Juki M0-6000S, M0-6900G, M0-6900R, M0-6900J Manual

PREFACE

This Engineer'sManual is written for the technical personnel who are responsible for the service and maintenance of the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel factory contains operating instructions in detail. And this manual describes "Standard Adjustment", "Adjustment Procedures", "Results of Improper Adjustment", and other important information which are not covered by the Instruction Manual.

It is advisable to use the relevant Instruction Manual and Parts List described below together with this Engineer's Manual when carrying out the maintenance of these machines.

In addition, for the motor for the sewing machine with thread trimmer, refer to the separate Instruction Manual or Engineer'sManual for the motor. And for the control panel, refer to the Instruction Manual for the control panel. This manual gives the "Standard Adjustment" on the former page under which the most basic adjustment value is described, and on the latter page "Results of Improper Adjustment" under which stitching errors and troubles arising from mechanical failures are described together with the CIAdjustment Procedures".

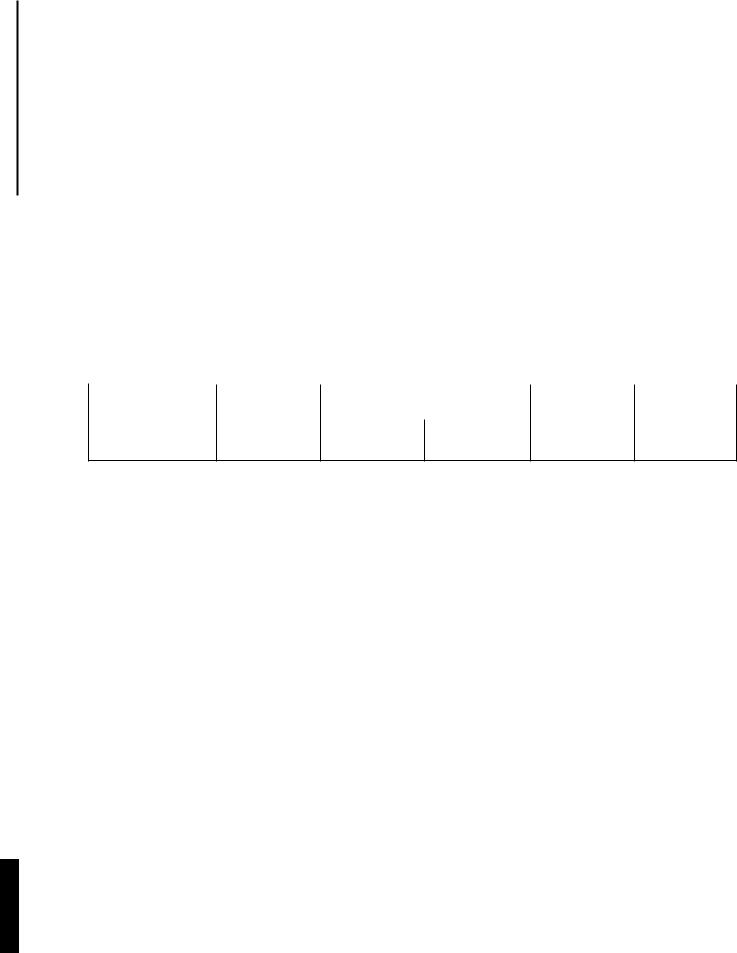

~ |

MO·6900S |

MO-6700S |

MO·6900G |

MO·6900R |

MO·6900J |

|

|||||

N |

|

|

|

|

|

Part No. |

Part No. |

Part No. |

Part No. |

Part No. |

|

|

|

|

|

|

|

Instruction Manual |

29351707 |

29351707 |

29351707 |

29356409 |

29363009 |

|

|

|

|

|

|

Parts List |

29351806 |

29352408 |

29352309 |

29356201 |

29362803 |

ii

ll

11

!

From the Library of Superior Sewing Machine & Supply LLC

CONTENTS

1. SPECIFICATIONS .......... |

•....•..•••.•.••••...•••..••••.••.••••••..•.••... |

••..•........ |

•..•••.•..•••.••.•... |

1 |

||||||

(1) MO-6700S SERIES ........................................................................................................... |

|

|

|

|

|

|

|

|

|

1 |

(2) MO-6900S SERIES ........................................................................................................... |

|

|

|

|

|

|

|

|

|

2 |

(3) MO-6900G SERIES •••••••..•••••••..•••••••... |

••••••..••••..••••.•••••.•.•••.•.... |

•.••... |

•••••... |

•.•••••.•.•.•.•••.•.•.•••.•. |

|

3 |

||||

(4) MO-6900R SERIES •.••.•••••••••••.••••.•••.••••••••.•••••.......•.•..••..•••... |

•....... |

•.•.•••.•.••..•... |

•..••..... |

•.•.•... |

• |

4 |

||||

(5) MO-6900J SERIES............................................................................................................. |

|

|

|

|

|

|

|

|

|

5 |

2. MODEL NUMBERING SYSTEM |

..••.••.•••..••••...••... |

•.•••••••.•••.•..•.••.•... |

•..•... |

••.•... |

•..... |

6 |

||||

3. STANDARD ADJUSTMENT ....••.•.•.•..•••..•.••••.••••••.... |

•...... |

•..•.•••.••...... |

•.•.••.••..... |

•.. |

8 |

|||||

(1) Adjusting the needle height............................................................................................ |

|

|

|

|

|

|

|

|

8 |

|

(2) Positioning the throat plate ............................................................................................ |

|

|

|

|

|

|

|

|

8 |

|

(3) Installing position of the needle Clamp ....................................................................... |

|

|

|

|

|

|

|

10 |

||

(4) Adjusting the length of the lower looper holder |

|

|

|

|

|

|

|

|||

(Applicable only to MO-6.616S / MO-6916R, G, J series) ........................................... |

|

|

|

|

10 |

|||||

(5) Adjusting the lower looper ._.......................................................................................... |

|

|

|

|

|

|

|

|

12 |

|

1) Returning amount of the lower looper .................................................................................................... |

|

|

|

|

|

|

|

|

12 |

|

2) Clearance between the lower looper and the needle ............................................................................. |

|

|

|

|

|

|

|

12 |

||

(6) Position of the upper looper guide ............................................................................... |

|

|

|

|

|

|

|

14 |

||

(7) Positioning the upper looper holder ............................................................................ |

|

|

|

|

|

|

|

16 |

||

(8) Positioning the upper looper ........................................................................................ |

|

|

|

|

|

|

|

|

18 |

|

1) Height of the upper looper ................................................................................................. |

|

|

|

|

|

|

|

~.................... |

|

18 |

2) Longitudinal position of the upper looper ................................................................................................ |

