KROHNE OPTISWIRL 4200 Specifications

Technical Datasheet

Technical Datasheet

OPTISWIRL 4200

OPTISWIRL 4200

OPTISWIRL 4200OPTISWIRL 4200

Technical DatasheetTechnical Datasheet

Vortex flowmeter

•

Integrated pressure and temperature compensation

•

Gross and net heat measurement for hot water and steam

•

Stable measurements even under demanding process conditions with advanced

technology for signal filtering (AVFD)

© KROHNE 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

CONTENTS

OPTISWIRL 4200

1 Product features 3

1.1 The all-in-one solution..................................................................................................... 3

1.2 Options and variants......................................................................................................... 5

1.3 Devices with integrated nominal diameter reduction ..................................................... 8

1.4 Functional principle.......................................................................................................... 9

2 Technical data 10

2.1 Technical data................................................................................................................. 10

2.2 Dimensions and weights ................................................................................................ 15

2.2.1 Flange versions..................................................................................................................... 15

2.2.2 Sandwich version .................................................................................................................. 22

2.2.3 Dimensions of remote version.............................................................................................. 24

2.3 Flow tables ..................................................................................................................... 25

3 Installation 28

3.1 Intended use ................................................................................................................... 28

3.2 Installation conditions ....................................................................................................30

3.2.1 Prohibited installation when measuring liquids .................................................................. 31

3.2.2 Prohibited installation when measuring steam and gases.................................................. 32

3.2.3 Pipelines with control valve .................................................................................................. 32

3.2.4 Preferred mounting position ................................................................................................ 33

3.3 Minimum inlet sections.................................................................................................. 34

3.4 Minimum outlet sections................................................................................................ 35

3.5 Flow straightener ........................................................................................................... 35

3.6 Heat insulation................................................................................................................ 36

4 Electrical connections 37

4.1 Connecting the signal converter .................................................................................... 37

4.2 Electrical connections .................................................................................................... 38

4.3 Connection of remote version ........................................................................................ 38

5 Order form 40

6 Notes 41

2

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

OPTISWIRL 4200

1.1 The all-in-one solution

Vortex flowmeters are suitable for a wide range of media. This is particularly true of the

OPTISWIRL 4200

OPTISWIRL 4200. Its capability to master even fluctuating pressures and temperatures turns it

OPTISWIRL 4200OPTISWIRL 4200

into an ideal all-rounder for the measurement of energy carriers in auxiliary and supply

processes.

PRODUCT FEATURES

1

Already the basic version of the OPTISWIRL 4200

for saturated steam applications. With the optional pressure sensor the flowmeter has an

integrated density compensation available, which even allows an exact measurement of gases

and superheated steam with varying process conditions. The additional integrated gross and net

heat measurement makes this flowmeter to be a reliable partner for advanced energy

management systems.

With the innovative AVFD (Advanced Vortex Frequency Detection) the OPTISWIRL 4200

with an up-to-date signal filter. It analyses the measured signal and eliminates interferences

and perturbations. Thereby, stable measurements can even be realised under demanding

process conditions.

This vortex flowmeter was designed for the safety-related applications from the very beginning.

It was developed according to the standard IEC 61508 edition 2. The certification is effected

within the scope of a full assessment by TUEV Sued. Thereby the flowmeter can be used for

continuous volume flow measurement in safety-related applications with classification SIL 2.

