Page 1

OPERATING MANUAL

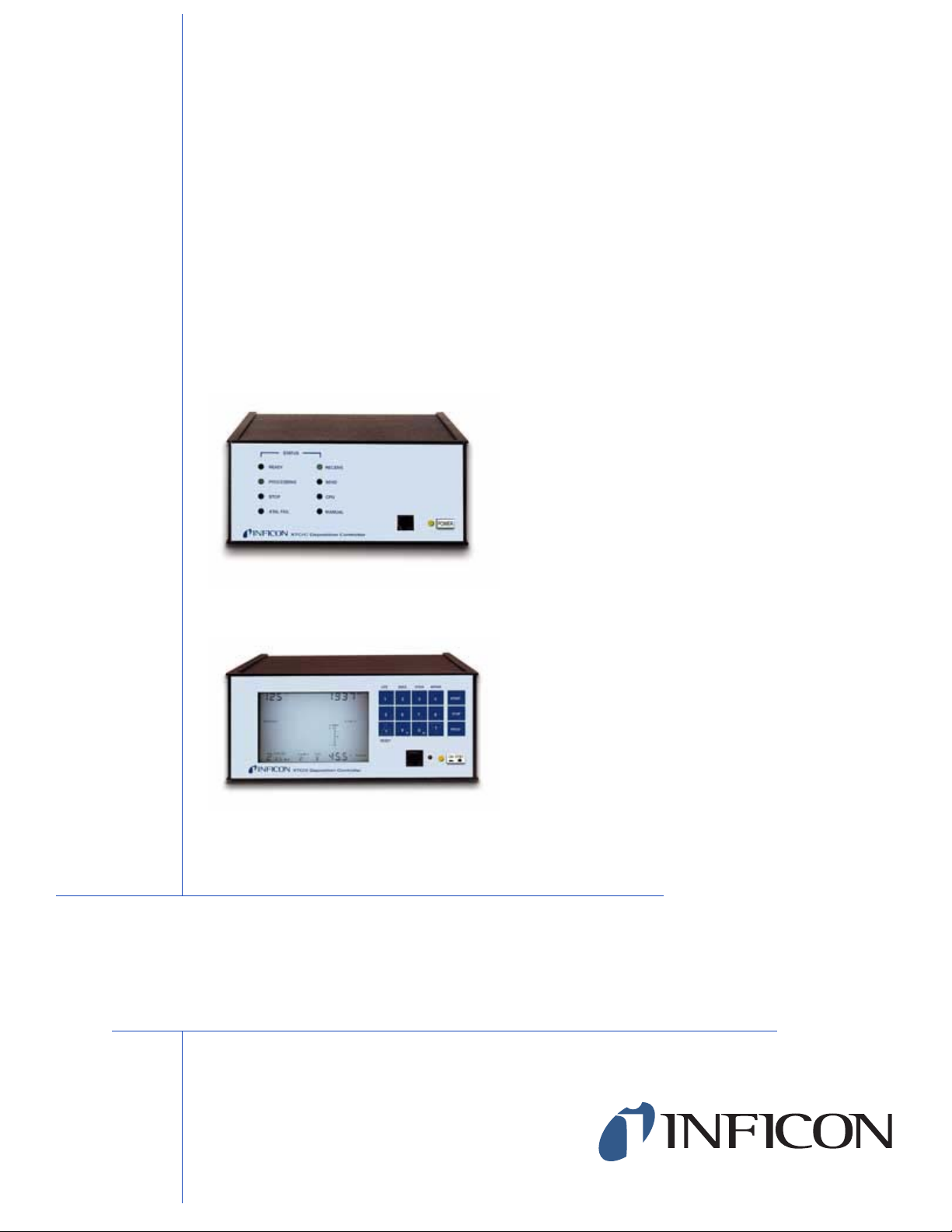

XTC/C

XTC/C XTC/2

Thin Film Deposition Controller

IPN 074-183

XTC/2

Page 2

Page 3

OPERATING MANUAL

XTC/C XTC/2

Thin Film Deposition Controller

IPN 074-183X

TWO TECHNOLOGY PLACE

EAST SYRACUSE, NY 13057-9714 USA

Phone: +315.434.1100

Fax: +315.437.3803

Email: reachus@inficon.com

VISIT US ON THE WEB AT www.inficon.com

©2001 INFICON 092304

ALTE LANDSTRASSE 6

LI-9496 BALZERS, LIECHTENSTEIN

Phone: +423.388.3111

Fax: +423.388.3700

Email: reach.liechtenstein@ inficon.com

BONNER STRASSE 498

D-50968 COLOGNE, GERMANY

Phone: +49.221.347.40

Fax: +49.221.347.41429

Email: reach.germany@i nficon.com

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON®, CrystalSix® are trademarks of INFICON Inc.

All other brand and product names are trademarks or registered trademarks of their respective companies.

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

©2001 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

2 Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the

market accordingly. It has been constructed in accordance with good engineering

practice in safety matters in force in the Community and does not endanger the safety

of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

Equipment Description: XTC/2 and XTC/C Deposition Controllers, including _

the Oscillator Package and Crystal Sensor as properly

installed. ________

Applicable Directives: 73/23/EEC as amended by 93/68/EEC

89/336/EEC as amended by 93/68/EEC

Applicable Standards: EN 61010-1 : 1993, Fixed Equipment

EN 55011, Group 1, Class A : 1991

EN 50082-2 : 1995 ____ ______

CE Implementation Date: January 3, 1995

Revised to include EMC Directive: January 2, 1997

Authorized Representative: Gary W. Lewis

Vice President – Quality Assurance

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF LEYBOLD INFICON'S PRODUCTS SHOULD

BE DIRECTED, IN WRITING, TO THE QUALITY ASSURANCE DEPARTMENT AT THE ABOVE ADDRESS.

04/15/97

Page 6

Page 7

Registration Card

Thank you for selecting INFICON instrumentation.

®

Please fill out and return this postage paid card as soon as possible.

Model

Serial #

Name

Title

Company

Address

City

Country

State Zip

Fax# Email

Bldg./MS

Phone #

Your help is very important in our continuing efforts to improve our manuals.

Using the table below, please circle the appropriate rank for each aspect.

In the Importance column, please indicate the importance of each aspect.

Manual Title

Very

VD

VD

074-

Dissatisfied

D

D

No

Opinion

NO

NO

Satisfied

S

S

Very

Satisfied

VS

VS

(ranked from

1 to 5, where

1 is low and

Part # (see Title Page)

Aspect

Found everything

I needed

Easy to read

Dissatisfied

Importance

5 is high)

Easy to use

Relevant to

my work

Accurate

information

Well-written

Well-organized

Technical Enough

Helped me

solve problems

VD

VD

VD

VD

VD

VD

VD

D

D

D

D

D

D

D

NO

NO

NO

NO

NO

NO

NO

S

S

S

S

S

S

If you have additional comments, please contact INFICON.

TWO TECHNOLOGY PLACE

EAST SYRACUSE, NY 13057-9714 USA

Phone: +315.434.1100

Fax: +315.437.3803

Email: reachus@inficon.com

VISIT US ON THE WEB AT www.inficon.com

ALTE LANDSTRASSE 6

LI-9496 BALZERS, LIECHTEN STEIN

Phone: +423.388.3111

Fax: +423.388.3700

Email: reach.liechtenstein@inficon.com

VS

S

VS

VS

VS

VS

VS

VS

®

BONNER STRASSE 498

D-50968 COLOGNE, GERMANY

Phone: +49.221.347.40

Fax: +49.221.347.41429

Email: reach.germany@inficon.com

Page 8

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 49 EAST SYRACUSE, NEW YORK

POSTAGE WILL BE PAID BY ADDRESSEE

INFICON INC.

