JVC MXG-50 Service manual

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

No.20978

Jul. 2001

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

MX-G50

MX-G50

Area Suffix

US

UW

UY

Singapore

Brazil,Mexico,Peru

Argentina

Contents

Safety Precautions

Important for laser products

Preventing static electricity

Disassembly method

Wiring connection

Adjustment method

Flow of functional operation

until TOC read

Maintenance of laser pickup

Replacement of laser pickup

Trouble shooting

Description of major ICs

1-2

1-3

1-4

1-5

1-20

1-21

1-25

1-26

1-26

1-27

1-30~43

DISC SKIP

VOLUME

VOLUME

+

–

RM–SMXG50U REMOTE CONTROL

STANDBY/ON

12

3

4

5

6

78

9

10

+10

SLEEP

SUBWOOFER

LEVEL

SOUND

MODE

FM MODE

TAPE A/B

FADE

MUTING

FM/AM

AUX

/

CD

TAPE

zzzzz

ECHO

CANCEL

/DEMO

PRESET

COMPU PLAY CONTROL

PLAY & EXCHANGE

STANDBY/ON

STANDBY

DISC CHANGE

SOUND

MODE

SUBWOOFER

LEVEL

CD-R

/

RW PLAYBACK

COMPACT

DIGITAL AUDIO

COMPACT COMPONENT SYSTEM

MX-G50

CLOCK

/

TIMER

DISPLAY

PHONES

REPEAT PROGRAM

REC START

/STOP

CD

REC START

DUBBING

TAPE A

TUNING

SET

TAPE B

RANDOM

EJECT

PLAY

FULL - LOGIC CONTROL

A

EJECT

REC/PLAY

CD SYNCHRO RECORDING

B

SP-MXG50

SP-MXG50CA-MXG50

(No MIC jack and MIC LEVEL volume for UY ver.)

MX-G50

1-2

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perfor m an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Good earth ground

Place this

probe on

each exposed

metal part.

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

1500 10W

0.15 F AC TYPE

!

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the J and C version)

MX-G50

1-3

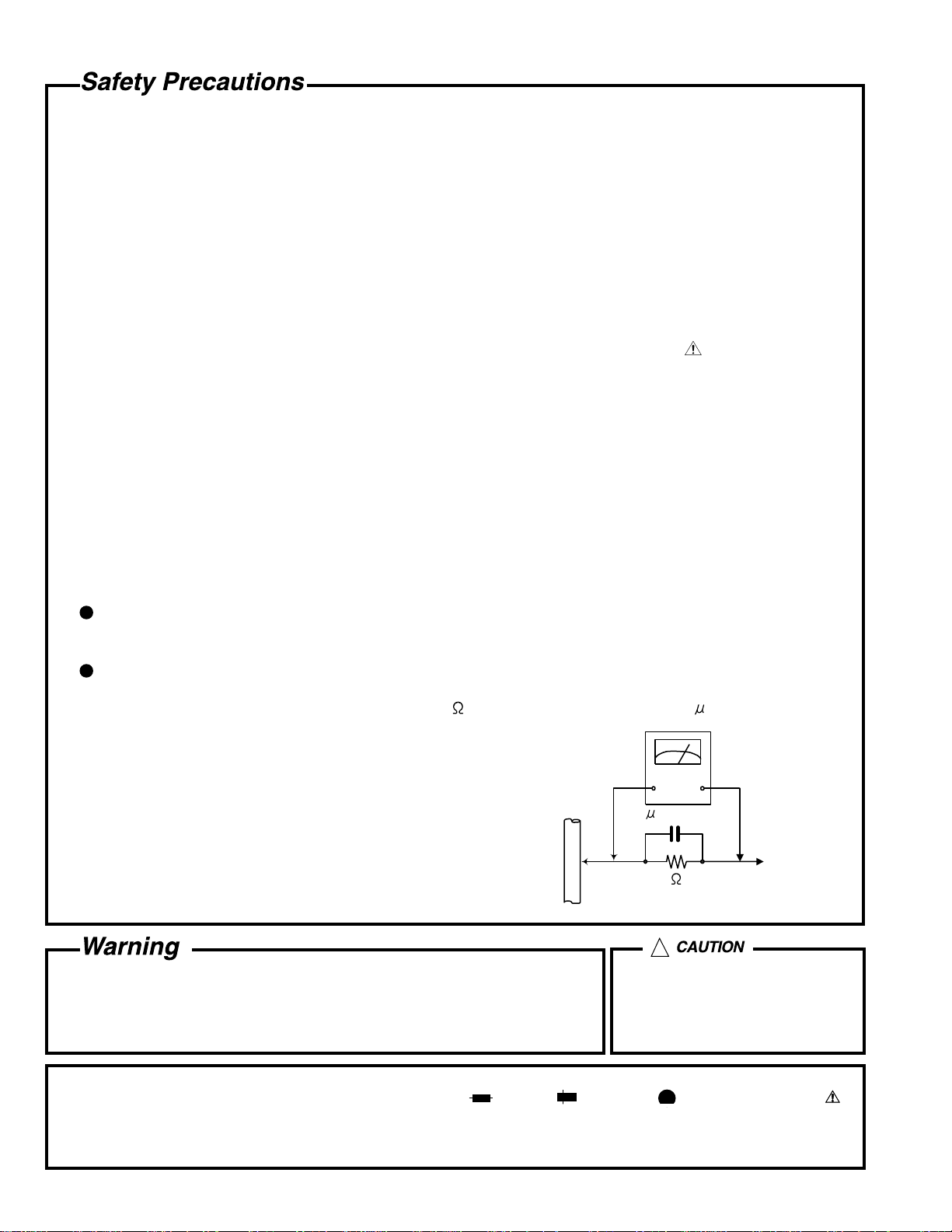

Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

Reproduction and position of labels

WARNING LABEL

!

CAUTION

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

CLASS 1

LASER PRODUCT

MX-G50

1-4

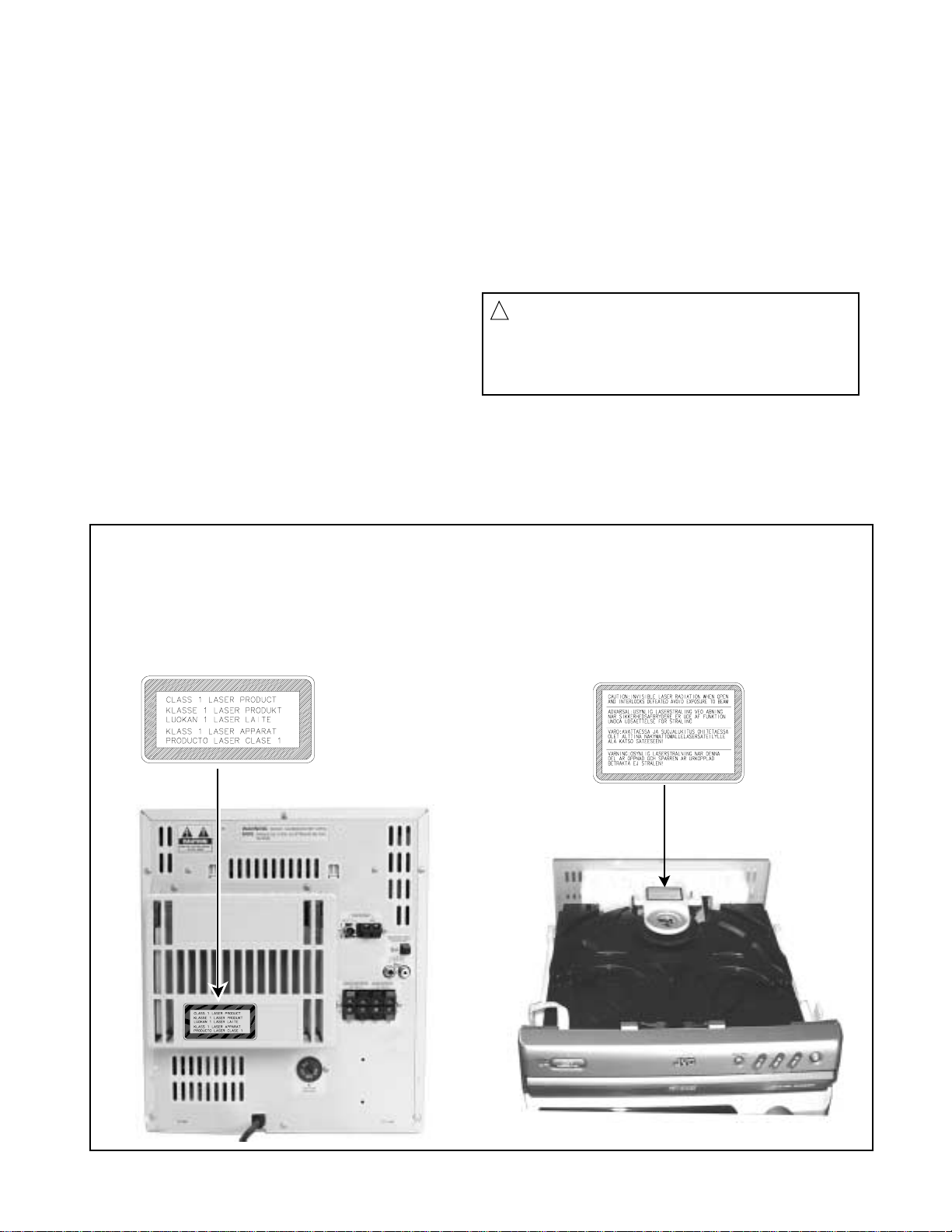

Preventing static electricity

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity of

the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

Conductive material

(conductive sheet) or iron plate

(caption)

Anti-static wrist strap

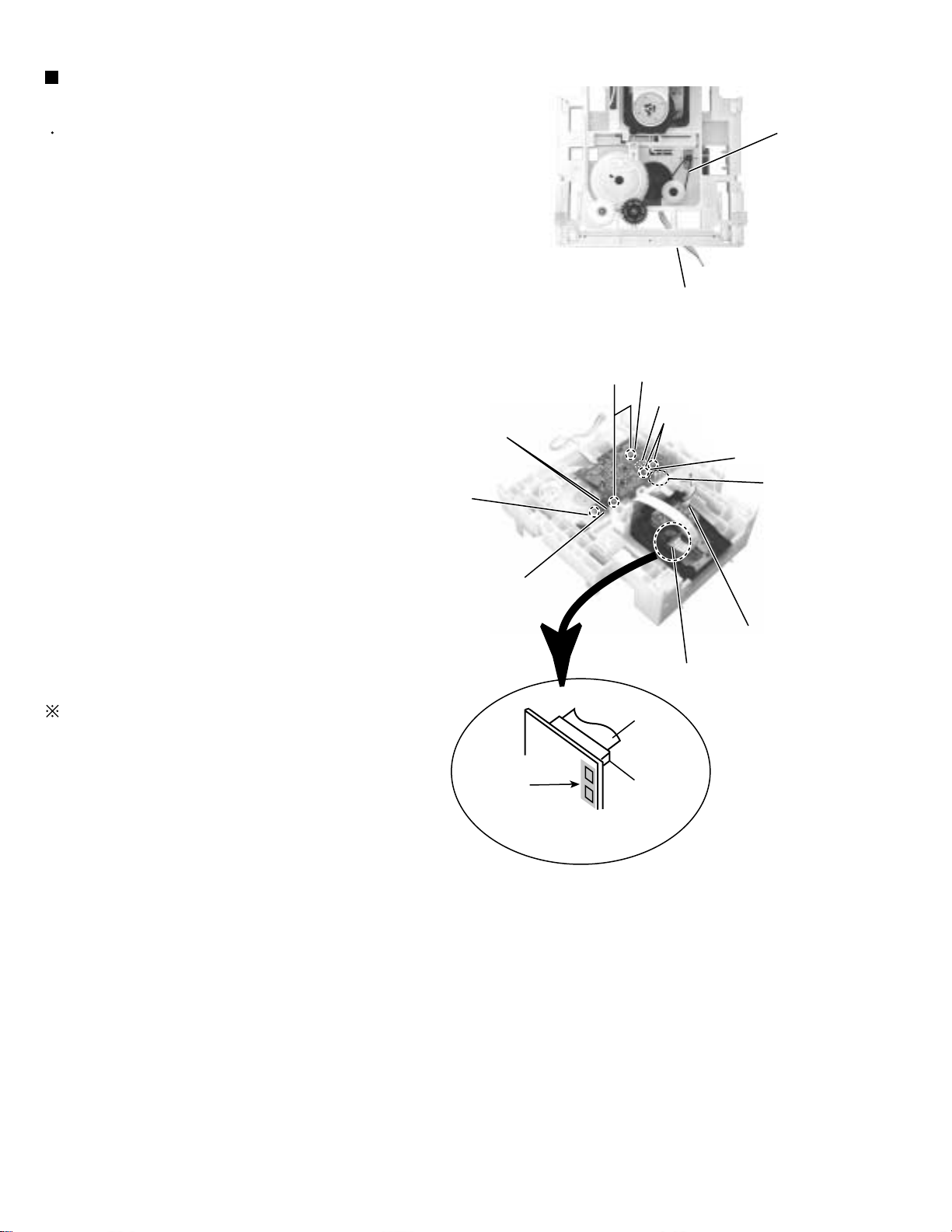

Attention when CD mechanism assembly is decomposed

1. Remove the CD changer unit.

2. Remove the CD changer mechanism.

3. Solder is put up before the card wire is removed from the pickup unit

connector on the CD mechanism assembly.

