KROHNE OPTIFLUX 6000 Specifications

Technical Datasheet

Technical Datasheet

OPTIFLUX 6000

OPTIFLUX 6000

OPTIFLUX 6000OPTIFLUX 6000

Technical DatasheetTechnical Datasheet

Electromagnetic flow sensor

for hygienic and sanitary applications

•

Robust stainless steel housing for hygienic and aseptic operation

•

Fully suitable for CIP and SIP

•

Typical food & beverage and pharmaceutical process connections and insertion

lengths

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

CONTENTS

OPTIFLUX 6000

1 Product features 3

1.1 Sanitary and hygienic solution ......................................................................................... 3

1.2 Options.............................................................................................................................. 5

1.3 Measuring principle.......................................................................................................... 7

2 Technical data 8

2.1 Technical data................................................................................................................... 8

2.2 Measuring accuracy ....................................................................................................... 13

2.3 Dimensions and weights ................................................................................................ 15

3 Installation 29

3.1 Intended Use................................................................................................................... 29

3.2 General notes on installation ......................................................................................... 29

3.2.1 Vibration ................................................................................................................................ 29

3.2.2 Magnetic field........................................................................................................................ 29

3.3 Installation conditions ....................................................................................................30

3.3.1 Inlet and outlet...................................................................................................................... 30

3.3.2 Bends in 2 or 3 dimensions................................................................................................... 30

3.3.3 T-section ............................................................................................................................... 31

3.3.4 Bends .................................................................................................................................... 31

3.3.5 Open discharge ..................................................................................................................... 32

3.3.6 Control valve ......................................................................................................................... 32

3.3.7 Pump ..................................................................................................................................... 32

3.3.8 Air venting and vacuum forces ............................................................................................. 33

3.3.9 Mounting requirements for self-draining ............................................................................ 34

3.3.10 Flange deviation .................................................................................................................. 35

3.3.11 Mounting position................................................................................................................ 35

3.4 Mounting......................................................................................................................... 36

3.4.1 Torques and pressures......................................................................................................... 36

3.4.2 Maximum pressures ............................................................................................................. 37

3.4.3 Installation of weld-on versions ........................................................................................... 38

3.4.4 Cleaning ................................................................................................................................ 38

4 Electrical connections 39

4.1 Safety instructions.......................................................................................................... 39

4.2 Grounding ....................................................................................................................... 39

4.3 Virtual reference for IFC 300 ( C, W and F version) ....................................................... 40

4.4 Connection diagrams ..................................................................................................... 40

5 Notes 41

2

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

OPTIFLUX 6000

1.1 Sanitary and hygienic solution

The OPTIFLUX 6000

OPTIFLUX 6000 electromagnetic flow sensor is specifically designed to stay clean and

OPTIFLUX 6000OPTIFLUX 6000

sterile in compliance with the most stringent demands prevailing in the food & beverages and

pharmaceutical industries. There are no crevices, gaps or blind spots and the flow sensor offers

full CIP/SIP possibilities. The flow sensor is conform FDA food contact material requirements,

for all wetted materials and is certified in accordance with EHEDG and 3A.

The flowmeter provides easy installation and commissioning and is available with the flow

converter seperate, or mounted directly on the flow sensor.Therefore it can be installed in

places difficult to access due to for example high temperatures or vibrations. The converter is

also available in a stainless steel housing for applications when for example regular cleaning

procedures with aggressive cleaning agents, may attack a standard polyurethane coating.

In addition to weld-end connections, this KROHNE flow meter offers a large number of other

hygienic connections, including DIN 11851, DIN 11864, clamp and SMS.

Because of its high accuracy, a precise measurement of the medium is possible enabling an

accurate measurement of flows whether it is required for blending, dosing or batching.

Furthermore its accuracy is maintained even in case of pulsating flows. When a medium has a

low conductivity for example in case of glucose or fruit concentrates, the device continious to

deliver an optimal performance.

PRODUCT FEATURES

1

Due to its reinforced liner the OPTIFLUX 6000 is an optimal solution for applications where high

temperatures or vacuum impacts can occur. The certified hygienic construction is also available

for larger diameters up to DN150, as volumes are increasing and larger pipe sizes are needed

with fast increase in the industrial production of beer, wine, milk and other beverages.

www.krohne.com02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

3

1

PRODUCT FEATURES

Highlights

• Robust stainless steel housing for hygienic and aseptic operation

• PFA liner reinforced with embedded stainless steel grid for vacuum resistance

• High form stability for good accuracy even with high pressures

• Unique L-shaped gasket extends lifetime by preventing protrusion into measurement tube

• Wide choice of the electrode materials, even for extreme chemical applications.

• Simple and effective CIP / SIP

• Typical food and beverages and pharmaceutical process connections and insertion lenghts

• Large diameter range DN2.5 up to DN150, to suit any F&B application

• All wetted materials are conform EC 1935/2004 and FDA food contact material regulation.

• Optimal hygienic performance conforming to EHEDG and 3A certification.

