Page 1

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

767 Calibrated Reference

for mV, pH, S, :S, °C

Instructions for Use

8.767.1023 08.2005 / ars

Page 2

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 3

Contents

Table of contents

1 Overview ............................................................... 1

1.1 Introduction ....................................................................................................1

1.2 Functional description ...................................................................................2

2 General instrument handling............................... 4

2.1 Storage ...........................................................................................................4

2.2 Maintenance ...................................................................................................4

2.3 Calibration ......................................................................................................4

2.4 ‘High-Impedance’, an important basic term’ ................................................4

2.5 Measurement of the insulation resistance ...................................................5

3 Procedure for checking instruments .................. 6

3.1 Basics .............................................................................................................6

3.2 pH Meters and Titrators.................................................................................6

3.2.1 U/mV, pH ..................................................................................................7

3.2.2 Polarization current and voltage source ..................................................8

3.2.3 Temperature (Pt 100/Pt 1000)..................................................................8

3.2.4 Tolerances ................................................................................................9

3.3 Conductivity meters .......................................................................................9

3.3.1 Conductance............................................................................................9

3.3.2 Temperature ...........................................................................................10

3.3.3 Tolerances ..............................................................................................10

3.4 Rancimat 617 and 679 ................................................................................ 10

4 Checking by means of the diagnosis

instructions ........................................................ 12

5 Appendix ............................................................. 13

5.1 Technical specifications ............................................................................. 13

5.1.1 Measuring source...................................................................................13

5.1.2 Temperature coefficient .........................................................................13

5.1.3

5.1.4 Ambient temperature..............................................................................14

5.1.5 Safety specifications ..............................................................................14

5.1.6 Electricity supply.....................................................................................14

5.1.7 Dimensions.............................................................................................14

5.2 Cables for connecting 767 – instrument X ................................................ 14

5.3 Standard equipment ................................................................................... 15

5.4 Warranty and conformity ............................................................................ 16

5.4.1 Warranty..................................................................................................16

5.4.2 Declaration of Conformity ......................................................................17

5.4.3 Quality Management Principles .............................................................18

Longterm stability (2 years)....................................................................13

6 Index ................................................................... 19

767 Calibrated Reference Instructions for Use I

Page 4

Contents

List of illustrations

Fig. 1: 767 Calibrated Reference...............................................................................................1

Fig. 2 Functional scheme: Position "Voltage source ON" .........................................................1

Fig. 3: Label on cover ................................................................................................................1

Fig. 4: Unloaded potential source .............................................................................................5

Fig. 5: On-load potential source................................................................................................5

Fig. 6: Measurement of the insulation resistance versus earthing ...........................................5

Fig. 7: Cable arrangement for 1st G value (15.3 kS →approx. 66 :S) ..................................11

Fig. 8: Cable arrangement for 2nd G value (14.3 kS → approx. 69 :S) ................................11