(When the card wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

4. Please remove solder after connecting the card wire with the pickup unit

connector when you install picking up in the substrate.

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the CD mechanism assembly.

Soldering

Fig.1

Fig.2

Card wire

Card wire

Pickup unit

connector

Pickup unit

connector

CD changer unit

CD changer

mechanism

MX-G50

1-5

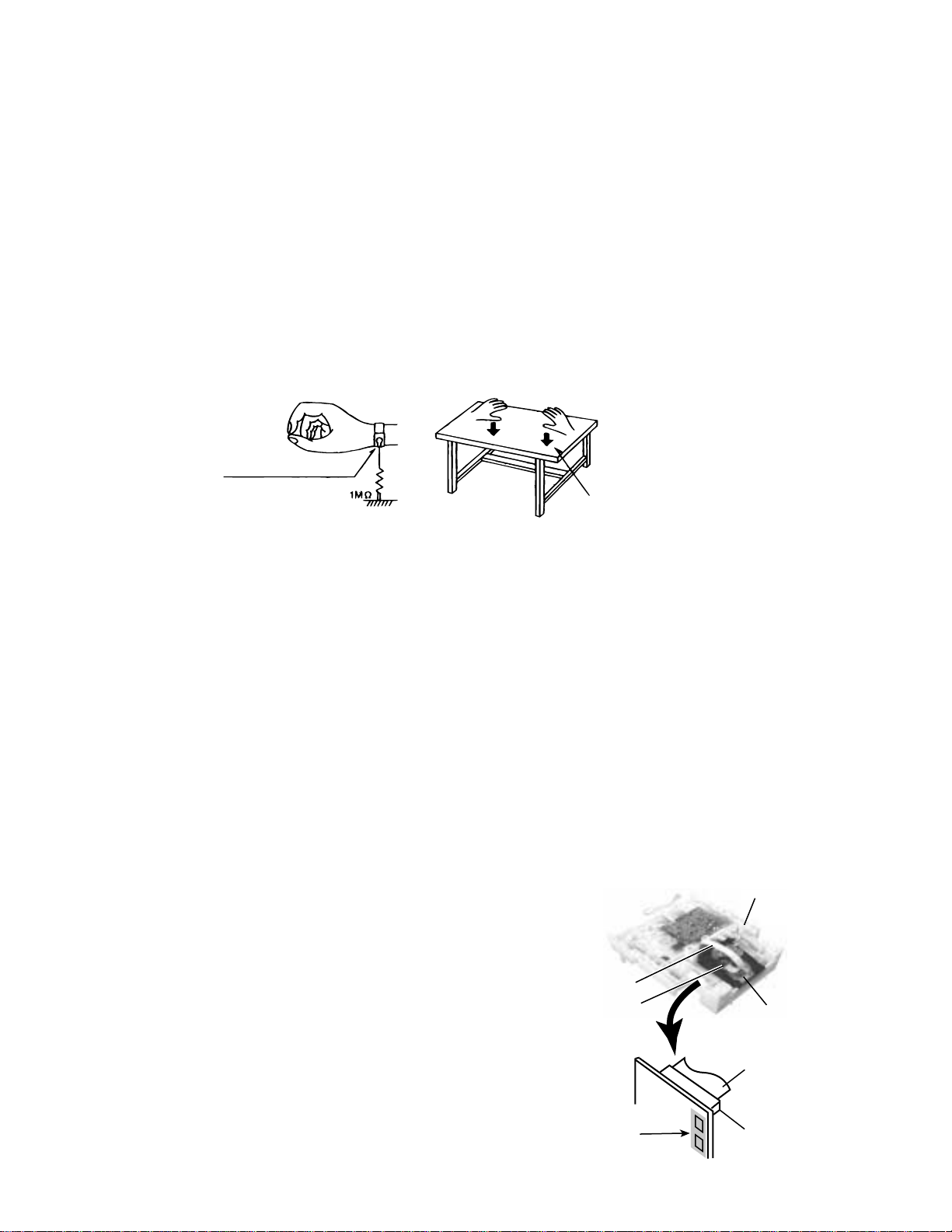

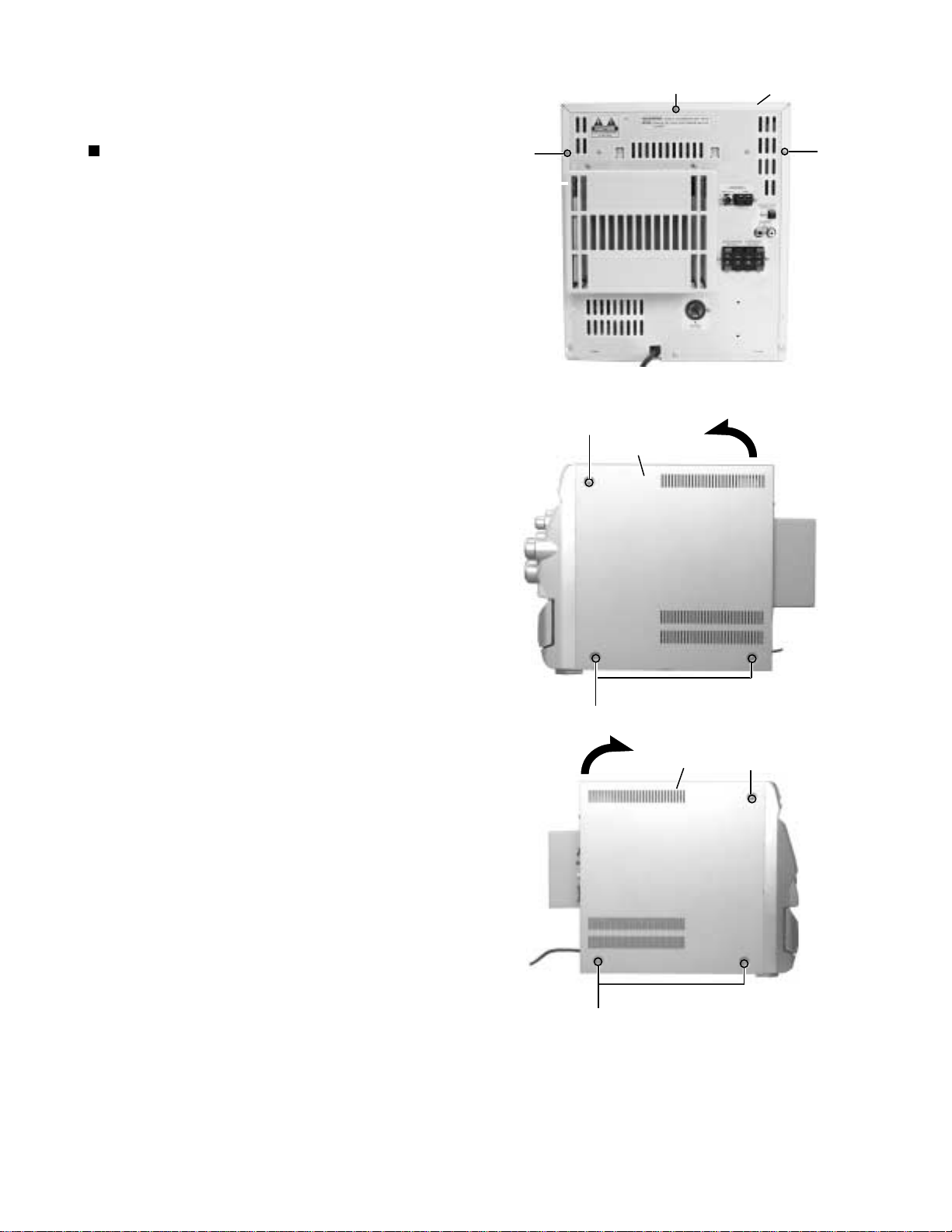

Remove the three screws A attaching the metal

cover on the back of the body.

Remove the six screws B attaching the metal cover

on both sides of the body.

Remove the metal cover from the body by lifting the

rear part of the cover.

1.

2.

3.

Disassembly method

<Main body>

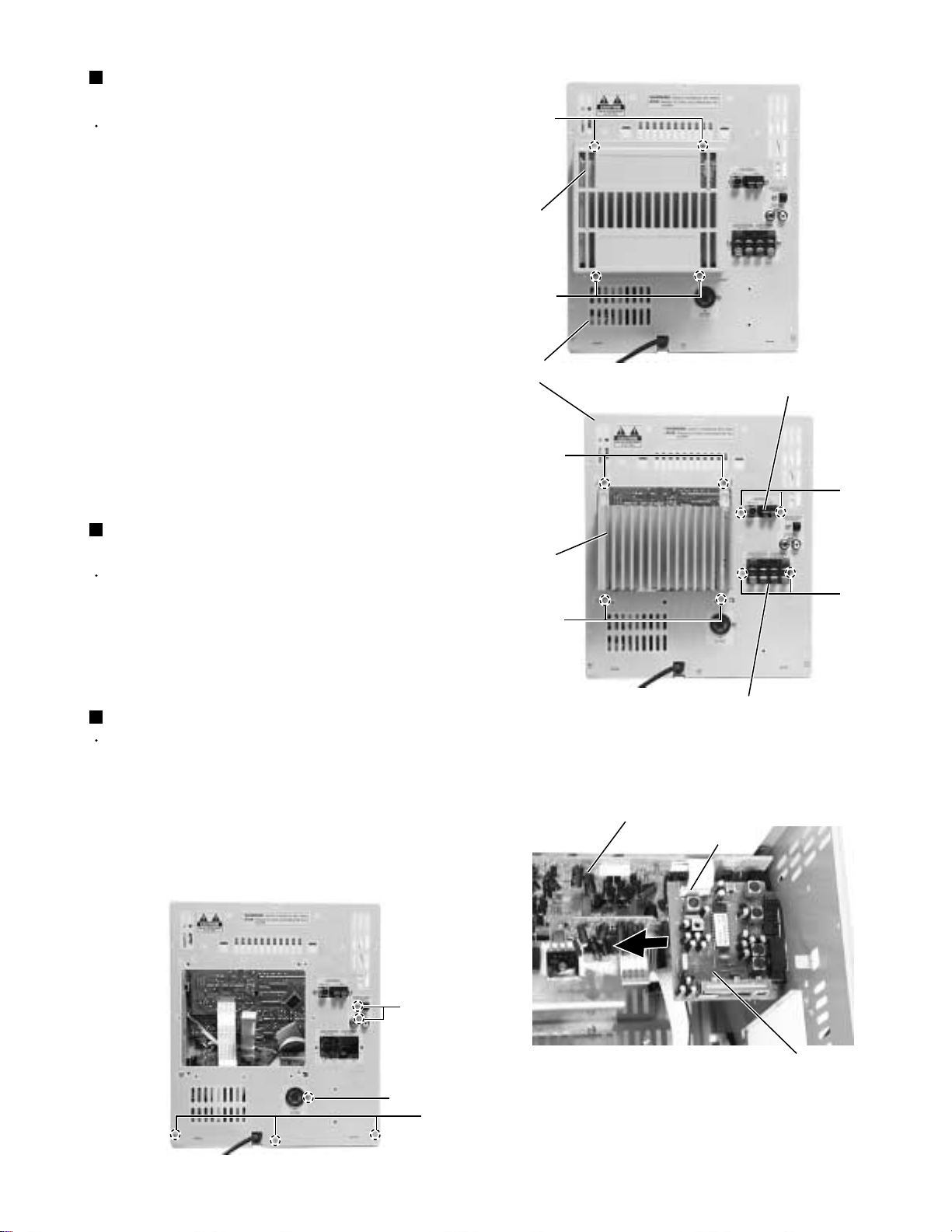

Removing the metal cover

(See Fig.1 to 3)

Do not break the front panel tab fitted

to the metal cover.

