Page 1

Translation of the original operating instructions

XL3000flex

Leak Detector

jina83en1-03-(1809)

Catalog No.

520-200

From software version

V2.72

Page 2

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

Page 3

INFICON Table of Contents

XL3000flex-Operating-instructions-jina83en1-03-(1809) iii

Table of Contents

1 About these instructions ...................................................................................................................................6

1.1 Other associated documents ....................................................................................................................6

1.2 Target groups ...........................................................................................................................................6

1.3 Warnings...................................................................................................................................................6

2 Safety ...............................................................................................................................................................7

2.1 Intended use .............................................................................................................................................7

2.2 Owner requirements .................................................................................................................................7

2.3 Duties of the operator ...............................................................................................................................8

2.4 Dangers ....................................................................................................................................................8

3 Scope of delivery and additional equipment...................................................................................................10

3.1 Accessory list:.........................................................................................................................................10

4 Description......................................................................................................................................................12

4.1 Function ..................................................................................................................................................12

4.2 Operation mode sniffing..........................................................................................................................13

4.3 Device setup ...........................................................................................................................................14

4.4 Technical data ........................................................................................................................................18

4.5 Factory settings ......................................................................................................................................19

4.6 Sniffer line SL3000XL .............................................................................................................................22

4.6.1 Device overview.......................................................................................................................... 22

4.6.2 Operating elements on the handle.............................................................................................. 23

4.7 Touchscreen elements ...........................................................................................................................24

4.8 Elements of the error and warning display .............................................................................................27

5 Operation........................................................................................................................................................28

5.1 Switching the device on ..........................................................................................................................28

5.2 Basic settings..........................................................................................................................................28

5.2.1 Setting the language ...................................................................................................................28

5.2.2 Setting date and time ..................................................................................................................29

5.2.3 Selecting a unit for the leak rate ................................................................................................. 29

5.2.4 Select display unit for pressure................................................................................................... 30

5.2.5 Select interface unit for pressure ................................................................................................30

5.2.6 Operator types and authorizations.............................................................................................. 30

5.2.6.1 Logging out the operator ....................................................................................................31

Page 4

Table of Contents INFICON

iv XL3000flex-Operating-instructions-jina83en1-03-(1809)

5.2.7 Setting the audio alarm ...............................................................................................................32

5.2.8 Cathode Selection....................................................................................................................... 32

5.2.9 Changing the display of the axes................................................................................................ 33

5.2.10 Changing the display of measured values .................................................................................. 34

5.2.11 Displaying Calibration Instructions .............................................................................................. 34

5.2.12 Show calibration request............................................................................................................. 34

5.2.13 Show warnings............................................................................................................................ 34

5.2.14 Automatic switch-off of the touchscreen .....................................................................................35

5.2.15 Changing the display brightness ................................................................................................. 35

5.2.16 Show setpoint ............................................................................................................................. 35

5.2.17 Assigning favorite buttons ........................................................................................................... 35

5.2.18 Selecting the type of expansion module .....................................................................................36

5.2.19 Assigning inputs and outputs ...................................................................................................... 36

5.2.20 Assigning the digital inputs of the I/O module ............................................................................. 39

5.2.21 Assigning the digital outputs of the I/O module........................................................................... 42

5.2.22 Operation mode “Sniffing” ........................................................................................................... 44

5.3 Settings for the measurements...............................................................................................................45

5.3.1 Select gas type (mass) ............................................................................................................... 45

5.3.2 Setting setpoints ......................................................................................................................... 45

5.3.3 Calibrating the device ................................................................................................................. 46

5.3.3.1 Time and general preferences ...........................................................................................46

5.3.3.2 External Calibration Configuration and Start......................................................................47

5.3.3.3 External calibration with sniffer line SL3000XL ..................................................................49

5.3.3.4 Check the calibration..........................................................................................................49

5.3.3.5 Calibration using the external calibration leak test.............................................................50

5.3.3.6 Entering the calibration factor ............................................................................................50

5.3.3.7 Calibration factor sniffing....................................................................................................50

5.3.4 Suppressing gas backgrounds with "ZERO" functions ...............................................................51

5.4 Measuring ...............................................................................................................................................53

5.5 Measurement result display with signal filters ........................................................................................53

5.6 Recording data .......................................................................................................................................55

5.7 Copying measurement data, deleting measurement data ......................................................................56

5.8 Updating the software.............................................................................................................................56

5.8.1 Updating the software of the control unit .................................................................................... 56

5.8.2 Updating the software of the I/O module .................................................................................... 57

Page 5

INFICON Table of Contents

XL3000flex-Operating-instructions-jina83en1-03-(1809) v

5.9 Calling up information .............................................................................................................................58

5.10 Display, save, load parameters ..............................................................................................................61

5.11 Resetting the settings .............................................................................................................................62

6 Installation ......................................................................................................................................................63

6.1 Setup ......................................................................................................................................................63

6.2 IO module - or bus module mounting (optional) .....................................................................................64

7 Warning and error messages .........................................................................................................................66

8 Cleaning and maintenance.............................................................................................................................74

8.1 Cleaning the housing ..............................................................................................................................74

8.2 Maintenance of the XL3000flex ..............................................................................................................74

8.2.1 Change the filter mat of the fan input.......................................................................................... 74

8.2.2 Replacing the fuses .................................................................................................................... 75

8.2.3 Replacing the filter cartridge on the sniffer probe .......................................................................75

8.3 Sending for repair or maintenance .........................................................................................................77

9 Decommissioning the measuring instrument..................................................................................................78

9.1 Sending in the device .............................................................................................................................78

10 CE Declaration of Conformity .........................................................................................................................80

Index...............................................................................................................................................................81

Page 6

1 | About these instructions INFICON

6 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

1 About these instructions

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification

purposes only and belong to the respective owner of the rights.

1.1 Other associated documents

Interface protocols jira54

Bus module BM1000 jiqb10

I/O module IO1000 jiqc10

1.2 Target groups

These operating instructions are intended for the owner and for technically qualified

personnel with experience in leak detection technology and integration of leak

detection devices in leak detection systems. In addition, the installation and use of the

device require knowledge of electronic interfaces.

1.3 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

Page 7

INFICON Safety | 2

XL3000flex-Operating-instructions-jina83en1-03-(1809) 7 / 84

2 Safety

2.1 Intended use

The XL3000flex is a helium or hydrogen leak detector for sniffing detection. With the

device you locate and quantify leaks on test objects.

A test object always contains gas under overpressure. Check the exterior of the test

objects for escaping gas using a sniffer line (sniffing method).

• Operate the device only according to this instruction manual.

• Comply with application limits, see "Technical Data".

Improper use

Avoid the following, non-intended uses:

• Use outside the technical specifications, see "Technical Data".

• Use in radioactive areas

• Use of accessories or spare parts, which are not included in this manual.

• Test of wet or damp test objects

• Sniffing of explosive, aggressive, corrosive, flammable, toxic or reactive

substances

• Sniffing of condensable fluids and vapors

• Sniffing of gases contaminated with particles

• Sniffing gas mixtures with a hydrogen concentration greater than 5%

• Using the device in potentially explosive atmospheres.

• Aspirate liquids into the device via the sniffer line

• Operation at too high ambient temperature

• Searching mains voltage-carrying lines or objects with a sniffer line

• Use of the device as a seat or step

• When lifting the device using the handles, the feet of the device must not point

upwards. Otherwise your hands may get trapped.

• Inserting the sniffer tip into body orifices.

2.2 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employee or third party.

Safety conscious operation

• Operate the device only if it is in perfect technical condition and has no damage.

Page 8

2 | Safety INFICON

8 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

• Only operate the device in accordance with this instruction manual, in a safety and

risk conscious manner.

• Adhere to the following regulations and observe their compliance:

– Intended use

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

Personnel qualifications

• Only have qualified personnel make the basic settings on the device. The handling

of the sniffer line can also be done by laymen according to instructions.

2.3 Duties of the operator

• Read, observe, and follow the information in this manual and in the work

instructions provided by the owner. This concerns in particular the safety

instructions and warnings.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, please contact Customer Service.

2.4 Dangers

The measuring instrument was built according to the state-of-the-art and the

recognized safety regulations. Nevertheless, improper use may result in risk to life and

limb on the part of the user or third parties, or damage to the measuring instrument or

other property may occur.

Hazards due to liquids

and chemicals

Liquids and chemical substances can damage the instrument.

• Comply with application limits, see "Technical Data".

• Do not suck up liquids with the instrument.

• Keep the hydrogen concentration below 5% to prevent ignition.

Dangers from electric

power

There is a danger to life from the contact of conductive parts inside the device.

• Disconnect the device from the power supply prior to any installation and

maintenance work. Make sure that the electric power supply cannot reconnected

without authorization.

The device contains electric components that can be damaged from high electric

voltage.

Page 9

INFICON Safety | 2

XL3000flex-Operating-instructions-jina83en1-03-(1809) 9 / 84

• Before connecting the device to the power supply, make sure that the supply

voltage specified on the device is the same as the local power supply.

Page 10

3 | Scope of delivery and additional equipment INFICON

10 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

3 Scope of delivery and additional

equipment

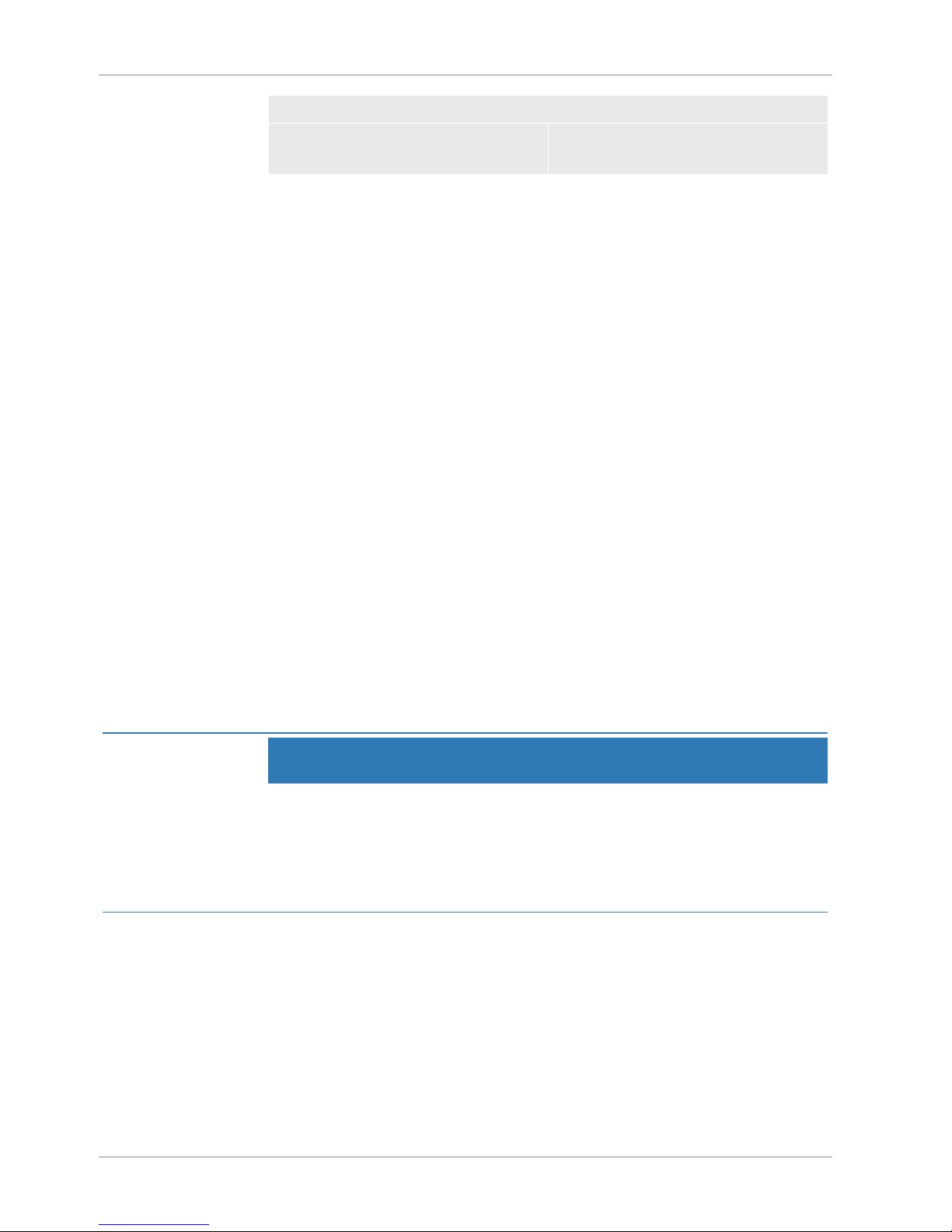

Item Quantity

XL3000flex 1

USB stick 1

Filter set for fans 2

Set of fuses 1

Power supply cable US 1

Power supply cable UK 1

Power supply cable JP 1

Power supply cable EU 1

Goods issue inspection log 1

Touch PIN 1

Operating instructions 1

►

Check the delivery contents after receiving the product to ensure it is complete.

Necessary accessories for operation

For operating the XL3000flex you need a sniffer line SL3000XL. It is available in

various lengths:

- SL3000XL XL, length 3 m, order number 521-011

- SL3000XL XL, length 5 m, order number 521-012

- SL3000XL XL, length 10 m, order number 521-013

- SL3000XL XL, length 15 m, order number 521-014

►

Always store the device in compliance with the technical data, see Technical data

[}18].

