Page 1

Service Manual

™

|

™

|

Anesthesia System

™

Page 2

Service Manual

™

|

™

|

Anesthesia System

™

Page 3

A5™, A4™, and A3™ are U.S. trademarks of Mindray DS USA, Inc.

Selectatec® is a registered trademark of Ohmeda.

Copyright © Mindray DS USA, Inc., 2010 to 2019. All rights reserved. Contents of this publication may not be reproduced in

any form without permission of Mindray DS USA, Inc.

Page 4

Page 5

Table of Contents

Table of Contents

Table of Contents .................................................................................................................................................................................................................1

Foreword .................................................................................................................................................................................................................................1

Warnings, Cautions, and Notes.......................................................................................................................................................................................1

Warnings..................................................................................................................................................................................................................................1

Cautions...................................................................................................................................................................................................................................2

Notes.........................................................................................................................................................................................................................................3

Theory of Operation ............................................................................................................................................ 1 - 1

Introduction..........................................................................................................................................................................................1 - 2

Electrical and Pneumatic Connections .......................................................................................................................................1 - 4

Electrical Connections (A3/A4).......................................................................................................................................................................1 - 4

Electrical Connections (A5)..............................................................................................................................................................................1 - 7

Pneumatic Connections (A3/A4)....................................................................................................................................................................1 - 9

Pneumatic Connection (A5).......................................................................................................................................................................... 1 - 13

Connections Between Pneumatic Circuit, Breathing System and Ventilator Control Board................................................1 - 17

Gas Flow .............................................................................................................................................................................................. 1 - 20

Pneumatic Circuit Diagram...........................................................................................................................................................................1 - 20

Parts List...............................................................................................................................................................................................................1 - 21

Key to Symbols.................................................................................................................................................................................................. 1 - 22

Description.......................................................................................................................................................................................................... 1 - 22

Anesthesia System Components ............................................................................................................................................... 1 - 38

Auxiliary Outlets................................................................................................................................................................................................1 - 38

Work Light Board..............................................................................................................................................................................................1 - 38

The Breathing System .................................................................................................................................................................... 1 - 41

Brief Introduction ............................................................................................................................................................................................. 1 - 41

Automatic Mode, Inspiration .......................................................................................................................................................................1 - 41

Automatic Mode, Expiration ........................................................................................................................................................................ 1 - 42

Manual Mode, Inspiration ............................................................................................................................................................................. 1 - 42

Manual Mode, Expiration............................................................................................................................................................................... 1 - 43

Pneumatic PEEP ................................................................................................................................................................................................1 - 44

Ventilator in Standby ......................................................................................................................................................................................1 - 44

Breathing System Components.................................................................................................................................................................. 1 - 44

Ventilator UI ....................................................................................................................................................................................... 1 - 46

Display..................................................................................................................................................................................................................1 - 46

CPU Board ...........................................................................................................................................................................................................1 - 53

Ventilator Control and Drive........................................................................................................................................................ 1 - 56

Mother Board..................................................................................................................................................................................................... 1 - 56

Ventilator Control and Drive Board ...........................................................................................................................................................1 - 66

Battery ..................................................................................................................................................................................................................1 - 73

Infrared Communication Board .................................................................................................................................................................. 1 - 75

Breathing System Heater............................................................................................................................................................................... 1 - 76

Ventilator Pneumatic- O2 Drive Gas ......................................................................................................................................... 1 - 77

Ventilator Pneumatic Drive...........................................................................................................................................................................1 - 77

Drive Pressure-High Pressure Regulator (200 kPa, 29 psi).................................................................................................................1 - 77

Drive Gas Assembly ......................................................................................................................................................................................... 1 - 77

Tube Color Coding........................................................................................................................................................................................... 1 - 77

Installation Guide ................................................................................................................................................ 2 - 1

Preparation - Additional Material Required ..............................................................................................................................2 - 2

Assembly................................................................................................................................................................................................2 - 3

Unpacking and Setup ........................................................................................................................................................................................2 - 3

Breathing System and Breathing System Accessories and Checkout Procedures................................................................... 2 - 17

Vaporizers (if available) .................................................................................................................................................................................. 2 - 17

Monitoring Products Mounting and Electrical Connection (if available).....................................................................................2 - 19

Software and License Key Installation...................................................................................................................................... 2 - 22

Functional Tests................................................................................................................................................................................ 2 - 22

Breathing System Leak Test.......................................................................................................................................................................... 2 - 22

A5/A4/A3™ Service Manual 046-001141-00 1

Page 6

Table of Contents

Check the AG Module Accuracy.................................................................................................................................................................. 2 - 30

Gas Module Verification................................................................................................................................................................................. 2 - 31

Gas Delivery System Tests............................................................................................................................................................................. 2 - 31

Check the Sensor Zero Point........................................................................................................................................................................ 2 - 33

Check the Flow Sensor Accuracy................................................................................................................................................................2 - 34

Check the Pressure Sensor Accuracy......................................................................................................................................................... 2 - 39

Check the electronic flowmeter accuracy ............................................................................................................................................... 2 - 43

Pneumatic Leak Tests ..................................................................................................................................................................... 2 - 46

N2O Cylinder Leak Test (A5 and A3 only)................................................................................................................................................ 2 - 46

O2 Cylinder Leak Test......................................................................................................................................................................................2 - 46

AIR Cylinder Leak Test..................................................................................................................................................................................... 2 - 46

Line Pressure Leak Tests................................................................................................................................................................................. 2 - 47

Line Pressure Gauges Accuracy Test.........................................................................................................................................................2 - 48

Breathing System Checks.............................................................................................................................................................. 2 - 49

Waste Gas Scavenger Test (if available) ................................................................................................................................................... 2 - 49

Internal Gas Connections Test..................................................................................................................................................................... 2 - 49

Drive Gas Pressure Loss Alarm, N2O Cutoff Test................................................................................................................................... 2 - 50

Performance Verification............................................................................................................................................................... 2 - 50

Manual Ventilation Test ................................................................................................................................................................................. 2 - 50

Manual Mode Ventilation Test..................................................................................................................................................................... 2 - 50

APNEA Alarm Test ............................................................................................................................................................................................ 2 - 51

