LG LS-T186ABL, LS-T186AHG, LS-T246ABL, LS-T266CBG, LS-T246LEL Service manual

SERVICE MANUAL

Room Air Conditioner

CAUTION

-BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

-ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL :

LS-T186ABL/ABG/CBG/CEL/EEL/CDL/ADL/ADG

LS-T186AHG/FBG/CBL/AEL/NEG/AEM/ABM

LS-T246ABL/CBG/CEL/EEL/QEG/SEG/CEM

LS-T266CBG/FBG/ABL/CEL

LS-T246LEL/LEM/ABM/AAL

WEBSITE http://biz.LGservice.com

E-MAIL http://www.LGEservice.com/techsup.html

Contents

Details of 2002 LG Model Name............................................................................................ 3

Functions................................................................................................................................4

Product References .............................................................................................................. 7

Dimensions............................................................................................................................. 8

Refrigeration Cycle Diagram............................................................................................... 10

Wiring Diagram..................................................................................................................... 11

Operation Details ................................................................................................................. 12

Display Function .................................................................................................................. 19

Self-diagnosis Function....................................................................................................... 19

Installation ............................................................................................................................ 20

Operation .............................................................................................................................. 31

Disassembly of the parts (Indoor Unit).............................................................................. 33

2-way, 3-way Valve................................................................................................................ 36

Cycle Troubleshooting Guide.............................................................................................. 43

Electronic Parts Troubleshooting Guide............................................................................ 44

Electronic Control Device.................................................................................................... 52

Schematic Diagram.............................................................................................................. 54

Exploded View and Replacement Parts List...................................................................... 57

-2-

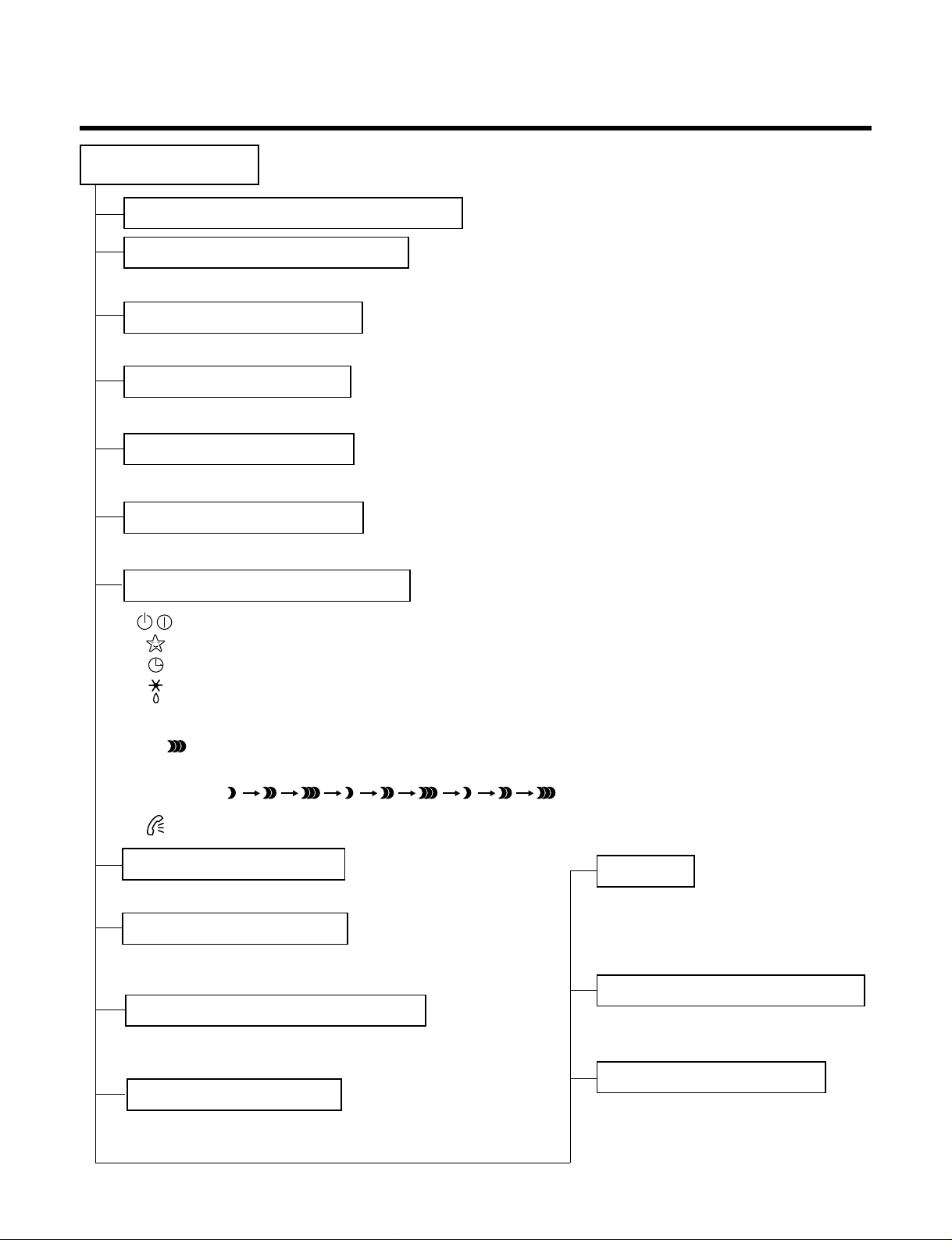

Details of 2002 LG Model Name

-3-

12

3456789

Code Type Code of Model Meaning

1,2 Type of Airconditioner A~Z LS: LG Split Type Airconditioner

3 Chassis A~Z Name of toll of Unit

Ex. LS-R ➔ S R Chassis

4,5 Capacity(Btu/h) 1~9 Cooling/Heating Capacity

Ex. "09" ➔ 9,000Btu/h

6 Electric Range 1~9 Electric Standard

1 ➔ 115V/60Hz 6 ➔ 220~240V/50Hz

2 ➔ 220V/60Hz 7 ➔ 110V, 50/60Hz

3 ➔ 208~230V/60Hz 8 ➔ 380~415V/50Hz

5 ➔ 200~220V/50Hz 9 ➔ 380~415V/60Hz

7 Serial No. 0~9

A~Z

8 Cooling/Heating A~Z

9 LG/OEM Brand A~Z L: LG Brand M: 1st OEM Brand

G: 2nd LG Brand N: 2nd OEM Brand

-

Basic A 0

Plasma Filter B 1

Auto Swing

+ Plasma Filter C 2

Telephone + LED Display D 3

Telephone + LCD Display E 4

Auto Swing

+ Plasma Filter + Telephone + LCD

F5

Low Ambient + Ambient/change G 6

Plasma Filter + Low Ambient + Ambient/change

H7

Internet J 8

Auto Swing + Plasma Filter + Oxygen Generator

K9

Auto Swing + Soft Start L Z

Auto Swing + Star Rating M Y

Auto Swing + Star Rating + Plasma Filter N X

Auto Swing + Soft Start + Star Rating P W

Auto Swing + Soft Start + Star Rating 4 + Plasma

QV

Auto Swing + Telephone + LCD R U

Auto Swing + Telephone + LCD + Soft Start

ST

C/O

C

A

D

G

K

H/P

H

B

E

J

L

E/H+C/O

X

5

7

-

-

E/H+H/P

Y

6

8

-

-

C/O

F

M

Q

-

-

H/P

R

P

S

-

-

C/O

V

W

1

3

H/P

N

Y

2

4

H/PTH/P

U

INDOOR

BASIC

BASIC

PLASMA

PLASMA

GOLD FIN

OUTDOOR

BASIC

GOLD FIN

GOLD FIN

BASIC

GOLD FIN

UNIT

R22

HFC R22+AC INV.

HFC+AC

INV.

HFC+DC

INV.

