Mitsubishi MCFH-GA35VB-E1, MCFH-GA50VB-E1, MCFH-GA60VB-E1 Service Manual

(When installed on the ceiling)

(When installed on the floor)

FLOOR AND CEILING TYPE AIR CONDITIONERS

INDOOR UNIT

SERVICE MANUAL

Wireless type

Models

Revision A:

● RoHS PARTS LIST has been added.

Please void OB380.

No. OB380

REVISED EDITION-A

MCFH-GA35VB MCFH-GA50VB MCFH-GA60VB -

E1

E1

E1

Outdoor unit service manual

MUCFH-GA•VB Series (OB381)

MXZ-A•WV Series (OB319)

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················2

3. SPECIFICATION·················································4

4. NOISE CRITERIA CURVES·······························5

5. OUTLINES AND DIMENSIONS·························6

6. WIRING DIAGRAM ············································7

7. REFRIGERANT SYSTEM DIAGRAM················8

8. SERVICE FUNCTIONS ······································9

9. TROUBLESHOOTING ······································11

10. DISASSEMBLY INSTRUCTIONS·····················19

11. PARTS LIST······················································21

12. RoHS PARTS LIST···········································23

13. OPTIONAL PARTS ···········································25

NOTE:

This service manual describes technical data of the indoor units.

RoHS compliant products have <G> mark on the spec name plate.

For servicing of RoHS compliant products, refer to the RoHS PARTS LIST (RoHS compliant).

(When installed on the floor)

(When the air inlet grille is opened.)

Deodorizing filter

(gray sponge type)(option)

Air filter

Air inlet

Operation section

Air cleaning filter

(white bellows type)(option)

Front panel

Receiving section

Operation indicator lamp

Horizontal vane

Vertical vanes

Emergency

operation switch

(When installed on the ceiling)

ACCESSORIES

Item

Installation plate

Unit fixing screw

5 o 12mm

Wireless remote

controller

Remote controller

mounting hardware

Fixing screw for

3.5 o 16mm (Black)

Battery (AAA) for

remote controller

Drain hose

Drain pipe cover

Knockout cover

Screw for 4 o 10mm

2

2

1

1

2

2

1

1

1

2

Q'ty

Remote controller

Revision A :

• RoHS PARTS LIST has been added.

