Page 1

915 KF Ti-Touch

Manual

8.915.8005EN / 2014-03-10

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

915 KF Ti-Touch

Program version 5.915.0030

8.915.8005EN / 2014-03-10

Manual

ebe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Melody for the BEEP command: excerpt from "En Altfrentsche", with kind

permission of the Laseyer Quartett, Appenzell.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Titration and measuring modes ................................................ 1

1.1.2 Connectors .............................................................................. 2

1.1.3 Intended use ........................................................................... 2

1.2 About the documentation ................................................... 3

1.2.1 Symbols and conventions ........................................................ 3

2 Safety instructions 5

2.1 General notes on safety ....................................................... 5

2.2 Electrical safety ..................................................................... 5

2.3 Tubing and capillary connections ....................................... 6

2.4 Flammable solvents and chemicals ..................................... 6

Table of contents

2.5 Recycling and disposal ......................................................... 7

3 Overview of the instrument 8

3.1 Front of the instrument ........................................................ 8

3.2 Rear of the instrument ......................................................... 9

4 Installation 10

4.1 Setting up the instrument .................................................. 10

4.1.1 Packaging .............................................................................. 10

4.1.2 Checks .................................................................................. 10

4.1.3 Location ................................................................................ 10

4.2 Connecting the power supply unit .................................... 10

4.3 Connecting MSB devices .................................................... 12

4.3.1 Connecting dosing devices .................................................... 13

4.3.2 Connecting an additional stirrer or titration stand .................. 14

4.3.3 Connecting a Remote Box ..................................................... 14

4.4 Connecting USB devices ..................................................... 15

4.4.1 General ................................................................................. 15

4.4.2 Connecting a USB hub ........................................................... 15

4.4.3 Connecting a printer .............................................................. 15

4.4.4 Connecting a balance ............................................................ 16

4.4.5 Connecting a PC keyboard ..................................................... 17

4.4.6 Connecting a barcode reader ................................................. 17

4.4.7 Connecting a Sample Processor ............................................. 18

915 KF Ti-Touch

4.5 Setting up the titration vessel ........................................... 19

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.6 Connecting sensors ............................................................ 19

4.6.1 General ................................................................................. 19

4.6.2 Connecting a polarizable electrode ........................................ 19

4.6.3 Connecting a temperature sensor .......................................... 20

4.7 Connecting the Ti-Touch to a network ............................ 21

5 Titrations 23

5.1 Water determination according to Karl Fischer (KFT) ..... 23

6 Operation 24

6.1 Switching the instrument on and off ............................... 24

6.2 Fundamentals of operation ............................................... 26

6.2.1 Touch-sensitive screen ........................................................... 26

6.2.2 Display elements and controls ................................................ 26

6.2.3 Status display ........................................................................ 27

6.2.4 Entering text and numbers ..................................................... 28

7 System settings 31

7.1 General system settings ..................................................... 31

7.1.1 Selecting the dialog language ................................................ 31

7.1.2 Setting the date, time and local time ..................................... 32

7.2 System-specific dialog options .......................................... 33

7.3 User administration ............................................................ 37

7.3.1 Editing the user configuration ................................................ 38

7.3.2 Creating an identification profile ............................................ 40

7.3.3 Defining login options ........................................................... 41

7.3.4 Password options .................................................................. 42

7.4 Measured value display ..................................................... 45

7.5 Acoustic signals .................................................................. 45

8 Titrants 46

8.1 Adding a new titrant .......................................................... 47

8.2 Editing titrant data ............................................................. 48

8.3 Monitoring the working life .............................................. 50

8.4 Dosing unit .......................................................................... 51

8.4.1 Parameters for preparing (PREP) and emptying (EMPTY) ......... 52

8.4.2 Tubing parameters ................................................................. 53

8.4.3 Shift direction of the valve disk .............................................. 56

■■■■■■■■

IV

8.5 Exchange unit ..................................................................... 57

8.5.1 Parameters for the preparation (PREP) .................................... 58

8.5.2 Tubing parameters ................................................................. 59

8.6 GLP test for exchange unit and dosing unit .................... 61

915 KF Ti-Touch

Page 7

■■■■■■■■■■■■■■■■■■■■■■

9 Reagents 66

10 Sensors 70

11 Device manager 74

Table of contents

8.7 Titer determination options and data .............................. 63

8.7.1 Titer validity ........................................................................... 63

8.7.2 Properties of the previous titer determinations ....................... 64

9.1 Editing reagent data .......................................................... 66

9.2 Reagent monitoring ........................................................... 67

10.1 Adding a new sensor ......................................................... 71

10.2 Editing the sensor data ...................................................... 71

10.3 Monitoring the working life .............................................. 72

11.1 Adding a new device .......................................................... 75

11.2 Configuring the instrument ............................................... 75

11.3 Ti-Touch ............................................................................... 76

11.3.1 E-mail .................................................................................... 77

11.3.2 PC/LIMS report ...................................................................... 78

11.3.3 Shared memory ..................................................................... 79

11.3.4 TCP/IP settings ....................................................................... 81

11.4 Metrohm control devices ................................................... 82

11.4.1 Properties – Measuring input ................................................. 83

11.4.2 Properties – MSB connector ................................................... 84

11.4.3 Properties – Peripheral devices ............................................... 85

11.5 USB Sample Processor ....................................................... 85

11.5.1 Properties – Sample Processor ............................................... 86

11.5.2 Properties – Tower ................................................................ 87

11.5.3 Properties – Swing Head ........................................................ 89

11.6 Sample racks ....................................................................... 93

11.6.1 Editing rack data .................................................................... 95

11.6.2 Rack adjustment .................................................................. 100

11.7 Printer ................................................................................ 101

11.7.1 PDF settings ......................................................................... 103

11.7.2 Network printer ................................................................... 104

11.7.3 More options ....................................................................... 105

11.8 Balance .............................................................................. 106

11.9 USB/RS-232 adapter ......................................................... 107

11.10 PC keyboard ...................................................................... 109

11.11 Barcode reader ................................................................. 110

915 KF Ti-Touch

■■■■■■■■

V

Page 8

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

12 File manager 113

12.1 Managing files .................................................................. 113

12.1.1 Copying a file ...................................................................... 115

12.1.2 Renaming a file ................................................................... 115

12.1.3 File properties ...................................................................... 116

12.2 External storage medium ................................................ 117

12.3 Creating backups / Restoring data ................................. 119

12.3.1 Restoring data ..................................................................... 119

13 GLP manager 121

13.1 Automatic system test ..................................................... 122

13.2 Test tools .......................................................................... 122

13.3 GLP tests for measurement and titration ...................... 123

13.3.1 Parameter description .......................................................... 124

13.4 System validation ............................................................. 127

13.4.1 Parameter description .......................................................... 128

13.5 System monitoring ........................................................... 131

13.5.1 Service interval .................................................................... 131

13.5.2 Backup interval .................................................................... 132

14 Common variables 133

14.1 Editing common variables ............................................... 134

14.2 Properties of common variables ..................................... 135

14.3 Monitoring validity ........................................................... 136

14.4 Assigning a result automatically to a common varia-

ble ...................................................................................... 137

15 Templates 139

15.1 Sample data ...................................................................... 139

15.1.1 Sample identification list ...................................................... 140

15.1.2 Sample assignment table ..................................................... 141

15.2 Custom result templates .................................................. 143

15.2.1 Editing result templates ....................................................... 144

15.3 Input lines ......................................................................... 147

15.3.1 Editing the input signal ........................................................ 148

■■■■■■■■

VI

15.4 Output lines ...................................................................... 149

15.4.1 Editing the output signal ...................................................... 151

15.5 Report header ................................................................... 152

16 Methods 154

16.1 Creating a new method ................................................... 154

915 KF Ti-Touch

Page 9

■■■■■■■■■■■■■■■■■■■■■■

17 Control 170

18 Favorites 174

19 Sample data 178

Table of contents

16.2 Saving a method ............................................................... 155

16.3 Loading a method ............................................................ 156

16.4 Editing a method .............................................................. 157

16.4.1 Inserting a command ........................................................... 158

16.5 Method options ................................................................ 159

16.5.1 Start options ........................................................................ 160

16.5.2 Stop options ........................................................................ 162

16.5.3 Sample data ........................................................................ 163

16.5.4 Method properties ............................................................... 167

16.5.5 Note .................................................................................... 167

16.5.6 Saving a determination automatically ................................... 167

18.1 Creating favorites ............................................................. 175

18.1.1 Editing favorites ................................................................... 175

19.1 Entering sample data in the main dialog ....................... 178

19.2 Requesting sample data at the start of the determina-

tion .................................................................................... 179

20 Sample table 181

20.1 General .............................................................................. 181

20.2 Edit the sample data ........................................................ 184

20.3 Properties .......................................................................... 186

21 Determination run 189

21.1 Carrying out a single determination ............................... 189

21.2 Performing a sample series ............................................. 190

21.3 Canceling determinations manually ............................... 191

22 Live modifications 192

22.1 Editing the sample data of the running determina-

tion .................................................................................... 192

22.2 Editing the sample table while a determination is run-

ning .................................................................................... 193

