Page 1

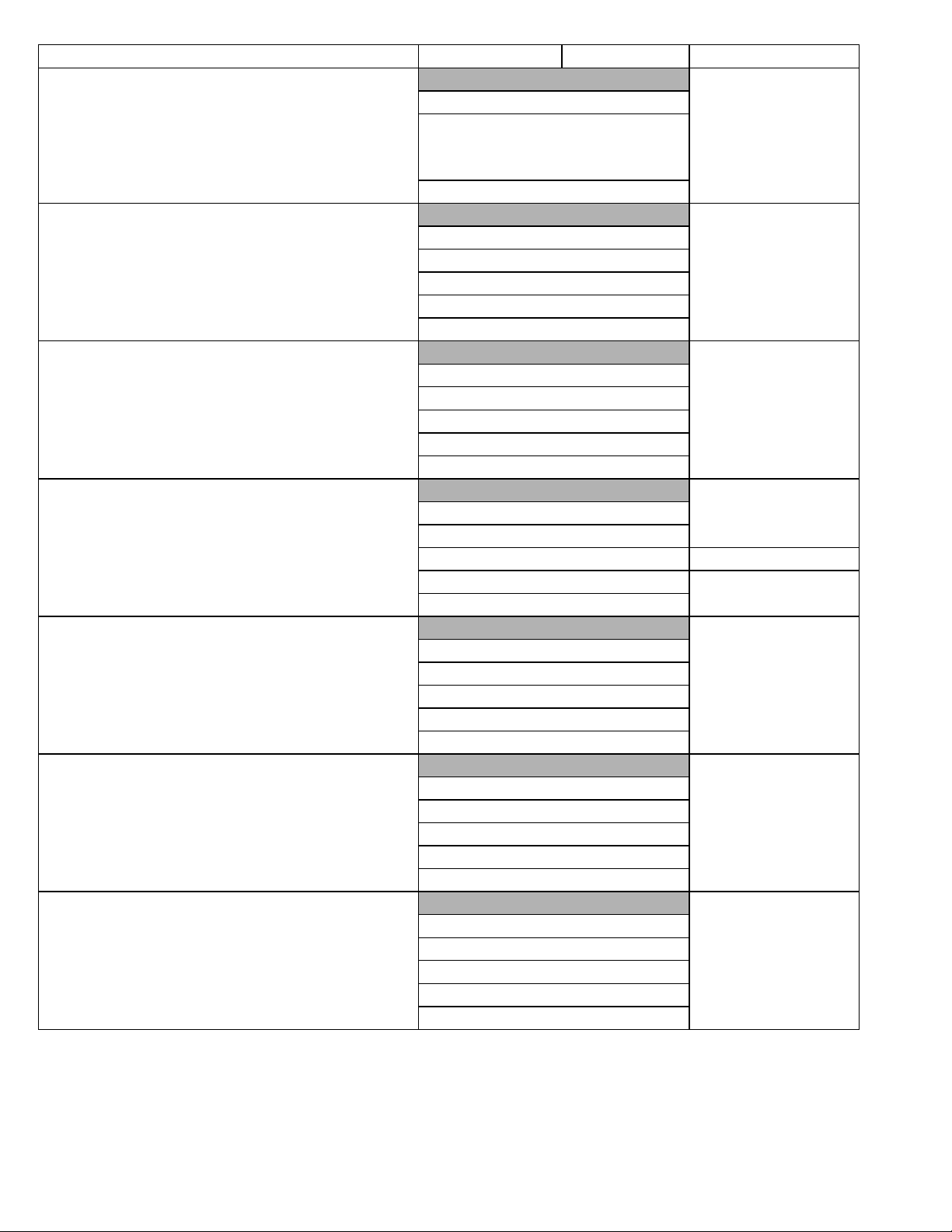

Service Bulletin List

No. Subject Date

MSB-97E26-001 CHANGE OF FRONT ROTOR FOR ABS

EQUIPPED VEHICLES (REVICED)

MSB-97E37-003 CHANGE IN TIE ROD NUT TIGHTENING TORQUE

VALUES

MSB-97E52-001 ADDITION OF SRS AIR BAG MAINTENANCE

PROCEDURE

MSB-98E00-011 CHANGE IN YEAR MODEL FOR ´99 PAJERO 1998-10-15

MSB-98E27-001 CHANGE OF ABS REAR ROTOR 1998-06-15

MSB-98E37-002 NEW SERVICE PROCEDURE FOR POWER

STEERING GEARBOX

MSB-98E42-502 CORRECTING MINIMUM ENTRAPMENT AMOUNT

FOR POWER WINDOW WITH SAFETY

MECHANISM

MSB-98E54-002 CORRECTION TO ELC 4-SPEED AUTOMATIC

TRANSMISSION CIRCUIT

MSB-99E11-502 CORRECTION OF 4M40 ENGINE IDLE UP SPEED

(FOR ANTI-SKID BRAKE)

MSB-99E16-001 CHANGE OF GLOW PLUG 2000-04-15

MSB-00E31-001 WHEEL BALANCE ADJUSTMENT PROCEDURE 2000-07-15

MSB-00E35-001 CHANGE TO ERASING OF ABS DIAGNOSTIC

CODES

MSB-00E37-501 ADDITION OF STEERING ANGLE ADJUSTMENT

PROCEDURE

1997-12-05

1998-01-16

1997-04-30

1999-08-15

1998-11-30

1998-11-30

1999-11-15

2000-05-30

2000-12-30

Page 2

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

Subject:

WHEEL BALANCE ADJUSTMENT PROCEDURE ALL MODELS 00-00

MSB-00E31-001

No.:

:

2000-07-15

Date

QUALITY INFORMATION ANALYSIS

<Model> <M/Y>

Group:

INFORMATION/

CORRECTION

1. Description:

There have been cases where the troubles failed to be removed completely because of incorrect

balancer machine handling or use of an inaccurately calibrated balancer machine. This Service

Bulletin informs you of the cautions to be taken when handling a balancer machine and the

balance check procedures to prevent such a case from recurring in a dealer.

2. Details:

To solve the problems caused by steering or body vibrations, it is essential to balance the wheels

and tires accurately. For this, the wheel and tire must be accurately centered with respect to the

balancer shaft, and the balancer must also be calibrated accurately.

WHEEL & TIRES

INTERNATIONAL

CAR

ADMINISTRATIO

OFFICE

Draft No.:

T.NITTA - PROJECT LEADER

AFTER SALES SERVICE & CS PROMOTION

99AL121708

Page 3

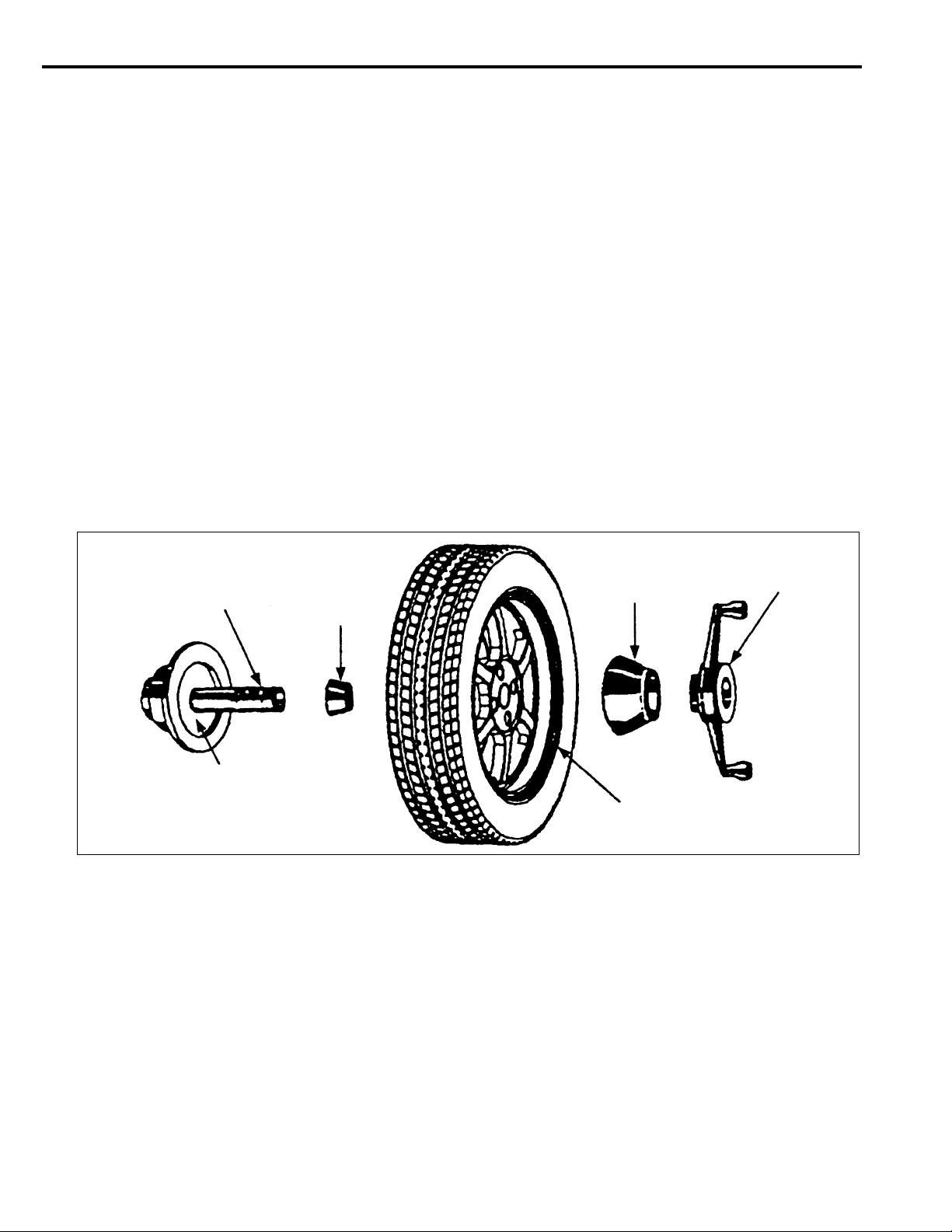

Procedures

1. Check to ensure that the balancer cone and the cone-contacting portion of the wheel are free from any

dirt, corrosion and damage.

Remove all balance weights attached, stones caught in the tire grooves and mud adhered from th

2.

wheel and tire.

Install the wheel and tire to the balancer in the following procedure:

3.

Caution:

The socket diameter of a Mitsubishi genuine wheel is

•

and

107.5 mm (4.23 in) the other types of vehicle. Be sure to use the balancer cone

ɸɸɸɸ

matching the socket diameter.

Use the black-mounted cone to secure the wheel to the balancer if possible. If installable i

•

this method, go to Step 4.

If the socket diameter of the wheel is too large to secure it with the back-mounted cone,

•

secure the wheel to the balancer with the front mounting cone. If the wheel is to be secured in

this way, go to Step 6.

Do not use the log nut hole mounting method because it does not allow the accurat

•

centering of the wheel.

4. When securing with back-mounted cone:

Operate the balancer to measure the imbalance, an attach weight in accordance with the

measurements.

Caution: Be sure to drive the weight straight in the wheel.

67.0 mm (2.64 in) for passenger cars

ɸɸɸɸ

HUB/SHAFT

ASSEMBLY

SPRING PLATE

WHEEL

MOUNTING

CONE

CLAMPING CUP

STANDARD WHEEL

RIM

WING NUT

X0043BY

5. Loosen the wing nut, rotate the wheel half a turn (180°) and tighten the nut again. Then, perform the

measurement again to confirm that the wheel is in balance. If not in balance, check if the balancer is

correctly calibrated. Go to Step 11.

2

Page 4

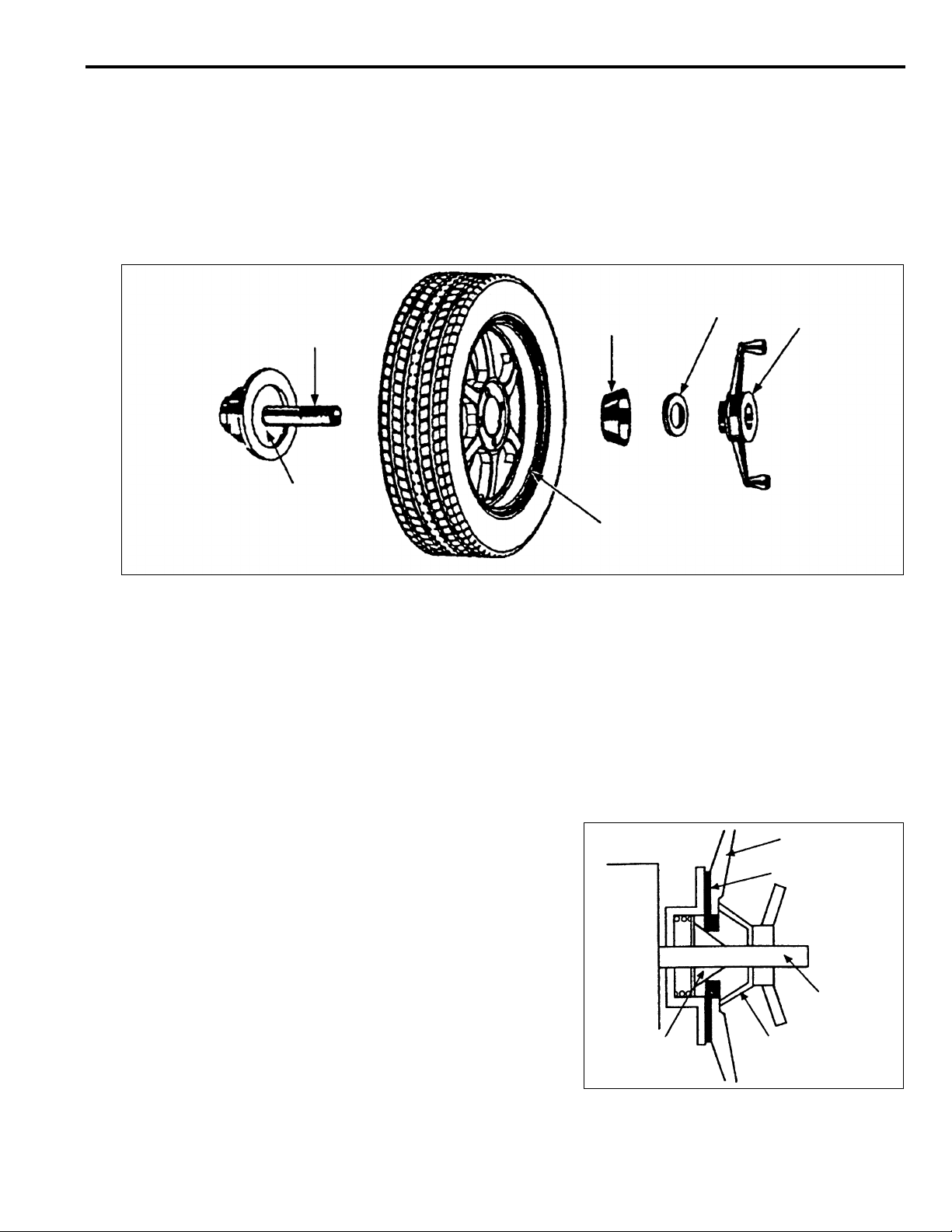

6. When securing with front-mounted cone:

Caution:

When pressing in the cone by tightening the wing nut slowly, hold the tire by hand such that

•

the wheel may contact the spring plate of the balancer evenly.