|

|

|

|

|

|

|

18 |

||

(9) Adjusting the double chain looper |

|

|

|

|

|

|

|

|

||

· (Applicable only to M0-6~16S/MO-6916R, G, J |

series) |

............................................... |

|

|

|

|

20 |

|||

1) Returning amount of the double chain looper......................................................................................... |

|

|

|

|

|

|

|

20 |

||

2) Longitudinal motion {Avoid motion) ........................................................................................................ |

|

|

|

|

|

|

|

|

20 |

|

3) Clearance between the double chain looper and the needle ................................................................. |

|

|

|

|

|

|

20 |

|||

(10) Adjusting the height and clearance of the needle guard .............. |

|

~.......................... |

|

|

22 |

|||||

1) For 1-needle or 2-needle overlock machine ........................................................................................... |

|

|

|

|

|

|

|

22 |

||

2) For safely stitch machine ........................................................................................................................ |

|

|

|

|

|

|

|

|

|

22 |

(11) Adjusting the height of the feed dog ......................................................................... |

|

|

|

|

|

|

|

24 |

||

(12) Adjusting the tillt of the feed dog ................................................................................ |

|

|

|

|

|

|

|

24 |

||

(13) Adjusting the differential feed ratio ........................................................................... |

|

|

|

|

|

|

|

26 |

||

(14) Longitudinal position of the feed dog ....................................................................... |

|

|

|

|

|

|

|

26 |

||

(15) Adjusting the presser foot .......................................................................................... |

|

|

|

|

|

|

|

|

28 |

|

1) Adjusting the tilt of the presser foot ........................................................................................................ |

|

|

|

|

|

|

|

|

28 |

|

2) Adjusting the micro-lifting mechanism of the presser foot |

...................................................................... |

|

|

|

|

|

|

28 |

||

(16) Positioning the upper knife arm shaft ....................................................................... |

|

|

|

|

|

|

|

30 |

||

(17) Positioning the upper and lower knives, and available overedge widths .............. |

30 |

|||||||||

1) lower knife ............................................................................................................................................. |

|

|

|

|

|

|

|

|

|

30 |

2) Upper knife ............................................................................................................................................. |

|

|

|

|

|

|

|

|

|

30 |

3) Overdging width ...................................................................................................................................... |

|

|

|

|

|

|

|

|

|

30 |

(18) Resharpening of the knife .......................................................................................... |

|

|

|

|

|

|

|

|

32 |

|

(19) Position of the thread cam (Applicable only to MO-6~16~ series) ........................ |

|

|

32 |

|||||||

1) Adjustment of the thread cam ............................................. |

|

:................................................................... |

|

|

|

|

|

|

32 |

|

2) Adjusting looper thread cam thread guides A and B and the looper thread cam nail ............................. |

|

|

32 |

|||||||

From the Library of Superior Sewing Machine & Supply LLC

rl!~

11

1·

I

I

l~i11

I

,,11

1~

I

I

!I

•l

!I~

I

(20) Adjusting the throat plate support ............................................................................. |

34 |

(21) Adjusting the feed mechanism cover presser .......................................................... |

34 |

(22) Adjusting the looper cover ......................................................................................... |

36 |

(23) Adjusting the cloth chip cover ................................................................................... |

36 |

(24) Adjusting the needle mechanism ............................................................................... |

38 |

(25} Position of the upper looper lubrication pin ............................................................. |

40 |

1) Orientation of the lubricating pin ............................................................................................................. |

40 |

2) Setting the lubricating pin ....................................................................................................................... |

40 |

(26) Longitudinal momentum of the top feed dog (Top feed amount) ........................... |

42 |

(27) Vertical momentum of the top feed dog .................................................................... |

44 |

(28) Adjusting the height of the top feed dog ................................................................... |

46 |

(29) Locus cut of the top feed dog .................................................................................... |

48 |

(30) Adjusting the longitudinal position of the top feed dog .......................................... |

48 |

(31) Adjusting the lateral position of the top feed dog .................................................... |

50 |

(32) Position of the motion of the top feed dog ............................................................... |

52 |

(33) Adjusting the feed bar guides A and B ................................................................. |

~.•.. 54 |

(34) Adjusting the top feed dog pressure ......................................................................... |

56 |

(35) Lifting amount of the top feed dog (when operating the pedal)••....••..••..••....... |

•..••.• 56 |

(36) Height of the presser (pedal operation) ..................................................................... |

58 |

(37} Lifting amount of the top feed dog (when the presser lifting lever is operated) .•• 60

(38) Position of the thread guides and the looper thread take-ups ................................ |

62 |

|

(39) Adjusting soft chain making mechanism .................................................................. |

64 |

|

1) Replacing·the parts with those exclusively designed for making soft chains ......................................... |

64 |

|

2) Adjustment value .................................................................................................................................... |

64 |

- |

3} Important points in adjustment ............................................................................................................... |

65 |

|

(40) Position of the thread guides and the looper thread take-ups of MO-6900G (J) ... |

66 |

|

4. ADDITIONAL INFORMATION AND PRECAUTIONS ..................................... |

68 |

|

(1) Thread tension ............................................................................................................... |

|

68 |

1) Strength of tension spring ....................................................................................................................... |

|

68 |

2) Springs used for each model. ................................................................................................................. |

|

68 |

(2) Upper looper·.................................................................................................................. |

|

69 |

(3) Center-to-center distance of the upper looper holder ............................................... |

69 |

|

(4) Caution in assembly ...................................................................................................... |

|

69 |

1) Application of sealant ............................................................................................................................. |

|

69 |

2) Precautions to be taken with respect to the lubricating components ............................................... |

~...... 71 |

|

(5) Kinds of motor pulleys, belts and frame support plate bolts .................................... |

72 |

|

1) Motor pulleys and belts ........................................................................................................................... |

|

72 |

2) Pat No. of frame support plate bolt ......................................................................................................... |

73 |

|

(6) Inspection and replacement of the cartridge filter ..................................................... |

73 |

|

5. ADJUSTMENT OF THE NEEDLE HEIGHT AND LOOPER TIMMING ........... |

74 |

|

(1) MO-60006. SERIES ........................................................................................................ |

|

74 |

6. TROUBLES AND CORRECTIVE MEASURES ............................................... |

75 |

|

7. DIMENSIONS OF TABLE ••... |

••.••..••••....•.•..•.•.••••.•..•••.•..••••..••.••••••..•••.•••.••..••.•.. |

87 |

(1) Semi-sunken type .......................................................................................................... |

|

87 |

(2) Fully-suken type .................. |

u ........................................................................................ |

