Nissan X-Trail 2005 Owner's Manual

C TRANSMISSION/TRANSAXLE

SECTION MT

MANUAL TRANSAXLE

CONTENTS

A

B

MT

D

E

PRECAUTIONS ......................................................... |

3 |

Service Notice or Precautions ................................. |

3 |

PREPARATION .......................................................... |

4 |

Special Service Tools .............................................. |

4 |

Commercial Service Tools ....................................... |

6 |

NOISE, VIBRATION AND HARSHNESS (NVH) |

|

TROUBLESHOOTING ............................................... |

8 |

NVH Troubleshooting Chart .................................... |

8 |

DESCRIPTION ........................................................... |

9 |

Cross-Sectional View .............................................. |

9 |

DOUBLE-CONE SYNCHRONIZER .................... |

11 |

TRIPLE-CONE SYNCHRONIZER ...................... |

11 |

REVERSE GEAR NOISE PREVENTION FUNC- |

|

TION (SYNCHRONIZING METHOD) ................. |

11 |

M/T OIL .................................................................... |

12 |

Changing M/T Oil .................................................. |

12 |

DRAINING .......................................................... |

12 |

FILLING .............................................................. |

12 |

Checking M/T Oil ................................................... |

12 |

OIL LEAKAGE AND OIL LEVEL ........................ |

12 |

SIDE OIL SEAL ....................................................... |

14 |

Removal and Installation ....................................... |

14 |

REMOVAL .......................................................... |

14 |

INSTALLATION .................................................. |

14 |

POSITION SWITCH ................................................. |

15 |

Checking ............................................................... |

15 |

BACK-UP LAMP SWITCH ................................. |

15 |

PARK/NEUTRAL POSITION SWITCH .............. |

15 |

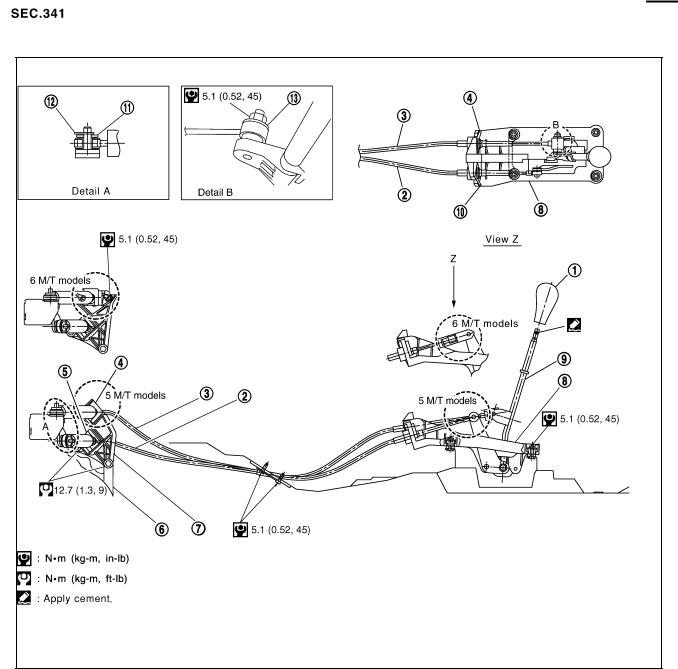

CONTROL LINKAGE .............................................. |

16 |

Components of Control Device and Cable ............ |

16 |

Removal and Installation ....................................... |

17 |

AIR BREATHER HOSE ........................................... |

18 |

Removal and Installation ....................................... |

18 |

TRANSAXLE ASSEMBLY ....................................... |

19 |

Removal and Installation ....................................... |

19 |

COMPONENTS ................................................. |

19 |

REMOVAL .......................................................... |

20 |

INSTALLATION .................................................. |

21 |

Disassembly and Assembly (RS5F51A) ............... |

22 |

COMPONENTS ................................................. |

22 |

DISASSEMBLY .................................................. |

26 |

ASSEMBLY ........................................................ |

30 |

ADJUSTMENT ................................................... |

36 |

Disassembly and Assembly (RS6F51A) ................ |

40 |

COMPONENTS .................................................. |

40 |

DISASSEMBLY .................................................. |

44 |

ASSEMBLY ........................................................ |

48 |

ADJUSTMENT ................................................... |

54 |

INPUT SHAFT AND GEARS ................................... |

58 |

Disassembly and Assembly (RS5F51A) ................ |

58 |

DISASSEMBLY .................................................. |

58 |

INSPECTION AFTER DISASSEMBLY ............... |

59 |

ASSEMBLY ........................................................ |

62 |

Disassembly and Assembly (RS6F51A) ................ |

66 |

DISASSEMBLY .................................................. |

66 |

INSPECTION AFTER DISASSEMBLY ............... |

67 |

ASSEMBLY ........................................................ |

69 |

MAINSHAFT AND GEARS ...................................... |

73 |

Disassembly and Assembly (RS5F51A) ................ |

73 |

DISASSEMBLY .................................................. |

73 |

INSPECTION AFTER DISASSEMBLY ............... |

74 |

ASSEMBLY ........................................................ |

76 |

Disassembly and Assembly (RS6F51A) ................ |

80 |

DISASSEMBLY .................................................. |

80 |

INSPECTION AFTER DISASSEMBLY ............... |

81 |

ASSEMBLY ........................................................ |

83 |

REVERSE IDLER SHAFT AND GEARS ................. |

89 |

Disassembly and Assembly (RS5F51A) ................ |

89 |

DISASSEMBLY .................................................. |

89 |

INSPECTION AFTER DISASSEMBLY ............... |

89 |

ASSEMBLY ........................................................ |

90 |

Disassembly and Assembly (RS6F51A) ................ |

90 |

DISASSEMBLY .................................................. |

90 |

INSPECTION AFTER DISASSEMBLY ............... |

91 |

ASSEMBLY ........................................................ |

91 |

FINAL DRIVE ........................................................... |

93 |

Disassembly and Assembly (RS5F51A) ................ |

93 |

PRE-INSPECTION ............................................. |

93 |

DISASSEMBLY .................................................. |

93 |

INSPECTION AFTER DISASSEMBLY ............... |

94 |

F

G

H

I

J

K

L

M

MT-1

ASSEMBLY ......................................................... |

94 |

Disassembly and Assembly (RS6F51A) ................ |

97 |

PRE-INSPECTION ............................................. |

97 |

DISASSEMBLY .................................................. |

97 |

INSPECTION AFTER DISASSEMBLY ............... |

98 |

ASSEMBLY ......................................................... |

98 |

SHIFT CONTROL ................................................... |

101 |

Inspection (RS5F51A) ......................................... |

101 |

SHIFT FORK .................................................... |

101 |

Inspection (RS6F51A) ......................................... |

102 |

SHIFT FORK .................................................... |

102 |

SERVICE DATA AND SPECIFICATIONS (SDS) ... |

103 |

General Specifications ......................................... |

103 |

TRANSAXLE .................................................... |

103 |

Gear End Play ..................................................... |

104 |

Baulk Ring Clearance .......................................... |

104 |

Available Snap Rings ........................................... |

105 |

INPUT SHAFT BEARING SPACER ................. |

105 |

6TH INPUT GEAR BUSHING .......................... |

105 |

5TH MAIN GEAR .............................................. |

105 |

Available C-Rings ................................................ |

105 |

MAINSHAFT C-RING ....................................... |

105 |

Available Thrust Washer ...................................... |

106 |

INPUT SHAFT THRUST WASHER .................. |

106 |

DIFFERENTIALSIDEGEARTHRUSTWASHER |

|

|

.106 |

Available Adjusting Shims .................................... |

106 |

4TH MAIN GEAR ADJUSTING SHIM ............... |

106 |

INPUT SHAFT REAR BEARING ADJUSTING |

|

SHIM ................................................................. |

107 |

MAINSHAFT REAR BEARING ADJUSTING |

|

SHIM ................................................................. |

107 |

REVERSE IDLER GEAR ADJUSTING SHIM ... |

107 |

6TH MAIN GEAR ADJUSTING SHIM ............... |

107 |

Available Shims ................................................... |

108 |

BEARING PRELOAD ........................................ |

108 |

DIFFERENTIAL SIDE BEARING ADJUSTING |

|

SHIM(S) ............................................................ |

108 |

MT-2

|

PRECAUTIONS |

|

|

PRECAUTIONS |

PFP:00001 |

Service Notice or Precautions |

ECS008BM |

● Do not reuse transaxle oil, once it has been drained.

● Check oil level or replace oil with vehicle on level surface.

● During removal or installation, keep inside of transaxle clear of dust or dirt.

