Page 1

m

be certain.

Series LX Laser Extensometer

Product Information

LX 500

LX 1500

015-207-801 F

Page 2

Copyright information © 1999–2001, 2006, 2009 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. These trademarks may be protected in other countries.

Super Glue is a trademark or Super Glue Corporation. All other trademarks or

service marks are property of their respective owners.

Publication information

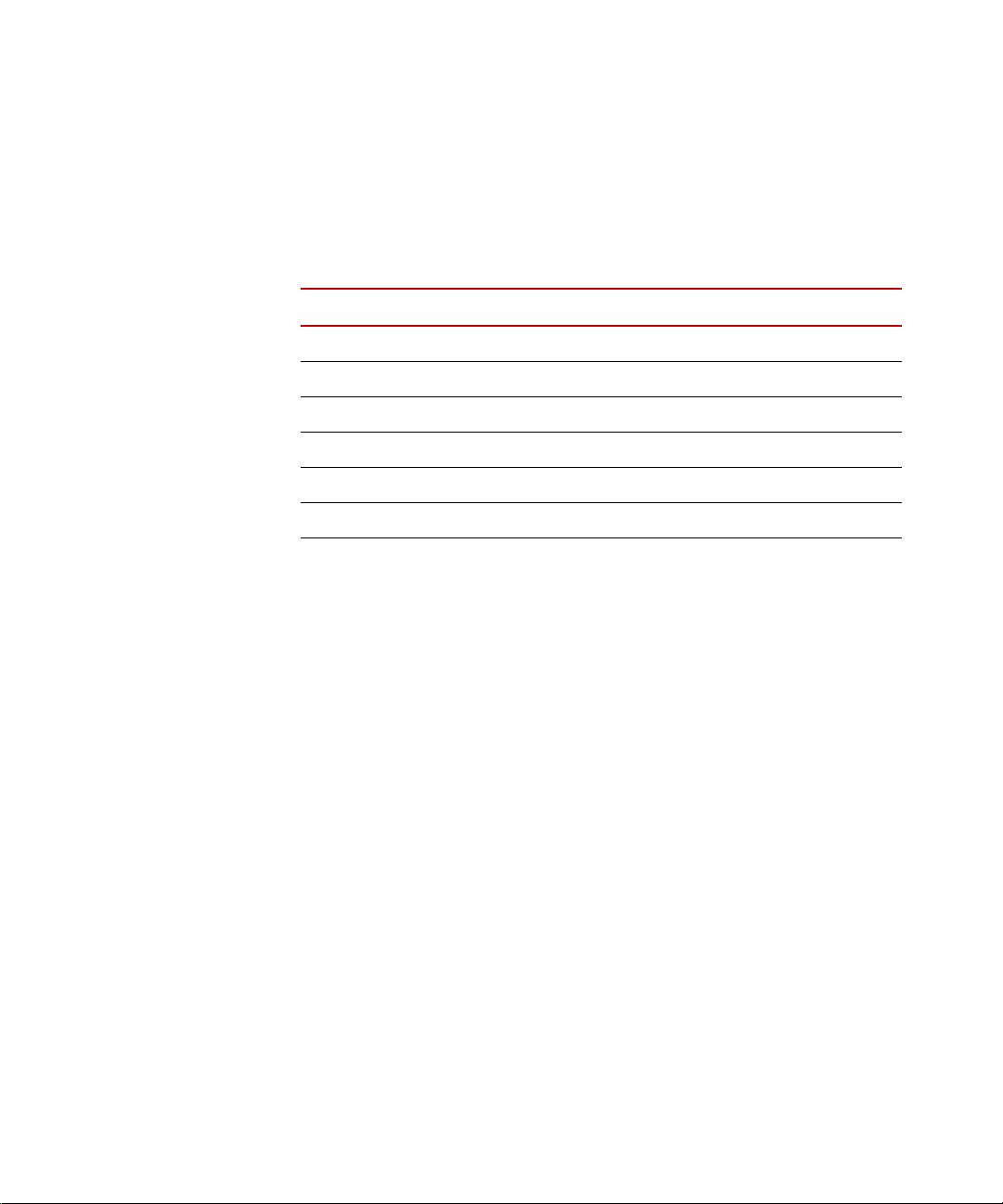

MANUAL PART NUMBER PUBLICATION DATE

015-207-801 A April 1999

015-207-801 B April 2000

015-207-801 C May 2001

015-207-801 D May 2006

015-207-801 E March 2009

015-207-801 F August 2009

Page 3

Contents

Technical Support 5

Preface 11

Conventions 12

Introduction 15

Specifications 17

Component Identification 19

Controls and Components 20

Safety 23

Labels and Warning Logotypes 25

Additional Safety Cautions 26

Safety Checkout 27

Installation 29

Mechanical Mounting 30

Electrical Connections 33

Modular Jack Pin Identification 33

Operation 35

Target Types and Considerations 36

Target Placement 37

Manual Name Contents

3

Page 4

Monitoring the Reflection Pulses 38

Using the Instrument 39

Setting the Operating Parameters from the Key Pad 39

Description of the Operating Parameters 40

Measuring Elongation 44

Using the Serial Interface 45

Serial I/O Port Cable Connections 46

Communications Parameters 47

Control Commands for Serial Input/Output Port 48

Calibration 52

Entering the Calibration Mode 53

Maintenance 55

Recommended Maintenance Schedule 56

Component Locations 57

Scan Aperture Cleaning Procedure 59

Replacing the Fuse 60

4

Contents

Manual Name

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

Technical support

outside the U.S.

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact MTS > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

LX Laser Extensometer Technical Support

5

Page 6

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Know information from

prior technical

The site number contains your company number and identifies your equipmen t

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

Technical Supp ort

6

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

LX Laser Extensometer

Page 7

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company , company

address, and the phone number where you can normally be reached.

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

LX Laser Extensometer Technica l Suppo rt

7

Page 8

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Technical Supp ort

8

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

LX Laser Extensometer

Page 9

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

LX Laser Extensometer Technica l Suppo rt

9

Page 10

Technical Supp ort

10

LX Laser Extensometer

Page 11

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and op eration and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

LX Laser Extensometer Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

12

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Preface

LX Laser Extensometer

Page 13

Conventions

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

LX Laser Extensometer Preface

13

Page 14

Conventions

14

Preface

LX Laser Extensometer

Page 15

Introduction

The MTS Series LX Laser Extensometers are precision, wide range instruments

specifically designed for accurate, non-contact, measurement of strain on various

materials under tensile or creep conditions. The instrument is completely self

contained. It is housed in a single, compact enclosure and utilizes the latest stateof-the-art laser diode technology for high performance, low maintenance

operation. The LX 500 is a high elongation version for measuring the strain of

elastomeric materials. It has a range of 5 to 132 mm (0.2 to 5.2 in). The LX 1500

has a range of approximately 380 mm (approximately 15 in).

The laser extensometer includes a LCD display, a 4-button keypad, a 0 to 10 V

(5 V optional) analog output, and a serial input/output port, all of which are

accessible from the control panel. In addition, the unit can be operated locally

from the control panel using the built-in keypad, or remotely via the Serial I/O

Port.

MTS Series LX Laser Extensometer

LX Laser Extensometer Introduction

15

Page 16

The laser extensometer uses a unique scanning laser beam technique to measure

elongation entirely from one side of the specimen. Two tiny retro-reflective

targets are attached to the specimen at the desired gauge length and the beam is

scanned along the specimen in the direction of elongation. Reflections from these

targets are then processed by the laser extensometer to provide measurement of

elongation (strain). This approach eliminates the need for a separate Scan

Receiver Unit mounted on the opposite side of the specimen.

