Page 1

OPERATING MANUAL

Q-pod

Quartz Crystal Monitor

IPN 074-547-P1B

™

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2012 INFICON

®

OPERATING MANUAL

Q-pod

Quartz Crystal Monitor

IPN 074-547-P1B

™

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

Q-pod™ is a trademark of INFICON GmbH.

Teflon® is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

Windows®, is a registered trademark of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2012 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION OF CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the

market accordingly. It has been constructed in accordance with good engineering

practice in safety matters in force in the Community and does not endanger the safety

of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

Equipment Description: Q-Pod Quartz Monitor

Applicable Directives: 2006/95/EC (LVD)

2004/108/EC (General EMC)

2002/95/EC (RoHS)

Applicable Standards:

Safety: EN 61010-1:2001

Emissions: EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

Immunity: EN 61326-1:1997/A1: 1998/A2: 2001 (General EMC)

Class A: Immunity per Table A1

(EMC – Measurement, Control & Laboratory Equipment)

RoHS: Fully compliant

CE Implementation Date: April 2007 (Updated February 2011)

Authorized Representative:

Steve Schill

_________________________

Thin Film Business Line Manager

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE

DIRECTED, IN WRITING, TO THE AUTHORIZED REPRESENTATIVE AT THE ABOVE ADDRESS.

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

Chapter 1

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 General Cautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 How to Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.3.1 Returning Your Q-pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.6 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.6.1 Base Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Q-pod Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Introduction

Chapter 2

Quick Start

2.1 Install Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Connect the Q-pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Using the Q-pod Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3.1 Main Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

IPN 074-547-P1B

2.3.1.1 Reading Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3.1.2 Materials Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.2 Setup Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.2.1 DataLog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.2.2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.2.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.2.4 Q-pods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.3 Graph Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

TOC - 1

Page 10

Q-pod Operating Manual

Chapter 3

Communications

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 ASCII Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 QPOD.DLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Registering QPOD.DLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.3 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Calculating Rate and Thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Sample Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4

Troubleshooting and Maintenance

4.1 Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1.1 LED illuminated steady. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1.2 LED flashes slowly (about 2 Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1.3 LED flashes rapidly (about 10 Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Troubleshooting the Q-pod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3 Troubleshooting Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.4 Troubleshooting Computer Communications. . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2 Replacing the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.1 Front Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.2 Cool Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.2.3 Bakeable Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.2.4 Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.2.5 Crystal Snatcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.3 Crystal Sensor Emulator IPN 760-601-G2 . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.3.1 Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.3.1.1 Measurement System Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . . 4-16

4.3.1.2 Feed-Through Or In-Vacuum Cable Diagnostic Procedure . . . . . . . . . . . . 4-17

4.3.1.3 Sensor Head Or Monitor Crystal Diagnostic Procedure. . . . . . . . . . . . . . . 4-18

4.3.1.4 System Diagnostics Pass But Crystal Fail Message Remains. . . . . . . . . . 4-19

4.3.2 Sensor Cover Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.1 Compatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.2 Incompatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

IPN 074-547-P1B

TOC - 2

4.3.3 Emulator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Page 11

Chapter 5

5.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Chapter 6

6.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.1.3 Z-match Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.1.4 Active Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Q-pod Operating Manual

Calibration Procedures

Measurement and Theory

Material Table

IPN 074-547-P1B

TOC - 3

Page 12

Q-pod Operating Manual

This page is intentionally blank.

TOC - 4

IPN 074-547-P1B

Page 13

1.1 Introduction

The INFICON Q-pod™ Transducer is a small, inexpensive and accurate way to

measure thin film depositon rate and thickness. No external oscillator or power

source is required.

The included Q-pod software displays rate, thickness, frequency, crystal life and a

graph of rate versus time, for up to 8 Q-pods simultaneously. Q-pod readings can

be logged to disk in spreadsheet friendly comma-delimited format.

There are also sample files included, written in Labview, Java and Visual Basic to

help aid in the integration of the Q-pod into a system that is managed via software.

See section section 3.5, Sample Programs, on page 3-4 for more details.

Figure 1-1 Q-pod

Q-pod Operating Manual

Chapter 1

Introduction

IPN 074-547-P1B

When reading this Q-pod manual, please pay particular attention to the NOTES,

CAUTIONS, and WARNINGS found throughout the text. The Notes, Cautions, and

Warnings are defined in section 1.2.1 on page 1-2. Also, note the general warnings

in section 1.2.2, General Cautions and Warnings, on page 1-3.

1 - 1

Page 14

Q-pod Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.1.1 Related Manuals

Sensors are covered in separate manuals. PDF files of these manuals are

contained in the 074-5000-G1 CD, part of the Ship Kit.

074-154 - Bakeable Sensor

074-156 - Front Load Sensor, Single/Dual

074-157 - Sputtering Sensor

147-800 - Cool Drawer Sensor, Single/Dual

1.2 Instrument Safety

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS and

WARNINGS found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum instrument

efficiency when followed.

Failure to heed these messages could result in damage

to the instrument.

Failure to heed these messages could result in personal

injury.

Dangerous voltages are present which could result in

personal injury.

IPN 074-547-P1B

1 - 2

Page 15

1.2.2 General Cautions and Warnings

CAUTION

WARNING

CAUTION

Do not open the instrument case! There are no

user-serviceable components within the instrument

case.

Refer all maintenance to technically qualified personnel.

Failure to operate the Q-pod in the manner intended by

INFICON can circumvent the safety protection provided

by the instrument and may result in personal injury.

Q-pod Operating Manual

Q-pod may not be suitable for use with RF sputtering

systems or other electrically noisy environments.

IPN 074-547-P1B

1 - 3

Page 16

Q-pod Operating Manual

1.3 How to Contact INFICON

Worldwide customer support information is available under Support at

www.inficon.com where you can contact:

A Technical Support Engineer with questions regarding applications for and

programming the Q-pod.

A Service Engineer with questions regarding troubleshooting, diagnosing or

repairing a defective Q-pod.

Sales and Customer Service, to find the INFICON Sales office nearest to you.

Repair Service, to find the INFICON Service Center nearest to you.

If you are experiencing a problem with your Q-pod, please have the following

information readily available:

The serial number and firmware version for your Q-pod.

A description of your problem.

An explanation of any corrective action that you may have already attempted.

The exact wording of any error messages that you may have received.

1.3.1 Returning Your Q-pod

Do not return any component of your Q-pod to INFICON without first speaking with

a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your Q-pod.

1.4 Specifications

Frequency Range. . . . . . . . . . . . . . . 1 to 6 MHz

Frequency Resolution . . . . . . . . . . . 0.05 Hz at 6 MHz @ 2 measurements per

Frequency Accuracy . . . . . . . . . . . . 0.002%

Frequency Stability. . . . . . . . . . . . . . ±2 ppm total, over 0º to 50ºC

Thickness & Rate Resolution . . . . . . 0.0613 Å (new crystal); 0.1091 Å (crystal @

Input . . . . . . . . . . . . . . . . . . . . . . . . . BNC

second)

4.5 MHz); over 500 ms sample for material

density = 1.0, Z-ratio = 1.0

IPN 074-547-P1B

1 - 4

Interface & Power. . . . . . . . . . . . . . . USB, v2.0 or later, 15 ft. (457 cm) maximum

allowable length

Size . . . . . . . . . . . . . . . . . . . . . . . . . 1 in. x 2 in. x 2.5 in. (25 mmx 50 mm x 64 mm)

Page 17

Weight . . . . . . . . . . . . . . . . . . . . . . . 2 oz. (32 gm)

Computer Requirements . . . . . . . . . Any PC running Windows® XP / 2000 /

1.5 Unpacking and Inspection

1 If the Q-pod has not been removed from its packaging, do so now.

2 Carefully examine the card for damage that may have occurred during

shipping. This is especially important if you notice obvious rough handling on

the outside of the container. Immediately report any damage to the carrier and

to INFICON.

3 Do not discard the packing materials until you have taken inventory and have

at least performed successful installation.

4 Take an inventory of your order by referring to your order invoice and the

information contained in section 1.6.1.

5 To install the Q-pod, see Chapter 2, Quick Start.

Q-pod Operating Manual

Windows 7 32-bit with one available USB

port for each Q-pod

6 For additional information or technical assistance, contact INFICON, refer to

section 1.3 on page 1-4.

