Operating Instructions

Washer-Extractor

WS 5073 SLUICE

It is essential to read these

operating instructions before

installing or using the machine,

to avoid the risk of accident

or damage to the machine. M.-Nr. 05 068 971 /03

G

2 M.-Nr. 05 068 971 /03

Contents

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Washing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparing the wash load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programme selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Opening the drum door at the end of the programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dispensing detergent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fabric conditioner / Starch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Additional functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Programme changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Opening the drum door in the event of a power failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Possible reasons for increased levels of foaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Explanation of symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Notes for the installer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Transit fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connection to water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Coin mechanism unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

The washer-extractor must be installed by an

approved service technician or an authorized

Service Dealer.

M.-Nr. 05 068 971 /03 3

Warning and Safety instructions

Please read the operating instructions be

fore using this machine for the first time.

They contain important information about

the safety, use and maintenance of the

machine. This way you will avoid the risk

of accidents and damage to the machine.

Appropriate use of the machine

This washer extractor is only intended for

items of laundry which have not been im

pregnated with dangerous or inflammable

substances.

Only machine wash articles which pos

sess a care label stating they are suit

able for machine washing.

It is the operator’s responsibility to en

sure that the standard of disinfection in

thermal as well as chemo thermal proce

dures is maintained (in accordance with §

18 IFSG) by carrying out suitable validation

tests. These procedures should be checked

on a regular basis, either thermo-electrically

using loggers, or bacteriologically with bio

indicators. The operator must pay particular

attention to maintaining the correct parameters in the procedure, including temperature

and with chemo thermal programmes the

chemical concentration used. Disinfection

programmes must not be interrupted, as this

can have a limiting effect on the disinfection

result.

On no account must solvents of the kind

used for dry cleaning be used in this ma

chine. There may be the danger of fire or ex

plosion.

Never use or store petrol or petroleum

based substances or any easily inflam

mable substances near the machine. Do not

use the machine lid as a resting place.

Danger of fire or explosion

-

-

-

-

-

-

-

-

-

Technical and electrical safety

The electrical safety of this appliance

can only be guaranteed when continuity

is complete between the appliance and an

effective earthing system which complies

with local and national regulations. It is most

important that this basic safety requirement

is regularly tested by a qualified electrician.

The manufacturer cannot be held responsi

ble for the consequences of an inadequate

earthing system.

Do not damage, remove or bypass the

safety features and controls on the ma

chine.

Where there is any damage to the ma

chine or to the cable insulation the ma

chine must not be used until it has been re

paired.

Any removable outer panels must be in

place, and all moving or electrical parts

shielded before the machine is operated.

The machine is only completely isolated

from the electricity supply either when

switched off at the wall isolator, or the mains

fuse is withdrawn from the socket

Repairs to machines operating with elec-

tricity, gas or steam should only be undertaken by a suitably qualified service engineer to ensure safety. Unauthorised repairs

could be dangerous.

Faulty components should only be ex

changed for Miele original spare parts.

Only when these parts are fitted can the

safety standards of the machine be guaran

teed.

The very best materials are used in the

manufacture of this machine, and every

care is taken in its manufacture. However,

with time, deterioration of parts can occur,

especially with rubber components such as

hoses. This should be borne in mind if oper

ating the machine without supervision.

Check the inlet hoses regularly for signs of

deterioration and replace in good time, to

avoid leaks and subsequent damage.

-

-

-

-

-

-

-

-

4 M.-Nr. 05 068 971 /03

Warning and Safety instructions

Local regulations regarding regular in

spection and maintenance of this ma

chine must be observed. (In Germany this

machine is subject to laundry regulations

UVV (VBG7y), Sections 36 and 37, which

stipulate that washer extractors with a kinetic

energy of more than 1500 Nm must be

checked once a year by a competent per

son for their operational safety and the re

sults entered in a test log (book) supplied

with the machine for the German market,

and which must be kept at the place of oper

ation and be available for inspection.)

Use of the machine

Never allow children to play in, on or

near the washer extractor, or to operate it

themselves. Please supervise its use by the

elderly or infirm.

Remember that the door porthole glass

can become hot during the operation of

the machine. Do not let children touch it.

When washing with high temperatures

steam can be emitted from the venting

slot behind the machine.

Do not grip between the suspended

drum unit and the seal of the front panel

cut-out during spin.

Always make sure the drum is stationary

before reaching in to remove washing.

Reaching into a moving drum is extremely

dangerous.

Water used for washing and rinsing must

not be used as drinking water. It must be

discharged into a proper sewerage system.

The machine should only be operated

unsupervised when there is a floor drain

(gully) in the direct vicinity of the machine.

Chlorine or agents containing chlorine

are corrosive, and can under certain

conditions lead to irreperable damage to

components.

-

-

-

-

Disinfecting and cleaning agents often

have compounds containing chlorides in

them. If these agents dry on to stainless

steel surfaces, the residual chlorides will at

tack the steel and can cause rusting.

To protect your machine from rust damage,

we recommend only using chloride free dis

infecting and cleaning agents for washing

and disinfecting programmes and for clean

ing stainless steel surfaces of the machine

itself.

-

If you are not sure about a particular agent,

contact the manufacturer of that agent for

advice.

If you accidentally spill an agent containing

chlorides on the machine it should be rinsed

off with water and dried using a soft cloth.