1

MCFH-A12WV- ➔ MCFH-GA35VB-

1. Model name has been changed.

MCFH-A18WV- ➔ MCFH-GA50VB-

1. Model name has been changed.

MCFH-A24WV- ➔ MCFH-GA60VB-

1. Model name has been changed.

2

TECHNICAL CHANGES

E1E1

E1E1

E1E1

PART NAMES AND FUNCTIONS

MCFH-GA35VB MCFH-GA50VB MCFH-GA60VB

2

MCFH-GA35VB

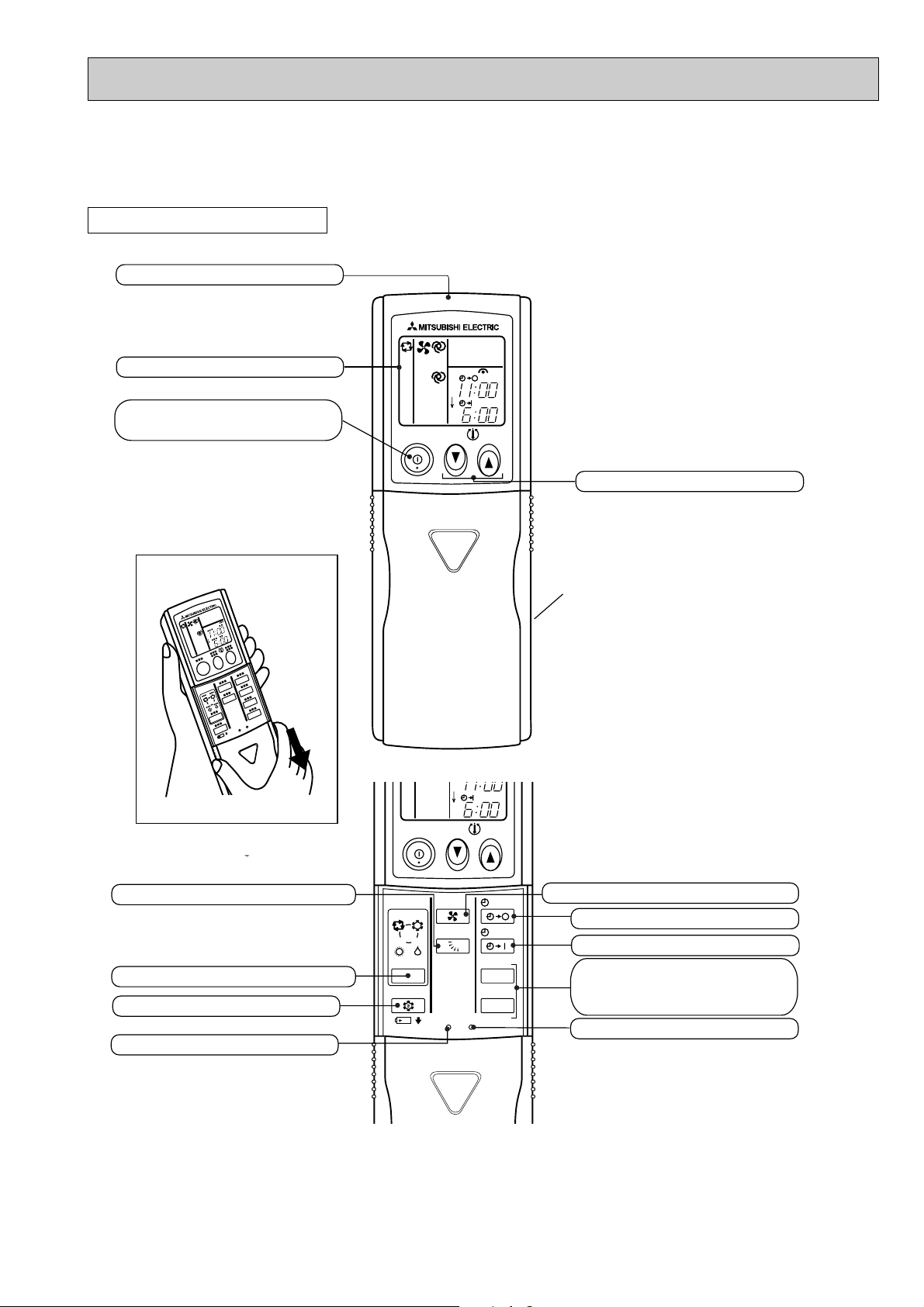

ON/OFF

FAN

TOO

WARM

TOO

COOL

VANE

MODE

ECONO COOL

STOP

START

HR.

MIN.

I FEEL

COOL

HEAT

DRY

PM

CLOCK

AM

RESET CLOCK

ON/OFF

TOO

COOL

PM

AM

TOO

WARM

Open the front lid.

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

TEMPERATURE buttons

OPERATION SELECT button

FAN SPEED CONTROL button

OFF-TIMER button

ON-TIMER button

RESET button

ECONO COOL button

VANE CONTROL button

CLOCK SET button

HR. button

MIN. button

(TIME SET button)

Indication of remote controller model

is on back.