Two Technology P lace

East Syracuse, New York 13057-9714

Page 9

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall in no event

exceed one (1) year from the date of shipment thereof by Seller. Seller's liability

under this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

TWO TECHNOLOGY PLACE

EAST SYRACUSE, NY 13057-9714 USA

Phone: +315.434.1100

Fax: +315.437.3803

Email: reachus@inficon.com

VISIT US ON THE WEB AT www.inficon.com

ALTE LANDSTRASSE 6

LI-9496 BALZERS, LIECHTEN STEIN

Phone: +423.388.3111

Fax: +423.388.3700

Email: reach.liechtenstein@inficon.com

BONNER STRASSE 498

D-50968 COLOGNE, GERMANY

Phone: +49.221.347.40

Fax: +49.221.347.41429

Email: reach.germany@inficon.com

Page 10

Page 11

XTC/C - XTC/2 Operating Manual

Table Of Contents

Chapter 1

Introduction and Specifications

1.1 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1.1 Notes, Cautions, Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1.2 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.3 Earth Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1.4 Main Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.2 Introduction to the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1 Specifications XTC/2 and XTC/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.3.1.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.3.1.2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1.3 Source Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.3.1.4 Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.3.1.5 Recorder Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.1.6 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.3.1.7 Process Recipe Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.3.1.8 Hardware interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.3.1.9 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.3.2 Transducer Specifications (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.3.3 XIU (Crystal Interface Unit) Specifications . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4 Guide to the Use of the Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.5 XTC/C Users and Installers Note. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.6 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.7 How To Contact Customer Support. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

IPN 074-183X

1.7.1 Application Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.7.2 Field Service and Repair Support . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1.7.3 Returning Your Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Chapter 2

Quick Use Guide

2.1 Unpacking, Initial Inspection and Inventory . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.1 Unpacking and Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.2 Inventory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2.1 XTC/2 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2.2 XTC/C System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

TOC - 1

Page 12

XTC/C - XTC/2 Operating Manual

2.1.2.3 Ship Kit - XTC/2 XTC/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Installation Guide and Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4 XTC/2 Front Panel Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.1 XTC/2 Front Control Panel Description. . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.2 XTC/2 Display Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5 XTC/C Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.6 Rear Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.1 Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.2 Configuration Switches 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.6.3 Grounding Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6.4 System I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.6.5 AUX I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.6.6 Sensor 1, Sensor 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.6.7 RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.6.8 Communication Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.6.9 Source 1,2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.6.10 Manufacturer’s Identific ation and

Serial Number Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.6.11 Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.7 Operation as a Deposition Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.7.1 Monitoring - Systems Without a Source Shutter . . . . . . . . . . . . . . . . . 2-29

2.7.2 Monitoring - Systems with a Source Shutter. . . . . . . . . . . . . . . . . . . . 2-30

2.7.3 Rate Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2.7.4 Nontraditional Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.7.4.1 Etching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.7.4.2 Immersion in Liquids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.7.4.3 Biological . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.7.4.4 Measurement of Liquids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

TOC - 2

2.8 Operation as a One Layer Controller . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

IPN 074-183X

2.8.1 Skipping a State Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.8.2 Idle State Processing Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.8.3 Manual Power Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.8.4 Time Power State Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.8.5 Controlling the Source Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.9 Operation as a Multi-Layer Controller. . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.9.1 Defining a Process Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Page 13

XTC/C - XTC/2 Operating Manual

Chapter 3

Installation

3.1 Installing the Instrument - Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 Control Unit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Electrical Grounding and Shielding Requirements. . . . . . . . . . . . . . . . .3-1

3.2.1 Verifying / Establishing Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.2 Connections to Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.3 Minimizing Noise Pickup from External Cabling. . . . . . . . . . . . . . . . . . .3-3

3.3 Connection to Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.3.1 The BNC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.3.2 The "D" Shell Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Sensor Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.5 Guidelines for Transducer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5.1 Sensor Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5.2 CrystalSix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.5.3 Check List for Transducer Installation . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.6 Use of the Test Mode (XTC/2 Only). . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.6.1 Operational Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.7 Input and Output Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3.7.1 Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3.7.2 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3.7.3 Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.7.4 Source Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.8 Computer Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.8.1 Communications Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.8.1.1 IEEE Settings for a National Instruments IEEE-GPIB Board . . . . . . . .3-21

3.8.2 Basic Command Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.8.3 Service Requests and Message Available. . . . . . . . . . . . . . . . . . . . . .3-24

3.8.4 Datalogging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

IPN 074-183X

3.8.5 Computer Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3.8.5.1 Echo Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3.8.5.2 Hello Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.8.5.3 Query Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3.8.5.4 Update Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.8.5.5 Status Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.8.5.6 Remote Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3.8.6 Examples of RS232 Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

3.8.6.1 Program Without Checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

3.8.6.2 Program With Checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

TOC - 3

Page 14

XTC/C - XTC/2 Operating Manual

3.8.6.3 Example of SEMI II Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3.8.7 Example of IEEE488 Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.9 Co-Deposition (Two Unit Interconnection) . . . . . . . . . . . . . . . . . . . . . 3-39

Chapter 4

Programming System Operation Details

4.1 State and Measurement System Sequencing. . . . . . . . . . . . . . . . . . . . 4-1

4.2 State Descriptions and Parameter Limits . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 Alarms and Stops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.2 Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.4 Recovering From "STOPS" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.5 Tuning the Control Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.5.1 Tuning a Fast Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.5.2 Tuning a Slow Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.5.3 Setting Maximum Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.6 Setting S&Q Parameters

(Soft Crystal Failures) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.6.1 Q-Factor (Quality) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.6.2 S-Factor (Stability) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.6.3 Determining Q and S Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7 Rate Ramps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.7.1 Rate Ramp to Zero Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.8 Use of the Hand Controller (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.9 Setting the Soak and Idle Power Levels . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.9.1 Setting Soak Power 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.9.2 Setting Soak Power 2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.9.3 Setting Idle Power Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.10 Implementing RateWatcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.11 Crystal Fail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.12 Completing on TIME-POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.13 Crystal Fail Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.14 Shutter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.15 Crystal Switch Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.15.1 Sensor Shutter / CrystalSwitch Output . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.16 Start Layer Without

Backup Crystal Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4.17 Crystal Life and Starting Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

IPN 074-183X

TOC - 4

Page 15

XTC/C - XTC/2 Operating Manual

Chapter 5

Calibration and Measurement

5.1 Importance of Density, Tooling and Z-ratio . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Laboratory Determination of Z-ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.5 Measurement Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.5.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.5.2 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.5.3 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.5.4 Z-Match Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.5.5 Active Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5.6 ModeLock Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.6 Control Loop Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Chapter 6

Adjustments and Problems

6.1 LCD Contrast Adjustment (XTC/2 only). . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Powerup Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2.2 Parameter Update Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.3 Other Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3.1 Major Instrument Components, Assem blies

and Mating Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.2 Troubleshooting the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.3.3 Troubleshooting Transducers/Sensors . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.4 Troubleshooting Computer Communications. . . . . . . . . . . . . . . . . . . .6-10

6.3.5 Leaf Spring Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

IPN 074-183X

6.4 Replacing the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.4.1 Standard and Compact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.4.2 Shuttered and Dual Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6.4.3 Bakeable Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6.4.4 Sputtering Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6.4.5 Crystal Snatcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4.6 CrystalSix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6.5 Crystal Sensor Emulator IPN 760-601-G1 or 760-60 1-G2 . . . . . . . . . .6-18

6.5.1 Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6.5.1.1 Measurement System Diagnostic Procedure. . . . . . . . . . . . . . . . . . . .6-19

6.5.1.2 Feed-Through Or In-Vacuum Cable Diagnostic Procedure . . . . . . . . .6-20

TOC - 5

Page 16

6.5.1.3 Sensor Head Or Monitor Crystal Diagnostic Procedure . . . . . . . . . . . 6-21

6.5.1.4 System Diagnostics Pass But

6.5.2 % XTAL Life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.5.3 Sensor Cover Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.5.3.1 Compatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.5.3.2 Incompatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.5.4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Appendix A

Index

XTC/C - XTC/2 Operating Manual

Crystal Fail Message Remains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Table of Densities and Z-ratios

TOC - 6

IPN 074-183X

Page 17

Introduction and Specifications

1.1 Instrument Safety

1.1.1 Notes, Cautions, Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS and

WARNINGS found throughout. For the purposes of this manual they are

defined as follows:

NOTE: Pertinent information that is useful in achieving maximum instrument

efficiency when followed.

CAUTION

Failure to heed these messages could result in damage

to the instrument.

XTC/C - XTC/2 Operating Manual

Chapter 1

WARNING

Failure to heed could result in personal injury.

WARNING

Dangerous voltages are present. Failure to heed could

result in personal injury.

IPN 074-183X

1 - 1

Page 18

XTC/C - XTC/2 Operating Manual

1.1.2 General Safety Information

WARNING

This product is not for use in a manner not specified by

the manufacturer.

There are no user serviceabl e compon ents within the

instrument case.

Potentially lethal voltages are present when the line

cord, system I/O or aux I/O are connected.

Refer all maintenance to qualified personnel.

CAUTION

This instrument contains delicate circuitry which is

susceptible to transient power line voltages.

Disconnect the line cord whenever making any

interface connections. Refer all mainte nance to

qualified personnel.

1 - 2

IPN 074-183X

Page 19

1.1.3 Earth Ground

This instrument is connected to earth via a sealed three-core (three-conductor)

power cable, which must be plugged into a socket outlet with a protective earth

terminal. Extension cables must always have three condu ctors, inclu ding a

protective earth conductor.

WARNING

XTC/C - XTC/2 Operating Manual

Never interrupt the protective earth circuit.

Any interruption of the protective earth connection

inside or outside the instrument, or disconnection of

the protective earth terminal is likely to make the

instrument dangerous.

This symbol indicates where the protective earth

ground is connected inside the instrume nt. Never

unscrew or loosen this connection .

IPN 074-183X

1 - 3

Page 20

XTC/C - XTC/2 Operating Manual

1.1.4 Main Power Connection

WARNING

This instrument has line voltage present on the

primary circuits whenever it is plugged into a main

power source.

Never remove the covers from the instrument during

normal operation.

There are no operator serviceable items within this

instrument.

Removal of the top or bottom covers must be done

only by a technically qualified person.

If this instrument is installed into a rack system which

contains a mains switch, this switch must break both

sides of the line when it is open and it must not

disconnect the safety ground. This configuration is

required in order to comply with accepted European

safety standards.