• Able to measure at low conductivity ≥ 1 µS/cm (for demin water ≥ 20 µS/cm)

• Wide process temperature range -40...140°C / -40...+284°F

• PMO certified

Industries

• Food & Beverages

• Pharmaceutical

• Cosmetics

OPTIFLUX 6000

Applications

• Exact blending, dosing and batching

• Beverages including soft drinks, beer, wine and fruits juices

• Milk and other dairy products

• Beverages containing solids (for example yoghurt containing cereals)

• Drugs, caustic sodas, acids, proteins, antibiotics

• CIP media including acids and caustic solutions

• For large-scale production plants with diameter up to DN150

4

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

OPTIFLUX 6000

1.2 Options

PRODUCT FEATURES

Reinforced PFA liner

Reinforced PFA liner

Reinforced PFA linerReinforced PFA liner

The OPTIFLUX 6000 has an FDA conform PFA liner

with an integrated stainless steel reinforcement that

ensures vacuum resistance and long-term

dimensional stability. The reinforced PFA liner

makes sure that the flowmeter keeps its form

stability even at high temperatures and very low

pressure or vacuum. Therefore the OPTIFLUX 6000

remains its accuracy over time.

1

Unique gasket adapter concept

Unique gasket adapter concept

Unique gasket adapter conceptUnique gasket adapter concept

A special sealing concept for stainless steel

adapters has been designed with support of TNO, a

member of the European EHEDG organization. The

sealing concept provides for a smooth and

dimensionally stable measuring section between the

two process connections. It prevents the gasket

from expanding into the measuring tube because

during CIP / SIP cleaning procedures, the gasket

expands into an expansion chamber. This leads to a

sharp sealing at the edge of the pipeline and a

perfect transition into the measuring section. In

addition, the gasket experiences less stress which

results in a longer life time and reduced

maintenance.

www.krohne.com02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

5

1

PRODUCT FEATURES

OPTIFLUX 6000

Hygienic Converter housing

Hygienic Converter housing

Hygienic Converter housingHygienic Converter housing

The sensor can be complemented with an IFC 100

converter housing made of stainless steel 1.4404.

This stainless steel converter housing for the Food

and Beverage Industry is specially designed to

ensure easy cleanability and resistance to regular

rinsing with detergents

A mounting angle of 10 degrees avoids pooling and

the special EPDM sealing all around, minimises

crevices. Furthermore, the display is made entirely

of polymer and can be used in "no glass" designated

zones.

