Page 1

Operating Instructions

Washer-Extractor

WS 5240

WS 5320

To prevent accidents

and machine damage read these

instructions before installing or

using the machine. M.-Nr. 05 649 900

UV

Page 2

Contents

Warning and Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Guide to the washer-extractor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Special options buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Language selection* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting current time and date* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Start up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Program selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Changing temperaure and spin speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adding detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Program end display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Program end - opening the drum door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Delayed Start W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Prewash T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Starch U. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Without spin V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Skipping program cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Program cancellation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Liquid dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Peak load cut-out / PC- Printer connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power failure - Emergency door release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

After each use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the dispenser box and siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Maintaining the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Guide to the symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Steam connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2

Page 3

Warning and Safety Instructions

WARNING

Read all instructions before installation or

use to prevent injury and machine dam

age.

This washer-extractor is only intended for

laundry not impregnated with dangerous

or flammable substances.

Dry cleaning solvents must not be used

in this machine. Such solvents could

cause a fire or explosion.

This appliance conforms to all uniform

safety codes and regulations. The manu

facturer cannot be held responsible for

damage or injury caused by improper use

of this appliance.

All personnel working with this machine

must be fully trained in its use and safety.

SAVE THESE INSTRUCTIONS AND REVIEW THEM PERIODICALLY

-

-

Electrical Safety

Installation, repair and maintenance

work should be by a Miele authorized

service technician. Work by unqualified persons could be dangerous.

Before installation make sure that the

voltage and frequency listed on the

data plate correspond with the site electrical

supply. This data must correspond to pre

vent injury and machine damage. Consult a

qualified electrician if in doubt.

Be certain your appliance is properly in

stalled and grounded by a qualified

technician.

To guarantee the electrical safety of this ap

pliance, continuity must exist between the

appliance and an effective grounding sys

tem. It is imperative that this basic safety re

quirement be met. If there is any doubt, have

the electrical system of the house checked

by a qualified electrician. The manufacturer

cannot be held responsible for damages

caused by the lack, or inadequacy of, an ef

fective grounding system.

-

-

-

-

The appliance is only completely iso

lated from the electrical supply when

the fuse is withdrawn, the circuit breaker has

been tripped, or the unit has been un

plugged.

Do not damage, remove or bypass the

safety features and controls of the ma

chine.

If there is any damage to the machine

or to the cable insulation, the machine

must not be used until it has been repaired.

Any removable outer panels must be in

place, and all moving or electrical parts

shielded before the machine is operated.

-

-

-

Use

Never use or store gasoline or gasoline

based substances or any easily flam

mable substances near the machine. Do not

use the machine lid as a storage area.

Danger of fire or explosion.

Only machine wash articles with a care

label stating they are suitable for machine washing.

Never attempt to force open the door of

the washer extractor. As a safety feature

the door handle has been designed with a

break line.

Never allow children to play in, on or

near the washer extractor, or to operate

it themselves. Please supervise its use by

the elderly or infirm.

The door porthole glass can become

hot during use of the machine. Do not

allow children to touch the glass.

-

-

Always make sure the drum is station

ary before reaching in to remove laun

dry. Reaching into a moving drum is ex

tremely dangerous.

Waste water from washing and rinsing

must not be used as drinking water. It

must be discharged into a proper sewage

system.

The machine should only be operated

unsupervised if there is a floor drain

(gully) in the direct vicinity of the machine.

-

-

-

-

3

Page 4

Warning and Safety Instructions

Only use genuine Miele accessories. If

unapproved parts are used, guarantee,

performance and product liability claims

may become void.

Chlorine or agents containing chlorine

are corrosive, and can under certain

conditions lead to permanent damage to

components.

Disinfecting and cleaning agents often

contain chloride (salts). If these sub

stances dry on steel surfaces the residual

chlorides can attack the steel and cause

rusting.

To protect your machine from rust damage,

only use chloride free disinfecting and

cleaning agents for washing and disinfect

ing, and for cleaning the machine. If you ac

cidentally spill an agent containing chloride

on the machine it should be rinsed off with

water and dried using a soft cloth.

Always follow the instructions of the

chemical manufacturer when using

cleaning agents and special application

chemicals. Only use such chemicals for the

purpose and in the situation specified by the

manufacturer in order to avoid the danger of

adverse chemical reactions and material

damage. If in doubt check the suitability of

the product for use in this machine with the

manufacturer before using it.

Where a chemical cleaning agent is

recommended on technical application

grounds, this does not imply that the manu

facturer of the machine takes responsibility

for the effect of the chemical on the material

of the items being cleaned or on the ma

chine. Please be aware that changes in for

mulation, storage conditions etc., which may

not be published by the chemical producer,

can have a negative effect on the cleaning

result.

-

-

-

-

-

Maintenance

Faulty components should only be re

placed with genuine Miele spare parts.

The safety standards of the machine can

only be guaranteed when Miele spare parts

are used.

Over time deterioration of parts can oc

cur, especially rubber components

such as hoses. Check the inlet hoses regu

larly for signs of deterioration or leaks, to

prevent water or machine damage.

Local regulations regarding regular in

spection and maintenance of this ma

chine must be observed.

-

Noise level

Wash cycle Spin cycle

WS 5240 60.3 dB 82.2 dB

WS 5320 60.0 dB 80.3 dB

-

-

-

-

-

Disposal of an old appliance

When disposing of an appliance first

make it unusable. Disconnect it from

electricity, cut off the power cord and remove the plug.

Disable the door lock, so children cannot accidentally shut themselves in. Make appropriate arrangements for the safe disposal of

the appliance.

KEEP THESE INSTRUCTIONS

IN A SAFE PLACE.

Dyes, dye removers and descaling

agents may only be used in this ma

chine if the manufacturer expressly states

that they are suitable for use in a washing

machine. There may be the danger of fire or

explosion.

Do not use high pressure cleaners to

hose down the machine.

4

-

Page 5

Caring for the environment

Disposal of the packing material

The transport and protective packing materi

als are environmentally friendly for disposal

and can normally be recycled. Please recy

cle.

Ensure that any plastic wrappings, bags etc.

are disposed of safely and kept out of the

reach of babies and young children.

Danger of suffocation!

-

Disposal of an old appliance

-

Old appliances contain materials that may

be recyclable. Please contact your local re

cycling authority about potential recycling,

before disposing of the appliance.