Alarm Silence Test............................................................................................................................................................................................ 2 - 51

VCV Adult Ventilation Mode Test ............................................................................................................................................................... 2 - 52

VCV Adult Ventilation Mode Test 2............................................................................................................................................................2 - 52

VCV Child Ventilation Mode Test................................................................................................................................................................ 2 - 53

Airway Disconnect Alarm Test.....................................................................................................................................................................2 - 54

PCV Adult Ventilation Mode Test ............................................................................................................................................................... 2 - 54

Pressure Support (PS) Ventilation Mode Test ........................................................................................................................................ 2 - 55

Alarms and Fail safe Functions.................................................................................................................................................... 2 - 56

Set Up....................................................................................................................................................................................................................2 - 56

Low FiO2 Alarm Test........................................................................................................................................................................................ 2 - 56

High FiO2 Alarm Test ......................................................................................................................................................................................2 - 56

Peak Pressure Alarms Test............................................................................................................................................................................. 2 - 57

Minute Volume Alarm Test ...........................................................................................................................................................................2 - 57

Miscellaneous Tests......................................................................................................................................................................... 2 - 58

Test the Line Voltage Alarm..........................................................................................................................................................................2 - 58

Top Light and Auxiliary Light Test..............................................................................................................................................................2 - 58

Touchpad /USB Mouse Test..........................................................................................................................................................................2 - 58

Vaporizer Interlock Test................................................................................................................................................................. 2 - 58

Vaporizer Accuracy Test ................................................................................................................................................................ 2 - 59

Electrical Tests................................................................................................................................................................................... 2 - 60

Auxiliary Electrical Outlet Test..................................................................................................................................................................... 2 - 60

Electrical Safety Inspection Test.................................................................................................................................................................. 2 - 60

Electrical Safety Inspection Form................................................................................................................................................................ 2 - 61

Periodic Maintenance.......................................................................................................................................... 3 - 1

Maintenance Schedule .....................................................................................................................................................................3 - 2

Periodical Maintenance Consumable Parts Kits ......................................................................................................................3 - 2

Periodical Maintenance Schedule ................................................................................................................................................3 - 2

Checklist before surgery................................................................................................................................................................... 3 - 3

Visual Inspection Checklist ..............................................................................................................................................................3 - 4

List of Periodic Maintenance Parts to be Replaced and Checked .....................................................................................3 - 4

Battery Maintenance and Replacement .....................................................................................................................................3 - 8

Functional Tests...................................................................................................................................................................................3 - 9

Breathing System Leak Test.............................................................................................................................................................................3 - 9

Check the AG Module Accuracy.................................................................................................................................................................. 3 - 16

Gas Module Verification................................................................................................................................................................................. 3 - 17

Gas Delivery System Tests............................................................................................................................................................................. 3 - 17

Check the Sensor Zero Point........................................................................................................................................................................ 3 - 19

2 046-001141-00 A5/A4/A3™ Service Manual

Page 7

Table of Contents

Check the Flow Sensor Accuracy................................................................................................................................................................3 - 20

Check the Pressure Sensor Accuracy......................................................................................................................................................... 3 - 25

Check the electronic flowmeter accuracy ............................................................................................................................................... 3 - 29

Pneumatic Leak Tests ..................................................................................................................................................................... 3 - 32

N2O Cylinder Leak Test (A5 and A3 only)................................................................................................................................................ 3 - 32

O2 Cylinder Leak Test......................................................................................................................................................................................3 - 32

AIR Cylinder Leak Test..................................................................................................................................................................................... 3 - 32

Line Pressure Leak Tests................................................................................................................................................................................. 3 - 33

Line Pressure Gauges Accuracy Test.........................................................................................................................................................3 - 34

Breathing System Checks.............................................................................................................................................................. 3 - 35

Waste Gas Scavenger Test (if available) ................................................................................................................................................... 3 - 35

Internal Gas Connections Test..................................................................................................................................................................... 3 - 35

Drive Gas Pressure Loss Alarm, N2O Cutoff Test................................................................................................................................... 3 - 36

Performance Verification............................................................................................................................................................... 3 - 37

Manual Ventilation Test ................................................................................................................................................................................. 3 - 37

Manual Mode Ventilation Test..................................................................................................................................................................... 3 - 37

APNEA Alarm Test ............................................................................................................................................................................................ 3 - 38

Alarm Silence Test............................................................................................................................................................................................ 3 - 38

VCV Adult Ventilation Mode Test ............................................................................................................................................................... 3 - 38

VCV Child Ventilation Mode Test................................................................................................................................................................ 3 - 39

Airway Disconnect Alarm Test.....................................................................................................................................................................3 - 39

PCV Adult Ventilation Mode Test ............................................................................................................................................................... 3 - 40

Pressure Support (PS) Ventilation Mode Test ........................................................................................................................................ 3 - 41

Alarms and Fail safe Functions.................................................................................................................................................... 3 - 42

Set Up....................................................................................................................................................................................................................3 - 42

Low FiO2 Alarm Test........................................................................................................................................................................................ 3 - 42

High FiO2 Alarm Test ......................................................................................................................................................................................3 - 42

Peak Pressure Alarms Test............................................................................................................................................................................. 3 - 43

Minute Volume Alarm Test ...........................................................................................................................................................................3 - 43

Miscellaneous Tests......................................................................................................................................................................... 3 - 44

Test the Line Voltage Alarm..........................................................................................................................................................................3 - 44

Top Light and Auxiliary Light Test..............................................................................................................................................................3 - 44

Touchpad /USB Mouse Test..........................................................................................................................................................................3 - 44

Vaporizer Interlock Test................................................................................................................................................................. 3 - 44

For 2 vaporizer Mount ....................................................................................................................................................................................3 - 44

For 3 vaporizer Mount ....................................................................................................................................................................................3 - 45

Vaporizer Accuracy Test ................................................................................................................................................................ 3 - 46

Electrical Tests................................................................................................................................................................................... 3 - 47

Auxiliary Electrical Outlet Test..................................................................................................................................................................... 3 - 47

Electrical Safety Inspection Test.................................................................................................................................................................. 3 - 47

Electrical Safety Inspection Form................................................................................................................................................................ 3 - 48