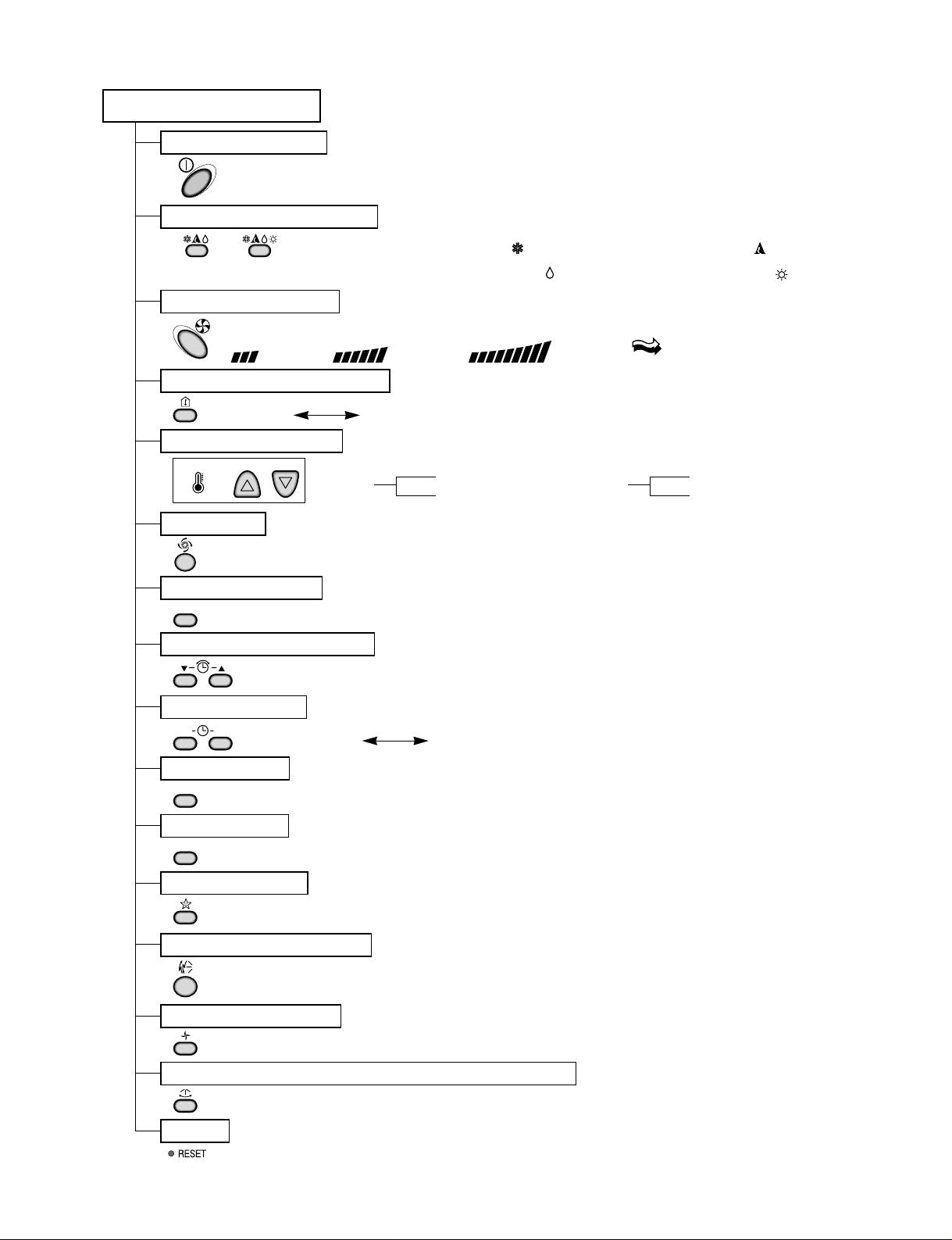

Functions

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 sec at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low, CHAOS, JET COOL

---

Lights up in operation

---

Lights up in Sleep Mode

---

Lights up in Timer Mode

---

Lights up in Defrost Mode (for Heating Model)

OUTDOOR---

Lights up in compressor operation (for Cooling Model)

---

The function illustrates its dynamic mode

by using a multiple lighting system.

()

---

Linghts up in Telephone Control operation.

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

• The function will be operated while in any

operation mode with selecting the function.

• The function is to be stopped while it is

operating with selecting the function.

• Both the indoor and outdoor fan stops during defrosting.

• The indoor fan stops until the

evaporator pipe temperature will be reached

at 28°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

PLASMA

-4-

Defrost(Deice) control (Heating)

Hot-start Control (Heating)

PLASMA

-5-

Healthy Dehumidification Operation Mode.

( )

Remote Control

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

JET COOL

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Fan Operation Mode

Horizontal Airflow Direction Control Button(Optional)

Room, Temperature Display

Setting the Time or Timer

PLASMA(Optional)

ON OFF

SET

PLASMA

CANCEL

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High:39°C Low:11°C)

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C

Up to 30°C

Heating

Down to 16°C

Up to 30°C

-6-

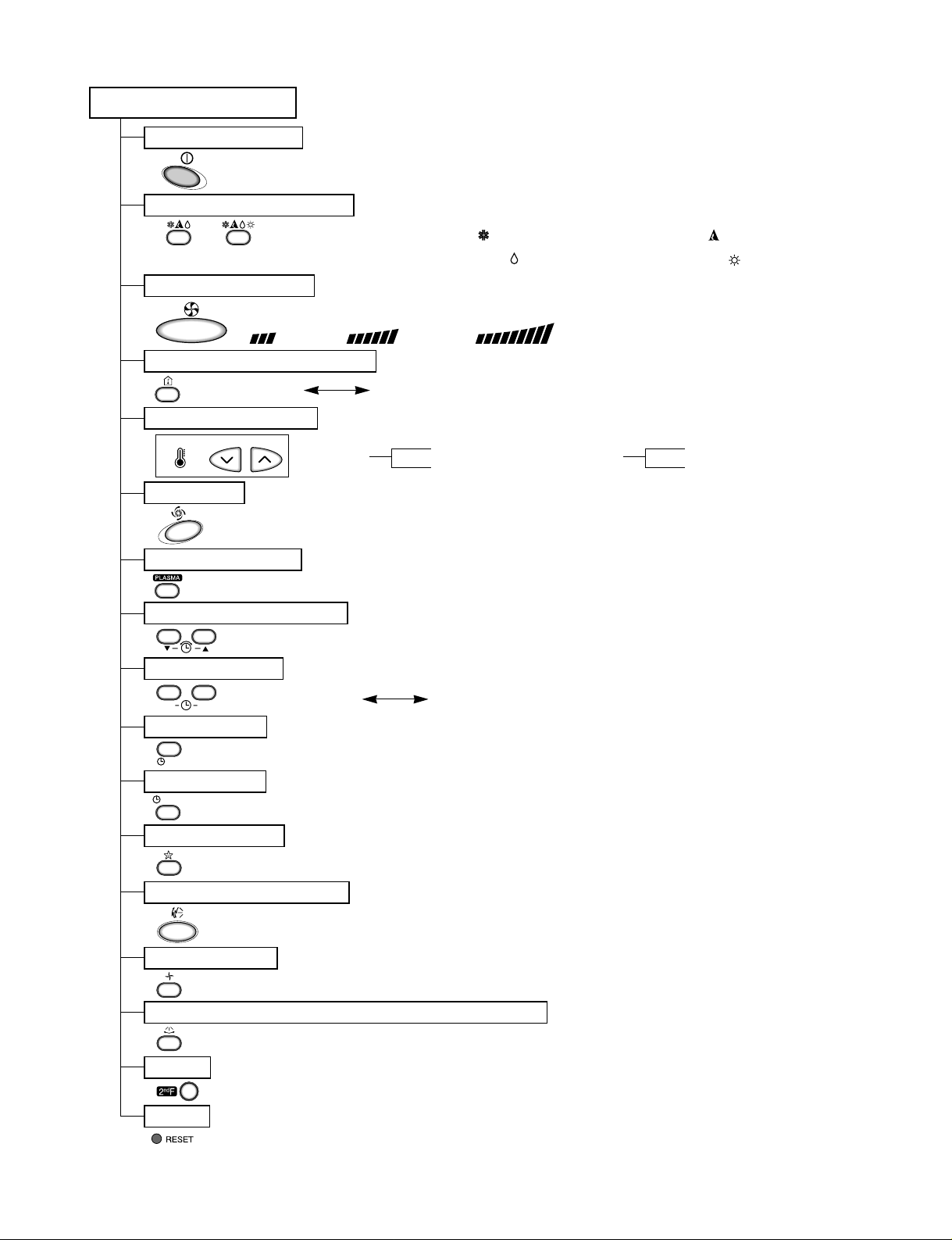

Healthy Dehumidification Operation Mode.

( )

Remote Control

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

JET COOL

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Air Circulation

Horizontal Airflow Direction Control Button(Optional)

Room, Temperature Checking

Setting the Time or Timer

PLASMA(Optional)

Fan Speed Selection

(Low) (Med) (High)

ON

OFF

CANCEL

SET

2nd F

: (High:39°CLow:11°C)

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C

Up to 30°C

Heating

Down to 16°C

Up to 30°C

-7-

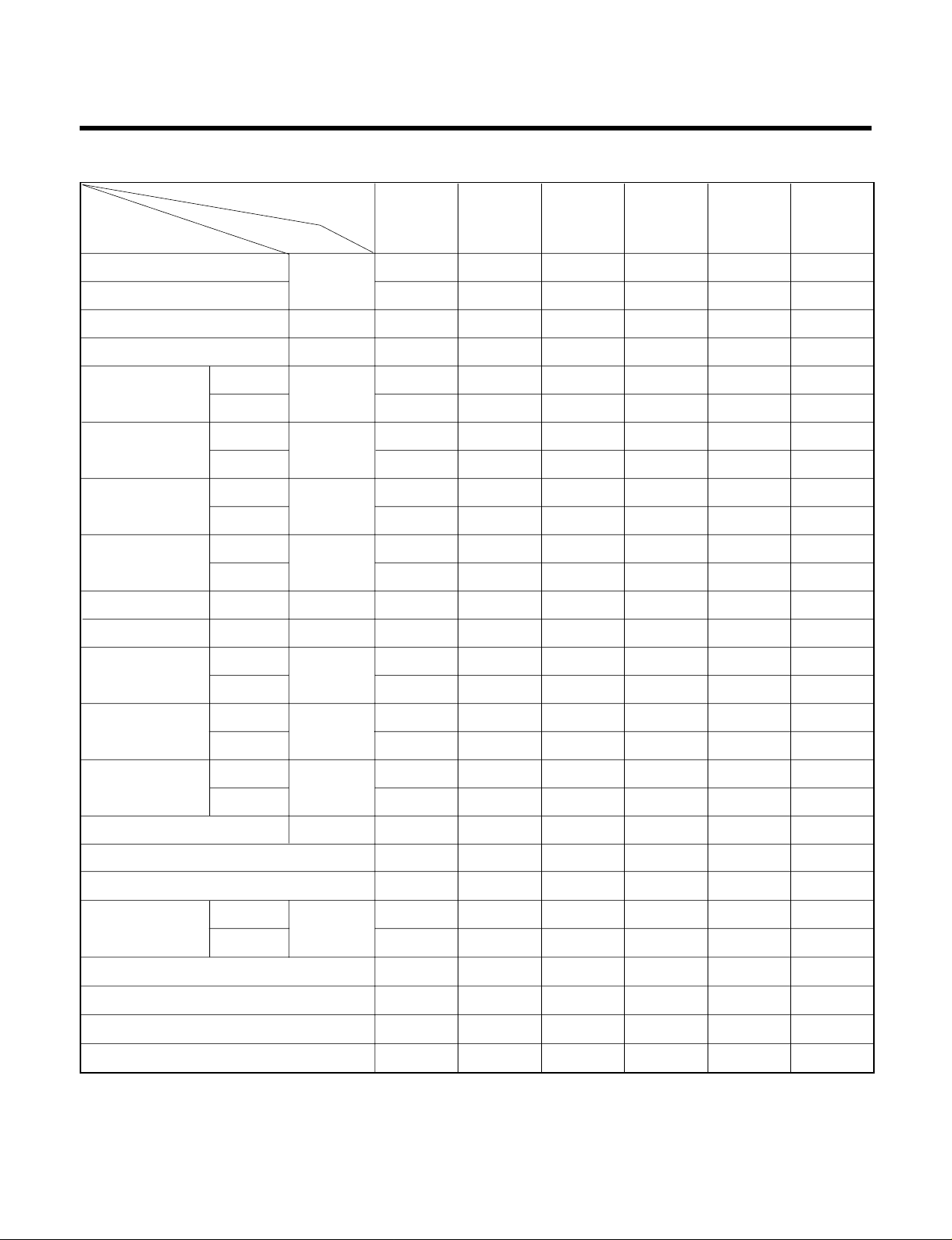

Product References

Model Name

Item Unit

Cooling Capacity

Btu/h

Heating Capacity

Moisture Removal l/h

Power Source Ø, V, Hz

Cooling

W

Heating

Running Cooling

A

Current Heating

E.E.R. Cooling Btu/hW

C.O.P Heating

Refrigerant g

Airflow Direction Control (Up & Down)