II 767 Calibrated Reference Instructions for Use

Page 5

1 Overview

1 Overview

1.1 Introduction

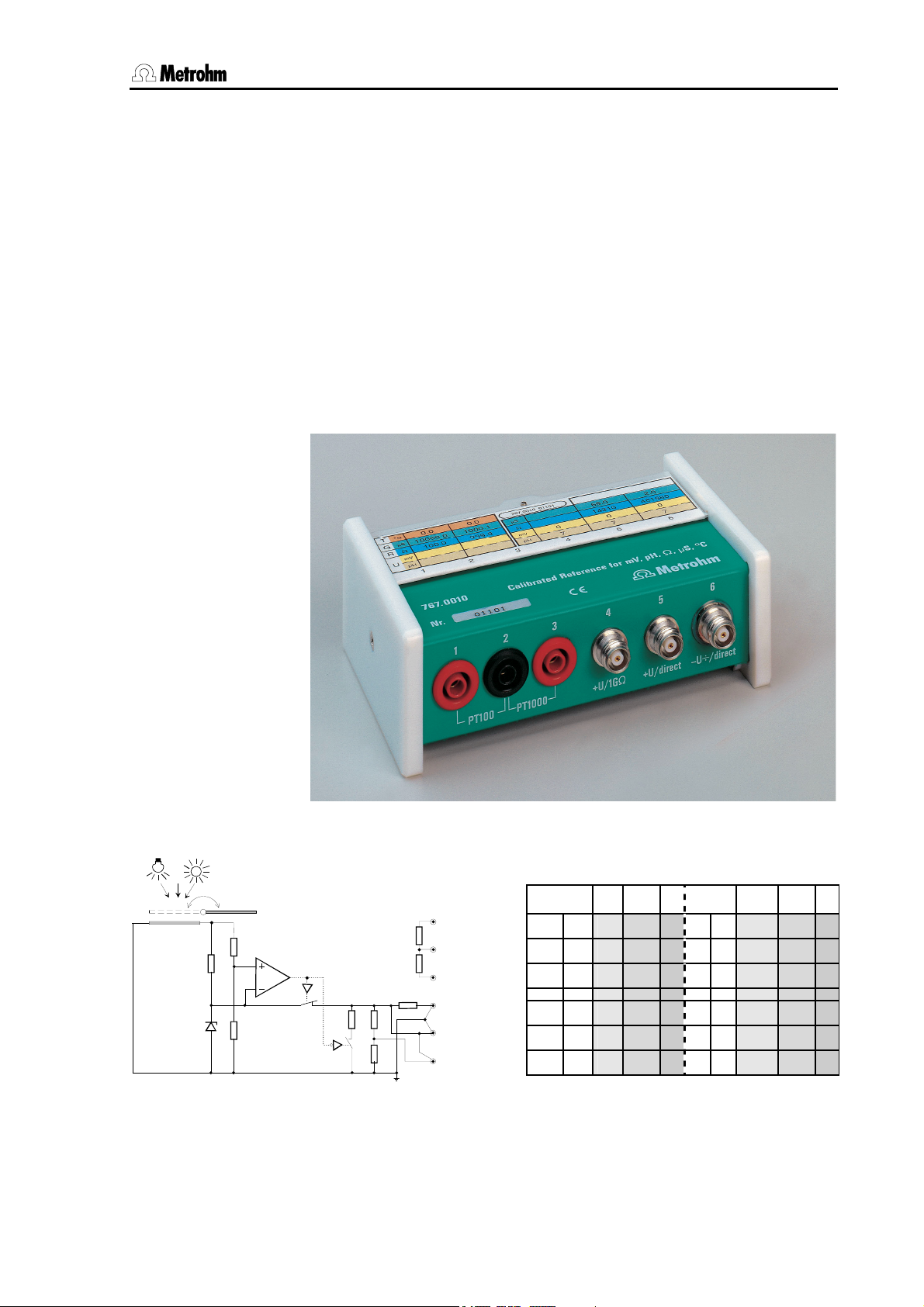

The measuring source 767.0010 Calibrated Reference for mV, pH,

Ω, µS, °C is a calibrated instrument for the quantities mentioned above.

It is connected instead of the electrodes and can be used for rapidly

and easily checking of the functioning and the basic accuracy of most

Metrohm instruments.

In addition the input resistance of high-impedance measuring amplifiers

(pH Meters, Titrators) and, for separate amplifiers, the insulation of the

reference point from the earth can be checked.

Fig. 1: 767 Calibrated Reference

U R G T U R G T

+U/1G

+U/direct

-U+/direct

(1)

(2)

(3)

(4)

(5)

(6)

solar cell

S1a

S1b

100 Ohm

1000 Ohm

1G

Pt 100

Pt 1000

Fig. 2 Functional scheme: Position "Voltage

source ON"

767 Calibrated Reference Instructions for Use 1

mV pH S :S °C mV pH S :S °C

100 10'000 0 100 10'000 0

1000 1000 0 1000 1000 0

(1200) 0 7 1G

1200 0 7 14'300 70

-341 12.7 0 7 460'000 2

Fig. 3: Label on cover

(exact values are given on the cover)

cover open ¦ cover closed

Page 6

1 Overview

1.2 Functional description

As mentioned before the input resistance of high-impedance measuring

amplifiers (pH Meters, Titrators) and, for separate amplifiers, the insulation of the reference point from the earth can be checked.

This is done using the potential of a reference diode (approx. 1200 mV)

on the one hand at output socket (5) +U/direct and on the other hand

a high-impedance resistor (1 GΩ) at socket (4) +U/1 GΩ. This potential

is also switched to socket (6) −U÷/direct by a divider. This means that

a lower potential (approx. 341 mV) with inverted polarity is also available; this can also be converted to a value within the pH scale (approx.

pH 12.7).

The reference diode is fed by a solar cell. This means that neither a

mains supply nor a battery is necessary and makes the instrument virtually maintenance-free. An internal potential monitor ensures that the

output potential is switched off under inadequate lighting conditions before the tolerance requirements are no longer fulfilled.

The solar cell can be covered and thus switched off. The potential

monitor then switches a second electronic switch so that the internal

resistance of the switched-off source is 14.3 kΩ. This resistance can be

used to check the current and voltage sources built into pH Meters and

Titrators in a very simple manner. The voltage divider at socket (6)

−U÷/direct gives a resistance of about 460 kΩ, which can also be used

for testing purposes.

For checking the temperature measuring amplifier the 0°C resistances

of the temperature sensors Pt 100 and Pt 1000 are built-in, see sockets (1), (2), (3). These are separated from the other circuits in the test

instrument. This means that no unwanted earthing loops can occur

when they are used.

This means that 4 resistance values which can be used for checking

conductivity meters.

For the 767 Calibrated Reference we have done without fine adjustment

and instead have entered the resulting exact values in the table on the

cover. In this way we have gained a considerable degree of accuracy

and stability. In addition we have converted the resistance values into

conductance (µS) and temperature (°C), and the potential into the exact

pH value wherever this makes sense. This means that it is possible to

compare the display of the instrument to be tested directly with the corresponding value in this table. Two different tables are provided for the

open and closed covers.

Practice has shown that problems are often caused by the electrode

cable. They are subjected to mechanical stress (tension, pressure, torsion, etc.) and on the other hand they constantly and unavoidably come

directly into contact with chemicals (spilt solutions, vapors, etc.). Nevertheless their insulation value must always remain exactly as good as

that at the measuring amplifier input. Such an exposed element must

therefore be included in a test at all costs. This is why this measuring

source is equipped with sockets which correspond to the plug head of

2 767 Calibrated Reference Instructions for Use

Page 7

1 Overview

Metrohm electrodes and means that a test can be carried out very easily:

Screw off cable at electrode plug-in head → plug into Calibrated

Reference → measure

If this check produces a variation from the expected result then it is not

immediately clear as to whether the error lies in the instrument to be

checked or in the cable. Therefore specially labeled cables are available in the accessories which are included with the instrument; these

can be temporarily used instead of the original cable (see list of cables

chap. 5.2). These accessory cables are also useful for sensors which

do not have a plug-in head.

Note

It must be mentioned here that under no circumstances can or should

the 767 Calibrated Reference replace the periodic maintenance of the

instrument, but should only be used for determining whether an error

is present or not if functional difficulties occur. In addition, the basic

accuracy and high impedance of the instrument can be checked at

regular intervals.