915 KF Ti-Touch

22.3 Live display ....................................................................... 194

22.4 Live parameters ................................................................ 196

■■■■■■■■

VII

Page 10

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

23 Results and more determination data 198

23.1 More determination data ................................................ 199

23.1.1 Details ................................................................................. 200

23.2 Messages ........................................................................... 202

23.3 Local common variables .................................................. 202

23.4 Determination properties ................................................ 203

23.5 Loading a determination ................................................. 204

23.5.1 Determination list ................................................................ 205

23.6 Saving a determination .................................................... 210

23.7 Curves ................................................................................ 210

23.8 Recalculation and reevaluation ....................................... 212

24 Statistics 214

24.1 Displaying details for a result .......................................... 216

24.2 Deleting statistical data ................................................... 217

24.3 Adding a determination to a determination series ....... 217

25 Result table 219

25.1 Properties .......................................................................... 220

25.2 Saving the result table ..................................................... 224

25.3 Loading the result table ................................................... 224

26 Printing 225

26.1 General report options ..................................................... 227

26.2 Settings of the individual reports ................................... 228

26.3 List of all printable reports .............................................. 229

27 Manual control 233

27.1 Opening and closing the manual control ....................... 234

27.2 Measuring ......................................................................... 235

27.2.1 Parameter description .......................................................... 236

27.3 Dosing ............................................................................... 237

27.3.1 Continuous dosing .............................................................. 239

27.3.2 Dosing fixed volumes ........................................................... 241

27.3.3 Preparing ............................................................................. 244

27.3.4 Emptying ............................................................................. 245

27.3.5 Filling .................................................................................. 245

27.3.6 Replacing reagent ................................................................ 246

VIII

■■■■■■■■

27.4 Stirring ............................................................................... 246

915 KF Ti-Touch

Page 11

■■■■■■■■■■■■■■■■■■■■■■

28 Parameters 259

Table of contents

27.5 Remote .............................................................................. 248

27.6 USB Sample Processor ..................................................... 249

27.6.1 Moving the lift ..................................................................... 251

27.6.2 Moving to a rack position .................................................... 253

27.6.3 External positions ................................................................ 254

28.1 Volumetric Karl Fischer titrations (KFT) ......................... 259

28.1.1 Start conditions ................................................................... 259

28.1.2 Control parameters .............................................................. 261

28.1.3 Titration parameters ............................................................ 264

28.1.4 Stop conditions ................................................................... 265

28.1.5 Conditioning ....................................................................... 266

28.1.6 Cell ...................................................................................... 268

28.1.7 Control device ..................................................................... 268

28.1.8 Sensor ................................................................................. 269

28.1.9 Dosing device ...................................................................... 270

28.1.10 Stirrer .................................................................................. 271

28.2 Measurements (MEAS) ..................................................... 272

28.2.1 Measuring parameters ......................................................... 272

28.2.2 Control device ..................................................................... 274

28.2.3 Sensor ................................................................................. 274

28.2.4 Stirrer .................................................................................. 276

28.3 Evaluations (EVAL) ........................................................... 277

28.3.1 Fixed endpoint evaluation (EVAL FIX-EP) .............................. 277

28.3.2 Minimum and maximum evaluation (EVAL MIN/MAX) .......... 279

28.3.3 Break point evaluation (EVAL BREAK) ................................... 280

28.3.4 Rate evaluation (EVAL RATE) ................................................ 282

28.4 Calculations ....................................................................... 283

28.4.1 Calculations (CALC) ............................................................. 283

28.4.2 Calculations (CALC LIVE) ...................................................... 291

28.4.3 Formula editor ..................................................................... 293

28.5 Reports (REPORT) ............................................................. 299

28.5.1 General report options ......................................................... 299

28.5.2 Settings of the individual reports .......................................... 300

28.5.3 List of reports ...................................................................... 301

28.6 Dosing and Liquid Handling ............................................ 304

28.6.1 Preparing an exchange or dosing unit (PREP) ........................ 304

28.6.2 Emptying a dosing unit (EMPTY) .......................................... 305

28.6.3 Dosing a specified volume (ADD) ......................................... 306

28.6.4 Liquid Handling (LQH) .......................................................... 311

28.7 Communication ................................................................ 314

28.7.1 Scanning remote lines (SCAN) .............................................. 314

28.7.2 Setting remote lines (CTRL) .................................................. 316

28.7.3 Scanning the RS-232 interface (SCAN RS) ............................. 317

28.7.4 Defining RS-232 commands (CONTROL RS) .......................... 318

915 KF Ti-Touch

■■■■■■■■

IX

Page 12

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

28.8 Automation ....................................................................... 319

28.8.1 Rotating sample rack (MOVE) .............................................. 319

28.8.2 Moving the lift (LIFT) ............................................................ 321

28.8.3 Controlling pumps (PUMP) ................................................... 322

28.8.4 Resetting the rack (RACK) .................................................... 323

28.8.5 Defining the sample variable (SAMPLE) ................................ 323

28.8.6 Creating a subsequence (SUBSEQ) ....................................... 324

28.9 Miscellaneous commands ................................................ 327

28.9.1 Controlling a stirrer (STIR) .................................................... 327

28.9.2 Pausing the method run (WAIT) ........................................... 328

28.9.3 Scan data (REQUEST) ........................................................... 329

28.9.4 Defining an acoustic signal (BEEP) ........................................ 330

28.9.5 Canceling the method run (END) ......................................... 330

29 Operation and maintenance 331

29.1 System initialization ......................................................... 331

29.2 Quality management and qualification with Metrohm 332

30 Troubleshooting 333

30.1 Editing methods ............................................................... 333

30.2 Sample table ..................................................................... 333

30.3 Results/Statistics ............................................................... 333

30.4 Printing .............................................................................. 334

30.5 Manual control ................................................................. 334

30.6 Titration stand with pump .............................................. 335

30.7 Karl Fischer titration ........................................................ 335

31 Appendix 338

31.1 Dosing unit ........................................................................ 338

31.1.1 Maximum dosing and filling rate .......................................... 338

31.1.2 Default parameters for preparing (PREP) and emptying

(EMPTY) ............................................................................... 338

31.2 Exchange unit ................................................................... 339

31.2.1 Maximum dosing and filling rate .......................................... 339

31.2.2 Default parameters for preparing (PREP) .............................. 339

31.3 Stirring rate ....................................................................... 339

31.4 Balance .............................................................................. 340

■■■■■■■■

X

31.5 Remote interface .............................................................. 341

31.5.1 Pin assignment of the remote interface ................................ 341

31.6 Result variables as parameter setting ............................ 344

31.7 Diagnosis ........................................................................... 345

31.7.1 LCD test .............................................................................. 346

915 KF Ti-Touch

Page 13

■■■■■■■■■■■■■■■■■■■■■■

32 Technical specifications 355

Table of contents

31.7.2 Formatting an external storage medium ............................... 347

31.7.3 Removing an external storage medium ................................ 347

31.7.4 Adjusting the touch screen .................................................. 347

31.7.5 Testing the touch screen ...................................................... 348

31.7.6 Software update (loading program versions and language

files) .................................................................................... 349

31.7.7 Service ................................................................................. 352

31.8 Arithmetic algorithms in the Ti-Touch ........................... 353

32.1 Touch screen ..................................................................... 355

32.2 Measuring inputs .............................................................. 356

32.2.1 Polarizer .............................................................................. 356

32.2.2 Temperature ........................................................................ 356

32.3 Internal stirrer ................................................................... 357

32.4 Pump ................................................................................. 357

32.5 Interfaces .......................................................................... 357

32.6 Power supply .................................................................... 358

32.7 Safety specifications ........................................................ 358

32.8 Electromagnetic compatibility (EMC) ............................. 358

32.9 Ambient temperature ...................................................... 359

32.10 Reference conditions ........................................................ 359

32.11 Dimensions ........................................................................ 359

33 Warranty (guarantee) 360

34 Accessories 362

Index 364

915 KF Ti-Touch

■■■■■■■■

XI

Page 14

Table of figures

Table of figures

Figure 1 Front 915 KF Ti-Touch ....................................................................... 8

Figure 2 Rear 915 KF Ti-Touch ........................................................................ 9

Figure 3 Connecting the power supply unit ................................................... 11

Figure 4 MSB connections ............................................................................ 12

Figure 5 MSB connector ............................................................................... 13

Figure 6 Connecting a polarizable electrode .................................................. 20

Figure 7 Connecting a temperature sensor .................................................... 21

Figure 8 Connecting the Ti-Touch to a network ............................................ 22

Figure 9 Reagent dosing for KFT ................................................................... 23

Figure 10 Dosing unit – port assignment ......................................................... 56

Figure 11 Exchange unit – tubing connections ................................................ 61

Figure 12 Live display "Preparing the dosing unit" ......................................... 244

Figure 13 Live display "Preparing the exchange unit" ..................................... 245

Figure 14 Evaluation of minimum and maximum ........................................... 279

Figure 15 Evaluation of a break point ............................................................ 280

Figure 16 Rotational speed depending on stirring rate .................................. 340

Figure 17 Connectors of the Remote Box ...................................................... 341

Figure 18 Pin assignment of remote socket and plug .................................... 341

■■■■■■■■■■■■■■■■■■■■■■

XII

■■■■■■■■

915 KF Ti-Touch

Page 15

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 915 KF Ti-Touch is a compact titration system for volumetric Karl

Fischer titration. This newly designed titrator combines in a single device

the touch-sensitive color monitor for convenient and efficient operation,

the titration unit, the magnetic stirrer and the integrated membrane pump

for adding and aspirating solvents. The upper side of the housing offers

space for the titrant and the titration cell. The titrator is standard-equipped for operation with an external dosing drive of the 800 Dosino type

with a dosing unit. You can however also use a 805 Dosimat with an

exchange unit. Thanks to its compact construction, you can use the

915 KF Ti-Touch in a small space as a stand-alone titrator.

You manage titrants, sensors, methods, etc. conveniently in the internal

memory of the 915 KF Ti-Touch. You can also save your files externally

through the USB connector, e.g. on a USB flash drive. On this storage

medium you can not only store your methods and determinations, but

also create a backup together with all of the data and settings of your system.

1 Introduction

The integrated Ethernet connection is available to you should you wish to

connect your 915 KF Ti-Touch to a network. The network connection

offers you the following advantages:

■ Saving data to a PC within the network

■ Printing reports on a network printer

■ Sending displayed messages as e-mails

1.1.1 Titration and measuring modes

The 915 KF Ti-Touch supports the following titration and measuring

modes.

■ KFT

Volumetric water content determination according to Karl Fischer.

Measuring modes:

– Ipol (voltametric measurement with selectable polarization cur-

rent)

– Upol (amperometric measurement with selectable polarization

voltage)

915 KF Ti-Touch

■■■■■■■■

1

Page 16

1.1 Instrument description

■ MEAS

1.1.2 Connectors

The 915 KF Ti-Touch is equipped with the following connectors:

■ Mains connection

■ Two MSB connectors (Metrohm Serial Bus)

■ USB connector

■ Sensor connectors

■ Ethernet connector

■ Two connection nipples

■■■■■■■■■■■■■■■■■■■■■■

Measuring modes:

– Ipol (voltametric measurement with selectable polarization cur-

rent)

– Upol (amperometric measurement with selectable polarization

voltage)

– T (temperature measurement)

For connecting to the mains supply with the aid of the power supply

unit provided.

For connecting dosing devices, stirrers or a Remote Box.

For connecting peripheral devices (printer, PC keyboard, etc.), a USB

Sample Processor, a USB flash drive or a USB hub.

One connection each for:

– polarizable electrodes

– temperature sensors (Pt1000 or NTC)

For connecting the Ti-Touch to a network.

For connecting tubing for aspirating solvent and extracting the contents of the titration cell.

1.1.3 Intended use

■■■■■■■■

2

The 915 KF Ti-Touch is designed for usage as a titrator in analytical laboratories. Its main application field is volumetric Karl Fischer titration.