1.6 Parts and Options Overview

1.6.1 Base Configuration

Q-pod Transducer w/Software . . . . . . . . .Q-POD

10 ft. USB Cable. . . . . . . . . . . . . . . . . . . .068-0472

6 in. BNC Cable . . . . . . . . . . . . . . . . . . . .755-257-G6

Technical Manual . . . . . . . . . . . . . . . . . . .074-547 on 074-5000-G1 CD

IPN 074-547-P1B

1.6.2 Sensors

5.5 MHz Test Crystal . . . . . . . . . . . . . . . .782-902-023

Front Load Single Sensor. . . . . . . . . . . . . . . . . . . . . SL-XXXXX

Cool Drawer Single Sensor . . . . . . . . . . . . . . . . . . . CDS-XXFXX

Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . 750-618-G1

Front Load UHV Bakeable Sensor . . . . . . . . . . . . . . BK-AXF

NOTE: Multi-crystal (rotary) sensors & dual sensors should not be used with the

Q-pod.

1 - 5

Page 18

Q-pod Operating Manual

This page is intentionally blank.

1 - 6

IPN 074-547-P1B

Page 19

2.1 Install Software

NOTE: If this is the initial Q-pod installation on this computer, you should install the

Q-pod Software before connecting a Q-pod to the USB port.

1 Place the INFICON Program Disk in the computer’s CD-ROM.

2 Ignore the prompt and double-click the My Computer icon.

3 Right-click the CD-ROM icon, then click Open.

4 Double-click the Q-pod Transducer file.

5 Double click QPOD_V#_SETUP.EXE.

6 Follow the on screen directions and select the default installation options.

7 When software installation is complete, exit the installation program.

Q-pod Operating Manual

Chapter 2

Quick Start

2.2 Connect the Q-pod

1 Connect the USB cable to a computer USB port, then to the Q-pod. See Figure

2-1.

1a If you are prompted to install the Q-pod drivers, select Install the Software

Automatically.

1b If you are prompted concerning Windows Logo Testing, select Continue

Anyway.

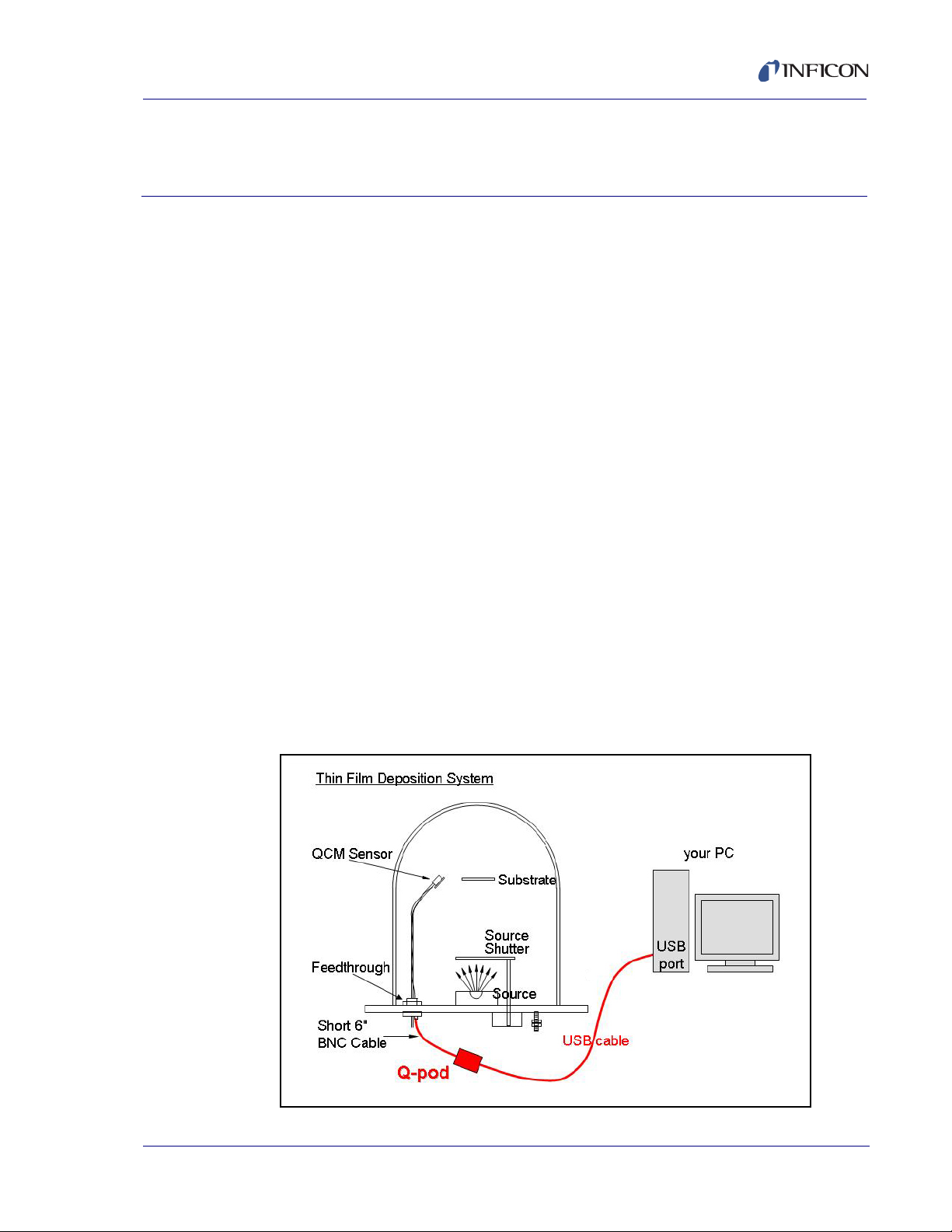

Figure 2-1 Q-pod Connections

IPN 074-547-P1B

2 - 1

Page 20

Q-pod Operating Manual

2 Use the 6 in. BNC cable provided to connect the Q-pod to the QCM sensor

feedthrough.

