment .....................................68

OUT SIDE HANDLE ROD ADJUSTMENT ..........68

Removal and Installation ........................................68

REMOVAL ...........................................................68

INSTALLATION ....................................................69

Disassembly and Assembly ....................................70

DISASSEMBLY ...................................................70

ASSEMBLY .........................................................70

BACK DOOR .............................................................71

Fitting Adjustment ...................................................71

VERTICAL/LATERAL CLEARANCE ADJU ST-

MENT .................................................................. 71

Back Door Assembly ..............................................72

REMOVAL AND INSTALLATION .........................72

INSPECTION ............................ ............. ..............73

Removal and Installation of Back Door Handle ...... 73

REMOVAL ........................................................ ....73

INSTALLATION ......................................... ...........73

Removal and Installation of Back Door Lock and

Actuator ........................ ............. ............. ............. ....73

REMOVAL ........................................................ ....73

INSTALLATION ......................................... ...........73

Disassembly and Assembly of Back Door Lock &

Back Door Lock Actuator ........................................73

DISASSEMBLY ................................................ ....73

ASSEMBLY ...................................................... ....74

Removal and Installation of Back Door Weatherstrip ...74

REMOVAL ........................................................ ....74

INSTALLATION ......................................... ...........74

FUEL FILLER LID OPENER .....................................75

Component Parts Location .....................................75

Removal and Installation of Fuel Filler Lid Opener

Cable ............................ ............. ............. ............. ....75

REMOVAL ........................................................ ....75

INSTALLATION ......................................... ...........75

VEHICLE SECURITY (THEFT WARNING) SYSTEM ...76

Component Parts and Harness Connector Location ...76

System Description .................................................77

DESCRIPTION ....................................................77

POWER SUPPLY AND GROUND .......................78

INITIAL CONDITION TO ACTIVATE THE SYS-

TEM .....................................................................78

THEFT WARNING SYSTEM ACTIVATION .........78

THEFT WARNING SYSTEM ALARM OPERA-

TION ....................................................................78

THEFT WARNING SYSTEM DEACTIVATION ....79

PA NIC ALARM OPERATION ...............................79

Schematic ...............................................................80

Wiring Diagram — VEHSEC — ..............................81

T erminals and Reference Value for Smart Entrance

Control Unit .............................................................86

Preliminary Check ...................................................87

Symptom Chart .......................................................88

Diagnostic Procedure 1 ...........................................89

Diagnostic Procedure 2 ...........................................90

Diagnostic Procedure 3 ...........................................90

Diagnostic Procedure 4 ...........................................91

Diagnostic Procedure 5 ...........................................92

Diagnostic Procedure 6 ...........................................94

Diagnostic Procedure 7 ...........................................94

Diagnostic Procedure 8 ...........................................96

NVIS (NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS) ........................................................................97

Component Parts and Harness Connector Location ...97

System Description .................................................98

System Composition ...............................................98

ECM Re-communicating Function ..........................99

Wiring Diagram — NATS — ..................................100

CONSULT-II ..........................................................101

CONSULT-II INSPECTION PROCEDURE ........101

CONSUL T-II DIAGNOSTIC TEST MODE FUNC-

TION ..................................................................102

HOW TO READ SE LF-DIAGNOSTIC RESUL TS .102

NVIS (NATS) SELF-DIAGNOSTIC RESULTS

ITEM CHART .....................................................103

Revision: 2006 July 2006 X-Trail

BL-2

Work Flow ............................................................ 104

Trouble Diagnoses ............................................... 105

SYMPTOM MATRIX CHART 1 ......................... 105

SYMPTOM MATRIX CHART 2 ......................... 106

DIAGNOSTIC SYSTEM DIAGRAM .................. 106

Diagnostic Procedure 1 ........................................ 107

Diagnostic Procedure 2 ........................................ 107

Diagnostic Procedure 3 .........................................110

Diagnostic Procedure 4 ......................................... 111

Diagnostic Procedure 5 .........................................112

Diagnostic Procedure 6 .........................................113

Diagnostic Procedure 7 .........................................114

How to Replace NATS IMMU ................................115

BODY REPAIR .........................................................116

Body Exterior Paint Color ......................................116

Body Component Parts .........................................117

UNDERBODY COMPONENT PARTS ...............117

BODY COMPONENT PARTS ............................119

Corrosion Protection ............................................ 121

DESCRIPTION ................................ .................. 121

ANTI-CORROSIVE WAX .................................. 122

UNDERCOATING ............................................. 123

STONE GUARD COAT ..................................... 124

Body Sealing ........................................................ 125

DESCRIPTION ................................ .................. 125

Body Construction ................................................ 128

BODY CONSTRUCTION .................................. 128

Body Alignment .................................................... 129

BODY CENTER MARKS .................................. 129

PANEL PARTS MATCHING MARKS .................130

DESCRIPTION ............................ ......................131

ENGINE COMPARTMENT ................................132

UNDERBODY ...................................................134

PASSENGER COMPARTMENT .......................136

REAR BODY ..... ....... ...... ....... ............................138

Handling Precautions for Plastics .........................140

HANDLING PRECAUTIONS FOR PLASTICS ..140

LOCATION OF PLASTIC PARTS ......................141

Precautions in Repairing High Strength Steel .......143

HIGH STRENGTH S TEEL (HSS) USED IN NIS-

SAN VEHICLES ................................................143

Replacement Operations ......................................146

DESCRIPTION ............................ ......................146

RADIATOR CORE SUPPORT ..........................149

RADIATOR CORE SUPPORT (PARTIAL

REPLACEMENT) ..............................................150

HOODLEDGE ...................................................151

HOODLEDGE (PARTIAL REPLACEMENT) .....153

FRONT SIDE MEMBER ....................................155

FRONT SIDE MEMBER (PARTIAL REPLACE-

MENT) ...............................................................157

FRONT PILLAR .................................................159

CENTER PILLAR ..............................................161

OUTER SILL .....................................................162

REAR FENDER . ....... .........................................163

REAR PANEL .... ....... ...... ....... ...... ....... ...............164

REAR FLOOR REAR ............................... ....... ..165

REAR SIDE MEMBER EXTENSION .................167

A

B

C

D

E

F

G

H

BL

K

M

J

L

Revision: 2006 July 2006 X-Trail

BL-3

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front sea t belt , helps t o redu ce th e r isk or s everi ty of injury to th e driv er an d front passenge r for c ertain

types of collision. Inform ation necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid rendering the SRS inope rative, which could increa se the risk of pers onal injury or de ath

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, in cluding incorrect removal a nd installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of th e system. For removal of Sp iral Ca ble an d Ai r

Bag Module, see the SRS section.

● Do not use electrical test equipme nt on any circuit related to the SRS unle ss instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses o r

harness connectors .

AIS005N4

Precautions for Work AIS005N5

● After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check

their operation.

● Check the lubrication level, damage, and wear of ea ch part. If necessary, grease or replace it.

Revision: 2006 July 2006 X-Trail

BL-4

PREPARATION

PREPARATION PFP:00002

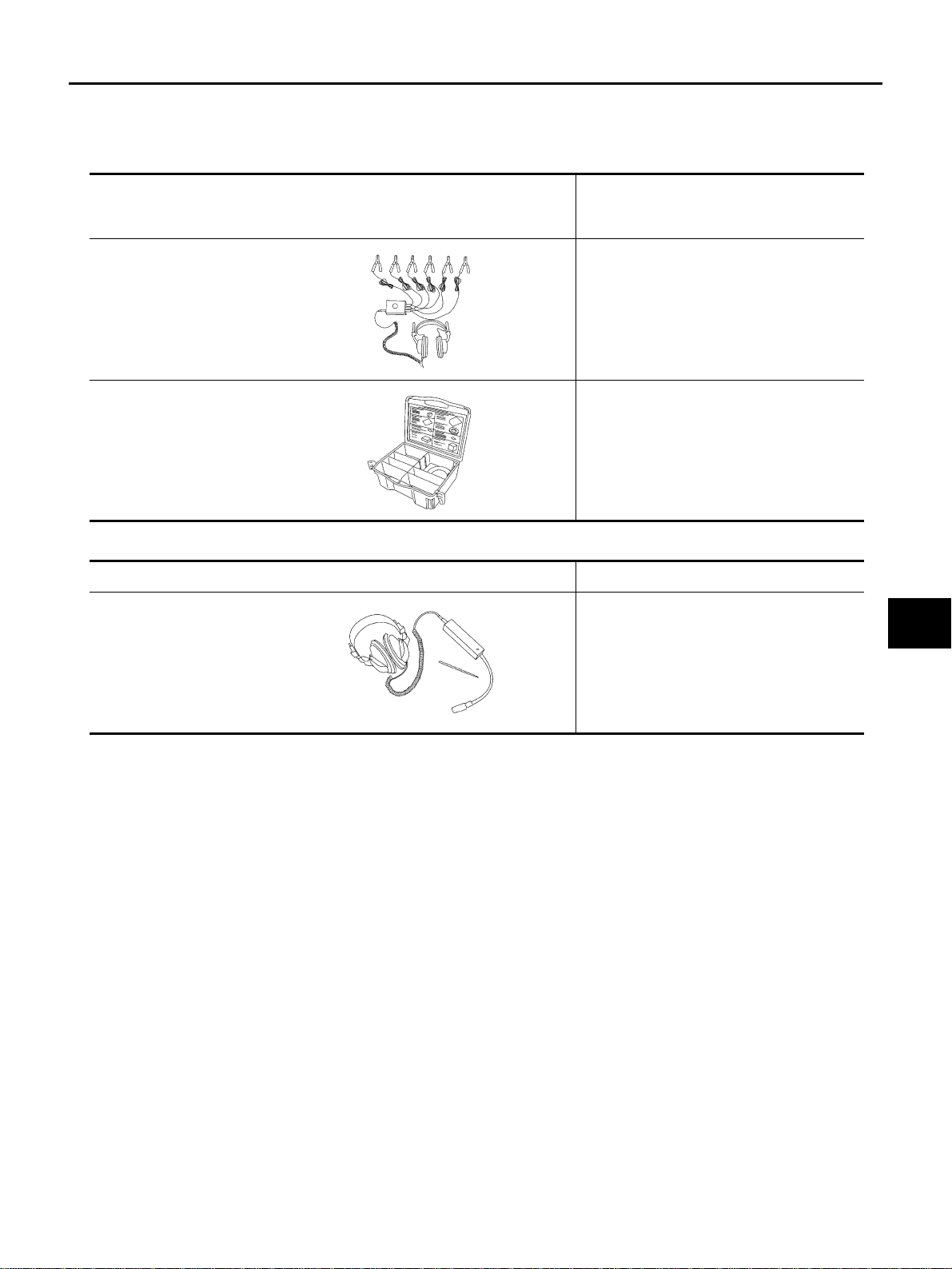

Special Service Tools AIS0063G

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Too l number

(Kent-Moore No.)