This instrument is suitable for processing chemicals and flammable samples. The usage of the 915 KF Ti-Touch therefore requires that the user

has basic knowledge and experience in the handling of toxic and caustic

substances. Knowledge with respect to the application of the fire prevention measures prescribed for laboratories is also mandatory.

915 KF Ti-Touch

Page 17

■■■■■■■■■■■■■■■■■■■■■■

1.2 About the documentation

CAUTION

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.2.1 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

1 Introduction

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

915 KF Ti-Touch

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

■■■■■■■■

3

Page 18

1.2 About the documentation

■■■■■■■■■■■■■■■■■■■■■■

NOTE

This symbol highlights additional information and

tips.

■■■■■■■■

4

915 KF Ti-Touch

Page 19

■■■■■■■■■■■■■■■■■■■■■■

2 Safety instructions

2.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

2.2 Electrical safety

2 Safety instructions

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

WARNING

915 KF Ti-Touch

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

■■■■■■■■

5

Page 20

2.3 Tubing and capillary connections

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

2.3 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

■■■■■■■■■■■■■■■■■■■■■■

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

2.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

■■■■■■■■

6

915 KF Ti-Touch

Page 21

■■■■■■■■■■■■■■■■■■■■■■

2.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

2 Safety instructions

915 KF Ti-Touch

■■■■■■■■

7

Page 22

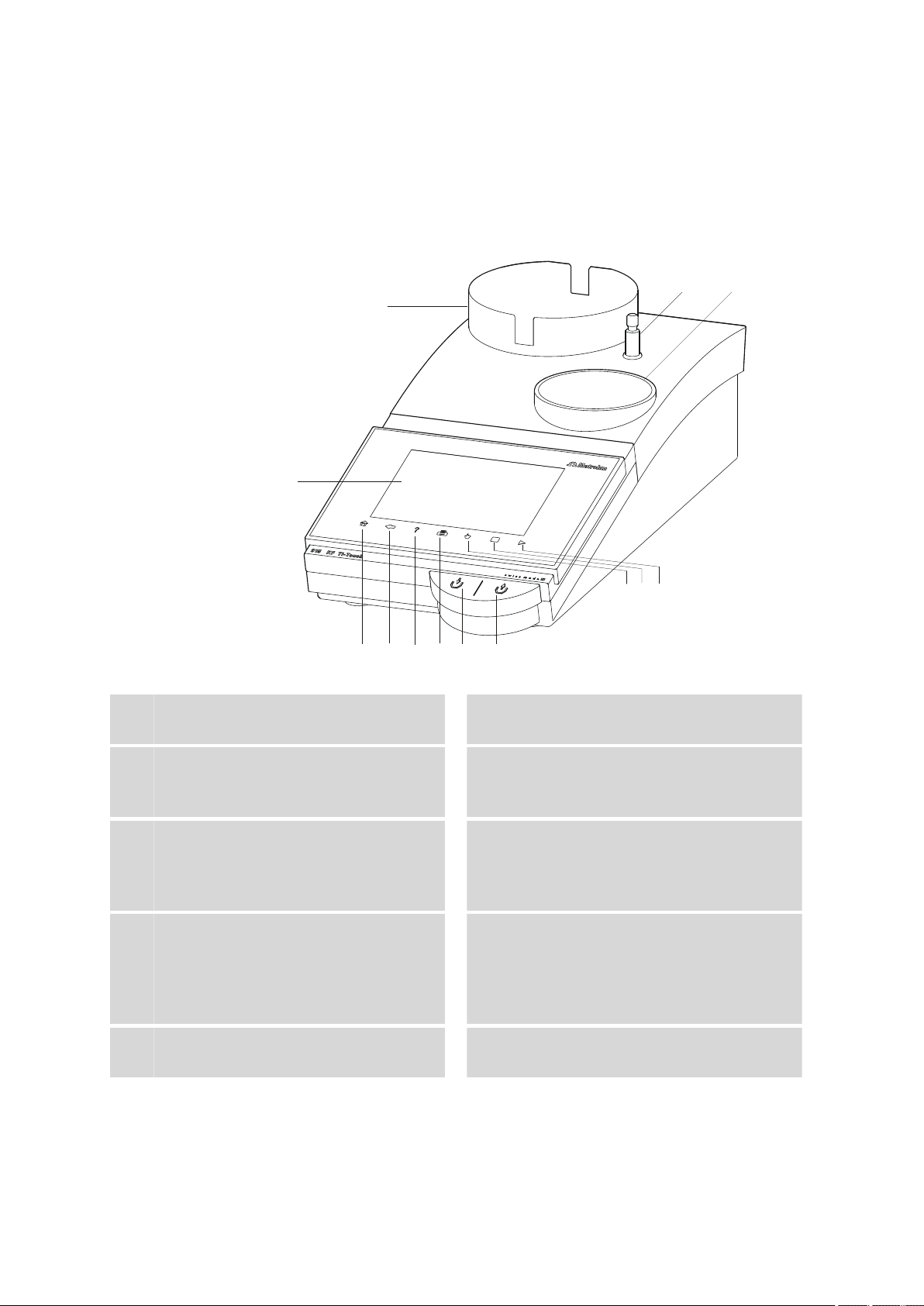

3.1 Front of the instrument

12

13

11

2

3

4

5

1

6

7

8 9 10

3 Overview of the instrument

3.1 Front of the instrument

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Front 915 KF Ti-Touch

Display

1

Touch-sensitive screen.

Fixed key [Back]

3

Saves the entry and opens the next-higher

dialog page.

Fixed key [Print]

5

Opens the print dialog.

Key

7

Pressing the key aspirates air out of the aspiration bottle. The vacuum in the aspiration

bottle suctions the liquid out of the KF titration cell and into the aspiration bottle.

Fixed key [STOP]

9

Cancels the running determination.

Fixed key [Home]

2

Opens the main dialog.

Fixed key [Help]

4

Opens the online help for the dialog displayed.

Key

6

Pressing the key pumps air into the solvent

bottle. The overpressure in the solvent bottle

pushes solvent into the KF titration cell.

Fixed key [Manual]

8

Opens the manual control.

Fixed key [START]

10

Starts a determination.

915 KF Ti-Touch

■■■■■■■■

8

Page 23

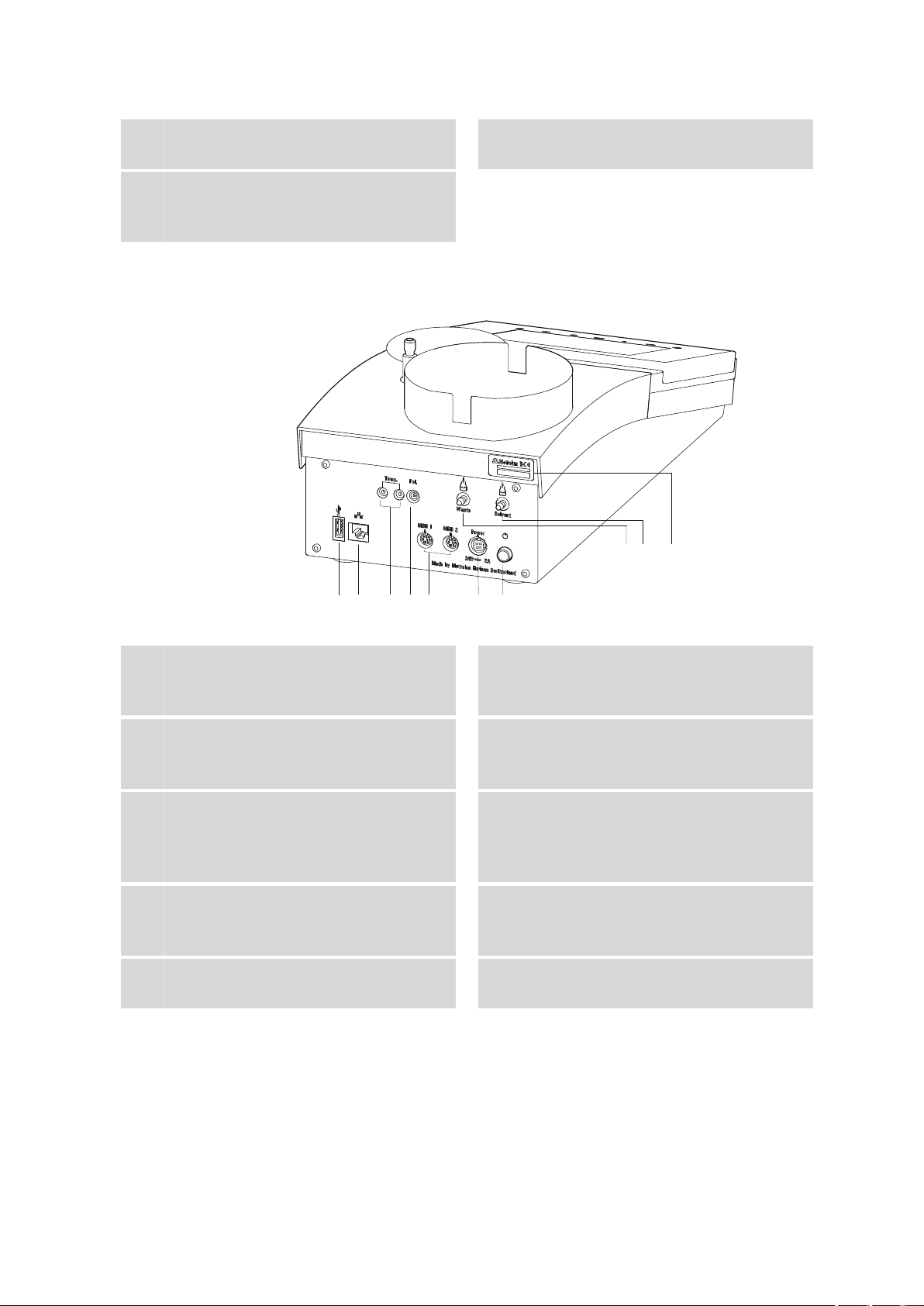

■■■■■■■■■■■■■■■■■■■■■■

8

9

3

5

6

10

3 Overview of the instrument

Bottle holder

11

With holding clips, for reagent bottle.

Titration stand

13

With built-in magnetic stirrer and membrane

pump for placement of the titration cell.

3.2 Rear of the instrument

Support rod (lower part)

12

For mounting the support rod (upper part).

Figure 2 Rear 915 KF Ti-Touch

USB connector (type A)

1

For connecting a printer, USB flash drive,

USB hub, USB Sample Processor etc.