ATTENTION:

Fig.1

Fig.2

Fig.3

Metal cover

A

A

A

Metal cover

B

Metal cover

B

B

B

MX-G50

1-6

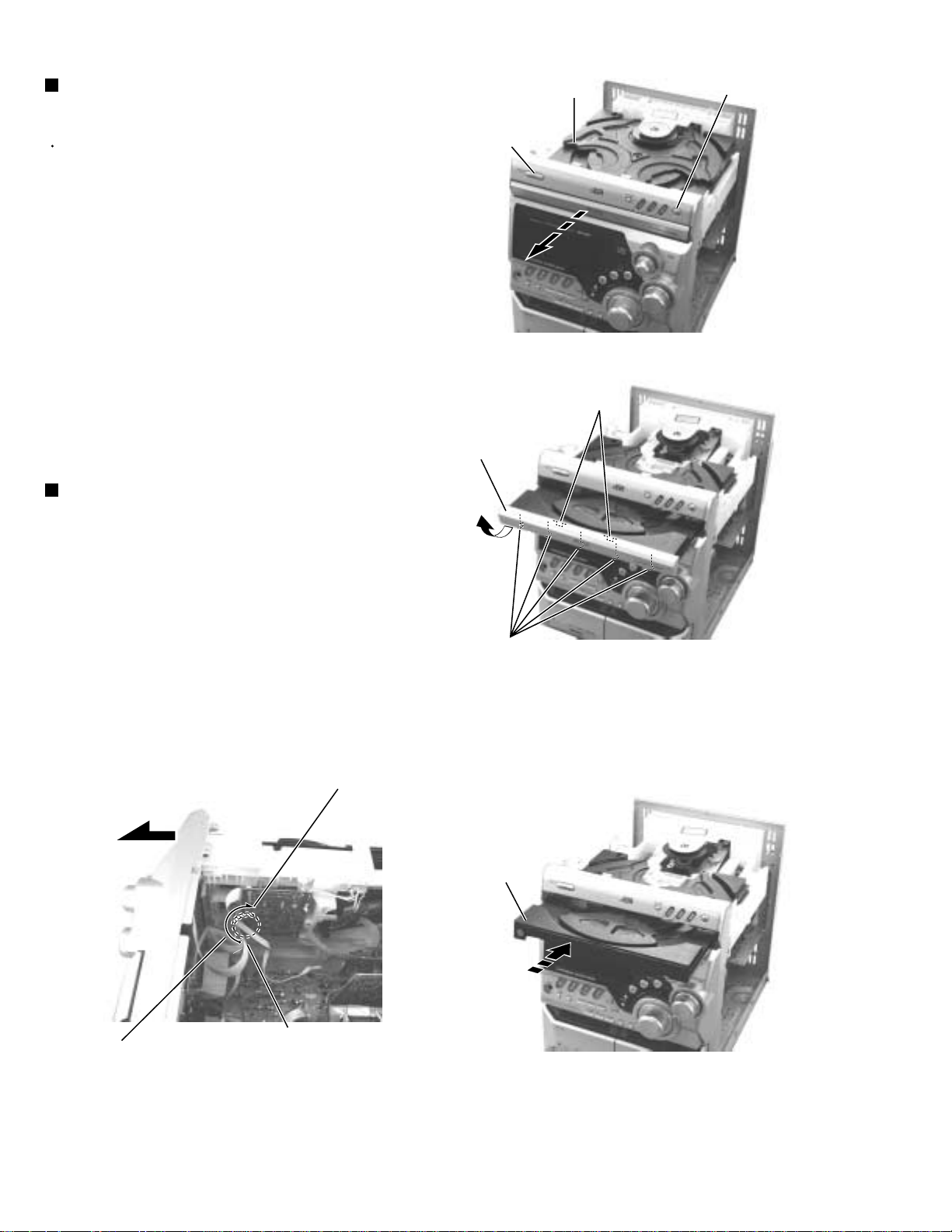

Prior to performing the following procedure, remove

the metal cover.

Press the POWER button. Press the OPEN/CLOSE

button to eject the CD tray.

After drawing the lower part of the tray fitting toward

the front, remove the five claws a. Then, while

moving the tray fitting upward, remove it.

Press the OPEN/CLOSE button to insert the tray.

1.

2.

3.

Removing the CD Tray fitting (1)

(See Fig. 4 to 6)

Turn the black loading pulley gear marked b from the

back of the CD changer unit as shown in Fig.7 and

draw the CD tray toward the front.

After drawing the lower part of the tray fitting toward

the front, remove the five claws a. Then, while

moving the tray fitting upward, remove it.

Push and insert the CD tray manually.

1.

2.

3.

Removing the CD Tray fitting (2)

(See Fig. 5 to 7)

- How to eject the CD tray without turning on power -

Fig.4

Fig.5

Fig.6

Fig.7

POWER button

OPEN/CLOSE button

CD tray

Joint

Claw a

CD tray fitting

(See Fig. 24)

CD tray

This slot of the board.

b

(Loading pulley gear)

MX-G50

1-7

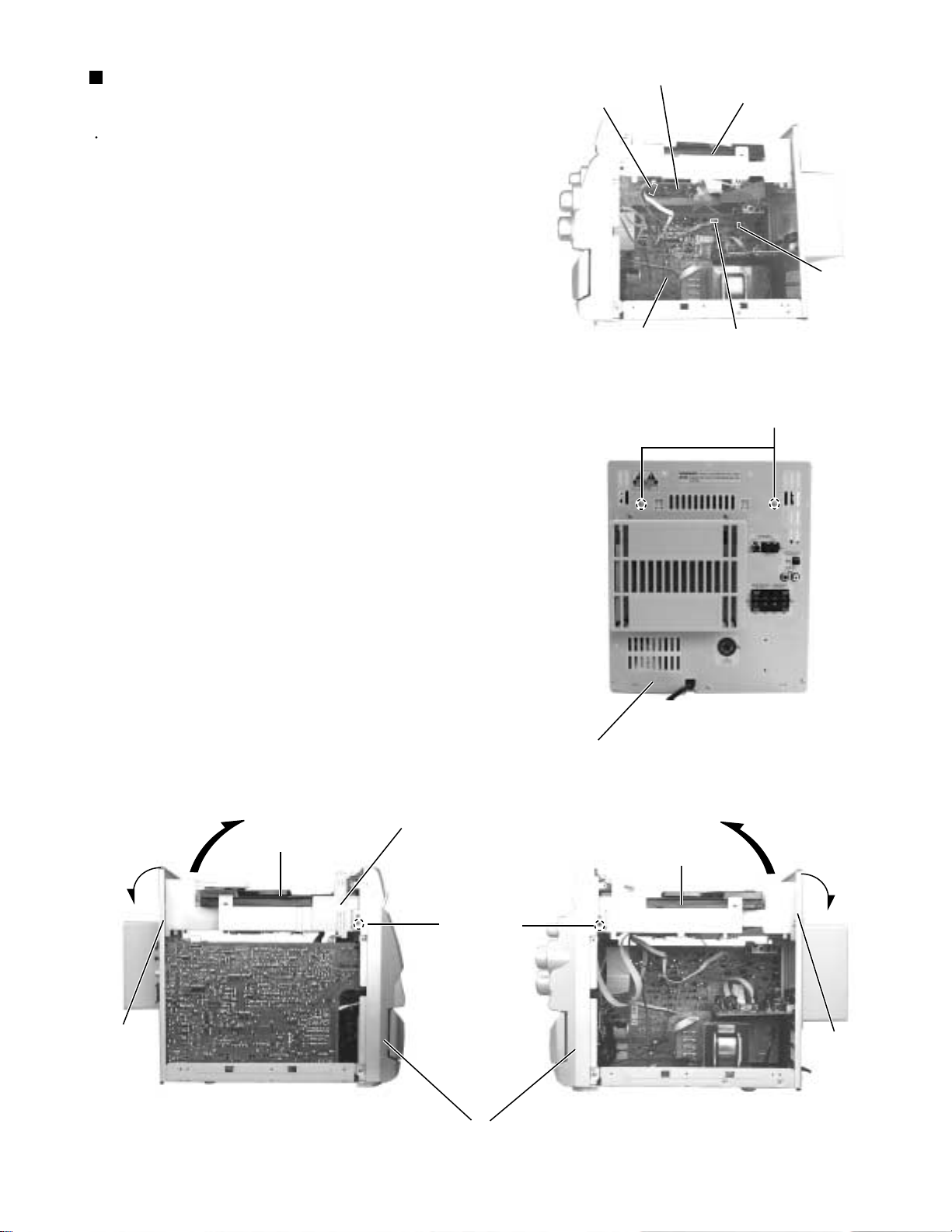

Prior to performing the following procedure, remove

the metal cover.

Disconnect the card wire which is attached with

adhesive to the left side of the CD changer unit.

Disconnect the card wire from connector CW105 of

the CD servo board on the back of the CD changer

unit.

Disconnect the harness from connector RCW6 &

OCW on the inner side of the main board in the

body.

Remove the two screws C attaching the CD changer

unit on the back of the body.

Remove the two screws D attaching the CD changer

unit on the both side of the body.

Draw the CD changer unit upward from behind while

pulling the rear panel outward.

1.

2.

3.

4.

5.

6.

Removing the CD changer unit

(See Fig.8 to 10)

Fig.8

Fig.9

Fig.10 aFig.10 b

CW105

CD servo board

CD changer unit

Main board

RCW6

OCW

Rear panel

C

D

D

Rear panel

Rear panel

Front panel assembly

Adhesive card wire strap

CD changer unit

CD changer unit

MX-G50

1-8

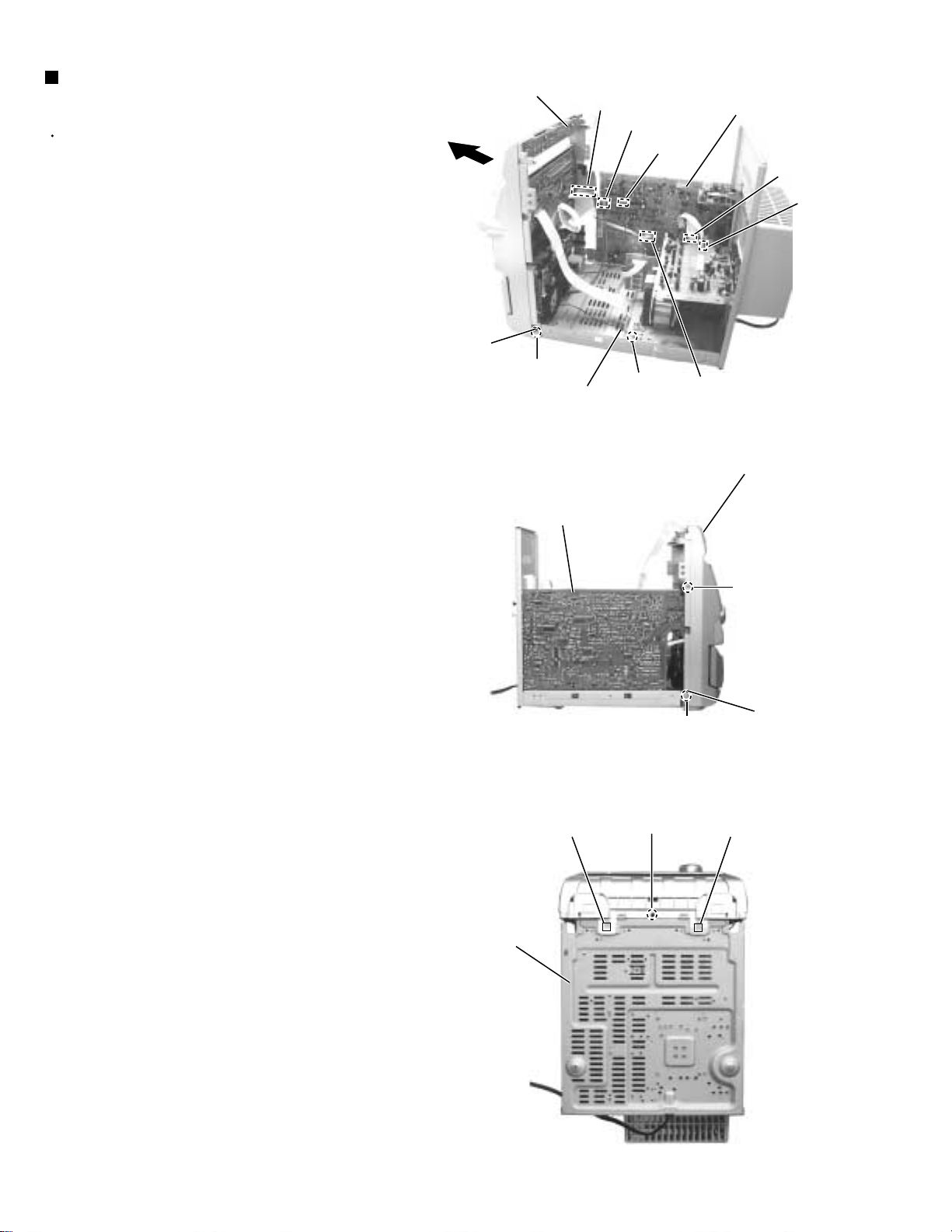

Prior to performing the following procedure, remove

the metal cover and the CD changer unit.

Disconnect the card wire from connector FCW3 and

the harness from connector JCW1, JCW2 and

HCW3 on the inner side of the main board in the

body.

Remove the two screws E attaching the front panel

assembly on both sides of the body.

Remove the screw F attaching the earth terminal

extending from the cassette mechanism assembly.

Remove the screw G attaching the front panel

assembly and main board.

Remove the screw H attaching the front panel

assembly on the bottom of the body.

Release the two joints c on both sides and two joints

d on the bottom of the body using a screwdriver.

1.

2.

3.

4.

5.

6.

Removing the front panel assembly

(See Fig.11 to 13)

Fig.11

Fig.12

Fig.13

Main board

FCW3

JCW2

JCW1

HCW3

ACW1

ACW2

Front panel assembly

Joint c

earth wire

E

F

Front panel assembly

G

E

Main board

H

Joint d

Joint d

Joint c

Bottom side

MX-G50

1-9

Prior to performing the following procedure, remove

the metal cover and the CD changer unit.

Remove the four screws I attaching the heat sink

cover on the back of the body. Remove the heat sink

cover.