88 |

From the Library of Superior Sewing Machine & Supply LLC

1.. SPECIFICATIONS

(1) MO-6700S SERIES

|

|

No. |

Item |

|

|

|

|

|

|

Specifications |

|

|

|

|

||||||||

|

|

1 |

|

Model |

|

M0-67048 |

|

|

|

M0-67148 |

|

. M0-6716$ |

|

|||||||||

|

|

2 |

|

Description |

1-neecile Overlock |

|

2-needle Overlock |

|

2-needle Safety stitch |

|

||||||||||||

|

|

|

|

|

|

machine |

|

|

|

|

|

machine |

|

machine |

|

|||||||

|

|

3 |

|

Stitch type F. S. T. |

JISE13 |

|

JISE24 |

|

JISE13+D12 |

|

||||||||||||

|

|

|

|

|

(USA standard : 504) |

|

(USA standard: 514) |

|

(USA standard =516) |

|

||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

Sewing speed |

|

|

|

|

|

|

|

7,000,pm |

|

|

|

|

||||||

|

|

5 |

|

Stitch length |

|

. 0.8to4mm |

1.5to4mm |

|

||||||||||||||

|

|

|||||||||||||||||||||

|

|

|

|

|||||||||||||||||||

|

|

6 |

|

Needle gauge |

- |

|

|

|

|

2, 2.4, 3.2 mm |

2. 3.2, 4, 4.8 mm |

|||||||||||

|

|

7 |

|

Overedging width |

1.6, 3.2, 4, 4.8 mm |

|

|

32,4,4.Bmm |

3.2, 4, 4.8, 6.4 mm |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

8 |

|

Differential feed ratio |

|

Gathering 1 =2 (Max.1 : 4), Stretching 1 : 0.7 (Max.1 : 0.6) |

||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

9 |

|

Needle bar stroke |

|

|

|

|

|

|

|

|

24.5mm |

|

|

|

|

|||||

|

|

10 |

|

Needle tilt angfe |

|

|

|

|

20· |

|

|

|

|

|

|

|

|

|||||

|

|

11 |

|

Needle |

|

ORGAN DC X 27 (Standard) (DC X 1can be used as well.) |

||||||||||||||||

|

|

12 |

|

Presser lifting amount |

|

7.0mm |

|

|

|

|

|

6.5nm |

7.0mm |

|||||||||

|

|

13 |

|

Presser foot pressure |

|

|

|

|

|

|

|

49N (5Kg) |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

Stitch acfJUstlng method |

|

|

|

|

|

|

By pushbutton |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

15 |

|

Upper knife |

|

|

|

|

|

|

|

|

FlatknHe |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

Differential feed adjustment |

|

By lever with micro adjustment medlanism |

|||||||||||||||||

|

|

17 |

|

Weight |

|

|

|

|

|

|

|

|

|

28kg |

|

|

|

|

||||

|

|

18 |

|

Lubrication |

|

|

|

|

Gear-type automatic lubrication |

|

|

|

|

|||||||||

|

|

19 |

|

Lubricating oil |

|

• JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) |

||||||||||||||||

|

|

20 |

|

Needle cooler |

|

|

|

|

|

|

|

|

Optional |

|

|

|

|

|||||

|

|

21 |

Needle thread heat remover |

|

|

|

|

|

|

|

|

Optional |

|

|

|

|

||||||

|

|

22 |

|

Micro presser lifting device |

|

|

|

|

|

Provided as standard |

|

|

|

|

||||||||

|

|

23 |

|

Motor |

|

|

|

|

2P 550W (In case of 7,000 rpm) |

|

|

|

|

|||||||||

|

|

|

|

|

|

2P 400W (in case of less than 7,000 rpm) |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m g )

-1 -

111

11

11

I'

·I

11

II

11

ij

L'I'

I

r·!I

·1

j

~i

I:

11i.

li

111

Ii

1'

Ii~

i

ii

'I

I i

I

l

.I

I

I

From the Library of Superior Sewing Machine & Supply LLC

(2) MO-6900S SERIES

|

|

|

|

No. |

|

Item |

|

|

|

Specifications |

|

|

|||||||||

|

1 |

|

|

|

|

|

Model |

MD-69045 |

|

M0-6914$ |

|

MQ-69168 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

Description |

1-needle Over1ock |

|

2-neeclle Over1ock |

|

2-needfe Safety stitch |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

machine |

|

machine |

|

|

machine |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

Stitch type F. S. T. |

JIS E13 |

|

JIS E24 |

|

JISE13+ D12 |

|||||||||

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(USA standard : 504) |

|

(USA standard: 514) |

|

(USA standard : 516) |

|||

|

|

|

4 |

|

|

|

|

|

Sewing speed |

8,500rpm |

|

|

8,000rpm |

||||||||

|

|

5 |

|

|

|

|

|

Stitch length |

|

0.8to4mm |

|

1.5to4mm |

|||||||||

|

|

6 |

|

|

|

|

|

Needle gauge |

- |

|

|

2, 2.4, 3.2 mm |

|

2, 3.2. 4, 4.8 mm |

|||||||

|

|

7 |

|

|

|

|

|

Overedging width |

1.6, 3.2, 4, 4.8 mm |

|

3.2, 4, 4.8 mm |

|

3.2, 4, 4.8, 6.4 mm |

||||||||

|

|

|

|

8 |

|

|

|

|

Differential feed ratio |

Gathering 1 : 2 (Max.1 : 4), Stretching 1 : 0.7 {Max.1 : 0.6) |

|||||||||||

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

9 |

|

|

|

|

|

Needle bar stroke |

|

|

|

24.5mm |

|

|

|||||

|

|

|

|

10 |

|

|

|

|

Needle tilt angle |

|

|

20· |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

.. 11 |

|

|

|

|

Needle |

ORGAN DC X 27 (Standard) (DC X 1 |

can be used as |

weil.) |

|||||||||

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

Presser lifting amount |

7.0mm |

|

6.5mm |

|

|

7.0mm |

|||||||

|

|

|

|

12 |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

13 |

|

|

|

|

Presser foot pressure |

|

|

|

49N (5Kg) |

|

|

||||||

|

|

|

|

14 |

|

|

|

Stitch adjusting method |

|

|

|

By pushbutton |

|

|

|||||||

|

|

|

|

15 |

|

|

|

Upper knife |

|

|

|

Flat knife |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

Differential feed adjustment |

|

By lever with micro adjustment mechanism |

|||||||||||

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

17 |

|

|

|

Weight |

|

|

|

28kg |

|

|

|||||||

|

|

|

|

18 |

|

|

|

Lubrication |

|

|

Gear-type automatic lubrication |

|

|

||||||||

|

|

|

|

19 |

|

|

|

Lubricatina oil |

" JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) |

||||||||||||

|

|

|

|

20 |

|

|

|

Needle cooler |

Provided as standard (Exduding some of subclass machines) |

||||||||||||

|

|

|

|

21 |

|

|

|

|

Needle thread heat remover |

Provided as standard {Excluding some of subdass machines) |

|||||||||||

|

|

|

|

22 |

|

|

|

Micro presser lifting device |

|

|

|

Provided as standard |

|

|

|||||||

|

|

|

23 |

|

|

|

Motor |

|

2P 550W (In case of not less than 7,000 rpm) |

||||||||||||

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2P 400W (In case of less than 7,000 rpm) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m ! )