Temperature sensor connector (Temp.)

3

For connecting temperature sensors (Pt1000

or NTC). Two B sockets, 2 mm.

MSB connector (MSB 1 and MSB 2)

5

Metrohm Serial Bus. For connecting external

dosing devices, stirrers or a Remote Box.

Mini DIN, 8-pin.

Mains switch

7

Switch the instrument on/off.

Connection nipple for PVC tubing

9

For aspirating solvent.

Ethernet connector (RJ-45)

2

For connecting to a network.

Electrode connector (Pol.)

4

For connecting polarizable electrodes, e.g.

double Pt electrodes. Socket F.

Mains connection socket (Power)

6

For connecting the external power supply

unit.

Connection nipple for PVC tubing

8

For aspiration of the contents of the titration

cell.

Type plate

10

Contains the serial number.

915 KF Ti-Touch

■■■■■■■■

9

Page 24

4.1 Setting up the instrument

4 Installation

4.1 Setting up the instrument

4.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

4.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

4.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

■■■■■■■■■■■■■■■■■■■■■■

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

4.2 Connecting the power supply unit

The 915 KF Ti-Touch has an external power supply unit for a 24 V power

supply (DC). This is connected to the mains connection of the Ti-Touch.

WARNING

An incorrect mains voltage can damage the device.

Operate the device only with the mains voltage specified for it. Use the

supplied power supply unit exclusively.

■■■■■■■■

10

915 KF Ti-Touch

Page 25

■■■■■■■■■■■■■■■■■■■■■■

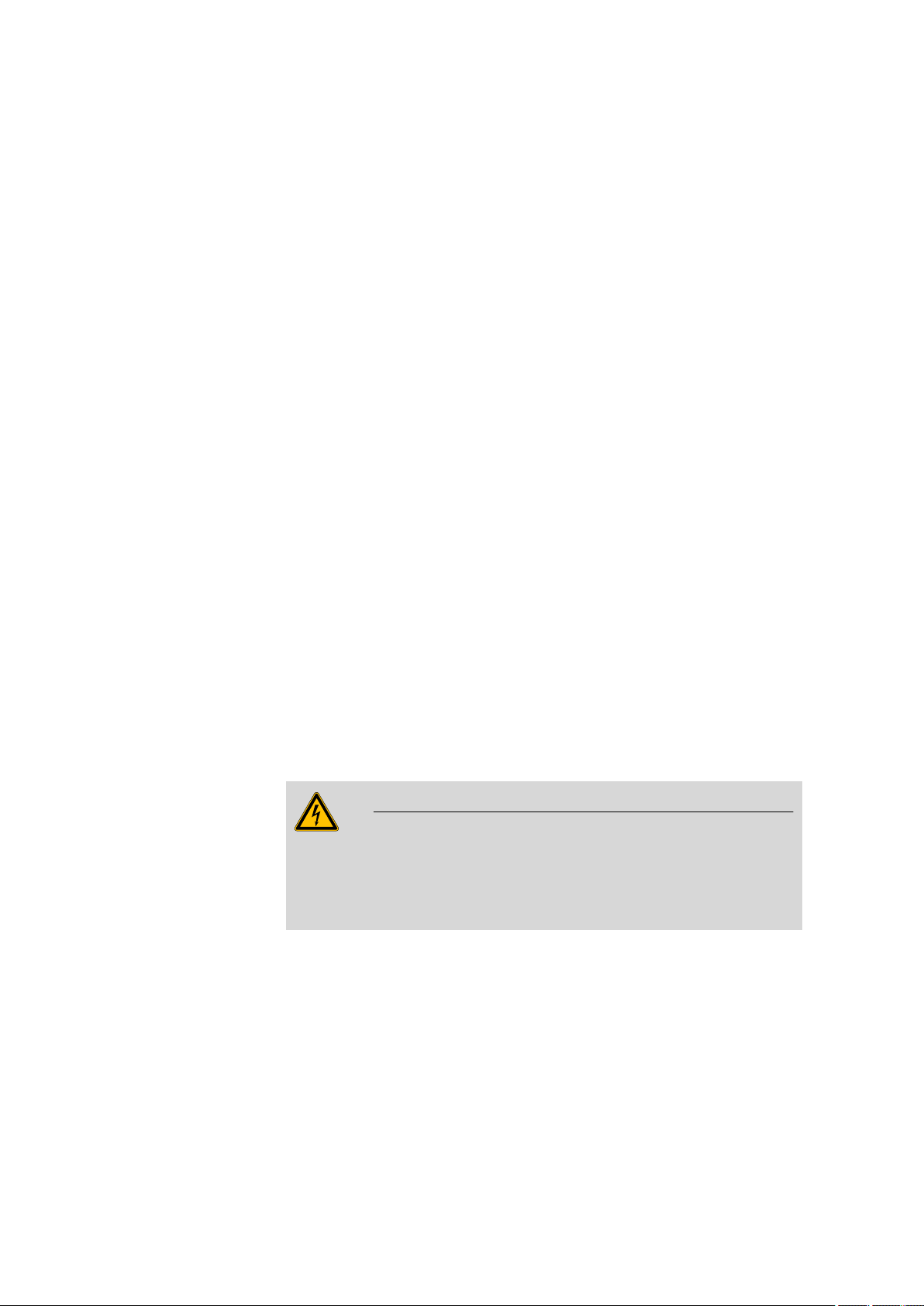

Figure 3 Connecting the power supply unit

Proceed as follows:

Connect the plug of the external power supply unit with the mains

1

connection of the Ti-Touch (see Figure 3, page 11).

4 Installation

NOTE

The plug of the power supply unit is protected against accidental

disconnection of the cable by means of a pull-out protection feature. If you wish to pull out the plug, you will first need to pull

back the outer plug sleeve marked with arrows.

Connect the mains cable with the external power supply unit of the

2

Ti-Touch and with the mains supply.

CAUTION

Switch off the Ti-Touch correctly by pressing the mains switch before

you disconnect the electricity supply. If this is not done, then there is a

danger of data loss.

915 KF Ti-Touch

■■■■■■■■

11

Page 26

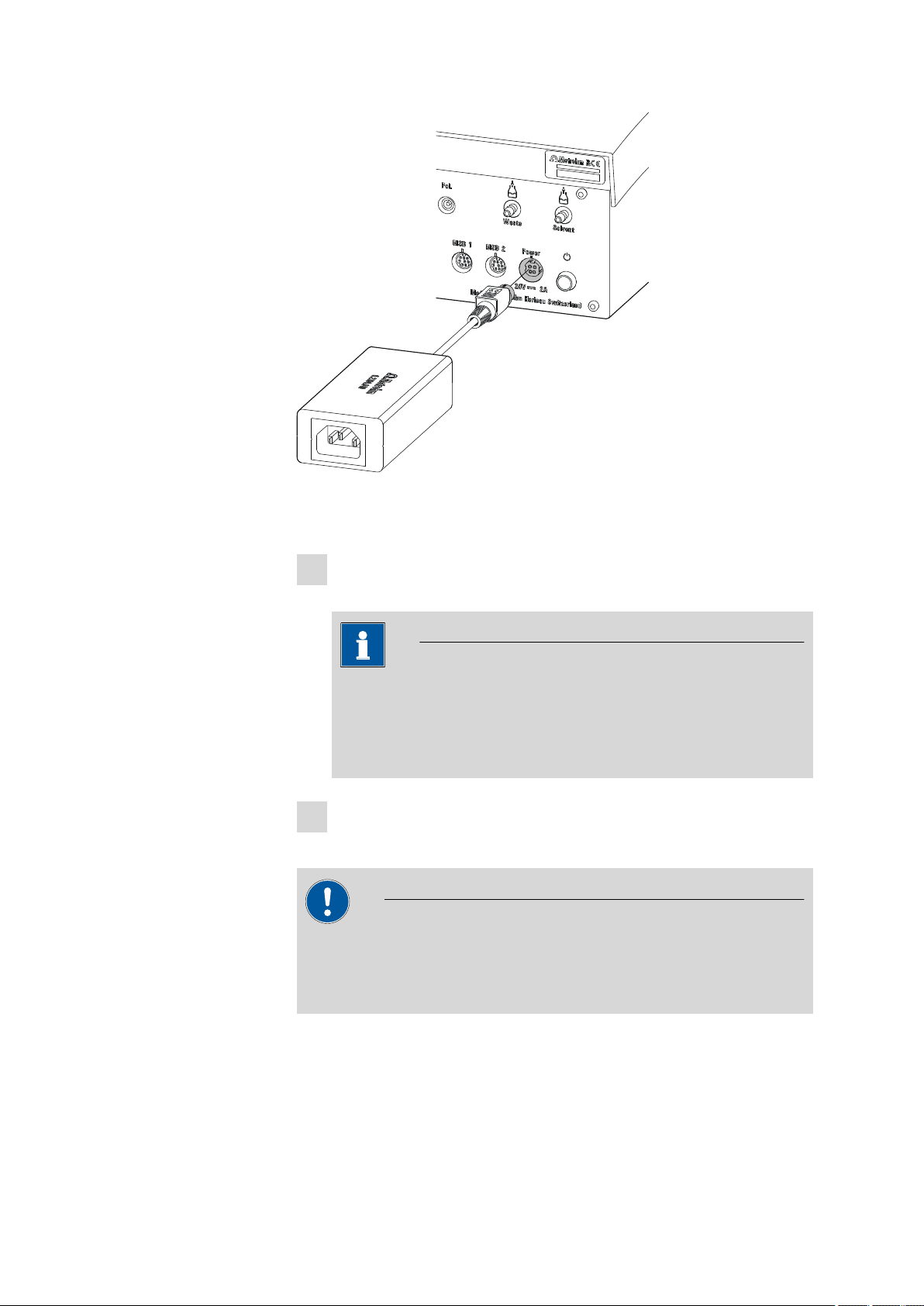

4.3 Connecting MSB devices

MSB

Stirrer / Ti Stand

Dosimat / Dosino

Dosimat

Remote Box

Dosino

Ti Stand / Stirrer

4.3 Connecting MSB devices

In order to connect MSB devices, e.g. dosing device or Remote-Box, the

Ti-Touch has two connectors at what is referred to as the Metrohm Serial

Bus (MSB). Various peripheral devices can be connected in sequence

(Daisy Chain) at a single MSB connector (8-pin Mini DIN socket) and be

controlled simultaneously by the Ti-Touch. In addition to the connection

cable, stirrers and the Remote Box are each equipped with their own MSB

socket for this purpose.