3 The status light on the Q-pod illuminates when a quartz crystal is detected.

2.3 Using the Q-pod Software

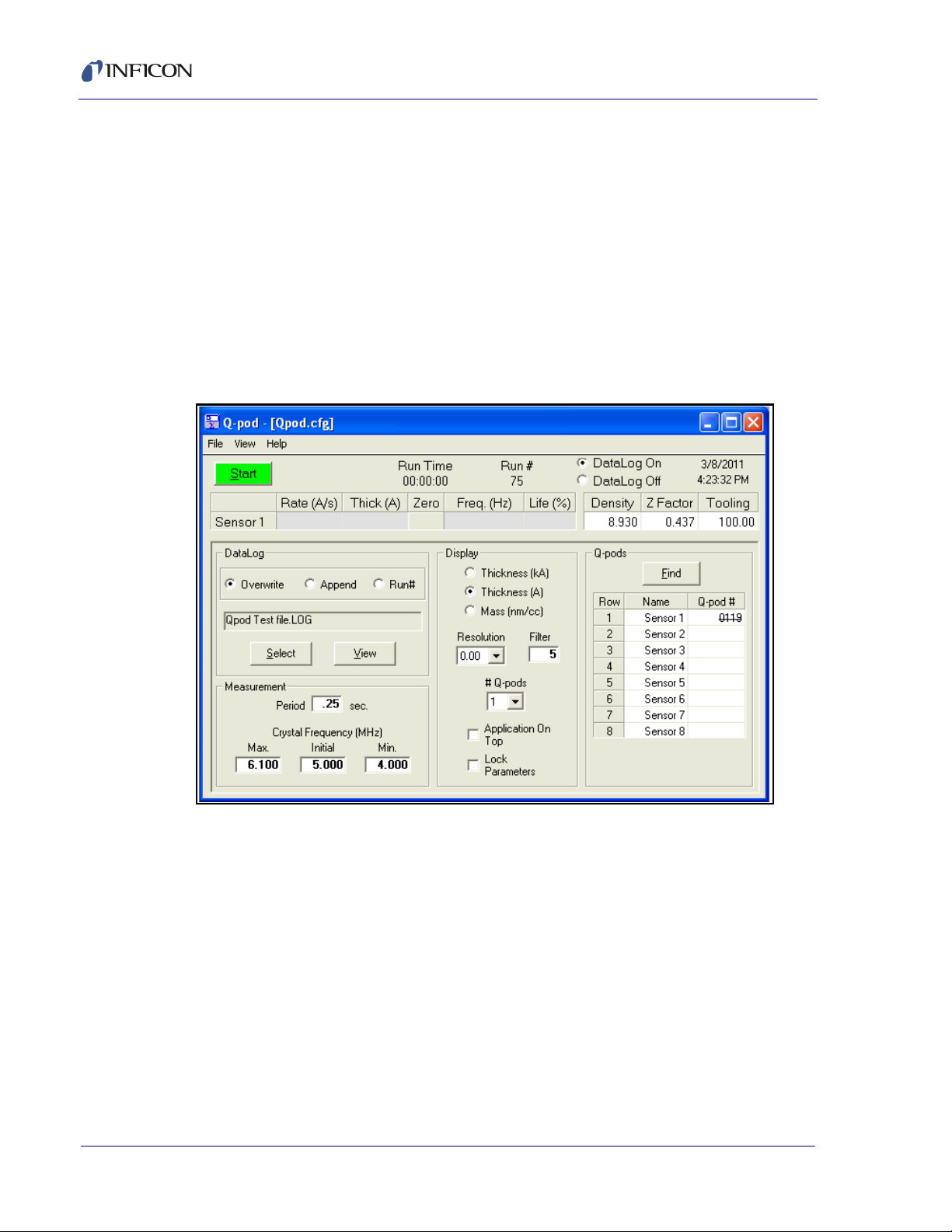

Click the Q-pod desktop icon, or click Start >> Programs >> Sigma Instruments

>> Q-pod. If you are prompted to assign Q-pod(s) to a channel, click Yes. Click

Help to get more detailed information on materials and operation. Select Setup or

Graph on the Main Screen menu to change the main screen display mode. See

Figure 2-2.

Figure 2-2 Main Screen

2.3.1 Main Display

The top of the main screen is the main display. Here the Start button is used to start

and record a run. Run time and run number are shown, along with the current time

and date. The option to datalog during any given run is also given.

2.3.1.1 Reading Grid

The left grid displays the measured values of each connected Q-pod. Click Start to

display Rate and Thickness readings. Frequency and Life readings are always

displayed. Click a channel’s Zero button to zero the channel thickness reading.

Shift-Click any channel Zero button to zero all thicknesses.

2 - 2

IPN 074-547-P1B

Page 21

2.3.1.2 Materials Grid

In the right grid, edit the Density, Z-Factor and Tooling values for the materials

being deposited. Move your mouse over each setting to see a brief description.

2.3.2 Setup Display

The lower section of the main screen is where run parameters can be changed and

Q-pod communication information is presented.

2.3.2.1 DataLog

Sets the file name, location and operation of disk data logging. Data log files can

be set to overwrite the file name each time it is saved. It can append the data, by

adding the newly recorded data to the end of the same file. It can also save each

run in a new file designated by run number. Data is saved in comma delimited

format for easy import into a spreadsheet.

2.3.2.2 Measurement

Sets the basic measurement parameters for all Q-pods. The values shown above

are correct for most applications.

Q-pod Operating Manual

2.3.2.3 Display

Sets the display parameters.Thickness can be displayed in kÅ or Å. Mass can be

displayed in ug/cm

2

. Rate will be changed to ng/cm2/sec if mass is the chosen

option. Resolution of displayed readings may also be changed here (0.0 or 0.00).

The rate reading filter can be set in this section. The Filter number represents how

many measurements are averaged together to produce the displayed rate. The

number of Q-pods being used is defined in this section as well.

2.3.2.4 Q-pods

Sets the name and displays the serial number of the Q-pod assigned to each

measurement channel. A strike-through serial number indicates the Q-pod is not

IPN 074-547-P1B

connected. The software can monitor a maximum of 8 Q-pods simultaneously.

2 - 3

Page 22

Q-pod Operating Manual

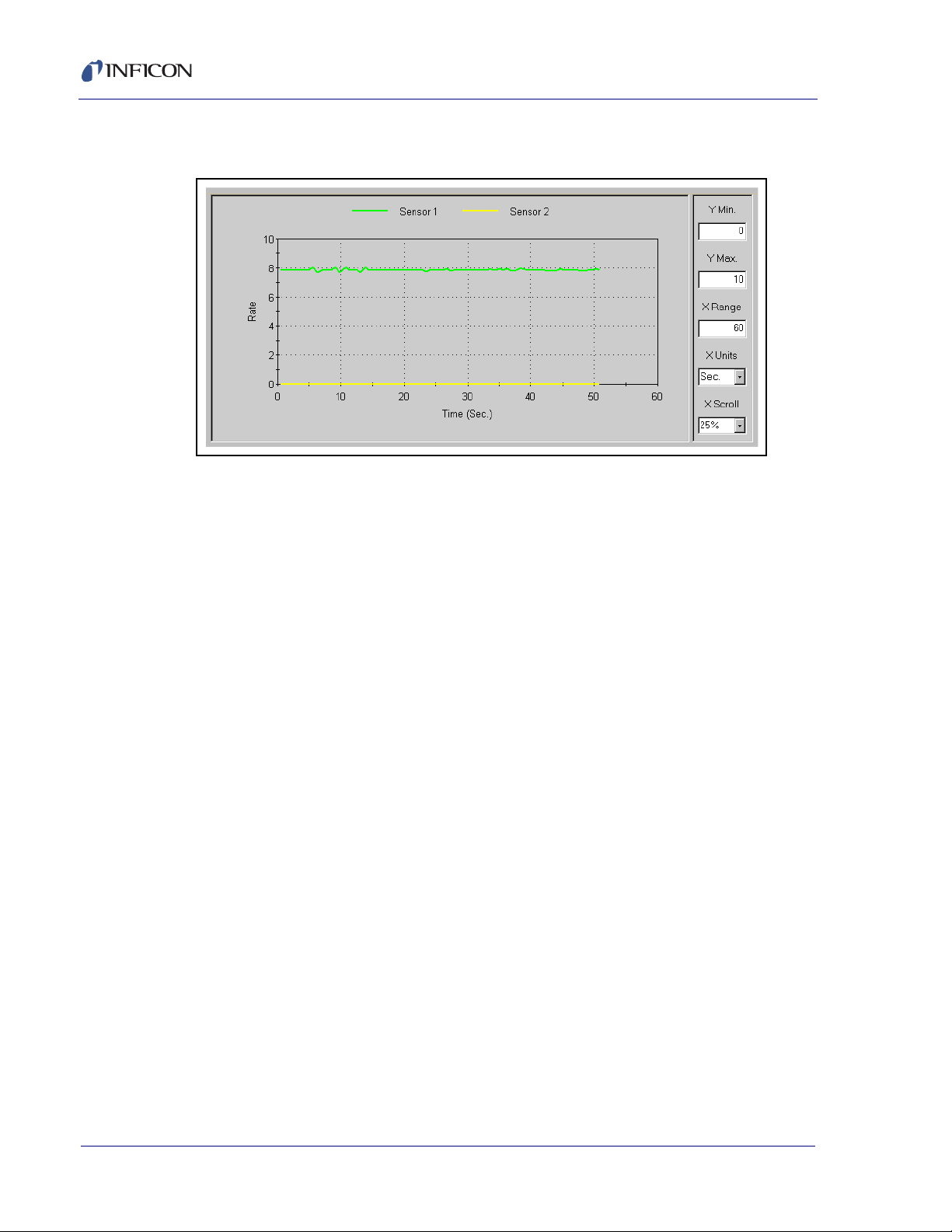

2.3.3 Graph Display

Figure 2-3 Graph Display

Graphs the deposition rate, thickness, or frequency of active measurement

channels when Start is clicked. The graph viewed can be changed from the view

option on the toolbar on the main screen. Settings to the right of the graph control

basic graph functions. See the Help menu for advanced graph setup.

2 - 4

IPN 074-547-P1B

Page 23

3.1 Introduction

The Q-pod communicates via a USB (or USB2) port and a simple ASCII command

set. An ActiveX DLL (Qpod.DLL) provides functions to set parameters, take

readings, and handle USB communications.

3.2 ASCII Command Set

The commands below assume you can open the proper USB port for

communications. The section on Qpod.DLL provides the tools needed to

communicate with the Q-pod without knowledge of USB functions.

A Q-pod command consists of an exclamation character (&H21), then the

command as detailed below, and terminated with a Carriage Return (&H13) and

Line Feed (&H10). The response has the same format, that is !<response>CrLf.