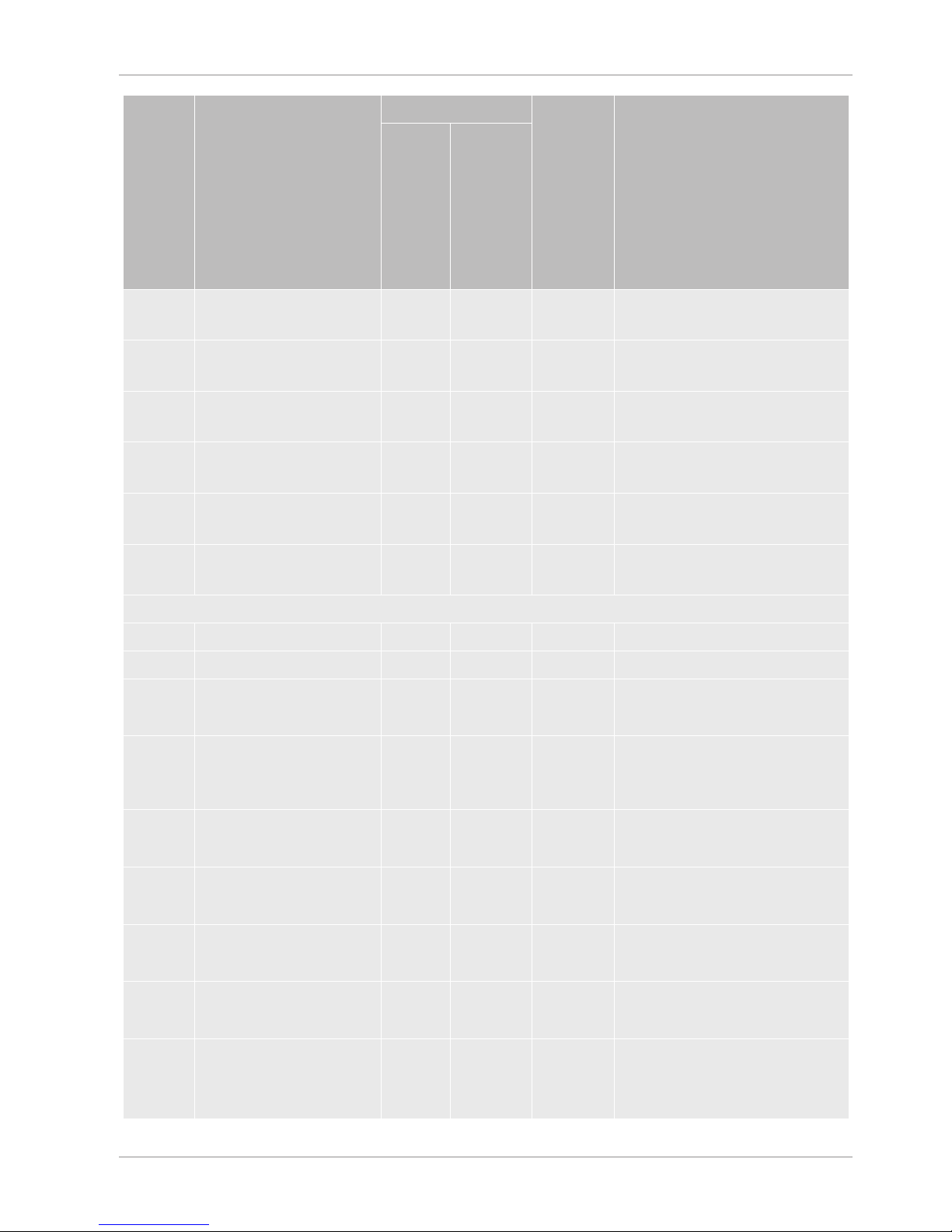

3.1 Accessory list:

The parts listed below can additionally be ordered.

Designation Catalog number

BM1000

Page 11

INFICON Scope of delivery and additional equipment | 3

XL3000flex-Operating-instructions-jina83en1-03-(1809) 11 / 84

Designation Catalog number

BM1000 PROFIBUS 560-315

BM1000 PROFINET IO 560-316

BM1000 DeviceNet 560-317

BM1000 EtherNet/IP 560-318

I/O1000 module, Analog/Digital 560-310

Data cable 0.5 m 560-334

Data cable 5m 560-335

Data cable 10 m 560-340

SL3000XL-3, 3m length 521-011

SL3000XL-5, 5m length 521-012

SL3000XL-10, 10m length 521-013

SL3000XL-15, 15m length 521-014

Adapter customer sniffer line P3000XL 521-015

Oil / Water Protection Tip for SL3000XL 521-016

Filter for Oil/Water Protection Tip 521-017

Sniffer tip ST312XL, 120 mm, rigid, 120 mm, rigid 521-018

Sniffer tip FT312XL, 120 mm, flexible, 120 mm, flexible 521-019

Sniffer tip ST385XL, 385 mm, rigid, 385 mm, rigid 521-020

Sniffer tip FT385XL, 385 mm, flexible, 385 mm, flexible 521-021

Sniffer tip FT250XL, 250 mm, flexible, 250 mm, flexible 521-022

Filter cartridge for SL3000XL (25x) 521-023

Page 12

4 | Description INFICON

12 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

4 Description

4.1 Function

The XL3000flex is a detection device for the tracer gases helium and hydrogen.

The device is designed for leak detection with the SL3000XL sniffer line, which is

available in different lengths. With this sniffer line, you can detect leaks at a greater

distance (high Flow) from the suspected leak if the detection limit has deteriorated and

switch to low flow for more accurate localization.

Digital data can be exchanged via the optionally available I/O module IO1000 or bus

module BM1000.

Page 13

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 13 / 84

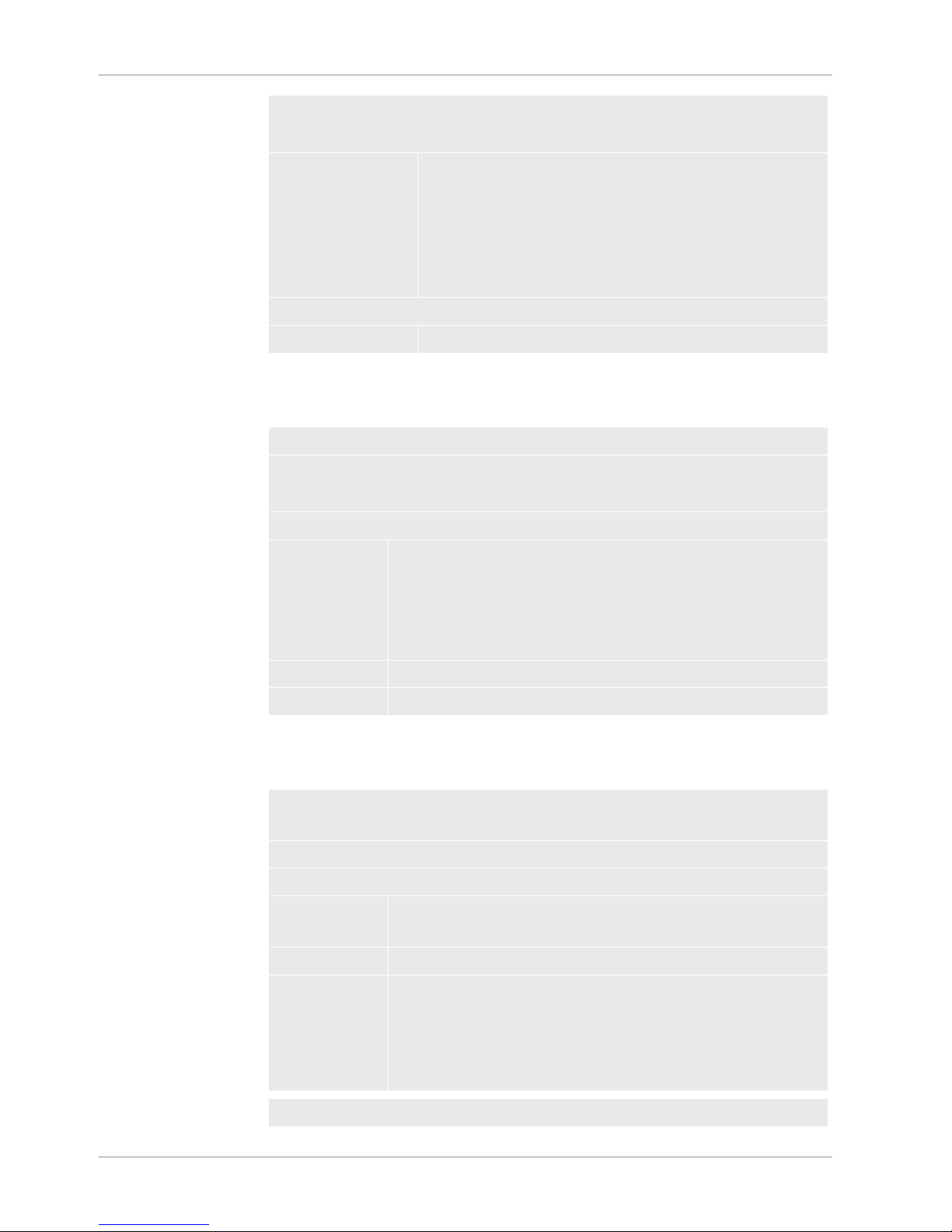

4.2 Operation mode sniffing

The XL3000flex has been developed exclusively for the "sniffing" mode. For operating

you need a sniffer line SL3000XL. It is available in various lengths, see "Scope of

delivery and additional equipment [}10]".

The sniffer line SL3000XL is connected to the connection provided on the front of the

device, see "Device setup [}14]".

Sniffer line SL3000XL

SL3000XL

Detection limit < 2 x 10-7 mbar l/s

Gas flow (low flow / high flow) (300 sccm / 3000 sccm)

Available lengths 3 / 5 / 10 / 15 m

Cable sleeve Plastic

Good-Bad-DIsplay Yes

ZERO via button Yes

Connection on the device via a separate sleeve on

the front of the device

Display with measurement view Yes

Acknowledge faults via buttons on the sniffer probe Yes

End standby via a button on the sniffer probe Yes

Acknowledge calibration via a button on the sniffer

probe

Yes

Page 14

4 | Description INFICON

14 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

4.3 Device setup

Front view

1

2

3

4

5

6

1 Connection for sniffer line

SL3000XL

4 Speaker

2 Touchscreen 5 Connection for USB stick

3 Area for fixing a holder for the

sniffer line

6 Status LED

Page 15

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 15 / 84

Back view

1

2

3

4

5

6

7

1 Filter ventilator inlet 5 Power cable connection

2 Filter ventilator inlet 6 Mounting screws for a profile rail

(for mounting the I/O module

IO1000 or the bus module,

optional)

3 Device power ON/OFF switch 7 Connection for the data cable of

the I/O module or bus module

4 Electrical fuse

Page 16

4 | Description INFICON

16 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

View from below

1

2

1 filter fan outputs 2 Rubber feet (4 pieces)

Page 17

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 17 / 84

Side handles for transportation

1

1

1 Transport handles

Do not open the device!

Page 18

4 | Description INFICON

18 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

4.4 Technical data

Mechanical data

XL3000flex

Dimensions (L×W×H) 544 x 404 x 358 mm

Weight 37.5 kg

Electrical data

XL3000flex

Power 280 VA

Operating voltage 100 -120 VAC 50/60 Hz

230 VAC 50/60 Hz

Main fuse 2x T6,3 A 250 V

Ingress protection IP 30

Physical data

XL3000flex

Run-up time 150 s

Detectable gases Helium, hydrogen

Detectable masses

4

He, H2, Mass 3 (e.g. H-D, 3He or H3)

Ion source 2 longlife Iridium filaments, Yttrium-oxide

coated

Gas flow

1

• High flow

• Low flow

3000 sccm

300 sccm

Minimum detectable leak rate (MDLR)

• Helium

• High flow

• Low flow

• Forming gas (95/5)

• High flow

• Low flow

2 x 10-6 mbar l/s

2 x 10-7 mbar l/s

2 x 10-6 mbar l/s

2 x 10-7 mbar l/s

Response time

Page 19

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 19 / 84

XL3000flex

• High flow

• Low flow

< 1 s

< 1 s

1

Measured at 1 atm (1013 mbar) at sea level. The gas pressure changes with

atmospheric pressure and thus also with the geographical altitude.

Ambient conditions

XL3000flex

Permissible ambient temperature (during

operation)

10 °C ... 40 °C

Max. altitude above sea level 2000 m

Max. relative humidity above 40 °C 50%

Max. relative humidity from 31 °C to 40°C80% ... 50% (decreasing linearly)

