Page 1

CH-9101 Herisau/Switzerland

Internet www.metrohm.com

E-Mail info@metrohm.com

6.6034.023

Metrodata

IC Net 2.2

8.110.8263 Software Manual

02.2003 / pkl

Page 2

All Rights Reserved.

Printed in Switzerland by Metrohm AG, CH-9101 Herisau 2003

Page 3

Table of contents

Table of contents

1 Introduction ...............................................................1

1.1 Purpose of program .................................................................. 1

1.2 Information about the software manual .................................. 2

1.3 Notation and pictograms .......................................................... 3

1.4 Installation ................................................................................. 4

1.4.1 Hardware requirements for the PC................................. 4

1.4.2 Software Installation ....................................................... 4

1.4.3 Software update ............................................................. 5

1.4.4 Software deinstallation ................................................... 6

1.4.5 Demo version ................................................................. 6

1.4.6 Registration..................................................................... 6

2 Fundamentals of the operation ................................7

2.1 Starting/closing the program ................................................... 7

2.1.1 Start the «IC Net» program ............................................. 7

2.1.2 Close the «IC Net» program ........................................... 7

2.2 Glossary..................................................................................... 8

2.3 Overview of program windows .............................................. 10

2.4 Main window elements ........................................................... 10

2.5 Icons of the main window....................................................... 11

2.6 Overview of file types ............................................................. 12

2.7 Context-sensitive menus........................................................ 13

2.8 Keyboard and mouse functions............................................. 13

2.9 Help .......................................................................................... 14

3 Software settings ....................................................15

3.1 Fonts ........................................................................................ 15

3.2 Security system....................................................................... 15

3.2.1 Security Options window.............................................. 16

3.3 Audit Trail ................................................................................ 19

IC Net 2.2

3.4 Global settings ........................................................................ 21

4 Systems ...................................................................24

4.1 System creation....................................................................... 24

4.1.1 System wizard .............................................................. 24

4.1.2 System window............................................................. 26

4.1.3 Add devices to an existing window.............................. 26

I

Page 4

Table of contents

4.2 System file handling ............................................................... 27

4.3 System functions .................................................................... 27

4.3.1 Connect and disconnect system.................................. 27

4.3.2 Start/stop hardware and record baseline..................... 28

4.3.3 Start/stop determinations ............................................. 29

4.3.4 Options for determinations........................................... 29

4.4 System settings....................................................................... 31

4.4.1 Modify system window ................................................. 31

4.4.2 Watch window display.................................................. 31

4.4.3 Set start mode .............................................................. 31

4.4.4 Install new devices........................................................ 32

4.4.5 Install existing devices.................................................. 32

4.4.6 Print system parameters............................................... 32

4.4.7 Show system parameters............................................. 33

4.4.8 Links.............................................................................. 33

4.5 System state window.............................................................. 33

4.5.1 Status messages.......................................................... 33

4.5.2 General error messages............................................... 34

4.5.3 Error messages for 761 Compact IC ........................... 34

5 Interfaces ................................................................36

5.1 Interface installation ............................................................... 36

5.1.1 Add interfaces with system wizard ............................... 36

5.1.2 Add interfaces in workplace window............................ 37

5.1.3 Delete interfaces........................................................... 37

5.2 762 IC Interface........................................................................ 38

5.2.1 762 IC Interface features .............................................. 38

5.2.2 762 icon on the toolbar................................................. 38

5.2.3 762 icons in the system window................................... 38

5.2.4 762 IC Interface window ............................................... 39

5.2.5 762 Event output lines .................................................. 41

5.3 771 Compact Interface............................................................ 45

5.3.1 771 Compact Interface features................................... 45

5.3.2 771 icon on the toolbar................................................. 45

5.3.3 771 Compact Interface window.................................... 45

5.4 Metrohm PC Board.................................................................. 47

5.5 Global timer ............................................................................. 48

5.5.1 Timer icon ..................................................................... 48

5.5.2 Timer program .............................................................. 48

II

6 Devices ....................................................................50

6.1 Device installation................................................................... 50

6.1.1 Install devices at system creation ................................ 50

6.1.2 Install new devices in system window.......................... 51

6.1.3 Install existing devices in system window .................... 51

6.1.4 Delete devices .............................................................. 51

IC Net 2.2

Page 5

Table of contents

6.2 Watch window ......................................................................... 52

6.2.1 Watch window icon ...................................................... 52

6.2.2 Watch window settings................................................. 52

6.3 732 IC Detector ........................................................................ 54

6.3.1 732 IC Detector features .............................................. 54

6.3.2 732 IC Detector icon..................................................... 54

6.3.3 732 IC Detector window ............................................... 55

6.4 761 Compact IC ....................................................................... 61

6.4.1 761 Compact IC features ............................................. 61

6.4.2 761 Compact IC icon ................................................... 61

6.4.3 761 Compact IC window .............................................. 62

6.4.4 Hardware settings ........................................................ 69

6.5 817 Bioscan ............................................................................. 73

6.5.1 817 Bioscan features.................................................... 73

6.5.2 817 Bioscan icon.......................................................... 73

6.5.3 817 Bioscan window .................................................... 73

6.6 733 IC Separation Center........................................................ 81

6.6.1 733 IC Separation Center features............................... 81

6.6.2 733 IC Separation Center icon ..................................... 82

6.6.3 733 IC Separation Center window................................ 82

6.7 709 IC Pump............................................................................. 85

6.7.1 709 IC Pump features................................................... 85

6.7.2 709 IC Pump icon......................................................... 86

6.7.3 709 IC Pump window ................................................... 86

6.8 Metrohm solvent delivery unit................................................ 89

6.8.1 Metrohm SDU features................................................. 89

6.8.2 Metrohm SDU icon ....................................................... 89

6.8.3 Metrohm SDU window.................................................. 89

6.9 752 Pump Unit ......................................................................... 94

6.9.1 752 Pump Unit features................................................ 94

6.9.2 752 Pump Unit icon...................................................... 94

6.9.3 752 Pump Unit window ................................................ 94

6.10 753 Suppressor Module.......................................................... 97

6.10.1 753 Suppressor Module features................................. 97

6.10.2 753 Suppressor Module icon ....................................... 97

6.10.3 753 Suppressor Module window.................................. 97

6.11 754 Dialysis Unit.................................................................... 100

6.11.1 754 Dialysis Unit features ........................................... 100

6.11.2 754 Dialysis Unit icon ................................................. 100

6.11.3 754 Dialysis Unit window............................................ 100

IC Net 2.2

6.12 793 Sample Prep Module ...................................................... 103

6.12.1 793 Sample Prep Module features............................. 103

6.12.2 793 Sample Prep Module icon................................... 103

6.12.3 793 Sample Prep Module window ............................. 103

6.13 812 Valve Unit ........................................................................ 106

6.13.1 812 Valve Unit features............................................... 106

6.13.2 812 Valve Unit icon..................................................... 106

III

Page 6

Table of contents

6.13.3 812 Valve Unit window................................................ 107

6.14 816 IC Eluent Selector ...........................................................109

6.14.1 816 IC Eluent Selector features .................................. 109

6.14.2 816 IC Eluent Selector icon ........................................ 109

6.14.3 816 IC Eluent Selector window................................... 109

6.15 828 IC Dual Suppressor.........................................................112

6.15.1 828 IC Dual Suppressor features ............................... 112

6.15.2 828 IC Dual Suppressor icon ..................................... 112

6.15.3 828 IC Dual Suppressor window ................................ 112

6.16 750 Autosampler ....................................................................116

6.16.1 750 Autosampler features .......................................... 116

6.16.2 750 Autosampler icon................................................. 116

6.16.3 750 Autosampler window ........................................... 117

6.17 766 IC Sample Processor ......................................................120

6.17.1 766 IC Sample Processor features............................. 120

6.17.2 766 IC Sample Processor icon................................... 120

6.17.3 766 IC Sample Processor window ............................. 121

6.18 788 IC Filtration Sample Processor ......................................129