Proprietary dyes, dye removers and

descaling agents may only be used in

this machine if the manufacturer expressly

states that they are suitable for use in a

washing machine. Follow manufacturer’s instructions on how to use them.

Always follow the instructions of the

chemical manufacturer when using

cleaning agents and special application

chemicals. Only use such chemicals for the

purpose and in the situation specified by the

manufacturer in order to avoid the danger of

adverse chemical reactions and material

damage.

If in doubt check the suitability of the prod

uct for use in this machine with the manufac

turer before using it.

Where a chemical cleaning agent is rec

ommended on technical application

grounds, this does not imply that the manu

facturer of the machine takes responsibility

for the effect of the chemical on the material

of the items being cleaned or on the ma

chine. Please be aware that changes in for

mulation, storage conditions etc., which may

not be publicised by the chemical producer,

can have a negative effect on the cleaning

result.

On no account use high pressure

cleaners or hose down the machine.

-

-

-

-

-

-

-

-

-

M.-Nr. 05 068 971 /03 5

Warning and Safety instructions

Use of accessories

Accessory parts may only be fitted when

expressly approved by Miele. If other

parts are used, guarantee, performance and

product liability claims may be invalidated.

Disposal of old machines or appliances

When disposing of an old washer extrac

tor first make it unusable. Disconnect

from all services, cut off the cable and the

plug from the cable.

Make the door lock inoperative, so that chil

dren cannot accidentally shut themselves in.

Make appropriate arrangements for the safe

disposal of the appliance.

All personnel working with this machine

must be fully trained in all aspects of its

use and safety.

Keep these instructions in a safe place.

-

-

6 M.-Nr. 05 068 971 /03

Disposal of the packing material

The transport and protective packing has

been selected from materials which are envi

ronmentally friendly for disposal and can

normally be recycled.

Ensure that any plastic wrappings, bags etc.

are disposed of safely and kept out of the

reach of babies and young children.

Danger of suffocation!

Rather than just throwing these materials

away, please ensure they are offered for re

cycling.

Disposal of your old machine

Old machines contain materials which can

be recycled. Please contact your local au

thorities or scrap merchant about potential

recycling schemes, before disposing of the

machine.

See also the section under "Warning and

Safety instructions".

-

-

Caring for the environment

-

M.-Nr. 05 068 971 /03 7

Guide to the machine

WS 5073 washer extractor, sluice machine

1 -Detergent dispenser box 7 -Cable entry for extra equipment

2 -Control panel 8 -Cable entry for dispenser pumps

3 -Drum door 9 -Cable entry for power supply

4 -Front wall panel 10 -Venting socket

5 -Flap for suds filter/drainage system 11 -Cold water connection

and emergency door release 12 -Hot water connection

6 -Four adjustable screw feet 13 -Opening for dispenser hoses

14 -Back wall

15 -Drainage

16 -Air gap

Control panel

12 3 4

1 -Temperature and time left display

2 -Push button switches

3 -Programme sequence indicator lights

4 -Programme and Temperature selector

8 M.-Nr. 05 068 971 /03

Guide to the machine

Push button switches

a Door

Opens the drum door, releases the "With

pre-wash" or "Starch" or "No final spin" but

tons, if any of these had been pushed in.

+i with Pre-wash

Can be selected with programmes

A, B, C, E

Display

h min /°C

Time display h(rs)/min(s)

(does not apply to programme

-

This display shows how long the wash

programme still has to run.

Indicator light m min lights up.

or

Temperature °C

)

m Starch

Can be selected with programmes

A, B, E

w No final spin

Can be selected with programmes

A, B, C, D, E

h Start

Starts the programme

From 20°C the temperature is shown rising

in 5°C-Steps.

Indicator light p°C lights up.

m min Time left

p°C Temperature

M.-Nr. 05 068 971 /03 9

Guide to the machine

Programme sequence indicator lights

On / Start

Pre-wash

Main wash

Rinses

Rinses

Rinses / Starch

Drain

Final spin

End

Water inlet / drain

Programme and Temperature selector

Sluice programme for heavily soiled cotton

and linen items.

Smaller loads, e.g. 5 kg Cottons are washed

more efficiently.

Add detergent to Pre-wash i and Main

wash j compartments.

Add fabric conditioner to p compartment.

The "Sluice" programme begins, consisting

of:

Cold water sluice cycles (high water level,

–

then drained)

Pre-wash 65°C

–

Main wash 75°C, held for 12 minutes

–

Rinses

–

Drain

–

Spin

–

Once the programme commences the door

cannot be opened until completion of the

whole programme, in full compliance with

DHSS requirements.

Programmes

–

A Cottons

–

B Minimum iron

–

C Delicates/Synthetics

–

D Woollens

–

E Short programme

–

F Sluice

For the same reason the options for change

available with other programmes during a

cycle are excluded and the programme cannot be cancelled.

Maximum spin speed per programme

A Cottons

D Wool

E Short programme

G Separate spin

B Minimum iron 900 rpm.

F Sluice 1200 rpm.

C Delicates/Synthetics 600 rpm.

1200 rpm.