16

Introduction

LX Laser Extensometer

Page 17

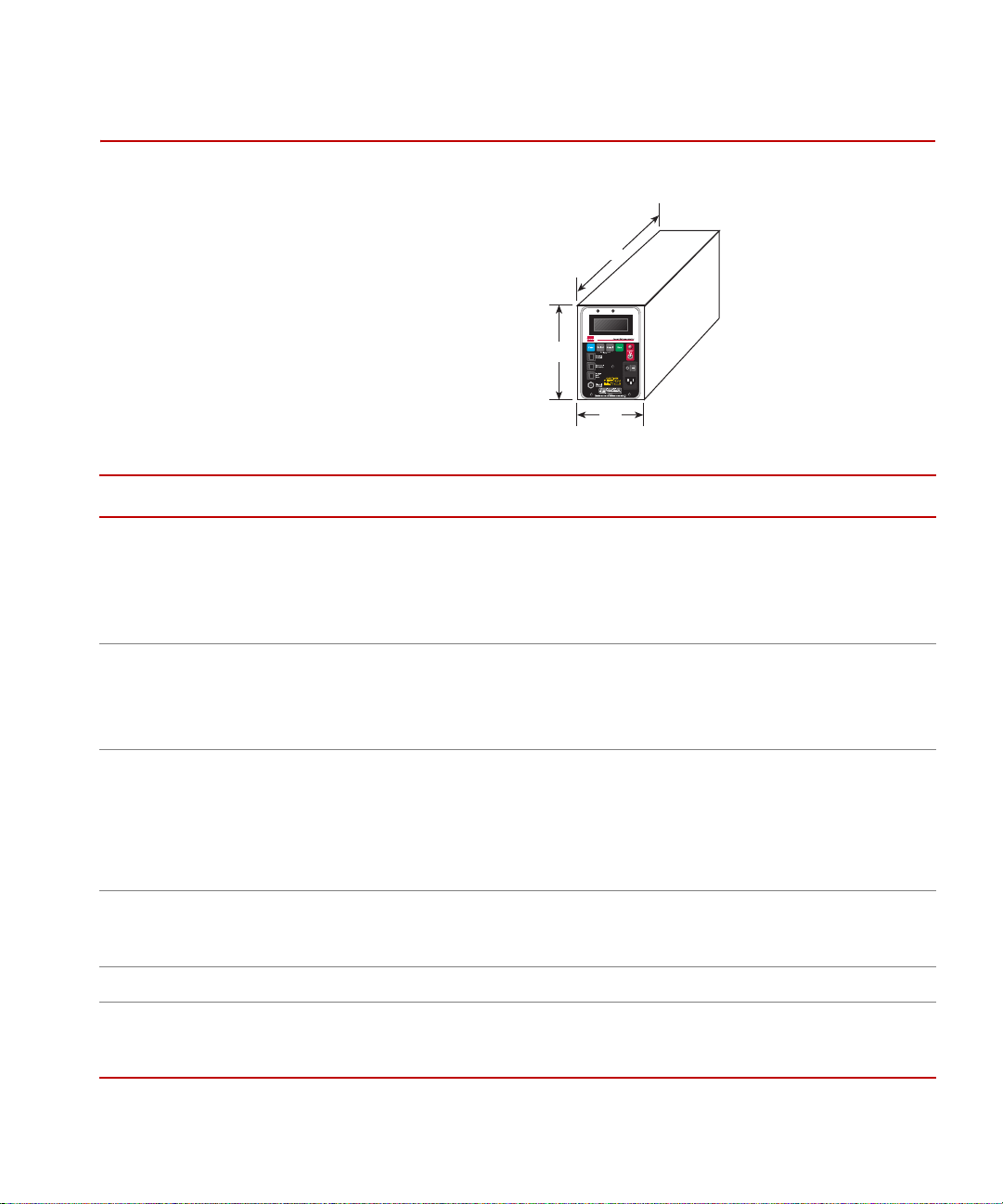

Specifications

W

H

L

Specifications

PARAMETER

Dimensions

(Length [L] x Width [W] x Height [H])

LX 500

LX 1500

Weight

LX 500

LX 1500

Power Input

Voltage

Current

Frequency

Operating Conditions 18 ºC to 28 ºC (64 ºF to 82 ºF)

Mounting Provisions 4 holes (1/4 - 20 thread) located in base

Laser Source 670 nm Diode Laser

TYPICAL SPECIFICATION

381 x 114 x 180 mm (15 x 4.5 x 7.1 in)

686 x 196 x 442 mm (27 x 7.7 x 17.4 in)

5.9 kg (13 lb)

21.8 kg (48 lb)

115 V AC (standard), or 230 V AC (optional), ± 10%

120 mA @ 115 V AC, 60 mA @ 230 V AC

50/60 Hz

25% to 75% relative humidity, noncondensing

0 to 2745 m (0 to 9000 ft) altitude

<1 mW maximum scanned output

CDRH compliant Class II Laser Instrument

*

LX Laser Extensometer Introduction

17

Page 18

Specifications

PARAMETER

TYPICAL SPECIFICATION

*

Scan Line Orientation Vertical

Scan Rate 100 scans/second

Unit System Selectable, millimeter or inch

Target Distance

LX 500

LX 1500

Measurement Range

LX 500

LX 1500

†

Selectable: 304 mm (12 in), 381 mm (15 in)

Selectable: 381 mm (15 in), 457 mm (18 in)

5 to 127 mm (0.2 to 5.0 in)

8 to 381 mm (0.3 to 15 in)

Resolution

LX 500

LX 1500

Nonlinearity (maximum)

LX 500

LX 1500

Repeatability

‡

LX 500

LX 1500

‡

0.001 mm (0.0001 in)

0.01 mm (0.001 in)

±0.025 mm (±0.0001 in)

±0.15 mm (±0.006 in)

±0.003 mm (±0.0001 in)

±0.03 mm (±0.001 in)

Zero Suppression Reading can be zeroed anywhere within the full scale range of the

instrument

Multiple Scan Averaging A moving window average is applied over a programmable number

of scans to digitally filter the output readings

Display 2-line, 16 characters/line LCD type display with LED backlighting

Analog Output Range ±10 V full scale (±5 V full scale optional)

Serial I/0 Port Standard 3-wire type, RS-232

Selectable baud (9600, 4800, 2400, 1200)

Options Consult MTS

* Specifications apply at 25

° C (77° F), 50% relative humidity.

† Contact factory for other ranges.

‡ Over optimum displacement range at calibrated target distance.

18

Introduction

LX Laser Extensometer

Page 19

Component Identification

CAUTION

An illustration of the controls necessary for operation is shown below. The Scan

Aperture is located on the opposite side of the instrument.

The scanning laser beam is emitted from the scan aperture.

Avoid exposure.

Component Identification

LX Laser Extensometer Introduction

19

Page 20

Component Identification

Controls and Components

Laser disable switch This switch shuts down the scanning laser beam.

Laser emission indicator This is a red LED lamp that illuminates when the scanning laser beam is present.

Power entry module The fuse holder, the power switch, and the ac line connector are contained in this

module.

Certification label This label certifies compliance with CDRH regulations.

Rear panel warning label This label warns of the presence Laser Radiation inside the instrument.

Warning logotype This label specifies the wavelength and maximum power output of the laser

radiation emitted from the instrument.

LCD display Displays specimen elongation in either inches or millimeters when the instrument

is in the Run mode, and displays the value of various operating parameters when

the instrument is in the Setup mode.

