Page 1

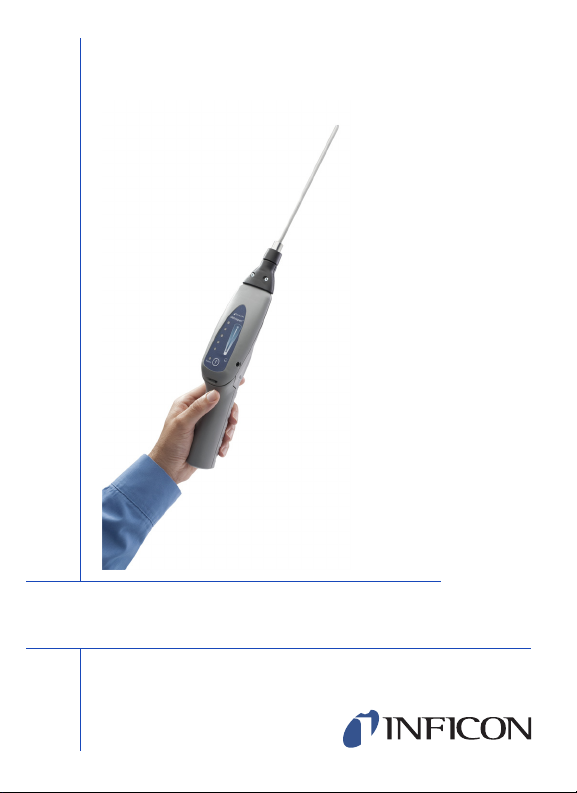

OPERATING MANUAL

Whisper

®

Ultrasonic Leak Detector

Page 2

Declaration Of Conformity

WARNING

This is to certify that this equipment, designed and manufactured by INFICON® Inc., Two

Technology Place, East Syracuse, NY 13057 USA, meets the essential safety

requirements of the European Union and is placed on the market accordingly. It has

been constructed in accordance with good engineering practice in safety matters in force

in the Community and does not endanger the safety of persons, domestic animals or

property when properly installed and maintained and used in applications for which it

was made.

Equipment Description . . . . . . . . . . . Whisper

Applicable Directives . . . . . . . . . . . . . 73/23/EEC as amended by 93/68/EEC

Applicable Standards. . . . . . . . . . . . . EN61010-1: 2001

CE Implementation Date . . . . . . . . . . January 15, 2001

Authorized Representative . . . . . . . . Brian King

Any questions relative to this declaration or to the safety of INFICON’s products should

be directed, in writing, to the quality assurance department at the above address.

This symbol is used to alert the user to the presence of important

operating and maintenance (servicing) instructions in the literature

accompanying this instrument.

INFICON® and Whisper® are trademarks of INFICON GmbH.

© 2011

®

Ultrasonic Leak Detector

2004/108/EC

2002/95/EC (RoHS)

EN61326-2-2:2006

EMC Cl A, Immunity Criteria B

Business Unit Manager, Service Tools

INFICON, Inc.

2

Page 3

Applications

A/C Refrigerant Leaks (Any and all types of refrigerant)

Checking seals around windows, refrigerators, etc. (when using ultrasonic

transmitter)

Diagnosing mechanical equipment such as pistons, solenoids, bearings, etc. (when

using contact probe)

Diagnosing Solenoid Operations

Leaks in Pneumatic Control Systems

Leaks in Compressed Air Systems

Leaks in Vacuum Systems

Steam Traps

Electrical Arcing

Specifications

Sensitivity . . . . . . . . . . . . . . . . . . . . Detects a leak through a 0.004" diameter orifice

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Indoor or Outdoor

Operating temperature range . . . . . . . . . . . . . . . . . +32°F to +122°F (0°C to +50°C)

Storage temperature range . . . . . . . . . . . . . . . . . +14°F to +140°F (-10°C to +60°C)

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85% RH NC Max.

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6500’ (2000 m)

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 "D" cell alkaline batteries

Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Approximately 165 hours

Pollution Degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overvoltage category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Weight (with battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 lb. (680 g)

at 5.0 psig from a 12" distance.

(may be operated for a limited

time in lower temperature

environments)

3

Page 4

Introduction

The Whisper will detect and locate sources of ultrasonic disturbance through the use of

sophisticated circuitry.

An ultrasonic disturbance is created when objects collide. Vacuum leaks create

collisions between molecules flowing through an orifice. Pressure leaks create collisions

between molecules exiting an orifice. All gases and liquids create disturbances if forced

into, or out of, an orifice. All solid materials create disturbances when any friction exists.