MCFH-GA50VB

MCFH-GA60VB

REMOTE CONTROLLER

3

3

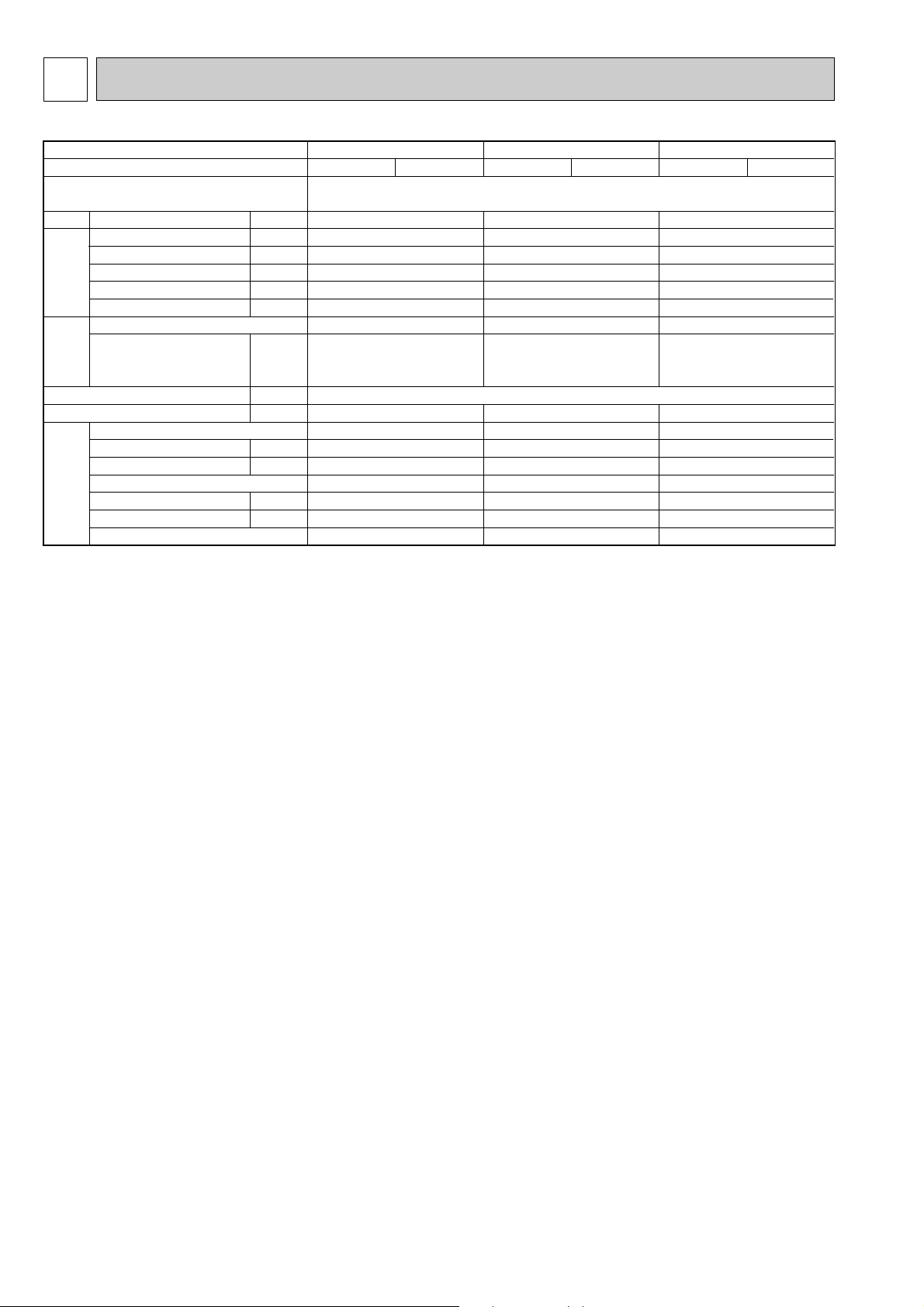

Indoor model

Function

Power supply

Air flow(High/Med.W/LowW)

Power outlet

Running current

Power input

Power factor

Fan motor current

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Air direction

Sound level(High/Med.W/LowW)

Fan speed(High/Med.W/LowW)

Fan speed regulator

Thermistor RT11(at25:)

Thermistor RT12(at25:)

Remote controller model

K /h

A

A

W

%

A

"

mm

kg

dB

rpm

k"

k"