6.18.1 788 IC Filtration Sample Processor features.............. 129

6.18.2 788 IC Filtration Sample Processor icon .................... 129

6.18.3 788 IC Filtration Sample Processor window............... 130

6.19 Data recorder..........................................................................138

6.19.1 Data recorder icon...................................................... 138

6.19.2 Select processing method and data source.............. 138

6.20 System timer ..........................................................................141

6.20.1 Timer icon ................................................................... 141

6.20.2 Timer program ............................................................ 141

7 Methods .................................................................142

7.1 Method file handling ..............................................................142

7.2 Passport..................................................................................142

7.2.1 General ....................................................................... 143

7.2.2 Sample........................................................................ 144

7.2.3 Column ....................................................................... 145

7.2.4 Eluent.......................................................................... 146

7.2.5 Comment .................................................................... 147

7.3 Method setup..........................................................................148

7.3.1 General ....................................................................... 148

7.3.2 Measure...................................................................... 148

7.3.3 Filters .......................................................................... 149

7.3.4 Processing.................................................................. 150

7.3.5 Math............................................................................ 151

IV

7.4 Integration ..............................................................................153

7.4.1 General information .................................................... 153

7.4.2 Setup........................................................................... 154

7.4.3 Events ......................................................................... 156

IC Net 2.2

Page 7

Table of contents

7.5 Calibration and quantification.............................................. 161

7.5.1 General information.................................................... 161

7.5.2 Notations .................................................................... 162

7.5.3 External standard calibration...................................... 163

7.5.4 Component table........................................................ 163

7.5.5 Peak identification ...................................................... 166

7.5.6 Concentration table .................................................... 167

7.5.7 Calibration curve......................................................... 169

7.5.8 Update calibration ...................................................... 171

7.5.9 Calibration data handling ........................................... 172

7.6 Report output......................................................................... 173

7.6.1 Report options window............................................... 173

7.6.2 Items to report ............................................................ 174

7.6.3 More items to report ................................................... 176

7.6.4 Report destination ...................................................... 179

7.6.5 Peak table................................................................... 179

7.6.6 Template options........................................................ 182

7.6.7 File output options...................................................... 182

7.6.8 Report elements ......................................................... 183

8 Chromatograms.....................................................188

8.1 Chromatogram window ........................................................ 188

8.2 Chromatogram file handling................................................. 189

8.2.1 Open chromatogram.................................................. 189

8.2.2 Save chromatogram................................................... 191

8.2.3 Close chromatogram.................................................. 191

8.2.4 Delete chromatogram ................................................ 191

8.2.5 Export chromatogram ................................................ 191

8.2.6 Import chromatogram ................................................ 192

8.3 Graphical representation...................................................... 193

8.3.1 Appearance ................................................................ 193

8.3.2 Other graphical functions ........................................... 197

8.4 Peak editor............................................................................. 198

8.4.1 Switching on/off the peak editor................................. 198

8.4.2 Peak editor functions.................................................. 198

8.4.3 Moving the cursor....................................................... 199

8.5 Printing................................................................................... 200

8.5.1 Page layout for printing .............................................. 200

8.5.2 Printer settings............................................................ 201

8.5.3 Print preview ............................................................... 201

8.5.4 Printing........................................................................ 201

IC Net 2.2

8.6 Miscellaneous functions....................................................... 202

8.6.1 Reintegration .............................................................. 202

8.6.2 Recalibration............................................................... 202

8.6.3 Electronic signature.................................................... 202

8.6.4 Subtraction of a chromatogram ................................. 204

8.6.5 Compare chromatogram............................................ 205

8.6.6 Data compression ...................................................... 206

V

Page 8

Table of contents

9 Sample queue........................................................209

8.6.7 Invert chromatogram .................................................. 207

8.6.8 Autodatabase ............................................................. 207

9.1 Sample queue file handling...................................................209

9.1.1 Open sample queue................................................... 209

9.1.2 Save sample queue.................................................... 209

9.1.3 Delete sample queue ................................................. 209

9.2 Sample queue control............................................................210

9.2.1 Sample queue overview table .................................... 210

9.2.2 Start sample queue .................................................... 211

9.2.3 Pause sample queue.................................................. 211

9.2.4 Cancel last run............................................................ 212

9.2.5 Reset sample queue................................................... 212

9.3 Sample queue editor..............................................................212

9.3.1 Open queue editor window ........................................ 212

9.3.2 Sample queue editor functions .................................. 213

9.3.3 Print sample queue..................................................... 214

9.3.4 Close sample queue editor ........................................ 214

10 Batch reprocessing ...............................................215

10.1 Batch reprocessing queue file handling ..............................215

10.1.1 Open batch reprocessing queue ............................... 215

10.1.2 Create new batch reprocessing queue...................... 215

10.1.3 Save batch reprocessing queue ................................ 216

10.2 Perform batch reprocessing .................................................216

10.2.1 Reprocess options window ........................................ 216

10.2.2 Merge chromatograms............................................... 222

10.3 Batch reprocessing queue editor .........................................223

10.3.1 Open batch reprocessing queue editor window........ 223

10.3.2 Batch reprocessing queue editor functions ............... 224

10.3.3 Print batch reprocessing queue ................................. 224

10.3.4 Close batch reprocessing queue editor..................... 224

11 Appendix ................................................................226

11.1 Software license.....................................................................226

11.2 Declaration of conformity – Software validation.................228

11.3 Ordering designations...........................................................228

11.3 Index........................................................................................229

VI

IC Net 2.2

Page 9

1.1 Purpose of program

1 Introduction

1.1 Purpose of program

«IC Net 2.2» is the name of the data acquisition and control

software for PC-controlled ion chromatographic systems consisting of Metrohm and Bischoff instruments. The current version is a

true 32-bit application. It was designed specially to operate under Windows 2000 and Windows XP and uses all its benefits.

The «IC Net 2.2» program can be used to create systems for recording and evaluating chromatograms. Time programs can also

be created in which a large number of instrument functions can

be triggered for each program step. It is also possible to use programmable signals to control external instruments.

The operating software meets all the requirements you could

place today on a modern integration software: single or multipoint calibration, internal or external standard, selectable algorithms for non-linear calibration, various integration modes with integration parameters and integration events, different methods for

peak recognition, peak editor, free scaling, superimposing several chromatograms, use of sample tables and batch reprocessing; a powerful and GLP-conform report generator with output interfaces for monitor, printer and external databases.

The «IC Net 2.2» software can be configured and used in order

to comply with the Electronic Records and Signatures Rule,

known as 21 CFR Part 11, established by the U.S. Food and

Drug Administration (FDA). For this purpose, the program contains password protection, user administration, electronic signatures, audit trail and administration of methods and results in databases. To use the 21 CFR Part 11 features of «IC Net 2.2» the

operating system Windows 2000 or Windows XP with NTFS file

system is required.

IC Net 2.2

1

Page 10

1 Introduction

1.2 Information about the software manual

This 8.110.8263 Software Manual provides a comprehensive

overview of the operation of the «IC Net» program. The manual is

organized as follows:

Section 1 Introduction

Installation

Section 2 Fundamentals of the operation

Program elements and features

Section 3 Software settings

Fonts, security system, global settings

Section 4 Systems

Creation of new systems, interfaces and devices,

determinations

Section 5 Interfaces

Installation, control and parameter settings of interfaces

Section 6 Devices

Installation, control and parameter settings of devices

Section 7 Methods

Method parameters, integration, calibration, quantification, report

Section 8 Chromatograms

Chromatogram appearance, peak editor

Section 9 Sample queue

Sample queue control and editor

Section 10 Batch reprocessing

Reprocessing of chromatograms

Section 11 Appendix

Software license, declaration of conformity, ordering

designations, index

To find the required information, you will find it an advantage to

use either the Table of contents or the Index at the back.

This Software Manual describes only the installation and operation of Metrohm instruments. For details concerning the Bischoff instruments, please refer to the on-line help in the program

and to the Bischoff instruction manuals.

2

Additional publications about ion chromatographic analyses are

available on request free of charge from your Metrohm agency.

The 8.732.2003 Metrohm Monograph «Ion chromatography»

provides an introduction to the theoretical fundamentals and general information on separating columns and sample pretreatment.

The 8.732.2013 IC Applications Collection contains all the

Application Notes on the subject of ion chromatography and

IC Net 2.2

Page 11

1.3 Notation and pictograms

can be updated at any time by downloading the latest applications from the Internet under «www.metrohm.com». Last, but not

least, you will find detailed information on the separating columns

available from Metrohm and on special IC applications in the relevant "Application Bulletins".

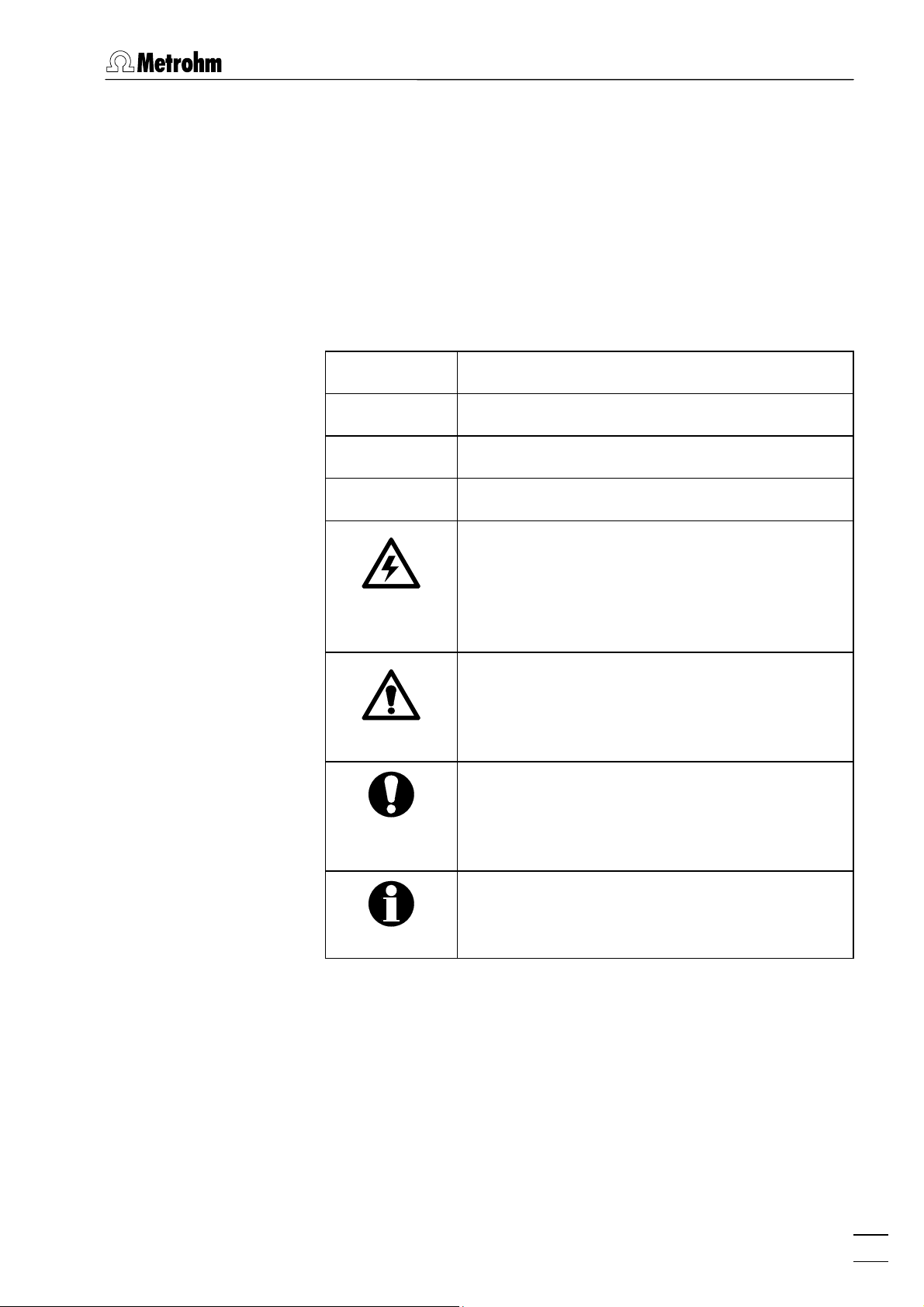

1.3 Notation and pictograms

The following notations are used in this software manual:

Range

SYSTEM STATE

<OK>

[ Ctrl ] Key

Menu item, parameter or entry value

Program window

Button

Danger/Warning

This symbol indicates a possible risk of death

or injury to the user and possible damage to

the instrument or its components by

electricity.

