Operation & Safety

Manual

Keep this manual with machine at all times.

Model

G6-42P

S/N 0160004018 & After

31200148

Original

November 25, 2008

An Oshkosh Corporation Company

CALIFORNIA PROPOSITION 65

BATTERY WARNING

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemical known to the

State of California

to cause cancer and

reproductive harm.

WASH HANDS

AFTER HANDLING!

CALIFORNIA PROPOSITION 65

EXHAUST WARNING

Diesel Engine exhaust and

some of its constituents

are known to the State of

California to cause cancer,

birth defects and other

reproductive harm.

Revision Log

Revision Log

November 25, 2008 - A - Original Issue of Manual

REVISION LOG

a31200148

Read This First

Read This First

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and

lessees with the precautions and operating procedures essential for the safe and

proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to

make specification changes without prior notification. Contact JLG Industries, Inc.

for updated information.

Operator Qualifications

The operator of the machine must not operate the machine until this manual has

been read, training is accomplished and operation of the machine has been

completed under the supervision of an experienced and qualified operator.

Operation within the U.S.A. requires training per OSHA 1910.178.

Operators of this equipment must possess a valid, applicable driver’s license, be in

good physical and mental condition, have normal reflexes and reaction time, good

vision and depth perception and normal hearing. Operator must not be using

medication which could impair abilities nor be under the influence of alcohol or any

other intoxicant during the work shift.

In addition, the operator must read, understand and comply with instructions

contained in the following material furnished with the material handler:

• This Operation & Safety Manual

• Telehandler Safety Manual (as required)

• All instructional decals and plates

• Any optional equipment instructions furnished

The operator must also read, understand and comply with all applicable Employer,

Industry and Governmental rules, standards and regulations.

Modifications

Any modification to this machine must be approved by JLG.

b 31200148

Read This First

This product must comply with all safety related bulletins. Contact JLG Industries,

Inc. or the local authorized JLG representative for information regarding safetyrelated bulletins which may have been issued for this product.

JLG Industries, Inc. sends safety related bulletins to the owner of record of this

machine. Contact JLG Industries, Inc. to ensure that the current owner records are

updated and accurate.

JLG Industries, Inc. must be notified immediately in all instances where JLG

products have been involved in an accident involving bodily injury or death of

personnel or when damage has occurred to personal property or the JLG product.

FOR:

• Accident Reporting and Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Applications and Safety

• Standards and Regulations Compliance Information

• Questions Regarding Product Modifications

CONTACT:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office

(Addresses on back cover)

In USA:

Toll Free: 1-877-JLG-SAFE (877-554-7233)

Outside USA:

Phone: +1-717-485-5161

E-mail: ProductSafety@JLG.com

Other Publications Available

Service Manual .............................................................91404002

Illustrated Parts Manual.................................................91404001

c31200148

Read This First

This Page Intentionally Left Blank

d 31200148

Table of Contents

TABLE OF CONTENTS

Revision Log

Read This First

Operator Qualifications ...................................................... b

Modifications ...................................................................... b

Other Publications Available .............................................. c

Table of Contents

Section 1 - General Safety Practices

1.1 Hazard Classification system...............................................1-1

Safety Alert System and Safety Signal Words................1-1

1.2 General Precautions ............................................................1-1

1.3 Operation Safety..................................................................1-2

Electrical Hazards ...........................................................1-2

Tip Over Hazard..............................................................1-3

Travel Hazard .................................................................1-6

Load Falling Hazard ........................................................1-7

Lifting Personnel .............................................................1-8

Driving Hazards on Slopes .............................................1-9

Pinch Points and Crush Hazards ..................................1-10

Fall Hazard....................................................................1-12

Chemical Hazards.........................................................1-13

Table of Contents

Section 2 - Pre-Operation and Inspection

2.1 Pre-Operation Check and Inspection...................................2-1

2.2 Safety Decals.......................................................................2-3

2.3 Walk-Around Inspection.......................................................2-6

2.4 Warm-Up and Operational Checks ...................................... 2-8

Warm-Up Check .............................................................2-8

Operational Check ..........................................................2-8

2.5 Operator Cab .......................................................................2-9

2.6 Windows ............................................................................2-10

Cab Door Window (if equipped)....................................2-10

Section 3 - Controls and Indicators

3.1 General ................................................................................3-1

3.2 Controls ...............................................................................3-2

Transmission Control Lever ............................................3-3

Ignition Switch .................................................................3-4

Boom Joystick .................................................................3-5

Attachment Tilt and Frame Sway Lever ..........................3-6

Auxiliary Control Joystick (if equipped) ...........................3-7

Dash Controls and Indicators.......................................... 3-8

Park Brake Switch........................................................... 3-9

i31200148

Table of Contents

Parking Procedure.......................................................... 3-9

Heater........................................................................... 3-10

3.3 Operator Seat.................................................................... 3-11

Seat Adjustments ......................................................... 3-11

Seat Belt ....................................................................... 3-13

3.4 Boom Angle and Extension Indicators .............................. 3-14

3.5 Mirror................................................................................. 3-14

Section 4 - Operation

4.1 Engine ................................................................................. 4-1

Starting the Engine ......................................................... 4-1

Cold Weather Starting Aids ............................................ 4-2

Battery Boosted Starting................................................. 4-3

Normal Engine Operation ............................................... 4-4

Shut-Down Procedure .................................................... 4-4

4.2 Operating with a Load ......................................................... 4-5

Lift Load Safely............................................................... 4-5

Picking Up a Load .......................................................... 4-5

Transporting the Load .................................................... 4-6

Leveling Procedure......................................................... 4-6

Placing the Load............................................................. 4-7

Disengaging the Load..................................................... 4-7

4.3 Operating with a Suspended Load ...................................... 4-8

Lift Load Safely............................................................... 4-8

Picking Up a Suspended Load ....................................... 4-8

Transporting a Suspended Load .................................... 4-9

Leveling Procedure......................................................... 4-9

Placing a Suspended Load........................................... 4-10

Disengaging a Suspended Load .................................. 4-10

4.4 Loading and Securing for Transport.................................. 4-11

Tiedown ........................................................................ 4-11

Lifting ............................................................................ 4-12

Section 5 - Attachments

5.1 Approved Attachments ........................................................ 5-1

5.2 Unapproved Attachments.................................................... 5-2

5.3 Telehandler/Attachment/Fork Capacity ............................... 5-3

5.4 Use of the Capacity Chart ................................................... 5-4

Capacity Indicator Locations .......................................... 5-4

Sample Capacity Chart................................................... 5-5

Example.......................................................................... 5-6

5.5 Attachment Installation ........................................................ 5-7

5.6 Adjusting/Moving Forks ....................................................... 5-9

5.7 Attachment Operation ....................................................... 5-10

Carriage w/Forks .......................................................... 5-11

ii 31200148

Crane Hook...................................................................5-12

Bucket ...........................................................................5-14

Truss Boom...................................................................5-16

Boom Head-Mounted Winch.........................................5-18

6 ft (1,8 m) Mast with 48 or 72 in (1,2 & 1,8 m)

Carriage ........................................................................5-19

6 ft (1,8 m) - 100° Swing Mast W/Side Shift..................5-21

Swing Carriage .............................................................5-23

Side Tilt Carriage ..........................................................5-25

Personnel Work Platform ..............................................5-27

Section 6 - Emergency Procedures

6.1 Towing a Disabled Product ..................................................6-1

Moving Short Distances ..................................................6-1

Moving Longer Distances ...............................................6-1

6.2 Emergency Lower of Boom..................................................6-2

6.3 Emergency Exit from Enclosed Cab ....................................6-2

Section 7 - Lubrication and Maintenance

7.1 Introduction ..........................................................................7-1

Clothing and Safety Gear................................................ 7-1

7.2 General Maintenance Instructions .......................................7-2

7.3 Service and Maintenance Schedules...................................7-3

10 & 1st 50 Hour Maintenance Schedule .......................7-3

50, 250 & 500 Hour Maintenance Schedule ...................7-4

1000 & 1500 Hour Maintenance Schedule .....................7-5

7.4 Lubrication Schedules .........................................................7-6

50 Hour Lubrication Schedule.........................................7-6

250 Hour Lubrication Schedule....................................... 7-7

7.5 Operator Maintenance Instructions......................................7-8

Fuel System ....................................................................7-8

Air Intake System ..........................................................7-10

Engine Oil ..................................................................... 7-12

Hydraulic Oil.................................................................. 7-13

Tires ..............................................................................7-14

Hydraulic Return Filter ..................................................7-17

Engine Cooling System................................................. 7-18

Battery........................................................................... 7-19

Table of Contents

Section 8 - Additional Checks

Section 9 - Specifications

9.1 Product Specifications .........................................................9-1

Fluid and Lubrication Capacities ..................................... 9-1

Tires ................................................................................9-2

Performance ...................................................................9-2

iii31200148

Table of Contents

Dimensions..................................................................... 9-3

Index

Inspection, Maintenance and Repair Log

iv 31200148

Section 1 - General Safety Practices

SECTION 1 - GENERAL SAFETY PRACTICES

1.1 HAZARD CLASSIFICATION SYSTEM

Safety Alert System and Safety Signal Words

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a potentiality hazardous situation which, if not avoided, may

result in minor or moderate injury.

OW0010

OW0021

OW0031

1.2 GENERAL PRECAUTIONS

WARNING

Before operation, read and understand this manual. Failure to comply with the

safety precautions listed in this manual could result in machine damage, property

damage, personal injury or death.

1-131200148

Section 1 - General Safety Practices

1.3 OPERATION SAFETY

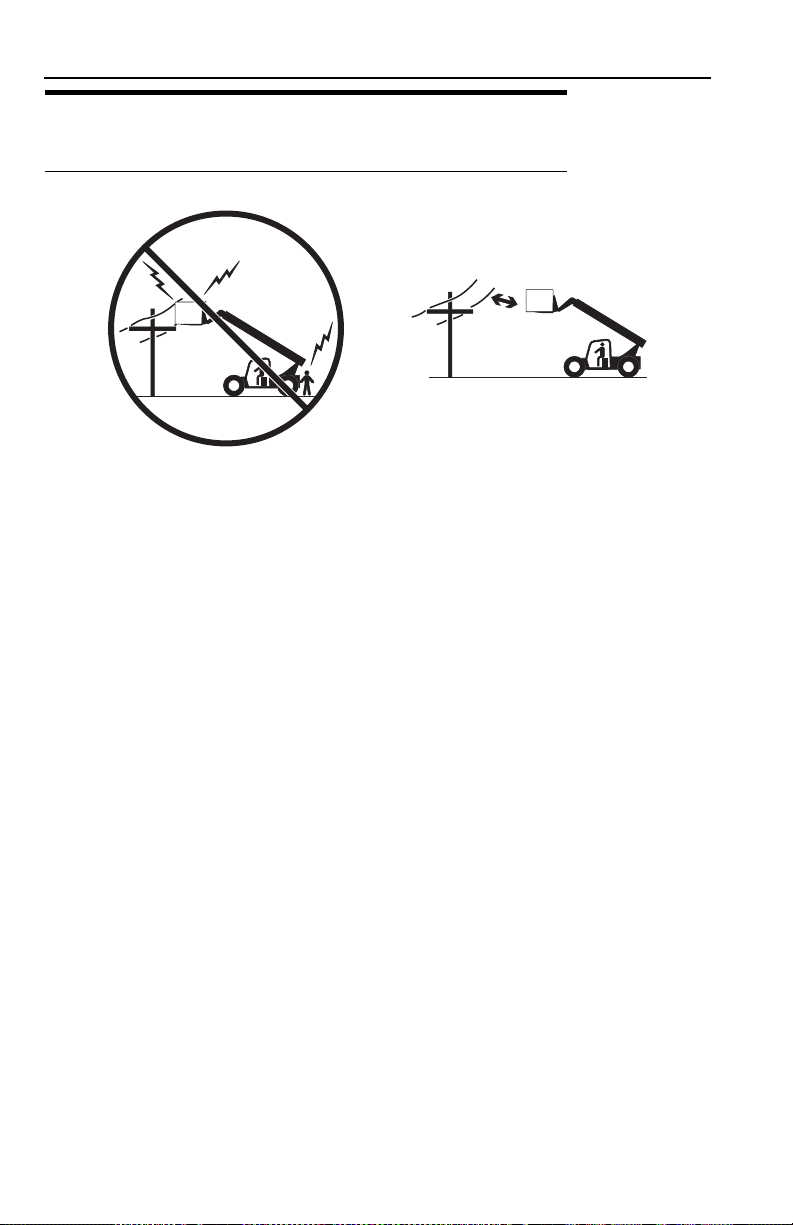

Electrical Hazards

10 FT

(3 M)

OW0040

• This machine is not insulated and does not provide protection from contact or

being near electrical current.

• NEVER operate the telehandler in an area where overhead power lines,

overhead or underground cables, or other power sources may exist without

ensuring the appropriate power or utility company de-energizes the lines.

• Always check for power lines before raising the boom.

• Follow employer, local and governmental regulations for clearance from

powerlines.