The Whisper is therefore capable of detecting and locating sources of ultrasonic

disturbances created by gases, liquids or solids.

The Whisper has different ways of indicating these disturbances. When used without

headphones, the detector's LEDs will illuminate and the unit will beep in response to

sources of ultrasonic noise. When headphones are plugged in, the unit's heterodyne

feature is enabled, bringing ultrasonic frequencies to a range audible to the human ear.

This is likely how you want to use the Whisper most of the time. You can also use the

metal contact probe on solid objects. Please refer to the appropriate sections of this

manual for more information on these features and how to best use them.

General Information

The Whisper is sensitive only to ultrasound (40.5 kHz) and is unaffected by audible

noise.

INTERNAL NOISE CONTROL (I.N.C.) allows the use of this instrument in extremely

noisy environments such as mechanical rooms, around operational chillers, etc. Drag

your finger upwards on the sensitivity touch pad to increase sensitivity when

experiencing little or no environmental noise. Drag your finger downwards on the

sensitivity touch pad to reduce sensitivity in response to an increase in environmental

noise. The I.N.C. works much like a two way radio squelch allowing only the strongest

and closest signals to penetrate the electronic wall built by the I.N.C. circuitry.

Many variables can affect the amount of ultrasound generated by the leakage of gas

through an orifice. Such factors include the pressure/vacuum versus the surrounding

environment, how smooth the edges of the orifice are, the diameter of the orifice, the

leak detector’s distance from the orifice and the presence of airflow, which may dissipate

the ultrasound.

As you use the Whisper, keep in mind that these factors may affect your ability to detect

ultrasonic leaks.

Locating Leaks

NOTE: Bumping the accessory probes or nose piece into objects while seeking leaks

will cause false alarms. Leaks will be indicated by an a beeping audio alarm

and flashing LEDs. Disregard occasional short alarms.

4

Page 5

WARNING

Always keep clear of hot and/or moving engine and machinery parts.

1. Press the Power button to turn the Whisper on. The Whisper will turn on in maximum

2. Point the Whisper in the direction of the suspected leak and scan the area by making

3. If you are using the Whisper without headphones, the Whisper will beep when it

4. Move closer to the suspected leak, continuing the sweeping pattern and narrowing

5. Repair all leaks as located and repeat scan.

Damage or injury could result.

sensitivity. The instrument will not beep or tick in an idle state but the "Battery" LED

will illuminate to indicate the detector has adequate power. When the "Battery" LED

flashes, the batteries are nearing the end of their useful life and will soon need to be

replaced.

a slow “X” (a vertical and horizontal type sweeping motion) while keeping the nose

piece (or rubber extension probe) pointed in the general direction of the suspected

leak.

detects an ultrasonic disturbance. If you are using the unit with headphones, the

Whisper will make a variety of different noises due to its heterodyne feature. (See

"Heterodyne Feature" for more information.) To isolate the ultrasonic disturbance,

gradually decrease sensitivity by slowly dragging your finger down the touch pad until

the beeping stops. The sensitivity level will be indicated briefly by the number of

illuminated LEDs next to the touch pad.

the range of the sweep by making smaller patterns until the ticking once again

increases. This will lead to the location of the disturbance. If an exact location is

desired, attach the flexible rubber extension to the probe and repeat step 3.

Heterodyne Feature

The Whisper features heterodyne capability, which converts the ultrasonic frequencies

detected by the instrument to sounds that can be heard by the human ear. This allows

you to more easily isolate the ultrasonic source.

Simply plug the included headphones into the jack on the right side of the Whisper to

enable heterodyne capability. Dragging your finger upwards/downwards on the

sensitivity touch pad will increase/decrease the volume of the headphones.

High Noise Environments

In noisy environments, it may be necessary to “tune out” unwanted signals from other

areas in close proximity to where you are scanning for leaks. Begin by attaching the

rubber extension probe over the nose piece. When the extension is attached, the

sensing angle of the system is reduced, increasing the directional capability and

reducing the effects of the adjacent noise sources. This allows the Whisper's detection

capabilities to become more directional. If you suspect your reading to originate from a

source other than what you are scanning, point the probe toward the suspected other

5

Page 6

source (maybe a compressor, v belt, discharging steam line, etc.) and slowly decrease

WARNING

sensitivity until the alarm stops. Turn the probe back toward the direction of the

suspected leak and continue to scan. This step may have to be repeated as you move

around to other locations in search of leaks. If the probe is close to internal moving parts

of equipment, and the alarm sounds, push the rubber probe against the equipment

housing. If the alarm still sounds, internal friction of moving parts and not a leak source,

may be causing the alarm.