Max. humidity up to 31 °C 80%

Storage temperature -20 °C ... 60 °C

Pollution degree 2

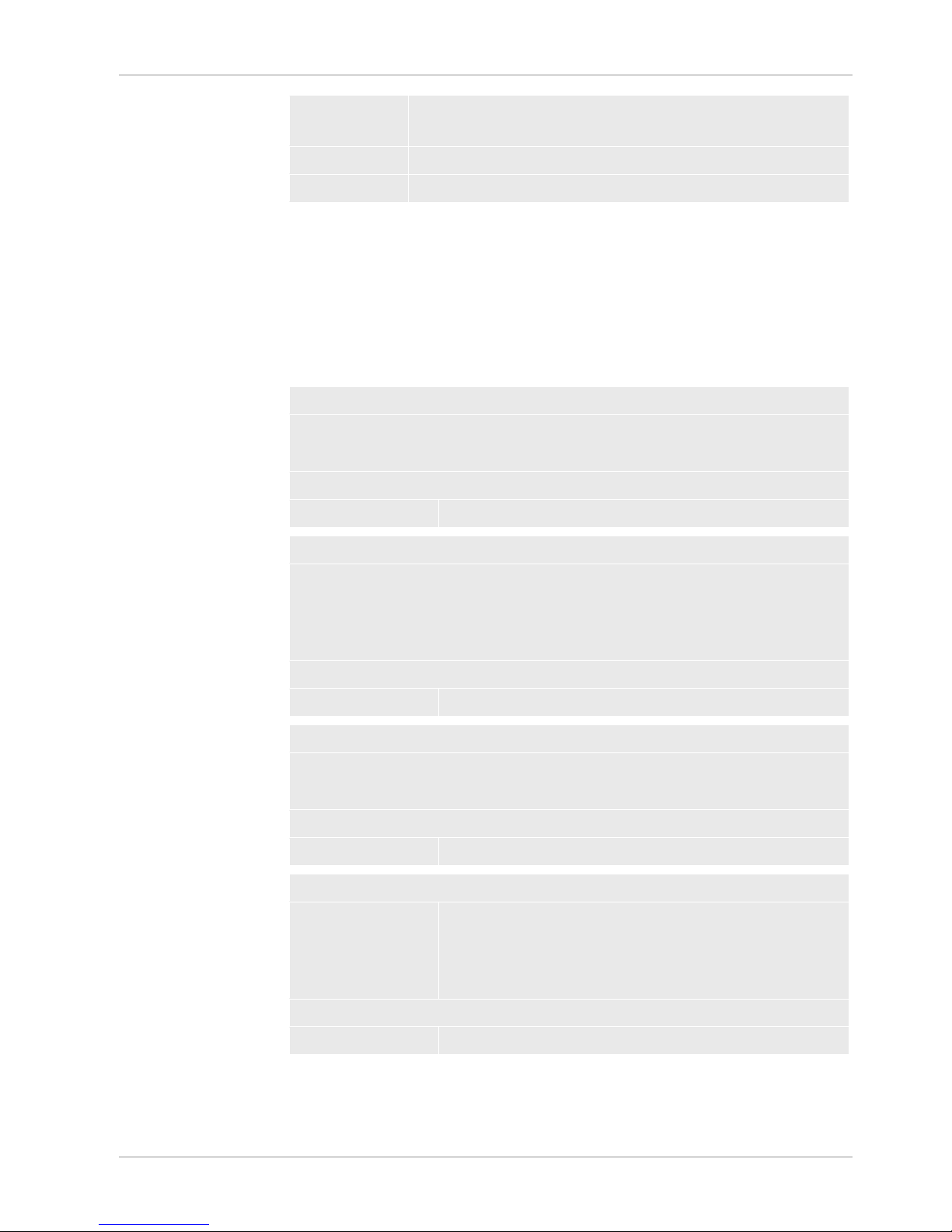

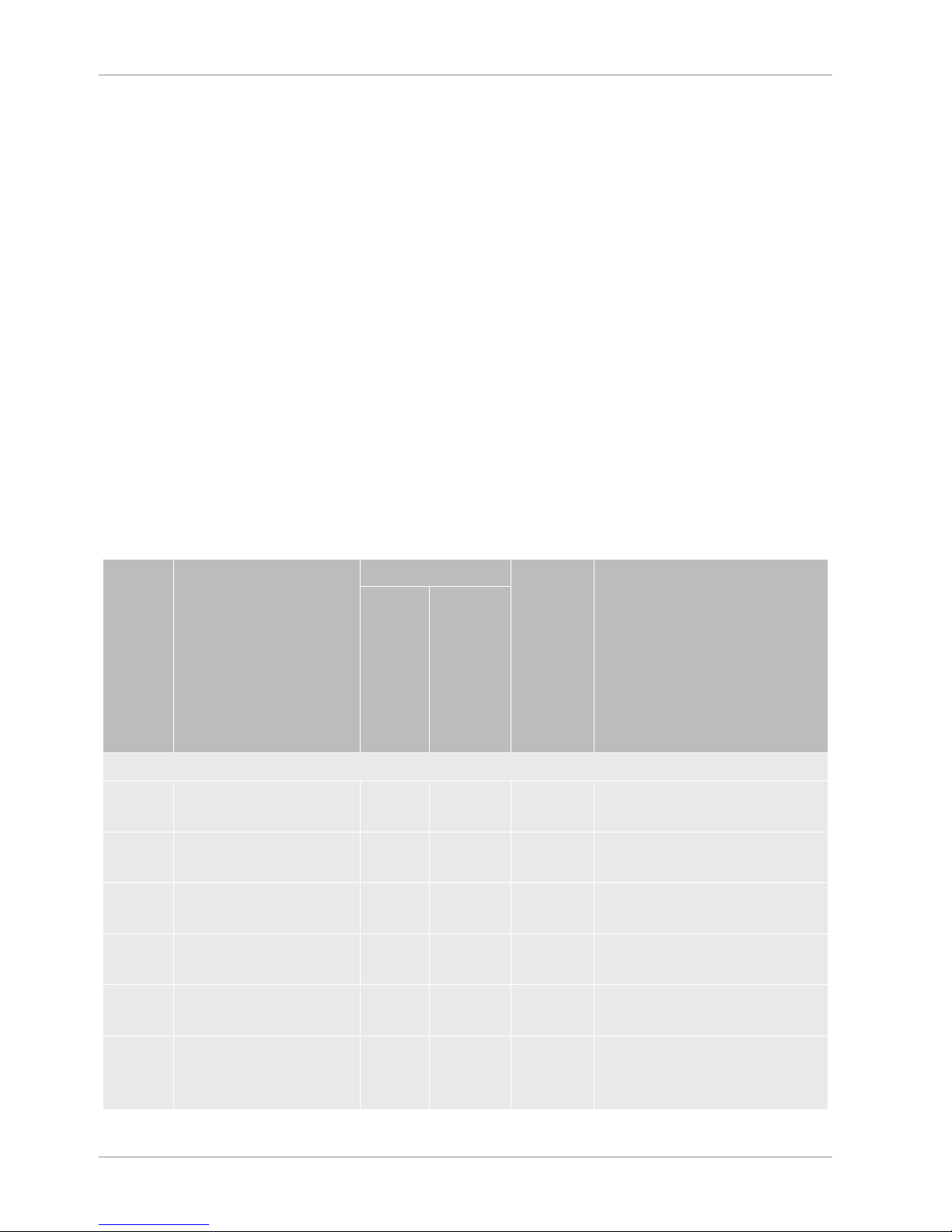

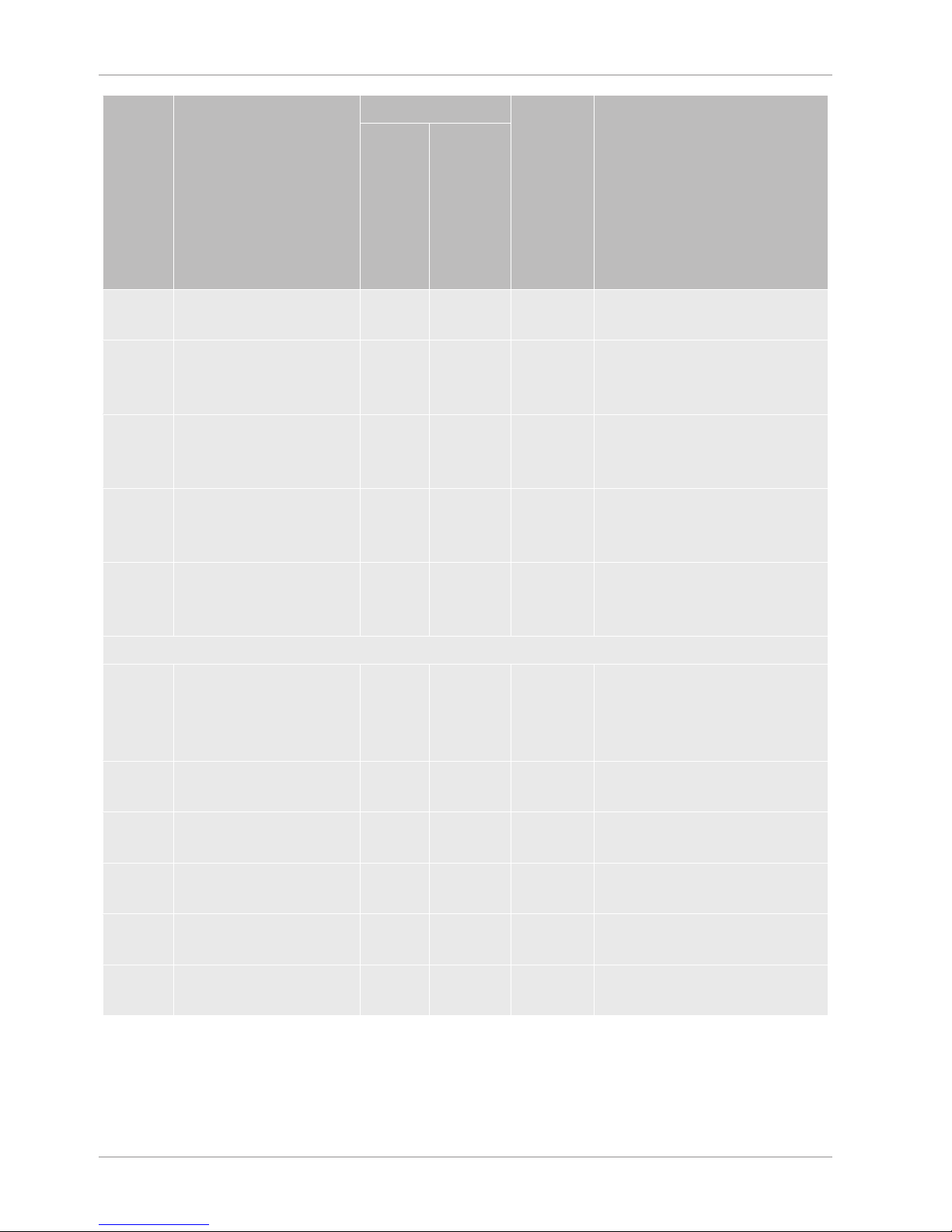

4.5 Factory settings

The following table shows the factory settings in the "Sniffing" mode.

Parameter Factory setting

AO upper limit exp. 1 x 10

-5

Operation mode XL Sniffer Adapter

Bus module address 126

Pressure capillary blocked

(Low Flow) 0.2 mbar

Pressure capillary broken

(Low Flow) 0.6 mbar

Clogged pressure capillary monitoring

- with XL Sniffer Adapter (High Flow) 150 mbar

Broken pressure capillary monitoring

- with XL Sniffer Adapter (High Flow) 400 mbar

Pressure unit (interface) mbar

Emission On

Filter leak rate threshold 1 x 10

-10

Page 20

4 | Description INFICON

20 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

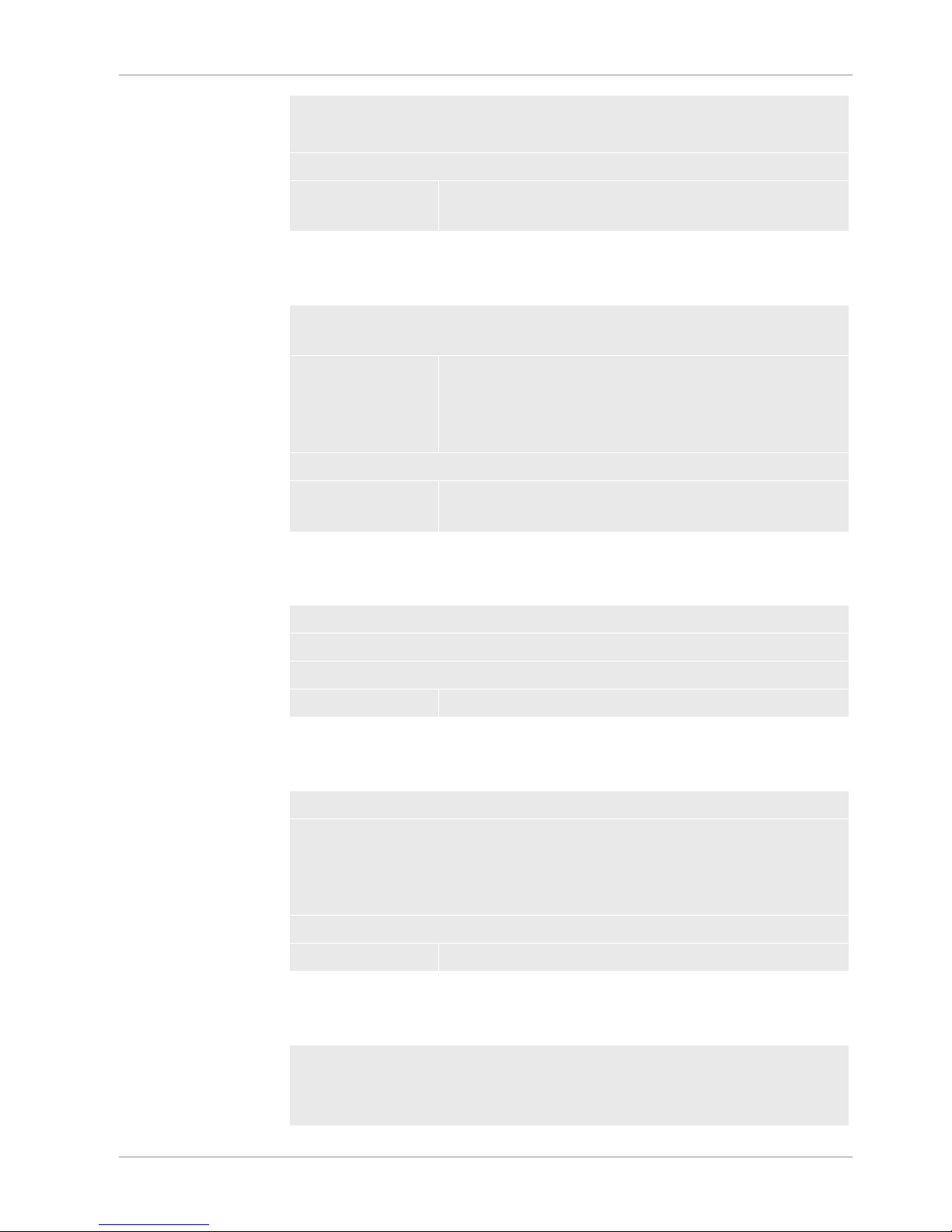

Parameter Factory setting

Filter ZERO time 5 s

Filter mode I-Filter

Gas percentage in H2 (M3, He) 5 % H2 , 100 % M3, 100% He

Gas ballast Off

I/O module log ASCII

Calibration request On

Calibration factor VAC/SNIF Mx

(for vacuum, sniffing and all masses)