Remove the four screws J attaching the heat sink &

amp. board to the rear panel on the back of the

body.

Remove the two screws K attaching the speaker

terminal to the rear panel on the back of the body.

Disconnect the card wire from connector ACW1 and

the harness from connector ACW2 on the amp.

board. (See Fig.11)

After moving the heat sink upward, remove the

claws. Then pull out the heat sink & AMP board

inward.

1.

2.

3.

4.

5.

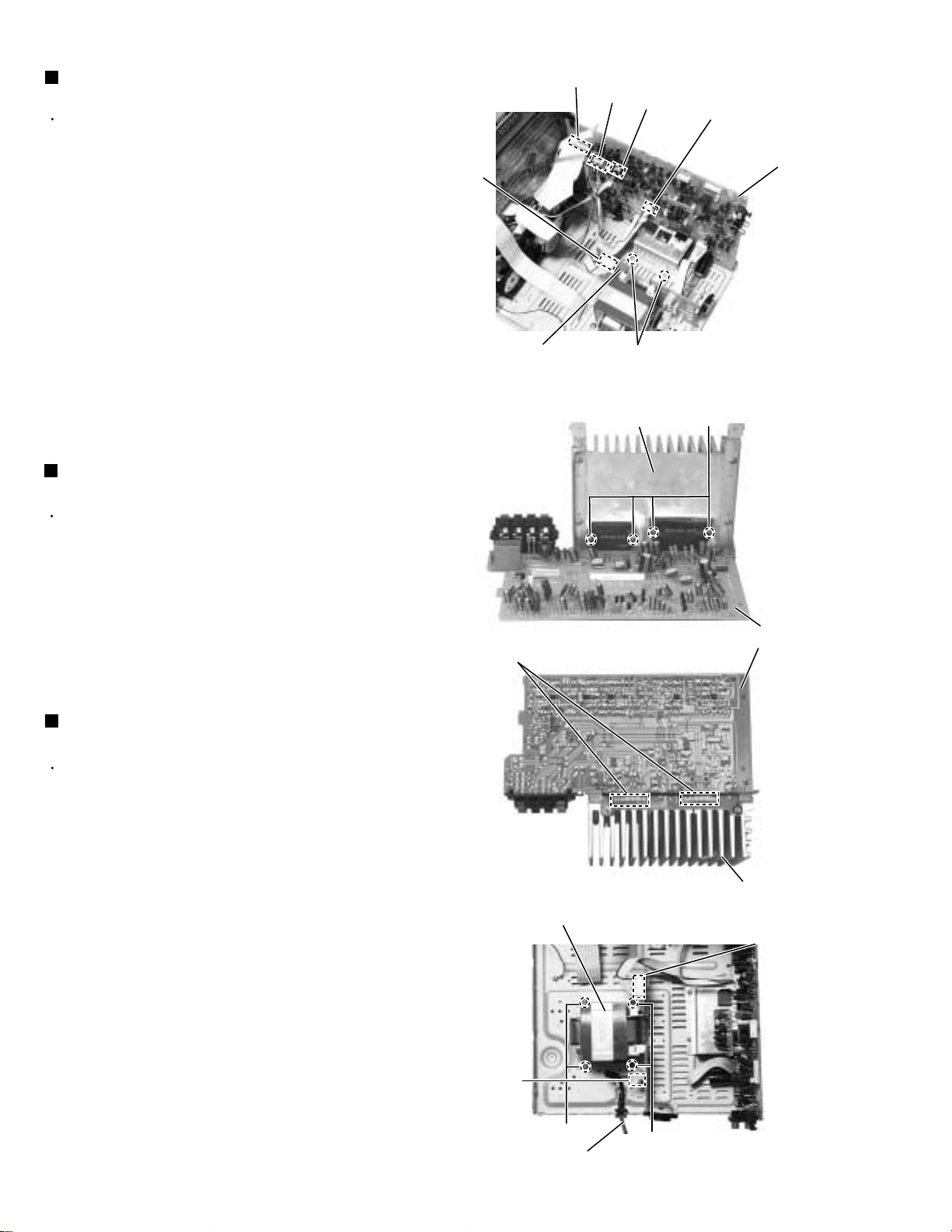

Removing the heat sink & amp. board

(See Fig.14 and 15)

Prior to performing the following procedure, remove

the metal cover and CD changer unit.

Disconnect the card wire from connector CON01 on

the tuner board.

Remove the two screws L attaching the tuner board.

1.

2.

Removing the tuner board

(See Fig.15 and 16)

Prior to performing the following procedure, remove

the metal cover, CD changer unit, heat sink & amp.

board and tuner board.

Remove the five screws M attaching the rear panel.

Remove the screw M' attaching the voltage selector.

(Only US/ UW)

1.

2.

Removing the rear cover (See Fig.17)

Fig.14

Fig.15

Fig.16

Fig.17

Rear panel

Heat sink

cover

Heat sink

Speaker terminal

Tuner terminal

K

L

I

I

Main board

Tuner board

CON01

J

J

M

M

M'

MX-G50

1-10

Prior to performing the following procedure, remove

the metal cover, CD changer unit and heat sink &

amp. board.

Remove the four screws P attaching the power ICs

to the heat sink.

Unsolder the power ICs solder point.

1.

2.

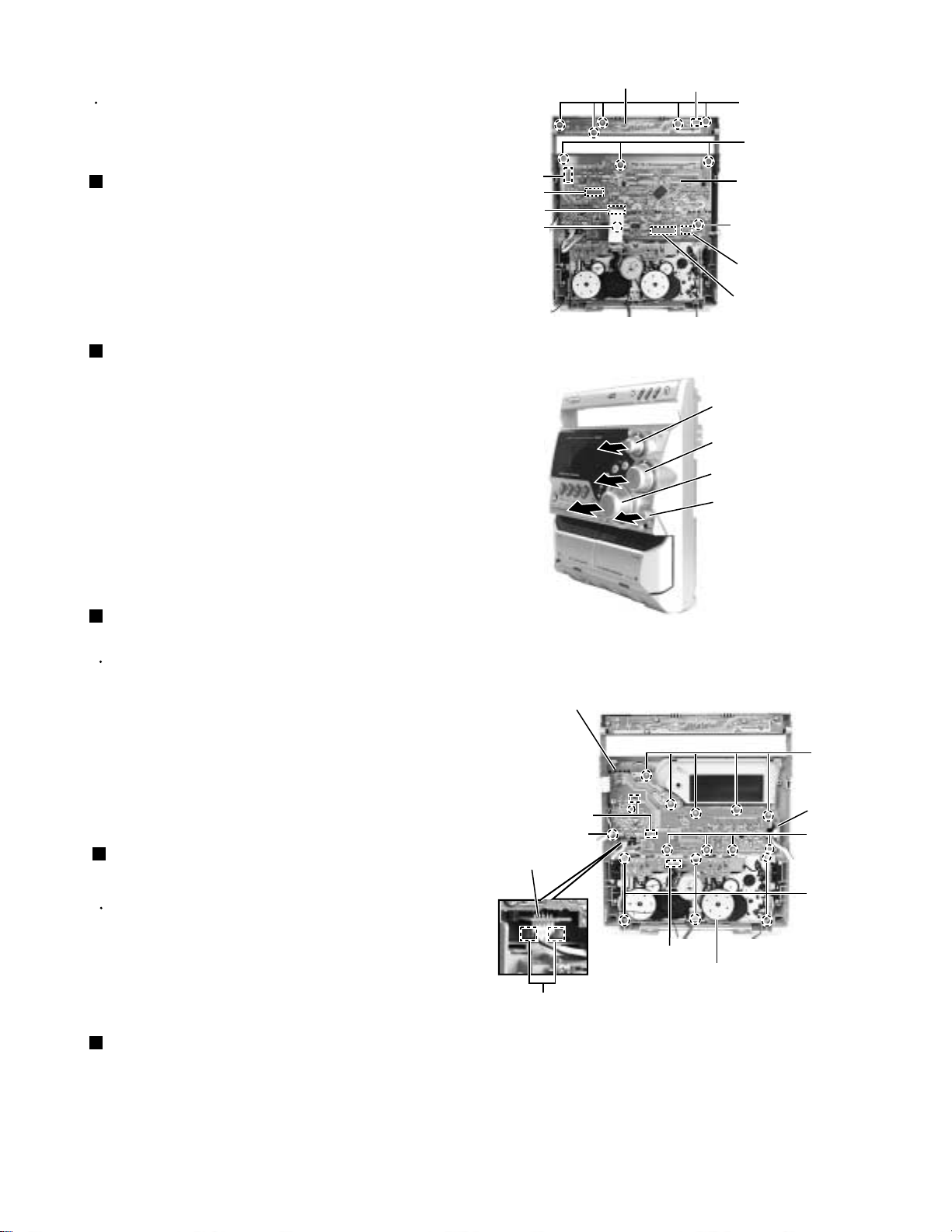

Removing the power ICs

(See Fig.19 and 20)

Prior to performing the following procedure, remove

the metal cover, CD changer unit, heat sink & amp.

board tuner board and rear cover.

Disconnect the card wire from connector FCW3 and

the harness from connector JCW1, JCW2 and

HCW3 on the main board.

Disconnect the harness from connector PCW1 on

the power transformer board.

Remove the screw G attaching the main board

holder. (See Fig.12)

Remove the two screws N attaching the heat sink

and bottom chassis.

1.

2.

3.

4.

Removing the main board

(See Fig. 18)

Prior to performing the following procedure, remove

the metal cover, heat sink & amp. board, tuner board

and rear cover.

Disconnect the power cord from connector RCW2 of

the power transformer board.

Disconnect the harness from connector PCW1 of the

power transformer board.

Remove the four screws R attaching the power

transformer and the screw S attaching the earth

terminal.

1.

2.

3.

Removing the power transformer

(See Fig .21)

Fig.21

Fig.20

Fig.19

Fig.18

Transformer board

N

R

R

P

Heat sink

Amp. board

FCW3

JCW2

JCW1

HCW3

PCW1

Heat sink

Power cord

Power transformer

Power ICs solder point

Main board

RCW2

PCW1

MX-G50

1-11

Disconnect the card wire from the connector UCW3,

UCW4,UCW5 and UCW6 on the FL display &

system control board.

Remove the five screws R attaching the FL display &

system control board.

Disconnect the card wire from the connector UCW2

on the FL display & system control board.

1.

2.

3.

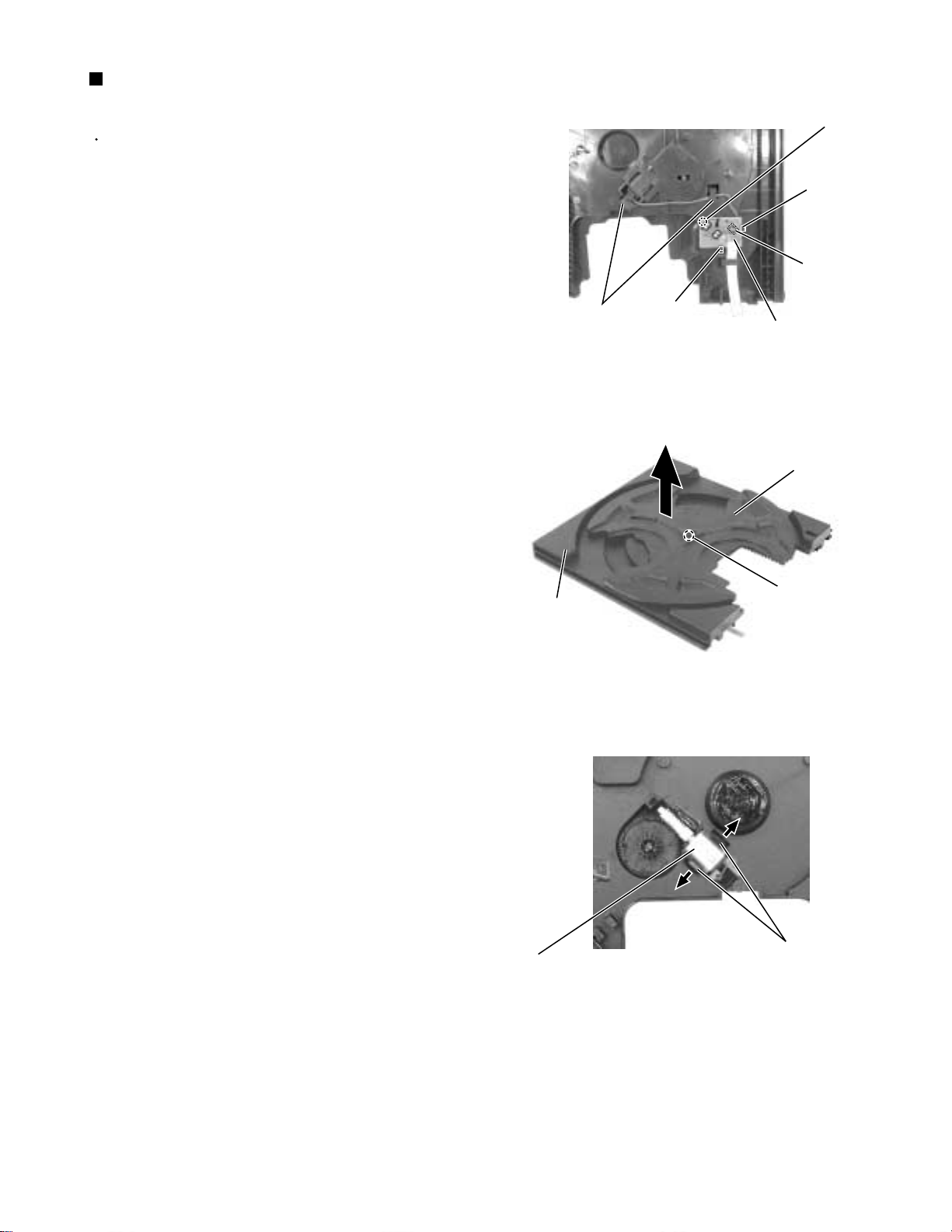

Removing the FL display & system

control board (See Fig.22)

Disconnect the card wire from connector UCW1 on

the power / CD switch board.