If this work is not performed with care, the wheel would fail to be centered correctly.

•

Futhermore, the cone-contacting area of the wheel would deform, preventing subsequent

wheel balancing from being performed accurately.

Operate the balancer to measure the imbalance. Mark the point attributable to the imbalance with a

piece of chalk.

(Do not attach any balance weight.)

PRESSURE

RING

WING NUT

HUB/SHAFT-ASSEMBLY

SPRING PLATE

LIGHT TRUCK

MOUNTING CONE

LIGHT TRUCK RIM

X0044BY

7. Loosen the wing nut, rotate the wheel half a turn (180°) and tighten the wing nut carefully again. Then,

perform the measurement again.

8. Repeat the measurement three times in the same manner, and take either of the following measures

according to the measurement again.

Caution: Be sure to drive the weight straight in the wheel.

If the results are the same in all measurements, attach a weight according to the indication on th

a.

machine.

b. If the weight difference among the three measurements is less than 0.5 oz and the thre indicated

points are all within a range of less than 8 inch (30°), attach a weight having the average weight at

the mean position.

c. If the weight difference among the three measurements is 0.5 oz or more or if the indicate

positions are not within a range of less than 8 inch (30°), check if th balancer is correctly calibrated.

Go to step 11.

9. Reinstall the tire to the vehicle, and perform a driving

WHEEL

test. If the tire still generates vibration, perform the Ste

10.

10. Attach the adapter (MB991820) on the back side of th

MB991820

wheel, and install the wheel onto the machine using the

back-mounted cone. Then, perform the balance

adjustment again. For the procedure, refer to Steps 4

and 5

Caution Check to ensure that the contactin

portions of the adapter, wheel and

balancer are free from any dirt, corrosion

and damage.

WHEEL

MOUNTING

CONE

CLAMPING

CUP

HUB/SHAFT

ASSEMBLY

X0045BY

3

Page 5

11. Checking for calibration.

Check your balancer’s calibration approximately every 100 balances. Your whee balancer’s instruction

manual should include calibration procedures. If the calibration procedures specifically for your balancer

are missing, use following steps for zero calibration, static balance, and dynamic balance checks. Th

wheel balancer calibration checks are also described in the flowchart on next page.

a. Mount an undamaged original-equipment alloy rim and tire assembly (wheel) onto your off-the-car

wheel balancer. Balance the wheel.

b.

Zero Calibration Check.

Loosen the balancer wing nut, rotate the wheel a half-turn (180°), and

retighten the nut. Recheck the balance.

i)

If the imbalance is 5 grams or less, the zero calibration is OK. Rebalance the wheel, then g

to Step d to check the static balance.

ii)

If the imbalance is more than 5 grams, go to Step c.

c. Loosen th balancer wing nut, rotate the wheel ¼ turn (90°), and retighten the nut. Recheck th

wheel balance

i)

If the imbalance is 5 grams or less, the wheel may not be centered on th balancer, or the

balancing cones, the cup, and/or wing nut are damaged, dirty, or inappropriate for the wheel.

You may need to refer to th balancer manufacturer’s instructions to verify the correct

attachments. After making the necessary correction, recheck the wheel balance. If OK, then

go to Step d.

ii)

If the imbalance is more than 5 grams, th balancer requires calibration, Contact th balancer

manufacturer for calibration by their repair representative.

d.

Static Balance Check.

Attach a 5-gram weight to the outer rim. Recheck the balancer. The

balancer should detect 5±2 grams of imbalance 170° to190° away from the 5-gram weight.

i)

If the imbalance is within specification, the static balance calibration is correct, Go to Step e

to check the dynamic balance.

ii)

If the imbalance is out of specification, th balancer requires calibration. Contact th balancer

manufacturer for calibration by their repair representative.

e.

Dynamic Balance Check.

Attach a 5-gram weight to the inner rim at 180° opposite the 5-gram

weight that was added in Step d. Recheck the balance. Th balancer should detect 5±2 grams of

imbalance 170° to 190° away from both the inner and outer 5-gram weights.

i)

If the imbalance is within specification, the dynamic balance calibration is correct. Th

balancer calibration checks are complete.

ii)

If the imbalance is out of specification, th balancer requires calibration. Contact th balancer

manufacturer for calibration by their repair representative.

4

Page 6

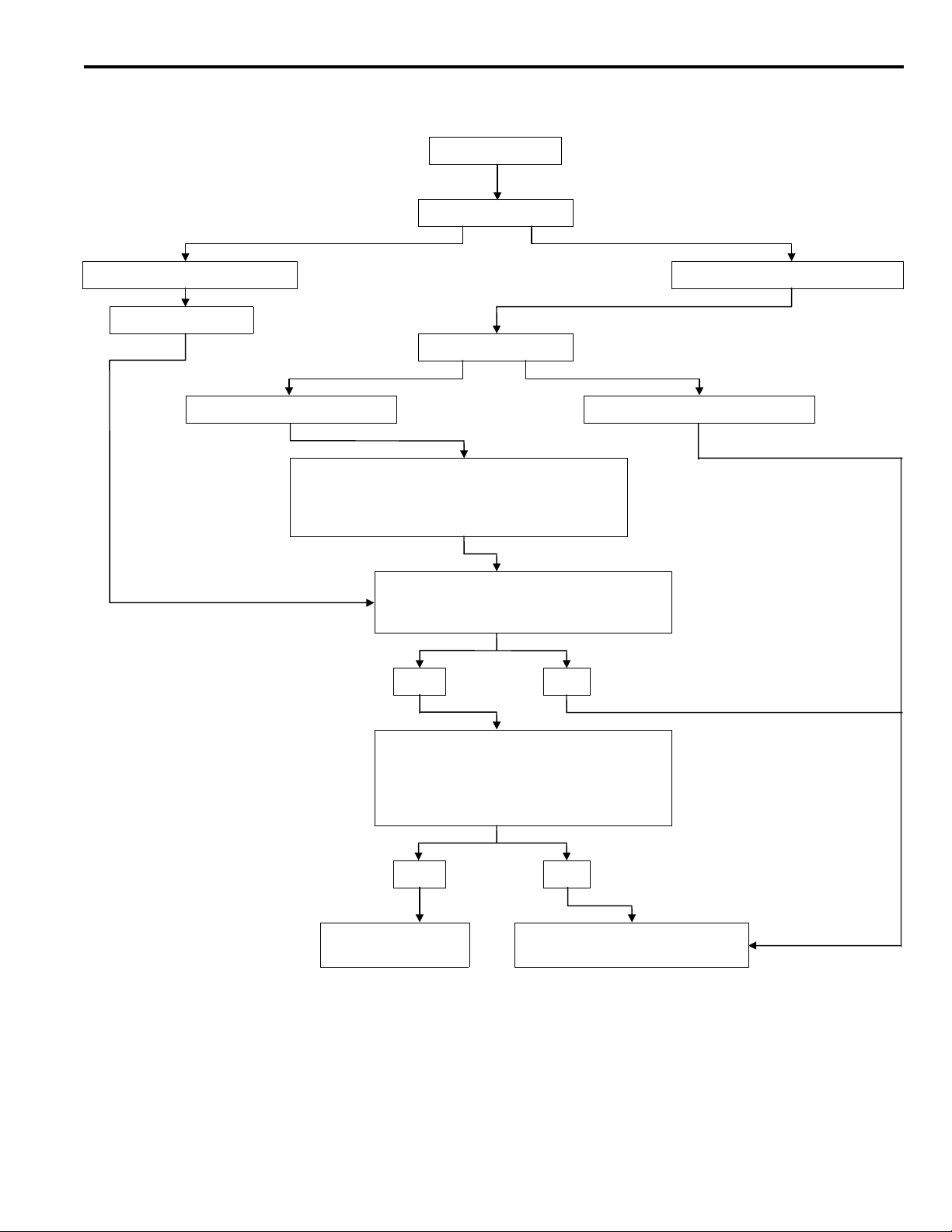

WHEEL BALANCER CALIBRATION CHECKS

Balance Wheel

Rotate wheel ½ turn

Imbalance is 5 grams or less Imbalance = more than 5 grams

Rebalance wheel

Rotate wheel ¼ turn

Imbalance = 5 grams or less Imbalance = more than 5 grams

Verify wheel is properly centered. Verify

cones, cup & wing nut are clean, undamaged &

appropriate for wheel. Make necessary

corrections, then recheck wheel balance

Attach a 5-gram weight to the rim.

Is the imbalance 5 ± 2 grams at 170-190

degrees away from the 5-gram weight?

(Zero Calibration Check)

(static balance Check)

YES NO

Attach a 5 gram weight to the inner rim

180 degrees opposite the weight on the

outer rim. Is the imbalance 5± 2 grams at

170-190 degrees away from both 5-gram

weights?

YES NO

Balancer does not

require calibration.

(Dynamic Balance Check)

Balancer requires calibration.

Contact balancer manufacturer.

5

Page 7

SERVICE BULLETIN

QUALITY INFORMATION ANALYSIS

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

MSB-00E35-001

SERVICE BULLETIN

Subject:

Group:

INFORMATION/

CORRECTION

1. Description:

This Service Bulletin informs you of erasing of the diagnostic codes for the cars mentioned below

that are equipped with the ABS-ECU

2. Applicable Manuals:

CHANGE TO ERASING OF ABS DIAGNOSTIC

CODES

SERVICE BRAKE

INTERNATIONAL

CAR

ADMINISTRATIO

OFFICE

No.:

:

2000-05-30

Date

Draft No.:

T.NITTA - PROJECT LEADER

AFTER SALES SERVICE & CS PROMOTION

99AL122308

<Model>

(EC)COLT/LANCER

(CKOA,CJOA)

(EC)PAJERO

(V10, 20, 30,40)

(EC)L400

(PA0 to PD0)

(EC)PAJERO

SPORT/MONTERO

SPORT

(K80W, K90W)

(EC)L200 (K60, k70)

<M/Y>

96-10

95-10

95-10

99-10

97-10

Manual Pub. No. Language Page(s)

’96 COLT/LANCER PWME9511 (English) 35-6

Workshop Manual Chassis PWMS9512 (Spanish)

PWMF9513 (French)

PWMG9514 (German)

PWMD9515 (Dutch)

PWMW9516 (Swedish)

’95 PAJERO PWJE9086-F (English) 35-36-4

Workshop Manual Chassis Supplement PWJF9088-F (French)

PWJG9089-F (German)

PWJD9090-F (Dutch)

PWJW9091-F (Swedish)

’95 MONTERO

PWJS9087-F (Spanish) 35-36

Workshop Manual Chassis Supplement

’95 L400 PWWE9410 (English) 35B-7

Workshop Manual Chassis PWWS9411 (Spanish)

PWWF9412 (French)

PWWG9413 (German)

PWWD9414 (Dutch)

PWWW9415 (Swedish)

’99 PAJERO SPORT PWJE9812 (English) 35B-4,5

Workshop Manual Chassis PWJF9814 (French)

PWJG9815 (German)

’99 MONTERO SPORT

PWJS9813 (Spanish) 35B-4,5

Workshop Manual Chassis

Page 8

Manual Pub. No. Language Page(s)

’97 L200 PWTE96E1 (English) 35b-5

Workshop Manual Chassis PWTS96E1 (Spanish)

PWTF96E1 (French)

PWTG96E1 (German)

2000 L200 PWTE96E2 (English) 35b-5

Workshop Manual Chassis PWTS96E2 (Spanish)

PWTF96E2 (French)

PWTG96E2 (German)

3. Effective date:

Model Effective Date ABS-ECU part No.

COLT/LANCER From March 1998 MR445910

PAJERO/MONTERO From September 1998 MR400413

L400 From September 1998 MR400415

PAJERO SPORT/

MONTERO SPORT

From the first production car MR235362*, MR307755*,

MR334886*

L200 From September 1998 MR400416, MR400417,

MR4469642*

* Integral Hydraulic unit. These part numbers are for the hydraulic unit.

4. Details:

’96 COLT/LANCER Workshop Manual Chassis (page 3.)