Too l name

Description

A

B

C

(J-39570)

Chassis ear

SIIA0993E

(J-43980)

NISSAN Squeak and

Rattle Kit

SIIA0994E

Locating the noise

Repairing the cause of noise

Commercial Service Tools AIS0063H

Tool name Description

Engine ear Locating the noise

SIIA0995E

D

E

F

G

H

BL

J

K

Revision: 2006 July 2006 X-Trail

BL-5

L

M

SQUEAK AND RATTLE TROUBLE DIAGNOSES

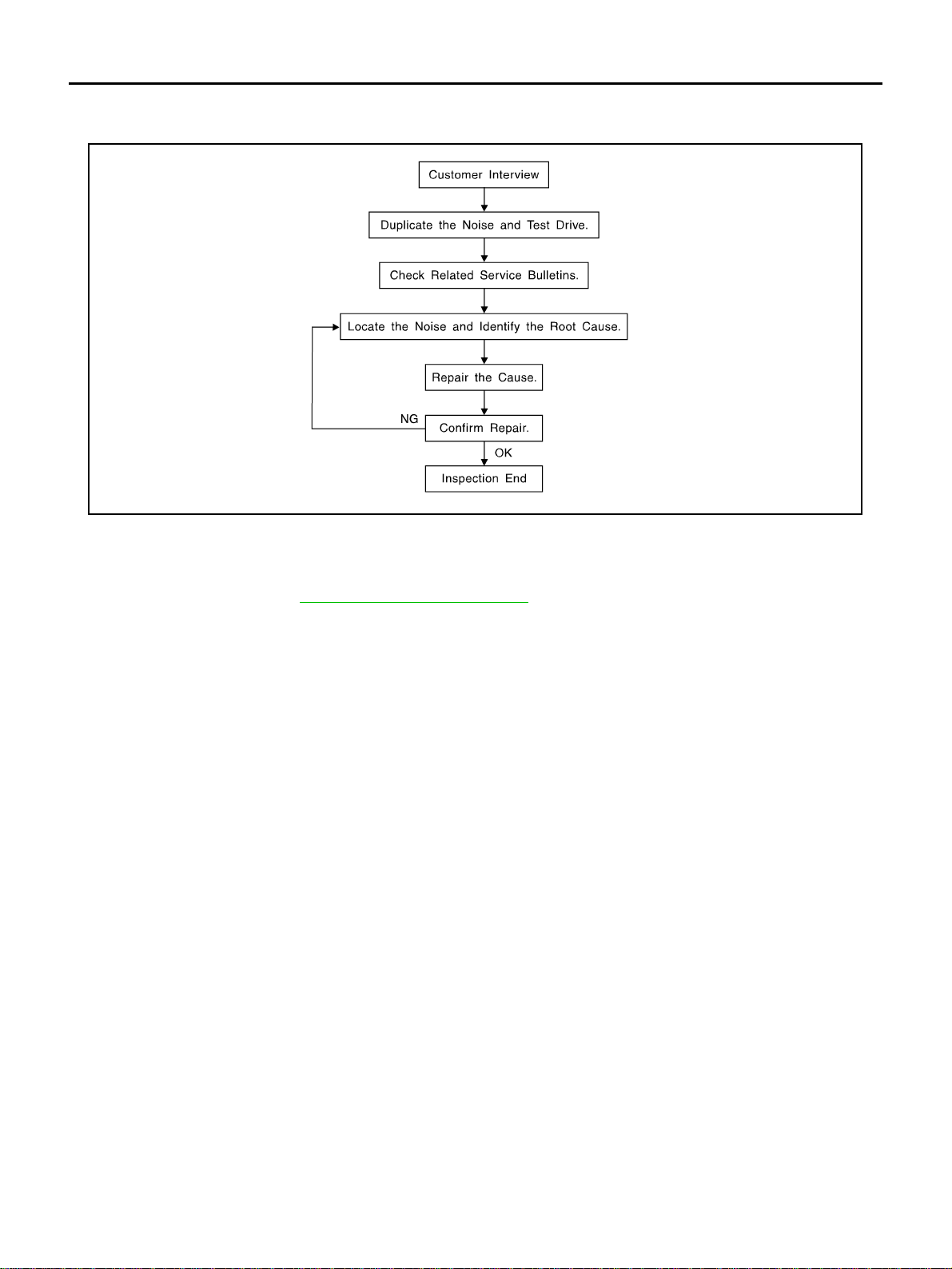

SQUEAK AND RATTLE TROUBLE DIAGNOSES PFP:00000 Work Flow AIS0060Y

SBT842

CUSTOMER INTERVIEW

Interview the cus to me r if po ss ib le , to de t ermi n e th e co nd iti on s th at exi st whe n th e no is e occu r s. Use th e D iagnostic Worksheet durin g the interview to docum ent the facts and conditio ns when the noise occu rs and any

customer's comments; refer to BL-10, "

conditions that exist when the noise occurs.

● The customer ma y not be able to provide a detailed description or t he location of th e noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

● If there is more than one n oise in th e veh icle , be s ure to di agno se an d repair th e noi se th at the cus tome r

is concerned about. This can be accomplished by test driving the vehicle with the customer.

● After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided s o the cus tomer, service adviser and techni cian are al l speaking the same language w hen

defining the noise.

● Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces=higher pitch noise/so fter surfaces=low er pitch noises/edge to surface=chirping

● Creak—(Like walking on an old w ooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

● Rattle—(Like shaking a baby rattle)

Rattle charac teristic s inclu de the fast repe ated c ontact/vibrat ion or simila r moveme nt/loose parts/missi ng

clip or fastener/incorrect clearance.

● Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

● Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose compon ents/can be caused by driver

action or road conditions.

● Thump—(Hea vy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

● Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

● Often the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

● Weather conditions, especially humidity and temperature, may have a great effect on noise level.

Diagnostic Worksheet" . This information is necessary to duplicate the

Revision: 2006 July 2006 X-Trail

BL-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Works heet regarding the co nditions or locatio n of the noise. This in formation can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to duplicate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

● Drive the vehicle an d att em pt to dup li ca te th e co nd iti on s th e cu stom er st at e s exi st w he n the no is e oc cu rs.

● If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

A

B

C

D

E

F

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

● removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

● tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or pu sh/pull the c omponent with excessive fo rce, otherwise the noise will be eliminated only

temporarily.

● feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

● placing a piece of paper between components that you suspect are causing the noise.

● looking for loose components and contact marks.

Refer to BL-8, "

Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE

● If the cause is a loose component, tighten the component securely.

● If the cause is insufficient c learance between components:

– separate components by re positioning or loosening and retightening the component, if possible.

– insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through your authorized Nissan Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/7688471L02: 15 × 25 mm (0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel .

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/7398250Y00: 10 mm (0.39 in) thick, 50 × 50 mm (1.97 × 1.97 in)

G

H

BL

J

K

L

M

Revision: 2006 July 2006 X-Trail

BL-7

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FEL T CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applicati ons.

68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/6 8239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, n ot found in the ki t, can also be used t o repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REP AIR

Confirm that the c ause of a n oise is repai red by test dr iving the ve hicle. Op erate the ve hicle und er the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting AIS0060Z

Refer to Table of Conte nts for specifi c component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instru ment panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar ga rni sh

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defros ter duct and duct j o int

These incide nts can usuall y be located by tapping or moving t he components to duplicate the nois e or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by applying felt cloth tape or silico n spray (in h ard to reac h areas ). Uret hane pads can be used to insul ate wiring harness.

CAUTION:

Do not use silicone s pray to isolate a s queak or rattle. If you saturate the ar ea with silicone , you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of thes e incidents. You can usu ally insu late the are as with f elt cloth tape or insula tor foam bl ocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

Revision: 2006 July 2006 X-Trail

BL-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsio n ba rs kn oc king together

4. A loose licen s e pla te or bra ck et

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) causing the noise.

A

B

C

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, r ail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insula ting with felt cloth tape.

SEATS

When isolati ng sea t noise i t's im por t ant to no te th e posi tion th e seat is in a nd the load place d on the sea t when

the noise is present. These conditions should be du plicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak betwe e n the seat pad c ushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the conditions under whi ch the no is e o cc urs . M os t of these incidents can be repaired by repositioning the co m ponent

or applying ur ethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components und er the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include :

1. Any component mounted to the e ngine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to is olate since they cann ot be reached fro m the int erior of th e vehic le. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be chan ged to isola te the noise . Repairs can usua lly be made by moving, adjusting, securing, or

insulating the component causing the noise.