Remove the five screws Q attaching the power / CD

switch board.

1.

2.

Prior to performing the following procedure, remove

the metal cover, the CD changer unit and the front

panel assembly.

Removing the power / CD switch board

(See Fig.22)

Prior to performing the following procedure, remove

the FL display & system control board.

Pull out the SOUND MODE knob, ACTIVE BASS

EX. LEVEL knob, VOLUME knob and MIC LEVEL

knob(Only US/ UW) from front side.

Remove the ten screws S attaching the front board

and release the two tabs e out ward.

1.

2.

Removing the front board

(See Fig.23 and 24)

<Front panel assembly>

Prior to performing the following procedure remove

the FL display & system control board.

You can pull out the headphone board.

Remove the mic jack board with releasing the tab f.

(Only US/ UW)

1.

2.

Removing the headphone board & mic

jack board (See Fig.24)

Disconnect the card wire x from the mechanism

board on the cassette mechanism assembly.

Remove the six screws T attaching the cassette

mechanism assembly.

1.

2.

Removing the cassette mechanism

assembly (See Fig.24)

Fig.22

Fig.23

Fig.24

Q

Power / CD switch board

R

R

FL display & system

control board

SOUND MODE knob

VOLUME knob

ACTIVE BASS EX.

LEVEL knob

UCW2

UCW3

UCW4

UCW5

UCW6

UCW1

MIC LEVEL knob

(Only US/ UW)

R

Headphone

board

Cassette mechanism assembly

S

S

T

Front board

Card wire x

Tab e

S

Mic jack board

(Only US/ UW)

Tab f

MX-G50

1-12

Turn the black loading pulley gear on the under side

of the CD changer unit in the direction of the arrow

and draw the CD tray toward the front until it stops.

Disconnect the card wire from connector CW103 of

the CD servo board on the upper side of the CD

changer unit.

Push down the two tray stoppers marked g and pull

out the CD tray.

1.

2.

3.

Align the gear-cam with the gear-tray as shown

fig.27, then mount the CD tray.

When assembling the CD tray, take extreme care not

engage with gear - synchro.

1.

2.

Prior to performing the following procedure, remove

the CD changer unit.

Removing the CD tray (See Fig.25 to 27)

Reinstall the CD tray (See Fig.28 to 29)

<CD changer unit>

Fig.26

Fig.25

Fig.27

Fig.28 Fig.29

Loading pulley gear

CD tray

CD tray

CD tray

Gear-convert

Gear-convert

Gear-cam

Gear-tray

Gear-synchro

Gear-tray

Gear-tray

Gear-cam

timing point

CD tray

CD servo board

CW103

g

(Tray stopper)

g (Tray stopper)

MX-G50

1-13

Prior to performing the following procedure, remove

the CD tray.

Remove the screw X attaching the sensor board and

release the two tabs h attaching the sensor board on

the under side of the CD tray.

Disconnect the harness from connector CW1 on the

sensor board and release the harness from the two

hooks i. Remove the sensor board.

Remove the screw Y attaching the turn table. Detach

the turn table from the tray.

Pull outward the tab marked j attaching the turn table

motor assembly on the upper side of the tray and

detach the turn table motor assembly from the tray.

1.

2.

3.

4.

Removing the sensor board / the turn

table motor assembly (See Fig.30 to 32)

Fig.31

Fig.29

Fig.32

h

h

i

Sensor board

CW1

Turn table

Tray

Y

Turn table motor assembly

j

X

MX-G50

1-14

Prior to performing the following procedure, remove

the CD tray.

Detach the belt from the pulley on the upper side of

the CD changer unit (Do not stain the belt with

grease).

Disconnect the card wire from the pickup unit

connector on the under side of the CD changer unit.

Attention : Solder is put up before the card wire is

removed from the pick-up unit

connector on the CD mechanism

assembly.

(When the card wire is removed without

putting up solder, the CD pick-up unit

assembly might destroy.)

Disconnect the motor wire harness from connector

on the CD servo board.

Remove the screw Z attaching the switch board and

release the two tabs k attaching the switch board

outward and detach the switch board.

Remove the two screws A' attaching the CD servo

board and . First release the n side of the two tabs l

and two tabs m attaching the CD servo board motor

to raise the CD servo board slightly, then release the

CD servo board.

If the tabs l and m are hard to release, it is

recommendable to unsolder the two soldered points

on the motor terminal of the CD servo board.

1.

2.

3.

4.

5.

Removing the belt, the CD servo board

and the switch board (See Fig.33 and 34)

Soldering

Card wire

Picup unit

connector

Fig.34

Fig.33

Belt

CD changer unit

A'

CD servo board

Tabs m

Tabs l

Soldered points

Motor

Switch board

Z

CW3

Tabs k

CD mechanism board

motor connecter

Pickup unit connector

MX-G50

1-15

Disconnect the harness from connector on the CD

mechanism board in the CD mechanism assembly

on the under side of the CD changer unit. Disconnect

the card wire from the pickup unit connector.

Attention : Solder is put up before the card wire is

removed from the pick-up unit

connector on the CD mechanism

assembly. (Refer to Fig. 34)

(When the card wire is removed without

putting up solder, the CD pick-up unit

assembly might destroy.)

Remove the screw B' attaching the shaft on the right

side of the CD mechanism holder assembly. Pull

outward the stopper fixing the shaft on the left side

and remove the CD mechanism holder assembly

from behind in the direction of the arrow y.

Turn the CD mechanism holder assembly half

around the lift up slide shaft n of the CD mechanism

holder assembly until the turn table is reversed, and

pull out the CD mechanism holder assembly.

1.

2.

3.

Removing the CD mechanism holder

assembly (mechanism included)

(See Fig.35 to 38)

Fig.35

Fig.36

Fig.37

Fig.38

Motor connecter

CD mechanism holder assembly

CD changer unit

Pickup unit connector

B'

CD mechanism holder assembly

Stopper

CD mechanism holder assembly

Lift up slide shaft n

Lift up slide shaft

CD mechanism holder assembly

y

MX-G50

1-16

Fig.2

Fig.1

Cut washer

Unsolder

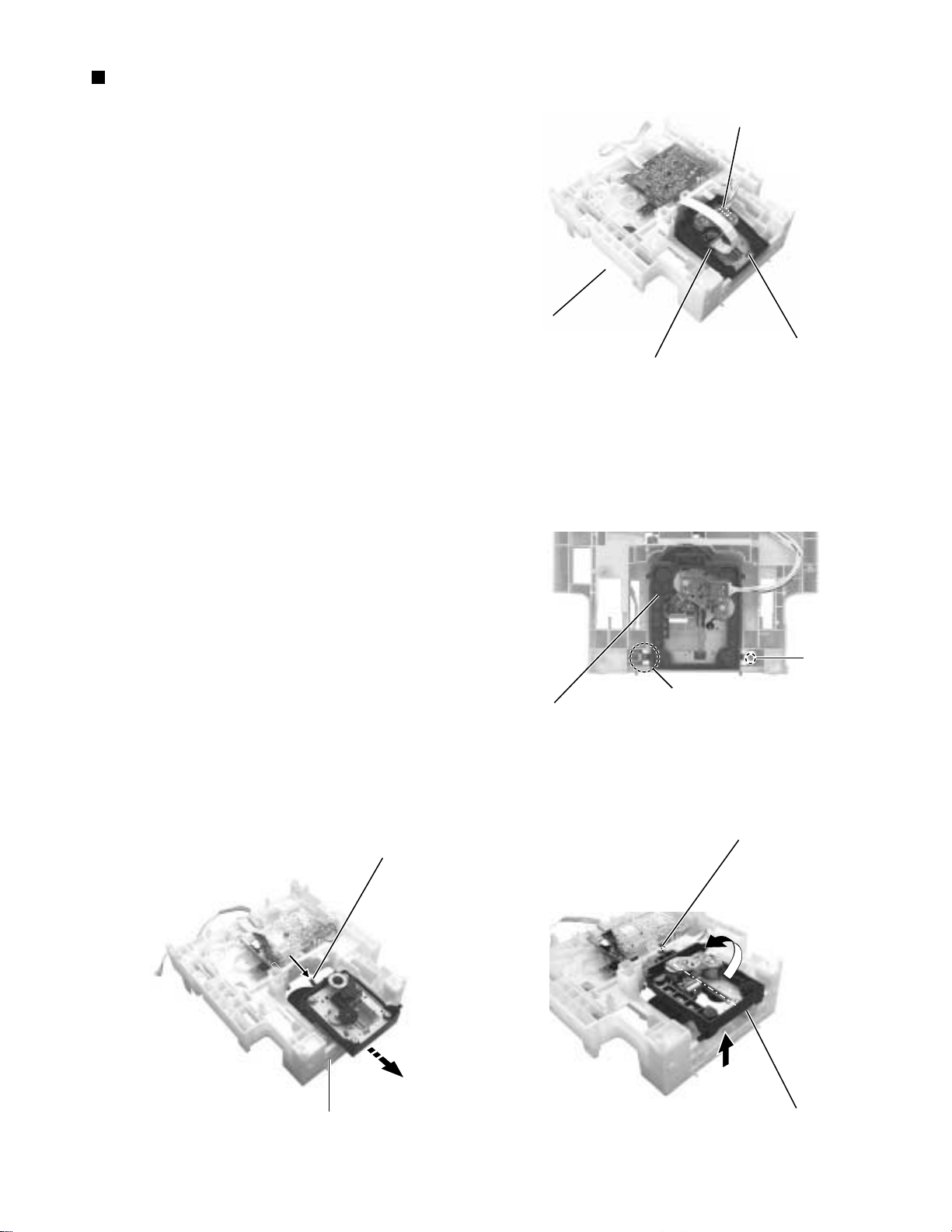

<CD mechanism section>

•

Removing the CD mechanism holder from the CD

chager unit.

(Refer to "Removing the CD mechanism holder

assembly" )

Removing the pickup unit. (

See Fig.1)

1. Removing the cut washer c on the feed gear

sleeve and pull out the feed gear.

2. Remove the two screws A fixing the pickup

shaft.

3. Removing the pickup unit.

Removing the feed motor. (

See Fig.1)

Remove the two motor fixing screws at B and

removing the feed motor.

Removing the spindle motor.

The spindle motor cannot be removed as a single unit.

When removing the spindle motor, change the chasis

and turntable together as aunit.

A

A

B

Shaft

Feed Gear

Shutter

Pickup unit

Motor board

Unsolder

Feed motor

Spindle motor

Removing the motor board.