Q-pod Operating Manual

Chapter 3

Communications

@ Get version

Returns: Qpod VX.XX

A# Get Frequency and Set Status LED

Returns frequency counts. The B & C commands (see below) must be used to

set the measurement period before using this command. The response is gate

counts, which are converted crystal frequency using:

Freq = 200 MHz * GatePeriod / Response

A response of –1 indicates that a new reading is not available.

The value sent with this command activates the Status LED. Send A1 to turn

on the LED (crystal good), or A0 to cause the LED to flash at the measurement

IPN 074-547-P1B

rate (crystal fail).

B# Set Gate Period

Sets the longest measurement period, determined by the lowest valid crystal

frequency. If the desired measurement period is 0.25 seconds, and the

minimum crystal frequency is 5.0MHz, then the command is: B1250000 (0.25

x 5MHz).

C# Set Measurement Period

The value sent is the period in seconds times the reference oscillator frequency,

50MHz. If the desired measurement period is 0.25 seconds, then the command

is:

C12500000 (0.25 x 50MHz)

3 - 1

Page 24

Q-pod Operating Manual

3.3 QPOD.DLL

QPOD.DLL is an Active-X DLL that provides the functions necessary to get rate

and thickness readings from up to 32 Q-pods.

In the function listings that follow, parameter and return value types are indicated

by the first letter of the variable name:

i: Integer (16 bits) f: Float (single) c: Char (8 bits) s: String

l: Long (32 bits) d: Double b: Byte (8 bits)

Functions parameters are passed By Value unless specifically designated as

ByReference (pointer).

Unless noted otherwise, the return values of functions are:

QPOD_SUCCESS = &H0 . . . . . . . . . Command successful

QPOD_BUSY = &H1. . . . . . . . . . . . . Communications already in progress

QPOD_TIMEOUT = &H2 . . . . . . . . . Did not respond

QPOD_NOREADING = &H3 . . . . . . No new reading ready

QPOD_OVERFLOW = &H4 . . . . . . Internal overflow error

QPOD_BADPARAM = &H5. . . . . . . Bad parameter value

QPOD_BADCMD = &H6 . . . . . . . . . Bad command

QPOD_BADSERNUM = &H7 . . . . . Serial number not connected

QPOD_XTALFAIL = &H8 . . . . . . . . . Crystal fail

QPOD_COMMERR = &H9 . . . . . . . . Unknown communications error

QPOD_UNKERR = &H99 . . . . . . . . . Unknown program error

3.3.1 Registering QPOD.DLL

QPOD.DLL and ccrpTmr.DLL (used for timing functions) must be registered by

Windows. The QpodDLL setup program installs and registers both files. To install

and register them manually, copy both files to the Windows\System32 folder.

Click Start, Run, and type

regsvr32\windows\system32\qpod.dll

click OK, then type

regsvr32\windows\system32\ccrpTmr.dll

IPN 074-547-P1B

3 - 2

and click OK.

Page 25

3.3.2 Functions

FindQpods (By Ref sSNArray(0 to 32)) [=lRtnVal]

Searches for Q-pods connected to the computer. Populates sSNArray() with

the serial numbers of up to 32 Q-pods. Return value is total number of Q-pods

found.

Most QPOD.DLL functions require the serial number of a Q-pod as their first

parameter. FindQpods should the first function called. Additional calls to

FindQpods can be made, but be sure to resend the parameters (period,

density, etc.) for each Q-pod serial number you will use.

InitFreq (dFmax, dFmin, dFinit) [=lRtnVal]

Initializes the maximum, minimum, and initial crystal frequency values for all

attached Q-pods. The default values are Fmax=6.1 MHz, Fmin=5.0 MHz,

Finit=6.0 MHz,. Crystal readings >Fmax or <Fmin will generate a crystal fail

response to the GetReadings call. Call InitFreq immediately after FindQpods.

GetReading (sSerNum, By Ref dRdgArray(0 to 3)) [=lRtnVal]

Populates dRdgArray with the Rate, Thickness, Frequency, and %Life for the

Q- pod serial number. Thickness is returned in kA.

Q-pod Operating Manual

You can call get readings and test the return value to see if a new readings was

ready (&H0) or not (&H3). Alternatively, you can set the Reading Timer and

QPOD.DLL will raise a QpodReading event when a reading is ready. See

SetReading Timer() and QpodReading() below.

Material (sSerNum, dDensity, dZFactor, dTooling) [=lRtnVal]

Sets the Density, Z Factor, and Tooling used to convert frequency change into

rate and thickness.

Period (sSerNum, dPeriod) [=lRtnVal]

Sets the measurement period in seconds. Valid values are 0.1 to 2.

IPN 074-547-P1B

SetReadingsTimer (dInterval) [=lRtnVal]

Sets the interval for polling Qpods for readings in milliseconds. A value of zero

disables the QpodReadings event (see below).

Zero (sSerNum) [=lRtnVal]

Sets the Q-pod thickness reading to zero.

ZeroAll () [=lRtnVal]

Sets all attached Q-pod thickness readings to zero.

Revision (sSerNum, ByRef sRev) [=lRtnVal]

Returns the firmware revision in sRev. A sRev value is: Qpod V1.00.

3 - 3

Page 26

Q-pod Operating Manual

3.3.3 Events

QpodReading (sSerNum, ByRef dRdgArray(0 to 3), Time)

If SetReadingsTimer (see above) is passed a non-zero interval, the QPOD.DLL

will poll every attached Q-pod for readings at the set interval.

For each Q-pod that has a new reading, a QpodReading event is raised. The

sSerNum parameter is the serial number of the Q-pod with a new reading. The

array dRdgArray holds Rate, Thickness, Frequency, and %Life for that Q-pod

serial number. Thickness is returned in kA.

3.4 Calculating Rate and Thickness

In the Q-pod software, thickness and rate are calculated using the Z-match

equation. The calculation can be divided into four parts:

1 Calculate Thickness:

Thickness = (AT_CONST * DENS_QUARTZ) / (PI * Density * Freq * ZRatio)

where AT_CONST = 16.68 x 10

Freq is the frequency calculated from the A command.

12

, DENS_QUARTZ= 2.648, PI=3.1416,

2 Correct for Z-Ratio:

Thickness

where Thickness was calculated in step 1 and FreqInit is the initial (new)

crystal frequency – typically 6MHz.

= Thickness * ArcTan(ZRatio * Tan(PI * (FreqInit - Freq) / FreqInit))

z

3 Correct for Tooling:

Thickness

= Thickness

T

4 Calculate Rate:

Rate = (Thickness

where Thickness

measurement, and Period is the elapsed time between measurements.

3.5 Sample Programs

On the INFICON CDROM in D:\Qpod Transducer_V100_SAMPLES.exe, run this

executable to set up the sample files for the Q-pod. When complete, they will be

located here: C:\Program Files\Sigma Instruments\Q-pod\Sample Programs.

These are sample interface files for use in Visual Basic and LabVIEW. These files

are meant to act as means to aid the user in creating their own software and to

allow the user to interface to the Q-pod with other devices in your operation.

* Tooling * 0.01

z

– Thickness

T

was calculated in step 3, Thickness

T

) / Period

T-1

was from the last

T-1

IPN 074-547-P1B

3 - 4

NOTE: For the sample programs to work correctly, you should also install Sigma's

Q-pod application.

Page 27

Q-pod Operating Manual

Before using the LabVIEW demo, it may be best to familiarize oneself with

operation of the Q-pod software. To run the LabVIEW demo(qpod.vi), click "Load

DLL", "Use Card" and then set the Sensor parameters as desired. Click "Start" to

display readings. Be sure to click "Unload DLL" before stopping the LabVIEW

program. Otherwise, a Windows error may occur, and LabVIEW may shut down.

LabVIEW 6 or higher is required.

NOTE: The sample LabView VI may require that you select the proper DLL for the

two Automation RefNum controls. Right click each control, then click

Select ActiveX Class. Check Show Creatable Objects Only, then select

Sigma Instruments Qpod ActiveX DLL.

Figure 3-1 Labview Sample Program

IPN 074-547-P1B

3 - 5

Page 28

Q-pod Operating Manual

This page is intentionally blank.

3 - 6

IPN 074-547-P1B

Page 29

Troubleshooting and Maintenance

CAUTION

4.1 Troubleshooting Guide

If the Q-pod fails to function, or appears to have diminished performance, the

following Symptom/Cause/Remedy charts may be helpful.

There are no user serviceable components within the

Q-pod case.

Refer all maintenance to qualified personnel.