6

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

OPTIFLUX 6000

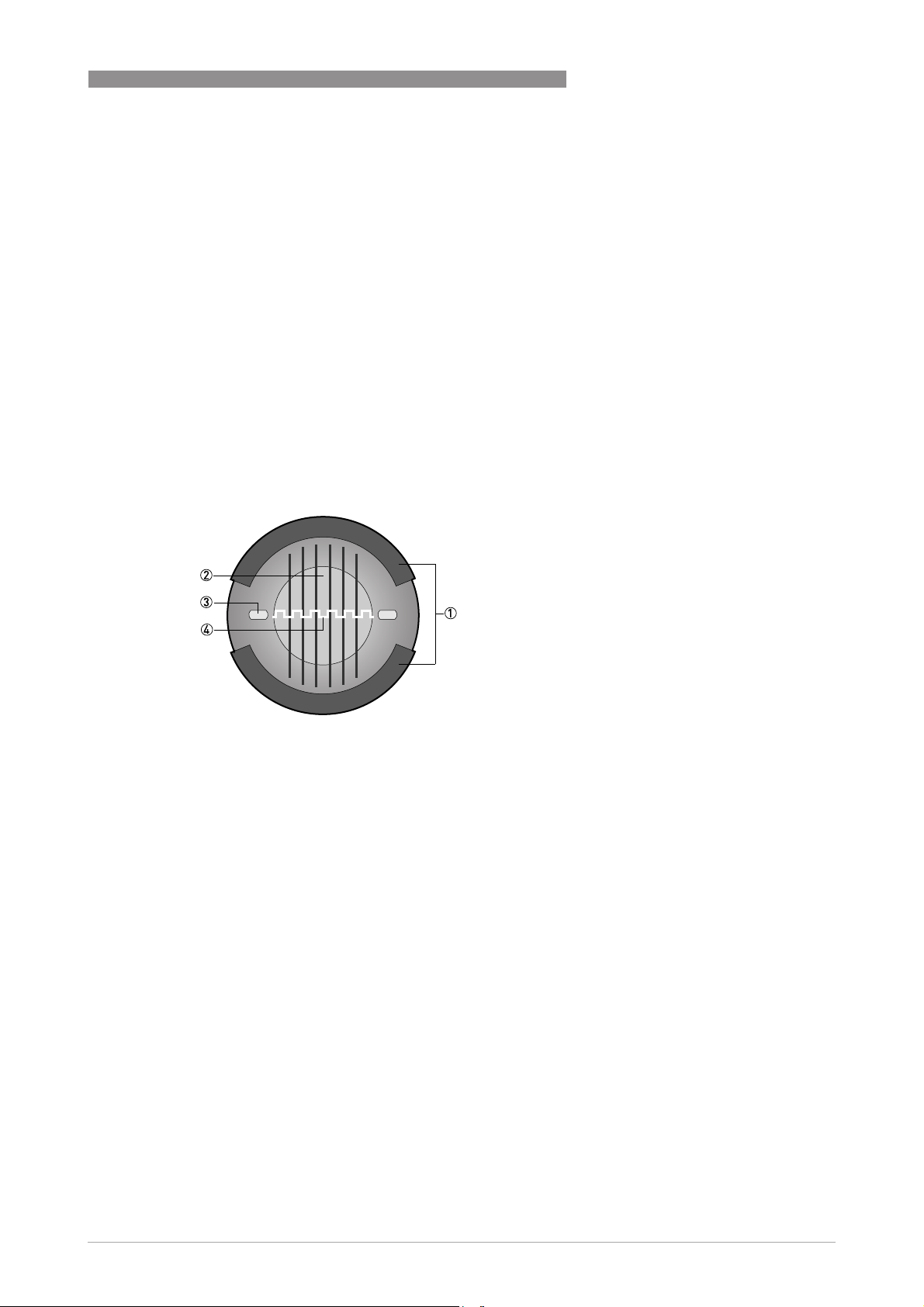

1.3 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils.

Inside of the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flowmeter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate Q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalizing, recording and output processing.

PRODUCT FEATURES

1

Figure 1-1: Measuring principle

1 Field coils

2 Magnetic field

3 Electrodes

4 Induced voltage (proportional to flow velocity)

www.krohne.com02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

7

2

TECHNICAL DATA

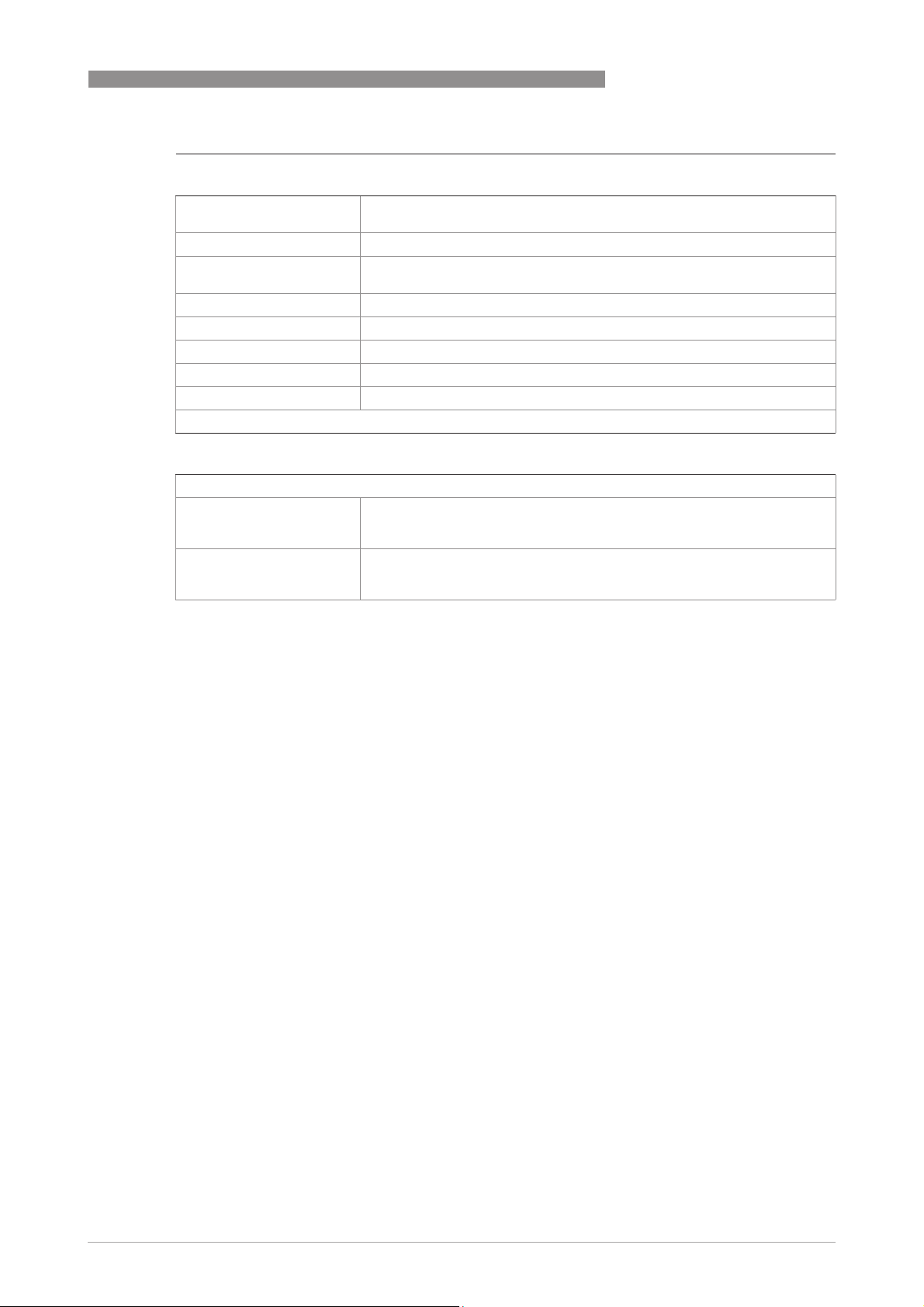

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle Faraday's law of induction

Application range Electrically conductive fluids

Measured value

Measured value

Measured valueMeasured value

Primary measured

value

Secondary measured

value

Design

Features Hygienic design

Modular construction The measurement system consists of a flow sensor and a signal converter.