OPTISWIRL 4200 is equipped with a temperature compensation

OPTISWIRL 4200OPTISWIRL 4200

OPTISWIRL 4200 is fitted

OPTISWIRL 4200OPTISWIRL 4200

www.krohne.com08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

3

1

PRODUCT FEATURES

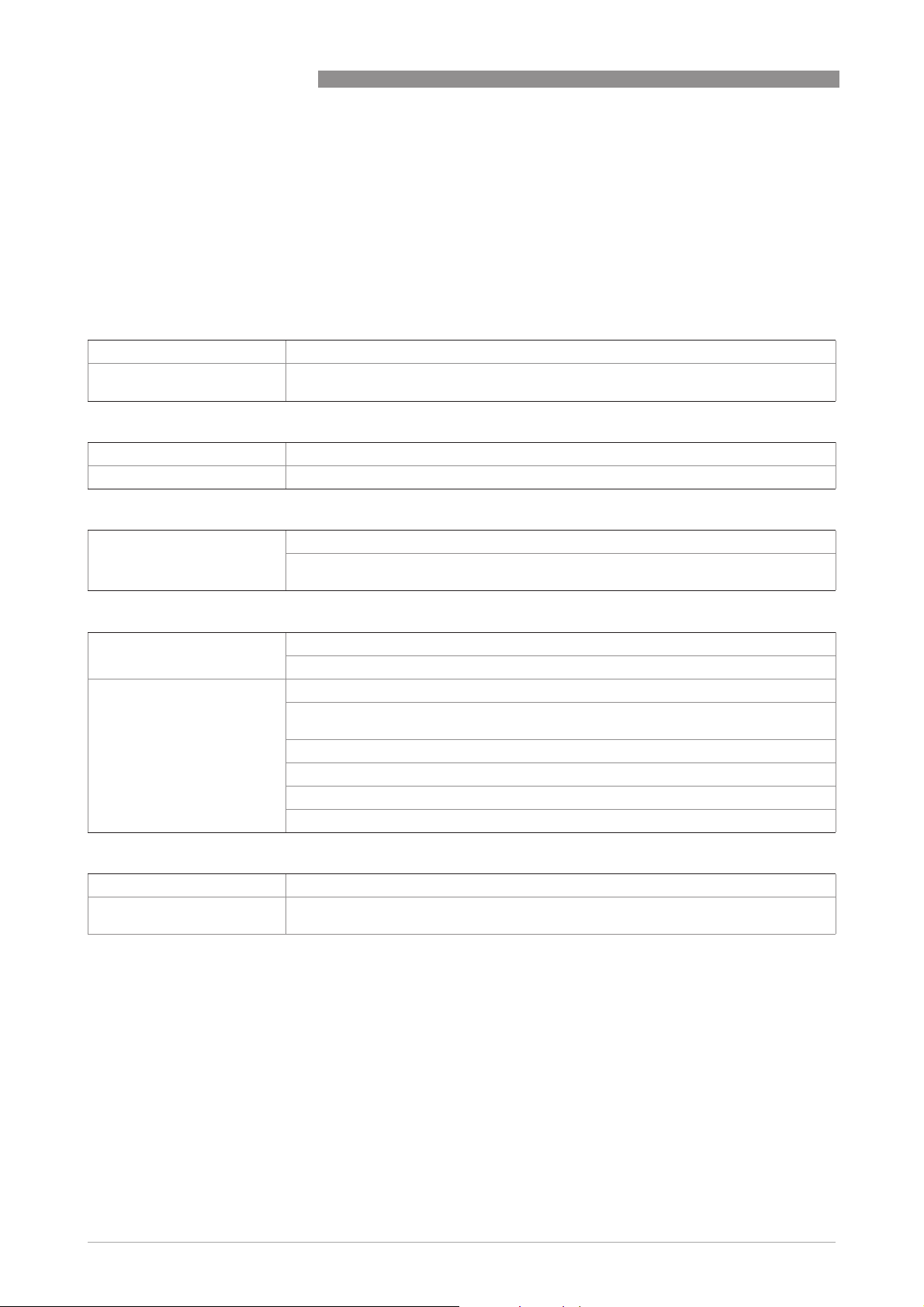

Highlights

• Development according to IEC 61508, edition 2

• Advanced technology for signal filtering - AVFD (Advanced Vortex Frequency Detection)

• Integrated pressure and temperature compensation

• Temperature compensation for saturated steam included as standard

• Integrated gross and net heat calculation for steam and hot water

• Comprehensive communication options

• Remote version with field housing converter with cable length up to 50 m / 164 ft

• Integrated reduction of nominal size

• Measurement of conductive and non-conductive liquids, gases and steam

Industries

• Chemicals

• Oil & Gas

• Power plants

• Food & Beverage

• Pharmaceuticals

• Iron, Steel and Metals

• Pulp & Paper

• Water

• Automotive industry

OPTISWIRL 4200

Applications

• Measurement of saturated steam and superheated steam

• Steam boiler monitoring

• Heat metering of steam and hot water

• Measurement of consumption of industrial gases

• Measurement of consumption in compressed air systems

• Monitoring of compressor output

• Evaluation of free air delivery (FAD)

• SIP and CIP processes in the food, beverage and pharmaceutical industries

• Safety-related measurement in SIL applications (SIL 2)

4

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

OPTISWIRL 4200

PRODUCT FEATURES

1.2 Options and variants

1. The universal device with temperature compensation for saturated steam integrated as

standard

The OPTISWIRL 4200 C

OPTISWIRL 4200 C as compact flowmeter in a

OPTISWIRL 4200 COPTISWIRL 4200 C

flange version is suitable for universal use in

measuring liquids, gases and vapours.

The temperature compensation for saturated steam

is integrated as standard, thus enabling direct

compensation of the density; the mass and energy

can also be measured.

The advanced signal filter technology AVFD

(Advanced Vortex Frequency Detection)

complements the high accurate measurement.

1

2. The easy to install sandwich version with optimised centering rings

The OPTISWIRL 4200 C

OPTISWIRL 4200 C as a compact flowmeter in a

OPTISWIRL 4200 COPTISWIRL 4200 C

sandwich version is suitable for universal use in the

measurement of liquids, gases and vapours.

The temperature compensation for saturated steam

is integrated as standard.

The flowmeter is provided with additional optimised

centering rings. The vortex flowmeter can be aligned

centrically by turning the centering rings,

eliminating any offset between the flowmeter and

the pipeline.

www.krohne.com08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

5

1

PRODUCT FEATURES

OPTISWIRL 4200

3. The one-of-a-kind 2-wire device with integrated pressure and temperature compensation

The OPTISWIRL 4200

OPTISWIRL 4200 as a flange or sandwich

OPTISWIRL 4200OPTISWIRL 4200

flowmeter is optinally available with integrated

pressure and temperature compensation for gases,

wet gases, gas mixtures or steam.

The advantage of this unique design couldn’t be

clearer:

• No additional cost-intensive installation of

pressure and temperature sensors

• No additional cabling work

• No faulty measurement results, because pressure,

temperature and volume flow can be read at a

single point

• Direct measurement of mass and/or energy

4. Vortex flowmeter with shut-off valve for the pressure measurement

As an option, the OPTISWIRL 4200

with a shut-off valve to allow the pressure sensor to

be exchanged without interrupting the process.

What is more, the pressure sensor can be shut off

for the purpose of pressure or leak testing of the

pipeline.

Using the built-in two-way valve, the pressure

sensor can also be calibrated and tested at a later

time.

OPTISWIRL 4200 can be supplied

OPTISWIRL 4200OPTISWIRL 4200

6

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

OPTISWIRL 4200

5. Dual measurement for twofold reliability

PRODUCT FEATURES

The OPTISWIRL 4200

OPTISWIRL 4200 is optionally available as a dual

OPTISWIRL 4200OPTISWIRL 4200

version.

This is a genuine redundant system with two

independent flow sensors and two signal converters.

This provides twofold functional reliability and

availability of the measurement.

This variant is ideally suited for measurements in

multi-product pipelines. In such pipelines, two

different products are moved through one after the

other.

One signal converter can be programmed for one

product, and the other signal converter for the other

product.