(See Fig.2)

1. Unsolder the motor terminal on the motor board.

2. Remove the moter board.

MX-G50

1-17

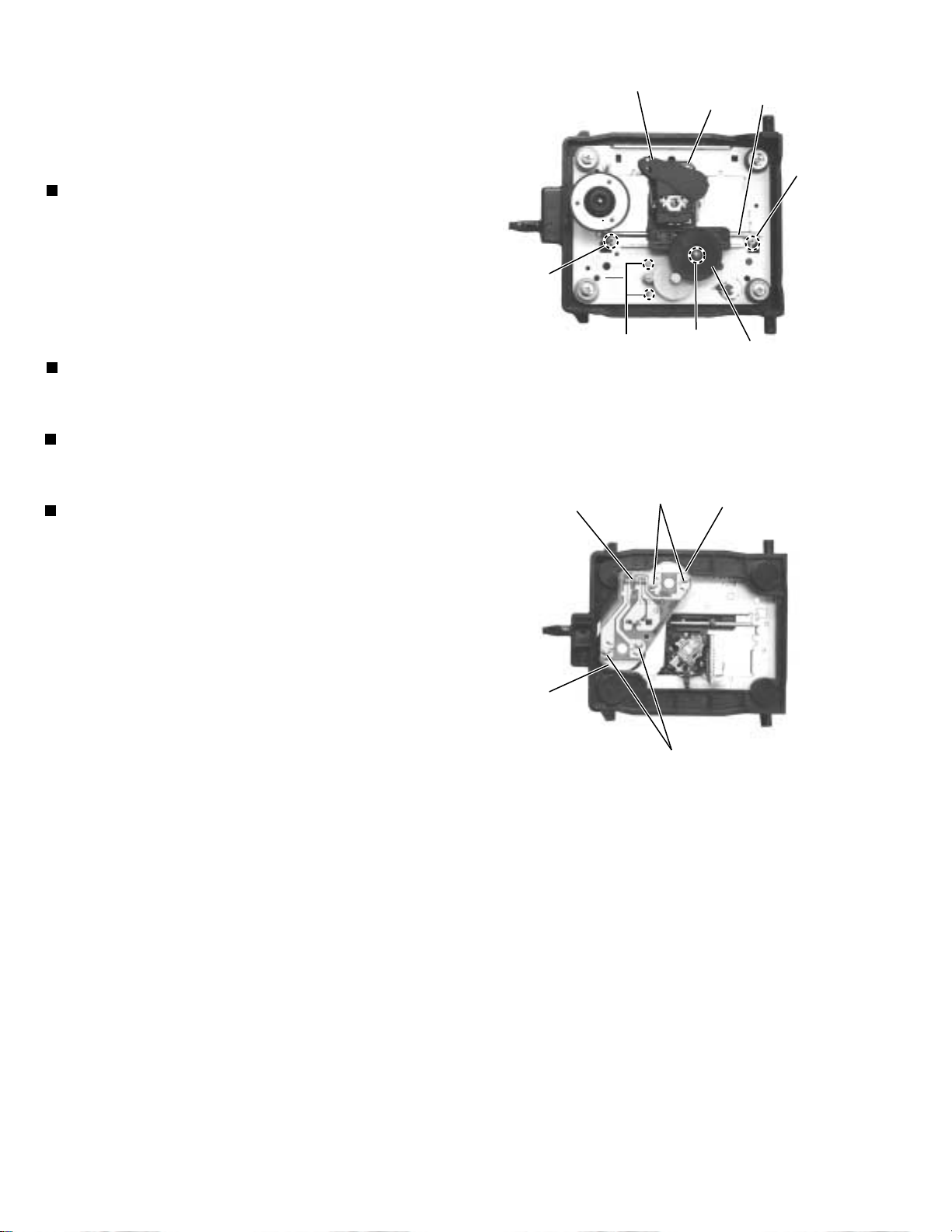

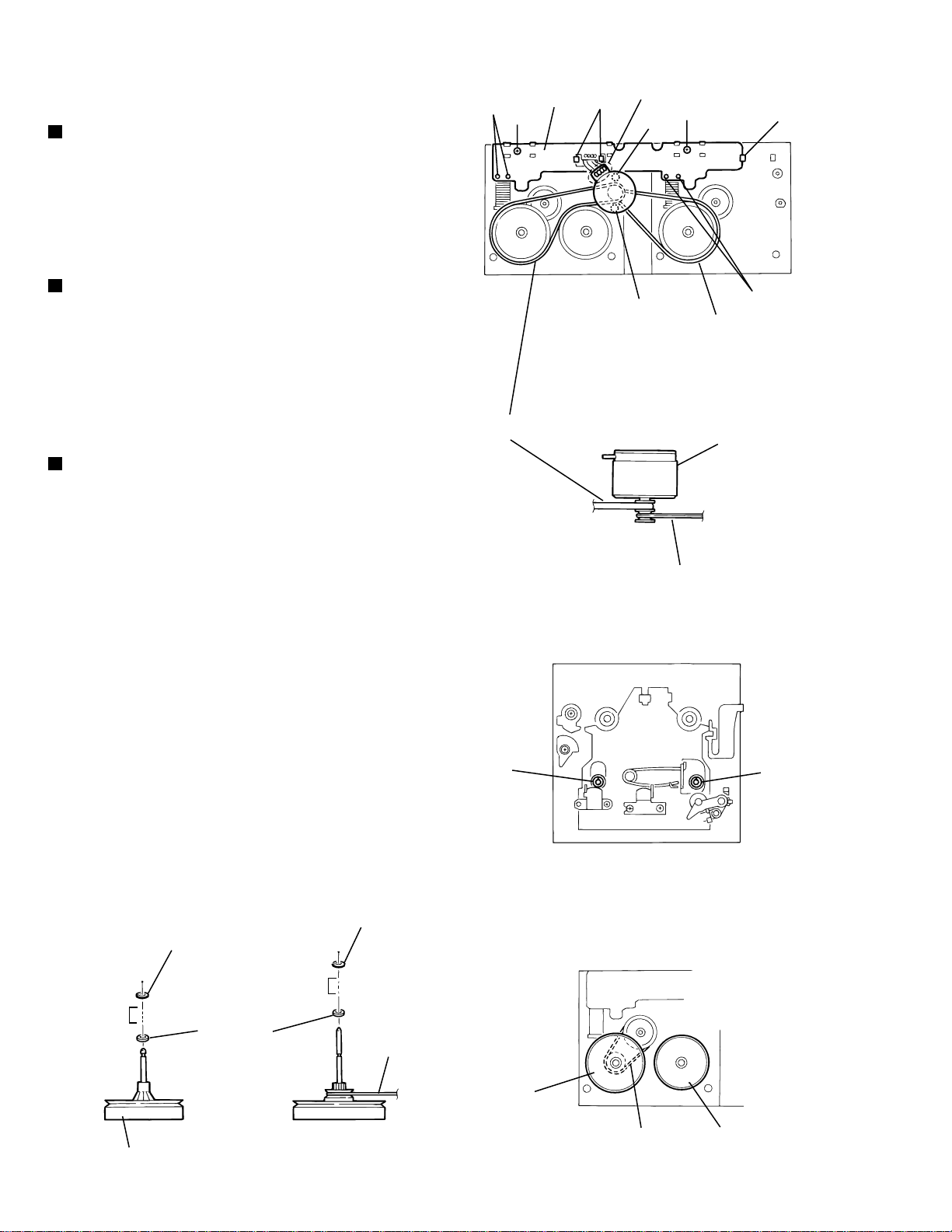

<Cassette mechanism section>

Removing the record/playback mechanism.

Removing the R/P head.

1. Remove the screw A on the right side of the

R/P head.(Fig.1, Fig.2)

2. Remove the screw B on the left side of the

R/P head.(Fig.1, Fig.2)

Remove the erase head.

Remove the screw C fixing the erase head.(Fig.1)

Removing the pinch roller.

1. Pull out the pinch roller by opening the pinch

roller stopper outward to unlock .(Fig.3)

2. When reassembling the pinch roller, refer to

fig. 4 to hook up the spring.

Fig.1

Fig.2

Fig.3

Fig.4

R/P Head

R/P Head

E. Head

Spring

Stoppsr

Pinch roller

assembly

A

A

B

B

C

Pinch roller

Pinch roller

stopper

Pinch roller

Pinch roller

spring

Return spring

Return spring

Return spring

MX-G50

1-18

Fig.5

Drive belt

Drive belt

Drive belt (Flat)

D

D

E

E

a

b

b

a

Motor

Motor

terminal

Motor

c

d

FR belt

FR belt

Washer

Capstan

washer

Flywheel

Flywheel

Flywheel

Capstan

washer

Mecha.

board

Fig.6

Fig.7

Fig.8Fig.9

Sleeve

Sleeve

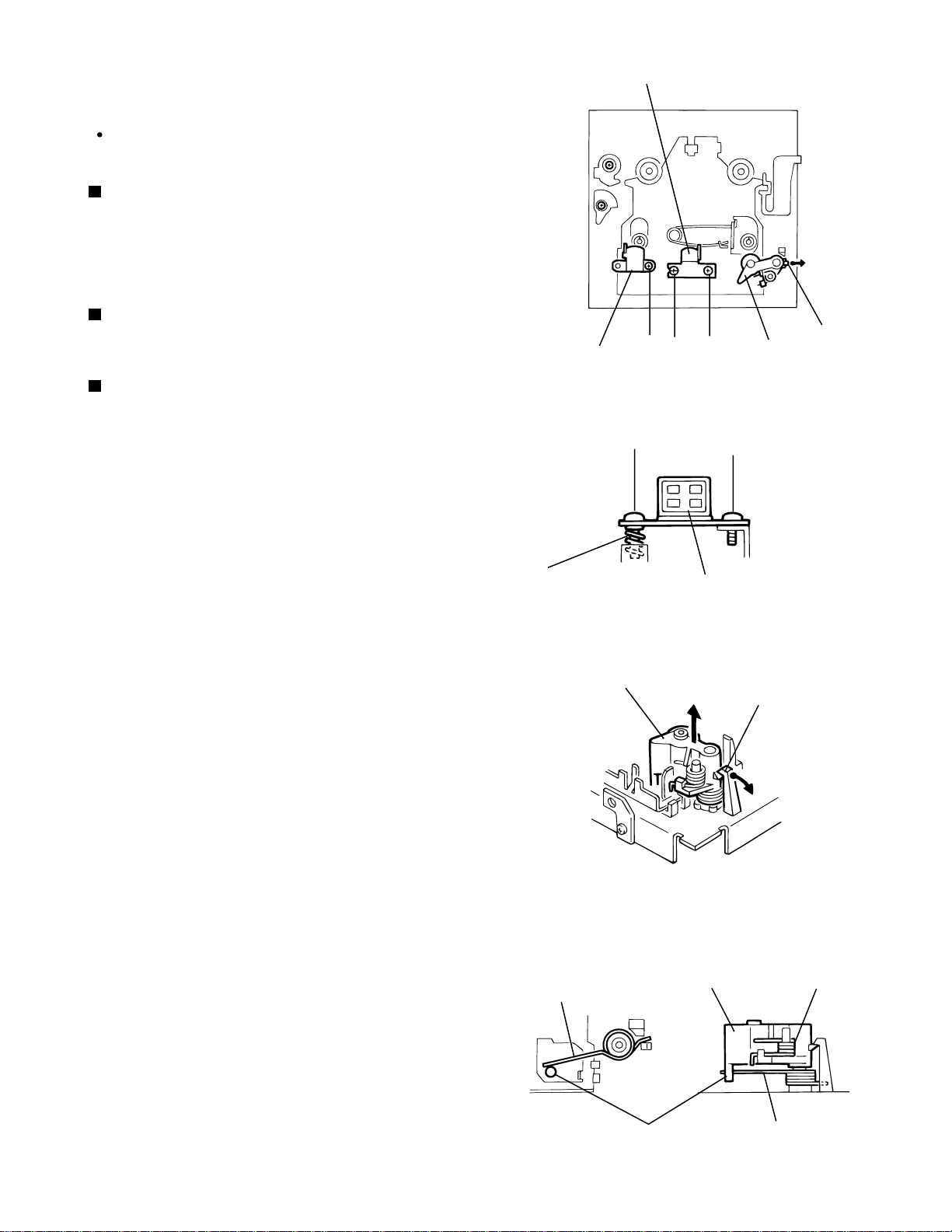

Removing the motor.

1. Remove the two screws D fixing the motor.

Be careful to grease's splash when the

drive belt comes off.(Fig.5, Fig.6)

2. Unsolder the motor terminal.(Fig.5)

Removing the mechanism board.

1.

Unsolder the four parts a on the solenoid

coil terminal.(Fig.5)

2. Remove the two screws E fixing the board.(Fig.5)

3. Unhook the three parts b from the board.(Fig.5)

4. Remove the mechanism board.(Fig.5)

Removing the flywheel.

Remove the cut-washers at c and d from the

capstan shaft, then remove the flywheel.

When reassembling the flywheel,

be sure to use new washers as they

cannot be reused.(Fig.8, Fig.9)

MX-G50

1-19

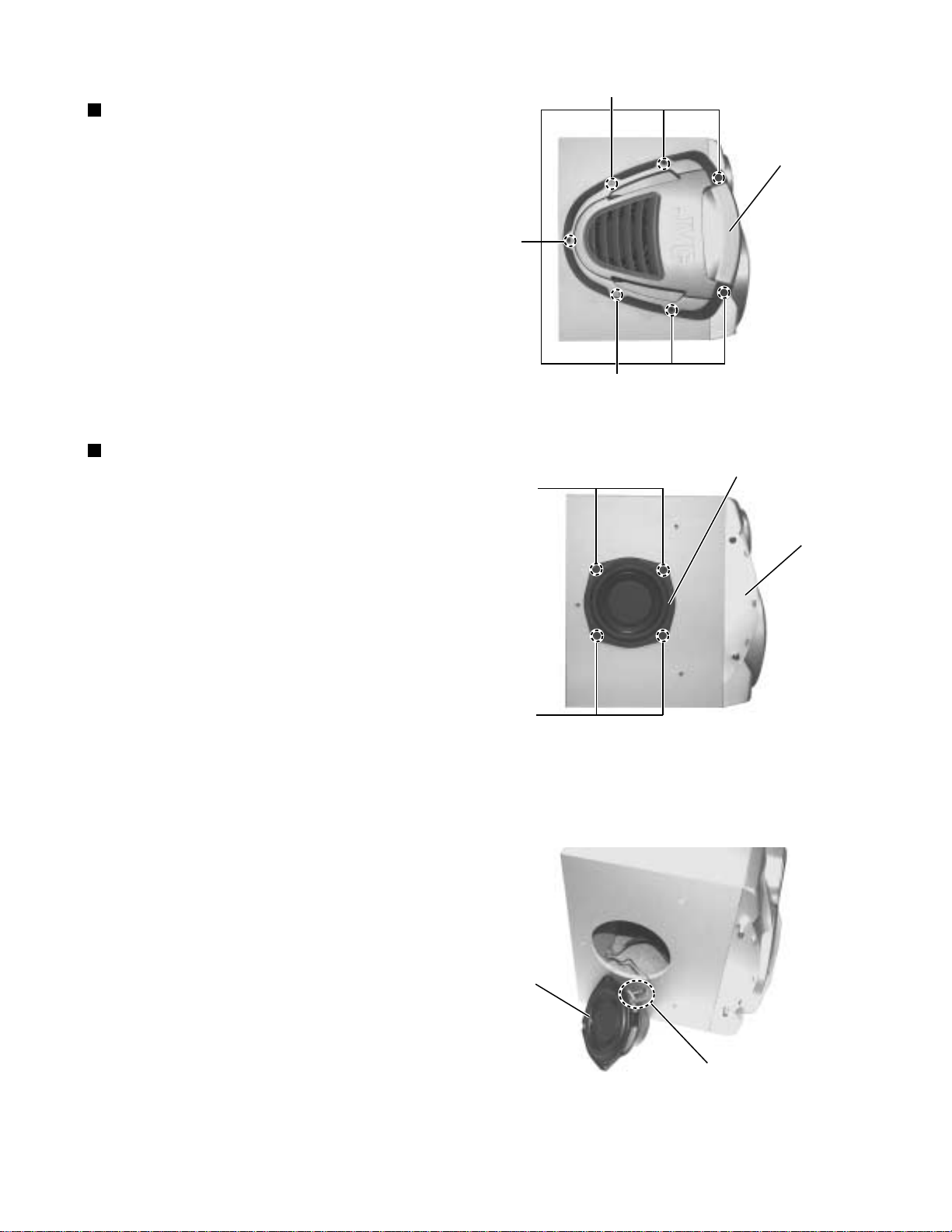

Prior to performing the following procedure, remove

the side panel.