Compact version With IFC 050 signal converter: OPTIFLUX 6050 C

Remote version In wall (W) mount version with IFC 050 signal converter: OPTIFLUX 6050 W

Nominal diameter DN2.5...150 / 1/10"...6"

Measuring range -12...+12 m/s / -40...+40 ft/s

OPTIFLUX 6000

Flow velocity

Volume flow

Stainless steel housing

Food & beverage and pharmaceutical process connections

It is available as compact and as separate version.

With IFC 100 signal converter: OPTIFLUX 6100 C

With IFC 300 signal converter: OPTIFLUX 6300 C

In wall (W) mount version with IFC 100signal converter: OPTIFLUX 6100 W

In field (F), wall (W) or rack (R) mount version with IFC 300 signal converter:

OPTIFLUX 6300 F, W or R

8

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

OPTIFLUX 6000

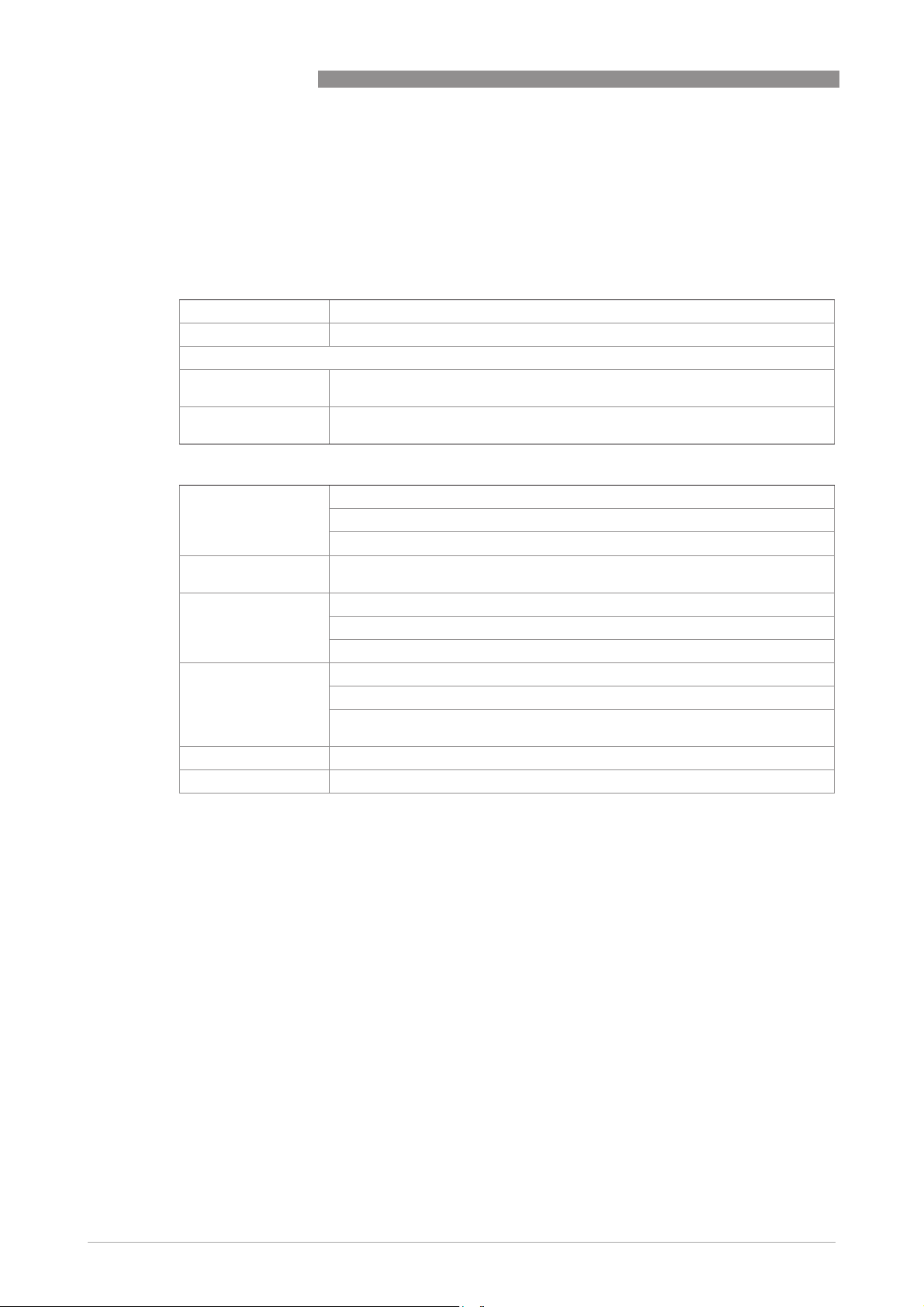

Measuring accuracy

Maximum measuring

error

Repeatability ±0.1% of MV, minimum 1 mm/s

Long term stability ±0.1% of MV

Special calibration On request

TECHNICAL DATA

Depending on signal converter and DN size.