Calibration............................................................................................................................................................ 4 - 1

Introduction..........................................................................................................................................................................................4 - 2

Calibration Warnings, Precautions, and Notes......................................................................................................................... 4 - 3

Warnings.................................................................................................................................................................................................................4 - 3

Cautions..................................................................................................................................................................................................................4 - 3

Notes........................................................................................................................................................................................................................4 - 3

System Calibration..............................................................................................................................................................................4 - 5

O2 Sensor Calibration........................................................................................................................................................................................4 - 6

Flow Calibration (User)...................................................................................................................................................................................4 - 15

Flow Calibration (Service)..............................................................................................................................................................................4 - 18

Pressure Calibration (Service) ......................................................................................................................................................................4 - 53

Pressure and Flow Zeroing (Service) .........................................................................................................................................................4 - 70

Electronic Flowmeter Zeroing (user).........................................................................................................................................................4 - 74

Calibrate the AG Module (A5/A4 with Gas Module) ............................................................................................................................ 4 - 78

ORC Calibration.................................................................................................................................................................................................4 - 79

Cylinder Yoke Regulator Calibration.........................................................................................................................................................4 - 85

Adjust the back pressure valve....................................................................................................................................................................4 - 90

A5/A4/A3™ Service Manual 046-001141-00 3

Page 8

Table of Contents

Repair and Troubleshooting............................................................................................................................... 5 - 1

Troubleshooting Guidelines ...........................................................................................................................................................5 - 2

Identify the problem ..........................................................................................................................................................................................5 - 2

Avoid shorting component leads together...............................................................................................................................................5 - 2

Use the proper equipment ..............................................................................................................................................................................5 - 2

Clean up the repair area....................................................................................................................................................................................5 - 2

Technical Alarms Check....................................................................................................................................................................5 - 3

Startup Alarm Messages ...................................................................................................................................................................................5 - 3

CPU Board Runtime Alarm ...............................................................................................................................................................................5 - 6

Power Board Runtime Alarm...........................................................................................................................................................................5 - 6

Fresh Flow Sensor Board Alarm .....................................................................................................................................................................5 - 8

Ventilator Control Board Runtime Alarm.................................................................................................................................................5 - 10

Real-time Alarms of External AG Module................................................................................................................................................. 5 - 13

Pneumatic Circuit System Problems......................................................................................................................................... 5 - 17

Tools for on-site Maintenance .....................................................................................................................................................................5 - 17

Gas Supplies and Drive Gas .......................................................................................................................................................................... 5 - 26

Anesthetic Gas Delivery System..................................................................................................................................................................5 - 35

Breathing System ............................................................................................................................................................................................. 5 - 50

Tidal Volume ...................................................................................................................................................................................................... 5 - 64

Sensors and Valves Problems ...................................................................................................................................................... 5 - 67

Correspondence with Pneumatic Circuit Components ..................................................................................................................... 5 - 67

Correspondence with Hardware Components ..................................................................................................................................... 5 - 67

Preparations before Using Diagnostic Tests........................................................................................................................................... 5 - 69

Zero Points of Flow & Pressure Sensors Problems ............................................................................................................................... 5 - 69

Connections and Measurement of the Flow Sensors Problems......................................................................................................5 - 69

Connections and Measurement of the Pressure Sensors Problems..............................................................................................5 - 70

Opening State of the Inspiratory Valve Problems ................................................................................................................................ 5 - 71

Opening States of the PEEP Safety Valve Problems............................................................................................................................. 5 - 72

Opening State of the PEEP Valve Problems............................................................................................................................................5 - 72

Hardware and Electrical Problems............................................................................................................................................. 5 - 73

Software Update and Software Configuration Activation................................................................................................ 5 - 75

Factory Setup .................................................................................................................................................................................... 5 - 79

Repair and Disassembly ...................................................................................................................................... 6 - 1

Prepare for Disassembly...................................................................................................................................................................6 - 2

Tools.........................................................................................................................................................................................................................6 - 2

Preparations ..........................................................................................................................................................................................................6 - 2

Bleed Gas Pressure..............................................................................................................................................................................................6 - 2

Disassemble the Assemblies........................................................................................................................................................... 6 - 3

Disassemble the Internal Assemblies of the Machine Upper Half.....................................................................................................6 - 3

Disassemble Hardware Box .............................................................................................................................................................................6 - 9

Disassemble the Work Surface.................................................................................................................................................................... 6 - 20

Disassemble the Display................................................................................................................................................................................6 - 30

Remove the Module Rack Assembly ......................................................................................................................................................... 6 - 38

Remove the Module Rack Fan ..................................................................................................................................................................... 6 - 39

Remove the Panel of Pressure Gauges.....................................................................................................................................................6 - 40

Remove the Auxiliary Gas Outlet Assembly............................................................................................................................................ 6 - 42

Remove the Rotating Block Cover of Breathing Circle........................................................................................................................6 - 43

Remove the AGSS Assembly ........................................................................................................................................................................6 - 43

Disassemble the Base Assembly................................................................................................................................................................. 6 - 44

Disassemble the Breathing System........................................................................................................................................... 6 - 53

Remove the O2 Sensor and Cable..............................................................................................................................................................6 - 53

Remove the Breathing Tubes.......................................................................................................................................................................6 - 54

Remove the Flow Sensor ............................................................................................................................................................................... 6 - 55

Remove the Manual Bag................................................................................................................................................................................ 6 - 56

Remove the Absorbent Canister................................................................................................................................................................. 6 - 56

Remove the CO2 Bypass Assembly............................................................................................................................................................6 - 58

Remove the Patient Circle Assembly.........................................................................................................................................................6 - 60

Remove the Bellows Assembly.................................................................................................................................................................... 6 - 60

Remove the Pop-off Valve Assembly ........................................................................................................................................................ 6 - 61

4 046-001141-00 A5/A4/A3™ Service Manual

Page 9

Table of Contents

Disassemble the Expiratory/Inspiratory Check Valve Assemblies ..................................................................................................6 - 63

Remove the Water Collection Cup.............................................................................................................................................................6 - 64

Remove the Airway Pressure Gauge ......................................................................................................................................................... 6 - 65

Remove the Bag Arm ...................................................................................................................................................................................... 6 - 65