Zero button Pressing the Zero button offsets the current value of specimen elongation to zero

and displays Offset on the LCD display. Subsequent elongation measurements

then become relative to this new zero point. Pressing the Zero button again

removes the offset.

Select button While in Run mode, pressing this button simultaneously with the Scroll button

forces the laser extensometer into the Setup mode. The Select button is then used

to select and accept major items from the Setup menu.

Scroll button While in Run mode, pressing this button simultaneously with the Select button,

forces the laser extensometer into the Setup mode. The Scroll button is then used

to change the value of the selected item in the Setup menu. The Select button

must then be pressed to accept the new value of the selected item.

Run button While in Setup mode, pressing this button returns the laser extensometer to the

Run mode.

Signal Output connector A BNC connector is provided for monitoring the reflections coming back from

the specimen using an oscilloscope. This is especially useful for initial setup or

troubleshooting.

Serial I/O Port connector A modular connector is provided to allow serial input/output connection to a host

computer.

20

Introduction

LX Laser Extensometer

Page 21

Component Identification

External Receiver

connector

Analog Output

connector

A modular connector is provided for this optional accessory.

A modular connector is provided here also. It allows connections to the Analog

Output (a ±10 V DC or

and connections for providing a 5 V level to actuate the optional Remote Laser

Disable function.

±5 V DC signal proportional to specimen elongation),

LX Laser Extensometer Introduction

21

Page 22

Component Identification

22

Introduction

LX Laser Extensometer

Page 23

Safety

CAUTION

Important The Series LX Laser Extensometers are intended for materials

testing laboratories.

The Series LX Laser Extensometers are Class II laser products and, in normal

usage, are not considered hazardous due to the low power of the scanned laser

beam. However, staring into the beam could cause damage to your eyes and

it is up to you to follow all safety precautions and safety labels.

The National Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration has established regulations for laser

manufacturers (FDA 21 CFR 1040.10 and 1040.11). The laser extensometer

complies with applicable sections of these regulations and is classified as a Class

II laser product.

A warning logotype, along with other labels identify the unit as a Class II laser

product. Both the warning logotype and the certification label are located on the

control panel, while the manufacturer's identification label is located on the

housing at the rear of the instrument.

In normal usage the laser extensometer is not considered hazardous due to the

low power of the scanned laser beam. However:

LX Laser Extensometer Safety

Staring into the beam could damage the operator’s eyes.

Use caution when measuring reflective parts.

It is up to the operator to follow all safety precautions and safety labels.

The laser extensometer has the following built-in safety features which should be

checked periodically for proper operation.

• A laser emission indicator that illuminates when power is applied to the

laser.

• A laser disable switch that shuts down the laser.

• A laser shutdown circuit that monitors the scan speed and automatically

disables the laser when the scan speed drops below the limit.

23

Page 24

Check operation of these safety features by performing the procedure in the

CAUTION

CAUTION

Safety Checkout section.

Laser radiation present inside. Do not remove case.

Customer servicing of the internal components of the laser extensometer is not

recommended. Return unit to factory for service.

Use of controls or adjustments or performance of procedures other than

those specified herein can result in hazardous radiation exposure.

Always follow the instructions contained in the documentation.

24

Safety

LX Laser Extensometer

Page 25

Labels and Warning Logotypes

Manufacture Date

Rev.

Laser Extensometer

Model No.

Serial No.

Assembly No.

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN U.S.A. 55344

Supply Rating

No user serviceable parts inside

V Hz

AVOID EXPOSURE

- Laser radiation

is emitted from this aperature

The following figure shows the labels and warning logotypes that are found on

the laser extensometer.

Labels and Warning Logotypes

LX Laser Extensometer Safety

25

Page 26

Labels and Warning Logotypes

CAUTION

Additional Safety Cautions

Besides the safety cautions listed on the previous page, you should read,

understand, and follow these additional safety cautions:

Before attempting to operate the instrument, read an d underst a nd the enti re

manual. Follow all safety precautions and warning labels.

This instrument is a technical product for use only by skilled personnel in an

indoor laboratory environment wit h a normal, controlled, 25ºC, 55% relative

humidity. This instrument is not for outdoor use. Do not expose to moisture.

Properly handle and install this instrument on a stable, solid mounting surface

suitable for safely handling its weight and size. Failure to do so can present a

safety hazard and result in damage to the instrument. The instrument is not for

hand held use.

There are 170 user serviceable components inside the instrument. Do not attempt

to open or remove the case. Dangerous voltages and laser radiation are present

inside. Return the instrument to the factory for service.

Do not make any modifications to the instrument. Doing so will void the warranty

and can also result in a hazardous condition.

To reduce the risk of electrical shock, the instrument must be connected to the AC

Main power line using the proper, grounded 3-prong line cord.

Before performing any maintenance, turn the power switch to OFF position and

disconnect unit from the AC Main power line.

Replace fuses with only the specified type and rating. Using incorrect fuses can

present a safety hazard and damage the instrument.

26

Safety

LX Laser Extensometer

Page 27

Safety Checkout

Labels and Warning Logotypes

1. Check the laser emission indicator.

With the laser extensometer ON and the LASER DISABLE SWITCH in the

LASER ON position, verify that the LA SER EMISSION INDICATOR is

illuminated only when the scanning Laser Beam is present.

2. Check the laser disable switch.

With the laser extensometer ON and the scanning Laser Beam present,

verify that the LASER DISABLE SWITCH shuts down the scanning Laser

Beam.

3. Check the laser shutdown circuit.

Verify this feature is functional by observing th e delayed appearance of the

scanning laser beam when the laser is enabled.

A. Start with the laser extensometer on and the scanning laser beam

present. Set the laser disable switch to the off position to shut down the

scanning laser beam.

B. Allow approximately one minute to elapse until the scan motor stops

rotating.

C. Return the laser disable switch to the on position and note the time

delay before the scanning laser beam appears.

D. The beam should appear a few seconds after

to the on position. If no time delay is observed, the laser shutdown

circuit is not operating properly. Contact MTS for service.

4. Check laser power level.

This check verifies the Laser Emission Level is within the acceptable range

for a Class II laser product. You will need an optical power meter calibrated

for a wavelength of 670 nm with a minimum full scale range of 1.0 mW.

A. Turn the laser extensometer on and allow a 30 minute warm up time.

B. Turn on the optical power meter. Set controls per the manufacturer's

instructions.

C. Position the measuring head of the optical power meter in the scanning

laser beam. Measure and record the power reading. The output power

reading must be less than 1.0 mW; if not, contact MTS for service.

setting the disable switch

LX Laser Extensometer Safety

27

Page 28

Labels and Warning Logotypes

CAUTION

Laser radiation present inside. Observe the following cautions:

Customer servicing of the internal components is not recommended; return

unit to factory for service. (Opening the case invalidates all warranties.)

Before performing maintenance, turn power switch to the off position and

disconnect the unit from the AC power line.

If a malfunction occurs, immediately shut down the malfunctioning unit and

contact MTS for repairs.

Do not open or remove the case. Laser radiation is present inside the instrument.

28

Safety

LX Laser Extensometer

Page 29

Installation

Contents Mechanical Mounting 30

Electrical Connections 33

LX Laser Extensometer Installation

29

Page 30

Mechanical Mounting

Mechanical Mounting

Proper installation of the unit is essential for best performance. It is important

that the instrument be solidly mounted on a flat surface and that the scanning

laser beam be properly positioned on the target; see “Tripod Mounting Adapter”

on page 31. It is recommended that the laser extensometer be mounted on four

machined spacers 12.7 mm (0.500 in) diameter by 12.7 mm (0.500 in) long, with

1/4-20 bolts using the four threaded mounting holes locate d in the base of the

unit. The purpose of these spacers is to provide 4 solid contact areas between the

bottom of the Laser Extensometer and the mounting surface. The spacers and the

mounting surface must be fabricated using good machining practice such that,

with the mounting bolts loose, the laser extensometer rests flat contacting all 4

spacers simultaneously.

