Page 1

IC Equipment Set

Flow Cell for Bioscan – 6.5331.0X0

Manual

8.110.8003EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

IC Equipment Set

Flow Cell for Bioscan – 6.5331.0X0

Manual

8.110.8003EN 26.03.2008 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Description ............................................................................ 1

1.2 About the Documentation ................................................... 1

1.2.1 Symbols and conventions ........................................................ 1

2 Installation 3

3 Technical Data 6

3.1 General .................................................................................. 6

3.2 Gold flow cell ....................................................................... 6

3.3 Glassy Carbon flow cell ........................................................ 7

3.4 Platinum flow cell ................................................................. 7

3.5 Silver flow cell ....................................................................... 8

Table of contents

4 Accessories 9

4.1 Equipment set with Au flow cell for Bioscan ..................... 9

4.2 Equipment set with GC flow cell for Bioscan ................... 10

4.3 Equipment set with Pt flow cell of Bioscan ..................... 11

4.4 Equipment set with Ag flow cell for Bioscan ................... 13

Index 15

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

III

Page 6

Table of figures

Table of figures

Figure 1 Parts and connections of flow cell ..................................................... 3

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

IV

IC Equipment Set Flow Cell for Bioscan

Page 7

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Description

The flow cell is used for amperometric detection with the Bioscan measuring instruments. The flow cell's construciton is based on the Wall-Jet-Principle. According to the Wall-Jet-Principle the inlet is positioned exactly

opposite to the working eleoctode, which allows for optimum measuring

perfomance.

The flow cell is available in four versions:

■ Gold flow cell (6.1254.010)

■ Glassy carbon flow cell (6.1254.050)

■ Platinum flow cell (6.1254.060)

■ Silver flow cell (6.1254.070)

For a more detailed description of the specification and intended use of

the individual cells, please see (see Chapter 3, page 6).

1 Introduction

1.2 About the Documentation

Caution

Please study this documentation carefully before you start to use the

instrument. The documentation contains information and warnings that

must be observed by the user in order to guarantee the safe use of the

instrument.

1.2.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

IC Equipment Set Flow Cell for Bioscan

This symbol draws attention to a possible life hazard

or risk of injury.