1 - 4

IPN 074-183X

Page 21

1.2 Introduction to the Instrument

The XTC/2 and XTC/C are quartz crystal transducer type deposition process

controllers with three layer capability. They are readily connected to interact

with and control the other instruments associated with a vacuum coating plant

of moderate complexity. These instruments incorporate the patented (US

#5,117,192—May 27, 1992) ModeLock measurement system. This innovative

system provides process security , measurement speed and precision at a level

that no active oscillator based instrume nt can provide.

The bright Liquid Crystal Display of the XTC/2 is easily read and keeps the

operator continuously informed with pertinen t deposition da ta including rate,

thickness, phase, rate deviatio n and ela psed time. Special messages such as

Stop, Crystal Fail or Time-Power are clearly presented to reduce operator

uncertainty and eliminate the possibility of costly mis takes.

The XTC/C is a variant of the XTC/2 that has a limited front panel. Instead of

an LCD display , it has 8 LED type status indicators that indicate process status

and instrument functional status. It is primarily designed for use in vacuum

coating plants that have a computer based central controller. The original

equipment manufacturer (OEM) will design a custom user input-output syst em

through his system controller. Once programmed and started, the XTC/C will

essentially run as independent of the central controller as is desired . The

deposition layer can complete without further intervention, freeing the central

controller for other tasks. Status and data may be queried as frequently as is

desired, however.

XTC/C - XTC/2 Operating Manual

Interaction with the coating system for both units is multifa ceted. All units come

with RS232 and support data rates to 9600 baud. The SECSII protocol is

supported. The optional computer interface is IEEE-488. The in strument is

configured to sequentially control two separate deposition sources with 15 bit

resolution using either PID or integrating type controller algorithms. Twelve

relays are used to manipulate various external devices such as source and

sensor shutters, heaters or valves. Lower power outputs are u sed to control the

IPN 074-183X

position of multi-hearth crucibles. There are eight input lines to provide the

ability to sense and react to discrete external signals.

There are numerous special control functions for accommodating the needs of

the deposition process. Full predeposit pro cessing is provide d, including

shutter delay which allows the establishment of the desired rate prior to opening

the substrate shutter. A Rate Ramp allows the deposition rate to be changed

during the deposit phase. The Ra teWatcher feature allows t he dep osition

stream to be periodically sampled, extendin g the life of the crystal.

These instruments are fully compatible with the complete family of INFICON

transducers, including Dual and CrystalSix®.

1 - 5

Page 22

XTC/C - XTC/2 Operating Manual

1.3 Specifications

At the time of this manual’s writing, the specifications for perform ance are as

published below. INFICON continuously improves its products, affecting the

instrument’s performance.

1.3.1 Specifications XTC/2 and XTC/C

1.3.1.1 General

Usage . . . . . . . . . . . . . . . . . . . . . .Indoor use only.

Altitude Range. . . . . . . . . . . . . . . .Up to 2000 m (6,561 ft)

Pollution Degree . . . . . . . . . . . . . .1—No pollut ion occurs

Overvoltage Category . . . . . . . . . .2—Local level, appliances, etc.

Cleaning . . . . . . . . . . . . . . . . . . . .The unit enclosure can be safely cleaned

with a mild detergent or spray cleaner

designed for that purpose. Care should be

taken to prevent any cleaner from entering

the unit.

1.3.1.2 Measurement

Crystal Range & Precision. . . . . . .6.0 to 5.0 MHz +/- .05 Hz

Thickness & Rate Resolution. . . . .0.0617Å (per 250 msec sample)

Thickness accuracy . . . . . . . . . . . .0.5%

Measurement frequency . . . . . . . .4 Hz

1.3.1.3 Source Controls

Source-Control Voltage . . . . . . . . .0 to +/- 10 v

Number of Sources . . . . . . . . . . . .2

Resolution . . . . . . . . . . . . . . . . . . .15 bits over full range (10 v)

Update Rate . . . . . . . . . . . . . . . . .4 Hz max.

Maximum Load . . . . . . . . . . . . . . .400 Ohm (100 Ohm internal impedance)

(per 250 msec sample)

Material density = 1.0; Z-Rati o = 1.0;

crystal frequency = 6 MHz.

Å/S/M = Angstroms/second/measurement.

IPN 074-183X

1 - 6

Page 23

1.3.1.4 Input/Output

Inputs . . . . . . . . . . . . . . . . . . . . . . 9 TTL inputs

Outputs

a) relay . . . . . . . . . . . . . . . . . . 12 SPST 2.5-amp relays rated

b) crucible select . . . . . . . . . . . 8 open col lector

Scan/Change Rate . . . . . . . . . . . . 4 Hz

1.3.1.5 Recorder Output

Voltage . . . . . . . . . . . . . . . . . . . . . 0 to +10 v

Resolution . . . . . . . . . . . . . . . . . . 13 bits over full range

Update Rate . . . . . . . . . . . . . . . . . 4 Hz

Function . . . . . . . . . . . . . . . . . . . . Rate / Thickness / Mass

Maximum Load . . . . . . . . . . . . . . . 2.0 KOhm (100 Ohm internal impedance)

XTC/C - XTC/2 Operating Manual

@ 30 V(dc) / 30 V(ac) / 42 V(peak) max.

(5 volt DC max sink, 5 TTL loads)

(one reserved for sign)

1.3.1.6 Display

Applies to XTC/2 only; the XTC/C provides LED annunciators.

Type . . . . . . . . . . . . . . . . . . . . . . . 4x multiplexed custom LCD with backlight.

If desired, backlight automatically dims

during prolonged period of inactivity,

automatically brightening when a ctivity

begins.

Thickness Resolution . . . . . . . . . . 1 Å

Rate Resolution . . . . . . . . . . . . . . .1 Å for 1 to 99.9 Å/sec

1 Å for 100 to 999 Å/sec

Update Rate . . . . . . . . . . . . . . . . . 1 Hz

IPN 074-183X

1.3.1.7 Process Recipe Storage

Film Programs . . . . . . . . . . . . . . . 9, 30 variables per program

Process layers . . . . . . . . . . . . . . . 3

1 - 7

Page 24

XTC/C - XTC/2 Operating Manual

1.3.1.8 Hardware interface

Sensors

Single. . . . . . . . . . . . . . . . . . . .2

Dual . . . . . . . . . . . . . . . . . . . . .1

CrystalSix. . . . . . . . . . . . . . . . .2

Sources. . . . . . . . . . . . . . . . . . . . .2 BNC female

Crucible Locations. . . . . . . . . . . . .8, 1 of 8 and BCD encoded

I/O

Standard (inputs/outputs) . . . . .8/12

Optional . . . . . . . . . . . . . . . . . .None

Communications

Standard. . . . . . . . . . . . . . . . . .RS232C

Optional . . . . . . . . . . . . . . . . . .IEEE

Chart Recorder . . . . . . . . . . . . . . .1 BNC female

1.3.1.9 Operation

Power Requirements

Operating Temperature . . . . . . . . .0 to 50 °C (32 to 122 °F)

Size . . . . . . . . . . . . . . . . . . . . . . . .3.5" H x 8" W x 12" D

Weight. . . . . . . . . . . . . . . . . . . . . .6 lb. (2.7 kg)

"115 V" input range. . . . . . . . . .90 to 132 V(ac), 49 to 61 Hz, 45 VA max.

fused at 3/8 Amp Type T fuse

"230 V" input range . . . . . . . . .180 to 264 V(ac), 49 to 61 Hz, 45 VA max.

fused at 3/16 Amp Type T fuse

(89 mm x 203 mm x 305 mm)

IPN 074-183X

1 - 8

Page 25

XTC/C - XTC/2 Operating Manual

1.3.2 Transducer Specifications (optional)

Max. Bakeout

Temperature*

CrystalSix Sensor 130 °C 3.5" dia. x 2.0" high

Standard Sensor 130 °C 1.063" x 1.33" x .69" high

Standard Sensor

with Shutter

Sputtering Sensor 105 °C 1.36" dia. x .47" high

Compact Sensor 130 °C 1.11" x 1.06" x 1.06" high

Compact Sensor

with Shutter

UHV Bakeable

Sensor

UHV Bakeable

Sensor with Shutter

Dual Sensor 130 °C 1.45" x 3.45" x 1.70" high

Shutter Assembly 400 °C two models available N/A 300-series SS 750-210-G1

*For Bake only; waterflow is required for actual deposition monitoring. These temperatures are conservative maximum

device temperatures, limited by the properties of Teflon (PTFE) at higher temperatures. In usage, the water cooling allows

operation in environments that are significantly elevated, without deleterious affects.