IFC 050: down to 0.5% of the measured value ± 1 mm/s.

IFC 100: down to 0.3% of the measured value ± 1 mm/s for DN10...150 (³/8...6").

down to 0.4% of the measured value ± 1 mm/s for DN2.5...6 (¹/10...¼").

IFC 300: down to 0.2% of the measured value ± 1 mm/s for DN10...150 (³/8...6").

down to 0.3% of the measured value ± 2 mm/s for DN2.5...6 (¹/10...¼").

Optional:

Optional:

Optional:Optional:

Optimised accuracy for IFC 050 and IFC 100.

For more details on optimised accuracy, see the concerning signal converter

documentation.

The additional typical measuring deviation for the current output is ±10 µA.

The maximum measuring error depends on the installation conditions.

For detailed information refer to

Measuring accuracy

on page 13.

2

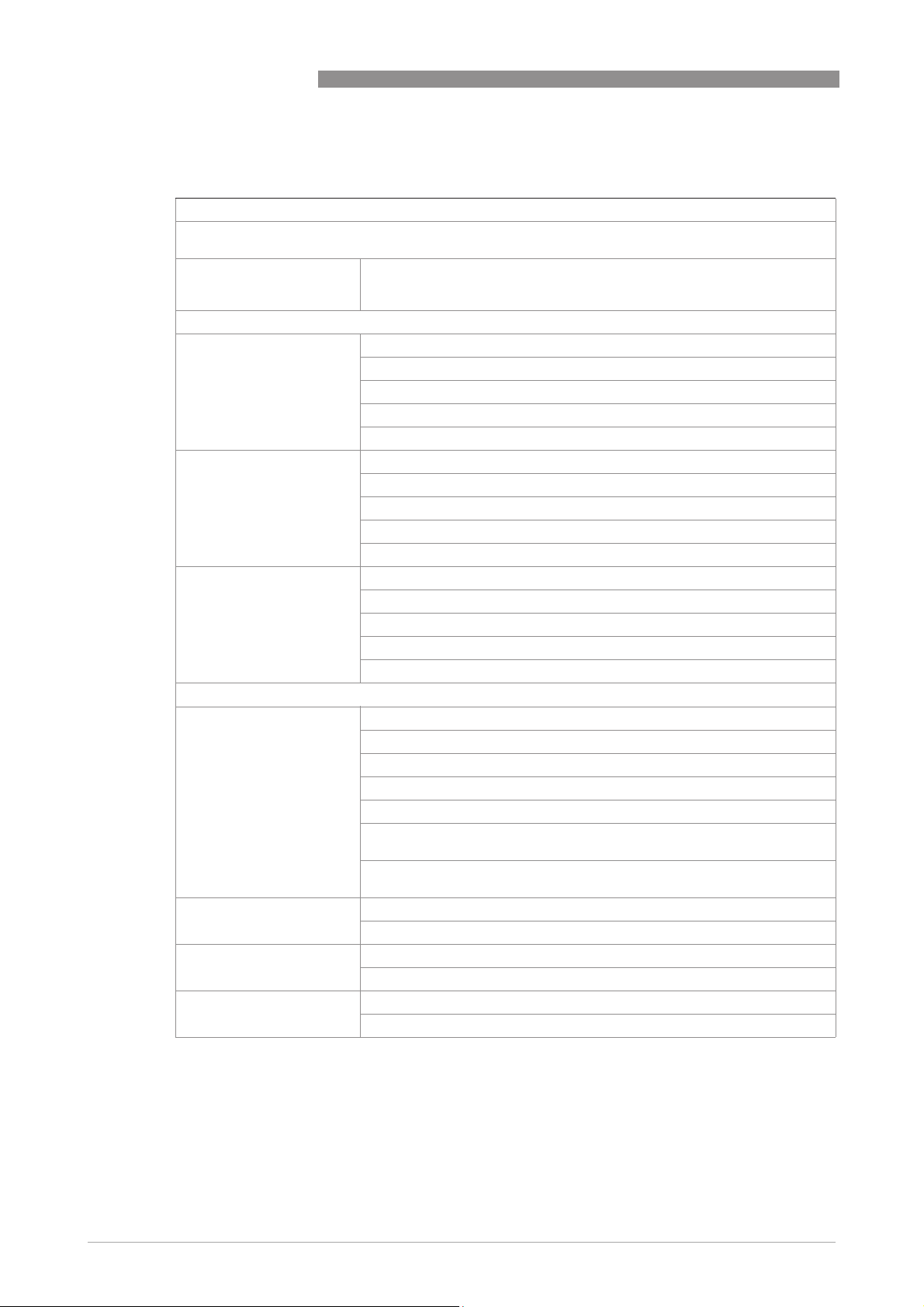

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Separate flow sensor: -40...+140°C / -40...+284°F

Compact with IFC 300 converter: -40...+140°C / -40...+284°F

Compact with IFC 050 and IFC 100 converter: -40...+120°C / -40...+248°F

at an ambient temperature ≤ 40 °C / 104 °F

For ISO 2852 and Tri-clamp versions: -40...+120°C / -40...+248°F

For Ex versions different temperatures are valid.