1.0

Cathode selection Auto Cat1

Compatibility mode XL Sniffer Adapter

Config. Analog output 1 Leak rate mantissa

Config. Analog output 2 Leak rate exponent

Config. Analog output scaling 0.5 V / decade

Configuration of digital outputs Pin 1: Trigger 1, inverted

Pin 2: Trigger 2, inverted

Pin 3: Trigger 3, inverted

Pin 4: Trigger 4, inverted

Pin 5: Ready

Pin 6: Error, inverted

Pin 7: CAL request, inverted

Pin 8: Open, inverted

Configuration of digital Inputs Pin 1: Select dyn. / normal CAL

Pin 2: Sniff

Pin 3: Start/Stop, inverted

Pin 4: ZERO

Pin 5: External CAL

Pin 6: Internal CAL

Pin 7: Clear

Pin 8: ZERO update

Pin 9: –

Pin 10: –

Leak rate unit SNIF, (display and

interface)

mbar l/s

Leak rate unit VAC, (display and

interface)

mbar l/s

Leak rate upper limit VAC (interface) 1.0 x 10

4

Leak rate lower limit VAC (interface) 1.0 x 10

-12

Leak rate upper limit SNIF (interface) 1.0 x 10

4

Leak rate lower limit SNIF (interface) 1.0 x 10

-8

Page 21

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 21 / 84

Parameter Factory setting

Fan mode Fan always on

Machine factor in standby Off

Machine factor / Sniff factor 1.0 (for all masses)

Mass 4

Module on the I/O connection IO1000

Nominal state TMP On

calibration leak external SNIF 9.9 x 10

-2

calibration leak external VAC 9.9 x 10

-2

calibration leak internal 9.9 x 10

-2

Open calibration leak internal Off

Sniffer line detection On

Sniffer LED Alarm Configured Flashing

Sniffer light brightness 5

Sniffer beep Trigger

Sniffer button Flow On

Sniffer key ZERO On

Language English

Muting the beep Off

TMP rotation speed 1000

Trigger level 1 (2, 3, 4) 2 x 10-4 mbar l/s

(1 x 10-5) mbar l/s

Preamplifier test at CAL On

Maintenance warning TMP and diaphragm pump

ZERO with start On

ZERO mode Suppress everything

Page 22

4 | Description INFICON

22 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

4.6 Sniffer line SL3000XL

4.6.1 Device overview

1

2

1 Connection SL3000XL, connection for

the sniffer line on the front

2 The status LED indicates the

operating status. A permanently lit

status LED shows that the sniffer line

is supplied with voltage.

Necessary accessories for operation

For operating the XL300flex you need the sniffer line SL3000XL. It is available in

different lengths (see Scope of delivery and additional equipment [}10]).

See also

2 Scope of delivery and additional equipment [}10]

Page 23

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 23 / 84

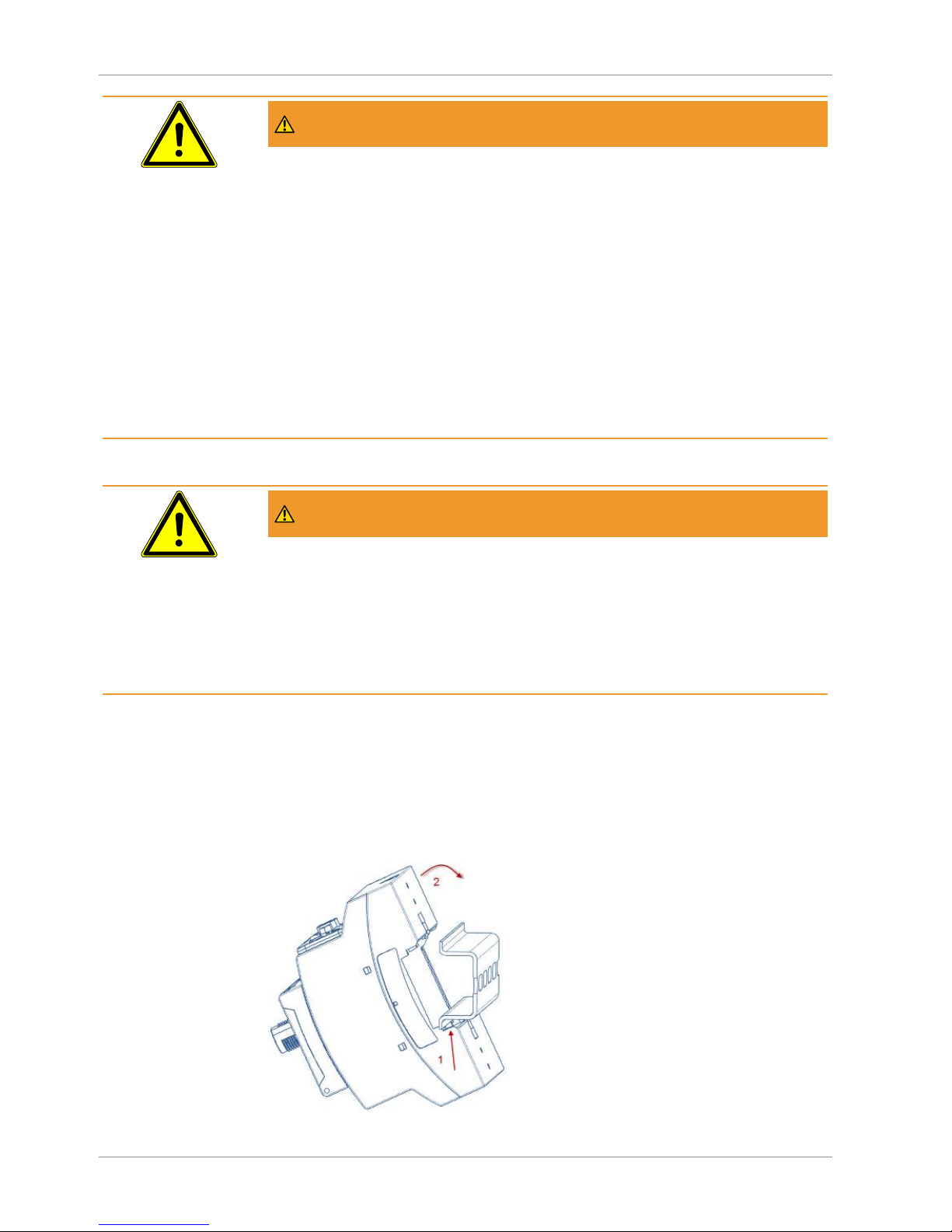

4.6.2 Operating elements on the handle

The display of the handle displays part of the information of the main display.

Fig.1:

Sniffer line SL3000XL

The leak rate is shown as a bar graph and displayed numerically. The unit of

measurement is the same as in the main display.

The display also shows the gas type and the tracer gas concentration. If the

XL3000flex is operated in the high flow operation mode, then the gas type display has

a dark background.

Warning or error messages are shown on the display. The message is confirmed with

the right button. The right button can otherwise be used to switch between low flow

and high flow.

The left button can be used for a ZERO-adjustment: The background display is set

toZERO by pressing the key.

The sniffer probe is equipped with LEDs for work in dimly lit places.

WARNING

Risk of eye damage

LEDs generate a bundled light that can damage your eyes.

► Do not look into the LEDs from a short distance or for longer periods of time.

Page 24

4 | Description INFICON

24 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

4.7 Touchscreen elements

1

2

3

4

5

6

7

1112

13

14

15

8

9

10

Fig.2:

Measurement display

1 Keyboard lock 2 Communication status 3 Operator

4 ZERO 5 Message 6 Tracer gas

7 Operation mode 8 Leak rate with peak hold

function

9 Graphic representation of the

leak rate and the peak hold

function

10 Time axis 11 Button "Favorite 2" 12 Button "Favorite 1"

13 Menu 14 Value axis 15 Value axis

1 - Keyboard lock

The control unit is locked or unlocked by pressing and holding the icon for the

keyboard lock.

2 - Icon for the communication status

• Icon connected: The device communicates with the mass spectrometer module.

Page 25

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 25 / 84

• Icon disconnected: The device does not communicate with the mass spectrometer

module.

Establish communication:

1

Reset control unit.

2

Checking the status of the mass spectrometer module.

3

Check cable connection.

3 - Operator

The registered operator is shown abbreviated.

Display Meaning

Ope Operator

Sup Supervisor

Int Integrator

Ser Service

4 - ZERO

Background suppression is active.

5 - Caution icon

Active warnings are stored in the unit.

The active warnings can be displayed via the menu "Info > History > Warnings".

6 - Tracer gas

Set tracer gas and tracer gas concentration percentage.

Display Meaning

He Helium (4He)

H2 Hydrogen

M3 E.g. H-D, 3He or H

3

7 - Operation mode

Configured operation mode

Display Operation mode

LOW FLOW XL sniffer adapter in LOW FLOW

HIGH FLOW XL sniffer adapter in HIGH FLOW

8 - Leak rate

Current measurement for the leak rate.

Page 26

4 | Description INFICON

26 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

9 - Graph

Graphic display of the leak rate Q(t).

10 - Leak rate

Time axis of the leak rate Q(t).

11 - Button "Favorite 2"

You can assign preferred parameters to this key.

12 - Button "Favorite 1"

You can assign preferred parameters to this key.

13 - Icon for the menu

All functions and parameters of the control unit can be accessed using the "Menu"

key .

A full representation of the menu is included on the supplied USB stick.

14 - Value axis

Value axis of the leak rate Q(t).

15 - Device of measurement

Device of measurement of the value axis.

Page 27

INFICON Description | 4

XL3000flex-Operating-instructions-jina83en1-03-(1809) 27 / 84

4.8 Elements of the error and warning display

Displayed

message

with details

Detailed display

further active

errors or

warnings

(if present)

To the display

further active

errors or

warnings

(if present)

WARNING

Number: 500

Pressure sensor not connected

(Value = 4.23E-2)

Further errors or warnings

To confirm

all messages

Information to

cause or remedy

to the message shown

above

501

502

Page 28

5 | Operation INFICON

28 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

5 Operation

5.1 Switching the device on

►

Turn on the XL3000flex via the power switch on the back of the device, see “Device

setup [}14]“.

ð The system is starting automatically.

ð After the start-up, the green LED on the front cover of the XL3000flex lights up.

5.2 Basic settings

The device is assembled and preconfigured so that basic settings have already been

made.

To check or change settings, first take a look at the factory defaults. See factory

settings of the XL3000flex (Factory settings [}19]).

5.2.1 Setting the language

Select the display language. The factory setting is English. (The display on the

handle of the SL3000XL sniffer line shows messages in English instead of in

Russian and Chinese.)

German

English

French

Italian

Spanish

Portuguese

Russian

Chinese

Japanese

Control unit Main Menu > Settings > Setup > Control unit >

Language

LD protocol Command 398

ASCII protocol *CONFig:LANG

Page 29

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 29 / 84

5.2.2 Setting date and time

Setting the date

Format: DD.MM.YY

Control unit Main Menu > Settings > Date/Time > Date

LD protocol Command 450

ASCII protocol *HOUR:DATE

Setting the time

Format: hh: mm

Control unit Main Menu > Settings > Date/Time > Time

LD protocol Command 450

ASCII protocol *HOUR:TIME

5.2.3 Selecting a unit for the leak rate

Leak rate unit display

Selecting the leak rate unit in the display for vacuum sniff

0 mbar l/s (factory setting)

1 Pa m3/s

2 atm cc/s

3 Torr l/s

4 ppm

5 g/a

6 oz/yr

Control unit Main Menu > Display > Units (Display) > Leak Rate Unit SNIF

LD protocol Command 396 (sniffing)

ASCII protocol Command *CONFig:UNIT:SNDisplay

Leak rate unit interface

Selecting the leak rate unit of the interfaces for sniff

0 mbar l/s (factory setting)

1 Pa m3/s

2 atm cc/s

3 Torr l/s

4 ppm

5 g/a

6 oz/yr

Page 30

5 | Operation INFICON

30 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

Control unit Settings > Set up > Interfaces > Units (interface) > Leak rate unit

SNIF

LD protocol Command 432 (sniffing)

ASCII protocol Command *CONFig:UNIT:LRSnif

5.2.4 Select display unit for pressure

Device of pressure

mbar

Pa

atm

Torr

Control unit Main menu > Display > Units (display) > Pressure unit

5.2.5 Select interface unit for pressure

Pressure unit

interface

Selecting the pressure device of the interfaces

0 mbar (factory setting)

1 Pa

2 atm

3 Torr

Control unit Main Menu > Settings > Setup > Interfaces > Units (Interface) >

Pressure Unit

LD protocol Command 430 (sniffing)

ASCII protocol Command *CONFig:UNIT:Pressure

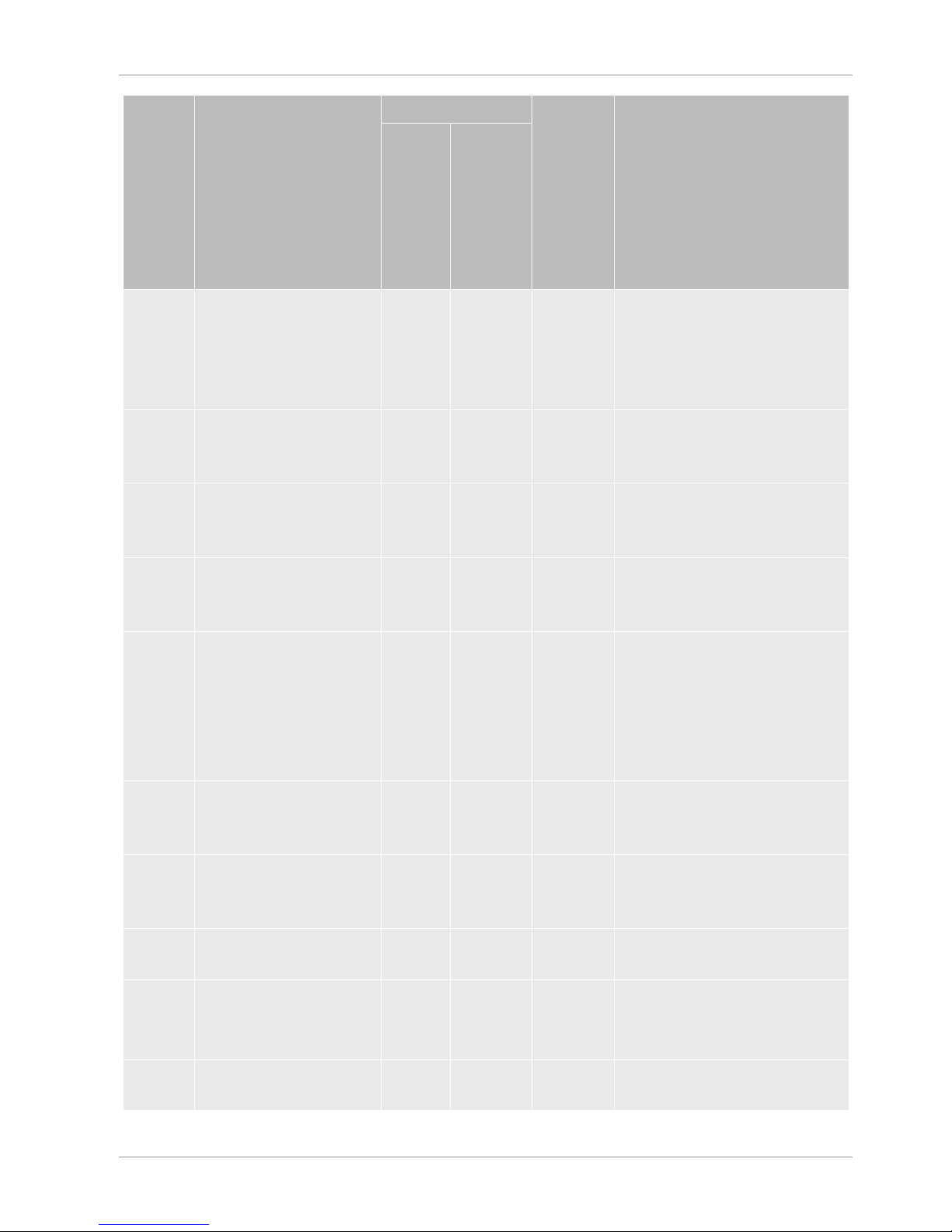

5.2.6 Operator types and authorizations

There are four different operator types that are distinguished by different

authorizations. The integrator is registered ex works.

