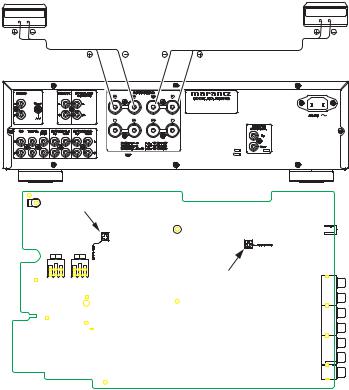

Marantz PM-7003 Service Manual

Service

Manual

PM7003 /F N/K1SG/N1SG

/N1B

Integrated Amplifier

INTEGRATED AMPL FIER PM7003

|

|

PHONO |

CD |

TUNER |

AUX DVD |

1 RECORDER |

MUTE |

|

|

|

INPUT SELECTOR |

|

|

|

|

|

|

VOLUME |

|

|

|

|

POWER AMP DIRECT |

|

SOURCE DIRECT |

|

|

|

|

STANDBY |

|

|

|

|

|

|

|

M N |

MAX |

|

SPEAKERS |

|

BASS |

|

TREBLE |

|

BALANCE |

|

|

POWER ON OFF |

|

A |

|

|

|

|

|

|

|

OFF |

B |

|

|

|

|

|

|

|

|

PHONES |

|

|

|

|

|

|

|

|

|

|

|

A+B |

|

|

|

|

|

|

|

|

|

|

- |

+ |

- |

+ |

L |

R |

|

|

TABLE OF CONTENTS |

|

SECTION |

PAGE |

|

1. |

TECHNICAL SPECIFICATIONS ........................................................................................... |

1 |

2. |

ALIGNMENTS....................................................................................................................... |

2 |

3. |

SERVICE MODE................................................................................................................... |

4 |

4. |

PROTECTION MODE ........................................................................................................... |

5 |

5. |

WRITING MAIN MICROPROCESSOR PROCEDURE ......................................................... |

7 |

6. |

WIRING DIAGRAM ............................................................................................................. |

25 |

7. |

BLOCK DIAGRAM .............................................................................................................. |

27 |

8. |

SCHEMATIC DIAGRAM...................................................................................................... |

29 |

9. |

PARTS LOCATION.............................................................................................................. |

37 |

10. |

EXPLODED VIEW AND PARTS LIST ................................................................................. |

47 |

11. |

MICROPROCESSOR AND IC DATA................................................................................... |

51 |

12. |

ELECTRICAL PARTS LIST ................................................................................................. |

56 |

13. |

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE ............................... |

71 |

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

P 7 03

PM7003

Part no. 90M24AJ855010 First Issue 2008.07 MZ

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound. Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which it is famous.

Parts for your MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified. The following information must be supplied to eliminate delays in processing your order :

1.Complete address

2.Complete part numbers and quantities required

3.Description of parts

4.Model number for which part is required

5.Way of shipment

6.Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE MAHWAH, NEW JERSEY 07430 USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO, KAWASAKI-KU, KAWASAKI-SHI, KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT BEEMDSTRAAT 11, 5653 MA EINDHOVEN THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD. MARKHAM, ONTARIO L3R 5B1 CANADA

PHONE : 905 - 415 - 9292 FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

CHUNG JIN B/D., #1001,

53-5, WONHYORO 3 GA, YONGSAN-GU, SEOUL, 140-719, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL NO.1600 NANJING (WEST) ROAD, SHANGHAI, CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol  Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol

Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol  . Any other component substitution (other than original type), may increase risk of fire or electrical shock hazard.

. Any other component substitution (other than original type), may increase risk of fire or electrical shock hazard.