-

5

Page 6

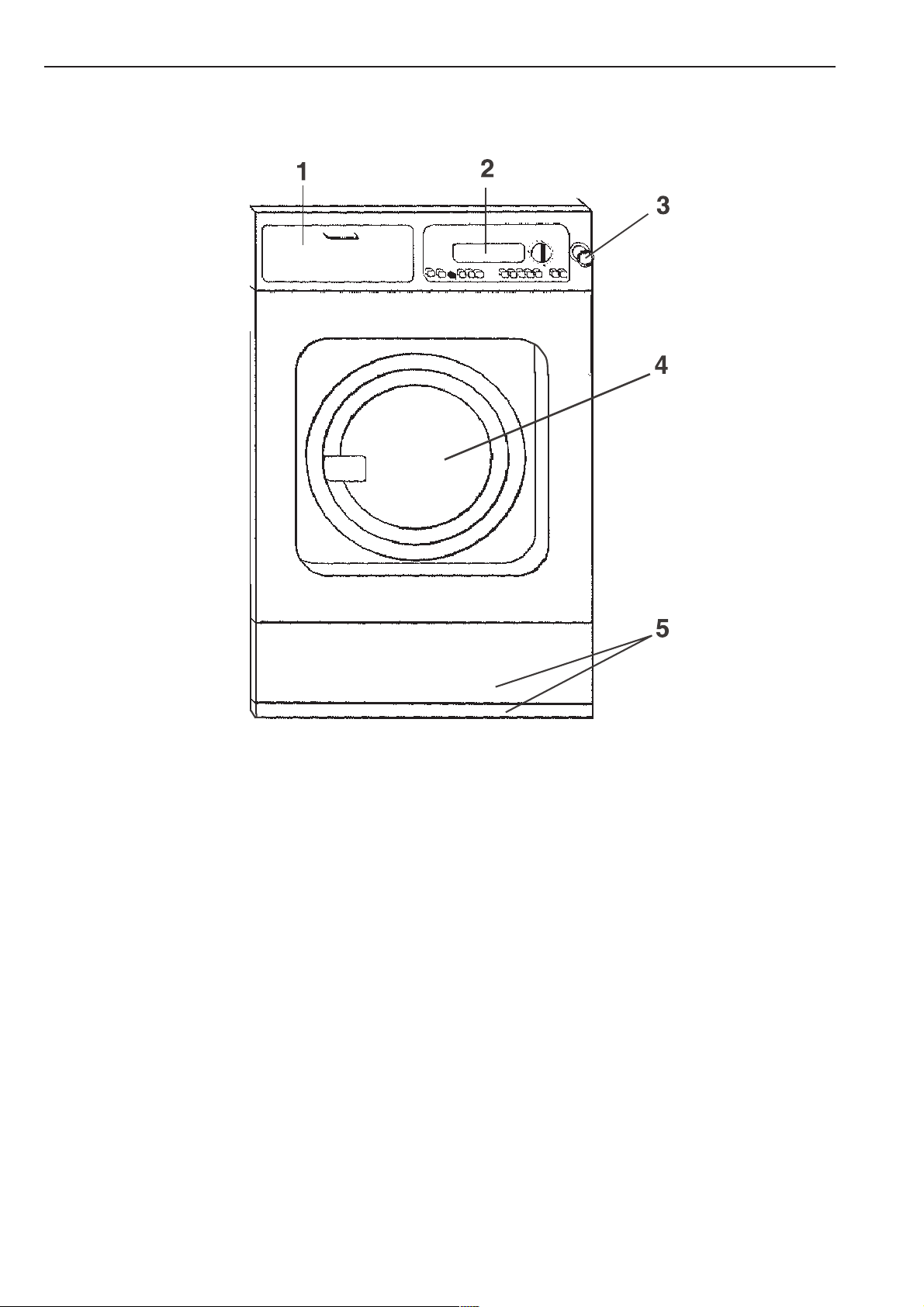

Guide to the washer-extractor

1 Detergent dispenser

2 Control panel

3 Emergency Stop button

4 Drum door

5 Service panel with plinth

6

Page 7

Control panel

Guide to the washer-extractor

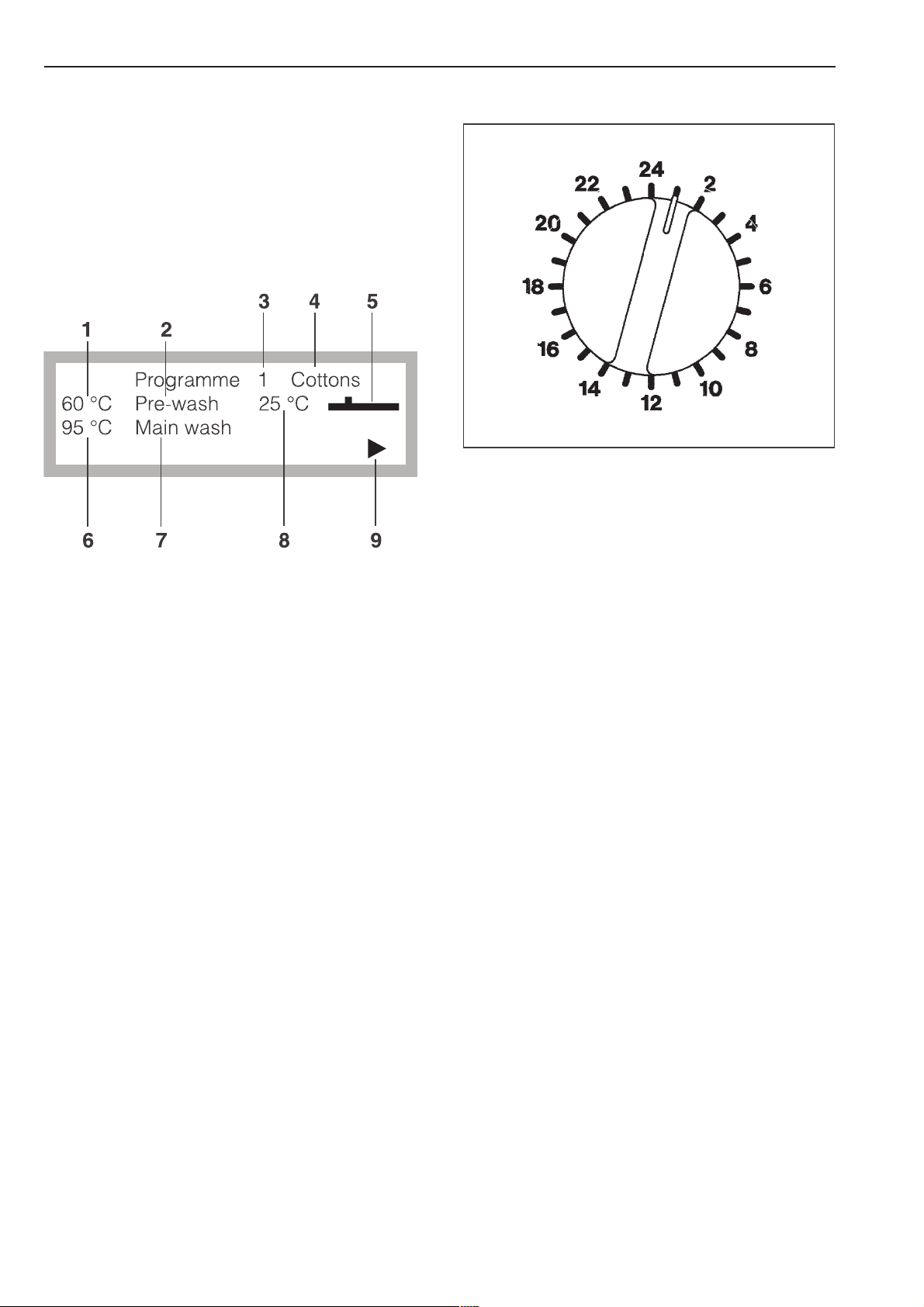

6 Display

7 Program selector

8 Y Power on button

9 Z Power off button

10 Access lock

11 Special options buttons

12 Cursor and input buttons

13 Delay Start button

14 X Start

15 7 End

16 Optic interface

7

Page 8

Guide to the washer-extractor

Display

The display content will appear once the

machine is turned on. It is up to four lines

and 40 digits long, showing which program

has been selected.

Display during a program

1 Planned temperature for the current cycle

2 Name of the current cycle

3 Program number

4 Program name

5 Time line for the current cycle

6 Planned temperature of the next cycle

7 Name of the next cycle

8 Actual temperature

Program selector

Program numbers 1 - 24 can be selected di

rectly.

Program numbers 25 - 99 can be selected

using selector position 24 and the 4 "Plus"

button.

The name of the selected program and its

corresponding number appear in the display. Program positions 1 - 10 are standard

programs.

The subsequent program positions vary according to the version of the model, and are

set out in the Programming Instruction. If the

program selector switch is turned to another

position after the start of the program, the

first line of the display flashes. The program

does not however change.