Additional operators can be registered. The following table shows options for

individual operator types to register new operator types.

Operator registration

Viewer Operator Supervisor Integrator

- Operator

Viewer

Supervisor

Operator

Viewer

Integrator

Supervisor

Operator

Page 31

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 31 / 84

Viewer Operator Supervisor Integrator

Viewer

For the types "Integrator", "Supervisor" and "Operator", a four-digit PIN must be

assigned during registration (0000 ... 9999). "0000" is assigned to all operators ex

works.

If an operator keeps the pin "0000", this operator will always be registered is during

the start up of the system (without PIN query).

A key-operated switch can be used in addition to a PIN if an I/O module is connected.

The key-operated switch is connected to the I/O module via three digital inputs (see

operating instructions of the LDS3000).

The following table shows the authorizations of individual operator types.

Function Viewer Operator Supervisor Integrator

Changing parameters - x x x

Changing the display

of error information

- x x x

Calling up factory

settings

- - - x

Entering

maintenance history

- - - x

The menu "Service" is accessible only to INFICON service staff.

Display error

information

The type of error information can be set differently for each operator type. The

Integrator always receives the complete information.

Number: Message number

text: Brief description

Info: Expanded message information

• Only numbers

• Number and text

• Number, text and info

Control unit Main Menu > Functions > Data >

Parameter > Error info Viewer (Operator,

Supervisor)

5.2.6.1 Logging out the operator

The operator activates access level "Viewer" to log out. "Access Ctrl > Viewer"

Page 32

5 | Operation INFICON

32 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

5.2.7 Setting the audio alarm

WARNING

Damage to the hearing due to loud audio

The alarm level of the device can exceed 85 dB(A).

► Adjust the volume accordingly.

► Only expose yourself a short time to the alarm.

► Use hearing protection.

Volume of the headphones or active speaker

--- No sound

Proportional: The frequency of the audible signal is proportional to the bar graph

display or diagram height. The frequency range is 300 Hz to 3300 Hz.

Setpoint: The pitch is proportional to the leak rate. The signal sounds if the leak rate

exceeds the selected trigger value.

Pinpoint: The sound of the acoustic signal changes its frequency within a specific

range of leak rates. Range: A decade below the selected trigger threshold up to one

decade above. The sound keeps at a constant low and a constant high frequency

below and above this range, respectively.

Trigger: If the selected trigger threshold is exceeded, a two-pitch signal sounds.

Control unit Main menu > Settings > Set up > Control unit > Audio > Audio

alarm mode

Behavior with warnings or error messages:

If the touch screen shows a warning or an

error, then a two-pitch signal sounds simultaneously.

5.2.8 Cathode Selection

Selecting a cathode

The mass spectrometer includes two cathodes. In the factory setting the device uses

cathode 1. If it is defective, the device automatically switches to the other cathode.

With this setting it is possible to select a certain cathode.

0 CAT1

1 CAT2

2 Auto Cat1 (automatic switching to cathode 2, factory setting)

3 Auto Cat2 (automatic switching to cathode 1)

4 OFF

Page 33

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 33 / 84

Control unit Main menu > Settings > Set up > MS module > Ion source >

Cathode selection

LD protocol 530

ASCII protocol *CONFig:CAThode *STATus:CAThode

5.2.9 Changing the display of the axes

The touchscreen grays out the parameters if

• the user is not authorized to modify the values,

• the older version of the software run by mass spectrometer module LDS3000 does

not support this parameter.

Scaling of the Q(t)axis

Linear or logarithmic

Lin.

Log.

Control unit Main menu > Display > Q(t) axis > Linear or logarithmic

Number of decades with logarithmic view

1

2

3

4

Control unit Main menu > Display > Q(t) axis > Decades

Autoscale

Off

On

Control unit Main menu > Display > Q(t) axis > Automatic scaling

Scaling of the time axis

Scaling of the time axis

15 s

30 s

60 s

120 s

240 s

480 s

960 s

Control unit Display > Time axis > Time axis scale

Page 34

5 | Operation INFICON

34 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

5.2.10 Changing the display of measured values

Measured value

display

Type of graphic display

Line graph

Bar graph

Control unit Main menu > Display > Measurement display > Measured

view

Numeric representation of the measurements

Off

On

Control unit Main menu > Display > Measurement display > Measured

view

5.2.11 Displaying Calibration Instructions

Suppress or allow the calibration note with the following content:

• Leak rate of the applied calibration leak

• No calibration should take place during the first 20 mins

OFF (suppressed)

ON (allowed)

Control unit Main menu > Settings > Set up > Control unit > Messages >

Displaying Calibration Instructions

5.2.12 Show calibration request

The calibration request can be allowed or suppressed.

OFF (suppressed)

ON (allowed)

Control unit Settings > Set up > Control unit > Messages > Show

calibration request

5.2.13 Show warnings

Warnings and error messages can be displayed on the touch screen.

Page 35

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 35 / 84

Off

On

Control unit Main menu > Settings > Set up > Control unit > Messages >

Show warnings

5.2.14 Automatic switch-off of the touchscreen

The touch screen can be switched off automatically after a specific time without any

operation to save energy.

30 s

1 min

2 min

5 min

10 min

30 min

1 h

∞ (=never)

Control unit Main menu >Settings > Set up > Control unit > Energy >

Display off after

5.2.15 Changing the display brightness

Display brightness

20 ... 100%

Control unit Main menu > Display > Brightness > Display brightness

5.2.16 Show setpoint

Selection of the trigger (leak rate threshold) displayed on the touchscreen.

1

2

3

4

Control unit Main menu > Settings > Trigger > Trigger sel.

5.2.17 Assigning favorite buttons

The favorite buttons offer direct access to individual functions. They can be assigned

with access control "Supervisor" or higher by the user.

Favorite 1: Center button

Page 36

5 | Operation INFICON

36 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

Favorite 2: Right button

Favorite 3: Button at the bottom right of the main menu.

CAL

ZERO

Measurement view

Start/Stop

View settings

Volume

- - - (= without function)

Check CAL

Flow switching

Control unit Main menu > Settings > Favorites > Favorite 1 (2, 3)

5.2.18 Selecting the type of expansion module

Selecting the

expansion module

Selecting the type of module connected to the I/O connection

I/O module

Bus module

Control unit Main Menu > Settings > Setup > Interfaces > Device select. >

Module on I/O connection

or

Main Menu > Settings > Setup > Accessories > Device select. >

Module on I/O connection

LD protocol –

ASCII protocol –

5.2.19 Assigning inputs and outputs

Assigning analog

outputs of the I/O

module

The analog outputs of I/O module IO1000 can with assigned with different

measurement value displays.

Possible functions: see the following table

Control unit Main Menu > Settings > Set up > Interfaces > I/O module >

Analog outp. > Config. Analog outputs 1/2

LD protocol Commands 222, 223, 224

ASCII protocol Command *CONFig:RECorder:LINK1

Command *CONFig:RECorder:LINK2

Command *CONFig:RECorder:SCALE

Command *CONFig:RECorder:UPPEREXP

Limit values can be defined for the output voltages.

Page 37

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 37 / 84

SNIF: Min. 1 x 10-9...1 x 10-1 mbar l/s

Max. 1 x 10-8...1 x 10-1 mbar l/s

Control unit Main Menu > Settings > Set up > Interfaces > LR limits

LD protocol Command 227 (Snif)

ASCII protocol Command *CONFig:LIMITS:SNIF

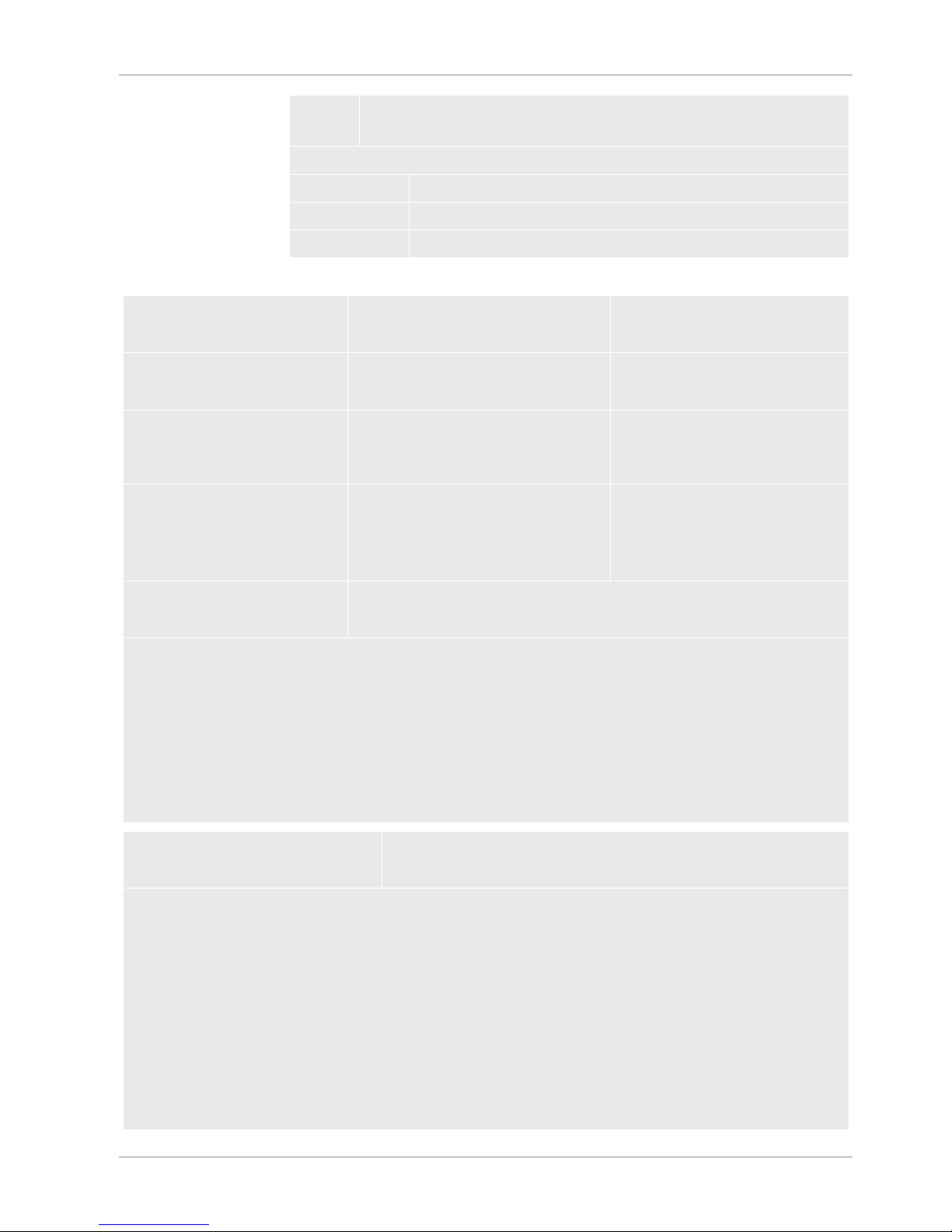

Functions, assignment of analog outputs:

Off The analog outputs are switched off

(Output voltage = 0 V).

Pressure p1 / Pressure p2 1 ... 10 V; 0.5 V / decade;

1 V = 1 x 10-3 mbar

Leak rate mantissa 1 ... 10 V; linear; in the selected unit Useful only if the other analog

output is assigned "Leak rate

exponent".

Leak rate exponent 1 ... 10 V; 0.5 V / decade;

Step function;

1 V = 1 x 10

-12

; in selected unit

Useful only if the other analog

output is assigned “Leak rate

mantissa” or “Leak rate ma. Hys."

is occupied.

Linear leak rate x... 10 V; linear;

in the selected unit

The upper limit (= 10 V) is set via the parameter "Upper limit exponent". The lower value is always 0 (leak

rate), which corresponds to 0 V output voltage. The exponent of the upper limit can be set in entire decades,

such as 1x10-4 mbarl/s.

Settings > Set up > Interfaces > I/O module > Analog scale > AO exponent upper limit.

