JVC MXGB-5, MXGB-6 Service manual

SERVICE MANUAL

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.MB160

2004/5

COMPACT COMPONENT SYSTEM

MB16020045

MX-GB6, MX-GB5

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

SP-MXGB6 SP-MXGB6

SP-MXGB5 SP-MXGB5

CA-MXGB6

CA-MXGB5

J ----------------------------- U.S.A.

C -------------------------- Canada

Area suffix

1-2 (No.MB160)

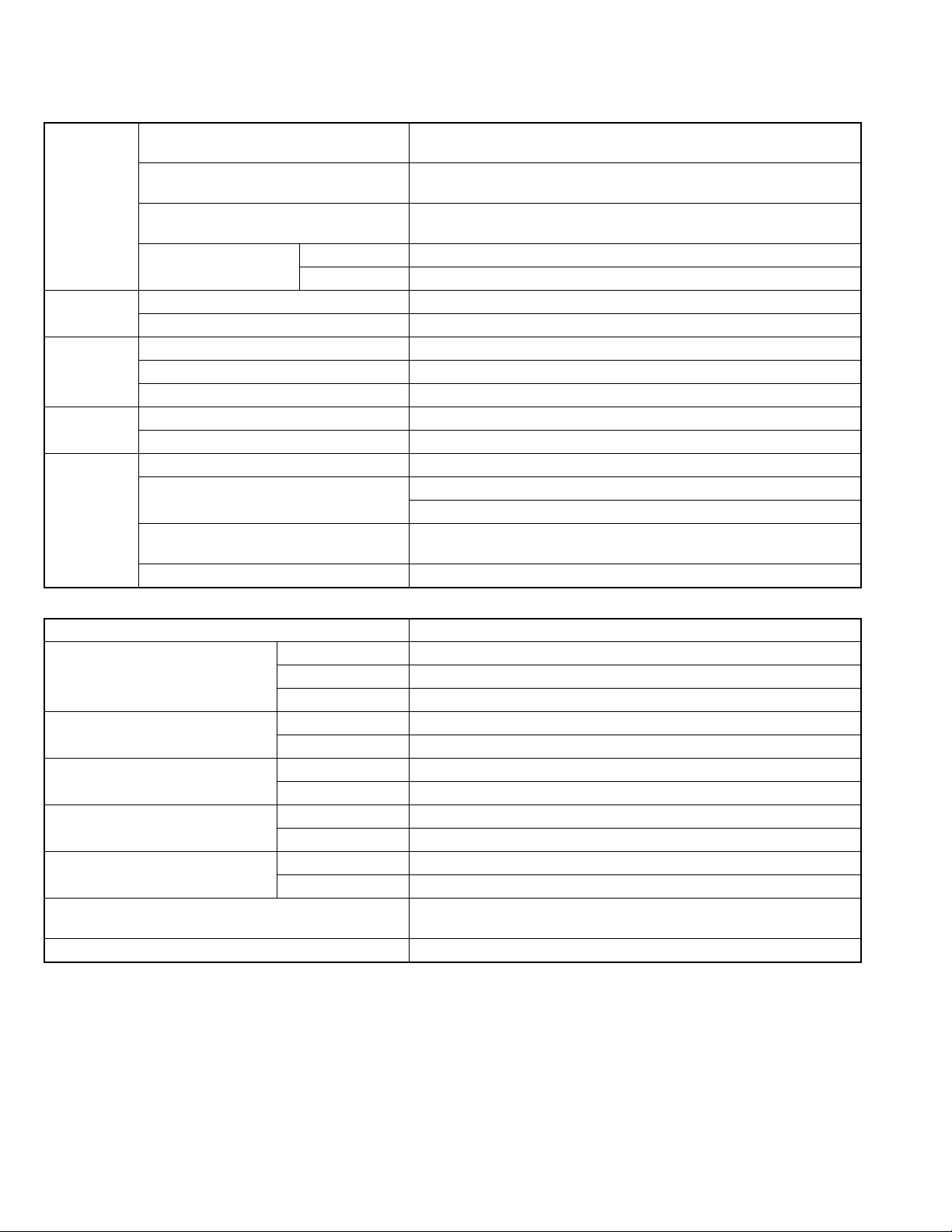

SPECIFICATION

Amplifier section-CA-MXGB6

Speaker section-SP-MXGB6

Design and specifications are subject to change without notice.

Output Power SUBWOOFERS 170 W per channel, min. RMS, driven into 6 Ω at 63 Hz with no more than

10% total harmonic distortion.

MAIN SPEAKERS 80 W per channel, min. RMS, driven into 4 Ω at 1 kHz with no more than

10% total harmonic distortion.

Audio input sensitivity/Impedance

(at 1 kHz, measured at MAIN SPEAKERS)

AUX:400 mV/50 kΩ

Speakers/Impedance Subwoofers 6 Ω - 16 Ω

Main speakers 4 Ω - 8 Ω

Tuner FM tuning range 87.50 MHz - 108.00 MHz

AM tuning range 530 kHz - 1 710 kHz

CD player CD Capacity 3 CDs

Dynamic range 85 dB

Signal-to-noise ratio 85 dB

Cassette deck Frequency response Normal (type I) 50 Hz - 14 000 Hz

Wow and flutter 0.15% (WRMS)

General Power requirement AC 120 V , 60 Hz

Power consumption 230 W (at operation)

23.8 W (on standby)

Dimensions (approx.) 270 mm × 317 mm × 480 mm (W/H/D)

(10 11/16 in. × 12 1/2 in. × 18 15/16 in.)

Mass (approx.) 10.5 kg (23.2 lbs)

Type 3-way bass-reflex type

Speaker units Subwoofer 20 cm (7 7/8 in.) cone × 1

Main Woofer 12 cm (4 3/4 in.) cone × 1

Tweeter 5 cm (2 in.) cone × 1

Power handling capacity Subwoofer 170 W

Main speaker 80 W

Impedance Subwoofer 6 Ω

Main speaker 4 Ω

Frequency range Subwoofer 25 Hz - 100 Hz

Main speaker 100 Hz - 20 000 Hz

Sound pressure level Subwoofer 75 dB/W·m

Main speaker 82 dB/W·m

Dimensions (approx.) 233 mm × 456 mm × 360 mm (W/H/D)

(9 3/16 in. × 18 in. × 14 3/16 in.)

Mass (approx.) 6.6 kg (14.6 lbs) each

(No.MB160)1-3

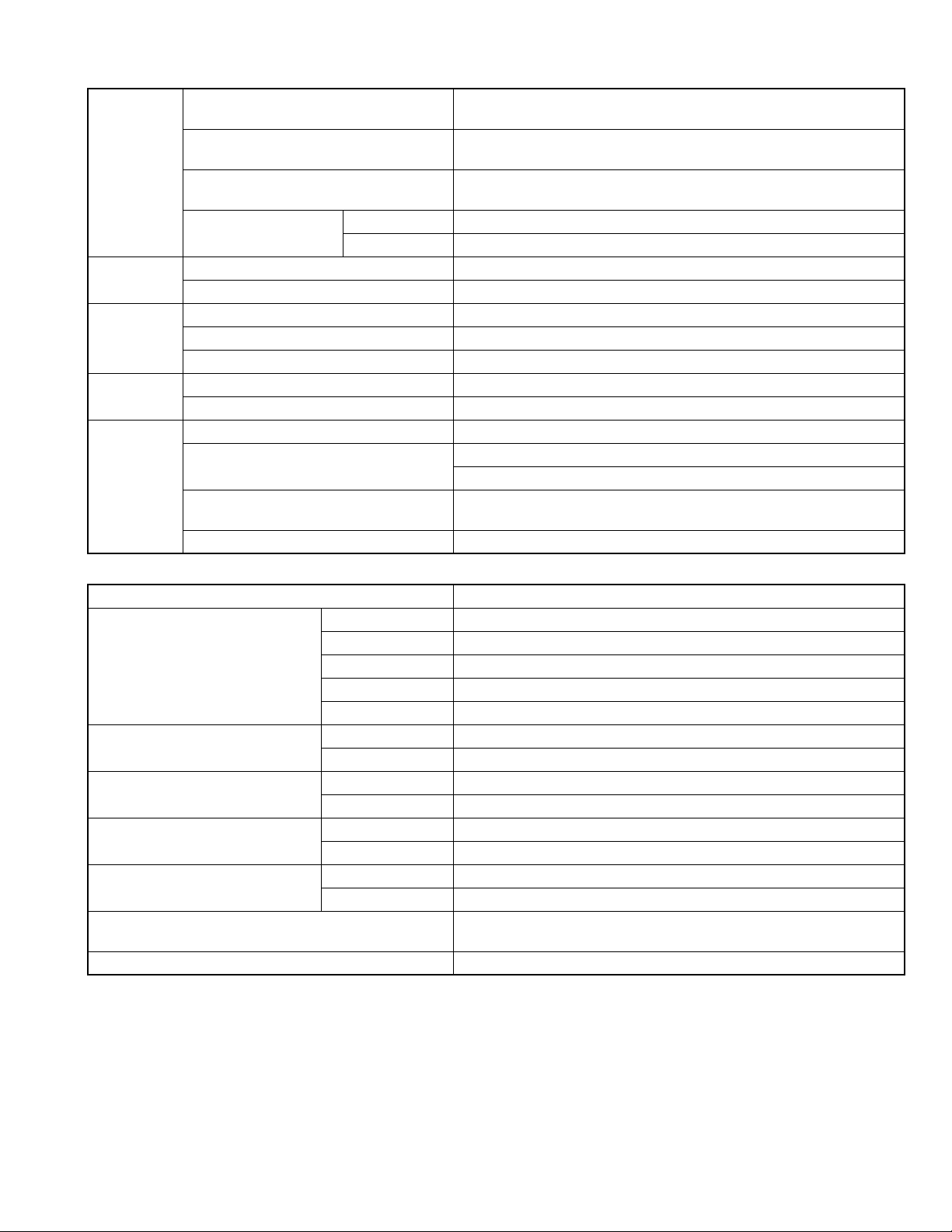

Amplifier section-CA-MXGB5

Speaker section-SP-MXGB5

Design and specifications are subject to change without notice.

Output Power SUBWOOFERS 160 W per channel, min. RMS, driven into 6 Ω at 63 Hz with no more than

10% total harmonic distortion.

MAIN SPEAKERS 70 W per channel, min. RMS, driven into 4 Ω at 1 kHz with no more than

10% total harmonic distortion.

Audio input sensitivity/Impedance

(at 1 kHz, measured at MAIN SPEAKERS)

AUX:400 mV/50 kΩ

Speakers/Impedance Subwoofers 6 Ω - 16 Ω

Main speakers 4 Ω - 8 Ω

Tuner FM tuning range 87.50 MHz - 108.00 MHz

AM tuning range 530 kHz - 1 710 kHz

CD player CD Capacity 3 CDs

Dynamic range 85 dB

Signal-to-noise ratio 85 dB

Cassette deck Frequency response Normal (type I) 50 Hz - 14 000 Hz

Wow and flutter 0.15% (WRMS)

General Power requirement AC 120 V , 60 Hz

Power consumption 220 W (at operation)

23.3 W (on standby)

Dimensions (approx.) 270 mm × 317 mm × 480 mm (W/H/D)

(10 11/16 in. × 12 1/2 in. × 18 15/16 in.)

Mass (approx.) 10 kg (22.1 lbs)

Type 4-way bass-reflex type

Speaker units Subwoofer 16 cm (6 5/16 in.) cone × 1

Main Woofer 16 cm (6 5/16 in.) cone × 1

Tweeter 2 cm (13/16 in.) dome × 1

Midrange 5 cm (2 in.) cone × 1

Tweeter 2 cm (13/16 in.) dome × 1

Power handling capacity Subwoofer 160 W

Main speaker 70 W

Impedance Subwoofer 6 Ω

Main speaker 4 Ω

Frequency range Subwoofer 25 Hz - 90 Hz

Main speaker 90 Hz - 20 000 Hz

Sound pressure level Subwoofer 75 dB/W·m

Main speaker 86 dB/W·m

Dimensions (approx.) 302.5 mm × 325.5 mm × 345 mm (W/H/D)

(11 15/16 in. × 12 7/8 in. × 13 5/8 in.)

Mass (approx.) 6.6 kg (14.6 lbs) each

1-4 (No.MB160)

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purpos-

es. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be per-

formed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteris-

tics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by us-

ing replacement components rated for higher voltage, watt-

age, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Ser-

vice Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety charac-

teristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassem-

bling.