The following figure provides an overview of the devices that can be connected to an MSB socket, along with a number of different cabling variations.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

12

Figure 4

MSB connections

NOTE

When connecting MSB devices together, the following must be

observed:

■ Only one device of the same type can be used at a single MSB con-

nector at one time.

■ When making the connection, take care to ensure that the flat part

of the MSB plug marked with arrows is pointing in the direction of

the marking on the MSB connector (see Figure 5, page 13).

915 KF Ti-Touch

Page 27

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

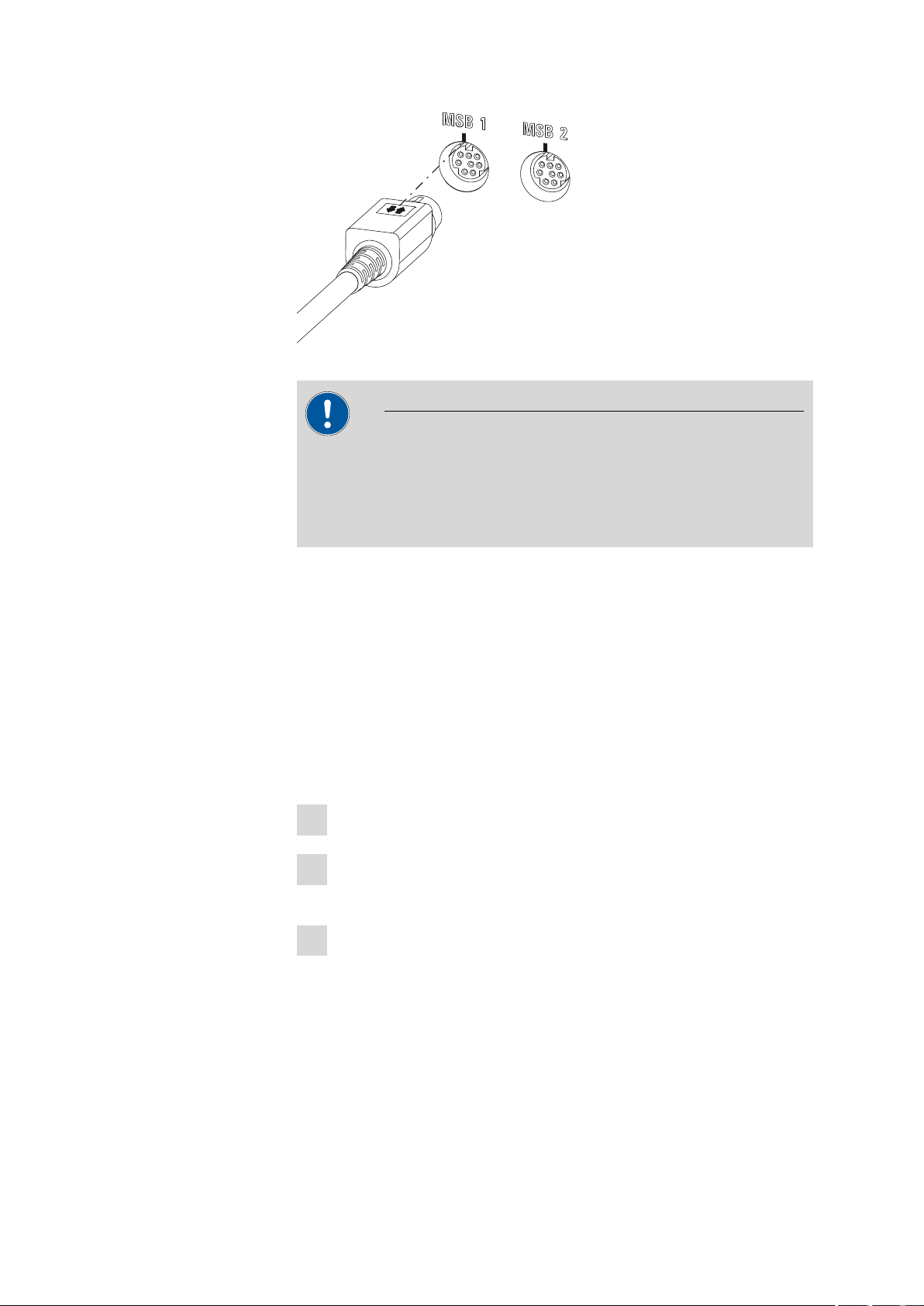

Figure 5 MSB connector

CAUTION

Switch off the Ti-Touch before you plug in MSB devices. When it is

switched on, the Ti-Touch automatically recognizes which device is connected to which MSB connector. The connected MSB devices are

entered automatically in the device manager.

MSB connections can be extended with the 6.2151.010 cable. The maximum connection length permitted is 6 m.

4.3.1 Connecting dosing devices

You can connect two dosing devices to the Ti-Touch.

The types of dosing devices that are supported are:

■ 800 Dosino

■ 805 Dosimat

Proceed as follows:

Switch off the Ti-Touch.

1

Connect the dosing device connection cable to an MSB connector

2

(2-5) on the rear side of the Ti-Touch.

Switch on the Ti-Touch.

3

915 KF Ti-Touch

■■■■■■■■

13

Page 28

4.3 Connecting MSB devices

■■■■■■■■■■■■■■■■■■■■■■

4.3.2 Connecting an additional stirrer or titration stand

In addition to the built-in magnetic stirrer, you can also use the magnetic

stirrers 801 Stirrer, 803 Ti Stand or the 804 Ti Stand with the propeller stirrer 802 Stirrer.

Proceed as follows:

Switch off the Ti-Touch.

1

Connect the connection cable of the magnetic stirrer or of the titra-

2

tion stand to MSB 2 (2-5) on the rear of the Ti-Touch.

Connect the propeller stirrer, if desired, to the stirrer connector of

3

the titration stand.

Switch on the Ti-Touch.

4

4.3.3 Connecting a Remote Box

Instruments that are controlled via remote lines and/or which send control

signals via remote lines can be connected using the 6.2148.010 Remote

Box. In addition to Metrohm, other instrument manufacturers also use

similar connectors that make it possible to connect different instruments

together. These interfaces are also frequently given the designations "TTL

Logic", "I/O Control" or "Relay Control" and generally have a signal level

of 5 volts.

Control signals are understood to be electrical line statuses or brief

(> 200 ms) electrical pulses which display the operational state of an

instrument or which trigger or report an event. Sequences on a variety of

instruments can thus be coordinated in a single complex automation system. No exchange of data is possible, however.

Proceed as follows:

Switch off the Ti-Touch.

1

Connect the Remote Box connection cable to an MSB connector

2

(2-5) on the rear side of the Ti-Touch.

Switch on the Ti-Touch.

3

■■■■■■■■

14

You can connect an 885 Compact Oven SC. The Remote Box also has an

MSB socket at which a further MSB device, e.g. a dosing device, can be

connected.

915 KF Ti-Touch

Page 29

■■■■■■■■■■■■■■■■■■■■■■

You will find precise information concerning the pin assignment of the

interface on the Remote Box in Appendix (see Chapter 31.5, page 341).

4.4 Connecting USB devices

4.4.1 General

The 915 KF Ti-Touch has a USB connector (Type A socket) for peripheral

devices with USB interface and for USB Sample Processors. If you wish to

connect more than one device to the USB, you can also use an additional

commercially available USB hub.

NOTE

We recommend that the Ti-Touch be switched off while you set up or

disconnect connections between the devices.

4.4.2 Connecting a USB hub

Use a USB hub with its own power supply.

4 Installation

Connect the USB hub as follows:

With the help of the 6.2151.030 cable (length 0.6 m) or the

1

6.2151.020 cable (length 1.8 m), connect the USB connector of the

Ti-Touch (Type A) with the USB connector of the hub (Type B, see

manual for the USB hub).

The USB hub is recognized automatically.

4.4.3 Connecting a printer

Printers that are connected to the 915 KF Ti-Touch must meet the following requirements:

■ Printer languages: HP-PCL, HP-PCL-GUI, Canon BJL Commands or

Epson ESC P/2

■ Paper format: A4 or Letter, single-sheet feed.

Connect the printer as follows:

With the aid of the 6.2151.020 cable, connect the USB connector of

1

the Ti-Touch (type A) with the USB connector of the printer (type B,

see manual for the printer).

Configure the printer in the device manager of the Ti-Touch (see

2

Chapter 11.7, page 101).

915 KF Ti-Touch

■■■■■■■■

15

Page 30

4.4 Connecting USB devices

4.4.4 Connecting a balance

If you wish to connect a balance to the Ti-Touch, you will require a USB/

RS-232 adapter (6.2148.050).