1

6. The OPTISWIRL 4200 F as remote version

The OPTISWIRL 4200

OPTISWIRL 4200 is also available as a remote

OPTISWIRL 4200OPTISWIRL 4200

version with field housing converter.

This feature allows separating the signal converter

from the flow sensor up to a distance of 50 m /

164 ft, in case the flow sensor is mounted in

inaccessible areas.

The remote mounted signal converter allows easy

operation and reading of values at eye level.

Additionally to the flow rates, measurements of the

integrated pressure and temperature sensors can

be displayed.

www.krohne.com08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

7

1

PRODUCT FEATURES

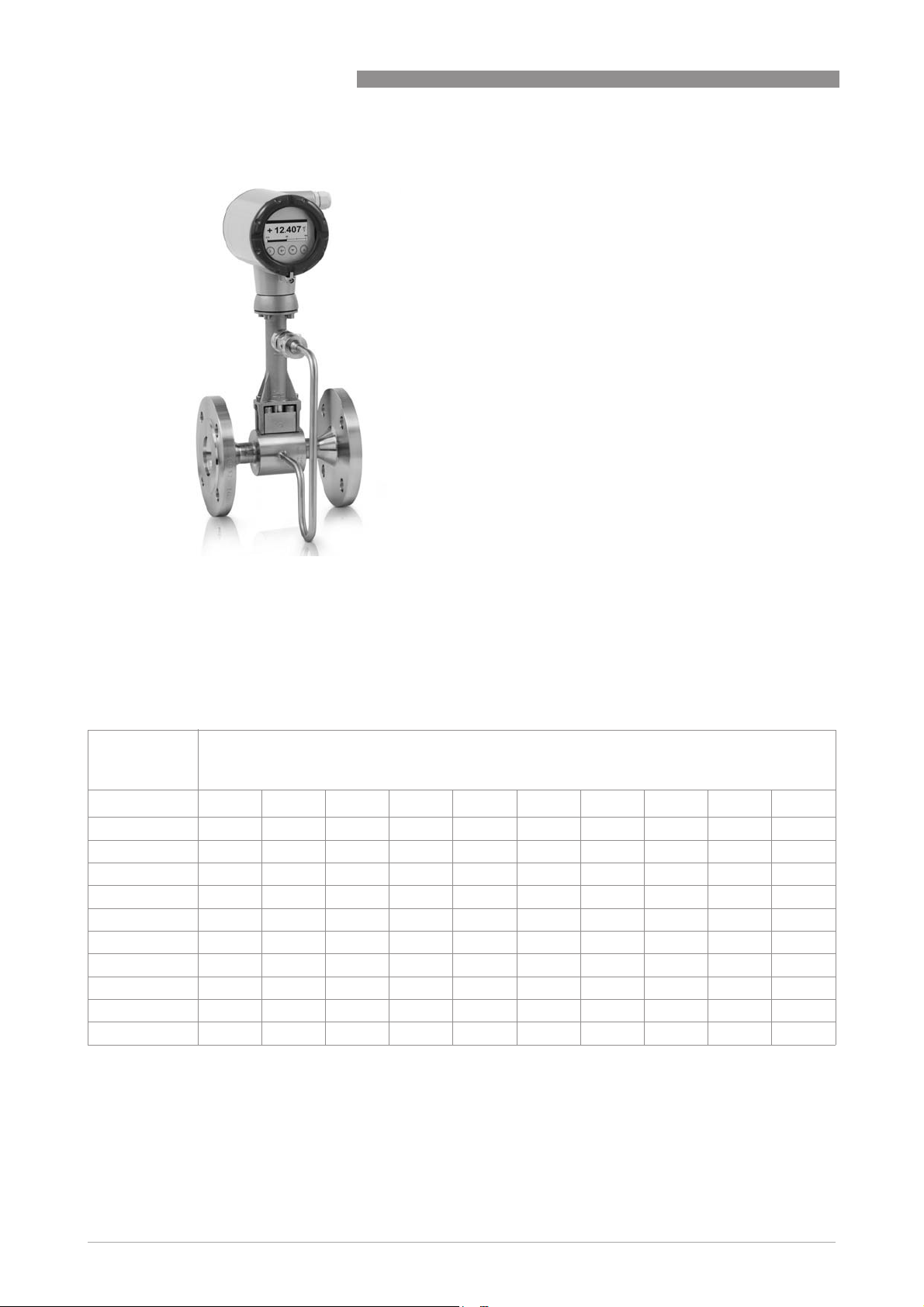

7. OPTISWIRL 4200 F1R / F2R with integrated nominal diameter reduction

The OPTISWIRL 4200 F1R / F2R

OPTISWIRL 4200 F1R / F2R with integrated

OPTISWIRL 4200 F1R / F2ROPTISWIRL 4200 F1R / F2R

nominal diameter reduction up to two nominal

diameter sizes assures best results in accuracy and

optimal measuring ranges even in pipelines with

large diameters, which have been designed for a low

pressure loss.

By forgoing complex pipeline reduction installations,

space and cost saving installations can be realized.

At the same time the number of potential leakages is

reduced to a minimum.