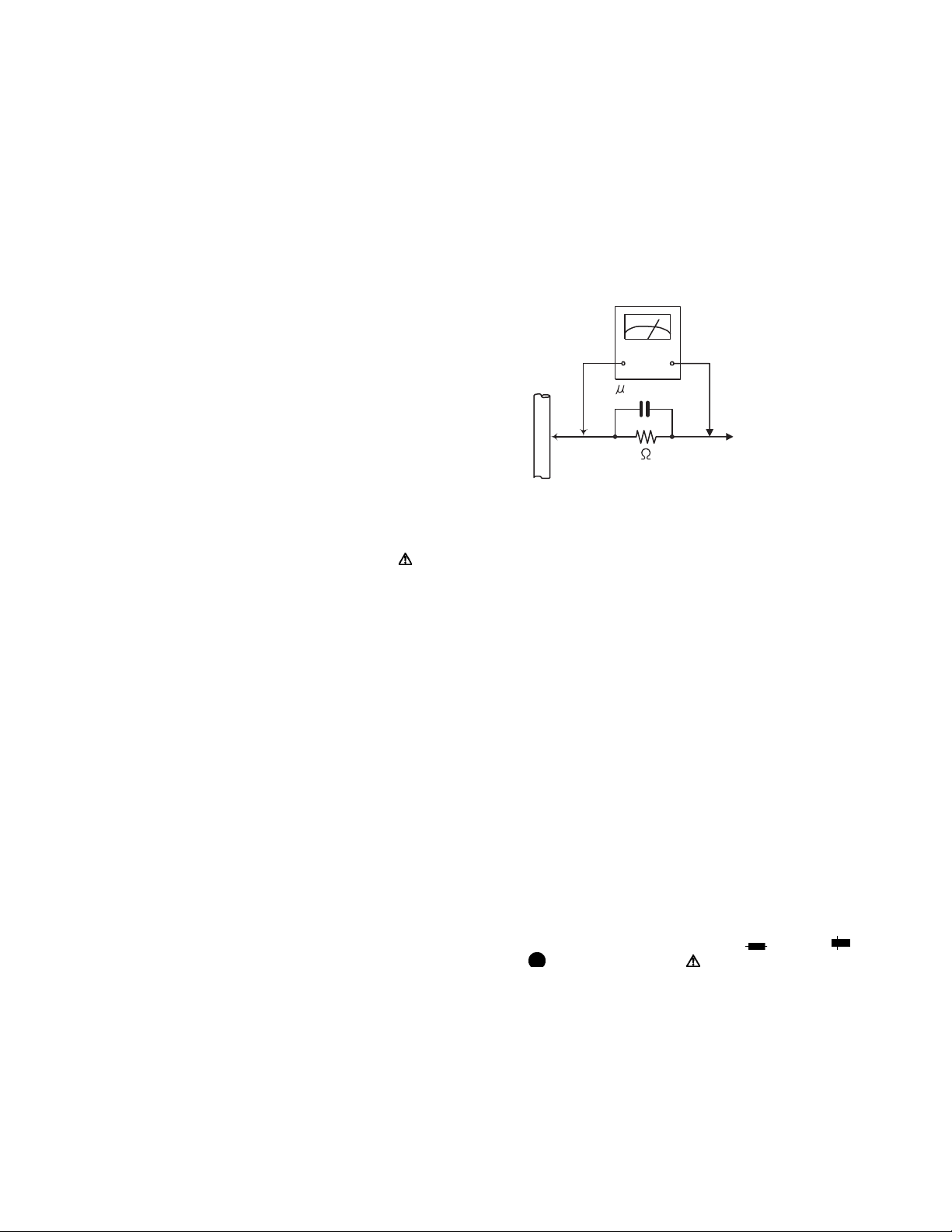

(5) Leakage shock hazard testing

After reassembling the product, always perform an isola-

tion check on the exposed metal parts of the product (an-

tenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particular-

ly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage cur-

rent must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000

Ω per volt or more sensitivity

in the following manner. Connect a 1,500

Ω 10W resistor

paralleled by a 0.15

µF AC-type capacitor between an

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of pre-

forming repair of this system.

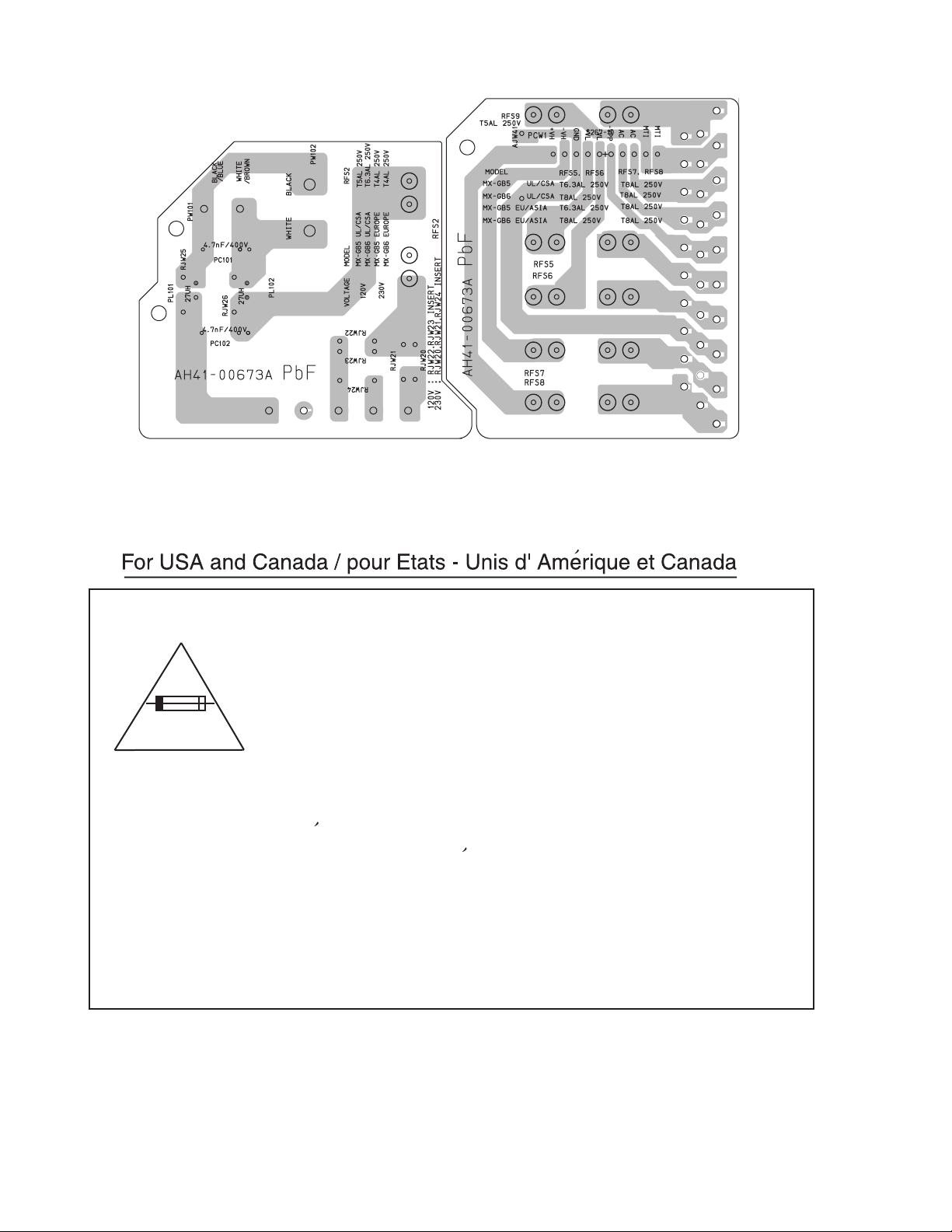

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

Good earth ground

Place this

probe on

each exposed

metal part.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

1500 10W

0.15 F AC TYPE

(No.MB160)1-5

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

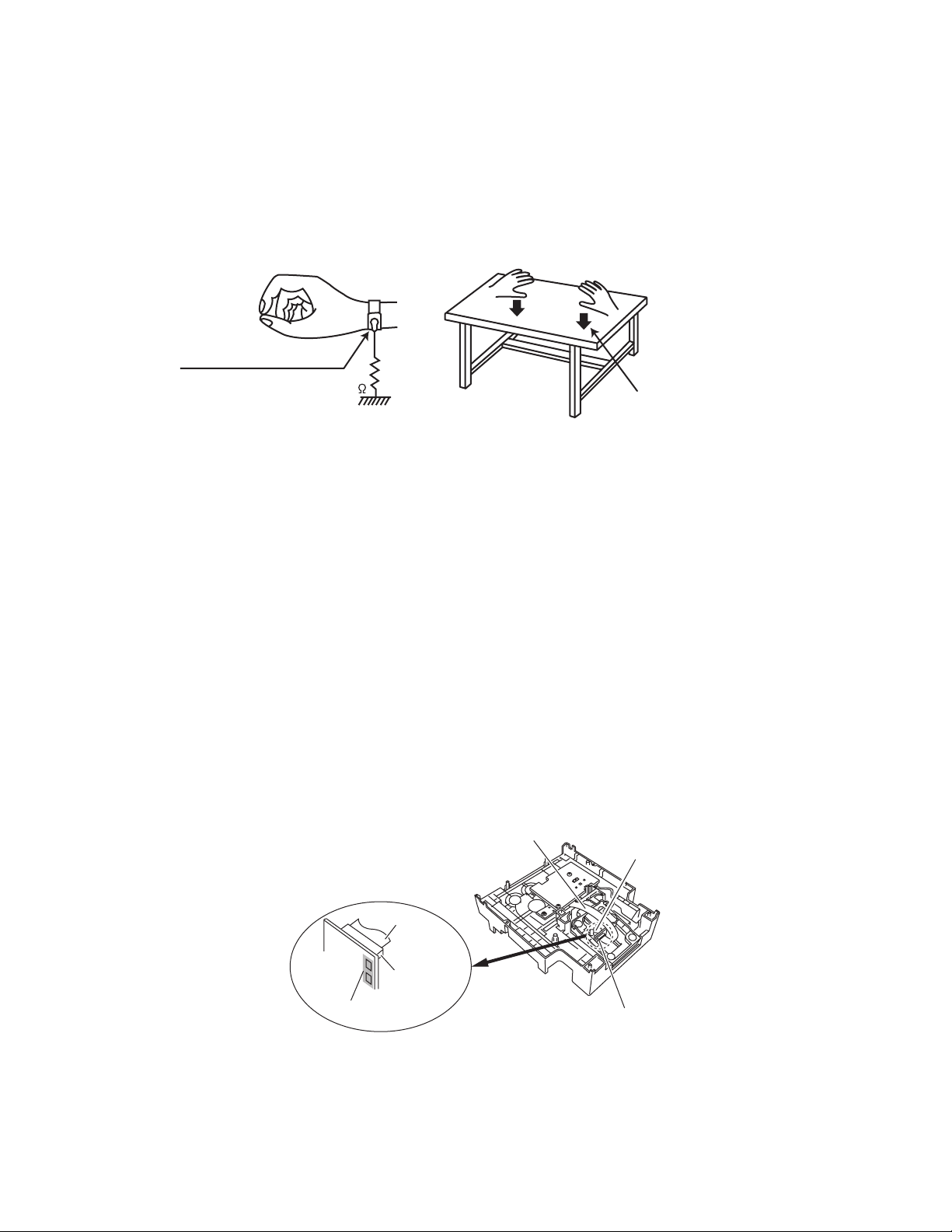

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the flexible

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

1M

Conductive material

(conductive sheet) or iron palate

(caption)

Anti-static wrist strap

Pickup unit connecto

r

Card wire

Pickup unit

connector

Short land section

Card wire

Pickup

1-6 (No.MB160)

1.8 Importance administering point on the safety

Caution: For continued protection against risk of

fire, replace only with same type 5 A/250 V[GB5]

(6.3 A/250 V[GB6]) for RFS2, 6.3 A/250 V[GB5]

(8 A/250 V[GB6]) for RFS5 and RFS6, 8 A/250 V

for RFS7 and RFS8, 5 A/250 V for RFS9.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de RFS2 comme le meme type

que 5 A/250 V[GB5](6.3 A/250 V[GB6]),

6,3 A/250 V[GB5](8 A/250 V[GB6]) pour RFS5 et

RFS6, 8 A/250 V pour RFS7 et RFS8, et

5 A/250 V pour RFS9.

Ce sont des fusibles suretes qui functionnes rapide.

^

(No.MB160)1-7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-8 (No.MB160)