Please check the relevant Ex documentation for details.

Ambient temperature -40...+65°C / -40...+149°F

IFC 100 stainless steel version: -40...+60°C / -40...+140°F

Storage temperature -50...+70°C / -58...+158°F

Pressure

Pressure

PressurePressure

Ambient pressure Atmospheric

Nominal flange

pressure

Vacuum load 0 mbar / 0 psi

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Physical condition Electrical conductive liquids

Electrical conductivity Standard: ≥ 1 μS/cm

Permissible gas

content

(volume)

Permissible solid

content

(volume)

For detailed information refer to

Water: ≥ 20 μS/cm

IFC 050: ≤ 3%

IFC 100: ≤ 3%

IFC 300: ≤ 5%

IFC 050: ≤ 10%

IFC 100: ≤ 10%

IFC 300: ≤ 70%

Dimensions and weights

on page 15.

www.krohne.com02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

9

2

TECHNICAL DATA

Installation conditions

Installation Assure that the flow sensor is always fully filled.

Flow direction Forward and reverse

Inlet run ≥ 5 DN

Outlet run ≥ 2 DN

Dimensions and

weights

Materials

Sensor housing DN2.5...15: stainless steel Duplex (1.4462)

Measuring tube Stainless steel AISI 304 (1.4301)

Adapters Stainless steel AISI 316 L (1.4404)

Liner PFA

Connection box

(F-version only)

Electrodes Standard:

For detailed information refer to

Arrow on flow sensor indicates positive flow direction.

For detailed information refer to

DN25...150: stainless steel AISI 304 (1.4301)

Other materials on request.

Standard:

Standard:

Standard:Standard:

Aluminum with a standard coating

Option:

Option:

Option:Option:

Stainless steel AISI (1.4408)

Standard:

Standard:Standard:

Installation

on page 29.

Dimensions and weights

OPTIFLUX 6000

on page 15.

Hastelloy® C

Option:

Option:

Option:Option:

Hastelloy® B2, platinum, stainless steel, tantalum, titanium

Gaskets Standard:

Standard:

Standard:Standard:

EPDM

FDA recommends EPDM gaskets only if medium ≤ 8% fat.

Option:

Option:

Option:Option:

Silicone (non-Ex only)

10

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

OPTIFLUX 6000

Process connections

DIN 11850 row 2

/ 11866 row A

DIN 11851 DN2.5...150

DIN 11864-2A

flange with notch

DIN 32676 DN25...150

ISO 2037 DN2.5...150

ISO 2852 DN2.5...150

SMS 1146 DN2.5...100

Tri Clamp 1/10"...6"

Note: sensor diameters < DN10 have DN10 connections, which means the sensor diameter is smaller.

Electrical connections

Signal cable

Signal cable

Signal cableSignal cable

Type A (DS) Standard cable, double shielded.

Type B (BTS) Optional cable, triple shielded.

TECHNICAL DATA

DN2.5...150

DN25...150

Max. length: 600 m / 1950 ft (dep. on electrical conductivity and measuring

sensor). See documentation of the converter for more information.

Max. length: 600 m / 1950 ft (dep. on electrical conductivity and measuring

sensor). See documentation of the converter for more information.

2

www.krohne.com02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

11

2

TECHNICAL DATA

Approvals and certificates

CE

CE

CECE

This device fulfills the statutory requirements of the EU directives.

The manufacturer certifies successful testing of the product by applying the CE mark.

Hazardous areas

Hazardous areas

Hazardous areasHazardous areas

ATEX Please check the relevant Ex documentation for details.

FM In combination with IFC 300 C or F converter:

CSA In combination with IFC 300 C or F converter:

Other approvals and standards

Other approvals and standards

Other approvals and standardsOther approvals and standards

Protection category acc. to

IEC/EN 60529

Hygienic 3A approved

Shock test IEC 60068-2-27

Vibration test IEC 60068-2-64

OPTIFLUX 6000

For full information of the EU directives and standards and the approved

certifications, please refer to the EU Declaration of Conformity or the

website of the manufacturer.

Compact version with IFC 300 C converter:

Compact version with IFC 300 C converter:

Compact version with IFC 300 C converter:Compact version with IFC 300 C converter:

II 2 G, II D, II 2 (1) G

Remote (F) version:

Remote (F) version:

Remote (F) version:Remote (F) version:

II 2 G, II 2 D

In combination with IFC 300 C or F converter:

In combination with IFC 300 C or F converter:In combination with IFC 300 C or F converter:

Class I, Div. 2, Groups A, B, C and D

Class II, Div. 2, Groups F and G

Class III, Div. 2, Groups F and G

Only available for DN2.5...15

In combination with IFC 300 C or F converter:

In combination with IFC 300 C or F converter:In combination with IFC 300 C or F converter:

Class I, Div. 2, Groups A, B, C and D

Class II, Div. 2, Groups F and G

Class III, Div. 2, Groups F and G

Only available for DN2.5...15

Standard

Standard

StandardStandard

IP 66/67 (NEMA 4/4X/6)

Option (F version only)

Option (F version only)

Option (F version only)Option (F version only)

IP 68 field (NEMA 6P)

IP 68 factory (NEMA 6P)

IP 68 is only available for separate design and with a stainless steel

connection box.

