LG DLG0332W, DLG2532W, DLG5932W, DLG5932S, DLG2511W Service Manual

...

Website:http://www.LGservice.com [For U.S.A]

www.lg.ca [For Canada]

ELECTRIC & GAS DRYER

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY TO DIAGNOSE

TROUBLES CORRECTLY BEFORE OFFERING SERVICE.

MODEL : DLE5911W DLG5911W

DLE2511W DLG2511W

DLE5932W DLG5932W

DLE5932S DLG5932S

DLE2532W DLG2532W

DLE0332W DLG0332W

MAR. 2003 PRINTED IN KOREA |

|

|

|

|

|

P/No.:3828EL3001B |

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing adequate backgrounds of electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

! WARNING !

To avoid personal injury, disconnect power before servicing this product. If electrical power is required for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path to ground are removed for service, they must be returned to their original position and properly fastened.

Do not try to light a match, or cigarette, or turn on any gas or electrical appliance.

Do not try to light a match, or cigarette, or turn on any gas or electrical appliance.

Do not touch any electrical switches. Do not use any phone in your building.

Do not touch any electrical switches. Do not use any phone in your building.

Clear the room, building or area of all occupants.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions carefully.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions carefully.

If you cannot reach your gas supplier, call the fire department.

If you cannot reach your gas supplier, call the fire department.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic control assembly. The new control assembly may appear to work well after repair is finished, but failure may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or unpainted metal in the appliance.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or unpainted metal in the appliance.

- OR -

Touch your finger repeatedly to a green ground connection point or unpainted metal in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground connection point or unpainted metal in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground connection point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.  When repackaging failed electronic control assembly in anti-static bag, observe above instructions.

When repackaging failed electronic control assembly in anti-static bag, observe above instructions.

2

CONTENTS

1. |

SPECIFICATIONS .................................................................................................................. |

4 |

2. |

FEATURES AND BENEFITS .................................................................................................... |

5 |

3. |

INSTALLATION INSTRUCTIONS ........................................................................................... |

6 |

4. COLUMBUS DRYER CYCLE PROCESS .................................................................................... |

9 |

|

5. COMPONENT TESTING INFORMATION .............................................................................. |

10 |

|

6. MOTOR DIAGRAM AND SCHEMATIC.................................................................................. |

13 |

|

7. |

CONTROL LAY - OUT ......................................................................................................... |

14 |

8. WIRING DIAGRAM ............................................................................................................ |

15 |

|

9. |

DIAGNOSTIC TEST ............................................................................................................. |

16 |

|

9-1. TEST 1 120VAC ELECTRICAL SUPPLY.......................................................................... |

17 |

|

9-2. TEST 2 THERMISTOR TEST --- MEASURE WITH POWER OFF ....................................... |

18 |

|

9-3. TEST 3 MOTOR TEST ................................................................................................ |

19 |

|

9-4. TEST 4 MOISTURE SENSOR .................................................................................... |

20 |

|

9-5. TEST 5 DOOR SWITCH TEST ................................................................................... |

21 |

|

9-6. TEST 6 HEATER SWITCH TEST - ELECTRIC TYPE........................................................... |

22 |

|

9-7. TEST 7 GAS VALVE TEST - GAS TYPE ......................................................................... |

23 |

10. CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS) ............................................... |

24 |

|

11. DISASSEMBLY INSTRUCTIONS ......................................................................................... |

26 |

|

12. EXPLODED VIEW .............................................................................................................. |

32 |

|

|

12-1. CONTROL PANEL & PLATE ASSEMBLY ....................................................................... |

32 |

|

12-2. CABINET & DOOR ASSEMBLY................................................................................... |

33 |

|

12-3-1. DRUM & MOTOR ASSEMBLY : ELECTRIC TYPE ........................................................ |

34 |

|

12-3-2. DRUM & MOTOR ASSEMBLY : GAS TYPE ............................................................... |

35 |

13. REPLACEMENT PARTS LIST ................................................................................................ |