Choose the mounting location of the laser extensometer such that the specimen to

be measured ends up at the appropriate target distance from the instrument,

where target distance refers to the distance between the front panel of the laser

extensometer and the targeted surface of the specimen. Try to locate the LX500

so that a 304 mm (12 in) target distance results; for the LX1500, try for a target

distance of 381 mm (15 in). If this is not a practical distance for the intended

application, then choose another distance: for the LX500, 381 mm (15 in); for the

LX1500, 457 mm (18 in).

30

Installation

Important Calibration is a function of target distance, and the instrument must

be calibrated at the target distance (or distances) it will be operated

at. Contact factory for details.

Orient the laser extensometer so that the scan line is aligned parallel with the

specimen's axis of elongation; see “Scan Line Orientation on Specimen” on page

32. It is important to position the laser extensometer properly with respect to the

specimen in order to avoid possible spurious reflections. These reflections

usually result from scanning orthogonally across a bright, shiny surface. This

happens in situations where the plane of the scan line is orthogonal to the plane

containing the surface of a shiny specimen. The presence of spurious reflections

is suspected when unstable or invalid readings occur. These reflections can

typically be eliminated by rotating the offending surface of the specimen a small

amount (≈5° to 10°) about the axis of the scan line; see “Scan Line Orientation on

Specimen” on page 32.

LX Laser Extensometer

Page 31

Mechanical Mounting

19.56

20.00

14.00

11.69

10.00

8.31

6.00

.00

.44

.00

.44

.81

2.31

3.81

4.19

4.62

.50

.25

.00

.62

2.56

1.03

4.00

10.00

9.125

8.00

.281 DIA THRU (4)

.428

1. 00

4.62

3.75

3.385

3.00

.435

.618

.810

3.308

3.385

#8-32 UNC-2B THRU

.25 X .25 Chamfer (4)

.38/35

.281 DIA THRU

3/8-16 UNC-2B THRU

.25 X .25

Chamfer (4)

#8-32 UNC-2B THRU (4)

.281 DIA THRU

.00

LX 500

LX 1500

The installation should then be checked with the specimen installed by

monitoring the reflection pulses at the Signal Output jack using an oscilloscope

per the procedure described in the Operation section of this manual under

Monitoring the Reflection Pulses.

Tripod Mou nting Adapter

LX Laser Extensometer Installation

31

Page 32

Mechanical Mounting

Side View

90º

Specimen

Scan Line

Viewed from the Side

Front View

Target #2

edge

Target #1

edge

Specimen

Scan Line

80º

Laser Extensometer Front Panel

Scan Line

Target Distance

Eliminating Spurious

Reflection Problem

Rotate specimen as shown to direct

spurious reflections away from the

scan line.

Spurious Reflection

Specimen

Top View

90º

Specimen

Top View

Laser Extensometer Front Panel

Scan Line

Target Distance

Spurious Reflection

Potential Spurious

Reflection Problem

Eliminating Spurious

Reflection Problem

Specimen

Target Distance

Rotate laser extensometer as shown

to direct spurious reflections away

from the scan line.

Top View

80º

Laser Extensometer Front Panel

Scan Line

Spurious Reflection

Scan Line Orientation on Specimen

32

Installation

LX Laser Extensometer

Page 33

Electrical Connections

The Series LX Laser Extensometers are connected to line voltage power using

the grounded cord provided.

The Analog Output signal, the Remote Laser Disable signal, and the Serial I/

O Port connections are made via the modular jacks located on the control panel

of the instrument. Note these jacks have 6 pins but only 4 pins are used. A

standard RJII 4-pin telephone type Modular Plug will mate with them and

automatically make contact only with the 4 active pins (pins 2, 3, 4, and 5).

For EMC compliance, when installing the LX 500 and LX 1500 Laser

Extensometers all cable connections must use shielded cables (this includes the

RJ11 modular plug connections and the AC Line Cord connections to the Laser

Extensometer). The shield must be tied to earth ground. The case of the Laser

Extensometer is also earth-grounded.

Note No external cables are to be connected to the BNC connector on the

Laser Extensometer because this is only a “test” connector and is not

normally used.

Electrical Connections

Modular Jack Pin Identification

Face the controls side of the laser extensometer. The notch in the jack is on the

left and the pins are numbered vertically, in sequential fashion, from 1 to 6 with

pin number 1 at the top.

Both the analog output signal and the remote laser disable signal connections are

located on the Analog Output jack. The Analog Output modular jack uses only

4 pins:

• pin 1 no connection

• pin 2 analog output (-) (gnd)

• pin 3 remote laser disable (-)

• pin 4 analog output (+)

• pin 5 remote laser disable (+)

• pin 6 no connection

LX Laser Extensometer Installation

33

Page 34

Electrical Connections

The laser extensometer must be configured in order for the remote laser disable

function to operate; contact MTS for configuration information. A 5 V level must

be applied across pins 5 and 3 to turn the laser on. Removing the applied 5 V

level turns the laser off.

The serial input/output connects to the modular jack labeled Serial I/O Port

located on the controls side of the instrument. The Serial I/O Port modular jack

uses only 4 pins:

• pin 1 not used (reserved)

• pin 2 gnd

• pin 3 transmit data

• pin 4 receive data

• pin 5 gnd

• pin 6 no connection

An accessory cable assembly (7.6 m [25 ft.], MTS part number

056-128-904) is available with a standard 9-pin D female connector for direct

connection to the serial port of an IBM compatible PC; contact MTS for

additional information.

34

Installation

LX Laser Extensometer

Page 35

Operation

CAUTION

Laser radiation present.

Before attempting to operate instrument:

• Read and understand the entire manual

• Follow all safety precautions and warning labels

• Do not stare directly into beam

• Use caution when measuring reflective parts

• Do not stare into reflected beam

The Series LX Laser Extensometers must be installed as described in the

Installation section of this Manual. The unit works by sensing reflections from

retro-reflective tape strips applied to the specimen. T wo tiny strips are attached to

the specimen, one at each end of the gauge length. These function as targets and

the laser extensometer, via the scanning laser beam, determines the distance

between selected edges of these targets.

LX Laser Extensometer Operation

35

Page 36

Target Types and Considerations

Target Types and Considerations

Basically , targeting the specimen is accomplished by either attaching tape strips

directly to the specimen or by applying the tape strips to tiny spring clips and

attaching these spring clips to the specimen. The spring clip type target is

reusable. Care must be taken to ensure no damage occurs to the retro-reflective

surfaces during use.

Note Some medical researchers have attached reflective tapes with surgical

sutures. Others have used a general purpose adhesive (such as Super

Glue).

The retro-reflectivity of both targets must be approximately the same. This will

be the case as long as the surface of both targets is kept clean, dry, and

undamaged. However, if the surface is damaged or if there is a buildup of foreign

matter, the targets must be replaced. It is advisable to replac e both tar gets as a set

(that is, do not replace individually).

In general, the target width should be kept as small as possible. However, if the

targets are too narrow, problems can arise. These potential problems can be

avoided by observing the minimum recommended target width of 1.02 mm

(0.040 in).

36

Operation

LX Laser Extensometer

Page 37

Target Placement

Depending on the measurement mode selected, the laser extensometer measures

the distance between the front edges of targets T

the front edges of targets T

each scan.

