Page 1

Inline Static Sensor

Important

Point

Reference

96M13428

SK-1000 Series

Instruction Manual

Read this instruction manual before using the product in order to achieve

maximum performance.

Keep this manual in a safe place after reading it for future reference.

Introduction

This manual describes the operations of and information related to the SK-1000

Series.

Read this manual carefully to ensure the safe performance and function of the

SK-1000 Series.

Keep this manual in a safe place for future reference.

Ensure that the end user of this product receives this manual.

Symbols

The following symbols are used in this instruction manual to enable you to

recognize important information at a glance.

Be sure to read this section carefully.

Indicates a hazardous situation which, if not avoided, will result in

DANGER

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result

WARNING

in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result

CAUTION

in minor or moderate injury.

Indicates a situation which, if not avoided, could result in product

NOTICE

damage as well as property damage.

Table of Contents

Introduction ...................................................................................... 1

Safety Precautions ........................................................................................ 2

General Precautions .........................................................................2

Safety Information for the SK-1000 series ........................................ 2

Abnormal Conditions ........................................................................ 2

Precautions for Use ..........................................................................2

Other Precautions .............................................................................2

Precautions for Regulations and Standards ..................................................2

1. Before Use ................................................................................................ 3

Checking the Package Contents ...................................................... 3

Part Names and Functions ...............................................................3

2. Installation and Connection .......................................................................4

Mounting and Wiring the Sensor Amplifier ....................................... 4

Connecting and Mounting the Sensor Head ....................................5

3. Basic Operations ....................................................................................... 7

Operation When the Power is Turned on for the First Time ..............7

Operations on the Main Screens ...................................................... 7

Initial Reset (Initialize) ....................................................................... 8

Setting the Tolerance Values ............................................................ 9

Zero Shift Function

(Shifting the Internal Measurement Value (R.V.)) ............................. 9

Bank Function (Registering Multiple Tolerance Setting Values) ...... 9

Key Lock Function 10

4. Setting Various Functions ....................................................................... 10

Basic Settings and Advanced Settings .......................................... 10

Simulation Mode ............................................................................. 17

5. Specifications .......................................................................................... 17

Specifications ................................................................................. 17

Circuit Diagram .............................................................................. 18

Dimensions ..................................................................................... 18

Response Time ............................................................................... 19

Indicates cautions and limitations that must be followed during

operation.

Indicates additional information on proper operation.

Indicates tips for better understanding or useful information.

Indicates the reference pages in this manual or the reference pages in

separate manuals.

6. Appendix .................................................................................................19

Troubleshooting .............................................................................. 19

Display Screen and Output ............................................................ 21

Factory Setting (Default Value) List ................................................ 21

1

E SK-1000 IM

Page 2

Safety Precautions

NOTICE

NOTICE

General Precautions

• At startup and during operation, be sure to monitor the functions and

performance of this product and confirm normal operation.

• We recommend that you take substantial safety measures to avoid any damage

in the event that a problem occurs.

• If the product is modified or used in any way other than those described in the

specifications, its functions and performance cannot be guaranteed.

• When this product is used in combination with other devices, the functions and

performance may be weakened, depending on the operating conditions,

surrounding environment, etc.

• Do not use this product for the purpose of protecting the human body.

• Do not subject this device, including peripheral devices, to rapid temperature

change. Product failure may occur due to condensation.

Safety Information for the SK-1000 series

• This product is only intended to detect the charge on object(s).

Do not use this product for the purpose to protect a human body

or a part of human body.

WARNING

• This product is not intended for use as explosion-proof product.

Do not use this product in hazardous location and/or potentially

explosive atmosphere.

Warming up

Leave the SK Series about 30 minutes after turning on the power.

The circuit is not stable immediately after the power turns on, so the display value

may gradually fluctuate.

Abnormal Conditions

If the following conditions occur, turn OFF the power immediately.

Continuing to use this product under abnormal conditions may

cause product failure.

NOTICE

• When water or foreign matter enters the SK Series

• When the SK Series is dropped or the case is damaged

• If smoke or unpleasant odor is present.

Precautions for Use

• Use with the correct power source and voltage. Otherwise, fire,

electric shock or product failure may result.

CAUTION

• Do not attempt to open or modify the SK Series. Doing so may

cause fire or electric shock.

• Before disconnecting the cables, make sure to turn off the main

unit and devices connected to the main unit. Otherwise, the unit

may be damaged.

• Do not turn off the power while modifying settings. Some or all

of the setting data may be lost.

• The measurement area is basically a guide for measurement. A

proper size of target with respect to the measurement area is

recommended to ensure a more accurate measurement.

Power ON Reset

After the power is turned ON, it will take approx. 3.5 seconds for the measurement

to start. The judgment results will be output after the sampling rate has elapsed.

Other Precautions

Power source

• Noise superimposed on the power supply may cause malfunction. Use a direct

current stabilized power source which uses an insulation transformer.

• When using a commercially available switching regulator, make sure to ground

the frame ground terminal.

Grounding precautions

A grounding wire is present in the I/O cable of the SK-1000 Series.

• For proper measurements, be sure to connect the blue wire

protruding from the SK-1000 Series to ground.

• Use class-D grounding-resistance not exceeding 100 Ω.

Precautions for Regulations and Standards

CE Marking

Keyence corporation has confirmed that this product complies with the essential

requirements of the applicable EC Directives, based on the following

specifications.

Be sure to consider the following specifications when using this product in the

Member States of European Union.

z EMC Directive

• Applicable standards EN61326-1, ClassA

• This product is intended to be used in an industrial electromagnetic

environment.

Remarks

These specifications do not give any guarantee that the end-product with this

product incorporated complies with the essential requirements of EMC Directive.

The manufacturer of the end-product is solely responsible for the compliance on

the end-product itself according to EMC Directive.

FCC regulations

This product complies with the following EMI regulations specified by the FCC.

• Applicable standards FCC part 15 subpart B, class A digital device

IC (Industry Canada) regulations

This product complies with the following EMI regulations specified by IC.

• Applicable standards ICES-003, class A digital apparatus

Installation environment

To use this product normally and safely, do not install this product in the following

locations. Product failure may occur.

• High-humidity, dusty or poorly-ventilated locations

• High-temperature locations where the unit is exposed to direct sunlight

• Locations where there is corrosive or combustible gas

• Locations where the unit may be directly subjected to vibration or impact

• Locations where water, oil or chemicals may splash onto the unit

• Locations that cause the unit to discharge its static electricity

Influence of dirt

Measurement errors may occur due to dust, water, oil, etc.

Anti-noise prevention

When the unit is installed near electric noise source such as a power source or

high-voltage line, operational errors or product failure may occur. Take adequate

measures such as using a noise filter, separating cables or insulating the sensor

amplifier and the sensor head.

E SK-1000 IM

2

Page 3

1. Before Use

Sensor amplifier x 1

Instruction manual x 1

SK-1000 (main unit)

Sensor amplifier x 1

SK-1050 (expansion unit)

Sensor head x 1

SK-050

OP-26751 (for SK-1000/1050)

End unit x 2

OP-87056 (2 m)

OP-87057 (5 m)

OP-87058 (10 m)

OP87059 (20 m)

Sensor head connection cable

(M8 straight connector) x 1

OP-87660 (2 m)

OP-87661 (5 m)

OP-87662 (10 m)

OP87663 (20 m)

Sensor head connection cable

(M8 L-shaped connector) x 1

OP-84338

Sensor head

cable connector x 2

OP-87934

Ion balance monitor unit

Expansion unit connecto

r*1

Sensor head connector

Amplifier control unit cover

Expansion unit connector

*2

Amplifier control unit

(1)

(2)

(3)

(4)

(5) (6) (7) (8)

(9) (10) (11)

(12)

(13)(14)(15)

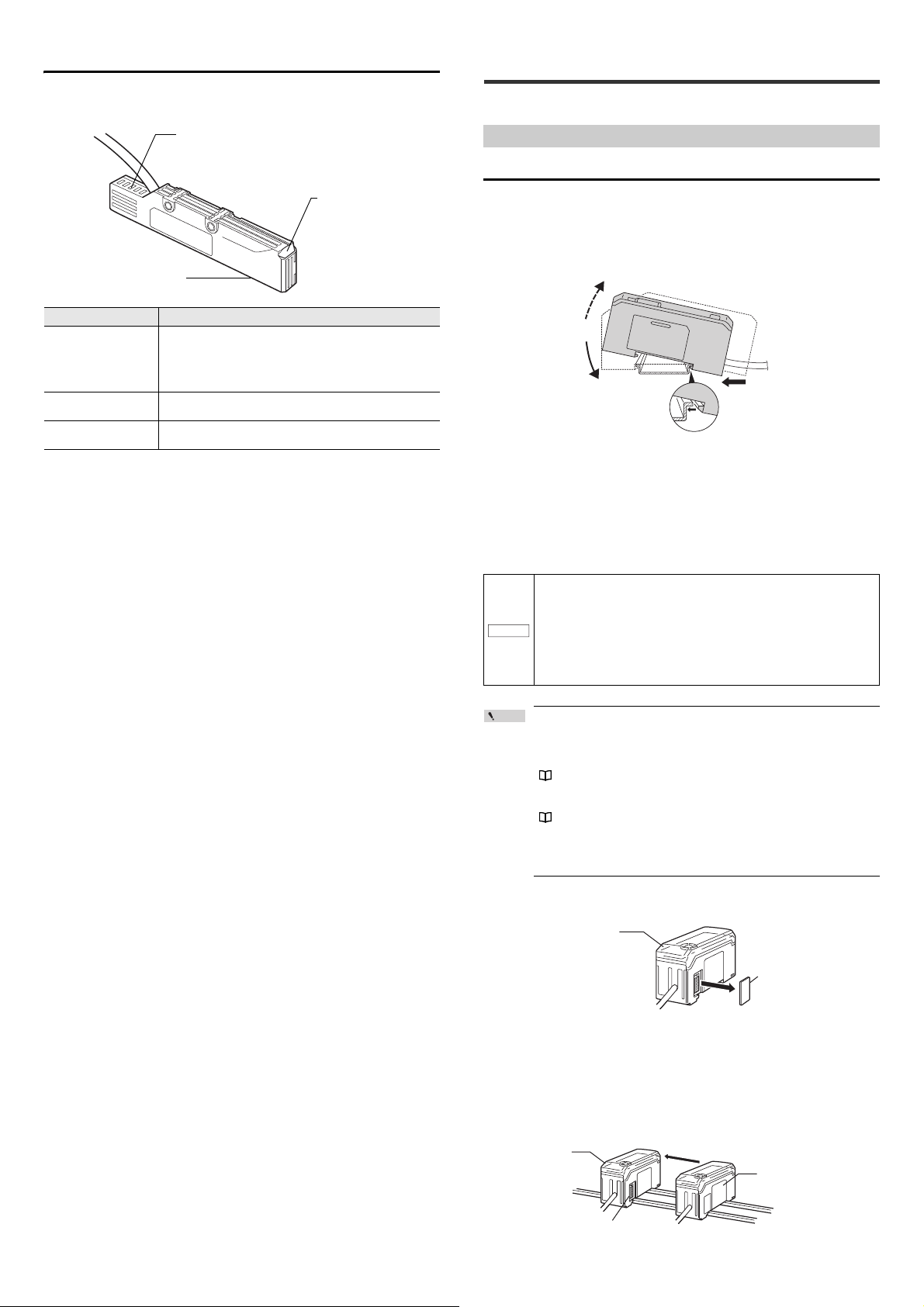

Part Names and Functions

This chapter gives an overview of the SK Series as well as the name and function

of each part.