Danger/Warning

This symbol indicates a possible risk of death

or injury to the user and possible damage to

the instrument or its components.

Caution

This symbol marks important information.

First read the associated directions before

you continue.

IC Net 2.2

Comment

This symbol marks additional information and

tips.

3

Page 12

1 Introduction

1.4 Installation

1.4.1 Hardware requirements for the PC

Computer Pentium III with 450 MHz or higher

Operating system Windows® 2000 or Windows® XP

Free space on hard disk 12 MB for program files

Working memory RAM 128 MB for Windows

Graphics resolution 800×600, better 1024×768 or more

Printer Any printer supported by the operat-

1.4.2 Software Installation

50 MB recommended for data files

®

2000

256 MB for Windows

®

XP

ing system

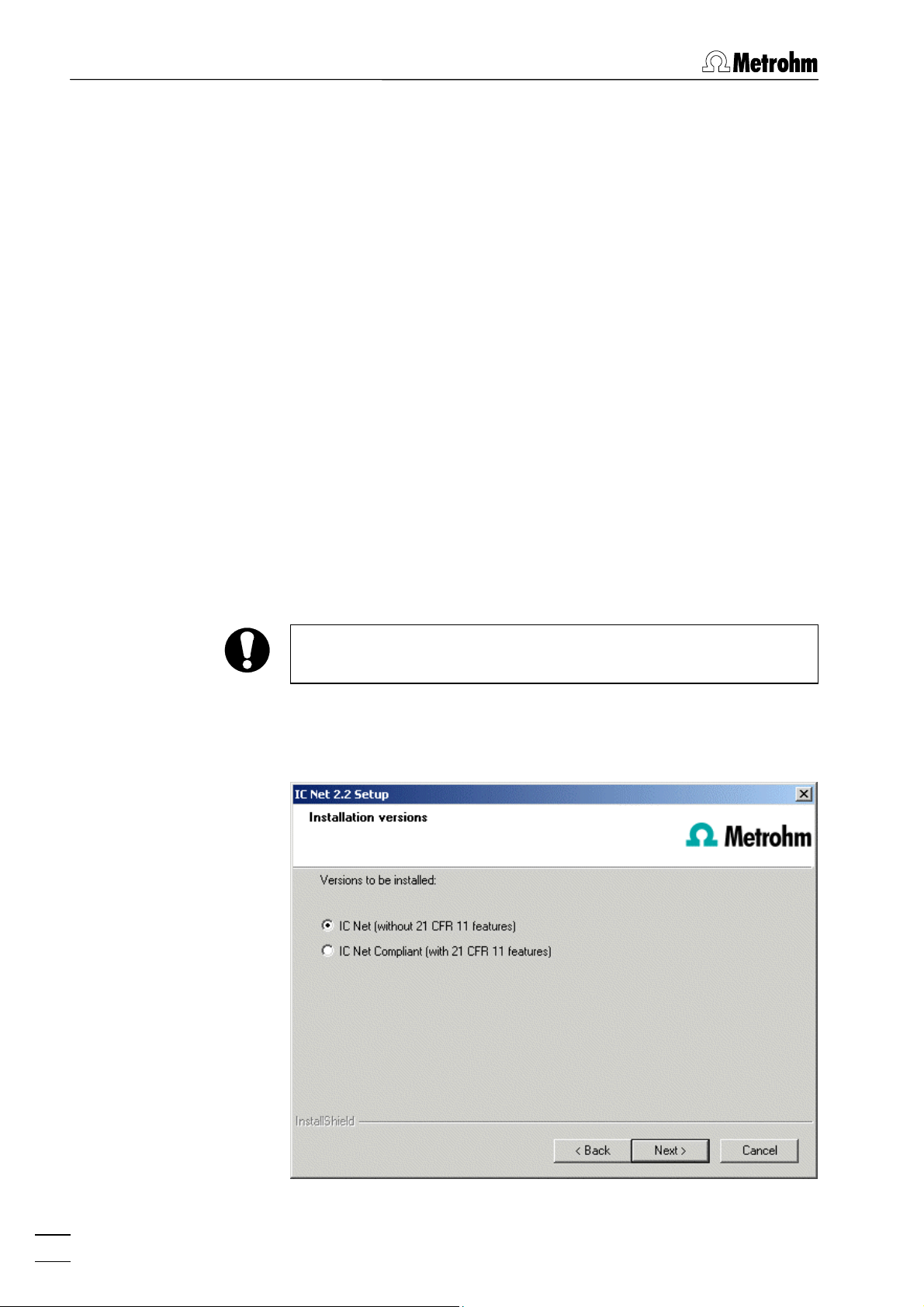

To use the 21 CFR Part 11 features of «ICNet 2.2» the operating

system Windows 2000 or Windows XP with NTFS file system is

required.

If you want to update from IC Net 2.1 to IC Net 2.2, proceed as

described in section 1.4.3.

Insert installation CD into CD drive. Select <Start> and Run. Find

the file setup.exe on the CD and click on <OK>. Click on IC Net in

the selection menu and follow the setup program instructions.

4

IC Net 2.2

Page 13

1.4 Installation

To change from an IC Net installation (without 21 CFR part 11

features) to an IC Net Compliant (with 21 CFR part 11 features)

installation (and back) you have to remove the previous installation! Pay attention to the corresponding dialog in the setup program.

The two software packages «IC Net 2.2» and «Autodatabase

1.0» will be installed in the desired directory. Icons are created in

the program folder, in the startup folder, and on the desktop. In

addition to the program files of the «IC Net» program, the following folders are installed:

Accounts Folder for user data, access is closed.

Data Folder for storage of chromatogram files (*.chw)

and batch reprocessing files (*.bar) with several

examples.

Devices Folder for storage of device files.(*.dev).

Flog Folder for Audit Trail files, access is closed.

Log Folder for storage of exception files (*.exc), His-

Methods Folder for storage of data acquisition method

Reports Folder for storage of report files (*) and graphic

Services Folder for user administration.

Systems Folder for storage of system files (*.smt).

1.4.3 Software update

For software update from IC Net 2.1 to IC Net 2.2, proceed as follows:

1. Switch on PC and start operating system.

tory files (*.hst) und Log files (*.log).

files (*.mtw) and sample queue files (*.que) with

several examples.

files (*.wmf).

IC Net 2.2

2. If you want to save chromatograms, methods and system files

created by IC Net 2.1, backup the folders

Systems in another directory on the hard disk.

Data, Methods, and

3. If you want to save data created by Autodatabase 1.0, backup

the folders Filters, Report templates, and User database in another directory on the hard disk.

4. Deinstall the IC Net 2.1 software by selecting <Start> / Settings

/ Control panel

, double-clicking the Software icon, selecting

5

Page 14

1 Introduction

Metrohm IC Net 2.1 in the list and clicking on <Add/remove>. All

program files and icons should be removed.

5. Delete the folder IC Net 2.1 in the program folder.

6. Install the IC Net 2.2 software (see section 1.4.2).

7. Copy the IC Net 2.1 backup files of the folders Data, Methods,

and Systems into the folders ..\IC Net 2.2\IC Net\Data, ..\IC Net

2.2\IC Net\Methods

, and ..\IC Net 2.2\IC Net\Systems.

8. Copy the Autodatabase backup files of the folders Filters, Re-

port templates

2.2\Autodatabase\Filters

plates

, and ..\IC Net 2.2\Autodatabase\User database.

, and User database into the folders ..\IC Net

, ..\IC Net 2.2\Autodatabase\Report tem-

The folder ..\IC Net 2.2\IC Net\Data is protected against unauthorized access and manipulation, if the 21 CFR Part 11 compliance is enabled. To copy the chromatograms from the backup

Data folder into the ..\IC Net 2.2\IC Net\Data folder start IC Net 2.2

and open the Chromatogram open window (see section 8.2.1),

select the backup Data folder, mark the chromatograms and

copy them into the ..\IC Net 2.2\IC Net\Data folder.

1.4.4 Software deinstallation

Select <Start> / Settings / Control panel. Double-click the Software

icon. Select Metrohm IC Net 2.2 in the list and click on

<Add/remove>. All program files and icons should be removed.

1.4.5 Demo version

If the «IC Net Software 2.2» is installed on a PC without installation of IC system components, this software can be used as a

demo version which is restricted to the display and recalculation of already recorded chromatograms.

1.4.6 Registration

6

Please send us your 8.110.8207 Registration card as soon as

possible. Only registered users will get updated program versions

at a special price.