OPTISWIRL 4200

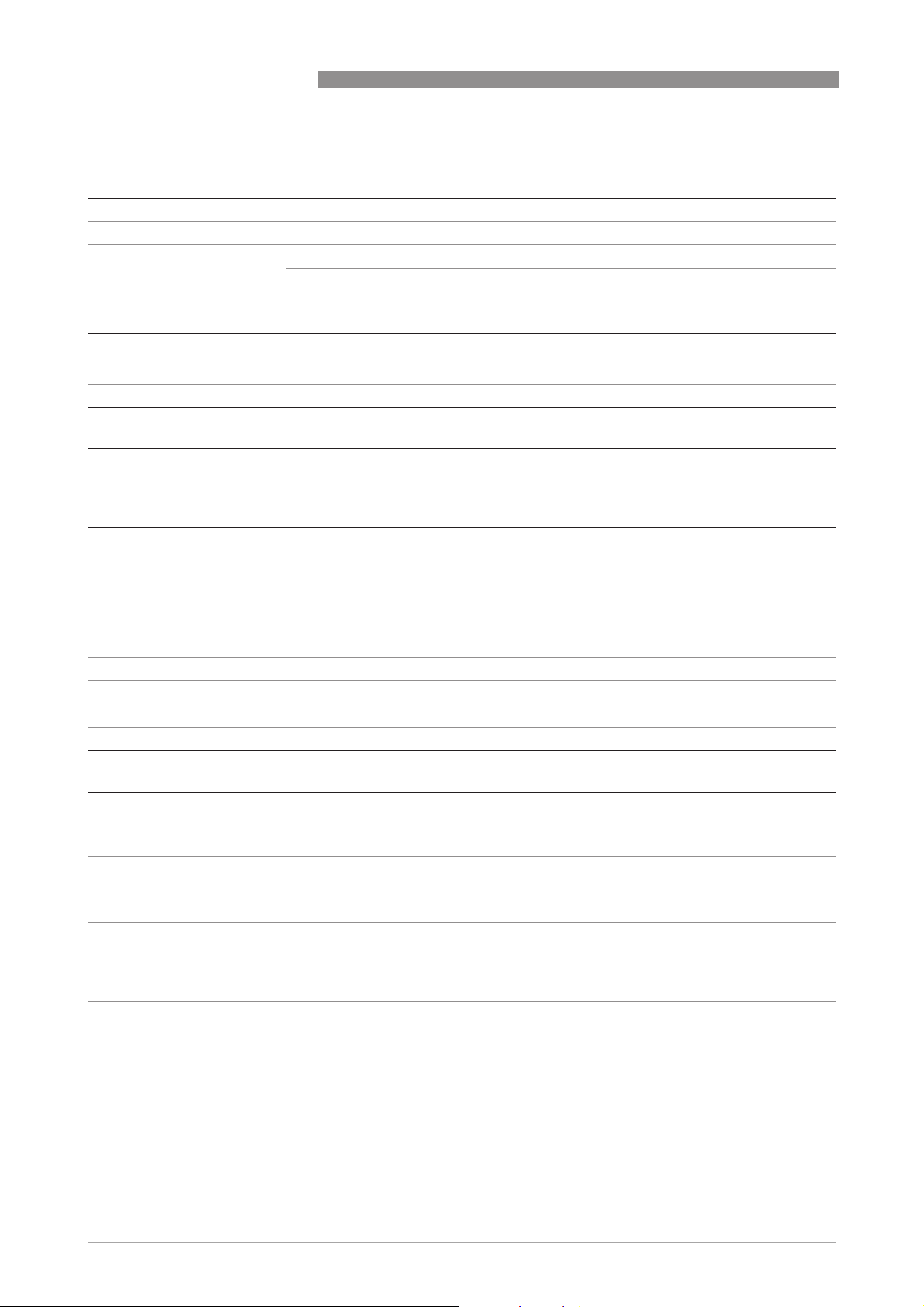

1.3 Devices with integrated nominal diameter reduction

The device versions F1R and F2R offer an integrated nominal diameter reduction up to two

nominal diameter sizes to assure best results in accuracy and optimum measuring ranges; even

in pipelines with large diameters, which have been designed for a low pressure loss.

