LG DLEX2550R, DLEX2550V, DLEX2550S, DLEX2550N, DLEX2650T Owner’s Manual

...

<![endif]>FRANÇAIS ENGLISH

OWNER’S MANUAL

DRYER

Please read this manual carefully before operating your dryer and retain it for future reference.

DLEX2550* DLGX2551*

DLEX2450* DLGX2451*

DLEX2650* DLGX2651*

DLEX2655* DLGX2656*

|

|

|

|

|

|

|

|

www.lg.com |

P/No. MFL67408112 |

|

|

||||||

IMPORTANT SAFETY INSTRUCTIONS |

|

What to Do if You Smell Gas................................... |

3 |

Basic Safety Precautions........................................ |

4 |

California Safe Drinking Water and Toxic |

|

Enforcement Act ................................................... |

4 |

Grounding Instructions........................................... |

5 |

Safety Instructions for Installation........................... |

5 |

Safety Instructions for Steam Functions................. |

6 |

Safety Instructions for Connecting Electricity ........ |

7 |

PARTS AND FEATURES |

|

Special Features..................................................... |

8 |

Key Parts and Components.................................... |

9 |

INSTALLATION INSTRUCTIONS |

|

Installation Location Requirements ...................... |

10 |

Clearances............................................................ |

10 |

Installation With Optional |

|

Pedestal Base or Stacking Kit.............................. |

11 |

Leveling the Dryer................................................. |

12 |

Optional Accessories ........................................... |

12 |

To Remove the Door ............................................ |

13 |

To Install the Door ................................................ |

14 |

Changing the Dryer Vent Location........................ |

15 |

Venting the Dryer................................................... |

16 |

Connecting Gas Dryers......................................... |

18 |

Connecting Electric Dryers .................................. |

20 |

Special Requirements for Manufactured |

|

or Mobile Homes .................................................. |

25 |

Final Installation Check ........................................ |

25 |

Installation Test (Exhaust check) .......................... |

26 |

HOW TO USE |

|

Control Panel Features ........................................ |

28 |

Operating the Dryer .............................................. |

29 |

Cycle Guide .......................................................... |

30 |

Sorting Loads ....................................................... |

31 |

Loading the Dryer ................................................ |

31 |

Check the Lint Filter Before Every Load .............. |

31 |

The Display .......................................................... |

32 |

Cycle Setting Buttons........................................... |

33 |

Special Functions ................................................. |

34 |

Custom Program .................................................. |

35 |

Steam Functions................................................... |

35 |

Steam Cycle Guide............................................... |

37 |

TROUBLESHOOTING |

|

Regular Cleaning ................................................. |

38 |

Before Calling for Service .................................... |

39 |

Using SmartDiagnosisTM....................................... |

42 |

THANK YOU!

Congratulations on your purchase

and welcome to the LG family. Your

new LG Dryer combines the most

advanced drying sensor technol-

ogy with simple operation and high

efficiency.

Follow the operating and care instructions in this manual and your

dryer will provide many years of reli-

able service

OPTIONAL ACCESSORIES |

|

Optional Accessories............................................ |

43 |

Pedestal Installation.............................................. |

44 |

Stacking Kit Installation........................................ |

46 |

SPECIFICATIONS |

|

Key Dimensions and Specifications...................... |

47 |

WARRANTY................................................... |

48 |

2

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, electric shock, or to prevent property damage, injury to persons , or death.

Your Safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or WARNING. These words mean:

wDANGER: You can be killed or seriously injured if you don’t immediately follow instructions.

wWARNING: You can be killed or seriously injured if you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

• Do not install a clothes dryer with flexible plastic venting materials. If flexible metal (foil type) duct is installed, it must be of a specific type identified by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting materials are known to collapse, be easily crushed, and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this appliance or any other appliances.

•Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

•Install the clothes dryer according to the manufacturer’s instructions and local codes.

•Save these instructions.

WHAT TO DO IF YOU SMELL GAS:

WHAT TO DO IF YOU SMELL GAS:

1.Do not try to light a match or cigarette, or turn on any gas or electrical appliance.

2.Do not touch any electrical switches. Do not use any phone in your building.

3.Clear the room, building, or area of all occupants.

4.Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions carefully.

5.If you cannot reach your gas supplier, call the fire department.

<![endif]>ENGLISH

3

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, electric shock, or to prevent property damage, injury to persons , or death.

BASIC SAFETY PRECAUTIONS

BASIC SAFETY PRECAUTIONS

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Read all instructions before using the dryer.

•Before use, the dryer must be properly installed as described in this manual.

•Do not place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may contribute to a chemical reaction that could cause a load to catch fire.

•Do not dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, dry-cleaning solvents, or other flammable or explosive substances as they give off vapors that could ignite or explode.

•Do not reach into the dryer if the drum or any other part is moving.

•Do not repair or replace any part of the dryer or attempt any servicing unless specifically recommended in this Use and Care Guide or in published user-repair instructions that you understand and have the skills to carry out.

•Do not tamper with controls.

•Before the dryer is removed from service or discarded, remove the door to the drying compartment.

•Do not allow children to play on or in the dryer.

Close supervision of children is necessary when the dryer is used near children.

•Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener or product.

•Do not use heat to dry articles containing foam rubber or similarly textured rubber-like materials.

•Keep area around the exhaust opening and adjacent surrounding areas free from the accumulation of lint, dust, and dirt.

•The interior of the dryer and exhaust vent should be cleaned periodically by qualified service personnel.

•Do not install or store the dryer where it will be exposed to the weather.

•Always check the inside of the dryer for foreign objects.

•Clean lint screen before or after each load.

•Do not store plastic, paper, or clothing that may burn or melt on top of the dryer during operation.

California Safe Drinking Water and Toxic Enforcement Act

California Safe Drinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances known to the state to cause cancer, birth defects, other reproductive harm and requires businesses to warn customers of potential exposure to such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide, formaldehyde, and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be minimized further by properly venting the dryer to the outdoors.

4

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, electric shock, or to prevent property damage, injury to persons , or death.

GROUNDING INSTRUCTIONS

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. This appliance must be equipped with a cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided with the appliance. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

This appliance must be connected to a grounded metal, permanent wiring system or an equipmentgrounding conductor must be run with the circuit conductors and connected to the equipmentgrounding terminal or lead on the appliance.

Electric shock can result if the dryer is not properly grounded.

wWARNING— Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service person if you are in doubt that the appliance is properly grounded.

<![endif]>ENGLISH

SAFETY INSTRUCTIONS FOR INSTALLATION

SAFETY INSTRUCTIONS FOR INSTALLATION

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Properly ground dryer to conform with all governing codes and ordinances. Follow details in the installation instructions. Electric shock can result if the dryer is not properly grounded.

•Before use, the dryer must be properly installed as described in this manual. Electric shock can result if the dryer is not properly grounded.

•Install and store the dryer where it will not be exposed to temperatures below freezing or exposed to the weather.

•All repairs and servicing must be performed by an authorized servicer unless specifically recommended in this Owner’s Guide. Use only authorized factory parts. Failure to follow this warning can cause serious injury, fire, electric shock, or death.

•To reduce the risk of electric shock, do not install the dryer in humid spaces. Failure to follow this warning can cause serious injury, fire, electric shock, or death.

• Connect to a properly rated, protected, and sized power circuit to avoid electrical overload. Improper power circuit can melt, creating electric shock and/or fire hazard.

• Remove all packing items and dispose of all shipping materials properly. Failure to do so can result in death, explosion, fire, or burns.

• Place dryer at least 18 inches above the floor for a garage installation. Failure to do so can result in death, explosion, fire, or burns.

• Keep all packaging from children. Packaging material can be dangerous for children. There is a risk of suffocation.

• Do not install near another source of heat such as a stove, cooking oven. Failure to do so can cause deform, smoke and fire.

• Do not place candles, smoking materials, or other flammables on top of the product.

Dripping wax, smoke, or fire can result.

• Remove all protective vinyl film from the product. Failure to do so can cause product

damage, smoke or fire.

5

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, electric shock, or to prevent property damage, injury to persons, or death.

SAFETY INSTRUCTIONS FOR INSTALLATION

SAFETY INSTRUCTIONS FOR INSTALLATION

wWARNING: To reduce the risk of injury to persons , follow all industry recommended safety procedures including the use of long sleeved gloves and safety glasses. Failure to follow all of the safety warnings in this manual could result in property damage, injury to persons or death.

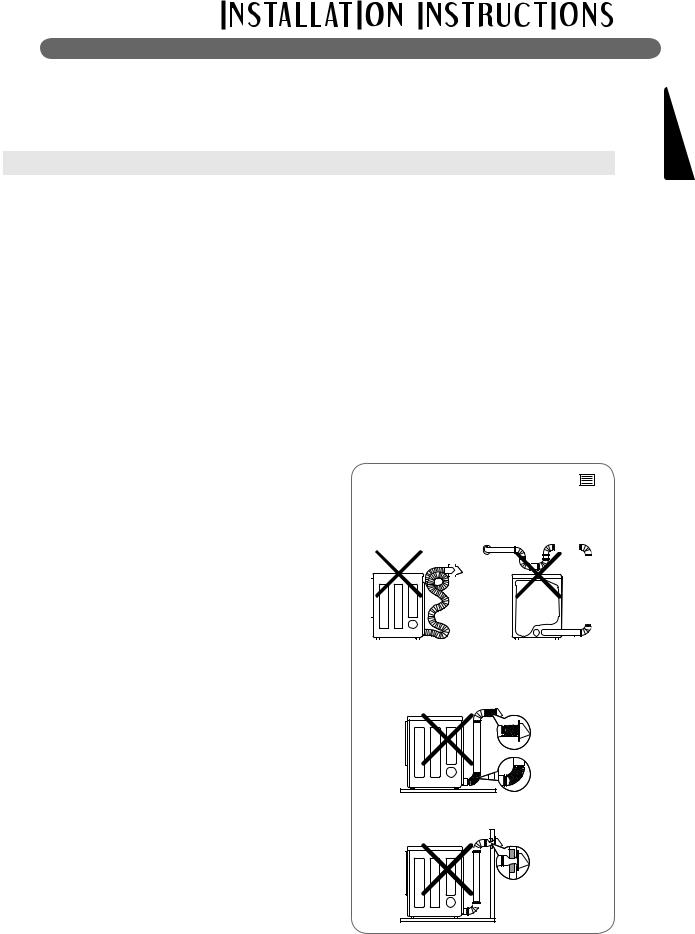

Exhaust/Ducting:

•Gas dryers MUST be exhausted to the outside. Failure to follow these instructions can result in fire or death.

•The dryer exhaust system must be exhausted to the outside of the dwelling. If the dryer is not exhausted outdoors, some fine lint and large amounts of moisture will be expelled into the laundry area. An accumulation of

lint in any area of the home can create a health and fire hazard.

•Use only rigid metal or flexible metal 4-inch diameter ductwork inside the dryer cabinet or for exhausting to the outside. Use of plastic or other combustible ductwork can cause a fire. Punctured ductwork can cause a fire if it collapses or becomes otherwise restricted in use or during installation.