● Check for the correct installation status prior to removal or disassembly. If matching mark are required, be certain they do not interfere with the function of the parts they are applied.

● In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If tightening sequence is specified, use it.

● Be careful not to damage sliding surfaces and mating surfaces.

A

B

MT

D

E

F

G

H

I

J

K

L

M

MT-3

PREPARATION

PREPARATION

Special Service Tools

PFP:00002

ECS008BN

Tool number |

Description |

|

Tool name |

||

|

||

|

|

|

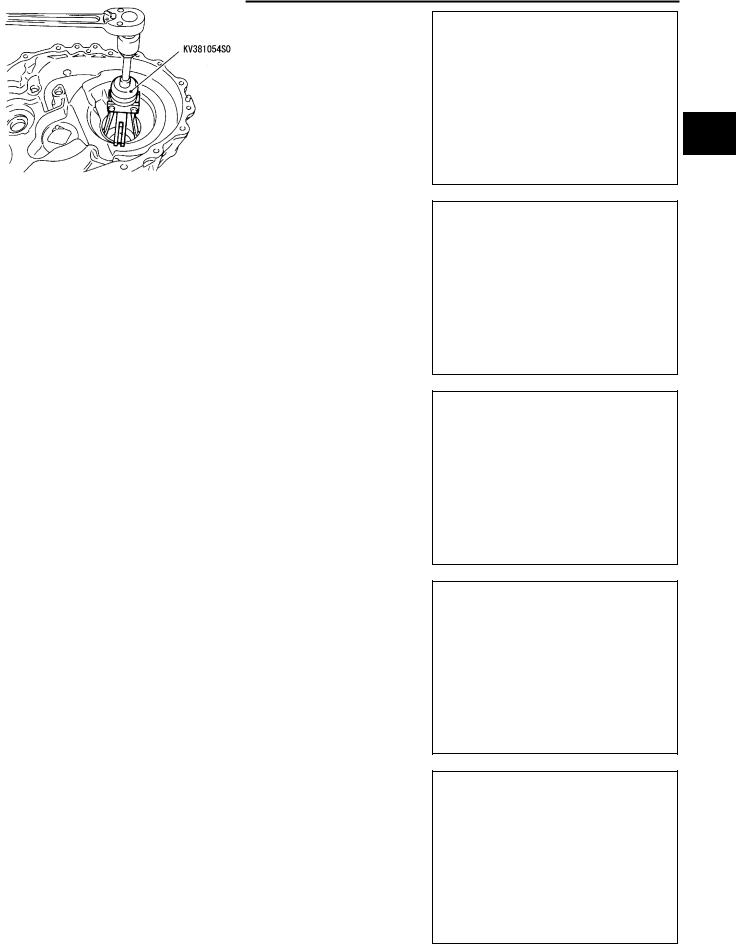

KV381054S0 |

● Removing differential side bearing outer |

|

Puller |

race |

|

|

● Removing mainshaft front bearing |

|

ZZA0601D |

|

|

|

|

ST35321000 |

● Installing input shaft oil seal |

|

Drift |

● Installing reverse main gear |

|

a: 49 mm (1.93 in) dia. |

||

● Installing 1st main gear bushing |

||

b: 41 mm (1.61 in) dia. |

||

|

||

|

● Installing 1st-2nd synchronizer hub |

|

|

assembly |

|

|

● Installing 2nd main gear bushing |

|

|

● Installing 3rd main gear |

|

|

ZZA1000D |

|

|

● Removing differential side bearing (clutch |

|

|

housing side for 4WD models) |

|

|

|

|

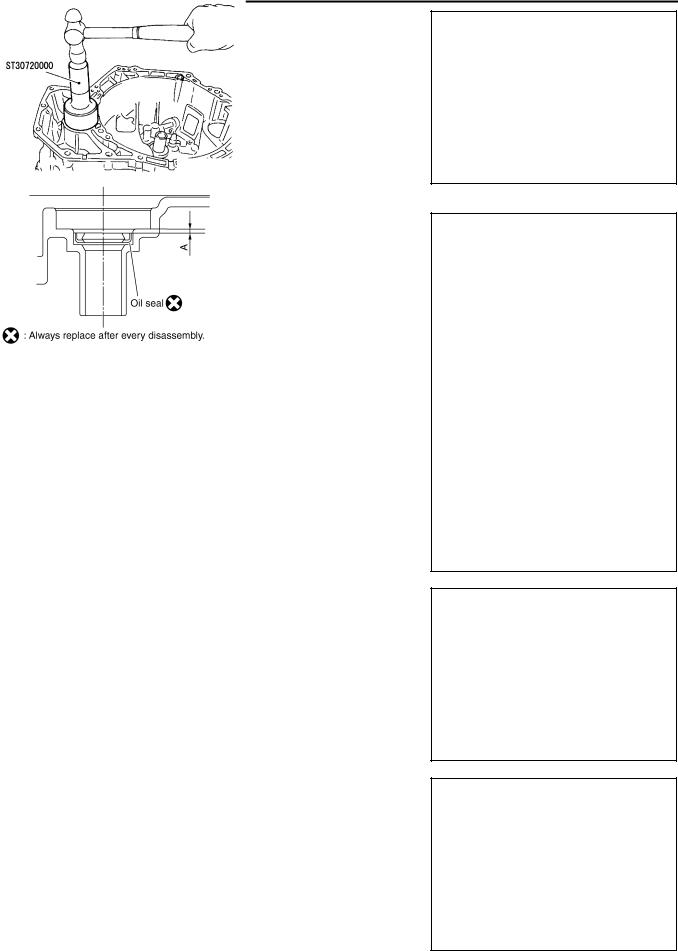

ST30720000 |

● Installing differential side oil seal |

|

Drift |

● Installing differential side bearing outer race |

|

a: 77 mm (3.03 in) dia. |

||

● Installing mainshaft rear bearing |

||

b: 55.5 mm (2.185 in) dia. |

||

|

||

|

● Installing differential side bearing |

|

|

ZZA0811D |

|

|

|

|

ST33200000 |

● Installing mainshaft front bearing |

|

Drift |

● Installing 6th input gear bushing |

|

a: 60 mm (2.36 in) dia. |

||

(RS6F51A) |

||

b: 44.5 mm (1.752 in) dia. |

||

● Installing 4th main gear |

||

|

||

|

● Installing 5th main gear |

|

|

● Installing 6th main gear (RS6F51A) |

|

|

ZZA1002D |

|

|

|

|

KV40105320 |

Installing differential side bearing outer race |

|

Drift |

|

|

a: 88 mm (3.46 in) dia. |

|

|

ZZA0898D |

|

|

|

|

ST33061000 |

● Installing bore plug |

|

Drift |

● Removing differential side bearing (clutch |

|

a: 38 mm (1.50 in) dia. |

||

housing side for 2WD models) |

||

b: 28.5 mm (1.122 in) dia. |

||

● Removing differential side bearing |

||

|

||

|

(transaxle case side for 4WD models) |

|

|

ZZA1000D |

MT-4

|

|

PREPARATION |

|

|

|

|

|

|

|

|

|

|

Tool number |

|

Description |

|

Tool name |

|

|

|

|

|

|

|

|

|

|

|

ST33052000 |

|

● Installing welch plug |

|

Drift |

|

● Removing input shaft rear bearing |

|

a: 22 mm (0.87 in) dia. |

|

|

|

|

● Removing input shaft bearing spacer and |

|

|

b: 28 mm (1.10 in) dia. |

|

|

|

|

5th stopper (RS5F51A) |

|

|

|

|

|

|

|

|

● Removing 5th input gear bushing, thrust |

|

|

|

washer, 4th input gear, 4th input gear |

|

|

|

bushing, 3rd-4th synchronizer hub |

|

|

|

assembly and 3rd input gear |

|

|

|

● Installing input shaft front bearing |

|

|

ZZA1023D |

● Removing 6th input gear and 6th input gear |

|

|

bushing (RS6F51A) |

|

|

|

|

|

|

|

|

● Removing mainshaft rear bearing |

|

|

|

● Removing 4th main gear and 5th main gear |

|

|

|

● Removing 6th main gear (RS6F51A) |

|

|

|

|

|

KV40105020 |

|

● Removing 5th input gear, 5th synchronizer |

|

Drift |

|

hub assembly (RS5F51A) and 5th-6th |

|

a: 39.7 mm (1.563 in) dia. |

|

synchronizer hub assembly (RS6F51A) |

|

b: 35 mm (1.38 in) dia. |

|

● Removing 3rd main gear, 2nd main gear, |

|

c: 15 mm (0.59 in) |

|

|

|

|

2nd main gear bushing, 1st-2nd |

|

|

|

|

|

|

|

|

synchronizer hub assembly, 1st main gear, |

|

|

|

reverse main gear and 1st main gear |

|

|

ZZA1133D |

bushing |

|

|

|

|

|

|

|

|

|

KV40105710 |

|

● Installing 3rd-4th synchronizer hub |

|

Press stand |

|

assembly |

|

a: 46 mm (1.81 in) dia. |

|

● Installing 4th input gear bushing |

|

b: 41 mm (1.61 in) |

|

|

|

|

● Installing 5th input gear bushing |

|

|

|

|

|

|

|

|

● Installing 5th synchronizer hub assembly |

|

|

|

(RS5F51A) |

|

|

|

● Installing 5th-6th synchronizer hub |

|

|

ZZA1058D |

assembly (RS6F51A) |

|

|

● Installing 2nd main gear bushing |

|

|

|

|

|

|

|

|

● Installing 3rd main gear |

|

|

|

|

|

ST38220000 |

|

● Installing reverse main gear |

|

Press stand |

|