■■■■■■■■

1

Page 8

1.2 About the Documentation

■■■■■■■■■■■■■■■■■■■■■■

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

■■■■■■■■

2

IC Equipment Set Flow Cell for Bioscan

Page 9

■■■■■■■■■■■■■■■■■■■■■■

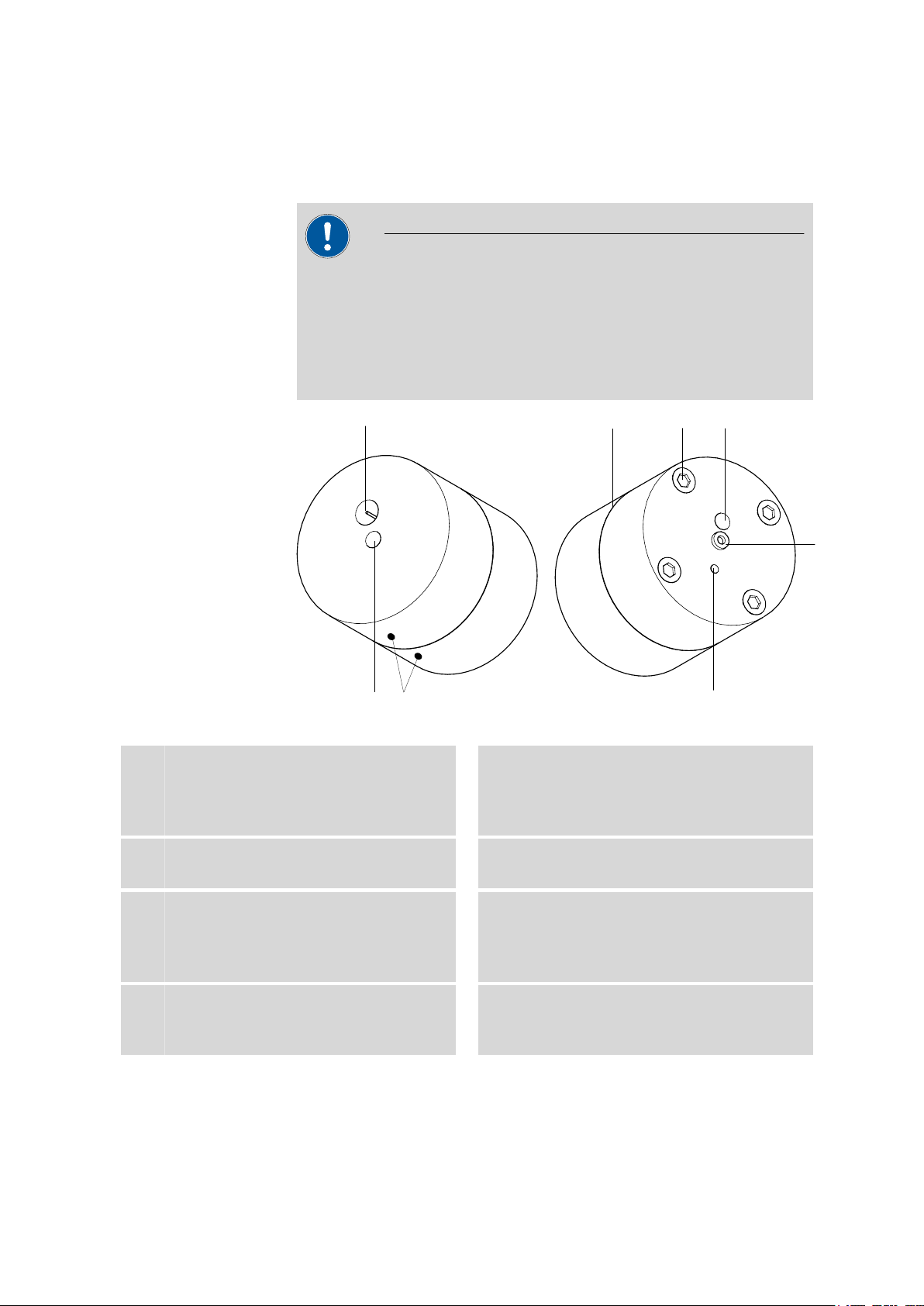

8

1

2

3

4

56

7

2 Installation

Never switch on the flow cell when it is..

■ ..not being rinsed through with a conducting eluent at the time; or

■ ..not completely connected; or

■ ..moist on the outside so that a short circuit could occur between

2 Installation

Caution

the connections of working eleoctrode and auxiliary electrode.

Figure 1 Parts and connections of flow cell

Reference electrode connection

1

For black electrode cable (6.2156.000).

Auxiliary electrode connection

3

For blue electrode cable (6.2156.000).

Outlet for eluent

5

Connection of PEEK capillary by 6.2744.130

KELF pressure screw only. PEEK pressure

screws may damage the threads of the cell.

7

Distance piece 50 µm (6.1254.020)

Defines the volume of the cell.

Inlet for eluent

2

Connection of PEEK capillary by 6.2744.130

KELF pressure screw only. PEEK pressure

screws may damage the threads of the cell.

Working eleoctrode connection

4

For red electrode cable (6.2156.000).

Mounting screws (4x)

6

Check marks

8

For correct alignment of the top and bottom

part of the flow-through cell.

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

3

Page 10

■■■■■■■■■■■■■■■■■■■■■■

Connect flow cell

1

Check mounting screws

Caution

Avoid overtightening the mounting screws (1-6), as this could

damage the distance piece (1-7)!

■ Use the provided hexagon key (6.2621.150) to loosen all four

mounting screws (1-6) by one rotation.

■ Then slighly tighten the screws again, e.g. by holding the hexagon

key between index finger and thumb only.

■ Finally, tighten all four mounting screws by a quarter rotation.

Always tighten opposing screws, i. e. tighten one screw antd then

its opposite.

2

Connect the electrode cable

■ Attach the electrode cable (6.2156.000 delivered with the 871

Advanced Bioscan) to the working electrode connection (1-4)

(red), the reference electrode connection (1-1) (black), and the

auxiliary electrode connection (1-3) (blue) of the flow cell.

■ Attach the other end to the connection for electrode cable of the

871 Advanced Bioscan.

3

Connect the separating column

■ Use a pressure screw (6.2744.130) to screw the column connec-

tion capillary of the separating column to the inlet for eluent

(1-2). Push the connection capillary into the inlet as far as it will

go (approx. 1.5 cm) and then fix it with the pressure screw (this

will prevent dead volume).

4

Connect waste tubing

■ To ensure sufficient back pressure, connect a PEEK capillary

(6.1831.010) of approx.1m length to the outlet for eluent (1-5).

Push the PEEK capillary into the outlet as far as it will go (approx.

0.5 cm) and then fix it with a pressure screw (6.2744.130) (this

will prevent dead volume).

■ Place the other end of the PEEK capillary into a waste container

and attach it.

■■■■■■■■

4

IC Equipment Set Flow Cell for Bioscan

Page 11

■■■■■■■■■■■■■■■■■■■■■■

5

Mount the flow cell

■ Attach the flow cell to the measuring cell holder of the Bioscan.