Remocon Type

inch(mm)

Sleeping Operation

Drain Hose

Connecting Cable

Power Cord

Air Circulation

Noise Level

Input

m3/min

dB (A)±3

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Service Valve

Motor Output

Dimensions

(W x H x D)

Net. Weight

W

mm

kg

NOTE: Please refer to Label Quality on the product since this specification may be changed for improving

performance

LS-T186_Series

LS-T186CDL

LS-T186ADG

LS-T186NEG

LS-T246_Series

LS-T266_Series

LS-T246QEG LS-T246AAL

18,000 18,500 17,500 24,000 24,000 24,000

19,000 - 18,000 24,000 24,000 -

2.2 2.2 2.2 2.88 2.88 2.88

1Ø, 220-240V, 50Hz 1Ø, 220-240V, 50Hz 1Ø, 220-240V, 50Hz 1Ø, 220-240V, 50Hz 1Ø, 220-240V, 50Hz 1Ø, 220-240V, 50Hz

13.4 13.4 13.4 14.9 14.9 14.9

42 42 42 42 14.9 14.9

42 42 42 47 47 47

55 55 55 57 58 58

1,860 1,610 1,590 2,700 2,300 2,700

1,870 - 1,630 2,650 2,300 -

9.2 9.2 7 12.6 10.5 12.6

9.2 - 7 12.2 10.5 -

9.6 9.6 11 8.88 10.4 9.0

2.98 - 3.23 2.69 3.06 22 22 22 35 35 35

61 61 82.9 82.9 82.9 82.9

1,090 x 314 x 1721,090 x 314 x 172 1,090 x 314 x 172 1,090 x 314 x 172 1,090 x 314 x 172 1,090 x 314 x 172

870 x 655 x 320 870 x 655 x 320 870 x 655 x 320 870 x 655 x 320 870 x 880 x 320 870 x 880 x 320

12 12 12 12 12 12

60 60 60 60 72 60

1,325(R22) 1,150(R22) 1,400(R22) 1,600(R22) 1,600(R22) 1,420(R-22)

Optional Optional Optional Optional Optional Optional

L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless

1/4" (6.35) 1/4" (6.35) 1/4" (6.35) 3/8" (9.52) 3/8" (9.52) 3/8" (9.52)

1/2" (12.7) 1/2" (12.7) 1/2" (12.7) 5/8" (15.88) 5/8" (15.88) 5/8" (15.88)

OOOOOO

OOOOOO

1.5mm2x 0.7mm21.5mm2x 0.7mm21.5mm2x 0.7mm22.5mm2x 0.7mm22.5mm2x 0.7mm22.5mm2x 0.7mm