**Aluminum body for heat transfer.

130 °C 1.06" x 2.24" x .69" high

130 °C 2.08" x 1.62" x 1.83" high

450 °C 1.35" x 1.38" x .94" high

400 °C 1.46" x 1.37" x 1.21" high

Size (Max. Envelope) Water Tube &

Coax Length

30" (762 mm) 304 SS (plate,

(89 mm dia. x 51 mm high)

30" (762 mm) 304 SS 750-211-G1

(27 mm dia. x 34 mm x 17.5 mm high)

(27 mm dia. x 57 mm x 17.5 mm high)

(34.5 mm dia. x 11.8 mm high)

(28 mm x 27 mm x 27 mm high)

(53 mm x 41 mm x 46 mm high)

(34 mm x 35 mm x 24 mm high)

(37 mm x 35 mm x 31 mm high)

(37 mm x 88 mm x 43 mm high)

30" (762 mm) 304 SS 750-211-G2

30" (762 mm) Au-plated BeCu 007-031

30" (762 mm) 304 SS 750-213-G1

30" (762 mm) 304 SS 750-213-G2

12" (305 mm)

20" (508 mm)

30" (762 mm)

12" (305 cm)

20" (508 cm)

30" (762 cm)

30" (762 mm) 304 SS 750-212-G2

Body & Holder IPN

750-446-G1

holders, & material shield)**

304 SS 007-219

007-220

007-221

304 SS 750-012-G1

750-012-G2

750-012-G3

750-005-G1

(Sputtering)

1.3.3 XIU (Crystal Interface Unit) Specifications

The XTC/2 Series instruments use a new type of "passive intelligent" oscillator.

IPN 074-183X

It is available with cable lengths of 15’ (4.572 m), 30’ (9.144 m), 50’ (15.24 m),

and 100’ (30.28 m) as IPN 757-305-G15, G30, G50, or G100, respectively.

Conventional, active style oscillators do not work with these instrum ents.

In-vacuum cable lengths to a maximum of 2 m (6.6’) are supported with this new

technology.

1 - 9

Page 26

XTC/C - XTC/2 Operating Manual

1.4 Guide to the Use of the Manual

This manual is configured to be used by both experie nced and inexperie nced

deposition process engineers. For those with significant experience, especially

on INFICON controllers, nearly all pertinent infor mation is containe d in Chapter

2, Quick Use Guide. Other sections contain the details that supplement the

information in the quick use section .

Every user should read the complete ma nual. It is strong ly sugges ted that t he

user or installer follow the following plan to gain the most information in the

shortest period of time.

Register the instrument to receive updates and important information from

the factory.

Read section 1.1.1, Notes, Cautions, Warnings, on page 1-1 to understand

the safety related issues.

Read Chapter 2, Quick Use Guide, to become familiar with the instrument’s

needs and capabilities. Use the other sections of the manual to supplement

areas where you do not feel you have an adequate un derstanding of the

material. Throughout Chapter 2 there will be frequent referenc es to the

manual sections that provide more detailed information. The final sections

of the Chapter 2 build the understanding of the full use of the instrument in

a logical progression, as suggested in section 2.3 on page 2-8.

1.5 XTC/C Users and Installers Note

The XTC/C can do anything that an XTC/2 can do, but it must be controlled

through the computer interface. In order to install and use this instrument

effectively , all aspects of XTC/2 operation must be understood. Because of this

additional burden, it is probably not cos t effective for an end-user of a singl e

unit to purchase and install the XTC/C version.

WARNING

There are no user serviceabl e compon ents within the

instrument case.

Potentially lethal voltages are present when the line

cord, System I/O or Aux I/O are connected.

Refer all maintenance to qualified personnel.

IPN 074-183X

1 - 10

Page 27

XTC/C - XTC/2 Operating Manual

1.6 Related Manuals

Transducers are covered under separate manuals.

IPN Transducer Type

074-154 . . . . . . Bake able

074-155 . . . . . . Cry stalSix

074-156 . . . . . . Sin gle/Dual/Compact

074-157 . . . . . . Sputtering

1.7 How To Contact Customer Support

If you cannot find the answer to your quest ion in this man ual, please co ntact

one of the following Customer Support groups after deciding whether:

your dif ficulty is with how you are using the instrument—in this case, cont act

Application Support.

or

your instrument needs repair—in this case, contact Field Service and

Repair Support.

When you contact Customer Support, please have this manua l at hand, a long

with the following information:

The serial number for your instrument.

A description of your problem.

An explanation of the corrective action that you may have already

attempted.

The exact wording of any error messages that you have received from the

instrument.

IPN 074-183X

Within the USA, you may reach Customer Support at the following phone

numbers. Please contact the location that is closest to you. If you are located

outside of the USA, please contact your sales office. A complete listing of

INFICON Worldwide Service Centers is available at www.inficon.com.

1.7.1 Application Support

Austin, TX. . . . . . .ph. 512-448-0488 . . . . . . . . . fax 512-448-0398

San Jose, CA . . . .ph. 408-361-1200 ext. 125 . . fax 408-362-1556

Syracuse, NY . . . . ph. 315-434-1128 . . . . . . . . . fax 315-437-3803

If you are located outside the USA, please contact your sales office. A complete

listing of INFICON Worldwide Service Centers is available at www.inficon .com.

1 - 11

Page 28

XTC/C - XTC/2 Operating Manual

1.7.2 Field Service and Repair Support

Austin, TX . . . . . . ph. 512-448-0488. . . . . . . . . .fax 512-448-0398

San Jose, CA . . . . ph. 408-361-1200 ext. 12 0 . . .fax 408-362-1556

Syracuse, NY . . . . ph. 315-434-1167. . . . . . . . . .fax 315-434-25 51

If you are located outside the USA, please contact your sales office. A complete

listing of INFICON Worldwide Service Centers is available at www.in ficon.com.

1.7.3 Returning Your Instrument

Do not send your instrument without first speaking with a Customer Support

Representative.

You must obtain an RMA (Return Material Authori zation) num ber from the

Customer Support Representative. If the delivery of a package without an RMA

number is attempted, INFICON will refuse the delivery and the package will be

returned to you.

If your instrument has been exposed to process materials, you will be required

to complete a Declaration Of Contamination form.

1 - 12

IPN 074-183X

Page 29

XTC/C - XTC/2 Operating Manual

Quick Use Guide

2.1 Unpacking, Initial Inspection and Inventory

2.1.1 Unpacking and Inspection Procedures

1 If you haven’t removed the instrument from its shipping containers, do so

now.

2 Carefully examine the unit for damage that may have occurred during

shipping. This is especially important if you notice signs of obvious rough

handling on the outside of the cartons. Report any damage to the carrier and

to INFICON, immediately.

3 DO NOT discard any packing materials until you have taken inventory and

have verified proper instrument operation to you r satisfactio n. See section

2.2 on page 2-4 for voltage selection and section 3.6 on page 3-11 for test

mode operation.

Chapter 2

2.1.2 Inventory

Make sure you have received all of the necessary equipment by checking the

contents of the shipping containers with the parts list below. INFICON ships

these products on a feature-option basis. Check your order for the part number

before comparing to the lists below.

IPN 074-183X

2 - 1

Page 30

XTC/C - XTC/2 Operating Manual

2.1.2.1 XTC/2 System Configuration

BASIC CONFIGURATION IPN # CODE#

115V 50/60 Hz 757-500-G1 1

230V 50/60 Hz 757-500-G2 2

Computer Communications Module

None 757-211-G1 1

IEEE-488 Parallel 760-142-G1 2

Remote Module

None 0

Hand Controller 755-262-G1 1

Rack Mounting

None 0

1 Unit Mounting Kit 757-212-G1 1

2 Unit Mounting Kit 757-212-G2 2

XTC/2 ---

2.1.2.2 XTC/C System Configuration

BASIC CONFIGURATION IPN # CODE#

115V 50/60 Hz 759-500-G1 1

230V 50/60 Hz 759-500-G2 2

Computer Communications Module

None 757-211-G1 1

IEEE-488 Parallel 760-142-G1 2

Remote Module

None 0

Hand Controller 755-262-G1 1

Rack Mounting

None 0

1 Unit Mounting Kit 757-212-G1 1

2 Unit Mounting Kit 757-212-G2 2

XTC/C ---

IPN 074-183X

2 - 2

Page 31

2.1.2.3 Ship Kit - XTC/2 XTC/C

Both instruments are shipped with the following accessories. To find which

accessories were shipped with your unit look for th e "X" which represents the

voltage of your particular instrument and follow that column.