–

G Separate Spin

–

H Separate Drain

–

F Sluice programme

10 M.-Nr. 05 068 971 /03

Detergent dispenser compartments

Guide to the machine

Compartment i - Pre-wash

Compartment j - Main wash

Compartment y - Liquid bleach

Compartment p - Fabric conditioner

M.-Nr. 05 068 971 /03 11

Washing

Before using for the first time

The first commissioning of the machine

should be carried out only by a Miele ser

vice technician or an authorized Miele

Service Dealer.

It is essential that the machine is installed

and connected to power, water and drain

age correctly.

Washing out the machine

Any residual lubricants and water from test

ing still in the machine should be flushed out

as follows:

^ Do not load any laundry in the machine.

-

-

-

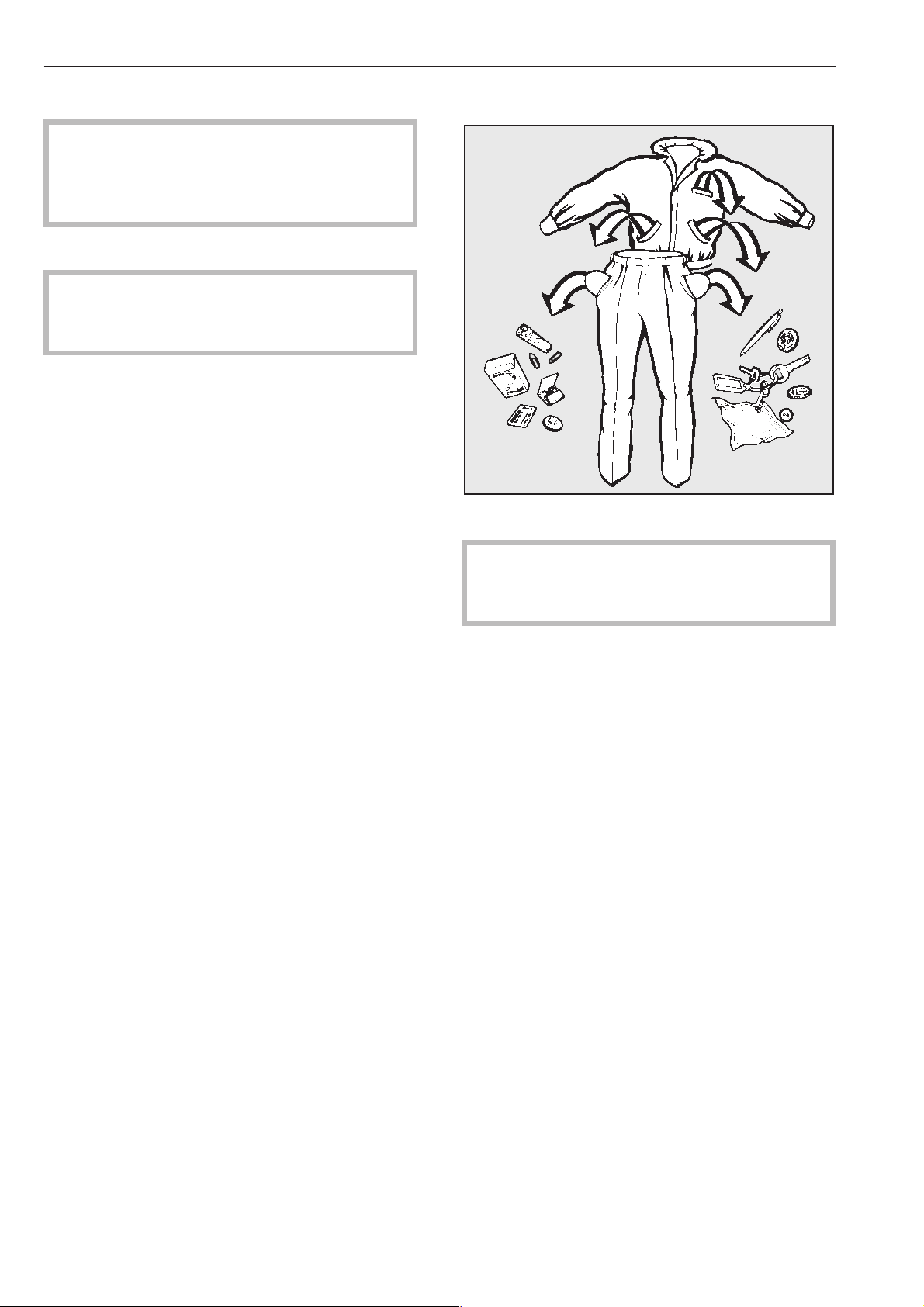

Preparing the wash load

Empty all pockets

^

^ Add a little detergent to compartment j.

^ Turn the programme selector switch to the

"A Cottons 60°C" programme.

^ Press the"h Start" button.

^ At the end of the programme turn the

programme and temperature selector to

the "r End " position.

Foreign objects, (eg nails, coins, paper

clips etc) can cause damage to textiles

and components in the machine.

Sort the laundry

Most garments have a textile care label in

the collar or side seam. Sort the laundry by

care label symbols.

Only wash items in this machine which are

stated by the manufacturer to be machine

washable on the textile care label.

Dark textiles often contain excess dye, and

should be washed separately several times

before being included in a mixed load.

Delicate textiles should be washed sepa

rately in a delicates programme.

Woollens and textiles containing wool must

only be washed in this machine if the care

label states that they are machine washable.