-

9 Points to a further display line

8

Main buttons

Y "Power on" button

Z "Power off" button

Page 9

Guide to the washer-extractor

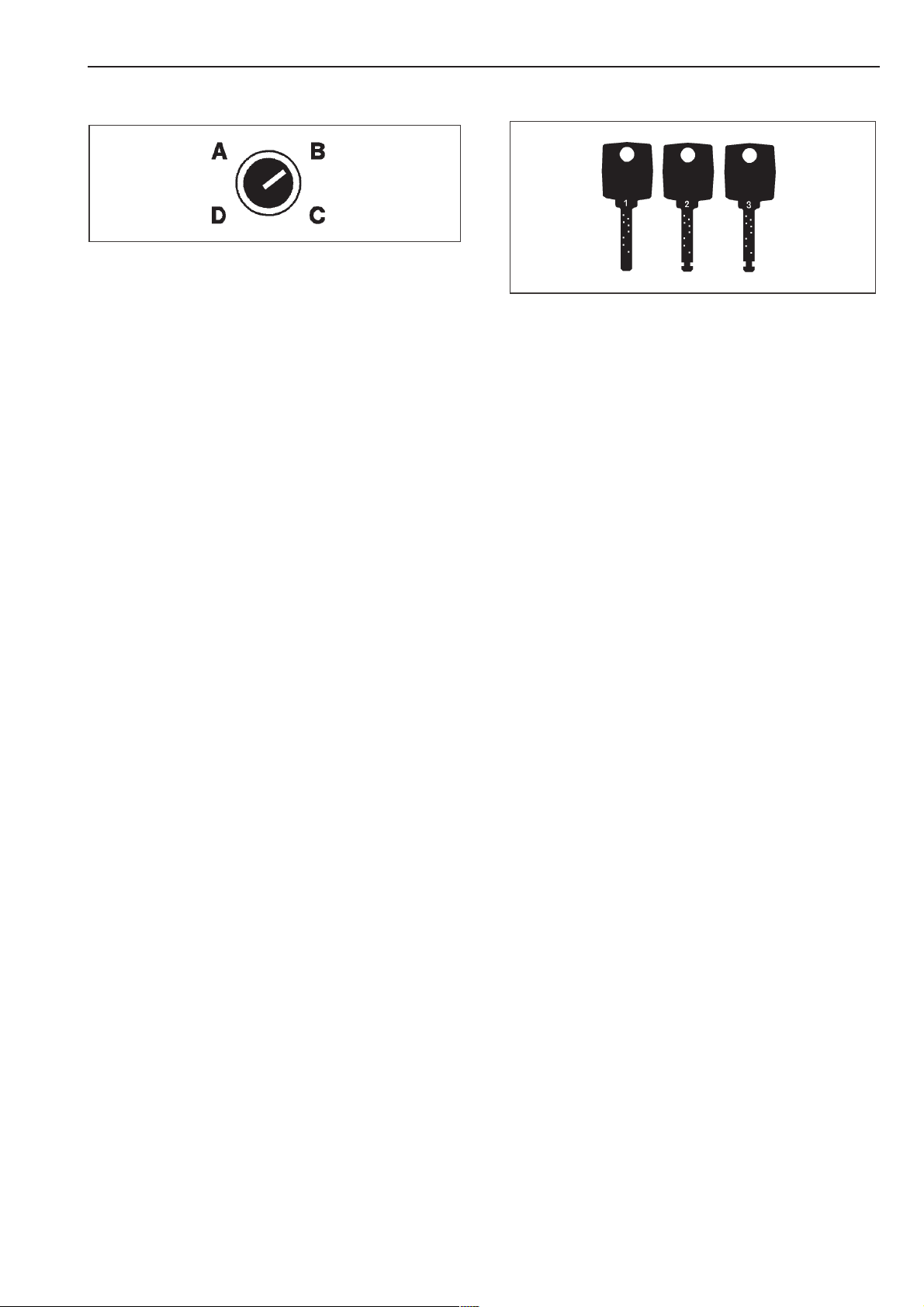

Key access lock

Position A - Free access

Programs which have been allocated free

access can be run.

See Programming Instructions for allocation

of free access.

Position B - Operation

All programs can be started in this position.

The display will show the selected program

information.

Position C - Programming

Access keys

Key 1 (2 supplied) for operating levels

A and B.

Key 2 for operating levels A, B, C.

Key 3 for operating levels A, B, C, D.

At this position, programming, copying, deleting, printing, altering, giving or barring

free access, and creating new program sequences can be done. See Programming Instructions.

Position D - Unlocking

At this operating level barred programs can

be unlocked. Locked Programs (e.g. Disinfection programs) can not be cancelled

once they have started. If the key switch is

turned to position D in such a program, the

program running is unlocked and can be

cancelled. See Programming Instructions.

9

Page 10

Guide to the washer-extractor

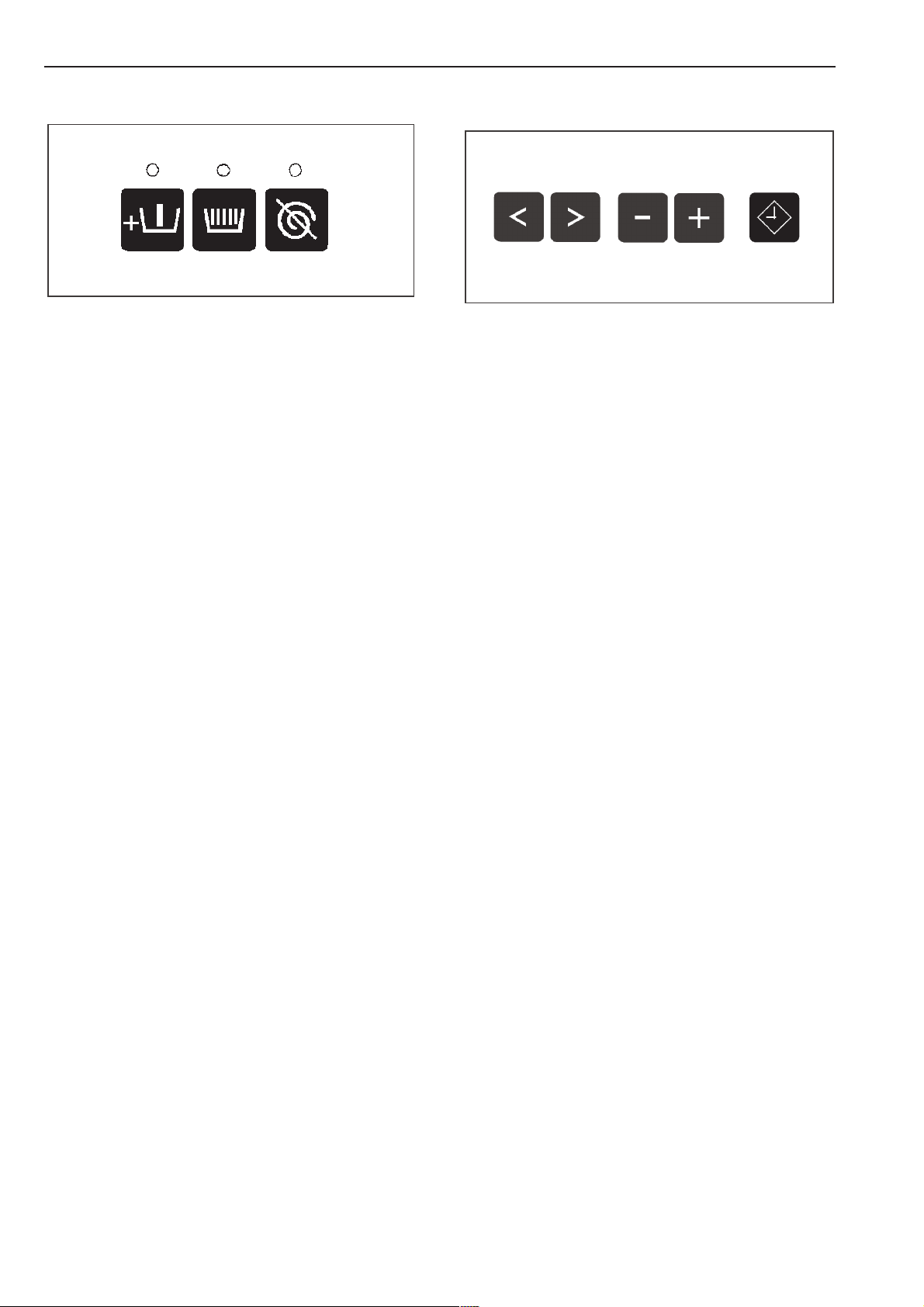

Special options buttons

The indicator above each button will light

when a special option is selected.