Remove the five screws A attaching the side panel,

then remove the side panel.

1.

Removing the side panel (See Fig. 1)

Remove the fore screws C attaching the side

speaker.

Pull out the side speaker and remove the speaker

cord from the speaker terminal.

1.

2.

Removing the side speaker

(See Fig. 2 and 3)

< Speaker section >

Side panel

Side speaker

Front panel

Side speaker

Speaker terminal

Fig.1

A

B

B

C

C

Fig.2

Fig.3

MX-G50

1-20

0

9

0

0

9

2

0

2

9

0

0

9

9

0

9

0

9

0

0

0

9

9

9

88

2

0

0

0

0

0

2

2

2

8

8

9

9

9

9

0

9

0

9

2

0

0

2

2

9

0

0

9

0

0

9

0

9

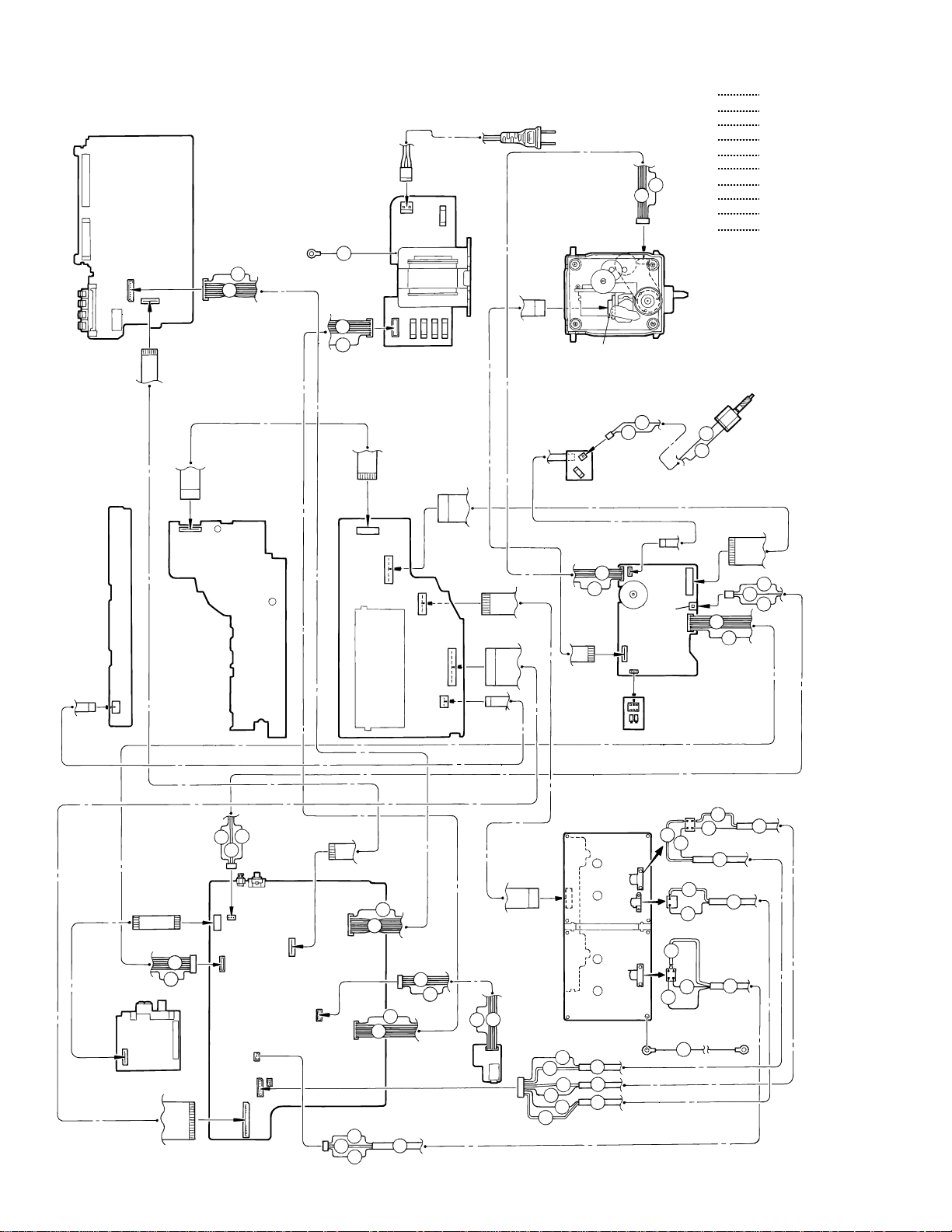

JW1

FCW3

JCW2

FCW3

JCW1

RCW6

OCW

FCW1

FCW2

HCW3

RW1

RW2

HCW2

Cassette mechanism

UCW1

UCW7

UCW2

UCW3

UCW4

UCW6

UCW5

CW3

CW101

CW104

CW102

CW103

CW106

CW107

CW105

CW2

CW1

CW3

AAN1

CD mechanism

RCW2

RFS2

Power transformer

RFS5

RFS6

RFS7

RFS8

PCW1

ACW1

ACW2

Front / Display board

3708-000122

3708-000258

3809-001228

AH39-20002D

AH39-00022A

AH39-00247A

AH39-00096D

AH39-20025S

3809-001185

AH39-00254A

AH39-00254A

3809-001224

AH39-20561P

3809-001121

16634-502-610

3809-001034

Amp board

CD key switch board

Front key switch board

Tuner board

Main board

E.phone J.board

Color codes are shown below.

1 Brown

2 Red

3 Orange

4 Yellow

5 Green

6 Blue

7 Violet

8Gray

9 White

0 Black

Wiring connection

MX-G50

1-21

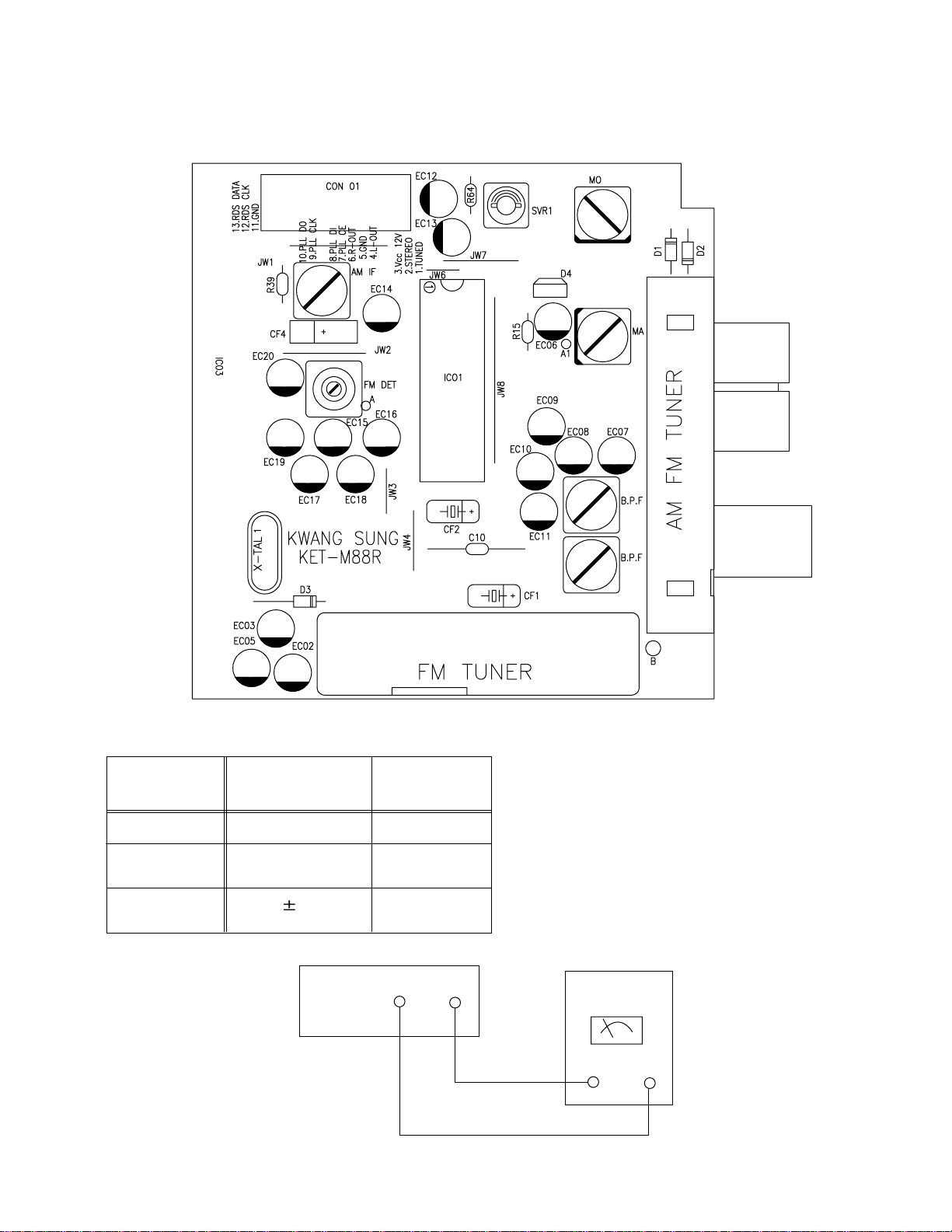

* Adjustment Location of Tuner PCB

AM(MW) OSC

Adjustment

Output

1~7.0 0.5V

Received FREQ.

Adjustment

point

522~1611 KHz

MO

AM(MW) RF

Adjustment

ITEAM

594 KHz

MA

Maximum

Output(Fig1-4)