’95 PAJERO Workshop Manual Chassis Supplement (page 5.)

’95 L400 Workshop Manual Chassis (page 7.)

’99 PAJERO SPORT Workshop Manual Chassis (page 9.)

’97 L200 Workshop Manual (page 11.)

’00 L200 Workshop Manual (page 13.)

2

Page 9

SERVICEBRAKES –

ABS Troubleshooting <Vehicles built from June,1994

4. Remedy the malfunctions indicated by th

diagnosis codes, disconnect the diagnosis code

check harness, and then install the valve relay.

Then turn the ignition switch to ON again t

check the ABS warning lamp. (Refer to P.35-36-

16.) If the lamp indicates a malfunction, th

valve relay system may be detective. (Refer to

P.35-36-14.)

ERASING DIAGNOSIS CODES

<Old>

With the MUT-II

Connect the MUT-II to the diagnosis connector (16pin), and then erase the diagnosis codes.

>

35-36-4

Without the MUT-II

Remove the battery cable from the battery (-)

terminal for 10 seconds or more, and the

reconnect the cable.

<New> See next page.

5

Page 10

<New>

With the MUT-II

Connect the MUT-II to the diagnosis connector (16-pin), then erase the diagnosis codes.

Caution

Turn the ignition switch off before connecting or disconnecting the MUT-II.

When diagnostic trouble codes (Nos. 21 to 24) (for vehicle wheel speed sensor system failures) occur,

normal MUT-II operation may not erase those codes. In that case, erase the diagnostic trouble codes

using the following procedures.

1. Perform erasing of the diagnostic trouble codes by special operation of the brake pedal. (See erasing

procedure for the diagnostic trouble codes without use of the MUT-II.)

2. Turn the ignition switch OFF.

3. Perform erasing of the diagnostic trouble codes by use of the MUT-II.

Without the MUT-II

1. Stop the car.

2. Place the stop lamp switch to ON (with brake pedal depressed).

3. Under the condition of 1 and 2 above, turn the ignition switch ON. After that, place the stop lamp

switch to OFF (with brake pedal released) within 3 seconds, and cycle the stop lamp switch ON and

OFF ten times consecutively.

NOTE:

When ABS-ECU stops functioning through the fail-safe mechanism, erasing of the diagnostic troubl

codes cannot be performed.

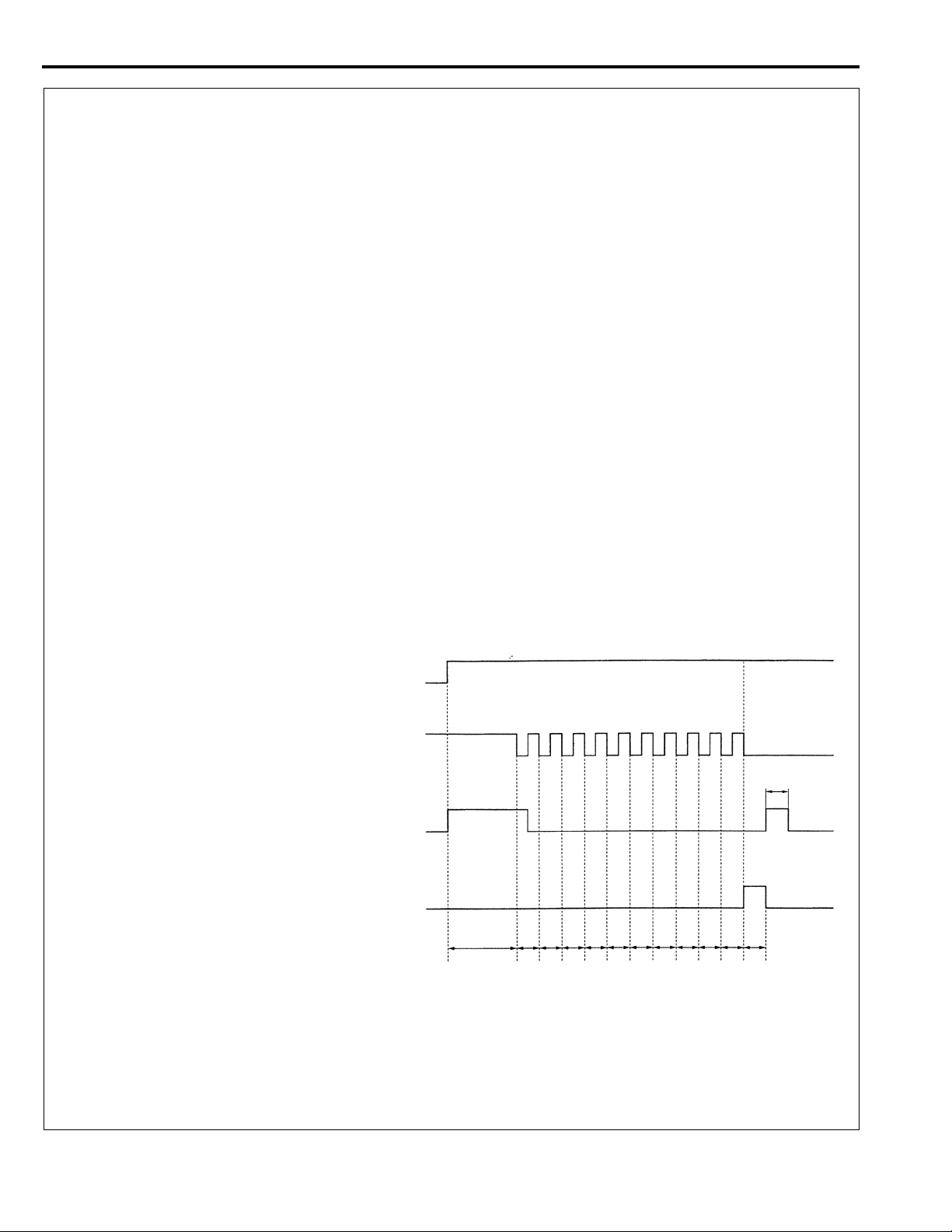

Ignition switch

ON

OFF

Stop lamp switch

ON

OFF

1s

ABS warning lamp

ON

OFF

Diagnostic trouble code memory

Within 3

seconds

Within 1s

1st

Within 1s

2nd

Within 1s

3rd

Within 1s

4th

Within 1s

5th

Within 1s

6th

Within 1s

7th

Within 1s

8th

Within 1s

9th

Within 1s

10th

Erasing completed

AW0558AS

4. Ensure that the diagnostic trouble codes have been erased. When diagnostic trouble codes (Nos. 21

to 24) (for vehicle wheel speed sensor system failures) occur, the above procedures may not eras

those codes. In that case, turn the ignition switch OFF, then repeat steps 1 to 3 above.

6

Page 11

SERVICE BULLETIN

QUALITY INFORMATION ANALYSIS

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

Subject:

Group:

INFORMATION/

CORRECTION

1. Description:

This Service Bulletin informs you that a cautionary description has been added on Steering Angle

Check.

2. Applicable Manuals:

PAJERO

Workshop Manual Chassis

MONTERO

Workshop Manual Chassis

PAJERO

Workshop Manual Chassis

’99 PAJERO SPORT

Workshop Manual Chassis

’99 MONTERO SPORT

Workshop Manual Chassis

Workshop Manual Chassis

’97 L200

Workshop Manual Chassis

’93 L200

Workshop Manual Chassis’97

ADDITION OF STEERING ANGLE

ADJUSTMENT PROCEDURE

STEERING

INTERNATIONAL

CAR

ADMINISTRATION

OFFICE

Manual Pub. No. Language Page(s)

Draft No.: 00SY040517

No.: MSB-00E37-501

Date: 2000-12-30 <Model> <M/Y>

(EC)PAJERO/

MONTERO

(V10, 20, 30, 40)

(EC)PAJERO

SPORT/MONTERO

SPORT

T.NITTA - PROJECT LEADER

AFTER SALES SERVICE & CS PROMOTION

PWJE9086 (English)

PWJS9087 (Spanish)

PWJF9088 (French)

PWJG9089 (German)

PWJD9090 (Dutch)

PWJW9091 (Swedish)

PWJE9812 (English)

PWJS9813 (Spanish)

PWJF9814 (French)’99 PAJERO SPORT

PWJG9815 (German)

PWTE96E1 (English) 37A-7

PWTS96E1 (Spanish)

PWTF96E1 (French)

PWTG96E1 (German)

PWTE9319 (English) 37-14

(K80W, K90W)

(EC)L200(K60, K70)

37-8

37A-7

00-10

99-10

93-10

3. Details:

Pajero Workshop Manual (PWJE 9086) (Page 2)

’99 PAJERO SPORT Workshop Manual Chassis (Page 3)

’93 L200 Workshop Manual Chassis (Page 4 to 5)

’97 L200 Workshop Manual Chassis (Page 6 to 7)

Page 12

37-8

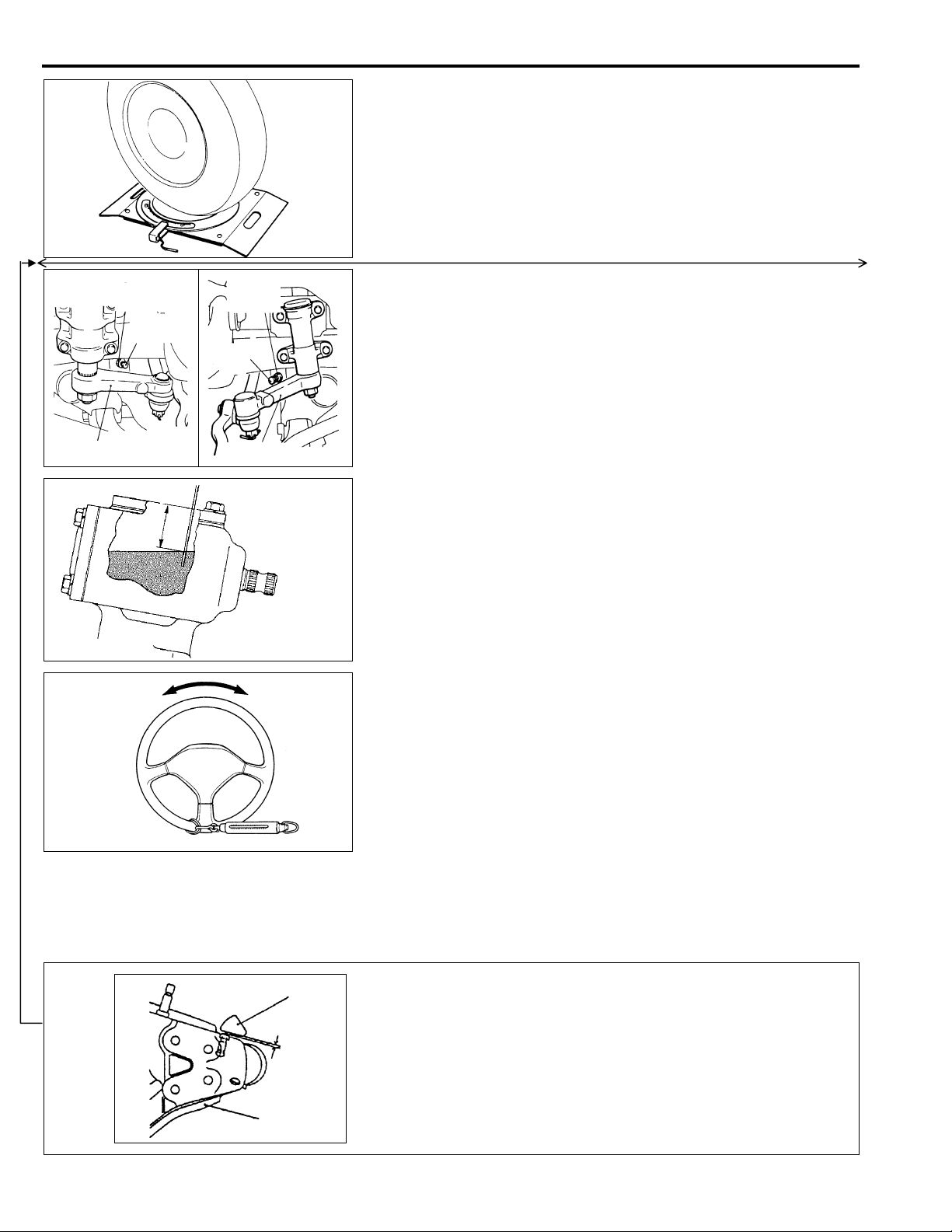

STEERING – Service Adjustment Procedures

Pitman arm

80Nm

8kgm

58 ft.lbs.

Stopper

bolt

80Nm

8kgm

58 ft.lbs.

Stopper bolt

Idler arm

13AO295

13E005213E0053

STEERING ANGLE CHECK

E37FDAH

1. Place the front whe el on a turn ing radius gauge and meas ure

the steering angle

Standard value: Inner wheel 32° 40’

0

-3°

Outer wheel 29° 45’

2. If the steering angle is outside the standard value, after

checking the toe-in, (Refer to GROUP 33-Service Adjustment

Procedures), adjust the steering angle with the stopper bolt.

STEERING GEAR OIL LEVEL CHECK

(MANUAL STEERING)

Remove the breather plug and check the oi l level in the stee r ing

gear box by using a s pecial gauge or a thin screwdriver.

Standard value: 25 mm (0.98 in.)

E37FEAAa

<Added>

13W002

13E0035

Knuckle

1 mm or more

STATIONARY STEERING EFFORT CHECK

(POWER STEERING)

1. Place the vehicle on a level surface and place the steering

wheel in the straight-ahead position.

2. Set the engine spee d to 1,000 r/min.

Caution

After checking the engine r/min., there must be a return to

the standard idling r/min.