2

1.5mm

2

1.5mm

2

1.5mm

2

2.5mm

2

2.5mm

2

2.5mm

2

-8-

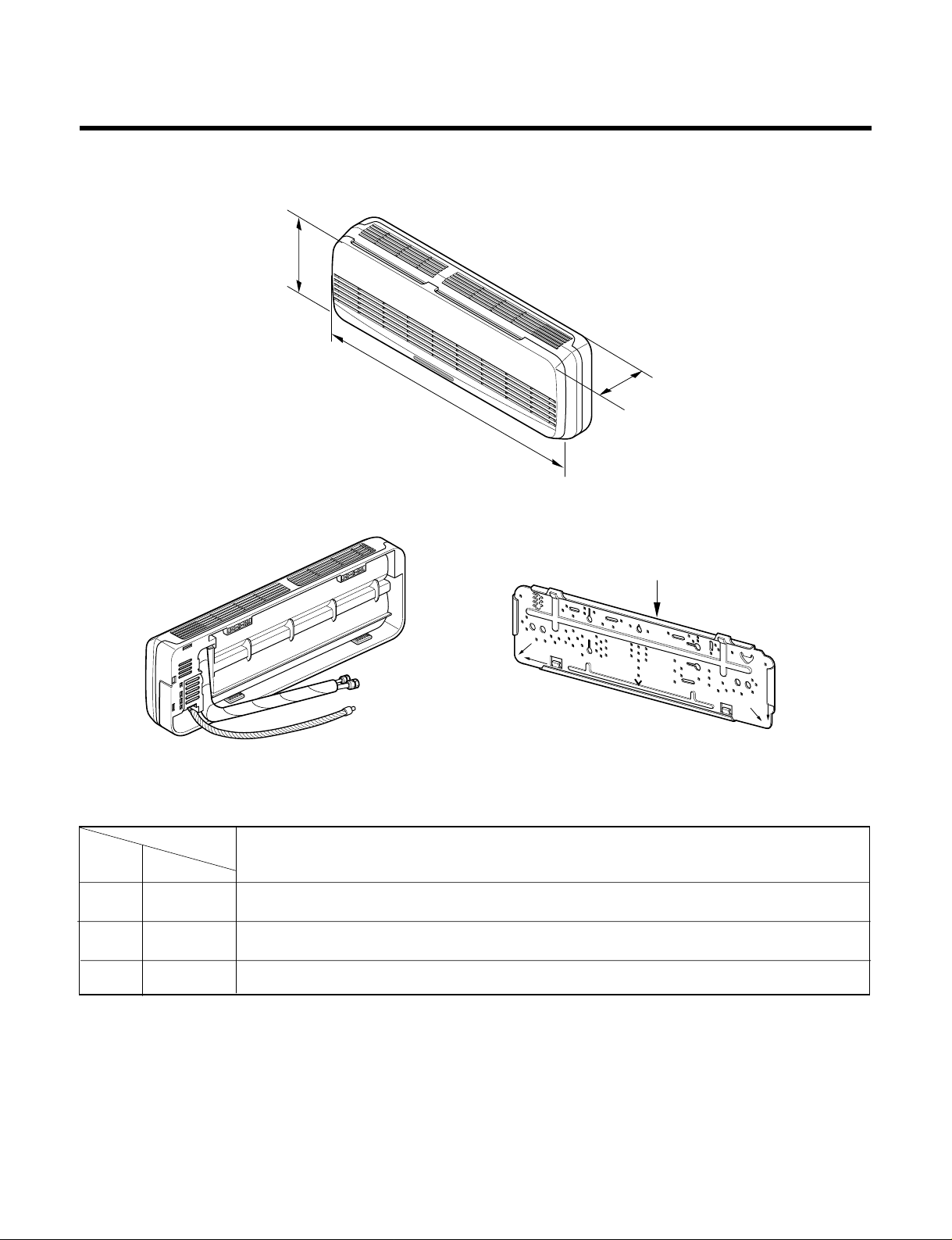

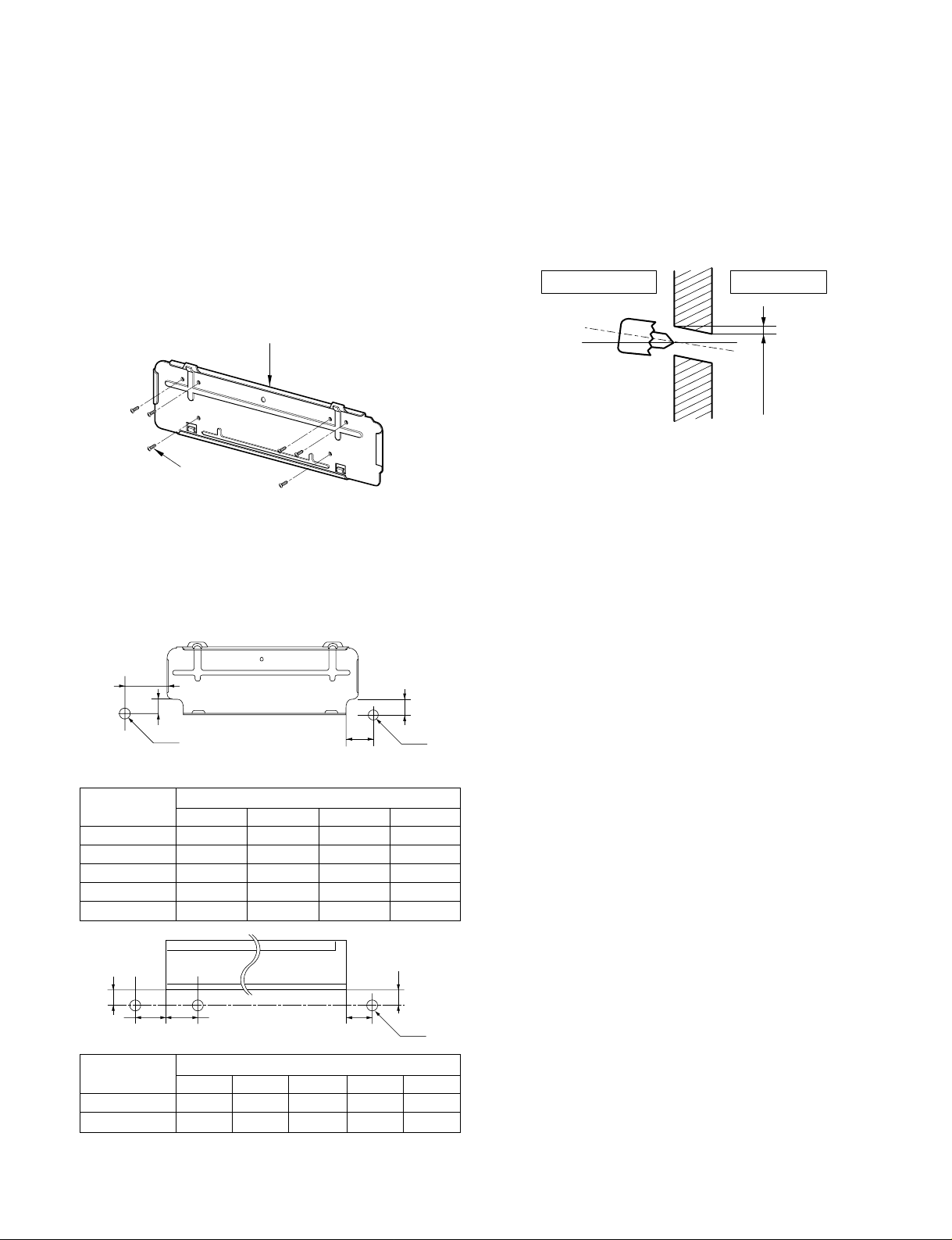

Installation plate

D

H

W

MODEL

DIM Unit

W mm 1090

H mm 314

D mm 172

ALL MODELS

Dimensions

(1) Indoor Unit

-9-

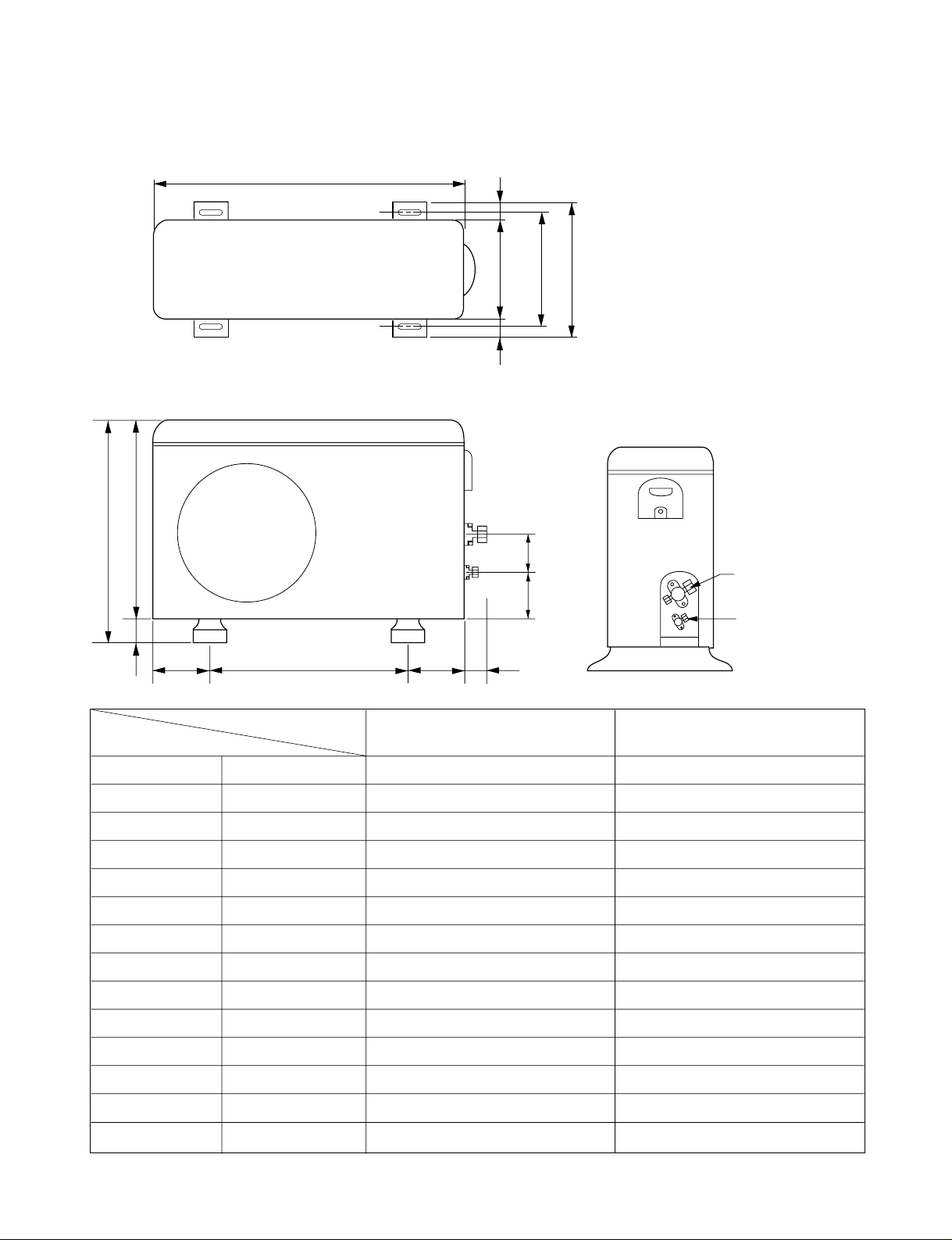

W

L7 L6 L8 L9

D

L1

L2

L3

L10L11

L4L5

H

Gas side

Liquid side

(2) Outdoor Unit

MODEL

DIM

W mm 870 870

H mm 655 880

D mm 320 320

L1 mm 370 370

L2 mm 340 340

L3 mm 25 25

L4 mm 630 855

L5 mm 25 25

L6 mm 546 546

L7 mm 162 162

L8 mm 162 162

L9 mm 54 54

L10 mm 74.5 74.5

L11 mm 79 79

ALL MODELS LS-T246QEG

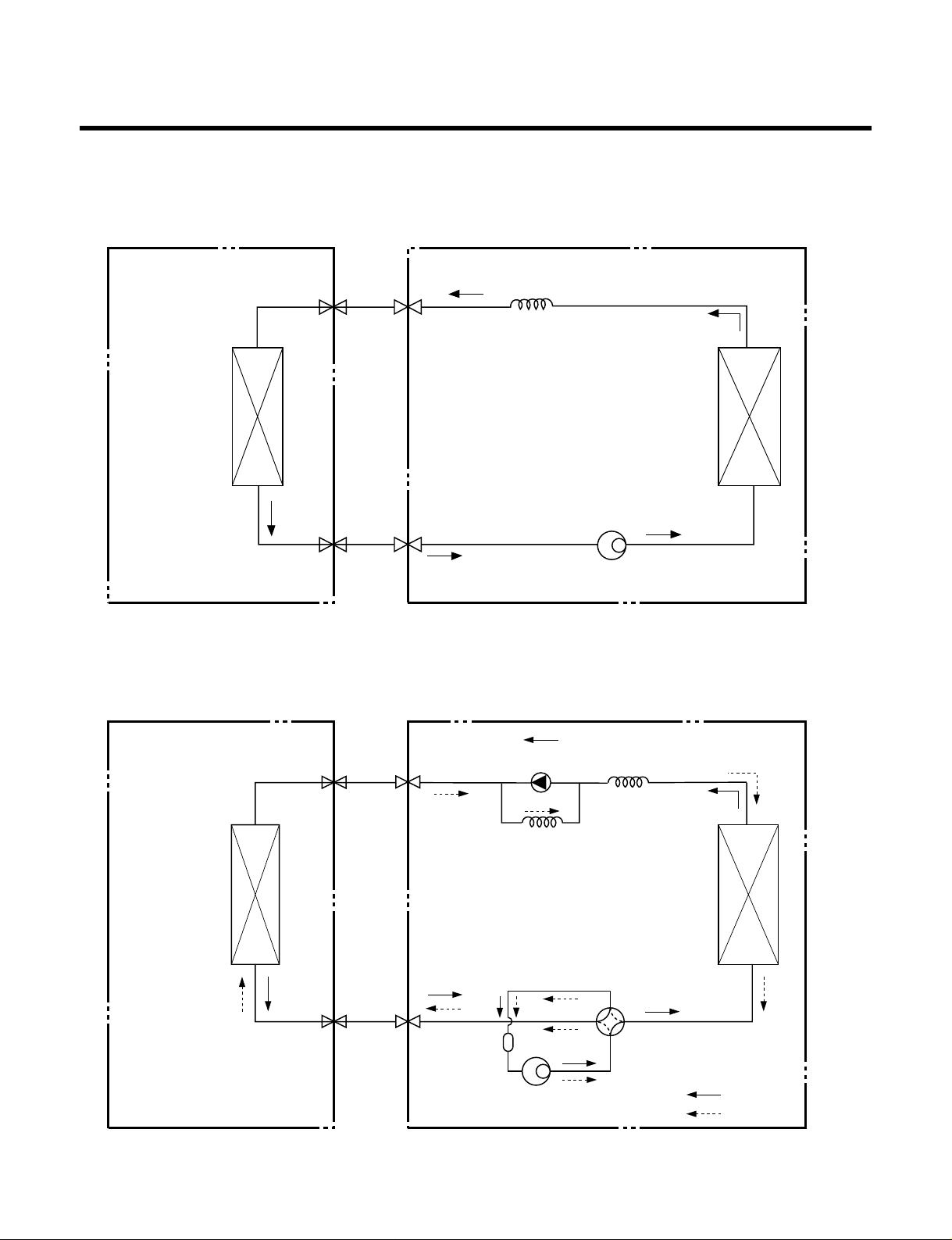

Refrigeration Cycle Diagram

-10-

INDOOR UNIT OUTDOOR UNIT

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

COMPRESSOR

ACCUMU

LATOR

GAS SIDE

GAS SIDE

VALVE

LIQUID SIDE

LIQUID SIDE

VALVE

CAPILLARY TUBE

CAPILLARY TUBE

CHECK VALVE

(Heating Model only)