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and verified before it is return to the user/customer.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

080702MZ

1. TECHNICAL SPECIFICATIONS

Power output |

|

|

|

(20 Hz – 20 kHz simultaneous drive of both channels) |

|

||

8 Ω load .............................................................. |

|

70 W x 2 |

|

4 Ω load ........................................................... |

|

100 W x 2) |

|

Total harmonic distortion |

|

|

|

(20 Hz – 20 kHz simultaneous drive of both channels, 8 Ω load) |

|

||

......................................................................... |

|

0.02 % |

|

Output band width (8 Ω load, 0.05 %) |

|

|

|

............................................................. |

5 Hz – 60 kHz |

|

|

Frequency response (CD, 1 W, 8 Ω load) |

|

|

|

................................................. |

5 Hz – 100 kHz ±3 dB |

|

|

Dumping factor (8 Ω load, 20 Hz – 20 kHz)...................... |

100 |

|

|

Input sensitivity/Input impedance |

|

|

|

PHONO (MM) ................................................ |

|

2 mV/47 kΩ |

|

CD, LINE, TUNER, AUX/DVD, RECORDER |

|

|

|

............................................................. |

200 mV/20 kΩ |

|

|

MAIN IN ......................................................... |

|

1.6 V/20 kΩ |

|

Output voltage/Output impedance |

|

|

|

PRE OUT ....................................................... |

|

1.6 V/600 Ω |

|

Maximum allowable PHONO input level (1 kHz) |

|

|

|

MM ....................................................................... |

|

100 mV |

|

RIAA deviation (20 Hz ~ 20 kHz) ......................... |

|

±0.5 dB |

|

S/N (IHF-A, 1 W, 8 Ω load) |

|

|

|

PHONO (MM)) ........................................................ |

|

85 dB |

|

CD, LINE, TUNER, AUX/DVD, RECORDER........... |

88 dB |

|

|

POWER AMP DIRECT IN..................................... |

|

106 dB |

|

Tone control |

|

|

|

Bass (50 Hz) ......................................................... |

|

±10 dB |

|

Treble (20 kHz)...................................................... |

|

±10 dB |

|

Power requirement |

|

|

|

[F] ..................................................... |

AC 100 V, 50/60 Hz |

|

|

[N] .......................................................... |

AC 230 V, 50 Hz |

|

|

Power consumption |

|

|

|

EN60065/J60065 .................................................... |

|

200 W |

|

Standby power consumption ......................................... |

|

0.3 W |

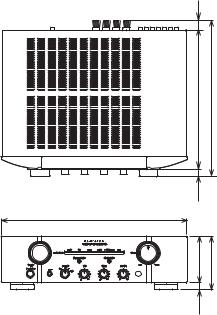

DIMENSIONS (unit : mm) |

|

|

|

|

Accessories |

|

Remote controller (RC003PM)........................................ |

1 |

AAA batteries.................................................................. |