3. Measure the tangential force with a spri ng bal ance by turn ing

the steering wheel clockwise and counter clock wise one and a

half turns.

Standard value: 37N (3.7kg, 8.21 Ibs) or less

4. If the stationary steering effort exceeds the standard value,

check for belt slackness, damage, insufficient oil, air mixed into

oil, collapsed or twisted hoses, etc., and repair if found.

Caution

When the steering wheel is turned to lock, check

that the clearance between the knuckle and the

stopper is 1 mm or more.

E37FFAG

Lower arm

X0520AA

2

Page 13

SERVICE BULLETIN

QUALITY INFORMATION ANALYSIS

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

MSB-97E26-001 REV

SERVICE BULLETIN

Subject:

Group:

INFORMATION

1. Description:

On the ABS equipped vehicles, the front rotor and the brake disc have been changed as follows:

(1) The front rotor has been changed to that made of sheet metal. Accordingly, bearing surface

has been added to the brake disc.

(2) The number of bolts used for mounting the front rotor has been changed form 2 to 4.

Accordingly, the bolt holes have been added to the bearing surface of the brake disc.

CHANGE OF FRONT ROTOR FOR ABS

EQUIPPED VEHICLES (REVICED)

FRONT AXLE

OVERSEAS

SERVICE

DEPT

No.:

:

1997-12-05

Date

Draftno:

96-SY-18

R. USAMI - MANAGER

QUALITY INFORMATION ANALYSIS

<Model> <M/Y>

(EC,EXP) L400

(PA0V)

(EC,EXP) PAJERO

(V10,V20,V30,V40)

97-10

97-10

2. Effective Date:

PAJERO/MONTERO

L400

3. Applicable Manuals:

Manual Pub. No. Language Page(s)

PAJERO Workshop Manual Chassis PWJE9086-F (English) 26-17

MONTERO Workshop Manual Chassis PWJS9087-F (Spanish)

’95 L400 Workshop Manual Chassis PWWE9410 (English) 26-18

Note:

This Service Bulletin makes correction of errors in and addition of interchangeability to the

previously published Service Bulletin MSB-97E26-001 (1997-02-28). The previous Service

Bulletin should be discarded.

From November 1996

From 1997 model year

PWJF9088-F (French)

PWJG9089-F (German)

PWJD9090-F (Dutch)

PWJW9091-F (Swedish)

PWWS9411 (Spanish)

PWWF9412 (French)

PWWG9513 (German)

PWWD9514 (Dutch)

PWWW9515 (Swedish)

4. Details:

PAJERO/MONTERO Workshop Manual, Page 2

’95 L400 Workshop Manual chassis, Page 3

Page 14

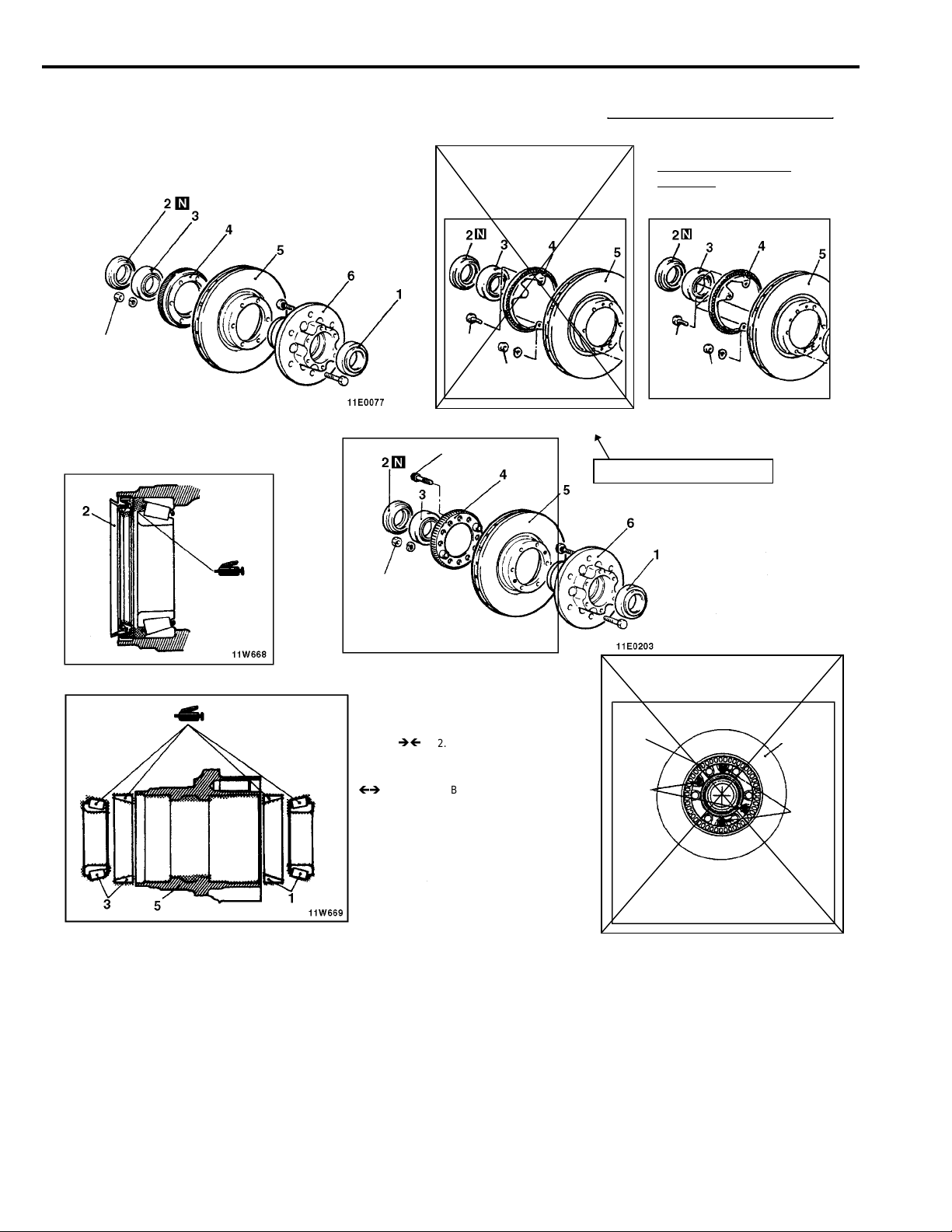

FRONT AXLE - Axle Hub

26-17

DISASSEMBLY AND REASSEMBLY (Front Axle Hub)

<New>

<Vehicles built up to May, 1994>

50-60 Nm

5.0-6.0 kgm

36-43 ft.lbs.

<Vehicles built from June, 1994>

Changed to be made of

sheet metal

<From November 1996>

22 Nm

2.2 kgm

16 ft.lbs.

50-60 Nm

5.0-6.0 kgm

36-43 ft.lbs.

13 Nm

1.3 kgm

9 ft.lbs.

<Deleted>

Up to October 1996

<New>

Two bolts changed to

<Deleted>

four bolts

<From November 1996>

22 Nm

2.2 kgm

16 ft.lbs.

50-60 Nm

5.0-6.0 kgm

36-43 ft.lbs.

<Added>

E26ll--

50-60 Nm

5.0-6.0 kgm

36-43 ft.lbs.

Disassembly steps

1. Outer bearing

2. Oil seal

3. Inner bearing

4. Rotor <Vehicles with ABS>

5. Brake disc

6. Front hub

<Deleted>

<Added>

<From November 1996>

Rotor

Tightening

by bolts

Note

When the rotor (2) is installed in the brake

disc (1), make sure that the rotor is aligned

with the bearing surface of the brake disc,

as shown.

Brake disc

Not

used

2

Page 15

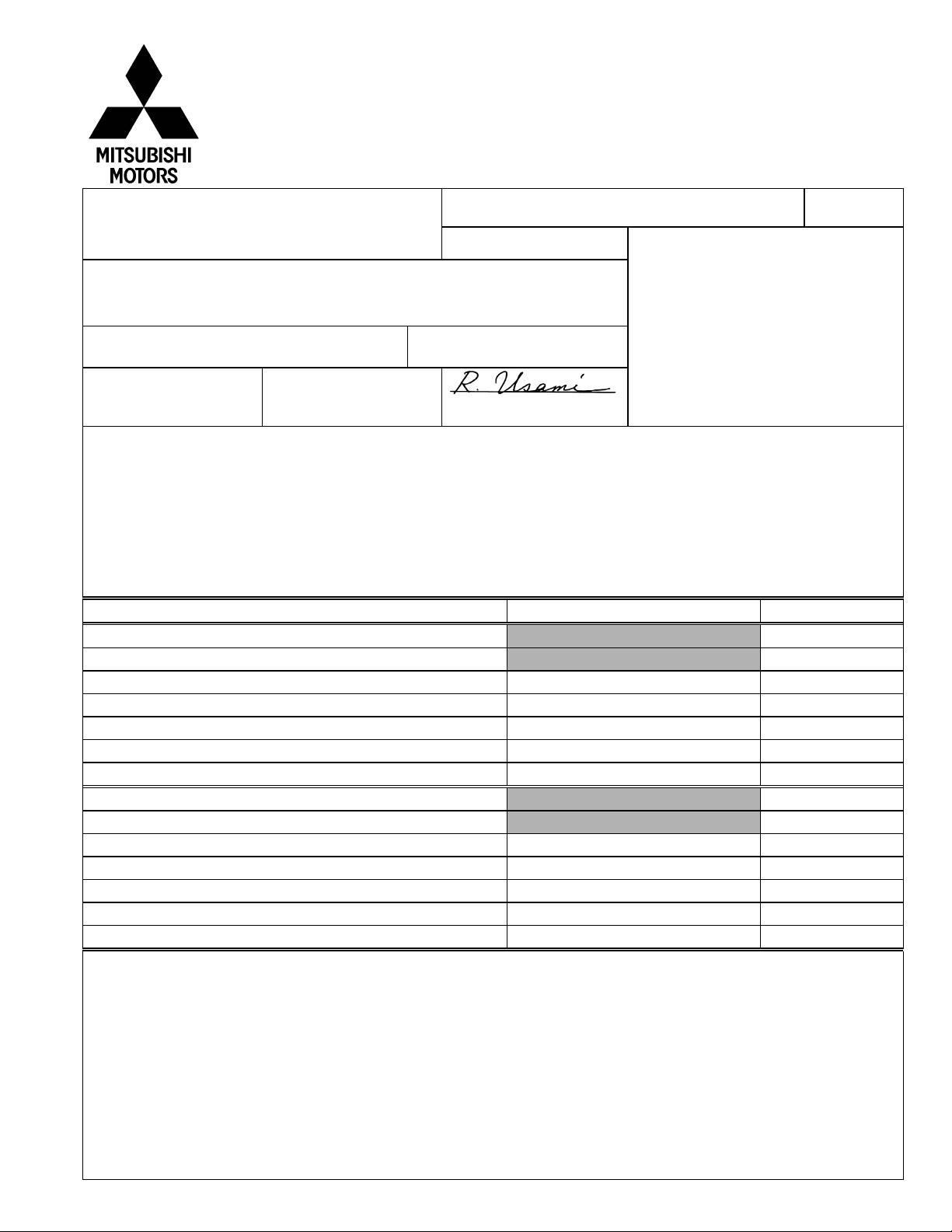

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

Subject:

CHANGE IN TIE ROD NUT TIGHTENING

TORQUE VALUES

MSB-97E37-003

No.:

:

1998-01-16

Date

QUALITY INFORMATION ANALYSIS

<Model> <M/Y>

(EC,EXP) PAJERO

(V10,V20,V30,V40)

93-10

Group:

INFORMATION

1. Description:

This Service Bulletin informs you that the tie rod nut tightening torque values have been changed.

2. Effective Date:

From July 1996

3. Applicable Manuals:

1983 PAJERO Workshop Manual PWJE8240 (English) 13A-3, 13A-20

1986 PAJERO Workshop Manual PWJE8508 (English) 37-5, 37-51

1986 MONTERO Workshop Manual PWJS8509 (Spanish) 37-5, 37-52

1986 PAJERO Workshop Manual PWJF8510 (French) 37-5, 37-52

1986 PAJERO Workshop Manual PWJG8511 (German) 37-5, 37-50

1986 PAJERO Workshop Manual PWJD8512 (Dutch) 37-5, 37-48

1986 PAJERO Workshop Manual PWJW8513 (Swedish) 37-5, 37-49

PAJERO Workshop Manual (Looseleaf edition) PWJE8817-D (English) 37-6, 37-45

PAJERO Workshop Manual (Looseleaf edition) PWJE9086-G (English) 37-42

MOTERO Workshop Manual (Looseleaf edition) PWJS9087-G (Spanish) 37-42

PAJERO Workshop Manual (Looseleaf edition) PWJF9088-G (French) 37-42

PAJERO Workshop Manual (Looseleaf edition) PWJG9089-G (German) 37-42

PAJERO Workshop Manual (Looseleaf edition) PWJD9090-G (Dutch) 37-42

PAJERO Workshop Manual (Looseleaf edition) PWJW9091-G (Swedish) 37-42

4. Details:

STEERING

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

Draftno:

96-SY-044

R. USAMI - MANAGER

QUALITY INFORMATION ANALYSIS

1983 PAJERO Workshop Manual, Page 2, 3

1986 PAJERO Workshop Manual, Page 4, 5

PAJERO Workshop Manual (Looseleaf edition), Page 6, 7

PAJERO Workshop Manual (Looseleaf edition), Page 8

Page 16

37-42

STEERING - Specifications

STEERING LINKAGE

REMOVAL AND INSTALLATION

Post-installation Operation

Adjustment of the Front Wheel

•

Alignment (Toe-in)

(Refer to GROUP 33 - Service

Adjustment Procedures.)