SECTION 3

DISASSEMBLY

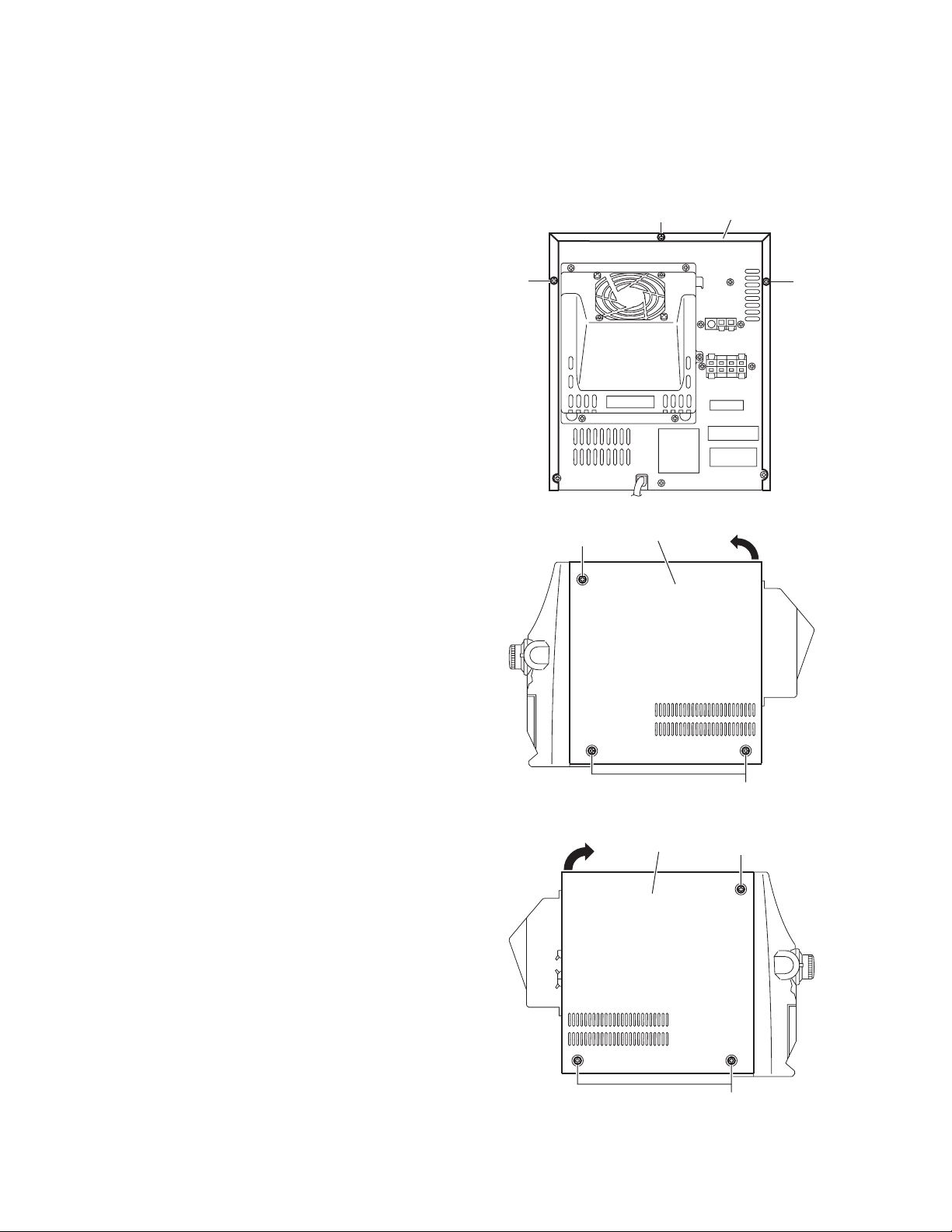

3.1 Main body section

3.1.1 Removing the top cabinet

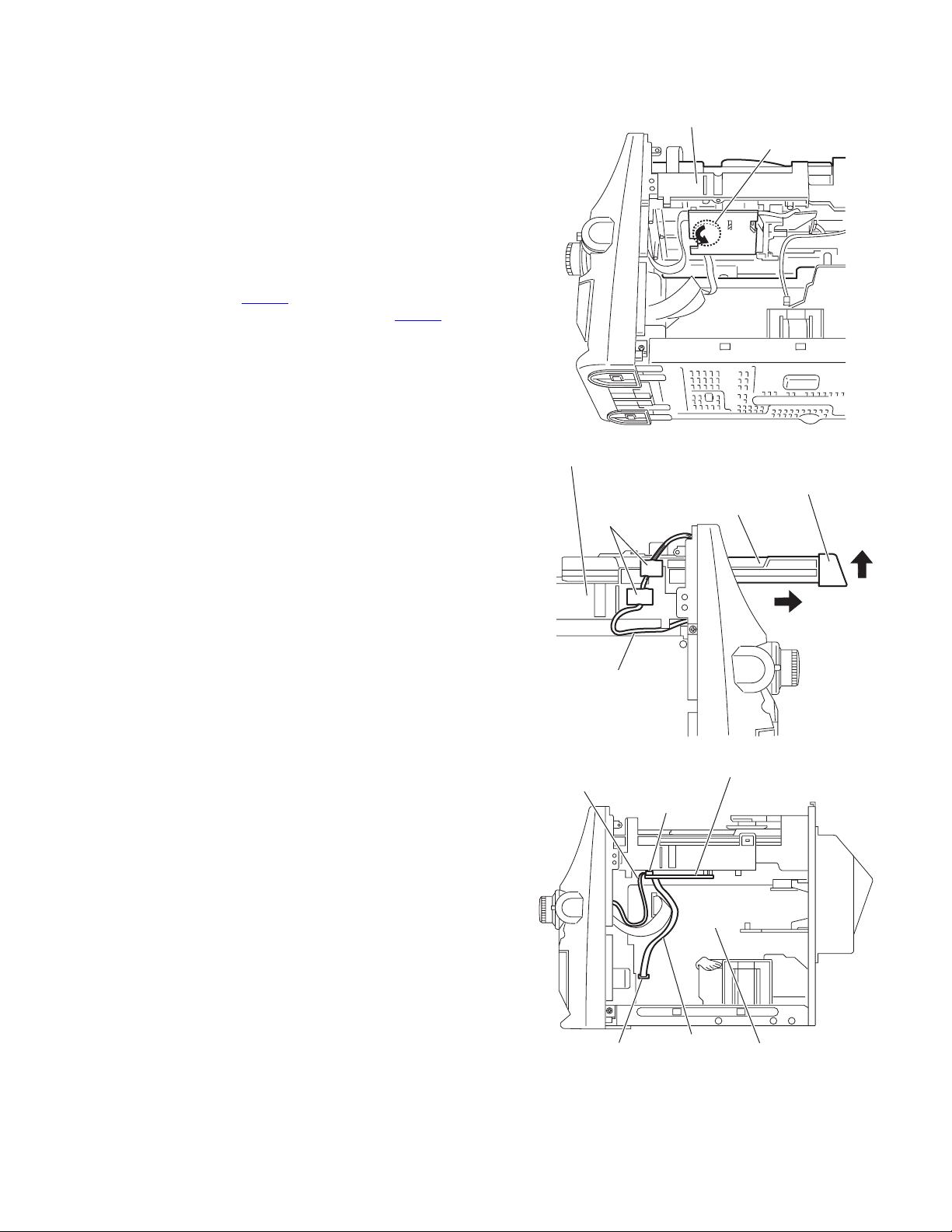

(See Figs.1 to 3)

(1) From the back side of the main body, remove the three

screws A attaching the top cabinet. (See Fig.1.)

(2) From the both sides of the main body, remove the six

screws B attaching the top cabinet. (See Figs.2 and 3.)

(3) Remove the top cabinet from the main body while lifting the

rear section of the top cabinet in the direction of the arrow.

(See Figs.2 and 3.)

Fig.1

Fig.2

Fig.3

Top cabinet

A

AA

Top cabinet

B

B

Top cabinet

B

B

(No.MB160)1-9

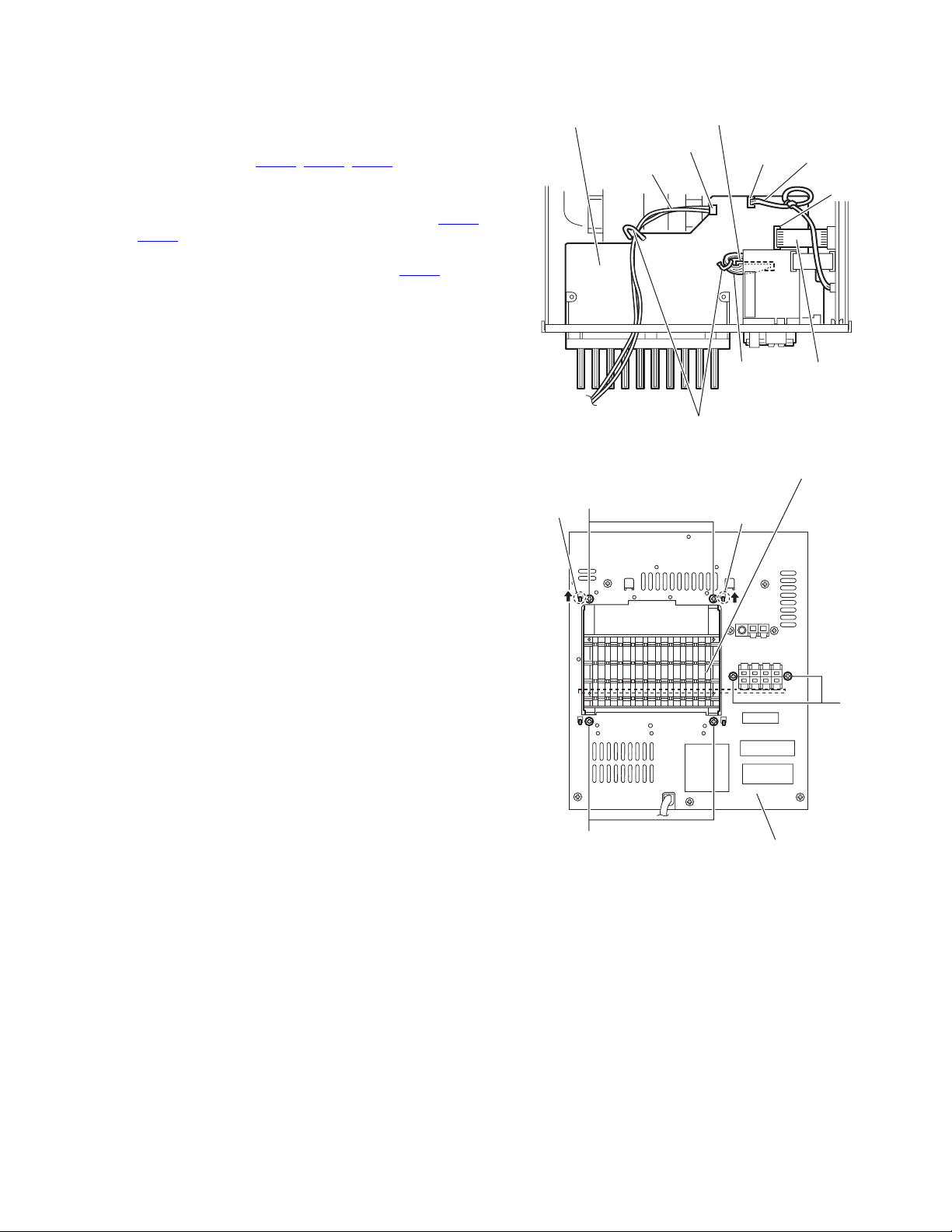

3.1.2 Removing the CD changer mechanism assembly

(See Figs.4 to 10)

• Prior to performing the following procedures, remove the top

cabinet.

(1) From the bottom side of the CD changer mechanism as-

sembly, turn the gear cam in the direction of the arrow and

draw the tray disc out of the CD changer mechanism as-

sembly in the direction of the arrow 1. (See Figs.4 and 5.)

(2) Remove the CD door assembly from the tray disc in the di-

rection of the arrow 2 and push in the tray disc. (See Fig.5.)

(3) From the left side of the main body, remove the spacers fix-

ing the wire. (See Fig.5.)

(4) From the right side of the main body, disconnect the wire

from the connector CW104

on the main board. (See Fig.6.)

(5) Disconnect the card wire from the connector CW105

on the

CD sub board. (See Fig.6.)

(6) From the back side of the main body, remove the five

screws C attaching the heat sink cover. (See Fig.7.)

Reference:

It is not necessary to disconnect the wire of the fan mo-

tor. (See Fig.8.)

(7) Remove the two screws D attaching the CD changer mech-

anism assembly. (See Fig.8.)

(8) From the both sides of the main body, remove the two

screws E attaching the CD changer mechanism assembly.

(See Figs.9 and 10.)

(9) Take out the CD changer mechanism assembly in the di-

rection of the arrow 2 while extending the rear cabinet in

the direction of the arrow 1. (See Figs.9 and 10.)

Fig.4

Fig.5

Fig.6

CD changer mechanism assembly

Gear cam

Tray disc

CD door assembly

CD changer mechanism assembly

Spacers

Wire

1

2

Card wire

Wire

CD sub board

Main board

CW105

CW104

1-10 (No.MB160)