D

E

F

G

H

BL

J

K

L

M

Revision: 2006 July 2006 X-Trail

BL-9

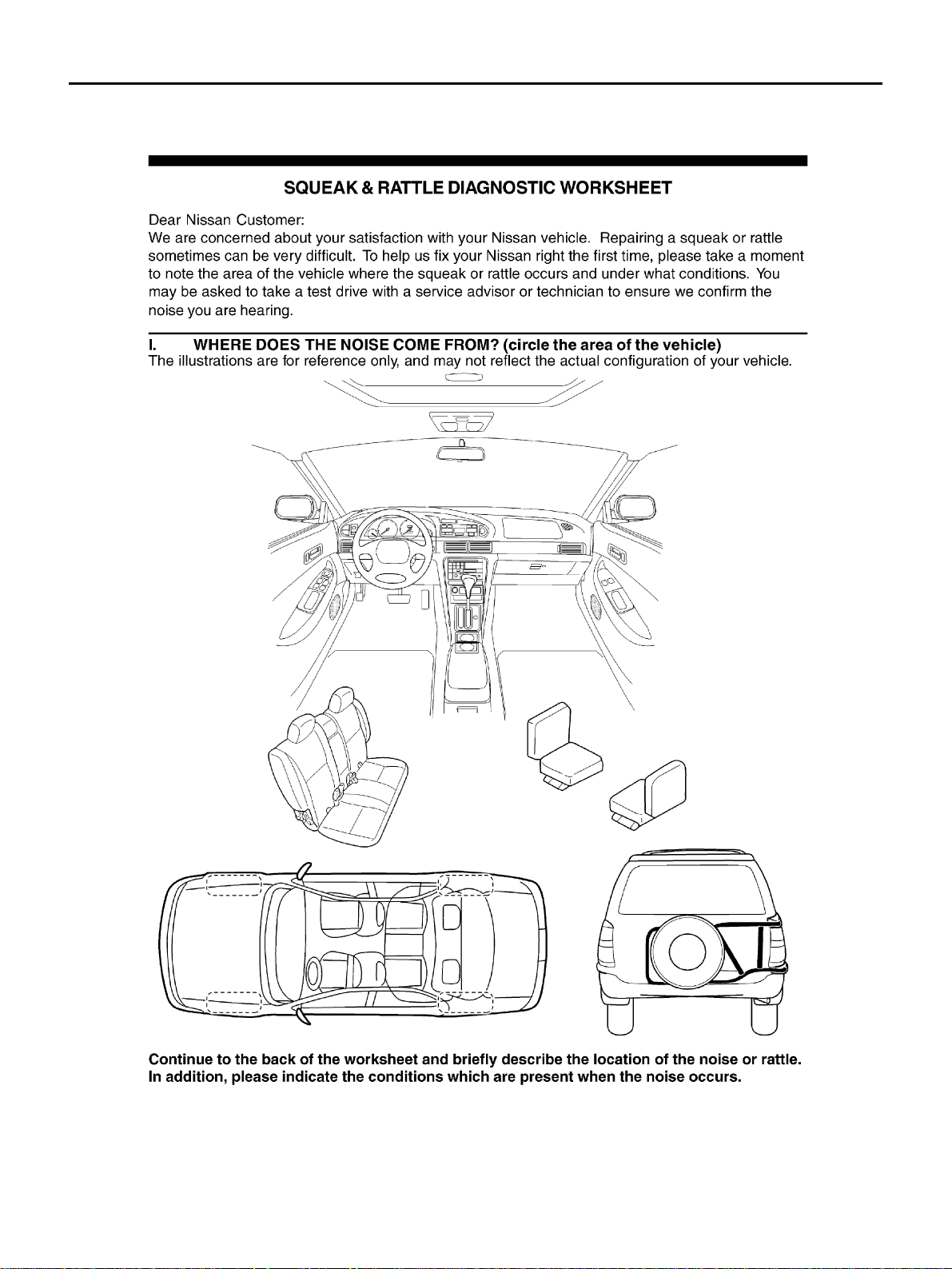

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Diagnostic Worksheet AIS00610

PIIB0723E

Revision: 2006 July 2006 X-Trail

BL-10

SQUEAK AND RATTLE TROUBLE DIAGNOSES

A

B

C

D

E

F

G

BL

H

J

K

L

M

SBT844

Revision: 2006 July 2006 X-Trail

BL-11

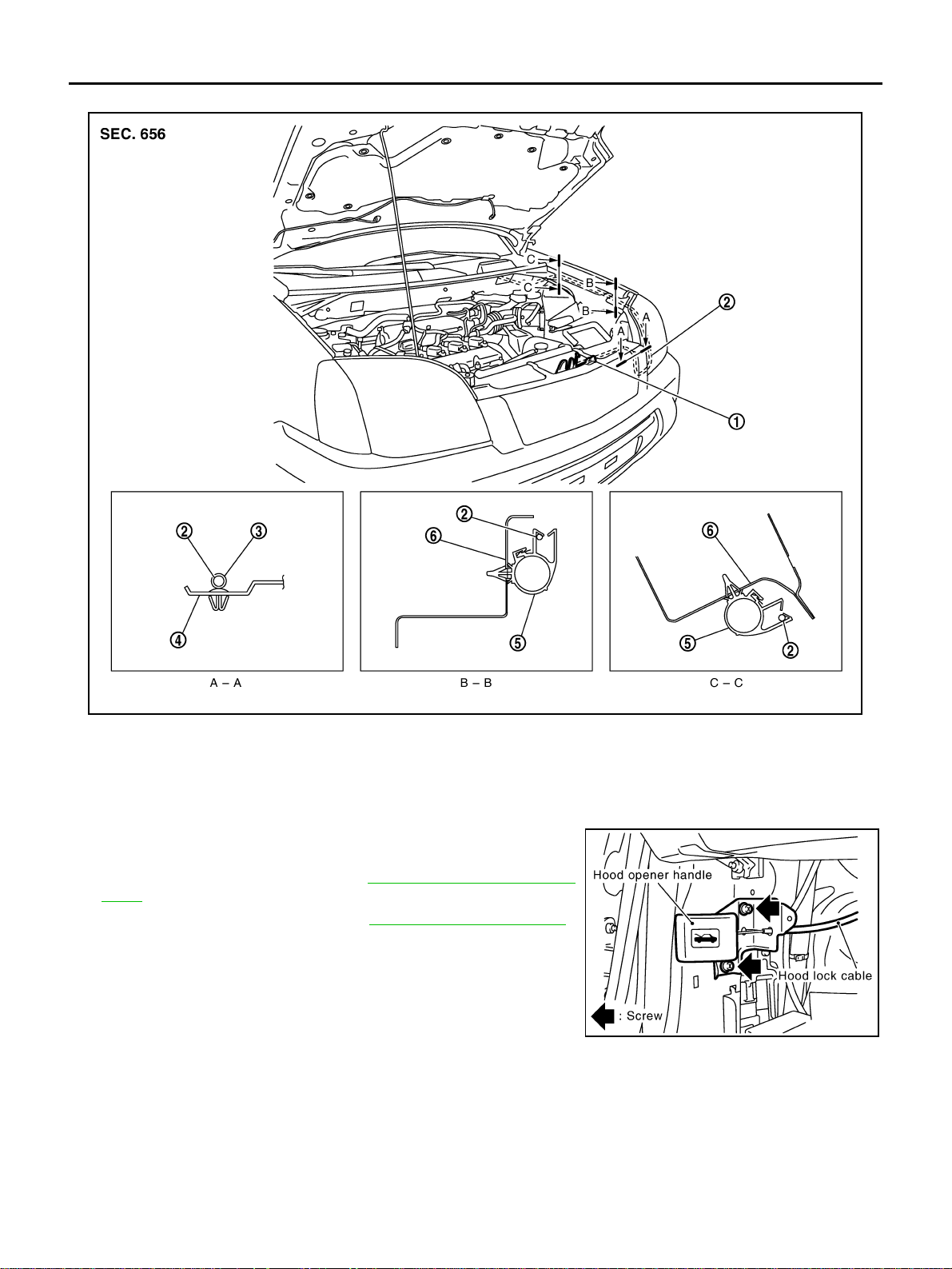

HOOD

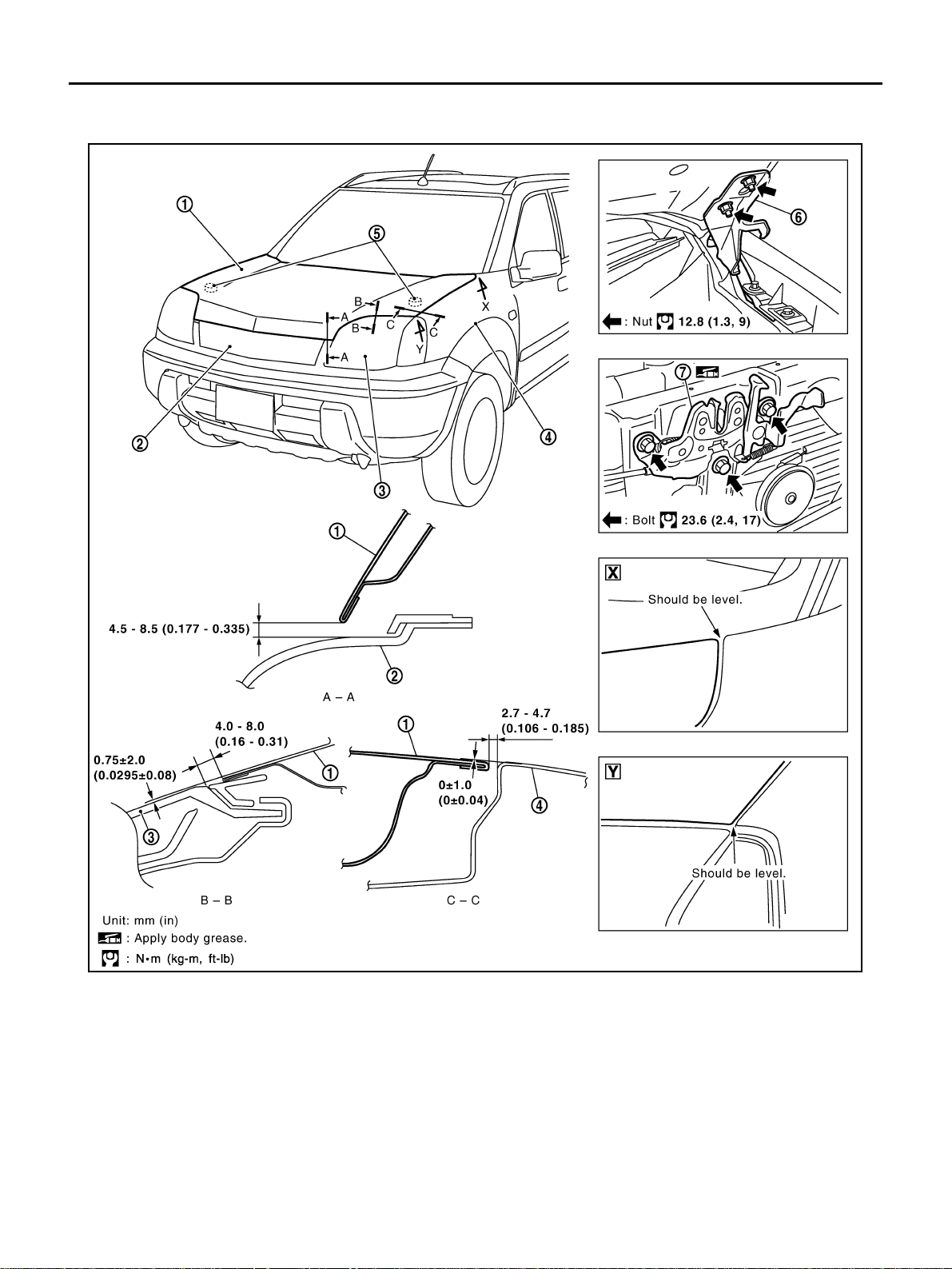

HOOD PFP:65100 Fitting Adjustment AIS005NB

PIIB1609E

1. Hood assembly 2. Front grille 3. Headlamp

4. Front fender 5. Bumper rubber 6. Hood hinge

7. Hood lock assembly

LONGITUDINAL AND LATERAL CLEARANCE ADJUSTMENT

1. Remove hood lock assembly, loosen the hood hinge nuts and close the hood.

2. Adjust the la te ral an d lo ngitudinal clearanc e, an d open the hood to tig ht en the hood hinge mo un ting bolts

to the specified torque.