Nominal

diameter of flow

sensor

DN15 StV

DN25 - StV

DN40 --StV

DN50 ---StV

DN80 ----StV

DN100 -----StV

DN150 ------StV

DN200 -------StV

DN250 --------StV

DN300 ---------StV

1 Standard version

Nominal size of process connections

DN15 DN25 DN40 DN50 DN80 DN100 DN150 DN200 DN250 DN300

1

F1RF2R-------

1

F1RF2R------

1

F1RF2R-----

1

F1RF2R----

1

F1RF2R---

1

F1R F2R - -

1

F1R F2R -

1

F1R F2R

1

F1R

1

8

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

OPTISWIRL 4200

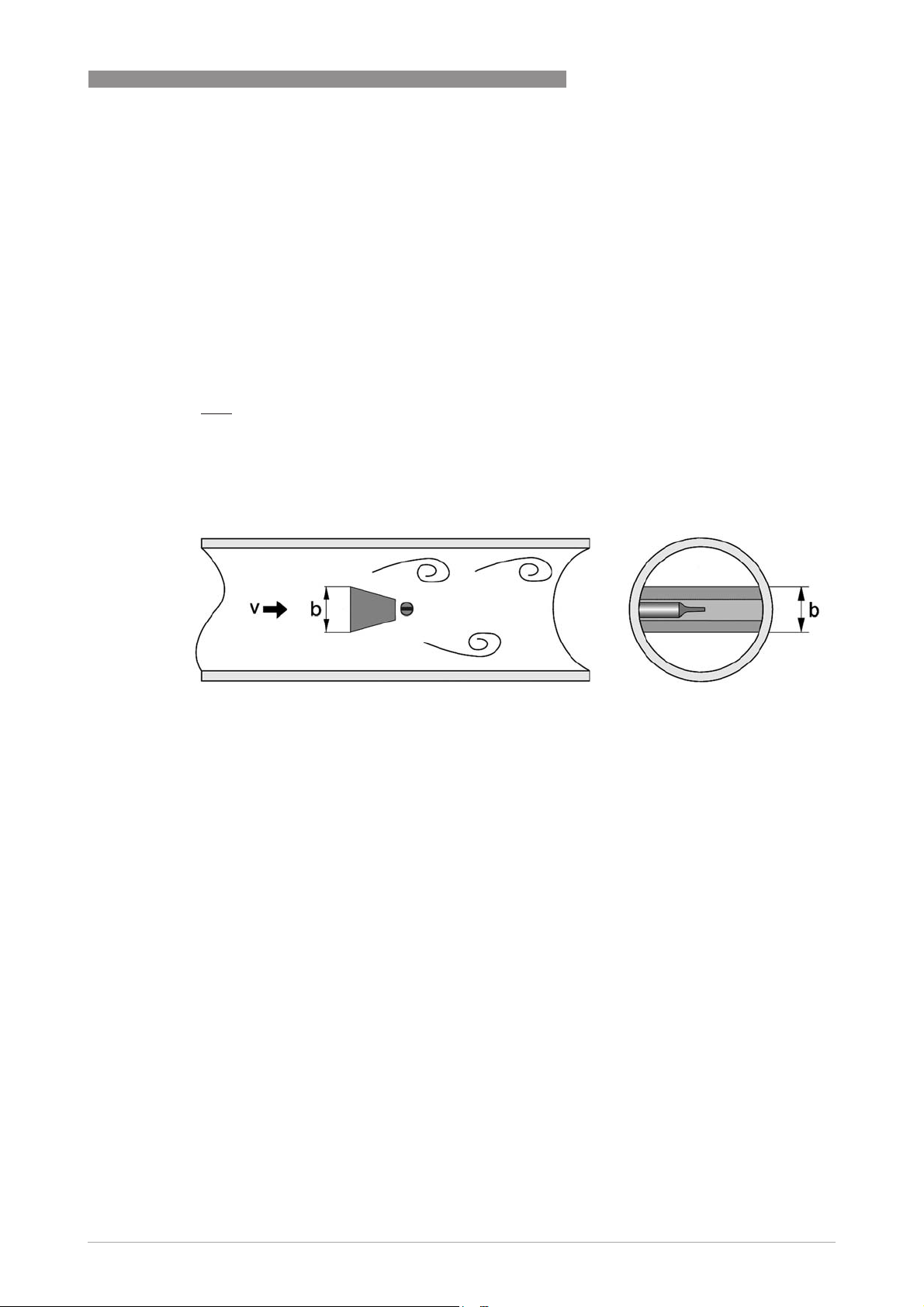

1.4 Functional principle

Vortex flowmeters are used to measure the flow of gases, vapours and liquids at completely

filled pipes.

The measuring principle is based on the Karman vortex street. The measuring tube contains a

bluff body at which vortex shedding occurs and which is detected by a sensor unit located behind.

The frequency ffff of the vortex shedding is proportional to the flow velocity vvvv. The non-dimensional

Stouhal number SSSS describes the relationship between vortex frequency ffff, width bbbb of the bluff

body and the average flow velocity vvvv:

S.v

f

=

b

The vortex frequency is recorded at the flow sensor and evaluated at the signal converter.