•Ductwork is not provided with the dryer, and you should obtain the necessary ductwork locally. The end cap should have hinged dampers to prevent backdraft when the dryer is not in use. Failure to follow these instructions can result in fire or death.

•The exhaust duct must be 4 inches

(10.2 cm) in diameter with no obstructions. The exhaust duct should be kept as short as possible. Make sure to clean any old ducts before installing your new dryer. Failure to follow these instructions can result in fire or death.

•Rigid or semi-rigid metal ducting is recommended for use between the dryer and the wall. In special installations

when it is impossible to make a connection with the above recommendations, a ULlisted flexible metal transition duct may be used between the dryer and wall connection only. The use of this ducting will affect drying time. Failure to follow these instructions can result in fire or death.

•DO NOT use sheet metal screws or other fasteners which extend into the duct that could catch lint and reduce the efficiency of the exhaust system. Secure all joints with duct tape. For complete details, follow the Installation Instructions. Failure to follow these instructions can result in fire or death.

SAFETY INSTRUCTIONS FOR STEAM FUNCTIONS

SAFETY INSTRUCTIONS FOR STEAM FUNCTIONS

wWARNING: To reduce the risk of fire, electric shock, or personal injury when using this appliance, follow basic precautions, including the following:

•Do not open the dryer door during steam cycles. Failure to follow these instructions can result in a burn hazard.

•Do not dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, dry-cleaning solvents, or other flammable or explosive substances as they give off vapors that could ignite or explode.

Failure to follow these instructions can result in fire or death.

6

•Do not fill the steam feeder with gasoline, dry-cleaning solvents, or other flammable or explosive substances. Failure to follow these instructions can result in fire or death.

•Do not touch the steam nozzle in the drum during or after the steam cycle. Failure to follow these instructions can result in a burn hazard.

•Do not fill the steam feeder with hot water (over 86 ˚F/30 ˚C). Failure to follow these instructions can result in a burn hazard.

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, electric shock, or to prevent property damage, injury to persons , or death.

SAFETY INSTRUCTIONS FOR CONNECTING ELECTRICITY

SAFETY INSTRUCTIONS FOR CONNECTING ELECTRICITY

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not, under any circumstances, cut or remove the ground prong from the power cord. To prevent injury to persons or damage to the dryer, the electrical power cord must be plugged into a properly grounded outlet.

•For personal safety, this dryer must be properly grounded. Failure to do so can result in electric shock or injury.

•Refer to the installation instructions in this manual for specific electrical requirements for your model. Failure to follow these instructions can create an electric shock hazard and/or a fire hazard.

•This dryer must be plugged into a properly grounded outlet. Electric shock can result if the dryer is not properly grounded. Have the wall outlet and circuit checked by a qualified electrician to make sure the outlet is properly grounded. Failure to follow these instructions can create an electric shock hazard and/or a fire hazard.

•The dryer should always be plugged into its own individual electrical outlet which has a voltage rating that matches the rating plate. This provides the best performance and also prevents overloading house wiring circuits which could cause a fire hazard from overheated wires.

•Never unplug your dryer by pulling on the power cord. Always grip plug firmly and pull straight out from the outlet. The power cord can be damaged, resulting in a risk of fire and electric shock.

•Repair or replace immediately all power cords that have become frayed or otherwise damaged. Do not use a cord that shows cracks or abrasion damage along its length or at either end. The power cord can melt, creating an electric shock and/or fire hazard.

•When installing or moving the dryer, be careful not to pinch, crush, or damage the power cord. This will prevent injury and prevent damage to the dryer from fire and electric shock.

<![endif]>ENGLISH

SAVE THESE INSTRUCTIONS

7

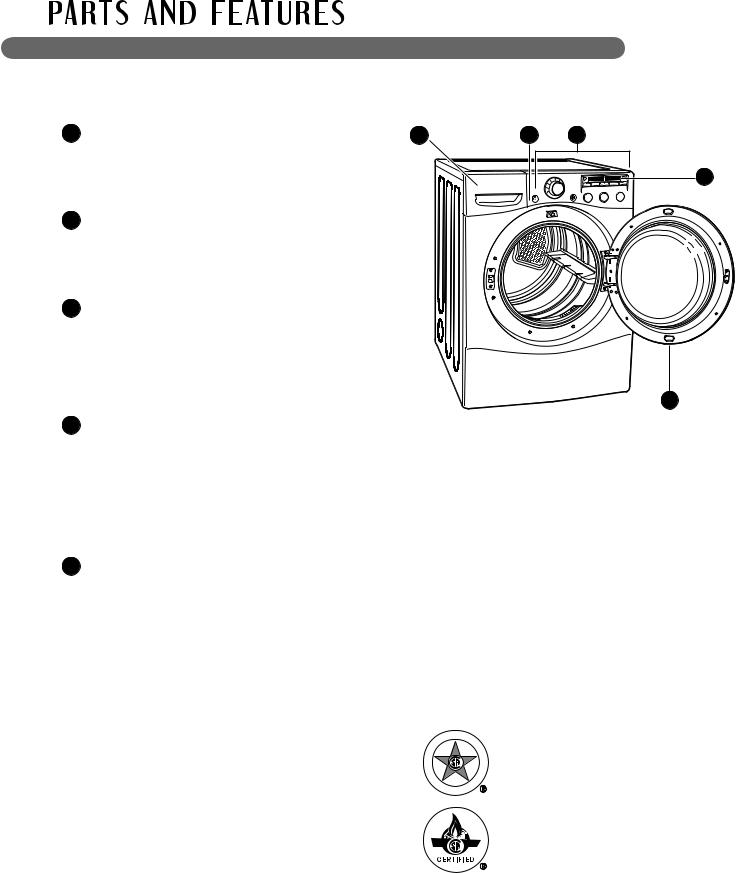

SPECIAL FEATURES

SPECIAL FEATURES

A Easy-to-USE Control Panel |

C |

E |

A |

Rotate the cycle selector knob to select the |

|

|

|

desired dry cycle. Add cycle options or adjust |

|

|

D |

settings with the touch of a button. |

|

|

|

|

|

|

B EASY-ACCESS REVERSIBLE DOOR

The wide-opening door provides easy access for loading and unloading. The door hinge can be reversed to adjust for installation location.

C STEAM FUNCTIONS

LG’s steam technology allows you to inject fabrics with a swirling jet of hot steam to refresh

clothes, reduce static, and make ironing easier. Simply select the STEAMFRESH™ cycle, or you

can add a Steam option to selected cycles.

B

DFLOW SENSE™ DUCT BLOCKAGE SENSING SYSTEM INDICATOR

The FLOW SENSE™ duct blockage sensing system detects and alerts you to blockages in the ductwork that reduce exhaust flow from the dryer. Clean exhaust systems increase efficiency and reduce drying times.

ESMARTDIAGNOSIS™

Should you experience any technical difficulty with your dryer, it has the capability of transmitting data via your telephone to the Customer Information Center. The call center agent records the data transmitted from your machine and uses it to analyze the issue, providing a fast and effective diagnosis (refer to page 41).

|

S |

E |

|

D |

|

I

G

N

C ER

T

|

|

D |

|

E |

|

I |

|

|

IF |

|

|

8

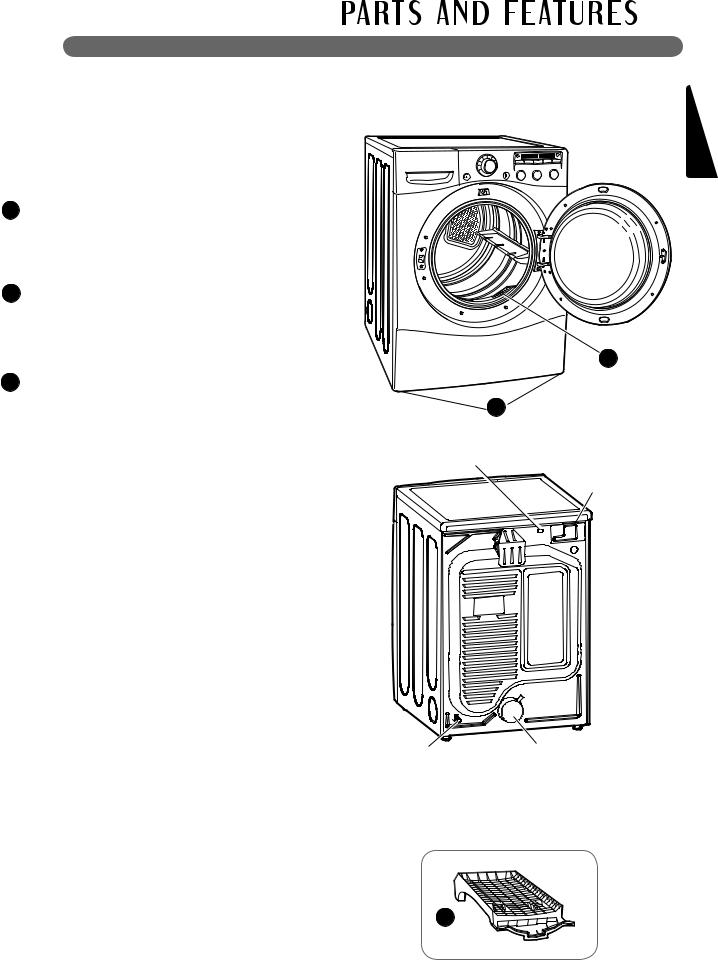

KEY PARTS AND COMPONENTS

KEY PARTS AND COMPONENTS

In addition to the special features and components outlined in the Special Features section, there are several other important components that are referenced in this manual.

AFRONT-MOUNT LINT FILTER

Front-mount lint filter allows for easy access and cleaning after every load.

BLeveling Feet

Four leveling feet (two in the front, and two in the back) adjust to improve dryer stability on uneven floors.

CDrying Rack

Use the drying rack with the RACK DRY cycle to safely dry such items as sweaters, delicates and gym shoes without tumbling or overheating.

<![endif]>ENGLISH

A

B

Power Cord Location

(Gas Models) Terminal Block

Access Panel

(Electric Models)

Gas |

Exhaust Duct |

|

Connection |

||

Outlet |

||

Location |

||

|

||

(Gas Models) |

|

Rear of Dryer

Included Accessories

C

Drying Rack

9

wWARNING: Read all installation instructions completely before installing and operating your dryer!

It is important that you review this entire manual before installing and using your dryer. Detailed instructions concerning electrical connections, gas connections, and exhaust requirements are provided on the following pages.

INSTALLATION LOCATION REQUIREMENTS

INSTALLATION LOCATION REQUIREMENTS

A location that allows for proper exhaust installation. A gas dryer must be exhausted to the outdoors. See

A location that allows for proper exhaust installation. A gas dryer must be exhausted to the outdoors. See

Venting Requirements.

A grounded electrical outlet located within 2 ft. (61 cm) of either side of the dryer. See Electrical Requirements.

A grounded electrical outlet located within 2 ft. (61 cm) of either side of the dryer. See Electrical Requirements.