Option IP69

Option IP69

Option IP69Option IP69

IP 67/69 is available for connection box and IFC 100 in stainless steel.

EHEDG

30 g for 18 ms

f = 20...2000 Hz, rms = 4.5 g, t = 30 min.

12

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

OPTIFLUX 6000

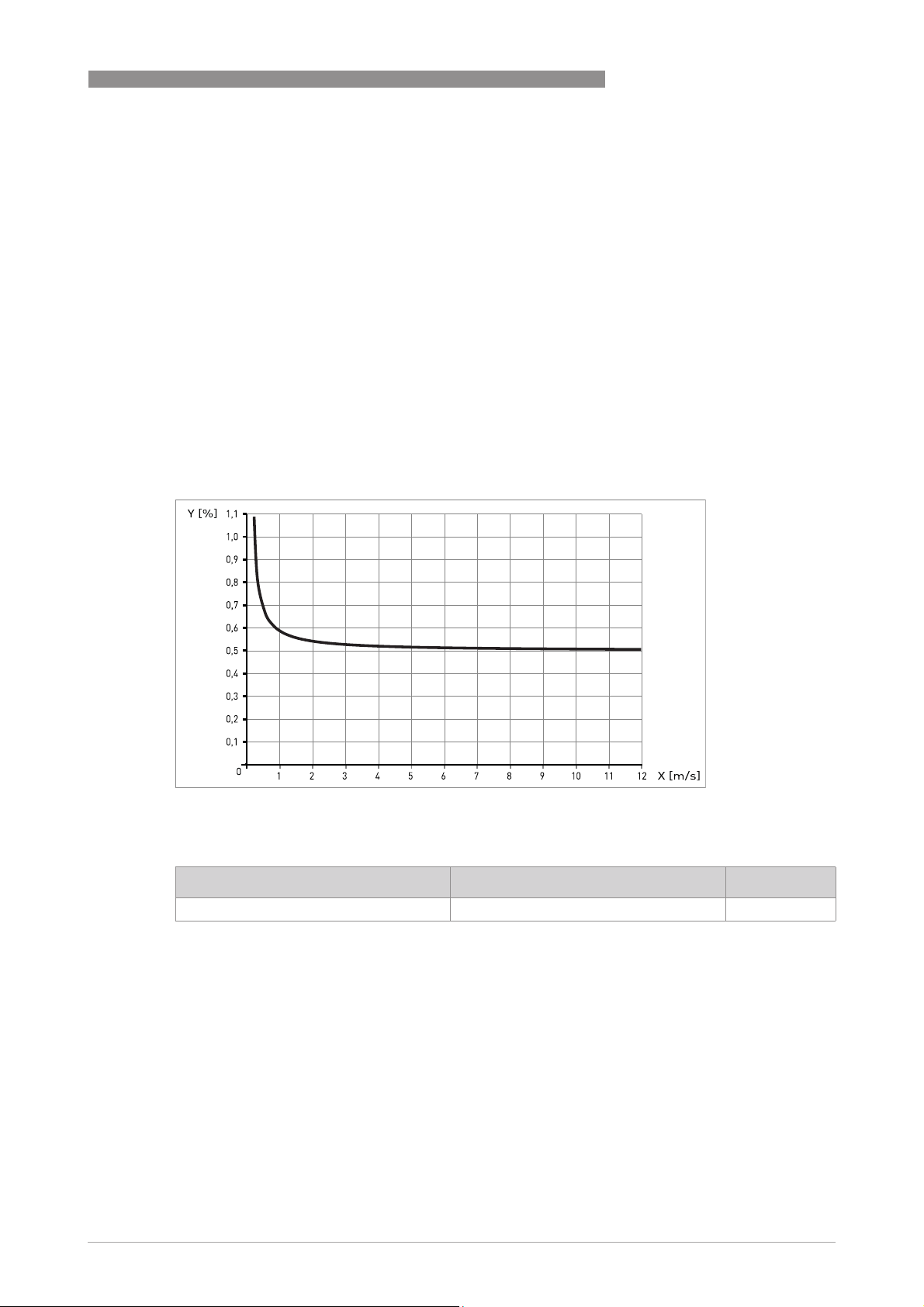

2.2 Measuring accuracy

Every electromagnetic flowmeter is calibrated by direct volume comparison. The wet calibration

validates the performance of the flowmeter under reference conditions against accuracy limits.

The accuracy limits of electromagnetic flowmeters are typically the result of the combined effect

of linearity, zero point stability and calibration uncertainty.

Reference conditions

• Medium: water

• Temperature: +5...35°C / +41...95°F

• Operating pressure: 0.1...5 barg / 1.5...72.5 psig

• Inlet section: ≥ 5 DN

• Outlet section: ≥ 2 DN

TECHNICAL DATA

2

Figure 2-1: Flow velocity vs. accuracy

X [m/s] : flow velocity

Y [%]: deviation from the actual measured value (mv)

Compact with IFC 050 Accuracy Curve

DN10...150 / 3/8...6" 0.5% of MV + 1 mm/s

Optionally for IFC 050; extended calibration at 2 points for optimised accuracy.