36 |

|

1SPECIFICATIONS

ITEM |

DLE5932W |

|

|

DLE5932S |

|

DLE2532W |

REMARK |

|||||

DLG5932W |

|

|

DLG5932S |

|

DLG2532W |

|||||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||

& |

|

Color |

White |

|

|

Titanium |

|

|

White |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Top Plate |

Porcelain |

|

|

Porcelain |

|

|

Painted |

|

||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||

|

Door Trim |

Silver |

|

|

Chrome |

|

|

White |

|

|||

|

|

|

|

|

|

|||||||

|

SUPPLY |

120V / 240V 60Hz (26A) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

MOTOR |

|

|

250W (4.5A) |

|

|

AC 120V |

||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

HEATER |

|

|

5400W (22.5A) |

|

|

AC 240V(ELECTRICTYPE) |

||||

|

|

|

|

|

|

|

|

|

||||

|

|

LAMP |

|

|

15W (125mA) |

|

|

AC 120V |

||||

|

|

|

|

|

|

|

|

|||||

|

|

GAS VALVE |

|

|

13W (110mA) X 2 |

|

AC 120V(GASTYPE) |

|||||

|

|

|

|

|

|

|

|

|

|

|

||

CONTROL TYPE |

|

|

|

Electronic |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

CAPACITY |

|

|

|

7.3 cu.ft. |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||

(lbs): Net/ Gross |

|

|

|

126 / 144 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

No. of Programs |

9 |

|

|

9 |

|

|

|

|

5 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. of Dry Option |

5 |

|

|

5 |

|

|

|

|

5 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature Controls |

5 |

|

|

5 |

|

|

|

|

5 |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

No. of Dry Levels |

5 |

|

|

5 |

|

|

|

|

3 |

|

||

|

|

|

|

|

|

|

|

|||||

End of Cycle Beeper |

High / Low / Off |

|

High / Low / Off |

|

|

On / Off |

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

Moisture |

|

|

|

Equipped |

|

|

Electro sensor |

||||

|

|

|

|

|

|

|

|

|

|