During maintenance the instrument is subjected to a far more stringent check (e.g. linearity of display and A/D converter, etc.). In addition the switches, motors, mechanical components, etc. are also checked for corrosion and wear and tear.

767 Calibrated Reference Instructions for Use 3

Page 8

2 General instrument handling

2 General instrument handling

2.1 Storage

It is best to store the Calibrated Reference in its own case (with closed

cover) together with its accessory cables. In this way it is protected

against dirt, mechanical stress and moisture.

2.2 Maintenance

The instrument needs no real maintenance (it also contains no batteries). Finger prints or other dirt on the solar cell should be removed with

a cloth which has been slightly moistened with window-cleaning liquid

or alcohol. The colored tables on the cover should not be exposed to

cleaning agents.

2.3 Calibration

The calibration certificate is printed on the cover and contains data required for retraceability purposes. The separately printed calibration

certificate also contains the dates of the last and next calibrations. We

recommend to carry out a service every 5 years.

It is best to send the instrument back to Metrohm for a new calibration.

Please include all cables belonging to the set so that they can also be

checked. It is expedient to transport the instrument in its own case,

which should be packed in suitable transport packing material.

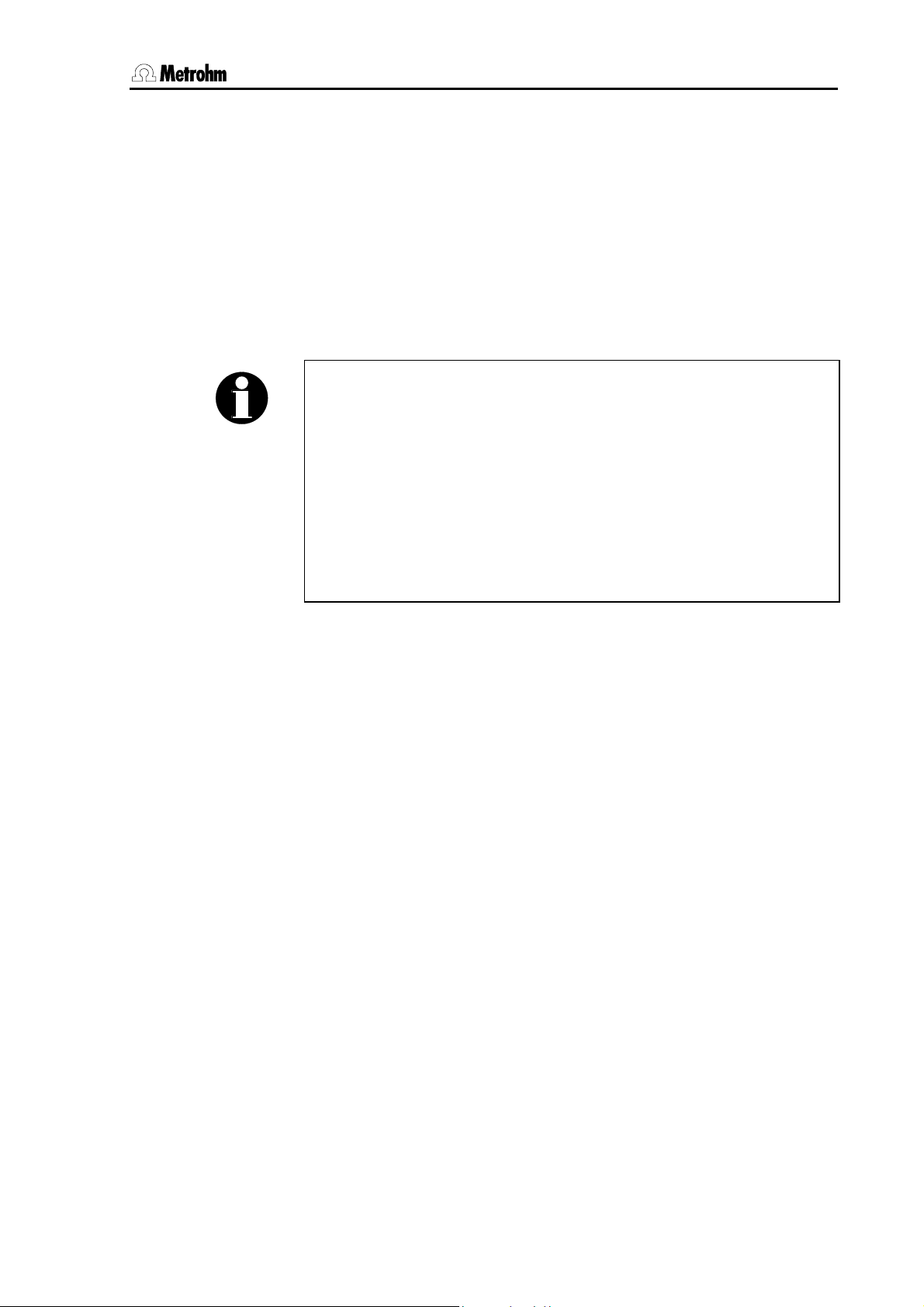

2.4 ‘High-Impedance’, an important basic term

pH electrodes are potential sources with a very high internal resistance.

If possible, no current should flow from the source in order not to falsify

the measuring potential. This means that the whole measuring circuit

consisting of electrode, cable, plug, socket, switching element up to the

measuring amplifier itself must be extremely well insulated. Only high

quality insulation material such as Teflon, polyethylene, glass, siliconized ceramics, etc. come into question. The intention is to achieve

an insulation resistance of up to 10

quirement. This value can be regarded as being infinite in the following

observations. From the Figure 4, p. 5 it can be seen that the potential E

in the amplifier is always effective, even when R

bly with the temperature (which is normal with electrodes).