T "Prewash"

Press this button to add a cycle to a pro

gram. A Prewash is added to the program.

Press the button a second time to deselect

the function.

U "Starch"

-

Cursor buttons and Delay Start

1 2 "Cursor"

The cursor buttons are used to pass back

wards or forwards into the input fields or into

the next display, (this appears as > <

flashing in the display).

Pressing continuously on the button runs

quickly through the display screens.

3 4 "Minus-/-Plus"

-

Press this button for starched laundry.

V "Spin-stop"

Press this button if a final spin is not required

after the final rinse.

The Minus/Plus buttons allow you to modify

an input field. Pressing continuously on the

buttons makes rapid changes.

W "Delay start"

The display indicates that a start time should

be selected. If the button is pressed again

the Delay start option is cancelled.

If the button is pressed after the start of a

program the current time of day and date

are shown.

^

Press this button to delay the start of a pro

gram.

-

10

Page 11

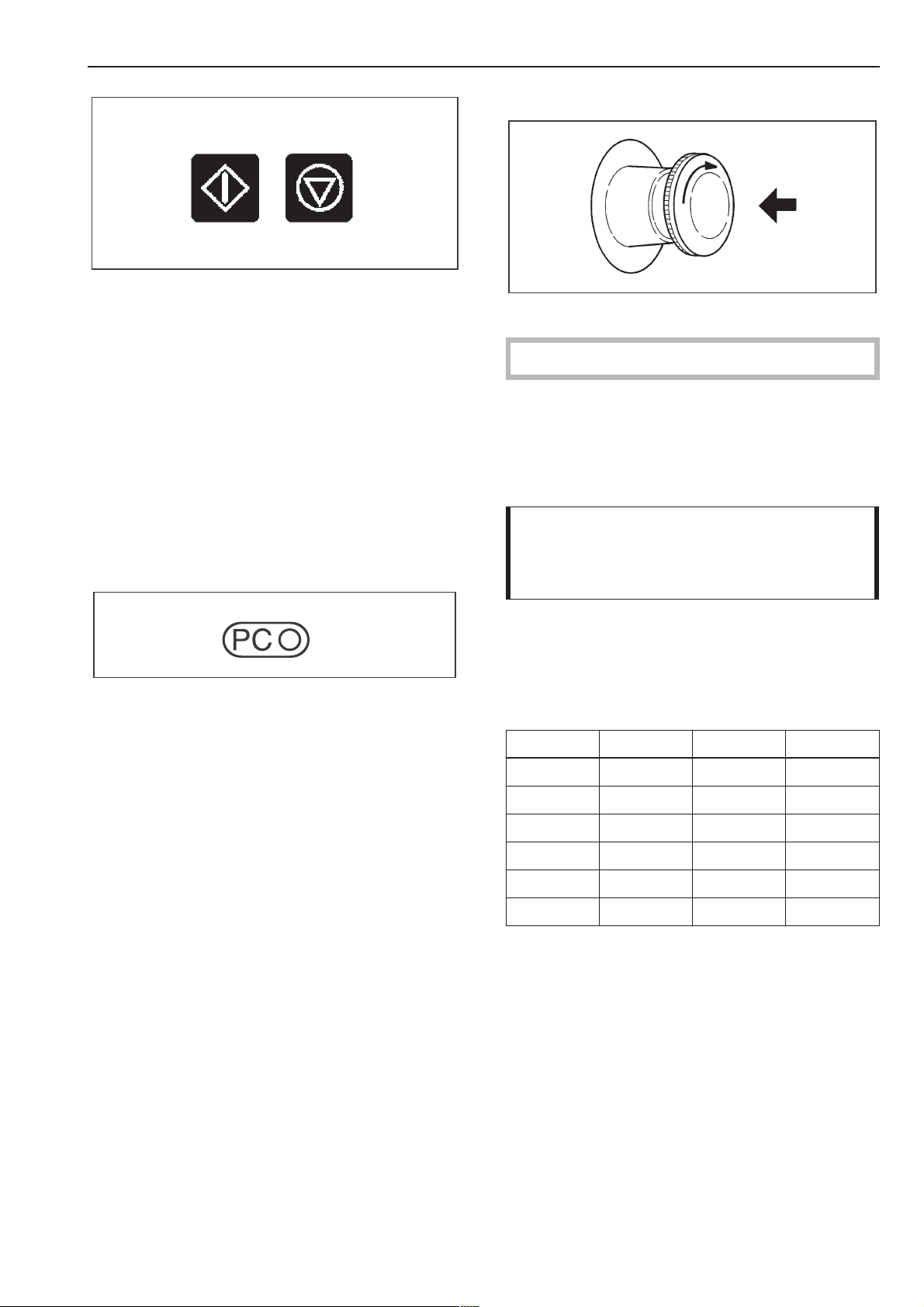

X "Start"

Guide to the washer-extractor

Emergency Stop Switch

Press this button to start the selected pro

-

gram.

7 "End"

Press this button to stop a program. Immedi

ately press once again to terminate a pro

gram. A stopped program can be restarted

by pressing the Start button.

9 Optic interface

Data transfer to and from the machine’s controls and a PC can take place using relevant

software. The optic interface on the machine’s control panel provides the connec

-

tion point.

Only to be used in an emergency.

The switch can be reset by turning the

-

ribbed disc clockwise.

After resetting the following appears in the

display:

PROGRAMME 1 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Please press the Start button.

^ Press X "Start" to continue the program.

Conversion of °C to °F

°C °F °C °F

10 50 70 158

20 68 80 176

30 86 90 194

40 104 100 212

50 122 110 230

60 140 120 248

11

Page 12

Operation

Language selection*

(if necessary)

Turn the unit on at the wall switch.

^

Turn the key to position B "Operation".

^

Press the "OFF" Z button to turn off the

machine.

Press the X "Start" button and the Y "ON"

^

button at the same time and hold pressed

in, until the display shows the following:

SETTING LOCAL LANGUAGE

DEUTSCH >ENGLISH<

After selection press Start button.

Select the desired language with the 1 2

^

"Cursor" buttons.

The display content being shown is immediately converted into the selected language.

^ Confirm the selected language by press-

ing the X "Start" button.

Setting current time and date*

Turn off the machine with the Z "Power off"

^

button.

Turn the key to position B "Operation".

^

Press the W "Delay start" button and the Y

^

"ON " button at the same time and hold

pressed in, until the display shows the fol

lowing:

SETTING TIME AND DATE

Time of the day >14< : 30 hrs

Date 23. 03. 1995

After selection press Start.

Use the 2 "Cursor" to position the cursor

^

on the input field to be changed and set

the change with the 3 4 "Minus or Plus"

buttons.

^ Position the 2 "Cursor" on the hours and

set the hours.

^ Position the cursor on the minutes and set

the minutes.

-

^ Position the cursor on Day and set the day.

^ Position the cursor on Month and set the

month.

^ Position the cursor on Year and set the

year.