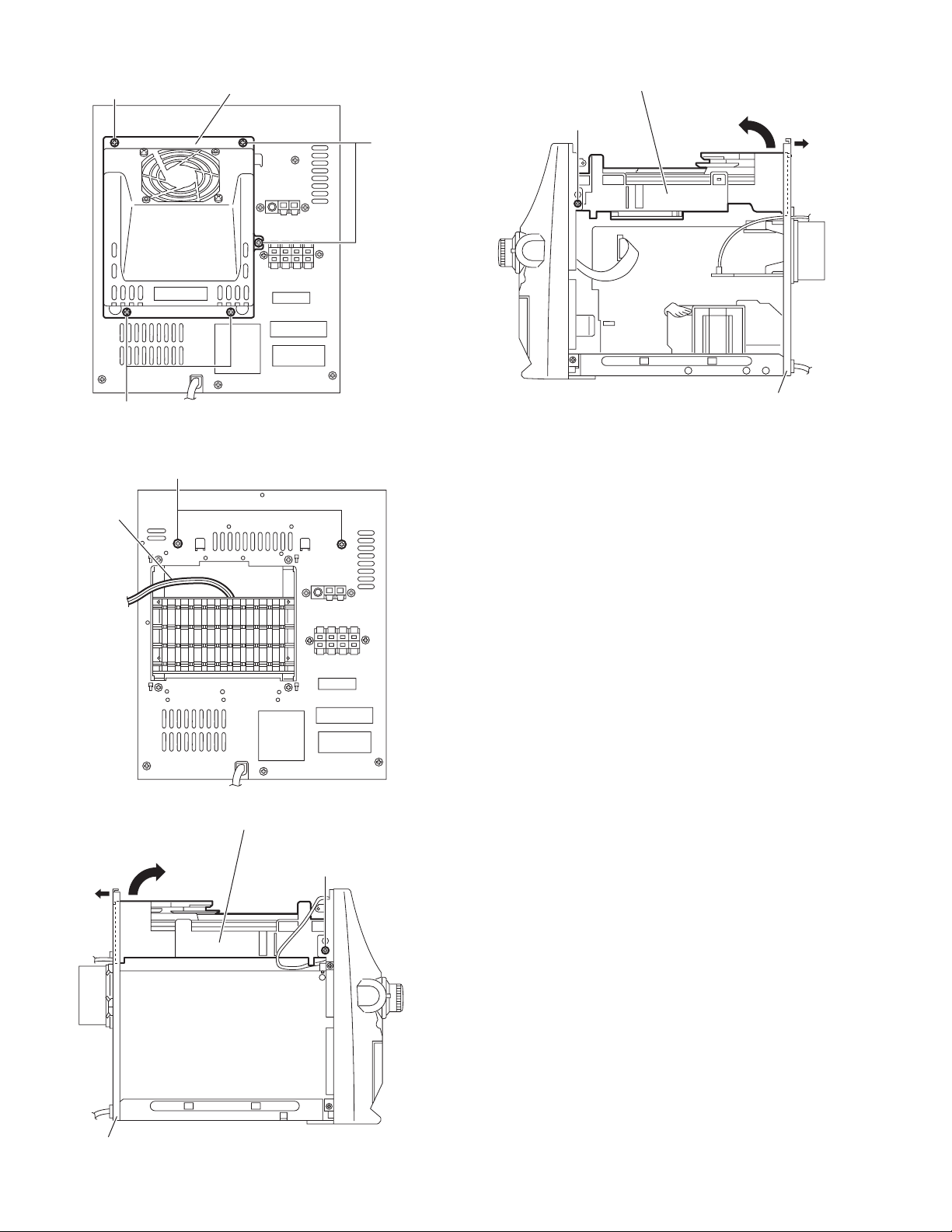

Fig.7

Fig.8

Fig.9

Fig.10

Heat sink cover

C

C

C

Wire

D

CD changer mechanism assembly

Rear cabinet

1

2

E

CD changer mechanism assembly

Rear cabinet

1

2

E

(No.MB160)1-11

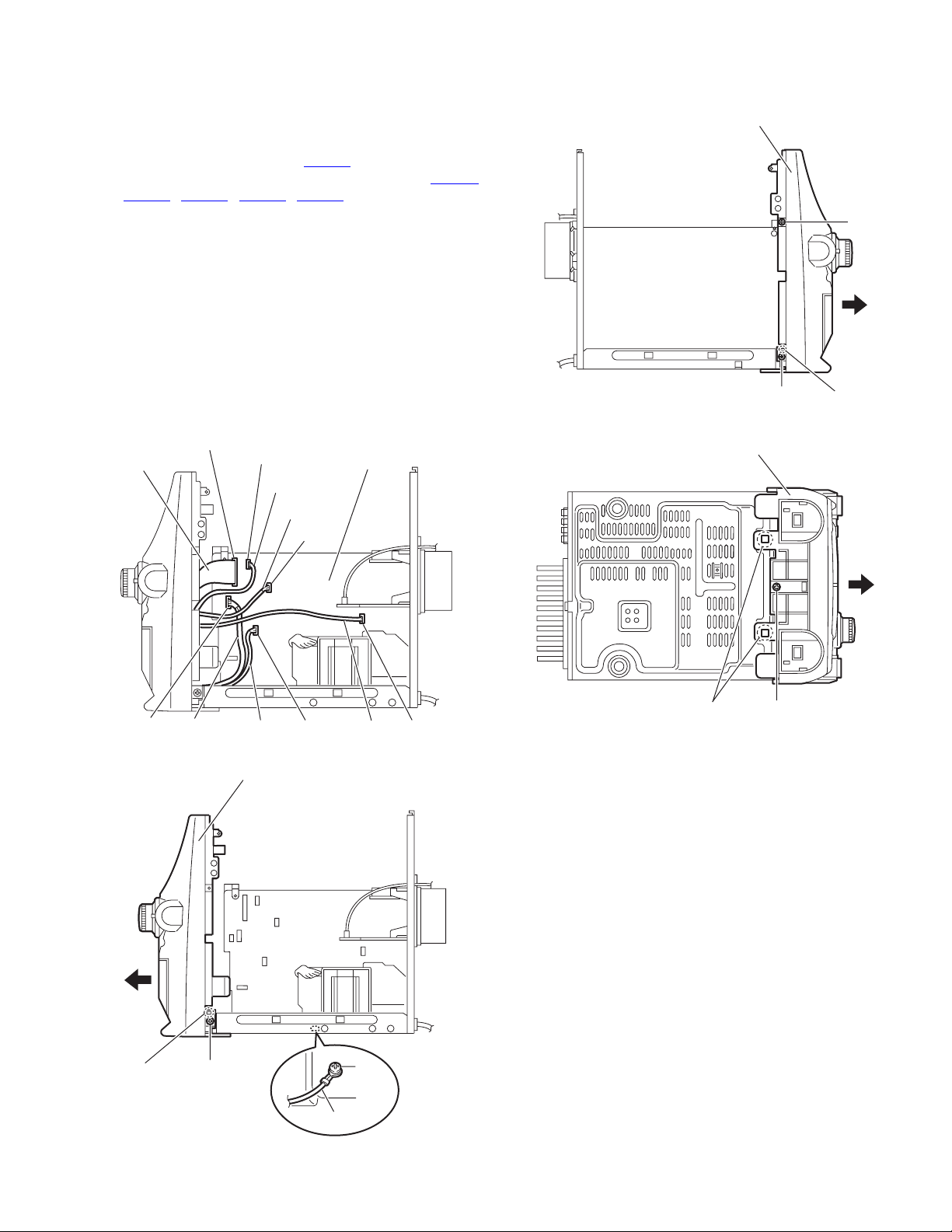

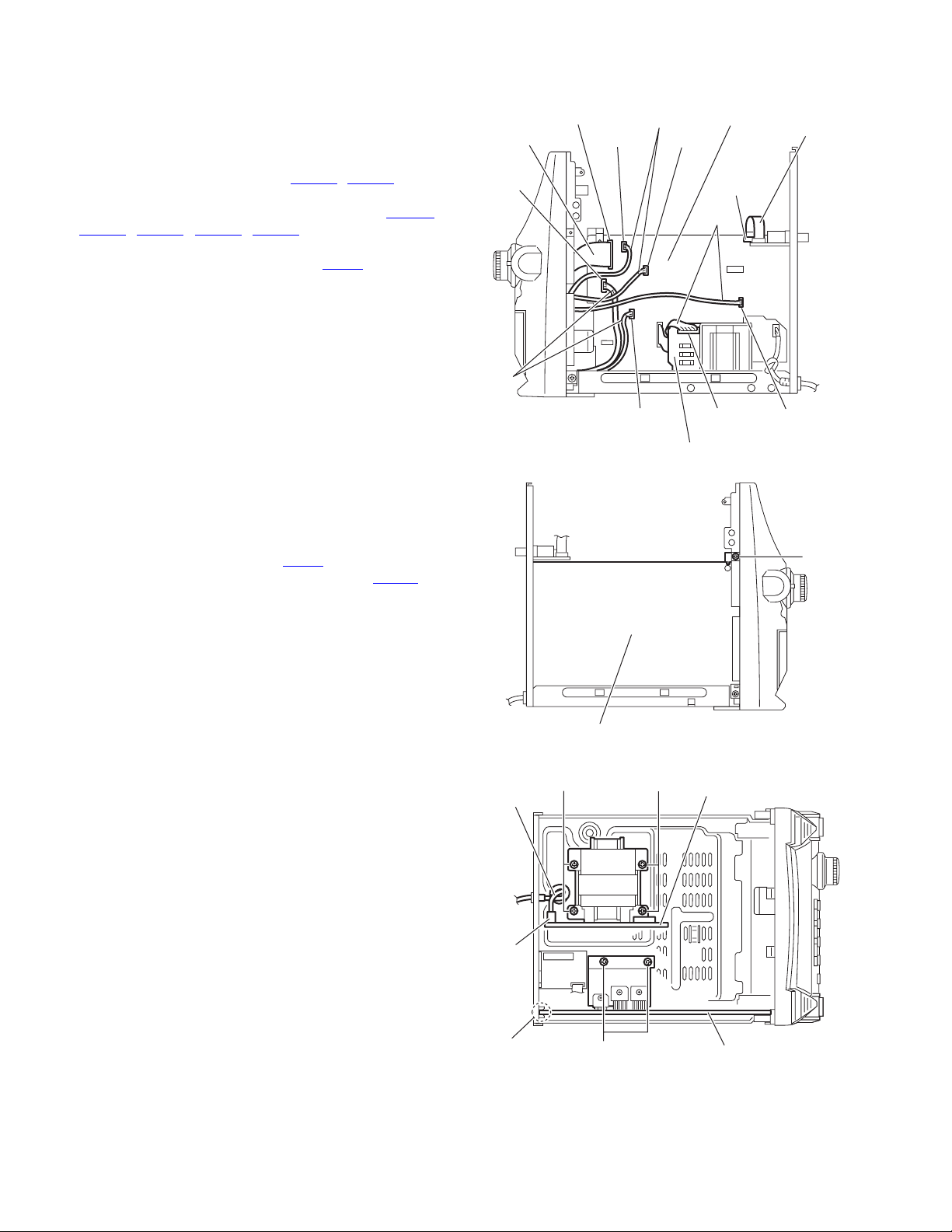

3.1.3 Removing the front cabinet assembly

(See Figs.11 to 14)

• Prior to performing the following procedures, remove the top

cabinet and CD changer mechanism assembly.

(1) From the forward side of the main board, disconnect the

card wire from the connector CW101

. (See Fig.11.)

(2) Disconnect the wires from the connectors (CW01A

,

CW108, CW109, CW111, CW112) on the main board.

(See Fig.11.)

(3) From the top side of the main body, remove the screw F at-

taching the earth wire. (See Fig.12.)

(4) From the both sides of the main body, remove the two

screws G attaching the front cabinet assembly. (See

Figs.12 and 13.)

(5) From the left side of the main body, remove the screw H at-

taching the front cabinet assembly. (See Fig.13.)

(6) From the bottom side of the main body, remove the screw

J attaching the front cabinet assembly. (See Fig.14.)

(7) Release the two joints a and two joints b, remove the front

cabinet assembly in the direction of the arrow. (See Figs.12

to 14.)

Fig.11

Fig.12

Fig.13

Fig.14

Card wire

Wire

Wire

Wire

Wire

Wire

CW101

CW112

CW111

CW108

CW109

Main board

CW01A

Earth wire

Front cabinet assembly

a

G

F

a

Front cabinet assembly

H

G

b

J

Front cabinet assembly

1-12 (No.MB160)

3.1.4 Removing the rear cabinet

(See Figs.15 to 17.)

• Prior to performing the following procedures, remove the top

cabinet.

(1) From the right side of the main body, disconnect the wires

from the connector ACW3

on the amplifier board. (See

Fig.15.)

(2) From the back side of the main body, remove the five

screws K attaching the heat sink cover. (See Fig.16.)

(3) Remove the thirteen screws L attaching the rear cabinet.

(See Fig.17.)

3.1.5 Removing the fan motor

(See Figs.15, 16 and 18)

• Prior to performing the following procedures, remove the top

cabinet.

(1) From the right side of the main body, disconnect the wires

from the connector ACW3

on the amplifier board. (See

Fig.15.)

(2) From the back side of the main body, remove the five

screws K attaching the heat sink cover. (See Fig.16.)

(3) From the back side of the heat sink cover, remove the two

screws M attaching the fan motor. (See Fig.18.)

Fig.15

Fig.16

Fig.17

Fig.18

Amplifier board

Wire

A

CW3

Heat sink cover

K

K

K

Rear cabinet

LL

L

L

L

Heat sink cover

Fan moto

r

M

(No.MB160)1-13

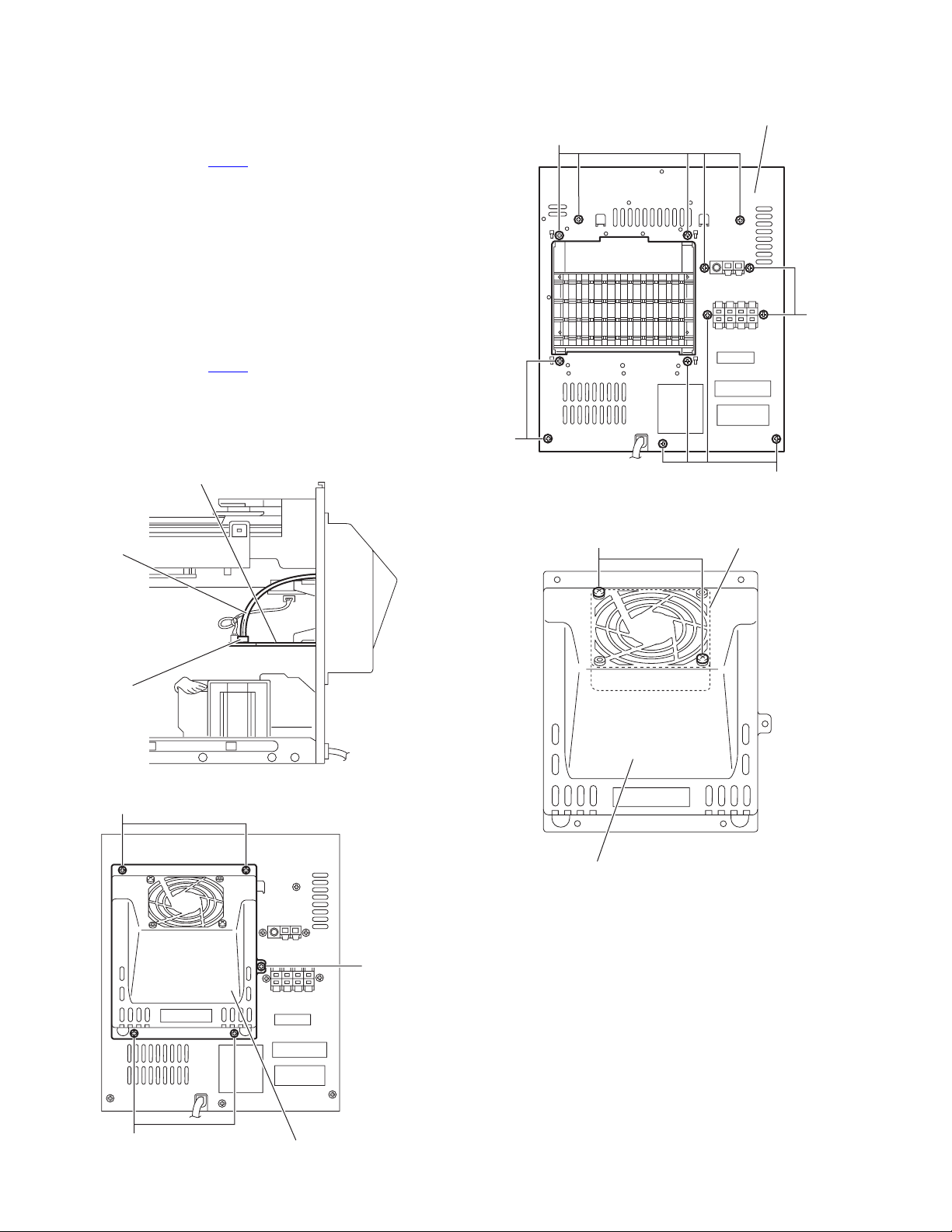

3.1.6 Removing the amplifier board

(See Figs.19 and 20)

• Prior to performing the following procedures, remove the top

cabinet and CD changer mechanism assembly.

(1) From the top side of the main body, disconnect the wires

from the connectors (ACW2

, ACW3, ACW4) on the ampli-

fier board. (See Fig.19.)

Reference:

After connecting the wires to the connectors (ACW2

,

ACW3

), fix the wires with the wire holders as before.

(See Fig.19.)

(2) Disconnect the card wire from the connector ACW1

on the

amplifier board. (See Fig.19.)

(3) From the back side of the main body, remove the six

screws N attaching the amplifier board. (See Fig.20.)

(4) Release the claws (c, d) from the rear cabinet and take out

the amplifier board from the inside of the main body. (See

Fig.20.)