This setting is for both analog outputs, if an appropriate output function is selected. Depending on the selected

leak rate unit there is a different absolute limit.

The selected range can be additionally narrowed by the limits, which is valid for all interfaces, see above.

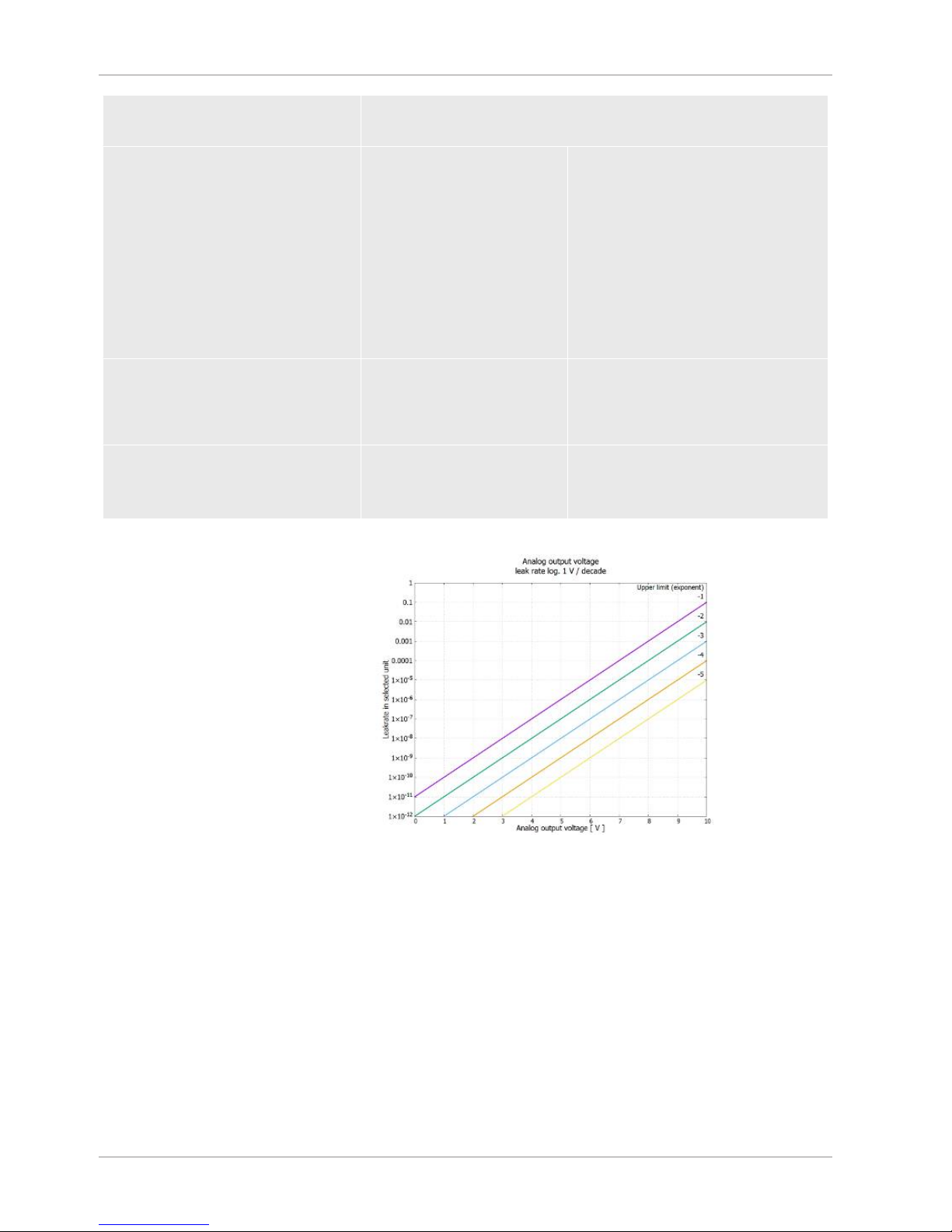

Leak rate log. x... 10 V; logarithmic;

in the selected unit

The upper limit (= 10 V) and the scale (V / decades) are set via the parameters "Upper limit exponent" and

"Scale for leak rate". For example:

Upper limit set to 1x10-5mbarl/s (=10 V). Scale set to 5 V / decade. Lower limit is at 1x10-7mbarl/s (=0 V).

The logarithmic output function of both the slope in V / decade as well as the upper limit (10 V limit) can be set.

This results in the minimum displayable value. The following slopes are available: 0.5, 1, 2, 2.5, 3, 5, 10 V/The

higher the selected slope value, the smaller the displayable area. The logarithmic settings are the most useful

when several decades can be displayed, so a setting of <10 V / decade. The upper limit is the same for both

analog outputs. In both of the following figures the 1 V / decade and 5 V / decade with different upper limit

settings are exemplified. Depending on the selected leak rate unit there is a different absolute limit. The

selected range can be additionally narrowed by the limits, which is valid for all interfaces, see above.

Page 38

5 | Operation INFICON

38 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

Set by interface The output voltage can be specified for tests with the LD log command

221.

Leak rate Ma. Hys. 0.7 ... 10 V; linear;

in the selected unit

Useful only if the other analog output

is assigned "Leak rate exponent".

Through an overlap of the mantissa in

the range 0.7 to 1.0, a constant

jumping between two decades is

prevented. 0.7 V corresponds to a

leak rate of 0.7 x 10-x. 9.9 V

corresponds to a leak rate of 9.9 x 10

-

x

.

Pressure p1 (1 V / Dec.)/

Pressure p2 (1 V / Dec.)

1 ... 10 V; 1 V / decade;

2.5 V = 1 x 10-3 mbar;

8.5 V = 1000 mbar

Leak rate log. H./

Leak rate exp. Inv.

Special function. Use only on

the recommendation of

INFICON.

Page 39

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 39 / 84

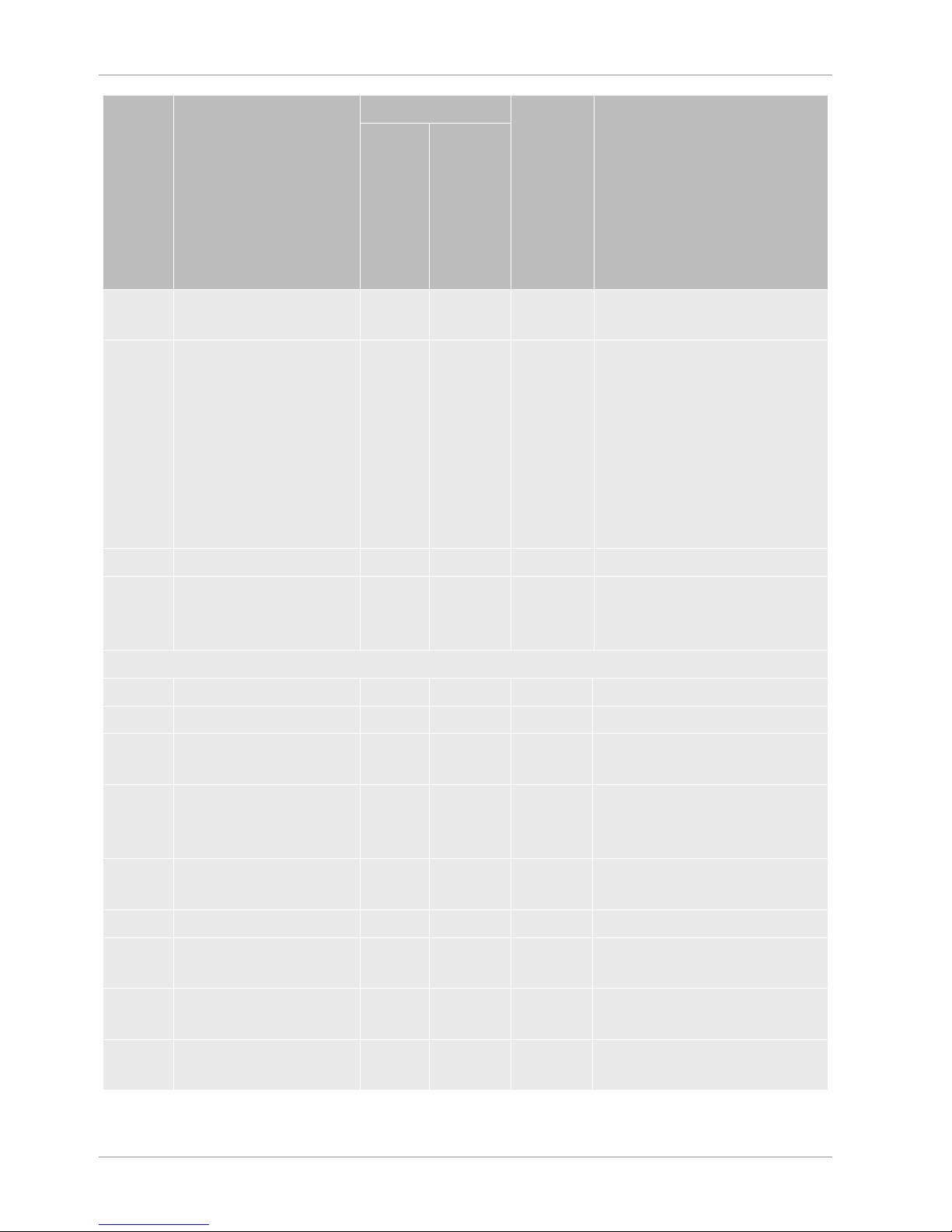

5.2.20 Assigning the digital inputs of the I/O module

The digital inputs PLC-IN 1 ... The available functions can be assigned in any way

necessary to the 10 I/O module.

– Active signal: typically 24 V

– Inactive signal: typically 0 V.

The 24V output of the I/O module can be used as an active signal.

Every function can be inverted.

Possible functions: see the following table

Control unit Settings > Set up > Interfaces > I/O module > Digital inputs >

Configuration PLC Input

LD protocol Command 438

ASCII protocol *CONFig:PLCINLINK:1 (2 ... 10)

Key-operated switch

An external key switch with up to three switching outputs can be connected via three

PLC inputs. The key switch can be used to select the access level of the operator of

the control unit.

Button 1 - Operator

Button 2 - Supervisor

Button 3 - Integrator

Example for a suitable key switch: Hopt+Schuler, No. 444-05

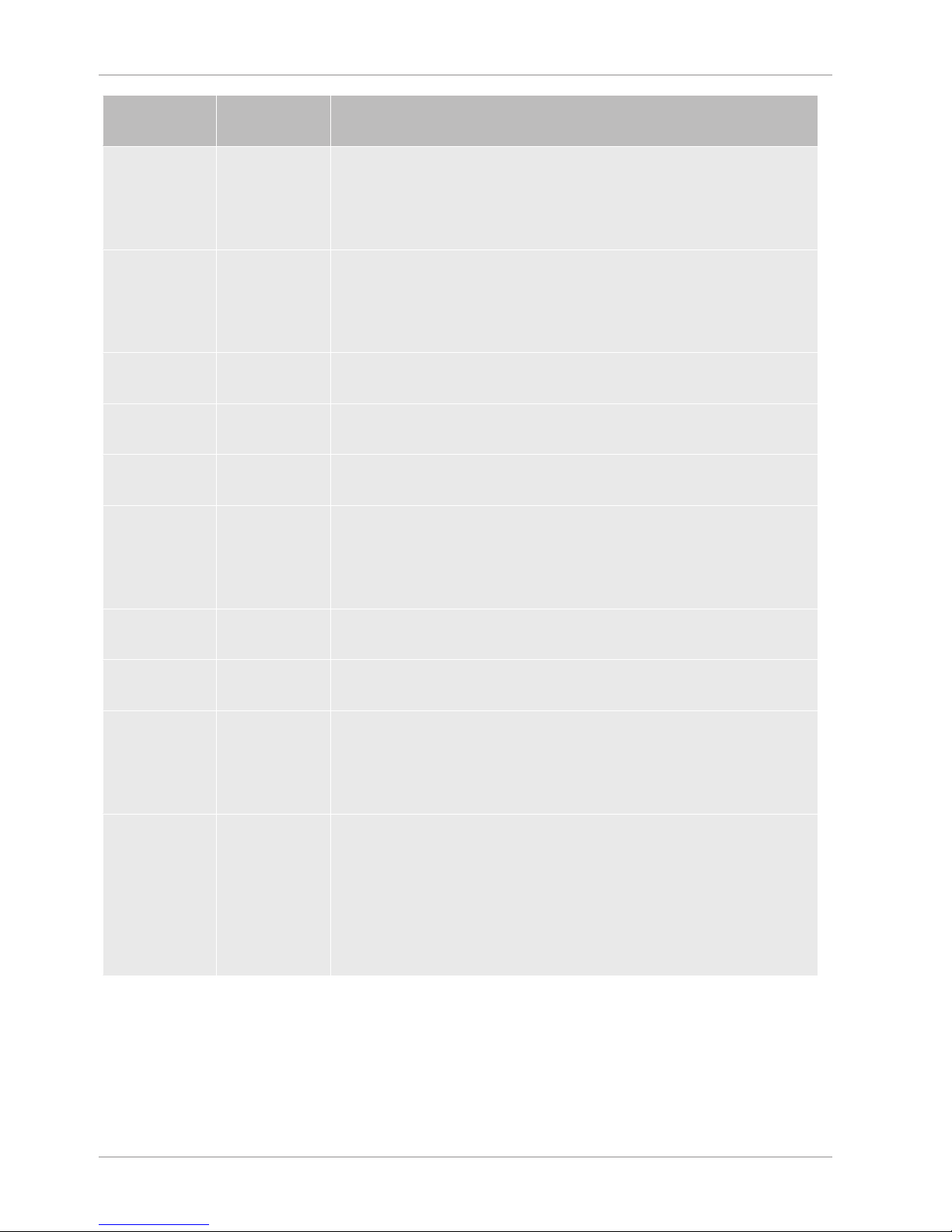

Functions, assignment of digital inputs:

Function Flank/state: Description

No function – No function

Page 40

5 | Operation INFICON

40 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

Function Flank/state: Description

CAL dynam. inactive→

active:

active→

inactive:

Start external dynamic calibration.