1-2 31200148

Section 1 - General Safety Practices

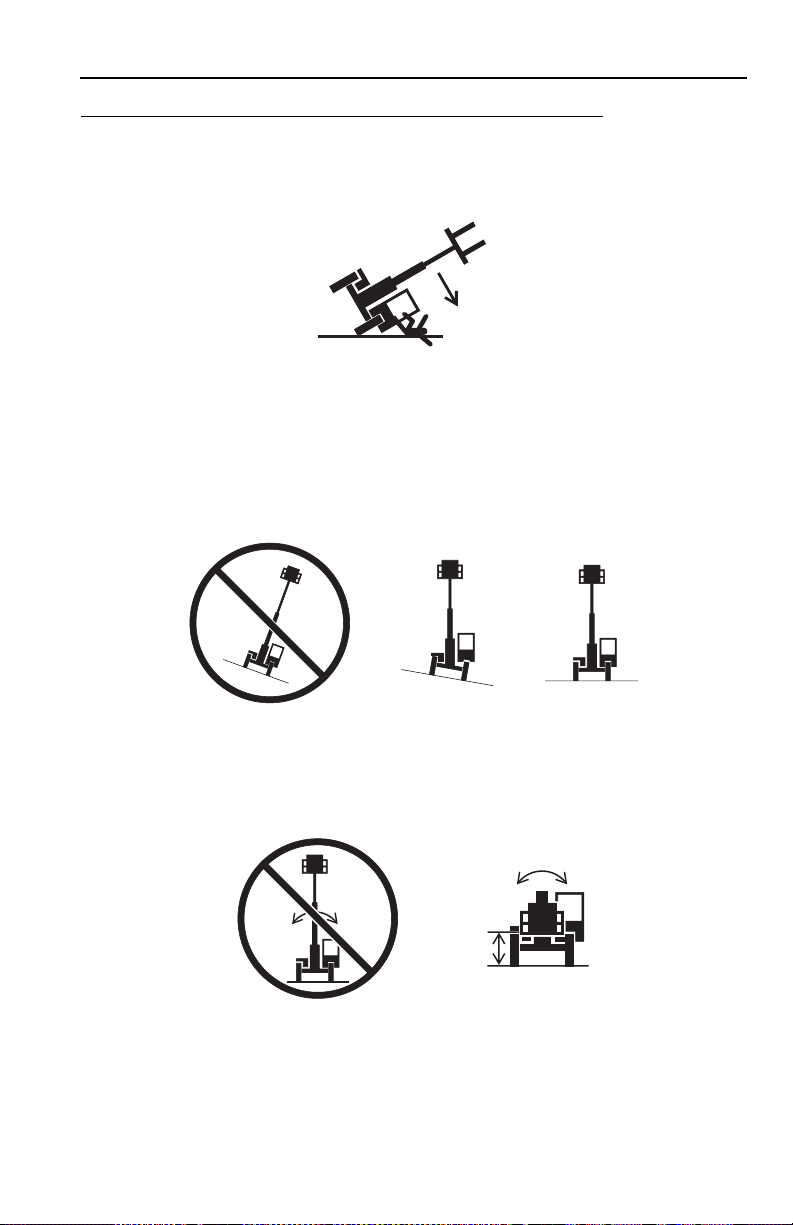

Tip Over Hazard

General

• For additional load requirements, refer to the appropriate capacity chart.

OW0050

• Never use an attachment without the appropriate JLG approved capacity chart

installed on the telehandler.

• Understand how to properly use the capacity charts located in cab.

• DO NOT exceed rated lift capacity.

• Be sure that the ground conditions are able to support the machine.

OW0080

• DO NOT raise boom unless frame is level (0 degrees), unless otherwised noted

on capacity chart.

4 FT

(1,2 M)

OW0100

• DO NOT level machine with boom/attachment above 4 ft (1,2 m).

(AUS - DO NOT level machine with load more than 11.8 in. (300 mm) above

ground surface).

1-331200148

Section 1 - General Safety Practices

OH2291

• MAINTAIN proper tire pressure at all times. If proper tire pressures are not

maintained, this machine could tip over.

• Refer to manufacturer’s specifications for proper fill ratio and pressure

requirements for tires equipped with ballast.

OH20911

• Always wear the seat belt.

• Keep head, arms, hands, legs and all other body parts inside operator’s cab at all

times.

OH2221

If the telehandler starts to tip over:

• DO NOT JUMP

• BRACE YOURSELF and STAY WITH THE MACHINE

• KEEP YOUR SEAT BELT FASTENED

•HOLD ON FIRMLY

• LEAN AWAY FROM THE POINT OF IMPACT

1-4 31200148

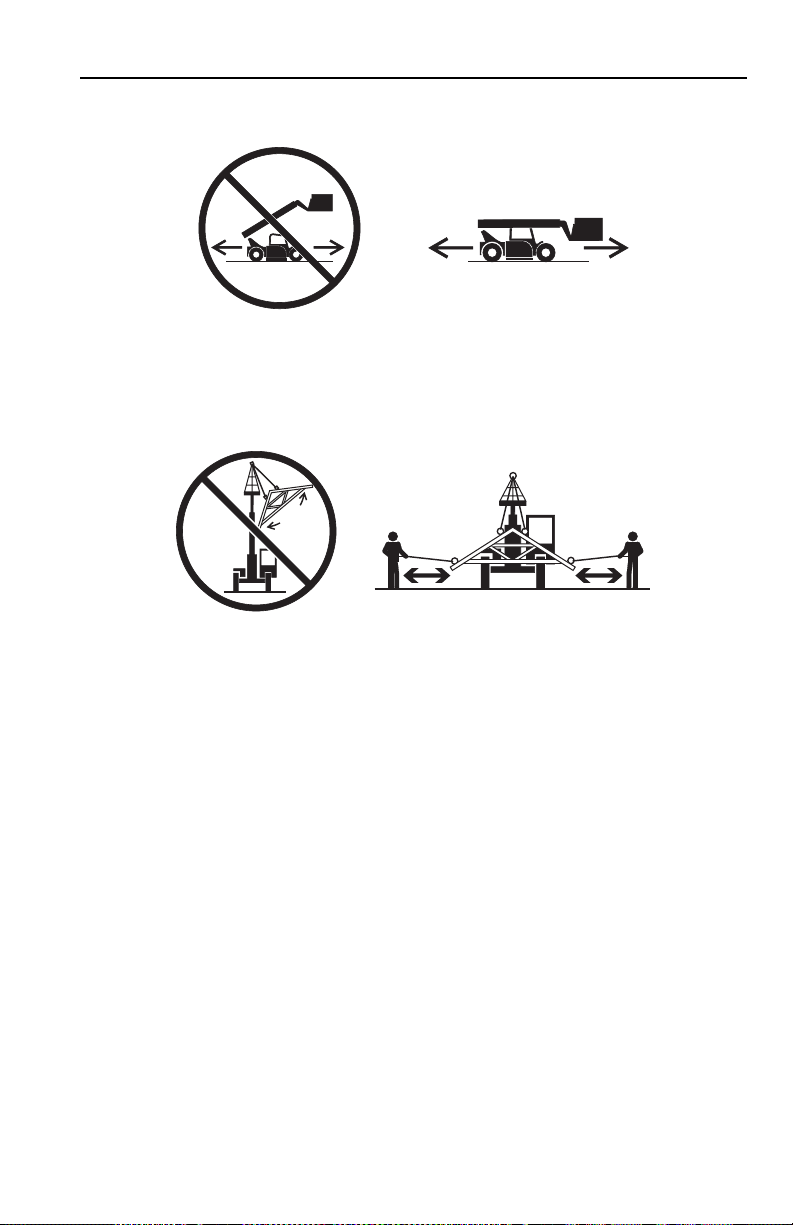

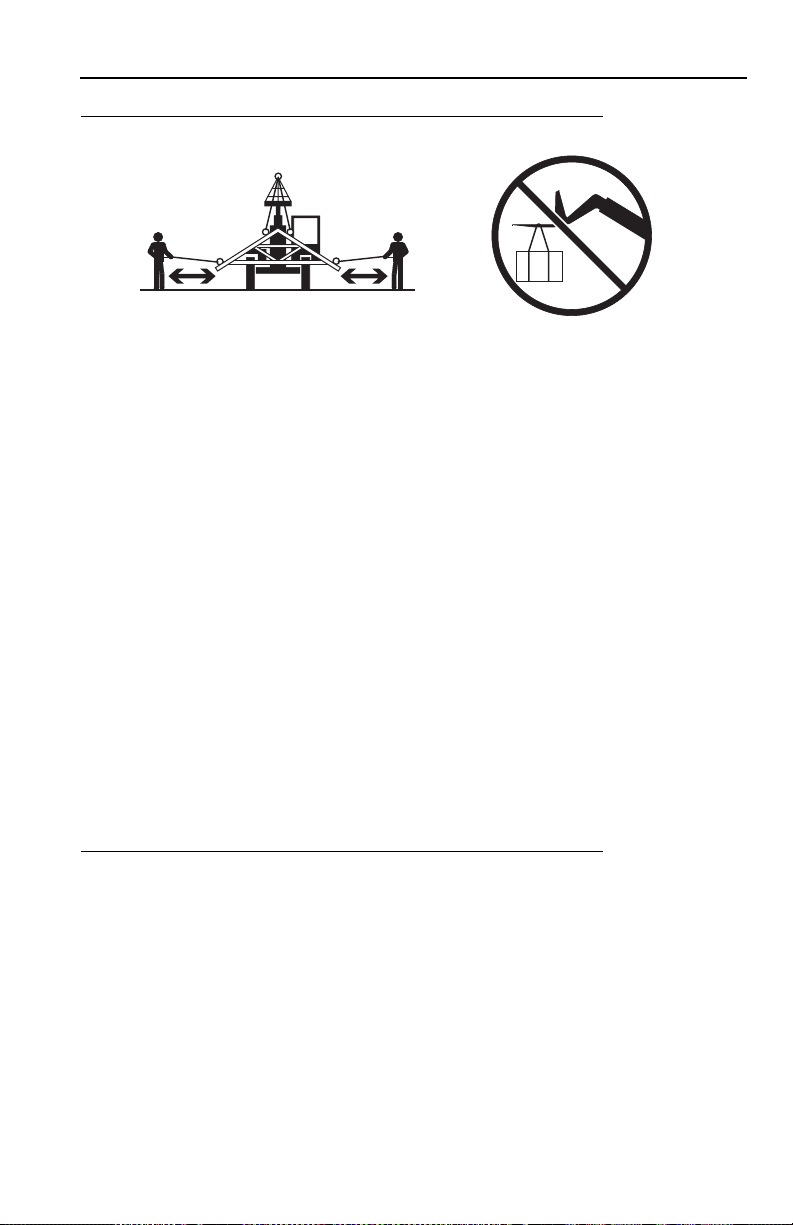

Non-Suspended Load

•DO NOT drive with boom raised.

Suspended Load

Section 1 - General Safety Practices

OW0060

OW0150

• Tether suspended loads to restrict movement.

• DO NOT raise the load more than 11.8 in (300 mm) above ground surface or the

boom more than 45°.

• Weight of all rigging (slings, etc.) must be included as part of load.

• Start, travel, turn and stop slowly to prevent load from swinging.

• When driving with the boom raised, DO NOT exceed walking speed.

• Beware of wind. Wind can cause a suspended load to swing and cause

dangerous side loads - even with tag lines.

• DO NOT attempt to use telehandler frame-leveling to compensate for load swing.

• Keep heavy part of load closest to attachment.

• Never drag the load; lift vertically.

1-531200148

Section 1 - General Safety Practices

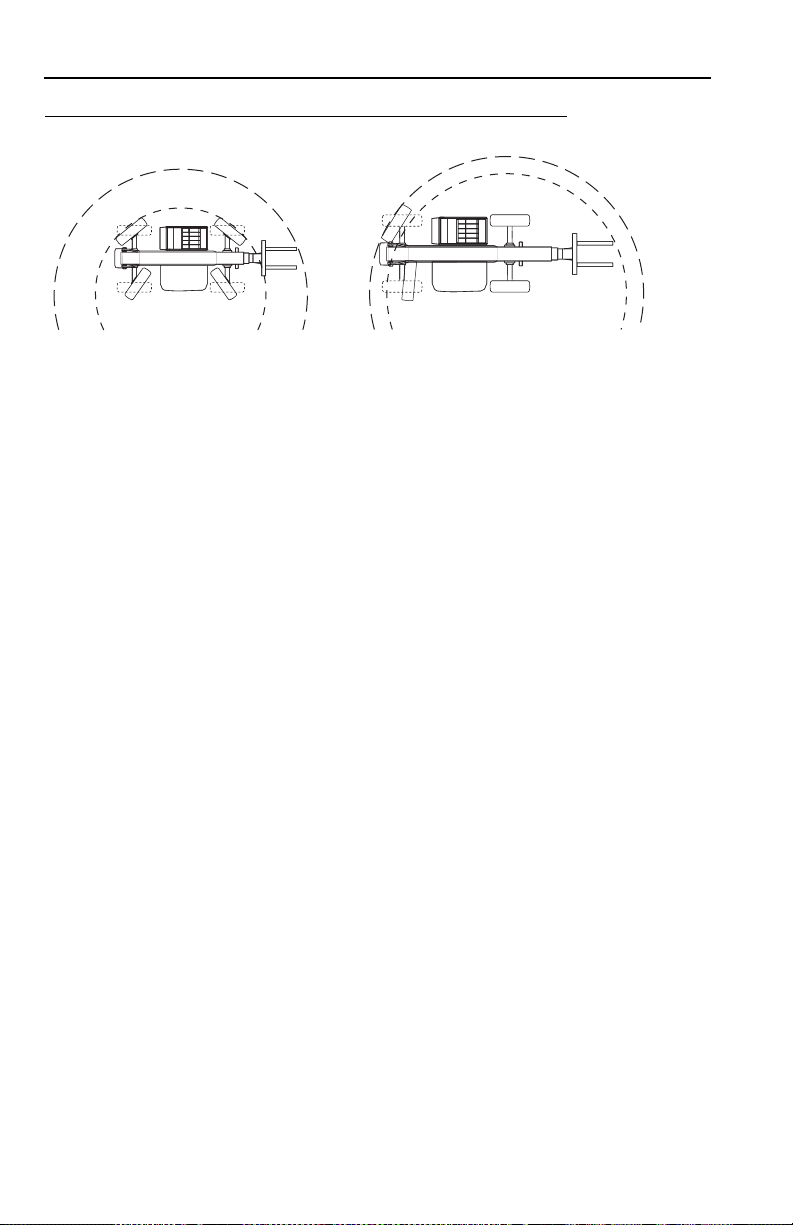

Travel Hazard

4-Wheel Steer Pivot Steer

OW0120

• Steering characteristics differ between 4-Wheel Steer & Pivot Steer telehandlers

as shown above. Identify the telehandler you are operating & others on the

jobsite.