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

(1) Cooling Only Models

(2) Cooling & Heating Models

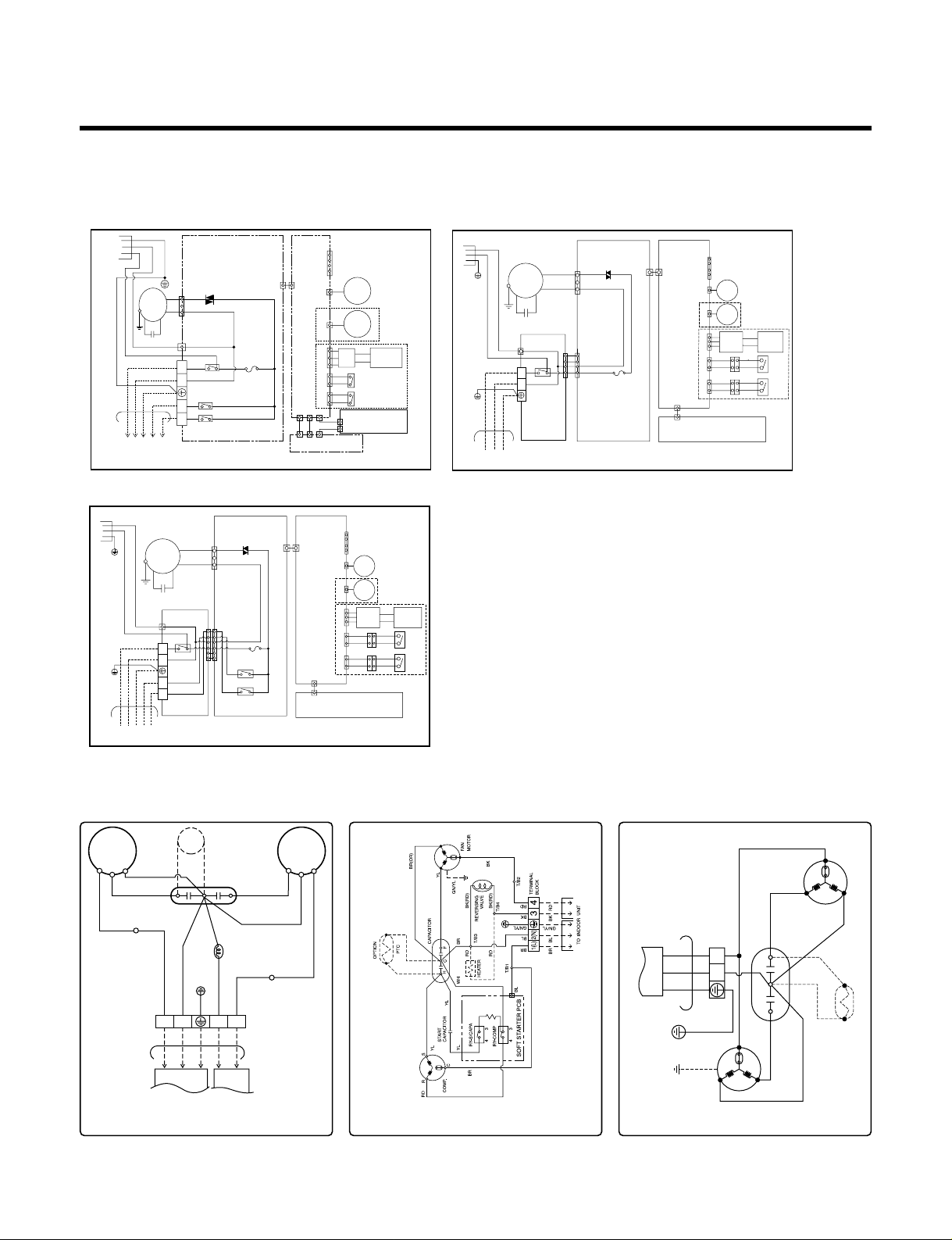

Wiring Diagram

-11-

POWER

BR

BRBLBKRDGN/YL

BL

1(L) 2(N)

34

MOTOR

CN-MOTOR

CN-TAB1

CN-AC/DC

CN-AC/DC

CN-TH

THERMISTOR

STEP

MOTOR

STEP

MOTOR

H.V.

ASM

RD

AIR

CLEAN

(

PLASMA

)

SAFETY S/W1

SAFETY S/W2

BK

BK

BK

BK

BK

CN-U/D

CN-L/R

CN-DISP

DISPLAY PWB ASM

SUB PWB ASM

CN-TELE

CN-LCD

INDOOR WIRING DIAGRAM

RY-4WAY

RY-FAN

T/BLOCK

TO OUTDOOR UNIT

TRIAC

AC PWB ASM DC PWB ASM

OR

BK

BR

4

RY-COMP

FUSE

250V T2A

3

YL

SH-CAPA

GN/YL

BR

(

BK/Plained

)

GN/YL

BL

(

WH/Ribbed

)

MOTOR

OR

RD

BK

BK BK

BK BK

BK BK

BK BK

POWER

BR(BK/Plained)

BL(WH/Ribbed)

BK

YL

SH-CAPA

T/BOARD

T-BLOCK

CN-MOTOR

THERMISTOR

STEP

MOTOR

CN-ACDC1

CN-ACDC2

CN-THCN-U/DCN-L/RCN-HVBCN-12V

CN-DISP

DISPLAY PWB ASM.

P/No : 3854A20238J

CN-CONT

TRIAC

AC PWB ASM. DC PWB ASM.

CN-TAB

RY-COMP

TO OUTDOOR UNIT

INDOOR WIRING DIAGRAM

43

1(L)

BR

BR

BL

GN/YL

2(N)

FUSE

250V T2A

STEP

MOTOR

H.V.

ASM.

S/W1

S/W2

AIR

CLEAN

(PLASMA)

GN/YL

GN/YL

MOTOR

OR

RD

BK

BK BK

BK BK

BK BK

BK BK

POWER

GN/YL

GN/YL

BR(BK/Plained)

BL(WH/Ribbed)

BK

YL

SH-CAPA

T/BOARD

T-BLOCK

RY-4WAY

RY-FAN

CN-MOTOR

THERMISTOR

STEP

MOTOR

CN-ACDC1

CN-ACDC2

CN-THCN-U/DCN-L/RCN-HVBCN-12V

CN-DISP

DISPLAY PWB ASM.

P/No : 3854A20238H

CN-CONT

TRIAC

AC PWB ASM. DC PWB ASM.

CN-TAB

RY-COMP

TO OUTDOOR UNIT

INDOOR WIRING DIAGRAM

43

1(L)

BR

BR

BL

BK

RD

GN/YL

2(N)

3 4

FUSE

250V T2A

STEP

MOTOR

H.V.

ASM.

S/W1

S/W2

AIR

CLEAN

(PLASMA)

(1) Indoor Unit

COMP

C

S

R

FAN

MOTOR

BR

BR

BL

RD

BK

GN/YL

BR

BL

RD

BK

YL

BK(RD)

BK

(RD)

BR(OR)

GN/YL

REVERSING

YL

CAPACITOR

RD

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM

TERMINAL

BLOCK

HCF

PTC

1(L)2(N

)

34

VALVE

T / B 2

T / B 1

OUTDOOR WIRING DIAGRAM (LS-T246QEG) OUTDOOR WIRING DIAGRAM (3854A20167B)

RD

BR(OR)

OPTION

PTC

YL

BK

(BR)

C

R

S

COMP.

BK

YL

FAN

MOTOR

TP

HC F

TO INDOOR UNIT

TERMINAL

BLOCK

BR

BL

GN/YL

GN/YL

GN/YL

T/B

CAPACITOR

1(L)

2(N)

(2) Outdoor Unit

Cooling

Heatpump

Operation Details

1. MAIN UNIT FUNCTION

• DISPLAY

1) C/O Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• ON while in sleep timer mode, OFF when sleep timer cancel or appliance operation pause.

Timer Indicator

• ON while in timer mode (on/off), OFF when timer mode is completed or canceled.

Comp. Running Incidator

• While in appliance operation, ON while in outdoor unit compressor running, OFF while in compressor off.

2) H/P Model

Operation Indicator

• ON while in appliance operation, OFF while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• ON while in sleep timer mode, OFF when sleep timer cancel or appliance operation pause.

Timer Indicator

• ON while in timer mode (on/off), OFF when timer mode is completed or canceled.

Defrost Indicator

• OFF except when hot start during heating mode operation or while in defrost control.

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan

stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C

Compressor OFF Temp ➲ Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote control. While in compressor

not running, operating with the low airflow speed regardless of the setting.

■ Healthy Dehumidification Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Intake Air Temp<26°C ➲ Intake Air Temp-1°C

18°C ≤ Intake Intake Air Temp<24°C ➲ Intake Air Temp-0.5°C

Intake Air Temp<18°C ➲ 18°C

-12-

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidifica-

tion operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C

Compressor OFF Temp. ➲ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation

• When the intake air temp reaches +3°…above the setting temp, the compressor is turned off. When below

the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 20°C, when above 28°C,it

operates with the low or setting airflow speed. When the indoor pipe temp is between 20°C and 28°C, it operates with Super-Low(while in sleep mode, with the medium airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C, when above 35°C,it

operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the

outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from freezing,

reversed to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• After 40 min heating mode operation, at 4 min interval, whether to carry out defrost control or not and the time

of defrost control are determined according to the following conditions.

1) While in heating mode operation, the maximum of the indoor pipe temperature is measured and it is com-

pared with the present indoor pipe temperature to get the difference of the indoor pipe temperatures (=the

maximum temperature of indoor pipe ? the present temperature of indoor pipe), according to which, whether

to carry out defrost control or not is determined.

2) According to the need of defrost control shown above and the elapsed time of heating mode operation at that

moment, the defrost control time is determined.

3) When the determined time of defrost control is below 7 min, heating mode operation continues without carry-

ing out defrost control. According to the procedure stated above, the determination is made again. When the

defrost control time is 7 min or longer, defrost control is then carried out.

• While in defrost control, the minimum temp of the indoor pipe is measured and it is compared with the present

temp of the indoor pipe to get the difference of the indoor pipe temperatures (=the present temperature of the

indoor pipe ? the minimum temperature of the indoor pipe). When the difference is 5°C or higher, defrost control is completed and heating mode operation is carried out.