Apply value for background and finish calibration.

CAL external inactive→

active:

active→

inactive:

Start external calibration.

Apply value for background and finish calibration.

SNIF/VAC inactive→

active:

Enable sniffer mode.

Start inactive→

active:

Switch to Meas. (ZERO is possible, all trigger outputs switch depending

on the leak rate.)

Stop inactive→

active:

Switch to Standby. (ZERO is not possible, all trigger outputs will return

"Leak rate threshold value exceeded".)

ZERO inactive→

active:

active→

inactive:

Switch ZERO on.

Switch ZERO off.

ZERO pulse inactive→

active:

Switching ZERO on or off.

Delete inactive→

active:

Erase warning or error message / cancel calibration.

Gas ballast inactive→

active:

active→

inactive:

Open gas ballast valve.

Close gas ballast valve unless always open.

Selection dyn/

norm

inactive→

active:

active→

inactive:

External calibration mode with activation of digital input "CAL":

External dynamic calibration (without auto tune, allowing for the

measuring times and pump cycle times set via the digital inputs)

External normal calibration (with auto tune, not considering the system-

specific measuring times and pump cycle times)

Page 41

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 41 / 84

Function Flank/state: Description

Start / Stop inactive→

active:

active→

inactive:

Switch to Meas. (ZERO is possible, all trigger outputs switch depending

on the leak rate.)

Switch to Standby. (ZERO is not possible, all trigger outputs will return

"Fail".)

Key 1 active: User "Operator"

Key 2 active: User "Supervisor"

Key 3 active: User "Integrator"

CAL inactive→

active:

When set to Meas, the device will start an external calibration.

ZERO update inactive→

active:

A new zero word is formed.

XL flow inactive→

active:

active→

inactive:

The XL flow is turned on with the XL Adapter.

The XL flow is turned off with the XL Adapter.

CAL Mach inactive→

active:

Start machine factor calibration

Internal PROOF inactive→

active:

Start the internal Proof function.

External

PROOF

inactive→

active:

Start the external Proof function.

START / STOP

impulse

inactive→

active:

Activate Start or Stop.

ZERO updated inactive→

active:

active→

inactive:

Update or switch on ZERO

No function

Flow inactive→

active:

active→

inactive:

Switch flow of SL3000XL to 3000 sccm (XL adapter)

Switch flow of SL3000XL to 300 sccm (XL adapter)

CAL machine inactive→

active:

Determining the machine factor or of the sniff factor

External CAL

check

inactive→

active:

Check calibration with external calibration leak

Page 42

5 | Operation INFICON

42 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

Function Flank/state: Description

Start / Stop

impulse

inactive→

active:

Switching between measuring operation and standby

Mass 2 / Mass4inactive→

active:

active→

inactive:

Activate mass 4

Activate mass 2

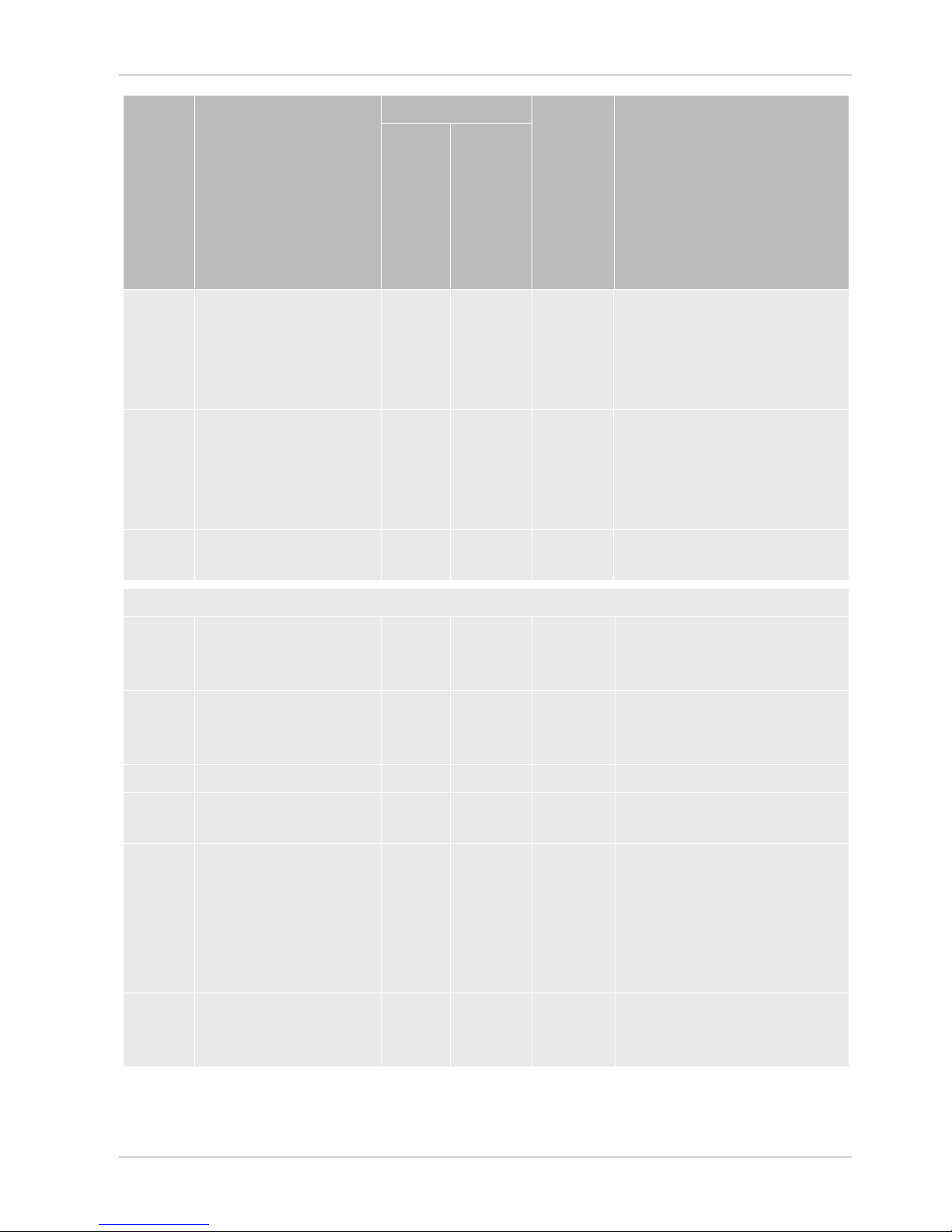

5.2.21 Assigning the digital outputs of the I/O module

The digital outputs PLC-OUT 1 ... The available functions can be assigned in any

way necessary to the 8 I/O module.

Every function can be inverted.

Possible functions: see the following table

Control unit Settings > Set up > Interfaces > I/O module > Digital outputs >

Configuration PLC Output

LD protocol Command 263

ASCII protocol *CONFig:PLCOUTLINK:1 (2 ... 8)

Functions, assignment of digital outputs:

Function State: Description

Open open: always open

Trigger 1 closed:

open:

Value exceeded leak rate threshold Trigger 1

Value fell below leak rate threshold Trigger 1

Trigger 2 closed:

open:

Value exceeded leak rate threshold Trigger 2

Value fell below leak rate threshold Trigger 2

Trigger 3 closed:

open:

Value exceeded leak rate threshold Trigger 3

Value fell below leak rate threshold Trigger 3

Trigger 4 closed:

open:

Value exceeded leak rate threshold Trigger 4

Value fell below leak rate threshold Trigger 4

Ready closed:

open:

Emission switched on, calibration process inactive, no error

Emission switched off or calibration process active or error

Warning closed:

open:

Warning

no warning

Error closed:

open:

Error

no error

Page 43

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 43 / 84

Function State: Description

CAL active closed:

open:

Device is to be calibrated.

Device is not to be calibrated.

CAL request closed:

closed:

open:

and no external calibration: Calibration request (with temperature change from

5°C or 30 minutes after the start-up or if default rotation speed was changed)

and external calibration or "CAL check": Request "Open or close external

calibration leak"

no request

Run-up closed:

open:

Run-up

no run-up

ZERO active closed:

open:

ZERO switched on

ZERO switched off

Emission on closed:

open:

Emission switched on

Emission switched off

Measuring closed:

open:

Measuring (ZERO is possible, all trigger outputs switch depending on the leak

rate.)

Standby or emission disabled (ZERO is not possible, all trigger outputs will

return "Leak rate threshold value exceeded".)

Standby closed:

open:

Standby (ZERO is not possible, all trigger outputs will return “Leak rate

threshold value exceeded”.)

Measuring (ZERO is possible, all trigger outputs switch depending on the leak

rate.)

SNIF closed:

open:

SNIF

VAC

Error or

warning

closed:

open:

Error or warning

No error or warning

Gas ballast closed:

open:

Gas ballast is active

Gas ballast is inactive

Calibration

leak open

closed:

open:

calibration leak is active

calibration leak is inactive

CAL stable closed:

open:

Calibration completed with calibration leak (see "Time and general

preferences")

Assignment not stable or calibration is inactive

Page 44

5 | Operation INFICON

44 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

Function State: Description

Cathode 2 closed:

open:

Cathode 2 is active

Cathode 1 is active

5.2.22 Operation mode “Sniffing”

The device has the sniffer mode with a high flow rate.

For the XL3000flex , only this operation mode makes sense.

Select operation mode

0

1

2

(Not applicable for XL3000flex!)

(Not applicable for XL3000flex!)

Operation mode XL sniffer adapter

Control unit Sniffer mode:

Main Menu > Functions > Start/Stop

LD protocol Command 401

ASCII protocol Command *CONFig:MODE

Page 45

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 45 / 84

5.3 Settings for the measurements

5.3.1 Select gas type (mass)

The machine, calibration and sniff factor are dependent on the configured mass and

are saved in the mass spectrometer module.

2

3

4

H2 (Hydrogen, forming gas)

3

He or deuterated hydrogen (HD)

4

He (Helium) (factory setting)

Control unit Main menu > Settings > Mass

LD protocol Command 506 with value 2 (3, 4)

ASCII protocol Command *CONFig:MASS 2 (3, 4)

5.3.2 Setting setpoints

You can set the leak rate for the setpoint to 1, 2, 3 and 4 separately.

When the setpoints are exceeded:

• If the setpoint 1 or 2 is exceeded, the measurement line in the measurement

window changes color.

• The setpoint relay of the digital output switches, see also "Assigning the digital

outputs of the I/O module [}42]" or the interface description.

Also setpoint 1 defines the trigger point for the different alarms, see also "Change

audio settings".

ü

Operator

or

Supervisor

rights

1

> Trigger

2

Set up.

3

Save .

Page 46

5 | Operation INFICON

46 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

5.3.3 Calibrating the device

5.3.3.1 Time and general preferences

NOTICE

Incorrect calibration because of operating temperature that is too low

If the instrument is calibrated immediately after power-on, it may provide incorrect

measurement results.

► For optimum accuracy the device should have been turned on at least 20 minutes

previously.

The device only needs to be calibrated once per shift for the desired gas. Thereafter

you can switch between the different flows without re-calibrating.

Calibration is also required after the following actions:

• Sniffer line replacement

• Filter change of the sniffer line

• Prompt for calibration by the system

Switching off the

preamplifier test

The device tests the installed preamplifier during calibration. You can switch off of

the amplifier test. This increases the speed of the calibration, but reliability drops off.

0 OFF

1 ON

Control unit Main Menu > Settings > Set-up> MS-module > Preamplifier

> Test > Preamplifier test with CAL

LD protocol Command 370

ASCII protocol Command *CONFig:AMPTest (ON,OFF)

Enabling calibration

request

If Calibration request is enabled, the device will prompt the operator to perform a

calibration 30 minutes after it has been switched on and in case of temperature

changes greater than 5°C.

0 OFF

1 ON

Control unit Main Menu > Functions > CAL > Settings > CAL request. >

Calibration request

Page 47

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 47 / 84

or

Main Menu > Settings > Set-up> CAL request. > Calibration

request

LD protocol Command 419

ASCII protocol *CONFig:CALREQ (ON,OFF)

Calibration warning

Wrn650

The warning message Wrn650 "Calibration within the first 20 minutes is not

recommended" can be allowed or suppressed.

0 OFF (suppressed)

1 ON (allowed)

Control unit Functions > CAL > Settings > CAL request. > Calibration

warning W650

or

Settings > Set-up> CAL request. > Calibration warning

W650

LD protocol Command 429

ASCII protocol *CONFig:CALWarn ON (OFF)

5.3.3.2 External Calibration Configuration and Start

Prerequisite for the calibration with the internal calibration leak is the one-time entry of

the leak rate of the calibration leak.

In Sniffer mode, sniffing with the sniffer line is always performed on the open

calibration leak.

Leak rate of external

calibration leak sniffing

Define the leak rate of the calibration leak you wish to use during calibration.

Calibration will not be possible unless you enter the value here.

A specific leak rate must be set for each gas (mass).

Control unit Main Menu > Settings > Set up > Operation modes > Sniffing

> Ext. calibration leak > Mass 2 (3, 4)

or

Main menu > Functions > CAL > Settings > Ext. calibration

leak (for current mass in selected unit)

LD protocol Command 392

ASCII protocol Command *CONFig:CALleak:EXTSniff (for current mass in

device selected unit)

Page 48

5 | Operation INFICON

48 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

► LD and ASCII protocol: The status must be queried via: Command 260 or

*STATus:CAL

1

Start calibration.

2

Wait until leak rate signal is tuned and stable.

3

Start calibration:

Control unit: Features > CAL > Extern

LD protocol: 4, Parameter 1

ASCII protocol: *CAL:EXT

IO1000: see the figure below.

ð Request to "close calibration leak"

4

Sniffer mode: Remove sniffer line from calibration leak.

ð Leak rate signal decreases.

5

Confirm measured background value is stable:

Control unit: "OK"

LD protocol: 11, Parameter 1

ASCII protocol: *CAL:CLOSED

IO1000 see the figure below.