|||

|

Temperature |

|

|

|

Equipped |

|

|

Thermistor |

||||

|

|

|

|

|

|

|

|

|

|

|||

Reversible Door |

|

|

|

Adopted |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

Drum |

|

|

Stainless Steel |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||

Dryer Rack |

|

|

|

Equipped |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||

Child lock |

|

|

|

Equipped |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||

Interior Light |

|

|

|

Equipped |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

(WXHXD) |

27" x 42 3/ |

" x 28 1/ " |

|

|

|||||||

|

|

|

|

|

|

4 |

|

|

|

3 |

|

|

|

(WXHXD) |

29 |

1/ |

" x 44 3/ |

" x 30 |

3/ |

" |

|

||||

|

|

|

|

2 |

|

4 |

|

|

4 |

|

|

|

4

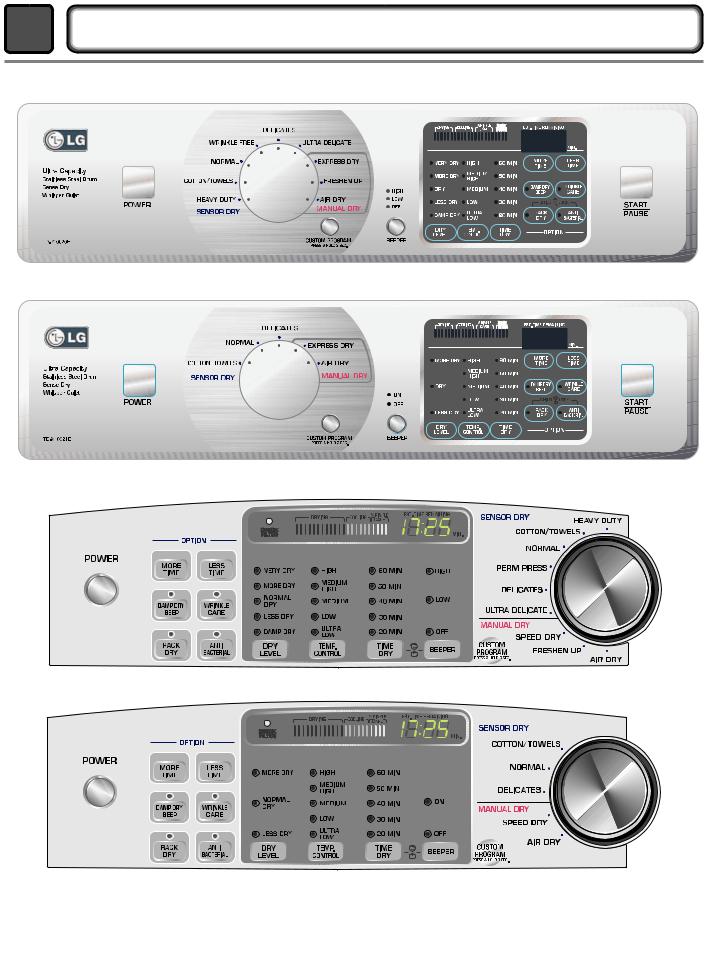

2FEATURES AND BENEFITS

DLE5911W / DLG5911W

DLE5911W / DLG5911W

DLE2511W / DLG2511W

DLE2511W / DLG2511W

DLE5932W / DLG5932W / DLE5932S / DLG5932S

DLE5932W / DLG5932W / DLE5932S / DLG5932S

DLE2532W / DLG2532W

DLE2532W / DLG2532W

5

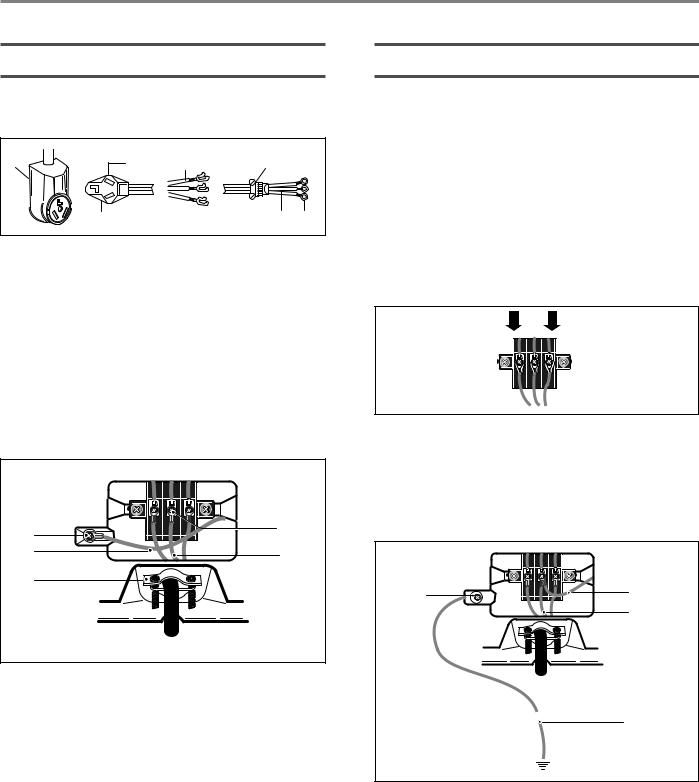

3INSTALLATION INSTRUCTIONS

POWER CORD

1) 4-wire connection

IMPORTANT: A 4-wire connection is required for mobile homes and where local codes do not permit the use of 3 wire connections.

3.Connect ground wire (green or bare) of power supply cable to external ground conductor screw. Tighten screw.

4.Connect neutral wire (white or center wire) of power supply cord to the center, silver colored terminal screw of the terminal block.

1 |

2 |

6 |

3 |

4 |

5 |

7 |

1.4-wire receptacle (NEMA type 14-30R)

2.4-prong plug

3.Ground prong

4.Neutral prong

5.Spade terminals with upturned ends

6.3/4 in. (1.9 cm) UL approved strain relief

7.Ring terminals

1.Remove center terminal block screw.

2.Remove appliance ground wire (green) from external ground connector screw. Fasten it under center, silver colored terminal block screw.