IC Net 2.2

Page 15

2.1 Starting/closing the program

2 Fundamentals of the operation

2.1 Starting/closing the program

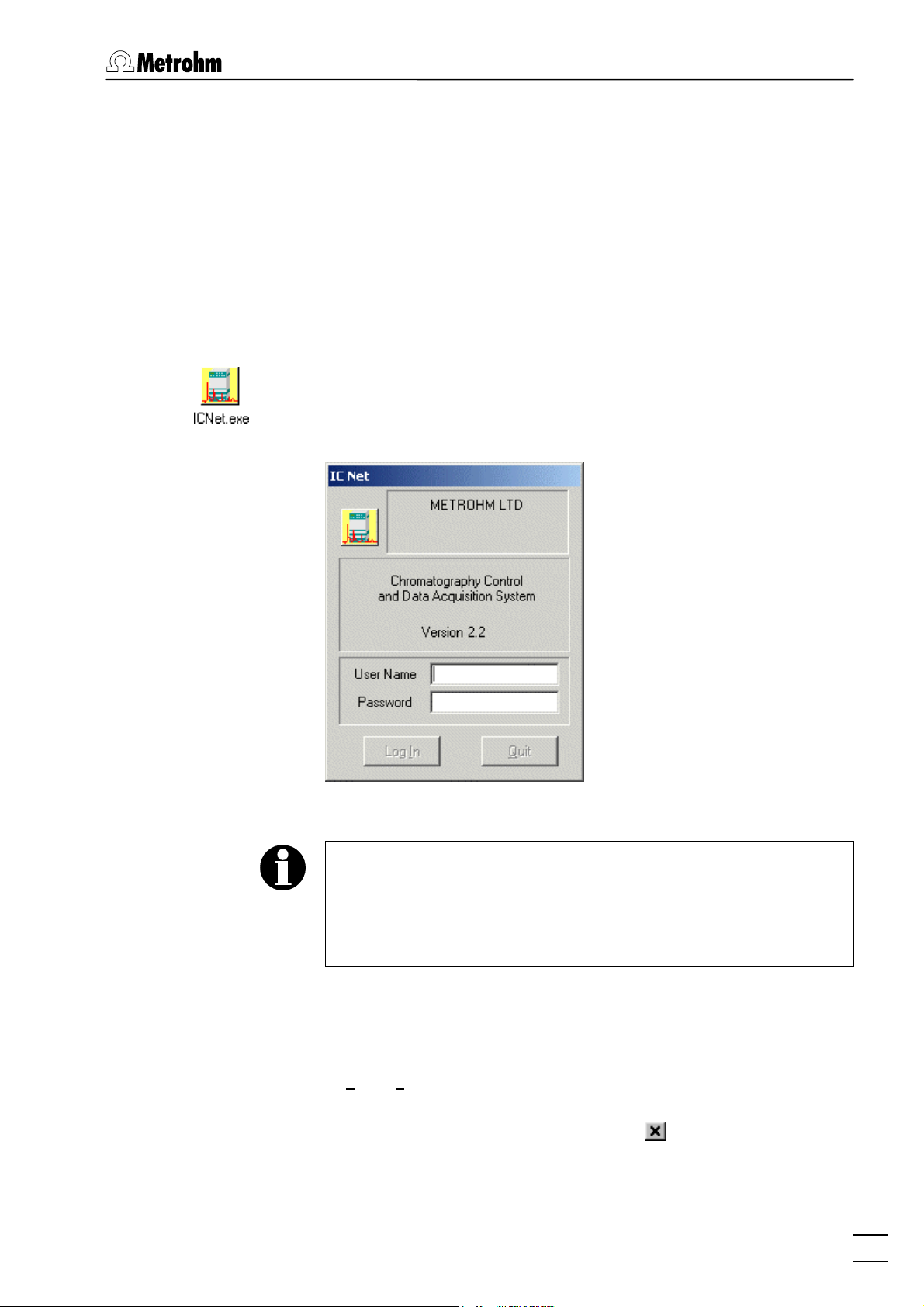

2.1.1 Start the «IC Net» program

Start the program

Double-click this icon or the ICNet.exe file to start the «IC Net 2.2»

program. The

IC Net login window appears:

Enter your User name and your Password and click on

After software installation at the first start of the software, the

User

window opens (see section 3.2.1)and a user with Adminis-

trator

access level is created. It is recommended to create users as a first action after the installation. For the definition of users, see section 3.2.

2.1.2 Close the «IC Net» program

IC NET / File / Exit (Alt+F4)

Exit the «IC Net 2.2» program.

The program is also quit by clicking on in the upper right part

of the main window.

<Log In>.

Add

IC Net 2.2

7

Page 16

2 Fundamentals of the operation

2.2 Glossary

Batch reprocessing

Batch reprocessing is understood to be the subsequent reprocessing of a series of chromatograms which have been loaded in

a batch reprocessing queue. During reprocessing with a selected

method the settings for calibration, integration, passport, appearance and report can be altered at will (for details, see section 10).

Calibration

Calibration is used to describe the method of determining the relationship between the peak height or peak area found for one

component and its concentration in the sample. The result of the

calibration is a calibration function (calibration curve), which

shows the relationship between the amount of sample and the

evaluated quantity.

The determination of the calibration function with reference solutions can be carried out as a one-point or as a multiple-point

calibration. The calibration method which is mainly used in ion

chromatography is the external standard calibration (absolute

calibration); calibration with an internal standard (relative calibration) or tabulated calibration are also possible (for details,

see section 7.5).

Chromatogram

A chromatogram is a graphic plot of the elution curve (signal vs.

time) recorded following a chromatographic separation on a

separating column.

Chromatograms are stored as chromatogram files (*.chw) in the

Data directory. As well as the measuring data the chromatogram

files also contain the method parameters and system settings

which have been used for data recording, data processing and

remote control (for details, see section 8).

Determination

In order to carry out a determination a suitable system must be

selected for the separating problem. The result of the determination is a chromatogram, in which the measuring data and results

of the determination are stored (for details, see section 8).

Device

The «IC Net» program supports remote control for Metrohm and

Bischoff instruments. Each instrument within a system is a de-

vice. Devices are stored as device files (*.dev) in the Devices directory. All Metrohm devices start with Me*.dev and all Bischoff

devices start with Bi*.dev (for details, see section 6).

8

Integration

Integration is to be understood as being the method for determining the peak area and peak height with the aid of approximate

baselines. The integration algorithm included in the program is in-

IC Net 2.2

Page 17

2.2 Glossary

fluenced by the integration parameters and the optionally programmable integration events which are defined in the method.

In addition, the integration can be manually corrected later with

the aid of the peak editor (see section 8.4), for details see sec-

tion 7.

Interface

The «IC Net» program supports remote control for interfaces

available from Metrohm and Bischoff. Interfaces generally convert

analog signals to digital form, which can be handled by the computer. Interfaces are stored as device files (*.dev) in the Devices directory. All Metrohm interfaces and Metrohm devices start

with Me*.dev; all Bischoff interfaces and Bischoff devices start

with Bi*.dev (for details, see section 5).

Method

A method contains all information necessary for data acquisition, integration, peak evaluation and quantification. It can

be considered as the chromatogram template, i.e. chromatogram

without raw data. Methods are stored as method files (*.mtw) in

the Methods directory.

Each system is linked to a method. This method is called proc-

essing method and is opened automatically at the start of a new

determination (for details, see section 7).

Sample queue

A sample queue is used for the automated processing of series

of samples, particularly in combination with a sample changer (for

details, see section 9).

System

The combination of Metrohm and Bischoff devices connected to

an interface is called a system. The system includes all the settings of the devices, their time program, the data acquisition parameters and the processing method which have been optimized

for the specific separating column and the determination to be

carried out with it. A system is used to start single determinations

or determinations with the help of a sample queue.

Systems are stored as system files (

tory (for details, see section 4).

Workplace

The workplace contains all interfaces and systems connected to

the PC COM. The icons of all these active interfaces and systems

are shown on the toolbar. They can also be displayed in the

place

window opened by selecting the Options / Devices setup

menu item.

*.smt) in the Systems direc-

Work-

IC Net 2.2

9

Page 18

2 Fundamentals of the operation

2.3 Overview of program windows

«IC Net 2.2» consists of different windows whose functionality is

linked together. The different windows are:

IC NET Main program window with menus for file

administration, printing, method modification, options, login and user rights, window

handling.

CHROMATOGRAM Chromatogram window for graphic plot of

running or recorded chromatograms.

SYSTEM System window for control of interfaces and

devices.

SYSTEM STATE System state window for status messages.

WATCH WINDOW Watch window for live display of instrument

values.

QUEUE EDITOR Queue editor window for edition of sample

2.4 Main window elements

The elements of the IC NET main window are the menu bar, the

toolbar and the status bar, indicating prompts and logged-in user.

Menu bar

Toolbar

queue tables and batch reprocessing tables.