PRODUCT FEATURES

1

Figure 1-1: Functional principle

www.krohne.com08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

9

2

TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

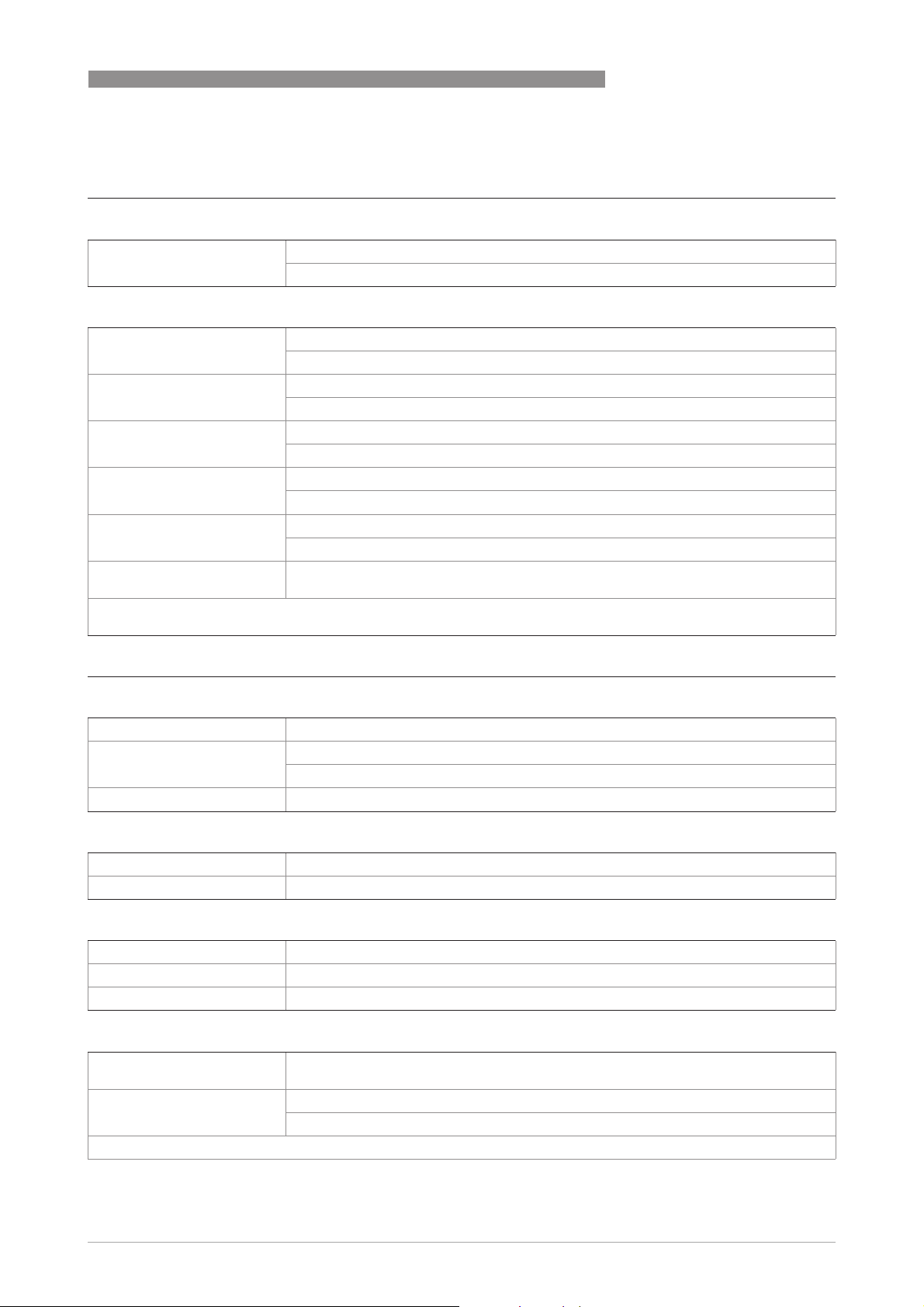

Measuring system

Application range Flow measurement of liquids, gases and vapours

Function / Measuring

principle

Measurement

Primary measured value Number of separated vortices

Secondary measured value Operating and standard volume flow and mass flow

Signal converter

Versions Compact

Karman vortex street

Remote version (in preparation)

Cable length: ≤ 50 m / 164 ft

OPTISWIRL 4200

Flow sensor

Standard Flange version (with integrated temperature measurement), flow sensor: F

Sandwich version (with integrated temperature measurement), flow sensor: S

Option Basic device with additional pressure measurement

Basic device with additional pressure measurement and shut-off valve for pressure

sensor

Dual measuring device in both flange and sandwich version (redundant measurement)

Dual measuring device with additional pressure measurement

Flange version with single reduction of nominal diameter, flow sensor: F1R

Flange version with double reduction of nominal diameter, flow sensor: F2R

Display and user interface

Local display Graphic display

Interface and display

languages

German, English, French; 22 further languages (in preparation)

10

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

OPTISWIRL 4200

TECHNICAL DATA

Measuring accuracy

Reference condition

Reference conditions Water at +20°C / +68°F

Air at +20°C / +68°F and 1.013 bara / 14.7 psia

Maximum measuring error

Volume flow

(liquid)

Volume flow

(gases and steam)

Mass flow

(gases and steam)

Mass flow

(liquid / water)

Normalised volume flow

(gas)

Repeatability

(volume flow)

1 The maximum error of measurement refers to measurement at an operating pressure >65% of the full scale value of

the applied pressure sensor.

±0.75% of measured value (Re ≥ 20000)

±2.0% of measured value (10000 < Re < 20000)

±1.0% of measured value (Re ≥ 20000) 1

±2.0% of measured value (10000 < Re < 20000) 1

±1.5% of measured value (Re ≥ 20000)

±2.5% of measured value (10000 < Re < 20000)

±1.5% of measured value (Re ≥ 20000)

±2.5% of measured value (10000 < Re < 20000)

±1.5% of measured value (Re ≥ 20000)

±2.5% of measured value (10000 < Re < 20000)