^

Store the changes by pressing the X

"Start" button.

*If pauses between programming steps

lasts longer than 25 seconds, the display

will return to the basic stage and the

changes will be lost.

12

Page 13

Operation

Start up

Open the on-site water valves, (and the

^

supply valves for steam, if relevant).

Turn on the electricity supply at the mains

^

(on site).

Turn the key to position B "Operation".

^

The functions described below are re

stricted only to the "Operation" condition.

Empty all pockets.

^

Foreign objects, (eg nails, coins, paper

clips etc) can cause damage to textiles

and components in the machine.

Load the laundry.

^

Close the drum door.

^

^ Press the Y "Power on" button.

-

Program selection

Select a program (e.g. Program 1 COT

^

TONS).

The display shows the following (example):

-

PROGRAMME 1 COTTONS

>95 °C< Main wash 1

Rinses 3 1000 RPM

-

^

Use the button T "Prewash" to select a

"Prewash" if required.

When T "Prewash" has been pressed the

following shows in the display:

PROGRAMME 1 COTTONS

>60 °C< Prewash 1

95 °C Main wash 1

Rinses 3 1000 RPM

13

Page 14

Operation

Changing temperaure and spin

speed

The following parameters can be changed

before the start of a program:

the temperature in 1 °C steps from cold,

–

15 °C to maximum 95 °C .

the spin speed in 100 rpm steps.

–

WS 5240 300 - 1100 rpm

WS 5320 300 - 1000 rpm

PROGRAMME 1 COTTONS

>60°< Prewash 1

95 °C Main wash 1

Rinses 3 1000 rpm

Use the 2 "Cursor" to position the cursor

^

on the input field for the Prewash tempera

ture, and set the temperature required

(here 60 °C) with the 3 4 "Minus or Plus".

^ Position the cursor on the input field for the

Main wash temperature, and set the temperature required with 3 4 """.

^ Position the cursor on the input field for the

Spin speed, and set the spin speed required with the 3 4 "Minus or Plus".

Adding detergent

For the standard programs add detergent

^

-

to compartment:

2 = for the main wash

1 = for the Prewash (if required)

3 = fabric softener

4 = liquid bleach

5 = liquid detergent

Detergent use

^ Only use low sudsing detergents.

^ Do not oversuds the unit with too much de-

tergent.

^ Take into account the water hardness, and

the detergent manufacturer’s instructions

when filling the dispenser.

^

Do not fill fabric softener or bleaching

agent higher than the level marker in the

relevant dispenser compartment. Other

wise they will be siphoned into the suds

container.

^

Press X "Start" to begin washing.

-

14

Page 15

Operation

The program sequence is shown in the dis

-

play after the start of the program.

PROGRAMME 1 COTTONS

60 °C Prewash 20 °C

95 °C Main wash

^

^^^^^^^^^

~

In the second display line, here Prewash, the

actual suds temperature is shown, and the

time line extending off to the right, underneath the next cycle of the program is

shown, here Main wash.

PROGRAMME 1 COTTONS

95 °C Main wash 20 °C

Rinse 1

^

^^^^^^^^^

~

When the Prewash cycle has finished, the

Main wash appears in the display, with the

actual suds temperature, and the time line

extending off to the right. Underneath the

next cycle of the program is shown, here

Rinse 1.

When an arrow appears at the right of the

last line (~), this indicates that there is a following display line.

Program end - opening the drum

door

At the end of the program, with a stationary

drum and no more water in the machine the

following display is shown (for example):

PROGRAMME 1 COTTONS

PROGRAM END

DOOR IS UNLOCKED

Pull the handle to open the door.

^

If the door can not be opened, press

^

against the door, and once again pull on

the handle.

Never use force to open the door.

Remove the laundry.

^

If the program is interrupted during a cycle,

the following display messages will appear:

PROGRAMME 1 COTTONS

PROGRAMME END

DOOR IS LOCKED

THERE IS WATER IN THE MACHINE

or:

Press the 2 "Cursor", and further information

on the program appears in the lower lines.

Program end display

PROGRAMME 1 COTTONS

Rinse 1

Rinse 2

Program end 11 : 25 hrs ~

After water from the last heating phase has

drained away, or after the last "Cool Down"

the program end time is shown in hours and

minutes.

^

^^^^^^^^^

PROGRAMME 1 COTTONS

PROGRAMME END

DOOR IS LOCKED

DRUM NOT YET STATIONARY

^

Select the separate drain or separate spin

program and start it. At the end of the pro

gram open the door.

If this was the last load of wash for the day,

or longer:

^

Leave the drum door open.

^

Turn off the machine.

^

Switch off the main power supply (at the

wall switch).

^

Turn off the on site water and steam (if ap

plicable) valves.

-

-

15

Page 16

Operation

Delayed Start W

Use the "Delay start" button to program the

unit to start automatically at a later time.

Turn the key to position B "Operation".

^

Turn on the machine and select the re

^

quired program with the program selector.

The display shows the following (example):

PROGRAMME 1 COTTONS

>95 °C< Main wash 1

Rinses 3 1000 RPM

Press W "Delay start".

^

Here the display shows the following:

PROGRAMME 1 COTTONS

Start time >14< : 30 hrs

After the time has been set

press the Start button

-

Press X "Start" to confirm the delayed

^

start, and the following will appear in the

display:

PROGRAMME 1 COTTONS

95 °C Main wash 1

Start time 18 : 30 hrs

When the start time is reached the program

begins and the display shows the program

sequence. If W "Delay start" is pressed dur

ing the program, the actual time of day and

date are shown.

If 7 "End" is pressed the delay start function

will be cancelled.

-

The current time of day (military time) is always displayed first.

The cursor points to the input field for

‘hours’.

^ Select the start time with 3 4 "Minus or

Plus" buttons.

^

Position the cursor on the input field for

minutes and select the minutes with 3 4

"Minus or Plus".

Before pressing the X "Start" button the

start time can be deleted by pressing

again on the W "Delay start" button, or by

turning the machine off and then on

again.

16

Page 17

Notes

Prewash T

A Prewash should be selected when the

load is heavily soiled.

-

A Prewash can be selected before the

^

start, in Programs 1 to 6, by pressing T

"Prewash". The indicator light above the

button lights up.

Starch U

Starching can be selected in all programs

(except "Separate spin" and "Separate

drain").

Powder and low viscosity starches

When the "Starch" point is reached in the se

quence, "Starch hold" flashes in the Display.

PROGRAMME 1 COTTONS

Rinse 3

STARCH HOLD

Press the Starch and Starch hold button.

Open the drum door and add the starch

^

formulation, prepared according to the

manufacturer’s instructions.

Shut the drum door.

^

The message "PROGRAM STOP POWER

CUT" appears in the display.

PROGRAMME 1 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Please press the Start button.

^ Press X "Start".

-

-

"Starch hold" flashes in the display when it is

time to add starch to the laundry.

Liquid starch

PROGRAMME 1 COTTONS

Rinse 3

STARCH HOLD

Press the Starch and Starch hold button.

^

Add liquid starch into compartment 3, 4 or

^^^^^^^^^

5. The wash time is automatically extended

by 4 minutes.

^

This message appears again:

PROGRAMME 1 COTTONS

Rinse 3

STARCH HOLD

Press the Starch and Starch hold button.

^

Press the U "Starch" button, (the indicator

light goes out) and the program continues.

^

Press U "Starch" to continue the program.

17

Page 18

Notes

Without spin V

Without spin can be selected in all programs

(except "Separate spin").

-

When the "Spin" program is reached, "Spin

stop" flashes in the display.

PROGRAMME 2 COTTONS

Rinse 3

^^^^^^^^^

WITHOUT SPIN

Press without spin or End button.

^

Bleaching agents

Only use bleaching agents on textiles with

the symbol y on the wash care label.