• Ensure that adequate clearance is provided between both rear tail swing and

front fork swing.

• Unlike a conventional 4-wheel steer telehandler the rear wheels of a pivot steer

telehandler turn a wider circle than the front wheels.

• Look out for and avoid other personnel, machinery and vehicles in the area. Use

a spotter if you DO NOT have a clear view.

• Before moving be sure of a clear path and sound horn.

• When driving, retract boom and keep boom/attachment as low as possible while

maintaining visibility of mirrors and maximum visibility of path of travel.

• Always look in the direction of travel.

• Always check boom clearances carefully before driving underneath overhead

obstructions. Position attachment/load to clear obstacles.

1-6 31200148

Section 1 - General Safety Practices

Load Falling Hazard

OW0130

• Never suspend load from forks or other parts of carriage.

• DO NOT burn or drill holes in fork(s).

• Forks must be centered under load and spaced apart as far as possible.

1-731200148

Section 1 - General Safety Practices

Lifting Personnel

OW0170

• When lifting personnel, USE ONLY a JLG approved personnel work platform,

with proper capacity chart displayed in the cab.

OW0190

• DO NOT drive machine from cab when personnel are in platform.

1-8 31200148

Section 1 - General Safety Practices

Driving Hazards on Slopes

OW0200

To maintain sufficient traction and braking capabilities, travel on slopes as follows:

• When unloaded, the rear of the machine is the “heavy end.” Drive with forks

pointed downhill.

• When loaded, the front of the machine is the “heavy end.” Drive with the forks

pointed uphill.

• For additional travel requirements, refer to the appropriate capacity chart.

• To avoid overspeeding the engine and drivetrain when driving down slopes,

downshift to a lower gear and use the service brake as necessary to maintain a

slow speed. DO NOT shift into neutral and coast downhill.

• Avoid excessively steep slopes or unstable surfaces. To avoid tip over DO NOT

drive across excessively steep slopes under any circumstances.

• Avoid turning on a slope. Never engage “inching” or shift to “Neutral” when going

downhill.

• DO NOT park on a slope.

1-931200148

Section 1 - General Safety Practices

Pinch Points and Crush Hazards

Stay clear of pinch points and rotating parts on the telehandler.

• Stay clear of moving parts while engine is running.

OW0220

• Keep clear of steering tires and frame or other objects.

OW0210

OW0230

• Keep clear from under boom.

1-10 31200148

Section 1 - General Safety Practices

OW0240

• Keep clear of boom holes.

OW0250

• Keep arms and hands clear of attachment tilt cylinder.

OW0260

• Keep hands and fingers clear of carriage and forks.

OW0960

• Keep others away while operating.

1-1131200148

Section 1 - General Safety Practices

Fall Hazard

OW0280

• Enter using the proper hand holds and steps provided. Always maintain 3-point

contact when mounting or dismounting. Never grab control levers or steering

wheel when mounting or dismounting the machine.

• DO NOT get off the machine until the shutdown procedure on page 4-4 has been

performed.

OW0290

• DO NOT carry riders. Riders could fall off machine causing death or serious

injury.

1-12 31200148

Section 1 - General Safety Practices

Chemical Hazards

Exhaust Fumes

• DO NOT operate machine in an enclosed area without proper ventilation.

• DO NOT operate the machine in hazardous environments unless approved for

that purpose by JLG and site owner. Sparks from the electrical system and the

engine exhaust can cause an explosion.

• If spark arrestors are required, ensure they are in place and in good working

order.

Flammable Fuel

OW0300

• DO NOT fill the fuel tank or service the fuel system near an open flame, sparks

or smoking materials. Engine fuel is flammable and can cause a fire and/or

explosion.

Hydraulic Fluid

OW0950

• DO NOT attempt to repair or tighten any hydraulic hoses or fittings while the

engine is running or when the hydraulic system is under pressure.

• Stop engine and relieve trapped pressure. Fluid in the hydraulic system is under

enough pressure that it can penetrate the skin.

• DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to

search for leaks. Wear gloves to protect hands from spraying fluid.

1-1331200148

Section 1 - General Safety Practices

This Page Intentionally Left Blank

1-14 31200148

Section 2 - Pre-Operation and Inspection

SECTION 2 - PRE-OPERATION AND INSPECTION

2.1 PRE-OPERATION CHECK AND INSPECTION

Note: Complete all required maintenance before operating unit.

WARNING

FALL HAZARD. Use extreme caution when checking items beyond your normal

reach. Use an approved ladder.

The pre-operation check & inspection, performed at beginning of each work shift or

at each change of operator, should include the following:

1. Cleanliness - Check all surfaces for leakage (oil, fuel or battery fluid) or foreign

objects. Report any leakage to the proper maintenance personnel.

2. Structure - Inspect the machine structure for dents, damage, weld or parent

metal cracks or other discrepancies.

OAH1000

PARENT METAL CRACK WELD CRACK

3. Safety Decals - Ensure all safety decals are legible and in place. Clean or

replace as required. See page 2-3 for details.

4. Operation and Safety Manuals - Operation and Safety Manual and AEM

Safety Manual (as required) are located in cab manual holder.

5. Walk-Around Inspection - See page 2-6 for details.

6. Fluid Levels - Check fluids, including fuel, hydraulic oil, engine oil and coolant.

When adding fluids, refer to Section 7 - Lubrication and Maintenance and

Section 9 - Specifications to determine proper type and intervals. Before

removing filler caps or fill plugs, wipe all dirt and grease away from the ports. If

dirt enters these ports, it can severely reduce component life.

7. Attachments/Accessories - Ensure correct load charts are installed on the

telehandler. If provided, reference the Operation and Safety Manual of each

attachment or accessory installed for specific inspection, operation and

maintenance instructions.

2-131200148

Section 2 - Pre-Operation and Inspection

8. Operational Check - Once the walk-around inspection is complete, perform a

warm-up and operational check (see page 2-8) of all systems in an area free of

overhead and ground level obstructions. See Section 3 - Controls and

Indicators for more specific operating instructions.

WARNING

If telehandler does not operate properly, immediately bring machine to a stop,

lower boom and attachment to ground and stop the engine. Determine cause and

correct before continued use.

2-2 31200148

Section 2 - Pre-Operation and Inspection

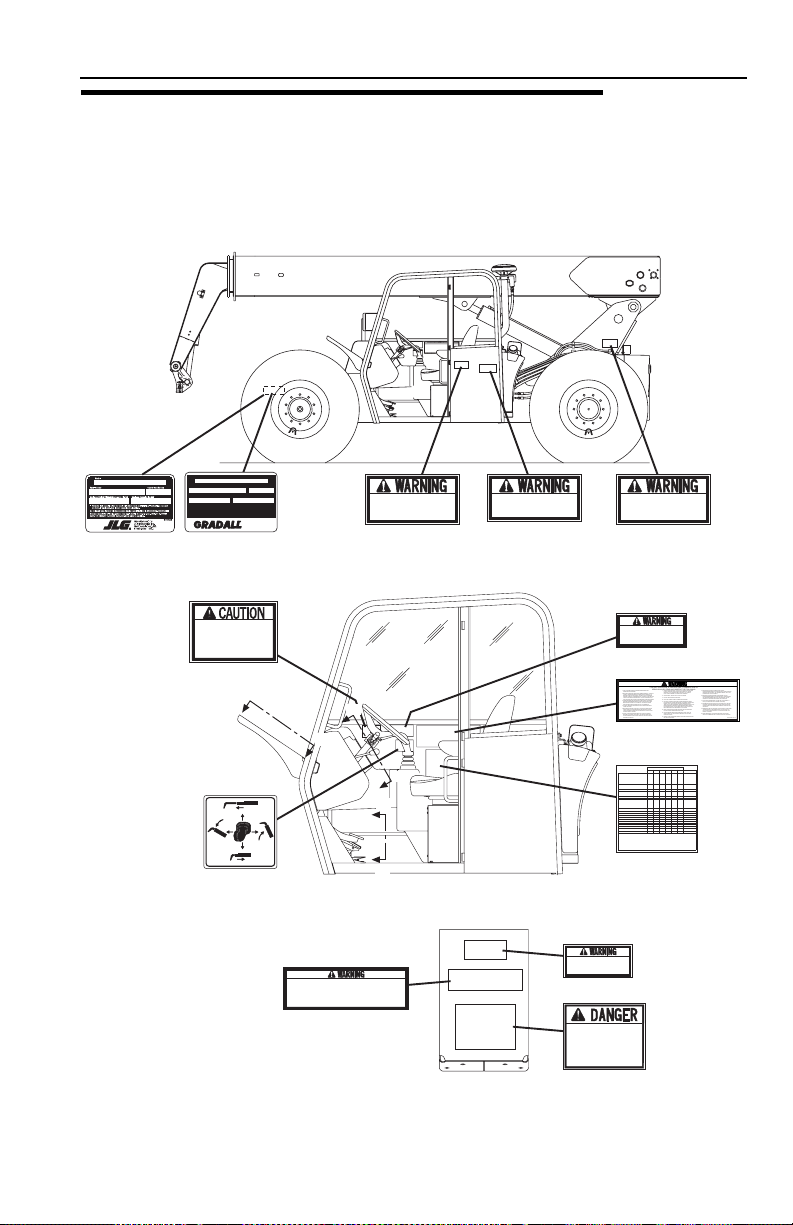

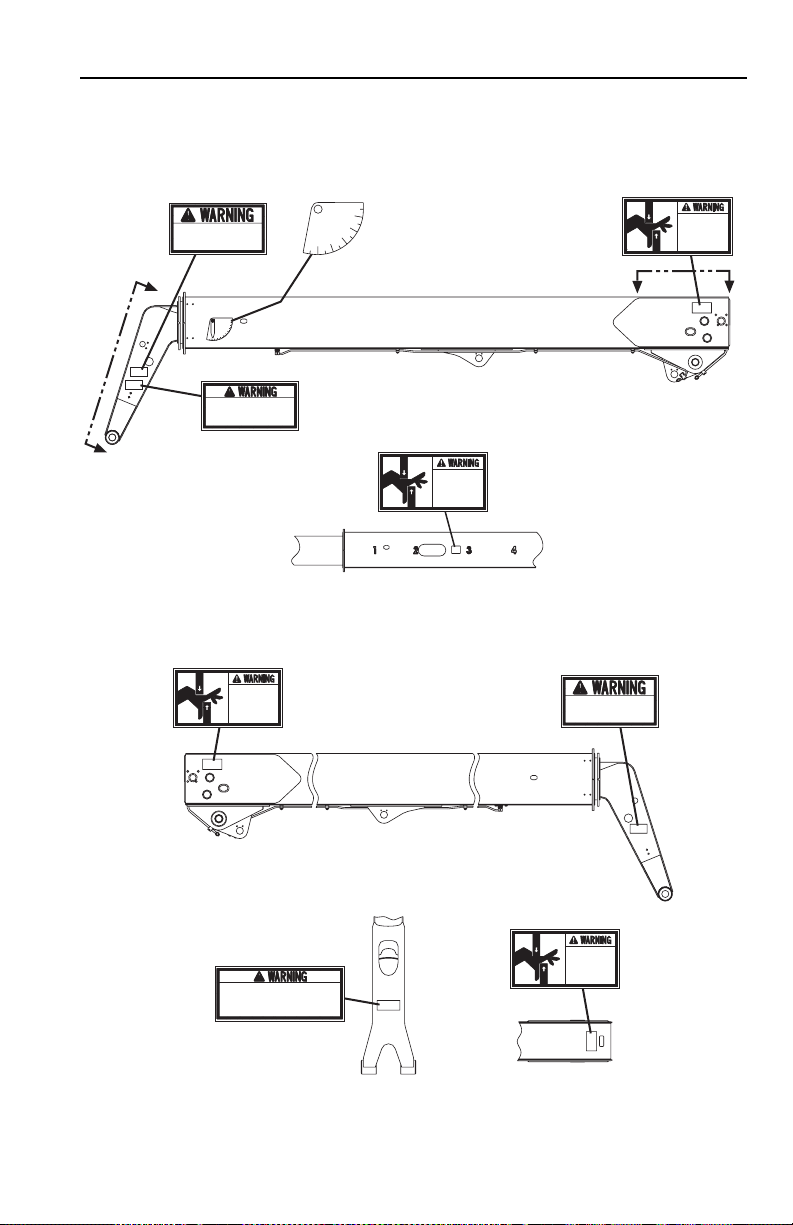

2.2 SAFETY DECALS

Ensure all DANGER, WARNING, CAUTION and instructional decals and proper

capacity charts are legible and in place. Clean and replace as required.