Q-pod Operating Manual

Chapter 4

4.1.1 Status LED

If there is a problem with the Q-pod, the status LED will indicate as to the likely

cause.

4.1.1.1 LED illuminated steady

Good crystal detected

4.1.1.2 LED flashes slowly (about 2 Hz)

No crystal connected

Crystal frequency range not set correctly in software

Crystal failure

IPN 074-547-P1B

4.1.1.3 LED flashes rapidly (about 10 Hz)

Software not installed

Driver not installed

Q-pod not detected by software

Q-pod not assigned to a sensor channel (click Find to locate Q-Pod and then

follow instructions to assign Q-Pod to a sensor channel)

Q-pod hardware failure

4 - 1

Page 30

Q-pod Operating Manual

4.1.2 Troubleshooting the Q-pod

Table 4-1 General Troubleshooting

SYMPTOM CAUSE REMEDY

1. Crystal fail message is

always on.

a. Q-pod and/or sensor not

connected.

a. Verify proper

Q-pod/sensor connections.

b. Q-pod malfunctioning. b. If available, insert a known

working Q-pod, or other

monitor, in place of suspect

one; if Q-Pod is confirmed

bad, contact INFICON

service department.

c. Defective cable from

feedthrough to Q-pod.

c. Use an Ohm meter or

DMM to check electrical

continuity or isolation as

appropriate.

d. Poor electrical contact in

the sensor, feedthroughs, or

in-vacuum cable.

d. Use an Ohm meter or

DMM to check electrical

continuity or isolation as

appropriate.

e. Failed crystal/no crystal. e. Replace crystal with new

INFICON crystal.

f. Two crystals placed into the

crystal holder.

f. Remove one of the

crystals.

g. Frequency of crystal out of

range,

g. Verify that the crystal

frequency is within the

required range, use

INFICON crystals. Set the

desired range on the main

screen on the software.

IPN 074-547-P1B

4 - 2

Page 31

Table 4-1 General Troubleshooting

SYMPTOM CAUSE REMEDY

Q-pod Operating Manual

2. Noisy signal a. Distance from sensor to

3. Frequency reading is

unstable or drifting

4.1.3 Troubleshooting Sensors

NOTE: Many sensor head problems may be diagnosed with a DMM (Digital

Multi-Meter). Disconnect the short oscillator cable from the feedthrough

and measure the resistance from the center pin to ground. If the reading is

less than 10 megohms, the source of the leakage should be found and

corrected. Likewise, with the vacuum system open check for center

conductor continuity, a reading of more than 1 ohm from the feedthrough

to the Q-pod indicates a problem. Cleaning contacts or replacing the

in-vacuum cable may be required.

Q-pod is longer than 40 in.

(101.6 cm).

b. Mechanical/electric noise

sources located near the

Q-pod/cable .

a. Temperature (of the

crystal) is changing. An

AT-cut crystal frequency may

drift as much as 10 Hz/°C.

b. Humidity (level on the

crystal) is changing. Moisture

being absorbed or exuded

from the crystal surface,

a. Replace cables to

preserve the maximum

allowable length.

b. Look for potential noise

sources. Reposition the

Q-pod/cables accordingly.

a. Control the temperature of

the chamber. Check watering

cooling for flow and

temperature. Check source

to crystal distance (12 in. is

ideal).

b. Control the humidity of the

chamber.

A somewhat more thorough diagnosis may be performed with the optional

IPN 074-547-P1B

Crystal Sensor Emulator, 760-601-G1. See section 4.3 on page 4-15 for a

discussion of its use and diagnostic capabilities.A more detailed

troubleshooting guide is shipped with the sensor. Refer to that manual for

more detailed information in some cases

.

4 - 3

Page 32

Q-pod Operating Manual

Table 4-2 Troubleshooting Sensors

SYMPTOM CAUSE REMEDY

1. Large jumps of thickness

reading during deposition.

a. Mode hopping. a. Mode hopping is a

byproduct of active

oscillation with a heavily

damped crystal. Temperature

stabilization is key in

diminishing this. Replace the

crystal.

b. Stress causes film to peel

from crystal surface.

b. Replace crystal or use

high performance

RunSaver™ crystal; consult

factory.

c. Particulate or "spatter"

from molten source striking

crystal.

c. Thermally condition the

source thoroughly before

deposition, use a shutter to

protect the crystal during

source conditioning.

d. Material build up,

scratches or foreign particles

on the crystal holder seating

d. Clean and polish the

crystal seating surface on the

crystal holder.

surface (improper crystal

seating.)

e. Small pieces of material

fell on crystal (for crystal

facing up sputtering

situation.)

f. Small pieces of magnetic

material being attracted by

the sensor magnet and

contacting the crystal

(sputtering sensor head.)

e. Check the crystal surface

and blow it off with clean air.

f. Check the sensor cover's

aperture and remove any

foreign material that may be

restricting full crystal

coverage.

IPN 074-547-P1B

4 - 4

Page 33

Table 4-2 Troubleshooting Sensors

SYMPTOM CAUSE REMEDY

Q-pod Operating Manual

2. Crystal ceases to oscillate

during deposition before it

reaches the end of its normal

life.

a. Crystal struck by

particulate or spatter from

molten source.

a. Thermally condition the

source thoroughly before

deposition, use a shutter to

protect the crystal during

source conditioning.

b. Material on crystal holder

b. Clean crystal holder.

partially masking crystal

cover aperture.

c. Existence of electrical

short or open condition.

c.Using an ohm meter or

DMM, check for electrical

continuity in the sensor

cable, connector, contact

springs, connecting wire

inside sensor, and

feedthroughs.

d. Thermally induced

d. See 2c above.

electrical short or open

condition.

NOTE: Crystal life is highly dependent on process conditions of rate, power radiated from

source, location, material, and residual gas composition.

3. Crystal does not oscillate

or oscillates intermittently

(both in vacuum and in air.)

a. Intermittent or poor

electrical contact (contacts

oxidized.)

b. Leaf springs have lost

retentivity (ceramic retainer,

center insulator.)

a. Use an Ohm meter or

DMM to check electrical

continuity, clean contacts.

b. Carefully bend leaves to

approx. 45° on ceramic

retainer and 60° inside the

sensor head.

c. RF interference from

IPN 074-547-P1B

sputtering power supply.

c. Verify earth ground, use

ground strap adequate for

RF ground, change location

of Q-pod and cabling away

from RF power lines.

d. Cables not connected, or

connected to wrong sensor

input.

d. Verify proper connections,

and inputs relative to

programmed sensor

parameter.

4 - 5

Page 34

Q-pod Operating Manual

Table 4-2 Troubleshooting Sensors

SYMPTOM CAUSE REMEDY

4. Crystal oscillates in

vacuum but stops oscillation

after open to air.

5. Thermal instability: large

changes in thickness reading

during source warm-up

(usually causes thickness

reading to decrease) and

after the termination of

deposition (usually causes

thickness reading to

increase.)

a. Crystal was near the end

of its life; opening to air

causes film oxidation which

increases film stress.

b. Excessive moisture

accumulates on the crystal.

a. Inadequate cooling

water/cooling water

temperature too high.

b. Excessive heat input to the

crystal.

c. Crystal not seated properly

in holder.

a. Replace crystal.

b. Turn off cooling water to

sensor prior to venting, flow

warm water through sensor

while chamber is open.

a. Check cooling water flow

rate, be certain that cooling

water temperature is less

than 30°C; refer to

appropriate sensor manual.

b. If heat is due to radiation

from the evaporation source,

move sensor further away

from source and use silver

crystals for better thermal

stability; install radiation

shield.

c. Clean or polish the crystal

seating surface on the crystal

holder.

d. Crystal heating caused by

high energy electron flux

(often found in RF

sputtering.)

e. Poor thermal transfer

(Bakeable.)

d. Use a sputtering sensor

head.

f. Use Al or Au foil washer

between crystal holder and

sensor body.

IPN 074-547-P1B

4 - 6

Page 35

Table 4-2 Troubleshooting Sensors

SYMPTOM CAUSE REMEDY

Q-pod Operating Manual

6. Poor thickness

reproducibility.

a. Variable source flux

distribution.

a. Move sensor to a more

central location to reliably

sample evaporant, ensure

constant relative pool height

of melt, avoid tunneling into

the melt.

b. Sweep, dither, or position

where the electron beam

strikes the melt has been

changed since the last

deposition.

b. Maintain consistent source

distribution by maintaining

consistent sweep

frequencies, sweep

amplitude and electron beam

position settings.

c. Material does not adhere

to the crystal.

c. Make certain the crystal

surface is clean; avoid

touching crystal with fingers,

make use of an intermediate

adhesion layer.

d. Cyclic change in rate. d. Make certain source's

sweep frequency is not

"beating" with the Q-pod’s

measurement frequency.