3. Install the hood lock temporarily, and align the hood striker and lo ck so tha t th e ce nt ers of s trik er and lock

become vertical viewed from the front, by moving the hood lock laterally.

4. Tighten hood lock mounting bolts to the specified torque.

Revision: 2006 July 2006 X-Trail

BL-12

HOOD

CAUTION:

Adjust right/left clearance between hood and each part to the following specification.

Hood and front grille (A–A) : Less than 1.0 mm (0.04 in)

Hood and fender (C–C) : Less than 1.0 mm (0.04 in)

FRONT END HEIGHT ADJUSTMENT

1. Remove the hood lo ck an d adju st the heigh t by ro t ating t he bu mper r ubbe r unti l the ho od be comes 1 to1. 5

mm (0.04 to 0.0 59 in) lower than the fender.

2. Temporarily tigh ten th e hoo d lo ck, and posi tio n it by enga ging it wi th the hood strike r. Check the lock and

striker for lo oseness, and tighten the hood lock mounting bolts to the specified torque.

A

B

C

D

E

F

G

BL

H

J

K

L

M

Revision: 2006 July 2006 X-Trail

BL-13

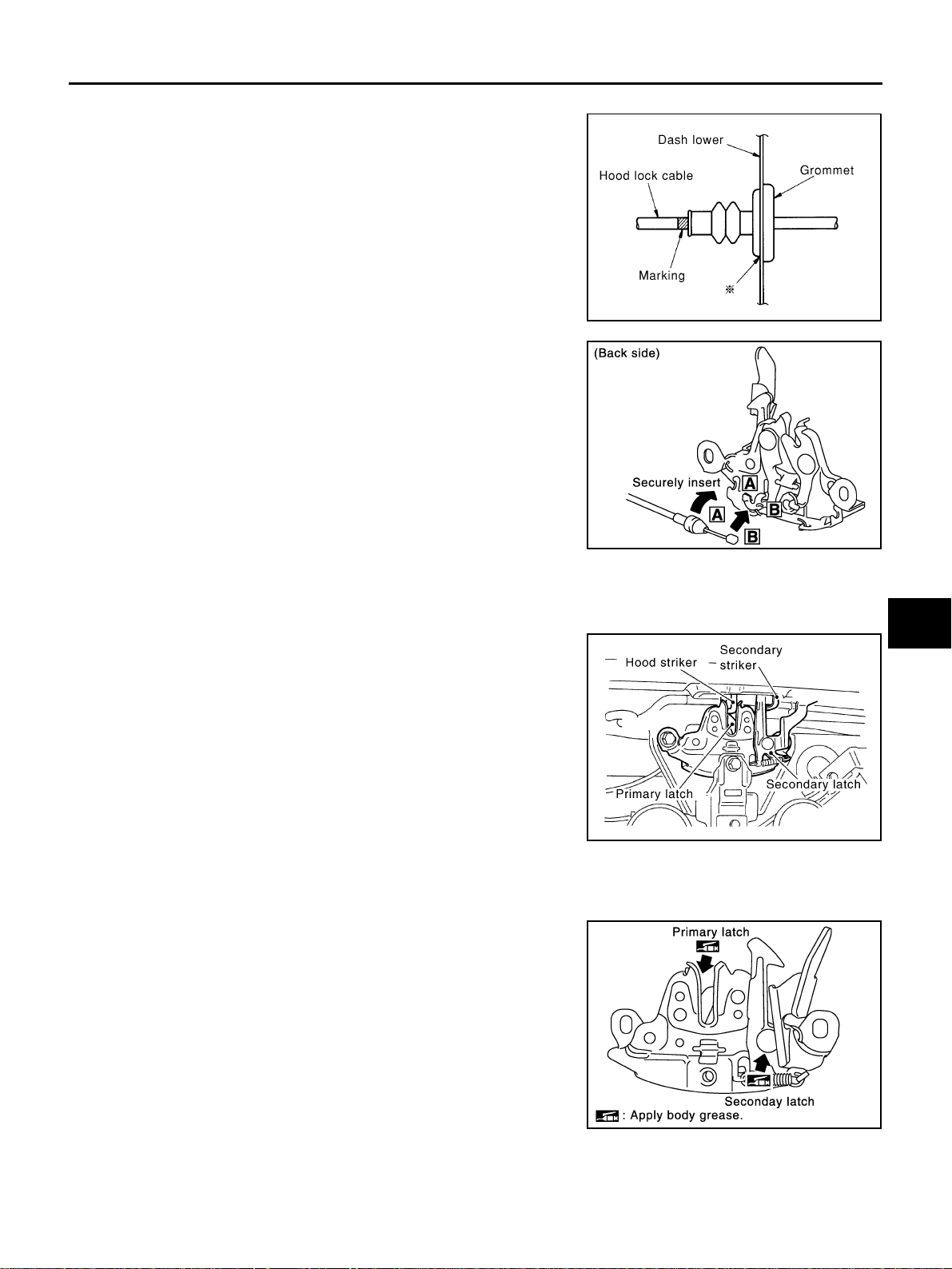

HOOD

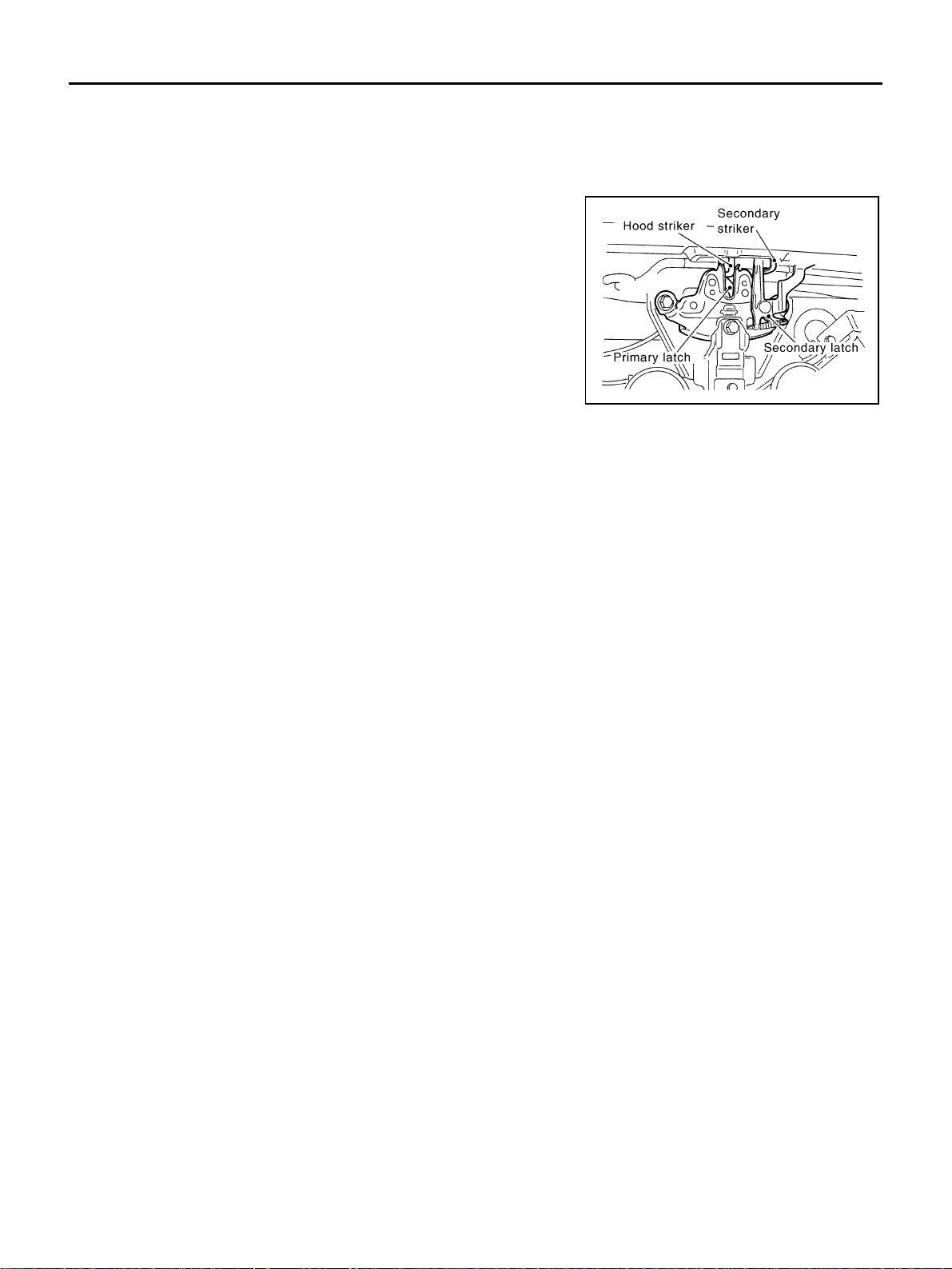

SURFACE HEIGHT ADJUSTMENT

1. Remove hood loc k, and adjus t the surface h eight difference o f hood, fender a nd headlamp according to

the fitting standard dimension, by rotating RH and LH bumper rubbers.