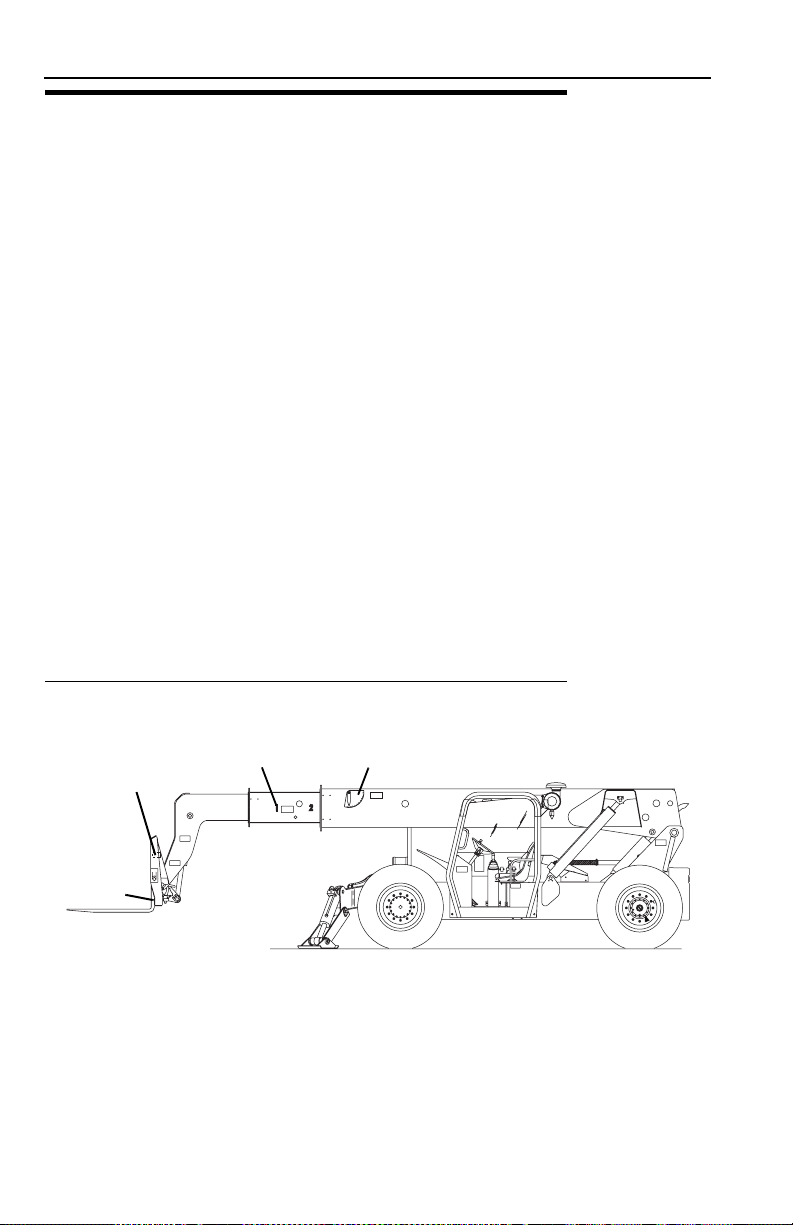

Model

Year of Manufacture

Serial Number

Maximim Capacity (lbs/kg)*

1705881

(After S/N

0160022389)

Maximum Weight Without Attachments (lbs/kg)

Refer to load capacity chart for truck with attachment, and individual load ratings stamped

on forks, if equipped. Use lowest capacity of all rattings.

As released from factory this truck meets design specifications in ASME B56.6-2002 Part III

One or more of the following patents may apply to this truck: U.S. Nos. 4,954,041 6,349,969

5,639,119 5,813,697 5,230,399 5,052,532. Other patents pending.

Manufactured by

JLG Industries Inc.

McConnellsburg, PA

17233-9533 USA

1705882

(Before S/N

0160022389)

NO RIDERS PERMITTED ON HANDLER.

OPERATOR ONLY IN MACHINE

WHILE RUNNING.

RIDERS COULD FALL OFF MACHINE

1705882

CAUSING SERIOUS INJURY OR DEATH.

9114-3283

91143283

DIESEL FUEL IS FLAMMABLE

EXTINGUISH ALL OPEN FLAME AND

SMOKING MATERIALS WHEN REFUELING

INJURY OR DEATH COULD RESULT

FROM FIRE.

91143286

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

9114-3286

CAUSE SERIOUS INJURY OR DEATH.

9114-3282

91143282

TURBOCHARGER DAMAGE CAN RESULT

FROM QUICK START-UP & SHUTDOWN.

FOR LONGER TURBOCHARGER LIFE

AND TO MINIMIZE TURBOCHARGER

DAMAGE, IDLE ENGINE AT LEAST

3-5 MINUTES AFTER START-UP

AND BEFORE SHUTDOWN.

91343016

A

91503102

9134-3016

9150-3102 REV. -

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK PLATFORM.

WHEN PERSONNEL ARE IN PLATFORM REMAIN SEATED IN CAB WITH PERSONNEL

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL BEFORE LIFTING PERSONNEL.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM CAPACITY CHART DISPLAYED IN CAB.

B

A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

DO NOT DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

IN DIRECT LINE OF SIGHT.

OPERATE CONTROLS LIGHTLY AND CAUTIOUSLY WHEN LIFTING PERSONNEL.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

90553027

91323030

NEVER OPERATE MACHINE WITHOUT

CONSULTING PROPER CAPACITY CHART FOR THE

CARRIAGE/FORK COMBINATION BEING USED.

9132-3030

90553028

FOR SAFE OPERATION OF MACHINE AND TO MINIMIZE RISK OF

SERIOUS INJURY, READ AND OBSERVE THE FOLLOWING:

15. BEFORE ADJUSTING OR SERVICING, PLACE

7. WHEN TRAVELING WITH LOAD, FULLY RETRACT BOOM AND

1. ONLY TRAINED AND AUTHORIZED PERSONNEL MAY

OPERATE THIS MACHINE.

2. BEFORE OPERATING, READ AND UNDERSTAND ALL CAPACITY

CHARTS, OPERATOR MANUALS AND SAFETY MANUALS. IF

MANUALS ARE NOT AVAILABLE, CONSULT AN AUTHORIZED

GRADALL DEALER. UNDERSTAND ALL CONTROLS IN CAB AND

CHECK FOR PROPER OPERATION. CLEAR LOOSE OBJECTS

OFF MACHINE AND SOUND HORN BEFORE STARTING ENGINE.

3. OPERATOR MUST BE SEATED WITH SEAT BELT FASTENED.

ASSURE FORWARD/REVERSE LEVER IS IN NEUTRAL,PARK

BRAKE APPLIED AND ALL HYDRAULIC CONTROLS ARE IN

NEUTRAL BEFORE IGNITION SWITCH IS TURNED ON.

4. DO NOT OPERATE MACHINE WITHOUT PROPER CAPACITY

CHART IN PLACE.

5. BEFORE MOVING, BE SURE OF A CLEAR PATH AND SOUND

HORN. WATCH FOR PEDESTRIANS AND OBSTRUCTIONS.

CHECK OVERHEAD AND SIDE CLEARANCES. ALWAYS LOOK

IN DIRECTION OF TRAVEL.

6. START, TURN, AND BRAKE SMOOTHLY. REDUCE TRAVEL

SPEEDS FOR TURNS, SLIPPERY, OR UNEVEN SURFACES.

AVOID RUNNING OVER LOOSE OBJECTS OR HOLES IN THE

ROADWAY SURFACE.

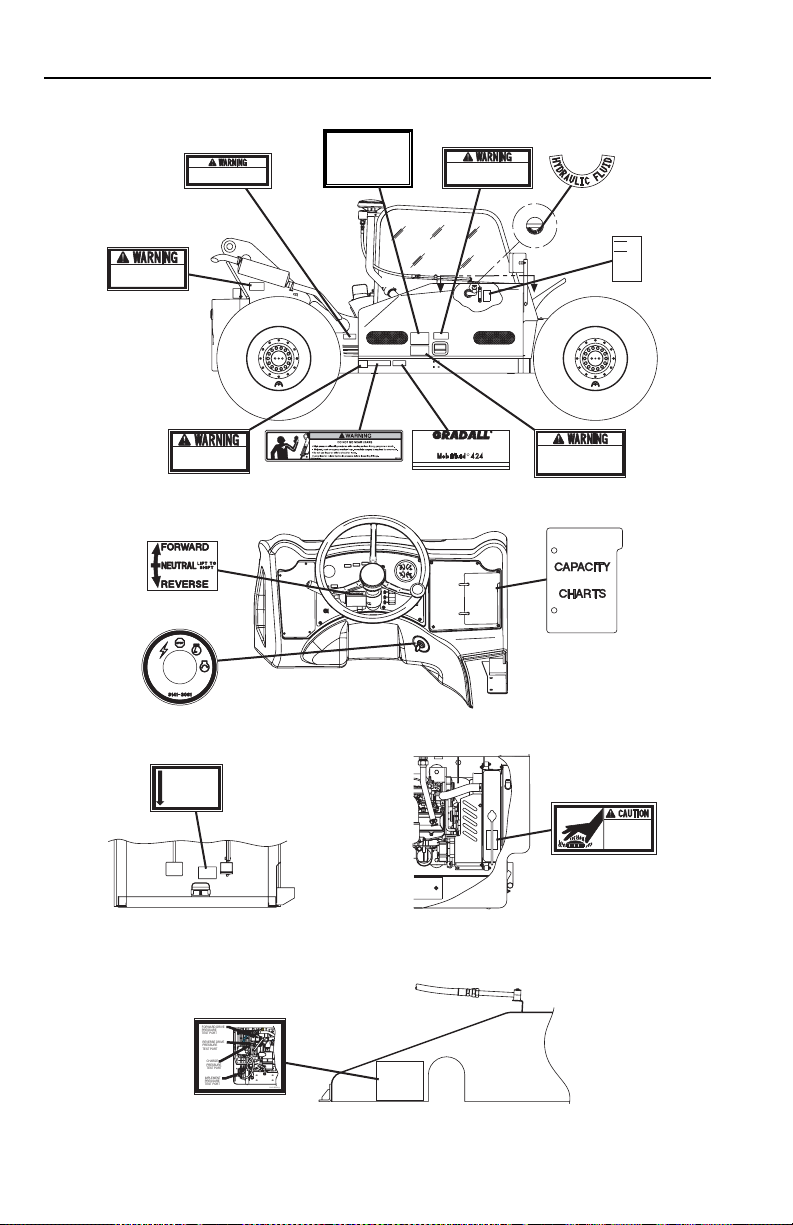

91413012

GRADALL HANDLER

SERVICE INSTRUCTIONS

FOR: G6-42P

DIESEL ENGINE

AIR CLEANER ELEMENT--------------**--------------------------------------------FUEL FILTERS--------------------------------------

B

C

OIL FILTER--------------------------------OIL (14.5 QT.) (13.6 LTR.)----DIESEL FUEL (38 GAL.) (143.8 LTR.)

HYDRAULIC SYSTEM

OIL (43 GAL.)------------------ -------------FILTERS--------------------------*----------------------------HYD.TANK BREATHER/FILTER CAP

FRONT AXLE LUBE

CENTER SECTION (15.75 QT.)(14.9 LTR.)

EACH WHEEL HUB (1.4 QT.)(1.3 LTR.)

REAR AXLE WHEEL END LUBE (4 PT.) (1.9 LTR.)

WHEEL NUT TORQUE-300/350 FT-LBS

RADIATOR

(1.9 GAL.) (7.2 LTR.) WATER

(1.9 GAL.) (7.2 LTR.) ANTI-FREEZE

(.5 QT.)(.47 LTR.) OF SUPPLIMENTAL

COOLANT ADDITIVE (SCA)

TIRES: (12 PLY)

65 PSI ------------------------------ -------------------------

----------------

TIRES: RADIAL 70 PSI

CYLINDER FITTINGS EACH END- ----****REAR AXLE (12) FITTINGS--------****FRONT AXLE PIVOT (2) FITTINGS

--------

-------------------

ALL BEARINGS PADS

FRONT BOTTOM BEARING PADS-- - -- - - -- - BOOM PIVOT (2) FITTINGS---------****HEAD PIN (2) FITTINGS-----------****-

QUICK SWITCH (1) FITTING------------RETRACT & EXTEND CHAIN --------------------SEE OPERATOR & MAINTENANCE MANUAL

RETRACT & EXTEND CHAIN SHEAVES----------------

THIS CHART MUST BE USED IN CONJUNCTION WITH SERVICE MANUAL AND RECOMMENDED PROCEDURE.

* CHECK INDICATOR ON HYDRAULIC FILTER. CHANGE FILTER IF NEEDLE IS IN RED

AT FULL THROTTLE AND AT OPERATING TEMPERATURE.

** CHECK AIR CLEANER RESTRICTION INDICATOR. CLEAN OR CHANGE PRIMARY FILTER IF NECESSARY.

SAFETY ELEMENT TO BE CHANGED EVERY 3RD CHANGE OF PRIMARY FILTER ELEMENT.

*** CONSULT DEALER FOR RECOMMENDATIONS AT EXTREME TEMPERATURES.

**** DAILY SERVICE MAY BE REQUIRED FOR OPTIMUM LIFE DEPENDING UPON APPLICATION SEVERITY.

*****IF COOLANT IS ADDED TO RADIATOR ADD 3% SCA BY VOLUME.

IT IS RECOMMENDED THAT FILTER ELEMENTS, FRONT AXLE LUBRICANT, AND ENGINE OIL BE

CHANGED AFTER FIRST 100 HRS ON NEW OR REBUILT UNITS.

PLACE FORKS IN CARRY POSITION (APPROX.12" ABOVE

GROUND). TILT CARRIAGE BACK SLIGHTLY TO CRADLE

LOAD. USE EXTREME CAUTION WHEN TURNING.

8. ON INCLINES, TRAVEL WITH LOAD UP-GRADE.

9. DO NOT USE BOOM AS WALKWAY.

10. USE TWO HANDS WHEN CLIMBING ON MACHINE.

11. USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK

PLATFORM FOR LIFTING PERSONNEL. NO RIDERS ON MACHINE,

FORKS, LOAD, OR OTHER LIFTING ATTACHMENTS AT ANY

TIME. DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN THE CAB. DO NOT

DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

12. KEEP OTHERS AWAY FROM MACHINE WHILE OPERATING.

DO NOT STAND UNDER BOOM OR LOAD.

13. USE EXTREME CARE WHEN HANDLING LONG, HIGH, OR

WIDE LOADS. DO NOT HANDLE UNSTABLE OR LOOSELY

STACKED LOADS.

14. FORKS TO BE CENTERED UNDER LOAD AND SPACED APART

AS FAR AS POSSIBLE.