Using the Contact Probe (if equipped)

If one is included with your Whisper, the metal contact probe offers additional capabilities

when used with your ultrasonic detector. The contact probe can be a useful accessory

in diagnosing machinery. For best results, always use the headphones when using the

contact probe so as to enable the heterodyne feature.

To use, twist the contact probe's threaded end into the Whisper detector's plastic nose

piece. Power the Whisper on. Then, touch the end of the contact probe to bearing

housings, solenoids, pistons and other mechanical equipment to allow the frequencies

to travel into the Whisper's ultrasonic transducer. Adjust sensitivity as needed.

Properly functioning machinery sounds smooth and clear, while poorly functioning

machinery may make irregular or grinding types of noises. Over time you will learn to

recognize when machinery sounds to be in good working order or when it sounds worn

and in need of maintenance.

Do not place the contact probe in running machinery, fan cages, drive

belts, or other moving parts. Always use extreme caution when using

the contact probe around machinery.

Ultrasonic Transmitter Accessory (if equipped)

The Whisper Ultrasonic Transmitter is an accessory which can be used with the Whisper

Ultrasonic Leak Detector to locate leaks in walk-in coolers/freezers, wall and ceiling

joints, around doors, windows, body seals, rubber moldings, ducts, etc. The Transmitter

produces the frequency detected by the Whisper. By placing the Transmitter in a sealed

area and scanning the exterior of this area, any signal escaping from the sealed area will

be indicated by the Whisper. A flaw in the seal can quickly and accurately be pinpointed.

1. Turn the transmitter power switch on. The LED will illuminate to indicate it is operating.

You will not be able to hear the tone generated by the transmitter.

2. Place the Transmitter into the area to be tested. Seal area to be tested completely.

3. Set the “Sensitivity” control of the Whisper to maximum.

4. Scan the exterior area for the suspect leaks.

5. To pinpoint leaks, see "Locating Leaks" on page 4.

6

Page 7

6. When using the transmitter with headphones plugged into the Whisper, the instrument

will indicate ultrasonic disturbances through a variable-pitch tone.

If your Whisper did not come with a transmitter, you may order one under part number

700-600-G1 from your authorized distributor.

Care and Maintenance

To clean exterior surfaces, wipe with a soft damp cloth.

When the batteries near the end of their useful life, the "Battery" LED will flash. To

change the batteries, depress the release tab using a coin or a screwdriver and slide the

cover back. Replace the batteries with two new "D" cell alkaline batteries. Replace the

cover by holding it in place along the side rails while sliding it forward to engage both the

rear hooks and the front release tab.

To avoid accidental damage to the Whisper instrument or headphones, unplug the

headphones from the detector when placing it in the case for storage.

Warranty

INFICON warrants your Whisper Ultrasonic Leak Detector to be free from defects of

materials or workmanship for two years from the date of purchase. INFICON does not

warrant items that deteriorate under normal use, such as power cells. In addition,

INFICON does not warrant any instrument that has been subjected to misuse,

negligence, or accident, or has been repaired or altered by anyone other than INFICON.

INFICON’s liability is limited to instruments returned to INFICON, transportation prepaid,

not later than thirty (30) days after the warranty period expires, and which INFICON

judges to have malfunctioned because of defective materials or workmanship.

INFICON’s liability is limited to, at its option, repairing or replacing the defective

instrument or part.

This warranty is in lieu of all other warranties, express or implied, whether of

merchantability or of fitness for a particular purpose or otherwise. All such other

warranties are expressly disclaimed. INFICON shall have no liability in excess of the

price paid to INFICON for the instrument plus return transportation charges prepaid.

INFICON shall have no liability for any incidental or consequential damages. All such

liabilities are excluded.

Accessory/Replacement parts

Ultrasonic transmitter. . . . . . . . . . . . . 711-600-G1

Contact probe . . . . . . . . . . . . . . . . . . 711-316-G1

Rubber extension probe . . . . . . . . . . 070-1128

Standard headphones . . . . . . . . . . . . 032-0404

Premium headphones . . . . . . . . . . . . 032-0427

7

Page 8

TWO TECHNOLOGY PLACE

EAST SYRACUSE, NY 13057-9714 USA

Phone: 1-800-344-3304

Fax: +315.437.3803

E-Mail: service.tools@inficon.com

www.inficonservicetools.com

074-504-P1B

Loading...

Loading...