-

Loading the drum

Unfold laundry and load loosely in the drum.

For best results make up mixed loads of

large and small items. This improves the

washing effect and distributes the load

better for spinning.

Overloading reduces the wash result and

causes more creasing.

12 M.-Nr. 05 068 971 /03

Maximum load (weight of dry washing):

A Cottons 7.5 kg

B Minimum iron 3.0 kg

C Delicates/Synthetics 1.5 kg

D Woollens 1.5 kg

E Short programme 7.5 kg

F Sluice 7.5 kg

Washing

Add detergent for the main wash to com

^

partment j - and if required detergent for

the pre-wash to compartment i, fabric

conditioner to compartment p and liquid

bleach to compartment y.

-

^ Shut the drum door

Grasp the door in the open position and

slam it shut, (mind your fingers).

At first the door may shut with difficulty.

This eases in due course.

Make sure no items of washing are caught

when the door is closed, or they could be

damaged.

^

Open the on-site stopcock.

^

Switch on the on-site main switch.

Programme selection

^

Select programme and temperature

(e.g. programme A Cottons 95°C).

M.-Nr. 05 068 971 /03 13

Washing

?

Additionally select pre-wash if required but

^

only with programmes A,B,C, E.

Press the "+i with pre-wash" button.

Opening the drum door at the end

of the programme.

After the "r End " indicator lights up:

At the end of the programme turn the

^

programme and temperature selector to

the "r End " position.

Press the "a Open door" button

^

- the drum door opens.

?

^ Press the "h Start" button.

- The indicator light "m min" goes out and

the indicator light "%°C" lights up. -

- The wash programme starts.

Temperature display

After the programme start the current suds

temperature for the main wash is shown in

5°C-steps until the set temperature has been

reached.

In programme F the current suds tempera

ture is shown in 5°C steps for the whole du

ration of the programme.

The indicator light "%°C Temperature" lights

up.

-

-

^ Take out the washing.

Only remove laundry from the machine

once the drum has stopped turning, otherwise you may seriously injure yourself.

Make sure the drum is empty, otherwise,

when the machine is next used items may

become damaged (e.g. shrink) or cause

other laundry to discolour.

If no more washing is to be done:

^

leave the drum door open.

^

switch the machine off at the on-site main

switch.

^

turn off the on-site stopcock(s).

Time display (Time left)

Once the temperature set for the main wash

has been reached the time left for the

programme to run shows in the display in

hours and minutes (does not apply to

programme F).

The indicator "m min time" lights up.

The time left counts down in 1 minute inter

vals.

14 M.-Nr. 05 068 971 /03

-

Dispensing detergent

Water hardness levels

Hardness

Hardness

range

I soft 0 – 1.3 0 - 7

II medium 1.3 – 2.5 7 - 14

III hard 2.5 – 3.8 14 - 21

IV very hard over 3.8 over 21

If you do not know the hardness level of the

water in your area you should contact your

local water authority for information.

Water

quality

level in

mmol/l

German

hardness

level °d

Dispensing detergent

Add the right amount of detergent as recom

mended on the packaging. It is important to

avoid overdosing as it can lead to excessive

foam. Use a low foaming detergent.

The amount dispensed will depend on the

following:

– the quantity of laundry

– the water hardness level

– the level of soiling.

too little detergent results in the following:

–

The laundry will not be properly clean and

will in time become grey and hard to

touch.

–

Greasy particles cling to the laundry.

Fabric conditioner / Starch

-

Bleaching agents

Only use bleaching agents on textiles with

the symbol y on the wash care label.

Liquid bleaching agents must only be added

to the compartment marked y. The agent

will then be dispensed automatically during

the 2nd rinse (cold bleaching).

Liquid bleaching agents should only be

used with coloureds if the textile manufacturer’s wash care label states that the textile

is colour fast and suitable for bleaching.

For cold bleaching the 4th rinse must be

programmed, (see Programmable func

tions).

Fabric conditioner

-

–

Lime deposits on the heater elements.

too much detergent results in the follow

ing:

–

Excessive foam.

–

Low level of agitation.

–

Poor washing, rinsing and spin results.

M.-Nr. 05 068 971 /03 15

-

Dispense according to the manufacturer’s

recommendations:

^

Open the lid of the compartment p.

^

Add fabric conditioner, but do not exceed

the max. level mark.

^

Close the compartment lid.

The conditioner is automatically dispensed

in the last rinse. At the end of the

programme a small amount of water remains

in the fabric conditioner compartment.

Dispensing detergent

Powder and liquid starch

Prepare and dispense the starch solution

^

as stated on the packaging.

Automatic dispensing of liquid starch

Pour the liquid starch into compartment

^

p (do not exceed the marker level).

Close the compartment lid.

^

Adding liquid or powder starch by hand

Select the programme required and also

^

push in the "Starch m" button. The

programme, and the "time left" indicator

will pause before the last rinse.

The starch "m " indicator light comes on.

Add starch formulation to compartment

^

i.

^ Press the "m Starch" button to release it

for the programme to continue.

"w No final spin" can be selected to keep

creasing to a minimum. The water is drained

away, and the load can be taken dripping

wet from the drum.

16 M.-Nr. 05 068 971 /03

Additional functions

By pressing one or more buttons

programmes can be adapted to offer addi

tional functions.

