Juki LS-341N Instruction Manual

®

CYLINDER-BED, 1-NEEDLE, UNISON-FEED lOCKSTITCH

MACHINE (WITH A VERTICAl-AXIS tiOOK)

1

I I

I

----

NOTE : Read safety instructions carefully and understand them before using your LS-341 N.

Retain this Instruction Manual for future reference.

No.02

From the library of: Superior Sewing Machine & Supply LLC 29176906

--------- IMPORTANT SAFETY INSTRUCTIONS ----

Congratulations on your purchase of a JUKI machine.

To get the most out of the many functions of this machine and operate it in safety, it is necessary to use this machine correctly.

Please read this Instruction Manual carefully before use. We hope you will enjoy the use of your machine for a long time. Please remember to keep this manual in a safe place.

1.Observe the basic safety measures, including, but not limited to the following ones, whenever you use the machine.

2.Read all the instructions, including, but not limited to this Instruction Manual before you use the machine. In addition, keep this Instruction Manual so that you may read it at anytime when necessary.

3.Use the machine after it has been ascertained that it conforms with safety rules/standards valid in your country.

4.All safety devices must be in position when the machine is ready for work or in operation. The operation without the specified safety devices is not allowed.

5.This machine shall be operated by appropriately-traine~d operators.

6.For your personal protection, we recommend that you wear safety glasses.

7.For the following, turn off the power switch or disconnect the power plug of the machine from th1~ receptacle.

7-1 For threading needle(s), looper, spreader etc. and replacing bobbin.

7-2 For replacing part(s) of needle, presse1r foot, throat plate, looper, spreader, feed dog, neeoHe guard, folder, cloth guide etc.

7-3 For repair work.

7-4 When leaving the working place or when the working place is unattended.

7-5 When using clutch motors without applying brake, it has to be waited until the motor stopped totally.

8.If you should allow oil, grease, etc. used with the machine and devices to come iru contact with ~rour eyes or skin or swallow any of such liquid by mistake, immediately wash the contacted areas and consult a medical doctor.

9.Tampering with the live parts and devices, regardless of whether the machine is powered, is prohibited.

10.Repair, remodeling and adjustment works must only be done by appropriately trained technicians or specially skilled personnel. Only spare parts designated by JUKI can be used for repairs.

11.General maintenance and inspection works have to be done by appropriately trained personnel.

12.Repair and maintenance works of electrical components shall be conducted by qualified electric technicians or under the audit and guidance of specially skilled personnel.

Whenever you find a failure of any of electrical components, immediately stop the machine.

13.Before making repair and maintenance works on the machine equipped with pneumatic parts such as an air cylinder, the air compressor has to be detached from the machine and the compressed air supply has to be cult off. Existing residual air pressure after disconnecting the air comp1ressor from the machine has to be expelled. Exceptions to this are only adjustments and performance checks done by appropriately trained technicians <Or specially skilled personnel.

14.Periodically clean the machine throughout the period of use.

15.Grounding the machine is always necessawy for the no1rmal operation of the machine. The machine has to be operated in an environment that is free from strong noise sources such as high-frequency welder.

16.An appropriate power plug has to be attached to the machine by electric technicians. Power plug has to be connected to a grounded receptacle.

17.The machine is only allowed to be u·sedfor the purpose intended. Other used are not allowed.

18.Remodel or modify the machine in accordance with the safety rules/standards while taking all the effective safety measures. JUKI assumes n.o responsibility for damag1e caused by remodeling or modification of the machine.

19.Warning hints are marked with the two shown symbols.

A

&

Danger of injury to operator or service staff

Items requiring special attention

From the library of: Superior-Sewingj - Machine & Supply LLC

-----FOR SAFE OPERATION---------

1.Keep yourr hands away from needle when you tum ON the power switch or while the machine is in operation.

2.During operation, be careful not to allow your or any other person'shead or hands to come close to the thread take-up, handwheel, V-belt, bobbin winder and motor. Also, do not place anything close to them.

3.. Do not operate yom machine with the~ finger guard, belt cover and any other protectors removed.

4.Before tilting the machnne head, be sure to confirm that the head support bar is pro_perly attached to your machine head.

5.Before tilting the machine or removnng the V belt, be sure to tum OFF the power switch and confirm that the motor of the sewing machine stops.

6.Tilt the machine head after removing the hook for the knee lifter.

7.When having tilted the machine head, wipe out oil on the bed underside, the top face of lbed support and hinge area, and then raise up the machine head.

8."fo ensure safety, never operate the machine with the ground wire for the power supply removed.

9.When inserting/removing the power plug, the power switch has to be turned OFF in advance.

10.In time of thunder and ~ightening, stop your work and disconnect the power plug from

t:he receptacle so as to ensure safety.

·11. If the machine is suddenly moved from a cold place to a warm place, dew condensation may be observed. In this case, turn ON the power to the machine after your have (~onfirmed that there is no danger of water drops in the machine.

12.lrurn OFF the power to the machine in the event of a power failure.

13.Do not allow the power cord to trail on the floor.

From the library of: Superior-Sewingn - Machine & Supply LLC

[!. SETTING UP THE SEWING MACHINE

Mounting the knee lifter

(Caution) The knee lifter should be mounted before the motor is installed.