A sturdy floor to support the total dryer weight of

A sturdy floor to support the total dryer weight of

200 lbs (90.7 kg). The combined weight of a companion appliance should also be considered.

A level floor with a maximum slope of 1 inch (2.5 cm) under entire dryer. If slope is greater than 1 inch (2.5 cm), install the Extended Dryer Feet Kit. Clothes may not tumble properly, and automatic sensor cycles may not operate correctly if dryer is not level.

A level floor with a maximum slope of 1 inch (2.5 cm) under entire dryer. If slope is greater than 1 inch (2.5 cm), install the Extended Dryer Feet Kit. Clothes may not tumble properly, and automatic sensor cycles may not operate correctly if dryer is not level.

For a garage installation, you will need to place the dryer at least 18 inches (46 cm) above the floor. If using a pedestal, you will need 18 inches (46 cm) to the bottom of the dryer.

For a garage installation, you will need to place the dryer at least 18 inches (46 cm) above the floor. If using a pedestal, you will need 18 inches (46 cm) to the bottom of the dryer.

Do not operate your dryer at temperatures below 45 ºF (7 ºC). At lower temperatures, the dryer might not shut off at the end of an automatic cycle. This can result in longer drying times.

The dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit, installation of the dryer in garages, closets, mobile homes or sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the same closet as a dryer.

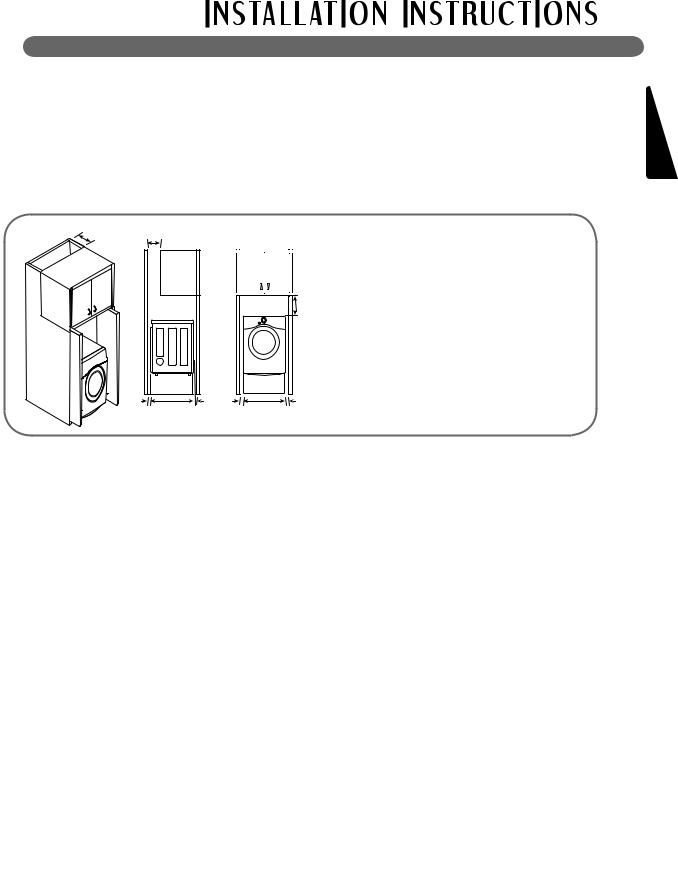

CLEARANCES

CLEARANCES

|

14" max.* |

|

|

(35.6 cm) |

|

|

18" min.* |

|

|

(45.7 cm) |

|

1"* |

30" |

5"** |

(2.5 cm) (76.1cm) |

(12.7 cm) |

|

|

14" max.* |

|

|

(35.6 cm) |

|

|

18" min.* |

|

|

(45.7 cm) |

|

1"* |

30" |

5"** |

(2.5 cm) |

(76.1cm) |

(12.7 cm) |

48 in.2*

(310 cm2)

24 in.2*

(155 cm2)

3"* |

|

|

|

|

(7.6 cm) |

|

|

|

|

|

|

0" |

|

|

|

|

(0 cm) |

|

|

|

|

39" |

|

|

|

|

(98.3 cm) |

|

|

3"* |

|

1" |

27" |

1" |

(7.6 cm) |

27" |

(2.5 cm) |

(68.6 cm) |

(2.5 cm) |

1" |

1" |

|

|

|

(2.5 cm) |

(68.6 cm) |

(2.5 cm) |

|

|

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this dryer. This dryer has been tested for spacing of 0 inches (0 cm) clearance on the sides and rear.

Recommended spacing should be considered for the following reasons:

Additional spacing should be considered for ease of installation and servicing.

Additional spacing should be considered for ease of installation and servicing.

Additional clearances might be required for wall, door and floor moldings.

Additional clearances might be required for wall, door and floor moldings.

Additional spacing should be considered on all sides of the dryer to reduce noise transfer.

Additional spacing should be considered on all sides of the dryer to reduce noise transfer.

For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

Companion appliance spacing should also be considered.

Companion appliance spacing should also be considered.

Suggestion: There should be at least a little space around the dryer (or any other appliance) to eliminate the transfer of vibration from one to the other. Too much vibration, it could cause them to make noise or touch each other causing paint damage and making even more noise.

10

INSTALLATION WITH OPTIONAL PEDESTAL BASE OR STACKING KIT

INSTALLATION WITH OPTIONAL PEDESTAL BASE OR STACKING KIT

WARNING : If you are installing your dryer using an optional pedestal base or stacking kit, please refer to Optional Accessories in this manual or to the instructions for your pedestal or stacking kit before proceeding with the installation.

WARNING : If you are installing your dryer using an optional pedestal base or stacking kit, please refer to Optional Accessories in this manual or to the instructions for your pedestal or stacking kit before proceeding with the installation.

Recommended installation spacing for cabinet installation

For cabinet installation with a door, minimum ventilation openings in the top of the cabinet are required.

For cabinet installation with a door, minimum ventilation openings in the top of the cabinet are required.

7"* (17.8 cm) |

7"* (17.8 cm) |

*Required spacing |

|

|

**For side or bottom venting, 2 inches |

|

|

(5.1 cm) spacing is allowed. |

|

|

9"** |

|

|

(22.9 cm) |

5"** |

30" |

1"** |

1" |

27" |

1" |

(12.7 cm) (76.1cm) |

(2.5 cm) |

(2.5 cm)(68.6 cm) (2.5 cm) |

|||

Closet ventilation requirements

Closets with doors must have both an upper and lower vent to prevent heat and moisture buildup in the closet. One upper vent opening with a minimum opening of 48 sq. in. (310 cm2) must be installed no lower than 6 feet above the floor. One lower vent opening with a minimum opening of 24 sq. in.

(155 cm2) must be installed no more than one foot above the floor. One example shown uses vent grilles in the door.

Recommended installation spacing for recessed or closet installation, with stacked washer and dryer

The dimensions shown are for the recommended spacing.

The dimensions shown are for the recommended spacing.

|

*Required spacing |

|

**For side or bottom |

|

venting, 2 inches |

771/2" |

(5.1 cm) spacing is |

(196.8 cm) |

allowed. |

|

1"* (2.5 cm) |

51/2"** |

|

||

|

|

(14 cm) |

<![endif]>ENGLISH

11

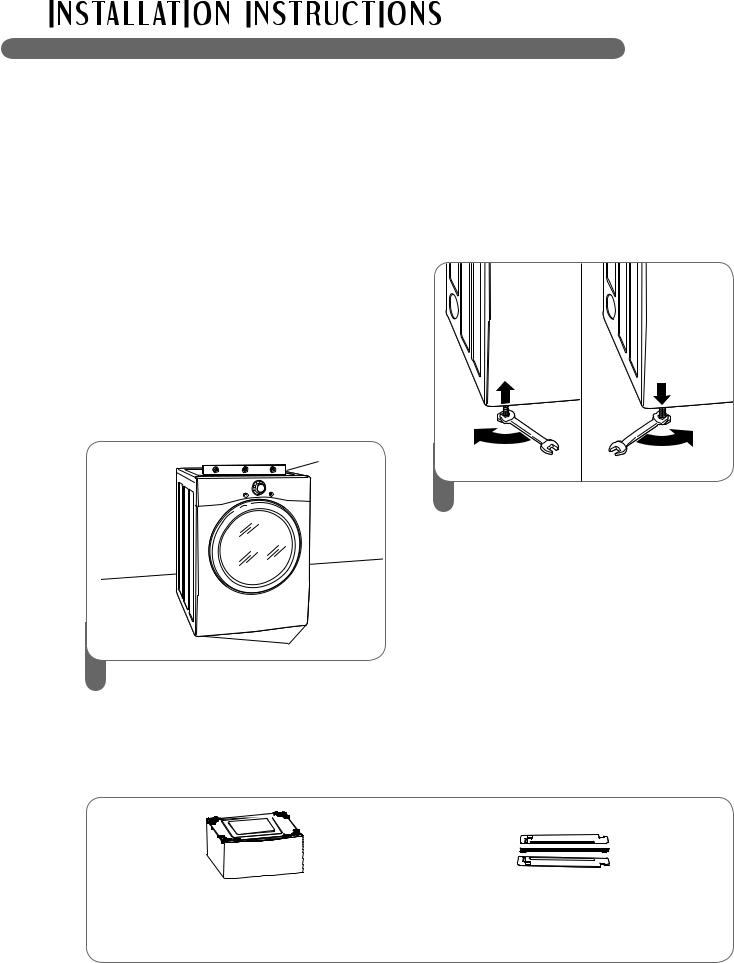

LEVELING THE DRYER

LEVELING THE DRYER

wWARNING

•To reduce the risk of injury to persons , adhere to all industry recommended safety procedures including the use of long sleeved gloves and safety glasses.

•The appliances are heavy. Two or more people are required when installing the dryer.

•Failure to follow all of the safety warnings in this manual could result in property damage, injury to persons or death.

To ensure that the dryer provides optimal drying performance, it must be level. To minimize vibration, noise, and unwanted movement, the floor must be a perfectly level, solid surface.

NOTE: Adjust the leveling feet only as far as necessary to level the dryer. Extending the leveling feet more than necessary can cause the dryer to vibrate.

Level

Leveling Feet

1Position the dryer in the final location. Place a level across the top of the dryer.

•All four leveling feet must rest solidly on the floor. Gently push on the top corners of the dryer to make sure that the dryer does not rock from corner to corner.

If you are installing the dryer on the optional pedestal, you must use the leveling feet on the pedestal to level the dryer. The dryer leveling feet should be fully retracted.

2Use an adjustable wrench to turn the leveling feet. Turn clockwise to raise the dryer or counterclockwise to lower it. Raise or lower the leveling feet until dryer is level from

side to side and front to back.

Make sure that all 4 leveling feet are in firm contact with the floor.

OPTIONAL ACCESSORIES

OPTIONAL ACCESSORIES

For these and other LG products, contact your local LG dealer, or visit our Web site at www.lg.com.