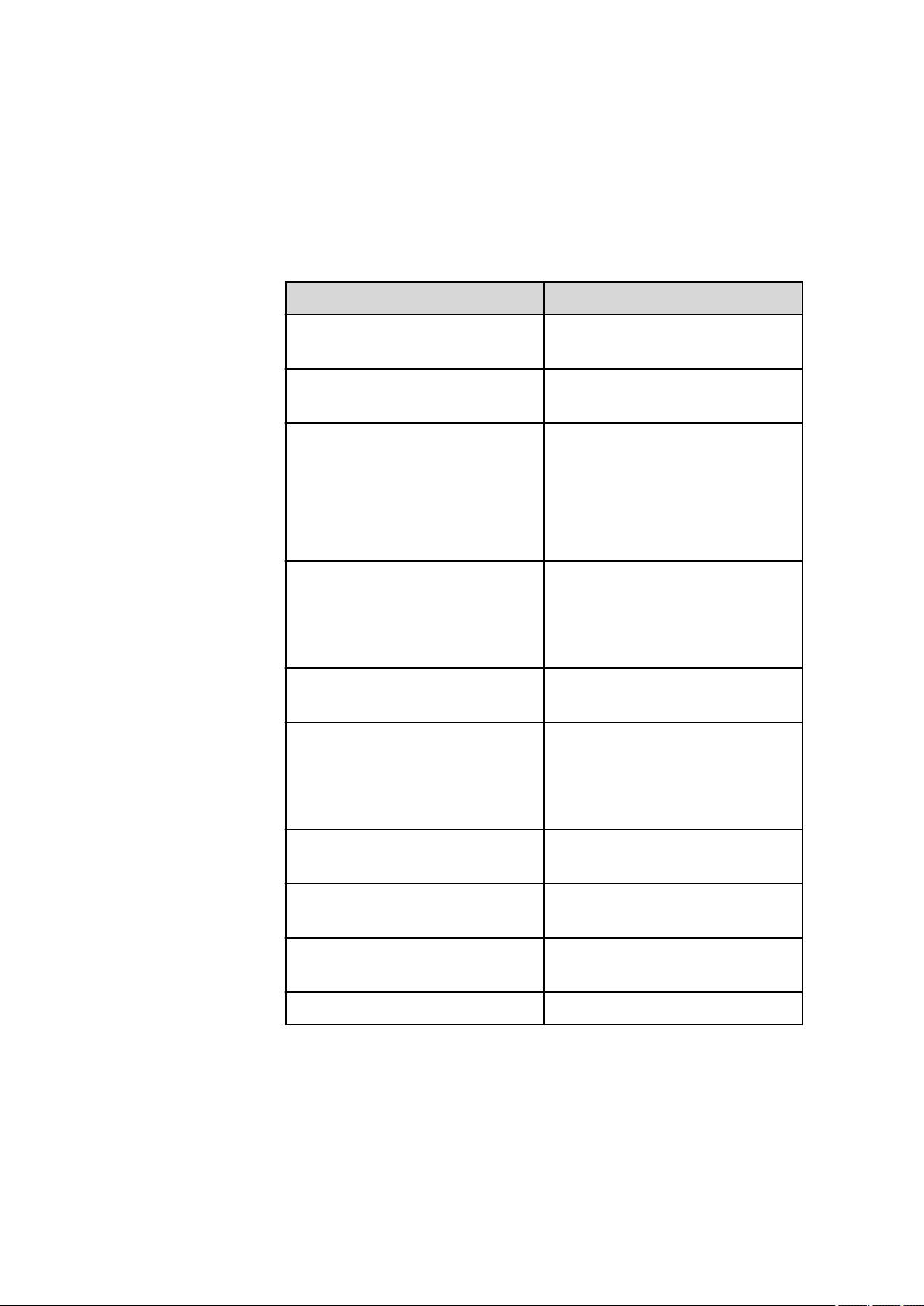

The following table offers an overview of the balances that you can use

together with the Ti-Touch and of which cable you will need for connection to the RS-232 interface:

Balance Cable

■■■■■■■■■■■■■■■■■■■■■■

AND ER, FR, FX with RS-232 inter-

6.2125.020 + 6.2125.010

face (OP-03)

Mettler AB, AG, PR (LC-RS9) In the scope of delivery for the

balance

Mettler AM, PM, PE with interface

option 016

or

Mettler AJ, PJ with interface

option 018

6.2146.020 + 6.2125.010

also from Mettler: ME 47473

adapter and either ME 42500

hand switch or ME 46278 foot

switch

Mettler AT 6.2146.020 + 6.2125.010

also from Mettler: ME 42500

hand switch or ME 46278 foot

switch

Mettler AX, MX, UMX, PG, AB-S,

6.2134.120

PB-S, XP, XS

Mettler AE with interface option

011 or 012

6.2125.020 + 6.2125.010

also from Mettler: ME 42500

hand switch or ME 46278 foot

switch

■■■■■■■■

16

Ohaus Voyager, Explorer, Analyti-

Cable AS017-09 from Ohaus

cal Plus

Precisa balances with RS-232-C

6.2125.080 + 6.2125.010

interface

Sartorius MP8, MC, LA, Genius,

6.2134.060

Cubis

Shimadzu BX, BW 6.2125.080 + 6.2125.010

915 KF Ti-Touch

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Connect the balance as follows:

Connect the USB plug of the USB/RS-232 adapter with the USB con-

1

nector of the Ti-Touch (Type A).

The USB/RS-232 adapter will be recognized automatically and

entered in the device manager of the Ti-Touch.

Connect the RS-232 interface of the USB/RS-232 adapter with the

2

RS-232 interface of the balance (see table for cable).

Switch on the balance.

3

If necessary, switch on the RS-232 interface of the balance.

4

Configure the RS-232 interface of the USB/RS-232 adapter in the

5

device manager of the Ti-Touch (see Chapter 11.9, page 107).

Enter and configure the balance in the device manager of the

6

Ti-Touch (see Chapter 11.8, page 106).

Make sure that the parameters of the USB/RS-232 adapter config-

7

ured in the device manager match those of the balance.

4 Installation

4.4.5 Connecting a PC keyboard

The PC keyboard is used as an aid for text and numerical input.

Connect the PC keyboard as follows:

Connect the USB plug of the keyboard with the USB connector of

1

the Ti-Touch (Type A).

Enter and configure the keyboard in the device manager of the

2

Ti-Touch (see Chapter 11.10, page 109).

4.4.6 Connecting a barcode reader

The barcode reader is used as an aid for text and numerical input. You can

connect a barcode reader with USB interface.

Connect the barcode reader as follows:

Connect the USB plug of the barcode reader with the USB connector

1

of the Ti-Touch (Type A).

915 KF Ti-Touch

■■■■■■■■

17

Page 32

4.4 Connecting USB devices

■■■■■■■■■■■■■■■■■■■■■■

Enter and configure the barcode reader in the device manager of the

2

(see Chapter 11.11, page 110).

Settings on the barcode reader:

Program the barcode reader as follows (also see manual for the barcode

reader):

Switch the barcode reader to programming mode.

1

Specify the desired layout for the keyboard (USA, Germany, France,

2

Spain, German-speaking Switzerland).

This setting must match the setting in the device manager.

Make sure that the barcode reader is set in such a way that Ctrl char-

3

acters (ASCII 00 to 31) can be sent.

Program the barcode reader in such a way that the ASCII character

4

02 (STX or Ctrl B) is sent as the first character. This first character is

normally referred to as the "Preamble" or "Prefix Code".

Program the barcode reader in such a way that the ASCII character

5

04 (EOT or Ctrl D) is sent as the last character. This last character is

normally referred to as the "Postamble", "Record Suffix" or "Postfix

Code".

Exit the programming mode.

6

4.4.7 Connecting a Sample Processor

If you wish to integrate your Ti-Touch in an automation system, then you

can connect the following Sample Processors to the USB connector:

■ 814 USB Sample Processor

■ 815 Robotic USB Sample Processor XL

The 6.2151.000 controller cable is required for connecting a USB Sample

Processor.

Connect the USB Sample Processor as follows:

Connect the USB Sample Processor to the mains supply.

1

Connect the USB Sample Processor to the Ti-Touch with the control-

2

ler cable.

■■■■■■■■

18

915 KF Ti-Touch

Page 33

■■■■■■■■■■■■■■■■■■■■■■

The USB Sample Processor will be recognized automatically and

entered in the device manager of the Ti-Touch.

NOTE

The plug on the controller cable is protected against accidental

disconnection by means of a pull-out protection feature. If you

wish to pull out the plug, you will first need to pull back the outer

plug sleeve marked with arrows.

Configure the USB Sample Processor in the device manager (see

3

Chapter 11.11, page 110).

4.5 Setting up the titration vessel

The tutorial for the 915 KF Ti-Touch includes a detailed description of how

to set up the Karl Fischer titration cell and what needs to be taken into

account while doing so.

4 Installation

4.6 Connecting sensors

4.6.1 General

The measuring interface includes one measuring input (Pol.) for a polarizable electrode and one measuring input (Temp.) for a temperature sensor

(Pt1000 or NTC).

4.6.2 Connecting a polarizable electrode

Connect the polarizable electrode as follows:

Plug the electrode plug into the Pol. socket of the Ti-Touch.

1

915 KF Ti-Touch

■■■■■■■■

19

Page 34

4.6 Connecting sensors

■■■■■■■■■■■■■■■■■■■■■■

Figure 6 Connecting a polarizable electrode

NOTE

The electrode cable is protected against accidental disconnection

of the cable by means of a pull-out protection. If you wish to

remove the plug, you will first need to pull back the outer plug

sleeve.

4.6.3 Connecting a temperature sensor

A temperature sensor of the Pt1000 or NTC type can be connected to the

Temp. connector.

Connect the temperature sensor as follows:

Plug the temperature sensor plugs into the Temp. sockets of the

1

Ti-Touch.

■■■■■■■■

20

915 KF Ti-Touch

Page 35

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

Figure 7 Connecting a temperature sensor

NOTE

The red plug must always be plugged into the red socket for the

purpose of shielding against disruptions.