SERVICE INTERVALS

DAILY

WEEKLY

EVERY

3 MO.

OR

OR

5WKS OR

OR

10 HRS

50 HRS

250 HRS

500 HRS

CHANGE

-------------------

CHANGE

-------------------

CHANGE-----

CHECK

--------------------------------

FILL

CHECK

INSPECT

------

------------CHECK

------

------------CHECK

------

-------------

------

CHECK

-------------------

TORQUE

------ --------------------------

*****

CHECK

--------------------------

CHECK

GREASE

--------------------------

GREASE

--------------------------

GREASE

-------------------------GREASE

--------------------------

CHECK

GREASE

-------------------

GREASE

--------------------------

GREASE

--------------------------

GREASE

--------------------------

-------------------

CHECK

--------------------------

GREASE

FORWARD/REVERSE LEVER IN NEUTRAL, REST BOOM ON

GROUND OR SUPPORT, SET PARKING BRAKE, SHUT OFF

ENGINE AND CHOCK WHEELS.

16. BEFORE LEAVING MACHINE UNATTENDED, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, LOWER BOOM,

SET PARKING BRAKE,AND SHUT-OFF ENGINE. CHOCK

WHEELS IF MACHINE MUST PARK ON AN INCLINE.

17. LEVEL MACHINE BEFORE LIFTING ANY LOAD ABOVE 4

FEET. (IF EQUIPPED WITH FRAME LEVELING).

18. OPERATOR PROTECTION (SUCH AS HARD HATS, SAFETY

GLASSES, AND/OR HEARING PROTECTION) SHOULD BE

WORN WHEN JOB CONDITIONS WARRANT. ALWAYS USE

SEAT BELT.

19. IMPROPER USE OF MACHINE COULD RESULT IN MACHINE

TIPPING OVER. IF MACHINE STARTS TO TIP OVER, DO

NOT LEAVE OPERATORS SEAT. LEAN AWAY FROM TIP &

BRACE YOURSELF.

20. KEEP MIRROR(S) CLEAN AND PROPERLY ADJUSTED.

OBJECTS IN MIRROR ARE CLOSER THAN THEY APPEAR.

9055-3028 REV. A

ANNUALLY

6 MO.

TYPE OR

OR

OR

EQUIVALENT

1500 HRS

1000 HRS

-------------

SAE 15W-40-CD ***

DIESEL FUEL #2

MOBIL 424

------

CHANGE

CHANGE

------

CHANGE

MOBIL 424

------

CHANGE

------

-----MOBIL 424

CHANGE

-------------

ETHYLENE GLYCOL

ANTI-FREEZE

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

MYSTIK TETRIMOLY

9141-3012

C

91323030

NEVER OPERATE MACHINE WITHOUT

CONSULTING PROPER CAPACITY CHART FOR THE

CARRIAGE/FORK COMBINATION BEING USED.

9132-3030

9055-3027 REV. A

80603022

AVOID HIGH VOLTAGE LINES.

IT IS UNLAWFUL TO PLACE

ANY PART OF THIS MACHINE

OR LOAD WITHIN 10 FEET

OF HIGH VOLTAGE LINES

UP TO 50,000 VOLTS.

DEATH OR INJURY MAY

RESULT FROM CONTACTING

ELECTRIC LINES.

8060-3022

OY1061

VIEW A-A

2-331200148

Section 2 - Pre-Operation and Inspection

91143282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

91163028

91413061

91143280

BEFORE

S/N 0160026801

EXHAUST SYSTEMS CAN BE HOT.

KEEP AWAY FROM EXHAUST SYSTEM WHEN HOT.

HOT EXHAUST COMPONENTS CAN CAUSE

SEVERE BURNS.

9114-3280

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

9114-3282

91143282

91143285

JUMP STARTING INSTRUCTIONS

WHEN JUMP STARTING MATERIAL HANDLER

* NEVER ALLOW VEHICLES TO TOUCH

* CONNECT THE POSITIVE (+) JUMPER CABLE TO

POSITIVE (+) POST OF DISCHARGED BATTERY

* CONNECT OPPOSITE END OF POSITIVE (+) JUMPER

CABLE TO POSITIVE (+) POST OF BOOSTER BATTERY

* CONNECT THE NEGATIVE (-) JUMPER CABLE TO

NEGATIVE (-) POST ON BOOSTER BATTERY

* CONNECT OPPOSITE END OF NEGATIVE (-) JUMPER

CABLE TO GROUND POINT ON MACHINE AWAY FROM

DISCHARGED BATTERY

* FOLLOW STANDARD STARTING PROCEDURES

* REMOVE CABLES IN REVERSE ORDER AFTER MACHINE

HAS STARTED

91083492

9114-3285

91143281

STAY CLEAR OF MOVING PARTS

WHILE ENGINE IS RUNNING.

MOVING PARTS CAN CAUSE

SERIOUS INJURY.

Genuine Parts

HYDRAULIC SYSTEM

FILL WITH TRACTOR HYDRAULIC FLUID

R

or equivalent.

For Mobil Product Information, Call 1-800-662-4525.

91143288

91403573

9114-3281

DD

* DO NOT USE SMOKING MATERIALS NEAR BATTERIES

* KEEP FLAMES AND SPARKS AWAY FROM BATTERIES

* WEAR SAFETY GLASSES

* ASSURE BATTERY IS NOT FROZEN AND ELECTROLYTE

IS AT PROPER LEVEL IN EACH CELL

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

9114-3288

LEAD ACID BATTERIES PRODUCE FLAMABLE AND

EXPLOSIVE GASSES

WHEN CHECKING, TESTING, USING

BOOSTER BATTERY OR CHARGING BATTERIES:

RESULT IN SERIOUS INJURY OR DAMAGE TO THE

ELECTRICAL SYSTEM

3

7

5

3

-

0

4

1

9

91403569

FULL

ADD

HYDRAULIC

OIL LEVEL

CHECK OIL LEVEL WITH

HANDLER LEVEL AND ALL

CYLINDERS RETRACTED.

2.5 GALLON BETWEEN

ADD AND FULL MARKS

9140-3569

9114-3284

91143284

9151-3207 REV.-

VIEW B-B

91403529

TRACTION LOCK

LOCKS FRONT & REAR AXLES

HYDRAULICALLY FOR INCREASED

TRACTION. DO NOT USE ON

IMPROVED SURFACES.

MACHINE MUST BE IN 4X4

MODE.

9140-3529

80603026

COOLING SYSTEM

IS PRESSURIZED.

REMOVE CAP SLOWLY.

HOT FLUID CAN

CAUSE BURNS.

8060-3026

+

VIEW C-C VIEW D-D

91413024

FORWARD DRIVE

PRESSURE

TEST PORT

REVERSE DRIVE

PRESSURE

TEST PORT

CHARGE

PRESSURE

TEST PORT

IMPLEMENT

PRESSURE

TEST PORT

9141-3024 (-)

OY1071

VIEW OF HYDRAULIC TANK

2-4 31200148

Safety Decals 3

Section 2 - Pre-Operation and Inspection

B

9114-3282

80603037

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

8060-3037-A

B

91143282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

4105262

0

8

0

7

60

50

40

20

0

9114-3282

30

-10

10

A

80°

70°

°

0

6

°

0

5

°

0

4

°

0

3

20°

10°

-1

0

0°

°

ATTACHMENT MUST BE SECURED TO MACHINE.

CHECK TO ASSURE QUICK SWITCH PLUNGER

PIN IS FULLY ENGAGED AND LOCKED AFTER

ATTACHMENT CHANGE.

IF PLUNGER PIN IS NOT FULLY ENGAGED

AND LOCKED ATTACHMENT MAY FALL OFF

CAUSING SERIOUS INJURY OR DEATH.

91143290

A

91513210

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

9114-3290

91513210

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

8060-3037-A

91143282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

8060-3037-A

CAUSE SERIOUS INJURY OR DEATH.

91513210

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED

PERSONNEL WORK PLATFORM.

ALL PERSONNEL IN PLATFORM MUST WEAR A FULL BODY HARNESS WITH

LANYARD ATTACHED TO A DESIGNATED ANCHORAGE POINT.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL

BEFORE OCCUPYING PERSONNEL WORK PLATFORM.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

9055-3026 REV. A

VIEW A-A

91513210

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

VIEW B-B

8060-3037-A

OY1250

2-531200148

Section 2 - Pre-Operation and Inspection

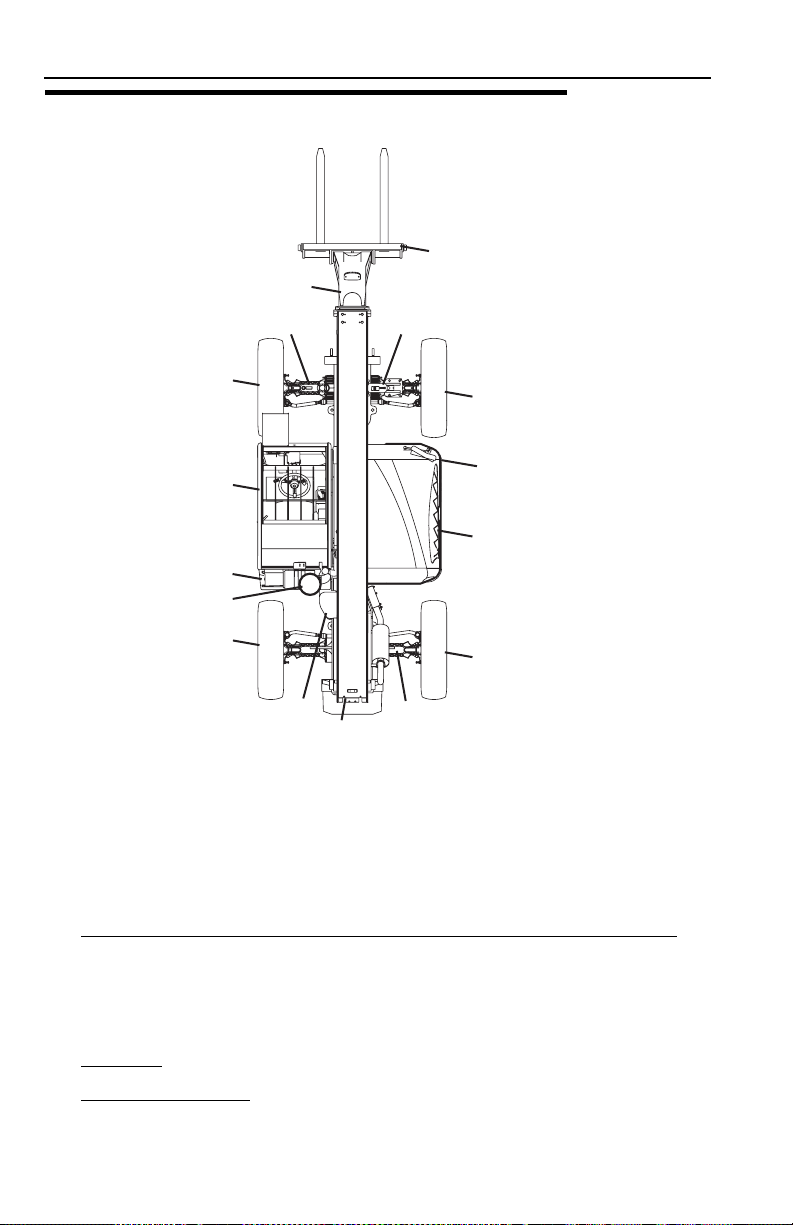

2.3 WALK-AROUND INSPECTION

16

1

2

3

4

5

6

7

8

9

Begin your walk-around inspection at item 1, as noted below. Continue to your right

(counterclockwise when viewed from top) checking each item in sequence.

INSPECTION NOTE: On all components, make sure there are no loose or missing

parts, that they are securely fastened and no visible leaks or excessive wear exists

in addition to any other criteria mentioned. Inspect all structural members including

attachment for cracks, excessive corrosion and other damage.

15

14

13

12

11

10

OY0181

1. Boom Sections & Lift, Tilt, Extend/Retract, Compensating (Slave) Cylinders

• Check front, top, side & rear slider pads for adequate grease.

• Pivot pins secure; hydraulic hoses undamaged, not leaking.

• Check extend/retract cables and adjustment blocks for adequate tension.

2. Front Axle

3. Wheel/Tire Assembly - Properly inflated and secured; no loose or missing lug

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

- Pivot pins secure; hydraulic hoses undamaged, not leaking.

-

2-6 31200148

Section 2 - Pre-Operation and Inspection

4. Cab & Electrical -

• Check window glass is in place and clean; gauges, switches, joysticks, foot

controls & horn operational.

• General appearance; no visible damage; proper load charts and applicable

Operator & Safety manual located in manual holder.

• Make sure emergency escape hammer is in place (enclosed cabs only).

• Check seat belt for damage, replace belt if frayed or cut webbing, damaged

buckles or loose mounting hardware.

5. Fuel Tank

- Check fluid level, refill as required; filler cap is securely fastened.

6. Air Cleaner

condition. Replace element as required.

7. Wheel/Tire Assembly

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

8. Main Control Valve

9. Back-up Alarm

10. Rear Axle

hydraulic hoses undamaged, not leaking.

11. Wheel/Tire Assembly

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

12. Engine Compartment

• Engine Crankcase and Radiator, check level & refill as required.

• Drive belts, check condition & replace as required.

• Hydraulic pump & reservoir, recommended fluid level on sight gauge

(lubricant must be cool), breather cap secure and working.

• Engine cover properly secured.

13. Mirrors

14. Wheel/Tire Assembly

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

15. Sway Cylinder

- Air cleaner element condition indicator, check for clogged

- Properly inflated and secured; no loose or missing lug

- See Inspection Note.

- See Inspection Note.

- Steer cylinders undamaged, not leaking; pivot pins secure;

- Properly inflated and secured; no loose or missing lug

-

- Clean and undamaged.

- Properly inflated and secured; no loose or missing lug

- Pins secure; hydraulic hoses undamaged, not leaking.

16. Attachment

- Properly installed, see “Attachment Installation” on page 5-7.