Fig.19

Fig.20

ACW3

ACW4

Wire

Wire

Wire holders

ACW2

ACW1

Amplifier board

Cord wire

Wire

Amplifier board

Rear cabinet

N

N

N

d

c

1-14 (No.MB160)

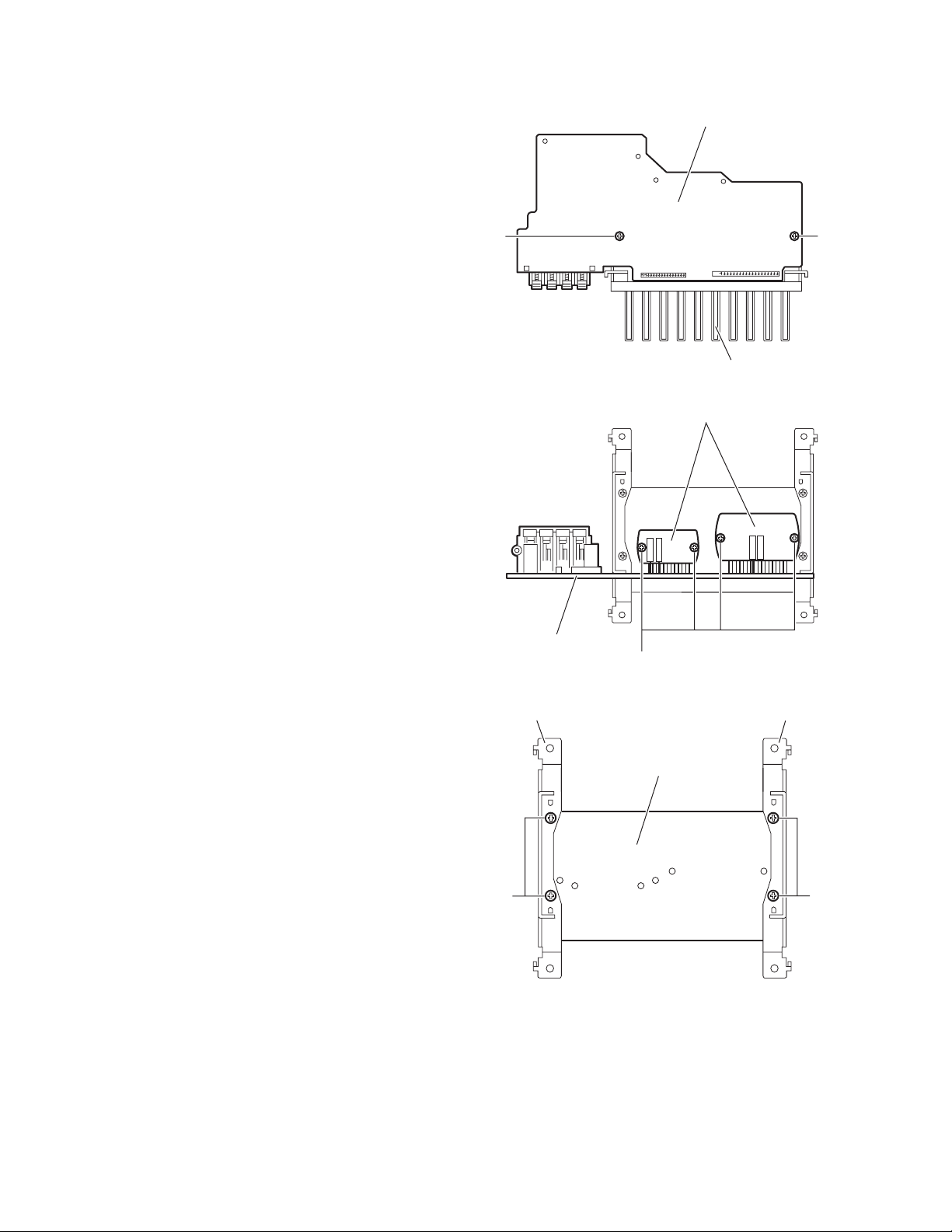

3.1.7 Removing the heat sink

(See Figs.21 to 23)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly and amplifier

board.

(1) From the reverse side of the amplifier board, remove the

two screws P attaching the heat sink. (See Fig.21.)

(2) From the forward side of the amplifier board, remove the

four screws Q attaching the power amplifier IC on the heat

sink. (See Fig.22.)

(3) From the bottom side of the heat sink, remove the four

screws R attaching the brackets on the heat sink. (See

Fig.23.)

Fig.21

Fig.22

Fig.23

Amplifier board

Heat sink

P

P

Q

Amplifier board

Power amplifier IC

R

R

Heat sink

BracketBracket

(No.MB160)1-15

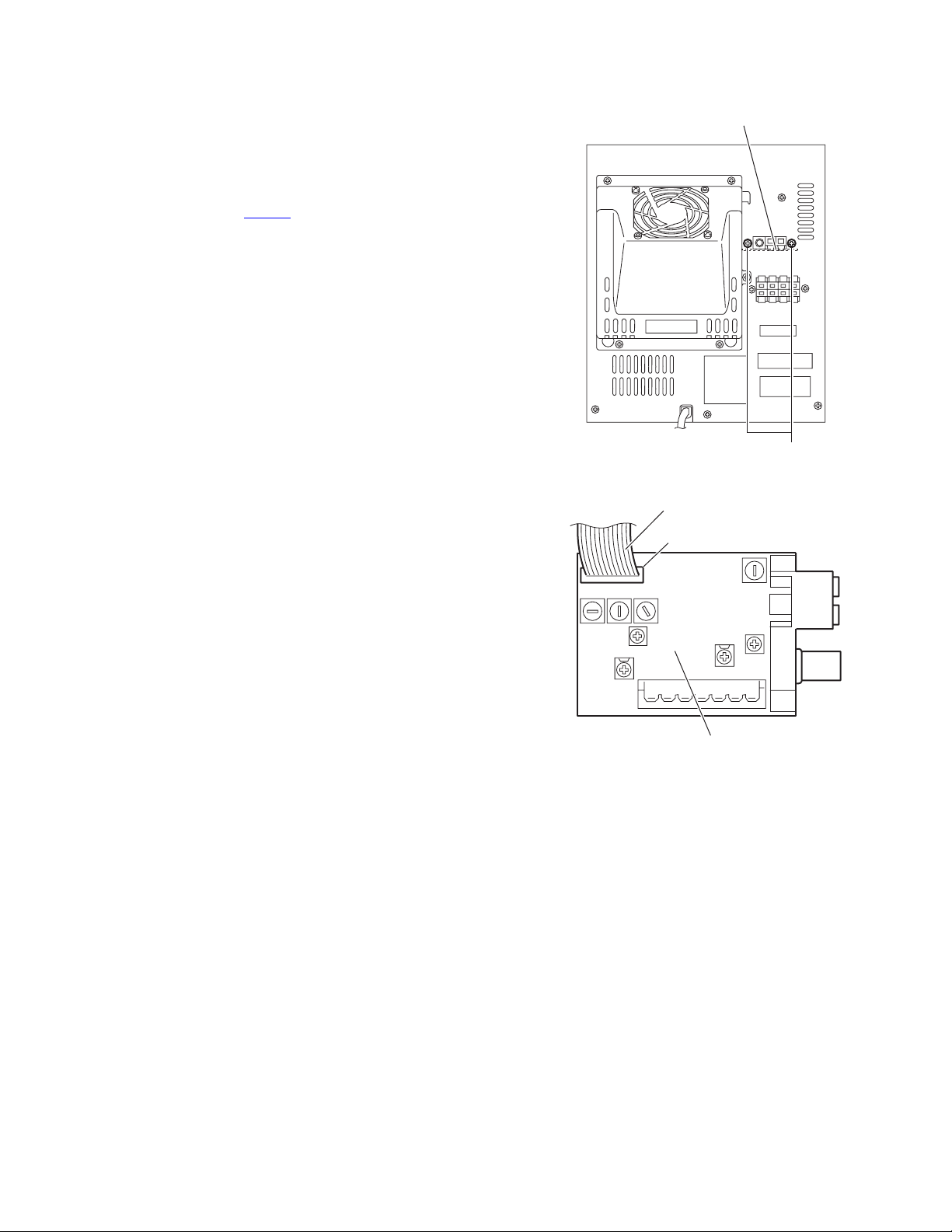

3.1.8 Removing the tuner

(See Figs.24 and 25)

• Prior to performing the following procedures, remove the top

cabinet.

(1) From the back side of the main body, remove the two

screws S attaching the tuner. (See Fig.24.)

(2) From the left side of the main body, take out the tuner.

(3) From the forward side of the tuner, disconnect the card wire

from the connector CON01

. (See Fig.25.)

Fig.24

Fig.25

S

Tuner

CON01

Card wire

Tuner

1-16 (No.MB160)

3.1.9 Removing the main board

(See Figs.26 to 28)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly and amplifier

board.

(1) From the forward side of the main board, disconnect the

card wires from the connectors (CW101

, CW102). (See

Fig.26.)

(2) Disconnect the wires from the connectors (CW01A

,

CW108

, CW109, CW111, CW112) on the main board.

(See Fig.26.)

(3) Disconnect the wire from the connector PCW1

on the pow-

er supply board. (See Fig.26.)

(4) From the left side of the main body, remove the screw T at-

taching the main board. (See Fig.27.)

(5) From the top side of the main body, remove the two screws

U attaching the main board. (See Fig.28.)

(6) Take out the main board from the main body.

Reference:

Insert the main board in the slot e before attaching the main

board to the bottom chassis. (See Fig.28.)

3.1.10 Removing the power supply board

(See Figs.26 and 28)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly and amplifier

board.

(1) From the forward side of the power supply board, discon-

nect the wire from the connector PCW1

. (See Fig.26.)

(2) Disconnect the power cord from the connector PW101 on

the power supply board. (See Fig.28.)

(3) From the top side of the main body, remove the four screws

V attaching the power supply board. (See Fig.28.)

(4) Take out the power supply board from the main body.

Fig.26

Fig.27

Fig.28

Card wire

Card wire

Wires

Wires

Wires

Power supply board

PCW1

CW109

CW101

CW01A

CW112

CW108

CW111

CW102

Main board

Main board

T

Power supply board

Power cord

PW101

Main board

e

V

V

U

(No.MB160)1-17

3.1.11 Removing the CD board

(See Fig.29)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly and front cabinet

assembly.

(1) From the inside of the front cabinet assembly, disconnect

the wire from the connector UCW05

on the VFD board.

(2) Remove the four screws W attaching the CD board.

Reference:

When attaching the CD board, align the projections (f, g) of the

front cabinet assembly in the holes of the CD board.

3.1.12 Removing the VFD board

(See Fig.29)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly and front cabinet

assembly.

(1) From the inside of the front cabinet assembly, disconnect

the wire from the connector UCW05

on the VFD board.

(2) Remove the three screws X attaching the VFD board.

(3) Take out the VFD board while releasing the claw h in the

direction of the arrow.

(4) From the forward side of the VFD board, disconnect the

card wire from the connector UCW7

.

Fig.29

f

g

h

CD board

Wier

UCW05

UCW7

Card wire

VFD board

X

W

W

X

1-18 (No.MB160)

3.1.13 Removing the front board

(See Figs.30 and 31)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly, front cabinet as-

sembly and VFD board.

(1) From the outside of the front cabinet assembly, pull out the

volume knob. (See Fig.30.)

(2) From the inside of the front cabinet assembly, remove the

thirteen screws Y attaching the front board. (See Fig.31.)

(3) Take out the front board while releasing the claw i in the di-

rection of the arrow. (See Fig.31.)

(4) From the forward side of the front board, disconnect the

card wire from the connector UCW06

. (See Fig.31.)

Reference:

When attaching the front board, align the projections (j, k) of

the front cabinet assembly in the holes of the front board.

Fig.30

Fig.31

Volume knob

Front cabinet assembly

k

j

i

Front cabinet assembly

UCW06

Cord wire

Front board

Y

Y

Y

Y

(No.MB160)1-19

3.1.14 Removing the AUX IN board

(See Fig.32)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly, front cabinet as-

sembly, VFD board and front board.

(1) From the inside of the front cabinet assembly, remove the

two screws Z attaching the holder.

(2) Take out the AUX IN board from the front cabinet assem-

bly.

3.1.15 Removing the phone board

(See Fig.32)

• Prior to performing the following procedures, remove the top

cabinet, CD changer mechanism assembly, front cabinet as-

sembly, VFD board and front board.

(1) From the inside of the front cabinet assembly, remove the

two screws AA attaching the holder.

(2) Take out the phone board from the front cabinet assembly.

Fig.32

3.1.16 Removing the cassette deck mechanism assembly

(See Fig.33)

• Prior to performing the following procedure, remove the top

cabinet, CD changer mechanism assembly and front cabinet

assembly.

(1) From the inside of the front cabinet assembly, disconnect

the card wire from the connector on the mechanism board.

(2) Remove the five screws AB and screw AB’ attaching the

cassette deck mechanism assembly.

Reference:

When attaching the screw AB’, attach the earth wire with it.