Checking the Package Contents

The following equipment and accessories are included in the package. Before

using the unit, make sure that all items are included.

Sensor Amplifier

DIN rail mount type

Sensor Head

Sensor Amplifier Unit

SK-1000

HOLD

HI

GO

LO

ZERO SHIFT

0

BANK

1

2

3

TEMP %RH

HI LO R.V.

V

ZERO SHIFT

TIMING

SELECT

SET MODE

SK-1000

ALARM

kV

*1 When shipped from the factory, a protective cover is installed over the

expansion slots.

*2 Not installed on the main unit.

Amplifier control unit

kV

ALARM

HOLD

HI

GO

LO

ZERO SHIFT

0

BANK

1

2

3

TEMP %RH

HI LO R.V.

V

ZERO SHIFT

TIMING

SET MODE

SELECT

SK-1000

List of Optional Parts

Forsensoramplifier

Forsensorhead

Item Description

(1) Main display Displays the judgment value (P.V.) and each setting item.

(2) HOLD indicator

(3) Judgment indicator

(4) Bank indicator

Lights up when the judgment value (P.V.) is held.

"6. Hold Function" (page 12)

Displays whether the judgment val ue (P.V.) is HI (over the upper

limit), GO (within the acceptable range) or LO (below the lower

limit) against the tolerance setting value.

"Changing the Tolerance Values" (page 9)

Displays a bank in use.

"Bank Function (Registering Multiple Tolerance Setting Values)"

(page 9)

(5) Zero shift button

(6) Sub display indicator

(7) Sub display

(8) Timing input indicator

(9) Zero shift indicator

Press this button to match the internal measurement value (R.V.)

to zero.

Lights up according to the type of values displayed on the sub

display.

Displays the internal measurement value (R.V.), temperature,

humidity, and each setting (selection) item.

Lights up while the timing input is ON when the timing input

(external input) is set to Level. Lights on approx. 0.5 sec. when

the timing input is set to Edge and the timing input is turned ON.

The zero shift indicator will light up for approx. 0.5 second when

the zero shift function is used.

(10) SET button Used to perform initializations.

(11) MODE button

(12) Arrow button

Used when setting items, entering/exiting setting modes or

moving items.

Used when selecting settings, changing display contents on the

sub display, etc.

(13) Alarm indicator Lights up in the alarm state or error state.

kV display unit

(14)

(15)

indicator

V display unit

indicator

Lights up when the judgment value (P.V.) display unit is kV.

Lights up when the judgment value (P.V.) display unit is V.

3

E SK-1000 IM

Page 4

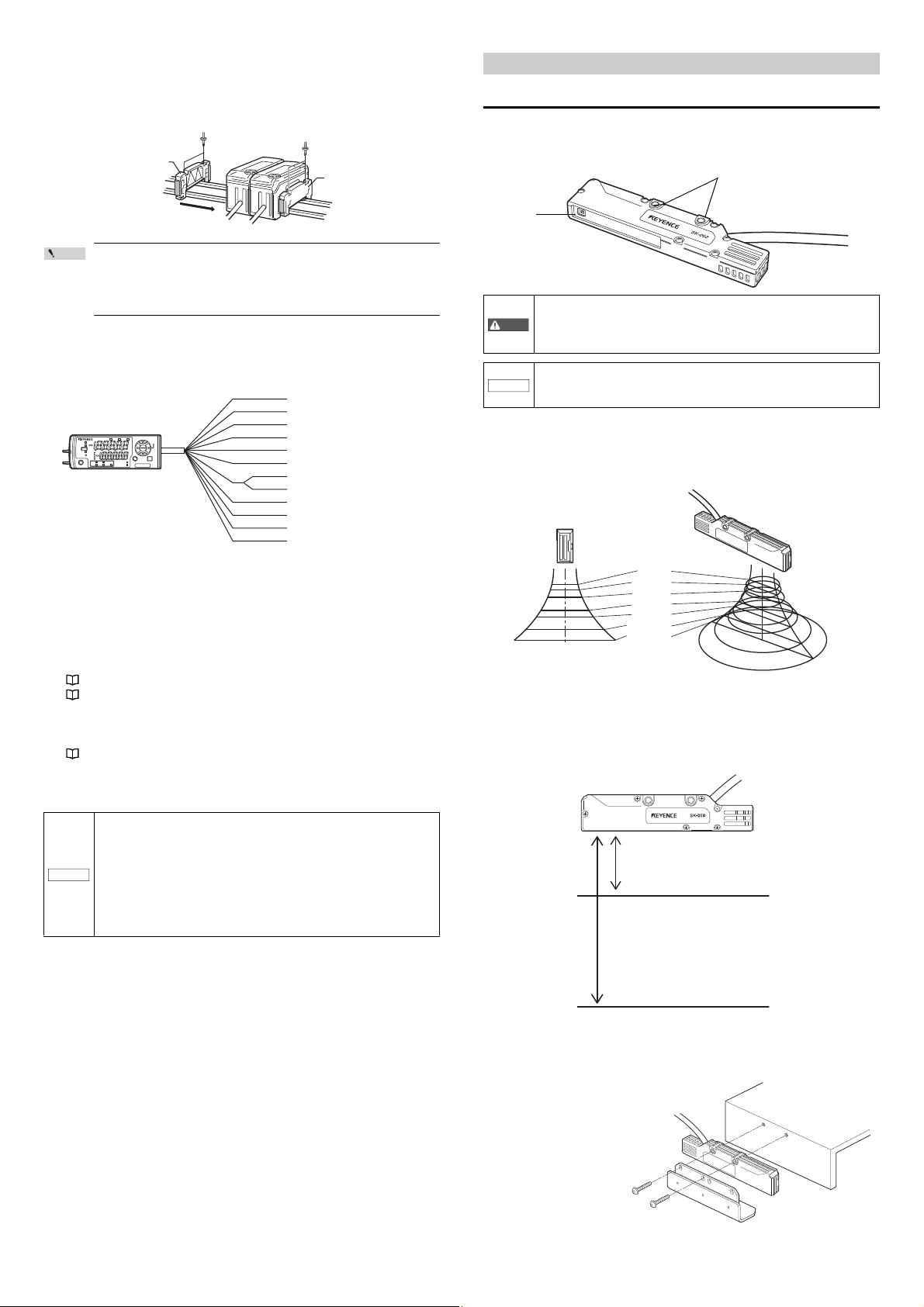

Sensor Head Unit

(3) Temperature/humidity sensor

(2) Surface potential sensor

(1) Sensor indicator light

NOTICE

①

②

③

Main unit

Connector cover

Main unit

Expansion unit

Connector

2. Installation and Connection

SK-050

Item Description

Lights up according to the judgment during normal operation.

(1) Sensor indicator light

Surface potential

(2)

sensor

Temperature/humidity

(3)

sensor

HI/LO: Lit in red

GO: Lit in green

OFF: Off

When an error occurs: Lit in red

This sensor detects the charge potential.

This sensor detects the temperature/humidity.

This chapter describes precautions when installing and connecting the SK Series.

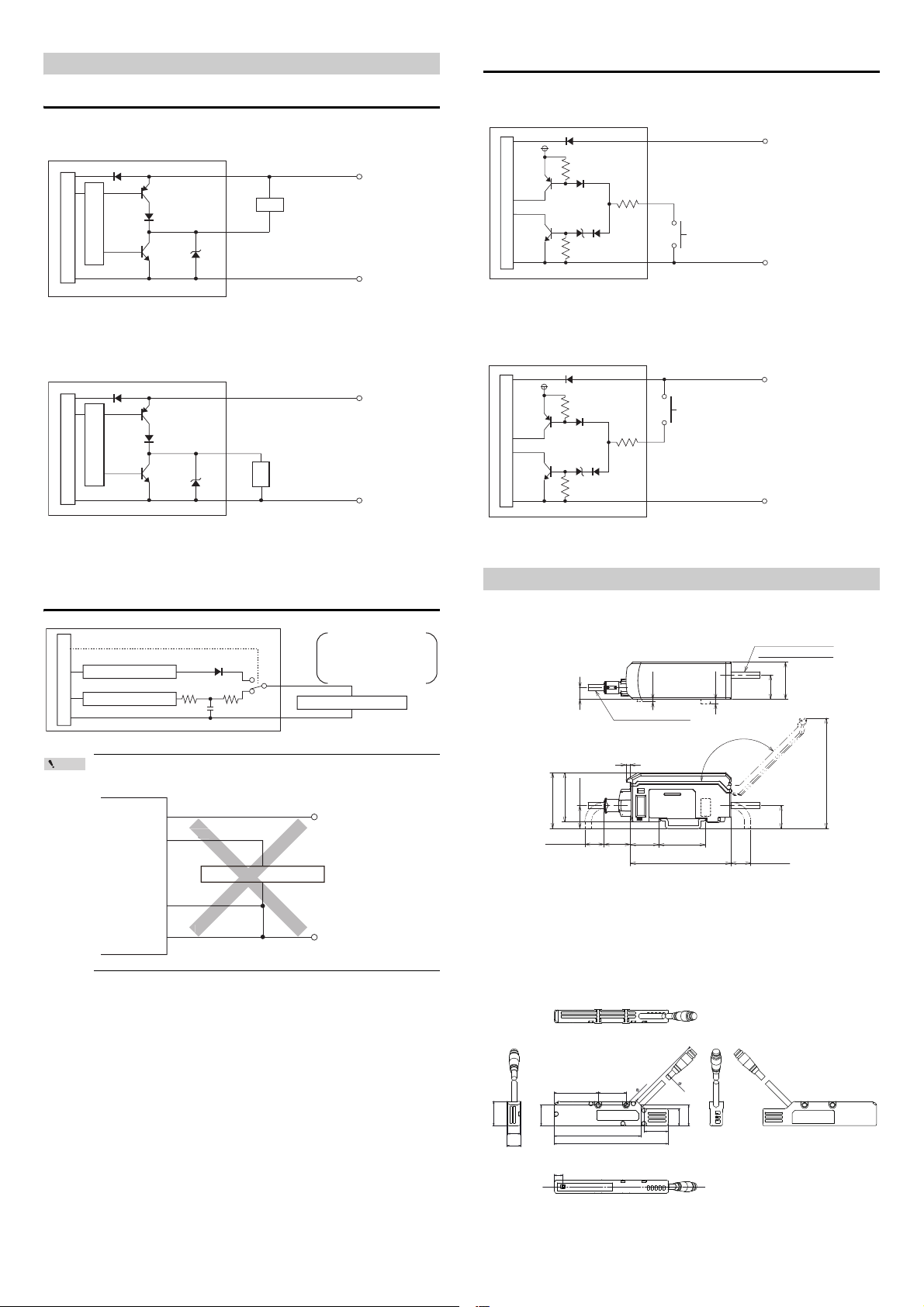

Mounting and Wiring the Sensor Amplifier

Mounting the Sensor Amplifier

SK-1000

1 Align the tab at the bottom of the amplifier body with the DIN rail.

While pushing the amplifier in the direction of the arrow (1), push

down in the direction of the arrow (2).