The target edges are labeled as follows:

• T

• T

• T

• T

and T2, T2 and T3, T3 and T4 successively during

1

is the front edge of target 1

1

is the front edge of target 2

2

is the front edge of target 3

3

is the front edge of target 4

4

Target Placement

and T2, or the distance between

1

In the T

- Tl measurement mode, the targets T1 and T2 are positioned such that

2

the front edges are coincident with the gauge length. In the multisegment

measurement mode, the targets T

the front edges of T

and T4 aligned with the gauge length.

1

, T2, T3, and T4 are arranged sequentially with

1

LX Laser Extensometer Operation

37

Page 38

Monitoring the Reflection Pulses

Reflection from

Target #2

Reflection from

Target #1

Normal reflection pulses viewed

on the oscilloscope at the Signal

Output jack on the control panel.

Spurious reflection pulse

viewed on the oscilloscope

at the Signal Output jack on

the control panel.

Direction of

Elongation

Front View

Target #2

edge

Target #1

edge

Specimen

Scan Line

Monitoring the Reflection Pulses

Connecting an oscilloscope to the Signal Output BNC connector allows the

reflection signal to be monitored. This is very handy during setup or

troubleshooting, especially when checking for spurious reflections from the

specimen.

Set the oscilloscope controls as follows:

• Time Base = 1 msec per division

• Amplitude = 2 V per division

• Trigger = Positive Slope

Adjust the oscilloscope trigger level until there are two pulses of 5 V amplitude

with sharp edges and flat tops; see “Reflection Pulses” below. Any additional

pulses indicate the presence of spurious reflections which must be identified and

eliminated for proper operation of the instrument.

Spurious reflections usually result from scanning orthogonally to shiny, flat

surfaces. These reflections can typically be eliminated by rotating the offending

surface a small amount (≈5° to 10°) about the axis of the scan line; see “Scan

Line Orientation on Specimen” on page 32.

38

Operation

Reflection Pulses

LX Laser Extensometer

Page 39

Using the Instrument

The laser extensometer can be controlled from the keypad on the control panel of

the instrument or from the Serial I/O Port via a remote computer. Serial

operation is covered in the Using the Serial Interface section of this manual.

Setting the Operating Parameters from the Key Pad

There are two modes of operation, the Setup mode and the Run mode. When the

laser extensometer is powered up it automatically enters the Run mode. In order

to change operating parameters, the unit must be placed in the Setup mode.

1. Attach the line cord and apply power to the unit and turn power switch to

“ON”. The LCD display will illuminate.

2. From the Run mode, press the Select button and the Scroll button

simultaneously. This causes the laser extensometer to enter the Setup mode

with the first menu Item appearing on the LCD display.

3. In the Setup mode, the Select button is used to select and accept major

items from the Setup menu while the Scroll button is used to change the

value of the item selected in the Setup menu.

Using the Instrument

4. After the selected menu item has been scrolled to a different value, the

Select button must then be pressed to accept this new value.

5. Press the Run button to return to the Run mode. Please Wait can appear

temporarily on the LCD display depending on the parameters changed in the

Setup mode.

LX Laser Extensometer Operation

39

Page 40

Using the Instrument

Description of the Operating Parameters

In Setup Mode, the selected parameter appears on the top line of the LCD display

along with its corresponding value appearing on the bottom line. A detailed

description of each parameter is given below.

1. Select Units - sets the units to Inches or Millimeters.

2. Analog Output - sets the full-scale range of the Analog Output. Because

the Analog Output has 16-bit resolution and is updated continuously at a

rate of 100 times per second, it can be used as a strain feedback signal for

closed loop applications. The full scale range of the Analog Output

depends on the system of units set in the Select Units parameter. The fullscale range choices for the LX 500 are:

0.1 in = 10 V (5 V) (for inch units)

2.0 mm = 10 V (5 V) (for mm units)

0.2 in = 10 V (5 V) (for inch units)

5.0 mm = 10 V (5 V) (for mm units)

0.5 in = 10 V (5 V) (for inch units)

10 mm = 10 V (5 V) (for mm units)

40

Operation

1.0 in = 10 V (5 V) (for inch units)

20 mm = 10 V (5 V) (for mm units)

2.0 in = 10 V (5 V) (for inch units)

50 mm = 10 V (5 V) (for mm units)

5.0 in = 10 V (5 V) (for inch units)

100 mm = 10 V (5 V) (for mm units)

Note The full-scale range choices for the LX 1500 are:

0.1 in = 10 V (for inch units)

2.0 mm = 10 V (for mm units)

through

20 in = 10 V (for inch units)

500 mm = 10 V (for mm units)

Six intermediate ranges are also included.

3. Target Distance - Sets the Target Distance. This is the distance from the

front panel of the Laser Extensometer to the targeted surface of the

specimen. This parameter depends on the system of units set in the SELECT

UNITS parameter. The choices appear on the LCD display.

LX Laser Extensometer

Page 41

Using the Instrument

4. # Scans Averaged - Sets the number of scans over which the elongation

measurements are averaged. The laser extensometer uses a moving window

method of averaging which allows smooth performance. Increasing the

number of scans averaged improves resolution and slows response time

(that is, bandwidth) of the elongation measurement. The choices are as

follows:

2 Scans Averaged

4 Scans Averaged

8 Scans Averaged

16 Scans Averaged

32 Scans Averaged

64 Scans Averaged

128 Scans A veraged

256 Scans A veraged

512 Scans A veraged

LX Laser Extensometer Operation

41

Page 42

Using the Instrument

5. Measurement Type - Sets the type of Measurement performed. The laser

extensometer measures the distance between the front edge of each target.

The target edges are labeled as follows:

= front edge of target 1

T

1

= front edge of target 2

T

2

= front edge of target 3

T

3

= front edge of target 4

T

4

The choices for measurement type are:

- TI distance between front edges of first two targets (T1 and T2)

T

2

MULTISEGMENT = simultaneous measurement of the 3 intervening

segments between front edges of targets T

- T1 = distance between front edges of first and second targets (T1 and

T

2

T

).

2

- T2 = distance between front edges of second and third targets (T2 and

T

3

T

).

3

--T2--T3--T4 respectively.

l

- T3= distance between front edges of third and fourth targets (T3 and T4).

T

4

For the T

- T1 measurement type setting, only two targets are required.

2

These targets are positioned such that the front edges are coincident with the

gauge length.

For the Multisegment measurement type setting all four targets are

required. They are arranged sequentially within the gage length and define

the three segments over which the measurements are taken. Segment 1 is

intervening distance between front edges of first two targets (T

-T1).

2

Similarly, Segment 2 is the distance between front edges of the second and

third targets (T

the third and fourth targets (T

-T2) and Segment 3 is the distance between front edges of

3

- T3). All three segments are measured

4

simultaneously. However, they are only available simultaneously over the

serial input/output port. Only one segment at a time can be monitored at the

Analog Output and on the LCD display. The segment being monitored is

indicated by a 1, 2, or 3 in the lower left corner of the LCD display. A 1

indicates the first segment (T

T

), and a 3 indicates the third segment (T4 -T3). Use the Scroll button to

2

-T1.), a 2 indicates the second segment (T3 -

2

select the segment you want to monitor; a segment displayed on the LCD

display is also applied to the Analog Output. The Zero button zeroes all

three segments simultaneously.

42

Operation

LX Laser Extensometer

Page 43

Using the Instrument

6. External Receiver - Sets up the laser extensometer to accept input from the

optional External Scan Receiver Unit. This optional accessory is useful for

applications where it is necessary to shoot through the specimen. It is

usually mounted behind the specimen in order to measure portions of the

scanning laser beam shadowed by the specimen. The External Scan

Receiver Unit must be connected before its use by the laser extensometer

can be enabled.