■ Rotate flow cell in its holder so that the outlet is located as high

as possible. This allows possibly occuring air bubbles to escape

from the cell.

2 Installation

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

5

Page 12

3.1 General

3 Technical Data

3.1 General

■■■■■■■■■■■■■■■■■■■■■■

Construction

Cell volume

Flow cell with working, reference and auxiliary electrode.

The cell volume depends on the thickness of the selected distance

piece:

Distance piece Cell volume

25 µM 0.15 µL

50 µM 0.29 µL

120 µM 0.71 µL

Working temperature

The flow cell should not be operated permanently at temperatures

higher than 45 °C.

Reference electrode

Type

Conversion to

Solid phase reference electrode

E

= E

Hy-REF

Ag/AgCl

3.2 Gold flow cell

- 328 + 29.9 pH (mV)

Ag/AgCl

Arbeitselektrode

Material

Durchmesser

Working electrode

Material

Diameter

Applications

Operating modes

Gold

3 mm

Gold

3 mm

Sugar and amino acids

■ mono-, di-, oligo- and polysaccharides

■ sugar alcohols

■ sugar amines

■ sugar acids

■ amino acids

■ antibiotics

DC and PAD

■■■■■■■■

6

IC Equipment Set Flow Cell for Bioscan

Page 13

■■■■■■■■■■■■■■■■■■■■■■

Operating range

Acidic medium

Alkaline

-0.35 V…+1.1 V

-1.25 V…+0.75 V

medium

3.3 Glassy Carbon flow cell

Working electrode

Material

Diameter

Glassy-Carbon

3 mm

3 Technical Data

Applications

Operating modes

Aromatics and amines

■ catecholamines, aromatic amines

■ inorganic anions (nitrite, sulfite ...)

■ phenols

■ vitamins

■ few amino acids

DC only (not PAD)