Fig.33

AUX IN board

Phone board

Holder Holder

Z

AA

Front cabinet assembly

Mechanism board

Earth wire

Cassette deck mechanism assembly

Connector

AB

AB

AB'

Card wire

1-20 (No.MB160)

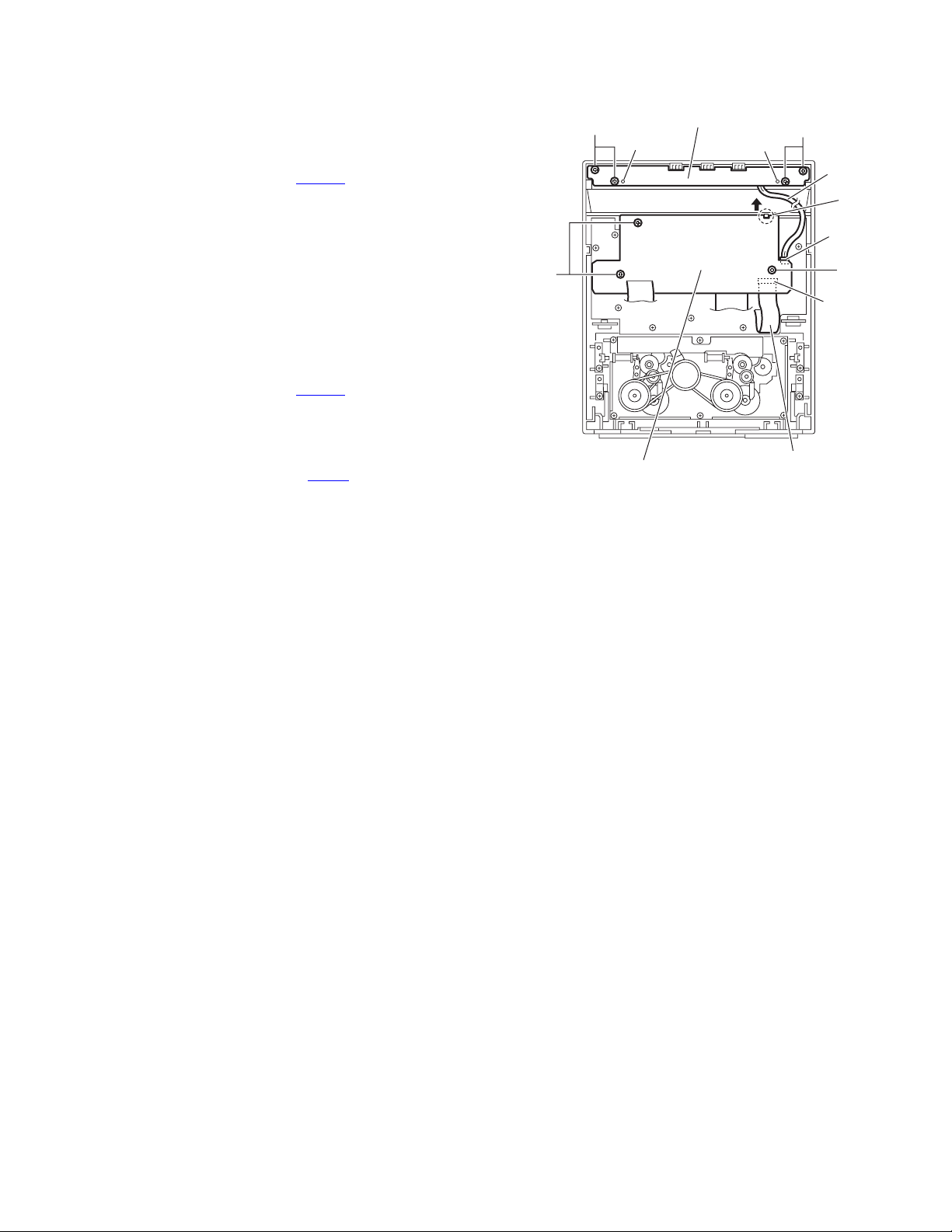

3.2 CD changer mechanism assembly section

• Prior to performing the following procedures, remove the CD changer mechanism assembly. (See "3.1.2 Removing the CD changer

mechanism assembly".)

3.2.1 Removing the tray disc

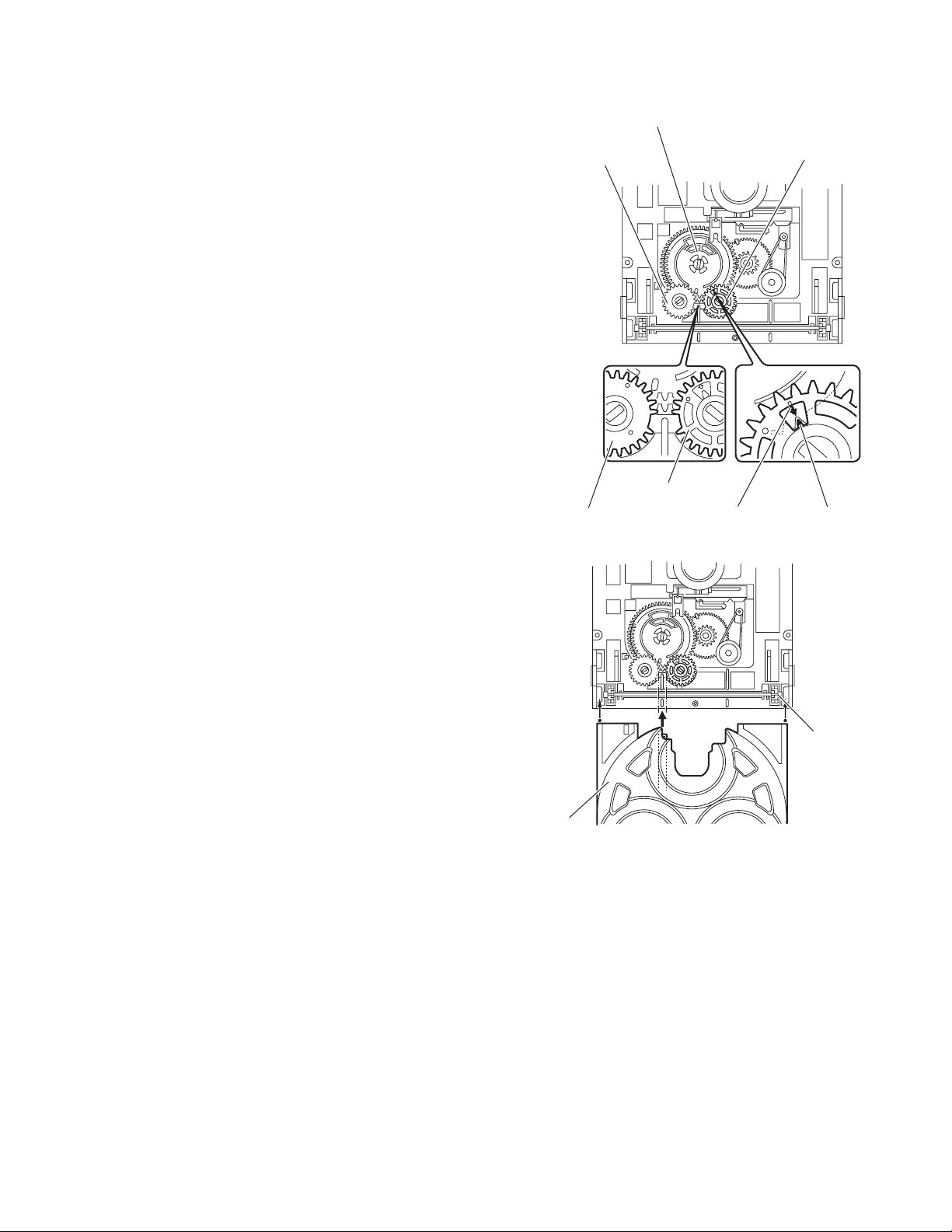

(See Figs.1 and 2)

(1) Turn the gear cam on the bottom side of the CD changer

mechanism assembly in the direction of the arrow and

draw the tray disc toward the front until it stops. (See Figs.1

and 2.)

(2) Disconnect the card wire from the connector CW103

on the

CD sub board. (See Figs.1 and 2.)

(3) Push down the two tray stoppers and pull out the tray disc.

(See Fig.2.)

Fig.1

Fig.2

Tray disc

CD sub board

Gear cam

CW103

Tray stoppe

r

Tray stopper

CW103

(on the CD sub board)

Tray disc

(No.MB160)1-21

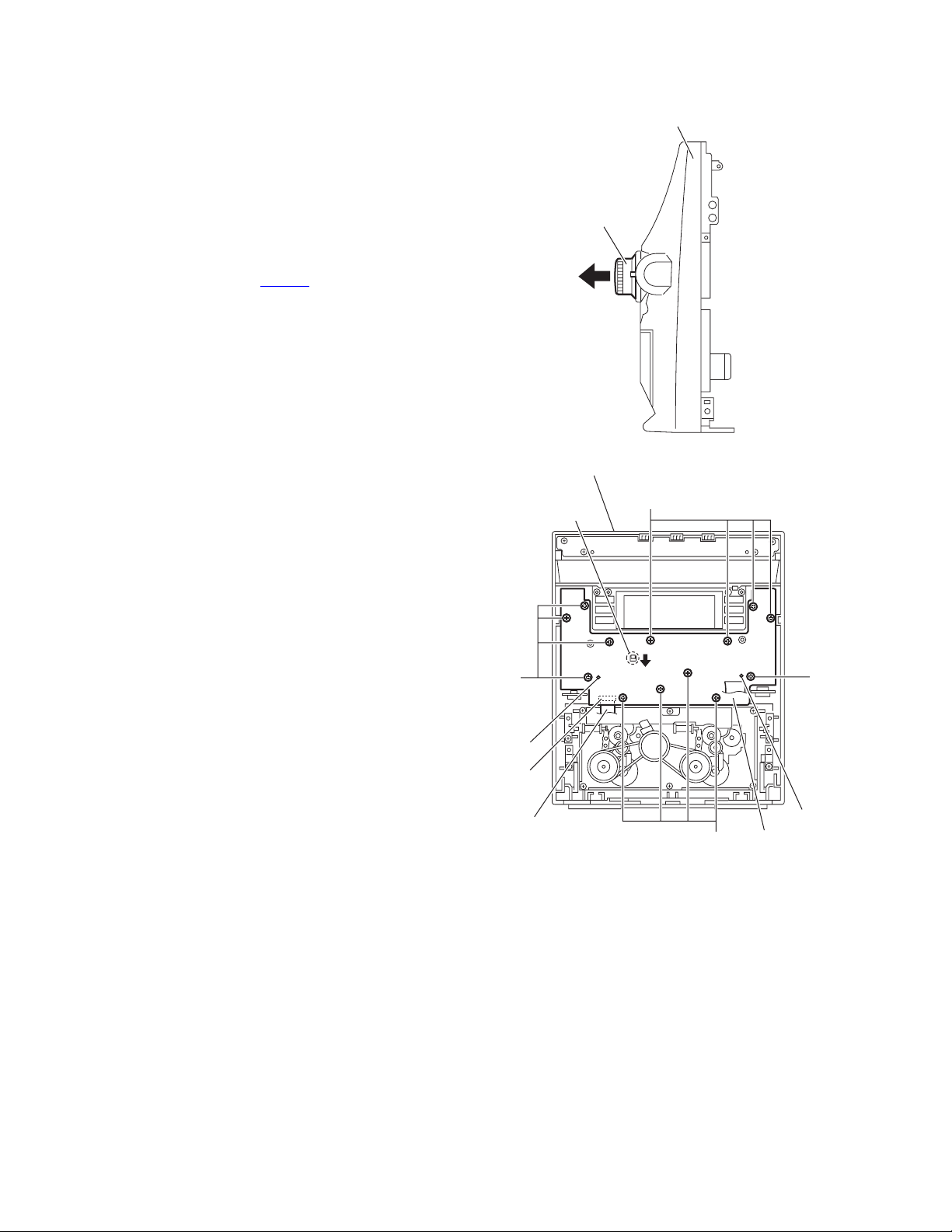

3.2.2 Reinstall the tray disc

(See Figs.3 and 4)

(1) Align the gear cam with the gear tray and then mount the

tray disc. (See Fig.3.)

(2) When assembling the tray disc, take extreme care not en-

gage with gear synchro. (See Fig.4.)

Fig.3

Fig.4

Gear convertor

Gear convertor

Gear tray

Gear tray

Gear tray

Gear cam

Gear cam

timing point

Gear synchro

Tray disc

1-22 (No.MB160)

3.2.3 Removing the sensor board

(See Fig.5)

• Prior to performing the following procedures, remove the tray

disc.

(1) Remove the screw A attaching the sensor board on the

tray disc.

(2) Remove the sensor board releasing the two tabs a.

(3) Disconnect the wire from the connector CW1

on the sensor

board.

Fig.5

3.2.4 Removing the loading motor

(See Figs.6 and 7)

• Prior to performing the following procedures, remove the tray

disc and sensor board.

(1) Remove the screw B attaching the tray roulette and re-

move the tray roulette from the base tray. (See Fig.6.)

(2) Release the tabs b attaching the loading motor on the base

tray in the direction of the arrow and remove the loading

motor. (See Fig.7.)

Reference:

Base tray + Tray roulette = Tray disc

Fig.6

Fig.7

CW1

Sensor board

Tray disc (reverse side)

Ta b a

A

Base tray

Tray roulette

B

Loading moto

r

Tabs b

Base tray (upper side)