Liquid bleaching agents must only be added

to compartment 4. The agent will then be

dispensed automatically during the second

rinse (cold bleaching).

Liquid bleaching agents should only be

used with colored fabrics if the textile manu

facturer’s wash care label states that the ma

terial is color fast and suitable for bleaching.

For cold bleaching the 4th rinse must be

programmed, (see Programming Instruc

-

tions).

-

^ Either press V "Without spin" again to con-

tinue the program with a spin, or press 7

"End", for the program to finish with water

in the machine.

18

Page 19

Notes

Skipping program cycles

Cycles of a program in progress can be

skipped or repeated.

Press 7 "End" and the program is

^

stopped.

PROGRAMME 2 COTTONS

Main wash

PROGRAMME STOP

PROGRAMME STOP flashes in the display.

Use the 1 or 2 "Cursor" to skip ahead or

^

move back to a cycle in the program.

At the position required press X "Start" to

^

continue the program again.

Program cancellation

To cancel a program, press 7 "End" twice

^

in succession.

If the program was cancelled while there

was water in the machine, or during a spin,

the following may appear in the display (ex

ample):

PROGRAMME 2 COTTONS

PROGRAMME END

DOOR IS LOCKED

WATER IS IN THE MACHINE

or:

PROGRAMME 2 COTTONS

PROGRAMME END

DOOR IS LOCKED

DRUM IS NOT YET STATIONARY

-

^ Run the Separate Drain or Separate Spin

program. On completion the door can be

opened.

Rinsing with hot water

Standard programs

1 Cottons 200 °F (95°C) and

2 Cottons 140 °F (60°C)

are programmed to rinse with hot water.

If a hot water supply is available it is an ad

vantage to run the final rinse with hot water.

This reduces the residual moisture content of

the laundry after spinning.

If the laundry is dried or ironed immediately

after washing, drying times will be shortened

and ironing easier.

19

Page 20

Liquid dispensing

Dispenser pump and Suction pipe

1 = Hose connection socket (suction side)

2 = Hose connection socket (pressure side)

3 = Leakage outlet

4 = Suction inlet opening

5 = Level indicator

When the dispenser container is empty

the pump and the machine will shut off.

Amount to be dispensed

Follow the detergent manufacturer’s guide

^

lines.

Always follow the instructions of the chemi

cal manufacturer when using cleaning

agents and special application chemicals.

Only use such chemicals for the purpose

and in the situation specified by the manu

facturer to prevent adverse chemical reac

-

-

tions and material damage.

If in doubt, contact the detergent manu

-

facturer to verify its safety in this machine.

Correct dosage also depends on the viscos

ity of the liquid detergent. It should stand at

normal room temperature before being used.

Maintenance of the dispensing system

^ Rinse the dispensing system through with

hot water every 2 weeks, or before shutting

the dispenser pumps down for any length

of time, to prevent the system clogging.

-

-

PROGRAMME - - - - - - - - - - -

PROGRAMME STOP

DISPENSING SYSTEM FAULT

Dispensing container 1 empty.

The display will indicate that the detergent

dispenser is empty.

The program will continue automatically

once the container has been refilled.

^ Rinse out the suction pipes with water.

^ Put the suction pipes in a container with

warm water, 104 - 122 °F (40 - 50 °C) .

^

In Service-Operation turn on each pump,

until the dispensing system is rinsed

through.

^

Check the connection points, hoses and

washers for leaks.

20

Page 21

Priming the dispensing pumps

Before the liquid dispensing pumps can be

used the liquid detergent must be drawn into

the system and the amount to be dispensed

set. Access the Service-Operation program

to do this.

Liquid dispensing

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D1< Disp. time 20 sec.

Cancel with the End button.

Cancel with the 7 "End" button.

^

Drawing in the liquid detergent

Insert the suction pipes into the liquid de

^

tergent containers.

Turn off the washer-extractor.

^

Turn the access selection key to position

^

B, "Operation" and set the program selec

tor to 24.

Turn on the washer-extractor, and within

^

4 seconds, press the T "Prewash" button

4 times in quick succession. This brings

you into Service-Operation.

SERVICE-OPERATION

>SERVICE PROGRAMMES< MACHINE DATA

After selection press Start button. ~

^ Press X "Start".

Repeat the whole process with the other

pumps.

-

>SERVICE PROGRAMMES< MACHINE DATA

SERVICE - OPERATION

After selection press Start button. ~

Press the X "Start" button, select the SER

^

VICE PROGRAMME 2, and press X "Start"

again.

To exit Service-Operation:

^ Press 7 "End" and turn off the machine.

^ Turn on the machine and select Program 8,

Separate Rinse and Spin, to flush the

proofing agent out of the machine.

To adjust the amount dispensed by the

pumps

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME >1<

After selection press Start button. ~

^

Select SERVICE PROGRAMME 2 with the

4 "Plus" button and press the X "Start"

button.

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D1< Disp. time 0 secs.

After selection press Start button.

^

With the 4 "Plus" button select D1, with the

2 "Cursor" button move to the input field

for dispensing time and with the 4 "Plus"

button set a dispensing time of approx. 20

seconds. Press X "Start", and the hoses of

pump 1 will be filled.

The amount to be dispensed is measured in

liters in the Service Program. The dispensing

time is then set in key access position C

"Programming".

^

Put the suction pipe into a deep measuring

container with sufficient liquid detergent

and keep it at the full level.

^

Continue as for Drawing in liquid deter

-

gent

21

Page 22

Liquid dispensing

A Pump for spray proofing

1 = "On-Off" switch

2 = Pressure control valve

With the pressure control valve the working

pressure can be set between 7.25 - 87 psi

(0.5 - 6 bar).

3 = Pressure connection

(for the pipe to the spray jet)

4 = Return feed connection

(Pipe into dispensing container for proofing

agent)

5 = Suction connection

(Pipe to suction pipe)

B Suction pipe

6 = Suction inlet opening

7 = Level indicator

When the dispenser container is empty the

pump and the machine will shut off.

PROGRAMME 18 WASH/ PROOF & SPRAY

PROGRAMME STOP

DISPENSING SYSTEM FAULT

Dispensing container 1 empty.

At the same time the display indicates that

the dispenser is empty.

^ Replace or refill the dispenser and press

the X "Start" button to continue the program.

,

Do not use liquids which attack brass.

Correct dosage also depends on the viscos

ity of the liquid detergent. It should stand at

room temperature before being used.

Amount to be dispensed

Follow the detergent manufacturer’s guide

-

lines.

-

22

Page 23

Priming the dispensing pumps

Before the liquid dispensing pumps can be

used the liquid detergent must be drawn into

the system and the amount to be dispensed

set. Access the Service Operation program

to do this.

Liquid dispensing

SERVICE-OPERATION

>SERVICE PROGRAMMES< MACHINE DATA

After selection press Start button. ~

Press the X "Start" button.

^

Drawing in the proofing agent and setting

the spray pressure.

Put the suction pipe and pump return feed

^

piping into the dispensing container.

^ Switch on the pump.

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME >1<

After selection press Start button. ~

Select SERVICE PROGRAMME 2 with the

^

4 "Plus" button and press X "Start".

SERVICE-OPERATION SERVICEPROGS

SERVICE PROGRAMME 2

Dispenser valve >D1< Disp. time 0 Secs.

After selection press Start button.

^ With the 4 "Plus" button select D6, with the

2 "Cursor" button move to the input field

for dispensing time and with the 4 "Plus"

button set a dispensing time.

Press the X "Start" button and the pump

runs.

^ The proofing agent comes out of the jet

when the hoses have filled up. Now the

spray pressure can be adjusted on the

pressure control valve to achieve the best

spray pattern.

^

Turn the pressure control valve to the mid

dle position.