-2-

From the Library of Superior Sewing Machine & Supply LLC

(3) MO-6900G SERIES

|

|

|

No. |

· Item |

|

|

Specifcations |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

1 |

Model |

M0-6904G |

|

M0-6914G |

|

|

|

|

|

M0-6916G |

|

|

|

|

|||||||

|

2 |

Description |

1-needle Overlock |

|

2-needle Overlock |

|

|

|

|

2-needle Safety stitch |

|

|

|

|

|

|||||||

|

|

|

|

|

machine |

|

machine |

|

|

|

|

|

machine |

|

|

|

|

|||||

|

3 |

Stitch type F. S. T. |

JIS E13 |

|

JISE24 |

|

|

JIS E13+ 012 |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

(USA standard : 504) |

|

(USA standard : 514) |

|

(USA standard: 516) |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Sewing speed |

|

|

6,000rpm |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

5 |

Stitch length |

2.5to5mm |

|

2.5to4mm |

|

|

|

|

2.5to5mm |

|

|

|

|

||||||||

|

6 |

Needle gauge |

- |

|

2.6mm |

|

|

|

|

4.8mm |

|

|

|

|

||||||||

|

7 |

Overeclging width |

4.8, 10mm |

|

6.4mm |

|

|

|

|

4.8,6.4mm |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

8 |

Differential feed ratio |

Gathering 1: 1.75 (Max.1 : 3.8) |

|

Gathering 1:2(Max.1 : 3.8) |

|

Gathering 1:1.75{Max.1 :3.8) |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

Stretchirg 1:0.6 |

|

Stretching 1 :0.7 (Max.1 : 0.6) |

|

Stretching 1:0.6 |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

9 |

Needle bar stroke |

|

|

28.8mm |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

10 |

Needle tilt angle |

|

20· |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

11 |

Needle |

|

|

ORGAN DO XS |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

12 |

Presser frfting amount |

|

|

Max.Bmm |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

13 |

Presser foot pressure |

|

|

49N(5Kg) |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

14 |

Stitch acfjUSting methcxJ |

|

|

By pushbutton |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

15 |

Upperknife |

|

|

Flat knife |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

16 |

Differential feed adjustment |

By lever with micro adjustment mechanism |

|

|

|

|

|||||||||||||||

|

17 |

Weight |

|

|

28kg |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

18 |

Lubrication |

|

Gear-type automatic lubrication |

|

|

|

|

|

|

|

· |

- |

|||||||||

|

19 |

Llbricating oil |

* JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) |

|||||||||||||||||||

|

||||||||||||||||||||||

|

|

·- |

||||||||||||||||||||

|

|

20 |

Needle cooler |

Provided as standard (Excluding some of subclass machines) |

|

|

|

|

||||||||||||||

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||

|

|

21 |

Needle thread heal remover |

Provided as standard (Excluding some of subclass machines} |

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|||||||||||||||||

|

|

22 |

Micro presser lifting device |

|

|

Provided as standard |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

23 |

Motor |

|

|

2P400W |

|

|

|

|

|

|

|

|

|

|

|

||||

•JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m 2 )

-3-

From the Library of Superior Sewing Machine & Supply LLC

t

I

l1

I~

~l

11

II

-!

II

I

I

11

I,!11\·

'I

l

fi

11

11

II

·I

i

11

!i

(4) MO-6900R SERIES

|

|

No. |

|

|

|

|

|

|

|

Item |

|

|

|

|

|

Specifications |

|

|

|

||||

|

1 |

|

Model |

|

M0-6904R |

|

|

M0-6914R |

|

|

|

M0-6916R |

|||||||||||

|

2 |

|

Feed type |

|

|

|

|

|

Vertical amount of top feed dog |

|

|

|

|||||||||||

|

3 |

|

Description |

|

1-needle Overlock |

|

2-needle Over1ock |

|

|

2-needle Safety stitch |

|||||||||||||

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

r:nachine |

|

|

machine |

|

|

|

machine |

||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

Stitch type F. S. T. |

|

JIS E13 |

|

JIS E24 |

|

JISE13+D12 |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

(USA standard : 504) |

|

(USA standard : 514) |

|

{USA standard : 516) |

|||||||

|

5 |

|

|

Sewing speed |

|

|

7,000 rpm (longitudinal amount of top feed less than 6 rrm) |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6,000 rpm (longitudinal amount of top feed 6 to 8.5 mm) |

|||||||||

|

6 |

|

|

Stitch length |

|

|

|

0.8to4mm |

|

|

|

1.5to4mm |

|||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

Needle gauge |

|

- |

|

|

2mm |

|

|

|

32,4.Bmm |

||||||||||

|

|

8 |

|

|

Overedaina width |

|

3.21 4, 4.8, 5.6 mm |

|

|

3.2.4nm |

|

|

3.2, 4, 4.8, 6.4 mm |

||||||||||

|

|

9 |

|

|

Differential feed ratio |

|

|

Gathering 1 : 2 (Max.1 : 4), Stretching 1 : 0.7 (Max.1 : 0.6) |

|||||||||||||||

|

|

|

|

|

|

||||||||||||||||||

|

|

10 |

|

|

Needle bar stroke |

|

|

|

|

|

|

24.5mm |

|

|

|

||||||||

|

|

11 |

|

|

Needle tilt angle |

|

|

|

|

20· |

|

|

|

|

|

|

|||||||

|

|

12 |

|

|

Needle |

|

|

ORGAN DC X 27 (Standard) (DC X 1 can be used as well.) |

|||||||||||||||

|

|

|

|

|

|

||||||||||||||||||

|

|

13 |

|

|

Presser lifting amount |

|

7.0mm |

|

|

6.5mm |

|

|

|

5.5mm |

|||||||||

|

|

14 |

|

|

Presser foot pressure |

|

|

|

|

|

|

49N (5Kg) |

|

|

|

||||||||

|

|

15 |

|

|

Stitch adjusting method |

|

|

|

|

|

By pushbutton |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

16 |

|

|

Upper knife |

|

|

|

|

|

|

Rat knife |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

17 |

|

|

Vertica! amount of top feed dog |

|

|

|

|

|

3.5to8.5mm |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

18 |

|

Lonaitudnal amountof top feed dog |

|

1 to 7.5 mm (deoending on the ~ifications of the respective machines) |

|||||||||||||||||

|

|

|

|

||||||||||||||||||||

|

|

19 |

|

|

Top feed adjusting type |

|

|

|

|

|

|

By lever |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

20 |

|

|

Differential feed adjustment |

|

|

|

By lever with micro adjustment mechanism |

||||||||||||||

|

|

21 |

|

|

Weight |

|

|

|

|

|

|

29kg |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

|

|

Lubrication |

|

|

|

|

Gear-~,pe automatic lubrication |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