Minute contamination caused by atmospheric deposits or spilt liquids

can influence the insulation values.

What happens in such a case?

14

Ohm. This is quite an extreme re-

changes very noticea-

i

An on-load potential source is formed and there is therefore a potential

drop at R

amplifier will be falsified by this amount.

4 767 Calibrated Reference Instructions for Use

(see Fig. 5, p. 5). The measuring potential effective at the

i

Page 9

2 General instrument handling

(6)

(4)

Ri

R

E

input

Ri

R

E

Rx

input

Fig. 4: Unloaded potential source

Fig. 5: On-load potential source

If the electrode is now calibrated, i.e. the electrode parameters are determined, then the instrument is in reality being adapted to the electrode. This means that the previously determined error will also be

compensated. The measurement will again be correct.

Why make so much fuss when everything is back in order?

One must be aware of the fact that such contaminations form an extremely unstable resistance, whose value alters with the atmospheric

humidity, temperature and many other chance occurrences. The resistance can therefore vary greatly. Together with R

, which is strongly de-

i

pendent on the temperature, this gives a very unstable potential divider.

This is then no longer compensated, at best during the next electrode

calibration (and therefore again by chance). Because this error is covered up again at every calibration it is often not noticed for a long time,

although it produces false (and above all unstable) results.

From this it can be seen that a constant additional monitoring of the

high impedance of pH Meters and Titrators must be a basic concern of

quality assurance. However, this only makes sense when the most exposed element, the sensor cable, is included in the monitoring process.

2.5 Measurement of the insulation resistance

Explanation for the steps 9-12, section 3.2.1 U/mV, pH.

R1

R2

Fig. 6: Measurement of the insulation resistance versus earthing

R

of the instrument to check via insulation of 6.2104.020 (6.2150.040)

Isol

cable and socket (5) is in parallel with R

With R

ok, e.g. > 108 Ω, there is no change in the display of the in-

Isol

strument to check.

using this interconnection.

2

767 Calibrated Reference Instructions for Use 5

Page 10

3 Procedure for checking instruments

3 Procedure for checking instru-

ments

3.1 Basics

The 767 Calibrated Reference is connected instead of the sensors, if

possible by means of the original sensor cable. If this is not possible

(e.g. for electrodes without a plug-in head) a list of suitable cables can

be found in the appendix, see chap. 5.2.

Each instrument can be checked with the Calibrated Reference within

the normal operating program and therefore also with the worked-out

methods. This has the advantage that methods and selected function

runs can be tested at the same time.

On the other hand the Instructions for Use of most instruments contain

a so-called diagnosis instructions, selective instructions for checking

the functioning of the instrument if malfunctioning is suspected. This type of check has the advantage that practically no (or only a very basic)

knowledge of operating the instrument is required. In addition, checking

the instrument by using the diagnosis instructions is usually significantly

faster.

This operating instructions for Calibrated Reference 767 are instructions

for checking the Metrohm instrument within the normal operating program. As the very large range of instruments means that for individual

instruments many different names and operating structures may have

been used, these instructions should therefore be interpreted logically.

It is not absolutely necessary to firmly screw down the electrode cap at

sockets (4), (5), (6); plugging it in is quite adequate.

3.2 pH Meters and Titrators

Place the Calibrated Reference on the bench near the sensor. Ensure

that light is not hindered from reaching the solar cell (no shadows from

cables or accessories). If necessary switch on the room lighting.

On the instrument to be tested the slope must be set to 1, pH

the measuring temperature to 25 °C for measuring the pH.

Please note:

• On the basis of the pH calibration the pH is determined from the

measured potential value. The pH checked here is therefore chiefly

relevant as a functionality check.

• If the endpoint is evaluated from a curve in a titration, the absolute

measured potential or pH value is not relevant.

• With KF titrators this check should be evaluated as a functionality

test.

to 7 and

as

6 767 Calibrated Reference Instructions for Use

Page 11

3 Procedure for checking instruments

3.2.1 U/mV, pH

carry out on instrument or sen-

sor:

1. screw off cable at sensor (for plug-in

head electrodes, otherwise use

corresponding accessory cable, see

chap. 5.2

2. connect sensor cable to

3. measure mV mV value (5)

4. open cover mV value (5) compare with

5. connect sensor cable to

6. connect sensor cable to

7. measure pH close cover pH value (6) set Uas to pH 7 if

8. open cover pH value (6) compare with

End of check

Steps 9...12 are of secondary importance. In general it is sufficient to carry out this check once per year.

For instruments with earthed circuits (e.g. all Titrinos and early series of 692/713) or for instruments without an earth socket (604,

704, 744) these steps are not relevant. Further Information to steps 9...12 can be found in chapter 2.5.

carry out on Calibrated

Reference:

close cover place sensor in

socket (5)

socket (4)

socket (6)

compare display

with:

permitted variation

mV value (6) observe polarity;

remarks

storage tube

permitted tolerance; note value

from value noted

under step 4:

±0.1 mV (shorttime larger deviations are normal)

(switch measuring

range if required);

compare with

permitted tolerance

necessary

permitted tolerance

9. measure mV connect sensor cable to

socket (5)

10. additionally connect cable

6.2150.020 (from accessories in case) to socket (6)

11. insert banana plug of cable in step

10 in earth socket of tested instrument. Banana plug of shielding re-

mains open.

12. remove cable from step 11 remove cable from

do not touch sockets (4),

(5), (6) during the measurement

socket (6)

If the variation of the measured values is too large then first exchange

the original sensor cable against the reference cable in the accessories.