2 |

Detachable AC power cable............................................ |

1 |

Maximum outer dimensions (Amplifier) |

|

Width.................................................................... |

440 mm |

Height .............................................................. |

126.8 mm |

Depth ................................................................... |

368 mm |

Weight (Amplifier) ................................................. |

10.5 kg |

22 |

|

328.5 |

368 |

17.5 |

|

440 |

|

110.5 |

126.8 |

16.3 |

|

1

2. ALIGNMENTS

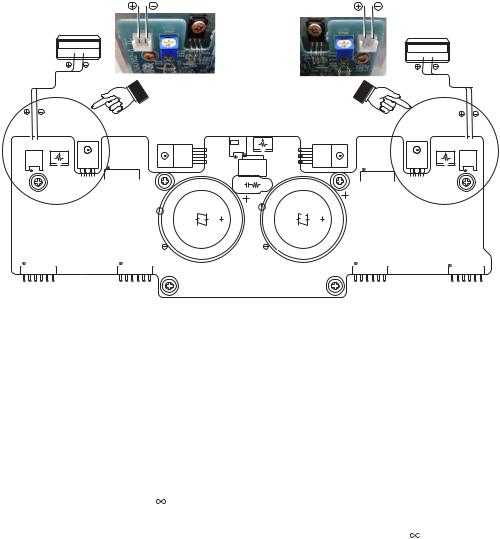

1.Idling Current Alignment

Digital Voltmeter

V

V

L ch

T.P. |

ADJ |

J707 |

R707 |

P701

2. ALIGNMENTS

Digital Voltmeter

V

V

R ch

ADJ |

T.P. |

R708 |

J708 |

Adjustment Procedure |

|

||

Set the power voltage to rated voltage for this adjustment. |

|

||

1. |

Adjust the Idling Current with the variable resistor R707 |

1. |

P701 R707 R708 |

|

and R708 on the PWB P701. |

|

|

2. |

Turn off the power. |

2. |

OFF |

3. |

"+" of Connect Digital Voltage is connected to the No. 1 |

3. |

P701 J707 |

|

pin and connected "-" to No. 2 pin of J707. |

|

J707 1 ( ) "+" |

4. |

"+" of Connect Digital Voltage is connected to the No. 1 |

|

2 "-" |

|

pin and connected "-" to No. 2 pin of J708. |

4. |

P701 J708 |

5. |

Before turning on the power, R707 and R708 have been |

|

J708 1 ( ) "+" |

|

counter clockwise turned with the adjustment driver. |

|

2 "-" |

6. |

Turn on the power, VOLUME is set as - . |

5. |

R707 R708 |

7. |

After 2 minutes. |

|

|

|

With seeing the digital voltage meter turn the variable |

6. |

- |

|

resister clockwise slowly to adjust the idling current. |

7. |

2 |

|

Idling adjustment with R707 (R708). |

|

P701 J707 J708 |

s 4URN 2 2 CLOCKWISE TO INCREASE THE IDLING |

|

R707 R708 |

|

|

current. |

|

|

s 4HE ADJUSTMENT VALUE OF IDLING CURRENT IS |

s |

R707 R708 |

|

|

5 mV(25 mA) ± 0.5 mV(2.5 mA) each. |

|

|

8. |

After 8 minutes. |

s |

|

|

Repeat the same procedure as 7. |

|

"5 mV(25 mA) ± 0.5 mV(2.5 mA)" |

s 4HE ADJUSTMENT VALUE OF IDLING CURRENT IS |

8. |

8 |

|

|

13.4 mV(67 mA) ± 0.5 mV(2.5 mA) each. |

|

7. |

Adjustment is completed. |

s |

|

|

9. |

Remove connection cable, attach the top cover. |

|

"13.4 mV(67 mA) ± 0.5 mV(2.5 mA)" |

NOTE : Idling current decreases with the temperature rise |

|

||

|

inside the unit, and it is set to 10 mV (50 mA) of |

9. |

|

|

setting value in about 30 minutes after turn on the |

|

|

|

power. |

: |

|

|

|

|

30 |

|

|

|

"10 mV(50 mA)" |

2

2. DC Offset Voltage Adjustment |

|

2. DC Offset Voltage Adjustment |

Digital Voltmeter |

|

Digital Voltmeter |

V |

|

V |

R ch |

|

L ch |

N |

R |

SYSTEM A L |

|

||

|

|

SYSTEM B |

|

|

N |

|

Y |

A |

|

|

B |

P101 R639

R640

Adjustment Procedure |

|

||

Set the power voltage to rated voltage for this adjustment. |

|

||

1. |

Before turning on the power, Insert Digital Voltage Meter |

1. |

ON SPEAKERS SYSTEM A |

|

between the SPEAKERS SYSTEM A (L CH) "+" and "-". |

|

L CH R CH "+" "-" |

|

Insert Digital Voltage Meter between the SPEAKERS |

|

|

|

SYSTEM A (R CH) "+" and "-". |

2. |

MIN |

2. |

Adjust the VOLUME to MIN. |

3. |

SPEAKERS A |

3. |

Turn on the power. Then turn the SPAKERS knob to A. |

|

|

|

Adjustment is started immediately after a speaker relay |

|

ON |

|

turns on. |

4. |

L CH |

4. |

First L CH is adjusted. |

|

P101 R639 L |

|

The variable resistor R639 on P101 is turned with |

|

CH |

|

adjustment driver, and the Digital Voltage Meter is |

|

"0 mv ± 3 mV" |

|

adjusted to "0 mV ± 3 mV". |

5. |

R CH |

5. |

Then, R CH is adjusted. |

|

P101 R640 R |

|