Service operation:

^

Turn off the washer-extractor.

^

Turn the access key to position B, "Opera

tion mode" and set the program selector to

24.

^

Turn on the washer-extractor and within 4

seconds press the T "Prewash" button.

This brings you into Service-Operation.

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D6< Disp. time 15 Secs.

-

^

Cancel with the 7 "End" button.

Cancel with the End button.

-

23

Page 24

Liquid dispensing

Setting the amount dispensed by the

pump

The amount to be dispensed is measured in

liters in the service program.

The dispensing time fixed is then set in oper

ating mode C "Programming".

Insert the suction pipe into a measuring

^

container with sufficient proofing agent

and maintain the fill level.

SERVICE-OPERATION

>SERVICE PROGS< MACHINE DATA

After selection press Start button.

After selection press the X "Start" button.

^

Select SERVICE PROGRAMME 2 and

press the X "Start" button.

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D1< Disp. time 0 Secs.

After selection press Start button.

^ With the 4 "Plus" button select D6.

Set the access key to position C "Pro

^

-

gramming" and select menu point ALTER.

Select the number of the Proofing program

^

with the 4 "Plus" or 3 "Minus" button.

-

Press X "Start".

If the U "Starch" button is pressed, the

^

LED lights up, and then the 2 "Cursor" (or

1) is pressed, the cycle is skipped

through to the end (or back again). In the

area programming and at each end of a

block the skipping is stopped and the dis

play calls for "saving".

If the X "Start" button is pressed this

jumps into the next block.

PROGRAMMING ALTER

PROGRAMME 18 WASH/PROOF & SPRAY

Dispensing 1 >D 1/ 0 Secs, D 1/ 0 Secs <

Disp. delay 1 >no< ~

^ Once the dispensing point has been

found, set D6 with the 4 "Plus" button and

with the 2 "Cursor" move to the input field

for dispensing time, and with the 4 "Plus"

button set the fixed dispensing time.

^ With the cursor button move to the input

field for dispensing time and with the 4

"Plus" button set a dispensing time.

SERVICE-OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D6< Disp. time 35 Secs.

After selection press Start button.

^

Press the X "Start" button and the pump

will draw a certain amount from the mea

suring container.

^

Repeat this process until the desired dis

pensing amount is set.

Maintain the dispensing time because this

time must be carried over into the program

to be run.

^

Cancel with the 7 "End" button and turn

off the machine.

^

Turn on the machine and select Separate

Drain, to flush the proofing agent deter

gent out of the machine.

PROGRAMMING ALTER

PROGRAMME 18 WASH/PROOF & SPRAY

Dispensing 1 >D 6/ 60 Secs, D 1/ 0 Secs<

Disp. delay 1 >no< ~

^

Skip the program through to the end and

press X "Start" to save.

^

To start the program turn the access key to

position B "Operation".

-

-

-

24

Page 25

Peak load cut-out

Peak load cut-out / PC- Printer connection

When the peak load (overload) cut-out func

tion is activated the heating is switched off

and the program is stopped. The following

message appears in the Display:

PROGRAMME 1 COTTONS

PROGRAMME STOP

PEAK LOAD CUT OUT ACTIVE

If the set temperature has not been reached,

the program sequence is stopped.

When the peak load cut out function is finished the program automatically carries on

from where it was left off.

PC- Printer connection:

The machine can be connected to a PC or

printer using an SD kit.

-

PC-Operation:

Program changes can be made via a PC, or

a new program can be downloaded. This requires a special Editor Program which is

available from the Miele Professional Department.

Printer-Operation:

It is possible to print out whole programs or

parts of programs. See "Programming In

structions".

-

25

Page 26

Problem solving guide

Power failure - Emergency door

release

With a short power failure:

The program remains in the last position,

and when power is restored the following

message appears in the display:

PROGRAMME 1 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Please press the Start button.

Press X "Start", to continue the program.

^

With an extended power failure:

Turn off the machine.

^

Switch off the main power supply at the

^

wall switch.

^ Turn off the on site valves for water or

steam.

To remove the laundry the drain valve will

need to be opened manually and the drum

door unlocked manually.

^

Open the drain valve by partially opening

the venting screw.

^

Use a wrench at the rear of the machine,

but do not unscrew completely. Drain off

the suds.

^

Be careful, some water will seep out of the

screw opening. Catch water in a suitable

container.

^ First position the screwdriver in the

opening, push in and hold firm.

^ Press against the door handle with your

right hand, and then pull on the door handle to open the door.

Never use force to open the door.

^

Take out the laundry.

Large articles of laundry stretching dur

-

ing the spin cycle

Large articles of laundry (e.g. table cloths)

might stretch during the spin cycle. This can

generally be prevented by reprogramming

the machine.

Procedure

Reprogram programs from program selector

setting 11.

Drain valve: program to "NO"

Drain with tumble: program to "NO"

^

Tighten up the venting screw and check

that there is no leak.

26

Page 27

Fault messages

Repairs should only be performed by a

qualified technician in accordance with

applicable codes and standards. Repairs

and other work by unqualified persons

could be dangerous and the manufacturer

will not be held responsible.

Problem solving guide

PROGRAMME 1 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Cut-out of heating sensor 1.

Call the Miele Technical Service Depart

^

ment.

-

Faults that occur before or after the start of a

program are shown in a flashing display.

PROGRAMME 1 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Please press the Start button.

When power is restored press X "Start".

^

This fault message can also indicate that the

winding protection of the drive motor has

overheated.

^ Allow the motor to cool down.

PROGRAMME 1 COTTONS

PROGRAMME STOP

WATER INLET FAULT

Open water stopcock and press Start button.

^ Open up the water stopcock (valve) and

press X "Start".

PROGRAMME 1 COTTONS

PROGRAMME STOP

DRAIN FAULT

Clean drain system and press Start button.

^

Check the drainage system on site and

press X "Start". A defective drain valve

should only be repaired by an authorized

service technician.

PROGRAMME 1 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Short circuit on heater sensor 1.

PROGRAMME 1 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Call the Miele Technical Service Depart

^

-

ment.

PROGRAMME 1 COTTONS

PROGRAMME STOP

DRIVE SYSTEM FAULT

Multiplug drive variants lacking.

^ Call the Miele Technical Service Depart-

ment.

PROGRAMME 1 COTTONS

95 °C Main wash 20 °C

Rinses 1

DRIVE SYSTEM FAULT

^

Call the Miele Technical Service Depart

^

^^^^^^^^^

ment if there is no drum movement after

this message.

PROGRAMME 1 COTTONS

PROGRAMME STOP

PEAK LOAD CUT OUT ACTIVE

At the end of the peak load cut out function

the program continues automatically.

PROGRAMME 1 COTTONS

PROGRAMME STOP

IMBALANCE SWITCH

Press the On-Off switch.

^

Call the Miele Technical Service Depart

ment.

-

^

Press Z "Power off" and Y "Power on".

27

Page 28

Problem solving guide

PROGRAMME 1 COTTONS

PROGRAMME STOP

PRESSURE MONITOR FAULT

Call the Miele Technical Service Depart

^

ment.

PROGRAMME 1 COTTONS

PROGRAMME STOP

DISPENSING SYSTEM-FAULT

Dispensing container 1 empty.

Change the dispensing container.

^

PROGRAMME 1 COTTONS

PROGRAMME STOP

HEATER SYSTEM FAULT

Dry step switch has cut out.

^ Call the Miele Technical Service Depart-

ment.

Possible reasons for excessive suds:

Detergent type

^ Only use detergent formulated for use in

commercial washer-extractors. Domestic

laundry detergent is not suitable.

Residues, e.g. detergent left on laundry

Run an additional Prewash without deter

^

-

gent and without selecting a temperature.