Operating range

Acidic medium

Alkaline

-0.8 V… +1.3 V

-1.5 V… +0.6 V

medium

3.4 Platinum flow cell

Working electrode

Material

Diameter

Applications

Platinum

3 mm

Special applications

■ alcohols

■ glycols

■ hydrogen peroxide

■ hydrazine

■ arsenite, hypochlorite

Operating modes

DC and PAD

Operating range

Acidic medium

Alkaline

-0.2 V… +1.3 V

-0.9 V… +0.65 V

medium

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

7

Page 14

3.5 Silver flow cell

3.5 Silver flow cell

Working electrode

Material

Diameter

Silver

2 mm

■■■■■■■■■■■■■■■■■■■■■■

Applications

Operating modes

Operating range

Acidic medium

Alkaline

medium

Environmental applications

■ halides

■ cyanide, sulfide

■ thiosulfate

■ pharmaceuticals

DC and PAD

-0.55 V… +0.4 V

-1.2 V… +0.1 V

■■■■■■■■

8

IC Equipment Set Flow Cell for Bioscan

Page 15

■■■■■■■■■■■■■■■■■■■■■■

4 Accessories

4.1 Equipment set with Au flow cell for Bioscan

6.5331.010 IC Equipment Set with Gold flow cell

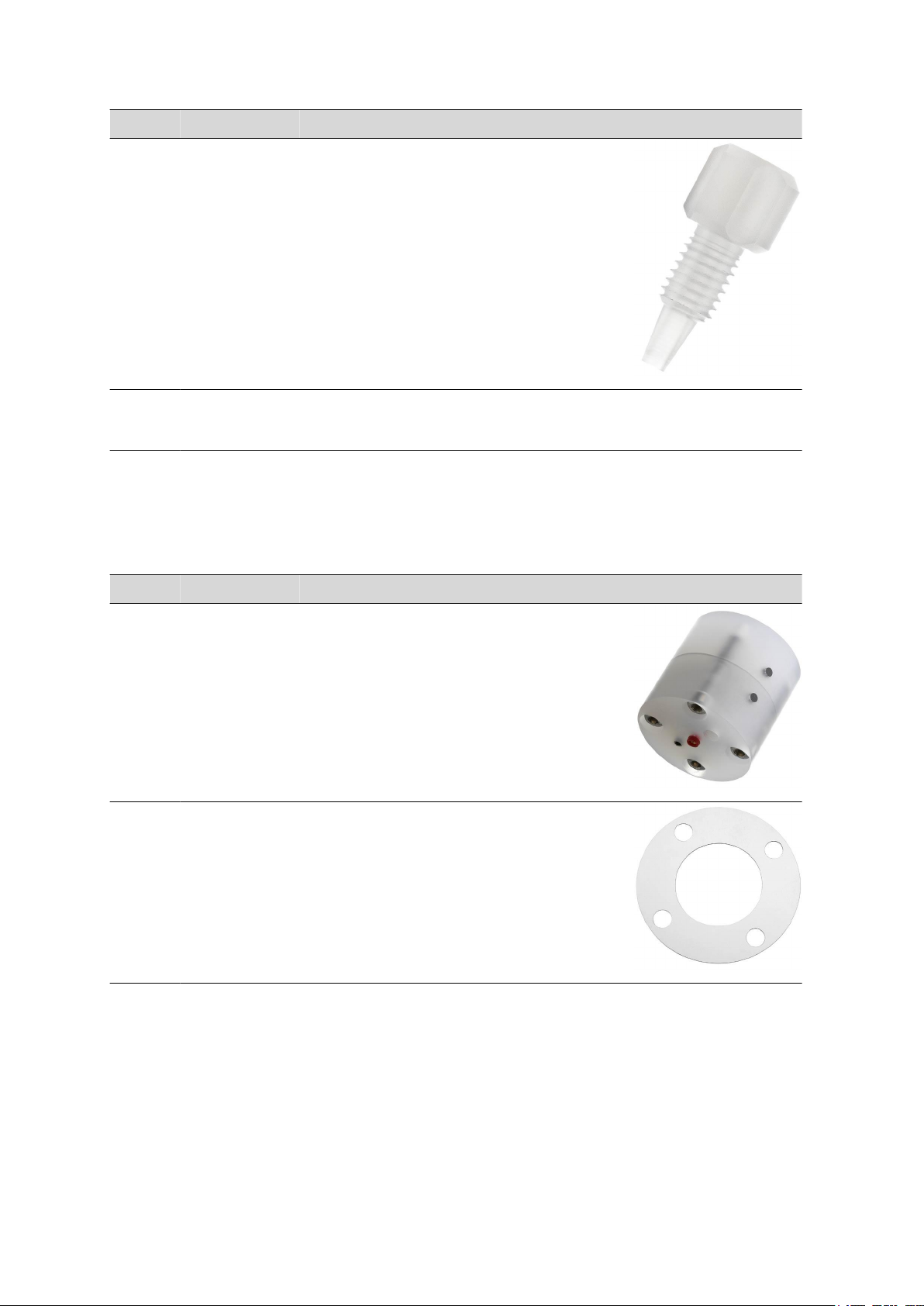

Qty. Order no. Description

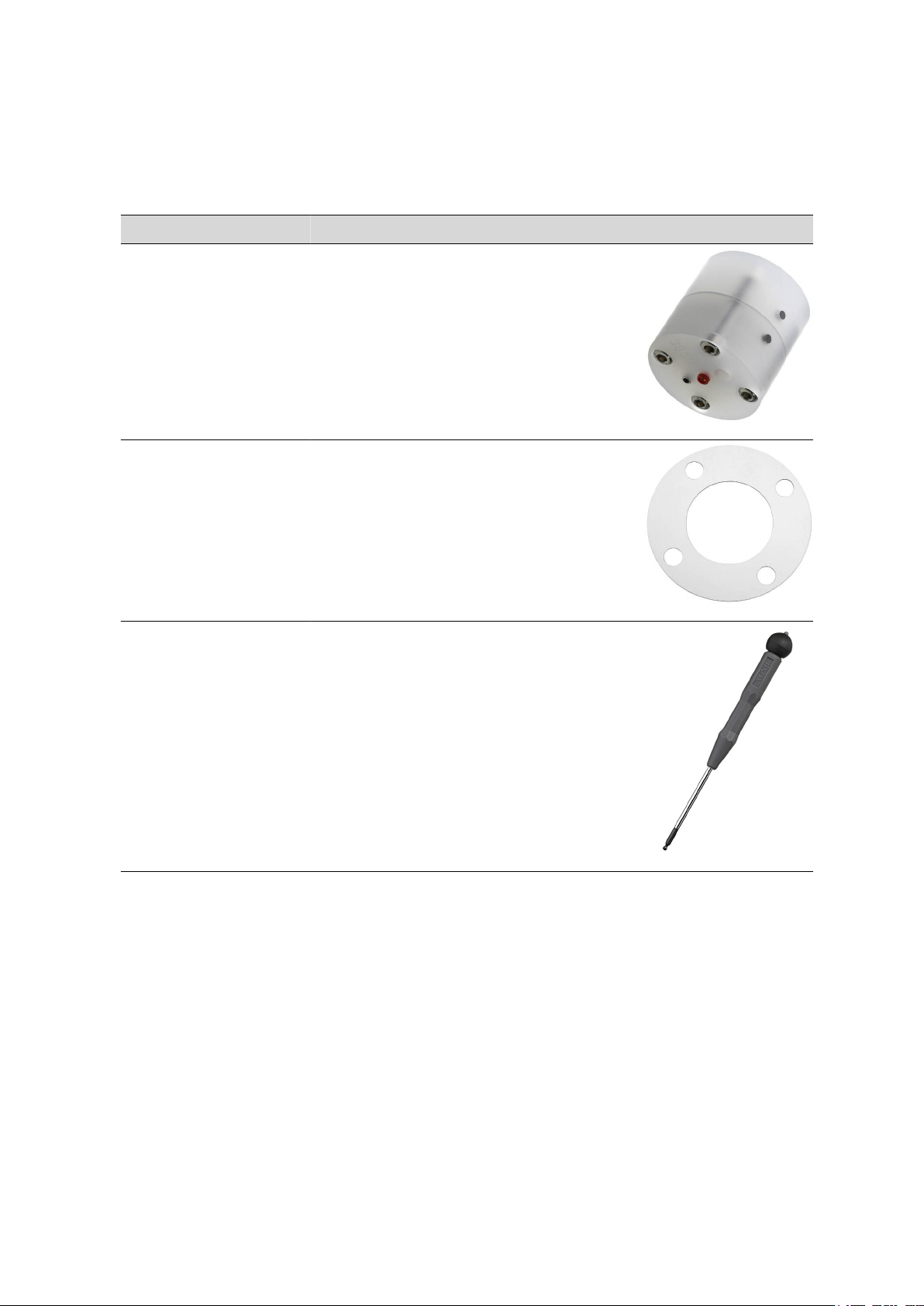

1 6.1254.010 Gold flow cell for Bioscan

Flow-through cell for Bioscan, electrode material: gold

Material: Gold

Material remark: Working electrode

4 Accessories

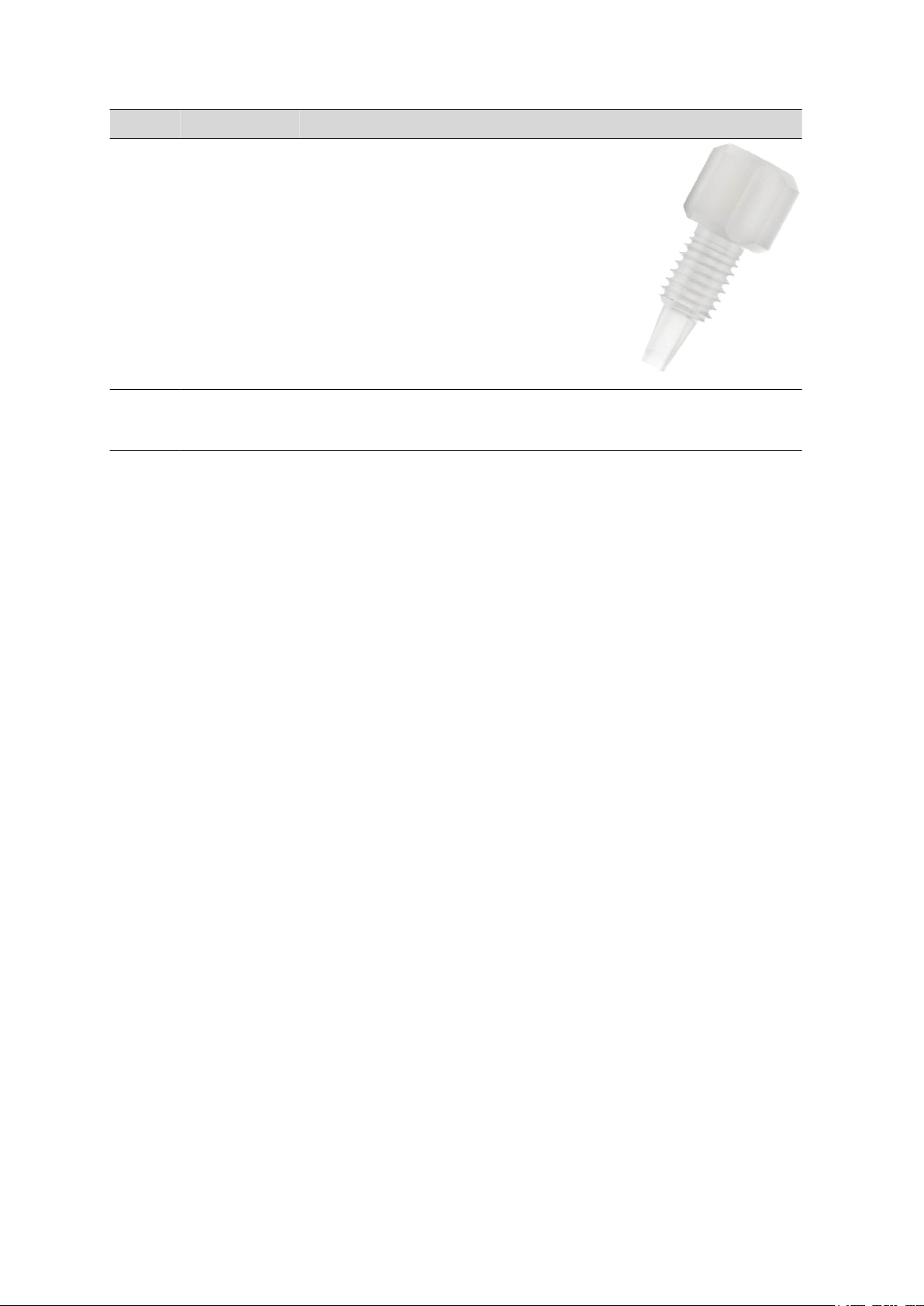

1 6.1254.020 Distance piece for Bioscan flow cell, 50 µm