+i "with pre-wash"

For heavily soiled or stained textiles in

programmes A, B, C, E.

m "Starching"

For freshly washed textiles such as table

cloths, napkins, work wear etc., in

programmes A, B, E.

w "without final spin"

Washing which is not to be spun but taken

dripping from the machine in programmes

A, B, C, D, E.

Cancelling a programme

Turn the programme selector to "r End".

^

The indicator lights flash through the other

programme stages until the "r End" light is

reached.

To cancel programme F the machine must

be switshed off at the mains.

To omit a programme stage

(does not apply to programme

Turn the programme selector to "r End".

^

As soon as the programme sequence light

for the stage at which the programme should

continue starts flashing:

Turn the selector switch to the appropriate

^

programme within 3 seconds.

)

Changing programme sequence

The programme can be changed at any time

where it makes sense (does not apply to

programme F).

^ Turn the programme selector to the re-

quired programme. The new programme

will carry on at the relevant stage.

Exceptions:

If the programme selector has been turned

through "r End".

Opting into or out of the following

programmes:

–

G Separate spin or

–

H Separate drain

breaks off the programme. The "h Start" but

ton must be pressed in again to start the re

quired programme.

When working through a coin unit or coin

counter the programme is locked after

3 minutes and no changes are possible.

-

To repeat a programme stage

(does not apply to programme

A programme stage must have been finished before it can be repeated:

^ turn the programme selector switch to

"r End".

When"r End" illuminates in the sequence

display:

^

Select the new programme required.

^

Press the "h Start" button.

^

After approx. 5 seconds, turn the

programme selector switch to "r End"

-

again.

As soon as the indicator light of the

programme stage to be repeated starts

flashing:

^

turn the programme selector switch to the

appropriate programme within a period of

3 seconds.

)

M.-Nr. 05 068 971 /03 17

Additional functions

Programmable functions

It is possible to programme additional func

tions or change programme sequences.

See Programme changes.

Any changes to the standard machine ver

sion must be noted in the machine’s log

book and also on the chart in this booklet,

see "Programme changes"as a record for

any subsequent servicing work . This is of

particular importance for the service techni

cian, when electronic units may need to be

exchanged.

Selecting a programme with a coin

unit in use

Open the on-site stopcocks(s).

^

^ Switch on the on-site mains switch.

^ Select a programme and temperature.

-

-

-

m "Starching" and w "without final spin" are

not available with coin operation.

^ Add detergent and any fabric conditioner.

^ Insert coins/tokens.

^ Press the "h Start" button.

Coin unit C 5002, C 5003, C 4060

Coins or tokens are "lost" if any of the follow

ing are done after the coins have been in

serted but before the "h Start" button has

been pressed:

–

the machine door is opened,

–

the programme selector has been turned

past "r End" to another programme.

–

a programme is interrupted for more than

20 seconds with the coin time cou-nter.

-

-

Note for the user:

Coins and tokens should be emptied on a

regular basis to ensure the coin box does

not get jammed full.

18 M.-Nr. 05 068 971 /03

Programme changes

To change individual programmes by re

programming

Programmes can be changed individually to

accommodate different wash processes and

methods.

20 Programmable functions can be changed

with up to 4 Options.

Before starting:

The on-site mains switch must be

–

switched on.

A previous programme must be com

–

pleted.

The drum door must be open.

–

-

-

To access programming mode

?

After the drum door is shut the "+i with

^

pre-wash" button must be pressed in and

released twice within 4 seconds.

– All the other buttons must be inoperative,

i.e. not pushed in.

P

- A "

display.

- The programme sequence indicators

"Pre-wash" and "Main wash" flash.

- Re-programming can be carried out (see

example).

" (for Programming) appears in the

–

The programme selector must be at the

"r End" position.

M.-Nr. 05 068 971 /03 19

Programme changes

Example:

Changing the temperature holding time in

the

main wash

from 10 minutes to 5 or 15 or 20 minutes.

15 minutes is required.

Option 3 corresponds to 15 mins.; see

Programme Change Chart No.8 / B Temper

ature holding time in minutes.

The following appear one after another in the

additional display

P 1

(10 minutes),

-

P 3

(15 minutes).

P 2

(5 minutes),

^ Turn the programme selector to 8 B. "

flashes in the additional display.

^

Press the "h Start" button 3 times.

P8

?

"

^ Press the "a open door" button.

- Pressing the "a open door" button saves

the change in memory and completes the

programming process.

^

Please enter this programming change in

the table on the following page.

^

Turn the programme selector to the

"r End" position.

See the next page for further possible pro

gramming changes.

?

-

20 M.-Nr. 05 068 971 /03

Programme changes

Programme selector setting Options

No. Programme function 1

2 3 4 Enter

Standard

Additional pre-wash

1 A 95 Wash time A,B (mins) no pre-w. 5 9

2 A Water level A,B low high

Pre-wash

3 A 60 Select pre-wash A,B,C,E via button gen/lly yes

4 A Wash times A,B (mins) 8 11 16 6

5 A 40 Temperature A,B,C,E (°C) 35 45 60 24

6 A Water level A,B,E,F low high

Main wash

7 B 95 Thermostop &. Heating active yes no

8 B Temp. holding time A,B,C (mins) 10 5 15 20

9 B 60 Water level A,B low high

10 B Suds cooling A,F (secs) 25 20 30

11 B 40 Temp. in Wool prog. D (°C) 30 25

2

pro

-

grammed

options

Rinses

12 B Increase water level A,B,D no

1

13 C 60 No. of rinse cycles A,B,C,F 34

slightly1average

3

1

high

3

5

2

14 C Rinse hold no yes

Final spin

15 C 30 Pre-spin no yes*

Special functions May only be changed by service technician.