● Installing 1st main gear bushing |

|

a: 63 mm (2.48 in) dia. |

|

|

|

|

● Installing 1st-2nd synchronizer hub |

|

|

b: 65 mm (2.56 in) |

|

|

|

|

assembly |

|

|

|

|

|

|

|

ZZA1058D |

|

|

|

|

|

|

ST30032000 |

|

● Installing 5th stopper and input shaft |

|

Drift |

|

bearing spacer (RS5F51A) |

|

a: 80 mm (3.15 in) dia. |

|

● Installing input shaft front bearing |

|

b: 38 mm (1.50 in) dia. |

|

|

|

|

|

|

|

c: 31 mm (1.22 in) dia. |

|

|

|

|

ZZA0978D |

|

|

|

|

|

|

ST30901000 |

|

● Installing input shaft rear bearing |

|

Drift |

|

● Installing 4th main gear |

|

a: 79 mm (3.11 in) dia. |

|

|

|

|

● Installing 5th main gear |

|

|

b: 45 mm (1.77 in) dia. |

|

|

|

|

|

|

|

c: 35.2 mm (1.386 in) dia. |

|

● Installing 6th main gear (RS6F51A) |

|

|

|

● Installing mainshaft rear bearing |

|

|

ZZA0978D |

|

|

|

|

|

A

B

MT

D

E

F

G

H

I

J

K

L

M

MT-5

|

PREPARATION |

||

|

|

|

|

|

|

|

|

Tool number |

Description |

||

Tool name |

|||

|

|

||

|

|

|

|

ST30031000 |

Measuring wear of inner baulk ring |

||

Puller |

|

|

|

|

ZZA0537D |

|

|

KV40101630 |

Installing reverse main gear |

Drift |

|

a:68 mm (2.68 in) dia.

b:60 mm (2.36 in) dia.

ZZA1003D |

|

|

|

|

|

KV38102510 |

● Installing 1st main gear bushing |

|

Drift |

● Installing 1st-2nd synchronizer hub |

|

a: 71 mm (2.80 in) dia. |

||

assembly |

||

b: 65 mm (2.56 in) dia. |

||

● Installing differential side bearing (clutch |

||

|

||

|

housing side for 2WD models) |

|

|

● Installing differential side bearing (transaxle |

|

ZZA0838D |

case side for 4WD models) |

|

|

|

|

KV40104830 |

Installing differential side bearing (clutch |

|

Drift |

housing side for 4WD models) |

|

a: 70 mm (2.76 in) dia. |

|

|

b: 63.5 mm (2.500 in) dia. |

|

|

ZZA0936D |

|

|

|

|

|

ST15243000 |

Measuring end play of side gear |

|

Drift |

|

|

a: 30 mm (1.18 in) dia. |

|

|

SCIA1088J |

|

|

|

|

|

Commercial Service Tools |

ECS008BO |

|

|

|

|

Tool name |

Description |

|

|

|

|

Puller |

Removing each bearing, gear and bushing |

|

ZZA0537D |

|

|

|

|

MT-6

|

|

PREPARATION |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Tool name |

|

Description |

|||

|

|

|

|

|

|

A |

|

Puller |

|

Removing each bearing, gear and bushing |

|||

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

NT077 |

|

|

|

MT |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Pin punch |

|

Removing and installing each retaining pin |

|

||

|

Tip diameter: 4.5 mm (0.177 in) dia. |

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

ZZA0815D |

|

|

||

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

H |

|

|

|

|

|

|

I |

|

|

|

|

|

|

J |

|

|

|

|

|

|

K |

|

|

|

|

|

|

L |

|

|

|

|

|

|

M |

MT-7

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

PFP:00003

ECS008BP

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

|

|

|

|

|

|

|

(RS6F51A) |

|

|

|

|

(RS6F51A) |

|

|

(RS6F51A) |

|

|||||

|

|

|

|

|

|

|

40 |

|

|

|

|

|

43 |

|

|

|

41 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Reference page |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

MA39- |

|

|

|

(RS5F51A),MT- |

|

MT16- |

|

|

(RS5F51A),MT- |

|

|

(RS5F51A),MT- |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT-22 |

|

|

|

|

|

MT-25 |

|

|

|

MT-23 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHECK BALL (Worn or damaged) |

|

|

|

|

|

|

|

|

|

SUSPECTED PARTS |

|

|

|

|

|

|

|

|

|

|

CHECK PLUG RETURN SPRING AND |

|

|

|

|

|

|

|

|

|

|

(Possible cause) |

|

|

|

|

|

|

|

|

SHIFT CONTROL LINKAGE (Worn) |

|

|

|

|

|

|

|

|

|

|||

|

|

OIL (Oil level is low.) |

OIL (Wrong oil.) |

OIL (Oil level is high.) |

GASKET (Damaged) |

OIL SEAL (Worn or damaged) |

O-RING (Worn or damaged) |

|

|

SHIFT FORK (Worn) |

GEAR (Worn or damaged) |

BEARING (Worn or damaged) |

|

|

BAULK RING (Worn or damaged) |

INSERT SPRING (Damaged) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

1 |

2 |

|

|

|

|

|

|

|

|

|

|

|

3 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Symptoms |

Oil leakage |

|

3 |

1 |

2 |

2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hard to shift or will not shift |