When using the knee liifting pedal, attach knee

lifter bracket A 8 in place using screws |

as |

illustrated in the figure. |

|

(Caution) Knee iifler bracket 8 |

and |

screws ~~ are supplied with the machine in the accessory box.

j2. LUBRICATION

WARNING:

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start ol the sewing machine.

*

*

*

Before starting the sewing machine

Prior to operation, apply adequate amount of oil to the

points marked with the arrows.

Lubricating the hook and hook shaft saddle

Shift the slide plate, and apply two or three drops of oil every day to the hole shown with the arrow And four or five drops of oil every day to the felt shown with the arrow 4D.

Lubricating the feed bar

Prior to operation, apply two or three drops of oil to the holes shown with the arrows (i, (g and@ without fail.

From the library of: Superior-Sewing2 - Machine & Supply LLC

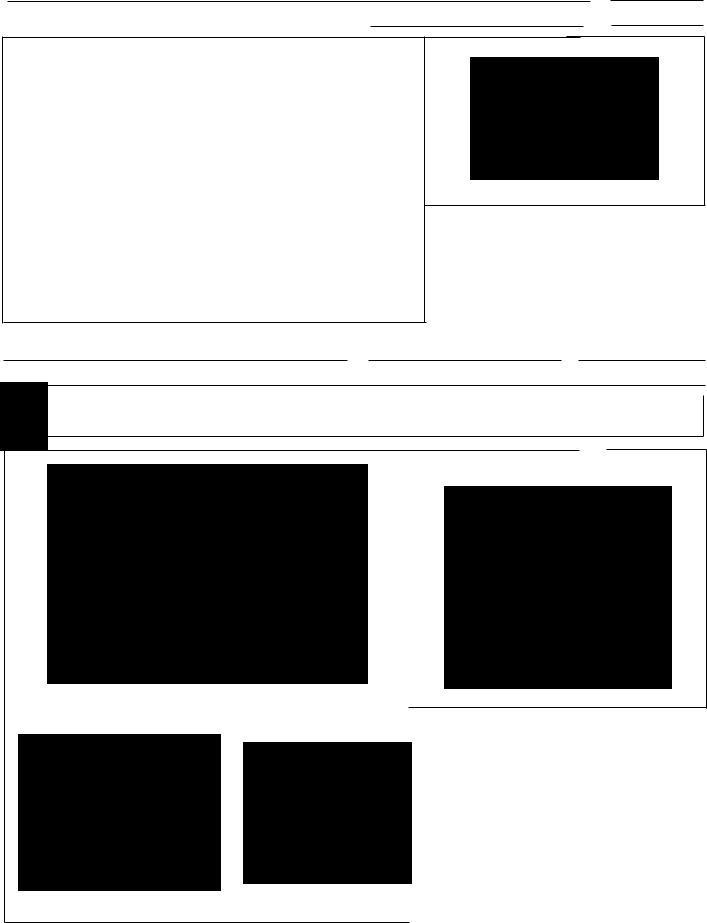

j3, INSTALLING THE THREAD STAND

Assembk the thread stand, and install it on the far right-hand side edge of the table using three screws Q.

!4. ~NSTALUNG THE BELT COVER AND THE BOBBIN WINDER

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turn OFF the power before starting the work so as to prevent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

accidents caused by abrupt start of the sewing machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1) |

Drill guide holeseand@for wooden screws to be used |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

in the table. |

|

|

|

|

|

|

|

|

|

|

|

|

|

2) |

|

Insert belt cover support 0 into the tapped hole in the |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

machine arm. |

|

|

|

|

|

|

|

|

|

|

|

|

|

3) |

|

Install belt cover support plate f) on the machine head. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4) Attach belt cover@! to support Oand support plate f). |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

5) |

|

Fit bobbin winder 8 in belt cover @!, and adjust the |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

position of the bobbin winder properly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6) Fix bobbin winder@ on the table. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

7) |

|

Put the V belt on the handwheel. Attach rid Gof the belt |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cover and top cover8 in place. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

~ 5. ATTACHING THE NEEDLE |

|

|

|

|

|

.AWARNING: |

|||||||||||

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turn OFF the power before starting the work so as to prevent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

accidents caused by abrupt start of the sewing machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

__Q_]B;/-8 |

|

|

|

|

|

|

• Turn OFF the power to the motor. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

:....--~ |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

'- |

|

tlr |

|

1) |

|

Turn the handwheel to move the needle bar up to its |

|||||||||

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

~~· |

|

|

|

|

|

|

|

|

|

highest position. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

2) |

|

Loosen needle clamp screw f). Hold needle 0 so that its |

||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

indented part(i.) faces exactly to the right. |

|

|

|

|

|

|

|

|

|

|

|

|

|

3) |

|

Insert the needle into the needle bar until it will go no |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

further. |

|

|

|

|

|

|

|

|

|

|

|

|

|

4) |

|

Securely tighten the needle clamp screw @. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[s. ATTACHING/REMOVING THE BOBBIN |

CASE |

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

~----------------------------------, |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turn OFF the power before starting the work so as to prevent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

accidents caused by abrupt start of the sewing machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1) |

|

Raise lever 0 of the hook, and remove the bobbin case |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

together with the bobbin in it. |

|

|

|

|

|

|

|

|

|

|

|

|

|

2) |

Fit the bobbin case into the hook driving shaft, and tilt the |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

lever. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From the library of: Superior-Sewing3 - Machine & Supply LLC

Loading...

Loading...