Pedestal |

Stacking Kit |

(sold separately) |

(sold separately) |

12

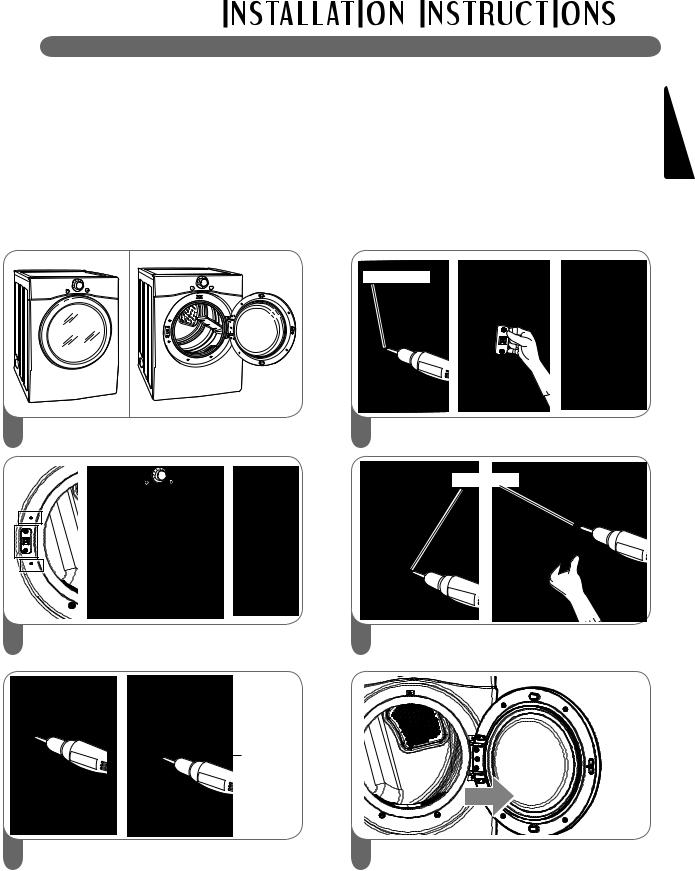

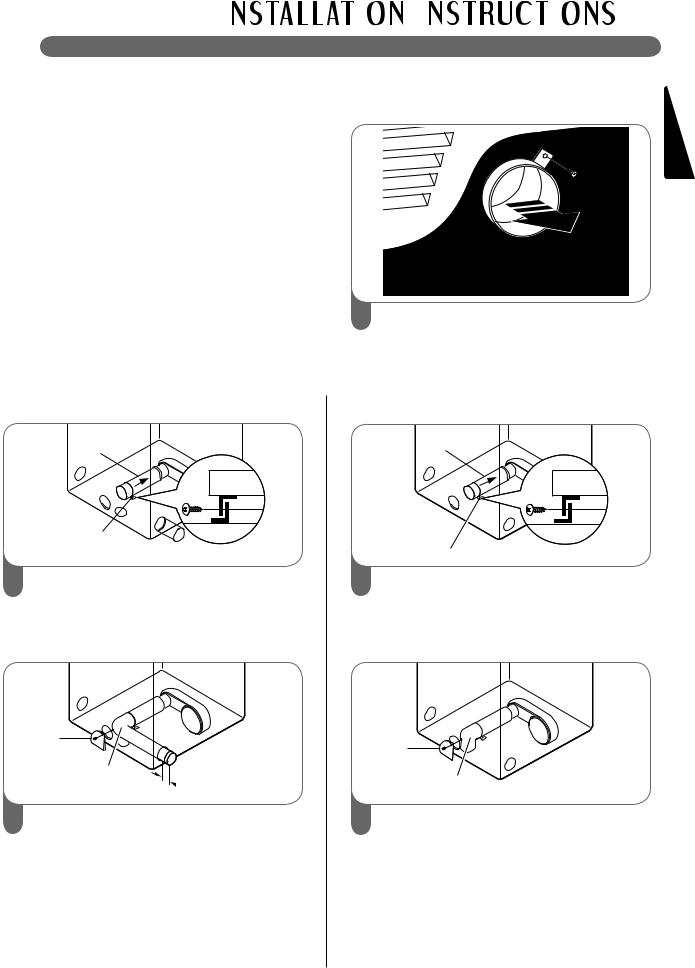

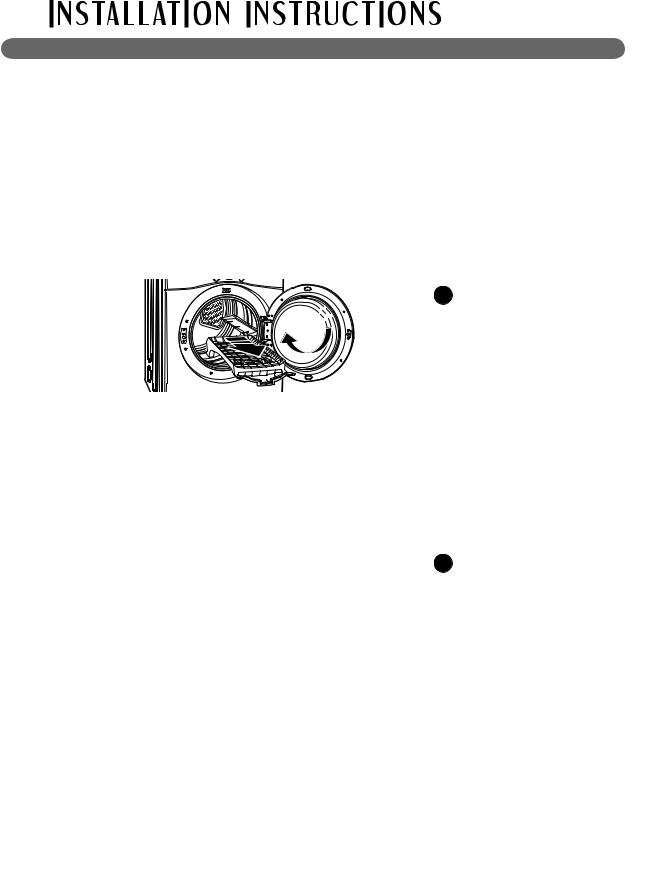

TO REMOVE THE DOOR

TO REMOVE THE DOOR

wWARNING

THE DRYER DOOR IS VERY LARGE AND HEAVY. Failure to follow the instructions below can result in damage to the dryer, property damage or injury to persons .

•To avoid damage to the dryer or the door, support the door with a stool or box that fits under the door, or have an assistant support the weight of the door.

•Always reverse the door BEFORE stacking the dryer on top of the washer.

•Avoid dropping the door to avoid damage to the door or the floor.

Latch Screw

Open Door

1 Open the door to reverse. |

4 Remove two screws and disassembly Latch. |

Hinge Screw

2 Check screws to remove (Left 6, Right 4). |

5 Hold on the hinge while remove 4 screws of |

|

hinge (to prevent door dropping). |

Hinge |

Remove |

|

Dummy |

||

Door |

||

Screw |

||

|

3 Remove four dummy screws by driver. |

6 Remove door from cabinet cover. |

<![endif]>ENGLISH

13

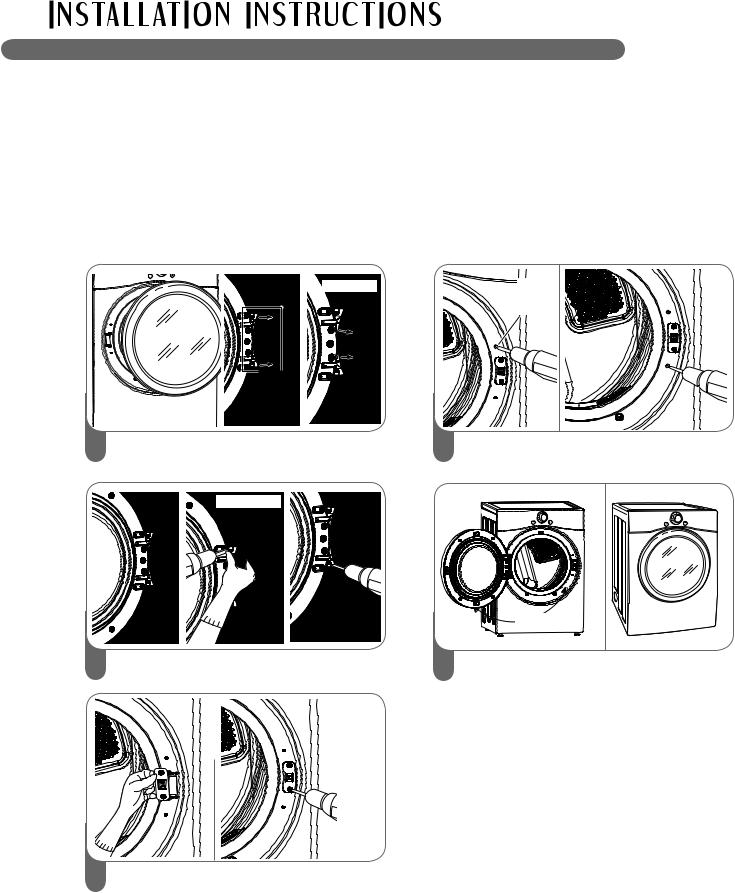

TO Install THE door

TO Install THE door

wWARNING

THE DRYER DOOR IS VERY LARGE AND HEAVY. Failure to follow the instructions below can result in damage to the dryer, property damage or injury to persons .

•To avoid damage to the dryer or the door, support the door with a stool or box that fits under the door, or have an assistant support the weight of the door.

•Always reverse the door BEFORE stacking the dryer on top of the washer.

•Avoid dropping the door to avoid damage to the door or the floor.

Hinge hole |

Hinge |

|

Dummy |

Screw

1Move door to left side and insert a hinge to hinge hole.

Hinge Screw

2Hold on hinge while screw down a hinge

(to prevent door dropping).

4 Screw down four dummy screws right side.

Swing Door

5Check that the door closes and latches properly.

Latch

Latch

Screw

3 Insert latch to right side and install screws.

14

CHANGING THE DRYER VENT LOCATION

CHANGING THE DRYER VENT LOCATION

wWARNING

•Use a heavy metal vent.

•Do not use plastic or thin foil duct.

•Clean old ducts before installing this dryer.

•To reduce the risk of injury to persons , adhere to all industry recommended safety procedures including the use of long sleeved gloves and safety glasses.

•Failure to follow all of the safety warnings in this manual could result in property damage, injury to persons or death.

Your new dryer is shipped to vent to the rear.

It can also be configured to vent to the bottom or side

(right-side venting is not available on gas models).

An adapter kit, part number 383EEL9001B, may be purchased from your LG retailer. This kit contains the necessary duct components to change the dryer vent location.

Retaining

Screw

Rear

Exhaust Duct

1Remove the rear exhaust duct retaining screw. Pull out the exhaust duct.

OPTION 1: Side Venting

Adapter

Duct

Bracket

Knockout

2Press the tabs on the knockout and carefully remove the knockout for the desired vent opening (right-side venting is not available on gas models). Press the adapter duct onto the blower housing and secure to the base of the dryer as shown.