7. Large drift in thickness

(greater than 200 Å for a

density of 5.00 g/cc) after

termination of sputtering.

a. Crystal heating due to poor

thermal contact.

b. External magnetic field

interfering with the sensor's

magnetic field (sputtering

sensor.)

a. Clean or polish the crystal

seating surface on the crystal

holder.

b. Rotate sensor magnet to

proper orientation with

external magnetic field, refer

to the sputtering sensor

manual IPN 074-157.

IPN 074-547-P1B

c. Sensor magnet cracked or

demagnetized (sputtering

sensor.)

c. Check sensor magnetic

field strength, the maximum

field at the center of the

aperture should be 700

gauss or greater.

4 - 7

Page 36

Q-pod Operating Manual

CAUTION

4.1.4 Troubleshooting Computer Communications

Table 4-3 Troubleshooting Computer Communications

SYMPTOM CAUSE REMEDY

1. Communications cannot

be established between the

host computer and the

Q-pod.

4.2 Replacing the Crystal

Always use clean nylon lab gloves and plastic tweezers

for handling the crystal (to avoid contamination which

may lead to poor adhesion of the film to the electrode).

Do not rotate the ceramic retainer assembly after it is

seated (as this will scratch the crystal electrode and

cause poor contact).

a. Improper cable

connection.

b. Driver not installed

properly.

a. Verify for cable

connections are seated

properly.

b. Reinstall drivers. Confirm

the operating sytem is an

accepted OS. If autorun

driver install feature does

not work, the driver can be

installed from the device

manager manually.

4 - 8

Do not use excessive force when handling the ceramic

retainer assembly since breakage may occur.

NOTE: Certain materials, especially dielectrics, may not adhere strongly to the

crystal surface and may cause erratic readings.

NOTE: Thick deposits of some materials, such as SiO, Si, and Ni will normally peel

off the crystal when it is exposed to air, as a result of changes in film stress

caused by gas absorption. When you observe peeling, replace the

crystals.

IPN 074-547-P1B

Page 37

4.2.1 Front Load

Front Load Crystal Holder

(IPN 750-172-G1)

Front Load Standard

Crystal Sensor Body

(IPN 750-207-G1)

Crystal (IPN 008-010-G10)

Fully Coated Face (Gold)

Finger Spring Contact

(IPN 750-171-P1)

Crystal Retainer

(IPN 007-023)

In-Vacuum Cable

To X IU

Water Tubes

Follow the procedure below to replace the crystal in the Front Load sensor: (see

Figure 4-1)

1 Gripping the crystal holder with your fingers, pull it straight out of the sensor

body.

2 Gently pry the crystal retainer from the holder (or use the Crystal Snatcher; see

Figure 4-6 on page 4-14).

3 Turn the retainer over and the crystal will drop out.

4 Install a new crystal, with the patterned electrode face up.

5 Push the retainer back into the holder and replace the holder in the sensor

body.

Figure 4-1 Front Load Crystal Sensor (Exploded)

Q-pod Operating Manual

IPN 074-547-P1B

4 - 9

Page 38

Q-pod Operating Manual

Contact Spring

4.2.2 Cool Drawer

Follow the procedure below to replace the crystal in a Next Generation Cool

Drawer™ sensor:

1 Using your thumb and index fingers, gently squeeze the sides of the retainer at

the mid section then lift it up, away from the drawer, as shown in Figure 4-2.

2 Hold the drawer by the handle and turn it upside down to remove the spent

crystal.

3 Install a new crystal in the drawer. Observe its orientation. The pattern

electrode should face upward as shown in Figure 4-3.

4 Hold the retainer by its sides. Align its orientation notch with the drawer then

gently and evenly push the retainer down until it snaps firmly into the drawer.

see Figure 4-3. Never push down (or pull up) on the contact spring, doing so

may permanently damage it.

5 Inspect the whole assembly. The retainer should be even and engage the

drawer at all four corners.

Figure 4-2 Cool Drawer - Removing The Crystal

4 - 10

IPN 074-547-P1B

Page 39

Figure 4-3 Cool Drawer - Replacing The Crystal

Orientation

Notch

Handle

Retainer

Crystal

Drawer

Q-pod Operating Manual

IPN 074-547-P1B

4 - 11

Page 40

Q-pod Operating Manual

Crystal Holder and

Retainer Spring

IPN 750-218-G1

Crystal IPN 008-010-G10

Fully Coated Face (Gold)

Crystal Retainer IPN 007-064

Clamping Spring IPN 007-094

Contact IPN 007-099

Insulator IPN 007-103

Spreader Bar

IPN 007-267-P2

Shoulder Washer

IPN 007-268-P1

Two Required

Shoulder Washer

IPN 007-269-P1

Cam Mechanism

IPN 007-095

Cover IPN 007-101

4.2.3 Bakeable Sensor

For the Bakeable sensor, the procedure is the same as the Front Load sensor

except that you must first unlock the cam assembly by flipping it up. Once the

crystal has been replaced, place a flat edge of the holder flush with the cam

mechanism and lock it in place with the cam. See Figure 4-4.

Figure 4-4 Bakeable Crystal Sensor

IPN 074-547-P1B

4 - 12

Page 41

4.2.4 Sputtering Sensor

Body Assembly

IPN 750-619-G1

In-Vacuum Cable Assembly

(29 in.) IPN 007-044

Ceramic Retainer

IPN 007-023

Crystal

IPN 008-009-G10

(Silver)

Crystal Holder

IPN 007-049

Sensor

Front Cover

IPN 007-047

Observe the general precautions for replacing crystals and follow the instructions

below to replace the crystal in a sputtering sensor.

1 Grip the body assembly with your fingers and pull it straight out to separate it

from the water-cooled front cover. (You may have to disconnect the sensor

cable in order to separate the parts.) See Figure 4-5.

2 Pull the crystal holder straight out from the front of the body assembly.

3 Remove the ceramic retainer from the crystal holder by pulling it straight out

with the crystal snatcher (see section 4.2.5 on page 4-14).

4 Turn the crystal holder over so that the crystal drops out.

5 Install a new crystal into the crystal holder with the patterned electrode facing

the back and contacting the leaf springs on the ceramic retainer.

6 Put the ceramic retainer back into the crystal holder and put the holder into the

body assembly of the sensor.

7 Align the position of the body assembly so that the connector matches with the

notch on the front cover of the sensor. Snap the two parts together. Reconnect

the sensor cable if it has been disconnected.

Q-pod Operating Manual

IPN 074-547-P1B

Figure 4-5 Sputtering Crystal Sensor

4 - 13

Page 42

Q-pod Operating Manual

4.2.5 Crystal Snatcher

Use the crystal snatcher, supplied with the sensor, as follows:

1 Insert crystal snatcher into ceramic retainer (1) and apply a small amount of

pressure. This locks the retainer to the snatcher and allows the retainer to be

pulled straight out (2). See Figure 4-6.

2 Reinsert the retainer into the holder after the crystal has been replaced.

3 Release the crystal snatcher with a slight side-to-side motion.

Figure 4-6 Use of the Crystal Snatcher

4 - 14

IPN 074-547-P1B

Page 43

4.3 Crystal Sensor Emulator

CAUTION

Female

BNC

Connector

Female

Microdot

Connector

Sensor

Cover

Connector

Thin Film

Controller

Crystal Interface

Unit (Oscillator)

Sensor Head

A

B

C

IPN 760-601-G2

NOTE: 760-601-G2 is fully compatible with all Thin Film Deposition Controllers.

The Crystal Sensor Emulator option is used in conjunction with the Thin Film

Deposition Controller to rapidly diagnose problems with the Deposition Controller's

measurement system. See Figure 4-7.

Figure 4-7 Crystal Sensor Emulator

Q-pod Operating Manual

The Crystal Sensor Emulator may be attached at various points in the

measurement system, from the oscillator to the sensor head. It provides a known

good monitor crystal with known good electrical connections. Using the emulator

and the controller in a systematic manner provides a fast means of isolating

measurement system, cable, or sensor problems. See Figure 4-8.