2-731200148

Section 2 - Pre-Operation and Inspection

2.4 WARM-UP AND OPERATIONAL CHECKS

Warm-Up Check

During warm-up period, check:

1. Heater, defroster and windshield wiper (if equipped).

2. Check all lighting systems (if equipped) for proper operation.

3. Voltmeter should show 13.5 to 14 volts.

4. Adjust mirror(s) for maximum visibility.

WARNING

CUT/CRUSH/BURN HAZARD. Keep engine cover closed while engine is running

except when checking hydraulic filter condition indicator.

Operational Check

When engine warms, perform an operational check:

1. Service brake and parking brake operation.

2. Forward and reverse travel.

3. Steering in both directions with engine at low idle.

4. Horn and back-up alarm. Must be audible from inside operators cab with engine

running.

5. All boom and attachment functions - operate smoothly and correctly.

6. Perform any additional checks described in Section 8.

7. Hydraulic Filter Condition Indicator.

2-8 31200148

Section 2 - Pre-Operation and Inspection

2.5 OPERATOR CAB

The telehandler is equipped with a standard open ROPS/FOPS cab. An optional

enclosed ROPS/FOPS cab is available.

WARNING

Never operate telehandler unless the overhead guard and cab structure are in

good condition. Any modification to this machine must be approved by JLG to

assure compliance with ROPS/FOPS certification for this cab/machine

configuration. If damaged, the CAB CANNOT BE REPAIRED. It must be

REPLACED.

2-931200148

Section 2 - Pre-Operation and Inspection

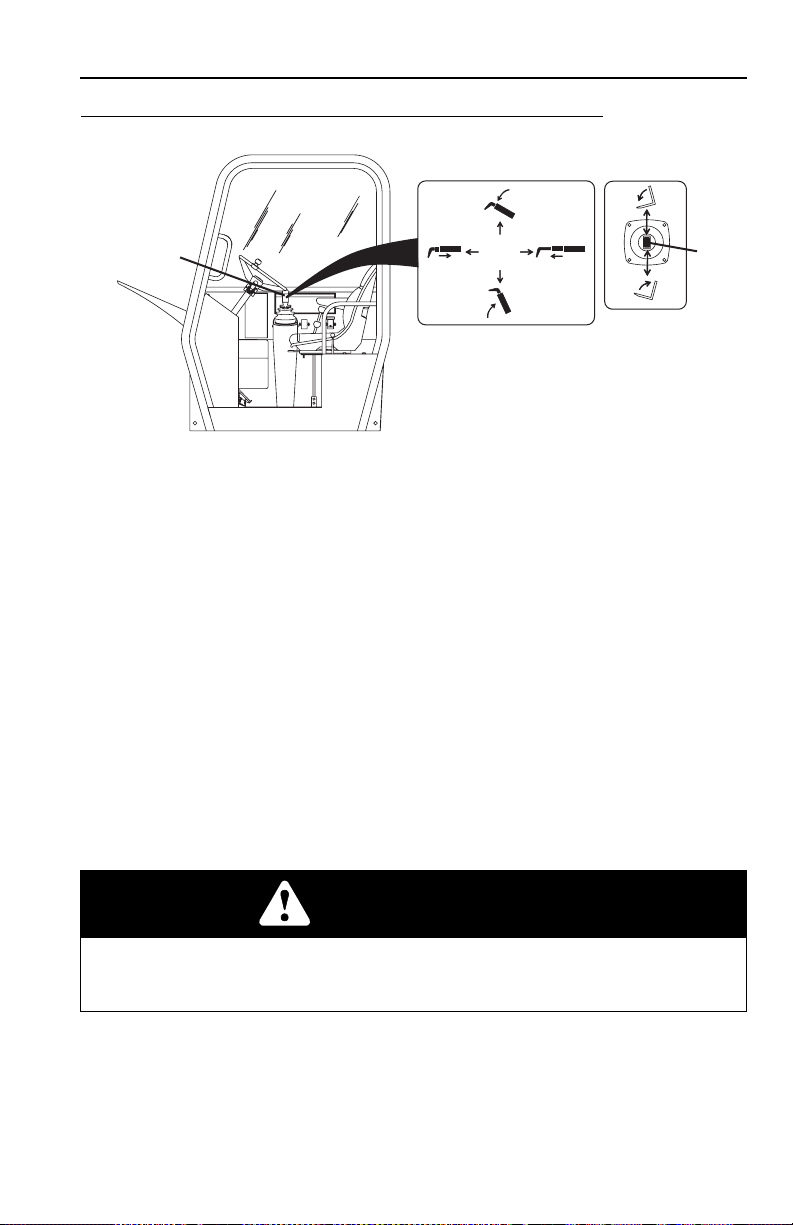

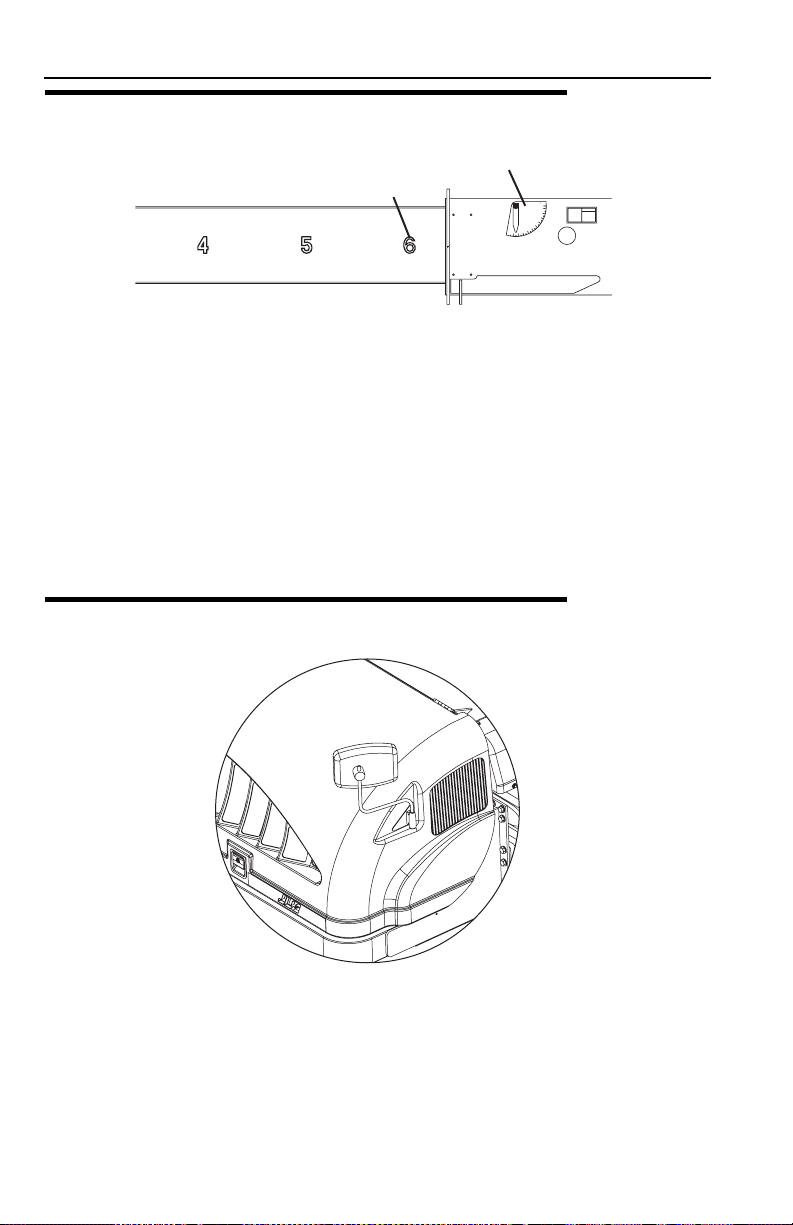

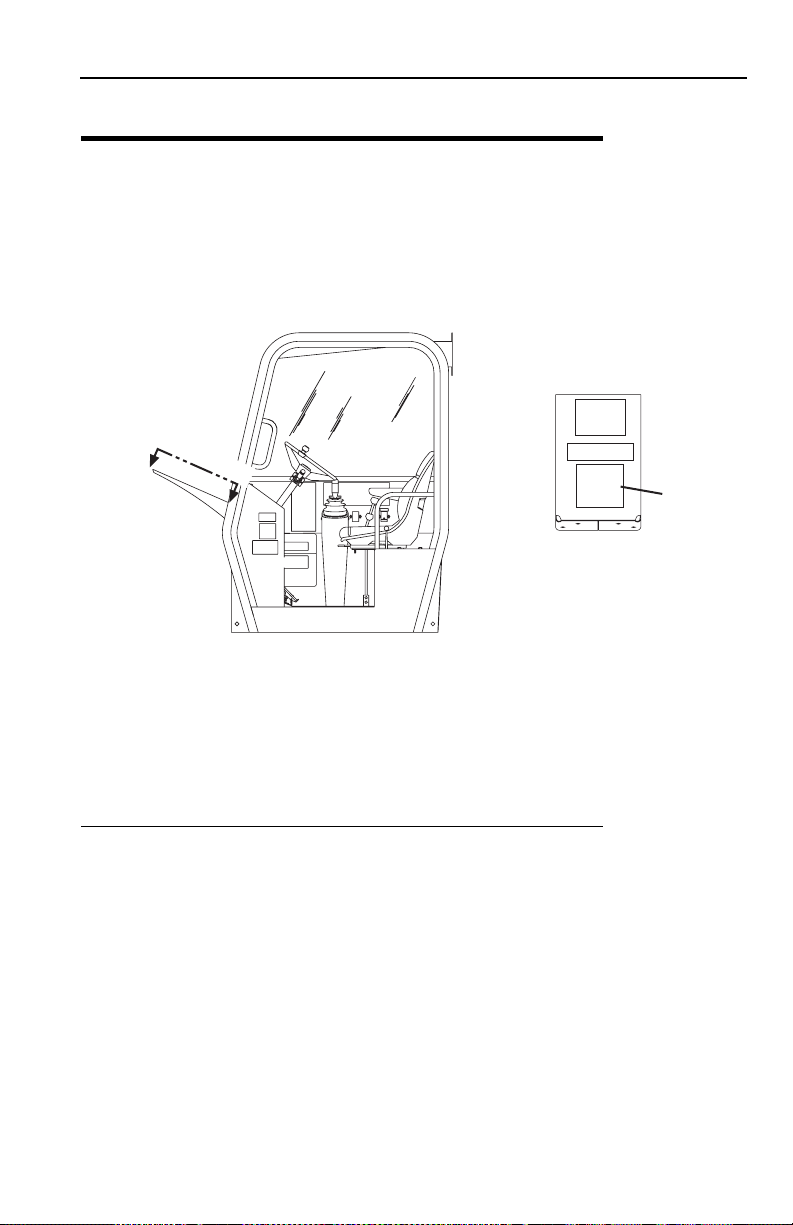

2.6 WINDOWS

Keep all windows and mirrors clean and unobstructed.

Cab Door Window (if equipped)

4

2

3

1

OAL0010

• During operation the window must either be latched open or closed.

• Open the cab door window (1) and secure it in the latch.

• Press the release button (2) inside the cab or pull on the lever (3) outside the cab

to unlatch the window.

• During operation the lower door (4) must be closed.

2-10 31200148

Section 3 - Controls and Indicators

SECTION 3 - CONTROLS AND INDICATORS

3.1 GENERAL

This section provides the necessary information needed to understand control

functions.

Note: The manufacturer has no direct control over machine application and

operation. The user and operator are responsible for conforming with good safety

practices.

NOTICE

EQUIPMENT DAMAGE. When a red light illuminates, immediately bring machine

to a stop, lower boom and attachment to ground and stop the engine. Determine

cause and correct before continued use.

3-131200148

Section 3 - Controls and Indicators

3.2 CONTROLS

4

3

2

1

11

10

9

8

7

1. Transmission Control Lever: See page 3-3.

5

6

OY0023

2. Instrument Panel

3. Steering Wheel

: See “Dash Controls and Indicators” on page 3-8.

: Turning the steering wheel to the left or right steers the

machine in the corresponding direction.

4. Frame Level Indicator

: Enables the operator to determine the left to right level

condition of the telehandler.

5. Boom Joystick

6. Heater Control (if equipped)

7. Accelerator Pedal

: See page 3-5.

: See page 3-10.

: Pressing down the pedal increases engine and hydraulic

speed.

8.

Traction Lock Pedal: Operates traction-lock valve which functions to restore

traction when a wheel spins.

9. Service Brake Pedal/Inching Travel Pedal: Operates the service brakes on the

front axle. Permits slow travel speed while engine speed is kept high for other

handler functions. The further the pedal is depressed, the slower the travel

speed.

10. Ignition Switch: Key activated. See page 3-4.

11. Attachment Tilt and Frame Sway Lever

Auxiliary Control Joystick (if equipped):

: See page 3-6

See page 3-7

3-2 31200148

Section 3 - Controls and Indicators

Transmission Control Lever

15

F

N

R

OX0081

Transmission control lever (15) engages forward or reverse travel.

• Lift and push lever forward for forward travel; lift and pull lever rearward for

reverse travel. Move lever to centered position for ‘Neutral’.

• When traveling in REVERSE, the back-up alarm will automatically sound.

• Drive in reverse and turn only at slow rates of speed.

• Do not increase engine speed with the transmission in forward or reverse and the

service brake depressed in an attempt to get quicker hydraulic performances.

This could cause unexpected machine movement.

WARNING

TIP OVER/CRUSH HAZARD. Bring telehandler to a complete stop before

shifting transmission control lever. A sudden change in direction of travel could

reduce stability and/or cause load to shift or fall.

3-331200148

Section 3 - Controls and Indicators

Ignition Switch

F

N

R

OFF

ACC

RUN

START

OY0051

• In "ACC" or "RUN" position, voltage is available for all electrical functions.

• Full clockwise rotation to "START" engages starter motor.

• Counter-clockwise rotation to "OFF" stops engine and removes voltage from all

electrical functions.

3-4 31200148

Boom Joystick

Section 3 - Controls and Indicators

1

IF EQUIPPED

The boom joystick (1) controls the boom and attachment tilt (if equipped) functions.