The choices for External Receiver are:

– enabled - External Receiver connected and enabled for use by laser

extensometer.

– disconnected - External Receiver not connected and can not be

enabled for use by the laser extensometer.

– disabled - External Receiver is connected but its use by the laser

extensometer is disabled (that is, not used).

7. BAUD - Sets the BAUD for the Serial I/O Port. The choices are: 9600,

4800, 2400, and 1200.

LX Laser Extensometer Operation

43

Page 44

Using the Instrument

CAUTION

Measuring Elongation

Do not stare directly into the beam.

Use caution when measuring reflective parts. Do not stare into reflected beam.

1. With the line cord attached and power applied to the unit, turn power switch

to O position. The LCD display will illuminate.

2. Set the laser disable switch to the Laser On position.

3. Set the operating parameters to the desired values using the procedure

previously described. Make certain that the target distance has been set to

the proper value.

4. Attach the retro-reflective targets to the specimen using the desired method

described previously under Target Types and Considerations.

5. Install the specimen to be measured in the test machine. Make certain that

the specimen is located at the proper target distance from the laser

extensometer and that the gauge length of the specimen lies well within the

length of the scan line.

6. Attach oscilloscope to Signal Output jack and check for proper reflection

signal following the procedure described earlier under Monitoring the

Reflection Pulses.

7. Attach a monitoring device (for example, chart recorder, data logger, system

controller, etc.) to the Analog Output jack of the laser extensometer, if

desired. Be certain the monitoring device is properly adjusted to accept the

elongation signal from the laser extensometer.

8. Observe the reading on the LCD display. Press the ZERO key to offset the

reading to zero, if desired, and begin the test. The elongation is displayed on

the LCD display in the chosen system of units. If, for some reason, there is a

problem with the reflection signal (that is, missing or extra reflection pulses)

invalid will appear on the LCD display.

44

Operation

LX Laser Extensometer

Page 45

Using the Serial Interface

This feature allows information to be read from and written to the laser

extensometer by a Host computer with a standard serial communications port.

The measured specimen displacement displayed on the LCD readout (that is, the

output of the laser extensometer) is reported as an ASCII value from -99999 to

+99999 (that is, 5 numerical characters with polarity sign and no decimal point)

back to the host computer via the serial input/output port.

When the laser extensometer is powered up it transmits the prompt character (:)

over the serial input/output port indicating that it is ready to receive a Command.

If the command received is not valid, the laser extensometer returns a ? followed

by a : (that is, the prompt character) to alert the host that it did not understand the

command received and is waiting for another. Valid commands execute as

described in the Command List section below.

Note The prompt character (:) is returned:

-after executing a valid command.

-after responding to an invalid command (see above).

-after receiving only a carriage return from the host.

Using the Serial Interface

LX Laser Extensometer Operation

45

Page 46

Serial I/O Port Cable Connections

Serial I/O Port Cable Connections

Connection to the Serial I/O Port on the laser extensometer is straight forward.

DTR/DSR and RTS/CTS handshaking requirements are not implemented and

only three wires are required for operation. An accessory cable assembly is

available for direct connection to the serial port of an IBM compatible PC. It is

supplied with a standard 9-pin D female connector on one end and a 4-pin RJ11

modular plug on the other. Contact MTS for additional details.

Serial I/O Port Interconnection Cable Wiring

ERIAL I/O PORT MODULAR JACK PC COMPATIBLE 9-PIN D CONNECTOR

S

Gnd pin 2, 5 pin 5 Gnd

Tr pin 3 pin 2 Rcv

Rcv pin 4 pin 3 Tr

Note See Electrical Connections section for modular jack pin identifications.

46

Operation

LX Laser Extensometer

Page 47

Communications Parameters

The communications parameters of the serial input/output port are:

• 1 Start Bit

• 1 Stop Bit

• 8 Data Bits

• No Parity

• Baud: 9600, 4800, 2400, or 1200

Baud is the only selectable parameter of the serial input/output setup. It is

selected manually from the Setup mode using the control panel keypad.

The Echo is normally set to OFF but it may be turned ON or OFF by a command

given over the Serial I/O Port.

Serial I/O Port Cable Connections

LX Laser Extensometer Operation

47

Page 48

Serial I/O Port Cable Connections

Control Commands for Serial Input/Output Port

The MTS Series LX Laser Extensometers use all capital letter commands. The

general command syntax is a single capital letter command followed by a

parameter (optional) and a carriage return. The command writes the parameter to

the laser extensometer if the proper parameter is present. If the parameter is

omitted (that is, a single letter command followed by a Carriage Return), the

current value of the parameter for that command is read back. A list of these

commands appears below.

Command List* (part 1 of 4)

OMMAND DESCRIPTION

C

E1 Echo ON Turns the Echo ON so that everything received by the laser extensometer is echoed back

to the Host computer (that is, the sender).

E0 Echo OFF Turns the Echo OFF so that nothing received by the laser extensometer is echoed back to

the Host computer (that is, the sender).

Z1 Zero ON Turns on the Zero Offset mode. Current Displacement Value is zeroed. Subsequent

displacements are referenced to this zero point (that is, same effect as manually pressing

Zero key on control panel of unit).

Z0 Zero OFF Turns off the Zero Offset mode.

UI Units in Sets the units to inches.

UM Units mm Sets the units to millimeters.

* These commands use capital alphanumeric characters.

Operation

48

LX Laser Extensometer

Page 49

C

OMMAND DESCRIPTION

Serial I/O Port Cable Connections

Command List* (part 2 of 4)

An Analog

Out

Sets the full scale range of the Analog Output. This command depends on which system

of units was set via the Units command. The number after the command specifies the

scale factor. The scale factor is a numeric value from 1 to 6. The choices are listed below.

Note The 5 V value in A1 through A6 only applies to the LX 500. A7 and A8 only

applies to the LX 1500.

Al Sets Range to: 0.1 in = 10 V (5 V) (for inch units)

2.0 mm = 10 V (5 V) (for mm units)

A2 Sets Range to: 0.2 in = 10 V (5 V) (for inch units)

5.0 mm = 10 V (5 V) (for mm units)

A3 Sets Range to: 0.5 in = 10 V (5 V) (for inch units)

10 mm = 10 V (5 V) (for mm units)

A4 Sets Range to: 1.0 in = 10 V (5 V) (for inch units)

20 mm = 10 V (5 V) (for mm units)

A5 Sets Range to: 2.0 in = 10 V (5 V) (for inch units)

50 mm = 10 V (5 V) (for mm units)

A6 Sets Range to: 5.0 in = 10 V (5 V) (for inch units)

100 mm = 10 V (5 V) (for mm units)

A7 Sets Range to: 10.0 in = 10 V (for inch units)

200 mm = 10 V (for mm units)

A8 Sets Range to: 20.0 in = 10 V (for inch units)

500 mm = 10 V (for mm units)

Tn Target

Distance

Sets the target distance (that is, the distance from the front panel of the l aser extens ometer

to the front surface of the retro-reflective target on the specimen). This command depends

on which system of units was set via the Units command. The number after the command

specifies the target distance selection. The target distance selection is a numeric value.

The distance choices are:

LX500: T1 = 381 mm (15 in), T2 = 304 mm (12 in)

LX1500: T1 = 457 mm (18 in), T2 = 381 mm (15 in)

* These commands use capital alphanumeric characters.