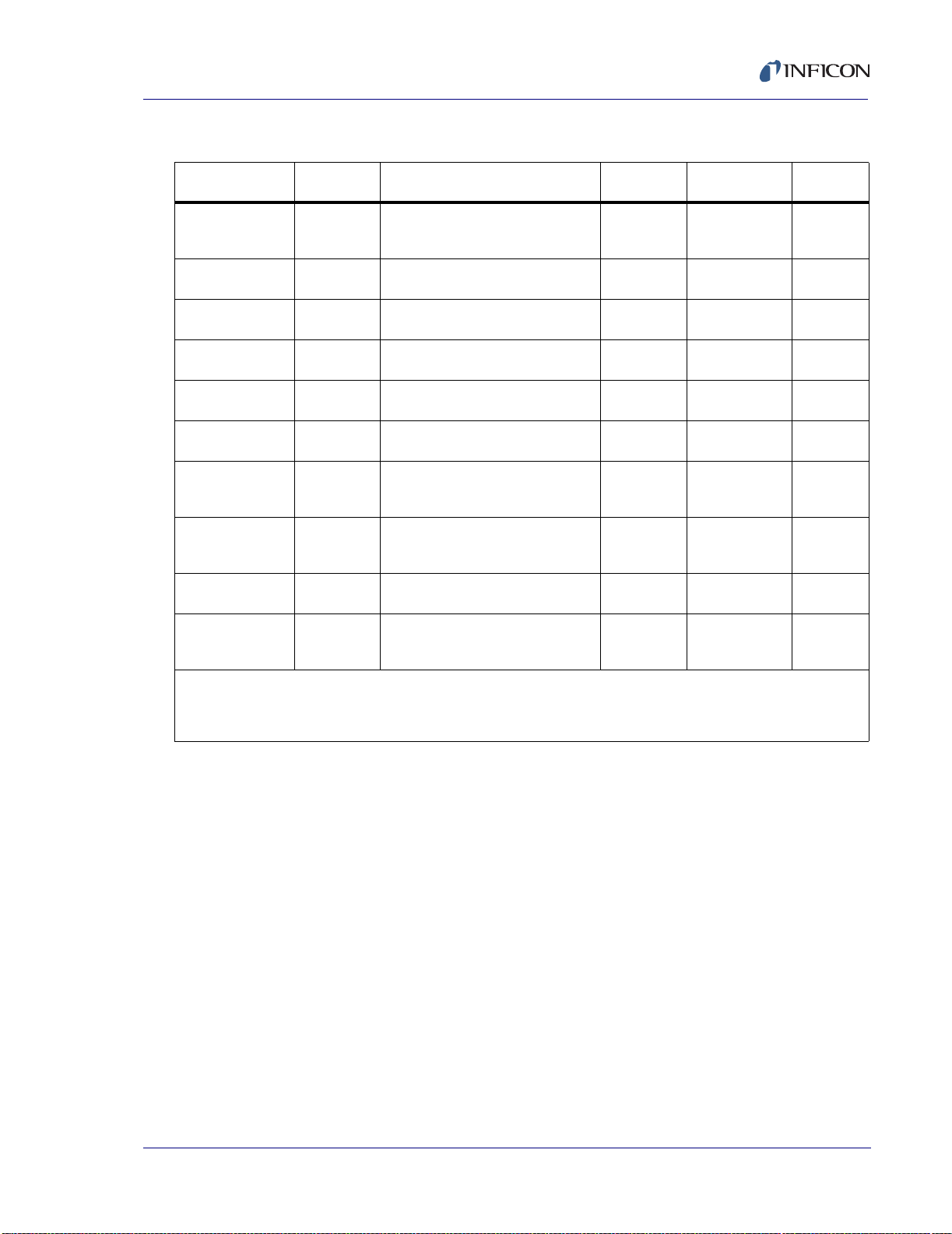

Table 2-1 Accessories

Qty

G2 G1

Item

01 - X 757-203-G1 Ship Kit - XTC/2 & XTC/C 115V

02 X - 757-203-G2 Ship Kit - XTC/2 & XTC/C 230V

03 - 1 068-0385 North American Power Cord, shielded

04 1 - 068-0390 European Power Cord, shielded

05 1 1 051-485 Conn 9 Pin Male D/Sub Sod. Cup

06 1 1 051-620 Cable Clamp 11.3015

07 2 2 051-483 Conn 25 Pin Female D/Sub Sod. Cup

(230V)(115V) IPN Number Part # and/or Description

XTC/C - XTC/2 Operating Manual

08 2 2 051-619 Cable Clamp

09 - 1 062-011 3/8 Amp Fuse Type T

10 1 - 062-053 3/16 Amp Fuse Type T

11 4 4 070-811 8014 Bumpon Feet

In addition, you have already found a copy of th is manual, IPN 074-1 83.

IPN 074-183X

2 - 3

Page 32

XTC/C - XTC/2 Operating Manual

2.2 Voltage Selection

Voltage selection is re quired only betwee n low (nominal 10 0-120 V) and high

(nominal 200-240 V) ranges. There is no distin ction between 50 and 60 Hz

supplies. Refer to section 1.3.1 on page 1-6 for specific power requirements.

CAUTION

Verify that the correct fuse is in place by visually

inspecting the fuse for the proper rating. Use of an

improperly sized fuse may create a safety hazard.

For 100-120 V(ac) operation use a 3/8 Amp Type T fuse.

For 200-240 V(ac) operation use a 3/16 Amp Type T fuse.

NOTE: These instruments are designed to operate betwee n 90 V(ac) a nd

132 V(ac) on Low Range and between 180 V(ac) and 264 V(ac) on

High Range.

WARNING

This instrument has line voltage present on the

primary circuits whenever it is plugged into a main

power source.

Potentially lethal voltages are present when the line

cord, system I/O or aux I/O are connected.

This instrument must be disconnect ed from the m ain

power source before inspecting or replacing th e fuse.

IPN 074-183X

2 - 4

Page 33

XTC/C - XTC/2 Operating Manual

To inspect the fuse, proceed as follows.

1 Pry open the power e ntry modu le cove r. See Figure 2-1.

Figure 2-1 Opening the Power Entry Module Cover

2 Pry the fuse holder out of th e housing. See F igure 2-2.

Figure 2-2 Removing the Fuse Holder

IPN 074-183X

2 - 5

Page 34

XTC/C - XTC/2 Operating Manual

3 Inspect the fuse. See Figure 2-3.

Figure 2-3 Clip, Fuse Holder, Fuse

Conversion Clip

Fuse

Holder

Fuse

The Corcom fuse holder has chambers for two 1/4" x 1 1/4" (5 mm x 20 mm)

fuses. Since only one fuse is used, that fuse must be on the live (hot) side and

a conversion clip is inserted to bridge the un used fuse cham ber in the neutral

side.

An additional function of the conversion clip is to act as a polarization key to

assure that only the neutral line can be bridged leaving the live (hot) line always

fused. A special feature has been built into the live side of the f use holder

compartment of the housing. It will interf ere with th e conversi on clip and

therefore stop the fuse holder from being ins erted fully int o the housing if the

clip is on the live side.

When the power entry module is flipped around for voltage changing , the

conversion clip must be re-installed to the other side. Otherwise, the fuse holder

will not seat completely into the housing and the po wer entry module will no t

function.

The proper location of the conversion clip is at the left hand side of the voltage

number selected, that is, the upright voltage numb er. See Figure 2-4.

IPN 074-183X

2 - 6

Page 35

XTC/C - XTC/2 Operating Manual

Figure 2-4 Proper Clip and Fuse Location

Once the fuse and clip have been configured, the fuse holder is inserted into

the power entry module housing with the fuse towards the bottom of the

instrument (and the clip towards the top) with the desired voltage showing

through the hole into the cover.

IPN 074-183X

2 - 7

Page 36

XTC/C - XTC/2 Operating Manual

2.3 Installation Guide and Schematic

Many experienced deposition monitor users will be able to fu lly install and use

the instrument by studying the installation schem atic, Figure 2-5 on the next

page, and the S tate Seque nce Diagrams, Figure 4-2 on page 4-2, Figure 4-3 on

page 4-3, Figure 4-4 on page 4-4, and Figure 4-5 on page 4-5.

A more systematic approach would be to start by reviewing the two figures and

then following the procedure below.

WARNING

Completely review section 1.1 on page 1-1 on safety.

All warnings in this section, as well as ones fo und in

other sections listed below, must be followed to ensure

the safety of the personnel operating this instrument.

1 Check for correct line voltage, sect ion 2.2 on page 2-4.

2 Verify basic unit operation by exercising it in the Test Mode, section 3.6 on

page 3-11.

3 Review the system interface capability as outlined in section 2.6 on pa ge

2-18. Be especially attentive of the special fe atures availab le on the

configuration switches, section 2.6.2 on page 2-19

4 Wire the necessary connectors following the installation procedures in

sections section 3.1 on page 3-1, section 3.2 on page 3-1, and section 3.3

on page 3-4.

5 Review the front panel controls and display descri ption per section 2.4 on

page 2-10 for the XTC/2 or section 2.5 on page 2-16 for the XTC/C.

6 Program the desired film parameter values per section 4.1 o n page 4-1 and

section 4.2 on page 4-6.

7 Verify the operation of the just programmed film utilizing the Test Mode.

8 Attach the XIU (757-305-G15, G30, or G100) to an existing transdu cer or

install a new transducer following the guidelines of section 3.5 on page 3-7

and Figure 3-3 on page 3-8.

IPN 074-183X

2 - 8

9 Exit the Test Mode and deposit when rea dy.

Page 37

STOP

INCR DE CR

X

T

A

L

XTC/C - XTC/2 Operating Manual

(Optional)

IPN 755-262-G1

Power Controller

Hand Held Manual

S

W

I

T

C

H

[To front of instrument]

IEEE 757-211-G1

Option

on sensor connector 1.