23 |

|

|

Lubricating oil |

|

|

|

* JUKJ MACHINE OIL 18 (Equivalent to ISO VG 18) |

||||||||||||||

|

|

24 |

|

|

Needle cooler |

|

|

Provided as standard (Exduding some of subclass machines) |

|||||||||||||||

|

|

25 |

|

|

Needle thread heat remover |

|

|

Provided as standard (Excluding some of subclass machines) |

|||||||||||||||

|

|

26 |

|

|

Micro presser lifting device |

|

|

|

|

|

Provided as standard |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

27 |

|

|

Motor |

|

|

|

2P 55DW (In case of not less than 7,0CYJ rpm) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2P 400W (In case of less than 7,000 rpm) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m f )

-4-

From the Library of Superior Sewing Machine & Supply LLC

(5) MO-6900J SERIES

|

|

No. |

|

|

Item |

|

|

. Specifications |

|

|

|

|

|

|||||||

|

1 |

|

|

Model |

M0-6904J |

|

|

M0-6914J |

|

|

|

M0-6916J |

||||||||

|

2 |

|

|

Feed type |

|

Vertical amount of top feed dog |

|

|

|

|

|

|

|

|||||||

|

3 |

|

|

Description |

1-needle Orerlock |

2-needle Overlock |

|

|

2-needle Safety stitch |

|||||||||||

|

|

|

|

|

|

|

machine |

|

|

machine |

|

|

|

machine |

||||||

|

4 |

|

|

Stitch type F. S. T. |

JIS E13 |

JISE24 |

|

JIS E13+ 012 |

||||||||||||

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

(USA standard: 504) |

(USA standard: 514) |

|

|

(USA standard : 516} |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

5 |

|

|

Sewing speed |

|

|

|

6,000rpm |

|

|

|

|

|

|||||||

|

6 |

|

|

Stitch length |

2.5to5mm |

2.5to4mm |

|

|

|

2.5to5mm |

||||||||||

|

7 |

|

|

Needle gauge |

- |

|

|

|

2.6mm |

|

|

|

4.8mm |

|||||||

|

8 |

|

|

Overedging width |

4.8mm |

|

|

6.4mm |

|

|

|

4.8,6.4mm |

||||||||

|

|

|

|

|||||||||||||||||

|

9 |

|

|

|

Differential feed ratio |

Gathering 1: 1.75 (Max.1 : 3.8) |

Gathering 1 : 2 (Max.1 : 3.8) |

|

Gathering 1: 1.75 (Max.1: 3.8) |

|||||||||||

|

||||||||||||||||||||

|

|

|

|

|

|

|

Stretching 1 : 0.6 |

Stretching 1: 0.7 (Max.1 : 0.6) |

Stretching 1 : 0.6 |

|||||||||||

|

10 |

|

|

|

Needle bar stroke |

|

|

|

|

28.8mm |

|

|

|

|

|

|||||

|

11 |

|

|

|

Needle tilt angle |

|

|

20· |

|

|

|

|

|

|

|

|

|

|||

|

12 |

|

|

|

Needle |

|

|

ORGAN DOX5 |

|

|

|

|

|

|||||||

|

13 |

|

|

|

Presser lifting amount |

|

|

|

Max.8mm |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

14 |

|

|

|

Presser foot pressure |

|

|

|

49N (5Kg) |

|

|

|

|

|

||||||

|

15 |

|

|

|

Stitch acfJUsting method |

|

|

By pushbutton |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

Upper knife |

|

|

Square knife |

|

|

|

|

|

|||||||

|

17 |

|

|

|

Vertical amount of top feed doa |

|

|

3.5to8.5mm |

|

|

|

|

|

|||||||

|

18 |

|

|

|

Longitudinal amount of top feed dog |

2.7 to 7.0 mm (depending on the specifications of the respective machines) |

||||||||||||||

|

19 |

|

|

|

Top feed adjusting type |

|

|

|

|

By lever |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

20 |

|

|

|

Differential feed adjustment |

|

By lever with micro adjustment mechanism |

||||||||||||

|

|

|

|

|

||||||||||||||||

|

|

21 |

|

|

|

Weight |

|

|

|

|

29kg |

|

|

|

|

|

||||

|

|

22 |

|

|

|

Lubrication |

|

Gear-type automatic lubrication |

|

|

|

|

|

|||||||

|

|

23 |

|

|

|

Lubricating oil |

*JUKI MACHINE OIL 18 (Equivalent to |

ISO VG |

18} |

|

||||||||||

|

|

24 |

|

|

|

Needle cooler |

Provided as standard (Exduding some of subclass machines) |

|||||||||||||

|

|

|

|

|||||||||||||||||

|

|

25 |

|

|

|

Needle thread heat remover |

Provided as standard (Excluding some of subclass machines) |

|||||||||||||

|

|

26 |

|

|

|

Micro presser lifting device |

|

|

Provided as standard |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

27 |

|

|

|

Motor |

|

|

|

|

2P400W |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*JUKI MACHINE OIL 18 (Equivalent to ISO VG 18) Part No. : MML018900CA (900 m £ )

I

I

I!l,

I,

11

I

i

ii

11

11

.I

l

-5-

From the Library of Superior Sewing Machine & Supply LLC

!j~'.

i

I

I

I

~I

1

11

II

I

ll

I

~

I

11

·I

11

ri! i

I

11:

11

I

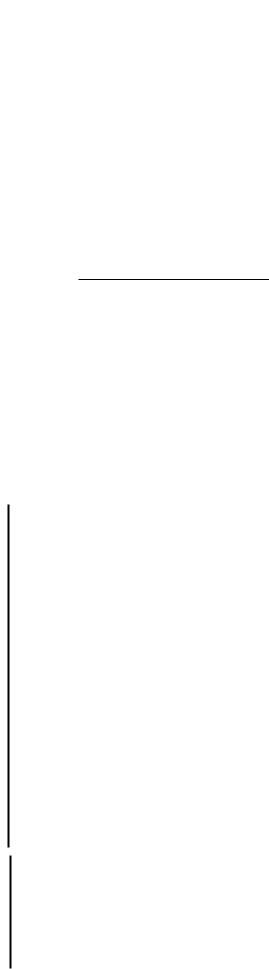

2. MODEL NUMBERING SYSTEM

MO-6000 SERIES MODEL NUMBERING SYSTEM

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 14 15 |

16 |

17 |

18 |

19 20 |

21 |

22 |

M06666DDD6666/D666-DO6

4 Machine code

7 ·6700 series

9 6900 series

7 Basic specification code

|

s |

Standard |

||

* |

G |

|

Extra heavy-weight materials |

|

* |

A |

Variable top feed type |

||

,I |

J |

|

Variable top feed type for |

|

|

|

|

extra heavy-weight materials |

|

|

|

|

|

|

|

* 6900only |

|||

5. 6 Seam code

03 |

Splicing |

|

|

|

|

04 |

1-needle 3-threa~ overtock (504) |

|

|

|

|

05 |

For blind hemmong (505) |

|

|

|

|

12 |

2-neeclle 4-thread mock safety stitch (512) |

|

|

|

|

14 |

2-needle 4-thread overtock (514) |

|

|

|

|

16 |

2-needle S.thread safety stitch (516) |

|

|

|

|

43 |

3-needle 6-thread safety stitch |

|

|

|

|

45 |

2-needle double chainstitch |

|

|

|

8 Needle gauge code

0 1-needle

B2.0mm

C2.4mm,

26 mm (for extra- heavy-weight materials)

D |

|

32mm |

|

||

|

|

|

E |

|

4.0mm |

|

|

|

F |

|

4.8mm |

|

|

|

1 |

|

4.8 mm+ 2.0 mm |

9 Overedging width code |

|

|

1O Feed dog code |

|

|

|

11 Material code |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

1.6mm |

|

|

4 |

2-row |

|

|

|

Classification based on materials to be used |

||||||

|

D |

3.2mm |

|

|

|

5 |

1-row |

|

|

1 |

Extra light-weight to light- |

For light-weight materials such as |

||||

|

|

|

||||||||||||||

|

E |

4.0mm |

|

|

|

6 |

3-row |

|

|

|

|

weight materials |

shirts or the Uke |

|||

|

|

|

|

|

|

|

|

|||||||||

|

F |

4.8mm |

|

|

|

7 |

4-row |

|

|

2 |

Light-weight to medium- |

Knit wear only |

||||

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

-----3 |

|

|

||||

|

H |

6.4mm |

|

|

|

|

|

|

weight materials |

General fabrics |

||||||

|

|

|

|

|

|

|

|

|||||||||

|

M |

10.0mm |

|

|

|

|

|

|

4 |

Medium-weight to heavy- |

Knit wear only such as sweater or |

|||||

|

|

|

|

|

|

|

|

|

|

|

-5 |

weight materials |

the fike |

|||

|

N |

18.0mm |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Medium·weightto heavy-weight |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

------ |

|

materials such as denim or the like |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For heavy-weight materials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

Heavy-weight to extra |

Heavy-weight materials for jeans, car |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

heavy-weight materials |

mattress, etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 Application code

Classification based on type of operation

and process

0 Standard

1For blind stitching

2Forgathering

4For attaching tape

5For binding

6For binding tape

DSplicing•

ECar mattress

FSoft chain

•In case of the splicing, 13th figure is (1).

- 6 -

From the Library of Superior Sewing Machine & Supply LLC

13 Special machine code

Special classification of machine, structure and specification other than gauge set

0 Standard

6Feed dog provided w~h a lip

7Upper looper high throw type

F For swim suits

H Upper looper extra high throw type

M For zipper

1 For splicing

15 to 18 Device and attachment code

G0'2/O141 |

Presser fo(?Vtape guide for attaching tape |

|

G39/Q141 |

Presser foot (for sharp curve)/tape guide for |

|

|

attaching tape |

|

|

|

|

L121 |

Blind hemming ruler |

|

|

|

|

S159 |

Swing type ruffler (pedal-intertocking type for safety |

|

|

stitch} |

|

|

|

|

S161 |

Swing type ruffler (Manual lever type for safety |

|

|

stitch) |

|

|

||

|

|

|

S162 |

Swing type ruffler (Manual lever type for over1ock) |

|

|

|

|

N077 |

Four-fold binder |

20 Machine head code

AStandard machine head (Common to all specifications)

21 Accessory code

A |

Fa general export * |

|

|

B |

ForJE |

|

|

G |

For China |

22 Machine head code

0Fully-sunken type

Semi-sunken type

The numberings after-..!'(hyphen) of 19th figure will be used on

and after Apnl 1, 2002. They are not described on the catalogue or the fike.

• The general export s~ification is for Hong Kong, U.SA, Japan and Singapore.

.. 7 -

I

J

l

j

I

I

11

lj

I,

\

I

i

I

II

·1

~

j:

11

I

11

11

I

,j

,,

ij!11

11

I

ll

I~

!

I

I

I

From the Library of Superior Sewing Machine & Supply LLC

i'

!

1·

I

I

j

I:

II'

I

I

I·

1;