55 - 65 Nm

5.5 - 6.5 kgm

40 - 47 ft.lbs.

45 Nm

4.5 kgm

33 ft.lbs.

13E0006

Sealant: 3M ATD Part No. 8661 or equivalent

<Old>

73 Nm

7.3 kgm

53 ft.lbs.

E37VA..

13E0005

<New>

95 Nm

9.5 kgm

69 ft.lbs.

140 Nm

14 kgm

101 ft.lbs.

45 Nm

4.5 kgm

33 ft.lbs.

<New>

95 Nm

9.5 kgm

69 ft.lbs.

73 Nm

7.3 kgm

53 ft.lbs.

35 Nm

3.5 kgm

25 ft.lbs

Removal steps

1. Tie rod assembly

2. Tie rod end, outer 8. Idler arm (complete)

3. Tie rod end, inner

4. Pipe 10. Dust cover

5. Dust cover 11. Idler arm support

6. Damper

<Old>

45 Nm

4.5 kgm

33 ft.lbs.

35 Nm

3.5 kgm

25 ft.lbs

7. Relay rod

9. Idler arm

45 Nm

4.5 kgm

33 ft.lbs.

13E0073

8

Page 17

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

Subject:

Group:

ADDITION OF SRS AIR BAG MAINTENANCE

PROCEDURE

INTERIOR

No.:

Date

Draftno:

QUALITY INFORMATION ANALYSIS

MSB-97E52-001

:

1997-04-30

96-AL-022

<Model> <M/Y>

ALL MODELS 91-10

INFORMATION

1. Description:

In the SRS air bag troubleshooting, items of cause of trouble in the inspection procedure for each

diagnostic trouble code, have been added.

2. Applicable Vehicles:

• ‘91~’10 SIGMA

• ‘92~’10 3000GT

• ’91~’10 COLT/LANCER

• ‘93~’10 GALANT

• ‘92~’10 SPACE RUNNER/SPACE WAGON

• ‘95~’10 L400

• ‘91~’10 PAJERO/MONTERO

• ‘97~’10 L200

3. Applicable Manuals:

SIGMA Workshop Manual chassis PWGE9004-G (English) 52B-14

3000GT Workshop Manual chassis PWUE9119-D (English) 52B-12

’97 3000GT Workshop Manual chassis

Supplement

COLT/LANCER Workshop Manual chassis PWME9117-D (English) 52B-12

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

QUALITY INFORMATION ANALYSIS

PWGS9005-F (Spanish)

PWGF9006-F (French)

PWGG9007-F (German)

PWGD9008-F (Dutch)

PWGW900-F (Swedish)

PWUE9119-F (English) 52B-6

PWMS9118-D (Spanish)

PWMF9119-D (French)

PWMG9120-D (German)

PWMD9121-D (Dutch)

PWMW9122-D (Swedish)

R. USAMI - MANAGER

Page 18

Manual Pub. No. Language Page(s)

95’COLT/LANCER Workshop Manual PWME9117-E (English) 52B-7

chassis Supplement PWMS9118-E (Spanish)

PWMF9119-E (French)

PWMG9120-E (German)

PWMD9121-E (Dutch)

PWMW9122-E (Swedish)

’97 COLT/LANCER Workshop Manual PWME9117-F (English) 52B-5

chassis Supplement PWMS9118-F (Spanish)

PWMF9119-F (French)

PWMG9120-F (German)

PWMD9121-F (Dutch)

PWMW9122-F (Swedish)

’96 COLT/LANCER Workshop Manual PWME9511 (English) 52B-8

chassis PWMS9512 (Spanish)

PWMF9513 (French)

PWMG9514 (German)

PWMD9515 (Dutch)

PWMW9516 (Swedish)

GALANT Workshop Manual chassis PWDE9211-B (English) 52B-13

PWDS9212-B (Spanish)

PWDF9213-B (French)

PWDG9214-B (German) 52B-11

PWDD9215-B (Dutch) 52B-13

PWDW9216-B (Swedish)

’96 GALANT Workshop Manual PWDE9211-D (English) 52B-7

chassis Supplement PWDS9212-D (Spanish)

PWDF9213-D (French)

PWDG9214-D (German)

PWDD9215-D (Dutch)

PWDW9216-D (Swedish)

SPACE RUNNER/SPACE WAGON PWDE9104-D (English) 52B-9

Workshop Manual chassis PWDS9105-D (Spanish)

PWDF9106-D (French)

PWDG9107-D (German)

PWDD9108-D (Dutch)

PWDW9109-D (Swedish)

’95 SPACE RUNNER/SPACE WAGON PWDE9104-E (English) 52B-8

Workshop Manual chassis Supplement PWDS9105-E (Spanish)

PWDF9106-E (French)

PWDG9107-E (German)

PWDD9108-E (Dutch)

PWDW9109-E (Swedish)

Page 19

Manual Pub.No. Language Page(s)

’97 SPACE RUNNER/SPACE WAGON PWDE9104-G (English) 52B-6

Workshop Manual chassis Supplement PWDS9105-G (Spanish)

PWDF9106-G (French)

PWDG9107-G (German)

PWDD9108-G (Dutch)

PWDW9109-G (Swedish)

’95 L400 Workshop Manual chassis PWWE9410 (English) 52B-9

PWWS9411 (Spanish)

PWWG9412 (French)

PWWG9413 (German)

PWWD9415 (Dutch)

PWWW9416 (Swedish)

’97 L400 Workshop Manual PWWE9410-B (English) 52B-5

chassis Supplement PWWS9411-B (Spanish)

PWWG9412-B (French)

PWWG9413-B (German)

PWWD9415-B (Dutch)

PWWW9416-B (Swedish)

PAJERO Workshop Manual chassis PWJE9086-F (English) 52B-10

MONTERO Workshop Manual chassis PWJS9087-F (Spanish)

PAJERO Workshop Manual chassis PWJF9088-F (French)

PWJG9089-F (German)

PWJD9090-F (Dutch)

PWJW9091-F (Swedish)

’96 PAJERO Workshop Manual

chassis Supplement

’96 MONTERO Workshop Manual

chassis Supplement

’96 PAJERO Workshop Manual PWJF9088-G (French)

chassis Supplement PWJG9089-G (German)

’97PAJERO Workshop Manual

chassis Supplement

’97 MONTERO Workshop Manual

chassis Supplement

’97 PAJERO Workshop Manual

chassis Supplement

’97 L200 Workshop Manual chassis PWTE96E1 (English) 52B-8

PWJE9086-G (English) 52B-10

PWJS9087-G (Spanish)

PWJD9090-G (Dutch)

PWJW9091-G (Swedish)

PWJE9086-H (English) 52B-6, 52B-7

PWJS9087-H (Spanish)

PWJF9088-H (French)

PWJG9089-H (German)

PWJD9090-H (Dutch) 52B-7

PWJW9091-H (Swedish) 52B-6, 52B-7

Page 20

SRS - Troubleshooting

52B-10

Code No.

21 or 22

(Comment)

(1) These diagnosis codes are output if there is abnormal resistance between the input

terminals of the air bag module (squib).

The trouble causes for each code No. are as follow

Code No. Trouble Symptom

21

22

(2) Diagnosis codes 21 and 22 are sometimes generated in combination with malfunction

codes relating to the front impact sensor (code Nor. 11, 12 and 13), but sometimes only

one should also be inspected at the same time.

The relationships between the codes are as follows.

Air bag module Short 11 or 21 12 or 21 13 or 21

(squib) Open circuit 11 or 22 12 or 22 13 or 22

Air bag module (squib) system Probable cause

Short in air bag module (squib) or harness short

•

Short in clock spring

•

Short in air bag module (squib) or front impact sensor harnesses

•

leading to the power supply

Open circuit in air bag module (driver’s side squib) or open harness

•

Open circuit in clock spring

•

Disconnected connector in the driver’s side air bag module (squib)

•

Open-circuit in clock spring due to inappropriate neutral position

•

Malfunction of connector contact

•

Short in air bag module (squib) or front impact sensor harnesses

•

leading to the power supply

Front impact sensor

Short Open circuit

(1 sensor)

Open circuit

(2 sensors)

Malfunction of clock spring

•

Open circuit in clock spring due to

•

inappropriate neutral position

Malfunction of harness or con-

•

nectors

Malfunction of air bag module

•

(squib)

Malfunction of SDU

•

<Added>

SDU

Battery

Insulating tape

Lock lever

Lock spring

Battery (-) cable

19E0164

Screwdriver

19X0353

1. Turn the ignition key to the “LOCK” position, disconnect the negative

battery cable and tape the terminal.

Caution

Wait at least 60 seconds after disconnecting the battery cable

before doing any further work. (Refer to P. 52B-4)

2. Remove the floor console assembly. (Refer to GROUP 52A - Floor

Console.)

3. Place a flat-tipped (-) screwdriver against the lock spring (metal portion)

of the SDU connector lock lever, and push the spring horizontally toward

the inside of the unit.

Caution

1. Do not use excessive force to raise the lock lever (green)

2. do not insert the screwdriver into the gap between the lock lever

(green) and the lock spring (metal portion).

4. Disconnect the red 14-pin connector from the SDU.

19

Page 21

52B-10

g

SRS - Troubleshooting

Code No. 21 or 22 Driver’s air bag module (squib) system Probable cause

•

(1) These diagnosis codes are output if there is abnormal resistance between the

input terminals of the driver’s air bag module (squib) .

Refer to table 1 for the conditions for output of each diagnosis code.

(2) Diagnosis codes 21 and 22 are sometimes generated in combination with

diagnosis codes relating to the front impact sensor (code Nos. 11, 12 and 13), but

sometimes only one may be output instead of both being memorised. Because of

this, the front impact sensor should also be inspected al the same time.

Refer to table 2 for the failure mode combinations.

malfunction of clock spring

•

Open-circuit in clock spring due to inappropriate

neutral position

•

Malfunction of harnesses or connectors

•

Malfunction of air bag module (driver’s side squid)

•

Malfunction of SDU

TABLE 1: CONDITIONS FOR OUTPUT OF EACH DIAGNOSIS CODE

Code No. Trouble symptoms

•

21

22

Short in air bag module (driver’s side squib) or harness short

•

Short in clock spring

•

Short in driver’s side air bag module (squib) or front impact sensor harnesses leading

to the power supply

•

Open circuit in air bag module (driver’s side squib) or open harness

•

Open circuit in clock spring

•

Disconnected connector in the driver’s side air bag module (squib).

•

Open circuit in clock spring due to inappropriate neutral position.

•

Malfunction of connector contact

•

Short in driver’s air bag module (squib) or front impact sensor harnesses leading to the

power supply

<Added>

<Added>

<Vehicles without front

passenger’s air bag>

Resistor (3Ω)

C-56

connector

Clock sprin

<Vehicles with front

passenger’s air bag>

C-56

connector

SRS check harness

(MB991530)

Clock spring

Resistor

(3Ω)

SRS check harness

(MB991349)

To next page

MUT-II SELF DIAG. CODE

Disconnect clock spring

•

connector C-56

Connect SRS-check

•

harness connector (1).

Erase diagnosis code

•

memory.

Are code Nos. 21 or 22

output?

19X0604

19X0604

Yes

NG

Clock spring inspection

OK

Check the following

connectors:

C-49 and C-56

OK

Check trouble symptoms.

NG

Replace the air bag module (driver’s side squib)

NG

NG

Repair

Repair

20

Page 22

SRS - Troubleshooting

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSTIC TROUBLE

Code No. 14 Analog G-sensor system in the SRS-ECU Probable cause

The SRS-ECU monitors the output of the analog G-sensor inside the SRS-ECU. It

outputs this code when any of the following are detected

•

When the analog-G sensor is not operating

•

When the characteristics of the analog-G sensor are abnormal

•

When the output from the analog G-sensor is abnormal

Replace the SRS-ECU

Code No.15 or 16 Safing G-sensor system in the SRS-ECU Probable cause

This code is output if there is a short or open circuit between the terminals of the

safing G-sensor inside the SRS-ECU.

The trouble causes for each diagnosis code No. Are as follows

Code No. Trouble Symptom

15 Short circuit in the safing G-sensor

16 Open circuit in the safing G-sensor

Replace the SRS-ECU

•

Malfunction of SRS-ECU

•

Malfunction of SRS-ECU

52B-6

Code No. 21, 22 or 61 Air bag module (driver’s side squib)

system

These diagnosis codes are output if there is abnormal resistance between the input

terminals of the air bag module (driver’s side squib).

The trouble causes for each code No. are as follows

<Added>

Probable cause

•

Malfunction of clock spring

•

Open-circuit in clock spring due to inappropriate neutral

position

•

Malfunction of harnesses or connectors

•

Malfunction of air bag module (driver’s side squib)

•

Malfunction of SRS-ECU

21

Page 23

52B-7

SRS - Troubleshooting

Code No. Trouble symptoms

21

22

61

Check the clock spring Repair

•

Short in air bag module (driver’s side squib) or harness short

•

Short in clock spring

•

Open circuit in air bag module (driver’s side squib) or open harness

•

Open circuit in clock spring

•

Disconnected connector in the driver’s side air bag module (squib).

•

Open circuit in clock spring due to inappropriate neutral position.

•

Malfunction of connector contact

•

Short in air bag module (driver’s side squib) harness leading to the power supply

NG

OK

<Added>

SRS check harness (MB991613)

19U0039

Dash wiring

harness

Clock spring

Check the following connectors: C-56, C-128

Check trouble symptom.

MUT-II SELF DIAG. CODE

Disconnect clock spring

•

connector C-56.

Connect SRS check harness

•

connector (1).

Connect negative battery

•

cable.

Erase diagnosis code

•

memory.

Are code Nos.21, 22 or 61

output?

19X0604

Yes

OK

NG

No

Check the following

connector:

bag module connector

Check trouble symptom.