Boom Functions

• Move the joystick back to lift boom; move joystick forward to lower boom; move

joystick right to extend boom; move joystick left to retract boom.

• The speed of boom functions depends upon the amount of joystick travel in

corresponding direction. Increasing engine speed will also increase function

speed.

• For two simultaneous boom functions, move the joystick between quadrants. For

example; moving the joystick forward and to the left will lower and retract boom

simultaneously.

Attachment Functions (if equipped)

Tilt control is actuated by the switch (2).

• Depress the rear of the switch to tilt up; depress the front of switch to tilt down.

2

OX0060

WARNING

TIP OVER/CRUSH HAZARD. Rapid, jerky operation of controls will cause rapid,

jerky movement of the load. Such movements could cause the load to shift or fall

or could cause the machine to tip over.

3-531200148

Section 3 - Controls and Indicators

- +

Attachment Tilt and Frame Sway Lever

F

80

FUEL

QUARTZ

000000

4

This lever (4) controls the attachment tilt and the left to right frame sway.

Attachment Tilt Function

• Move lever forward to tilt attachment down; move lever back to tilt attachment up.

Sway Function

• Move the lever left to sway frame left, move the lever right to sway frame right.

• A level indicator is located in the upper front window frame to permit operator to

determine whether the telehandler frame is level.

OIL

E

0

240

16

TEMP

VOLTS

10

100

WORK

OFF

RUN

ACC

START

IGNITION

TRAVEL

MACHINE MUST BE

IN NEUTRAL AND

PARK BRAKE ON

TO START

OY0143

WARNING

TIP OVER HAZARD. Always move boom as low as possible while allowing for

best visibility of right hand mirror before leveling frame. Attempting to level

machine with boom raised could cause it to tip over.

3-6 31200148

Section 3 - Controls and Indicators

- +

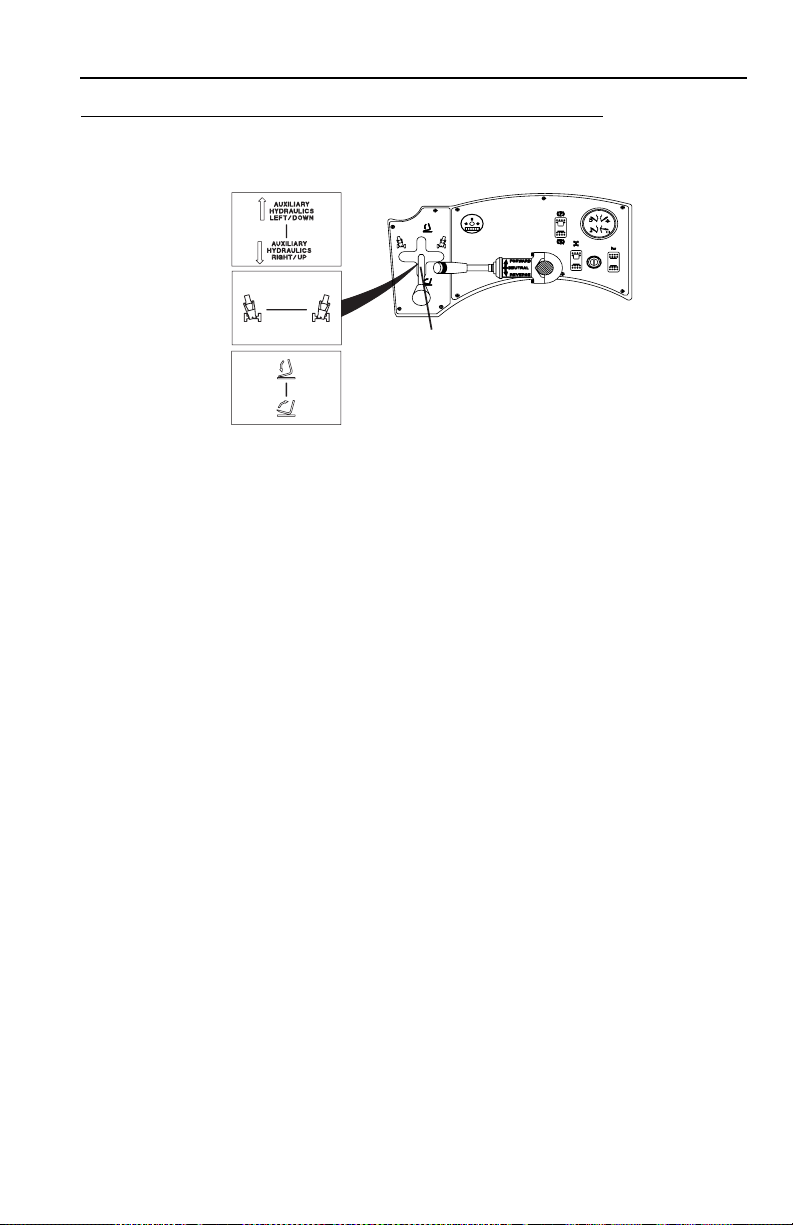

Auxiliary Control Joystick (if equipped)

Auxiliary

Hydraulics

QUARTZ

000000

F

80

FUEL

OIL

E

0

240

16

TEMP

VOLTS

10

100

WORK

OFF

RUN

ACC

START

IGNITION

TRAVEL

MACHINE MUST BE

IN NEUTRAL AND

PARK BRAKE ON

TO START

Sway

(optional)

1

Attachment

Tilt

(optional)

OX0224

The auxiliary control joystick (1) controls the auxiliary hydraulic functions, left to right

frame sway (if equipped), and attachment tilt (if equipped).

Auxiliary Hydraulics Function

• Controls function of attachments that require hydraulic supply for operation. See

Section 5 - Attachments for approved attachments and control instructions.

Frame Sway (if equipped)

• Move the joystick left to sway frame left, move the joystick right to sway frame

right.

• A level indicator is located in the upper front window frame to permit operator to

determine whether the telehandler frame is level.

Attachment Tilt (if equipped)

• Move joystick up to tilt down; move joystick down to tilt up.

3-731200148

Section 3 - Controls and Indicators

- +

Dash Controls and Indicators

.

123

F

80

FUEL

QUARTZ

000000

1. Hourmeter: Indicates total time of engine operation in hours and tenths of

hours.

OIL

E

0

240

16

TEMP

VOLTS

10

100

WORK

OFF

RUN

ACC

START

IGNITION

TRAVEL

MACHINE MUST BE

IN NEUTRAL AND

PARK BRAKE ON

TO START

WORK

OFF

RUN

ACC

IGNITION

TRAVEL

5

START

46

OY0084

2. Park Brake Switch

3. 4-in-1 Gauge

: See page 3-9.

:

a. Engine Coolant Temperature Gauge

b. Engine Oil Pressure Gauge

c. Fuel Gauge

d. Voltmeter indicates alternator output and battery condition.

4. Horn Button

5. Ignition Switch

: Depress button to sound horn.

: See page 3-?.

6. 4X2/4X4 Switch: Engages and disengages rear-wheel drive motors. Rear drive

motors are engaged for four-wheel drive. Indicator light on switch glows (amber)

to indicate four-wheel drive is engaged. When park brake is applied, light will

not glow.

3-8 31200148

Park Brake Switch

Section 3 - Controls and Indicators

F

N

R

OY0122

Park brake switch controls the application and release of the park brake. Indicator

light illuminates to indicate brake is applied.

• With the engine running and the park brake switch in "OFF" position (1), park

brakes are disengaged.

• With switch in "ON" position (2), park brake is engaged and transmission will not

engage forward or reverse.

1

2

WARNING

MACHINE ROLL-AWAY HAZARD. Always move park brake switch to "ON"

position, lower boom to ground and stop engine before leaving cab.

WARNING

CRUSH HAZARD. Turning engine off applies the park brake. Applying park brake

or turning engine off while traveling will cause unit to stop abruptly and could

cause load loss. Either may be used in an emergency situation.

Parking Procedure

1. Using service brake, stop telehandler in an appropriate parking area.

2. Follow “Shut-Down Procedure” on page 4-4.

3-931200148

Section 3 - Controls and Indicators

Heater

3

4

3

2

1

6

5

OY0060

1. Heater

2. Access Cover/Heat Vent

3. Air Vents

4. Defroster Fan: Two speed fan. Press fan switch down for slow speed; press

switch up for fast speed. Return switch to middle position to turn off.

5. Temperature Control Switch

6. Heater Fan Switch: On/Off switch.

3-10 31200148

Section 3 - Controls and Indicators

3.3 OPERATOR SEAT

Seat Adjustments

Before S/N 0160016100

2

1

OX0012

Prior to starting engine adjust seat for position and comfort as follows:

1. Use handle to move seat fore and aft

2. A two inch seat belt is standard equipment. If required, an optional three inch

belt is available.

3-1131200148

Section 3 - Controls and Indicators

S/N 0160016100 & After

3

4

1

2

OX0520

Prior to starting engine adjust seat for position and comfort as follows:

1. Turn the knob on the front of seat to adjust the suspension. Turn the knob

clockwise to increase stiffness. Turn the knob counterclockwise to reduce

stiffness.

2. Pull up on handle to move seat fore and aft.

3. Arm rest can be moved up or down for comfort.

4. A two inch seat belt is standard equipment. If required, an optional three inch

belt is available.

3-12 31200148

Section 3 - Controls and Indicators

Seat Belt

OH20912

Fasten seat belt as follows:

1. Grasp both free ends of the belt making certain that belt webbing is not twisted

or entangled.

2. With back straight in the seat, couple the retractable end (male end) of the belt

into the receptacle (buckle) end of the belt.

3. With belt buckle positioned as low on the body as possible, pull the retractable

end of the belt away from the buckle until it is tight across the lap.

4. To release belt latch, depress red button on the buckle and pull free end from

buckle.

3-1331200148

Section 3 - Controls and Indicators

3.4 BOOM ANGLE AND EXTENSION INDICATORS

1

2

°

0

8

70°

60°

50°

40°

30°

20°

°

0

1

-1

0°

0

°

OX0540

• The boom angle indicator (1) is located on the left side of the boom. Use this

indicator to determine the boom angle when using the capacity chart (see “Use

of the Capacity Chart” on page 5-4).

• The boom extension indicators (2) are located on the left side of the boom. Use

these indicators to determine boom extension when using the capacity chart

(see “Use of the Capacity Chart” on page 5-4).

3.5 MIRROR

OW0500

• Keep all windows and mirror(s) clean and unobstructed.

• Adjust mirror(s) as required for maximum visibility, before and during operation.

3-14 31200148

Section 4 - Operation

SECTION 4 - OPERATION

4.1 ENGINE

Starting the Engine

This machine can be operated under normal conditions in temperatures of 0°F to

104°F (-20°C to 40°C). Consult JLG for operation outside this range or under

abnormal conditions.

1. Make sure all controls are in “Neutral” and all electrical components (lights,

heater, defroster, etc.) are turned off. Set parking brake.

2. Turn ignition switch to “START” to engage starting motor. Release key

immediately when engine starts. If engine fails to start within 20 seconds,

release key and allow starting motor to cool for a few minutes before trying

again.

3. After engine starts, observe oil pressure gauge. If gauge remains on zero for

more than ten seconds, stop engine and determine cause before restarting

engine. Reference engine manual for minimum pressure at operating

temperature.

4. Warm up engine at approximately 1/2 throttle.

Note: Engine will not start unless transmission control lever is in “Neutral” and park

brake switch is applied.

WARNING

UNEXPECTED MOVEMENT HAZARD. Always ensure that transmission control

lever is in neutral and the service brake is applied before releasing park brake.

Releasing park brake in either forward or reverse could cause the machine to

move abruptly, causing an accident.

4-131200148

Section 4 - Operation

Cold Weather Starting Aids

JLG approved starting aids employ ether. If your telehandler is equipped with an

ether starting aid, the following applies:

• Injection of ether is triggered by temperature sensor located on engine.

• At start-up, temperature sensor on engine will detect if ether is needed. Follow

normal start-up procedure.

• Ether will be automatically injected if needed, to keep engine running.

• A second battery is added for additional cold-cranking capacity.

WARNING

ENGINE EXPLOSION. If your telehandler is equipped with a cold start aid, do

not spray additional ether into air cleaner. If machine is not equipped with cold

start aid, follow instructions listed in the engine manual supplied with the

telehandler.

4-2 31200148

Section 4 - Operation

Battery Boosted Starting

OW0530

If battery-boost starting (jump-start) is necessary, proceed as follows:

• Never allow vehicles to touch.

• Connect the positive (+) jumper cable to positive (+) post of discharged battery.

• Connect the opposite end of positive (+) jumper cable to positive (+) post of

booster battery.

• Connect the negative (-) jumper cable to negative (-) post on booster battery.

• Connect opposite end of negative (-) jumper cable to ground point on machine

away from discharged battery.

• Follow standard starting procedures.

• Remove cables in reverse order after machine has started.

WARNING

BATTERY EXPLOSION HAZARD. Never jump start or charge a frozen battery

as it could explode. Keep sparks, flames and lighted smoking materials away

from the battery. Lead acid batteries generate explosive gases when charging.

Wear safety glasses.

4-331200148

Section 4 - Operation

Normal Engine Operation

• Observe gauges frequently to be sure all engine systems are functioning

properly.

• Be alert for unusual noises or vibration. When an unusual condition is

noticed, park machine in safe position and perform shut-down procedure. Report

condition to your supervisor or maintenance personnel.

• Avoid prolonged idling. If the engine is not being used, turn it off.

Shut-Down Procedure

When parking the telehandler, park in a safe location on flat level ground and away

from other equipment and/or traffic lanes.

1. Apply the park brake.

2. Shift the transmission to “Neutral.”

3. Lower forks or attachment to the ground.

4. Operate engine at low idle for 3 to 5 minutes. DO NOT over rev engine.

5. Shut off engine and remove ignition key.

6. Exit telehandler properly.

7. Block wheels (if necessary).

4-4 31200148

Section 4 - Operation

4.2 OPERATING WITH A LOAD

Lift Load Safely

• You must know the weight and load center of every load you lift. If you are not

sure of the weight and load center, check with your supervisor or with the

supplier of the material.