16 C Switching over Sep.rinse Hygiene Sluice*

17 D Water inlet KW+WW KW KW-hard

KW-soft

18 D 30 Max. Temperature in HW

90 85 80

KW+Hot

ter-water

-

A,B,D (°C)

19 D Separate spin free yes no

20 E 40 3 external disp. pumps comb. 1 comb. 2 comb. 3 comb. 4

1)

Load dependent if no. 2,6,9 has a standard setting KW = Cold-Water

2)

chemothermal Disinfection Temp.= 60°C WW = Hot water

3)

with bleach select 4 or 5 rinses. HW = Main wash

* standard setting

M.-Nr. 05 068 971 /03 21

Cleaning and Care

Cleaning the washing machine

Clean the casing with a mild non-abrasive

detergent or soap and water. Wipe dry with

a soft cloth.

Clean the facia panel with a damp cloth and

dry with a soft cloth.

The drum and any other stainless steel parts

can be cleaned using a proprietary stainless

steel cleaner according to the manufac

turer’s instructions.

Do not use any scouring agent or solvent

cleaner.

To ensure the correct functioning of the air

gap, any significant detergent residues must

be removed from the canal.

Remove any deposits from the door seal

with a damp cloth.

-

To clean the filter in the inlet hose:

Close the stopcock.

^

Build-up of rust

The drum and suds container are manufactured from rust-free stainless steel.

It is, however, possible that water with a high

iron content or foreign bodies in the wash,

(e.g. paper clips or metal buttons), may lead

to the formation of superficial rust spots in

the drum and/or suds container, especially if

the machine is not used for a long time.

Stainless steel components should be

cleaned regularly with a proprietary cleaning

agent for stainless steel. This must be done

if rust appears!

Door seals should also be regularly checked

to make sure that nothing has got trapped in

them. Clean them regularly.

Cleaning the filters in the water inlet

^ Carefully unscrew the knurled coupling

connecting the inlet hose to the stopcock.

^ Remove the rubber seal from the recess.

^ Using pointed pliers, take hold of the plas-

tic filter bar, remove the filter and clean.

^ Put the filter and seal back in the reverse

order.

The filters in the inlet hose should be

checked and cleaned approx. every 6

months.

Inspect the inlet hose which is subjected to

high pressure while the machine is in opera

tion. The hose should be replaced if there

are small cracks in the surface, or if it has

been otherwise damaged.

If replacing the inlet hose only use a hose

able to withstand pressure up to 70 bar.

Miele’s own hoses meet this requirement.

-

The washing machine has the following fil

ters to protect the inlet valves:

–

in the free end of any water inlet hose,

–

in the water inlet valve(s) for connection

hose to machine.

22 M.-Nr. 05 068 971 /03

-

Cleaning and Care

After use the detergent box should be

^

cleaned with warm water to remove any

detergent residues.

The siphon tubes in compartments § and

^

y should also be cleaned.

To clean the filter in the water inlet valve:

Using pliers, carefully loosen the ribbed

^

plastic nut on the inlet valve, and unscrew.

^ Unscrew the screws next to the siphon

tubes. Pull the siphon tubes upwards to remove for cleaning in warm water. Replace

in the reverse order (the siphon tubes must

be hooked in correctly).

^ Use water pump pliers to withdraw the

plastic filter by the bar (see illustration).

^ Clean and put back in the reverse order.

The machine must not be used without

the two dirt filters being put back in place.

If the machine is not going to be used for

a longer period of time (4 weeks or more)

the drum should be rotated several times

after the last use. The drum should be ro

tated every 4 weeks to prevent damage to

the bearings.

-

M.-Nr. 05 068 971 /03 23

Problem solving guide

Any work on the electrical components of

this machine should only be carried out

by a suitably qualified and competent

person. Unauthorized repairs could be

dangerous.

There are, however, minor faults which can

be corrected without contacting the Service

Department.

Opening the drum door in the event

of a power failure

Turn the programme selector to "r End"

^

Press against the drum door and pull on

^

the emergency door opening mechanism

(see illustration).

^ Open the drain valve access flap.

Always make sure the drum is stationary

before reaching in to remove washing.

Reaching into a moving drum is extremely

dangerous.

^

Press the emergency release lever down

wards, (see illustration) and hold down un

til no more water drains out.

24 M.-Nr. 05 068 971 /03

-

-

Problem solving guide

A selected programme does not begin.

The "I On/ Start" indicator light does not

light up.

Check that the door is properly closed, the

^

mains plug is plugged in and that the fuse

or circuit breaker has not tripped.

The check light "p" flashes, although the

programme has finished as usual.

The water inlet system is partially blocked:

Stopcocks not fully opened.

–

Inlet hose kinked or trapped.

–

The water pressure is too low.

–

The filters in the inlet hoses are clogged

–

(see "Cleaning and Care").