Remove the Back Upper Cover and Back Lower Cover Assemblies............................................................................................... 6 - 66

Remove the Front Upper Cover, Median Plate and Front Lower Cover Assemblies ...............................................................6 - 68

Disassemble the Automatic/Manual Ventilation Switch Assembly ............................................................................................... 6 - 70

Remove the APL Valve Assembly ............................................................................................................................................................... 6 - 72

Replacement Parts............................................................................................................................................... 7 - 1

Introduction..........................................................................................................................................................................................7 - 2

Ordering Replaceable Parts.............................................................................................................................................................................7 - 2

Diagrams and Tables..........................................................................................................................................................................................7 - 3

Old Version .......................................................................................................................................................................................................................... 24

New Version ........................................................................................................................................................................................................................ 25

Warranty............................................................................................................................................................... 8 - 1

Disclaimers ............................................................................................................................................................................................8 - 2

Manufacturer's Responsibility........................................................................................................................................................8 - 2

Phone Numbers and How to Get Assistance ............................................................................................................................8 - 2

Password................................................................................................................................................................................................8 - 2

A5/A4/A3™ Service Manual 046-001141-00 5

Page 10

Table of Contents

This page intentionally left blank.

6 046-001141-00 A5/A4/A3™ Service Manual

Page 11

Foreword Introduction

Foreword

This Service Manual is intended as a guide for technically qualified personnel performing repair and

calibration procedures.

Warnings, Cautions, and Notes

Please read and adhere to all warnings, cautions, and notes listed here and in the appropriate areas

throughout this manual.

A WARNING is provided to alert the user to potential serious outcomes (death, injury, or serious

adverse events) to the patient or the user.

A CAUTION is provided to alert the user to use special care necessary for the safe and effective use of

the device. They may include actions to be taken to avoid effects on patients or users that may not be

potentially life threatening or result in serious injury, but about which the user should be aware.

Cautions are also provided to alert the user to adverse effects on this device of use or misuse and the

care necessary to avoid such effects.

A NOTE is provided when additional general information is applicable.

Warnings

WARNING: Whenever using anesthetic gases, nitrous oxide, oxygen, or any

WARNING: Use only an approved lubricant on any O-ring in contact with oxygen.

WARNING: For continued protection against fire hazard, replace all fuses with the

WARNING: In order to prevent an electric shock, the machine (protection class I)

WARNING: Remove all accessory equipment from the shelf before moving the

WARNING: Possible explosion hazard. Do not operate machine near flammable

WARNING: The use of anti-static or electrically conductive respiration tubes, when

hospital gas, always follow the appropriate agent evacuation/

collection procedures. Use the hospital gas evacuation system.

Krytox® is the recommended oxygen service lubricant.

specified type and rating.

may only be connected to a correctly grounded mains connection

(socket outlet with grounding contact).

anesthesia machine over bumps or on any inclined surface. Heavy top

loading can cause the machine to tip over causing injury.

anesthetic agents or other flammable substances. Do not use

flammable anesthetic agents (e.g., ether or cyclopropane.)

utilizing high frequency electric surgery equipment, may cause burns

and is therefore not recommended in any application of this machine.

WARNING: Possible electric shock hazard. The machine may only be opened by

authorized service personnel.

A5/A4/A3™ Service Manual 046-001141-00 1

Page 12

Introduction Cautions

WARNING: Compressed gasses are considered Dangerous Goods/Hazardous

WARNING: Avoid exposure to respiratory gases by always directing the fresh gas

WARNING: When using the AG module to perform AG measurements on the

WARNING: Remove the airway sampling line from the patient’s airway and seal the

WARNING: Before connecting the exhaust line to the sample gas outlet on the

WARNING: Perform factory calibration in the working environment after

Materials per I.A.T.A (International Air Transport Association). and

D.O.T. (Department Of Transport) regulations. It is a violation of federal

and international law to transport dangerous goods without the

packages being appropriately identified, packed, marked, classified,

labeled and documented according to D.O.T. and I.A.T.A. regulations.

Please refer to the applicable I.A.T.A. Dangerous Goods Regulations

and /or the Code of Federal Regulations 49 (Transportation, Parts 171-

180) for further information.

flow from the fresh gas outlet to the waste gas scavenger.

patients who are receiving or have recently received anesthetic

agents,connect the outlet to the waste gas disposal system to prevent

the medical staff from breathing in the anesthetic agents.

sample port while nebulized medications are being

delivered.Nebulized medications interfere with accuracy gas reading.

compact airway module,ensure the other end is connected to the

sample gas return port on the anesthesia machine.Incorrect

connections may cause patient injury.

completion of anesthesia machine assembling.Contact us if factory

calibration is required during system use.

WARNING: Do not perform testing or maintenance on A5/A4/A3 anesthesia

WARNING: Items can be contaminated due to infectious patients.Wear sterile

WARNING: Obey infection control and safety procedures.Used equipment may

machine while it is being used on a patient.Possible injury can result.

rubber gloves.Contamination can spread to you and others.

contain blood and body fluids.

Cautions

CAUTION: This device uses high pressure compressed gas. When attaching or

disconnecting backup gas cylinders, always turn the cylinder valves

slowly. Use the A5/A4/A3 flow meters to bleed down the pressure,

watching the cylinder gauge indicate the depleting cylinder pressure,

before disconnecting the cylinder from the yoke. Always open and

close cylinder valves fully.

CAUTION: This device operates using compressed gas at high pressures from the

CAUTION: Refer to section 3.3 Periodical Maintenance Schedule for assistance

hospital central supply. When connecting gas supply lines attach the

hose connection to the machine before connecting the quick

disconnect fitting to the hospital source. Disconnect the supply hose

from the hospital source connection prior to disconnecting it from the

A5/A4/A3 gas connection fittings.

when performing scheduled periodic maintenance.

2 046-001141-00 A5/A4/A3™ Service Manual

Page 13

Notes Introduction

CAUTION: Do not leave gas cylinder valves open if the pipeline supply is in use

CAUTION: Use cleaning agent sparingly. Excess fluid could enter the machine,

CAUTION: This machine must only be operated by trained, skilled medical staff.