Cover

Plate

Elbow

11/2"

11/2"

(3.8 cm)

3Preassemble a 4 inches (10.2 cm) elbow to the next 4-inches (10.2 cm) duct section, and secure all joints with duct tape. Be sure that the male end of the elbow faces AWAY from the dryer. Insert the elbow/duct assembly through the side opening and press it onto the adapter duct. Secure in place with duct tape.

Be sure that the male end of the duct protrudes 1½ inches (3.8 cm) to connect the remaining ductwork.

Attach cover plate to the back of the dryer with included screw.

OPTION 2: Bottom Venting

Adapter

Duct

Bracket

2Press the adapter duct onto the blower housing and secure to the base of the dryer as shown.

Cover

Plate

Elbow

3Insert the 4 inches (10.2 cm) elbow through the rear opening and press it onto the adapter duct. Be sure that the male end of the elbow faces down through hole in the bottom of the dryer. Secure in place with duct tape.

Attach the cover plate to the back of the dryer with included screw.

15

<![endif]>ENGLISH

VENTING THE DRYER

VENTING THE DRYER

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not crush or collapse ductwork. Failure to follow these instructions can result in fire or death.

•Do not allow ductwork to rest on or contact sharp objects. Failure to follow these instructions can result in fire or death.

•If connecting to existing ductwork, make sure it is suitable and clean before installing the dryer. Failure to follow these instructions can result in fire or death.

•Venting must conform to local building codes. Failure to follow these instructions can result in fire or death.

•Gas dryers MUST exhaust to the outdoors.

Failure to follow these instructions can result in fire or death.

•Use only 4-inch (10.2 cm) rigid or flexible metal ductwork inside the dryer cabinet and for venting outside. Failure to follow these instructions can result in fire or death.

•To reduce the risk of fire, combustion, or accumulation of combustible gases, DO NOT exhaust dryer air into an enclosed and unventilated area, such as an attic, wall, ceiling, crawl space, chimney, gas vent, or concealed space of a building. Failure to follow these instructions can result in fire

or death.

•To reduce the risk of fire, DO NOT exhaust the dryer with plastic or thin foil ducting.

Failure to follow these instructions can result in fire or death.

•The exhaust duct must be 4 inches

(10.2 cm) in diameter with no obstructions. The exhaust duct should be kept as short as possible. Make sure to clean any old ducts before installing your new dryer. Failure to follow these instructions can result in fire or death.

•Rigid or semirigid metal ducting is recommended for use between the dryer and the wall. In special installations when it is impossible to make a connection with the above recommendations, a UL-listed flexible metal transition duct may be used

between the dryer and wall connection only. The use of this ducting will affect drying

time. Failure to follow these instructions can result in fire or death.

•DO NOT use sheet metal screws or other fasteners which extend into the duct that could catch lint and reduce the efficiency of the exhaust system. Secure all joints with duct tape. Failure to follow these

instructions can result in fire or death.

•To maximize operating results, please observe the duct length limitations noted in the chart on page 17. Failure to follow these

instructions can result in fire or death.

•Ductwork is not provided with the dryer. You should obtain the necessary ductwork locally. The end cap should have hinged dampers to prevent backdraft when the dryer is not in use. Failure to follow these

instructions can result in fire or death.

•The Total length of flexible metal duct shall not exceed 8 ft. (2.4m)

•In Canada, that only those foil-type flexible ducts, if any, specifically identified for use

with the appliance by the manufacturer shall be used. In the United States, that only those foil-type flexible ducts, if any, specifically identified for use with the appliance by the manufacturer and that comply with the Outline for Clothes Dryer Transition Duct, Subject 2158A, shall be used.

16

VENTING THE DRYER (cont.) |

|

<![if ! IE]> <![endif]>ENGLISH |

||

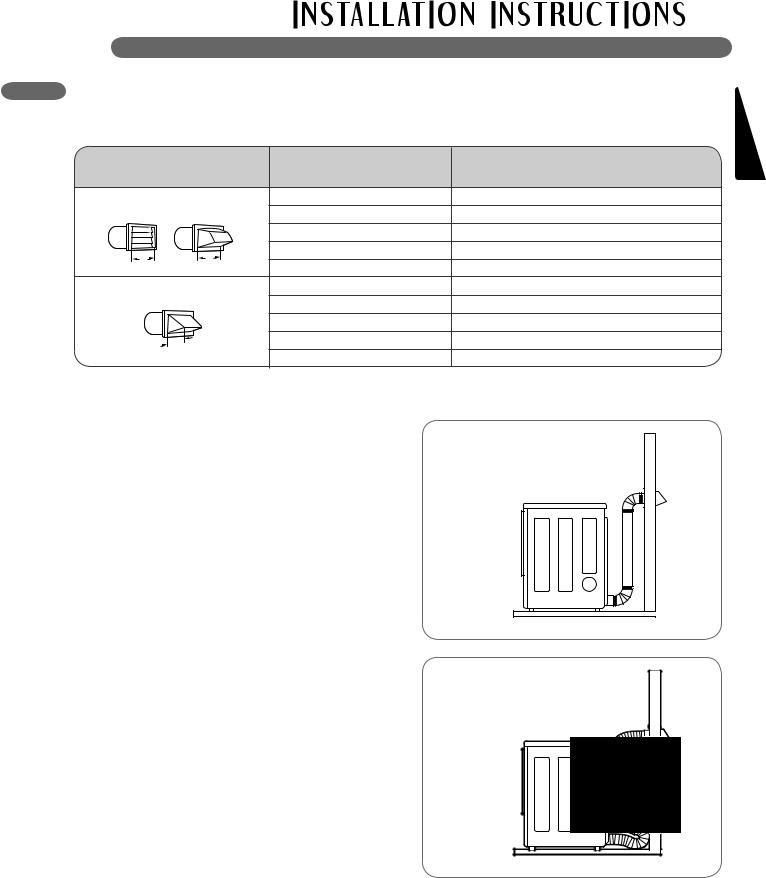

Ductwork |

|

|

|

|

Wall Cap Type |

Number of 90° Elbows |

Maximum Length of 4-inch Diameter |

||

Rigid Metal Duct |

|

|||

|

|

|

|

|

Recommended |

0 |

65 ft. (19.8 m) |

|

|

1 |

55 ft. (16.8 m) |

|

||

|

|

|

||

|

|

2 |

47 ft. (13.7 m) |

|

4" |

4" |

3 |

36 ft. (11.0 m) |

|

|

|

|

||

(10.2 cm) |

(10.2 cm) |

4 |

28 ft. (8.5 m) |

|

|

|

|

||

Use Only for Short |

0 |

55 ft. (16.8 m) |

|

|

Run Installations |

1 |

47 ft. (13.7 m) |

|

|

|

|

|

||

|

|

2 |

41 ft. (12.5 m) |

|

21/2" |

|

3 |

30 ft. (9.1 m) |

|

|

|

|

|

|

(6.35 cm) |

|

4 |

22 ft. (6.7 m) |

|

|

|

|

||

NOTE: Deduct 6 ft. (1.8 m) for each additional elbow. It is not recommended to use more than four 90° elbows.

Routing and Connecting Ductwork

Follow the guidelines below to maximize drying performance and reduce lint buildup and condensation in the ductwork.

NOTE: Ductwork and fittings are NOT included and must be purchased separately.

•Use 4-inch (10.2 cm) diameter rigid or semirigid metal ductwork.

•The exhaust duct run should be as short as possible.

•Use as few elbow joints as possible.

•The male end of each section of exhaust duct must point away from the dryer.

•Use duct tape on all duct joints.

•Insulate ductwork that runs through unheated areas in order to reduce condensation and lint buildup on duct surfaces.

IMPORTANT: Failure to exhaust the dryer correctly will void the dryer’s warranty.

Correct Venting |

Incorrect Venting |

17

ConnecTING GAS DRYERS

ConnecTING GAS DRYERS

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

• Gas supply requirements:

As shipped from the factory, this dryer is configured for use with natural gas. It can be converted for use with LP (Liquefied Propane) gas. Gas pressure must not exceed 13 inches of water column.

•A qualified service or gas company technician must connect the dryer to the gas service.

Failure to do so can result in fire, explosion, or death.

•Isolate the dryer from the gas supply system by closing its individual manual shutoff valve during any pressure testing of the gas supply.

Failure to do so can result in fire, explosion, or death.

•Supply line requirements:

Your laundry room must have a rigid gas supply line to your dryer. In the United States, an individual manual shutoff valve MUST be installed within at least 6 ft. (1.8 m) of the dryer, in accordance with the National Fuel Gas Code

ANSI Z223.1 or Canadian gas installation code CSA B149.1. A 1⁄8 - inch NPT pipe plug must be installed. Failure to do so can result in fire, explosion, or death

•If using a rigid pipe, the rigid pipe should be

½- inch IPS. If acceptable under local codes and ordinances and when acceptable to your

gas supplier, 3⁄8 - inch approved tubing may be used where lengths are less than 20 ft.

(6.1 m). Larger tubing should be used for lengths in excess of 20 ft. (6.1 m). Failure to do so can result in fire, explosion, or death.

•Connect the dryer to the type of gas shown on the nameplate. Failure to do so can result in fire, explosion, or death.

•To prevent contamination of the gas valve, purge the gas supply of air and sediment before connecting the gas supply to the dryer. Before tightening the connection between the gas supply and the dryer, purge remaining air until the odor of gas is detected. Failure to do so can result in fire, explosion, or death.

•DO NOT use an open flame to inspect for gas leaks. Use a noncorrosive leak-detection fluid.

Failure to do so can result in fire, explosion, or death.

•Use only a new AGAor CSA-certified gas supply line with flexible stainless steel connectors. Failure to do so can result in fire,

explosion, or death.

•Securely tighten all gas connections. Failure to do so can result in fire, explosion, or death.

•Use a pipe-joint compound that is insoluble in Liquefied Petroleum (LP) gas on all pipe threads. Failure to do so can result in fire, explosion, or death.

•DO NOT attempt any disassembly of the dryer; any disassembly requires the attention and tools of an authorized and qualified service person or company. Failure to do so can result in fire, explosion, or death.