10

Status bar

Logged-in userPrompts, information

IC Net 2.2

Page 19

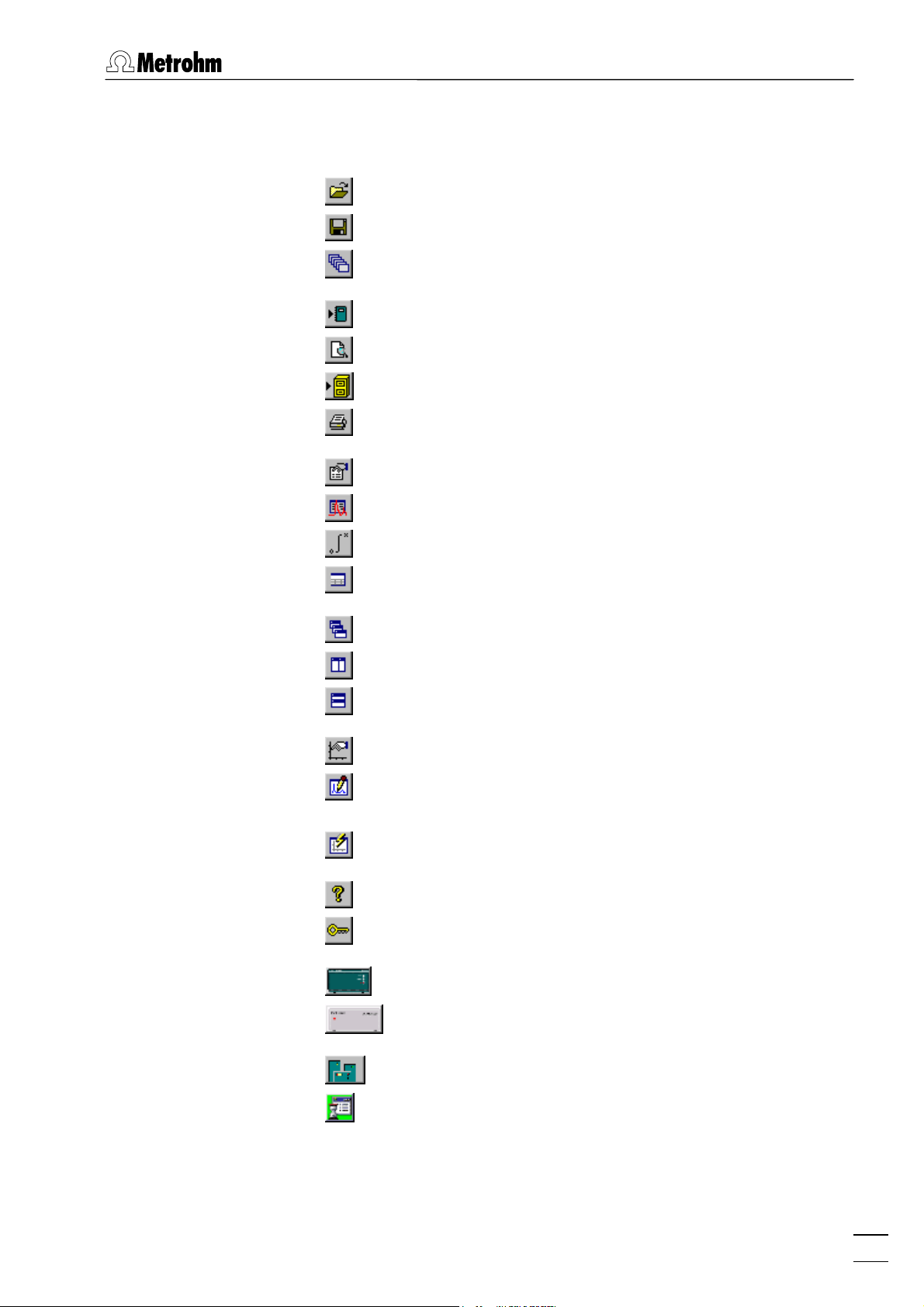

2.5 Icons of the main window

2.5 Icons of the main window

The following icons are displayed in the IC NET main window:

Open chromatogram

Save chromatogram

Open last batch reprocessing file

Make report

Print preview

Send chromatograms to Autodatabase

Print chromatogram

Passport

Method setup

Integration

Components

Cascade all opened chromatogram windows

Vertical tiling of open chromatogram windows

Horizontal tiling of open chromatogram windows

Appearance

Enable/disable peak editor mode. If the Peak editor

mode is enabled, the peak editor icons appear.

View all

Help

Lock system

IC Net 2.2

762 IC Interface

771 Compact Interface

Connected system

Global timer

11

Page 20

2 Fundamentals of the operation

2.6 Overview of file types

The following file types are produced by the «IC Net» software:

*.adb Autodatabase file

Contains chromatogram and method data of all determinations.

*.bar Batch reprocessing file (binary file)

Contains batch reprocessing data. The *.bar file is

stored automatically in the Data folder.

*.cal Calibration file (binary file)

Contains calibration data, which can be exported with

Net / Method / Calibration / Export calibration

The *.cal file is stored automatically in the Methods

folder.

*.chw Chromatogram file (binary file)

Contains chromatogram, system and method data of a

determination.

The *.chw file is stored automatically in the Data folder.

IC

.

*.exc Exception file (ASCII file)

Contains exceptions from normal running and error

messages.

The *.exc file is stored automatically in one of the day

subfolders of the Log folder.

*.hst History file (ASCII file)

Contains history of commands and program actions.

*.hst file is stored automatically in one of the day

The

subfolders of the

*.log Log file (ASCII file)

Log folder.

Contains log file of data communication between PC

and instruments.

The *.log file is stored automatically in one of the day

subfolders of the Log folder.

*.mtw Method file (binary file)

Contains the data acquisition method, which can be

linked to a system.

*.mtw file is stored automatically in the Methods

The

folder.

12

*.que Sample queue file (binary file)

Contains a sample data table.

The

*.que file is stored automatically in the Systems

folder.

IC Net 2.2

Page 21

2.7 Context-sensitive menus

*.rtt Report file (ASCII file)

Contains a report template.

The *.rtt file is stored in the program folder.

*.smt System file (ASCII file)

Contains the system settings.

The *.smt file is stored automatically in the Systems

folder.

*.dev Device file (ASCII file)

Contains drivers for devices.

The *.dev file is stored in the Devices folder.

2.7 Context-sensitive menus

Some of the menu functions of the program windows are also accessible by clicking on the desired window or item and pressing

the right mouse button. The pop up windows have different

contents and functions depending on the selected active window

or item type.

2.8 Keyboard and mouse functions

The mouse can be used to carry out the normal program operat-

ing functions such as the selection of menu items and fields. It

can additionally be used for magnifying a section of a chromatogram (zooming). To zoom a portion of the plot it is necessary

to place the mouse cursor to the upper left corner of the square

to zoom, press the left mouse button and drag the cursor to the

lower right corner of the rectangle. After releasing of the left

mouse button the selected region will be zoomed full-screen. If

the cursor is active in the peak editor mode then it can be moved

by pressing down the right-hand mouse key.

The keyboard can also be used to scale a chromatogram in the

window, as described below.

Keyboard quick reference

Cursor is inactive:

[ up ] Increases sensitivity on the Y axis.

[ down ] Reduces sensitivity on the Y axis.

[ right ] Expands a chromatogram on the X axis.

IC Net 2.2

[ left ] Shrinks a chromatogram on the X axis.

[ Ctrl ] + [ Home ] Autoscale procedure on the X axis (shows

all on X).

[ Ctrl ] + [ End ] Autoscale procedure on the Y axis (shows

all on Y).

[ PageUp ] Shifts a chromatogram on 1/10 part of a

screen upwards.

13

Page 22

2 Fundamentals of the operation

[ PageDown ] Shifts a chromatogram on 1/10 part of a

[ Shift ] + [ up ] Increases a distance between channels of a

[ Shift ] + [ down ] Reduces a distance between channels of a

[ 0 (Zero) ] Adjusts a zero on the last point of a chro-

Only part of the chromatogram is on screen:

[ Ctrl ] + [ right ] Moves one window right (without change of

[ Ctrl ] + [ left ] Moves one window left (without change of

[ Home ] Shows the beginning of a chromatogram

[ End ] Shows the end of a chromatogram (without

screen downwards.

chromatogram.

chromatogram.

matogram (running chromatogram) or its

lowest level (finished run).

scale on X and Y axes).

scale on X and Y axes).

(without change of scale on X and Y).

change of scale on X and Y).

2.9 Help

[ 0 (Zero) ] Adjusts a zero on the lowest level in the

window.

Cursor is active:

[ 0 (Zero) ] Adjust a zero in site of the cursor.

[ right ] Moves cursor left to right.

[ Shift ] + [ right ] Quickly moves cursor left to right.

[ left ] Moves cursor to the left.

[ Shift ] + [ left ] Quickly moves cursor to the left.

[ Home ] Moves cursor to beginning of a window.

[ End ] Moves the cursor to end of a window.

[ Shift ] + [ End ] Sets the beginning of a window in site of

the cursor.

[ Shift ] + [ Home ] Sets the end of a window in site of the cur-

sor.

By clicking on , by clicking on , by selecting the

Help / Contents menu item, or by pressing the [ F1 ] key you can

get on-line help on the current topic anywhere in the program.

14

Green texts can be clicked to jump to a different Help

topic.

Violet texts identify the dialog item, parameter or button

in the corresponding window.

Blue texts identify important information.

IC Net 2.2

Page 23

3.1 Fonts

3 Software settings

3.1 Fonts

IC NET / Options / Fonts

This option allows the selection of fonts used by the system.

Font for dialogs... Selection of font used for dialog boxes.

Default setting: MS Sans Serif / Standard / 8 pt.

Font for reports... Selection of font used for report output to the

screen or printer.

Default setting:

Courier New / Standard / 10 pt.

Font for tables... Selection of font used for data presentation in

Font for plots... Selection of font used for labels on chroma-

Save fonts configuration

3.2 Security system

In accordance with GLP and 21 CFR Part 11 requirements the

«IC Net» software supports security with password protection of

the system. Every user has his own User Name, Password and Ac-

cess Level

tables on the screen. It is not used for presentation of tables in the report.

Default setting: MS Sans Serif / Bold / 8 pt.

togram plots and calibration curves.

Default setting: Times New Roman / Bold / 10 pt.

Save chosen font configuration.

If you want to reset the modified font settings to the

initial default settings, delete the

fonts.cfg file in the

program path.

that restricts the set of possible actions.

IC Net 2.2

IC Net / Options / Security opens the user administration of IC Net.

When this menu item is chosen, the System log in window is

called up first (see section 2.1.1).

The access to the user administration is restricted according to

the Access level of the user, therefore different windows are called.

15

Page 24

3 Software settings

User Window Possible actions

Novice,

Master

Administrator Security options This window allows editing the

New Password

3.2.1 Security Options window

IC NET / Options / Security

This window contains the user administration and password options. Only a user with Administrator access level can open it. It

consists of the two tabs User List and Password Options.