2 To dismount the sensor, raise the main body in the direction of the

arrow (3) while pushing the main body in the direction of the arrow

(1).

Expansion unit (SK-1050)

Incorporate multiple units into one system by connecting expansion units to the

main unit.

Up to 7 expansion units can be connected to one main unit.

• Always mount expansion units onto a DIN rail.

• When connecting multiple amplifiers (expansion units), first

check to make sure that the power is turned OFF to all of the

main and expansion units. Connecting the units with the power

turned ON may cause damage to the units.

• Position the amplifiers (expansion units) as close as possible to

the main unit. Improper connections may damage the

equipment.

Point

• When connecting the expansion units, make sure to initialize the

connected expansion units and set the output polarity.

(1)Turning on the amplifier for the first time after connecting the

sensor head

"Operation When the Power is Turned on for the First Time"

(page 7)

(2)Performing the initial reset

"Initial Reset (Initialize)" (page 8)

• Expansion units with different setting of output polarity (such as

an NPN output expansion unit and a PNP output main unit)

cannot be connected together.

1 Remove the expansion protective cover from the SK-1000 (main unit)

2 Install the amplifiers (expansion units) on the DIN rail.

For details on how to install the unit, see the above explanation for the SK-1000.

3 Push the expansion unit into the main unit connector until a clicking

sound can be heard.

The expansion unit installed next to the main unit is referred to as expansion

unit 1. Subsequent expansion units are referred to as expansion unit 2,

expansion unit 3, etc.

E SK-1000 IM

4

Page 5

4 Install the end units (OP-26751: 2 units in a set, optional accessory)

Point

End unit

End unit

HOLD

HI

V

kV

ALARM

BANK

SET MODE

SELECT

ZERO SHIFT

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Brown

Blue

Black

White

Gray

Light blue

Orange

Shield

Pink

Yellow

Pink/Purple

Purple

Green

10 to 30 VDC

0 V, grounding wire

HI judgment output

LO judgment output

GO judgment output

Analog output (surface potential)

Analog output GND

Zero shift input

Reset input

Timing input

Bank A Input

Alarm output

*1

*4

*1

*1

*2

*2

*3

*3

*3

*3

WARNING

NOTICE

Mounting holes

Sensor

unit

Tightening torque:

1.2 Nm (12kgf•cm) or less

50 mm

60 mm

100 mm

120 mm

25 mm

12 mm

5 mm

φ 200

φ 250

φ 500

φ 620

φ 80

φ 30

φ12

High-precision mode: 25 mm

Wide-range mode: 100 mm

Tightening torque:

1.2 Nm (12kgf•cm) or less

on both sides of the amplifiers (main and expansion units). Secure

the end units in place with screws on top (2 on each end unit).

The end units are mounted in the same way as the amplifiers.

Fix the amplifiers securely using the end units (OP-26751: 2 units

in a set, optional accessory) or a commercially available DIN rail

fixing tool to prevent the amplifiers from moving on the DIN rail or

coming off of the DIN rail due to machine vibration.

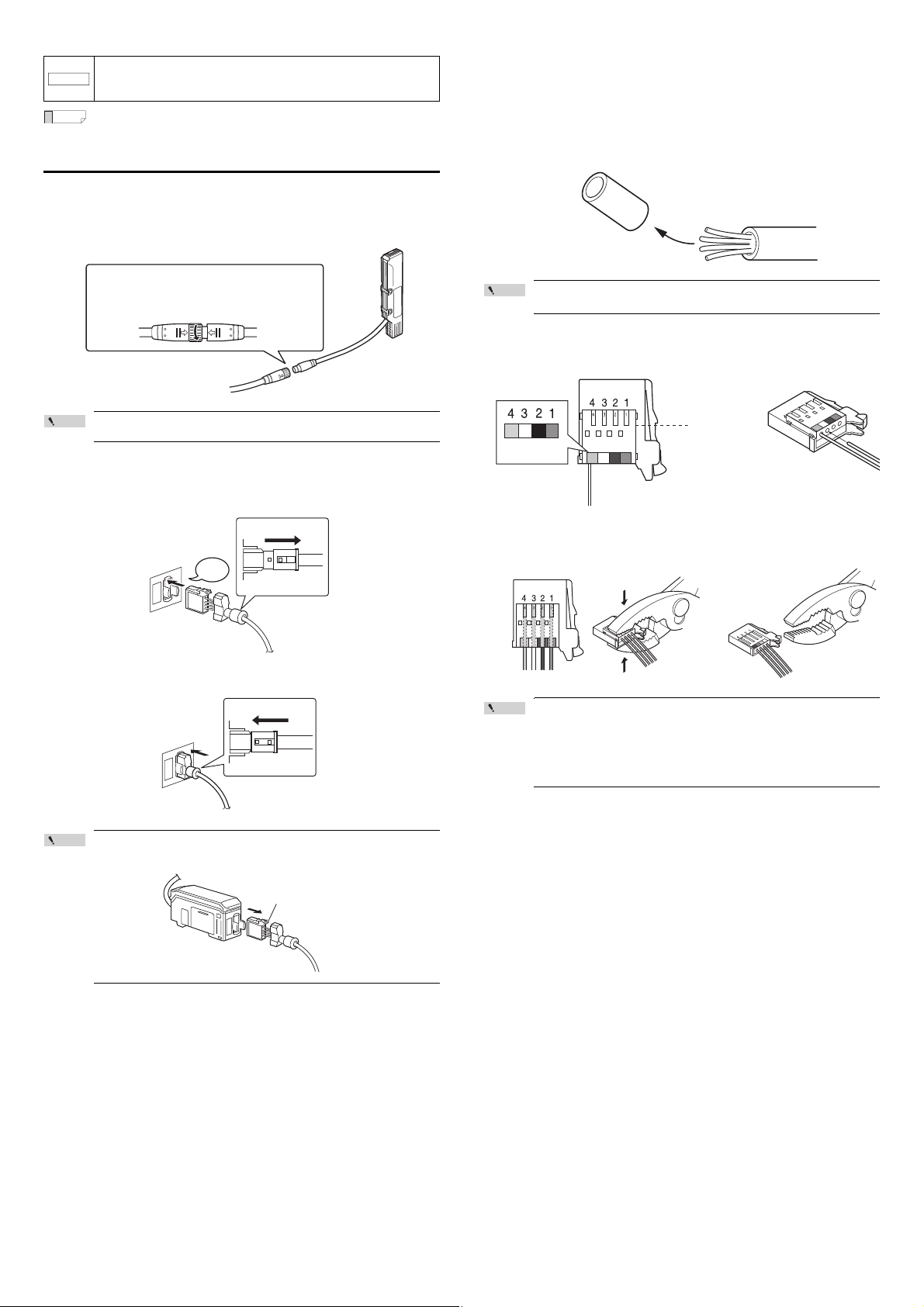

Power/Input-output cable

z "Output Circuit Diagram" (page 18)

Connecting and Mounting the Sensor Head

Mounting the Sensor Head

Attach the sensor head using the dedicated mounting bracket.

When you attach the sensor head, be careful not to touch the aperture. Doing so

may lead to malfunctions.

Install the sensor unit (including its metal parts) so that nothing

touches it during measurement. Failing to do so not only prevents

proper measurements of static electricity but may also lead to

electric shock and product breakdown.

Do not cover the area around the temperature/humidity sensing

unit. Doing so will prevent you from correctly measuring the

ambient temperature/humidity.

Measurement area

The following figures briefly show the measurement area of the SK-050.

The measured value is the average of the values detected within the measurement

area as seen in the figures.

*1 The SK-1050 (expansion unit) does not have brown, blue, or light blue wires.

Power is supplied to the expansion unit through the SK-1000 (main unit).

Use D-class grounding to ground the blue wire.

*2 The analog output (surface potential) specifications change according to the

measurement range.

The analog output can be set to one of the following values when the power is

first turned on and when initializations are performed.

None (OFF), -5 to 5 V, 0 to 5 V, 1 to 5 V, or 4 to 20 mA

" Operation When the Power is Turned on for the First Time" (page 7)

" Initial Reset (Initialize)" (page 8)

*3 In addition to the above values, you can select from the following options for

external input.

Bank B input or do not use (OFF)

" 10. External input" (page 15)

*4 When you expand the system to 6 or more units, use a power supply voltage

of 20 to 30 V.

• This device's 0 V power supply wire, analog output GND wire,

and grounding wire are all shared. Ensure that an electric

potential difference does not occur between their terminals due

to wiring or due to electric potential differences between

NOTICE

external devices. Failing to do so may lead to accidents or

breakdowns involving the external devices and this product.

• Use power supplies that are isolated from each other or so that

negative grounding is present between them. You cannot use

positive grounding.

Measurement distance

The SK-050 provides a high-precision mode and a wide-range mode. Each mode

offers different measurement distances between the sensor head and the target.

The figure below shows the reference distance for measurements in each

measurement mode. The reference plane is the bottom surface of the sensor head.

Attaching the ion balance monitor unit (OP-87934)

Fix with screws using the mounting holes in the sensor's main body and those of

the ion balance plate.

5

E SK-1000 IM

Page 6

Reference

Point

Point

Be sure to fasten screws from the ion balance plate side. If

(1) Align the arrow position of the connector to

insert.

(2) Rotate the connector screw to tighten.

Click

Lock cover

Unlocked

Lock cover

Unlocked

Lock lever

Blue

White

Black

Brown

Insert the

wires beyond

this point

fastened from the main body side, the ion balance plate can

NOTICE

contact other parts, resulting in incorrect measurement.

The ion balance plate can be mounted from either side of the sensor

head.

Connection and Wiring

Connecting the sensor head and amplifier

1 Attach the sensor head connection cables to the sensor head cable

Tighten the connectors securely by hand.

2 Attach the sensor head connection cable to the amplifier connector.

Remove the lock cover of the connector and insert it into the connectors of

amplifier until a clicking sound is heard.

Attaching the sensor head cable connector (OP-84338:

optional accessory)

Cut the sensor head connection cable to the required length and attach the new

connector to use the sensor.

1 Cut the cable to the required length and strip approx. 15 mm of

insulation from the end of the cable.

Point

Do not strip the core wire insulation.

2 Insert the wires into the connector holes of the matching color.

The cables should be inserted to the end and held in place.

3 Attach the lock cover to the connector to secure the cable.

When removing the sensor head connection cable, push in the

lock lever and pull it out.

3 Confirm that all wires are inserted to the specified position and

crimp them using pliers or a similar tool.

Point

After the connector is changed, connect it to the amplifier and

confirm normal operation.

If it does not operate normally, crimp the connector again with

pliers.