Replace the driver’s air bag

module

C-56 and Air

OK

NG

NG

Repair

SRS check harness (MB991613)

19U0039

22

Check the harness between the

SRS-ECU and clock spring.

Disconnect clock spring

•

connector C-56.

Connect SRS check harness

•

connector (1).

Disconnect SRS-ECU

•

connector C-128.

Connector SRS check

•

harness connector (3)

Resistance between terminals

•

(5) - (6)

OK: Approx. 3

19L0567

NG

OK

Ω

Repair

Replace the SRS-ECU.

Page 24

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

No.:

MSB-98E00-011

QUALITY INFORMATION ANALYSIS

Date

:

1998-10-15

Subject:

Group:

INFORMATION

1. Description:

This Service Bulletin informs you of change in year model for the 1999 Pajero.

2. Applicable Manuals:

’98 PAJERO PWJE9086-I (English)

Workshop Manual Chassis PWJS9087-I (Spanish)

3. Details:

CHANGE IN YEAR MODEL FOR ’99 PAJERO (EC,EXP)PAJERO

GENERAL

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

Draftno:

98SY020216

T.NITTA - VICE GENERAL MANAGER

QUALITY INFORMATION ANAL YSIS

PWJF9088-I (French)

PWJG9089-I (German)

PWJD9090-I (Dutch)

PWJW9091I

(Swedish)

<Model> <M/Y>

V10,V20,V30,V40

99-10

Page 25

General ..................................................

00

WORKSHOP MANUAL

SUPPLEMENT

FOREWORD

This manual outlines changes in servicing procedures

related to the chassis including vehicle inspections,

adjustments and improvements in the newly equipped

models.

Use the following manuals in combination with this

manual as required

TECHNICAL INFORMATION MANUAL

PYJE9002

WORKSHOP MANUAL

ENGINE GROUP PWEE

(Looseleaf edition)

CHASSIS GROUP PWJE9086

(Looseleaf edition)

PWJE9086-G

(Supplement)

PWJE9086-H

(Supplement)

PWJE9086-I

(Supplement)

ELECTRICAL WIRING PWJE9026

(Looseleaf edition)

PWJE9026-D

(Supplement)

PWJE9026-E

(Supplement)

PWJE9026-F

(Supplement)

PWJE9026-G

(Supplement)

PWJE9026-H

(Supplement)

PARTS CATALOGUE B6035609A

!!!!

!

Fuel ........................................................

Engine Electrical...................................

Service Brakes .....................................

Body.......................................................

13

16

35

42

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We however, reserve the right to make

changes at any time without prior notice or obligation.

© Mitsubishi Motors Corporation April 1998

3

Page 26

00-1

GENERAL - Vehicle Identification

GROUP 00

GENERAL

VEHICLE IDENTIFICATION

MODELS

<2-DOOR MODELS>

Model code Body style Engine model Transmission model Fuel supply

system

V24C NSGL6* Canvas top

V23C

V24W NDGL6*

V24WG NXGL6/R6* Wagon with

V26W NDGL6* Wagon

V26WG NXGL6/R6* Wagon with

V23W NHVL6 Wagon

V23WG NXVL6/R6

V25WG NXVL6/R6 V5M31 (5M/T)

NOTE

*:Indicates change.

GNHVL6/R6

GRHVL6/R6

NHGL/R6*

RXVL6/R6

RXVL6/R6

Canvas top with

blistered fender

Wagon

blistered fender

blistered fender

Wagon with

blistered fender

Wagon with

blistered fender

4D56 [2,477 m!]

with

turbocharger

and inter-cooler

6G72 [2,972 m!]

4D56 [2,477 m!]

with turbocharger and

inter-cooler

4M40 [2.835 m!]

with

turbocharger and

inter-cooler

6G72 [2,972 m!]

6G72 [3,497 m!]

V5MT1 (5M/T)

V4AW3 (4A/T)

V5MT1 (5M/T)

V5MT31 (5M/T)

V5MT31 (5M/T)

V4AW3 (4A/T)

V4AW3 (4A/T)

Injection

MPI

Injection

MPI

4

Page 27

GENERAL - Vehicle Identification

<4-DOOR MODELS>

Model code Body style Engine model Transmission model Fuel supply

system

V44W

V44WG NXGL6/R6* Wagon with

V46W NDGL6* Wagon

V46WG NXGL6*/R6* V5M31 (5M/T)

V43W NHVL6/R6 V5MT1 (5M/T)

V43WG NXVL6/R6 V5MT1 (5M/T)

V45WG NXVL6/R6 V5MT31 (5M/T)

NOTE

*:Indicates change

NDGL6* Wagon

NDGCL6* Wagon without 3rd

seat row

NHGL6* Wagon

blistered fender

NDGCL6* Wagon without 3rd

seat row

NHGL6/R6*

RHGR6*

RXGL6*/R6*

RHVL6/R6

RXVL6/R6

RXVL6/R6

Wagon

Wagon with

blistered fender

Wagon

Wagon with

blistered fender

4D56 [2,477 m!]

with turbocharger and

inter-cooler

4M40 [2,835 m!]

with turbocharger and

inter-cooler

6G72 [2,972 m!]

6G74 [3,497 m!]

V5MT1 (5M/T)

V5M31 (5M/T)

V4AW3 (4A/T)

V4AW3 (4A/T)

V4AW3 (4A/T)

V4AW3 (4A/T)

V4AW3 (4A/T)

Injection

MPI

00-2

5

Page 28

00-3

GENERAL - Vehicle Identification

CHASSIS NUMBER

The chassis number is stamped on the side wall of the frame near

the right rear wheel.

Z00E0022

1. Asia 7. Body style

0: Frame

2. Japan 8. Model year

X: 1999*

3. MITSUBISHI

A: Right hand drive for Europe

B: Left hand drive for Europe

4. Sorts

0: 4 or 2-door with tailgate (backdoor)

A: 2-door semi-open (canvas top)

5. Transmission

N: 5 x 2-speed manual transmission

R: 4 x 2-speed automatic transmission

6. Development order

V23: 2,972 m

Petrol engine <2-door models>

V24: 2,477 m

Diesel engine <2-door models>

V25: 3,497 m

Petrol engine <2-door models>

V26: 2,835 m

Diesel engine <2-door models>

V43: 2,972 m

Petrol engine <4-door models>

V44: 2,477 m

Diesel engine <4-door models>

V45: 3,497 m

Petrol engine <4-door models>

V46: 2,835 m

Diesel engine <4-door models>

!

!

!

!

!

!

!

!

9. Plant

J, P, Y: Oye Plant of NAGOYA Motor Vehicle Works

10. Serial number

000001 -

NOTE

*: Indicates change

6

Page 29

FUEL SYSTEM - General / ENGINE ELECTRICAL - General/

Starting System / SERVICE BRAKES - General / BODY - General

13-1, 16-1

35-1, 42-1

GROUP 13

FUEL SYSTEM

GENERAL

OUTLINE OF CHANGE

The idle-up mechanism in vehicles mounted with the anti-skid brake (ABS) system was

•

eliminated. <Diesel-powered vehicles>

GROUP 16

ENGINE ELECTRICAL

GENERAL

OUTLINE OF CHANGE

The general specifications were set as follows due to changes in the 4D56 engine’s starter motor.

•

STARTING SYSTEM

GENERAL SPECIFICATIONS

STARTER MOTOR

Items Specifications

Type Planetary gear reduction drive

Rated output kW/V 2.2/12

No. Of teeth 12

GROUP 35

SERVICE BRAKES

GENERAL

OUTLINE OF CHANGE

The idle-up solenoid valve in vehicles mounted with the anti-skid brake (ABS) system was eliminated.

•

<Diesel-powered vehicles>.

Intercooler

ABS idle-up solenoid

valve <eliminated>

A14E0221

GROUP 42

BODY

GENERAL

OUTLINE OF CHANGE

The clutch slip force inspection was eliminated due to the elimination of the sunroof wrench in the tools

•

provided with the vehicle.

7

Page 30

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

No.:

MSB-98E27-001

QUALITY INFORMATION ANALYSIS

Date

:

1998-06-15

Subject:

Group:

INFORMATION

1. Description:

The rear rotor for the anti-lock brake system (ABS) equipped car has been changed to a sheet

metal one. Accordingly, the applicable service procedures have been changed as described on

the following pages.

2. Applicable Manuals:

’96 PAJERO PWJE9086-G (English) 27-2, 3, 6, 11

Workshop Manual Chassis PWJF9088-G (French)

SUPPLEMENT PWJG9089-G (German)

’96 MONTERO

Workshop Manual Chassis

SUPPLEMENT

‘95 L400 PWWE9410 (English) 27-5, 20, 24, 27, 30

Workshop Manual Chassis PWWS9411 (Spanish)

‘95 L300 PWWE9404 (English) 27-3, 5, 14, 18

Workshop Manual Chassis PWWG9405 (German)

3. Effective Date:

CHANGE OF ABS REAR ROTOR (EC,EXP)L300(P5T)

(EC,EXP)L400(PA0V)

REAR AXLE

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

Draftno:

R. USAMI - MANAGER

QUALITY INFORMATION ANALYSIS

PWJD9090-G (Dutch)

PWJW9091-G (Swedish)

PWJS9087-G (Spanish)

PWWF9412 (French)

PWWG9413 (German)

PWWD9414 (Dutch)

PWWW9415 (Swedish)

97-SY-001

(EC,EXP)PAJERO

(V10,V20,V30,V40)

<Model> <M/Y>

95-10

95-10

96-10

From June 2, 1997

4. Interchangeability:

Not interchangeable

Page 31

27-2

REAR AXLE - General/Specifications

GENERAL

OUTLINE OF CHANGES

•

The dust cover of the rear axle shaft and the ABS wheel-sped sensor rotor have been redesigned.

With this change, the service procedure for the axle shaft has been added.

•

Vehicles with 3500 petrol engine and 2800D Diesel engine has used a hybrid type LSD.

With this change, the service procedure has been added.

SPECIFICATIONS

GENERAL SPECIFICATION

Items Standard wheelbase 2800D, 3500 Long wheelbase 2800D

Differential

Differential size No. 7.5 No. 7.5

Reduction gear type Hypoid gear

(fine pitch type)

Reduction ratio 4.636 4.900

LSD type Hybrid type

(Helical gear + VCU*)

NOTE

* : Viscous Coupling Unit

Hypoid gear

(fine pitch type)

Hybrid type

(Helical gear + VCU*)

SERVICES SPECIFICATION

Items Specifications

Standard value

Press-fitting force of retainer N

Initial press-fitting force 49,000

Final press-fitting force 98,000-108,00

Clearance of snap ring and retainer mm 0-0,166

Final drive gear backlash mm 0.13-0.18

Drive pinion turning torque

Without oil seal Nm

With anti-rust agent (new) 0.6-0.9

With gear oil applied (new or used) 0.4-0.5

Without oil seal Nm

With anti-rust agent (new) 0.85-1.15

With gear oil applied (new or used) 0.65-0.75

Limit

Drive gear runout mm 0.05

<Added>

Distance between bearing case and rotor mm 19.4-20.0

2

Page 32

REAR AXLE - Specifications/Special Tools

LUBRICANTS

Items Specified lubricant Quantity

Rear axle gear oil

Hybrid type LSD Hypoid gear oil

API classification GL-5 or higher

SAE viscosity No. 90, 80 W

SEALANT AND ADHESIVES

Items Specified lubricant Quantity

Bearing case

Differential carrier mounting

surface of axle housing

Drive gear threaded hole 3M Stud Locking 4170 or equivalent Anaerobic sealant

SPECIAL TOOLS

Tool Number Name Use

MB990211

MB990212

MB990590 Sliding hammer Removal of axle shaft

MB990241 Rear axle shaft puller Removal of axle shaft

3M ATD Part No. 8663 or equivalent Semi-drying sealant

3.2

(Use together with MB990241)

Removal of axle housing oil seal

(Use together with MB990590)