CAUTION: Perform the electrical safety inspection as the last step after

CAUTION: After changing the CO2 absorbent, carry out a system leak test.

CAUTION: Only Selectatec™ compatible vaporizers with Interlock-System may be

CAUTION: After each exchange of a vaporizer, carry out a system Leak test.

CAUTION: Do not clean the machine while it is on and/or plugged in.

CAUTION: Pressing "cancel" at any time during the procedure will cancel the

CAUTION: Depleted sodalime changes color. Replace the sodalime if

and the system master switch is turned to 'ON'. If used simultaneously,

cylinder supplies could be depleted, leaving an insufficient reserve

supply in the event of pipeline failure.

causing damage.

completing a repair or after routine maintenance. Perform this

inspection with all covers, panels, and screws installed.

used with the A5/A4/A3 unit.

session's settings and reload the previously-stored calibration

coefficients.

approximately 2/3 of the absorber content is discolored. CO2 absorbent

can be safely changed without stopping mechanical ventilation.

CAUTION: This equipment contains parts sensitive to damage by electrostatic

CAUTION: The watertrap collects water drops condensed in the sampling tube and

CAUTION: The watertrap has a filter preventing bacterium,vapor and patient

CAUTION: Strong scavenging suction on the AG monitor exhaust port nay change

discharge (ESD). Use ESD precautionary procedures when touching,

removing, or inserting parts or assemblies.

therefore prevents them from entering the AG module.If the collected

water reaches a certain amount, you should drain it to avoid airway

blockage.

secretions from entering the module.After a long-term use,dust or

other subtances may compromise the performance of the filter or even

block the airway.In the case, replace the watertrap.Replacing the

watertrap once a month is recommended.

the operating presure of the monitor and cause inaccurate readings or

internal damage.

Notes

NOTE: Unauthorized servicing may void the remainder of the warranty. Check

NOTE: The VT PLUS device in the manual can be replaced by VT650/VT900.

with the factory or with a local authorized distributor to determine the

warranty status of a particular instrument.

See section 9.0 (pg. 9-1) "Appendix".

A5/A4/A3™ Service Manual 046-001141-00 3

Page 14

Introduction Notes

This page intentionally left blank.

4 046-001141-00 A5/A4/A3™ Service Manual

Page 15

1.0

Theory of Operation

Introduction .................................................................................................................................................................................................1-2

Electrical and Pneumatic Connections ....................................................................................................................................... 1-4

Gas Flow ......................................................................................................................................................................................................1-20

Anesthesia System Components.................................................................................................................................................1-38

The Breathing System......................................................................................................................................................................... 1-41

Ventilator UI...............................................................................................................................................................................................1-46

Ventilator Control and Drive........................................................................................................................................................... 1-46

Ventilator Pneumatic- O2 Drive Gas........................................................................................................................................... 1-77

A5/A4/A3™ Service Manual 046-001141-00 1 - 1

Page 16

Introduction Theory of Operation

1.1 Introduction

The A5/A4/A3 Anesthesia System is a continuous flow inhalation gas anesthesia system that delivers

anesthetic vapor, and provides for automatic and manual modes of ventilation. It is equipped with a

monitoring system for ventilation, inspired, and expired gas. The A5/A4/A3 is intended for use in

operating rooms. It will be used with O2, N2O, and AIR supplied by a medical gas pipeline system or

by externally mounted gas cylinders. Anesthetic agents can be delivered via vaporizers mounted on

the machine.

Electronic PEEP is available in all ventilation modes. User control over inspiratory flow (Tslope) is

possible in PCV, SIMV, and PS modes. Automatic fresh gas compensation limits the effect on the

patient ventilation from changes in fresh gas flow rate by the operator. The traditional bellows system

is driven by oxygen and makes patient disconnections clearly visible.

The A5/A4/A3 fresh gas dosing subsystem offers the ease of use and features of a traditional

anesthesia system. The dual-flow tubes electronic flowmeter, which includes redundant numerical

readouts, displays the O2, N2O, and Air flows at all times. A knob guard prevents inadvertent

movement of the flow control knobs. Gas supply gauges and auxiliary O2/Air flowmeters with

blended output indicate the gas pipeline supply pressures and gas cylinder pressures. An auxiliary O2

flowmeter is placed at a convenient location for the operator. The O2 flush button is in the traditional

location near the front left corner of the table top.

Safety systems within the A5/A4/A3 work to prevent hypoxic mixtures from being delivered to the

patient. Nitrous oxide will not be delivered unless oxygen pressure is present. A pneumatic safety

system assures that at least 21% O2 is present when setting mixtures of O2 and N2O.

The A5/A4/A3 breathing system is warmed to minimize condensation inside the breathing system

block and to return humid gas to the patient. The breathing system provides easy access to the

Airway Pressure Limiting (APL) valve and breathing bag, and easy viewing of the Airway Pressure

gauge (PAW). The APL valve has a comfortable, single turn knob that provides a clear view of the

manual breathing pressure setting. The absorber assembly incorporates a cam lock device that is

convenient to open and close. CO2 absorbent Pre-paks or loose fill can be used. A water trap that can

be drained is also provided on the absorber assembly.

Two flow sensors in the breathing system measure inspired and expired gases for control and

monitoring. Spirometry is standard on the A5. Inspired oxygen is monitored via a fuel-cell type sensor.

Breathing pressure is also monitored. The breathing system can swivel into position. A test plug, next

to the two main hose connections, allows automated leak testing during startup. The Anesthesia Gas

Scavenging System (AGSS) connections are at the rear of A5/A4/A3.

The A5/A4/A3 is powered by an AC power source. In turn, the A5/A4/A3 power management system

provides DC power for its main system functions while charging its internal battery supply. In case of

AC power failure, the A5/A4/A3 operates on battery power for a minimum of 75 minutes with one (1)

new battery installed (A3) or 150 minutes with two (2) new batteries installed (A5). A recessed main

switch is provided to power the system ON and OFF. Four (4) auxiliary AC outlets on the A5 and three

(3) auxiliary AC outlets on the A3 at the rear of the machine operate independently of the main

switch position.

1 - 2 046-001141-00 A5/A4/A3™ Service Manual

Page 17

Theory of Operation Introduction

NOTE: The breathing system warmer does not operate when the A5/A4/A3 is

NOTE: If the main switch is set to OFF, the O2 fresh gas flow will not flow.

on battery power.