2. Install hood lock temporarily, and move hood lock laterally until the centers of striker and lock become vertical when viewed from the front.

3. Make sure that the hood lock secondary latch is properly

engaged with the secondary striker with hood's own weight.

4. Make sure that the hood lo ck prima ry latch i s secure ly engage d

with the hood striker with hood's own weight by dropping hood

from approx. 200 mm(7.87 in) height.

CAUTION:

Do not drop hood from a height of 300 mm (11.81 in) or

more.

5. Move hood lockup and down until striker smoothly engages the

lock when the hood is closed.

6. When pulling the hood open er leve r gentl y, make sure that front

end of the hood rises by ap pro xi ma te ly 20 m m (0.7 9 in ) an d th at hood striker and hood lo ck pri ma ry latc h

is disengaged. Also make sure that hood opener returns to the original position.

7. After adjustment, tighten lock bolts to the specified torque.

PIIB1082E

Revision: 2006 July 2006 X-Trail

BL-14

HOOD

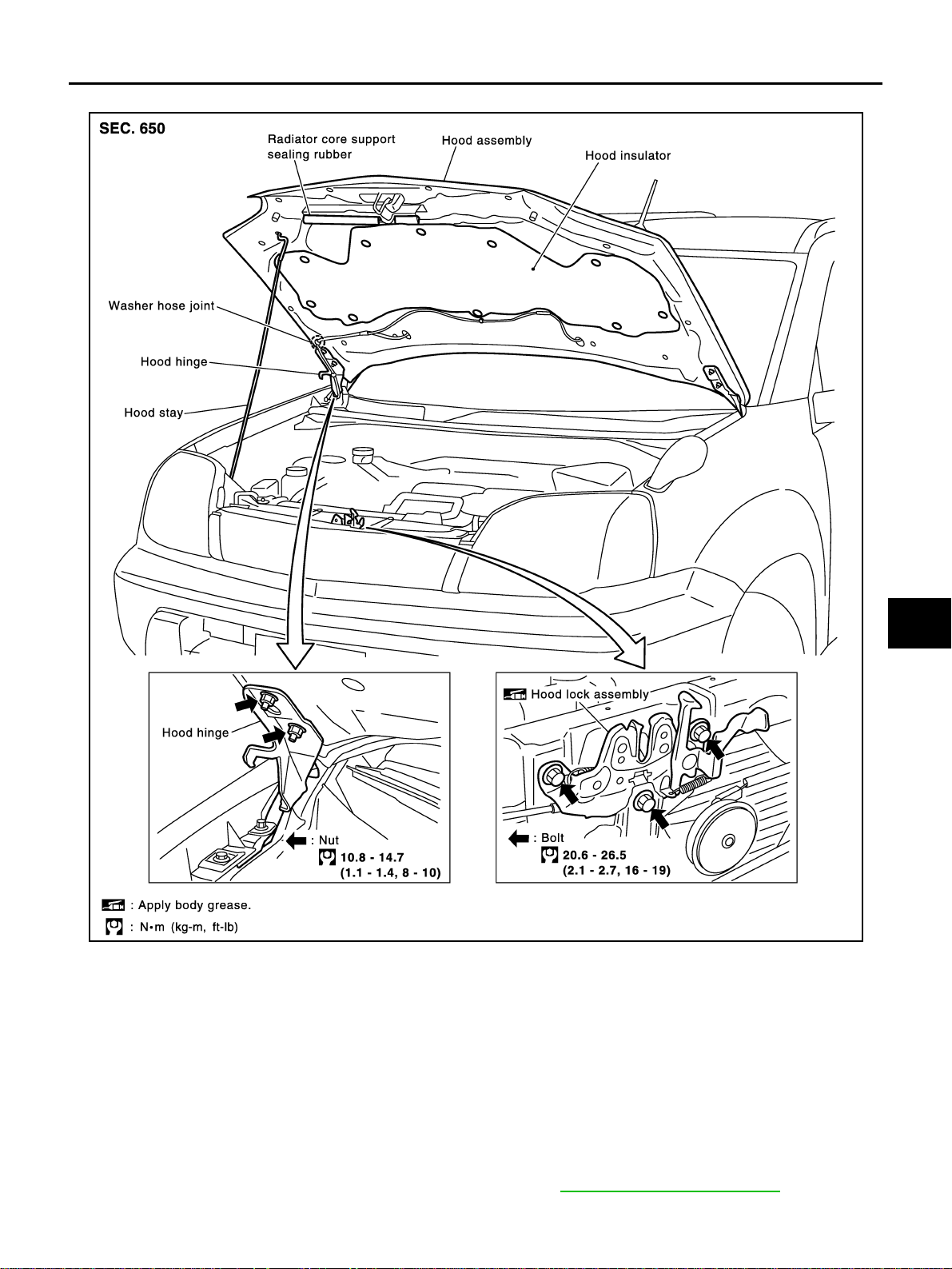

Removal and Installation of Hood Assembly AIS005NC

A

B

C

D

E

F

G

REMOVAL

1. Disconnect washer hose at the connection.

2. Remove hood hinge mounting nut s on the hood and then t he hood assembly.

CAUTION:

Operate with tw o workers, because of its hea vy weight.

H

BL

J

K

L

M

SIIA0154E

INSTALLATION

Install in the reverse order of removal.

CAUTION:

● Before installing ho od hinge, appl y anticorrosive agent onto th e mounting surf ace of the veh icle

body.

● After installing, perform hood fitting adjustment. Refer to BL-12, "Fitting Adjustment" .

Revision: 2006 July 2006 X-Trail

BL-15

HOOD

Removal and Installation of Hood Lock Control AIS005ND

1. Hood lock assembly 2. Hood lock cable 3. Cable clip

Radiator core support sealing rub-

4.

ber

5. Harness clip 6. H oodl edge upper

REMOVAL

1. Remove hood lock cable from hood lock and clip of upper portion of radiator core supp ort an d hoo d le dg e.

2. Remove fender p rotector. Refer to EI-20, "

TOR" .

3. Remove dash sid e fini sher. Refer to EI-36, "

4. Remove attaching screw and then the hood opener.

5. Remove dash panel grommet and pull h ood lock cable toward

the passenger compartment.

NOTE:

When pulling the cable, be careful not to strip or scratch the

outer surface.

FENDER PROTEC-

BODY SIDE TRIM" .

PIIB1610E

PIIB1611E

Revision: 2006 July 2006 X-Trail

BL-16

HOOD

INSTALLATION

1. Pass hood lock cable through the opening while keeping the

winding radius 100 mm (3.94 in) or larger.

2. After confirming that the grommet is properly positioned, push

the grommet securely into the hole.

3. Apply sealant to the area on the grommet indicated with the *

mark.

A

B

C

PIIA0173E

4. Connect cable securely to the lock.

5. After connection, confirm proper adjustment and operation for

both hood lock and hood opener.

PIIA3552E

Hood Lock Control Inspection AIS005NE

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Make sure that the hood lock secondary latch is securely

engaged with the secondary strike r with hood's own weight.

2. Make sure that the hood lock primary latch is securely engaged

with the hood strik er with hoo d's own w eig ht by dro pping it f rom

approx 200 mm (7 .87 in) height.

CAUTION:

Do not drop hood from a height of 300 mm (11.81 in) or

more.

D

E

F

G

H

BL

J

K

PIIB1082E

3. When pulli ng hood opener lever gently, make sure that front end of the hood ris es by approximately 20

mm (0.79 in) and that hood striker and hood lock primary latch are disengaged. Also make sure that hood

opener returns to the original position.

4. Confirm hood lock is properly lubricated. If necessary, apply

“body grease” at the point shown in the figure.