The Security Options window is accessible only to Adminis-

trator users. If there is no Active Administrator, e.g. because he

has forgotten his password, you have to reinstall the «IC Net»

software to gain access. Therefore it is highly recommended to

create a second Administrator user as a backup. Store his

password in a safe place.

This window allows the user to

change his Password.

User List and the Password Options

, it is also possible for an

administrator user to change his

Password.

User List

The User List displays the User name, Full Name, access Level and

user Status of each user created. The list can be sorted alphabetically according to one of the four columns by clicking the title.

A star ( * ) at the end of the title indicates the sorting criterion.

16

<Add user> Add new user to the User's List, opens the Add

User window.

IC Net 2.2

Page 25

3.2 Security system

<Modify user> Edit current user's settings (username, full

name, access level, status), opens the Modify

User

window.

<Password> Change the password of the administrator

logged in. Opens the New Password window.

Add/Modify User

User User name of the user.

Full Name Full name of the user, this name is displayed

in the status bar of the main window throughout an IC Net session.

Level Access level of the user.

Novice Restricted access to program functions. Al-

lows only start and stop of determinations using existing system and method files and

manual control of the devices. Modifications of

system, method and data files are not allowed.

Master Access to all program functions with few ex-

ceptions: the user cannot set

ences

, open the Workplace window, change

Global prefer-

hardware settings of interfaces and devices,

change

Administrator Access to all program functions. This level

Security options.

should be switched on only while installing the

system or in the case of configuration change.

The administrator user is authorized to change

name, access level and status of other users.

IC Net 2.2

Status Status of the user.

Active The User is able to work with «IC Net» within

the limitations of the access

Level assigned to

him by the Administrator.

Inactive The User is not able to work with «IC Net». The

user Status is also set Inactive if the number of

17

Page 26

3 Software settings

Password Options

failed Login attempts exceeds the limit set in

the Password Options.

The user can be set Active again by the Admin-

istrator

Removed The User is not able to work with «IC Net», he

.

is removed from the system but he is still listed

in the User List.

The user can be set Active again by the Admin-

istrator

.

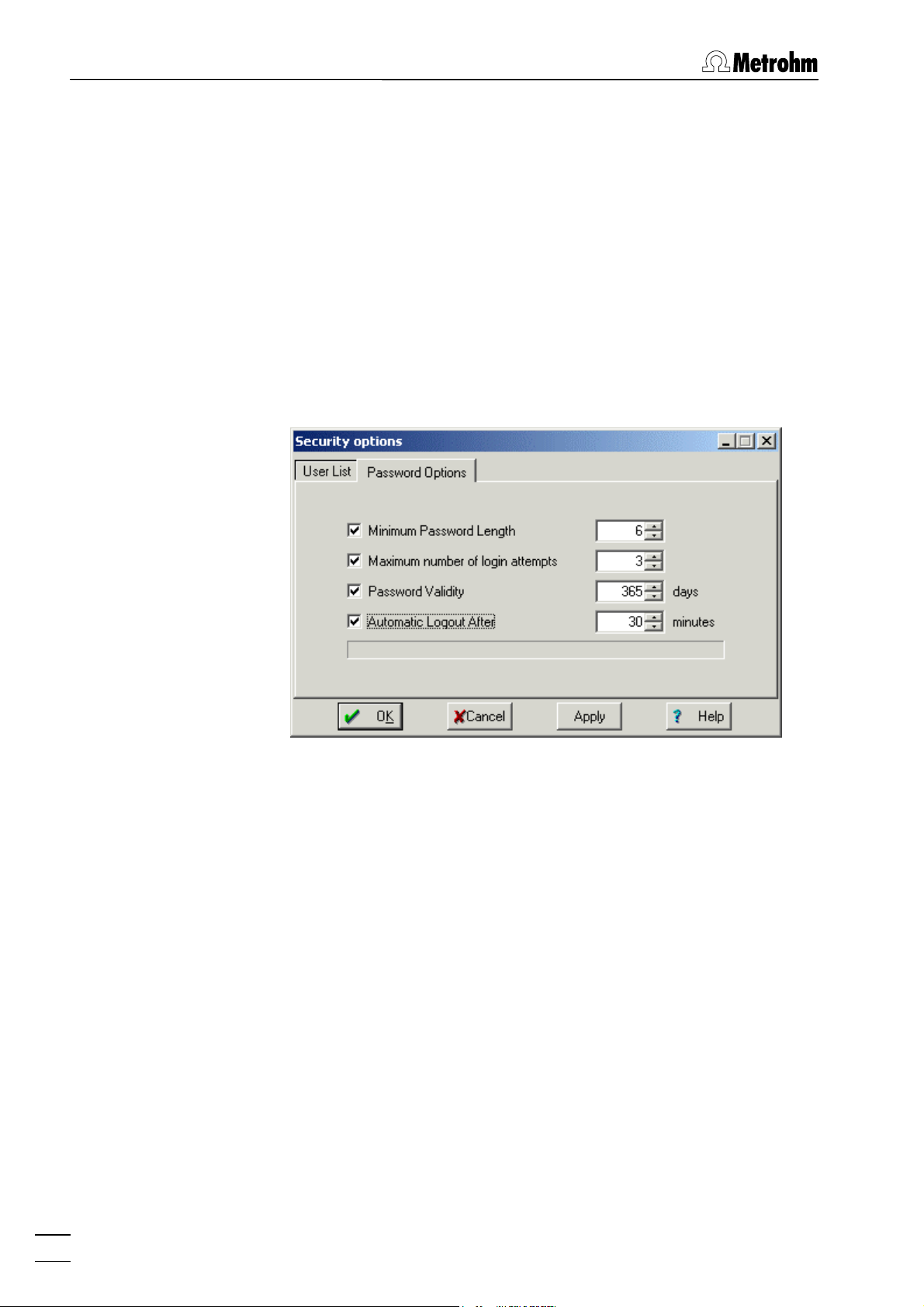

This tab allows to specify Password and Login related security settings.

Minimum Password Length

Minimum number of characters for the Pass-

word

.

Range: 2...10, default 6.

Maximum number of login attempts

If the number of failed Login’s exceeds this

value, the

User is set Inactive.

Range: 2...10, default 3.

Password Validity

Number of days the Password of a User remains valid. If the password is expired, the

user is prompted at the system log in to

change his password.

Range: 1...999, default 365.

18

IC Net 2.2

Page 27

3.3 Audit Trail

Automatic Logout After

After the specified period of inactivity (in minutes) the system is locked, to protect it against

unauthorized access.

Range: 1,...999, default 30.

The program prompts for username and password every time the

system starts. This username stamps methods, chromatograms

and reports, created during the working session. During the work

it is possible to change the current user with the menu item IC NET

/ O

ptions / Lock system.

3.3 Audit Trail

IC NET / Options / Audit Trail

The Audit Trail is a part of the Security system. IC Net automatically tracks all user logins and actions that create, modify or delete electronic records. The Audit Trail records every event with

time, date and the user who performed it.

The Audit Trail window is accessible only to Administrator

users.

This option displays the Audit Trail records in the Audit Trail window.

Chromatogram Open the Audit Trail window that displays all

changes made to the chromatogram. Displays Date, Time, User, Item changed in the

chromatogram,

Old Value and New Value.

This option is only available if the interesting

chromatogram is open and the active window

of IC Net.

Changes to the Audit Trail of a chromatogram are made when

the chromatogram is saved.

IC Net 2.2

History Open the Audit Trail window that displays all

actions performed in the IC Net window.

Displays Date, Time, User, Item worked on and

Value of every action logged.

Tool to track the login and user administration

history.

19

Page 28

3 Software settings

Audit Trail window

The Audit Trail window displays the Audit Trail records of the IC

Net or Chromatogram History in a table. Easy access to spe-

cific information is enabled by several sort and filter options of the

log window. The Log Window can be sorted according to one of

the six columns by clicking the title. A star ( * ) at the end of the title indicates the sorting criterion.

Refresh window, not available for Chroma-

togram History.

Open Save Audit Trail As window to export

Audit Trail records.

Sort, open the Sort window.

Filter the table according to the content and

column of a selected field. This filter option

can be applied sequentially to reduce the

displayed data.

Reset filter.

Open Help.