Once the connector is crimped, it cannot be reused.

E SK-1000 IM

6

Page 7

3. Basic Operations

Point

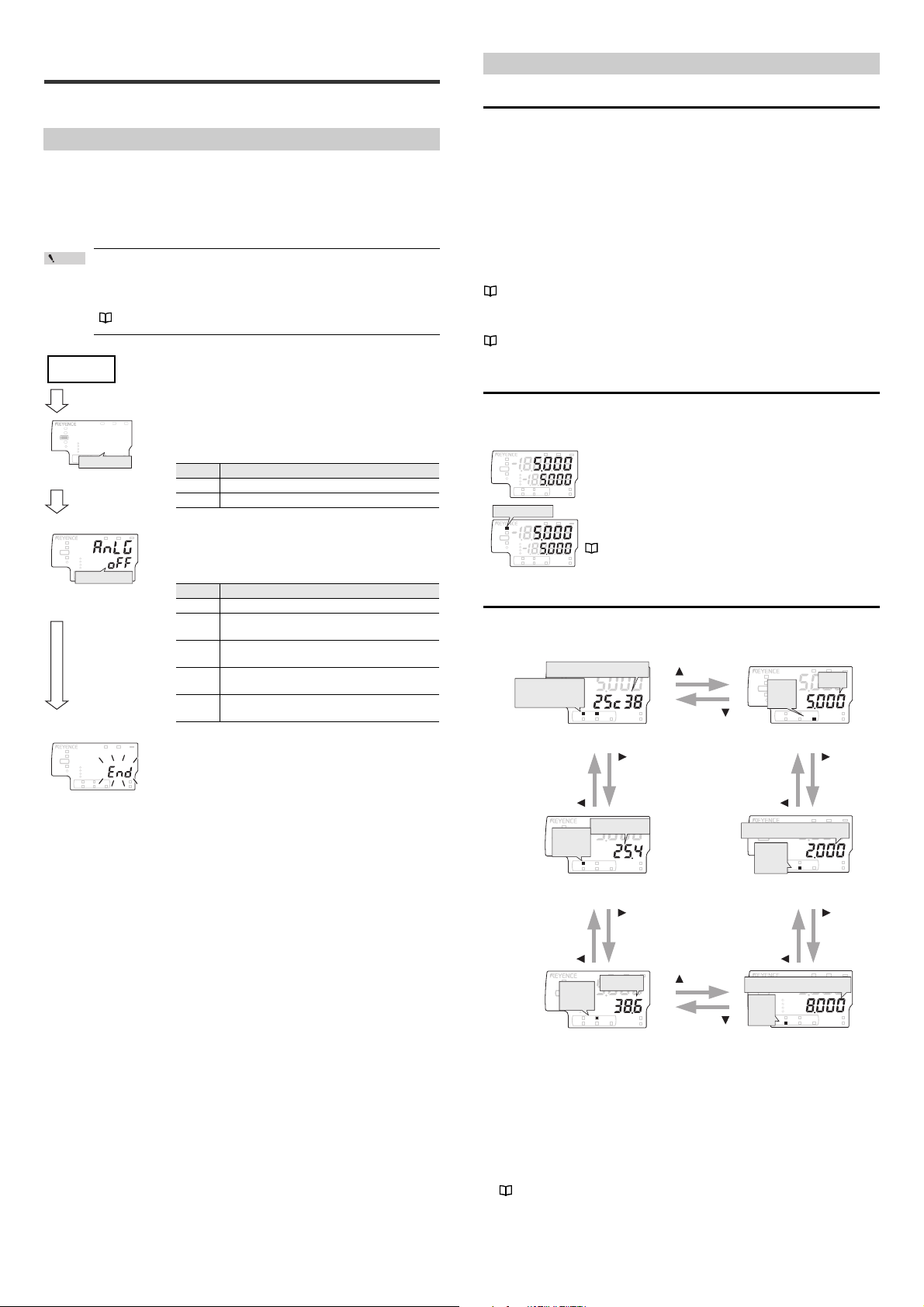

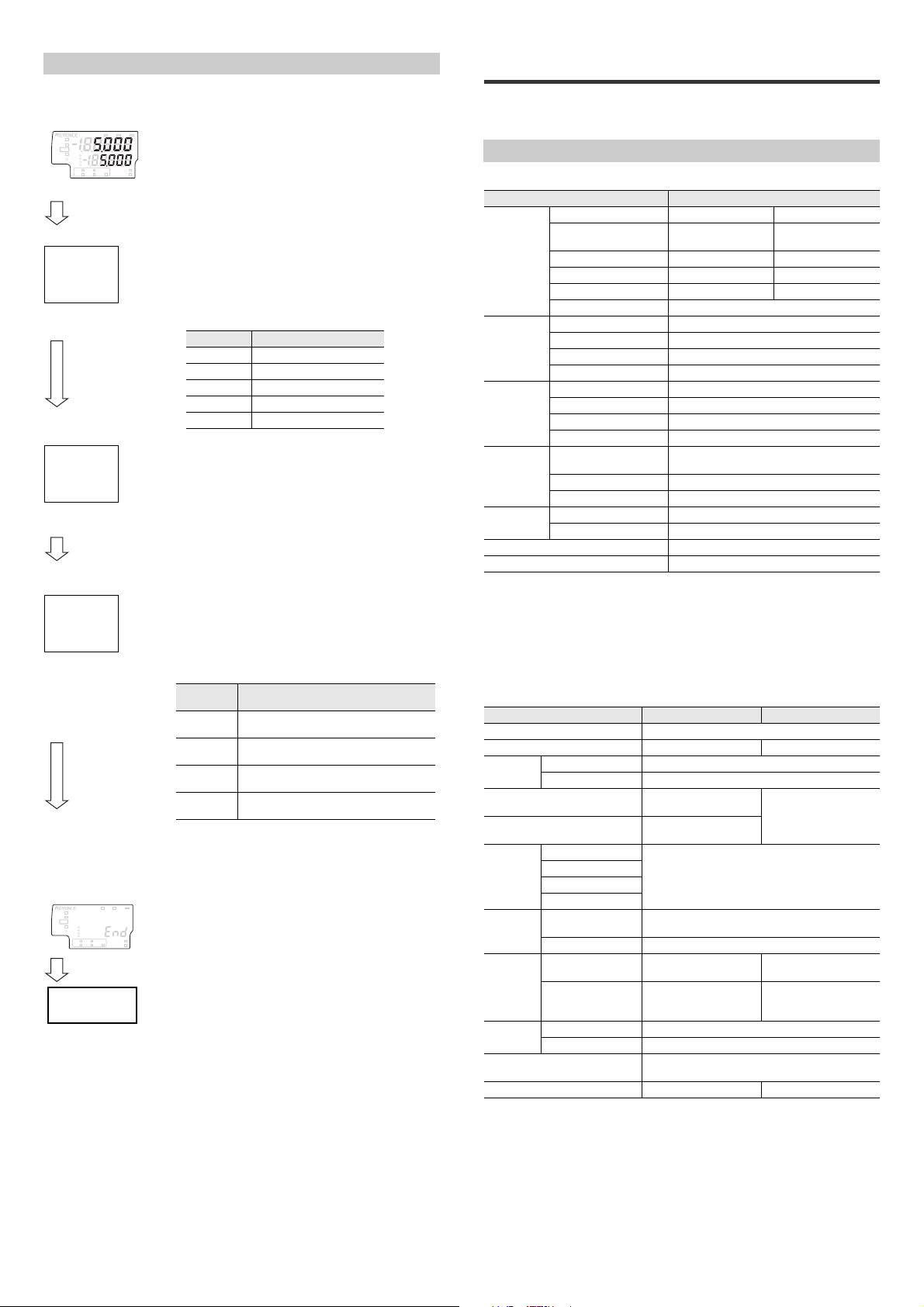

Power ON

PRP

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

QWV

GO

HOLD CALC

CHECK

Output polarity

Setting value

Description

npn

NPN output

pnp

PNP output

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Analog output

Setting value

Description

off

Not output

0-5u

Analog output after the judgment value (P.V.) is

converted to the range from 0 to 5 V.

-5-5u

Analog output after the judgment value (P.V.) is

converted to the range from -5 to 5 V.

1-5u

Analog output after the judgment value (P.V.) is

converted to the range from 1 to 5 V.

aMpr

Analog output after the judgment value (P.V.) is

converted to the range from 4 to 20 mA.

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

R.V.

[

R.V.

]

ON

[HI]

ON

HI side setting value

LO side setting value

[LO]

ON

TEMP][%RH]

ON

[

TEMP

]

ON

Temperature

Temperature/Humidity

Humidity

[%RH]

ON

(1) Temperature/humidity display screen (6) R.V. display screen

(2) Temperature display screen (5) LO side setting value screen

(3) Humidity display screen (4) HI side setting value screen

Operations on the Main Screens

This chapter describes basic operations and settings for the SK Series.

Operation When the Power is Turned on for the First Time

When the amplifier is turned on for the first time after the sensor head is

connected, the initial setting screen appears after a few seconds. Adjust the initial

settings according to the following procedure.

The initial setting is necessary for both the main unit and the expansion units when

they are added.

Once the initial setting is completed, the initial setting display will

not appear when the power is turned on the second time or

thereafter.

To change these settings, perform an initial reset.

"Initial Reset (Initialize)" (page 8)

1 Press S / T button to select the polarity of

judgment output and alarm output, and then

press [MODE] button.

[MODE] button

2 Press S / T button to select the type of

analog output and press [MODE] button.

(For SK-1000 only)

R.V. (Internal Measurement Value) and P.V. (Judgment Value)

This section describes R.V. (Internal Measurement Value) displayed on the sub

display (lower level) and P.V. (Judgment Value) displayed on the main display

(upper level).

R.V. (Internal Measurement Value)

R.V. (Internal Measurement Value) is the value displayed when a target is inserted

into the measurement range. Only the charge potential can be displayed.

* R.V. = Raw Value

P.V. (Judgment Value)

P.V. (Judgment Value) is the value to set the judgment output to ON/OFF

according to the tolerance setting value. Also, the analog output is output based

on the P.V.. Only the charge potential can be displayed.

* P.V. = Present Value

"Changing the Tolerance Values" (page 9)

The Judgment value (P.V.) and the Internal Measurement Value (R.V.) are typically

the same value. However, when the hold function, step-count filter, or the calculation

function is used, they will become different values.

"6. Hold Function" (page 12)

* The R.V. and P.V. cannot be displayed for the temperature and humidity.

Main Display (Upper Level)

The judgment value (P.V.) is shown on the main display.

The display varies according to the functions used such as Normal, Hold function,

and the Calculation function.

ALARM

kV

V

HOLD

HI

GO

LO

0

BANK

1

2

3

TEMP %RH

HI LO R.V.

[HOLD] ON

HOLD

HI

GO

LO

0

BANK

1

2

3

TEMP %RH

HI LO R.V.

Normal

The same value as the internal measurement value (R.V.) is

displayed as a judgment value (P.V.).

ZERO SHIFT

TIMING

When the hold function is used

ALARM

kV

V

The judgment value (P.V.) is held according to the hold

function settings.