ii

I

.I

I! i

I

I

I

I

3. STANDARD ADJUSTMENT

Standard Adjustment

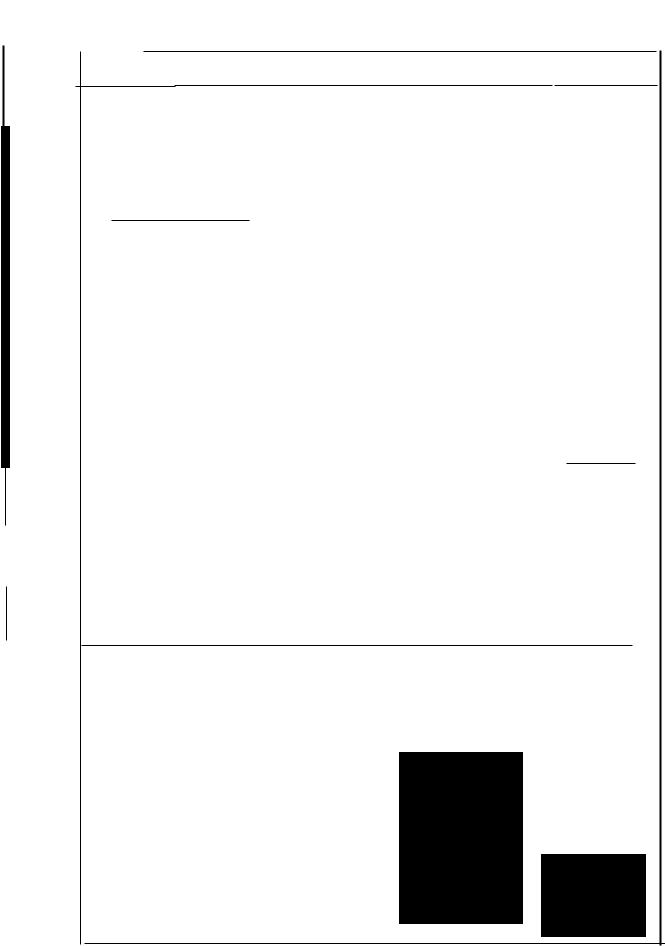

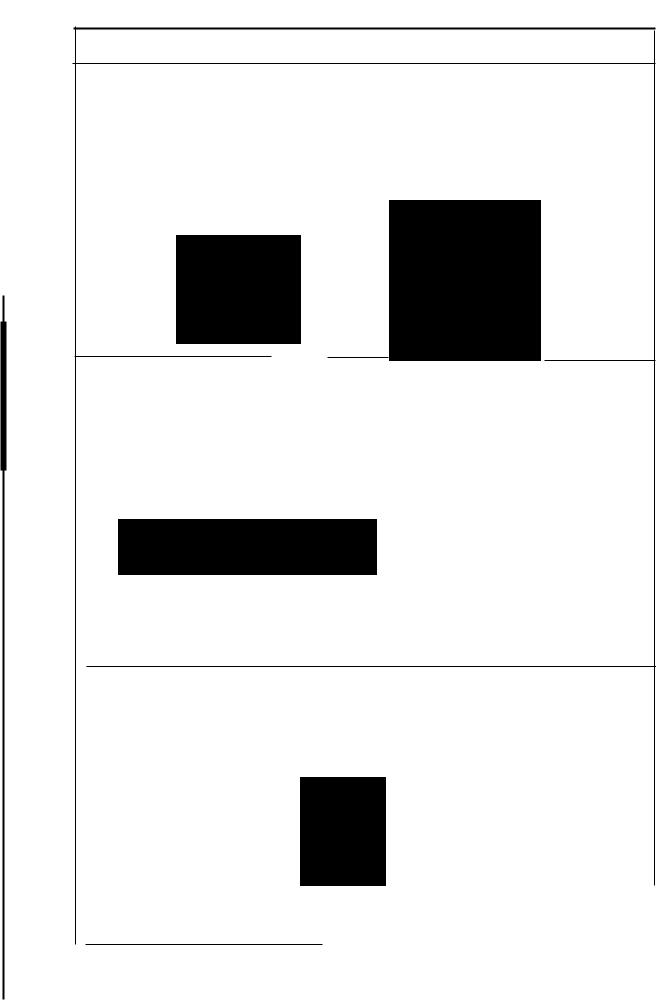

(1) Adjusting the needle height

When the needle(s) is in the highest position,

the needle height from the throat plate surface should be as shown below.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Unit: mm) |

|

|

|||

|

6~046 |

|

|

- |

|

|

|

|

|

|

|

|

|

Model |

|

|

1-needle/ |

2-needle : right |

|

|

||||||||

|

·· |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-needle : left |

|

|

|

|

|

|

||

|

|

|

|

|

30 - |

|

|

MO6l!.04S(R) -l!.66 |

·l!..60 |

10.5 |

|

|

- |

|

|

|

|

|||||||||||

|

11 z,z 1 ,inJ,a |

|

|

|

|

|

|

|

|

|

|

|

|

-Lib.6 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

SD |

~ |

:I |

|

|

MO6604S |

|

-D.D.D. |

·66H |

11.3 |

|

|

- |

|

|

|

|

||||||||

|

|

|

|

Cl) |

:II," |

Cl) |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

~ |

|

|

|

n |

::i., |

CD |

|

|

|

|

|

|

|

|

|

SOM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

g: R |

~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

66146 |

|

|

|

|

|

|

|

|

|

MO- 6/\05S |

-606 |

|

-66.H |

11.3 |

|

|

- |

|

|

|

|

||||||

|

|

|

|

|

|

|

fl) |

|

|

|

|

|

|

|

|

|

507 |

11 :0 |

|

|

9.4 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

::, |

|

|

|

MO- 6.6.125 |

|

-D.D.D. |

SOF |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

3 Cl) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Cl) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

.,[!~zzma |

|

|

|

|

I» |

|

|

MOSD.12S |

|

-CE4 |

-40H |

11.3 |

|

|

9.9 |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

n |

a, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

0 |

|

|

|

MO· 6614S (R) -B66 - |

0H |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

2:o |

|

|

MOSb14S (R) -8~6 |

-3c7 |

10.5 |

|

|

9.1 |

|

|

|

|

||||||||||

|

|

|

|

|

|

:, |

< |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

CD |

Cl> |

|

|

|

|

|

|

|

|

|

2 |

|

11.3 |

|

|

9.9 |

|

|

|

|

||

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

::i. |

|

|

|

|

|

|

|

|

|

40H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

':,t: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

66166 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

MO- 6b16S(R)-D.D.b |

-.t.60 |

|

10.5 |

|

|

- |

|

|

|

|

||||||||

|

n |

|

|

|

|

en |

|

|

MO- Sil16S(R)-b.66 |

-l!..6H |

|

11.3 |

|

|

|

- |

|

|

|

|

||||||||

|

|

|

|

3 e. |

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

II> |

a, |

|

|

MO- 6Li16S(R)-A.6.L'l |

-60H |

|

13 |

|

|

- |

|

|

|

|

||||||||||

|

|

|

|

g.~ |

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

-· en |

|

|

MO6943R |

|

-6.D.6 |

-b.l::,7 |

|

10.5 |

|

|

9.9 |

|

|

|

|

|||||||||

|

|

|

|

i~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

MO66.43S |

|

-61::J.{:j, |

·6.D.H |

|

11.3 |

|

|

9.9 . - |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

::r |

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

C2'Z2222Z]n |

|

|

|

|

|

|

|

MO- 6/\45S |

|

-D.b.l:l |

-360 |

|

9.8 |

|

|

- |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

:i5: |

|

|

|

MO· 6903G |

|

-ON6 |

-3D1 |

|

15.4 |

|

|

- |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

0 |

|

|

|

MO· 6904GCJl-OF6 |

-700 |

|

14.4 |

|

|

- |

|

|

|

|

||||||||

|

|

|

|

|

|

0, |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

CD |

|

|

|

MO6905G |

|

·OM6 |

-760 |

|

15.4 |

|

|

- |

|

|

|

|

||||||

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

p |

|

|

|

MO- 6914G(Jl-CH6 |

-700 |

|

14.1 |

|

|

12.6 |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

<- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MO- 6916G(J)-F.0.6 |

-700 |

|

14.1 |

|

|

- |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

The adjustment of needle height for the 2-needle overlock machine should be made in reference to the left needle.