PIIA3550E

Revision: 2006 July 2006 X-Trail

BL-17

L

M

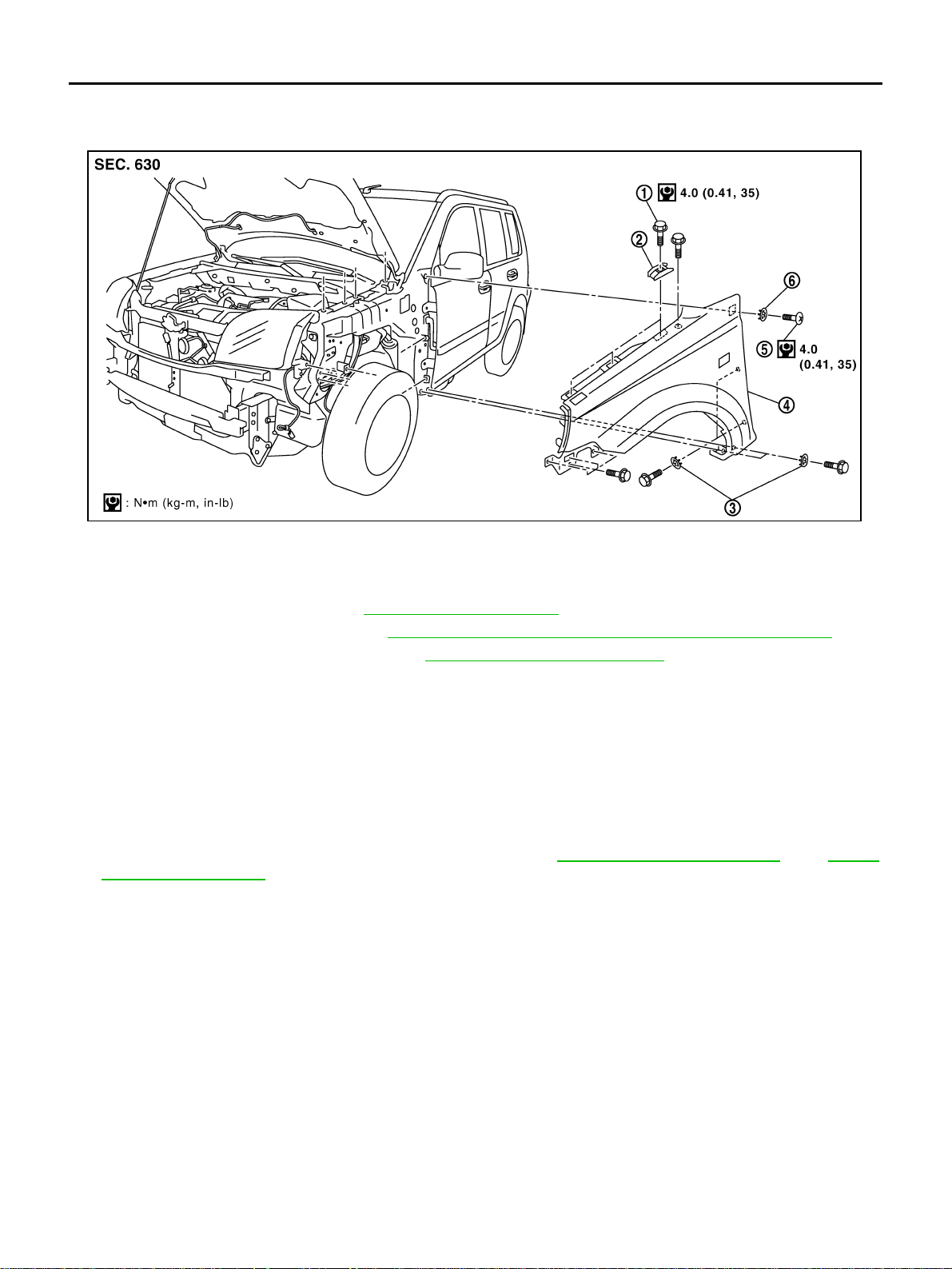

FRONT FENDER

FRONT FENDER PFP:63100 Removal and Installation AIS0061L

PIIB1612E

1. Bolt 2. Stiffener 3. Spring washer

4. Front fender 5. TORX bolt (T20) 6. Spring washer

REMOVAL

1. Remove the front bumper. Refer to EI-14, "FRONT BUMPER" .

2. Remove the turn signal lamp. Refer to LT-29, "

3. Remove the front fender protector. Refer to EI-20, "

Removal and Installation of Front Turn Signal Lamp" .

FENDER PROTECTOR" .

4. Remove the mounting bolt and remove the front fender.

CAUTION:

While removing use a shop cloth to protect body from damaging.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

● After installing, apply touch-up paint (the body color) onto the head of the front fender mounting

bolts.

● After installing, check front fender adjustment. Refe r to BL-12, "Fitting Adjustment" and BL-19,

"Fitting Adjustment" .

Revision: 2006 July 2006 X-Trail

BL-18

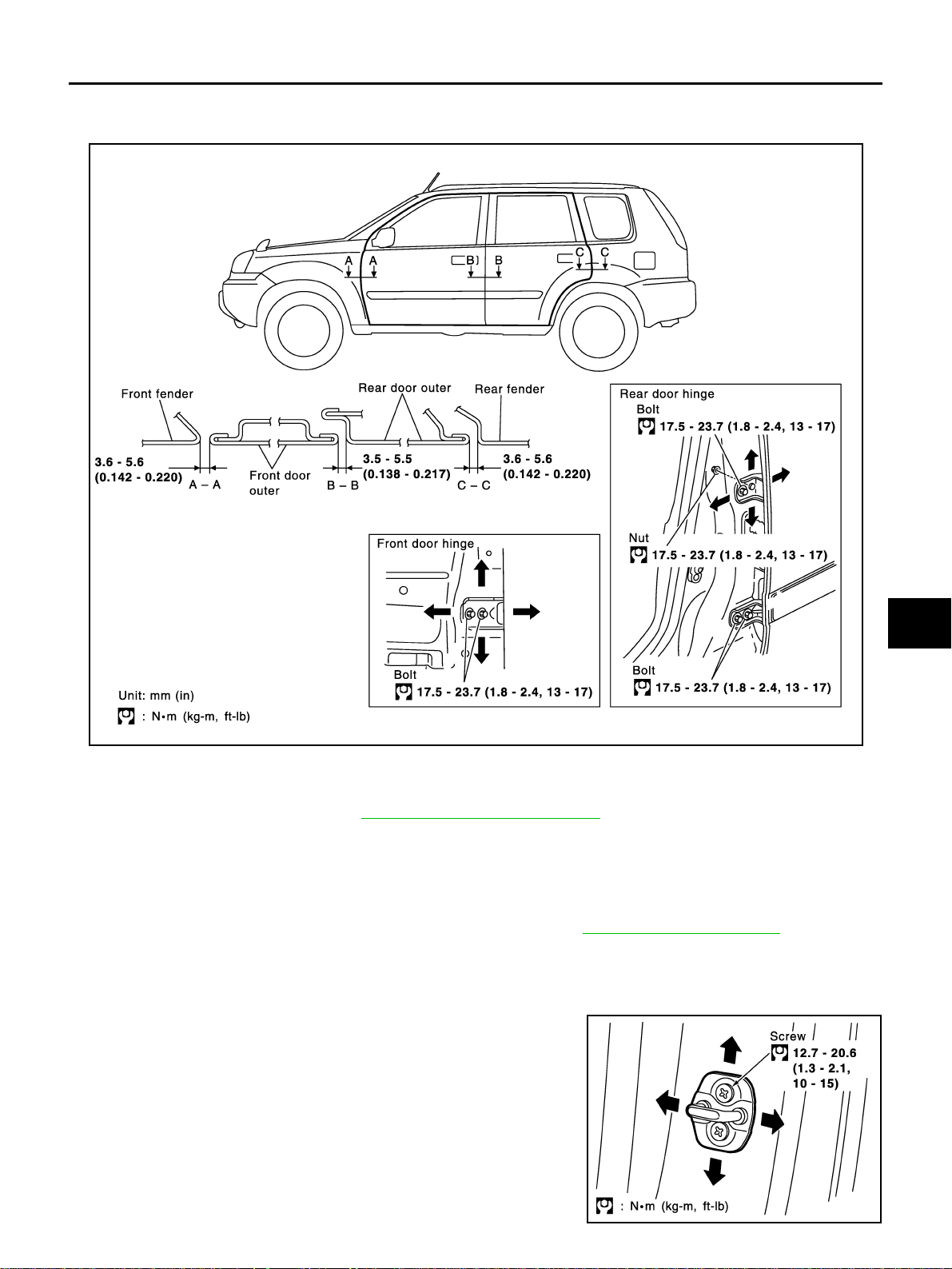

DOOR

DOOR PFP:80100

Fitting Adjustment AIS005NF

A

B

C

D

E

F

G

PIIA3652E

FRONT DOOR

Longitudinal Clearance and Surface Height Adjustment at Front End

1. Remove fender protector. Refer to EI-20, "FENDER PROTECTOR" .

2. Working fro m th e in si de th e fe nder, loosen hinge moun t bolts on the body. Li ft re ar en d of th e fr o nt do or to

adjust clearance and surface difference properly.

REAR DOOR

Longitudinal Clearance and Surface Height Adjustment at Front End

1. Remove upper and lower garnishes on the center pillar. Refer to EI-36, "BODY SIDE TRIM" .

2. Loosen mounting bolts from outside of vehicle, mounting nuts from inside of vehicle. Open rear door.

Raise rear end of it to adjust.

STRIKER ADJUSTMENT

Adjust striker until it is parallel to the lock engagement direction.

H

BL

J

K

L

M

PIIA0555E

Revision: 2006 July 2006 X-Trail

BL-19

DOOR

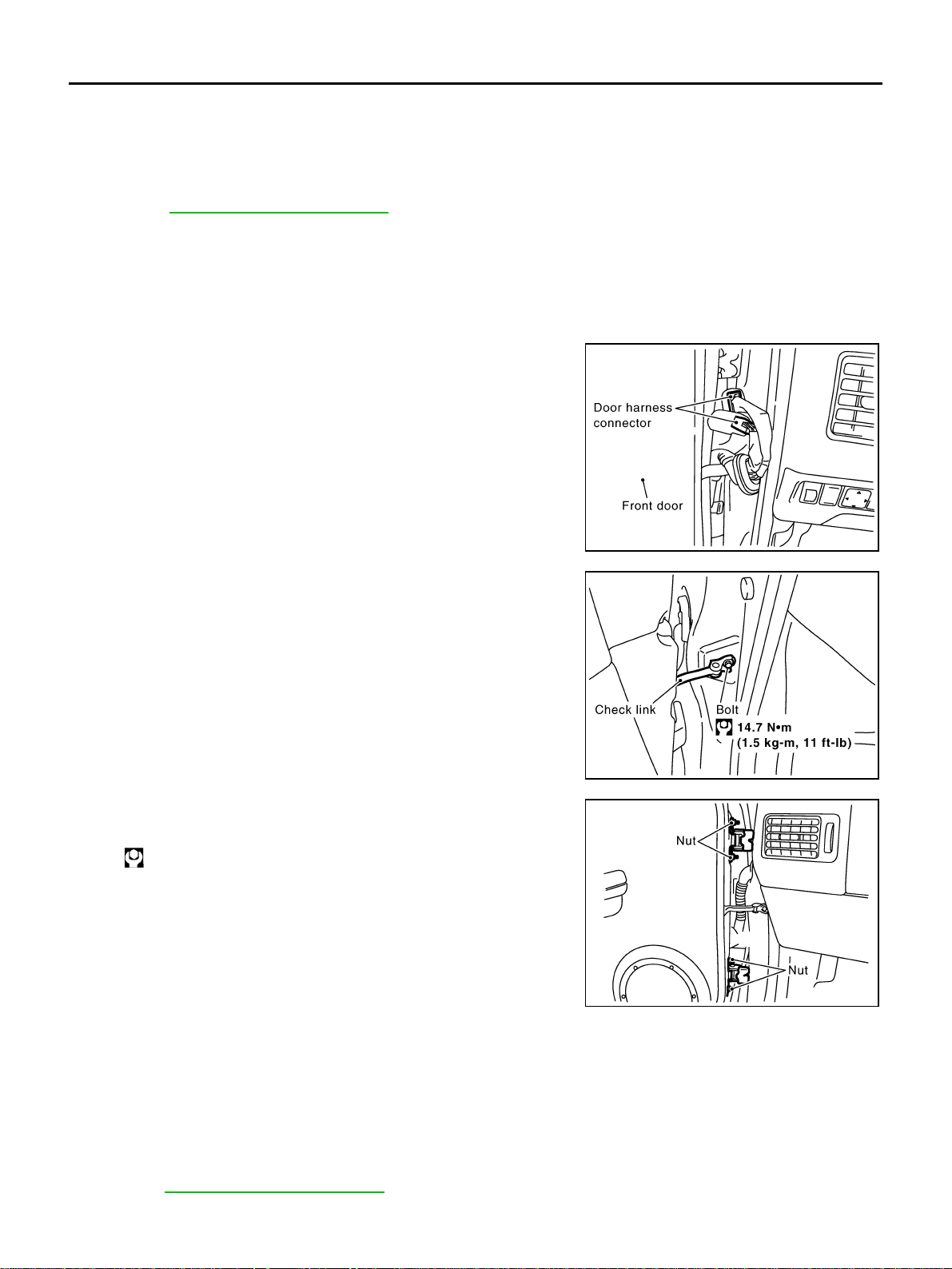

Removal and Installation of Front Door AIS005NG

CAUTION:

● When removing and installing the front door a ssembly, support the door with a jack and cloth to

protect the door and body.