LX Laser Extensometer Operation

49

Page 50

Serial I/O Port Cable Connections

OMMAND DESCRIPTION

C

Command List* (part 3 of 4)

Sn Scans

Averaged

Mn Measurem

ent Type

Sets the number of scans over which the measurements are averaged. The choices are as

follows:

S1 2 Scans Averaged

S2 4 Scans Averaged

S3 8 Scans Averaged

S4 16 Scans Averaged

S5 32 Scans Averaged

S6 64 Scans Averaged

S7 128 Scans A veraged

S8 256 Scans A veraged

S9 512 Scans A veraged

Sets the Measurement Type. The number after the command specifies the choice for this

parameter and is a numeric value from 1 to 9 or the letter A as follows:

M1 T

M2 Reserved (T

M3 Reserved (T

-T1 mode

2

- T1)

3

- TI)

4

M4 Reserved (T

M5 Reserved (T

M6 Reserved (T

M7 Reserved (Curve Fit T

M8 Reserved (Curve Fit T

- T2)

3

- T2)

4

- T3)

4

)

1

)

2

M9 Reserved (Tsw)

MA Multisegment mode

L0 Laser OFF Disables the laser beam scanning.

L1 Laser ON Enables the laser beam scanning.

* These commands use capital alphanumeric characters.

Operation

50

LX Laser Extensometer

Page 51

Serial I/O Port Cable Connections

Command List* (part 4 of 4)

OMMAND DESCRIPTION

C

R Read Data Read specimen displacement expressed in the unit system selected by the Units

Command. This command reports the specimen displacement displayed on the LCD

readout as an ASCII value from -99999 to +99999 (that is, five numerical characters with

polarity sign and no decimal point). This command is read only.

Note 1.If the R command is executed and the laser extensometer is busy (that is, when

Please Wait is displayed on the LCD and no displacement readings are

available), then a * will be returned.

2.If the R command is executed and the displacement reading on the Laser

Extensometer is Invalid (that is, when Invalid is displayed on the LCD), then a 1

will be returned.

3.If the R command is executed in the Multisegment mode, the displacement of

all three segments is returned simultaneously (that is, T

- T1, T3 - T2, T4 - T3).

2

B Read

Binary

C Read

Counts

X External

Receiver

Read specimen displacement expressed in the unit system selected by the Units

command. This command reports the specimen displacement displayed on the LCD

readout as a binary value (that is, a 3-byte word in two's compliment, LSB first, no

decimal point). This command is read-only.

Note If the B command is executed in the Multisegment mode the displacement of all

three segments is returned simultaneously (that is, T2 - T1, T3 - T2, T4 - T3,

respectively). The data is transmitted with no spaces between each 3-byte word

(that is, nine bytes total).

Returns raw count value of T1. This command is for factory use and is only functional

with the Curve Fit T

measurement type. If the C command is executed in any other

1

mode, a ? is returned. This command is read-only.

Note 1.If the C command is executed and the laser extensometer is busy (that is, when

Please Wait is displayed on the LCD and no displacement readings are available)

then a * will be returned.

2.If the C command is executed and the displacement reading on the laser

extensometer is invalid (that is, when Invalid is displayed on the LCD) then a ! will

be returned.

Check if external scan receiver unit is present. This command is read-only.

0 is returned if not connected.

1 is returned if connected.

* These commands use capital alphanumeric characters.

LX Laser Extensometer Operation

51

Page 52

Calibration

Calibration

Important The calibration procedure alters the output readings of the

instrument and must be performed by qualified personnel only.

Note Calibration is performed under software control from the outside of the

unit. It is NOT necessary to access any internal components of the

instrument.

This following procedure sets the slope and offset calibration constants used by

the laser extensometer in calculating the elongation readings. Within the laser

extensometer, the raw internal readings are applied to a linear function of the

form

Y=Mx

where: x is the raw data to be calibrated,

M is the slope correction factor, and

Y is calibrated output.

If desired, the calibration constants can be defeated by following the procedure

described later.

52

Important

Considerations

Operation

Note Entry into Calibrati on mode is permitted only when the laser

extensometer is in the (T

Before commencing the calibration procedure, be certain to set all operating

parameters properly and allow the laser extensometer to run for at least one hour

to ensure it is thoroughly warmed up. You must perform the calibration for the

measurement type T

laser extensometer. It is recommended that the calibration procedure be

performed in situ with the laser extensometer installed on the test machine and

the calibration fixture installed in place of the specimen.

Handle the calibration fixtures carefully. Keep them clean. It is especially

important to keep the retro-reflective surfaces of the calibration targets clean and

free of any dirt, film, fingerprints, etc.

-Tl at the exact target distances where you are operating the

2

- T1) measurement mode.

2

LX Laser Extensometer

Page 53

Entering the Calibration Mode

1. With the laser extensometer powered up and running, be certain that the

target distance parameter is properly set. The calibration must be performed

at the exact target distance, where the laser extensometer is operated. Also

be certain that the proper measurement type is set in the Setup mode.

Calibration must be performed for the measurement type being used.

Note Access to the calibration mode is permitted only for measurement types

T2 - T1. Each of these measurement types requires its own individual

calibration.

2. Install the calibration fixture properly at the target distance where the

calibration is to be performed. Ideally, calibration should be performed inplace on the test machine with the calibration fixture installed instead of the

specimen.

3. Adjust the digital micrometer head of the calibration fixture until the

calibration targets are at the desired starting position (usually 0.125 inch

apart) in the measurement area, taking care to remove any backlash in the

micrometer. Zero the reading on the digital micrometer head of the

calibration fixture. This is now the zero reference position of the calibration

fixture.

Calibration

4. Go into the Setup mode by simultaneously pressing the Select and Scroll

buttons.

5. Press Select button until the serial number screen appears on the LCD

display.

6. While holding in the Zero button, press Select and Scroll buttons

simultaneously. The re-calibrate screen will appear on the LCD display.

Note Press Run to exit without disturbing the existing calibration state of the

laser extensometer.

7. Press the Select button, the set lower length screen is now displayed on the

LCD display. This value sets the displacement of the lower calibration point

from the zero reference position of the calibration fixture; 0.0000 is the

default value.

8. Press the Select button to accept the displayed value, or, use the Scroll

button change it. The value is incremented by using the Scroll button alone

and decremented by holding the Zero button depressed while using the

Scroll button. After setting the desired value, press the Select button to

continue.

LX Laser Extensometer Operation

53

Page 54

Calibration

9. The Set Upper Length screen is now displayed on the LCD display. This

value sets the displacement of the upper calibration point from the zero

reference position of the calibration fixture; 1.0000 is the default value.

10. Press the Select button to accept this value, or, use the Scroll button (as

described earlier) to change it. Press the Select button to continue.

11. The Set Zero Offset screen is now displayed on the LCD display.

12. After the reading on the LCD display of the laser extensometer has

stabilized, press the Zero button on the laser extensometer. The reading on

the LCD display of the laser extensometer is now at 0.0000 and if the lower

length calibration point was set to a number other than 0.0000 (in steps 6

and 7), the

move to __ . _____ in screen is displayed (lower length calibration point).

Otherwise, the MOVE TO __ . _____ in screen is displayed (upper length

calibration point).

13. Set the digital micrometer head of the calibration fixture exactly to the value

requested on the LCD display.

14. After the reading on the LCD display of the laser extensometer has

stabilized, press the Select button.

15. If the lower length calibration point was set to a number other than 0.0000

(in steps 6 and 7), the MOVE TO __ . _____ in screen is displayed. Y ou

must set the digital micrometer head of the calibration fixture exactly to the

value requested on the LCD display, and, after the reading on the LCD

display has stabilized, press the Select button. Otherwise, skip over this step

and go directly to step 16.