When the check is finished recalibrate the electrodes.

note display as

under step 4

observe display

while connecting

the cable

permitted variation:

±0.1 mV display as

under step 5

(short-time larger

deviations are

normal)

767 Calibrated Reference Instructions for Use 7

Page 12

3 Procedure for checking instruments

3.2.2 Polarization current and voltage source

carry out on instrument or sen-

sor:

1. screw off cable at sensor close cover place sensor in

2. connect sensor cable to

3. set instrument to function Upol or

Ipol

carry out on Calibrated

Reference:

socket (5)

cover always remains closed calculate R value

compare display

with:

(5) according to

equation, see below

remarks

storage tube

compare with permitted tolerance;

take display resolution into account

If the variation of the measured values is too large then first exchange

the original sensor cable against the reference cable in the accessories.

Equations for the calculation:

U pol: I = (U/R) = selected Upol potential / Ω value (5)

I pol: U = (IxR) = selected Ipol current x Ω value (5)

For different instruments the different control limits according to the individual technical data must be observed → observe overload display.

Example:

1 µA x 14 345 Ω = 14.345 mV

Consider resolution of display!

3.2.3 Temperature (Pt 100/Pt 1000)

carry out on instrument or sen-

sor:

1. remove cable (with sensor) from

instrument

2. connect temperature measuring

input to Calibrated Reference with

2x banana cables (6.2150.000)

3. set instrument to temperature function

Note

During the pH measurement the two Pt 100 / Pt 1000 resistances at

sockets (1)....(3) can also be used at the same time with the pH mea-

surement (see above). Please note that the measuring temperature of

the instrument to be tested is approx. 0°C, while the information in the

table refers to 25°C. This must be converted accordingly.

For the Pt 1000 measuring input the following applies: value between

sockets (1) and (3) (R-Pt100 and R-Pt1000 in series) corresponds approximately to 25°C (for the exact individual value see certificate for

767.0010).

carry out on Calibrated

Reference:

close cover

depending on sensor, connect:

Pt 100 : sockets (1) (2)

Pt 1000: sockets (2) (3)

Pt 100 : sockets (1) (2) →

Pt 1000: sockets (2) (3) →

compare display

with:

°C value (1)(2)

°C value (2)(3)

remarks

compare with permitted tolerance

8 767 Calibrated Reference Instructions for Use

Page 13

3 Procedure for checking instruments

3.2.4 Tolerances

Instruments with digital display:

Potential U ± 1 mV

pH value ± 0.02

Temperature ± 0.5 °C

Polarization functionality test

Instruments with analog display:

The tolerance is within the reading accuracy.

Example:

Theoretical potential value: 1200.7 mV

Instrument resolution: 1 mV, i.e. nominal pot. value =1201 mV.

The test is OK when the read off value lies between 1200...1202 mV.

If the measurements lie outside the tolerances they should be repeated

with the reference cable from the accessories case.

If the measurements are still outside the tolerance range please contact

your local Metrohm agency to arrange for the instrument to be serviced.

3.3 Conductivity meters

Read off and note the cell constant, the temperature coefficient, and the

temperature on the instrument to be tested. Then set cell constant and

temperature coefficient to 1 and the temperature to the reference temperature valid for the instrument. Set the measuring frequency to

"automatic switchover".

Please note that a check carried out with this instrument and the diagnosis instructions (if available, see Instructions for Use of the Conductivity meter) may be quicker.

3.3.1 Conductance

carry out on instrument or sen-

sor:

1. screw off cable at sensor (for plug

head electrodes, otherwise use

corresponding accessory cable)

2. connect cable to socket (5)

3. set instrument to ‘conductivity’ function

4. connect cable to socket (6) G value (6) compare with per-

If further results are required:

5. remove measuring cable remove measuring cable

6. connect conductivity measuring

input to Calibrated Reference with

2x banana cables (6.2150.000)

carry out on Calibrated Reference:

close cover place sensor in

cover always remains closed G value (5) compare with per-

connect cable to sockets (1) (2)

connect cable to sockets (2) (3)

compare display with

G value (1)(2)

G value (2)(3)

remarks

storage tube

mitted tolerance

mitted tolerance

compare with permitted tolerance

767 Calibrated Reference Instructions for Use 9

Page 14

3 Procedure for checking instruments

3.3.2 Temperature

Checking the temperature, see chapter 3.2.3.

Note

During the measurement the two Pt 100 / Pt 1000 resistances at sock-

ets (1)....(3) can also be used at the same time as the conductance

measurement (see further up). Please note that the measuring temperature of the instrument to be tested is approx. 0°C, while the information in the table refers to 20°C. This must be converted accordingly.

When the test is finished the cell constant, temperature coefficient and

the temperature must be set again to their current values.

3.3.3 Tolerances

Instruments with digital display:

G value (5) ± 0.1 µS/cm

G value (6) ± 0.7 µS/cm

Temperature ± 0.5 °C

Instruments with analog display:

The tolerance lies within the reading accuracy.

If the measurements lie outside the tolerances they should be repeated

with the reference cable from the accessories case.

If the measurements are still outside the tolerance range please contact

your local Metrohm agency to arrange for the instrument to be serviced.

3.4 Rancimat 617 and 679

The Rancimat carries out conductivity measurements via the measuring

channels. The function of the measuring channels and the presentation

on the printer can be checked channel by channel by means of the

Calibrated Reference. The conductance can be read off from the display. By variation of the conductance the sensitivity of the measurement

can be shown on the printer in approximately the correct scale. The

temperature of the heating block plays no role in the following measurements (if the instrument has reached the operating temperature the

check can be started immediately). If this is not the case then the start

condition should be achieved (for 679: > 50°C).