1 |

2 |

|

3 |

||

|

1 |

4 |

|

5 |

||

2 |

||

6 |

||

|

||

3 |

|

1.External ground connector

2.Green or bare copper wire of power supply cord

3.3/4 in. (1.9 cm) UL-listed strain relief

4.Center silver-colored terminal block screw

5.Neutral grounding wire (green)

6.Neutral wire (white)

5.Connect the other wires to outer terminal block screws. Tighten screws.

6.Tighten strain relief screws.

7.Insert tab of terminal block cover into slot of dryer rear panel Secure cover with hold-down screw.

1.External ground connector - Dotted line shows position of NEUTRAL ground wire before being moved to center terminal block screw

2.Center silver-colored terminal block screw

3.Green wire of harness

6

2) 3-wire connection

Use where local codes permit connecting cabinet-ground conductor to neutral wire.

1 |

2 |

4 |

5 |

|

3 |

|

|

7 |

6 |

1.3-wire receptacle (NEMA type 10-30R)

2.3-wire plug

3.Neutral prong

4.Spade terminals with up turned ends

5.3/4 in. (1.9 cm) UL approved strain relief

6.Ring terminals

7.Neutral (white or center wire)

1.Loosen or remove center terminal block screw.

2.Connect neutral wire (white or center wire) of power supply cord to the center, silver colored terminal screw of the terminal block. Tighten screw.

1 |

3 |

|

|

2 |

4 |

|

|

5 |

|

1.External ground connector

2.Neutral grounding wire (green)

3.Center silver-colored terminal block screw

4.Neutral wire (white or center wire)

5.3/4 in. (1.9 cm) UL-listed strain relief

3.Connect the other wires to outer terminal block screws. Tighten screws.

4.Tighten strain relief screws.

5.Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-down screw.

3) Optional 3-wire connection

Use where local codes permit connecting cabinet-ground conductor to neutral wire.

1.Remove center terminal block screw.

2.Remove appliance ground wire (green) from external ground connector screw. Connect appliance ground wire and the neutral wire (white or center wire) of power supply cord/cable under center, silver colored terminal block screw. Tighten screw.

3.Connect the other wires to outer terminal block screws. Tighten screws.

4.Tighten strain relief screws.

5.Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-down screw.

6.Connect a separate copper ground wire from the external ground connector screw to an adequate ground.

1 |

2 |

|

|

|

3 |

4

1.External ground connector

2.Neutral grounding wire (green)

3.Neutral wire (white or center wire)

4.Grounding path determined by a qualified electrician

7

3-2. Connect Gas Supply Pipe (Gas Dryer ONLY)

For further assistance, refer to section on Gas Requirements.

1.Make certain your dryer is equipped for use with the type of gas in your laundry room. Dryer is equipped at the factory for Natural Gas with a 3/8” N.P.T. gas connection.

2.Remove the shipping cap from the gas connection at the rear of the dryer. Make sure you do not damage the pipe thread when removing the cap.

3.Connect to gas supply pipe using a new flexible stainless steel connector.

4.Tighten all connections securely. Turn on gas and check all pipe connections (internal & external) for gas leaks with a non-corrosive leak detection fluid.

5.For L.P. (Liquefied Petroleum) gas connection, refer to section on Gas Requirements.

1

1

2

2

5

5  3

3

4

4

1 |

New Stainless Steel Flexible Connector - Use |

4 |

Black Iron Pipe |

|

only if allowed by local codes (Use Design |

|

Shorter than 20’ (6.1 m) - Use 3/8” pipe |

|

A.G.A. Certified Connector) |

|

Longer than 20’ (6.1 m) - Use 1/2” pipe |

2 |

1/8” N.P.T. Pipe Plug |

5 |

3/8” N.P.T. Gas Connection |

|

(for checking inlet gas pressure) |

|

|

3Equipment Shut-Off Valve-Installed within 6’ (1.8 m) of dryer

8

4COLUMBUS DRYER CYCLE PROCESS

|

|

|

Default |

|

|

Conditions of operation and termination |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cycle |