50 µm Spacer for Bioscan flow-through cell

Material: Plastic

Height (mm): 0.05

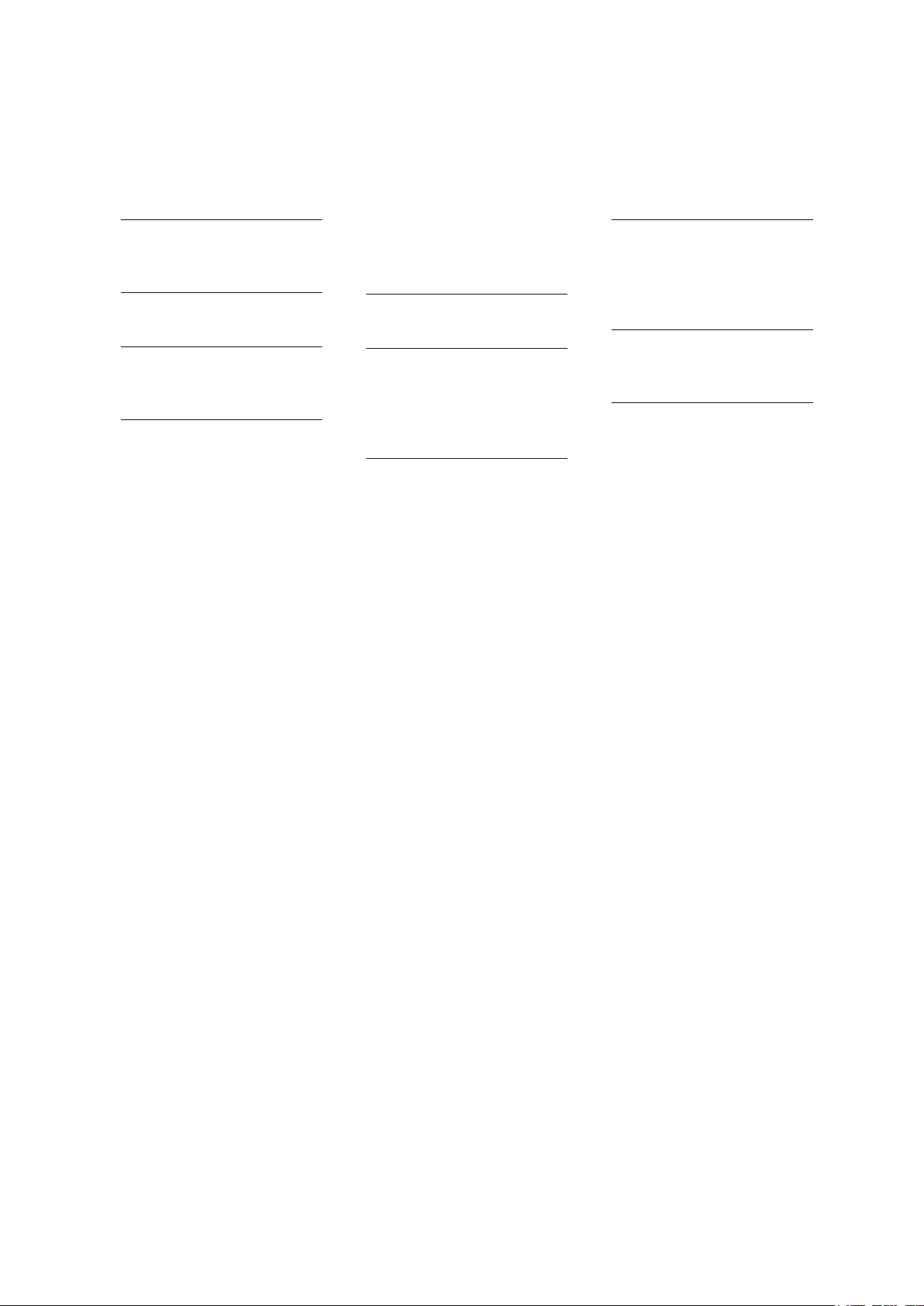

1 6.2621.150 Hexagon key 3 mm for Bioscan

Hexagon key 3 mm for Bioscan

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

9

Page 16

4.2 Equipment set with GC flow cell for Bioscan

Qty. Order no. Description

4 6.2744.130 Pressure screw for Bioscan measuring cell

For connecting 1/16 in. capillaries.