(No.MB160)1-23

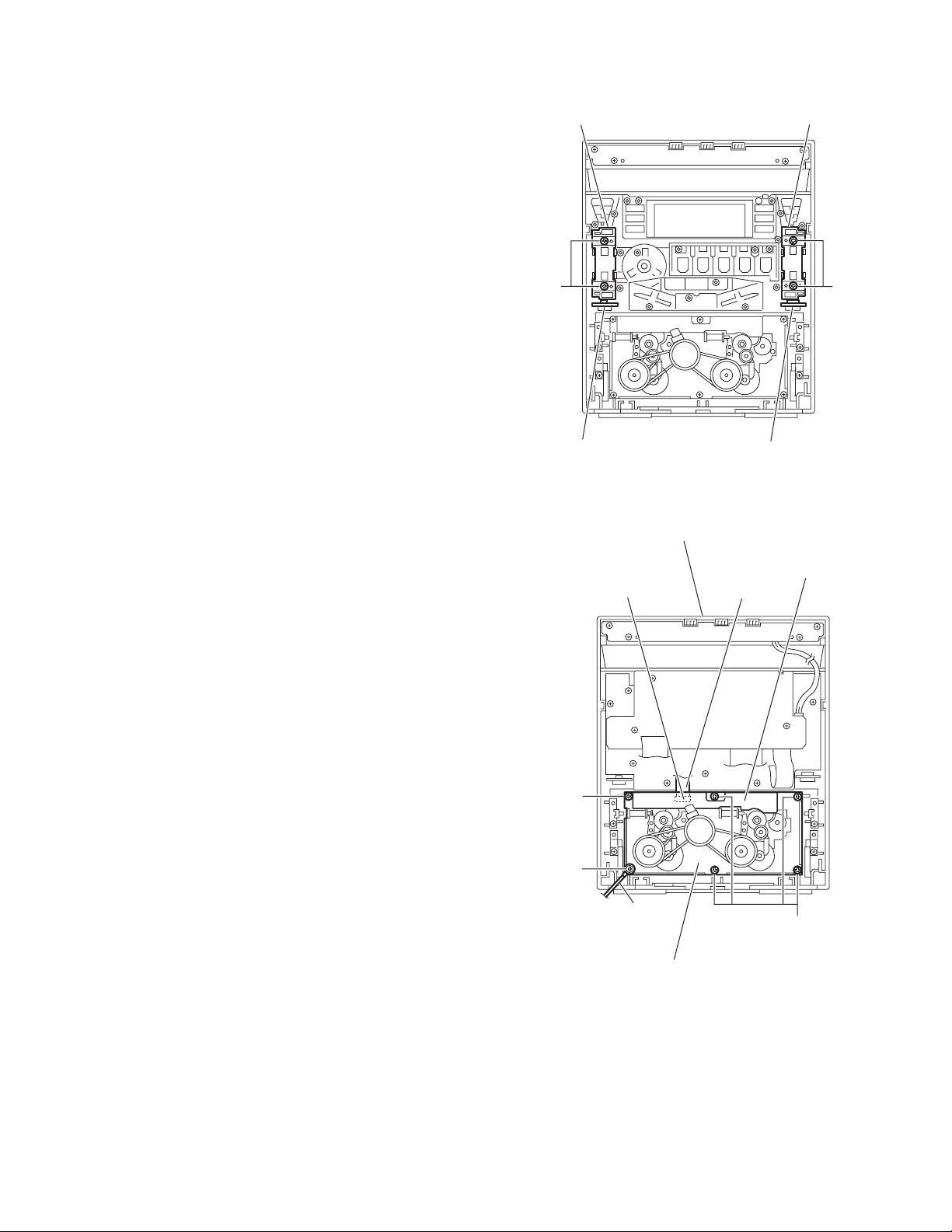

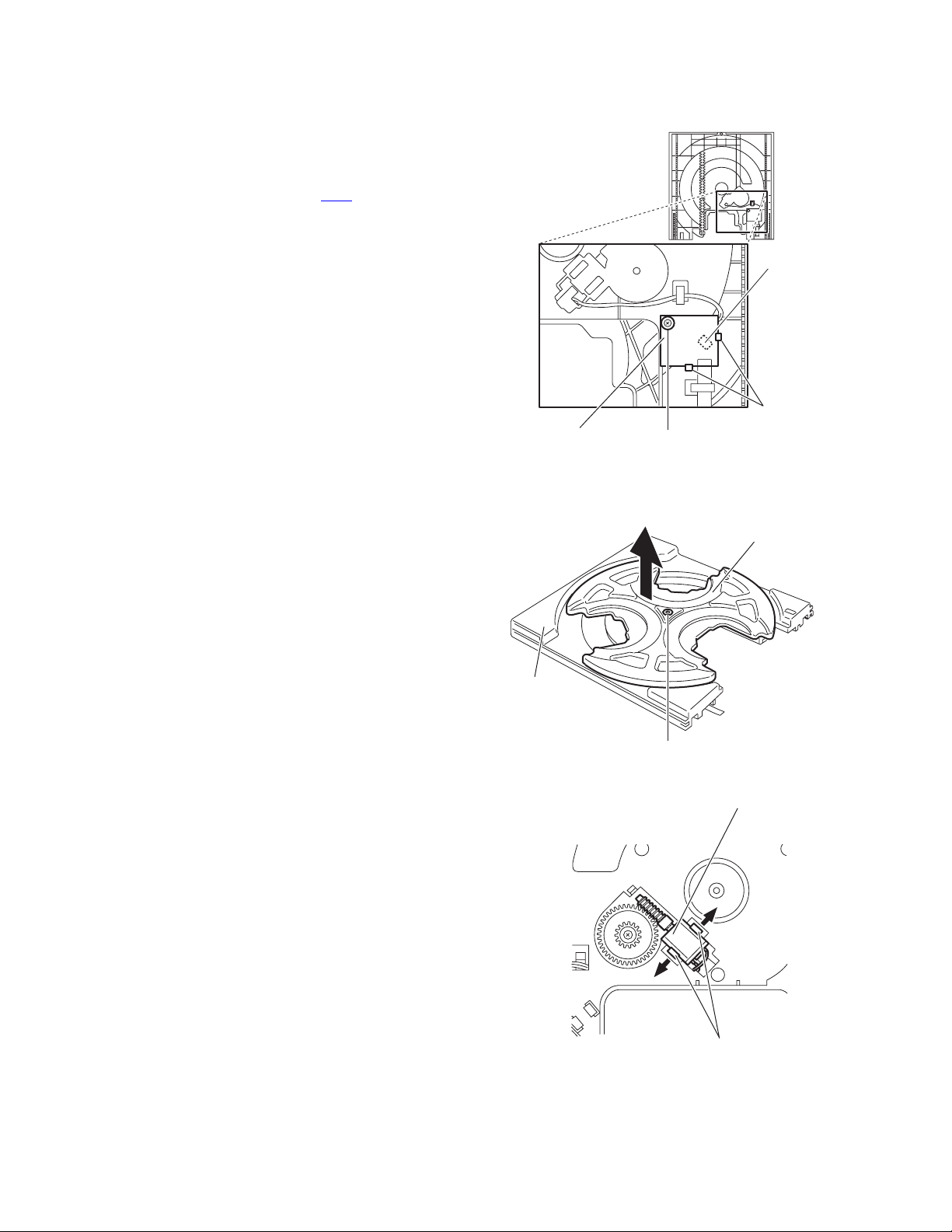

3.2.5 Removing the belt load, CD sub board and switch board

(See Figs.8 and 9)

• Prior to performing the following procedures, remove the tray

disc.

(1) Remove the belt load from the pulley on the top side of the

CD changer mechanism assembly. (See Fig.8.)

Note:

Do not strain the belt load with grease.

(2) Disconnect the card wire from the pickup unit connector on

the bottom side of the CD changer mechanism assembly.

(See Fig.9.)

Attention:

Solder is put up before the card wire is removed from the

pickup unit connector on the CD mechanism assembly.

(When the card wire is removed without putting up sol-

der, the pickup unit might destroy.) (See Fig.9.)

(3) Disconnect the wire from the connector on the CD mecha-

nism board. (See Fig.9.)

(4) Remove the two screws C attaching the CD sub board.

(See Fig.9.)

(5) Release the two tabs c and two tabs d attaching the motor

and then remove the CD sub board. (See Fig.9.)

Reference:

If the tabs c and d are hard to release, it is recommend-

able to unsolder the two soldered parts on the motor ter-

minal of the CD sub board.

(6) Remove the two screws D attaching the switch board and

take out the switch board while releasing the two tabs e at-

taching the switch board outward. (See Fig.9.)

Fig.8

Fig.9

Belt load

CD changer mechanism assembly

CD sub board

CD mechanism

board

Soldered parts

Motor

Switch board

Pickup unit connector

D

Ta bs e

Ta bs d

Ta bs c

C

Card wire

Pickup unit

connector

Soldering

Connecto

r

Wire

C

Card wire

1-24 (No.MB160)

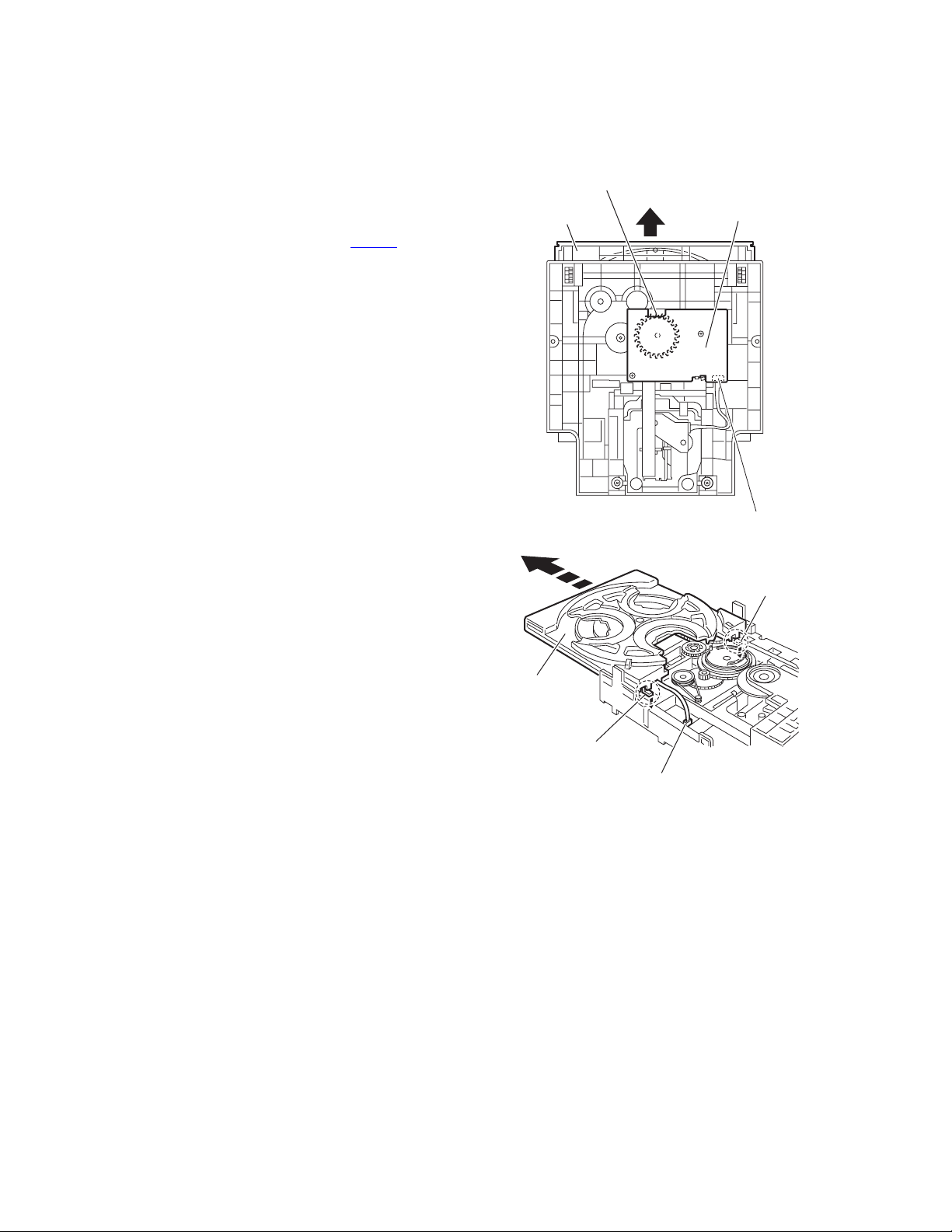

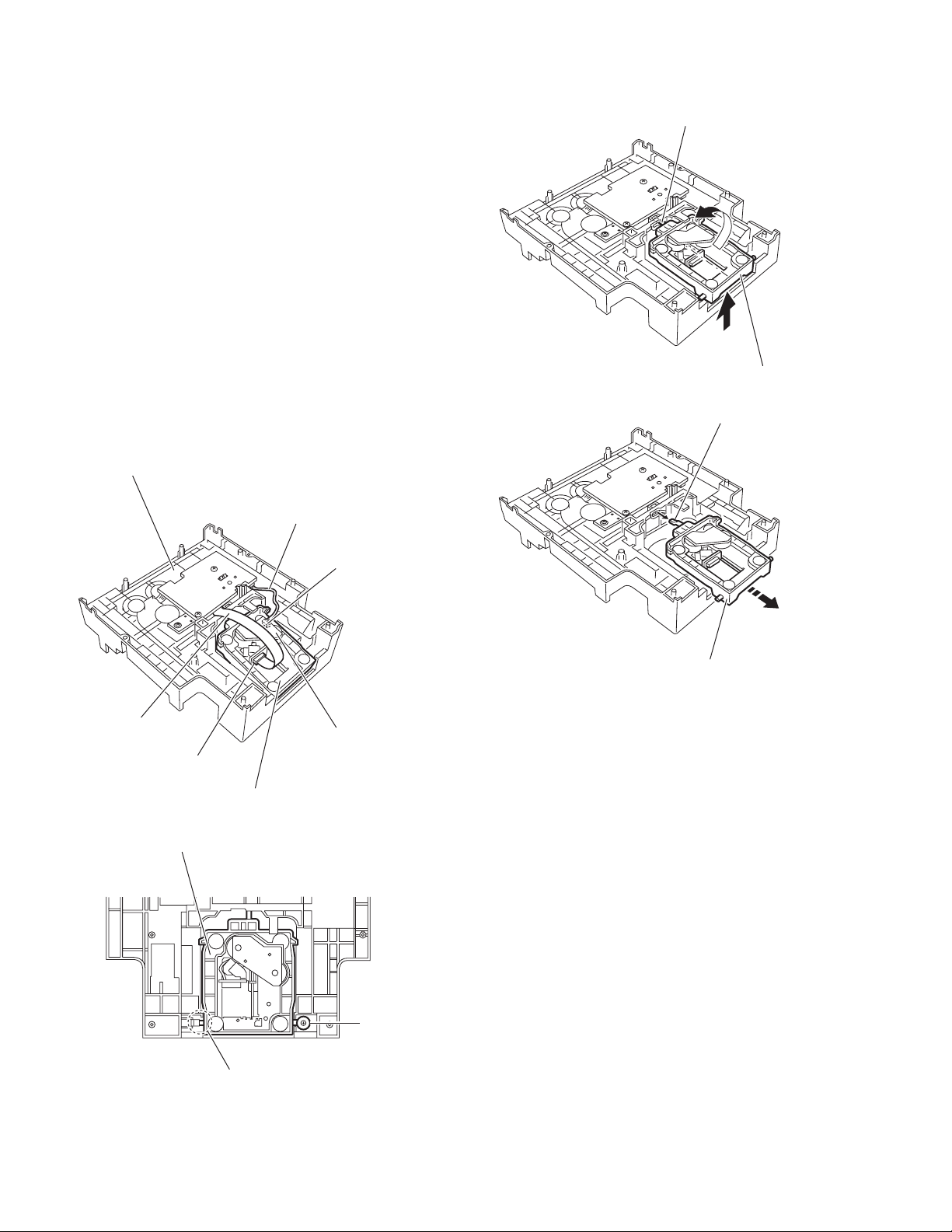

3.2.6 Removing the CD mechanism holder assembly (mechanism included)

(See Figs.9 to 13)

(1) Disconnect the wire from the connector on the CD mecha-

nism board in the CD mechanism holder assembly on the

bottom side of the CD changer mechanism assembly. (See

Fig.10.)