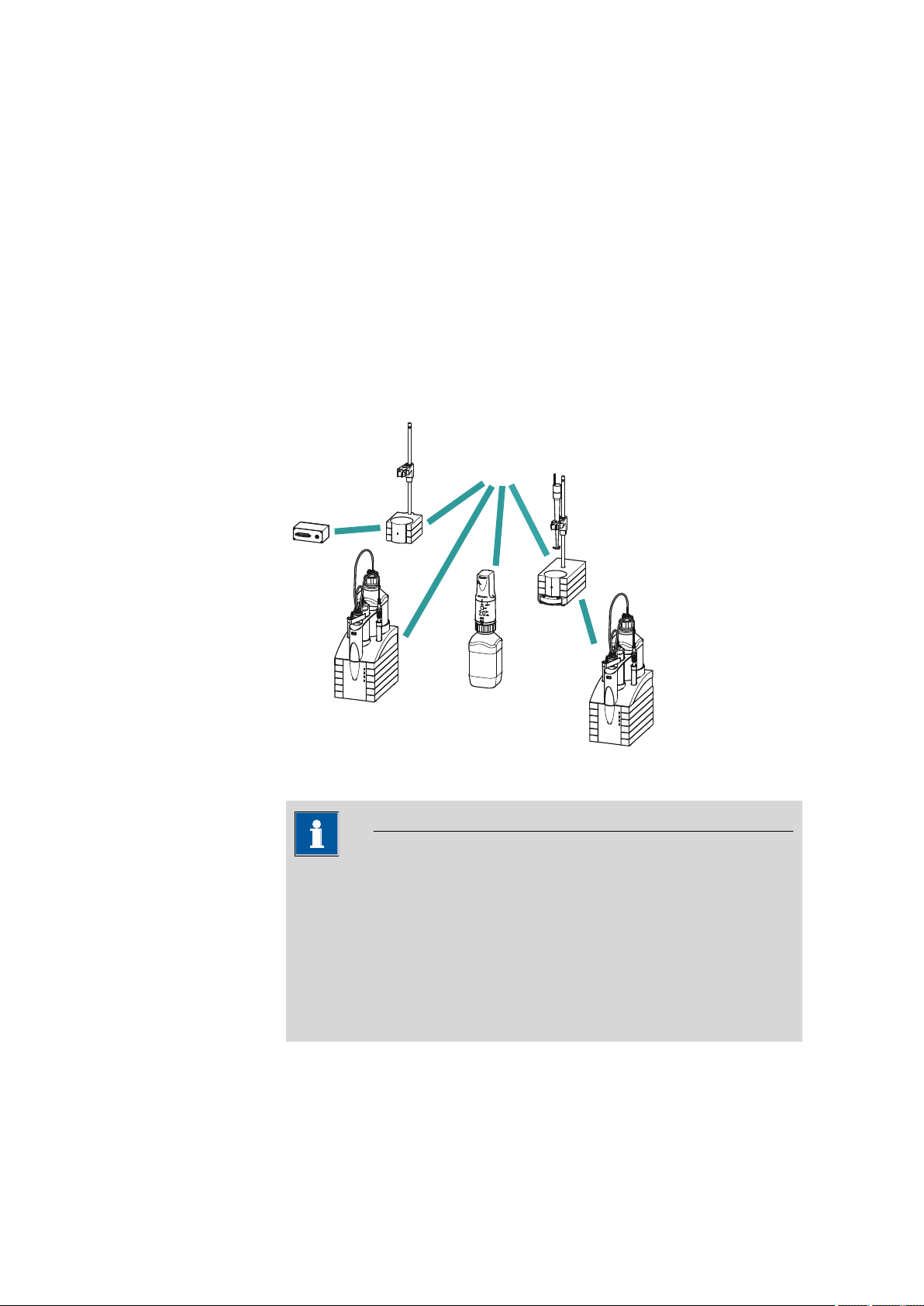

4.7 Connecting the Ti-Touch to a network

The 915 KF Ti-Touch has a network connection (Ethernet). This can be

used to integrate your Ti-Touch in your network. You can, for example,

store data on a PC within the network or print reports on a network

printer. In Chapter 11, page 74, you will find information as to which

settings are necessary for the network connection.

915 KF Ti-Touch

■■■■■■■■

21

Page 36

4.7 Connecting the Ti-Touch to a network

Figure 8 Connecting the Ti-Touch to a network

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

22

915 KF Ti-Touch

Page 37

■■■■■■■■■■■■■■■■■■■■■■

EP

KFT Ipol

KFT Upol

EP

V/mL

Continuous

dosing

Initial

dosing

V/mL

V/mL

U/mV

t/s

I/µA

Control range

Control range

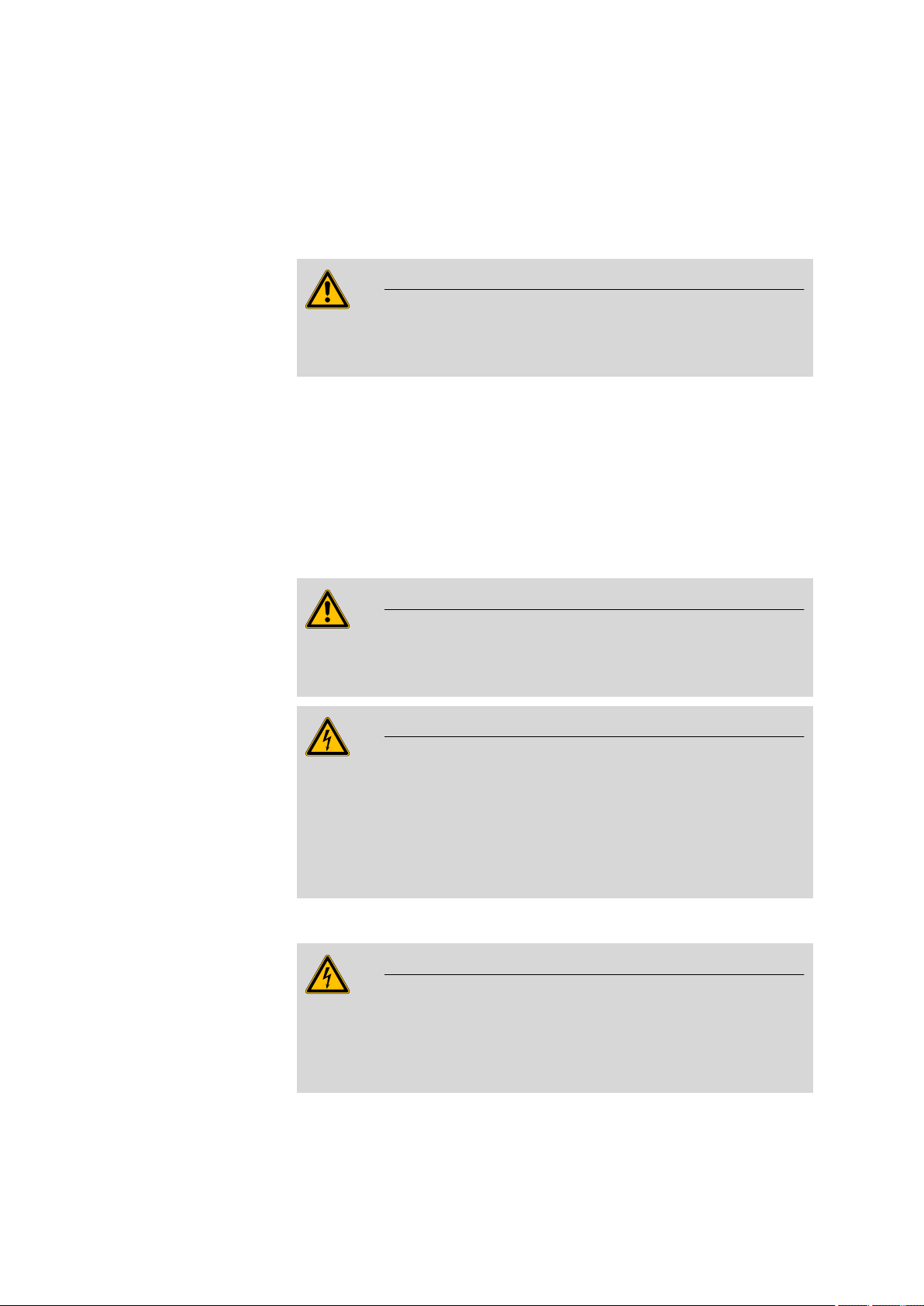

5 Titrations

5 Titrations

5.1 Water determination according to Karl Fischer (KFT)

Karl Fischer Titration is a method for volumetric water determination. Conditioning is carried out automatically both before and after the actual titration. The reagent dosing is controlled in such a way that a predefined

endpoint is reached as quickly and as accurately as possible. The volume

steps and the rate of reagent dosing are regulated by the difference

between the current measured value and the predefined endpoint. This

means that titration is performed more slowly in the control range and

that smaller volumes are added. The titration is stopped at the endpoint

either drift-controlled or after a waiting time. The volume dosed until the

endpoint is used to calculate the water content of the sample.

915 KF Ti-Touch

Figure 9

Reagent dosing for KFT

■■■■■■■■

23

Page 38

6.1 Switching the instrument on and off

6 Operation

6.1 Switching the instrument on and off

Switching on the instrument

CAUTION

Peripheral devices (e.g. printers) must be switched on before you switch

on the 915 KF Ti-Touch.

Proceed as follows:

■ Press the mains switch on the left-hand side of the rear panel of

1

the 915 KF Ti-Touch.

The 915 KF Ti-Touch is initialized. A system test is performed. This

process takes some time.

■ If a buret unit is attached, then a request appears to carry out the

Prepare function:

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

24

All tubings and the cylinder are rinsed with the

Prepare function.

The preparing of the buret unit is described in chapter 27.3.3,

page 244.

■ Confirm the message with [OK].

The main dialog is displayed:

915 KF Ti-Touch

Page 39

■■■■■■■■■■■■■■■■■■■■■■

6 Operation

Switching off the instrument

CAUTION

The 915 KF Ti-Touch must be switched off by pressing the mains switch

on the rear of the instrument before the electricity supply is interrupted.

If this is not done, then there is a danger of data loss.

Proceed as follows:

■ Press the mains switch on the left-hand side of the rear panel of

1

the 915 KF Ti-Touch.

The current data is saved and the system is shut down. This process

takes just a short time. At the same time, all other devices connected

to the 915 KF Ti-Touch via a USB cable are also being switched off.

915 KF Ti-Touch

■■■■■■■■

25

Page 40

6.2 Fundamentals of operation

6.2 Fundamentals of operation

6.2.1 Touch-sensitive screen

The entire Ti-Touch user interface is touch-sensitive. Simply touch a few of

the buttons on the interface to learn how a touch-sensitive screen reacts.

You can always return to the main dialog by touching [ ].

In order to activate an element on the Ti-Touch user interface, just touch

the screen with your fingertip, finger nail, the eraser of a pencil or a stylus

(special tool for operating instruments with touch-sensitive screens).

CAUTION

Never touch the touch screen with a pointed or sharp object such as a

ballpoint pen.

In the default setting, the software is configured in such a way that an

acoustic signal will be generated every time an active control is touched.

This setting can be deactivated in the system settings (see Chapter 7.5,

page 45).

■■■■■■■■■■■■■■■■■■■■■■

6.2.2 Display elements and controls

The following display elements and controls are available:

Table 1

Fixed keys which are always available

[Home] always opens the main dialog.

■■■■■■■■

26

915 KF Ti-Touch

Page 41

■■■■■■■■■■■■■■■■■■■■■■

6 Operation

[Back] saves the entry and opens the next-higher dialog

page.

[Help] opens the online help feature for the dialog displayed.

[Print] opens the printing dialog.

[Manual] opens the manual control.

[Stop] cancels the ongoing determination.

[Start] starts a determination.

The method loaded, the time and the system status are displayed in the

main dialog in the Title bar.

In the other dialogs, the title bar shows the headings of the next upper

level and of the displayed dialog. This is an aid for orientation during navigation through the user dialog.

Table 2

6.2.3 Status display

The current status of the system is displayed in the upper right-hand corner of the title bar:

Screen elements

Buttons open a new dialog when they are tapped.

Inactive buttons with gray lettering indicate

that the respective function is not available at the

moment.

Input fields open an input dialog when tapped

with the finger.

Tapping on the selection symbol opens a selection list.

A check box can also be activated or deactivated by tapping on it.

915 KF Ti-Touch

The instrument is in normal status.

■■■■■■■■

27

Page 42

6.2 Fundamentals of operation

■■■■■■■■■■■■■■■■■■■■■■

The working medium is being conditioned.

Conditioning has been paused.

The working medium is conditioned.

A method has been started.

A method has been paused.

An action has been started in manual control.