The following test can be used as a functionality test.

carry out on instrument or sen-

sor:

1. unplug sensor from instrument close cover (Sensor can remain

2. plug in cable 6.2150.010 instead of

the sensor

carry out on Calibrated

Reference:

Plug in cable according to

diagram (see Fig. 7, p. 11)

so that 15.3 kΩ is obtained

compare display

with:

remarks

in the measuring

vessel)

10 767 Calibrated Reference Instructions for Use

Page 15

3 Procedure for checking instruments

3. note following parameters, then set

(example 679) :

temperature (see above) 50°C

cond. range 20 µS/cm

paper feed 20 cm/h

4. press start see G value for

5. wait until the printer is print-

6. if necessary repeat steps 1 - 5 for all

channels

Rancimat in certificate for 767.0010

(approx. 66 µS

G value (5)

ing out a channel which has

not been checked.

Replug cable (see Fig. 8,

p. 11), so that 14.3 kΩ ≅

approx. 69 µS is obtained

(see G value (5))

(ca. 69 µS 1))

allow all channels

to write out 2 - 3 x

(the zero line is

1)

shown in all chan-

)

nels)

allow all channels

to write out 2 - 3 x.

In the checked

channel the line will

be offset by the

amount of the alteration in conductance → check by

measuring with

ruler

1) Please consider the small number of decimal places in the display!

767

1 2

3 4 5 6

cable 6.2150.020

Rancimat

cable 6.2150.010

Fig. 7: Cable arrangement for 1st G value

(15.3 k

S

→approx. 66 :S)

767

1 2

cable 6.2150.010

3 4 5 6

cable 6.2150.020

Rancimat

Fig. 8: Cable arrangement for 2nd G value

(14.3 kS → approx. 69 :S)

767 Calibrated Reference Instructions for Use 11

Page 16

4 Checking by means of the diagnosis instructions

4 Checking by means of the di-

agnosis instructions

For most Metrohm instruments the so-called diagnosis instructions can

be found in the Instructions for Use. These are intended to provide the

possibility of testing an instrument with real or suspected malfunctions

in a simple way.

Until now when checking the measuring inputs the difficulty was always

experienced that for the quantities ‘potential’ and ‘resistance’ there was

often no suitable source available in the laboratories. In addition these

could no longer be connected to the high impedance sockets of our instruments. This difficulty has now been remedied in an outstanding

manner by our 767 Calibrated Reference.

In the diagnosis instructions of previous instruments the measuring

source 767 Calibrated Reference for mV, pH, Ω, µS, °C is not mentioned. However, it is easy to see how the instrument is to be connected

from the diagnosis instructions. The operation of the Calibrated Reference is almost self-evident and it is not difficult to derive the way in

which it is to be used from section 1 of these Instructions for Use (please note that polarization current and potential sources can be very

quickly checked in the diagnosis: connect sensor cable to socket (5),

close cover, start test, read off !)

For measurement at the differential inputs (e.g. Ind I / Ind II) it should be

noted that both inputs cannot be connected to the Calibrated Reference at the same time as this would short-circuit the output sockets.

This problem can be avoided by actually connecting both inputs, but alternately shorting one of the two inputs with cable 3.496.5070. However, should this appear to be expedient under exceptional circumstances, two different, but separately earthed instruments can be

connected to the same Calibrated Reference (to sockets (5) and (6)).