Electrical

data

Fan

motor

Special

remarks

Capacity

MCFH-GA35VB MCFH-GA50VB MCFH-GA60VB

Cooling Heating

780/636W/492W

10

0.30

66

96

0.30

RB4V25-AC

WHT-BLK 182.2 BLK-YLW 68.9

YLW-BLU 47.5 BLU-BRN 31.5

BRN-RED 22.9

25

5

46/41W/36W

1,240/1,060/845

3

10

10

KM04M

Cooling Heating

Single phase

230V, 50Hz

840/696W/570W

10

0.36

80

97

0.36

RB4V36-AC

WHT-BLK 82.9 BLK-YLW 65.6

YLW-BLU 36.0 BLU-BRN 27.0

BRN-RED 13.7

1100 ✕ 650 ✕ 180

25

5

48/44W/39W

1,320/1,145/960

3

10

10

KM04M

Cooling Heating

840/744W/642W

10

0.36

80

97

0.36

RB4V36-DB

WHT-BLK 84.0 BLK-YLW 46.2

YLW-BLU 37.2 BLU-BRN 45.2

BRN-RED 13.6

25

5

48/45W/42W

1,320/1,190/1,060

3

10

10

KM04M

SPECIFICATION

NOTE: Test conditions are based on ISO 5151

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C WB 15°C

Outdoor DB35°C WB(24°C) Outdoor DB 7°C WB 6°C

Indoor-Outdoor piping length : 5 m

w Reference value

4

4

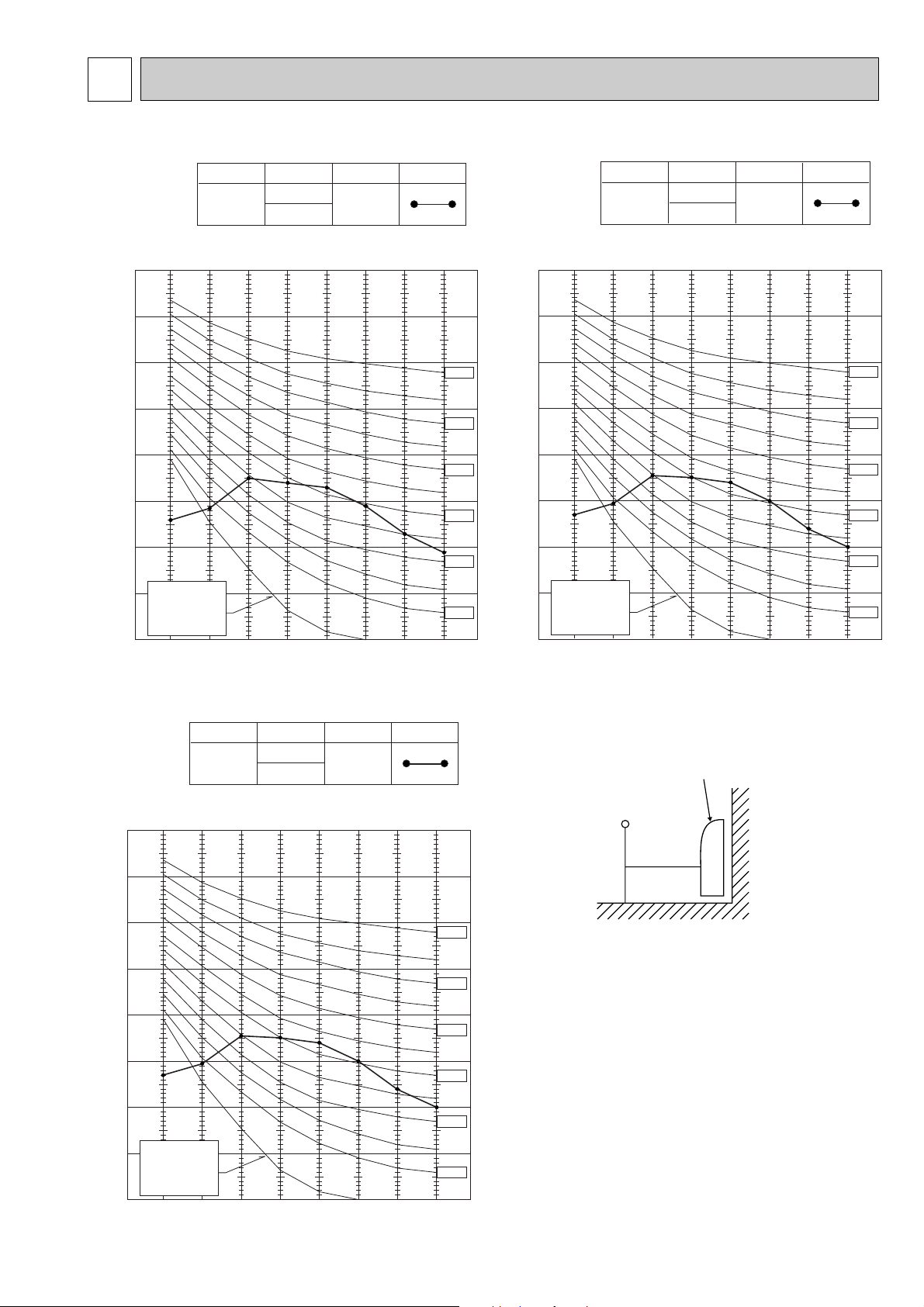

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:\

Heating : DB 20: WB 15:

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

COOLING

HEATING

FUNCTION

High

FAN SPEED

48

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:\

Heating : DB 20: WB 15:

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

COOLING

HEATING

FUNCTION

High

FAN SPEED

46

SPL(dB

(A)) LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions,

Cooling : DB 27: WB 19:\

Heating : DB 20: WB 15:

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

COOLING

HEATING

FUNCTION

High

FAN SPEED

48

SPL(dB

(A)) LINE

INDOOR UNIT

WALL

1m

1m

MICROPHONE

NOISE CRITERIA CURVES

MCFH-GA35VB

MCFH-GA50VB

MCFH-GA60VB

5

5

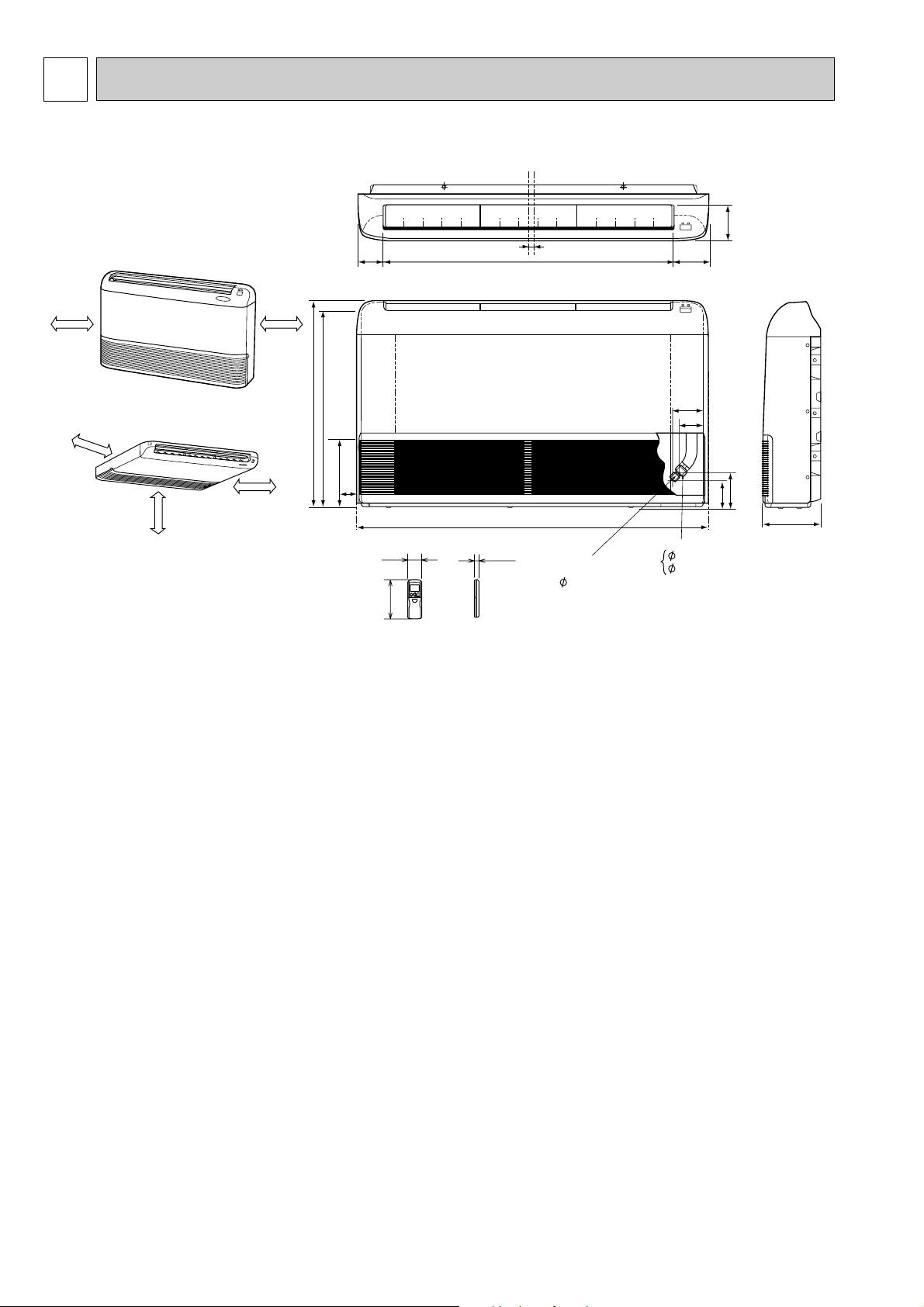

(When installed on the floor)

(When installed on the ceiling)

50cm or more

5

0

c

m

o

r m

o

re

50cm or more

50cm or more

100cm or more

650

616.5

80.8 906 112.8

114

16

1100

93

77

113

143

180

17042.5

12.7 (MCFH-GA35/GA50VB)

15.88 (MCFH-GA60VB)