The indicator light goes out when the

programme selector switch is turned to the

"r End" position.

The check light "p" flashes, the

"r End", indicator light is on, but the

laundry in the machine has not been

washed.

The water inlet system is turned off.

^ Turn the programme selector switch to

"r End".

^

Turn on the water supply at the stopcocks.

The Pre-wash indicator light "i" is flash

ing in the sequence display.

Start the programme again.

^

If the indicator still flashes call the Service

^

Department.

The Main wash indicator light "j"

flashes during, or after the end of a

programme.

If it also flashes on the next programme

there is a technical fault.

Call the Service Department.

^

Despite adequate water supply pressure,

the machine takes a long time to fill.

The filters in the water inlet might be

blocked.

^ Clean as described under the section

"Cleaning and Care".

Large amounts of unused detergent remain in the dispenser.

Water supply pressure is too low.

^ Clean filters (as described in the section

"Cleaning and Care").

^ Check if the water flow through the stop-

cock is 5 litres in 15 seconds.

-

^

Select a programme.

^

Press the "h Start" button.

If little or no water is taken in during the next

programme, the water pressure may be too

low.

If it is adequate there may be a technical

fault.

^

In this case, call your local service dealer

or the Miele Service Department.

The indicator light "q" is flashing.

^

Check whether the drainage system is

clogged.

Washing powder becomes viscous when

used together with a water softener.

^

In future pour washing powder into the de

tergent dispenser before adding water

softener.

Fabric conditioner or bleaching agent is

not completely dispensed or water re

mains in the dispensing compartment.

The siphon tube is either incorrectly posi

tioned or clogged.

^

Lift the lid and remove the siphon.

^

Rinse out the dispenser compartment and

the siphon with warm water.

-

-

-

M.-Nr. 05 068 971 /03 25

Problem solving guide

Possible reasons for increased

levels of foaming

detergent type

–

Only use detergent formulated for use in

^

commercial washer extractors. Domestic

laundry detergent is not suitable.

overdosing of detergent

–

Dispense detergent following the deter

^

gent manufacturer’s instructions on the

packaging and in accordance with local

water hardness levels.

detergent creates too much foam

–

Use a lower foaming detergent or contact

^

your detergent application specialist.

very soft water

–

In areas with hardness level 1 dispense

^

less detergent in accordance with the de

tergent manufacturer’s instructions.

– soiling level of the laundry

^ For lightly soiled laundry dispense less de-

tergent in accordance with the detergent

manufacturer’s instructions.

– residues, e.g. detergent are left on laun-

dry

^ Run an additional pre-wash without deter-

gent and without selecting a temperature.

Laundry which has been soaked before

washing must be thoroughly

rinsed before running a wash programme.

–

small loads

^

Reduce the amount of detergent dis

pensed according to the size of the load.

-

-

-

Laundry is either not spun at all or not

spun satisfactorily.

The "w No final spin" button was pushed

–

in.

The machine was not able to distribute the

–

laundry load evenly. To protect the ma

chine, laundry was either only spun at a

reduced speed or not at all.

Large items which tangle or roll up in the

–

drum (e.g. bath mats) can cause an imbal

ance during the spin cycle.

For safety reasons, the machine does not

spin if this is the case. Attempts to build

up spin speed are repeated, however, until

the time allocated to spinning has expired.

It is therefore important to make up mixed

–

loads consisting of large and small items.

The drain system may be clogged.

–

The "n" indicator light flashes.

The machine has switched off because of

serious imbalance.

^ Switch the on-site mains switch off and

then on again or

open the drum door with the emergency

release as described in "Opening the door

in a power cut".

The machine shakes during the spin cy

cle.

The most likely cause is that the four ma

chine feet are not resting securely on the

floor.

^

Level the machine as described in "Notes

for the installer".

-

-

-

-

26 M.-Nr. 05 068 971 /03

After sales service

Should a fault occur please contact your

nearest authorized Service Dept.

When contacting the Service Department,

please quote the model type, (Typ), the ma

chine number, (Fabr.-Nr.) und Part-no.

(M.-Nr.). These can be found on the data

plate:

With the door open at the top of the door

ring, or:

Problem solving guide

-

at the rear of the machine towards the top.

Only use genuine spare parts. When order-

ing spare parts the Spare Parts Dept will

also need to know the model type (Typ), ma

chine number (Fabr.-Nr.) und Part-no.

(M.-Nr.).

-

M.-Nr. 05 068 971 /03 27

Explanation of symbols on the data plate

1 Machine type

2 Machine number/year of manufacture*

3 Voltage/Frequency

4 Control fusing

5 Drive motor

6 Plate diameter*/Plate quantity*

7 Drum data

8 Drum diameter/drum depth

9 Spin speed

10 Drum volume/Laundry dry weight

11 Kinetic energy

12 Ex. time to top speed

13 Braking time

14 Heating

15 Electric heating

16 Fusing (on site)

17 Steam heating indirect*

18 Steam heating direct*

19 Gas heating*

20 Commissioning date

21 Water registration DVGW-test cert

(Water)*

22 Field for CE test symbol....

(Product-ID-No./Gas)*

*) not applicable to WS 5073

Noise emission

During wash During spin

58.5 dB 74.3 dB

(measured in Germany in accordance with

DIN (IEC) 45 635, machine noise regulations

3. GSGV p1. 1.a)

28 M.-Nr. 05 068 971 /03

The washer-extractor must be installed by

an approved service technician or an au

thorized Service Dealer.