27-3

<Added>

MB990787

MB991552 Axle shaft bearing and case

remover

MB991601 Extension bar

MB990560 Axle shaft bearing remover Removal of the axle shaft bearing

MB990799 Bearing inner race installer Press-fitting of the axle shaft

MB990787 Axle shaft bearing remover Installation of rotor

Removal of the axle shaft bearing

and bearing case

inner case

bearing inner race

Press-fitting of the axle shaft

retainer

3

Page 33

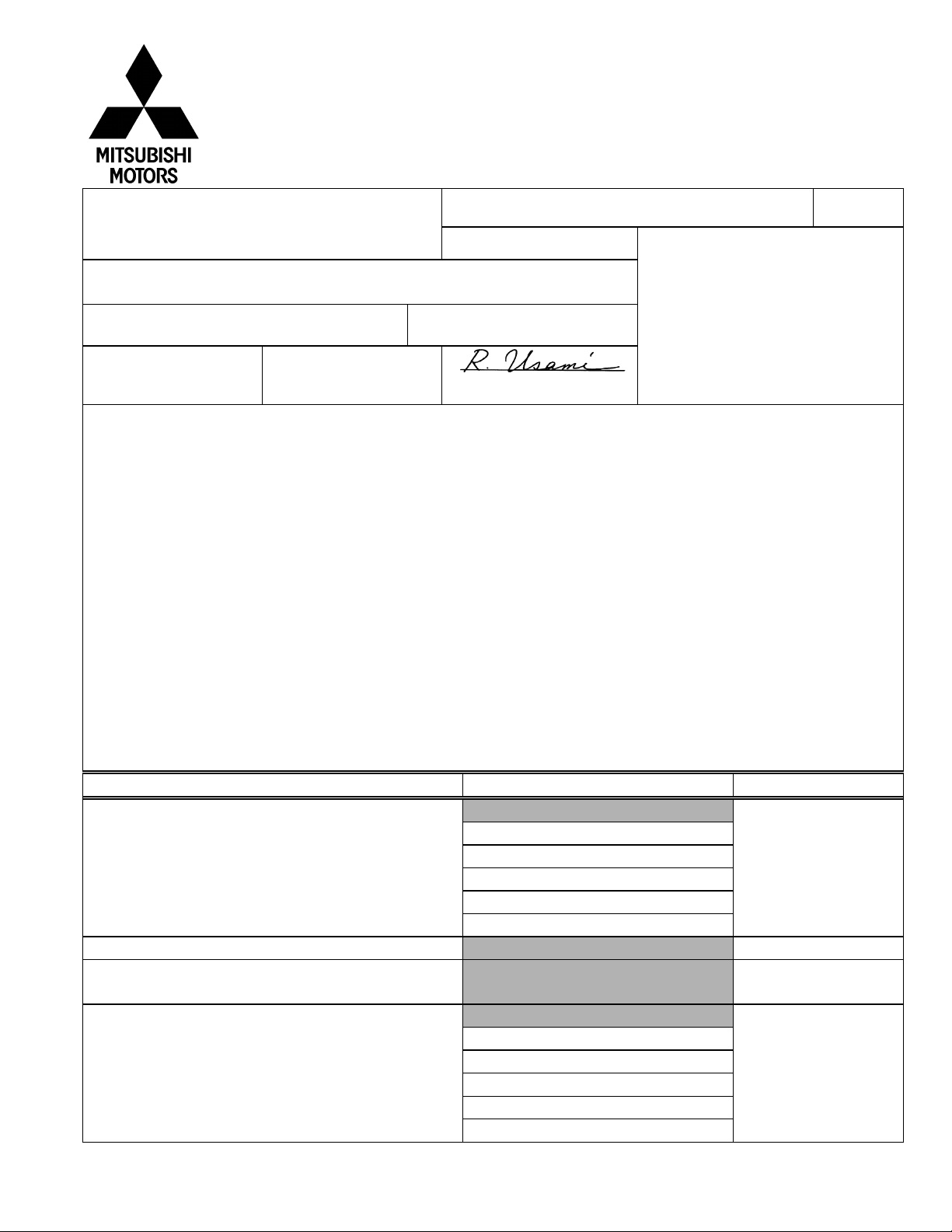

27-6

AXLE SHAFT

REMOVAL AND INSTALLATION

<Old>

REAR AXLE - Axle Shaft

Post-installati on Operation

•

Ai r Bleeding from Brake Lines

•

Parking Brake Lever Stroke Adjustment

<New>

<Added>

7-1. Rotor

Removal steps Installation steps

1. Brake tube connection

2. Rear brake assembly 19. O-ring

3. Brake disc 18. Bearing case

4. Parking brake assembly

5. Parking brake cable attaching bolt 16. Backing plate

6. Parking brake cable end 15. Axle shaft

A

B

C

D

E

F

7. Axle shaft assembly 14. Dust cover

8. Snap ring 12. Bearing inner race (outer)

9. Retainer

10. Axle shaft sub assembly

(Parts from step12 to step 15)

11. Bearing inner race (inner)

12. Bearing inner race (outer) 7. Axle shaft assembly

13. Oil seal 6. Parking brake cable end

14. Dust cover 5. Parking brake cable attaching bolt

15. Axle shaft 4. Parking brake assembly

16. Backing plate 3. Brake disc

17. Bearing outer race 2. Rear brake assembly

18. Bearing case 1. Brake tube connection

19. O-ring

20. Oil seal

<Deleted>

<Added>

G

7-1. Rotor

20. Oil seal

A

17. Bearing outer race

B

13. Oil seal

C

11. Bearing inner race (inner)

D

E

F

9. Retainer

8. Snap ring

11E021a

NOTE

<Deleted>

4

* :For vehicles with ABS, the sensor rotor has been integrated.

Page 34

(1)

)

(2)

g

REAR AXLE - Axle Shaft

27-11

MB990787

Snap ring

Retainer

Rotor

11E0174

F

G

SNAP RING INSTALLATION

After installing the snap ring, measure the clearance (A

between the snap ring and the retainer with a thickness gauge,

and check that it is within the standard values.

Standard value (A): 0-0.166 mm

If the c learance exceeds the standard value, change the snap

ring so that the clearance is at the standard value.

Thickness of snap ring mm Identification colour

2.17

2.01 Yellow

1.85 Blue

1.69 Purple

1.53 Red

ROTOR INSTALLATION

Usin

the special tool, install the rotor until the standard

dimension between the rotor and the bearing case is obtained.

Standard value (A): 19.4-20.0 mm

T0808AA

<Added>

5

Page 35

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

No.:

MSB-98E37-002

QUALITY INFORMATION ANALYSIS

Date

:

1999-08-15

Subject:

Group:

INFORMATION

1. Description:

The mainshaft valve assembly in the power steering gearbox is now available only as an

assembly (supply of individual components and parts discontinued). Accordingly, the service

procedure for the power steering gearbox is also changed as shown in the attached sheets.

2. Applicable Manuals:

’97 L200 PWTE96E1 (English) 37A-3-~6, 28-34

Workshop Manual CHASSIS PWTS96E1 (Spanish)

’95 PAJERO PWJE9086-F (English) 37-3, 4, 6, 25-32

Workshop Manual CHASSIS PWJF9088-F (French)

’95 MONTERO

Workshop Manual CHASSIS

3. Interchangeability:

NEW SERVICE PROCEDURE FOR POWER

STEERING GEARBOX

STEERING

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

Draft No.:

T.NITTA - VICE GENERAL MANAGER

QUALITY INFORMATION ANAL YSIS

PWTF96E1 (French)

PWTG96E1 (German)

PWJG9089-F (German)

PWJD9090-F (Dutch)

PWJW9091-F (Swedish)

PWJS9087-F (Spanish)

98SY100912 (EC,EXP) PAJERO

<Model> <M/Y>

(EC,EXP) L200

(K00)

(V10,V20,V30,V40)

97-10

95-10

Not interchangeable

4. Effective Date:

From when the part stock has been exhausted

Page 36

STEERING – Specifications

Items Specifications

Pressure switch activation oil pressure

Mpa (kg/cm2, psi)

OFF → ON

ON→ OFF

Mainshaft starting torque (Manual steering)

<Deleted>

Mainshaft axial play (Power steering) mm (in.) 0.03 – (0.0012) or less

Cross-shaft axial play mm (in.)

Manual steering’ 0.05 (0.0020)

Power steering 0.05 (0.0020)

Mainshaft total starting torque Nm (kgcm, in.lbs.)

Manual steering 0.65 – 0.85 (6.5 – 8.5, 5.7 – 7.3)

Power steering 0.45 – 1.25 (4.5 – 12, 5, 4 – 11)

Ball joint starting torque Nm (kgcm, in.lbs.)

Tie rod end 1 – 3 (10 – 30, 8.9 – 26)

Idler arm 0.5 – 2.0 (5 – 520, 4 – 17)

Idler arm turning torque Nm (kgcm, in.lbs.) 0.3 – 2.0 (3 – 20, 3 – 17)

Spring balance reading N (kg,lbs) 2.3 – 15.4 (0.23 – 1.54, 0.5 – 33.9)

Limit

Steering wheel free play mm (in.)

Manual steering 50 (1.97)

Power steering 50 (1.97)

Steering gear backlash mm (in.) 0.5 (0.020)

Ball joint axia play mm (in.) 1.5 (0.059)

Backlash between ball groove of rack piston

And balls mm (in.) 0.05 (0.0020)

Gap between vane and rotor groove mm (in.) 0.06 (0.0024)

Clearance between oil pump drive shaft

And pump body mm (in.) 0.1 (0.004)

Nm (kgcm, in.lbs.) 0.35 – 0.55 (3.5 – 5.5, 3 – 5)

1.5 – 2.0 (15 – 20, 21-284)

0.7 – 1.2 (7.2 – 12, 100-171)

37-3

13

Page 37

37-4

STEERING – Specifications

LUBRICANTS

Items Specified lubricant Quantity

Manual steering gear oil Hypoid gear oil API

GL-4 or higher SAE 80

Power steering fluid

L.H. drive vehicles

<2800D> 11.1 dm3 (1.17 U.S.qts.,

<Except 2800D> 1.06 dm3 (1.12 U.S.qts.,

R.H. drive vehicels Automatic transmission fluid

<2800D> 1.02 dm3 (1,08 U.S.qts.,

<Except 2800D> 0.97 dm3 (1.02 U.S. qts.,

Power steering gear box

Bearing, O-ring and oil seal

<Deleted>

Oil pump

Flow control valve and O-ring

Friction surface of rotor, vane, cam ring

and pump cover

DEXRON or DEXRON II

Automatic transmission fluid

DEXRON or DEXRON II

Automatic transmission fluid

DEXRON or DEXRON II

210 cm3 (12.81 cu.in.)

0.98 lmp.qts.)

0.93 lmp.qts.)

0.90 lmp.qts.)

0.85 lmp.qts.)

As required

As required

E37CD--

SEALANTS AND ADHESIVES

Items Specified sealant and adhesive Remarks

Steering column cover assembly

installation hole

Dash panel cover installed surface

Manual steering gear box top cover

packing

Manual steering gear box cross-shaft

adjusting and lock nut

Manual steering gear box top cover bolt

Manual steering gear box adjusting shim

Tie-rod end dust cover installed surface

Inside of steering column lower pipe

bearing

Connection of steering column upper and

steering column lower (Nut side)

Steering column upper bearing 3M ATD Part No. 8001 or equivalent Semi-drying sealant

3M ATD Part No. 861 or equivalent Semi-drying sealant

3M Stud Locking Part No. 4170 or

equivalent

Semi-drying sealant

E37CE--

14

Page 38

37-6

Tool Number Name Use

STEERING – Special Tools/Service Adjustment Procedure

MB990925 Bearing and oil seal

installer set

MB991151

MB990685

Torque wrench Measurement of the mainshaft starting

Installation of the oil seal and the ball

bearing

(Refer to GROUP 26.)

MB990938, MB99028,MB990926,

MB991203

torque

<Deleted>

MB991006 or

MB990228

Preload socket Measurement of the mainshaft total

starting torque

<Deleted>

MB991367 Special spanner

MB991394 Pin set

MB990326 Preload socket Measurement of the ball joint starting

MB990778 Ball joint remover Disconnection of idler arm from relay

Removal and installation of the lock nut

torque

rod

13E0034

SERVICE ADJUSTMENT PROCEDURES

STEERING WHEEL FREE PLAY CHECK

MANUAL STEERING

Standard value:

Limit:

If the measured value exceeds the repair limit, check the

steering gear backlash and ball joint axial play.

26.6 mm (1.05 in.) or less

50 mm (1.97 in.)

E37FAAF

15

Page 39

STEERING – Specifications

37-25

DISASSEMBLY

E37NF--

<New>

<Old>

!"

!"

!"

!"

!"

16

13W703

Disassembly steps

01. Jam nut 17. Circulator

02. Pitman arm 18. Ball

03. Dust cover

04. Side cover and cross-shaft assembly

05. Adjusting bolt lock nut

06. Cross-shaft

07. Adjusting bolt

08. Adjusting plate 24. Seal ring

09. O-ring 25. Bearing race

10. Y-packing 26. O-ring

11. Side cover

12. Main shaft and valve assembly

13. Rack piston 29. Valve housing

14. Seal ring 30. Oil seal

15. O-ring 31. Y-packing

16. Circulation holder 32. Gear box housing

<Deleted>

!"

!"

!"

!"

!"

!"

!"

19. Lock nut

20. Main shaft

21. Bearing race

22. Cage

23. Ball

27. Bearing

28. Oil seal

<Deleted>

Page 40

37-26

STEERING – Power Steering Gear Box

13V018

13W056

SERVICE POINTS OF DISASSEMBLY

E37NGAE

2. REMOVAL OF PITMAN ARM

4. REMOVAL OF SIDE COVER AND CROSS-SHAFT ASSEMBLY

With the mainshaft and cross-shaft placed in the straight ahead

position, tap the bottom of the cross-shaft with a plastic hammer to

take out the cross-shaft together with the side cover.

10. REMOVAL OF Y-PACKING

Do not remove the Y-packing at the rear of the needle bearing

unless there is fluid leakage from the threads of the adjusting bolt.

If there is leakage, replace the Y-pacing with a new one.

<Deleted>

13. REMOVAL OF RACK PISTON

Remove the rack piston form the mainshaft by turning it

counterclockwise.

Caution

Be careful not to lose the 26 balls inside the rack piston.

Main shaft

13W094

13W719

Bearing race

13W091

REMOVAL OF LOCK NUT

19.

20. REMOVAL OF MAIN SHAFT/21. BEARING RACE/22. CAGE/23.

BALL

When removing the main shaft, remove it while pressing the

bearing race so that the balls do not come out.

17

Page 41

<Deleted>

STEERING – Power Steering Gear Box

27. REMOVAL OF BEARING/28. OIL SEAL

Using a socket, remove the oil seal and the bearing from the valve

housing simultaneously.

Socket

13W087

37-27

C13156

13W0049

INSPECTION

BACKLASH BETWEEN BALL GROOVE OF RACK PISTON AND

BALLS

Set the rack piston to the position shown in the figure, and then

measure the backlash by using a dial gauge.

Limit: 0.05 mm (0.0020 in.)

PITMAN ARM BALL JOINT STARTING TORQUE

Standard value: 1-3 Nm (10-30 kgcm, 9-26 in.lbs.)

E37NHAD

18

Page 42

37-28

STEERING – Power Steering Gear Box

REASSEMBLY

50Nm

5 kgm

36 ft.lbs.