ð Calibration is completed if:

Control unit: Old and new calibration factor are displayed

LD protocol LD instruction 260 provides 0 (READY)

ASCII protocol: Command *STATus:CAL? provides IDLE

IO1000 see the figure below.

Page 49

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 49 / 84

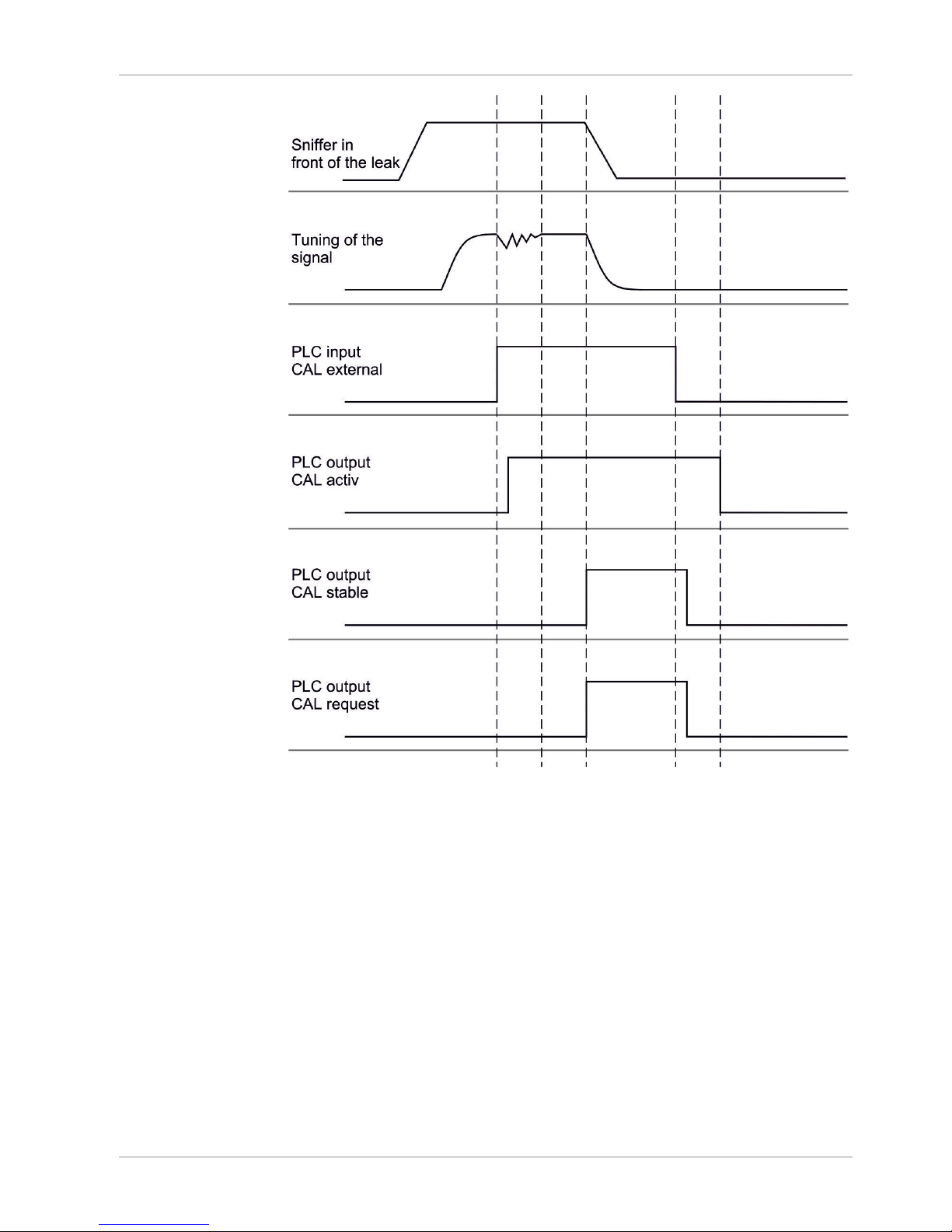

Fig.3:

External calibration with IO1000 using the example of sniffer line SL3000XL, description

of PLC inputs and outputs: "Assigning inputs and outputs [}36]"

5.3.3.3 External calibration with sniffer line SL3000XL

Low flow and high flow must be calibrated separately.

To ensure optimal calibration with hydrogen or forming gas for low flow and high flow,

the calibration leak must meet the following requirements:

– 100 % H2: LR > 1 x 10

-4

– Forming gas (95/5): LR > 2 x 10

-3

For calibration, we recommend our calibration leak with catalog number 12322.

5.3.3.4 Check the calibration

To check whether a re-calibration is necessary, check the already existing.

Page 50

5 | Operation INFICON

50 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

5.3.3.5 Calibration using the external calibration leak test

► LD and ASCII protocol: The status must be queried via: Command 260 or

*STATus:CAL

1

Hold the sniffer line to the test leak.

2

Wait until leak rate signal is tuned and stable.

3

Start test:

Control unit: Functions > CAL > Test ext.

LD protocol: 4, Parameter 5

ASCII protocol: *CAL:PROOFEXT

IO1000 compare figure in "External Calibration Configuration and Start".

ð Request to "close calibration leak"

4

Sniffer mode: Remove sniffer line from calibration leak.

ð Leak rate signal decreases.

5

Confirm measured background value is stable:

Control unit: "OK"

LD protocol: 11, Parameter 1

ASCII protocol: *CAL:CLOSED

IO1000 compare figure in "External Calibration Configuration and Start".

ð Test is completed if:

Control unit: Result is displayed

LD protocol: As with the other steps, the status must be queried

ASCII protocol: As with the other steps, the status must be queried

IO1000 compare figure in "External Calibration Configuration and Start".

5.3.3.6 Entering the calibration factor

The calibration is usually determined by the appropriate calibration routine. Therefore,

it is usually not necessary to adjust the calibration factor manually.

An incorrectly set calibration inevitably leads to wrong leak rate indicator!

5.3.3.7 Calibration factor sniffing

Entry of the calibration factors for masses

2, 3, 4 in low flow and in high flow.

The values will be overwritten during the

next calibration.

"High Flow-" or XL settings are available

only in operation mode "XL Sniffer

Adapter".

Page 51

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 51 / 84

The calibration factors are managed

separately to earth and to "High Flow"

and "Low Flow".

0.01 … 100

Control unit Main Menu > Settings > Set up > Operation modes > SNIF >

Calibration factor

Mass Calibration factor SNIF

2 H2

3 M3

4 He

2XL XL H2

3XL XL M3

4XL XL He

LD protocol Commands 519, 521

ASCII protocol Command *FACtor:CALSniff or *FACtor:CALSXL for the

current mass

5.3.4 Suppressing gas backgrounds with "ZERO" functions

Unwanted sample gases can be suppressed with ZERO. If ZERO is enabled, the

currently measured leak rate value will be interpreted as carrier gas and subtracted

from all subsequently measured values. The background value suppressed by ZERO

is adjusted automatically if the background changes inside the device. The

background value is automatically adjusted depending on the set ZERO time, except

for filter setting I•CAL, see "Measurement result display with signal filters [}53]".

Activating and

deactivating <variable

linkid="658744588"

name="1035">ZERO</

variable>

ZERO aktivate/deaktivate

0 On

1 Off

Control unit Main menu > Function > ZERO > ZERO

LD protocol Command 6

ASCII protocol Command ZERO

Setting ZERO mode

Specified the level of the helium background suppressed by ZERO (not with filter

I•CAL).

0 all decades

1 1 – 2 decades

2 2 – 3 decades

3 2 decades

Page 52

5 | Operation INFICON

52 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

4 3 – 4 decades

5 19/20 of the tracer gas are suppressed

Control unit Main Menu > Settings > ZERO/filter > ZERO > ZERO mode

LD protocol Command 410

ASCII protocol Command *CONFig:DECADEZero

Deactivating the ZERO

key on the sniffer

Deactivation of the ZERO-key (ZERO-alignment) prevents that the measurement is

influenced inadvertently.

0 On

1 Off

Control unit Main Menu > Settings > Setup > Modes > Sniff > Sniffer > Button

> ZERO at startup

LD protocol Command 412

ASCII protocol Command *CONFig:BUTSniffer

Page 53

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 53 / 84

5.4 Measuring

ü The sniffer line SL3000XL is optionally connected to the rear side of the device, see

Device setup [}14]".

ü Possible alternatives to the operating possibilities on the device are set up

(optional):

I/O-Modul or Bus-Modul, see “Accessory list: [}10]“.

1

Switch on the leak detector via the mains switch.

ð After start-up, the device is ready for operation; no special start procedure for

measuring is required.

2

Make sure that the correct basic settings and the settings for the current

measurement are carried out, see “Basic settings [}28]“ and “Settings for the

measurements [}45]“.

3

Make sure that calibration takes place daily.

ð When performing a calibration, note the 20 minute warm-up time, see

“Calibrating the device [}46]“.

4

To measure, hold the sniffer tip close to the possible leak or run it along a weld,

for example.

ð The tip must touch the test object.

ð If the detection limit has deteriorated, you can detect leaks at a greater

distance (high flow) from the suspected leak and switch to low flow using the

right button of the sniffer handle for more accurate location.

5

Track the measurement result either as a line or as a bar graph, see

“Touchscreen elements [}24]".

6

To measure small leak rates more clearly, use the ZERO function. To switch on,

press the ZERO button on the sniffer handle for a longer period (> 5 s), see also

Operating elements on the handle [}23]“.

ð To activate ZERO on the sniffer probe, it must be activated in the menu, see

also Suppressing gas backgrounds with "ZERO" functions [}51]“.

ð If ZERO is switched on, you will see the text ZERO with white background in

the measurement window.

7

Record the measured values if necessary, see "Recording data [}55]" and

"Copying measurement data, deleting measurement data [}56]".

8

Switch the instrument off.

5.5 Measurement result display with signal filters

Select signal filter

With the signal filters, the leak rate indicator regarding slope and noise behaviorcan

be influenced.

Page 54

5 | Operation INFICON

54 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

– Generally select signal filter I-Filter for the operation mode "Sniff".

– If the signal filter should simulate the time behavior of older units, then select filter

"Fixed" or "2-Zone".

I•CAL The leak rates are averaged at time intervals that are optimized

for the range of the leak rates. The algorithm used offers

excellent sensitivity and response time. Use of this setting is

strongly recommended.

fixed The leak rates are averaged at fixed intervals of 0.2 seconds.

2-zone The filter is compatible with LDS1000 and LDS2000. The

averaging period is switched depending on the filter leak rate

threshold.

I-Filter Filter optimized for sniffer mode.

(Default with XL Sniffer Adapter set)

I-Filter slope

suppress.

Same as I-Filter, but with additional slope suppression. The

edge suppression corrects the measurement changes during

the warm-up phase.

Control unit Main Menu > Settings > ZERO/Filter > Filter > Filter mode

LD protocol Command 402

ASCII protocol Command *CONFig:FILTER

Setting the filter leak

rate threshold

Leak rate background in mbar l / s for the averaging period. The averaging period is

10.24 s below this value. Above this value, the averaging period is 160 ms. Setting

applies only to filter "2-stage".

1E-11 ... 9.9E-3

Control unit Main Menu > Settings > ZERO/Filter > Settings > Filter 2-zone

LD protocol Command 403

ASCII protocol Command *CONFig:LRFilter

Setting filter ZERO

time

Update interval for the offset value with negative leak rate signal (except for I•CAL

filter).

Resolution 0.1 s (50 = 5.0 s)

Control unit Main Menu > Settings > ZERO/Filter > Settings filter > ZERO

time

LD protocol Command 411

ASCII protocol Command *CONFig:ZEROTIME

Page 55

INFICON Operation | 5

XL3000flex-Operating-instructions-jina83en1-03-(1809) 55 / 84

5.6 Recording data

The data is saved as a TXT file. Each TXT file contains the following information:

• Date created

• Software version

• Serial number

• Start time

• Time stamp (measurement indicates offset in seconds in relation to start time)

• File name

• Leak rate (expressed in selected unit)

• Pressure p1 (expressed in selected unit)

• Device status

Switching on/off

Switching data recording on/off

• Off

• On

Control unit Main Menu > Functions > Data >

Recorder > Settings > Data recording

Record interval

Time interval between data recordings

• 100 ms, 200 ms, 500 ms, 1 s, 2 s, 5 s

Control unit Main Menu > Functions > Data >

Recorder > Settings > Record interval

Memory location

The data stored in the control unit can be saved to a USB stick. The memory in the

control unit is limited to the recording of a 24-hour measurement.

• USB flash drive

• Control unit

Control unit Main Menu > Functions > Data >

Recorder > Settings > Storage location

Copy data

The data stored in the control unit can be saved to a USB stick. The memory in the

control unit is limited to the recording of a 24-hour measurement.

• USB flash drive

• Control unit

Control unit Main Menu > Functions > Data >

Recorder > Copy > Copy files

Deleting data

The data stored in the control unit can be saved to a USB stick. The memory in the

control unit is limited to the recording of a 24-hour measurement.

• USB flash drive

Page 56

5 | Operation INFICON

56 / 84 XL3000flex-Operating-instructions-jina83en1-03-(1809)

• Control unit

Control unit Main Menu > Functions > Data >

Recorder > Delete > Delete files

5.7 Copying measurement data, deleting

measurement data

The measurement data can be saved to a USB stick, see Device setup [}14].

• "Main Menu > Functions > Data > Recorder > Copy > Copy files"

• "Main Menu > Functions > Data > Recorder > Delete > Delete files”Delete

filesDelete files

5.8 Updating the software

Software updates from INFICON are installed with the aid of a USB flash drive. The

update function of the device can be found under "Functions > Data > Update".

An update is possible,

• if one or several updates are available on the USB-Stick, but only one update per

type at most (control unit, MSB box, I/O module),

• if these parts are also connected free of disturbances and have an update

function.

The corresponding buttons in the update menu such as "Control Unit", "MSB Box",

and "I/O Module" are active and can be activated individually.

NOTICE

Aborted connection

Data loss due to an aborted connection

► Do not switch off the device and do not remove the USB flash drive while the

software is being updated!

►

Switch the device off and back on after a software update has taken place.