Laundry which has been soaked before

-

washing must be thoroughly rinsed before

running a wash program.

Small loads

Reduce the amount of detergent dis

^

-

pensed according to the size of the load.

Drum speed too high during the wash

(Profitronic-controls)

Reduce the drum speed and wash rhythm.

^

Water hardness levels

Hard

-

ness

range

I soft 0 - 130 0 - 7

II medium 131 - 250 7 - 14

III hard 251 - 380 14 - 21

IV very hard over 380 over 21

Water

quality

Hardness

level in ppm*

Hardness

level in

gr/gal*

*) Contact the local water authority for the

hardness level of the water supplied to the

machine.

Overdosing of detergent

^

Dispense detergent following the deter

gent manufacturer’s instructions on the

packaging and adjust to local water hard

ness levels.

Detergent creates too many suds

^

Use a low sudsing detergent or contact

your detergent application specialist.

Very soft water

^

In areas with soft water dispense less de

tergent.

Soiling level of the laundry

^

For lightly soiled laundry dispense less de

tergent.

-

-

-

-

28

Page 29

After sales service

In the event of a fault which you cannot

correct yourself please contact:

Miele Technical Service

USA 1-800-999-1360

techserv@mieleusa.com

CDN 1-800-565-6435

service@miele.ca

When contacting Technical Service please

quote the model and serial number of the

machine.

These can be found on the data plate with

the door open,

Service interval

If the following message appears in the dis

play after turning the machine on:

PROGRAMME 1 COTTONS

PLEASE CALL THE SERVICE DEPARTMENT

(SERVICE INTERVAL 1)

The machine needs to be serviced.

The Service interval display will go out after

5 seconds or by pressing the X "Start" but

ton.

-

-

or at the rear of the machine towards the

top.

29

Page 30

Cleaning and Care

After each use

Never use high pressure cleaners to hose

down the machine.

The machine should be cleaned immediately

after use.

After use do not shut the drum door but

^

leave it slightly ajar, to allow the machine to

dry out.

Cleaning the exterior

Never use abrasive cleaners, scouring

,

pads, steel wool or caustic cleaners on

the washer-extractor. They will

the surface.

Plastic

All plastic surfaces and the control panel

can be cleaned with warm water and liquid

dish soap applied with a soft sponge.

^ Wipe dry using a soft cloth.

damage

Cleaning the dispenser box and

siphon

After use the dispenser compartment should

be cleaned with warm water to remove any

detergent or other residues.

The siphon tube in the detergent dispenser

should also be cleaned.

Pull the siphon tubes upwards to remove

^

for cleaning in warm water. Replace in the

reverse order checking that the siphon

tubes are hooked in correctly.

Cleaning the cooling fan

,

Do not use too much water when

cleaning the controls. Water could penetrate into the electronics and cause damage.

Stainless steel

Stainless steel surfaces can be cleaned us

ing a non-abrasive stainless steel cleaner.

To help prevent resoiling, a conditioner for

stainless steel can also be used.

^

Apply sparingly with even pressure.

-

The ventilation slats in the cover for the cool

ing fan at the rear of the machine must be

regularly checked for lint and dirt and

cleaned whenever necessary.

-

30

Page 31

Cleaning and Care

Cleaning the filters

The filters in the water inlet valves must be

checked periodically for build up and

cleaned if necessary.

Cleaning the drum

The drum is made of non-rusting stainless

steel. It is however possible that water with a

high iron content or foreign bodies in the

wash, (e.g. paper clips or metal buttons),

may lead to the formation of superficial rust

spots especially, if the machine is not used

for some time. If this occurs the drum can be

cleaned with a scouring powder.

Maintaining the drum

After about 1000 running hours:

^

Apply Arcanol L 12 V to both grease nip

ples of the drum.

-

31

Page 32

Guide to the symbols on the data plate

1 Machine type

2 Serial number/year of manufacturer*

3 Voltage/Frequency

4 Control fusing

5 Drive motor

6 Plate diameter/Plate quantity *

7 Drum data

8 Drum diameter/Drum depth *

9 Spin speed

10 Drum volume/Laundry dry weight

11 Kinetic Energy

12 Ex. time to top speed

13 Braking time

14 Heating

15 Electric heating

16 Fusing (on site)

17 Steam heating indirect

18 Steam heating direct

19 Gas heating

20 Commissioning date

21 Water-Registration

DVGW-test cert (Water)

22 Field for CE test symbol /

(Product ID-No./Gas)

*does not apply to WS 5240 / WS 5320

32

Page 33

This machine is for use only with articles

which have not been treated with danger

ous or flammable substances.

To prevent frost damage do not install this

machine in a room exposed to frost.

It is essential that the machine is level, and

secured (see Installation diagram supplied).

The machine must not be moved without

all the outer panels in place.

Shipping struts

Once the machine has been set in its final

position the red-marked shipping struts

must be removed. Ensure they are re

moved before using the machine.

-

-

Installation

The plinths for the front and rear panels are

secured with the rear panel, and should be

fitted when the machine has been installed.

The screws are found in the pre-drilled

holes.

The shipping struts should be stored in a

safe place for future use. They must be re

fitted if the machine is moved.

-

^

The red-marked shipping struts "A" on the

diagram, 2 at the side front and 2 at the

side rear are each fixed with 3 M 10

(SW 17) hex screws. Remove these.

The red-marked shipping struts "B" on the

diagram, 2 at the front and 2 at the rear are

each fixed with 3 M 10 (SW 17) hex screws.

^

To remove them detach the front service

panel and the rear panel. Unscrew the 3

M6 hex screws (SW 8) at the bottom edge

of the front service panel, and take it off.

Unscrew 8 hex screws in the rear panel

and remove.

33

Page 34

Installation

Please take note of the Installation Dia

gram and instructions supplied. They are

important for the proper connection of

supplies.

-

Plumbing

The water hook up is by a water valve, which

conforms with local and national regulations.

This work must be carried out by an autho

rized Miele service technician.

To ensure the machine is correctly con

nected please follow the installation plan

and the installation instructions supplied with

the machine.

The inlet pressure hoses supplied with the

machine must be used for connection to the

water supply. To ensure the hot water inlet

hose (marked 194°F/90°C) lasts for many

years, do not hook the hose up to a hot

water connection supplying water hotter

than 158°F/70°C. This hose should only be

replaced with a genuine Miele spare part.

-

-

Before connecting the inlet hoses to the ma

chine ensure that the filters and seals sup

plied in the accessories pack have been

correctly fitted.

A water pressure flow rate of at least 30 psi

(2 bar), maximum 145 psi (10 bar) is re

quired.

Water taken into the machine must not ex

ceed a temperature of 70°C/158°F.

Connection to cold water only

See the Installation diagram supplied

-

-

-

-

34

Page 35

Electrical connection

All electrical work must be performed by a

qualified technician in accordance with ap

plicable codes and standards.

The machine must only be connected to the

voltage and frequency shown on the data

plate.

The machine is supplied as standard for

connection to a 208 V, 60 Hz, 20 A, 3-phase

electricity supply.

The electric heater rating is factory preset

to 24 kW (WS 5240), 30 kW (WS 5320).

-

Installation

The minimum suds level required for activat

ing the heating is 110 mm column of water.

The motor has an overload protection

switch.

Connection should be made via a suitable,

approved isolator, with an on-off switch easily accessible for servicing.

WARNING

THIS APPLIANCE MUST BE

GROUNDED !

Steam connection

Steam connection must only be undertaken

by an authorized Miele installer.

All removable outer housing parts must

be refitted after the machine has been in

stalled and the necessary connections

made to on-site supplies.

-

-

35

Page 36

Alteration rights reserved / 000 USA - 4401

This paper is made from cellulose bleached without the use of chlorine.

Loading...

Loading...