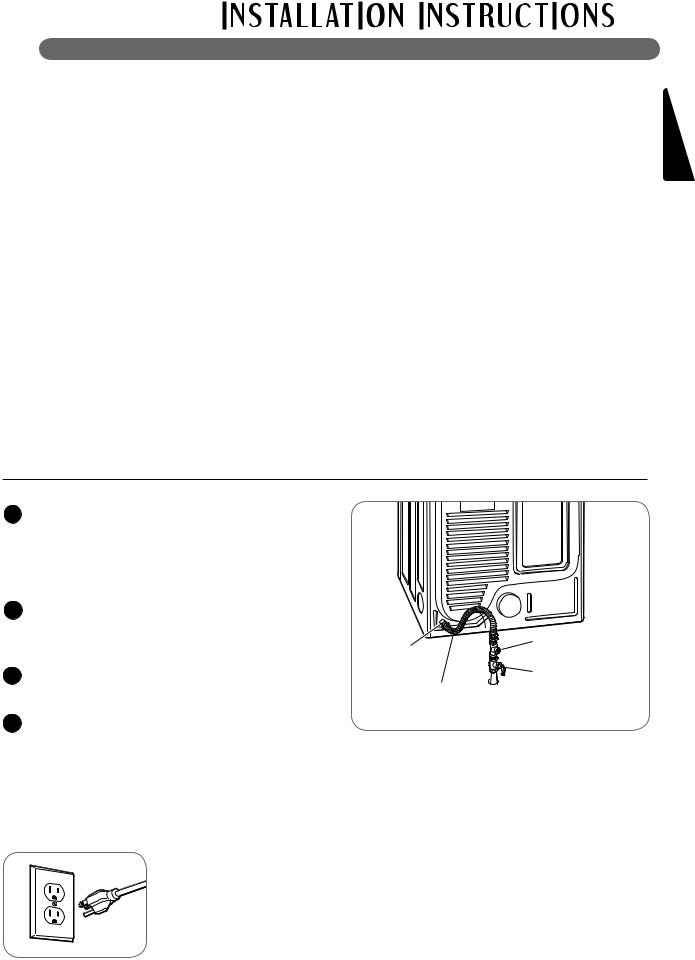

Electrical Requirements for Gas Models Only

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. Failure to follow this warning can result in fire, explosion, or death.

•For personal safety, this dryer must be properly grounded. Failure to follow this warning can result in fire, explosion, or death.

•The power cord of this dryer is equipped with a 3-prong (grounding) plug which mates with a standard 3-prong (grounding) wall outlet

to minimize the possibility of electric shock hazard from this appliance. Failure to follow this warning can result in fire, explosion, or death.

•This dryer must be plugged into a

60 Hz, 120 VAC. grounded outlet protected by a 15-ampere fuse or circuit breaker. Failure to follow this warning can result in fire, explosion, or death.

•Where a standard 2-prong wall outlet is encountered, it is your personal responsibility and obligation to have it replaced with a properly grounded 3-prong wall outlet. Failure to follow this warning can result in fire, explosion, or death.

18

ConnecTING GAS DRYERS (cont.)

ConnecTING GAS DRYERS (cont.)

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Installation and service must be performed by a qualified installer, service agency, or the gas supplier. Failure to do so can result in fire, explosion, or death.

•Use only a new stainless steel flexible connector and a new AGA-certified connector. Failure to do so can result in fire, explosion, or death.

•A gas shutoff valve must be installed within 6 ft. (1.8 m) of the dryer. Failure to do so can result in fire, explosion, or death.

•The dryer is configured for Natural Gas when shipped from the factory. Make sure that the dryer is equipped with the correct burner orifice for the type of gas being used (Natural Gas or Liquefied Petroleum). Failure to do so

can result in fire, explosion, or death.

•If necessary, the correct orifice (for the LP orifice kit order part number 383EEL3002D) should be installed by a qualified technician and the change should be noted on the dryer.

Failure to do so can result in fire, explosion, or death.

•All connections must be in accordance with local codes and regulations. Failure to do so can result in fire, explosion, or death.

•Gas dryers MUST exhaust to the outdoors.

Failure to do so can result in fire, explosion, or death.

Connecting the Gas Supply

1Make sure that the gas supply to the laundry room is turned OFF. Confirm that the type of gas available in your laundry room is

appropriate for the dryer. The dryer is prepared for Natural Gas with a 3⁄8 - inch NPT gas connection.

2Remove the shipping cap from the gas connection at the back of the dryer. Be careful not to damage the threads of the gas connector when removing the shipping cap.

3Connect the dryer to your laundry room’s gas supply using a new flexible stainless steel connector with a 3⁄8 - inch NPT fitting.

4Securely tighten all connections between the dryer and your laundry room’s gas supply. Turn on your laundry room’s gas supply and check all pipe connections (both internal and external) for gas leaks with a noncorrosive leak-detection fluid.

|

1/8” NPT Pipe |

3/8” NPT Gas |

Plug |

Connection |

Gas Supply |

|

|

AGA/CSA-Certified |

Shutoff Valve |

|

|

Stainless Steel |

|

Flexible Connector |

|

Electrical Connection

Plug dryer into a

120 VAC, 60 Hz grounded 3-prong outlet.

High-Altitude Installations

The BTU rating of this dryer is AGA-certified for elevations below 10,000 feet.

If your gas dryer is being installed at an elevation above 10,000 feet, it must be derated by a qualified technician or gas supplier.

<![endif]>ENGLISH

19

CONNECTING ELECTRIC DRYERS

CONNECTING ELECTRIC DRYERS

wWARNING: To help prevent fire, electric shock, serious injury, or death, the wiring and grounding must conform to the latest edition of the National Electrical Code, ANSI/NFPA 70 and all applicable local regulations. Please contact a qualified electrician to check your home’s wiring and fuses to ensure that your home has adequate electrical power to operate the dryer.

Electrical Requirements for Electric Models Only

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•This dryer must be connected to a grounded metal, permanent wiring system, or an equipment-grounding conductor must

be run with the circuit conductors and connected to the equipment-grounding terminal or lead on the dryer. Failure to do so can result in fire, explosion, or death.

•The dryer has its own terminal block that must be connected to a separate 240 VAC, 60-Hertz, single-phase circuit, fused at 30 amperes (the circuit must be fused on both sides of the line). ELECTRICAL SERVICE FOR THE DRYER SHOULD BE OF THE MAXIMUM RATE VOLTAGE LISTED ON THE

NAMEPLATE. DO NOT CONNECT DRYER TO 110-, 115-, OR 120-VOLT CIRCUIT. Failure to follow these instructions can result in fire, explosion, or death.

•If branch circuit to dryer is 15 ft. (4.5 m) or less in length, use UL (Underwriters Laboratories) listed No.-10 AWG wire (copper wire only), or as required by local

codes. If over 15 ft. (4.50 m), use UL-listed No.-8 AWG wire (copper wire only), or as required by local codes. Allow sufficient slack in wiring so dryer can be moved from its normal location when necessary. Failure to do so can result in fire, explosion, or death.

•The power cord (pigtail) connection between wall receptacle and dryer terminal block IS

NOT supplied with dryer. The pigtail must be the correct plug and wire gauge and must conform to local codes and with instructions on the following pages. Failure to follow these instructions can result in fire, explosion, or death.

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January

1, 1996. A 4-wire connection must be used where local codes do not permit grounding through the neutral wire. Failure to do so can result in fire, explosion, or death.

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Do not modify the plug and internal wire provided with the dryer.

•The dryer should be connected to 4-hole outlet.

•If it does not fit the outlet, a proper outlet will need to be installed by a qualified electrician.

Special Electrical Requirements for Mobile or Manufactured Homes

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this appliance, follow basic precautions, including the following:

•Any installation in a manufactured or mobile home must comply with the Manufactured Home Construction and Safety Standards Title 24 CFR, Part 32-80 or Standard CAN/

CSA0Z240 MH and local codes and ordinances.

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996.

Failure to do so can result in fire, explosion, or death.

20

CONNECTING ELECTRIC DRYERS (cont.)

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

•Connect the power cord to the terminal block. Each colored wire should be connected to same color screw. Wire color indicated on manual is connected to the same color screw in block. Failure to follow these instructions may result in a short or overload.

•Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductor.

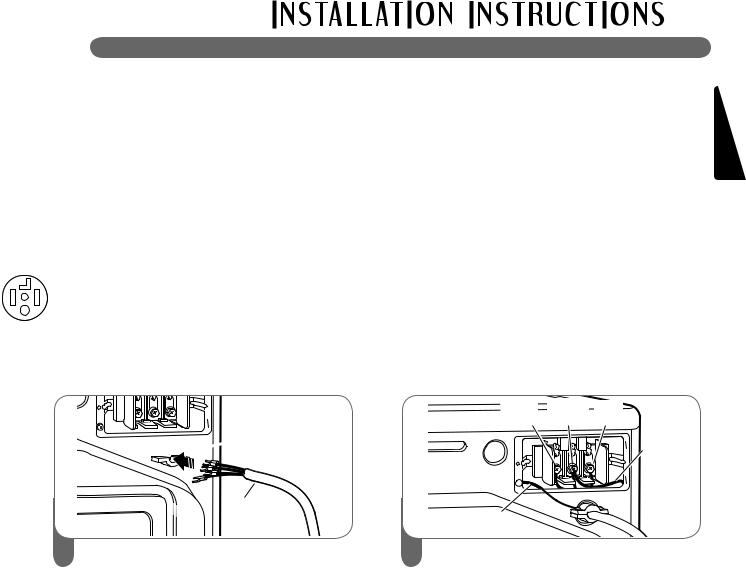

Four-Wire Connection for Electric Dryers: Power Cord

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996.

•A UL-listed strain relief is required.

Terminal

Block

Block

UL-Listed

Strain Relief

Strain Relief

UL-Listed 4-Wire Power Cord

•Use a 30 A, 240 V, UL-listed power cord with #10 AWG-minimum copper conductor and closed loop or forked terminals with upturned ends.

Hot |

Neutral |

Hot |

(Black) |

(White) |

(Red) |

Neutral Grounding

wire

Ground Screw

Power Cord

Ground Wire

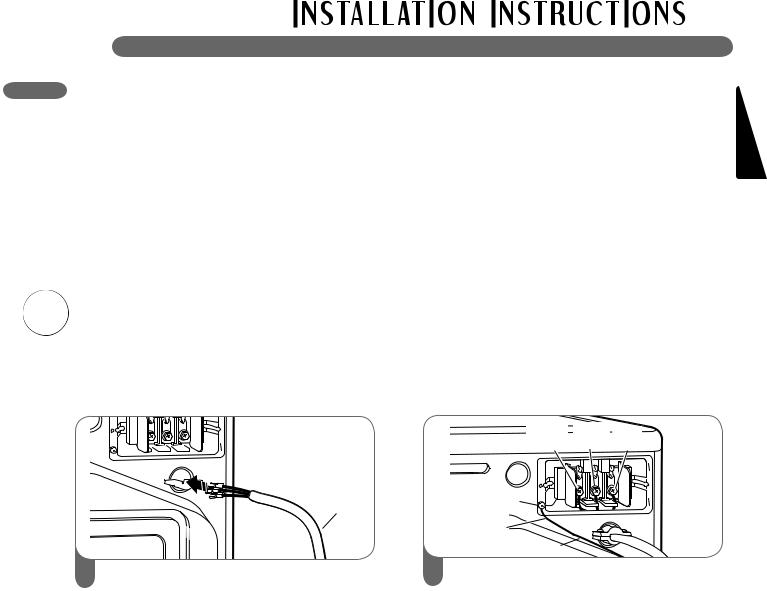

1Remove the terminal block access cover on the upper back of the dryer. Install a UL-listed strain relief into the power cord through-hole; then thread a UL-listed,

30 A, 240 V, 4-wire, #10 AWG-minimum copper conductor power cord through the strain relief.

2Transfer the dryer’s ground wire from behind the green ground screw to the center screw of the terminal block. Attach the two hot leads of the power cord to the outer terminal block screws. Attach the white neutral wire to the center terminal block screw. Attach the power cord ground wire to the green ground screw. Tighten all screws securely. Reinstall the terminal block access cover.