ZERO SHIFT

"6. Hold Function" (page 12)

TIMING

Sub Display (Lower Level)

[MODE] button

3 After the setting is complete, [end] blinks

several times on the sub display and the main

screen appears.

4 Change other settings as necessary.

The sub display can be switched with the arrow buttons W / X Depending on the

type of displayed value, the sub display indicator [R.V. / TEMP / %RH / HI / LO]

lights up.

(1) Temperature/humidity display screen

The temperature and humidity detected by the sensor head are displayed.

(2) Temperature display screen

The temperature detected by the sensor head is displayed.

(3) Humidity display screen

The humidity detected by the sensor head is displayed.

(4) HI side setting value screen

The upper limit of the acceptable range (tolerance setting value) for the target

is displayed. This setting value can be changed. If the judgment value (P.V.)

exceeds the value set here, the HI judgment output turns on.

"Changing the Tolerance Values" (page 9)

7

E SK-1000 IM

Page 8

(5) LO side setting value screen

HOLD

HI

V

kV

ALARM

BANK

SET MODE

SELECT

ZERO SHIFT

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

SK-1000

Buttons used

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

PRP

LASER

BANK

0

1

2

3

HI

LO

R.V.

ANALOG

HI SHIFT

ZERO SHIFT

TIMING

LO

ALIGNMENT

QWV

GO

HOLD CALC

CHECK

Output polarity

Setting value

Description

npn

NPN output

pnp

PNP output

Setting value

Description

off

Not output

0-5u

Analog output after the judgment value (P.V.) is

converted to the range from 0 to 5 V.

-5-5u

Analog output after the judgment value (P.V.) is

converted to the range from -5 to 5 V.

1-5u

Analog output after the judgment value (P.V.) is

converted to the range from 1 to 5 V.

aMpr

Analog output after the judgment value (P.V.) is

converted to the range from 4 to 20 mA.

The lower limit of the acceptable range (tolerance setting value) for the target

is displayed. This setting value can be changed. If the judgment value (P.V.)

falls below the value set here, the LO judgment output turns on.

"Changing the Tolerance Values" (page 9)

(6) R.V. display screen

The internal measurement value (R.V.) is displayed. The displayed value is not

held even if a hold function is enabled.

Setting Operations

This section explains the functions of the main screen and the functions of each

setting screen.

Functions Operable on the Main Screen

Main screen

Press W or X button.

Switching the sub display (lower level; page

7)

The internal measurement value (R.V.), HI

side setting value, LO side setting value,

temperature and humidity, temperature, or

humidity is displayed, and the settings can

be changed.

"Changing the Tolerance Values" (page 9)

Set the HI side tolerance setting value and

the LO side tolerance setting value. The value

is judged as HI, GO, or LO and is displayed

and output.

While pressing down [MODE], press S or T button.

"Bank Function (Registering Multiple

Tolerance Setting Values)" (page 9)

The HI side setting value, LO side setting

value, and shift target value can be saved in

up to four different banks, and the bank can

be switched.

Press [MODE] and S buttons for approx. 2 seconds.

or

Press [MODE] and S buttons for approx. 2 seconds.

"Key Lock Function" (page 10)

This function prevents unwanted button

operations during measurement.

Available Functions from the Main Screen

Main screen

Press [MODE] button for approx. 2 seconds.

"Basic Settings and Advanced Settings"

(page 10)

Basic settings

Configure basic settings such as the

measurement mode and the averaging rate.

Advanced settings

Configure more advanced settings such as

the hold function and the timing input in order

to use the unit in a wider range of

applications.

While pressing the [MODE] button, press the

[SET] button 5 times.

"Initial Reset (Initialize)" (page 8)

All settings, excluding the calibration

function, are initialized.

[While pressing the [MODE] button, press the

W button 5 times.

"Simulation Mode" (page 17)

You can use this function to check that the I/O

E SK-1000 IM

wires for control have been wired correctly.

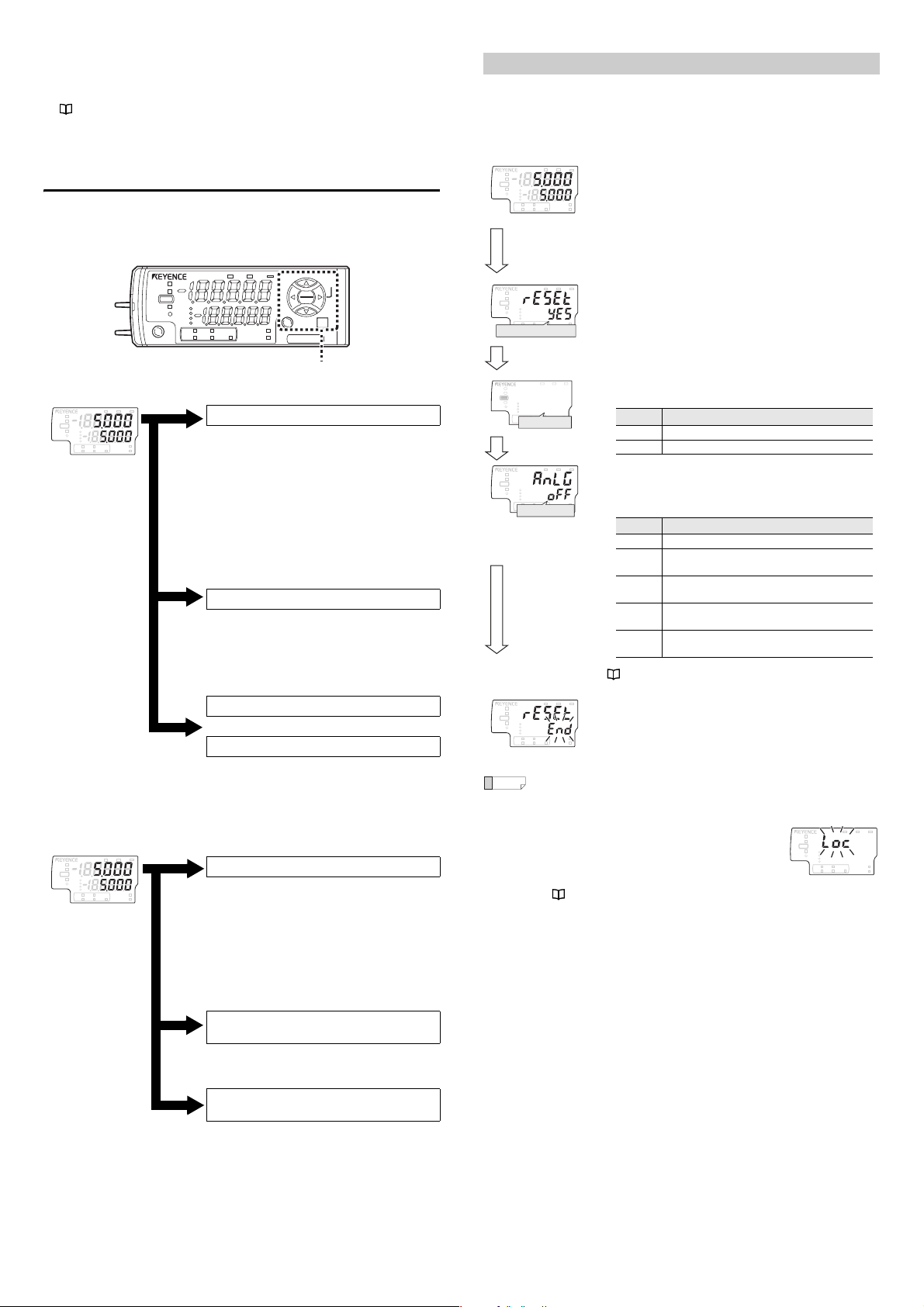

Initial Reset (Initialize)

When an initial reset is performed, all settings, excluding the calibration function,

are initialized.

The judgment output's polarity and analog output setting can also be changed

through the same operation.

Main screen

ALARM

kV

V

HOLD

HI

GO

LO

0

BANK

1

2

3

ZERO SHIFT

TEMP %RH

HI LO R.V.

While pressing

the [MODE]

button, press the

[SET] button 5

times.

kV

V

HOLD

HI

GO

LO

0

BANK

1

2

3

ZERO SHIFT

TEMP %RH

HI LO R.V.

Performing the initial reset

[MODE] button

TIMING

TIMING

1 While pressing the [MODE] button on the

main screen, press the [SET] button 5 times.

[reset] is displayed on the main display (upper

level).

ALARM

2 Press S / T button to select [yes] and press

the [MODE] button.

If [no] is selected at this point, only the output

polarity and analog output settings can be changed

without performing the initial reset.

3 Press S / T button to select the output

polarity and press the [MODE] button.

[MODE] button

ALARM

kV

V

HOLD

HI

GO

LO

0

BANK

1

2

3

ZERO SHIFT

TEMP %RH

TIMING

HI LO R.V.

Analog output

[MODE]button

kV

V

HOLD

HI

GO

LO

0

BANK

1

2

3

ZERO SHIFT

TEMP %RH

TIMING

HI LO R.V.

• When buttons other than the S/T button and [MODE] button are

Reference

pressed during the initial reset procedure, the initial reset is

canceled and the screen in step 2 is restored.

• When you attempt to initialize the unit while

the key lock function is set, the screen shown

on the right appears and the initialization fails.

Cancel the key lock before attempting to

initialize the unit.

8

4 Press S / T button to select the analog

output and press the [MODE] button.

(For SK-1000 only)

"9. Analog output scaling" (page 14)

ALARM

5 After the initialization is complete, [end] blinks

several times on the sub display and the main

screen is restored.

"Key Lock Function" (page 10)

HOLD

HI

GO

LO

BANK

0

1

2

3

TEMP %RH

HI LO R.V.

ALARM

kV

V

ZERO SHIFT

TIMING

Page 9

Changing the Tolerance Values

Reference

Reference

Judgment indicator

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

[LO]

ON

HI side setting value

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

The tolerance values consist of the upper limit value (HI side setting value) and the

lower limit value (LO side setting value). By setting these values, judgments are

made in three levels: when the judgment value (P.V.) goes beyond the upper limit (HI

judgment), when the judgment goes beyond the lower limit (LO judgment) and

when the judgment is within the acceptable range (GO judgment). Subsequently,

the corresponding indicator and judgment output will be turned ON/OFF.

Judgme nt

Judgment output

HI GO LO HI GO LO

*1

Judgment indicator

HI ON OFF OFF Red OFF OFF

GO OFF ON OFF OFF Green OFF

LO OFF OFF ON OFF OFF Red

*3

Error

ON OFF ON Red OFF Red

*2

*1 When the state of judgment output is Normally Open (default value) ON/OFF

is reversed when the state is Normally Closed.

*2 "3. Output state" (page 11)

*3 "Error Displays and Corrective Actions" (page 20)

HOLD

HI

GO

LO

ZERO SHIFT

0

BANK

1

2

3

TEMP %RH

HI LO R.V.

V

ZERO SHIFT

TIMING

SELECT

SET MODE

SK-1000

kV

ALARM

When the setting "HI side setting value < LO side setting value" is

chosen, the judgment output is as follows.