• While in defrost control, if the defrost time determined before the start of defrost control is completed, defrost

control stops and heating mode operation is carried out regardless of the above condition.

• When the indoor pipe temp is 42°C or above, defrost control is not carried out even if the condition is one of

the defrost conditions above.

• While in defrost control, the compressor is on and the indoor fan, the outdoor fan, and the 4 way valve are off.

-13-

-14-

■ Fuzzy Operation (C/O Model)

• According to the temperature set by Fuzzy rule, when the intake air temp is 0.5°C or more below the setting

temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp< 26°C ➲ Intake Air Temp + 1°C

22°C ≤ Intake Air Temp< 24°C ➲ Intake Air Temp + 0.5°C

18°C ≤ Intake Air Temp< 22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the

temperature.

■ Fuzzy Operation (H/P Model)

• When any of operation mode is not selected like the moment of the power on or when 3 hrs has passed since

the operation off, the operation mode is selected.

• When determining the operation mode, the compressor, the outdoor fan, and the 4 way valve are off and only

the indoor fan is operated for 15 seconds. Then an operation mode is selected according to the intake air

temp at that moment as follows.

24°C ≤ Inatake Air Temp ➲ Fuzzy Operation for Cooling

21°C ≤ Inatake Air Temp<24°C ➲ Fuzzy Operation for Dehumidification

Inatake Air Temp<21°C ➲ Fuzzy Operation for Heating

• If any of the operation modes among cooling / dehumidification / heating mode operations is carried out for 10

sec or longer before Fuzzy operation, the mode before Fuzzy operation is operated.

1) Fuzzy Operation for Cooling

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp +0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C≤ Intake Air Temp ➲ 25°C

24°C≤ Intake Air Temp<26°C ➲ Intake Air Temp + 1°C

22°C≤ Intake Air Temp<24°C ➲ Intake Air Temp + 0.5°C

18°C≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

-15-

2) Fuzzy Operation for Dehumidification

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp<26°C ➲ Intake Air T emp+1°C

22°C ≤ Intake Air Temp<24°C ➲ Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan repeats the low airflow speed or pause as in

dehumidification operation.

3) Fuzzy Operation for Heating

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 3°Cormoreabove

the setting temp, the compressor is turned off. When below the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp

Compressor OFF Temp ➲ Setting Temp + 3°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

20°C≤Intake Air Temp ➲ Intake Air Temp + 0.5°C

Intake Air Temp<20°C ➲ 20°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is set to the high or the medium according to the

intake air temperature and the setting temperature.

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

■ On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

-16-

■ Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

■ Off-Timer ↔ On-Timer Operation

• When the set time is reached after the on/off time is input by the remote control, the on/off-timer operation is

carried out according to the set time.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to the

low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

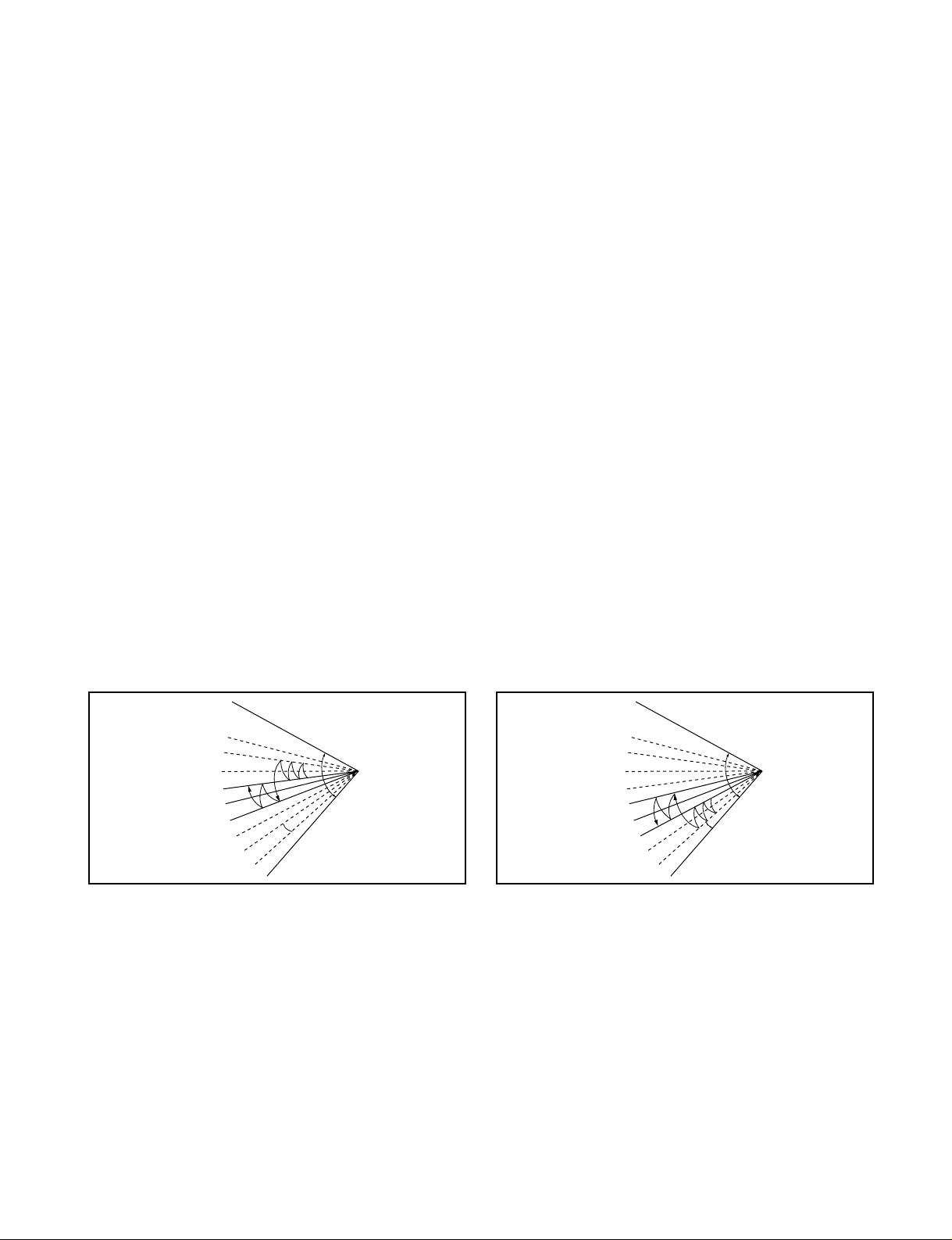

■ Chaos Swing Mode

• By the Chaos Swing key input, the upper/lower vane automatically operates with the Chaos Swing or they are

fixed to the desired direction.

• While in Chaos Swing mode, the angles of cooling and heating cycle operations are different.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

CLOSED

OPEN

< Cooling Mode >

8°

CLOSED

OPEN

< Heating Mode >

8°

-17-

■ Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (H/P Model)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the other

mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18

°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Forced Operation

• Operation procedures when the remote control can't be used.

• The operation will be started if the power button is pressed.

• If you want to stop operation, re-press the button.

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds 10 times to

indicate the forced operation.

■ Test operation

•

During the TEST OPERATION, the unit operates in cooling mode at high speed fan, regardless of room temperature and resets in 18±1 minutes.

•

During test operation, if remote controller signal is received, the unit operates as remote controller sets.

If you want to use this operation, open the front panel upward and Press the power button let it be pressed for

about 3 seconds.

•

If you want to stop the operation, re-press the button.

■ Auto restart

•

In case the power comes on again after a power failure, Auto Restarting Operation is the function to operate

procedures automatically to the previous operating conditions.

■ Air Cleaner Operation

•

When an air cleaner function is selected during Air Conditioner operation

- Plasma air cleaner function will be operated while in any operation mode with selecting the function.

- The function is to be stopped while it is operating with selecting the function.

•

When an air cleaner function is selected during operation off

- The function will be only operated.

•

When inlet grille of air conditioner is opened during plasma operation, High Voltage Generator(H.V.B) is to be

stopped. When inlet grille of air conditioner is closed during plasma operation, High Voltage Generator(H.V.B)

will be operated again.

Heat pumpModel

Cooling Model

Room Temp. ≥ 24°C21°C ≤Room Temp. < 24°C Room Temp.< 21°C

Operating mode Cooling Cooling Healthy Dehumidification Heating

Indoor FAN Speed

High High High High

Setting Temperature

22°C22°C23°C24°C

-18-

■ Remote Control Operation Mode

• When the remote control is selected by the slide switch on the main unit, the appliance operates according to

the input by the remote control.

■ Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause while in cooling cycle operation mode, the compressor and the outdoor fan are turned off in order to protect the indoor

evaporator pipe from frosting.

• When the indoor pipe temp is 7°C or higher after 3 min. pause of the compressor, the compressor and the

outdoor fan is turned on according to the condition of the room temperature.

■ Buzzer Sounding Operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

• When a key is input by the remote control while the slide switch on the main unit of the appliance is on the

forced operation position, the error sound "beep-beep-beep-beep-beep-" is made 10 times to indicate that the

remote control signal cannot be received.