Installation

Notes for the installer

Front transit fitting

-

A concrete floor is the most suitable installa

tion surface.

Please note:

The machine must be level and securely

^

positioned.

Do not install the machine on a ‘soft’ base

^

such as floorboards as this could result in

more vibration during the spin cycles.

If the machine is installed on a raised

^

plinth it should be secured using the butt

straps supplied with the machine.

If there is not already a concrete plinth

on-site, the Miele Spare Parts department offer a steel plinth. It must be ensured that the

steel plinth is secured to the floor, (see the

enclosed installation plan).

To avoid the possibility of frost damage on

no account install the machine in a room

which is exposed to frost.

-

"A" (1 piece)

The front panel must be taken off, (2 internal

torx T20 screws at the bottom) to remove the

front transit fitting (3 SW-13 screws) .

Rear transit fitting

Do not install the machine on carpeted flooring if the carpet pile blocks the ventilation

gap at the base of the machine.

Transit fittings

When the machine has been installed in its

final position, only then remove the red tran

sit fittings marked "A", "B". and "C".

The machine must not be moved without

the transit fittings in place.

The transit fittings should be stored in a safe

place for future use. They must be re-fitted if

the machine is moved again.

-

"B" (1 piece) "C" (1 piece)

The rear panel must be taken off, (just

loosen 15 internal torx T20 screws at the bot

tom) to remove the rear transit fitting

(3 SW13 screws each) .

The machine must not be moved without

all the outer panels in place.

-

M.-Nr. 05 068 971 /03 29

Notes for the installer

Levelling

The machine must stand level to ensure

smooth operation.

The adjustable feet can compensate for an

uneven base.

^ Screw the foot or feet out until the machine

stands level.

^ Hold the foot tight using a pipe wrench.

^ Tighten the counternut using a screwdriver

as indicated.

Connection to water supply

Connection must be made to the water sup

ply via a stopcock which conforms with local

and national regulations. This work must be

carried out by a suitably qualified and com

petent person.

To ensure the machine is correctly con

nected please observe the installation plan

and the installation instructions supplied with

the machine.

See the installation diagram supplied for in

structions on connection to the water supply

and for drainage.

The inlet pressure hoses supplied with the

machine must be used for connection to the

water supply

To ensure the hot water inlet hose (marked

90°C) lasts for many years it is advised not

to use it on a hot water connection supplying

water hotter than 70°C.

If replacing an inlet hose only use a hose

able to withstand a burst pressure of at least

70 bar and a temperature of 90°C. This also

applies to all connection parts.

Miele "Original" spare parts meet this requirement.

-

-

-

-

A water pressure flow rate of at least 1 bar,

maximum 10 bar is essential to ensure the

smooth operation of this machine.

Water taken into the machine must not ex

ceed a temperature of 70°C.

Connection to cold water only

-See the Installation Plan provided.

Water connection Australia

To prevent back-syphonage, the water con

nection must be via an approved

Dual-Check-Valve.

Drainage

The machine empties through a motor con

trolled drain valve. A DN 50 angle connector

can be used to make connection to an

on-site drainage system, (sink box with

odour trap).

-

-

-

30 M.-Nr. 05 068 971 /03

Notes for the installer

Coin mechanism unit

The washer-extractor can be fitted with a

coin unit.

It can also be connected to an existing coin

unit. The correct connection cable is re

quired for this. For the C 4030 / 4031,

C 4050 / 4051 and C 4065 / 4070 using

timed operation an AD 3 adapter is required.

The machine has to be reprogrammed for

this connection. This must only be done by a

Miele authorized service engineer.

The coin unit and connection cable are

available at extra cost from the Miele Spare

Parts Department, or from Miele specialist

dealers.

-

Electrical connection

All electrical work must be carried out by a

suitably competent person in compliance

with national and local regulations.

Please take note of the Installation diagram

and the Wiring diagram. They are important

for electrical connection.

The electrical safety of this machine

(WS 5073, 5100, 5140, 5101, 5141) is in ac

cordance with IEC 335.

The minimum suds level required for activat

ing the heating is given in mm column of wa

ter: WS 5073 45 mm column of water

The voltage and frequency are given on the

data plate. The machine must only be con

nected if these match the mains supply.

Variants: 3N AC 380-415 V 50 Hz

1 AC 220-240 V 50 Hz

-

-

-

-

The motor is fitted with an overload protection switch.

For extra safety it is advisable to install a residual current device with a trip current of

100 mA.

Nominal rated load and fuse rating are given

on the data plate. Ensure that these are

compatible with the electricity supply.

WARNING

THIS APPLIANCE MUST BE EARTHED

Connection should be made via a suitable

isolator which complies with national and lo

cal regulations, and the on/off switch should

be easily accessible for servicing work.

When installation and connection have

been completed all removable outer pan

els must be re-fitted before the machine is

operated

-

-

M.-Nr. 05 068 971 /03 31

32 M.-Nr. 05 068 971 /03

M.-Nr. 05 068 971 /03 33

Alteration rights reserved 43.03

This paper consists of cellulose which has been bleached without the use of chlorine.

Loading...

Loading...