• GO judgment output is not output regardless of the judgment value

(P.V.). (When "HI side setting value = LO side setting value =

judgment value (P.V.)" and hysteresis = 0.000, the GO judgment

output is turned on.)

• When the judgment value (P.V.) simultaneously exceeds the HI side

setting value and falls below the LO side setting value, the HI

judgment output and LO judgment output are output at the same

time.

Setting the tolerance

Zero Shift Function (Shifting the Internal Measurement Value (R.V.))

The internal measurement value (R.V.) is shifted (offset) to zero. The judgment

value (P.V.) is shifted (offset) as well.

The following two methods can be used.

• Press the [ZERO SHIFT] button (<1 second).

• Set the external input (zero shift input) to ON for 20 ms or more.*

* When the zero shift input is set for the external input 1 (pink wire), the zero shift

is enabled when the input is triggered.

"10. External input" (page 15)

Enabling the Zero Shift

When the following operation is performed on the main screen, the zero shift

indicator [ZERO SHIFT] lights up for approx. 0.5 second and the current internal

measurement value (R.V.) shifts to zero.

• Press the zero shift button [ZERO SHIFT] (<1 second).

• Turn ON the zero shift input of external input for 20 ms or more.

Point

• If the power is turned OFF after a zero shift is performed by

external input, the previous state before the zero shift function is

restored. If you wish to keep the shifted state of the internal

measurement value (R.V.) even after the power is turned OFF, set

the zero shift value memory function to ON.

"12. Zero shift value memory function" (page 16)

• When the internal measurement value (R.V.) is [-----], [FFFF], or

[-FFFF] - that is, when the value is too large (a value outside of

±500 V in near mode and a value outside of ±12.5 kV in far mode)

- the zero shift function cannot be used.

ALARM

kV

BANK

TEMP %RH

0

1

2

3

HI LO R.V.

V

ZERO SHIFT

TIMING

HOLD

HI

GO

LO

When the zero shift is performed by pressing the zero shift button, the

Reference

shifted state of the internal measurement value (R.V.) is preserved

even after the power is turned off.

This is the method to directly enter the tolerance setting value (HI side setting

value, LO side setting value).

1 Press the W / X button several times on the main screen. Then

display the HI side setting value on the sub display (lower level).

"Sub Display (Lower Level)" (page 7)

2 Press S / T button to set the HI side setting value.

Item Setting range Default value

HI side setting value -99.999 to 99.999 1.000

3

Press the X button once and display the LO side setting value on the

sub

display (lower level).

ALARM

kV

BANK

[LO]

ON

0

1

2

3

TEMP %RH

HI LO R.V.

V

ZERO SHIFT

TIMING

HOLD

LO side setting value

HI

GO

LO

4 Press S / T button to set the LO side setting value.

Item Setting range Default value

LO side setting value -99.999 to 99.999 -1.000

After setting, press W / X button to return the sub display to the original

display as necessary.

Canceling the Zero Shift (Reset)

When the following operation is performed on the main screen, the zero shift is

canceled and the internal measurement value (R.V.) returns to the previous state

(initial state) before the zero shift function is used.

• Press the zero shift button [ZERO SHIFT] for 2 seconds or more.

The following screen appears after operation.

Bank Function (Registering Multiple Tolerance Setting Values)

Using the bank function, you can register up to four patterns of specified tolerance

settings.

By using the bank function, multiple setting items registered beforehand can be

switched easily.

Settings Registered with each Bank

Settings Reference page

HI side setting value

LO side setting value

"Changing the Tolerance Values" (page 9)

As soon as the HI side setting value and the LO side setting value are

entered, the judgment and output begin with the new setting value.

9

E SK-1000 IM

Page 10

How to Switch Banks

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Lock set

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Lock canceled

1. rnG

2. AvE

3. out

4. dst

5. HLd

6. HLd

7. tiM

8. HYS

9. AnG

10. in

11. bnK

12. SFt

13. dSP

Banks can be switched by either of the methods below.

• Front panel commands on the amplifier.

• Use the external inputs (Bank A input, Bank B input)*

* If the bank switching method is set to external input, and bank A input or bank

B input is set for the external input, banks can be switched with the external

input.

"10. External input" (page 15)

"11. Bank switching method" (page 16)

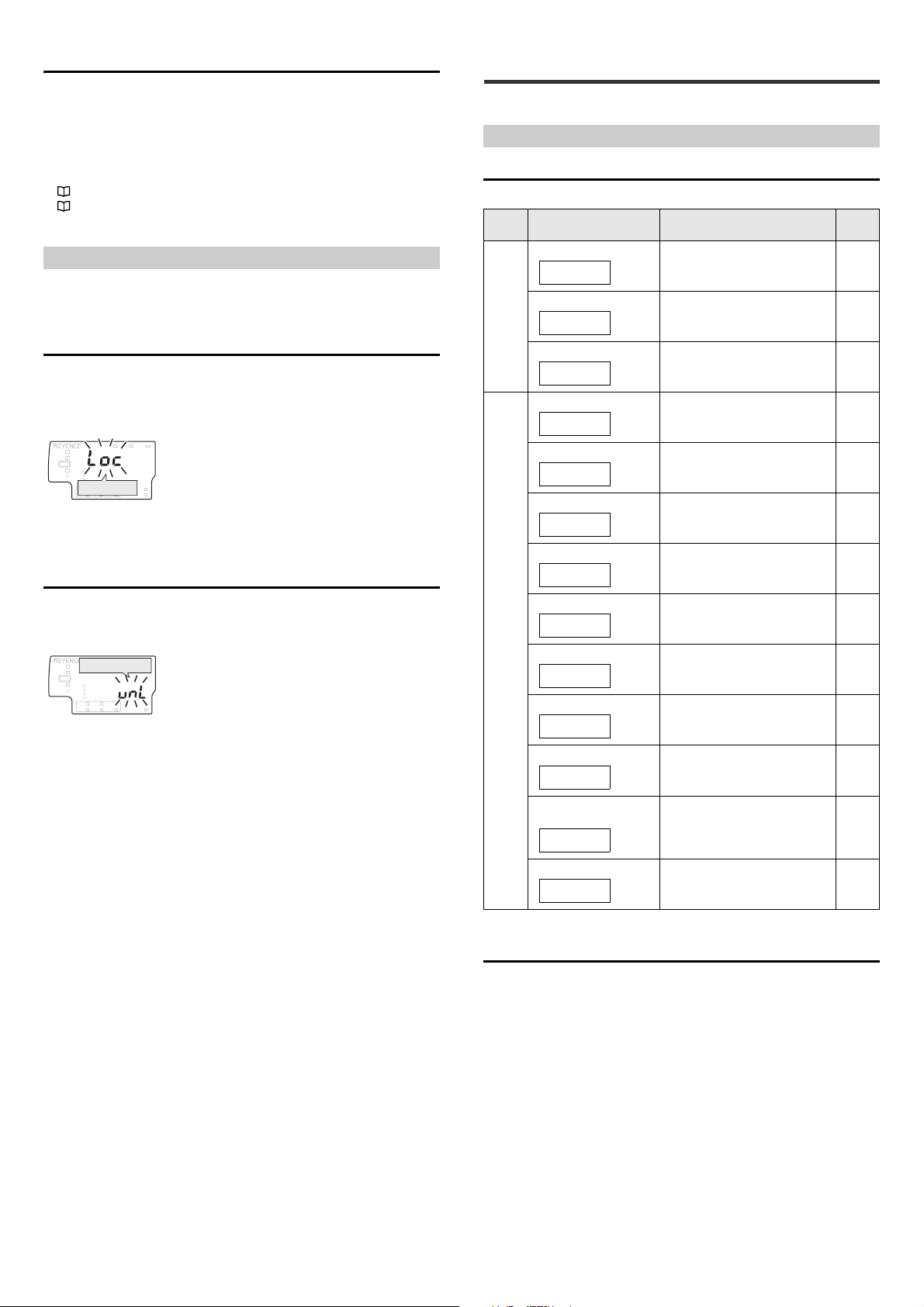

Key Lock Function

The key lock function prevents unwanted button operations during measurement.

When the key lock function is active, operations other than switching the main

screen and canceling the key lock function are disabled.

Starting the Key Lock

While pressing the [MODE] button on the main screen, press S or T button for 2

seconds or more.

After [Loc] blinks on the main display (upper level) for several seconds, the main

screen is restored.

4. Setting Various Functions

This chapter describes the various functions of the SK Series.

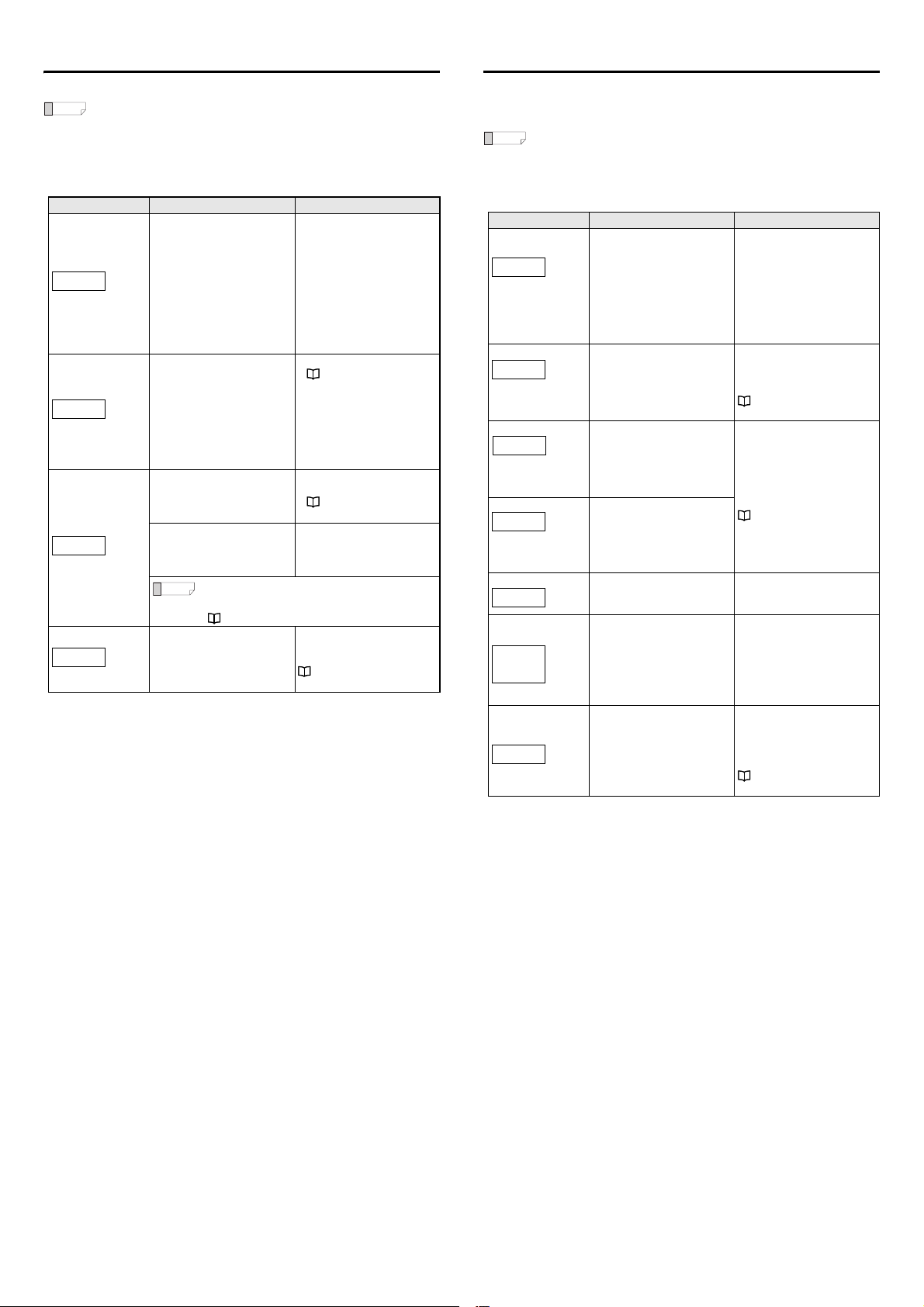

Basic Settings and Advanced Settings

List of Setting Items

The following items can be set.