Outputs

1,2 Thickness setpoint

3,4 Feedtime (SOAK 2)

5,6 Crystal Fail

7,8 Alarms

9,10 Source 1 / Source 2

11,12 End Deposit

Inputs

13 Input common (GND)

14 Crucible valid

15,16,17 Input common (GND)

Open Collector Outputs

18 Crucible select 1

19 Crucible select 2

20 Crucible select 3

21 Crucible select 4

22 Crucible select 5

23 Crucible select 6

24 Crucible select 7

25 Crucible select 8

NOTE: Crucible select is also BCD encoded

Description

Pin #

1 Not used

2 TXD Data transmitted from XTC

3 RXD Data received by XTC

4 Not used

5 GND Signal ground

6 DTR Output from XTC indicating ready to transmit

7 CTS Input to XTC indicating stop transmitting

8 Not used

9 GND Shield ground

Pin #

Also Available

Source Shutter 2 3,4

Sensor Shutter 2 7,8

Stop 8,10

End Of Process 11,12

Inputs

Input Common 13,14,15,16,17

Start Deposition 18

Stop Deposition 19

End Deposit 20

Sample Initiate 21

Sample Inhibit 22

Crystal Fail Inhibit 23

Zero Thickness 24

Outputs

5

6

Soak 2 Hold 25

1

2

Sensor Shutter 1

[N.O. Relay Contact]

From Local Line Power

100-120 V(ac) ±10%

200-240 V(ac) ±10%

Sensor Shutter 1

Outputs Pin #

Optional

Chart

Recorder

Earth

Ground

50-60 Hz

Feed Thru

IPN 750-030-G1

(Oscillator Kit 757-305-GXX: option)

(Option)

Cooling

Water

Source Shutter 1

[N.O. Relay Contact]

Source Shutter 1

Figure 2-5 Installation Guide Schematic

Air, 80 PSI, 110 PSI Max.

Optional

Cajon

Coupling

IPN 074-183X

Standard Sensor with Shutter

IPN 750-211-G2

(Option)

Sensor

Shutter

Source

Shutter

Source to Sensor

10” Minimum

Beam Gun

Such As Electron

Source Controller

Actuator

Pneumatic

XIU (Oscillator)

IPN 757-302-G1

In

Out

Shutter

IPN 007-199

Power Supply

Solenoid Assy.

Power Supply

24 V(ac) or V(dc)

Rotary

Feed Thru

Air

Actuator

Power Supply

Compressed

2 - 9

Page 38

XTC/C - XTC/2 Operating Manual

2.4 XTC/2 Front Panel Description

The description of the XTC/2 front panel is divided into two sections, the display

area and the front control panel.

Figure 2-6 Front Panel XTC/2

1 2345 6

7

8

9

18

2.4.1 XTC/2 Front Control Panel Description

1— LCD DISPLAY

Highly visible display of current information. See section 2.4.2 on page

2-12 for details.

2— LIFE

Pressing the 1 key momentarily switches the display to percent of crystal

life used, software version, crystal frequency, and S and Q values, when

the display is in the operate mode.

3— ZERO

Pressing the 2 key zeros the displayed thickness when the display is in the

operate mode.

4— XTSW

Crystal Switch. Pressing the 3 key advances the CrystalSix to the next

available crystal or changes the active crystal of the dual head when the

display is in the operate mode. (See section 4.15.1 on page 4-25.)

5— MPWR

Manual. Pressing the 4 key places the unit in manual power control or rate

control mode when the display is in the operate mode.

1011121314151617

IPN 074-183X

2 - 10

6— START

Initiates action. (Starts State Sequencing, see Figure 4-2 on page 4-2 and

Figure 4-3 on page 4-3.)

7— STOP

Halts State Sequencing, see Figure 4-2 on page 4-2 and Figure 4-3 on

page 4-3.

8— PROG

Program. Toggles the display between the program and operate mod es.

Page 39

XTC/C - XTC/2 Operating Manual

9— ON/STBY

Switches secondary power of the instrument between ON and STANDBY.

10—

Green LED indicates that the unit is connected to an active line power

source and the ON/STBY switch is set to ON.

11—

Access to adjust LCD contrast, see section 6.1 on page 6-1.

12—

Connection for optional manual power and crystal switch hand controller

(IPN 755-262-G1).

WARNING

This connector is not for telecommunications

equipment. Do not connect a phone to this connector.

13—

Enter and cursor down. Two function switch used when the display is in the

program mode. All numeric and "Y" "N" parameter entries need to be

followed by a . Also used to manuall y decrease sou rce power when in

MPWR and the display is in the operate mode.

14— 0/N

Zero or no. Two function switch used when the display is in the program

mode. Also, places unit in communications set up mode if held down during

power up, see section 3.8.1 on page 3-20.

15— 9/Y

Nine or yes. Two function switch used when display is in progra m mode.

16— /RESET

IPN 074-183X

Clear and cursor up. Two function switch that is also used to "reset" the

instrument to the beginning of a process from a STOP state. Also used to

increase source power when in MPWR and the display is in the operate

mode.

17— DIGITS (0-9)

Decimal based key pad for data entry. If the nine key is held down during

power-up, all of the LCD segments will remain lit until t he key is rel eased ,

see Figure 2-7 on page 2-12.

18—

Optional mounting kit, (IPN 757-212-G1) for mo unting one unit in f ull rack

or (757-212-G2) for mounting two units side by side in full rack .

2 - 11

Page 40

XTC/C - XTC/2 Operating Manual

2.4.2 XTC/2 Display Description

Figure 2-7 XTC/2 Display

1 23

20

19

18

17

16

15

14

4

5

6

7

8

910111213

1— RATE DISPLAY GROUP

Indicates the deposition or etching rate in Å/sec or the version level of the

installed firmware when the LIFE key is pressed and display is in the

Operate mode. When the display is in the Program mode , it is used to

display and enter the values of parameters requiring three significant digits.

2— COMMUNICATIONS & TEST GROUP

A message area that:

a. Indicates that the I/O has been put into external communication control

through the R-15 through R-18 commands.

b. The instrument is in TEST mode, see section 3.6 on page 3-11.

c. The in strument is send ing or receiving an exte rnal comput er

COMMunication command.

3— DEPOSITION (ETCH) RATE and THICKNESS SUBGROUP

Indicators and annunciators for parameter entry of starting DEPosition

RATE, film’s FINAL THicKness and an intermediate THicKness SetPoinT.

4— THICKNESS and FREQUENCY GROUP

Indicates the deposited (etched) thickness or the active crystal’s frequency

in KHz when the LIFE key is pressed when the display is in the operate

mode. When the display is in the Program mode i t is us ed to di splay and

enter the values of parameters that require four signific ant digits.

5— RATEWATCHER SUBGROUP

Indicator annunciator and cursor array for the definition of the RateWatcher

parameters when the display is in the Program mode. Used as an indicator

of the SAMPLE and HOLD deposition substrates when the display is in the

Operate mode.

IPN 074-183X

2 - 12

Page 41

XTC/C - XTC/2 Operating Manual

6— RATE DEVIATION GROUP

A graphic annunciator that displays the current deviation of the deposition

rate from the value of the active film’s DEP RATE pa ra me t er. Thi s

annunciator structure is updated each 250ms measurement when the

display is in the Operate mode. A 0% deviation is indicated when the

computed value is less than +/-2%. The plus or minus 10% val ues are

indicated when the computed value is more than +/-10%, resp ectively.

7— ACTIVE CRYSTAL INDICATION GROUP

A graphic annunciator that provid es info rmation con cerning t he prese ntly

active crystal or the availability of backup crystals. Its meaning is somewhat

altered by the instrument’s configuration regarding the crystal switch type,

see section 2.6.2 on page 2-19.

a. If the instrument is configured for "Single Heads", the annunciator will

indicate which sensor is active.

b. If the instrument is configured for "Dual Sensor Head", the annunciator

will display the number representing the active crystal’s "sensor

number." Whenever the instrument is operating with the secondary

(backup) crystal the number of the backup crystal will be flashing as an

indication of the lack of a subsequent backup crystal.

c. If the instrument is configured for one or two CrystalSix, the annunciator

will display the numbers of all crystals of the active sensor’s output that

are "good." The "active" crystal’s number will flash. The absence of all

numbers may also indicate that the switcher is not opera ting.

8— STATUS MESSAGE GROUP

A group of annunciators that provide information conc erning the state of

the instrument.

a. READY — when illuminated the instrument will accept a start command

to begin state processing of the active layer.

b. STOP — when illuminated indicates that the instrument is in the STOP

state, see section 4.3 on page 4-9 and section 4.4 on page 4-10.

c. TIME PW R — when illuminated ind icates that the inst rument is in the

Time-Power state. See section 4.12 on page 4-22 .

d. CONTINUE — when illuminated the instrument will again execute state

IPN 074-183X

processing of the active layer, allowing for any previously accumulated

material, when the ST ART key is pressed. Pressing the RESET key prior

to the ST AR T key reset s the process to layer 1; see section 4.4 on page

4-10.

e. MANUAL —when illuminated the instrument is in the manual power

control mode and the source’s power level is modified by eit her the

optional hand controller or the front panel keys (XTC/2 only).

f. XTAL FAIL — this indicator illuminates when the active crystal has

failed. In the case of instruments configured for dual or CrystalSix

operation it indicates that no further crystals are availab le.