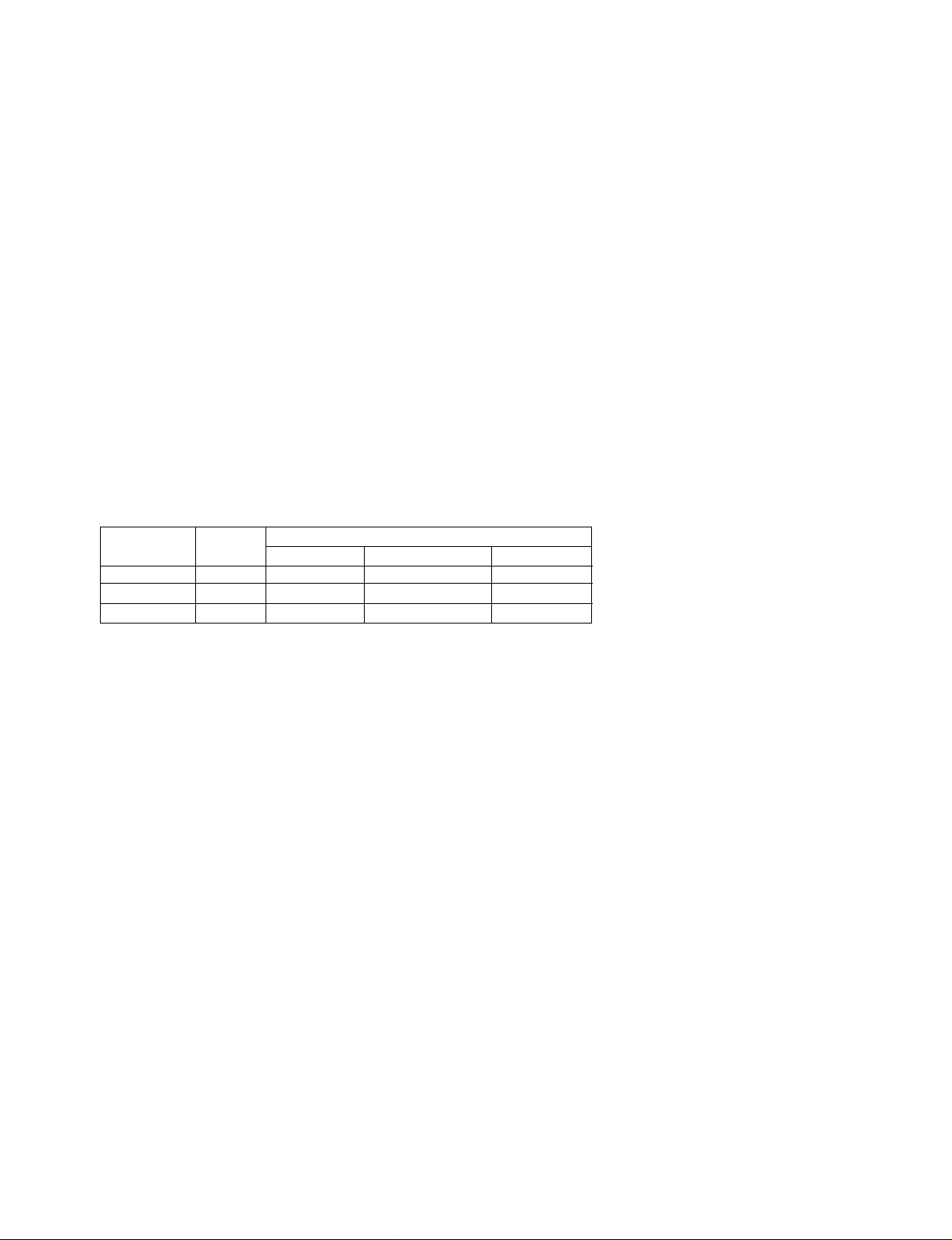

Display Function

-19-

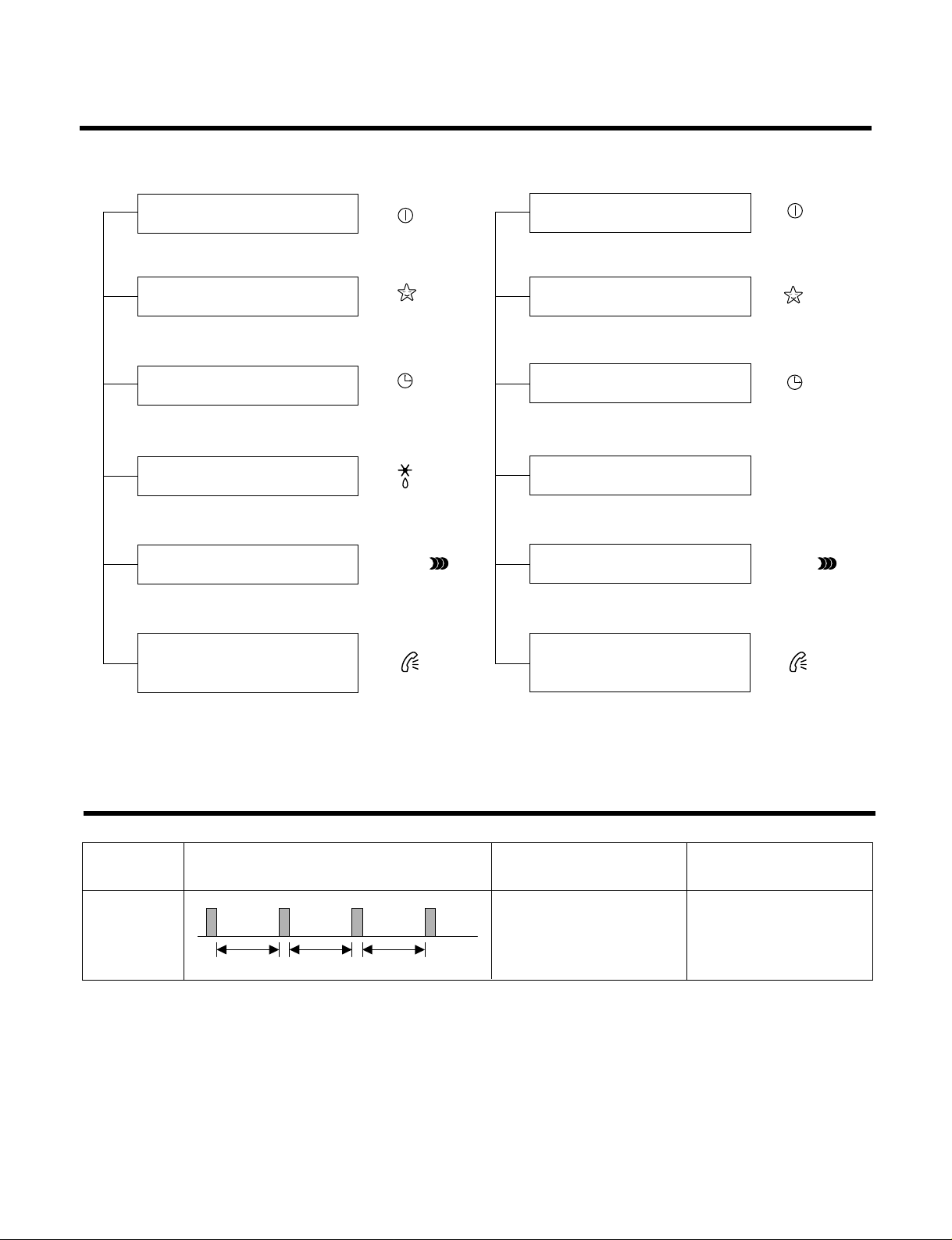

Self-diagnosis Function

3sec 3sec 3sec

(once)

Error

Code

1

Error Display LED

(Indoor body operation LED)

Error contents

• Indoor room temperature

thermistor open/short

• Indoor pipe temperature

thermistor open/short.

• Indoor Thermistor

assembly check

SVC check point

1. Heating Model 2. Cooling Model

• Cooling, Soft Dry, Fan, Heating • Cooling, Soft Dry, Fan

• Sleep Mode • Sleep Mode

• Timer Mode • Timer Mode

• Hot-start, Defrost

• PLASMA Mode • PLASMA Mode

• Telephone Control Mode • Telephone Control Mode

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Defrost Indicator

PLASMA Indicator

Telephone control

Indicator

Telephone control

Indicator

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Compressor on Indicator

PLASMA Indicator

OUTDOOR

PLASMA PLASMA

1) Selection of the best location

1. Indoor unit

• Do not have any heat or steam near the unit.

• Select a place where there are no obstacles in front of

the unit.

• Make sure that condensation drainage can be conveniently routed away.

Do not install near a doorway.

• Ensure that the space around the left and right of the

unit is more than "A". The unit should be installed as

high on the wall as possible, allowing a minimum of

"B" from ceiling.

• Use a stud finder to locate studs to prevent unnecessary damage to the wall.