Attention:

Solder is put up before the card wire is removed from the

pickup unit connector on the CD mechanism assembly.

(When the card wire is removed without putting up sol-

der, the pickup unit might destroy.) (See Fig.9.)

(2) Disconnect the card wire from the pickup unit connector.

(See Fig.10.)

(3) Remove the screw E attaching the shaft on the right side of

the CD mechanism holder assembly. (See fig.11.)

(4) Pull outward the stopper fixing the shaft on the left side and

remove the CD mechanism holder assembly from behind

in the direction of the arrow. (See Figs.11 and 12.)

(5) Turn the CD mechanism holder assembly half around the

lift up slide shaft of the CD mechanism holder assembly un-

til the turntable is reversed, and pull out the CD mechanism

holder assembly. (See Figs.12 and 13.)

Fig.10

Fig.11

Fig.12

Fig.13

Connecter

CD mechanism holder assembly

CD changer mechanism assembly

Pickup unit connecter

Card wire

CD mechanism board

Wire

Stopper

CD mechanism holder assembly

E

CD mechanism holder assembly

Lift up slide shaft

CD mechanism holder assembly

Lift up slide shaft

(No.MB160)1-25

3.3 CD mechanism section

• Prior to performing the following procedures, remove the CD mechanism holder assembly from the CD changer mechanism assem-

bly. (See "3.2.6 Removing the CD mechanism holder assembly".)

3.3.1 Removing the pickup unit

(See Fig.1)

(1) Remove the cut-washer on the feed gear sleeve and pull

out the feed gear.

(2) Remove the two screws A fixing the pickup shaft.

(3) Remove the pickup unit.

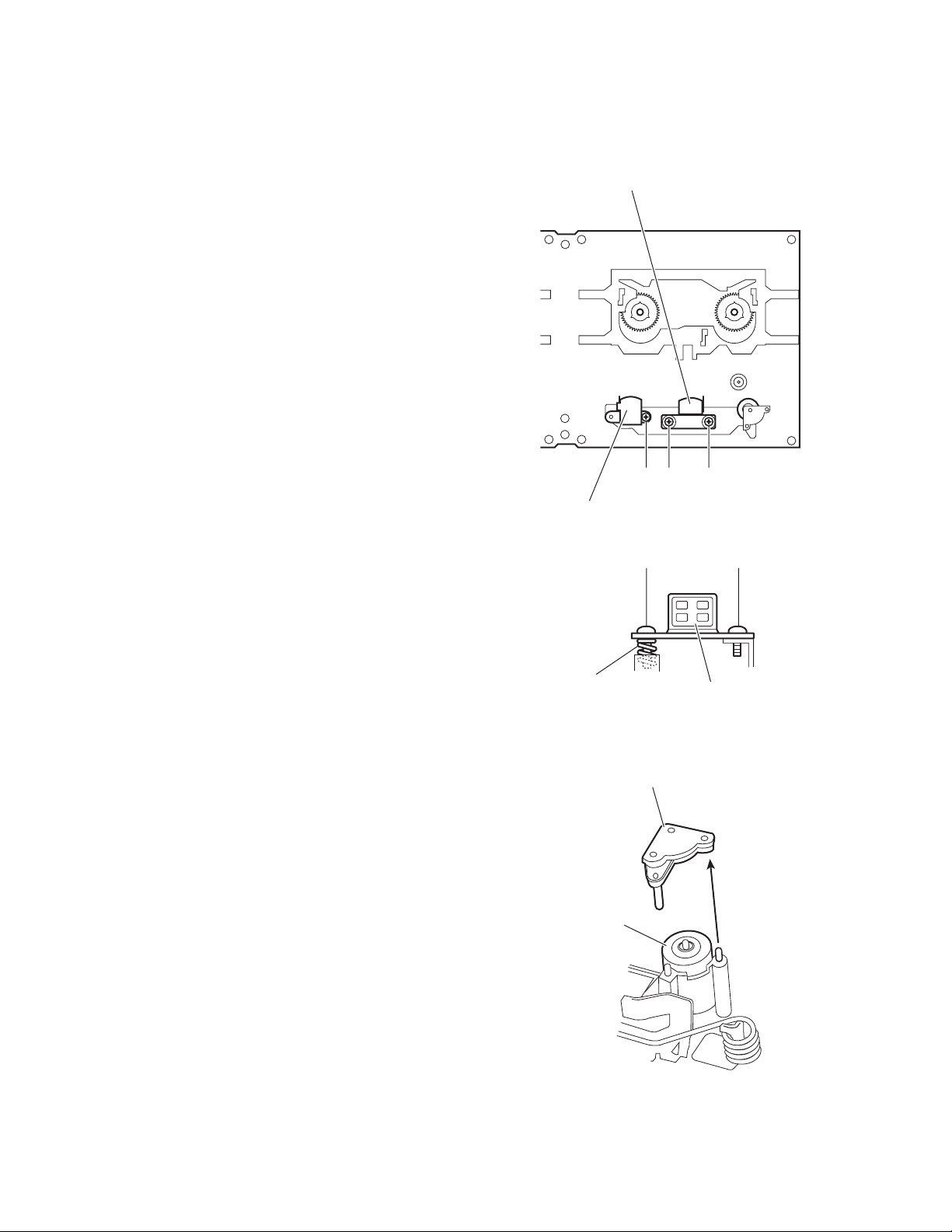

3.3.2 Removing the motor board

(See Fig.2.)

(1) Unsolder the motor terminal on the motor board.

(2) Remove the motor board.

3.3.3 Removing the feed motor

(See Fig.1.)

• Prior to performing the following procedures, remove the CD

motor board.

(1) Remove the two screws B and remove the feed motor.

(2) From the bottom side of the CD mechanism holder assem-

bly, take out the feed motor.

3.3.4 Removing the spindle motor

(See Fig.2.)

Reference:

The spindle motor cannot be removed as a single unit.

When removing the spindle motor, change the chassis and

turntable together as a unit.

Fig.1

Fig.2

Pickup unit

Cut-washer

Feed Gear

Pickup shaft

AA

B

Feed motor

Unsolder

Unsolder

Feed motor

Spindle motor

Motor board

1-26 (No.MB160)

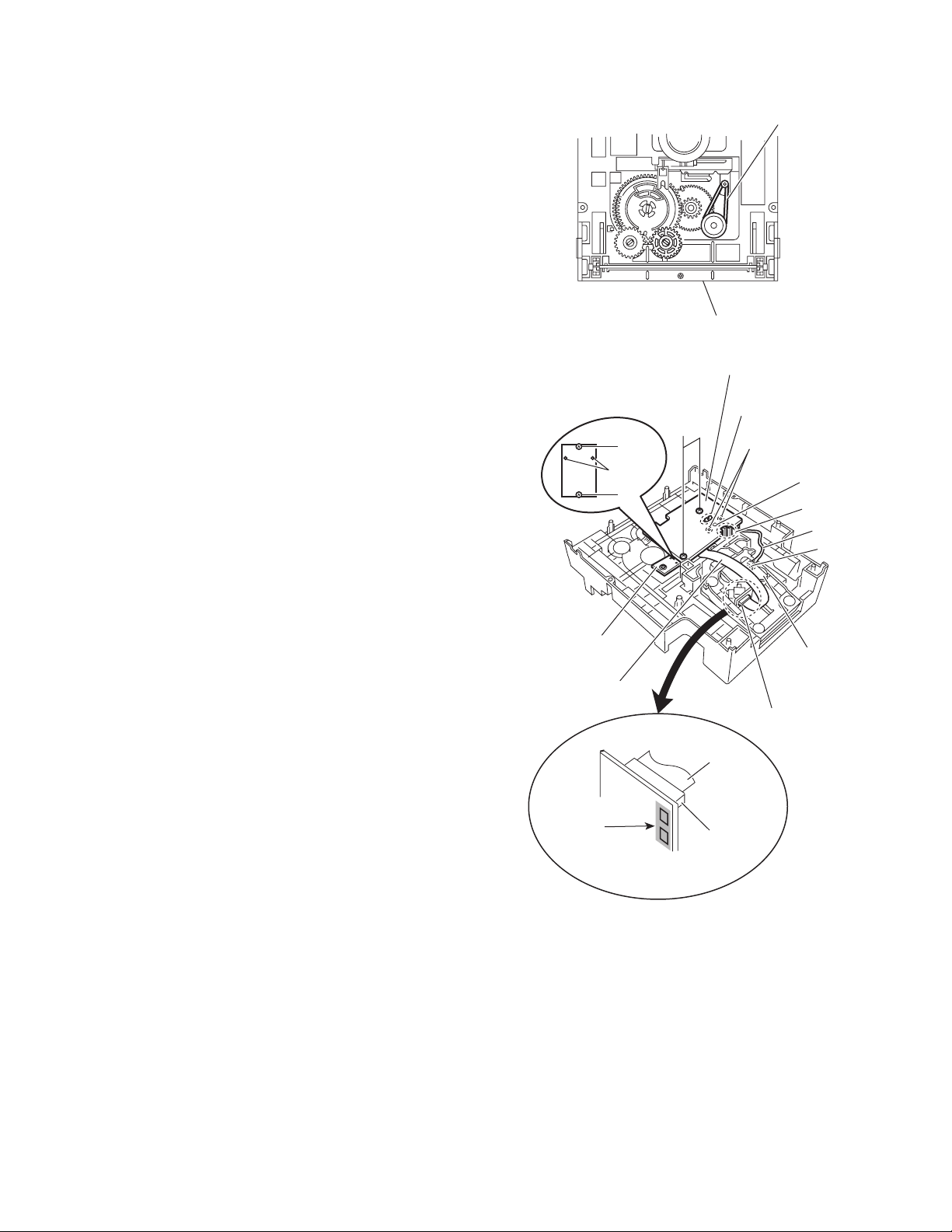

3.4 Cassette mechanism section

• Prior to performing the following procedures, remove the cassette deck mechanism assembly. (See "3.1.16 Removing the cassette

deck mechanism assembly".)

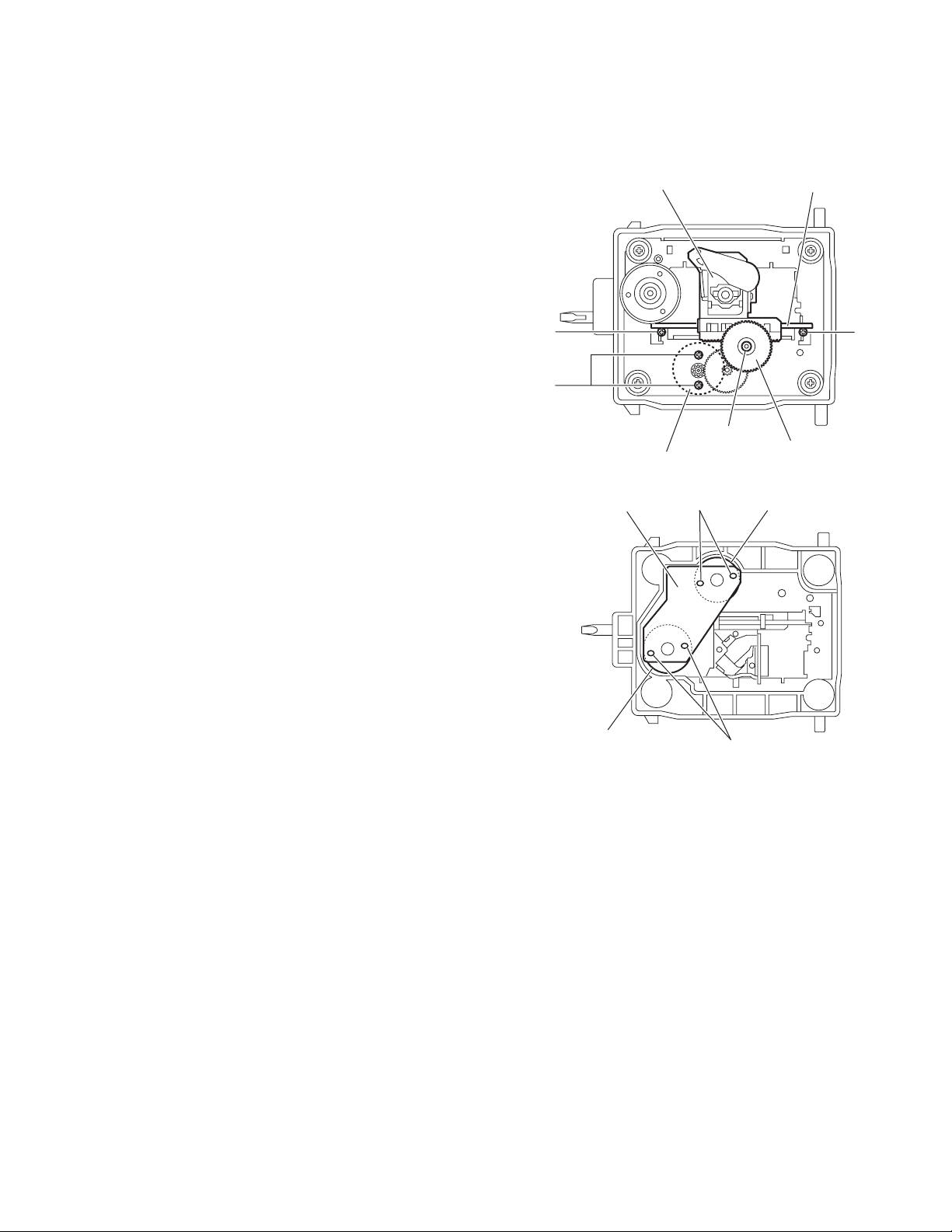

3.4.1 Removing the R/P head

(See Figs.1 and 2)

(1) Remove the screw A attaching the R/P head.

(2) Remove the screw B attaching the R/P head.

Note:

After attaching the R/P head, perform the electrical adjust-

ment. (See "ADJUSTMENT" section.)

3.4.2 Removing the erase head

(See Fig.1)

Remove the screw C attaching the erase head.

Fig.1

Fig.2

3.4.3 Removing the pinch roller

(See Fig.3)

(1) Pull out the pinch roller stopper.

(2) Pull out the pinch roller.

Fig.3

R/P Head

Erase head

ABC

Spring

R/P Head

AB

Pinch roller

Pinch roller stopper

Loading...

Loading...