Gas line

6.35

Liquid line

Wireless remote controller

162

19

58

OUTLINES AND DIMENSIONS

MCFH-GA35VB

MCFH-GA50VB

MCFH-GA60VB

Unit: mm

6

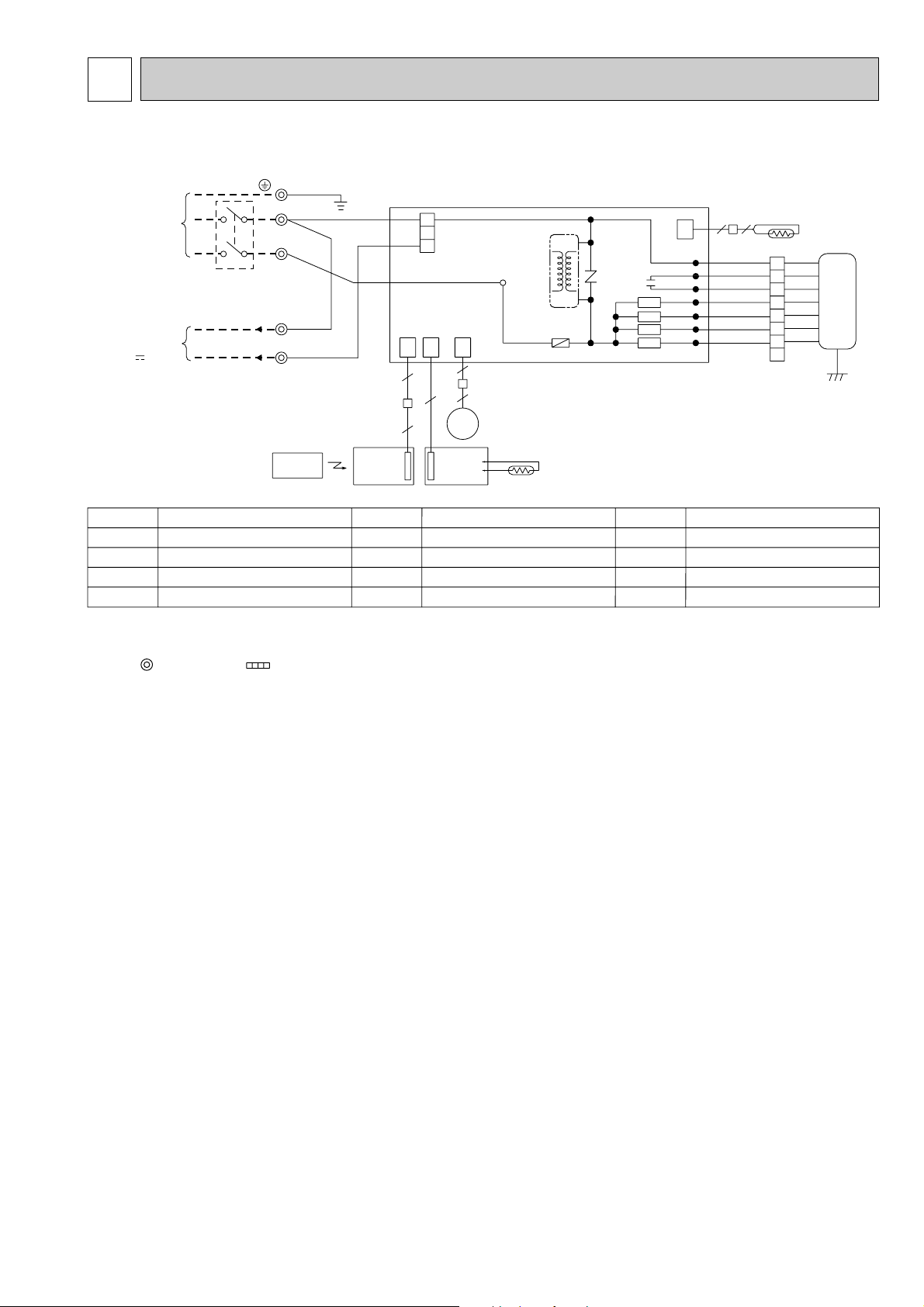

WIRING DIAGRAM6

TAB12

ELECTRONIC CONTROL P.C BOARD

SR142

SR143

X144

CN201

BRN

RECEIVER

P.C.BOARD

CONTROLLER

REMOTE

DISP/

12V

CONNECTING

TO OUTDOOR

UNIT

3

N

RT11

P.C.BOARD

SW/THERMO

113 151101

MV

4

5

5

5

6

CN CN CN

C11

50Hz

SUPPLY

POWER

L

N

1

3

2

7

8

LDFH

LDFL

LDFM

LDC12

LDC11

LDCOM

BLK

BLU

YLW

6

5

4

ORN

RED

WHT

2

3

1

GRN/YLW

BLK

MF

BLU

BRN

YLW

ORN

RED

WHT

2

112

CN

2

RT12

BLU

RED

BLU

TB1

GRN/YLW

~/N 230V

BRN

SR141

LDFVL

TB2

PE

CIRCUIT BREAKER

HIC1

F11

NR11

SYMBOL

SR141~SR143

TB1, TB2

X144

SYMBOL

MV

NR11

RT11

RT12

NAME

NAME NAME

INDOOR FAN CAPACITOR

FUSE (3.15A)

DC/DC CONVERTER

INDOOR FAN MOTOR(INNER FUSE)

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMIST OR

INDOOR COIL THERMISTOR

SOLID STATE RELAY

TERMINAL BLOCK

RELAY

1.About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2.Use copper conductors only. (For field wiring)

3.Symbols below indicate.

: Connector

: Terminal block

NOTES:

SYMBOL

C11

F11

HIC1

MF

MCFH-GA35VB MCFH-GA50VB MCFH-GA60VB

7

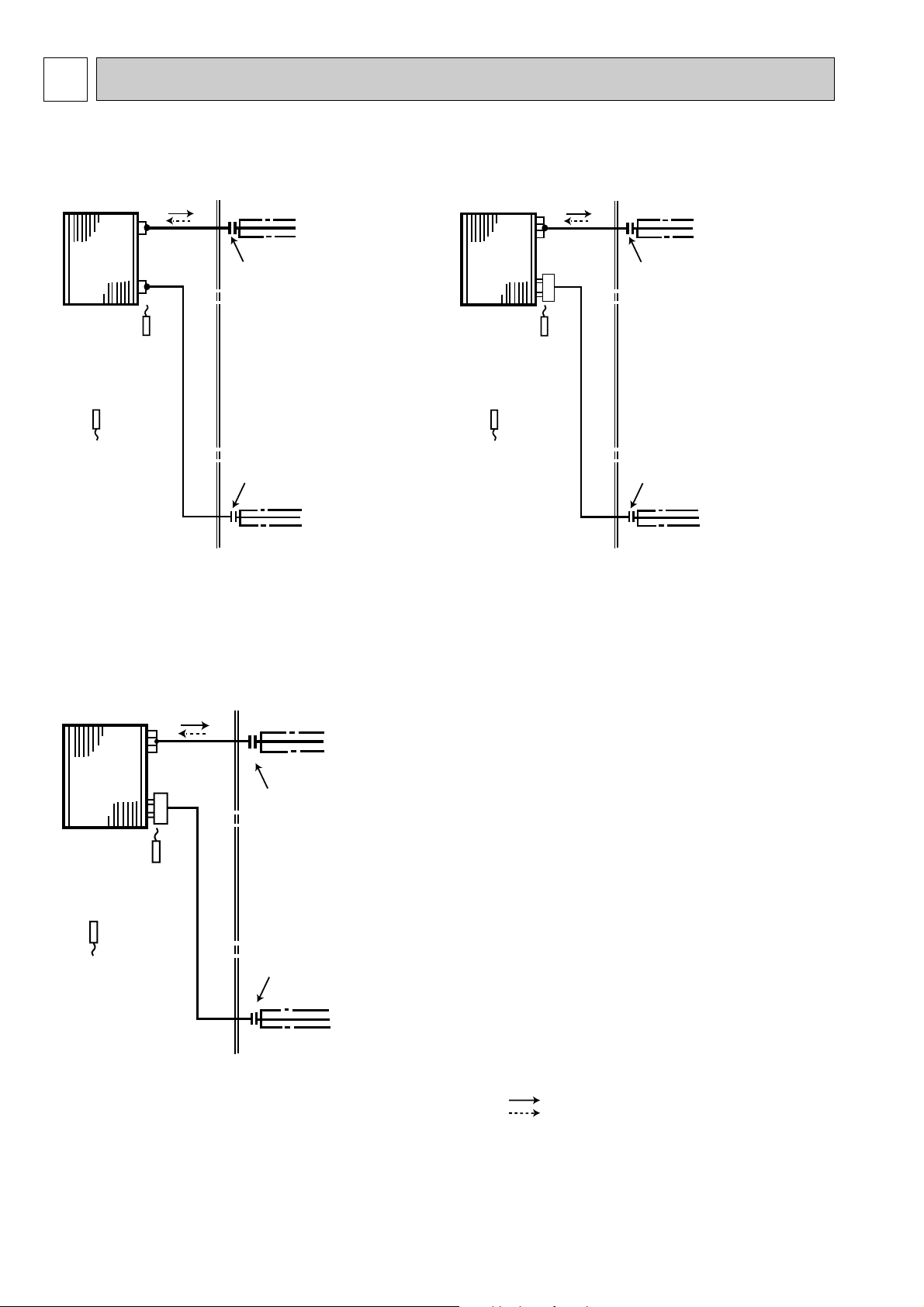

REFRIGERANT SYSTEM DIAGRAM7

Indoor

heat

exchanger

Distributor

Flared connection

Room temperature

thermistor

RT11

Flared connection

Refrigerant flow in cooling

Refrigerant flow in heating

Refrigerant pipe [15.88

(with heat insulator)

Refrigerant pipe

[6.35

(with heat insulator)

Indoor coil

thermistor

RT12

Indoor

heat

exchanger

Distributor

Flared connection

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Flared connection

Refrigerant pipe [12.7

(with heat insulator)

Refrigerant pipe

[6.35

(with heat insulator)

Indoor

heat

exchanger

Distributor

Flared connection

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Flared connection

Refrigerant pipe [12.7

(with heat insulator)

Refrigerant pipe

[6.35

(with heat insulator)

MCFH-GA35VB

Unit : mm

MCFH-GA50VB

MCFH-GA60VB

8

SERVICE FUNCTIONS8

No. 1 unit

No. 2 unit

No. 3 unit

No. 4 unit

1 unit operation

No modification

–

–

–

2 units operation

Same as at left

Solder J1

–

–

3 units operation

Same as at left

Same as at left

Solder J2

–

4 units operation

Same as at left

Same as at left

Same as at left

Solder both J1 and J2

MCFH-GA35VB MCFH-GA50VB MCFH-GA60VB

8-1. TIMER SHORT MODE

For service, set time can be shortened by short circuit of JPG and JPS on the electronic control P.C. board.

The time will be shortened as follows. (Refer to 9-6.)

3-minutes time delay : 3-minutes → 3-seconds

Set time : 1 minute ➔ 1-second

Set time : 3 minute ➔ 3-second (It takes 3 minutes for the compressor to start operation. However, the starting time is

shortened by short circuit of JPG and JPS.)

8-2. P.C. BOARD MODIFICATION FOR INDIVIDUAL OPERATION

A maximum of 4 indoor units with wireless remote controllers can be used in a room. In this case, to operate each

indoor unit individually by each remote controller, P.C. boards of remote controller must be modified according to the

number of the indoor unit.