|

1 |

1 |

|

|

|

|

2 |

|

|

|

|

|

|

|

3 |

3 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Jumps out of gear |

|

|

|

|

|

|

|

|

1 |

2 |

|

3 |

3 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT-8

DESCRIPTION

DESCRIPTION

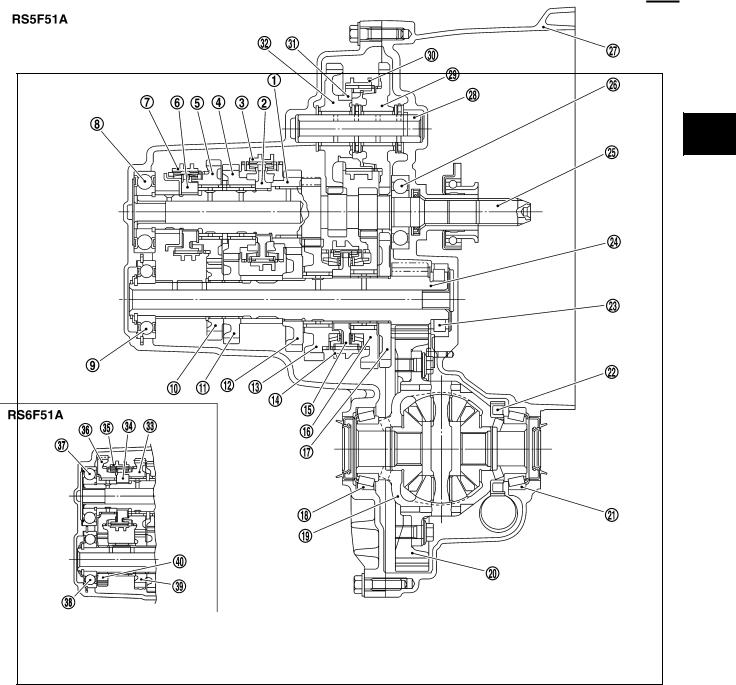

Cross-Sectional View

PFP:00000

A

ECS008BQ

2WD models

B

MT

D

E

F

G

H

I

J

K

L

M

PCIB1456E

1. |

3rd input gear |

2. |

3rd-4th synchronizer hub |

3. |

3rd-4th coupling sleeve |

4. |

4th input gear |

5. |

5th input gear |

6. |

5th synchronizer hub |

7. |

5th coupling sleeve |

8. |

Input shaft rear bearing |

9. |

Mainshaft rear bearing |

10. |

5th main gear |

11. |

4th main gear |

12. |

3rd main gear |

13. |

2nd main gear |

14. |

1st-2nd coupling sleeve |

15. |

1st-2nd synchronizer hub |

16. |

1st main gear |

17. |

Reverse main gear |

18. |

Differential side bearing |

19. |

Differential case |

20. |

Final gear |

21. |

Differential side bearing |

22. |

Speedometer drive gear |

23. |

Mainshaft front bearing |

24. |

Mainshaft |

25. |

Input shaft |

26. |

Input shaft front bearing |

27. |

Clutch housing |

28. |

Reverse idler shaft |

29. |

Reverse idler gear (Front) |

30. |

Reverse coupling sleeve |

31. |

Reverse synchronizer hub |

32. |

Reverse idler gear (Rear) |

33. |

5th input gear |

34. |

5th-6th synchronizer hub |

35. |

5th-6th coupling sleeve |

36. |

6th input gear |

37. |

Input shaft rear bearing |

38. |

Mainshaft rear bearing |

39. |

5th main gear |

40. |

6th main gear |

|

|

|

|

MT-9

DESCRIPTION

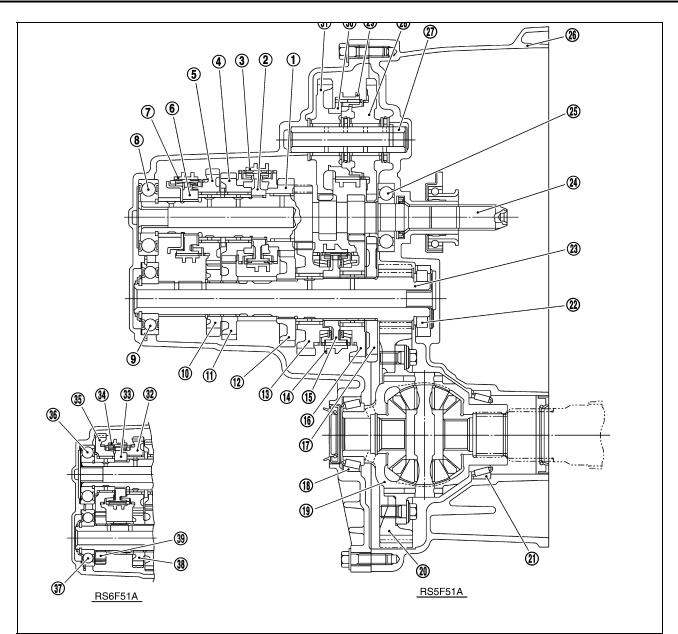

4WD models

PCIB0773E

1. |

3rd input gear |

2. |

3rd-4th synchronizer hub |

3. |

3rd-4th coupling sleeve |

4. |

4th input gear |

5. |

5th input gear |

6. |

5th synchronizer hub |

7. |

5th coupling sleeve |

8. |

Input shaft rear bearing |

9. |

Mainshaft rear bearing |

10. |

5th main gear |

11. |

4th main gear |

12. |

3rd main gear |

13. |

2nd main gear |

14. |

1st-2nd coupling sleeve |

15. |

1st-2nd synchronizer hub |

16. |

1st main gear |

17. |

Reverse main gear |

18. |

Differential side bearing |

19. |

Differential case |

20. |

Final gear |

21. |

Differential side bearing |

22. |

Mainshaft front bearing |

23. |

Mainshaft |

24. |

Input shaft |

25. |

Input shaft front bearing |

26. |

Clutch housing |

27. |

Reverse idler shaft |

28. |

Reverse idler gear (Front) |

29. |

Reverse coupling sleeve |

30. |

Reverse synchronizer hub |

31. |

Reverse idler gear (Rear) |

32. |

5th input gear |

33. |

5th-6th synchronizer hub |

34. |

5th-6th coupling sleeve |

35. |

6th input gear |

36. |

Input shaft rear bearing |

37. |

Mainshaft rear bearing |

38. |

5th main gear |

39. |

6th main gear |

MT-10

DESCRIPTION

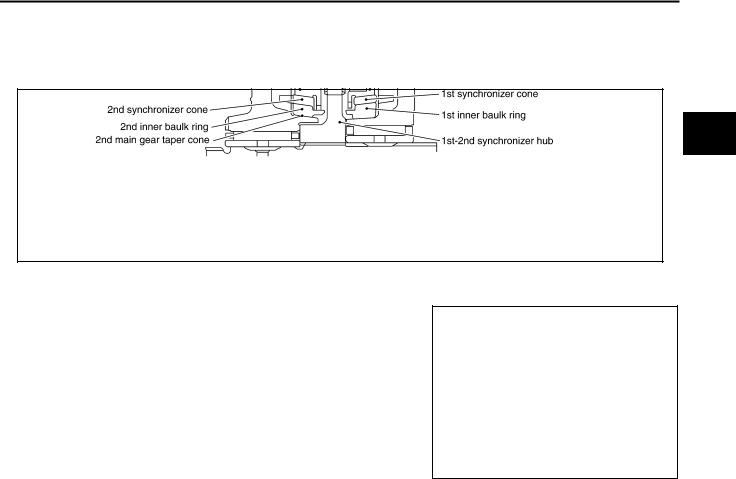

DOUBLE-CONE SYNCHRONIZER

Double-cone synchronizer is adopted for 3rd gear to reduce operating force of the shift lever.

TRIPLE-CONE SYNCHRONIZER

Triple-cone synchronizer is adopted for 1st and 2nd gears to reduce operating force of the shift lever.

PCIB1454E

REVERSE GEAR NOISE PREVENTION FUNCTION (SYNCHRONIZING METHOD)

Reverse gear can be matched smoothly in a structure by setting synchronizer hub, coupling sleeve, baulk ring and insert spring to reverse gear, and letting reverse gear be synchronized.

PCIB0775E

A

B

MT

D

E

F

G

H

I

J

K

L

M

MT-11

M/T OIL

M/T OIL

Changing M/T Oil

DRAINING

PFP:KLD20

ECS008BR

1.Start engine and let it run to warm up transaxle.

2.Stop engine. Remove drain plug and then drain oil.

3.Set a gasket on drain plug and install it to transaxle case. Tighten drain plug to the specified torque. Refer to MT-22, "Case and Housing Components" (RS5F51A) or MT-40, "Case and Housing Components" (RS6F51A).

CAUTION:

Do not reuse gasket.

FILLING

1.Remove plug (for 2WD models) or filler plug (for 4WD models). Fill with new oil to transaxle.

|

Oil grade and viscosity: |

Refer to MA-17, "Fluids and |

|

|

|

Lubricants" . |

|

|

Oil capacity (reference): |

Approx. 2.2 (3-7/8 lmp pt) |

|

2. |

After refilling oil, check oil level. |

||

3. |

Set a O-ring on plug (for 2WD models) or gasket on filler plug |

||

|

(for 4WD models) and then install it to clutch housing. |

||

|

CAUTION: |

|

PCIB1572E |

|

Do not reuse O-ring or gasket. |

||

|

|

||

4.Tighten plug mounting bolt (for 2WD models) or filler plug (for 4WD models) to the specified torque. Refer to MT-22, "Case and Housing Components" (RS5F51A) or MT-40, "Case and Housing Components" (RS6F51A).

Checking M/T Oil |

ECS008BS |

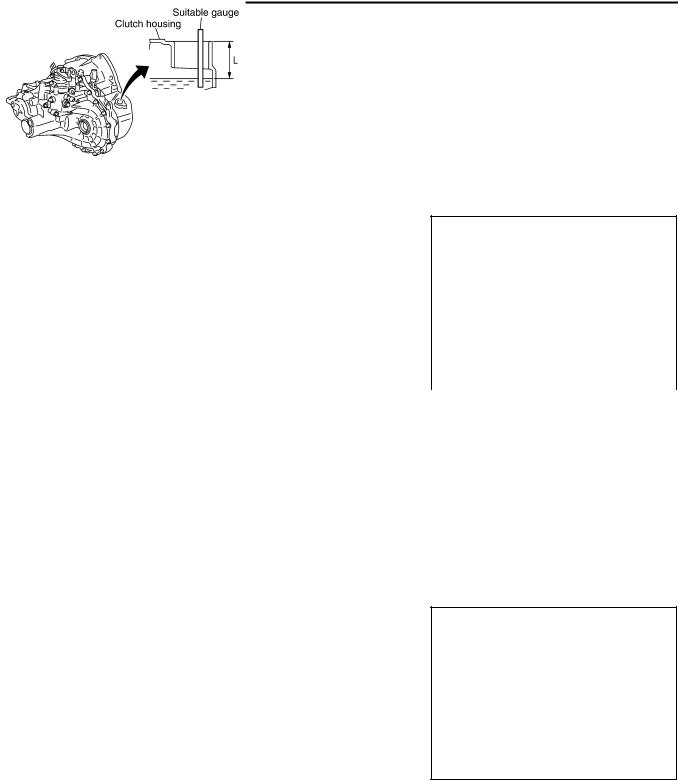

OIL LEAKAGE AND OIL LEVEL

●Make sure that oil is not leaking from transaxle or around it.