WARNING

TIP OVER HAZARD. Exceeding lift capacity of the telehandler could damage the

equipment and/or cause tip over.

• Know the rated load capacities (refer to Section 5) of the telehandler to

determine the operating range in which you can safely lift, transport and place a

load.

Picking Up a Load

• Note the conditions of the terrain. Adjust travel speed and reduce amount of load

if conditions warrant.

• Avoid lifting double-tiered loads.

• Make sure load is clear of any adjacent obstacles.

• Adjust spacing of forks so they engage the pallet or load at maximum width. See

“Adjusting/Moving Forks” on page 5-9.

• Approach load slowly and squarely with fork tips straight and level. NEVER

attempt to lift a load with just one fork.

• NEVER operate telehandler without a proper and legible Capacity Chart in the

operator’s cab for the telehandler/attachment combination you are using.

4-531200148

Section 4 - Operation

Transporting the Load

OW0540

After engaging the load and resting it against the backrest, tilt the load back to

position it for travel. Travel in accordance with the requirements set forth in Section

1 - General Safety Practices and Section 5 - Attachments.

Leveling Procedure

1. Position machine in best location to lift or place load.

2. Apply parking brake and move transmission control lever to NEUTRAL.

3. Move boom/attachment to 4 ft (1,2 m) off ground.

4. Observe level indicator to determine whether machine must be leveled prior to

lifting load.

Important things to remember:

• Never raise the boom/attachment more than 4 ft (1,2 m) above ground unless

telehandler is level.

• The combination of sway and load could cause the telehandler to tip over.

The telehandler is designed to permit swaying the main frame 8° to left or right to

compensate for uneven ground conditions.

4-6 31200148

Section 4 - Operation

Placing the Load

Before placing any load be sure that:

• The landing point can safely support the weight of the load.

• The landing point is level; front to back and side to side.

• Use the capacity chart to determine safe boom extension range. See “Use of the

Capacity Chart” on page 5-4.

• Align forks at the level load is to be placed, then position boom slowly until load is

just above area where it is to be placed.

• Lower the boom until the load rests in position and the forks are free to retract.

Disengaging the Load

Once the load has been placed safely at the landing point, proceed as follows:

1. With the forks free from the weight of the load, the boom can be retracted

and/or the telehandler can be backed away from under the load if surface will

not change level condition of telehandler.

2. Lower the carriage.

3. The telehandler can now be driven from the landing location to continue work.

4-731200148

Section 4 - Operation

4.3 OPERATING WITH A SUSPENDED LOAD

Lift Load Safely

• You must know the weight and load center of every load you lift. If you are not

sure of the weight and load center, check with your supervisor or with the

supplier of the material.

WARNING

TIP OVER HAZARD. Exceeding lift capacity of the telehandler could damage the

equipment and/or cause tip over.

• Know the rated load capacities (refer to Section 5) of the telehandler to

determine the operating range in which you can safely lift, transport and place a

load.

Picking Up a Suspended Load

• Note the conditions of the terrain. Adjust travel speed and reduce amount of load

if conditions warrant.

• Avoid lifting double-tiered loads.

• Make sure load is clear of any adjacent obstacles.

• NEVER operate telehandler without a proper and legible capacity chart in the

operator cab for the telehandler/attachment combination you are using.

• Only use approved lifting devices rated for the lifting of the load.

• Identify the proper lifting points of the load, taking into consideration the center of

gravity and load stability.

• Ensure to always properly tether loads to restrict movement.

• Refer to See “Use of the Capacity Chart” on page 5-4. for proper lifting guidelines

in addition to the appropriate capacity chart in the operator cab.

4-8 31200148

Transporting a Suspended Load

Section 4 - Operation

OZ3160

• Travel in accordance with the requirements set forth in Section 1 - General

Safety Practices and Section 5 - Attachments.

• For additional requirements, refer to the appropriate capacity chart in the

operator cab.

Important things to remember:

• Ensure the boom is fully retracted.

• Never raise the load more than 11.8 in (300 mm) above ground surface or the

boom more than 45°.

• The combination of frame leveling and load could cause the telehandler to tip

over.

• The guide men and operator must remain in constant communication (verbal or

hand) and be in visual contact with the operator at all times.

• Never place the guide men between the suspended load and the telehandler.

• Only transport the load at walking speed, 0.9 mph (0.4 m/s), or less.

OW0130

Leveling Procedure

1. Position machine in best location to lift or place load.

2. Apply parking brake and move transmission control lever to NEUTRAL.

3. Move boom so load is no more than 11.8 in (300 mm) above ground surface

and boom/or boom is raised no more than 45°.

4. Observe level indicator to determine whether machine must be leveled prior to

lifting load. Level machine with frame level joystick.

The telehandler is designed to permit leveling the main frame 8° to left or right to

compensate for uneven ground conditions.

4-931200148

Section 4 - Operation

Placing a Suspended Load

Before placing any load be sure that:

• The landing point can safely support the weight of the load.

• The landing point is level; front to back and side to side.

• Use the capacity chart to determine safe boom extension range. See “Use of the

Capacity Chart” on page 5-4.

• Align load at the level load is to be placed, then position boom slowly until load is

just above area where it is to be placed.

• Ensure that the guide men and operator remain in constant communication

(verbal or hand) when placing the load.

Disengaging a Suspended Load

• Never place the guide men between the suspended load and the telehandler.

• Once at the destination of the load, ensure to bring the telehandler to a complete

stop and apply the park brake prior to disengagement of the lifting devices and

tethers.

4-10 31200148

Section 4 - Operation

4.4 LOADING AND SECURING FOR TRANSPORT

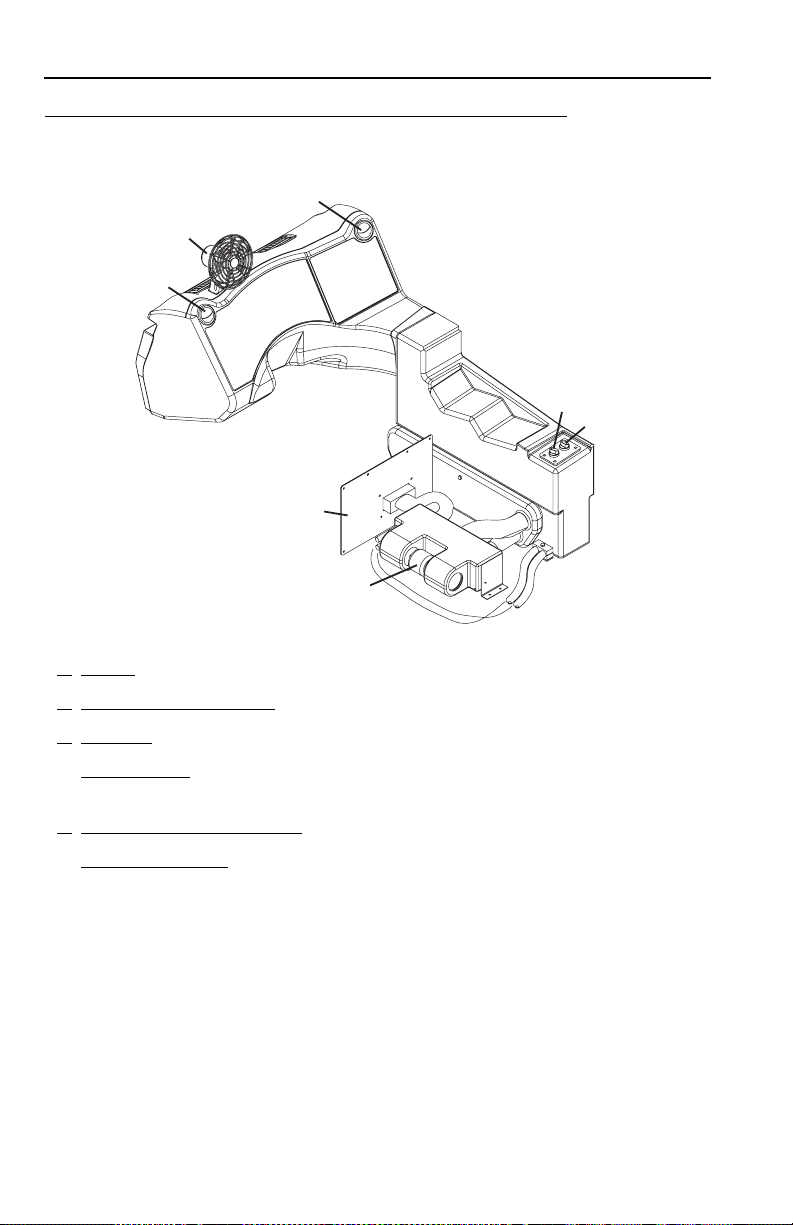

Tiedown

Front Rear

OX0381

1. Level the telehandler prior to loading.

2. Using a spotter, load the telehandler with boom as low as possible.

3. Once loaded, apply parking brake and lower boom until boom or attachment is

resting on deck. Move all controls to “Neutral,” stop engine and remove ignition

key.

4. Secure machine to deck by passing chains through the designated tiedown

points as shown in the figure.

5. Do not tiedown front of boom.

Note: The user assumes all responsibility for choosing the proper method of

transportation and tie-down devices, making sure the equipment used is capable of

supporting the weight of the vehicle being transported and that all manufacturer’s

instructions and warnings, regulations and safety rules of their employer, the

Department of Transportation and/or any other state or federal laws are followed.

WARNING

TELEHANDLER SLIDE HAZARD. Before loading telehandler for transport,

make sure deck, ramps and telehandler wheels are free of mud, snow and ice.

Failure to do so could cause telehandler to slide.

4-1131200148

Section 4 - Operation

Lifting

• When lifting machine, it is very important that the lifting device and equipment is

attached only to designated lifting points. If machine is not equipped with lifting

lugs contact JLG Product Safety for information.

• Make adjustments to the lifting device and equipment to ensure the machine will

be level when elevated. The machine must remain level at all times while being

lifted.

• Ensure that the lifting device and equipment is adequately rated and suitable for

the intended purpose. See Section 9 - Specifications for machine weight.

• Remove all loose items from machine prior to lifting.

• Lift machine with smooth, even motion. Set machine down gently. Avoid quick or

sudden motions that could cause shock loads to machine and/or lifting devices.

4-12 31200148

Section 5 - Attachments

SECTION 5 - ATTACHMENTS

5.1 APPROVED ATTACHMENTS

To determine if an attachment is approved for use on the specific telehandler you are

using, perform the following prior to installation.

Before S/N 0160037689

• The attachment model/option number on the attachment identification plate must

match the attachment number on a capacity chart located in the operator cab.

• The model on the capacity chart must match the model telehandler being used.

• The load center of the fork (if equipped) must match the load center as indicated

on the capacity chart.

• Hydraulically powered attachments must only be used on machines equipped

with auxiliary hydraulics.

• Hydraulically powered attachments that require auxiliary electrics must only be

used on machines equipped with auxiliary hydraulics and electrics.

S/N 0160037689 & After

• The attachment type, weight, dimensions and load center must be equal to or

less than the data shown on a capacity chart located in the operator cab.

• The model on the capacity chart must match the model telehandler being used.

• Hydraulically powered attachments must only be used on machines equipped

with auxiliary hydraulics.

• Hydraulically powered attachments that require auxiliary electrics must only be

used on machines equipped with auxiliary hydraulics and electrics.

If any of the above conditions are not met, do not use the attachment. The

telehandler may not be equipped with the proper capacity chart or the attachment

may not be approved for the model telehandler being used. Contact JLG or a local

distributor for further information.

5-131200148

Section 5 - Attachments

5.2 UNAPPROVED ATTACHMENTS

Do not use unapproved attachments for the following reasons:

• Range and capacity limitations for “will fit,” homemade, altered, or other

non-approved attachments cannot be established.

• An overextended or overloaded telehandler can tip over with little or no warning

and cause serious injury or death to the operator and/or those working nearby.

• The ability of a non-approved attachment to perform its intended function safely

cannot be assured.

WARNING

Use only approved attachments. Attachments which have not been approved for

use with your telehandler could cause machine damage or an accident.

5-2 31200148

Section 5 - Attachments

5.3 TELEHANDLER/ATTACHMENT/FORK CAPACITY

1

3

2

OW0550

Prior to installing the attachment verify it is approved and the telehandler is equipped

with the proper capacity chart. See “Approved Attachments” on page 5-1.

To determine the maximum capacity of the telehandler and attachment, use the

smallest of the following capacities:

• Capacity stamped on the attachment identification plate (1).

• Fork capacities and load centers are stamped on the side of each fork (2)

(if equipped). This rating specifies the maximum load capacity that the individual

fork can safely carry at the maximum load center (3). Total attachment capacity is

multiplied by the number of forks on the attachment (if equipped), up to the

maximum capacity of the attachment.

• Maximum capacity as indicated on the proper capacity chart. See “Approved

Attachments” on page 5-1.

• When the load rating of the telehandler differs from the capacity of the forks or

attachment, the lower value becomes the overall load capacity.

Use the proper capacity chart to determine maximum capacity at various machine

configurations. Lifting and placing a load may require use of more than one capacity

chart based on machine configuration.

Other than block forks, all forks should be used in matched pairs, block forks used in

matched sets.

WARNING

Never use an attachment without the appropriate JLG approved capacity chart

installed on the telehandler.

5-331200148

Section 5 - Attachments

5.4 USE OF THE CAPACITY CHART

To properly use the capacity chart (see page 5-5), the operator must first determine

and/or have the following:

1. A JLG approved attachment. See “Approved Attachments” on page 5-1.

2. The proper Capacity Chart(s).

3. Weight of the load being lifted.

4. Load placement information:

a. HEIGHT where the load is to be placed.