For more details on optimised accuracy, see the concerning signal converter documentation.

www.krohne.com02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

13

2

TECHNICAL DATA

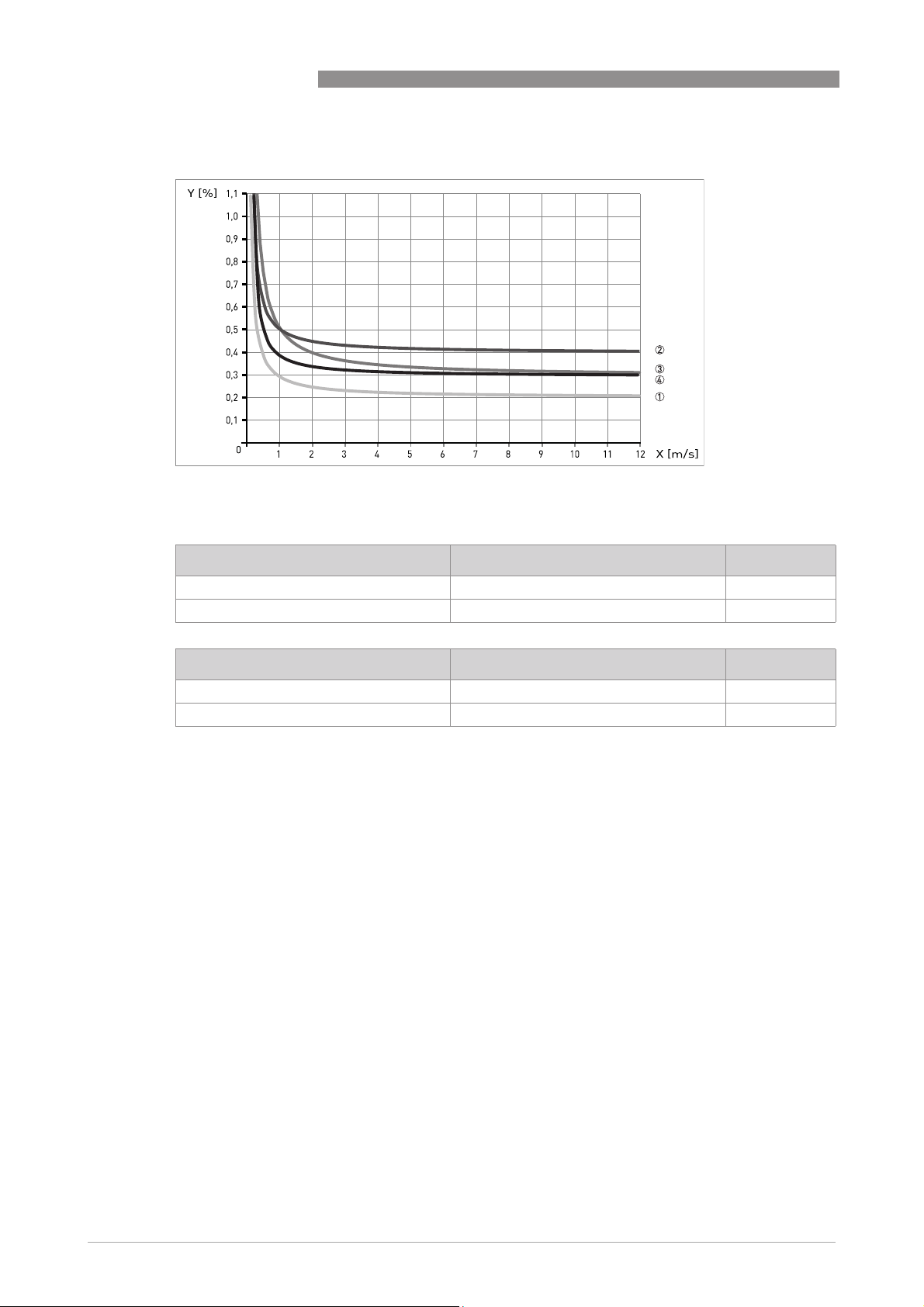

Figure 2-2: Flow velocity vs. accuracy

X [m/s] : flow velocity

Y [%]: deviation from the actual measured value (mv)

OPTIFLUX 6000

Compact with IFC 300 Accuracy Curve

DN2.5...6 / 1/10...1/4" 0.3% of MV + 2 mm/s 3

DN10...150 / 3/8...6" 0.2% of MV + 1 mm/s 1

Compact with IFC 100 Accuracy Curve

DN2.5...6 / 1/10...1/4" 0.4% of MV + 1 mm/s 2

DN10...150 / 3/8...6" 0.3% of MV + 1 mm/s 4

Optionally for IFC 100; extended calibration at 2 points for optimised accuracy.

For more details on optimised accuracy, see the concerning signal converter documentation.

14

www.krohne.com 02/2019 - 4000127010 - TD OPTIFLUX 6000 R12 en

Loading...

Loading...