<![endif]>ENGLISH

21

CONNECTING ELECTRIC DRYERS (cont.)

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

•Connect the power cord to the terminal block. Each colored wire should be connected to same color screw. Wire color indicated on manual is connected to the same color screw in block. Failure to follow these instructions may result in a short or overload.

•Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductor.

Four-Wire Connection for Electric Dryers: Direct Wire

•A 4-wire connection is required for all mobile and manufactured home installations, as well as all new construction after January 1, 1996.

•A UL-listed strain relief is required.

1" (2.5 cm)

Ground Wire

5" (12.7 cm)

•Use UL-listed 4-wire #10 AWG-minimum copper conductor cable.

•Allow at least 5 ft. (1.5 m) length to allow for removal and reinstallation of the dryer.

Hot |

Neutral |

Hot |

(Black) |

(White) |

(Red) |

|

|

Neutral |

|

|

Grounding |

Ground Screw |

|

wire |

|

|

|

Ground Wire |

|

|

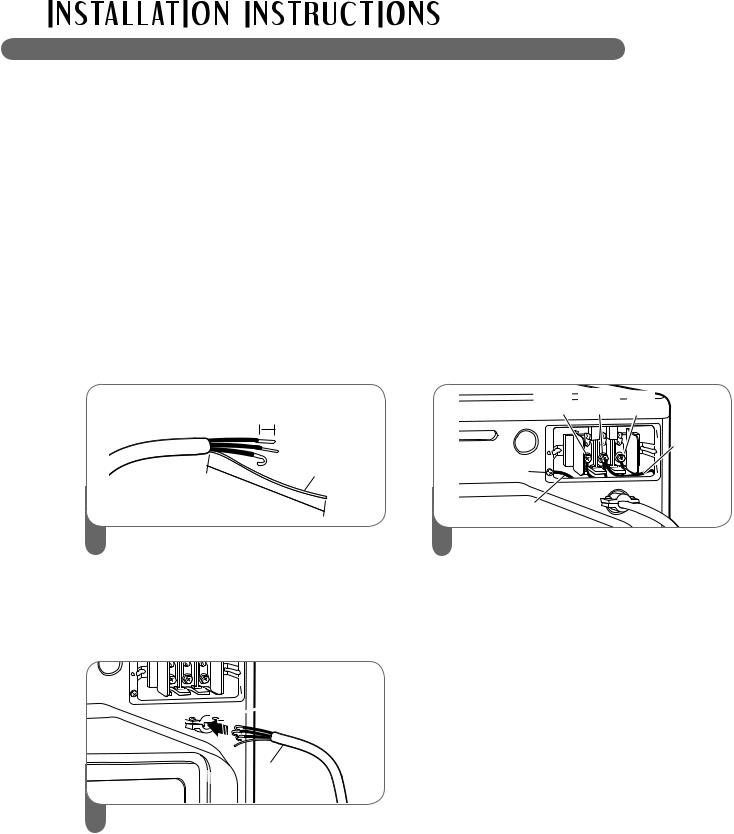

1Remove 5 inches (12.7 cm) of the outer covering from the wire. Remove 5 inches of insulation from the ground wire. Cut off

approximately 11⁄2 inches (3.8 cm) from the other three wires and strip 1 inch (2.5 cm) insulation from each wire. Bend the ends of the three shorter wires into a hook shape.

Terminal

Block

Block

UL-Listed

Strain Relief

Strain Relief

UL-Listed 4-Wire Power Cord

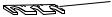

2Remove the terminal block access cover on the upper back of the dryer. Install a

UL-listed strain relief into the power cord through-hole; then thread the power cable prepared in Step 1 through the strain relief.

3Transfer the dryer’s ground wire from behind the green ground screw to the center screw of the terminal block. Attach the two hot leads of the power cable to the outer terminal block screws. Attach the white neutral wire to the center terminal block screw. Attach the power cable ground wire to the green ground screw. Tighten all screws securely. Reinstall the terminal block access cover.

22

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

•Connect the power cord to the terminal block. Each colored wire should be connected to same color screw. Wire color indicated on manual is connected to the same color screw in block. Failure to follow these instructions may result in a short or overload.

•Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductor.

Three-Wire Connection for Electric Dryers: Power Cord

Three-Wire Connection for Electric Dryers: Power Cord

•A 3-wire connection is NOT permitted on new construction after January 1, 1996.

•A UL-listed strain relief is required.

Terminal

Block

Block

UL-Listed

Strain Relief UL-Listed

Strain Relief UL-Listed

3-Wire

Power Cord

1Remove the terminal block access cover on the upper back of the dryer. Install a UL-listed strain relief into the power cord through-hole; then thread a UL-listed,

30 A, 240 V, 3-wire, #10 AWG-minimum copper conductor power cord through the strain relief.

•Use a 30 A, 240 V, UL-listed power cord with #10 AWG-minimum copper conductor and closed loop or forked terminals with upturned ends.

Hot |

Neutral |

Hot |

(Black) |

(White) |

(Red) |

Ground Screw |

|

|

Neutral |

|

|

Grounding wire |

|

|

Ground Wire |

|

|

2Attach the two hot leads of the power cord to the outer terminal block screws. Attach the neutral wire to the center terminal block screw. Connect the external ground (if required by local codes) to the green ground screw. Tighten all screws securely. Reinstall the terminal block access cover.

<![endif]>ENGLISH

23

CONNECTING ELECTRIC DRYERS (cont.)

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

WARNING:

•Connect the power cord to the terminal block. Each colored wire should be connected to same color screw. Wire color indicated on manual is connected to the same color screw in block. Failure to follow these instructions may result in a short or overload.

•Grounding through the neutral conductor is prohibited for: (1) new branch-circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductor.

Three-Wire Connection for Electric Dryers: Direct Wire

•A 3-wire connection is NOT permitted on new construction after January 1, 1996.

•A UL-listed strain relief is required.

1" (2.5 cm)

•Use UL-listed 3-wire #10 AWG-minimum copper conductor cable.

•Allow at least 5 ft. (1.5 m) length to allow for removal and reinstallation of the dryer.

Hot |

Neutral |

Hot |

(Black) |

(White) |

(Red) |

Ground Screw |

|

|

Ground Wire

1Remove 31⁄2 inches (8.9 cm) of the outer covering from the wire. Strip 1 inch (2.5 cm) insulation from each wire. Bend the ends of the three wires into a hook shape.

Terminal

Block

Block

UL-Listed

Strain Relief

Strain Relief

UL-Listed 3-Wire Power Cord

2Remove the terminal block access cover on the upper back of the dryer. Install a UL-listed strain relief into the power cord through-hole; then thread the power cable prepared in Step 1 through the strain relief.

3Attach the two hot leads of the power cord to the outer terminal block screws. Attach the neutral wire to the center terminal block screw. Connect the external ground (if required by local codes) to the green ground screw. Tighten all screws securely. Reinstall the terminal block access cover.

24

SPECIAL REQUIREMENTS FOR MANUFACTURED OR MOBILE HOMES

SPECIAL REQUIREMENTS FOR MANUFACTURED OR MOBILE HOMES

Any installation in a manufactured or mobile home must comply with the Manufactured Home Construction and Safety Standards Title 24 CFR, Part 32-80 or Standard CAN/CSA0Z240 MH and local codes and ordinances. If you are uncertain whether your proposed installation will comply with these standards, please contact a service and installation professional for assistance.

•A gas dryer must be permanently attached to the floor.

•The electrical connection for an electric dryer must be a 4-wire connection. More detailed information concerning the electrical connection is provided in the section Connecting Electric Dryers.

•To reduce the risk of combustion and fire, the dryer must be vented to the outside.

•DO NOT vent the dryer under a manufactured home or mobile home.

•Electric dryers may be vented to the outside using the back, left, right, or bottom panel.

•Gas dryers may be vented to the outside using the back, left, or bottom panel. Gas dryers may not be vented to the outside using the right side panel because of the burner housing.

•The dryer exhaust duct must be affixed securely to the manufactured or mobile home structure, and the exhaust duct must be made of a material that will resist fire and combustion.

It is recommended that you use a rigid or flexible metal duct.

•DO NOT connect the dryer exhaust duct to any other duct, vent, chimney, or other exhaust duct.

•Make sure the dryer has adequate access to outside fresh air to ensure proper operation. The opening for outside fresh air must be at least 25 in2 (163 cm2).

•It is important that the clearance of the duct from any combustible construction be at least 2 inches (5 cm), and when venting the dryer to the outdoors, the dryer can be installed with a clearance of 1 inch (2.5 cm) at the sides and back of the dryer.

•Please be aware that venting materials are not supplied with the dryer. You should obtain the venting materials necessary for proper installation.

FINAL INSTALLATION CHECK

FINAL INSTALLATION CHECK

Once you have completed the installation of the dryer and it is in its final location, confirm proper operation with the following tests and Duct Condition Testing on the following page.

Testing Dryer Heating

GAS MODELS

Close the dryer door, press the ON/OFF switch to turn the dryer on, and start the dryer on a heat setting. When the dryer starts, the igniter should ignite the main burner.

NOTE: If all air is not purged from the gas line, the gas igniter may turn off before the main burner ignites. If this happens, the igniter will reattempt gas ignition after approximately

two minutes.

ELECTRIC MODELS

Close the dryer door, press the ON/OFF switch to turn the dryer on, and start the dryer on a heat setting. The exhaust air should be warm after the dryer has been operating for 3 minutes.

Checking Airflow

Effective dryer operation requires proper airflow. The adequacy of the airflow can be measured by evaluating the static pressure. Static pressure in the exhaust duct can be measured with

a manometer, placed on the exhaust duct approximately 2 ft. (60.9 cm) from the dryer. Static pressure in the exhaust duct should not exceed 0.6 inches (1.5 cm) of water column. The dryer should be checked while the dryer is running with no load.

Checking Levelness

Once the dryer is in its final location, recheck the dryer to be sure it is level. Make sure it is level front to back and side to side, and that all 4 leveling feet are firmly on the floor.

<![endif]>ENGLISH

25

INSTALLATION TEST (Exhaust check)

INSTALLATION TEST (Exhaust check)

Once you have completed the installation of the dryer, use this test to make sure the condition of the exhaust system is adequate for proper operation of the dryer. This test should be performed to alert you to any serious problems in the exhaust system of your home.

• Your dryer features FlowSense, an innovative sensing system that automatically detects blockages and restrictions in dryer ductwork. Keeping ductwork clean of lint buildup and free of restrictions allows clothes to dry faster and reduces energy use.

NOTE : The dryer should be cool before starting this test. If the dryer was warmed up during installation, run the Air Dry cycle for a few minutes to reduce the interior temperature.

To activate the Installation test :

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO BARS: |

FOUR BARS: |

|||||||||||

|

|

OK |

RESTRICTED |

|||||||||

Four bars indicates that the exhaust system is severely restricted. Have the system checked immediately, as performance will be poor.

1Remove the drying rack and literature, and then close the door.