The variable resistor R640 on P101 is turned with |

|

CH |

|

adjustment driver, and the Digital Voltage Meter is |

|

"0 mv ± 3 mV" |

|

adjusted to "0 mV ± 3 mV". |

: (R639 R640) DC |

|

NOTE : DC offset voltage drops when turn the semi-fixed |

|

|

|

|

resistor (R639 and R640) clockwise. DC offset |

|

DC |

|

voltage rises when turn the semi-fixed resistor un- |

|

|

|

clockwise. Please turn it slowly, because value of |

6. |

DC |

|

Digital Voltage Meter changes slowly. |

|

SPEAKERS SYSTEM A L CH R CH |

6. |

Although after-adjustment DC offset voltage has some |

|

"+" "-" DC "0 mV ± 20 |

|

change, Please check that the range of DC offset voltage |

|

mV" |

|

between L ch (R ch) "+" and L ch (R ch) "-" terminal of |

|

|

SPEAKERS SYSTEM A is "0 mV ± 20 mV". CHART OF

FACTORY MODE

3

3. |

SERVICE MODE |

|

|

|

3. SERVICE MODE |

||||||||

Microprocessor (QU01) version check |

|

|

Microprocessor (QU01) version |

||||||||||

1. |

Connect the mains cord into the unit. |

|

1. |

|

|||||||||

2. |

Press the POWER button with pressing the SOURCE |

2. |

SOURCE DIRECT POWER |

||||||||||

|

DIRECT button on the Unit. |

|

|

|

|

|

|||||||

3. |

The firmware version is displayed on the front LED. |

3. |

FIRMWARE LED |

||||||||||

|

(Display time is only for 3 seconds.) |

|

|

|

( 3 ) |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PHONO |

CD |

TUNER |

|

AUX/DVD |

1 |

|

RECORDER |

|

2 MUTE |

||

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Version : 8 |

4 |

2 |

1 |

|

|

|

|

|

|||

The firmware version is displayed in the lighting position of |

LED |

|||||

LED. |

|

|

|

|||

Ex. : |

|

RECORDER 2 [1 ], Version 1 |

||||

|

Light up RECORDER-2 [1 ], Version : 1 |

|

RECORDER 2 [1 ] and AUX/DVD [4 ], Version 5 |

|||

|

Light up RECORDER-2 [1 ] and AUX/DVD [4 ], Version : 5 |

|

RECORDER 2 [1 ] and TUNER [8 ], Version 9 |

|||

|

Light up RECORDER-2 [1 ] and TUNER [8 ], Version : 9 |

4. LED |

||||

4. |

Each LED light up then all LED light up. |

|

|

|

|

|

5. |

Turn off the power to quit Service Mode. |

5. SERVICE |

||||

|

(The unit to the default status) |

|

( |

|||

|

|

|

|

) |

|

|

4

4. PROTECTION MODE

Explanation of microprocessor (QU01) [PROT-1 (pin6) and

PROT-2 (pin7)].

[A]The PROT-1 (pin6) is the port to detect the following abnormalities of the Power AMP

1.Detection of an abnormality in the DC offset voltage from the Speaker Output terminal.

If the voltage from the Speaker Output terminal exceeds approximately 1.2V (DC), Q955 or Q956 will turn on and the signal from the PROT-1 terminal will change to L from H.

2.Detection of an abnormal current from the power transistors (Q713 ~ Q716).

If an electric current of over 7A flows in Q713 or Q715, Q951, Q953 and Q957 turn on, and the signal from the PORT-1 terminal will change to L from H.

If an electric current of over 7A flows in Q714 or Q716, Q952, Q954 and Q957 turn on, and the signal from the PORT-1 terminal will change to L from H.

3.Detection of an abnormal temperature of the Heat Sink. If the temperature of the Heat Sink exceeds approximately +110 degrees C, the posistor (R969) will turn on Q958 and the signal from the PROT-1 terminal will change to L from H.

If any of the above three abnormalities is detected, the signal from the PROT-1 terminal will change to L from H, and the protection circuit will be activated, the signal from the SPK_OUT (pin10) changing to H from L and the speaker relays L751, L752 and L753 immediately turned off.

What this protection operation results in after this depends on how long the signal from the PROT-1 has to remain L.

s)F THE 02/4 PIN RECOVERS TO ( WITHIN AS SHORT A period of time as one second or less.