|

Dry |

|

|

|

Drying |

Cooling |

Wrinkle care |

|||

|

Temp- |

|

Display |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

erature |

Level |

|

time |

|

Electro- |

Temp- |

Default |

Temp- |

Time |

|

|

|

|

|

|

|

|

sensor |

Control |

time |

Control** |

||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heavy Duty |

High |

(Normal) |

|

54min |

|

Saturation |

70±5°C |

(5min) |

47±5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cotton/ |

Medium |

(Normal) |

|

55min |

|

Saturation |

66±5°C |

(5min) |

47±5°C |

|

|

|

Towel |

High |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sense |

Normal |

Medium |

(Normal) |

|

41min |

|

Saturation |

62±5°C |

(5min) |

47±5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

3Hr |

|

Dry * |

Perm. |

|

|

|

|

|

|

55±5°C |

|

47±5°C |

||

|

|

|

|

|

|

|

|

|||||

|

Permanent |

Low |

(Normal) |

|

36min |

|

Saturation |

(5min) |

|

|||

|

Press |

|

|

|

|

|

|

|

|

|

|

|

|

Delicate |

Low |

(Normal) |

|

32min |

|

Saturation |

55±5°C |

(5min) |

38±5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ultra |

Extra |

(Normal) |

|

34min |

|

Saturation |

45±5°C |

(5min) |

38±5°C |

|

|

|

Delicate |

low |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Speed dry |

(High) |

- |

|

25min |

|

Saturation |

(70±5°C) |

(5min) |

(47±5°C) |

|

|

Manual |

|

|

|

|

|

|

|

|

|

|

|

|

Freshen Up |

(Medium |

- |

|

20min |

|

Saturation |

(66±5°C) |

(5min) |

(47±5°C) |

3Hr |

||

Dry ** |

High) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air dry |

- |

- |

|

30min |

|

Saturation |

No |

N/A |

N/A |

|

|

|

|

|

heater |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Off Time: 6min |

|

|

|

Motor |

|

|

|

|

|

|

On Time: 10sec |

||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Load |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature Control for each cycle |

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

Heater |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

* Sense dry : “Dry Level” is set by users.