A5/A4/A3™ Service Manual 046-001141-00 1 - 3

Page 18

Electrical and Pneumatic Connections Theory of Operation

B3

B1

P8

B8

J9˖Ethernet

P1

P8

B2

P9

J8˖USB

P10

B9/B10/B11:

J1˄Mon Brd˅

J2˄Valve Brd˅

J4˄Valve Brd˅

J8˄Valve Brd˅

J6˄Mon Brd˅

J7˄Mon Brd˅

J5˄Mon Brd˅

J3˄Mon Brd˅

J2

DB50

System

Switch

J4

J1

B14

J3

J7

J8

J9

J10

J11

P12

TFT

15"

LCD

B7

Inverter

B4

P14

O2 Source Switch

Manual/Auto

Switch

Oxygen

sensor

P11

Circuit Switch

CO2 Switch

P13

P5

P2

Lin

Nin

Lout Nout

P6

P3

Lin

Nin

Lout Nout

P7

P4

Lin

Nin

Lout Nout

J1

J3

J1

J2

J3

J1

J1

J2

J4

J5

J6

B5

J1

#1

#3

#2

#15

#18

#14

#17

#16

#5

#5

#5

#5

#5

#5

#5

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#7

#8

#8

#8

#9

#6

#13

B6

J4˖RS-232

Pressure Switch

J13

#4

B13

J2

#11

Top lighting Switch

J1

B15

J3

J1

#10

#19

J5

P15

VT PLUS

PF-300

J1 J2

B8˖ USB Interface J8

B12

J2

#2

#5

J12˄Mon Brd˅

#13 #13

P16

1.2 Electrical and Pneumatic Connections

1.2.1 Electrical Connections (A3/A4)

FIGURE 1-1 A3/A4 Electrical Connections

1 - 4 046-001141-00 A5/A4/A3™ Service Manual

Page 19

Theory of Operation Electrical and Pneumatic Connections

No. Description P/N

B1 Power Board 801-0631-00025-00

B2 Battery Interface Board 801-0631-00109-00

B3 Mother Board 801-0631-00108-00

B4 Warning Light Board 801-0631-00019-00

B5 Indicator Light Board 801-0631-00004-00

B6 Touch Screen Control Board 801-0631-00018-00

B7 Display Interface Board 801-0631-00017-00

801-0633-00004-00

115-052901-00 (A4)

115-056938-00 (A5 EPSON,

New)

B8 CPU Board

B9-11 Ventilator Control Board

B12 Sensor Interface board 801-0631-00089-00 (A3)

B13 Top Lighting Board 801-0631-00039-00

B14 Electronic Flowmeter Assembly 115-046746-00

B15 Aux FlowMeter Lighting Board /

P1 Filter Power 250VAC 15A Panel Mount (0633) 801-0633-00003-00

P2-4 Auxiliary Output Socket 801-0631-00032-00

P5-7 Breaker (3.0A) 801-0631-00031-00

P8 Lithium-ion Battery 115-018012-00

P9 Speaker and Connecting Cable 801-0631-00038-00

P10 Fan 801-0631-00028-00

P11 Drive Gas Assembly

P12 Display Exchange Package 801-0631-00075-00

P13 Circuit Heater 115-034450-00

P14 Solenoid valve assembly 801-0631-00046-00

P15 A5 Calibration set FRU

P16 Touch Screen 801-0631-00014-00

#1 Cable, battery 009-000969-00

#2 Cable, Patient Monitor 009-000971-01

#3 Cable, System Switch 009-001776-00

115-056937-00 (A3 EPSON,

New)

115-056941-00 (A5 DSP,

New)

115-056940-00 (A4 DSP,

New)

801-0631-00027-00

115-058771-00 (DSP)

801-0631-00047-00 (For

software bundle versions

earlier than 02.04.00,

EPSON platform)

115-020937-00(For

software bundle version

02.04.00 and later, EPSON

platform)

115-052762-00 (DSP

platform)

801-0631-00121-00/115062775-00

A5/A4/A3™ Service Manual 046-001141-00 1 - 5

Page 20

Electrical and Pneumatic Connections Theory of Operation

No. Description P/N

#4 Cable, Indicator 009-000977-00

#5 Cable, Ventilator 009-000979-00

#6 Cable, Breathng System 009-000980-00

#7 Cable, Sodalime Canister Switch Cable 009-000987-00

#8 Cable, Circuit Switch 0621-20-78593

#9 Cable, O2 Pressure Switch 0621-20-69588

#10 Cable, Top Lighting A 009-000982-00

#11 Cable, Lighting Switch 009-000981-00

#12 Cable, AC Power Cable 009-002224-00

#13 Cable, Power, AC Internal 009-000985-01

#14

#15 Cable, Display 009-000973-00

#16 Cable, Touch Screen 009-000978-00

#17 Cable, Alarm 009-000976-00

#18

#19 Cable, Display Lighting 009-000986-00

Cable, Inverter Cable(old)

Cable,LED Backlight Input(new)

Cable, Inverter LED (old)

Cable,Screen Backlight (new)

NOTE: When there is a Screen Backlight Board (See

section 1.6.1.3 (pg. 1-48) "Screen Backlight

Board"), please use the new cable.