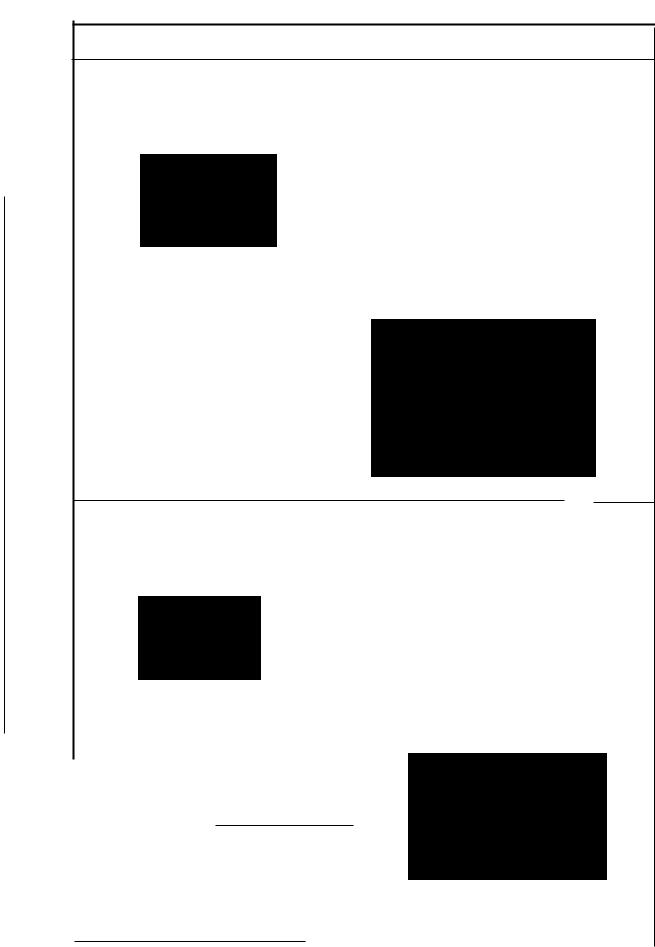

(2) Positioning the throat plate

The needle entry point should be such that the distances listed below are provided between the needle slot edge of the throat plate and the center of needle.

Over1ock side A |

1.3 |

|

|

|

(Unit: mm) |

Double·chainstitchside B |

1.0 |

|

|

|

|

Note that "A:=1.8" and "8=1.5"' |

A |

|

for M0-6~16S (R) -n6.6-60H, |

||

|

||

"A=1.6" and "8=1.3" for M0-69~6G, J |

|

-8-

From the Library of Superior Sewing Machine & Supply LLC

Adjustment Procedures |

Results of Improper Adiustment |

|

|

|

|

1) Take off the upper cover, loosen setscrew 8. of needle driving |

o Any other needle height than |

|

forked crank O and move needle driving forked crank O up or |

specified here will badly affect |

|

down to adjust the needle height. |

the action of the lower looper. |

|

|

the timing for.catching the upper |

|

|

looper thread, etc. |

|

(Caution) Do not fully loosen the setscrew 8 of the needle |

o |

Improper lateral position of the |

||

driving forked crank 0. |

|

needle driving forked crank will |

||

If the needle driving forked crank has got out of position |

|

cause seizure, play, or other |

||

laterally when its setscrew was loosened, fully loosen the |

|

troubles. |

|

|

setscrew and turn pulley to allow the forked crank to tum |

|

|

|

|

until it settles by itself. Then tighten the setscrew to fix the |

|

|

|

|

forked crank at that position. |

|

|

|

|

|

|

|

||

1} Loosen setscrews 8 of throat plate base O and move throat |

o |

Improperly positioned throat |

||

plate base 8 back and forth to adjust dimension A or B. |

|

plate will |

cause |

needle |

|

|

breakage, |

contact |

of the |

|

|

needles will the throat plate, or |

||

other troubles.

-9-

From the Library of Superior Sewing Machine & Supply LLC

,11

!I

:-1

;ii

II

I

1l

Ii

I

'I

!1

'I

11

'!i~

I

Standard Adjustment

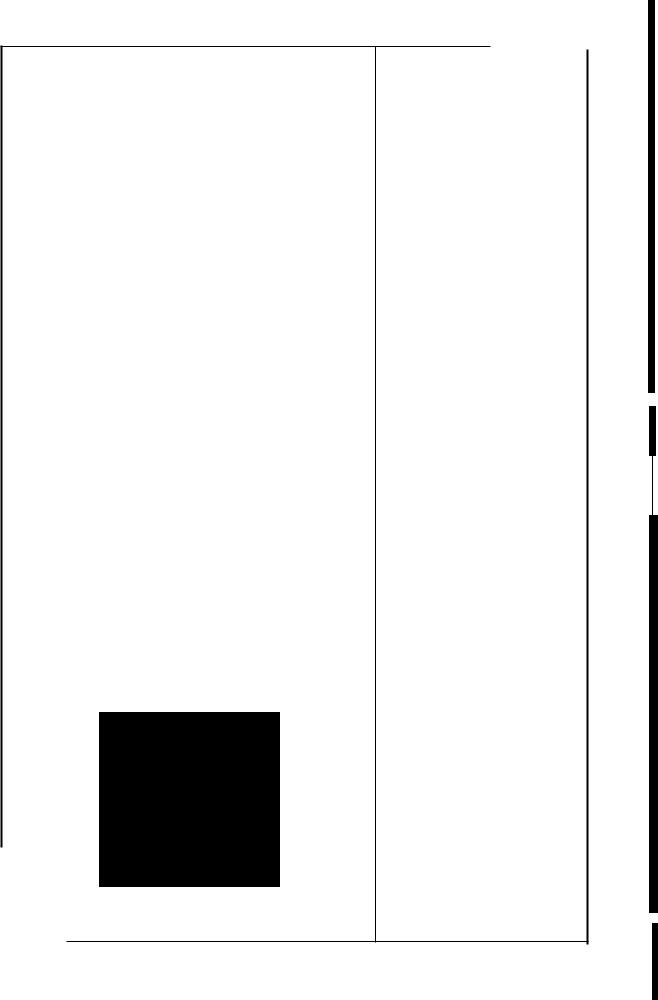

(3) Installing position of the needle clamp

Needle clamp connecting stud O should fit with the bottom end of needle bar 8 or spaced within oto

0.5mm.

Oto 0.5 mm

Butt the needle clamp with the |

0 |

bottom end of the needle bar. |

|

(4) Adjusting the length of the lower looper holder (Applicable only to M0-6~16S / M0-6916R, G, J series)

The center-to-center distance should be 26 mm.

At this time, the clearance between the end surface of the arm and the neck of the ball should be

3.5mm.

26mm

-10 -

From the Library of Superior Sewing Machine & Supply LLC

|

Adjustment Procedures |

Results of Improper Adjustment |

|

|

|

|

|

|

1) Loosen setscrew O and adjust, by slightly turning needle clamp |

o If the clearance provided |

|

|