●Remove plug (for 2WD models) or filler plug (for 4WD models).

●Measure oil level using a suitable gauge as shown in the figure, and then check if it is within the specifications.

CAUTION:

Do not start engine while checking oil level.

–For 2WD models

Oil level “L” |

: 55.0 - 61.0 mm (2.17 - 2.40 in) |

PCIB1477E

MT-12

M/T OIL

–For 4WD models

Oil level “L” |

: 168.0 - 174.0 mm (6.61 - 6.85 in) |

PCIB1478E

●Set a O-ring on plug (for 2WD models) or gasket on filler plug (for 4WD models) and then install it to clutch housing.

CAUTION:

Do not reuse O-ring or gasket.

●Tighten plug mounting bolt (for 2WD models) or filler plug (for 4WD models) to the specified torque. Refer to MT-22, "Case and Housing Components" (RS5F51A) or MT-40, "Case and Housing Components"

(RS6F51A).

A

B

MT

D

E

F

G

H

I

J

K

L

M

MT-13

SIDE OIL SEAL

SIDE OIL SEAL

Removal and Installation

REMOVAL

PFP:32113

ECS008BT

●Clutch housing side oil seal used on 4WD vehicles is attached to transfer. Be sure to replace it when transfer is removed.

1.Remove drive shaft from transaxle. Refer to FAX-11, "Removal and Installation" .

2.Remove oil seal with a flat-bladed screwdriver.

CAUTION:

Be careful not to damage the case surface when removing oil seal.

SCIA0824E

INSTALLATION

1.Using the drift, drive the oil seal straight until it protrudes from the case end equal to dimension A shown in the figure.

Dimension “A”

: Within 0.5 mm (0.020 in) of flush with the case.

Drift to be used: |

|

Transaxle case side |

: ST30720000 |

Clutch housing side |

: ST30720000 |

CAUTION:

●Apply multi-purpose grease onto oil seal lip. (For clutch housing side of 4WD models)

●Do not reuse oil seal.

2.Install all parts in the reverse order of removal and check oil level after installation. Refer to MT-12, "Checking M/T Oil" .

SCIA1776E

MT-14

|

POSITION SWITCH |

POSITION SWITCH |

|

Checking |

|

BACK-UP LAMP SWITCH |

|

● Check continuity. |

|

|

|

Gear position |

Continuity |

|

|

Reverse |

Yes |

|

|

Except reverse |

No |

|

|

PARK/NEUTRAL POSITION SWITCH

● Check continuity.

Gear position |

Continuity |

|

|

Neutral |

Yes |

|

|

Except neutral |

No |

|

|

PFP:32005

A

ECS008BU

B

MT

D

SCIA5644E E

F

G

H

I

J

K

L

M

MT-15

CONTROL LINKAGE

CONTROL LINKAGE

Components of Control Device and Cable

PFP:34103

ECS008BV

PCIB0777E

1. |

Control lever knob |

2. |

Select cable |

3. |

Shift cable |

4. |

Lock plate (shift side) |

5. |

Lock plate (select side) |

6. |

Clutch housing |

7. |

Cable mounting bracket |

8. |

Control device assembly |

9. |

Control lever |

10. |

Lock plate |

11. |

Washer |

12. |

Snap pin |

13. |

Washer |

|

|

|

|

MT-16

CONTROL LINKAGE

Removal and Installation |

ECS00CY6 |

Note the following, when removal and installation.

●Shift the control lever to the neutral position for removal.

●Keep in mind that the select side lock plate for securing control cable is different from the shift side lock plate.

●After assembly, make sure selector lever automatically returns to Neutral when it is moved to 1st, 2nd, or Reverse.

Install select cable according to the following procedure.

1.Install select cable of transaxle side to control assembly.

2.Install select cable to pin on select lever part of control device assembly.

PCIB0815E

3.Push lock part (A) of select cable all the way to the direction of the arrow. (For 6M/T models)

4.Slide stopper part (B) all the way to lock part (A) as shown by the arrow. (For 6M/T models)

CAUTION:

Make sure that select cable and select lever are installed securely.

PCIB0817E

A

B

MT

D

E

F

G

H

I

J

K

L

M

MT-17

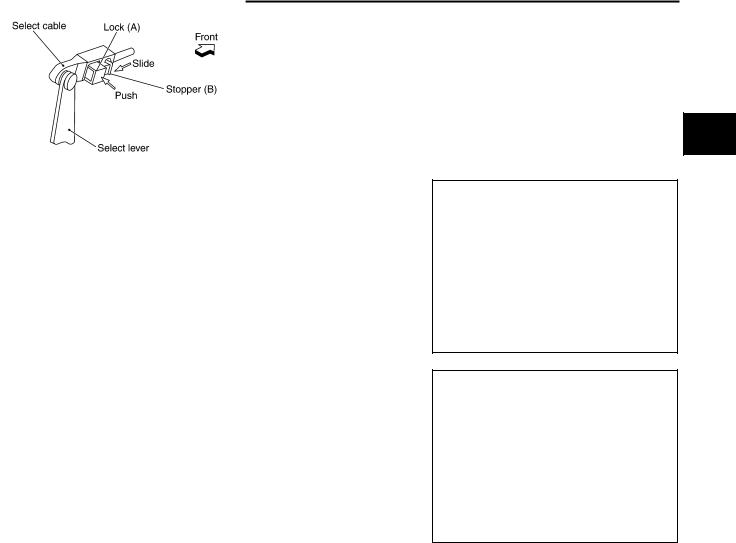

AIR BREATHER HOSE |

|

|

|

AIR BREATHER HOSE |

PFP:31098 |

Removal and Installation |

ECS008BW |

Refer to the figure for air breather hose removal and installation information. |

|

QR engine models |

|

PCIB0778E

1. |

Air cleaner case |

2. |

Transaxle assembly |

3. |

Clip |

4. |

Air breather hose |

5. |

Clip |

6. |

PCV hose |

7.Resonator

YD engine models

PCIB0779E

1. |

Air cleaner case |

2. |

Transaxle assembly |

3. |

Clip |

4. |

Clip |

5. |

Air breather hose |

6. |

Clip |

7. |

Bracket |

8. |

Mass air flow sensor |

|

|

CAUTION:

●Make sure there are no pinched or restricted areas on air breather hose caused by bending or winding when installing it.

●Be sure to insert air breather hose into air breather tube until overlap area reaches the spool.