The MUTE indicator starts flickering, thereby indicates that the protection circuit has come into operation and automatically turns down the volume. The protection circuit is deactivated after approximately 15 seconds, so that readjusting the volume will allow normal use of the unit again. This protection operation is intended for the situation wherein the user has misused the unit temporarily and automatically resets the unit while the amp circuit is functioning properly.

s)F THE 02/4 PIN REMAINS , FOR MORE THAN ONE SECOND

The amp will be powered off by the P_ON (pin15) changing to H from L and Power relay L852 turned off Then, the STANDBY indicator flickers, thereby indicating that an error has occurred. This protection operation is intended for a failure in the amp circuit and immediately turns the power off to avoid the risk of any damage. Depending on how the user is handling the unit, this operation may be performed no matter if the amp is functioning properly.

4. PROTECTION

(QU01) PROT-1 (pin6) PROT-2 (pin7)

[A]PROT-1 (pin6)

1.DC

1.2V (DC) Q955Q956 ON PROT-1 "H→L"

2.(Q713 Q716)

Q713 Q715 7A Q951, Q953, Q957 ON PROT-1 "H→L"

Q714 Q716 7A

Q952,Q954,Q957 ON PROT-1 "H→L"

3. ヒートシンクの温度が約110

(R969) Q958 ON PROT-1 "H→L"

1. 3. PROT-1 "H→L"SPK_OUT (pin10) "L→H"L751, L752, L753 OFF

PROTECTION PROT-1 "L"

sPROT-1 (pin6) 1 "H"

MUTE PROTECTION15PROTECTION

sPROT-1 (pin6) 1 "L"

P_ON (pin15) "H→L" L852 OFF

このときSTANDBY PROTECTION

SW

1 SW

PROTECTION

SW PROT-1 (pin6) "L"