2 - 13

Page 42

XTC/C - XTC/2 Operating Manual

9— POWER and PROCESS GROUP

Indicates the relative source power when the display is in the Operate

mode and displays the % xtal life when the LIFE key is pressed. When th e

display is in the Program mode, these three digits are used for the entry of

some 3 digit film parameter values. It is also used to define the instrument’s

sequencing of multi-layers, see section 2.9 on page 2-36.

10— SENSOR and SOURCE SUBGROUP

The annunciators and cursors for the definition of a film’s:

a. SENSOR # — designates the active or primary (for dual head) sensor

as 1 or 2.

b. SOURCE # — designates the film’s active source control output

as 1 or 2.

c. CRUCIBLE # — de signates the activ e film’s crucible pocket as 1-8,

corresponding to crucible select outputs 1-8. A value of 0 disables th is

parameter and associated outputs; see section 2.6.5 on page 2-24 .

11— CONTROL PARAMETER SUBGROUP

The annunciators and cursors for entering the values used in a film’s Rate

Control algorithm; see section 4.5 on page 4-11.

12— CRYSTAL and PROCESS SUBGROUP

When the display is in the Program mode:

a. the XTAL SWCH parameter ’s values are entered fo r S & Q as labeled.

b. the "FILM #" parameter value defines the particular film’s (1-9) values

being programmed/displayed.

c. The "LYR #" defines the process layer to be assigned a film. This

parameter works with the power and process display group .

When the display is in the Operate mode:

a. "FILM #" parameter value defines the film being executed and the

"LAYER #" parameter value defines the layer being executed.

2 - 14

13— TIMER GROUP

When the display is in the Operate mode, serves as the el apsed time

indicator and unit annunciator. Also displays S & Q values when the LIFE

key is pressed. The values in the S accumulator replace the time display

while the LIFE key is pressed. When the key is released the value of the Q

accumulator is shown for about 1 second. Used for entering and displaying

the value of time-based parameters when the display is in the Program

mode.

14— CALIBRATION SUBGROUP

Annunciators and cursors used when the display is in the Program mode.

Allows conversion of the crystal’s fr equency shift to material thickness; see

section 5.1 on page 5-1 through section 5.4 on page 5-3.

IPN 074-183X

Page 43

XTC/C - XTC/2 Operating Manual

15— CRYSTAL FAIL SUBGROUP

Annunciators and cursors used when the display is in the program mode to

determine tolerated levels of crystal performance a nd subseq uent

instrument actions.

a. TIME PWR Y-N — defines the action taken when a crystal fails; see

section 4.11 on page 4-22.

b. XTAL SWCH S-Q — a two parameter data field used with the digits in

the crystal and process subgroup. These are used to set the level of so ft

crystal failures tolerated; see section 4.6 on page 4-14.

16— POST DEPOSIT SUBGROUP

Annunciators and cursors used to define the source’s post deposition

power levels; see section 4.9.3 on page 4-21.

17— RATE RAMP SUBGROUP

Annunciators and cursors used to define a change in de position rate during

the deposit state; see section 4.7 on page 4-19.

18— DEPOSIT STATE INDICATOR

Annunciator used to indicate that the instrument is exe cuting the de posit

state of the active film; see section 4.1 on page 4-1.

19— PRE DEPOSIT SUBGROUP

Annunciators and cursors used to define the pred eposition source

conditioning when the display is in the Program mode.

a. RISE TIME 1-2 — defines the length of the rise 1 (2) state.

b. SOAK PWR 1-2 — defines the power level(s) of the

soak 1 (2) state.

c. SOAK TIME 1-2 — define s the length of the soak 1 (2) state.

These parameters, together, define a two step source power profile with

linear changes in power between levels as shown graphically in Figure 2-8.

d. SHUTR DLY Y-N — executes (Y) or skips (N) the shutter delay phase;

see section 4.14 on page 4-23.

Figure 2-8 Source Power Level Profile

IPN 074-183X

2 - 15

Page 44

XTC/C - XTC/2 Operating Manual

20— PROGRAMMING and PHASE INDICATOR GROUP

Annunciators and cursors for navigating, displaying and changing a film’s

individual parameter values when the display is in the Program mode.

The annunciators are also used to indicate the cu rrent state of the film

being executed when the display is in the Operat e mode.

2.5 XTC/C Front Panel Description

Figure 2-9 Front Panel XTC/C

1

2

3

4

56 7 8 910

12

11

1— READY

When the associated LED is illuminated the instrument is in the READY T O

START state.

2— PROCESSING

When the associated LED is illuminated the instrument is state executing

a layer. See Figure 4-2 on page 4-2.

3— STOP

When the associated LED is illuminated the instrument is in the STOP

state.

4— XTAL FAIL

When the associated LED is illuminated the measurement crystal has

failed. In the case of units configured for dual or CrystalSix operation it

indicates that there are no further crystals available.

IPN 074-183X

2 - 16

5— RECEIVE

When the associated LED is illuminated the instrument is receiving

information from the connected computer c ontroller.

6— SEND

When the associated LED is illuminated the instrument is sending

information to the connected computer contro ller.

7— CPU

When the associated LED is illuminated the instrument’s computer is not

operating normally.

Page 45

XTC/C - XTC/2 Operating Manual

8— MANUAL

When the associated LED is illuminated the instrument is capable of

responding to power changes as directed by the optional manual power

controller.

9—

Connection for optional manual power and crystal switch hand controller

(IPN 755-262-G1).

10—

Green LED indicates that the unit is connected to an active line power

source and the ON/STBY switch is set to ON.

11 — ON/ S TB Y

Switches secondary power of the instrument between ON and STANDBY.

12—

Optional mounting kit for mounting one instrument in full rack (IPN

757-212-G1) or for mounting two units side by side in full rack (IPN

757-212-G2).

IPN 074-183X

2 - 17

Page 46

XTC/C - XTC/2 Operating Manual

2.6 Rear Panel Description

The rear panel provides the interface for all external conne ctions to the

instrument.

Figure 2-10 Rear Panel

2

3

2.6.1 Power Module

Allows selection of optional voltages, contai ns the instrument fuse and provides

modular connection to line power. Refer to section 2.2 on page 2-4.

Figure 2-11 Power Module

1

4

5

6

891011

7

2 - 18

IPN 074-183X

Page 47

2.6.2 Configuration Switches 1 & 2

Two eight position DIP switches used to customize the instrument as follows.

Figure 2-12 Configuration Switch

CAUTION

The configuration switches are only read on

instrument power up. If an option is changed, the

instrument must be switched to standby and then

powered up.