** Manual dry : “Temperature control” is set by users. Default settings can be adjusted by users.

9

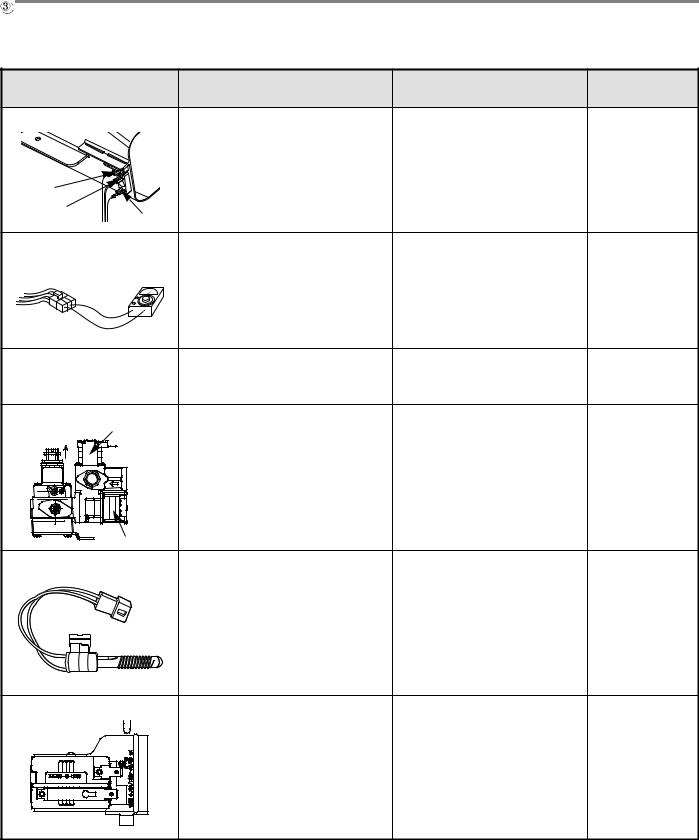

5COMPONENT TESTING INFORMATION

!CAUTION

Component |

Test Procedure |

Check result |

|

Remark |

1. Thermal cut off |

Measure resistance of terminal |

If thermal fuse is open must |

• Heater case- |

|

|

to terminal |

be replaced |

|

Safety |

|

Open at 266 ± 12°F |

Resistance value |

∞ |

• Electric type |

|

(130 ± 7°C) |

|

|

|

• Check Top Marking : |

Auto reset -31°F (-35°C) |

Continuity (250°F |

) < 1Ω |

|

Same shape as Outlet Thermostat. |

|

|

|

|

N130 |

|

|

|

|

|

|

|

|

|

2. Hi limit Thermostat |

Measure resistance of terminal |

|

|

• Heater case - |

(Auto reset) |

to terminal |

|

|

Hi limit |

|

Open at 257 ± 9°F |

Resistance value |

∞ |

• Electric type |

|

(125 ± 5°C) |

|

|

|

|

Close at 221 ± 9°F |

Resistance value < 5Ω |

|

|

|

(105 ± 5°C) |

|

|

|

3. Outlet Thermostat |

Measure resistance of terminal |

|

|

• Blow housing - |

( Auto reset) |

to terminal |

|

|

Safety |

|

Open at 185 ± 9°F |

Resistance value |

∞ |

• Electric type |

|

(85 ± 5°C) |

|

|

|

|

Close at 149 ± 9°F |

Resistance value < 5Ω |

|

|

• Check Top Marking : |

(65 ± 5°C) |

|

|

|

|

|

|

|

|

N85 |

Same shape as Thermal cut off. |

|

|

|

4. Lamp holder |

Measure resistance of terminal |

Resistance value : |

|

|

|

to terminal |

80Ω ~ 100Ω |

|

|

5. Door switch |

Measure resistance of the |

|

|

The state that |

|

following terminal |

|

|

Knob is |

|

1) Door switch knob : open |

|

|

pressed is |

|

Terminal : “COM” - “NC” (1-3) |

Resistance value < 1Ω |

opposite to |

|

|

Open |

|||

|

Terminal : “COM” - “NO” (1-2) |

Resistance value |

∞ |

|

|

condition. |

|||

|

2) Door switch push : push |

|

|

|

|

|

|

|

|

|

Terminal : “COM” - “NC” (1-3) |

Resistance value |

∞ |

|

|

Terminal : “COM” - “NO” (1-2) |

Resistance value < 1Ω |

|

|

6. Idler switch |

Measure resistance of the |

1. lever open |

|

|

|

following terminal : |

Resistance value < 1Ω |

|

|

|

|

|

||

|

“COM - NC” |

2. Lever push (close) |

|

|

|

|

Resistance value |

∞ |

|

10

Component |

Test Procedure |

Check result |

Remark |

|

7. Heater |

Measure resistance of the |

|

• Electric type |

|

|

following terminal |

|

|

|

|

Terminal : 1 |

(COM) - 2 |

Resistance value : 10Ω |

|

|

Terminal : 1 |

(COM) - 3 |

Resistance value : 10Ω |

|

|

Terminal : 2 |

- 3 |

Resistance value : 20Ω |

|

8. Thermistor |

Measure resistance of terminal |

Resistance value : 10Ω |

• Heater case - |

|

|

to terminal |

|

|

Hi limit |

|

Temperature condition : |

|

• Electric type |

|

|

58°F ~ (10~40°C) |

|

|

|

|

58°F ~ 104F (10~40°C) |

|

|

|

9. Motor |

|

|

• See Page 13 |

10. Gas valve |

valve 1 |

Measure resistance of the |

• Gas type |

|

following terminal |

|

|

|

|

|

|

|

|

Valve 1 terminal |

Resistance value : > 1.5kg ~ |

|

|

Valve 2 terminal |

Resistance value : |

|

|

|

> 1.5~2.5kg |

|

valve 2 |

|

|

11. Igniter |

Measure resistance of terminal Resistance value : 100~800Ω • Gas type |

|

to terminal |

12. Frame Detect |

Measure resistance of terminal |

• Gas type |

|

to terminal |

|

|

Open at 370°F ((Maximum) |

Resistance value ∞ |

|

Close at 320°F |

Resistance value < 1Ω |

11

Loading...

Loading...