3 STANDBY

PROTECTION

5

To check if the amp is in order, switch off the unit and switch |

[B] PROT-2 (pin7) |

||

it on again one minute later. This action will deactivate |

1. |

|

|

the protection operation. If the PROT-1 (pin6) remains |

|

+48V -48V |

|

"L", which constitutes an abnormality, the unit shuts down |

|

R801 R802 ±1.2V(DC) |

|

approximately 3 seconds later and the STANDBY indicator |

|

Q903 Q904 ON PROT-2 (pin7) " |

|

starts flickering. |

|

→ " |

|

If the protection operation will not be deactivated after the |

2. |

|

|

power is turned on again, the amp circuit may be broken. |

|

Q901 Q902 +28V -28V |

|

|

|

|

R905 R906 |

[B] The PROT-2 (pin7) is the port to detect abnormalities |

|

±1.2V(DC) Q901 Q902 ON |

|

|

of the power supply circuit. |

|

PROT-2 (pin7) "H→L" |

1. |

Detection of an abnormality in the power amp power |

3. |

|

|

supply circuit. |

|

+24VL 80 mA |

|

This port monitors the midpoint voltage of the power amp |

|

Q815, Q901 ON PROT-2 (pin7) "H→L" |

|

power supply between +48V and -48V. If the voltage at |

|

|

|

the connection point of R801 and R802 exceeds DC |

|

|

|

±1.2V, Q903 or Q904 will turn on to change the signal |

1. 3. P_ON (pin15) |

|

|

from the PROT-2 (pin7) to L from H. |

"L→H" L852 OFF |

|

2. |

Detection of an abnormality in the preamp power supply |

STANDBY |

|

|

circuit. |

|

|

|

Q901 and Q902 monitor the midpoint voltage between |

|

|

|

+28V and -28V. If the voltage at the connection point of |

PROTECTION |

|

|

R905 and R906 exceeds DC ±1.2V, Q901 or Q902 will |

|

|

|

turn on to change the signal from the PROT-2 (pin7) to L |

|

|

|

from H |

|

|

3. |

Detection of an abnormality in the function relay power |

SW 1 SW |

|

|

supply circuit. |

|

|

|

If the +24VL of the relay power supply receives an |

PROTECTION |

|

|

electric current of over 80 mA, Q815 and Q901 will turn |

SW PROT-2 (pin7) "L" |

|

|

on to change the signal from the PORT-2 (pin7) to L from |

3 STANDBY |

|

|

H. |

|

|

|

|

PROTECTION |

|

If any of the above three abnormalities is detected, the signal |

|

||

from the P_ON (pin15) terminal will be changed to L from |

|

||

H, the power relay L852 will be turned off and the unit will |

|

|

|

be shut down. Then, the STANDBY indicator flickers and |

|

|

|

indicates that an abnormality has occurred. |

|

|

|

This protection operation is intended for a breakdown of the AMP circuit or the power supply circuit and immediately shut s off the power in order to avoid the risk of damage.

To check if the amp circuit or the power supply circuit is broken, switch off the power and then switch it on again one minute later. This action will deactivate the protection operation.

If the RPOT-2 (pin7) remains L after the power is switched on again, the unit will be shut down again three seconds later with the STANDBY indicator flickering.

If the unit is powered on again and yet cannot get the protection operation deactivated, the amp circuit or the power supply circuit may be broken.

6

5. WRITING MAIN MICROPROCESSOR |

5. WRITING MAIN MICROPROCESSOR |

PROCEDURE |

PROCEDURE |

Microprocessor needs writing software, when a |

QU01 QU01 |

microprocessor (QU01) is replaced. |

|

NECESSARY EQUIPMENT |

|

s 7INDOWS 0# OR 80 WITH 3ERIAL 0ORT |

s Windows PC (2000 XP Serial ) |

s 23 # #ABLE STRAIGHT TYPE 0IN FEMALE 0IN |

s RS-232C (9Pin -9Pin ) |

female) |

s (90M-PM11S1JI') |

s #ONNECTION *)' - 0- 3 *)' |

s (FlashProg.exe ) |

s 7RITING 4OOL AND SOME FILES &LASH0ROG EXE ETC IN |

s (PM7003_xxxx.h16) |

TM86FH47pass folder) |

|

s 7RITING DATA 0- ?XXXX H |

|

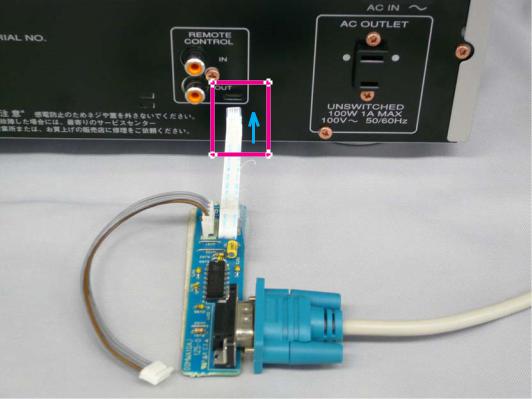

WRITING PROCEDURE

1.Disconnect the mains cord from the unit.

2.#ONNECT 23 # ON THE CONNECTION *)' AND 3ERIAL 0ORT of windows PC with RS-232C cable.

3.Connect FPC (upside contact) to the rear panel of the

UNIT FROM CONNECTION *)'

4.Reconnect the mains cord to the unit.

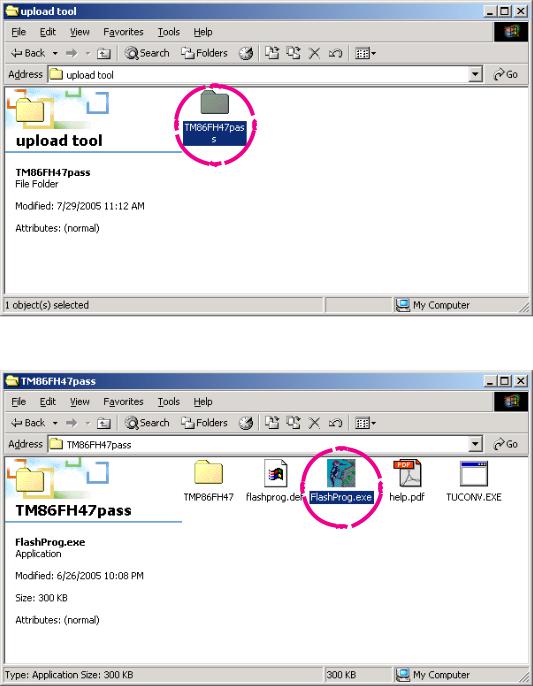

5.Put the "TM86FH47pass" folder into anywhere on your PC’s hard disc.