Typ e Setting item Description

Basic

settings

1.Measurement range

2.Averaging rate

3.Output state

4.Distance setting

Set the measurement range. 11

Set the number of samples to average. 11

Select the output state (N.O./N.C.) of the

judgment output to turn ON/OFF

according to the judgment value.

Set the distance correction. 11

Reference

page

11

If buttons other than display switching button on the sub display (lower level) are

operated in the key-locked state, [Loc] is displayed on the main display (upper

level) and setting change operation is ignored.

Canceling the Key Lock (Unlock)

While pressing the [MODE] button, press S or T button for 2 seconds or more.

After [

unL] blinks on the sub display (lower level) for several seconds, the main

screen is restored.

5. Area scaling

6. Hold function

7.Timing input

8.Hysteresis

Advanced

9.Analog output scaling

settings

10.External input

11.Bank switching method

12.Zero shift value memory

function

13. Display digit

Set the area scaling. 12

Set the method to use in holding the

judgment value (P.V.)

Set the timing input type used for the

hold function.

Set the hysteresis value for the tolerance

setting value.

Set the analog output scaling for the

judgment value (P.V.).

Select the functions of the four external

inputs.

Set the bank switching method. 16

Set whether to store in the nonvolatile

memory (EEPROM) the state of the

display as shifted by the zero shift

function.

Set the number of displayed digits of the

judgment value (P.V.) and the internal

measurement value (R.V.).

12

14

14

14

15

16

16

E SK-1000 IM

Setting Screen

This section describes operations and the setting screen to modify the basic

settings and the detailed setting.

How to go to the setting screen

Press the [MODE] button for approx. 2 seconds on the main screen.

The setting screen appears.

Basic operations on the setting screen

Changing the setting value: S / T button

Go to the next setting item: [MODE] button or X button

Return to the previous setting item: W button

Skip the rest of the settings and finish: Press and hold the [MODE] button for

approx. 2 seconds.

Setting screen view

The setting item is displayed on the main display (upper level) and the setting

value is displayed on the sub display (lower level).

10

Page 11

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Basic setting

Main screen

1.Measurement

range

2.Averaging

rate

[MODE]

Press for 2

seconds.

[MODE]

or X

[MODE]

or X

[MODE]

or X

Select the advanced

settings

Return to the

main screen.

To the 4. Distance

setting screen

(page 11) (page 11)

Basic setting

complete

3.Output state

[MODE]

or X

(page 11)

S or T

[MODE]

or X

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Advanced settings

4.Distance

setting

[MODE]

or X

Advanced setting

complete

[MODE]

or X

5.Area scaling

[MODE]

or X

[MODE]

or X

8.Hysteresis

9.Analog output

scaling

10.External input

11.Bank switching

method

12.Zero shift value

memory function

(page 11) (page 12)

(page 14) (page 14) (page 14)

(page 15) (page 16) (page 16)

From the advanced

settings selection screen

[MODE]

or X

[MODE]

or X

[MODE]

or X

[MODE]

or X

[MODE]

or X

[MODE]

or X

[MODE]

or X

7.Timing input

Return to the

main screen.

13.Display digit

(page 16)

[MODE]

or X

6.Hold function

(page 12)

1. rnG

near

far

ib

2. Ave

3. Output state

NOTICE

3. out

4. dst

defLt

Usr

Usr

4. dst

25

U-dst

[MODE]

or

X

Usr

4. dst

100

U-dst

[MODE]

or

X

Set the output state (N.O./N.C.) of judgment output ON/OFF.

Item Description

Output state no (Normally Open), nC (Normally Closed) no

There are three judgment outputs:

• HI judgment output (Black wire)

• GO judgment output (Gray wire)

• LO judgment output (White wire)

The judgment output is turned ON/OFF according to the tolerance setting value.

"Changing the Tolerance Values" (page 9)

When Normally Open is set

Judgment

HI ON OFF OFF

GO OFF ON OFF

LO OFF OFF ON

*1

Error

"-----"

ON OFF ON

*2

OFF OFF OFF

Judgment output

HI GO LO

When Normally Closed is set

Judgment

HI OFF ON ON

GO ON OFF ON

LO ON ON OFF

*1

Error

"-----"

OFF ON OFF

*2

ON ON ON

Judgment output

HI GO LO

*1 "Error Displays and Corrective Actions" (page 20)

*2 When the judgment value (P.V.) is "-----".

Regardless of the output state setting, the judgment indicator on the sensor

Reference

amplifier only matches the judgment output when Normally Open is set.

Default

value

1. Measurement range

You can switch the measurement mode according to the voltage to be measured.

Switch the measurement mode to match the application.

Measurement range Description

High-precision mode

Wide-range mode

Ion balance mode

2. Averaging rate

Set the averaging of the data acquired at the sampling rate.

z Averaging rate

The average value is the moving average. If the measured values fluctuate, stable

measurements can be obtained by increasing the average count.

Averaging rate 1/2/4/8/16/64/256/1024/4096/16384 64

Item Description

Measurement can be performed in the range of 0 to

±2 kV and the reference distance for measurement

is 25 mm.

Measurement can be performed in the range of 0 to

±50 kV and the reference distance for

measurement is 100 mm.

The ion balance is measured. The measurement

reference distance is 25 mm.

(* An optional ion balance plate is required.)

Default

value

c

Default

value

4. Distance setting

Set the distance correction. When the sensor head cannot be installed at the

reference distance (25 mm for "near" and 100 mm for "far"), you can correct the

measured value by setting the installation distance.

Distance setting Description

Default setting

User setting

The distance will not be corrected. c

The distance will be corrected. Set the installation

distance (the setting range).

If the measurement range is "near:" 5 to 50

If the measurement range is "far:" 60 to 120 (unit:

mm)

Distance setting screen

When set to the default setting, [defLt], the following screens are skipped.

When you set this to the user setting, [Usr], the distance setting screen is displayed.

z User setting, [Usr]

• If the measurement range is [near]

4.Distance setting Distance

Press the S and T buttons to specify the

distance. (Setting range: 5 to 50)

• If the measurement range is [far]

4.Distance setting Distance

Press the S and T buttons to specify the

distance. (Setting range: 60 to 120)

Decreasing the installation distance makes the measurement

range narrower.

11

E SK-1000 IM

Default

value

Page 12

5. Area scaling

5. ScL

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

Press the S/T buttons and specify the correction value.

(Setting range: 0.10 to 1.50)

0

5

10

15

20

25

30

35

40

45

50

-200 -150 -100 -50 0 50 100 150

200

1.0

0.9

0.8

0.7

0.6

1.01.0

0.90.9

0.80.8 0.70.7 0.60.6

Measurement area [mm]

Distance to the target [mm]

60

70

80

90

100

110

120

-450 -350 -250 -150 -50 50 15 0 25 0 350 45 0

1.3

1.2

1.1

1

0.9

0.7

1.31.3

1.2

1.2

1.11.1

0.90.9

0.70.7

11

Measurement area [mm]

Distance to the target [mm]

60

70

80

90

100

110

120

-450 -350 -250 -150 -50 50 15 0 25 0 350 45 0

1.3

1.2

1.1

1

0.9

0.7

1.31.3

1.2

1.2

1.1

1.1

0.90.9

0.70.7

1

1

Measurement area [mm]

Distance to the target [mm]

Correction

value is 1.1.

The measurement area ranging from

-200 mm to +200 mm covers

φ400 mm.

60

70

80

90

100

110

120

-450 -350 -250 -150 -50 50 150 250 35 0 450

1.3

1.2

1.1

1

0.9

0.7

1.3

1.2

1.1

1.3

1.2

1.1

0.9

0.7

1

0.9

0.7

1

Measurement area [mm]

Distance to the target [mm]

The measurement area ranging from

-390 mm to +390 mm covers φ780 mm.

Correction

value is 1.3.

Reference

6. HLd

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

[HOLD] ON

S-H

P-H

b-H

A-H

Auto.P

Auto.b

Auto.A

S-H

Display value

Time

Judgment value (P.V.)

Internal measurement value (R.V.)*

2

Timing Input

ON

OFF

Power ON or

Reset input *

1

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

6. Hold Function

This function configures the settings related to area scaling. The area scaling

function corrects errors in the measured value due to size differences of

measurement targets by setting a correction value according to the size of the

target.

Item Setting range initial value

Area scaling 0.10 to 1.50 1.00

Refer to the correction table shown below to setting the correction value.

z Area scaling correction table

(1) High-precision mode

(2) Wide-range mode

[How to use the correction table and setting example]

Take a wide-range mode as an example for setting a correction value where the

distance to the target is 100 mm and the size of target is φ400 mm.

In this case, use the correction table for the wide-range mode.

The hold method is set for the judgment value (P.V.).

Functions other than "Auto peak hold", "Auto bottom hold" and "Auto absolute

value hold" require the use of the external input (timing input).

While the judgment value (P.V.) is held, the hold indicator on the sensor

amplifier lights up.

Hold function Description

Sample hold

Peak hold

Bottom hold

Absolute value hold

Auto peak hold

Auto bottom hold

When the timing input is turned ON, the judgment

value (P.V.) is held.

"Sample hold" (page 12)

The maximum value of the specified period

(sampling period) is held as the j udgment value

(P.V.).

"Peak hold" (page 13)

The minimum value of the specified period

(sampling period) is held as the j udgment value

(P.V.).

"Bottom hold" (page 13)

Within the specified period (sampling period), the

absolute value of the maximum measured value is

held as the judgment value (P.V.).

"Absolute value hold" (page 13)

Until the hold-reset input is turned ON, the

maximum value is held as the judgment value (P.V.).

External input is not necessar y.

"Auto peak hold" (page 13)

Until the hold-reset input is turned ON, the minimum

value is held as the judgment value (P.V.).

External input is not necessar y.