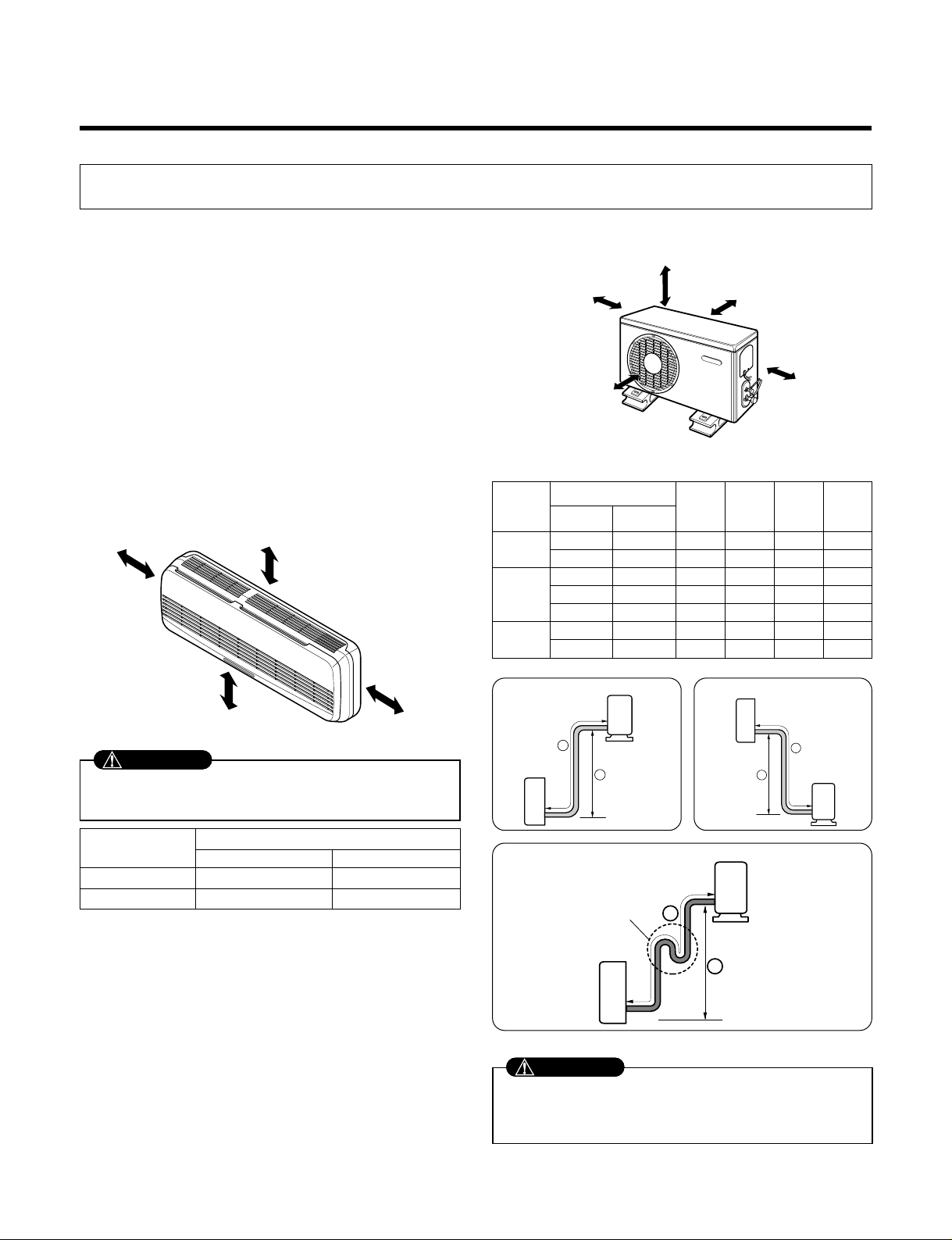

2. Outdoor unit

• If an awning is built over the unit to prevent direct sunlight or rain exposure, make sure that heat radiation

from the condenser is not restricted.

• Ensure that the space around the back and sides is

more than 10cm. The front of the unit should have

more than 70cm of space.

• Do not place animals and plants in the path of the

warm air.

• Take the air conditioner weight into account and select

a place where noise and vibration are minimum.

• Select a place so that the warm air and noise from the

air conditioner do not disturb neighbors.

2) Piping length and elevation

Installation

1. Installation of indoor, Outdoor unit

-20-

More than "A"

More than "B"

More than 2.3m

More than "B"

More than 10cm More than 10cm

More

than 60cm

More than 60cm

More than 70cm

Install the indoor unit on the wall where the height

from the floors more than 2.3 meters.

CAUTION

• Capacity is based on standard length and maximum

allowance length is on the basis of reliability.

• Oil trap should be installed every 5~7 meters.

CAUTION

Grade

Clearance(cm)

AB

7K~28K 10 5

30K~38K 30 12

Pipe Size

Capacity

(Btu/h)

GAS LIQUID

Max.

Length

A (m)

Additional

Refrigerant

(g/m)

Max.

Elevation

B (m)

Standard

Length

(m)

7k~14k

3/8"(Ø9.52) 1/4"(Ø6.35) 4or7.5 7 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 4or7.5 7 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 4or7.5 15 30 20

18k~28k 5/8"(Ø15.88) 1/4"(Ø6.35) 4or 7.5 15 30 20

5/8"(Ø15.88) 3/8"(Ø9.52) 4or7.5 15 30 30

30k~38k

5/8"(Ø15.88) 3/8"(Ø9.52) 7.5 15 30 30

3/4"(Ø19.05) 3/8"(Ø9.52) 7.5 15 30 50

If case more than 5m

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

3) How to fix installation plate

The wall you select should be strong and solid enough

to prevent vibration

1. Mount the installation plate on the wall with four

type A screws. If mounting the unit on a concrete

wall, use anchor bolts.

• Mount the installation plate horizontally by aligning

thecenterlineusingalevel.

2. Measure the wall and mark the centerline. It is

also important to use caution concerning the

location of the installation plate-routing of the

wiring to power outlets is through the walls typically. Drilling the hole through the wall for piping

connections must be done safely.

4) Drill a hole in the wall

• Drill the piping hole with a ø70mm hole core drill. Drill

the piping hole at either the right or the left with the

hole slightly slanted to the outdoor side.

-21-

Installation Plate

Type "A" screw

5-7mm

(3/16"~5/16")

Indoor

WALL

Outdoor

Installation plate

Ø70mm

Left rear piping Right rear piping

C

D

B

A

Ø70mm

Ø70mm

Left rear piping

Right rear piping

CE A

B

D

Installation plateInstallation plate

ABCD

SJ 90 20 80 20

SL, SK 45 40 80 20

SQ 75 12 80 12

SR 0 40 20 40

ST 105 0 210 0

CHASSIS

(Grade)

Distance (mm)

ABCDE

SM 180 115 - 115 50

SN 180 115 195 115 -

CHASSIS

(Grade)

Distance (mm)

-22-

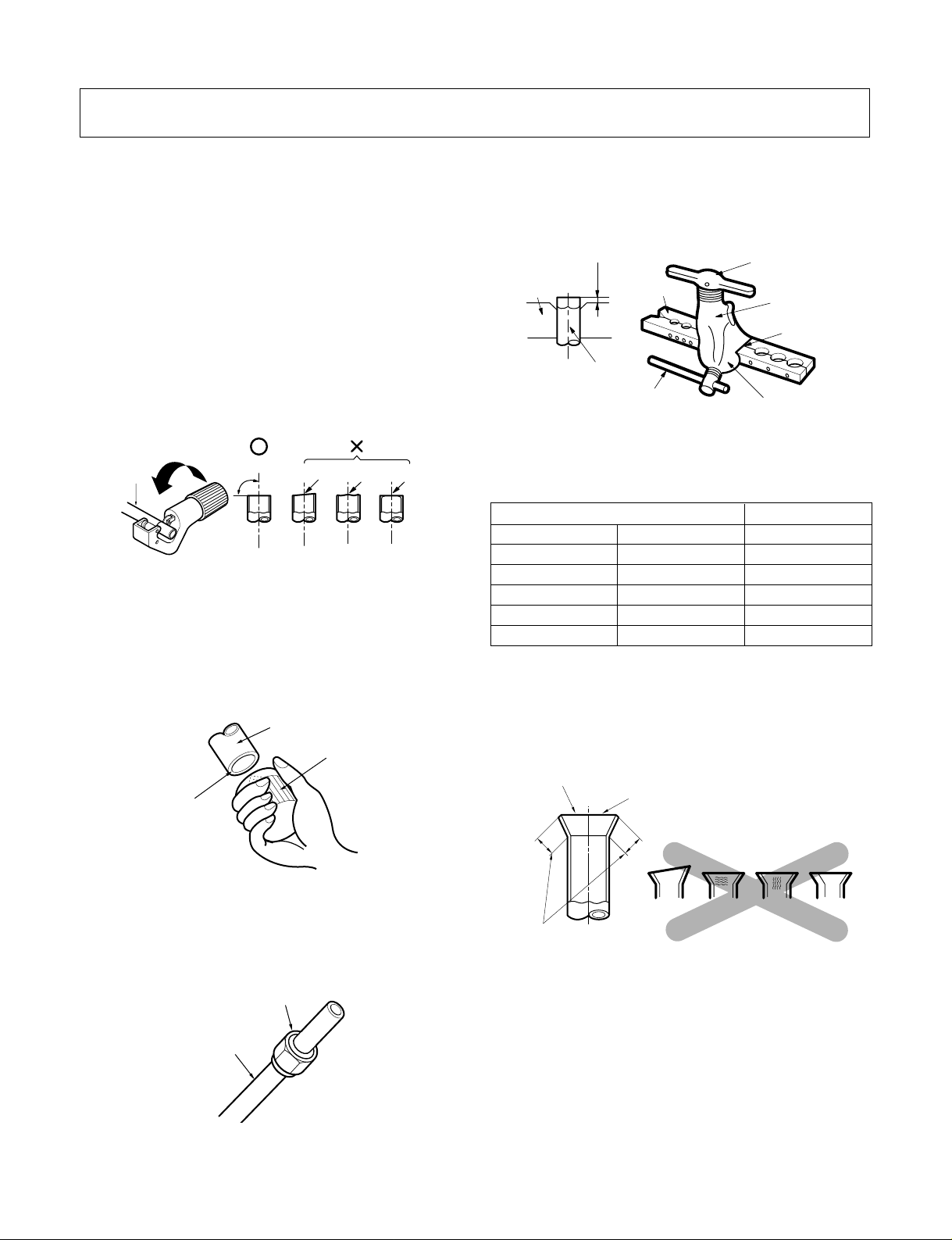

2. Flaring Work and Connection of Piping

1) Flaring work

Main cause for refrigerant leakage is due to defect in

the flaring work. Carry out correct flaring work using the

following procedure.

1. Cut the pipes and the cable.

•

Use the piping kit accessory or pipes purchased locally.

• Measure the distance between the indoor and the

outdoor unit.

• Cut the pipes a little longer than the measured

distance.

• Cut the cable 1.5m longer than the pipe length.

2. Burr removal

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe in a downward

direction as you remove burrs in order to avoid dropping burrs into the tubing.

3. Putting nut on

• Remove flare nuts attached to indoor and outdoor

unit, then put them on pipe/tube having completed

burr removal.

(not possible to put them on after flaring work)

4. Flaring work

• Firmly hold copper pipe in a die in the dimension

showninthetableabove.

• Carry out flaring work using flaring tool as shown

below.

5. Check

• Compare the flared work with figure below.

• If flare is noted to be defective, cut off the flared sec-

tion and re-flare it.

Copper

pipe

90°

Slanted Uneven Rough

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Pipe

Reamer

Point down

Flare nut

Copper tube

mm inch mm

Ø6.35 1/4 0~0.5

Ø9.52 3/8 0~0.5

Ø12.7 1/2 0~0.5

Ø15.88 5/8 0~1.0

Ø19.05 3/4 1.0~1.3

Outside diameter

Loading...

Loading...