12 767 Calibrated Reference Instructions for Use

Page 17

5 Appendix

5 Appendix

5.1 Technical specifications

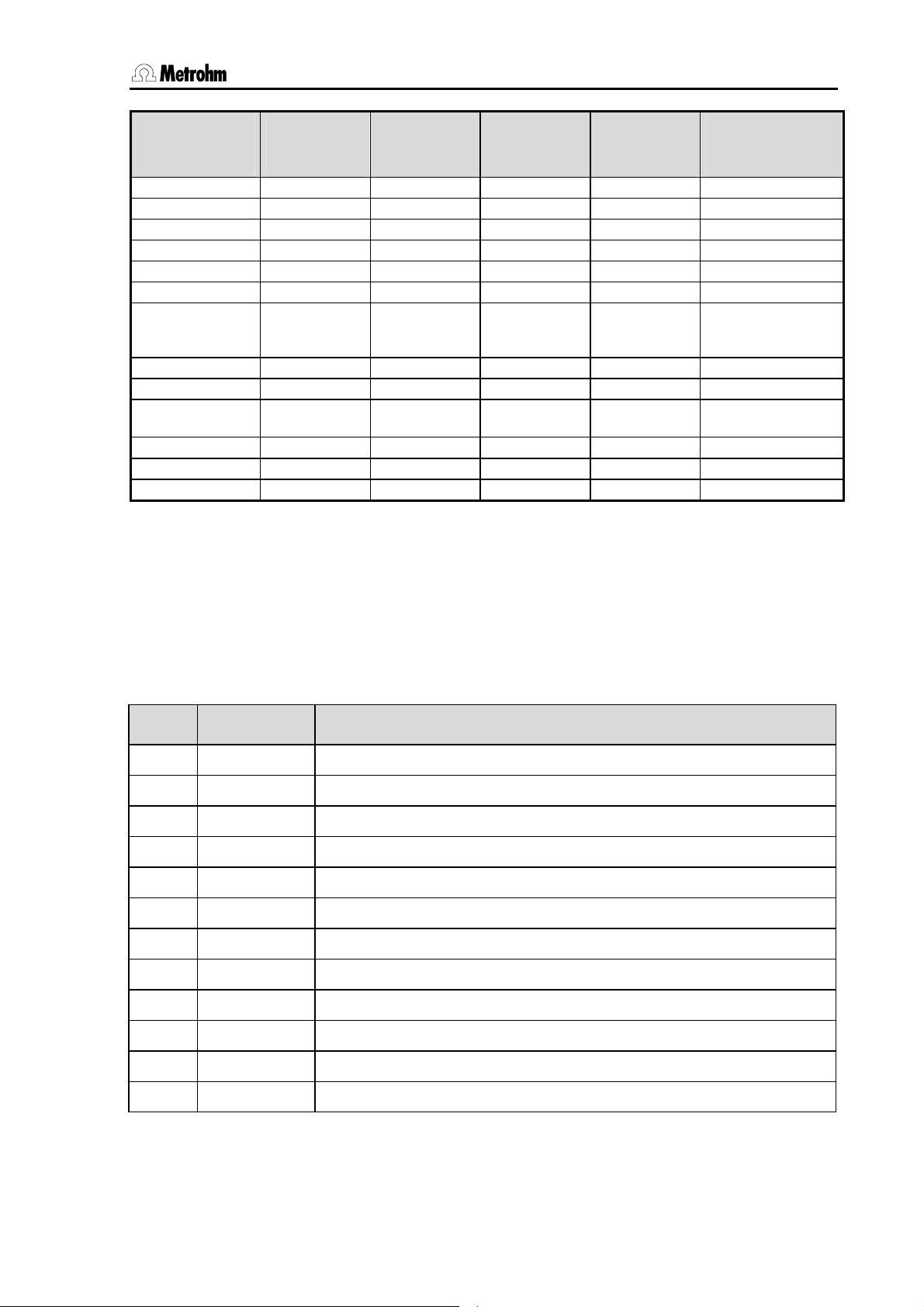

5.1.1 Measuring source

3 outputs with socket G:

socket (4)

socket (5)

socket (6)

Outputs with sockets B (temperature measurement):

socket (1)

socket (2)

socket (3)

The individual data are given in the two tables on the cover. Individual additional data

can be found in the certificate.

cover closed cover open

voltage resistance voltage

0 mV

0 mV

0 mV

(pH = 7)

100 S (Pt100)

1 GS

14.3 kS

460 kS

1000 S

(Pt 1000)

5.1.2 Temperature coefficient

cover closed cover open

socket (1)

socket (2)

socket (3)

socket (4) 100 ppm/°C 40 ppm/°C

socket (5) 100 ppm/°C 40 ppm/°C

socket (6) 100 ppm/°C 40 ppm/°C

25 ppm/°C 25 ppm/°C

25 ppm/°C

approx. 1200 mV

approx. 1200 mV

approx. - 341 mV

(pH = 12.7)

25 ppm/°C

5.1.3

767 Calibrated Reference Instructions for Use 13

Longterm stability (2 years)

cover closed cover open

socket (1)

socket (2)

socket (3)

socket (4) 5 ‰ 1.5 ‰

socket (5) 5 ‰ 1.5 ‰

socket (6) 5 ‰ 1.5 ‰

1.3 ‰ 1.3 ‰

6 ‰

6 ‰

Page 18

5 Appendix

5.1.4 Ambient temperature

Nominal working range 5 ... 40 °C

Storage – 20 ... 60 °C

Transport – 40 ... 60 °C

5.1.5 Safety specifications

Construction and testing according to IEC publication 1010, protection class 3

5.1.6 Electricity supply

Solar cells (no batteries)

5.1.7 Dimensions

Width

Height

Depth

Weight

Weight (with accessories)

125 mm

45 mm

85 mm

approx. 350 g

approx. 1 kg

5.2 Cables for connecting 767 – instrument X

Please note that the cables in the 767.0010 accessories carry an ID and therefore

have a new ordering number (see title lines).

ordering number of

original cable

with ID

Conductometers

527 X

587 X

644 X

660, 712 X X

pH Meters

500, 510 X X

512 X (X)

520, 532, 588, 603 X

604 X

605, 610 X X

620, 632 X

654 X X X

691, 692, 713 X X X

704, 744 X X

6.2104.020

6.2150.040

6.2104.050

6.2150.030

6.2104.080

6.2150.020

2x 6.2106.020

2x 6.2150.000

6.2150.010

14 767 Calibrated Reference Instructions for Use

Page 19

5 Appendix

ordering number of

original cable

with ID

Titrators

526 X

536 X X

576 X

636, 670 X X

672, 682, 686 X X

702, 716, 718, 719,

720, 721, 726, 736,

751, 785

KF instruments

678 X X

684, 701, 737, 758,

784

707, 768 X

Rancimat

617, 679 X

6.2104.020

6.2150.040

X X

X

6.2104.050

6.2150.030

6.2104.080

6.2150.020

2x 6.2106.020

2x 6.2150.000

6.2150.010

With newer instruments you can normally use the cables 6.2150.040 (pH/mV measurement) and 6.2150.000 (temperature measurement).

5.3 Standard equipment

Immediately upon receipt of the instrument please check that the delivery is complete.

Order no. 2.767.0010

The following accessories are included:

no. order no. Description

1 1.767.0010 Calibrated Reference for mV, pH, S, :S, °C

1 6.2103.130 Adapter red, 2 mm plug / 4 mm socket

1 6.2103.140 Adapter black, 2 mm plug / 4 mm socket

2 6.2150.000 Cable plug B / plug B

1 6.2150.010 Cable plug B 2x / plug DIN

1 6.2150.020 Cable plug B 2x / plug head G

1 6.2150.030 Cable plug head G / plug E

1 6.2150.040 Cable plug head G / plug F

1 6.2716.020 Case for 767 Calibrated Reference

1 8.767.1023 Instructions for Use for 767 Calibrated Reference

1 8.767.1203 Quick references for 767 Calibrated Reference

1 Certificate for 767 Calibrated Reference

767 Calibrated Reference Instructions for Use 15

Page 20

5 Appendix

5.4 Warranty and conformity

5.4.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In this case the defects will be rectified

in our workshops free of charge. Transport costs are to be paid by the

customer.