<New>

38 Nm

3.8 kgm

27 ft.lbs.

<Old>

E37NI--

<Old>

50Nm

5 kgm

36 ft.lbs.

3.5 Nm

0.35 kgm

2.5 ft.lbs.

13W699

Gear box seal kit

<New>

50Nm

5 kgm

36 ft.lbs.

150-170 Nm

15-17 kgm

108-123 ft.lbs.

Reassembly steps

13W111

Cross-shaft

plate set

<Deleted>

13B0093

Cross-shaft

seal kit

01. Gear box housing 18. Circulator

"!

02. Y-packing 19. Circulator holder

"!

03. Oil seal

"!

04. Oil seal 21. Mainshaft and valve assembly

"!

05. Bearing 22. Y-packing

"!

20. Valve housing

06. Bearing case 23. O-ring

07. O-ring

"!

08. Seal ring

"!

09. Cage

"!

10. Ball

"!

11. Bearing race 28. Side cover

"!

12. Mainshaft

"!

13. Lock nut

"! •

Adjustment of main shaft axial play torque

"!

24. Adjusting plate

"!

25. Adjusting bolt

"!

26. Cross-shaft

"!

27. Adjusting bolt lock nut

"!

29. Side cover and cross-shaft assembly

"! •

Adjustment of main shaft total staring

14. O-ring 30. Dust cover

15. Seal ring

"!

16. Rack piston 32. Jam nut

"!

31. Pitman arm

17. Ball

13W703

A13V0108

<Deleted>

19

Page 43

STEERING – Power Steering Gear Box

A

37-29

LUBRICATION AND SEALING POINTS

Automatic transmission fluid

DEXRON or DEXRON II

<Old>

13W706

Automatic

transmission

fluid DEXRON

or DEXRON II

13W707

13W701

<Deleted>

13W705

utomatic transmission

fluid DEXRON or DEXRON II

<New>

13W703

13E0003

13W698

13W005

Oil seal

Y-Packing

13w0061

Automatic transmission fluid

DEXRON or DEXRON II

Sealant: 3M ART Part

13E0004

No. 8661 or

equivalent

SERVICE POINTS OF REASSEMBLY

2. INSTALLATION OF Y-PACKING/3. OIL SEAL

(1) Install the Y-packing facing the direction shown in the

illustration.

(2) Use the special tool to press-fit the oil seal to the

gearbox housing so that it faces in the direction shown

in the illustration.

INSTALLATION OF OIL SEAL

4.

Apply a coating of the specified fluid to the outside of the oil

seal. Using the special tools, press the oil seal into the valve

housing.

Specified fluid: Automatic transmission fluid DEXRON

or DEXRON II

E37NJAE

<Deleted>

13w0071

20

Page 44

37-30

<Deleted>

STEERING – Power Steering Gear Box

INSTALLATION OF BEARING

5.

Apply a coating of the specified fluid to the outside of the

bearing. Using the special tools, press the oil seal into the

valve housing.

Specified fluid: Automatic transmission fluid DEXRON

or DEXRON II

13W070

Seal ring

Vinyl tape

13W704

13W705

8. INSTALLATION OF SEAL RING

When installing seal ring, press firmly into valve groove.

INSTALLATION OF CAGE/10. BALL/11. BEARING

9.

RACE/12. MAIN SHAFT

(1) Apply specified fluid to valve body.

Specified fluid: Automatic transmission fluid

DEXRON or DEXRON II

(2) Wrap vinyl tape around the serrated part so that the oil

seal won’t be damaged when the valve body is installed

tot he valve housing.

(3) Mount the valve body to the valve housing

(4) Align the cage’s hole and the channel in the main shaft,

and insert two or three balls.

(5) Insert the remainder of the balls into the cage’s hole

while pressing the ball with the bearing race.

13W058

13W089

(6) When installing the main shaft, connect it to the valve

housing while pressing the bearing race so that the balls

do not come out.

21

Page 45

<Deleted>

STEERING – Power Steering Gear Box

INSTALLATION OF LOCK NUT

13.

Using the special tool,tighten carefully until the lock nut

contacts the bearing race.

13W719

ADJUSTMENT OF MAIN SHAFT AXIAL PLAY

•

(1) Adjust the play by tightening the lock nut gradually so

that the mainshaft axial play will meet the range of

standard value.

37-31

Dial gauge

13W700

13E0077

13W063

Standard value: 0.03 mm (0.0012 in.) or less

(2) Use a punch to crimp the circumference of the lock nut

so as to secure the lock nut.

(3) Check to be sure that the mainshaft rotates smoothly.

INSTALLATION OF RACK PISTON

16.

(1) Install the rack piston until it comes in contact with the

edge of the main shaft.

(2) Rotate the main shaft to align the ball raceway with the

19-ball insertion hole.

NOTE

The balls must be inserted so that there is no clearance

between the balls.

(3) Set the remaining seven balls in the circulator, and

install the circulator to the rack piston.

22

13W093

Page 46

37-32

Adjusting

bolt

Adjusting

plate

13C592

STEERING – Power Steering Gear Box

INSTALLATION OF VALVE HOUSING

<Deleted>

13Y553

20.

(1) Apply specified automatic transmission fluid to the seal

ring of the rack piston.

Specified fluid: Automatic transmission fluid

(2) Insert the valve housing.

(3) Rotate the main shaft until the rack piston moves to the

neutral position (center).

INSTALLATION OF ADJUSTING PLATE/25. ADJUSTING

24.

BOLT

(1) Install the adjusting plate so that the beveled part is

facing downward.

(2) Using a thickness gauge, measure the clearance

between the adjusting bolt and cross-shaft.

Standard value: 0 - 0.05 mm (0 – 0.002 in.)

(3) If the clearance is exceeded the standard value, replace

with a suitable adjusting plate.

INSTALLATION OF CROSS-SHAFT/27. ADJUSTING

26.

BOLT LOCK NUT

Install the cross-shaft to the side cover, and then temporarily

tighten the adjusting bolt lock nut.

DEXRON or DEXRON II

Y-packing

Oil seal

13W059

13W698

INSTALLATION OF SIDE COVER AND CROSS-SHAFT

29.

ASSEMBLY

Install the side cover assembly (with the corss-shaft) to the

gear box.

NOTE

Apply specified automatic transmission fluid to the teeth and

shaft areas of the rack piston, and apply multipurpose

grease to the oil seal lip.

Specified fluid: Automatic transmission fluid DEXRON

or DEXRON II

Caution

Do not rotate the side cover during installation. Take

care not to damage the cross-shaft oil seal.

23

Page 47

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

No.:

MSB-98E42-502

QUALITY INFORMATION ANALYSIS

Date

:

1999-06-30

Subject:

Group:

CORRECTION

1. Description:

Minimum entrapment amount detected for the power window with safety mechanism, has been

corrected.

2. Applicable Manuals:

’98 PAJERO PWJE9086-I (English) 42-6

Workshop Manual chassis PWJS9087-I (Spanish)

3. Details:

CORRECTING MINIMUM ENTRAPMENT

AMOUNT FOR POWER WINDOW WITH SAFETY

MECHANISM

BODY

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

Draft No.:

T.NITTA - VICE GENERAL MANAGER

QUALITY INFORMATION ANAL YSIS

PWJF9088-I (French)

PWJG9089-I (German)

PWJD9090-I (Dutch)

PWJW9091-I (Swedish)

98SY012115

<Model> <M/Y>

(EC,EXP)PAJERO

(V10,V20,V30,V40)

98-10

Page 48

42-6

BODY - Door

Inspection Procedure 6

The glass is not lowered when something is jammed in the

window

The cause may be a malfunction of the revolution detection sensor in the power

window motor-ECU.

Replace the power window motor-ECU.

Probable cause

•

Malfunction of the power window motor-ECU

Inspection Procedure 7

10 mm

<Corrected>

When the glass is fully raised, it then lowers automatically.

When the window is within 15 mm of being fully closed, the limit switch turns off to

prevent the window from being lowered. However, the above problem can occur if

there is a malfunction of the limit switch in the power window motor-ECU.

Limit switch operation position adjustment (Refer to P.42-13.)

Check trouble symptoms.

NG

Replace the power window motor-ECU

Probable cause

•

Malfunction of the power window motor-ECU

2

Page 49

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

No.:

MSB-98E54-002

QUALITY INFORMATION ANALYSIS

Date

:

1998-11-30

Subject:

Group:

INFORMATION

1. Description:

This Service Bulletin informs you as to rectification of omission of the A/T-ECU (16-pin) connector

and correction of pin numbers, in the Wiring Harness Configuration Diagrams and in the ELC-4speed Automatic Transmission Circuit Diagram.

2. Applicable Manuals:

’98 PAJERO PWJE9086-I (English) 23-1, 3

Workshop Manual PHJS9087-G (Spanish) 23-1, 3

Supplement PHJF9088-G (French)

’98 PAJERO

Electrical Wiring

Supplement

3. Details:

CORRECTION TO ELC 4-SPEED AUTOMATIC

TRANSMISSION CIRCUIT

CHASSIS

ELECTRICAL

OVERSEAS

SERVICE

DEPT

Manual Pub. No. Language Page(s)

Draft No.:

T.NITTA - VICE GENERAL MANAGER

QUALITY INFORMATION ANAL YSIS

PHJG9089-G (German)

PHJD9090-G (Dutch)

PHJW9091-G (Swedish)

PHJE9026-G (English) 2-28, 29, 32, 33,

PHJS9027-G (Spanish) 2-16, 17

PHJF9028-G (French) 4-54, 55, 56, 57, 59,

PHJG9029-G (German) 60

PHJD9030-G (Dutch)

PHJW9031-G (Swedish)

98SY042011

<Model> <M/Y>

(EC,EXP) PAJERO

(V10,V20,V30,V40)

4-96, 97, 98, 99,

101, 102

98-10

Page 50

AUTOMATIC TRANSMISSION - General/Specifications/Lubricants

23 -1

GROUP 23

AUTOMATIC TRANSMISSION

GENERAL

OUTLINE OF CHANGES

•

A 6G74-SOHC 24-valve engine has been added to correspond to this, the maintenance service procedures which

are different from the previous V4AW3-7-type automatic transmission are given below.

•

The shift pattern for V4AW3-type automatic transmission for vehicles with 6G72-SOHC 24-valve engine has been

changed. To correspond to this, the maintenance service procedures which are different from the previous V4AW3type automatic transmission are given below.

•

A/T-ECU connectors have been changed.

SPECIFICATIONS

TRANSMISSION MODEL TABLE

<Added>

Transmission model Speedometer gear ratio Vehicle model Engine model (Engine displacement)

V4AW3-B-LIA 29/9 V43W 6G72-SOHC 24 Valve (3,000)

V4AW3-7-LILA 29/9 V43W 6G72-SOHC 24 Valve (3,000)

V4AW3-B-LHA 28/9 V23C, V23W 6G72-SOHC 24 Valve (3,000)

V4AW3-B-LHLA 28/9 V23C, V23W 6G72-SOHC 24 Valve (3,000)

V4AW3-B-MFA 26/9 V25W, V45W 6G74-SOHC 24 Valve (3,500)

V4AW3-B-MFLA 26/9 V25W, V45W 6G74-SOHC 24 Valve (3,500)

SERVICE SPECIFICATIONS

Item 6G72-SOHC 24 Valve 6G74-SOHC 24 Valve

Stall speed r/min 2,000 - 2,500 2,200 - 2,700

Dimensions of inner cable stopper and

outer cable end mm

34 - 35 34 - 35

LUBRICANTS

Item Specified lubricants Quantity

Automatic transmission fluid DIA QUEN ATF-SP, ATF DEXRON II or equivalent Approx. 9.8

l

Page 51

AUTOMATIC TRANSMISSION - Troubleshooting

<6G74-SOHC 24 Valve Engine>

Normal pattern

Throttle opening (%)

Output shaft speed r/min

Output shaft speed r/min

23-3

Power pattern

Throttle opening (%)

Output shaft speed r/min

3

Page 52

SERVICE BULLETIN

OVERSEAS SERVICE DEPT. MITSUBISHI MOTORS CORPORATION

SERVICE BULLETIN

No.:

MSB-99E11-502

QUALITY INFORMATION ANALYSIS

Date

:

1999-11-15

Subject:

Group:

INFORMATION

1. Description:

This service bulletin informs you of correction of 4M40 Engine Idle up speed (For Anti-Skid brake).

2. Applicable Manuals:

’97 PAJERO PWJE9086-H (English)

Workshop Manual PWJS9087-H (Spanish)

SUPPLEMENT PWJF9088-H (French)

CORRECTION OF 4M40 ENGINE IDLE UP

SPEED (FOR ANTI-SKID BRAKE)

ENGINE

INTERNATIONAL

CAR

ADMINISTR ATION

OFFICE

Manual Pub. No. Language Page(s)

Draft No.:

98-SY-610211

T.NITTA - PROJECT LEADER

AFTER SALES SERVICE & CS PROMOTION

PWJG9089-H (German)

PWJD9090-H (Dutch)

PWJW9091-H (Swedish)

<Model> <M/Y>

(EC) PAJERO

(V10,V20,V30,V40)

97-10

3. Effective Date:

’97, ’98 model year

4. Details:

Refer to the attached sheets.

Page 53

ENGINE

GENERAL

OUTLINE OF CHANGES

Idle up speed (For Anti-Skid Brake) of 4M40 engine was changed.

SPECIFICATIONS

SERVICE SPECIFICATIONS

Items Standard value

Idle up speed (for anti-skid brake) r/min. 1500 ± 50 (’97, ’98 Model Year)

ENGINE <4M40>

SERVICE ADJUSTMEN PROCEDURE

THROTTLE OPENER INSPECTION AND ADJUSTMENT FOR ABS