20

IC Net 2.2

Page 29

3.4 Global settings

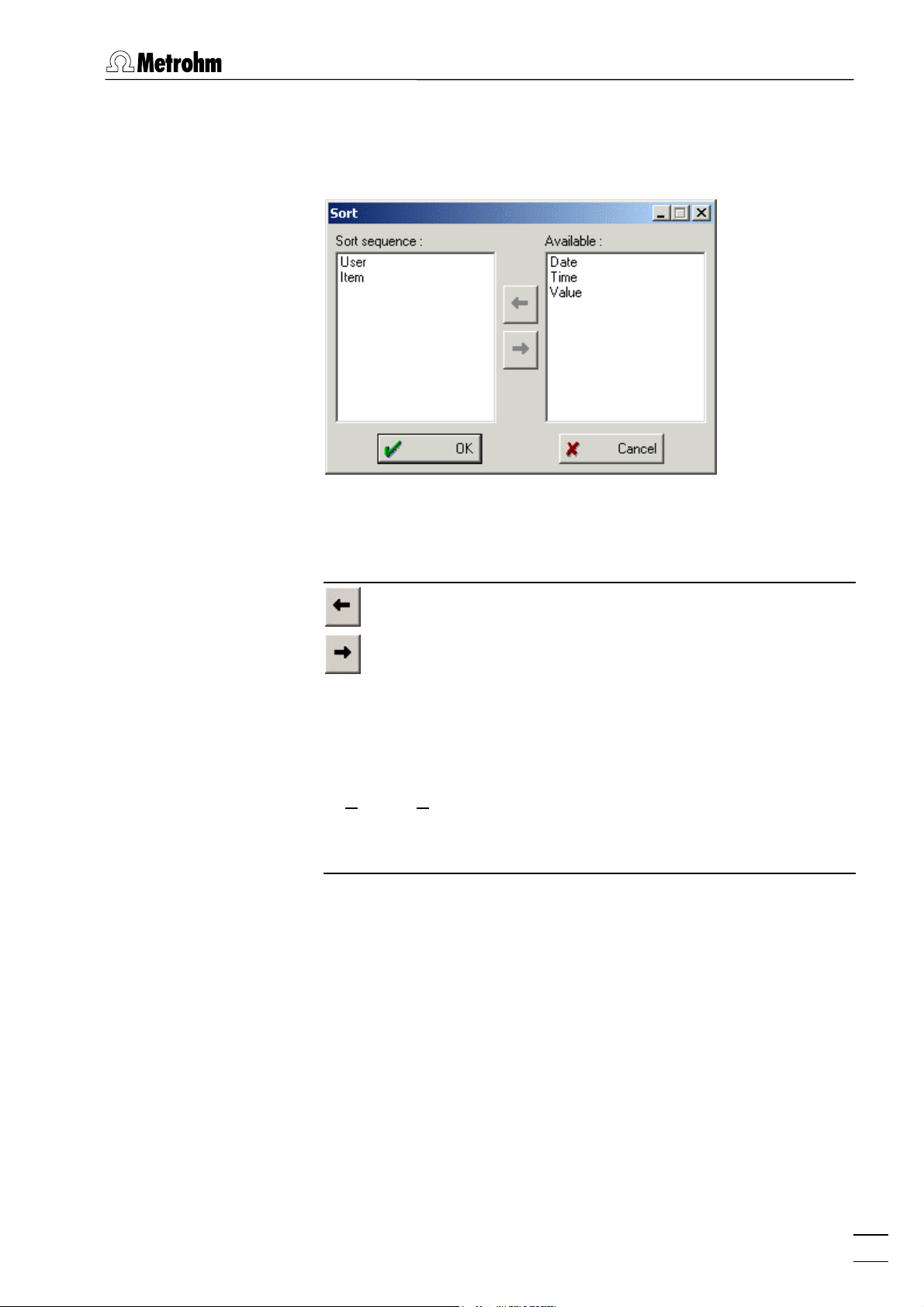

Sort window

This window offers a more refined possibility to arrange log data

by combining the column titles of the Audit Trail window to a Sort

Sequence

where the Audit Trail records are sorted.

Sort Sequence Sort criteria of the Sort Sequence, the sort

criteria are applied in the order of their entry

in the list.

Available Unused sort criteria.

3.4 Global settings

IC NET / Options / Global preferences

This window is used for global program settings. It can be

opened only by the user with Administrator access level.

Data file overwrite Global settings for overwriting of chroma-

Select marked sort criterion.

Deselect marked sort criterion.

togram files:

Never Chromatogram files cannot be overwritten.

A modified chromatogram is saved as new

file with the file name number raised by 1.

Ask The user is asked if the chromatogram

should be overwritten.

IC Net 2.2

Always Chromatogram files are always overwritten

without confirmation.

21

Page 30

3 Software settings

If method changed Global settings for saving of method files:

Don’t ask to save The method file is not saved automatically.

It can be saved only with File / Save / Method.

Ask to save The user is asked if the method should be

saved.

Overwrite without asking

Method files are overwritten without confirmation.

If disk method is newer

Global settings for overwriting of method

files:

Ask to overwrite The user is asked if the method should be

overwritten.

Overwrite without asking

Method files are overwritten without confirmation.

User comments

Changes on methods, systems, chromatograms,… :

Require Comment on changes

The user has to comment a change.

22

Opening chromatograms

Global settings for opening chromatograms:

Ignore last data directory

If this option is enabled, the directory is

opened where the current selected chroma-

IC Net 2.2

Page 31

3.4 Global settings

togram is saved.

If this option is disabled, the directory is

opened where the last opened chromatogram is saved.

21 CFR Part 11 On Switch on/off global 21 CFR Part 11 set-

tings. Is automatically activated and cannot

be altered, if IC Net Compliant is installed.

The following parameter settings are automatically set:

Data file overwrite = Never

If method changed = Ask to save

If disk method is newer = Ask to overwrite

User comments = Require Comment

on changes enabled

GLP On = enabled

GLP On Switch on/off global GLP settings. The fol-

lowing parameter settings are automatically

set:

Data file overwrite = Never

If method changed = Ask to save

If disk method is newer = Ask to overwrite

System face

Stacked recorder icons

If this option is enabled, only one recorder

icon with different tabs appears in the system window if several data recorders are

installed.

OK, Apply buttons mean

Save object to file If this option is enabled, the <Apply> button

in system settings windows is replaced by

the <Save> button. The system settings are

saved if the <Save> or <OK> button is

clicked.

Chromatogram units Units for chromatograms:

Flow Unit for flow rate: µL/min, mL/min

Pressure

Print via print spooler

Unit for pressure: MPa, psi, bar, atm

Switch on/off printing via print spooler.

Switch off this option if problems with printing occur.

IC Net 2.2

<Default colors> Default colors for chromatographic win-

dows (details see section 8.3.1).

23

Page 32

4 Systems

4 Systems

The combination of Metrohm and Bischoff devices connected to

an interface is called a system. The system includes all the settings of the devices, their time program, the data acquisition parameters and the processing method which have been optimized

for the specific separating column and the determination to be

carried out with it. A system is used to start single determinations

or determinations with the help of a sample queue. Systems are

stored as system files (*.smt) in the Systems directory.

4.1 System creation

4.1.1 System wizard

IC NET / File / New / System

The New system wizard window and a new SYSTEM window are

opened. The New system wizard guides you trough the installation

routine step-by-step to build a new system. The next step of the

system installation is reached with <Next>, the previous step with

<Back> and the installation is completed with <Finish>.

The first step of the system installation is to enter a name for a

new system folder within the «IC Net» program path

...\ICNet\Systems. For every instrument combination, a new folder

should be created.

24

After clicking on <Next>, the window for addition of interfaces to

the toolbar appears. This step can be skipped if the desired interface has been already added to the toolbar (see section 5.1.2). If

this is not the case, the interface has to be selected from the

Metrohm Interfaces or Bischoff Interfaces groups. After selecting the

serial port where the interface is connected to and clicking on

IC Net 2.2

Page 33

4.1 System creation

<Add to workplace>, the interface icon will appear on the toolbar

(PC Boards will not appear on toolbar).

After clicking on <Next>, the window for addition of devices (see

6.1.1) to the system window appears.

For every device to be controlled with «IC Net», open the group

which contains this device, select the device and the Serial port of

the interface where the device is connected to. After clicking on

<Add to system>, the device is added to the SYSTEM window. If

desired, an additional data recorder and a timer of the More mod-

ules

group can be added to the system.

IC Net 2.2

After clicking on

<Next>, the window for selection of processing

method linked to the system and data source appears (details

see section 6.1, 6.2).

25

Page 34

4 Systems

w

After clicking on <Finish>, the user is asked to save the new system as a system file (*.smt) in the new system folder. The new

system is now ready to start a determination (see section 4.3.3).

4.1.2 System window

A system window is opened with IC NET / File / Open / System and

the selection of the desired system file. It contains icons for Data

recorder, Watch window (screen) and all the devices installed

with the system wizard.

Watch windo

4.1.3 Add devices to an existing window

SYSTEM / Setup / New devices/ Install new device

Add new devices to the open SYSTEM window. For every device

to be added to the system, open the group which contains this

device and select the device and the serial port of the interface

where the device is connected to. After clicking on

tem>

, the device is added to the SYSTEM window. If desired, an

additional data recorder and a timer of the More modules group

can be added to the system.

26

Devices

<Add to sys-

IC Net 2.2

Page 35

4.2 System file handling

4.2 System file handling

The following menu items are used for opening, changing, saving

and closing of systems:

IC NET / File / Open / System

Load an existing system file (*.smt) from the Systems directory and

open the corresponding SYSTEM window. The name of the folder

and of the system file are displayed in the title bar of the SYSTEM

window. A star ( * ) at the end of the name indicates that the system settings have been changed since the last saving.

SYSTEM / System / Open other

Load an existing system file (*.smt) from the desired system folder

in the Systems directory and open a new SYSTEM window for parameter settings. The old system remains connected.

SYSTEM / System / Change

Open the selected new system in the desired system folder. The

current system is disconnected and closed, and the new system

is connected.

SYSTEM / System / Save

Save the current system file (*.smt) in the desired folder of the

Systems directory.

SYSTEM / System / Close

Close the selected system.

Delete a system

To delete an existing system, delete the *.smt file in the Systems

folder.

4.3 System functions

4.3.1 Connect and disconnect system

To make possible manual control of the system devices and start

of determinations, the selected system must be connected to the

workplace. Systems are connected and disconnected as follows:

IC Net 2.2

SYSTEM / Control / Connect to workplace

Connect selected system to the workplace. Only one system from

the same system folder can be connected at the same time.

The

SYSTEM window is always displayed in front of all other windows.

icon appears on the toolbar. If this icon is clicked, the

27

Page 36

4 Systems

SYSTEM / Control / Disconnect from workplace

Disconnect selected system from the workplace. If a system is

disconnected, manual control is not available for this system, but

all other system settings can be modified and saved. Start deter-

mination

and Startup hardware is only possible if no other system

from the same system folder is connected. In this case, the system is automatically connected.

4.3.2 Start/stop hardware and record baseline

SYSTEM / Control / Startup hardware (Measure Baseline)

With this menu item the following actions are executed automatically:

• Send System startup values to the devices.

• Start Metrohm solvent delivery systems and Bischoff solvent

delivery systems.

• Start Metrohm additional modules and Bischoff additional

modules.