How to modify the remote controller P.C. board

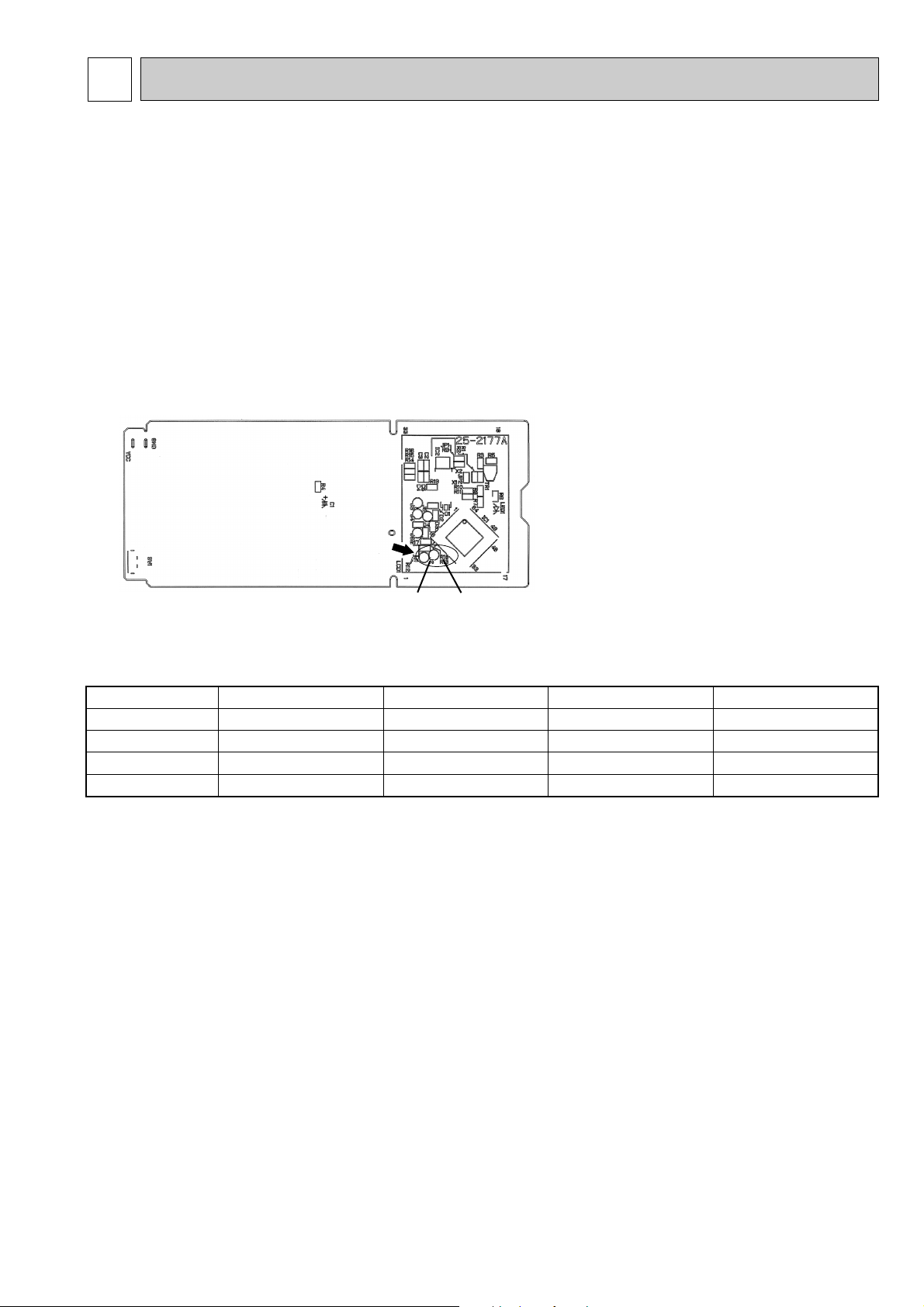

Remove batteries before modification. The board has a print as shown below;

NOTE : For remodelling, take out the batteries and

press the OPERATE/STOP(ON/OFF) button

twice or 3 times at first.

After finish remodelling, put back the

batteries then press the RESET button.

J2J1

The P.C. board has the print “J1” and “J2”. Solder “J1” and “J2” according to the number of indoor unit as shown in

Table 1. After modification, press the RESET button.

Table1.

How to set the remote controller exclusively for particular indoor unit

After you turn the breaker ON, the first remote controller that sends the signal to the indoor unit will be regarded as the

remote controller for the indoor unit.

The indoor unit only accepts the signal from the remote controller that has been assigned to the indoor unit once they are

set.

The setting will be cancelled if the breaker has turned OFF, or the power supply has shut down.

Please conduct the above setting once again after the power has restored.

9

Loading...

Loading...