XTC/C - XTC/2 Operating Manual

IPN 074-183X

2 - 19

Page 48

XTC/C - XTC/2 Operating Manual

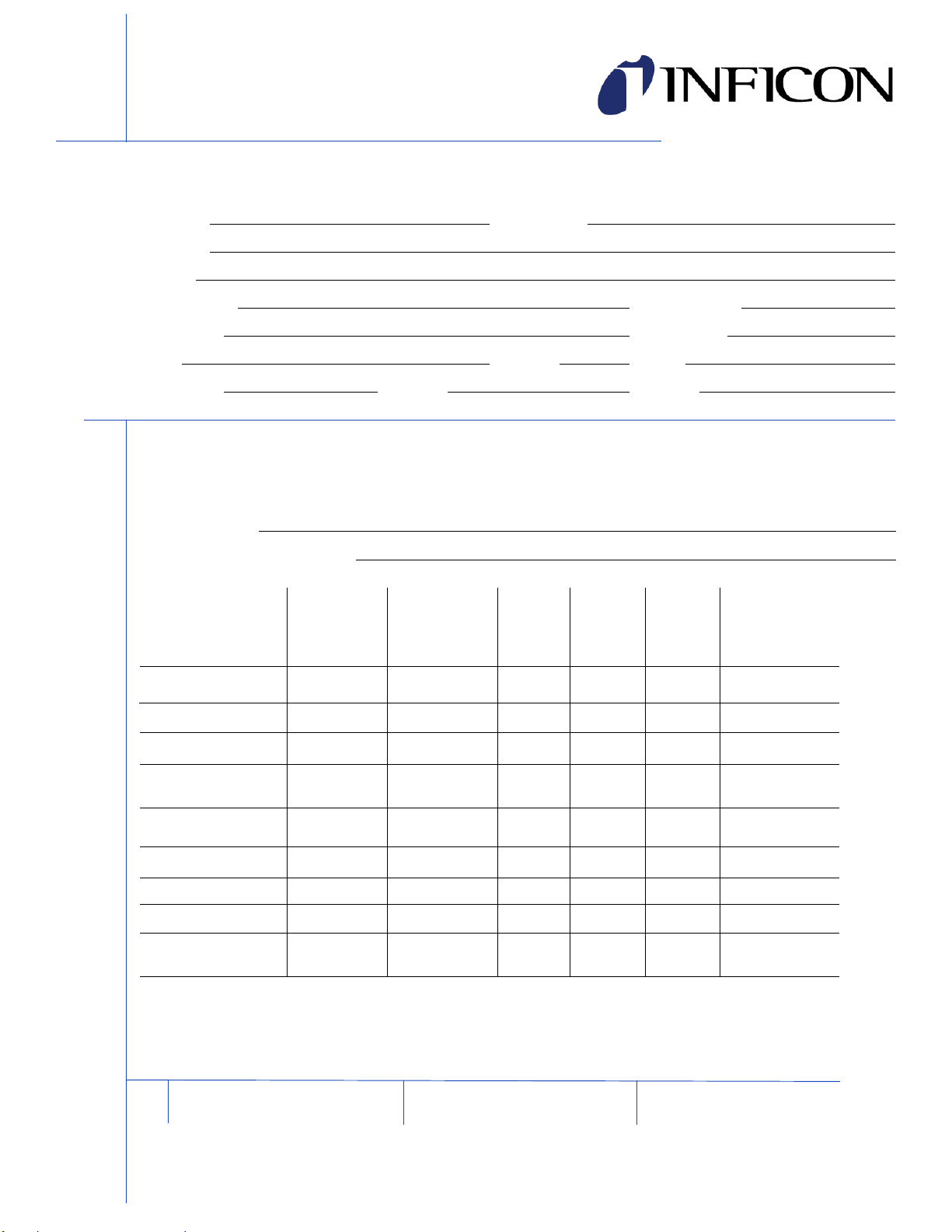

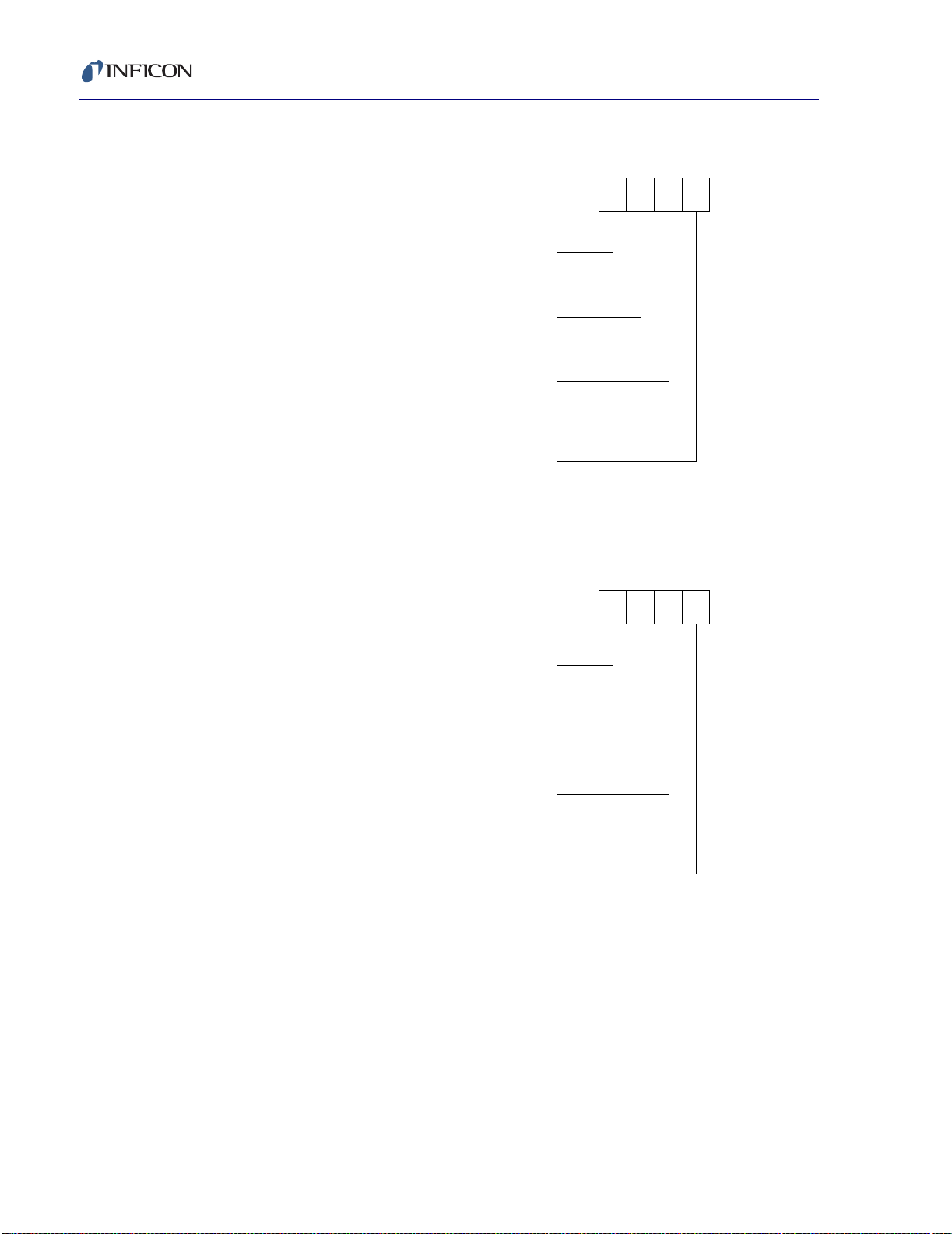

Table 2-2 Configuration Switch Settings

XTC/2 XTC/C

Switch 1 Test Mode (0 = off, 1 = on) Communications

(2

4

)

Address

3

Switch 2 Parameter Lock (0 = off, 1 = on) Communications

(2

)

Address

2

Switch 3 Control Mode (0 = deposit, 1 = etch) Communications

(2

)

Address

1

Switch 4 Stop On Alarms (0 = no, 1 = yes) Communications

(2

)

Address

0

Switch 5 Stop on Max Power (0 = no, 1 = yes) Communications

(2

)

Address

XTC/C Switches 1-5 are only used for the optional IEEE488 (IPN 760-142-G1 or 757-122-G1).

[Addresses 0 to 30 are allowed.]

Switch 6 Recorder Type MSB Communications Protocol

0 = INFICON, 1 = SECS

Switch 7 Recorder Type Baud Rate MSB

Switch 8 Recorder Type LSB Baud Rate LSB

NOTE: for the XTC/2

000 designates Rate, 100 Å/s full scale (unfiltered)

001 designates Rate, 1000 Å/s full scale (unfiltered

010 designates Thickness, 100 Å full scale

011 designates, 1000 Å full scale

100 designates Power %

101 designates Rate Deviation (±50 Å/s)

110 designates Rate 100 Å/s full scale - smoothed

111 designates Rate 1000 Å/s full scale - smoothed

NOTE: for the XTC/C

00 is 9600 baud

01 is 4800 baud

10 is 2400 baud

11 is 1200 baud

Switch 9 Beep On/Off (0=on, 1=off) Checksum (0 = no, 1 = yes)

Switch 10 Backlight Dim (0 = no, 1 = yes) Unused

Switch 11 Start Layer without

backup crystal

(0 = no, 1 = yes) Start Layer

without backup

0 = no, 1 = yes)

crystal

IPN 074-183X

2 - 20

NOTE: See section 4.16 on page 4-26 for description

Page 49

Table 2-2 Configuration Sw itch Settings

XTC/2 XTC/C

XTC/C - XTC/2 Operating Manual

Switch 12 Input Option

Unused

0 = standard

1 = film select

Switch 13 Relay Option

1 = on

Relay 7 = End of Film

Relay 10 = In Process

0 = off

Relay 7 = Thickness Setpoint

Relay 10 = Alarms

1 = on

Relay 7 = End of Film

Relay 10 = In Process

0 = off

Relay 7 = Thickness Setpoint

Relay 10 = Alarms

Switch 14 Crystal Switch Type MSB Crystal Switch Type MSB

Switch 15 Crystal Switch Type LSB Crystal Switch Type LSB

NOTE:

00 designates single head(s)

01 designates one dual head

10 designates one CrystalSix, on SENSOR 1

11 designates two CrystalSixs

Switch 16 Source Control

Voltage polarity 0 = neg, 1 = pos

Source Control

Voltage polarity 0 = neg, 1 = pos

IPN 074-183X

2 - 21

Page 50

XTC/C - XTC/2 Operating Manual

2.6.3 Grounding Stud

Recommended point for connecting the syste m ground strap. Fo r speci fic

recommendations see 3.2, Electrical Grounding and Shielding Requirements.

Figure 2-13 Grounding Stud

2 - 22

IPN 074-183X

Page 51

2.6.4 System I/O

A 25-pin male "D" type connector for interface connection. (See Figure 2-14 on

page 2-24 and section 3.7 on page 3-15 for details.)

Relay# Outputs

*Also used for crystal switch, see section 4.15.1 on page 4-25

Input # Inputs

XTC/C - XTC/2 Operating Manual

Pin # Function

11,2

23,4

35,6

47,8

59,10

Source Shutter 1

Source Shutter 2

Sensor Shutter 1*

Sensor Shutter 2*

STOP