• Start Bischoff detectors.

• Switch Metrohm Autosamplers and Bischoff Autosamplers to

remote control.

• Start recording of the measurement signal using the method of

the connected system. Independently of the set chromatogram

Duration, the measurement signal is recorded until the data ac-

quisition is stopped if a new determination is started with Start

determination

or by clicking the icon of the chromatogram

window. In this case the user is asked if the recorded baseline

should be saved or not.

SYSTEM / Control / Shutdown hardware

With this menu item the devices are stopped as follows:

• Stop Metrohm solvent delivery systems and Bischoff solvent

delivery systems.

• Stop Metrohm additional modules and Bischoff additional

modulesVariotherm.

• Stop Bischoff detectors.

28

• Switch Metrohm Autosamplers and Bischoff Autosamplers to

local control.

• Stop running determination.

• Stop active sample queue.

SYSTEM / Control / Stop data acquisition

Stop recording of the baseline.

IC Net 2.2

Page 37

4.3 System functions

4.3.3 Start/stop determinations

SYSTEM / Control / Start determination

Start determination using the settings of the selected system.

At this start command, the System startup values are set at the devices. The time programs of the different devices and the data recording are started either immediately (Start with determination) or

after switching the injection valve to the "Inject" position (Start with

inject

) as set in the Start mode window.

SYSTEM / Control / Stop determination

Stop running determination. Data acquisition and time pro-

grams are terminated immediately. The recorded chromatogram

is saved automatically if the Save chromatogram after the run option

on the

Passport / Processing tab is enabled.

Alternatively the determination can be stopped by clicking the

icon of the chromatogram window. In this case the user is asked

always if the determination should be saved or not.

If the Auto restart option is enabled or if a sample

queue is active, a new determination is started immediately after the running determination is stopped. If you

want to avoid this, disable the Auto restart option or

Pause the sample queue.

SYSTEM / Control / Stop data acquisition

Stop data acquisition of the running determination immediately

and save the recorded chromatogram automatically if the Save

chromatogram after the run

option on the Passport / Processing tab

is enabled. The time programs of the running determination are

continued normally.

4.3.4 Options for determinations

SYSTEM / Control / Auto restart

If this option is enabled, a new determination is started automatically using the current system after the preceding determination

has been finished normally or stopped manually.

The Auto restart option is disabled if determinations are made

with an active sample queue. This option allows to make an infinite batch cycle with the current system

SYSTEM / Control / Verify sample

If this option is enabled, the Edit sample description window is

opened automatically at the start of each determination for entry

of the following sample information:

IC Net 2.2

29

Page 38

4 Systems

Ident User defined identifier (title) for the chroma-

togram to be displayed in the title bar of the

chromatogram window and in the Chroma-

togram

open window.

Calibration level Calibration level (0 = sample; 1…n = cali-

bration solutions).

Info 1 / Info 2 Sample description.

Volume Injected volume in µL.

Dilution Dilution of the sample.

Vial number Autosampler vial position to take sample

from.

Amount Sample amount. If this value is different for

the calibration run (c) and the sample run

(s), the component concentrations of the

sample are calculated as follows:

C

= Cc • Amounts / Amountc

s

Internal standard amount

Concentration of the internal standard

component for relative concentration calculations.

Date/time when... Date and time of sample collection (the de-

fault values are equal to the date and time

when the chromatogram starts).

30

The Verify sample option is disabled if determinations are made

with an active sample queue.

IC Net 2.2

Page 39

4.4 System settings

4.4 System settings

4.4.1 Modify system window

SYSTEM / Setup / Drag icons

If this option is enabled, the device icons can be resized and

moved in the SYSTEM window and the SYSTEM window itself can

be resized.

To resize an icon or the window, move the cursor to the desired

object until appears. Press the left mouse button and resize

the object to the desired size.

To move an icon, move the cursor to the desired object until

appears. Press the left mouse button and move the object to the

desired place.

4.4.2 Watch window display

SYSTEM / Setup / Watch window

If this option is enabled, the WATCH WINDOW is automatically

opened if a determination or measure baseline is started (see

section 6.2).

4.4.3 Set start mode

SYSTEM / Setup / Start mode

This menu item opens the Start mode window for definition of start

mode for time programs and data acquisition.

IC Net 2.2

This window contains the following two fields:

Start with determination

The time program of the loaded object or

the data acquisition (RECORDER) is started

at the moment the determination is

started.

31

Page 40

4 Systems

Start with inject The time program of the loaded object or

The objects can be moved from one field to the other using the

or buttons.

4.4.4 Install new devices

SYSTEM / Setup / New devices/ Install new device

Add new devices to the open SYSTEM window. For every device

to be added to the system, open the group which contains this

device and select the device and the serial port of the interface

where the device is connected to. After clicking on <Add to sys-

tem>

, the device is added to the SYSTEM window. If desired, an

additional data recorder and a timer of the More modules group

can be added to the system.

the data acquisition (RECORDER) is started

at the moment the sample is injected.

4.4.5 Install existing devices

SYSTEM / Setup / New devices/ Link to existing device

4.4.6 Print system parameters

SYSTEM / Setup / Parameters / Print

A report of the system parameters including the time program is

created and opened using the «Microsoft Word» program. The

*.rtf file opened can be printed, saved and exported into other

programs. The system report includes the following elements:

STARTUP HARDWARE

Add devices to the open SYSTEM window which

are already present on the toolbar. This is mostly

used to add the 762 IC Interface events. For every

device to be added to the system, select the device and click on <OK>.

Name of the method linked to the system

Main measurement channel

Configuration settings for the devices

System startup values

32

START WITH DETERMINATION

Objects defined in the Start mode window.

The time programs are printed if the programs are enabled.

START WITH INJECT Objects defined in the Start mode window.

The time programs are printed if the programs are enabled.

IC Net 2.2

Page 41

4.5 System state window

4.4.7 Show system parameters

SYSTEM / Setup / Parameters / Startup hardware

Display of the name of the method linked to the system, the main

measurement channel, the configuration settings for the devices,

and the system startup values.

SYSTEM / Setup / Parameters / Start with determination

Display of the objects defined in the Start mode window. The time

programs are displayed if the programs are enabled.

SYSTEM / Setup / Parameters / Start with inject

Display of the objects defined in the Start mode window. The time

programs are displayed if the programs are enabled.

4.4.8 Links

SYSTEM / Setup / Links

Display of all devices of the system (including watch window and

data recorder).

4.5 System state window

SYSTEM STATE window is automatically opened if a system is

The

connected. It shows status and error messages for this system.

Messages concerning a device are followed by

messages concerning the loaded system are followed by

name"]

lowing messages can appear:

4.5.1 Status messages

Checking on-line

(name of the folder who contains the system file). The fol-

["device name"],

["folder

Checking connection between PC and device.

IC Net 2.2

On-line

UploadStartupValues

Initialisation

Ready

Starting

Connection between PC and device ok.

Hardware or system startup values have

been loaded to the device.

Hardware or system initialization.

Device is ready.

Starting program or chromatogram data

acquisition.

33

Page 42

4 Systems

Running

Running program or chromatogram data

acquisition.

Running program

(xxx min left)

Waiting for INJECT

INJECT done

Stopping

Finished

SHUTDOWN

4.5.2 General error messages

Detection of hardware failed

Running time program with time display.

Waiting for "INJECT" to start program

and/or chromatogram data acquisition as

defined in the Start mode.

Injection valve has been switched to the

"INJECT" position.

Determination has been stopped.

Program or chromatogram data acquisition

has been finished.

System is shutdown.

Bad connection between PC and device or

device switched off (check connecting cable or switch on instrument).

4.5.3 Error messages for 761 Compact IC

LEAK DETECTED

The leak detector has detected a leak

(check IC system and connections).

E1

Program checksum wrong (call Metrohm

service).

E2

E200

RAM faulty (call Metrohm service).

Invalid instrument adjustment (call Metrohm

service).

E237

Storage of configuration values failed (repeat last action; if error reappears, call

Metrohm service).

E238

Storage of instrument number failed (repeat

last action; if error reappears, call Metrohm

service).

E240

EEPROM faulty (call Metrohm service).

34

E258

Storage of setup values failed (repeat last

action; if error reappears, call Metrohm service).

IC Net 2.2

Page 43

4.5 System state window

E295

Storage of memory values failed (repeat

last action; if error reappears, call Metrohm

service).

E296

E297

E298

E299

E300

E301

E302

Instrument stopped (restart instrument; if

error reappears, call Metrohm service).

Storage of remote line values failed (repeat

last action; if error reappears, call Metrohm

service).

Storage of flow correction value failed (repeat last action; if error reappears, call

Metrohm service).

Storage of break time values failed (repeat

last action; if error reappears, call Metrohm

service).

High-pressure pump faulty (restart pump; if

error reappears, call Metrohm service).

Injection valve blocked (check injection

valve; if error reappears, call Metrohm service).

Suppressor module blocked (check suppressor; if error reappears, call Metrohm

service).

E303

Storage of maintenance information failed

(repeat last action; if error reappears, call

Metrohm service).

IC Net 2.2

35

Page 44

5 Interfaces

5 Interfaces

The «IC Net» program supports remote control for interfaces

available from Metrohm and Bischoff. Interfaces generally convert

analog signals to digital form, which can be handled by the computer. Interfaces are stored as device files (*.dev) in the Devices directory. All Metrohm interfaces and Metrohm devices start

with Me*.dev; all Bischoff interfaces and Bischoff devices start

with Bi*.dev.

5.1 Interface installation

5.1.1 Add interfaces with system wizard

IC NET / File / New / System

The New system wizard window and a new SYSTEM window are

opened. The New system wizard guides you trough the installation

routine step-by-step to build a new system. The next step of the

system installation is reached with <Next>, the previous step with

<Back> and the installation is completed with <Finish>.