MT-18

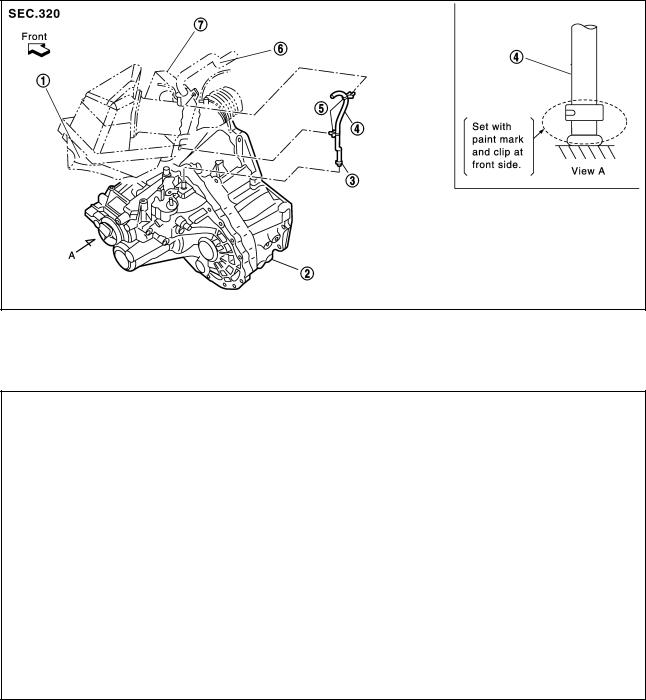

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY |

|

|

|

PFP:32010 |

|||

Removal and Installation |

|

|

|

|

|

A |

|

|

|

|

ECS008BX |

||||

COMPONENTS |

|

|

|

|

|

|

|

|

|

|

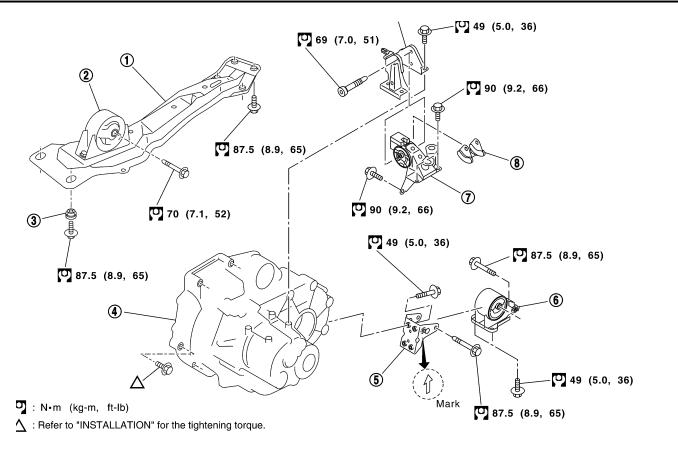

2WD models |

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

J |

|

|

|

|

|

|

|

K |

|

|

|

|

|

PCIB0866E |

|

|

|

1. Rear engine mounting insulator |

2. |

Rubber seat |

3. Rear engine mounting bracket |

|||

|

4. Grommet |

5. |

Center member |

6. |

|

|

L |

|

Transaxle assembly |

||||||

|

7. LH engine mounting insulator |

8. |

Stopper |

9. |

Rubber seat |

||

|

10. LH engine mounting bracket |

|

|

|

|

|

M |

|

|

|

|

|

|

|

|

MT-19

TRANSAXLE ASSEMBLY

4WD models

|

|

|

|

|

PCIB1476E |

1. |

Center member |

2. |

Front engine mounting insulator |

3. |

Grommet |

4. |

Transaxle assembly |

5. |

Rear engine mounting bracket |

6. |

Rear engine mounting insulator |

7. |

LH engine mounting insulator |

8. |

Stopper |

9. |

LH engine mounting bracket |

REMOVAL

1.Disconnect the battery cable from the negative terminal.

2.Remove air cleaner, air duct and battery. Refer to EM-16, "Removal and Installation" (QR engine models) or EM-142, "Removal and Installation" (YD engine models).

3.Remove air breather hose. Refer to MT-18, "Removal and Installation" .

4.Remove clutch operating cylinder. Refer to CL-12, "Removal and Installation" .

CAUTION:

Do not depress clutch pedal during removal procedure.

5.Disconnect control cable from transaxle assembly. Refer to MT-17, "Removal and Installation" .

6.Drain gear oil. Refer to MT-12, "DRAINING" .

7.Disconnect PNP switch, back-up lamp switch and ground harness connectors.

8.Remove exhaust front tube. Refer to EX-2, "Removal and Installation" .

9.Remove drive shaft. Refer to FAX-11, "FRONT DRIVE SHAFT" .

10.Remove transfer (for 4WD models). Refer to TF-57, "Removal and Installation" .

11.Remove starter motor. Refer to SC-27, "Removal and Installation" .

12.Support transaxle assembly with a jack.

CAUTION:

When setting a jack, be careful not to bring it into contact with switches.

13.Remove center member, engine insulator and engine mount bracket. Refer to EM-81, "ENGINE ASSEMBLY" (QR engine models) or EM-222, "ENGINE ASSEMBLY" (YD engine models).

14.Remove suspension members (for 4WD models). Refer to FSU-12, "FRONT SUSPENSION MEMBER" .

15.Support engine with a jack under oil pan.

16.Remove transaxle assembly mounting bolts.

MT-20

TRANSAXLE ASSEMBLY

17.Remove transaxle assembly from the vehicle.

CAUTION:

Secure transaxle assembly to a jack while removing it.

MTD0062D

INSTALLATION

Note the following, and install in the reverse order of removal.

●When installing the transaxle assembly to the engine, install the mounting bolts following the standard below.

CAUTION:

When installing transaxle assembly, be careful not to bring transaxle input shaft into contact with clutch cover.

–QR engine models

Bolt No. |

1 |

2 |

3* |

4 |

|

5 |

6 |

|

|

|

|

|

|

|

|

Quantity |

2 |

1 |

1 |

2 |

|

2 |

2 |

|

|

|

|

|

|

|

|

Bolt length “ ” |

40 |

75 |

45 |

40 |

|

30 |

40 |

mm (in) |

(1.57) |

(2.95) |

(1.77) |

(1.57) |

|

(1.18) |

(1.57) |

|

|

|

|

|

|

|

|

Tightening torque |

|

74.5 |

|

|

42.7 |

35.3 |

|

N·m (kg - m, ftlb) |

|

(7.6, 55) |

|

(4.4, 31) |

(3.6, 26) |

||

|

|

|

|

|

|

|

|

*: Tightening the bolt for 4WD models.

SCIA0353E

A

B

MT

D

E

F

G

H

I

–YD engine models

Bolt No. |

1 |

2 |

|

3 |

4 |

5 |

|

6 |

|

|

|

|

|

|

|

|

|

Quantity |

2 |

2 |

|

1 |

1 |

3 |

|

1 |

|

|

|

|

|

|

|

|

|

Bolt length “ ” |

55 |

50 |

|

120 |

45 |

40 |

|

35 |

mm (in) |

(2.17) |

(2.76) |

|

(4.72) |

(1.77) |

(1.57) |

|

(1.38) |

|

|

|

|

|

|

|

|

|

Tightening torque |

|

|

44 |

|

|

33.5 |

||

N·m (kg - m, ftlb) |

|

(4.5, 32) |

|

(3.4, 25) |

||||

|

|

|

|

|

|

|

|

|

●After installation, check oil level, and check for leaks and loose mechanisms. Refer to MT-12, "Checking M/T Oil" .