16. The Calibrate Done screen is now displayed.

17. To save this new calibration and exit to Run mode, press the Run button. T o

go through the calibration procedure again press the Select button.

To Defeat the Calibration Constants

At the CALIBRATE screen, hold the Scroll button in and press the Select button

to defeat the slope calibration constants. This procedure sets the Y=Mx

calibration constants as follows: M, the slope correction factor, is set to 1.0.

Consult MTS for further information regarding calibration.

54

Operation

LX Laser Extensometer

Page 55

Maintenance

Contents Recommended Maintenance Schedule 56

Component Locations 57

Scan Aperture Cleaning Procedure 59

Replacing the Fuse 60

LX Laser Extensometer Maintenance

55

Page 56

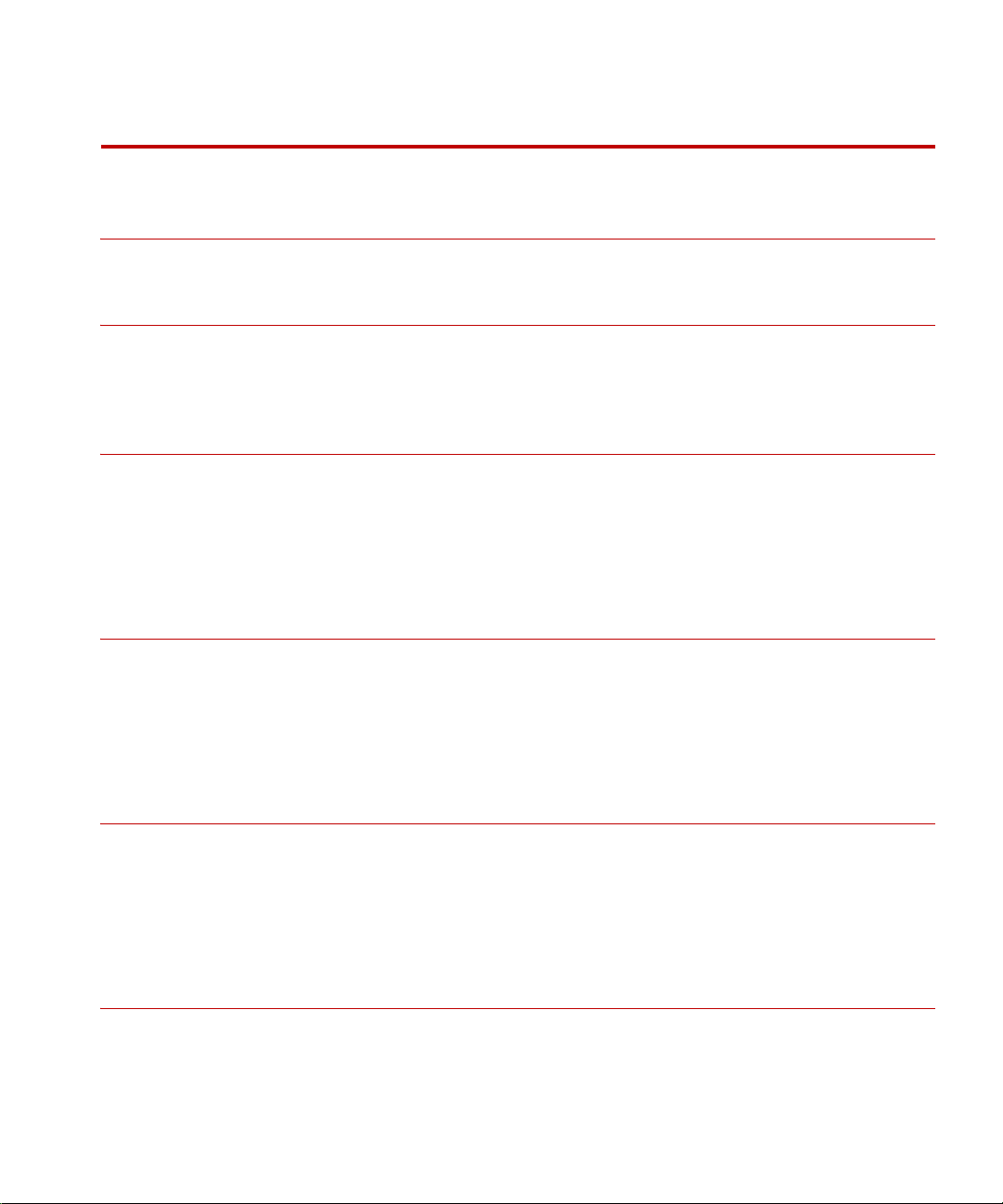

Recommended Maintenance Schedule

Recommended Maintenance Schedule

PROCEDURE FREQUENCY

Safety Check Perform every 6 months.

Scan Aperture Check Depends on environment.

Check elongation measurement

calibration

As required, depends on application.

56

Maintenance

LX Laser Extensometer

Page 57

Component Locations

Manufacture Date

Rev.

Laser Extensometer

Model No.

Serial No.

Assembly No.

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN U.S.A. 55344

Supply Rating

No user serviceable parts inside

V Hz

AVOID EXPOSURE

- Laser radiation

is emitted from this aperature

Laser Radiation Emitted Here

Aperture Label

Identification Label

Top View

Component Locations

LX Laser Extensometer Maintenance

57

Page 58

Component Locations

Keypad Buttons

(Zero, Select, Scroll, Run)

Rear View

LCD Display

Laser Emission Indicator

Laser Disable Switch

Power Entry Module

Warning Logotype

Certification Label

Rear Panel Warning Label

Analog Output Jack

External Receiver Jack

RS-232 Jack

Serial Output Jack

Maintenance

58

LX Laser Extensometer

Page 59

Scan Aperture Cleaning Procedure

CAUTION

Turn the power switch off and disconnect the line cord from the AC power

line.

Be sure power is disconnected before attempting to check or clean the scan

aperture.

The scan aperture must be kept clean. Any buildup of dirt, film, or smudges on

the scan aperture window will affect performance of the laser extensometer.

Periodically check the scan aperture and clean as follows:

1. Make sure unit is off and disconnected from AC power line. Make sure laser

emission indicator is off.

2. Visually inspect the scan aperture window. If dust is present, clean with an

anti-static lens cleaning brush or with clean, dry, filtered air duster available

in small pressurized containers (such as those used for cleaning

photographic lenses).

Scan Aperture Cleaning Procedure

3. If film or smudges are present, use a soft lens cleaning tissue saturated with

isopropyl alcohol. Wipe gently in one direction. Then use a dry lens

cleaning tissue to gently wipe the window dry.

4. Visually inspect the window and repeat the cleaning procedure if required.

LX Laser Extensometer Maintenance

59

Page 60

Replacing the Fuse

CAUTION

CAUTION

Replacing the Fuse

Turn the power switch off and disconnect the line cor d fro m the AC power

line.

Be sure power is disconnected before attempting to replace any fuses.

1. The fuse holder is in the power entry module which is located on the rear

panel. The AC line cord MUST be removed from the power entry module in

order to open fuse compartment.

2. Insert small screw driver blade into slot above POWER SWITCH and

carefully pry open fuse compartment cover and pull out fuse drawer.

3. Remove fuse from fuse drawer, inspect, and replace fuse if necessary with a

new one of the same type and rating.

60

Maintenance

Replace fuses only with the specified type and rating.

Using incorrect fuses present a safety hazard and damage the instrument.

4. Reinstall the fuse drawer and close the fuse compartment cover.

LX Laser Extensometer

Page 61

Page 62

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...