Figure 4-8 Crystal Sensor Emulator Attachment Points

IPN 074-547-P1B

This product is designed as a diagnostic tool, and is not

intended for use in vacuum. Do not leave the Crystal

Sensor Emulator installed in the vacuum system during

processing.

4 - 15

Page 44

Q-pod Operating Manual

4.3.1 Diagnostic Procedures

The following diagnostic procedures employ the Crystal Sensor Emulator to

analyze a constant Crystal Fail message. The symptom is a Crystal Fail message

that is displayed by the Q-pod software even after the monitor crystal has been

replaced with a new good monitor crystal.

4.3.1.1 Measurement System Diagnostic Procedure

1 Refer to Figure 4-8 on page 4-15. Remove the six-inch BNC cable from the

Feed-Through at point A.

2 Connect the Crystal Sensor Emulator to the 6 inch BNC cable at Point A.

If the Crystal Fail message disappears after approximately five seconds,

the measurement system is working properly. Re-install the six-inch BNC

cable to the Feed-Through. Go to section 4.3.1.2.

If the Crystal Fail message remains, continue at step 3.

3 Disconnect the six-inch BNC cable from the Oscillator and from the Emulator.

4 Visually inspect the six-inch BNC cable to verify that the center pins are seated

properly.

5 Use an Ohm meter to verify the electrical connections on the six-inch BNC

cable.

There must be continuity (<0.2 ohms, after accounting for resistance of

ohmeter leads) between the center pins.

There must be isolation (>10 megohms) between the center pins and the

connector shield.

There must be continuity between the connector shields.

Replace the six-inch BNC cable if it is found to be defective and repeat Step 2

of this procedure.

6 If the six-inch BNC cable is not defective, re-connect the six-inch cable to the

oscillator and to the Crystal Sensor Emulator. If the Crystal Fail message

remains, contact INFICON.

IPN 074-547-P1B

4 - 16

Page 45

4.3.1.2 Feed-Through Or In-Vacuum Cable Diagnostic Procedure

1 Refer to Figure 4-8 on page 4-15. Remove the In-Vacuum cable from the

Sensor Head at point B.

2 Connect the Crystal Sensor Emulator to the In-Vacuum cable.

If the Crystal Fail message disappears after approximately five seconds,

the Feed-Through and In-Vacuum Cable are working properly. Re-install

the In-Vacuum cable to the Sensor Head. Go to section section 4.3.1.3 on

page 4-18.

If the Crystal Fail message remains, continue at step 3.

3 Disconnect the In-Vacuum cable from the Feed-Through and the Emulator.

Disconnect the six-inch BNC cable from the Feed-Through.

4 Using an Ohm Meter, verify electrical continuity from the BNC center pin on the

Feed-Through to the Microdot center pin on the Feed-Through. A typical value

would be less than 0.2 ohms.

5 Verify electrical isolation of the center pin on the Feed-Through from the

electrical ground (Feed-Through body). A typical value would be in excess of

10 megohms.

Q-pod Operating Manual

If the Feed-Through is found to be defective, replace the Feed-Through, re-attach

the BNC and In-Vacuum cables, and repeat this procedure starting at Step 2,

otherwise continue at step 6.

6 Verify electrical continuity from center pin to center pin on the In-Vacuum cable.

7 Verify that the center pin of the In-Vacuum cable is electrically isolated from the

In-Vacuum cable shield.

If the In-Vacuum cable is found to be defective, replace the In-Vacuum cable.

Re-attach the BNC and In-Vacuum cables, and repeat this procedure starting at

Step 2, otherwise continue at step 8.

IPN 074-547-P1B

8 Connect the In-Vacuum Cable to the Feed-Through.

9 Verify electrical continuity from the center pin on the BNC connector of the

Feed-Through to the center pin on the un-terminated end of the In-Vacuum

cable.

10 Verify electrical isolation from the center pin to electrical ground (Feed-Through

body).

If the Feed-Through/In-Vacuum cable system is found to be defective, look for

defective electrical contacts at the Feed-Through to In-Vacuum cable connection.

Repair or replace the Feed-Through as necessary. Re-attach the BNC and

In-Vacuum cables and repeat this procedure starting at step 2. Otherwise, continue

at step 11.

4 - 17

Page 46

Q-pod Operating Manual

11 Connect the six-inch BNC cable to the Feed-Through and disconnect it from the

Q-pod.

12 Verify electrical continuity from the center pin of the Microdot connector on the

Feed-Through to the un-terminated end of the six-inch BNC cable.

13 Verify electrical isolation from the center pin to electrical ground (Feed-Through

body).

If the Feed-Through/six-inch BNC cable system is found to be defective, look for

defective contacts at the Feed-Through to BNC cable connection. Repair or

replace the Feed-Through as necessary, re-attach the BNC cable to the XIU and

In-Vacuum cable to the Crystal head and repeat this procedure starting at step 2.

4.3.1.3 Sensor Head Or Monitor Crystal Diagnostic Procedure

NOTE: The procedure is for use with front load style sensor heads.

1 Remove the Crystal Cover from the Sensor Head.

2 Refer to Figure 4-7 on page 4-15. Connect the Crystal Sensor Emulator to the

Sensor Head at Point C.

If the Crystal Fail message disappears after approximately 5 seconds the

Sensor Head is operating properly. Remove the Crystal Sensor Emulator

and re-insert the Crystal Cover into the Sensor Head.

If the Crystal Fail message remains, continue at step 3.

3 Disconnect the In-Vacuum cable from the Sensor Head and the Feed-Through.

Remove the Crystal Sensor Emulator from the Sensor Head.

4 Using an Ohm meter, verify the electrical connections on the Sensor Head.

Verify there is electrical continuity from the center pin contact on the

Microdot connector on the Sensor Head to the leaf spring contact in the

Sensor Head. Take care not to apply to much pressure on the center pin of

the microdot connector as it may become damaged.

There must be electrical isolation between the center pin of the Microdot

connector and the Sensor Head body.

If the Sensor Head is found to be defective, contact INFICON to have the

Sensor Head repaired.

IPN 074-547-P1B

4 - 18

Page 47

5 Connect the In-Vacuum Cable to the Sensor Head.

Verify there is continuity (<0.2 ohm) from the leaf spring contact in the

Sensor Head to the center pin on the un-terminated end of the In-Vacuum

cable.

Verify there is isolation (>10 megohm) between the leaf spring contact and

the In-Vacuum cable shield.

If the Sensor Head or the In-Vacuum cable system is found to be defective, look for

defective contacts at the In-Vacuum cable to Sensor Head connection, repair or

replace the Sensor Head as necessary. Re-attach the In-Vacuum cable to the

Feed-Through and repeat this procedure starting at step 2.

6 Ensure that the leaf springs in the Sensor Head and those in the Ceramic

Retainer are bent to an angle of approximately 60º and 45º from flat,

respectively.

4.3.1.4 System Diagnostics Pass But Crystal Fail Message Remains

If the system is operating properly yet the Crystal Fail message is still displayed,

perform the following tasks.

Q-pod Operating Manual

1 On the Ceramic Retainer verify that the center rivet is secure. Repair or replace

the Ceramic Retainer as necessary.

2 Inspect the inside of the Crystal Holder for build-up of material. Clean or replace

the Crystal Holder as necessary.

After verifying the Sensor Head contacts, the Sensor Head/In-Vacuum cable

connection and the ceramic retainer contacts, re-assemble the system. If the

Crystal Fail message remains, replace the monitor crystal with a new monitor

crystal. Verify that the monitor crystal works properly by inserting it into a known

good measurement system. If you continue to experience problems, contact

INFICON.

IPN 074-547-P1B

4 - 19

Page 48

Q-pod Operating Manual

4.3.2 Sensor Cover Connection

The Crystal Sensor Emulator can be used to verify the measurement system for

INFICON Thin Film Deposition Controllers and Monitors.

However, the Crystal Sensor Emulator's Sensor Cover Connector is compatible

with some sensor heads, and is incompatible with others. This is discussed in the

following sections.

4.3.2.1 Compatible Sensor Heads

The Sensor Cover Connection will fit the sensor heads shown in Table 4-4.

Table 4-4 Compatible Sensor Heads

Sensor Head Part Number

Front Load Single Sensor Head SL-XXXXX

Front Load Dual Sensor Head DL-AEXX

4.3.2.2 Incompatible Sensor Heads

The Sensor Heads for which the Crystal Sensor Emulator's Sensor Cover

Connector will not fit are shown in Table 4-5.