J

K

L

M

SCIA0748E

MT-21

TRANSAXLE ASSEMBLY

Disassembly and Assembly (RS5F51A) |

ECS008C0 |

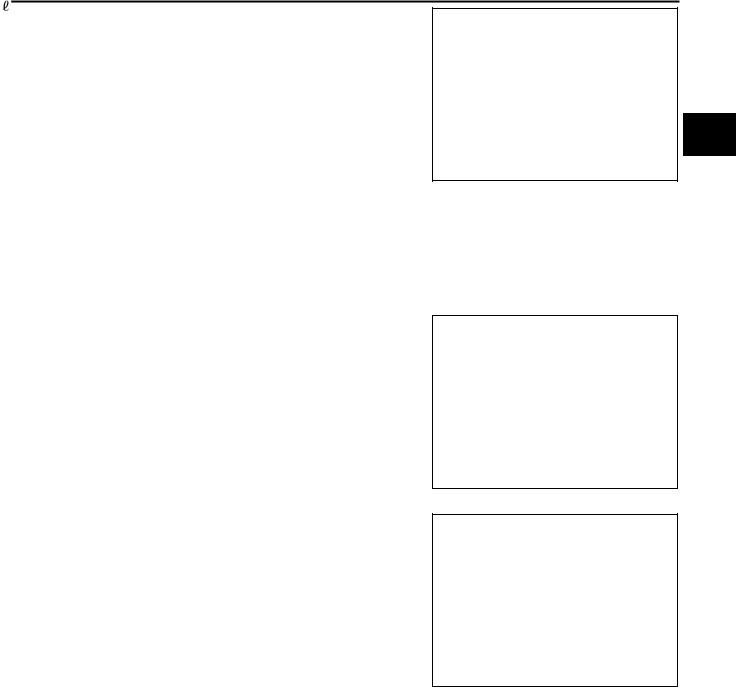

COMPONENTS

Case and Housing Components

PCIB1459E

1. |

Clutch housing |

2. |

Differential side oil seal |

3. |

Ball pin |

4. |

Washer |

5. |

Input shaft oil seal |

6. |

Oil channel |

7. |

Magnet |

8. |

Gasket |

9. |

Filler plug |

10. |

O-ring |

11. |

Plug |

12. |

Air breather tube |

13. |

Back-up lamp switch |

14. |

Oil gutter |

15. |

Baffle plate |

16. |

Transaxle case |

17. |

Plug |

18. |

Welch plug |

19. |

Bore plug |

20. |

Drain plug |

21. |

Differential side oil seal |

22. |

Park/Neutral position (PNP) switch |

|

|

|

|

MT-22

TRANSAXLE ASSEMBLY

Gear Components

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

J |

|

|

|

|

|

PCIB1458E |

|

|

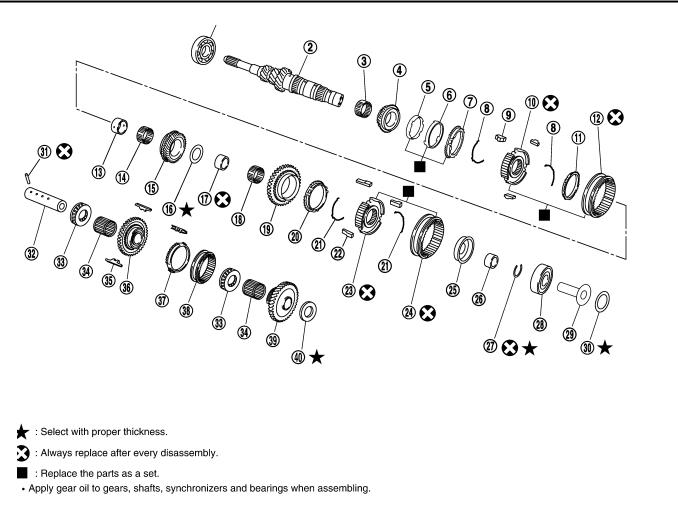

1. |

Input shaft front bearing |

2. |

Input shaft |

3. |

3rd needle bearing |

|

|

4. |

3rd input gear |

5. |

3rd inner baulk ring |

6. |

3rd synchronizer cone |

K |

|

7. |

3rd outer baulk ring |

8. |

3rd-4th spread spring |

9. |

3rd-4th shifting insert |

|

|

10. |

3rd-4th synchronizer hub |

11. |

4th baulk ring |

12. |

3rd-4th coupling sleeve |

|

|

13. |

4th input gear bushing |

14. |

4th needle bearing |

15. |

4th input gear |

L |

|

16. |

Thrust washer |

17. |

5th input gear bushing |

18. |

5th needle bearing |

|

|

19. |

5th input gear |

20. |

5th baulk ring |

21. |

5th spread spring |

|

|

22. |

5th shifting insert |

23. |

5th synchronizer hub |

24. |

5th coupling sleeve |

M |

|

25. |

5th stopper |

26. |

Input shaft bearing spacer |

27. |

Snap ring |

|

|

28. |

Input shaft rear bearing |

29. |

Oil channel |

30. |

Input shaft rear bearing adjusting |

|

|

|

|

|

|

|

shim |

|

|

31. |

Retaining pin |

32. |

Reverse idler shaft |

33. |

Thrust needle bearing |

|

|

34. |

Reverse idler gear needle bearing |

35. |

Reverse insert spring |

36. |

Reverse idler gear (Front) |

|

|

37. |

Reverse baulk ring |

38. |

Reverse coupling sleeve |

39. |

Reverse idler gear (Rear) |

|

|

40 |

Reverse idler gear adjusting shim |

|

|

|

|

|

|

MT-23

TRANSAXLE ASSEMBLY

PCIB0783E

1. |

Mainshaft front bearing |

2. |

Mainshaft bearing retainer |

3. |

Mainshaft |

4. |

Reverse main gear |

5. |

1st main gear |

6. |

1st main gear bushing |

7. |

1st needle bearing |

8. |

1st inner baulk ring |

9. |

1st synchronizer cone |

10. |

1st outer baulk ring |

11. |

1st-2nd spread spring |

12. |

1st-2nd shifting insert |

13. |

1st-2nd synchronizer hub |

14. |

2nd outer baulk ring |

15. |

2nd synchronizer cone |

16. |

2nd inner baulk ring |

17. |

1st-2nd coupling sleeve |

18. |

2nd main gear bushing |

19. |

2nd needle bearing |

20. |

2nd main gear |

21. |

3rd main gear |

22. |

3rd-4th mainshaft spacer |

23. |

4th main gear adjusting shim |

24. |

4th main gear |

25. |

5th main gear |

26. |

Snap ring |

27. |

Mainshaft rear bearing |

28. |

Mainshaft C-ring |

29. |

C-ring holder |

30. |

Snap ring |

31. |

Snap ring |

32. |

Mainshaft rear bearing adjusting shim |

|

|

MT-24

TRANSAXLE ASSEMBLY

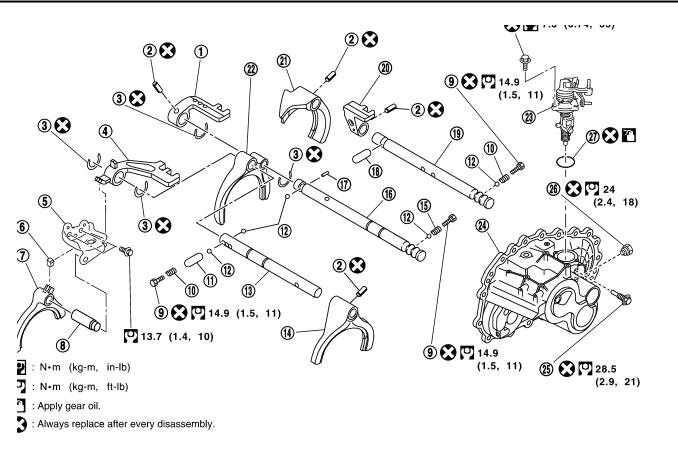

Shift Control Components

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

PCIB0868E |

|

I |

|

|

|

|

|

|

|

|

|

1. |

3rd-4th bracket |

2. |

Retaining pin |

3. |

Stopper ring |

|

|

|

4. |

5th-reverse bracket |

5. |

Reverse lever assembly |

6. |

Shifter cap |

|

|

J |

7. |

Reverse shift fork |

8. |

Reverse fork rod |

9. |

Check plug |

|

|

|

|

|

|

||||||

10. |

Check spring |

11. |

Shift check sleeve |

12. |

Check ball |

|

|

|

13. |

5th-reverse fork rod |

14. |

5th shift fork |

15. |

Check spring |

|

|

K |

16. |

3rd-4th fork rod |

17. |

Interlock pin |

18. |

Shift check sleeve |

|

|

|

|

|

|

||||||

19. |

1st-2nd fork rod |

20. |

1st-2nd bracket |

21. |

1st-2nd shift fork |

|

|

|

22. |

3rd-4th shift fork |

23. |

Control assembly |

24. |

Transaxle case |

|

|

L |

25. |

Stopper bolt |

26. |

Shift check |

27. |

O-ring |

|

|

|

|

|

|

M

MT-25

TRANSAXLE ASSEMBLY

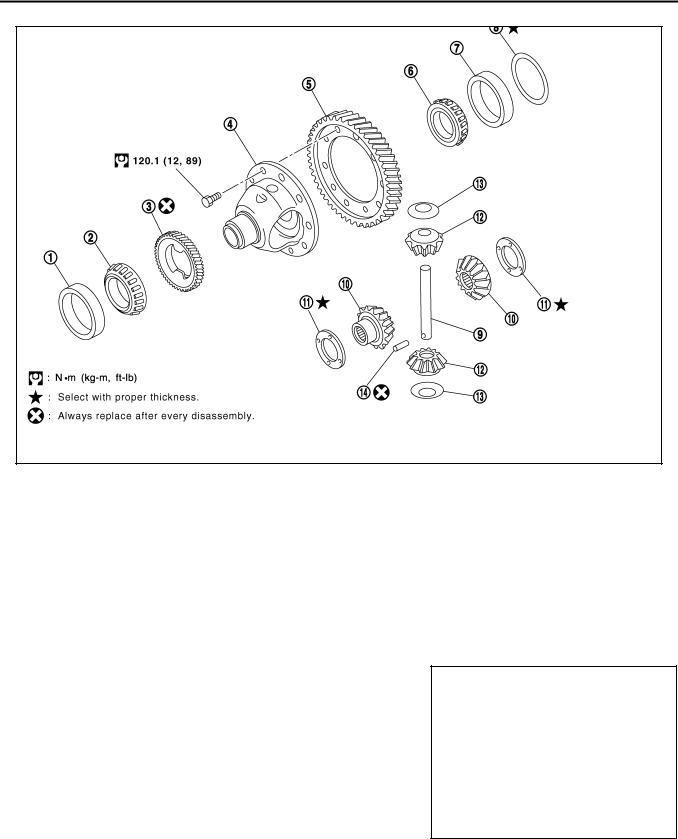

Final Drive Components

PCIB0869E

1.Differential side bearing outer race (clutch housing side)

4.Differential case

2.Differential side bearing (clutch housing side)

5.Final gear

3.Speedometer drive gear (for 2WD models)

6.Differential side bearing (transaxle case side)