For day and night operation the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty period. For parts from

outside manufacturers, insofar as these constitute an appreciable part

of our instrument, the warranty stipulations of the manufacturer in question apply.

With the regard to the guarantee of accuracy the technical specifications in the instruction manual are authoritative.

Concerning defects in materials, construction or design as well as the

absence of guaranteed features the purchaser has no rights or claims

except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

Lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned then the original packaging should be used if at all possible. This applies above all to instruments and electrodes. Before embedment in wood shavings or similar

material the parts must be packed in a dustproof package (for instruments the use of a plastic bag is essential). If open assemblies are included that are sensitive to electromagnetic voltages (e. g. data interfaces, etc.) then these must be returned in the associated original protective packaging (e. g. conductive protective bag). (Exception: assemblies with a built-in voltage source belong in non-conductive protective packaging).

For damage which arises as a result of non-compliance with these instructions no warranty responsibility whatsoever will be accepted by

Metrohm.

16 767 Calibrated Reference Instructions for Use

Page 21

5 Appendix

5.4.2 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical appliances and accessories,

as well as to the standard specifications for security and to system validation issued by the manufacturing company.

Name of commodity

767 Calibrated Reference

Description Instrument for verification of measured values: tension U/mV, pH, resistance, tempera-

ture, conductance.

This instrument has been built and has undergone final type testing according to the standards:

Electromagnetic compatibility: Emission

EN50081-1/92, EN55022/class B

EN55011/class B Generic emission

Electromagnetic compatibility: Immunity

EN50082-1/92 Immunity

IEC801-2/91 (level 2) Static discharge

IEC801-3, ENV50140/93+ENV50204/93 (level 2) Radiated rf electromag.field immunity

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

www.metrohm.com

Safety specifications

IEC1010 class3, EN61010 class3, UL3101-1, EN60947:IP31

The instrument meets the requirements of the CE mark as contained in the EU directives 89/336/EWG und 73/23/EWG

EN 50081-1 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control equipment

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for quality assurance in

design/development, production, installation and servicing.

The technical specifications are documented in the instruction manual.

Herisau, March 14, 1998

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Responsible for Quality Assurance

and fulfils the following specifications:

767 Calibrated Reference Instructions for Use 17

Page 22

5 Appendix

5.4.3 Quality Management Principles

Metrohm Ltd., CH-9101 Herisau, Switzerland

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Metrohm Ltd. holds the ISO 9001 Certificate, registration number 10872-02, issued by

SQS (Swiss Association for Quality and Management Systems). Internal and external audits are carried out periodically to assure that the standards defined by Metrohm’s QM

Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments are fully documented and the resulting reports are archived for ten years. The development of software for PCs and instruments is also duly documented and the documents and source

codes are archived. Both remain the possession of Metrohm. A non-disclosure agreement may be asked to be provided by those requiring access to them.

The implementation of the ISO 9001

quality system is described in Metrohm’s

QM Manual, which comprises detailed

instructions on the following fields of

activity:

Instrument development

The organization of the instrument design, its planning and the intermediate

controls are fully documented and traceable. Laboratory testing accompanies all

phases of instrument development.

Software development

Software development occurs in terms of

the software life cycle. Tests are performed to detect programming errors

and to assess the program’s functionality in a laboratory environment.

Components

All components used in the Metrohm

instruments have to satisfy the quality

standards that are defined and implemented for our products. Suppliers of

components are audited by Metrohm as

the need arises.

Manufacture

The measures put into practice in the

production of our instruments guarantee

a constant quality standard. Production

planning and manufacturing procedures,

maintenance of production means and

testing of components, intermediate and

finished products are prescribed.

Customer support and service

Customer support involves all phases of

instrument acquisition and use by the

customer, i.e. consulting to define the

adequate equipment for the analytical

problem at hand, delivery of the equipment, user manuals, training, after-sales

service and processing of customer

complaints. The Metrohm service organization is equipped to support customers in implementing standards such

as GLP, GMP, ISO 900X, in performing

Operational Qualification and Performance Verification of the system components or in carrying out the System Validation for the quantitative determination

of a substance in a given matrix.

18 767 Calibrated Reference Instructions for Use

Page 23

6 Index

6 Index

A

Ambient temperature ..............14

C

Cable.......................................14

Calibration

767...................................4

Electrode .....................5, 7

Cleaning

Solar cell .......................... 4

Conductivity meter................2, 9

Conductometer.......................14

Connecting cable....................14

Cover ....................................2, 4

D

Depth ......................................14

Dimensions.............................14

E

Electricity supply.....................14

Electrode

Calibrate ......................5, 7

H

Height .....................................14

High-Impedance.......................4

I

ISO 9001 .................................17

K

KF instrument..........................15

M

Maintenance .........................3, 4

P

pH Meter .............................6, 14

pH value.................................... 6

Polarization current ...................8

Polarization potential ................8

Potential .................................... 6

Pt 100/Pt 1000 ......................2, 8

R

Rancimat........................... 10, 15

S

Safety specifications...............14

Solar cell ...................................2

Cleaning...........................4

Standard equipment ...............15

Storage .....................................4

T

Temperature .............................8

Temperature coefficient ..........13

Temperature sensor..................2

Titrator.................................6, 15

Tolerance

:S/cm, °C ......................10

mV, pH, °C .......................9

W

Warranty.................................. 16

Weight.....................................14

Width.......................................14

767 Calibrated Reference Gebrauchsanweisung 19

Loading...

Loading...