±0.1% of measured value

2

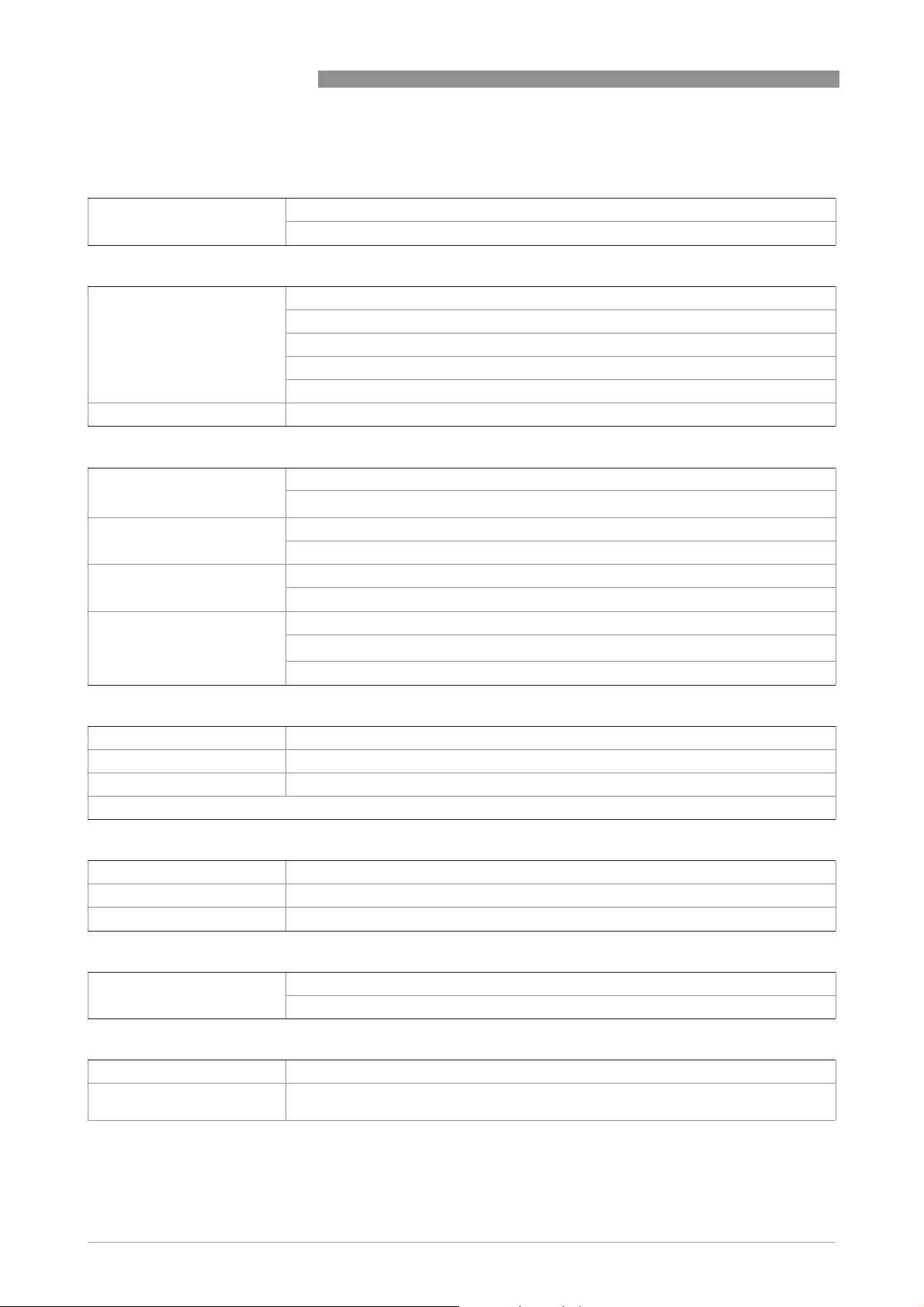

Operating conditions

Temperature

Medium temperature -40…+240°C / -40…+465°F

Ambient temperature Non-Ex: -40…+85°C / -40…+185°F

Ex: -40...+65°C / -40...+140°F

Storage temperature -40...+85°C / -40...+185°F

Pressure

Medium pressure Max. 100 bar / 1450 psi (higher pressures on request)

Ambient pressure Atmosphere

Media properties

Density Taken into consideration when sizing.

Viscosity < 10 cP

Reynold's number > 10000

Recommended flow velocities

Liquids 0.25…7m/s / 0.82…23 ft/s (optional up to 10 m/s / 32.8 ft/s taking cavitation into

Gases and steam 2.0…80 m/s / 6.6…262.5 ft/s

For further information refer to

account)

DN15: 3.0…45 m/s / 9.8…148 ft/s; DN25: 2.0…70 m/s / 6.6…230 ft/s

Intended use

on page 28.

www.krohne.com08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

11

2

TECHNICAL DATA

OPTISWIRL 4200

Other conditions

Ingress protection Compact version: IP66/67

Remote version: signal converter housing: IP66/67; flow sensor housing: IP66/67

Installation conditions

Inlet section ≥ 15 x DN without disturbing flow, after pipe narrowing, after a single 90° bend

≥ 30 x DN after a double bend 2x90°

≥ 40 x DN after a double three-dimensional bend 2x90°

≥ 50 x DN after control valves

≥ 2 DN before flow straightener; ≥ 8 DN after flow straightener

Outlet section ≥ 5 x DN

Materials

Flow sensor and process

connections

Electronics housing Aluminium die-cast, two-layer coating (epoxy/polyester)

Pressure sensor gasket Standard: FPM

Measuring tube gasket (Pickup)

Standard: 1.4404/316L

Option: Hastelloy® C-22 on request

Option: die-cast aluminium with finish for advanced requirements

Option: FFKM

Standard: 1.4435/316L

Option: Hastelloy® C-276

Selection depends on flow sensor material / medium.

Process connections of flange version

DIN EN 1092-1 DN15...300 - PN16...100 (higher pressures on request)

ASME B16.5 ½...12" - 150…600 lb (higher pressures on request)

JIS B 2220 DN15...300 - JIS 10…20 K (higher pressures on request)

For detailed information on combination flange/pressure rating, refer to section "Dimensions and weights".

Process connections of sandwich version

DIN DN15...100 - PN100 (higher pressures on request)

ASME ½...4" - 600 lb (higher pressures on request)

JIS DN15...100 - 10…20 K (higher pressures on request)

Electrical connections

Power supply Non-Ex: 12…36 VDC

Ex: 12…30 VDC

Inputs and outputs

General All inputs and outputs are electrically isolated from one another.

Time constant The time constant corresponds to 63% of the elapsed time of a processor procedure.

0...100 seconds (rounded up to 0.1 seconds)