7. |

Differential side bearing outer race |

8. |

Differential side bearing adjusting |

9. |

Pinion mate shaft |

|

(transaxle case side) |

|

shim |

|

|

10. |

Side gear |

11. |

Side gear thrust washer |

12. |

Pinion mate gear |

13. |

Pinion mate thrust washer |

14. |

Retaining pin |

|

|

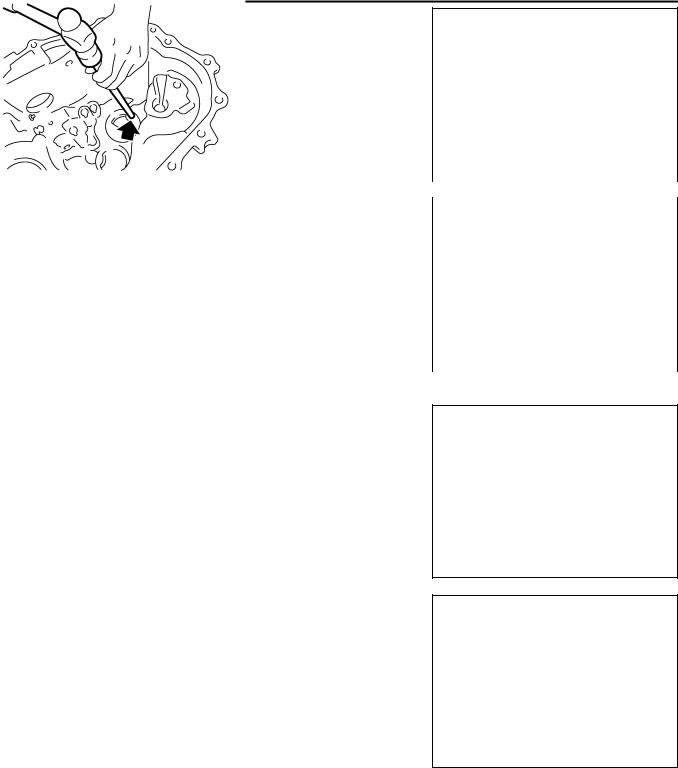

DISASSEMBLY

1.Remove plug (for 2WD models) or filler plug (for 4WD models) from clutch housing.

2.Remove drain plug and plug from transaxle case.

3.Remove park/neutral position switch and back-up lamp switch from transaxle case.

4.Remove shift check and stopper bolt from transaxle case, and then remove control assembly from transaxle case.

SCIA0389E

MT-26

TRANSAXLE ASSEMBLY

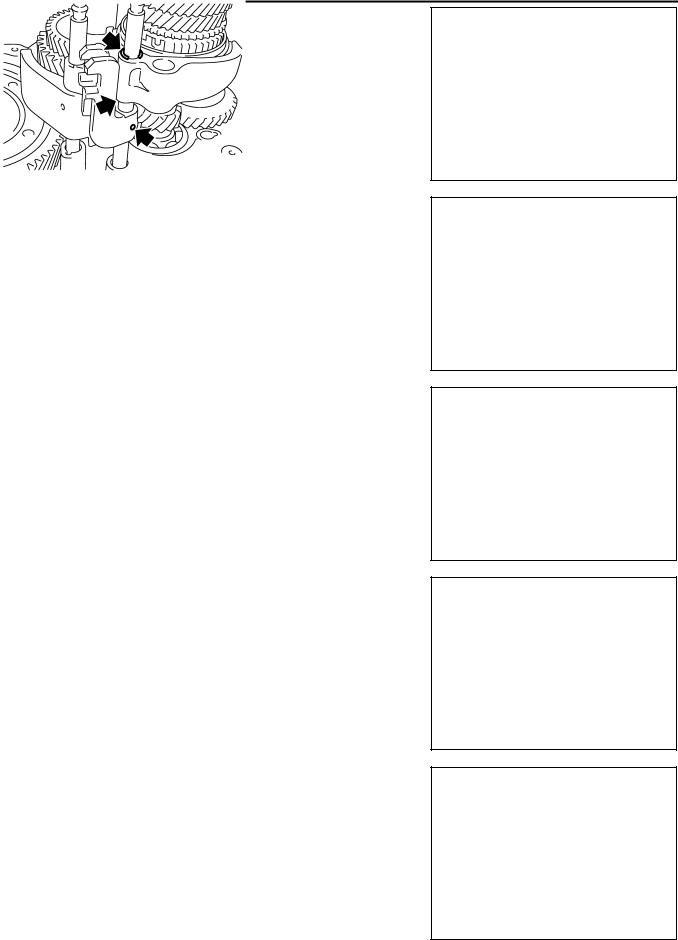

5.Remove check plugs (3 pieces), check springs (3 pieces), check

|

balls (3 pieces) and shift check sleeve (1 piece). |

|

|

A |

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

MT |

|

|

|

|

|

|

|

SCIA0396E |

||

6. |

Remove transaxle case mounting bolts. |

|

|

D |

|

|

|

||

|

|

|

||

7. |

Remove bore plug from transaxle case. |

|

|

|

|

CAUTION: |

|

|

E |

|

Be careful not to damage transaxle case. |

|

|

|

8.While spreading the snap ring of mainshaft rear bearing located

at bore plug hole, remove transaxle case from clutch housing. |

F |

9.Remove oil gutter, baffle plate from transaxle case.

10.Remove snap ring, mainshaft rear bearing adjusting shim from

transaxle case. |

|

G |

11. Remove input shaft rear bearing adjusting shim and reverse |

SCIA0983E |

|

idler gear adjusting shim. |

|

H |

|

|

|

12.Remove differential side bearing outer race from transaxle case using the puller, and then remove differential side bearing adjusting shim from transaxle case.

I

J

K

SCIA0897E

13. Remove welch plug from transaxle case.

L

M

SCIA0402E

MT-27

TRANSAXLE ASSEMBLY

14.Remove differential side oil seal from transaxle case.

CAUTION:

Be careful not to damage transaxle case.

15.Remove magnet from clutch housing.

SCIA0397E

16.With shift lever in 5th position, remove mounting bolts from reverse lever assembly. Lift reverse lever assembly to remove.

CAUTION:

Be careful not to lose shifter cap.

17.Pull out reverse fork rod then remove reverse shift fork.

SCIA0390E

18.Shift 3rd-4th fork rod to 3rd position. Remove retaining pin of 5th shift fork using a pin punch.

SCIA0391E

19.Remove stopper rings for 5th-reverse bracket.

20.Pull out 5th-reverse fork rod and remove 5th shift fork and 5threverse bracket.

21.Remove check balls (2 pieces) from clutch housing.

SCIA0392E

22.Remove retaining pin of 3rd-4th bracket using a pin punch.

23.Remove stopper rings for 3rd-4th shift fork.

24.Pull out 3rd-4th fork rod and remove 3rd-4th shift fork and 3rd4th bracket.

25.Remove interlock pin and shift check sleeve from clutch housing.

SCIA0393E

MT-28

TRANSAXLE ASSEMBLY

26.Remove retaining pin of 1st-2nd shift fork using a pin punch.

27.Pull out 1st-2nd fork rod with 1st-2nd bracket.

28.Remove 1st-2nd shift fork.

29.Remove retaining pin of 1st-2nd bracket using a pin punch and separate 1st-2nd fork rod and 1st-2nd bracket.

30.Remove gear components from clutch housing in the following procedure.

a.Remove input shaft assembly, mainshaft assembly and reverse idler gear assembly as a set, tapping input shaft with plastic hammer.

CAUTION:

Always withdraw mainshaft straight out. Failure to do so can damage resin oil channel on clutch housing side.

b.Remove final drive assembly.

31.Remove mainshaft bearing retainer and then mainshaft front bearing from clutch housing using the puller.

32.Remove oil channel from clutch housing.

33.Remove differential side oil seal from clutch housing.

CAUTION:

Be careful not to damage clutch housing.

34.Remove differential side bearing outer race from clutch housing using the puller.

SCIA0394E

SCIA0395E

SCIA1077J

SCIA1068J

SCIA1069J

A

B

MT

D

E

F

G

H

I

J

K

L

M

MT-29

TRANSAXLE ASSEMBLY

35.Remove input shaft oil seal from clutch housing.

CAUTION:

Be careful not to damage clutch housing.

ASSEMBLY

1.Install input shaft oil seal to clutch housing using the drift.

Dimension |

A: 1.8 - 2.8 mm (0.071 - 0.110 in) |

CAUTION:

Do not reuse input shaft oil seal.

2.Install differential side oil seal until it become flush with end face of clutch housing using the drift.

CAUTION:

●Do not reuse differential side oil seal.

●Apply multi-purpose grease onto oil seal lip. (For 4WD models)

3.Install oil channel on mainshaft side.

CAUTION:

Be careful with the orientation of installation.

SCIA0398E

PCIB0873E

SCIA1070J

SCIA0986E

MT-30

Loading...

Loading...