2.Windows PC Serial Port RS-232C

3.FPC

5.TM86FH47pass Windows PC

7

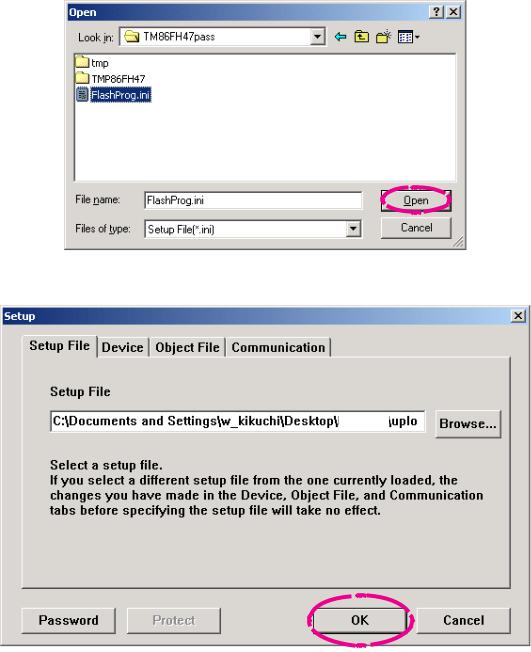

6. Double click the TM86FH47pass folder. |

6. TM86FH47pass |

7. Double click FlashProg.exe. |

7. FlashProg.exe |

8

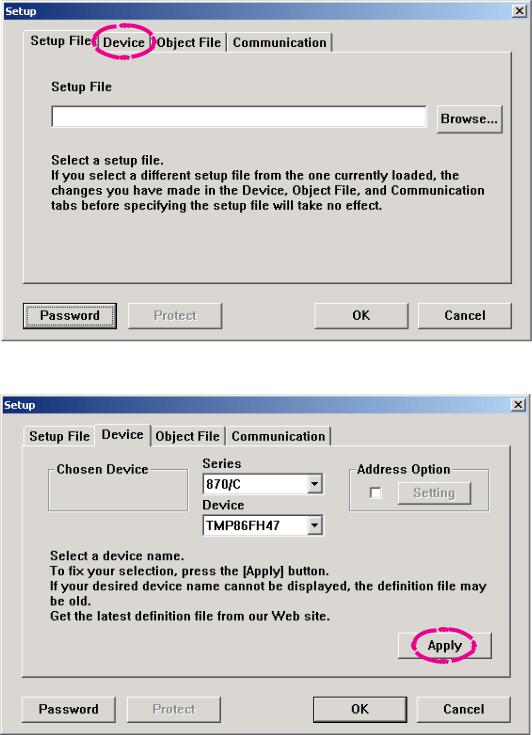

8. Click Device. |

8. Device |

9. Click Apply. |

9. Apply |

9

10.TMP86FH47 appear in Chosen Device. |

10.Chosen Device TMP86FH47 |

11.Click Object File, and click Browse... |

11.Object File Browse... |

10

12.Choose iHEX Fomat[*.h16,*.h20] in Files of type. |

12.Files of type iHEX Fomat[*.h16,*.h20] |

Choose writing data, and click Open. |

Open ( |

|

) |

PM7003_V09.h16

13.Click Communication. |

13.Communication |

PM7003

11

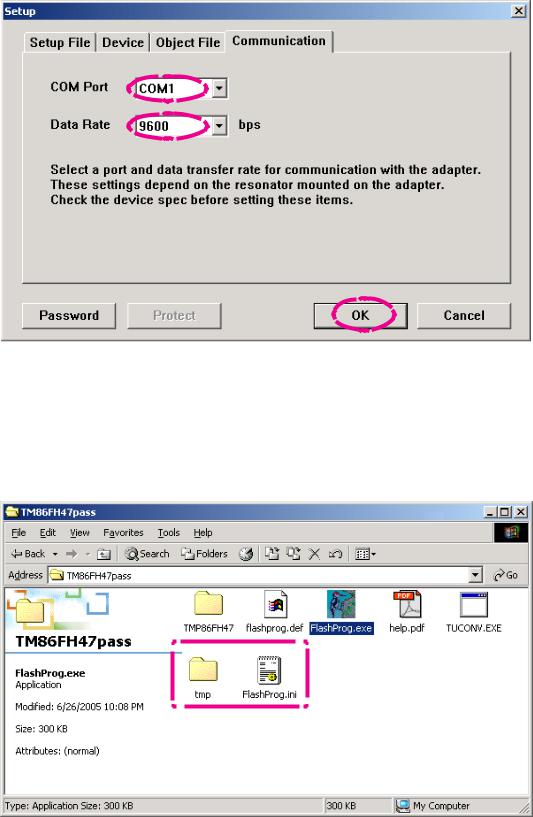

14.Choose COM port number in COM port. |

14.COM Port COM Port |

Choose 9600 in Data Rate. |

Data Rate 9600 |

Click OK. |

OK |

15.When Setup window is closed, the tmp folder and |

15. TMP86FH47pass tmp |

FlashProg.ini file are created simultaneously. |

FlashProg.ini |

NOTE : These are the original set-up configuration files for |

: Windows PC |

that PC. They do not operate, if these files moved |