● When removing and installing front door assembly, be sure to carry out the fitting adjustment.

Refer to BL-19, "

● Operate with two workers, because of its heavy weight.

● After installing, apply touch-up paint (the body color) onto the head of the hinge mounting nuts.

● Check the hi nge rotating part fo r poor lubrication. If necessary, apply “body grease”.

● Check front door open/close operation after installation.

REMOVAL

1. Grommet is pu lled out, and th e front door h arness connec tor is

detached.

Fitting Adjustment" .

2. Remove the mounting bolts of the check link on the vehicle.

3. Remove the door-side hinge mounting nuts, and remove the

door assembly.

: 20.6 N·m (2.1 kg-m, 15 ft-lb)

PIIB1369E

PIIA6020E

PIIB1337E

INSTALLATION

Install in the reverse order of removal.

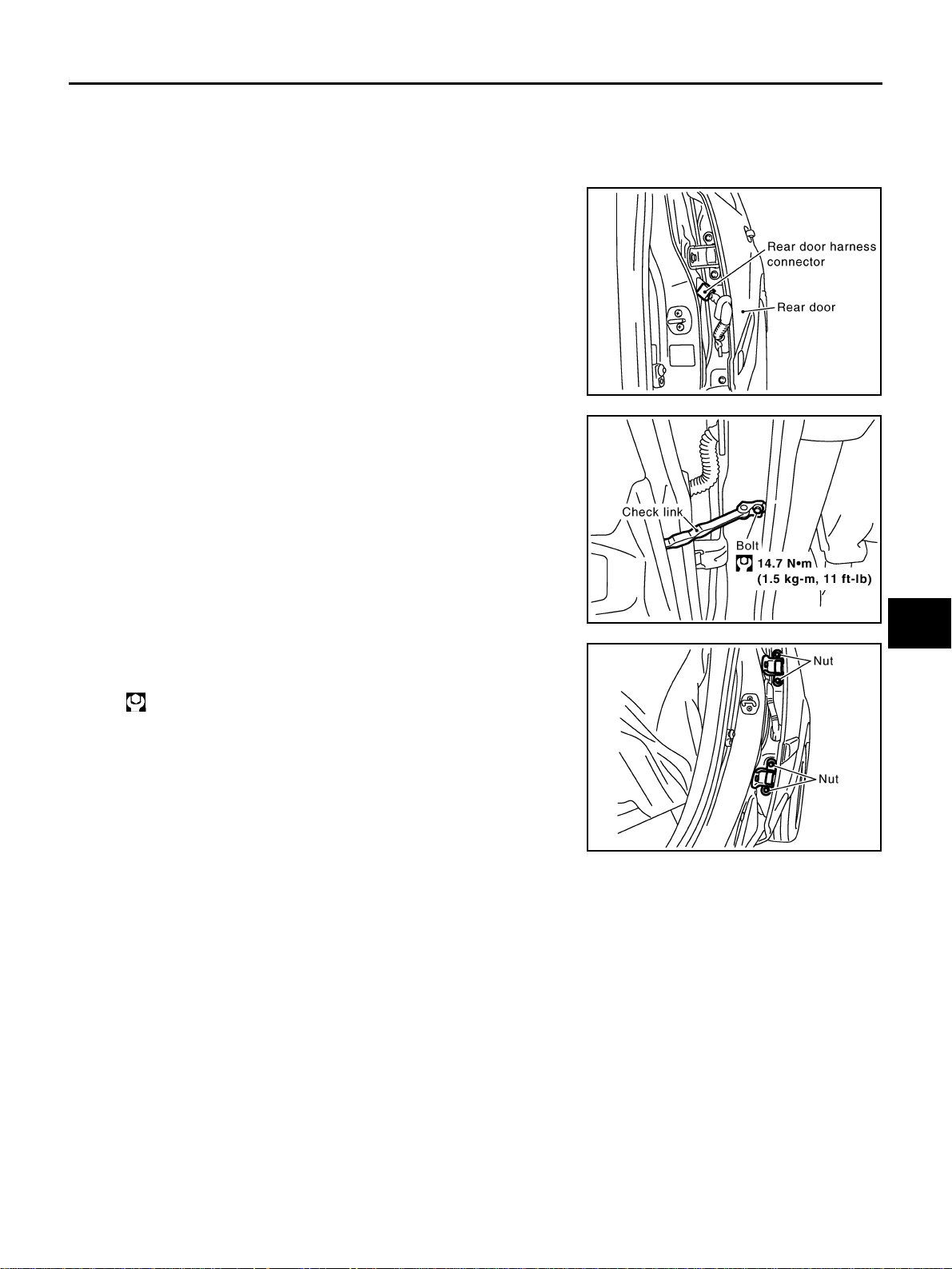

Removal and Installation of Rear Door AIS005NH

CAUTION:

● When removing and in stalling the rear door assembly, support the door with a ja ck and cloth to

protect the door and body.

● When removing and installing rear door assembly, be sure to carry out the fitting adjustment.

Refer toBL-19, "

● Check the hi nge rotating part fo r poor lubrication. If necessary, apply “body grease”.

Revision: 2006 July 2006 X-Trail

Fitting Adjustment" .

BL-20

DOOR

● After installing, apply touch-up paint (the body color) onto the head of the hinge mounting nuts.

● Operate with two workers, because of its heavy weight.

● Check rear door open/close ope rati on after ins tallation.

A

REMOVAL

1. Grommet is pulled out, and the rear door harness connector is

detached.

2. Remove the mounting bolts of th e check link on the v ehicle.

3. Remove the door-side hinge mounting nuts, and remove the

door assembly.

: 20.6 N·m (2.1 kg-m, 15 ft-lb)

PIIB1370E

PIIA6022E

B

C

D

E

F

G

H

BL

J

INSTALLATION

Install in the reverse order of removal.

K

L

PIIB1336E

M

Revision: 2006 July 2006 X-Trail

BL-21

DOOR

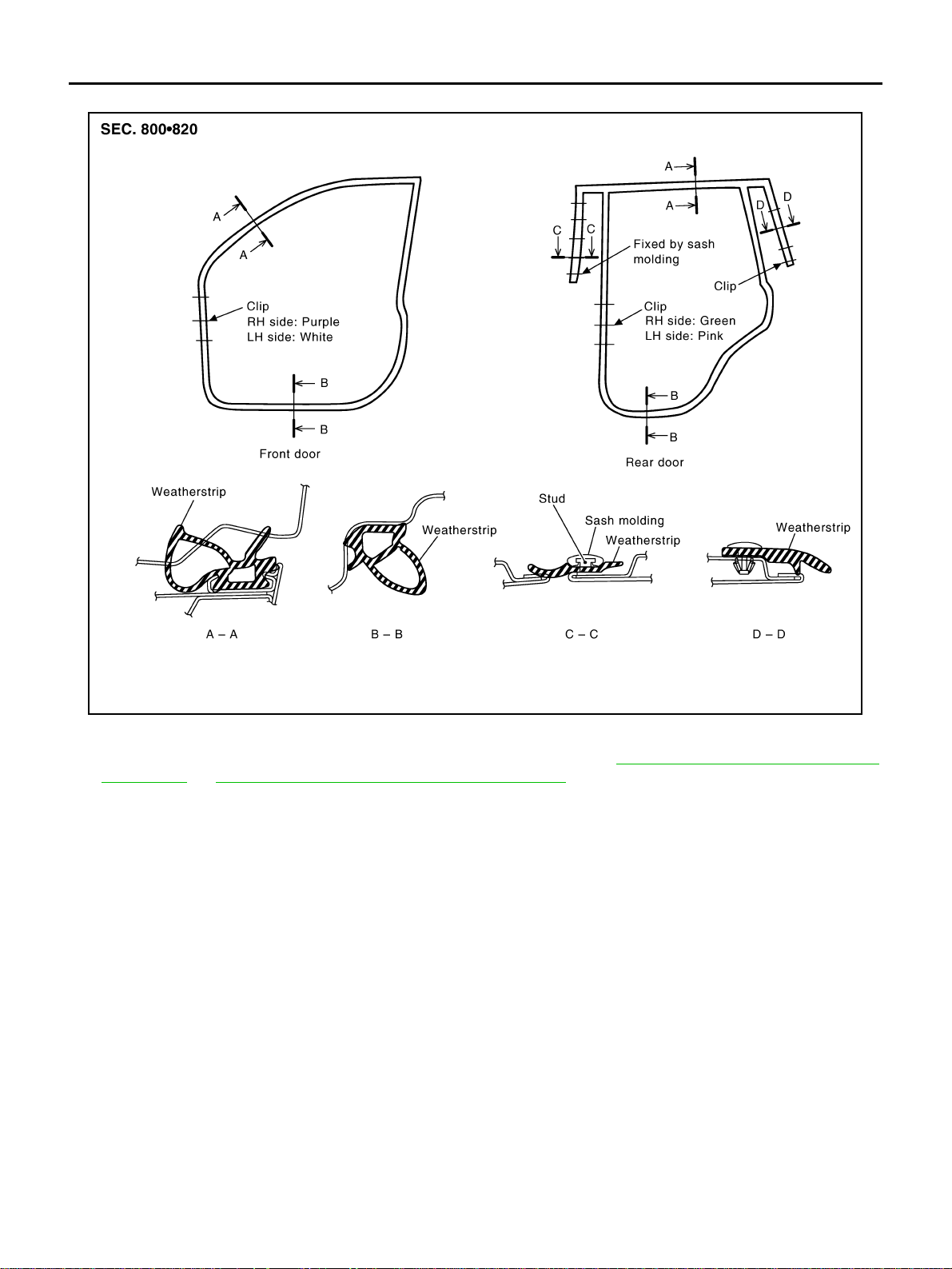

Door Weatherstrip AIS005NI

SIIA0157E

REMOVAL

1. Remove the mounting bolts of the check link on the vehicle. Refer to BL-20, "Removal and Installatio n of

Front Door" or BL-20, "Removal and Installation of Rear Door" .