1 8.110.8003EN Manual IC Equipment Set – Flow Cell for

Bioscan 6.5331.0X0

■■■■■■■■■■■■■■■■■■■■■■

4.2 Equipment set with GC flow cell for Bioscan

6.5331.020 IC Equipment Set with Glassy carbon flow cell

Qty. Order no. Description

1 6.1254.050 Glassy carbon flow cell for Bioscan

Flow cell for Bioscan, electrode material: glassy carbon

Material: Glassy carbon

Material remark: Working electrode

1 6.1254.020 Distance piece for Bioscan flow cell, 50 µm

50 µm Spacer for Bioscan flow-through cell

Material: Plastic

Height (mm): 0.05

■■■■■■■■

10

IC Equipment Set Flow Cell for Bioscan

Page 17

■■■■■■■■■■■■■■■■■■■■■■

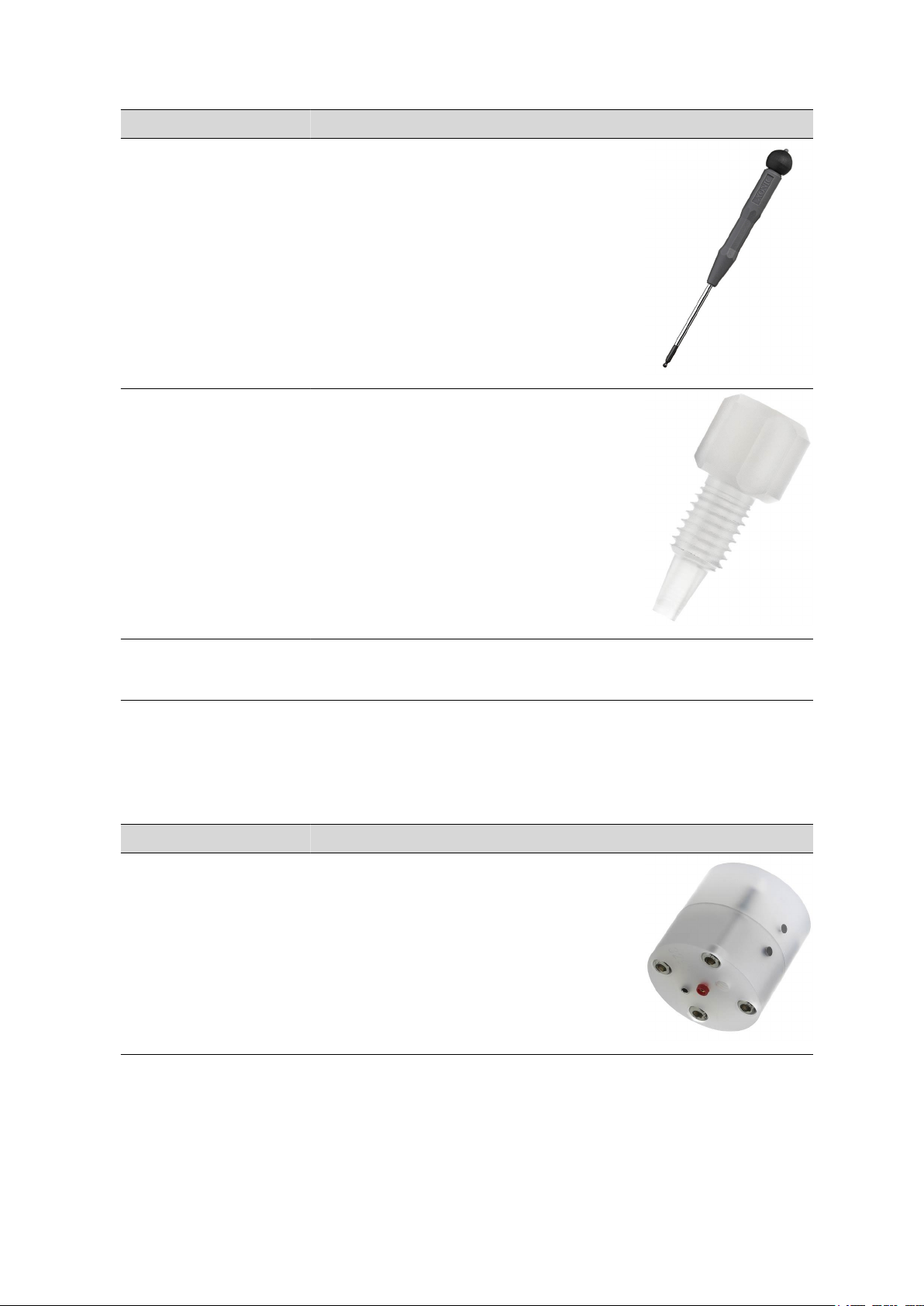

Qty. Order no. Description

1 6.2621.150 Hexagon key 3 mm for Bioscan

Hexagon key 3 mm for Bioscan

4 6.2744.130 Pressure screw for Bioscan measuring cell

For connecting 1/16 in. capillaries.

4 Accessories

1 8.110.8003EN Manual IC Equipment Set – Flow Cell for

Bioscan 6.5331.0X0

4.3 Equipment set with Pt flow cell of Bioscan

6.5331.030 IC Equipment Set with Platinum flow cell

Qty. Order no. Description

1 6.1254.060 Platinum flow cell for Bioscan

Flow cell for Bioscan, electrode material: Platinum

Material: Platinum

Material remark: Working electrode

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

11

Page 18

4.3 Equipment set with Pt flow cell of Bioscan

Qty. Order no. Description

1 6.1254.020 Distance piece for Bioscan flow cell, 50 µm

50 µm Spacer for Bioscan flow-through cell

Material: Plastic

Height (mm): 0.05

1 6.2621.150 Hexagon key 3 mm for Bioscan

Hexagon key 3 mm for Bioscan

■■■■■■■■■■■■■■■■■■■■■■

4 6.2744.130 Pressure screw for Bioscan measuring cell

For connecting 1/16 in. capillaries.

1 8.110.8003EN Manual IC Equipment Set – Flow Cell for

Bioscan 6.5331.0X0

■■■■■■■■

12

IC Equipment Set Flow Cell for Bioscan

Page 19

■■■■■■■■■■■■■■■■■■■■■■

4.4 Equipment set with Ag flow cell for Bioscan

6.5331.040 IC Equipment Set with Silver flow cell

Qty. Order no. Description

1 6.1254.070 Silver flow cell for Bioscan

Flow cell for Bioscan, electrode material: Silver

Material: Silver

Material remark: Working electrode

1 6.1254.020 Distance piece for Bioscan flow cell, 50 µm

50 µm Spacer for Bioscan flow-through cell

Material: Plastic

Height (mm): 0.05

4 Accessories

1 6.2621.150 Hexagon key 3 mm for Bioscan

Hexagon key 3 mm for Bioscan

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

13

Page 20

4.4 Equipment set with Ag flow cell for Bioscan

Qty. Order no. Description

4 6.2744.130 Pressure screw for Bioscan measuring cell

For connecting 1/16 in. capillaries.

1 8.110.8003EN Manual IC Equipment Set – Flow Cell for

Bioscan 6.5331.0X0

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

14

IC Equipment Set Flow Cell for Bioscan

Page 21

■■■■■■■■■■■■■■■■■■■■■■

Index

Index

A

Accessories ................................. 9

auxiliary electrode ...................... 3

C

Cell volume ................................ 6

D

Distance piece ............................ 3

Distand piece ............................. 6

G

Glassy Carbon flow cell

Technical data ...................... 7

Glassy Carbon Flow-through Cell

Accessory ........................... 10

Gold flow cell

Accessory ............................. 9

Technical data ...................... 6

I

Installation ................................. 3

P

Platinum flow cell

Technical data ...................... 7

Platinum Flow-through Cell

Accessory ........................... 11

R

reference electrode .................... 3

S

Silver flow cell

Technical data ...................... 8

Silver Flow-through Cell

Zubehör ............................. 13

T

Technical data ............................ 6

Temperature ............................... 6

W

working electrode ...................... 3

IC Equipment Set Flow Cell for Bioscan

■■■■■■■■

15

Loading...

Loading...