PC |

to another PC. When you make it operate with other |

PC |

PC, delete the tmp folder and the FlashProg.ini file |

tmp FlashProg.ini |

and redo a setup. |

|

12

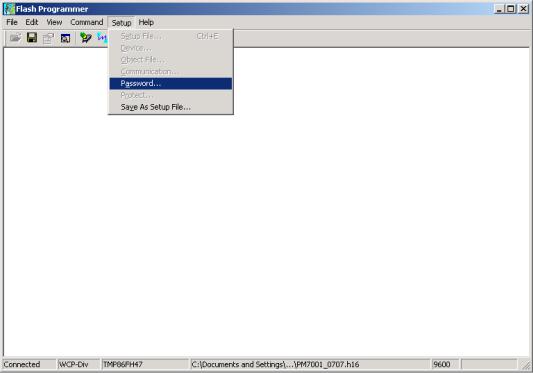

16.The Flash Programmer is launched. |

16.setup Flash Programmer |

Click setup icon. |

setup |

17.Click Browse.... |

17.Browse... |

13

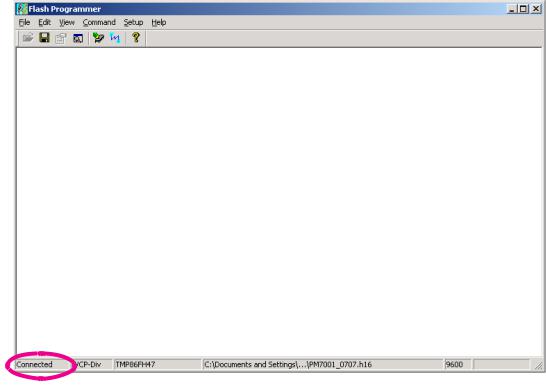

18.Choose FlashProg.ini in TM86FH47pass folder, and |

18.TM86FH47pass FlashProg.ini |

click Open. |

Open |

19.Click OK. |

19.OK |

PM7003

14

20.Press the POWER ON/OFF button, and turn on the unit. |

20. |

Status indication at lower left in Flash Programming |

Flash Programming |

window is changed to "Connected" from "Connecting". |

Connecting Connected Connected |

When it did not changed, check the connection of FPC or |

|

RS-232C cable. |

|

15

21.Select Password in Setup. |

21.Setup Password |

16

22.Setup Password opens. |

22.Setup Password |

s When writing in a blank microprocessor |

s |

Refer to next page |

s ( ) |

s When writing (update) in the already written-in |

19 |

microprocessor |

|

Refer to 19 page |

|

17

Loading...

Loading...