TESTER

MAIN

PCB

VT GND

Fig 1-4 OSC Voltage

Adjustment method

1. Tuner

MX-G50

1-22

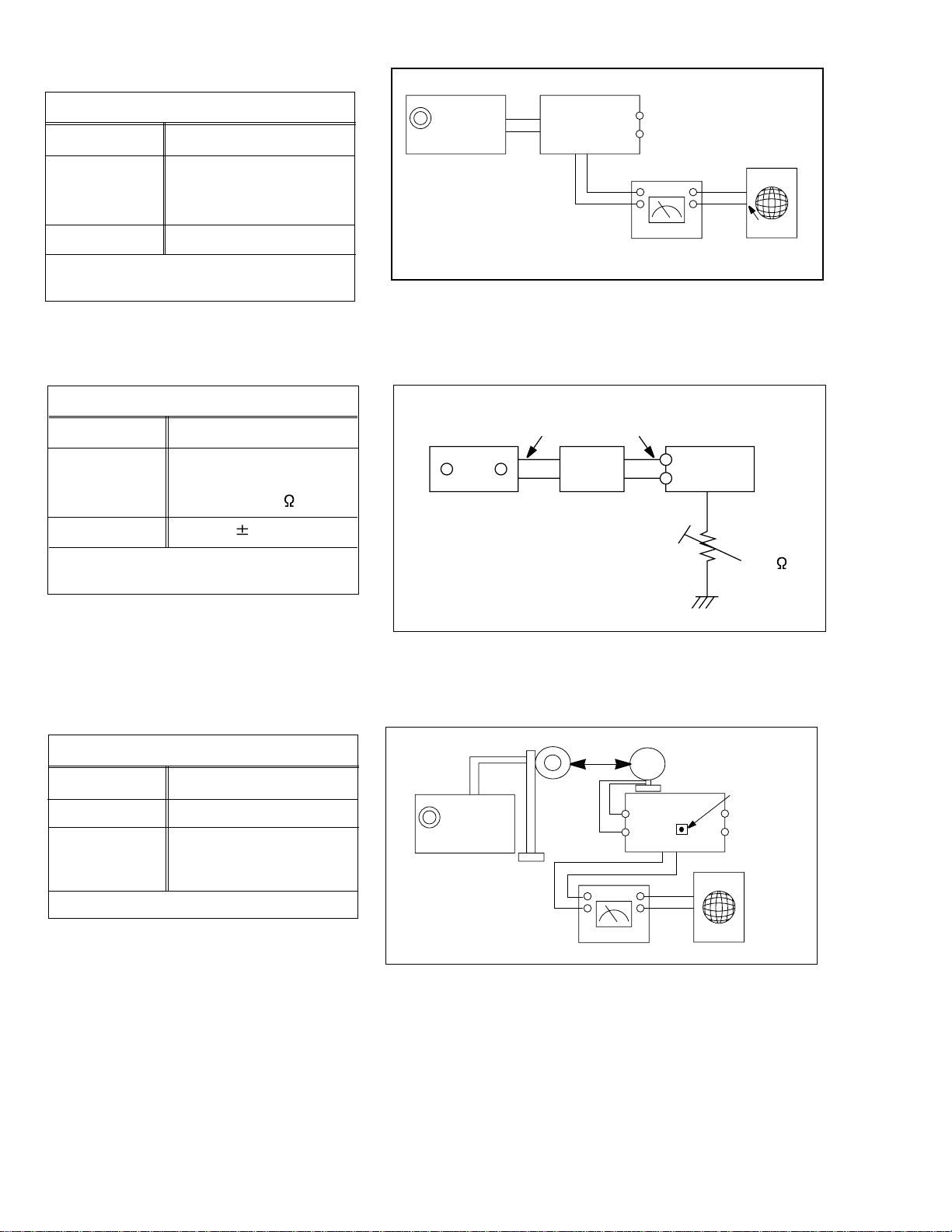

FM THD Adjustment

Output

Output

28 dB(

2dB)

60 dB

Minimum Distortion (0.4% below)

(Figure 1-1)

SSG FREQ.

Adjustment

point

(FM DET)

98 MHz

FM DETECTOR COIL

FM Search Level Adjustment

Adjust SVR1 so that "TUNED" of FL T

is lighted (Figure 1-2)

Figure1-2 FM Auto Search Level Adjustment

*Adjust FM S.S.G level to 28dB

Figure1-1 IF CENTER and THD Adjustment

SSG FREQ.

Adjustment

point

(SVR1)

98 MHz

BEACON

SENSITIVITY

SEMI-VR(20K )

FM S.S.G

GND

28 dB

FM S.S.G

Output

GND

Speaker

Terminal

FM

Antenna

Terminal

Distortion Meter

Input

SET

Input

output

Oscilloscope

FM IN

FM Antenna

SET

20 k

OUTPUT

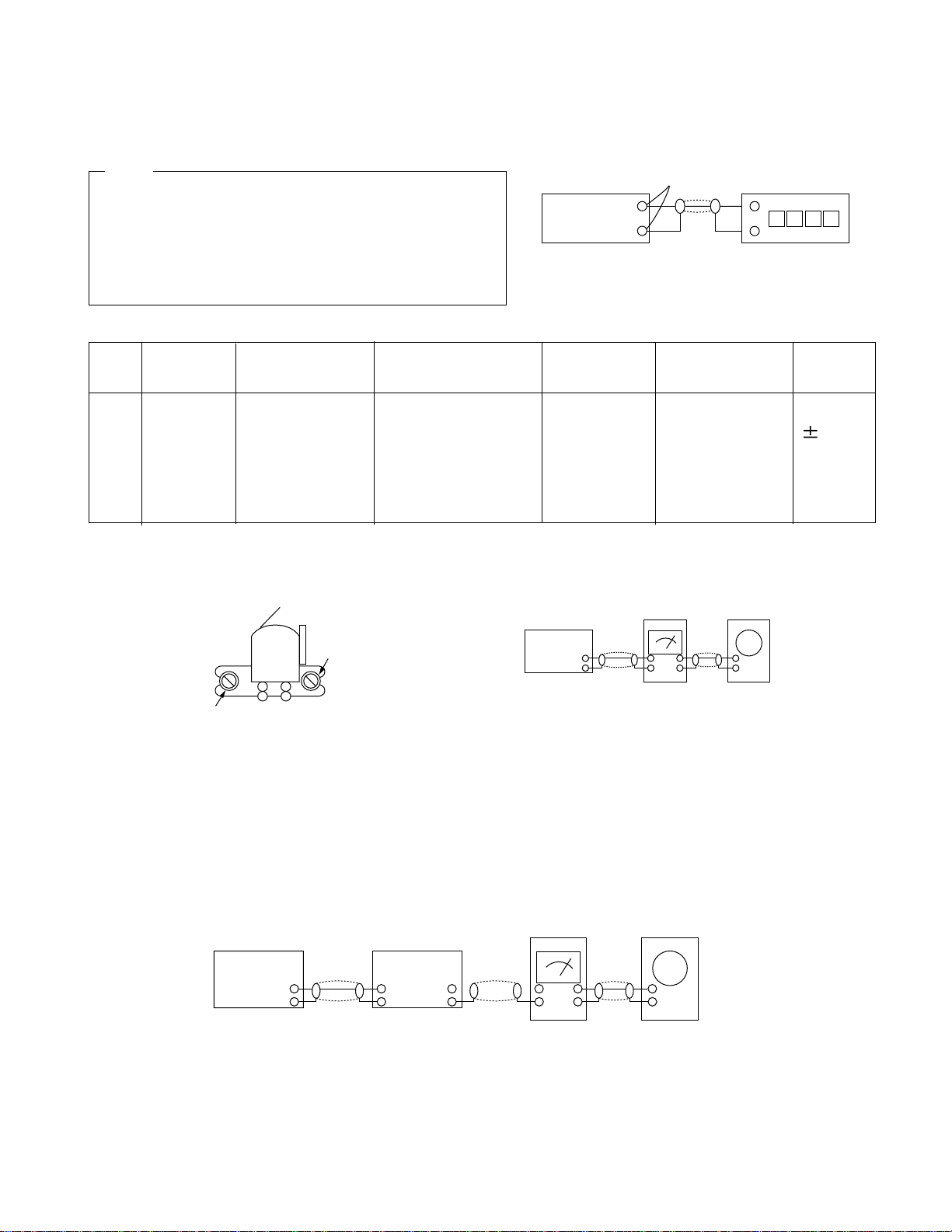

AM SSG

450KHZ

INPUT

AM ANT

IN

Speaker Terminal

60cm

AM IF

VTVM Oscilloscope

AM(MW) I.F Adjustment

Maximum output (Figure 1-3)

SSG FREQ.

Frequency

Adjustment

point

450 kHz

522 kHz

AM IF

Figure1-3 AM I.F Adjustment

OUTPUT

MX-G50

1-23

(GND)

VTVM

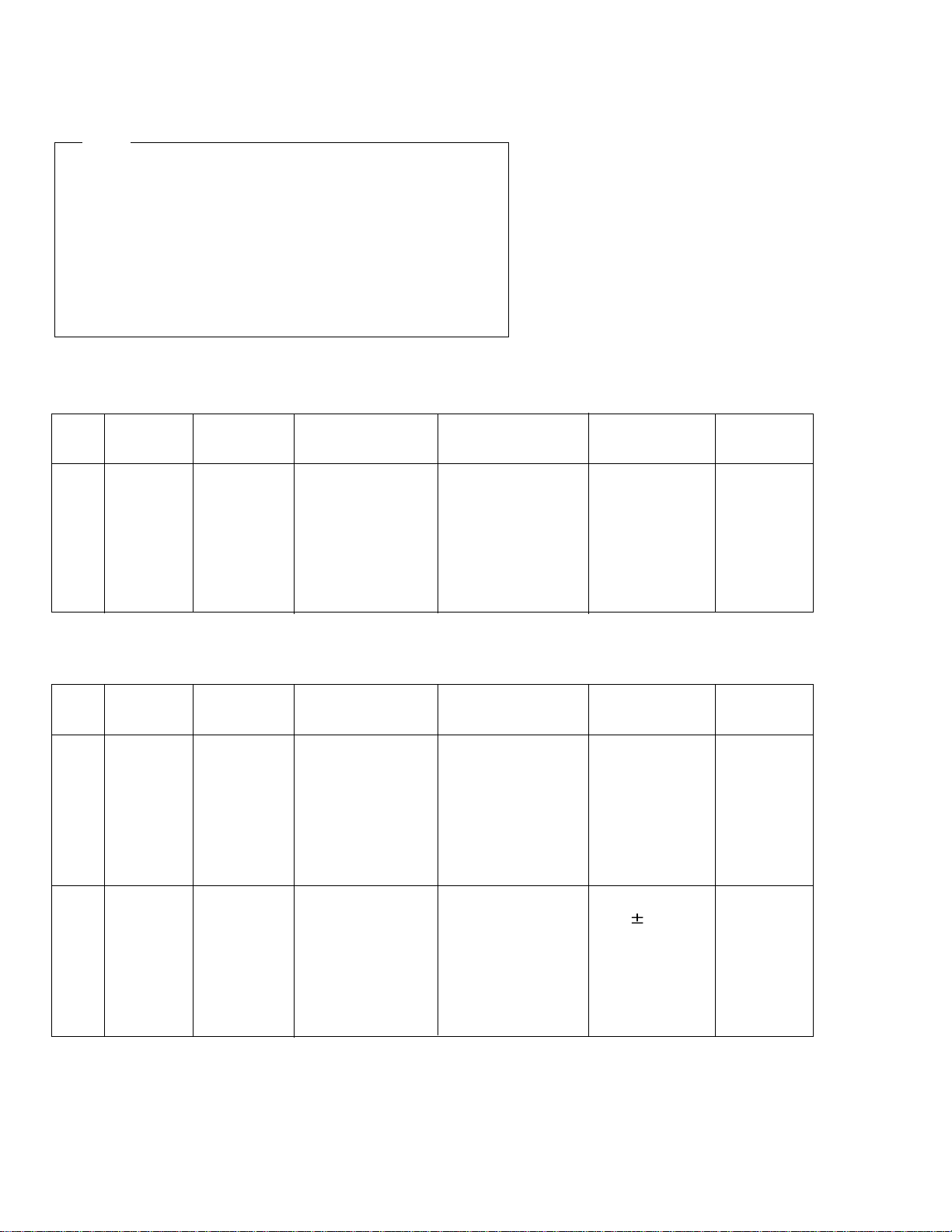

To adjust tape speed

1) Measuring tape: i) VT-712(or equivalent)

(Tapes recorded with 3kHz)

ii) AC-225(or equivalent)

2) Connect the cassette deck to the frequency counter

as in figure 1-5.

Notes

NOR

SPEED

Control

1

OUT

(connected

to the frequency

counter)

Turn VSR1 to

left and right

(FRONT PCB)

3KHz

Remark

Standard

To Adjust

Pre-Setup

Item

Step

Pre-Setup

Condition

1) Deck A:VT-712

2) Press PLAY

SW button

3) Deck B:Same

as above

Cassette Deck

output

SPK OUT

Frequency Counter

Figure 1-5

Figure 1-6

SPK OUT

Recording /Play head

AZIMUTH control screw

Figure 1-7

In Out

Cassette Deck

Oscilloscope

2 Cassette Deck

range

Figure 1-8

Audio OSC.

SET

(MAIN PCB)

Oscilloscope

AUX IN

LINE OUT

VTVM

IN

JCW3

IN OUT

TP

1%

MX-G50

1-24

1) Before the actual adjustment, clean the play/recording

head.

2) Measuring tape :

i) VT-703(or equivalent 10kHz AZIMUTH control)

3) The cassette deck is connections as shown in figure 1-7.

Notes

AZIMUTH

1

SPK OUT

(VTVM is

connected to

the scope)

- Turn the control

screw to as shown

in Figure 1-6.

Max output

and same phase

(both channels)

After

adjustment

secure it with

REGION

LOCK.

Remark

Standard

To Adjust

Pre-Setup

Item

Step

Pre-Setup

Condition

AZIMUTH

1

2

SPK OUT

(VTVM is

connected to

the scope)

- Turn the control

screw to as shown

in Figure 1-6.

Max output

and same phase

(both channels)

After

adjustment

secure it with

REGION

LOCK.

7mV(

mV)

Turn JSR2L,JSR2R

to the right and left

Remark

Standard

To Adjust

Pre-Setup

Item

Step

Pre-Setup

Condition

Fig 1-8

After putting VT-703

into Deck B

1)Press FWD PLAY

button.

After putting AC-225

into Deck B

1)Press REC PLAY

button.

2)MAIN PCB JCW3,

connectted to VTVM

Recording

Bias

Voltage

To adjust plabyback level/REC

2. Adjust Deck B Play Level/REC BIAS

1. Adjust Deck A Play Level

0.5

ii) AC-225(or equivalent)

After putting VT-

703 into Deck A

- Press FWD

PLAY button.

Loading...

Loading...