6.2.4 Entering text and numbers

In the editing dialog for text or numerical input, enter the individual characters by tapping in the input field. The following functions are available:

Text editor

■■■■■■■■

28

915 KF Ti-Touch

Page 43

■■■■■■■■■■■■■■■■■■■■■■

6 Operation

Editing function Description

[OK] The modification is applied and the editing dialog

is exited.

[Cancel] The editing dialog is exited without applying the

modification.

[Delete entry] The content of the input field is deleted com-

pletely.

[⌫] The character in front of the cursor is deleted.

[⇦] The cursor within the input field is shifted to the

left by one character.

[⇨] The cursor within the input field is shifted to the

right by one character.

[a…z] The lower-case letters are displayed. The label

changes to [A…Z]. The upper case letters are

displayed by tapping again.

[0…9] Numbers and mathematical characters are dis-

played.

[Special characters]

Special characters are displayed. You can use the

button [More] to navigate through all available

characters.

Number editor

915 KF Ti-Touch

Editing function

Description

[OK] The modification is applied and the editing dialog

is exited.

■■■■■■■■

29

Page 44

6.2 Fundamentals of operation

■■■■■■■■■■■■■■■■■■■■■■

Editing function Description

[Cancel] The editing dialog is exited without applying the

modification.

[Delete entry] The content of the input field is deleted com-

pletely.

[off] If not only numbers but also special values (e.g.

off) can be entered, then the corresponding but-

tons will be shown to the right of the numerical

keypad.

[R1] For many parameters, a result previously defined

in the method can also be entered in place of a

number (see Chapter 31.6, page 344). You can

select the result variable by touching [R1].

NOTE

A commercially available USB keyboard can be connected to make it

easier to enter text and numbers. The key assignment is described in

Chapter 11.10, page 109.

■■■■■■■■

30

915 KF Ti-Touch

Page 45

■■■■■■■■■■■■■■■■■■■■■■

7 System settings

Main dialog: System ▶ System settings

This chapter describes the various system settings and configurations.

7 System settings

■ Selecting the dialog language (see Chapter 7.1.1, page 31).

■ Setting the date and time (see Chapter 7.1.2, page 32).

■ Defining system-specific dialog options (see Chapter 7.2, page 33).

■ User administration (see Chapter 7.3, page 37).

■ Defining settings for the measured value display (see Chapter 7.4,

page 45).

■ Configuring settings for acoustic signals (see Chapter 7.5, page 45).

7.1 General system settings

7.1.1 Selecting the dialog language

The user interface is available in several languages. In addition to the two

default dialog languages English and German, additional languages can

be selected.

Proceed as follows to select the dialog language:

1

Open the system settings

■ In the main dialog, tap on [System].

■ Tap on [System settings].

915 KF Ti-Touch

The dialog System / System settings is displayed.

■■■■■■■■

31

Page 46

7.1 General system settings

2

Select the dialog language

■ Tap on the list box Dialog language and select the desired lan-

guage.

3

Save the settings

Tap on the fixed keys [ ] or [ ].

The main dialog is displayed in the respective dialog language.

7.1.2 Setting the date, time and local time

The Ti-Touch displays the date and time in accordance with ISO standard

8601.

Proceed as follows to set the date and time:

1

Open the system settings

■ In the main dialog, tap on [System].

■ Tap on [System settings].

■■■■■■■■■■■■■■■■■■■■■■

The dialog System / System settings is displayed.

2

Enter the date

■ Tap on the input field for the date.

The editor opens.

■ Enter the current date in the format YYYY-MM-DD and confirm

with [OK].

The arrow keys [⇦] and [⇨] are used to move the cursor to the

left or to the right by one character.

The input is saved and the editor is closed.

3

Enter the time

■ Tap on the input field for the time.

The editor opens.

■ Enter the current time in the format hh:mm:ss (24-hour format)

and confirm with [OK].

The arrow keys [⇦] and [⇨] are used to move the cursor to the

left or to the right by one character.

The input is saved and the editor is closed.

■■■■■■■■

32

915 KF Ti-Touch

Page 47

■■■■■■■■■■■■■■■■■■■■■■

4

Enter the local time

■ Tap on the list box Local time - UTC and select the difference

from the UTC (Coordinated Universal Time).

The selection off means that the time is saved with no difference

from the UTC.

5

Save the settings

Tap on the fixed keys [ ] or [ ].

The time settings are saved.

7.2 System-specific dialog options

Main dialog: System ▶ System settings ▶ Dialog options

7 System settings

Dialog

915 KF Ti-Touch

If you work without a login function, in this dialog you can define

whether the system should generally be operated in expert mode or in

routine mode. If you work with the login function activated, you must

define this setting separately for each user (see Chapter 7.3.1, page 38).

Dialog mode in which the user may operate the system.

Selection Expert dialog | Routine dialog

Expert dialog

All functions that are supported by the system are available.

Routine dialog

The user dialog can be limited for routine operations. Only selected

functions are available (see Configuring the routine dialog, page 35).

■■■■■■■■

33

Page 48

7.2 System-specific dialog options

[Command list]

[Fixed keys]

[Routine dialog]

■■■■■■■■■■■■■■■■■■■■■■

Block unneeded method commands (see "Blocking unneeded commands

and fixed keys", page 34).

Block unneeded fixed keys (see "Blocking unneeded commands and fixed

keys", page 34).

Configure functions for the routine dialog (see "Configuring the routine

dialog", page 35).

Selecting the dialog mode

Proceed as follows to change the dialog mode:

1

Select the dialog mode

Open the selection list Dialog and select either Expert dialog or

Routine dialog.

2

Save the settings

Tap on the fixed keys [ ] or [ ].

The setting will apply to all dialogs.

NOTE

If you have selected Routine dialog and if the routine dialog was

configured in such a way that the dialog System settings / Dia-

log options is blocked, then you can switch back over to the

expert dialog as follows:

■ Operation without login function:

In the main dialog, enter User = Metrohm.

■ Operation with login function:

A user who works with expert dialog must log in.

Blocking unneeded commands and fixed keys

This following configurations apply for both dialog modes: routine dialog

and expert dialog.

■■■■■■■■

34

915 KF Ti-Touch

Page 49

■■■■■■■■■■■■■■■■■■■■■■

Blocking commands

Proceed as follows to block unneeded commands:

1

Display the command list

Tap on the button [Command list].

The list of all command groups is displayed.

2

Deactivate command groups

Deactivate those command groups which are not permitted to be

used.

3

Save the settings

Tap on the fixed keys [ ] or [ ].

All deactivated commands appear grayed out in the method editor

and cannot be used for creating methods.

7 System settings

Blocking fixed keys

Proceed as follows to block unneeded fixed keys:

1

Display fixed keys which can be blocked

Tap on the button [Fixed keys].

All fixed keys which can be blocked are displayed.

2

Deactivate fixed keys

Deactivate those fixed keys which are not permitted to be used.

3

Save the settings

Tap on the fixed keys [ ] or [ ].

Deactivated fixed keys cannot be used.

Configuring the routine dialog

A suitable Standard configuration has already been saved for routine

operations.

915 KF Ti-Touch

■ Methods can only be loaded, but not modified or created.

■ Determinations cannot be recalculated.

You can readjust this standard configuration by disabling additional functions or re-enabling disabled functions.

■■■■■■■■

35

Page 50

7.2 System-specific dialog options

■■■■■■■■■■■■■■■■■■■■■■

NOTE

The configuration of the routine dialog applies for all routine users. You

also have the option of defining user-specific routine settings. To do

this, you must work with the login function activated and create an

identification profile for each user (see Chapter 7.3.2, page 40).

Proceed as follows to modify the configuration for the routine dialog:

1

Open the dialog

Tap on the button [Routine dialog].

The list of all buttons in the main dialog, in the manual control, etc. is

displayed:

■■■■■■■■

36

2

Deactivate buttons

Deactivate those buttons which are not permitted to be used.

All deactivated buttons will appear grayed-out, i.e. they are inactive.

3

Deactivate other functions

Many additional buttons and parameters can be disabled in the dialogs of [System], [Load method], [Control], [Edit parameters]

and [Results]. The corresponding option must be activated in order

to enable these buttons.

4

Save the settings

Tap on the fixed keys [ ] or [ ].

915 KF Ti-Touch

Page 51

■■■■■■■■■■■■■■■■■■■■■■

All deactivated functions will appear grayed-out, i.e. they are inactive.

7.3 User administration

Main dialog: System ▶ System settings ▶ User admin.

All of the functions of the user administration are described in this chapter. No user administration is mandatory for the simple operation of a

titration system.

NOTE

If you work with the login function activated, then the user administration is accessible only for users with administrator rights. This means

that you must ensure that at least two users have administrator rights

so at least one of them will be available. Keep the access rights for a

user with administrator rights in a safe place so that they are accessible

in an emergency.

7 System settings

915 KF Ti-Touch

The following data is displayed in the user list for each user:

■ Name

■ Dialog mode in which the user may operate the system.

■ Status

You can use the user list two different ways:

■ Operation with login function:

If you work with the login function activated, i.e. if each user must log

into the system before starting work, then only those users entered in

the list can log in. The user who is currently logged in is shown in the

main dialog.

■■■■■■■■

37

Page 52

7.3 User administration

[Login options]

[Create ID profile]

[New]

[Delete]

■■■■■■■■■■■■■■■■■■■■■■

■ Operation without login function:

If you work without the login function, the users whose names are

entered in the list can be selected in the main dialog or a user name

can be entered. This makes it possible to document who has operated

the titration system.

Define the settings for the login (see Chapter 7.3.3, page 41).

Create an identification profile for the selected user on a storage medium

(see Chapter 7.3.2, page 40).

Add a new user to the list (see Chapter 7.3.1, page 38).

Delete the selected user from the list.

NOTE

Once you have worked with the login function and password protection, users can no longer be deleted, even if the password protection is

disabled again. The status of these users must be set to inactive.

The last user with administrator rights cannot be deleted.

[Edit]

Edit the data of the selected user (see Chapter 7.3.1, page 38).

7.3.1 Editing the user configuration

User list: User ▶ New / Edit

■■■■■■■■

38

915 KF Ti-Touch

Page 53

■■■■■■■■■■■■■■■■■■■■■■

User

Full name

Dialog

7 System settings

The designation of the user is used for unambiguous identification, e.g.

the company internal shorthand symbol or the personal number. The user

name is printed out in all reports containing determination data and

stored in the determination file. Each file always contains the name of the

user who created it and the name of the last user to edit it.

Entry 24 characters maximum

Default value empty

Complete name of the user.