009-000988-00 (old)

009-006382-00 (new)

009-000974-00 (old)

009-006731-00 (new)

1 - 6 046-001141-00 A5/A4/A3™ Service Manual

Page 21

Theory of Operation Electrical and Pneumatic Connections

B3

B1

P11

B8

J9˖

Ethernet

P1

P12

B2

P13

J8˖USB

P14

B9/B10/B11:

J1˄Mon Brd˅

J2˄Valve Brd˅

J4˄Valve Brd˅

J8˄Valve Brd˅

J6˄Mon Brd˅

J7˄Mon Brd˅

J5˄Mon Brd˅

J3˄Mon Brd˅

J2

DB50

System

Switch

J4

J1

B14

J3

J7

J8

J9

J10

J11

P12

TFT

15"

LCD

B7

Inverter

B4

P19

O2 Source Switch

Manual/Auto

Switch

Oxygen

sensor

P16

Circuit Switch

CO2 Switch

P18

J1

J3

J1

J2

J3

J1

J1

J2

J4

J5

P22

J1

#1

#4

#2

#15

#18

#19

#17

#16

#5

#5

#5

#5

#5

#5

#5

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#7

#8

#8

#8

#6

B6

J4˖RS-232

Pressure Switch

J13

B13

J2

#11

Top lighting

Switch

J1

B15

J3

J1

#10

#20

J5

P20

VT PLU S

PF-300

J1 J2

B8˖ USB Interface J8

B12

J2

#2

#5

J12˄Mon Brd˅

P21

P7

P3

Lin

Nin

Lout Nout

P8

P4

Lin

Nin

Lout Nout

P9

P5

Lin

Nin

Lout Nout

P10

P6

Lin

Nin

Lout Nout

#13

P2

Lout

Nout

Lin

Nin

#13

#13 #13

Input1 Input2 Input3 Input4

#12

P15

J1

#2

#3

B5

J1

#2

#14

B17

B16

#2

#9

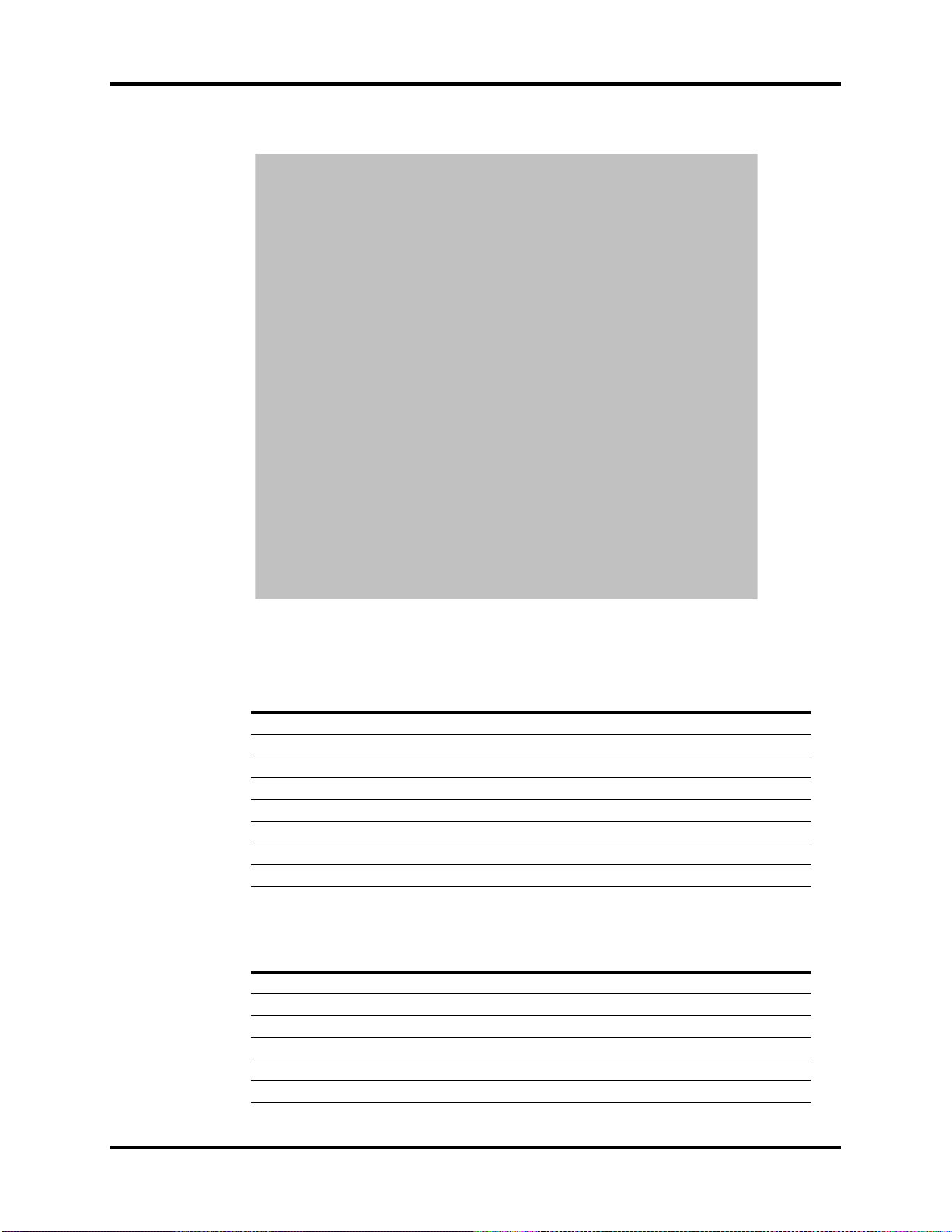

1.2.2 Electrical Connections (A5)

A5/A4/A3™ Service Manual 046-001141-00 1 - 7

FIGURE 1-2 A5 Electrical Connections

Page 22

Electrical and Pneumatic Connections Theory of Operation

No. Description P/N

B1 Power Board 801-0631-00025-00

B2 Battery Interface Board 801-0631-00109-00

B3 Mother Board 801-0631-00108-00

B4 Warning Light Board 801-0631-00019-00

B5 Indicator Light Board 801-0631-00004-00

B6 Touch Screen Control Board 801-0631-00018-00

B7 Display Interface Board 801-0631-00017-00

801-0631-00026-00 (A5

B8 CPU Board PCBA

B9-11 Ventilator Control Board

B12 Sensor Inter face board

B13 Top Lighting Board 801-0631-00039-00

B14 Electronic flowmeter assembly 115-046746-00

B15 Aux FlowMeter Lighting Board /

B16 Infrared Communication Board 801-0621-00165-00

B17 AG Module 6800-30-50502

P1 Filter Power 250VAC 10A Panel Mount (0631) 801-0631-00029-00

P2 Breaker (10.0A) 801-0631-00030-00

P3-6 Auxiliary Output Socket 801-0631-00032-00

P7-10 Breaker (3.0A) 801-0631-00031-00

P11-12 Lithium-ion Battery 115-018012-00

P13 Speaker and Connecting Cable 801-0631-00038-00

P14 Fan 801-0631-00028-00

P15 Touchpad 801-0631-00052-00

P16 Drive Gas Assembly

P17 Display Exchange Package 801-0631-00075-00

P18 Circuit Heater 801-0631-00069-00

P19 Solenoid valve assembly 801-0631-00046-00

P20 A5 calibration set FRU

P21 Touch Screen 801-0631-00014-00

P22 Fan 024-000407-00

EPSON Platform)