2. Remove the weatherstrip clips and remove weatherstrip.

CAUTION:

After removal, do not pull strongly on the weatherstrip.

INSTALLATION

Install in the reverse order of removal.

Revision: 2006 July 2006 X-Trail

BL-22

POWER DOOR LOCK SYSTEM

POWER DOOR LOCK SYSTEM PFP:24814

Component Parts and Harness Connector Location AIS005X9

A

B

C

D

E

F

G

PIIB1463E

System Description AIS005XA

OPERATION

Power is supplied at all times

● through 10A fuse [No. 26, located in the fuse block (J/B)]

● to smart entrance control unit terminal 49,

● through 40A fusible link (letter B , located in the fusible link and fuse box)

● to smart entrance control unit terminal 51.

Ground is supplie d at all time s

● to smart entrance control unit terminal 43 and 64

● through grounds M27 and M70.

H

BL

J

K

L

M

Revision: 2006 July 2006 X-Trail

BL-23

POWER DOOR LOCK SYSTEM

When ignition switch is in ON or START position, power is supplied

● through 10A fuse [No. 5, located in the fuse block (J/B)]

● to smart entrance control unit terminal 27.

When key switch is in INSERTED position, power is supplied

● through 10A fuse [No. 28, located in the fuse block (J/B)]

● through key s witch terminal 1

● through key switch terminal 2 and

● to smart entrance control unit terminal 25.

DOOR LOCK/UNLOCK SWITCH (POWER WINDOW MAIN SWITCH) OPERATION

When power window main switch (door lock/unlock switch) is in LOCK position, ground is supplied

● to smart entrance control unit terminal 5

● through power window main switch (door lock/unlock switch) terminal 17

● through power window main switch (door lock/unlock switch) terminal 19 and

● through grounds M27 and M70.

Then all doors are locked.

When power window main switch (door lock/unlock switch) is in UNLOCK position, ground is supplied

● to smart entrance control unit terminal 4

● through power window main switch (door lock/unlock switch) terminal 18

● through power window main switch (door lock/unlock switch) terminal 19 and

● through grounds M27 and M70.

Then all doors are unlocked.

DOOR LOCK/UNLOCK SWITCH (PASSENGER SIDE) OPERATION

When door lock/unlock switch (passenger side) is in LOCK position, ground is supplied

● to smart entrance control unit terminal 5

● through door lock/unlock switch (passenger side) terminal 2

● through door lock/unlock switch (passenger side) terminal 3 and

● through grounds M27 and M70.

Then all doors are locked.

When door lock /unlock switch (passenger side) is in UNLOCK position, ground is supplied

● to smart entrance control unit terminal 4

● through door lock/unlock switch (passenger side) terminal 1

● through door lock/unlock switch (passenger side) terminal 3 and

● through grounds M27 and M70.

Then all doors are unlocked.

DOOR KEY CYLINDER SWITCH OPERATION

Driver Side

When door key cylinder switch (driv er side) is in LOCK position, ground is s upplied

● to smart entrance control unit terminal 11

● through door key cylinder switch (driver side) terminal 1

● through door key cylinder switch (driver side) terminal 2 and

● through grounds M27 and M70.

Then all doors are locked.

When door key cylinder switch (driver side) is in UNLOCK position, ground is supplied

● to smart entrance control unit terminal 10

● through door key cylinder switch (driver side) terminal 3

● through door key cylinder switch (driver side) terminal 2 and

● through grounds M27 and M70.

Then all doors are unlocked.

Revision: 2006 July 2006 X-Trail

BL-24

POWER DOOR LOCK SYSTEM

Passenger Side

When door key cylinder switch (passenger side) is in LOCK position, ground is supplied

● to smart entrance control unit terminal 1 1

● through door key cylinder switch (passenger side) terminal 3

● through door key cylinder switch (passenger side) terminal 2 and

● through grounds M27 and M70.

Then all doors are locked.

When door key cylinder switch (passenger side) is in UNLOCK position, ground is supplied

● to smart entrance control unit terminal 10

● through door key cylinder switch (passenger side) terminal 1

● through door key cylinder switch (passenger side) terminal 2 and

● through grounds M27 and M70.

Then all doors are unlocked.

KEY REMINDER SYSTEM

● If the ignition key is in the igni tion key c ylinder an d doors are open, setti ng lock/un lock switc h, lock k nob,

key or multi-remote controller to “LOCK” locks the door once but then immediately unloc k s all doors.

A

B

C

D

E

F

G

BL

H

J

K

L

M

Revision: 2006 July 2006 X-Trail

BL-25

POWER DOOR LOCK SYSTEM

Schematic AIS005XB

TIWB0043E

Revision: 2006 July 2006 X-Trail

BL-26

POWER DOOR LOCK SYSTEM

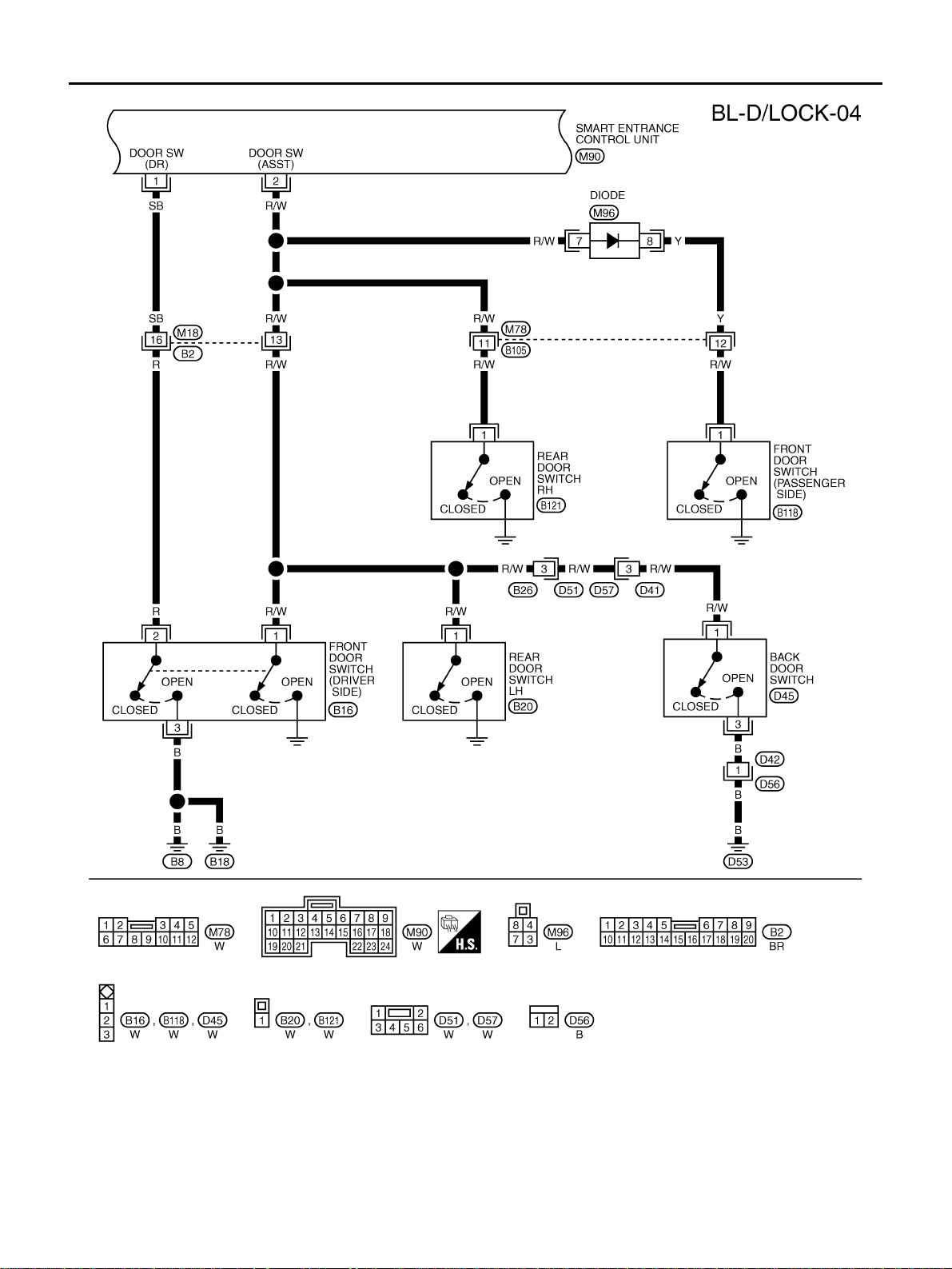

Wiring Diagram — D/LOCK — AIS005XC

A

B

C

D

E

F

G

BL

H

J

K

L

M

TIWA0550E

Revision: 2006 July 2006 X-Trail

BL-27

POWER DOOR LOCK SYSTEM

TIWB0044E

Revision: 2006 July 2006 X-Trail

BL-28

POWER DOOR LOCK SYSTEM

A

B

C

D

E

F

G

BL

H

J

K

L

M

TIWB0045E

Revision: 2006 July 2006 X-Trail

BL-29

POWER DOOR LOCK SYSTEM

TIWB0046E

Revision: 2006 July 2006 X-Trail

BL-30

Loading...

Loading...