Do not load anything in the drum for this test, as in may affect the accuracy of the results.

2Press and hold the SIGNAL and TEMP

CONTROL buttons and then press the POWER button.

This button sequence activates the

installation test. The code  will display if the activation is successful.

will display if the activation is successful.

3Press START/PAUSE button.

The dryer will start the test, which will last about two minutes. The heat will be turned on and the temperatures in the drum will be measured.

4Check the display for results.

During the two minute test cycle, monitor the FlowSense display on the control panel. If no bars are displayed, when the cycle ends, the exhaust system is adequate. If the exhaust system is severely restricted, the display will show four bars. Other problems may also be shown with error codes. Refer to the next page for error code details and solutions.

5END of Cycle.

At the end of the test cycle,  will display. The test cycle will end and the dryer will shut off automatically after a short delay.

will display. The test cycle will end and the dryer will shut off automatically after a short delay.

26

INSTALLATION TEST (Exhaust check)

INSTALLATION TEST (Exhaust check)

• Check the Error Code before you call for service

Error Code |

Possible Causes |

|

Solutions |

|||

|

|

|

|

|||

tE1 or tE2 |

• Temperature sensor failure |

|

• Turn off the dryer and call for |

|||

|

|

service. |

||||

|

|

|

|

|||

HS |

• Humidity Sensor failure. |

|

• Turn off the dryer and call for |

|||

|

|

service. |

||||

|

|

|

||||

|

|

|

||||

|

• Electric dryer power cord is not con- |

• Check the power supply or the |

||||

|

nected correctly, or house power |

connection of power cord to |

||||

|

supply is incorrect. |

|

the terminal block. Refer to the |

|||

|

|

|

Connecting Electric Dryers |

|||

|

|

|

section of this manual for |

|||

PSor PF or nP |

|

|

complete instructions. |

|||

• House fuse is blown, circuit |

breaker |

• Reset circuit breaker or replace |

||||

|

||||||

|

has tripped, or power outage has oc- |

fuse. |

||||

|

curred. |

|

Do not increase the fuse capacity. |

|||

|

|

|

If the problem is a circuit over- |

|||

|

|

|

load, have it corrected by a |

|||

|

|

|

qualified electrician. |

|||

|

|

|

|

|

|

|

• Check the duct condition |

Restricted or Blocked Airflow |

|

|

|||

|

|

|||||

|

|

|

|

|

|

|

If the test displays four bars, check the exhaust system for restrictions and damage. Repair or replace the exhaust system as needed.

NOTE: When the dryer is first installed, this test should be performed to alert you to any existing problems with the exhaust duct in your home. However, since the test performed during normal operation provides more accurate information on the condition of the exhaust duct than does the installation test, the number of bars displayed during the two tests may not be the same.

IMPORTANT: Do not interrupt the test cycle, as this could result in the wrong results.

NOTE: Even if no bars are displayed during the test cycle, some restrictions may still be present in the exhaust system. Refer to the Venting the Dryer section of this manual for complete exhaust system and venting requirements.

Avoid long runs or runs with multiple elbows or bends.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Excess or crushed |

|

|

Too many elbows |

||||||||||||||||

|

|

|

transition duct |

or exhaust too long |

|||||||||||||||

Check for blockages and lint buildup.

Lint buildup or blockage

Make sure the ductwork is not crushed or restricted.

Crushed or damaged exhaust

<![endif]>ENGLISH

27

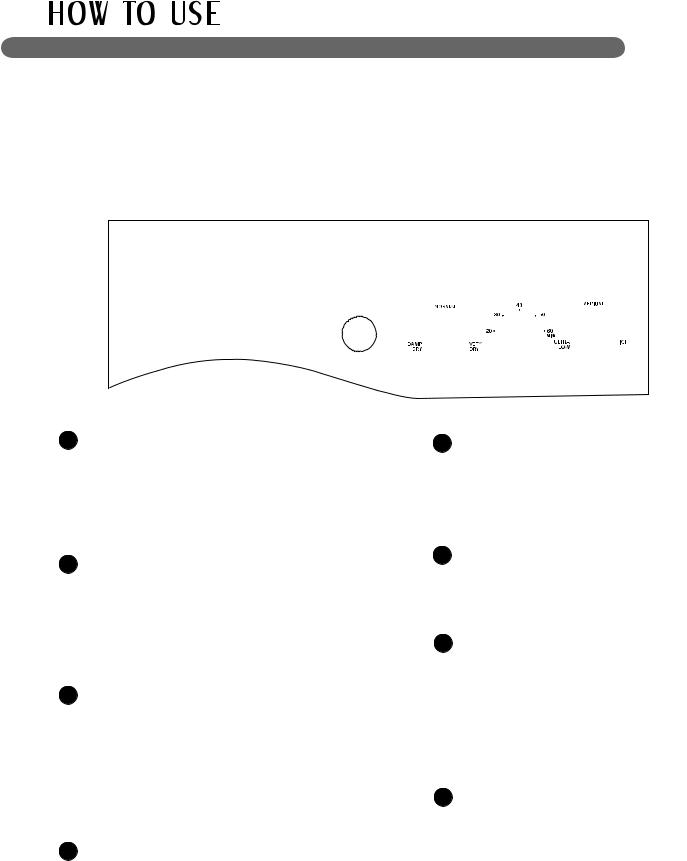

CONTROL PANEL FEATURES

CONTROL PANEL FEATURES

Following are instructions for starting and using your new dryer. Please refer to specific sections of this manual for more detailed information.

w WARNING: To reduce the risk of fire, electric shock, or injury to persons , read this entire manual, including the Important Safety Instructions, before operating this dryer.

H H D F

G

A |

B |

C |

E |

A POWER ON/OFF BUTTON |

|

|

E CYCLE SETTING BUTTONS |

Press to turn the dryer ON. Press again to turn the dryer OFF.

NOTE: Pressing the ON/OFF button during a cycle will cancel that cycle and any load settings will be lost.

BCYCLE SELECTOR KNOB

Turn this knob to select the desired cycle.

Once the desired cycle has been selected, the standard presets will be shown in the display. On MANUAL DRY cycles, these settings can be adjusted using the cycle setting buttons anytime before starting the cycle.

CSTART/PAUSE BUTTON

Press this button to START the selected cycle. If the dryer is running, use this button to PAUSE the cycle without losing the current settings.

NOTE: If you do not press the START/PAUSE button to resume a cycle within 4 minutes, the dryer turns off automatically.

DMORE TIME/LESS TIME BUTTONS

To adjust the drying time, use these buttons with MANUAL DRY, TIME DRY, and STEAM FRESH™ cycles, as well as the REDUCE STATIC

|

and EASY IRON options. Press the MORE TIME |

|

button to increase the selected manual cycle |

|

time by a minute; press LESS TIME to decrease |

28 |

the cycle time by a minute. |

|

Use these buttons to select the desired cycle settings for the selected cycle. The current settings are shown in the display. Press the button for that option to view and select other settings.

FTIME AND STATUS DISPLAY

The display shows the settings, estimated time remaining, options, and status messages for your dryer.

GOPTION BUTTONS

The OPTION buttons allow you to select additional cycle options. Certain buttons also allow you to activate special functions by pressing and holding the button for 3 seconds.

For detailed information about the individual options, please see the following pages.

HSTEAM FUNCTIONS

LG’s steam technology allows you to inject fabrics with a swirling jet of hot steam to refresh clothes, reduce static, and make ironing easier. Simply select the steamfresh™ cycle, or you can add a STEAM option to selected cycles.

For detailed information about the individual options, please see the following pages.

OPERATING THE Dryer

OPERATING THE Dryer

1CLEAN THE LINT FILTER

If the lint filter has not already been cleaned, lift out the filter and remove the lint from the last load. This will help ensure the fastest and most efficient drying performance.

2LOAD THE DRYER

Load the dryer with the wet laundry from the washer.

If the load is extra large, you may need to divide it into smaller loads for proper performance and fabric care.

3TURN ON THE DRYER

Press the POWER button to turn on the dryer. The cycle

LEDs will illuminate and a beep will sound, if turned on. Refer to page 27.

4SELECT A CYCLE

Turn the cycle selector knob either direction until the LED for the desired cycle is on. The preset temperature, dry level, and option settings for that cycle will be shown. Refer to page 29.

5SELECT CYCLE MODIFIERS

Default settings for the selected cycle can now be changed if desired. This can be done using the cycle modifier buttons as shown on page 32.

NOTE: Not all options or modifiers are available on all cycles. A different chime will sound and the LED will not come on if the selection is not allowed.

6SELECT CYCLE OPTIONS

Cycle options can be added using the option buttons as shown on page 32-33.

NOTE: Not all options or modifiers are available on all cycles. A different chime will sound and the LED.

7BEGIN CYCLE

Press the START/PAUSE button to begin the cycle. The cycle can be paused at any time either by opening the door or by pressing the START/PAUSE button. If the cycle is not restarted within 4 minutes, the dryer will shut off and the cycle settings will be lost.

8END OF CYCLE

When the cycle is finished, the chime will sound if it is set. Remove your clothing from the dryer immediately to reduce wrinkling. If wrinkle care is selected, the dryer will tumble briefly every few minutes to help prevent wrinkles from setting in the clothes.

<![endif]>ENGLISH

29

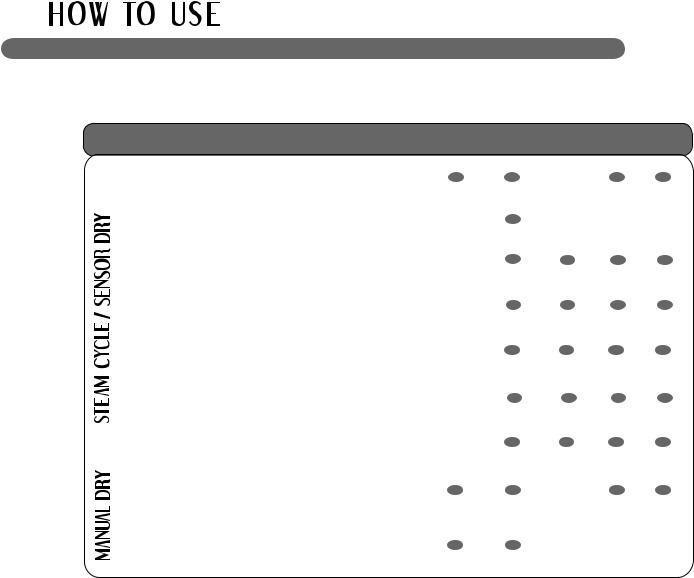

CYCLE GUIDE

CYCLE GUIDE

The cycle guide below shows the options and recommended fabric types for each cycle.

Type Cycle |

Fabric Type |

Dry |

Temperature |

Time More Time/ |

Wrinkle |

Damp Dry Reduce |

Easy |

|||||

Level |

in Min. Less Time |

Care |

Signal |

Static |

Iron |

|||||||

|

|

|||||||||||

|

STEAM |

Comforter, Shirts, |

Off |

MID HIGH |

20 |

|

|

|

|

|

||

|