115-052902-00 (A5

DSP platform)

801-0631-00027-00 (A5

EPSON Platform)

115-058771-00

801-0631-00089-00

(EPSON)

801-0631-00047-00

(For software bundle

versions earlier than

02.04.00, EPSON

platform)

115-020937-00(For

software bundle

version 02.04.00 and

later, EPSON platform)

115-052762-00 (DSP

platform)

801-0631-00121-00/

115-062775-00

1 - 8 046-001141-00 A5/A4/A3™ Service Manual

Page 23

Theory of Operation Electrical and Pneumatic Connections

No. Description P/N

#1 Cable, battery 009-000969-00

#2 Cable, Patient Monitor 009-000971-01

#3 Cable, Touchpad 009-000972-00

#4 Cable, System Switch 009-001776-00

#5 Cable, Ventilator 009-000979-00

#6 Cable, Breathng System 009-000980-00

#7 Cable, Sodalime Canister Switch Cable 009-000987-00

#8 Cable, Circuit Switch 0621-20-78593

#9 Cable, O2 Pressure Switch 0621-20-69588

#10 Cable, Top Lighting A 009-000982-00

#11 Cable, Lighting Switch 009-000981-00

#12 Cable, Auxiliary Outlet 009-000984-00

#13 Cable, Power, AC Internal 009-000985-01

#14 Cable, Indicator 009-000977-00

#15 Cable, Display 009-000973-00

#16 Cable, Touch Screen 009-000978-00

#17 Cable, Alarm 009-000976-00

#18

#19

#20 Cable, Display Lighting 009-000986-00

Cable, Inverter LED (old)

Cable,Screen Backlight(new)

Cable, Inverter Cable(old)

Cable,LED Backlight Input(new)

NOTE: When there is a Screen Backlight Board (See

section 1.6.1.3 (pg. 1-48) "Screen Backlight

Board"), please use the new cable.

009-000974-00 (old)

009-006731-00 (new)

009-000988-00 (old)

009-006382-00 (new)

1.2.3 Pneumatic Connections (A3/A4)

NOTE: This diagram reflects the latest version of the pneumatic connections.

Please refer to label on the back of the service door of the anesthesia

system.

NOTE: The green tube in the tube diagram needs to paste the oxygen label.

NOTE: The orange tube in the tube diagram needs to paste the air label.

NOTE: The blue tube in the tube diagram needs to paste the N2O label.

NOTE: The black tube in the tube diagram needs to paste the neutral label.

A5/A4/A3™ Service Manual 046-001141-00 1 - 9

Page 24

Electrical and Pneumatic Connections Theory of Operation

FIGURE 1-3 A3 Pneumatic Connections

1 - 10 046-001141-00 A5/A4/A3™ Service Manual

Page 25

Theory of Operation Electrical and Pneumatic Connections

!

FIGURE 1-4 A4 Pneumatic Connections

A5/A4/A3™ Service Manual 046-001141-00 1 - 11

Page 26

Electrical and Pneumatic Connections Theory of Operation

S/N From To P/N

25 Total Flow Meter Vaporizer Manifold M6G-020014---

26 Back Pressure Regulator Total Flow Meter M6G-020014---

27 N2O Flow Sensor Gas Mixer M6G-020026---

28 Air Flow Sensor Gas Mixer M6G-020026---

29 O2 Flow Sensor Gas Mixer M6G-020026---

30 Restrictor Assembly ORC Assembly M6G-020026---

31 ORC Assembly Air Flow Sensor M6G-020026---

33 ORC Assembly Y2 M6G-020026---

34 N2O Cylinder Yoke Y1 M6G-020045---

35 Y1 N2O Regulator M6G-020045---

36 Air Cylinder Yoke Y1 M6G-020045---

37 Y1 Air Regulator M6G-020045---

38 Y1 Y1 M6G-020045---

39 O2 Pipeline Pressure Gauge O2 Pipeline Assembly M6G-020046---

40 N2O Pipeline Pressure Gauge N2O Pipeline Assembly M6G-020046---

41 Air Pipeline Pressure Gauge AIR Pipeline Assembly M6G-020046---

42 O2 Regulator Y2 M6G-020026---

43 Y2 System Switch M6G-020026---

44 Y2 O2 Flush Button M6G-020026---

45 System Switch O2 Needle Valve M6G-020026---

46 Y2 ORC Assembly M6G-020026---

47 Y1 O2 Regulator M6G-020045---

48 N2O Regulator ORC Assembly M6G-020046---

49 ORC Assembly N2O Needle Valve M6G-020026---

50 Air Regulator Y2 M6G-020026---

51 Y2 Air Needle Valve M6G-020026---

52 O2 Flush Button Common Gas Outlet M6G-020026---

53 Vaporizer Manifold Common Gas Outlet M6G-020014---

54 Y1 Air Pipeline Assembly M6G-020045---

55 Exhalation Valve Assembly Gas Reservoir M6G-020026---

56 Y2 Y2 M6G-020026---

57 Y2 Auxiliary O2 Assembly M6G-020026---

58

59 Y1 O2 Pipeline Assembly M6G-020045---

60 O2 Cylinder Yoke Y1 M6G-020045---

62 Y1 N2O Pipeline Assembly M6G-020045---

63 Y1 Exhalation Valve Assembly M6G-020045---

64 Auxiliary Air Assembly Y2 M6G-020026---

65 Auxiliary O2 Assembly Y2 M6G-020026---

66 Y2 Auxiliary Gas Outlet M6G-020026---

67 Y2 Auxiliary Air Assembly M6G-020026---

Gas Mixer or Electronic Flowmeter

Assembly

Back Pressure Regulator M6G-020014---

1 - 12 046-001141-00 A5/A4/A3™ Service Manual

Page 27