12

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

OPTISWIRL 4200

TECHNICAL DATA

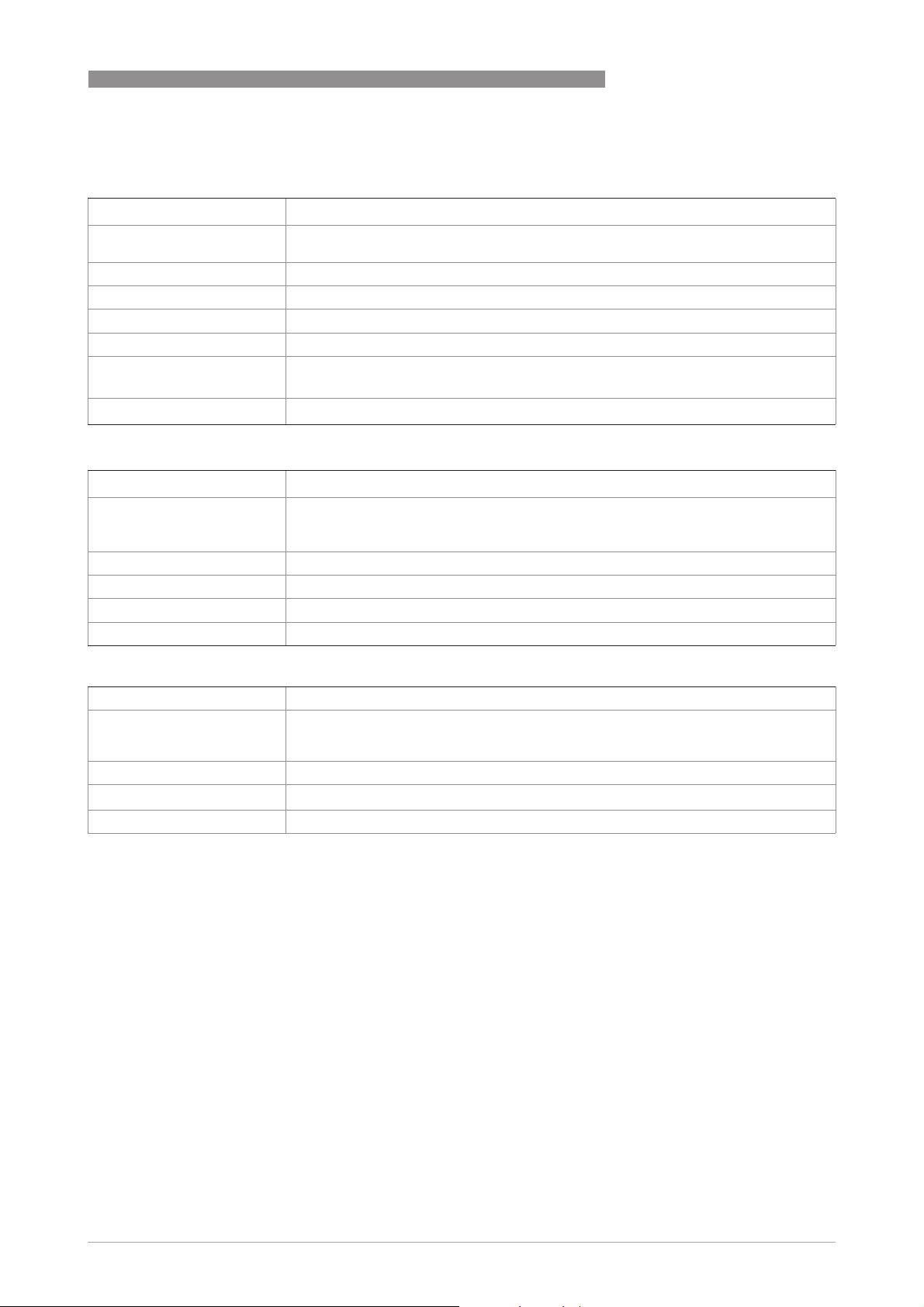

Current output

Type

Output data Volume flow, mass flow, norm. volume flow, gross/net power, free air delivery, density,

Resolution 5 µA

Linearity / accuracy 0.1% (of read value)

Temperature coefficient 50 ppm/K (typically), 100 ppm/K (max.)

Error signal According to NE 43

Description of abbreviations U

Load Minimum 0 Ω; maximum RL = ((U

®

HART

4...20 mA HART® (passive)

temperature (internal sensor), pressure, vortex frequency, flow velocity

= external voltage;

ext

= load + resistance

R

L

- 12 VDC) / 22 mA)

ext

HART® protocol via passive current output

2

HART® revision HART® 7

Manufacturer ID 00069 (0x45)

Device type code 00205 (0xCD)

System requirements Load min. 250 Ω

Multidrop operation 4mA

Burst mode

Catch device

Binary output

Function Pulse, frequency, status, limit switch

Type Passive

Temperature coefficient 50 ppm/K

Residual current < 0.2 mA at 32 V (Ri = 180 kΩ)

Pulse width 0.5...2000 ms

Proximity sensor acc. to DIN EN 60947-5-6 (NAMUR sensor) or pulse output signal acc.

to VDI/VDE 2188 (category 2)

www.krohne.com08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

13

2

TECHNICAL DATA

OPTISWIRL 4200

Pulse output

Output data Volume, mass, norm. volume, gross/net energy

Pulse rate Max. 1000 pulses/s

Power supply Non-Ex: 24 VDC as NAMUR or open < 1 mA, maximum 36 V, closed 120 mA, U < 2 V

Ex: 24 VDC as NAMUR or open < 1 mA, maximum 30 V, closed 120 mA, U < 2 V

Frequency output

Output data Volume flow, mass flow, norm. volume flow, gross/net power, free air delivery, density,

Max. frequency 1000 Hz

temperature (internal sensor or via external input), pressure, vortex frequency, flow

velocity, spec. enthalpy, spec. heat capacity, Reynolds number

Status output

Output data Status acc. to NE 107 (F, S, C), flow totalizer overflow, energy totalizer overflow, fluid

type (in steam applications)

Limit switch

Output data Volume flow, mass flow, norm. volume flow, volume, mass, norm. volume, gross/net

power, gross/net energy, free air delivery, density, temperature (internal sensor or via

external input), pressure, vortex frequency, flow velocity, spec. enthalpy, spec. heat

capacity, Reynolds number

Current input

Type 4...20 mA (passive)

Resolution 6 µA

Linearity / accuracy 0.1% (of read value)

Temperature coefficient 100 ppm/K (typically), 200 ppm/K (max.)

Voltage drop 10 V

Approvals and certificates

ATEX ATEX II2 G - Ex ia IIC T6...T2 Gb

IECEx IECEx - Ex ia IIC T6...T2 Gb

QPS (USA & Canada) QPS Ordinary Locations

ATEX II2 G - Ex d ia IIC T6...T2 Gb

ATEX II3 G - Ex nA IIC T6...T2 Gc

ATEX II2 D - Ex tb IIIC T70°C Db

IECEx - Ex d ia IIC T6...T2 Gb

IECEx - Ex nA IIC T6...T2 Gc

IECEx - Ex tb IIIC T70°C Db

QPS IS Class I Div 1

QPS XP Class I Div 1 (in preparation)

QPS NI Class I Div 2 (in preparation)

QPS DIP Class II, III Div 1 (in preparation)

14

www.krohne.com 08/2016 - 4003952204 - TD OPTISWIRL 4200 R04 en

Loading...

Loading...