"Auto bottom hold" (page 13)

Until the hold-reset input is turned ON, the absolute

Auto absolute value hold

value of the maximum measured value is held as

the judgment value (P.V.).

External input is not necessar y.

"Auto absolute value hold" (page 14)

Default

Sample hold

When the timing input is turned ON, the judgment value (P.V.) is held.

value

c

The 100 mm on the vertical axis and 200 mm and -200 mm on the horizontal axis

make two intersecting points, crossing the lines marked with the S symbol, which

indicate a correction value of 1.1. So, input 1.1 into the amplifier unit.

• When the measurement target is larger than the outermost lines

of the correction table:

Example: In wide-range mode, with a distance of 100 mm to the

target, and a target size of φ780 mm, if the target is larger than the

outermost lines indicating the correction value of 1.3, set the

correction value to 1.3.

NOTICE

E SK-1000 IM

The same is true when using high-precision mode. If the target is

larger than the outermost lines indicating a correction value of

1.0, set the correction value to 1.0.

z When "Level" is set for "7. Timing input" (page 14)

The judgment value (P.V.) is held only while the timing input is ON.

Display value

Timing Input

OFF

ON

Judgment value (P.V.)

Internal measurement value (R.V.)*

Time

1

z When "Edge" is set for "7. Timing input" (page 14)

The judgment value (P.V.) is held in between rising edges of the timing input.

12

Page 13

Peak hold

P-H

Display value

Time

Timing Input

Sampling period Sampling periodSampling period

ON

OFF

Power ON or

Reset input *

1

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

Judgment value (P.V.)

Internal measurement value (R.V.)*

2

b-H

Display value

Time

Timing Input

Sampling period Sampling periodSampling period

ON

OFF

Power ON or

Reset input *

1

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

Judgment value (P.V.)

Internal measurement value (R.V.)*

2

Display value

Time

Timing Input

Sampling period Sampling period Sampling period

ON

OFF

Power ON or

Reset input *

1

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

Judgment value (P.V.)

Internal measurement value (R.V.)*

2

A-H

Absolute value-hold value

Display value

Time

Timing Input

ON

0

OFF

Power ON or

Reset input

Sampling period Sampling period Sampling period

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

Measurement value

Auto.P

Auto peak hold value

Display value

Time

Timing Input

ON

OFF

Reset input

ON

OFF

Measurement value

Auto.b

Auto bottom hold value

Display value

Time

Timing Input

ON

OFF

Reset input

ON

OFF

Measurement value

The maximum value of the specified period (sampling period) is held as a

judgment value (P.V.).

z When "Level" is set for "7. Timing input" (page 14)

When the timing input is turned ON, the maximum value of the internal

measurement value (R.V.) during the sampling period is held as the judgment

value (P.V.). When the timing input is turned OFF, the next sampling period begins.

Display value

Judgment value (P.V.)

Internal measurement value (R.V.)*

2

Absolute value hold

Within the specified period (sampling period), the absolute value of the maximum

value of the measured value is held as the judgment value (P.V.).

z When "Level" is set for "7. Timing input" (page 14)

When the timing input is turned ON, the maximum absolute value of the internal

measurement value (R.V.) during the sampling period is held as the judgment

value (P.V.). When the timing input is turned OFF, the next sampling period begins.

Time

Timing Input

Power ON or

Reset input *

Sampling period Sampling periodSampling period

ON

OFF

1

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

z When "Edge" is set for "7. Timing input" (page 14)

When the timing input is turned ON, the maximum value of the internal

measurement value (R.V.) during the sampling period is held as the judgment

value (P.V.). Also, when the timing input is turned ON, the next sampling period

begins.

Bottom hold

The minimum value of the specified period (sampling period) is held as a

judgment value (P.V.).

z When "Level" is set for "7. Timing input" (page 14)

When the timing input is turned ON, the minimum value of the internal

measurement value (R.V.) during the sampling period is held as the judgment

value (P.V.). When the timing input is turned OFF, the next sampling period begins.

z When "Edge" is set for "7. Timing input" (page 14)

When the timing input is turned ON, the maximum absolute value of the internal

measurement value (R.V.) during the sampling period is held as the judgment

value (P.V.). Also, when the timing input is turned ON, the next sampling period

begins.

Timing Input

Power ON or

Reset input

Display value

ON

OFF

Measurement value

Absolute value-hold value

Sampling period Sampling period

After the power is turned on or reset is input, the judgment value (P.V.) is

[- - - - -] until the timing input is first turned ON.

Sampling period

Time

Auto peak hold

Until the reset input is turned ON, the maximum value is held as the judgment

value (P.V.). External input is not necessary.

z When "Edge" is set for "7. Timing input" (page 14)

When the timing input is turned ON, the minimum value of the internal

measurement value (R.V.) during the sampling period is held as the judgment

value (P.V.). Also, when the timing input is turned ON, the next sampling period

begins.

Auto bottom hold

Until the reset input is turned ON, the minimum value is held as the judgment

value (P.V.). External input is not necessary.

13

E SK-1000 IM

Page 14

Auto absolute value hold

Reference

Reference

Auto.A

7. tiM

8. HYS

Time

Hysteresis

Hysteresis

Judgment value (P.V.)

HI side setting value

LO side setting value

ON

OFF

ON

OFF

ON

OFF

HI judgment output

GO judgment output

LO judgment output

9. AnG

dEFLt

Free

(V)

5

1

Lower limit Upper limit

Judgment

value

(P.V.)

Output upper

limit

Output lower

limit

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

9.Analog Output

Scaling

Upper-limit setting

screen

Lower-limit setting

screen

[MODE]

or X

10.External Input

[MODE]

or X

[MODE]

or X

Until the hold-reset input is turned ON, the maximum absolute value of the

measured value is held as the judgment value (P.V.). External input is not

necessary.

Display value

b

a

0

a

c

b

Auto-absolute value-hold value

c

Measurement value

Time

z Relation of voltage and analog output in default state (dEFLt)

Measurement range Upper limit Lower limit

NEAR 5.000 -5.000

FAR 50. 000 -50.000

The upper and lower limits for the different selections of analog outputs are as

follows.

Analog setting Output upper limit Output lower limit

OFF Not output

0-5v 5 V 0 V

-5-5v 5 V -5 V

1-5v 5 V 1 V

AMPr 20 mA 4 mA

Timing Input

Reset input

OFF

OFF

ON

ON

7. Timing input

Set the external input (timing input) operation used for "6. Hold Function" (page

12).

If "Auto peak hold," "Auto bottom hold," or "Auto absolute value hold" is set, this

item is skipped.

Item Description

Timing input LeveL (Level), edGe (Edge) LEvEL

Default

value

For details, refer to the "6. Hold Function" (page 12).

8. Hysteresis

Set the hysteresis for the tolerance setting value.

If the judgment value (P.V.) fluctuates close to the tolerance setting value, causing

the judgment output to repeatedly turn ON and OFF, increase the hysteresis value

to stabilize the judgment output.

Item Description

Default

value

Hysteresis 0.000 to 99.999 0.100

Above is the timing chart for when the judgment output state is

Normally Open (default value). ON/OFF is reversed for Normally Close.

9. Analog output scaling

The analog output scaling for the judgment value (P.V.) is set.

If the analog output is set to no output, this screen is skipped.

"Operation When the Power is Turned on for the First Time" (page 7)

"Initial Reset (Initialize)" (page 8)

Analog output scaling Description

Default setting

Scaling is not performed. c

Default

value

Upper limit setting screen and lower limit setting screen

When set to the default state [dEFLt], the following screens will be skipped.

When set to free range, the upper limit setting and lower limit setting screens will

appear.

z For free range (FrEE)

Press S / T button on each setting screen to specify the upper limit and the lower

limit.

z Setting range for analog output scaling

If free range is selected for the analog output scaling state, the upper limit and

lower limit can be set within the range shown below.

Measurement range Description Default value

Upper limit -99.999 to 99.999 10.000

Lower limit -99.999 to 99.999 -10 .000

Analog Output Accuracy

The analog output can be selected from ± 5 V, 1 to 5 V, 0 to 5 V or 4 to 20 mA.

Voltage output Current output

Output range

± 5 V

(Full scale 10 V)

Output resistance 100 Ω -

Maximum load resistance - 350 Ω

Repeatability ± 1 mV ± 1.5 μA

Accuracy in respect to display ± 0.05% of F.S. ± 0.25% of F.S.

Temperature characteristics ± 0.005% of F.S./°C ± 0.01% of F.S./°C

Refresh rate

*1

Same as sensor head sampling rate

*1 The averaging is as follows for averaging greater than 1024 times:

1024 times: Sampling rate x 4

2048 times: Sampling rate x 8

4096 times: Sampling rate x 16

4 to 20 mA

(Full scale 16 mA)

Free range

Example 1: Lower limit < Upper limit

(Analog output 1 to 5 V)

(V)

Output upper

limit

Output lower

limit

E SK-1000 IM

5

1

If Upper limit = Lower limit is set, the analog output is as follows:

Judgment value (P.V.) < Upper limit: Analog output lower limit (1V in

the case of 1V to 5V output range)

Judgment value (P.V.) > Upper limit: Analog output upper limit (5V in

the case of 1V to 5V output range)

Lower limit Upper limit

Scaling is performed. The analog output range can

be changed by specifying the upper limit and lower

limit of the judgment value (P.V.).

Example 2: Lower limit > Upper limit

(Analog output 1 to 5 V)

Judgment

value

(P.V.)

14

Page 15

10. External input

Reference

10. in

dEFLt

Usr

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

HOLD

HI

V

kV

ALARM

BANK

ZERO SHIFT

TIMING

TEMP %RH

HI LO R.V.

0

1

2

3

LO

GO

10.External Input External input 1

setting screen

External input 2

setting screen

External input 3

setting screen

External input 4

setting screen

11.Bank switching

method

[MODE]

or X

[MODE]

or X

[MODE]

or X

[MODE]

or X

[MODE]

or X

Internal measurement

value (R.V.)

Max. 20 ms

Min. 20 msMin. 20 ms

R.V. before shift R.V. after shift

ON

OFF

Zero shift input

Judgment value

(P.V.) judgment

output

T1

Min. 20 ms

Min. 20 ms

Before resetting [-----]

ON

OFF

Reset input

Max. 2 msMax. 2 ms

Min. 2 msMin. 2 ms

ON

OFF

Max. 2 ms

Sampling does not start Sampling period Sampling starts

Previous result

Judgment value

(P.V.) judgment

output

Timing Input

Judgment value

(P.V.) judgment

output

Max. 2 msMax. 2 ms

Min. 2 msMin. 2 ms

ON

OFF

Timing Input

Sampling period 1

Sampling period 1 result Sampling period 2 resultPrevious result

Sampling period 2 Sampling period 3

Judgment value

(P.V.) judgment

output

Max. 8 ms

Max. 20 ms

Max. 20 ms

Min. 20 ms

ON

OFF

Bank A input

ON

OFF

Bank B input

Max. 20 ms

Bank 1 Bank 2 Bank 3Bank 0

In this example, after 8 ms have passed, Bank A

and Bank B are judged as OFF and operation at

Bank 0 may be performed.