Table 4-5 Incompatible Sensor Heads

Sensor Head Part Number

Front Load UHV Bakeable Sensor Head BK-AXX

Cool Drawer Single Sensor Head CDS-XXXXX

Sputtering Sensor Head 750-618-G1

CrystalSix Sensor Head 750-446-G1

Cool Drawer Dual Sensor Head CDD-XXXX

Crystal12 Sensor Head XL12-XXXXXX

RSH-600 Sensor Head 15320X-XX

NOTE: The Crystal Sensor Emulator’s Sensor Cover will not fit the crystal holder

opening of the older style INFICON transducers that have the soldered

finger springs.

IPN 074-547-P1B

4 - 20

Page 49

4.3.3 Emulator Specifications

Dimensions

1.58 in. diameter x 1.79 in.

(40.13 mm diameter x 45.47 mm)

Temperature Range

0 to 50

Frequency

760-601-G2: 5.5 MHz ± 1 ppm at room temperature

Materials

304 Stainless Steel, Nylon, Teflon®, brass. Some internal components contain

zinc, tin, and lead.

o

C

Q-pod Operating Manual

IPN 074-547-P1B

4 - 21

Page 50

Q-pod Operating Manual

This page is intentionally blank.

4 - 22

IPN 074-547-P1B

Page 51

Q-pod Operating Manual

Density g cm

3

D

1

T

x

T

m

-------

=

Calibration Procedures

5.1 Importance of Density, Tooling and Z-Ratio

The quartz crystal microbalance is capable of precisely measuring the mass added

to the face of the oscillating quartz crystal sensor. The Q-pod's knowledge of the

density of this added material (specified in the density parameter in material grid)

allows conversion of the mass information into thickness. In some instances, where

highest accuracy is required, it is necessary to make a density calibration as

outlined in section 5.2.

Because the flow of material from a deposition is not uniform, it is necessary to

account for the different amount of material flow onto the sensor compared to the

substrates. This factor is accounted for in the tooling parameter in material grid.

The tooling factor can be experimentally established by following the guidelines in

section 5.3 on page 5-2.

Chapter 5

If the Z-Ratio is not known, it could be estimated from the procedures outlined in

section 5.4 on page 5-2.

5.2 Determining Density

NOTE: The bulk density values retrieved from Table A-1 are sufficiently accurate

for most applications.

Follow the steps below to determine density value.

1 Place a substrate (with proper masking for film thickness measurement)

adjacent to the sensor, so that the same thickness will be accumulated on the

crystal and substrate.

2 Set density to the bulk value of the film material or to an approximate value.

IPN 074-547-P1B

3 Set Z-Ratio to 1.000 and tooling to 100%.

4 Place a new crystal in the sensor and make a short deposition

(1000-5000 Å).

5 After deposition, remove the test substrate and measure the film thickness with

either a multiple beam interferometer or a stylus-type profilometer.

6 Determine the new density value with equation [1]:

[1]

5 - 1

Page 52

Q-pod Operating Manual

Tooling (%) TF

i

T

m

T

x

-------

=

where:

= Initial density setting

D

1

= Thickness reading on Q-pod

T

x

= Measured thickness

T

m

7 A quick check of the calculated density may be made by programming the

Q-pod with the new density value and observing that the displayed thickness is

equal to the measured thickness, provided that the Q-pod's thickness has not

been zeroed between the test deposition and entering the calculated density.

NOTE: Slight adjustment of density may be necessary in order to

achieve T

= Tm.

x

5.3 Determining Tooling

1 Place a test substrate in the system's substrate holder.

2 Make a short deposition and determine actual thickness.

3 Calculate tooling from the relationship shown in equation [2]:

where

T

= Actual thickness at substrate holder

m

= Thickness reading in the Q-pod

T

x

= Initial tooling factor

TF

i

4 Round off percent tooling to the nearest 0.1%.

5 When entering this new value for tooling into the program, T

calculations are done properly.

NOTE: It is recommended that a minimum of three separate evaporations be

made when calibrating tooling. Variations in source distribution and other

system factors will contribute to slight thickness variations. An average

value tooling factor should be used for final calibrations.

5.4 Laboratory Determination of Z-Ratio

A list of Z-values for materials commonly used are available in Table A-1. For other

materials, Z can be calculated from the following formula:

will equal Tx if

m

[2]

IPN 074-547-P1B

5 - 2

Page 53

Q-pod Operating Manual

Z

d

qq

df

f

------------

1

2

---

=

Z 9.378 105df

f

-

1

2

---

=

T

f

Zq10

4

2zp

--------------------

1

F

co

--------

ATan zTan

F

co

F

q

-----------

1

F

c

-----

ATan zTan

F

c

F

q

---------

–

=

where:

= density (g/cm3) of deposited film

d

f

= shear modulus (dynes/cm2) of deposited film

µ

f

= density of quartz (crystal) (2.649 gm/cm3)

d

q

= shear modulus of quartz (crystal) (3.32 x 1011 dynes/cm2)

µ

q

The densities and shear moduli of many materials can be found in a number of

handbooks.

[3]

[4]

Laboratory results indicate that Z-values of materials in thin-film form are very close

to the bulk values. However, for high stress producing materials, Z-values of thin

films are slightly smaller than those of the bulk materials. For applications that

require more precise calibration, the following direct method is suggested:

1 Establish the correct density value as described in section 5.2 on page 5-1.

2 Install a new crystal and record its starting frequency, F

frequency will be displayed on the main screen.

. The starting

co

3 Make a deposition on a test substrate such that the percent crystal life display

will read approximately 50%, or near the end of crystal life for the particular

material, whichever is smaller.

4 Stop the deposition and record the ending crystal frequency F

IPN 074-547-P1B

5 Remove the test substrate and measure the film thickness with either a multiple

beam interferometer or a stylus-type profilometer.

6 Using the density value from step 1 and the recorded values for F

adjust the Z-ratio value in thickness equation [5] to bring the calculated

thickness value into agreement with the actual thickness. If the calculated value

of thickness is greater than the actual thickness, increase the Z-Ratio value. If

the calculated value of thickness is less than the actual thickness, decrease the

Z-Ratio value.

.

c

and Fc,

co

[5]

5 - 3

Page 54

Q-pod Operating Manual

where:

= thickness of deposited film (kÅ)

T

f

= starting frequency of the sensor crystal (Hz)

F

co

= Final frequency of the sensor crystal (Hz)

F

c

= Nominal blank frequency = 6045000 (Hz)

F

q

z = Z-ratio of deposited film material

Z

= Specific acoustic impedance of quartz = 8765000 (MKS units)

q

p = density of deposited film (g/cc)

For multiple layer deposition (for example, two layers), the Z-value used for the

second layer is determined by the relative thickness of the two layers. For most

applications the following three rules will provide reasonable accuracies:

If the thickness of layer 1 is large compared to layer 2, use material 1 Z-value

for both layers.

If the thickness of layer 1 is thin compared to layer 2, use material 2 Z-value for

both layers.

If the thickness of both layers is similar, use a value for Z-Ratio which is the

weighted average of the two Z values for deposition of layer 2 and subsequent

layers.

IPN 074-547-P1B

5 - 4

Page 55

6.1 Basics

M

f

M

q

-------

F

F

q

-----------=

T

f

KF

d

f

----------------=

Q-pod Operating Manual

Chapter 6

Measurement and Theory

The Quartz Crystal deposition Monitor, or QCM, utilizes the piezoelectric sensitivity

of a quartz monitor crystal to added mass. The QCM uses this mass sensitivity to

control the deposition rate and final thickness of a vacuum deposition. When a

voltage is applied across the faces of a properly shaped piezoelectric crystal, the

crystal is distorted and changes shape in proportion to the applied voltage. At

certain discrete frequencies of applied voltage, a condition of very sharp

electro-mechanical resonance is encountered. When mass is added to the face of

a resonating quartz crystal, the frequency of these resonances are reduced. This

change in frequency is very repeatable and is precisely understood for specific

oscillating modes of quartz. This heuristically easy to understand phenomenon is

the basis of an indispensable measurement and process control tool that can easily

detect the addition of less than an atomic layer of an adhered foreign material.

In the late 1950’s it was noted by Sauerbrey

frequency, DF = F

frequencies, F

and Fq respectively, is related to the change in mass from the

c

added material, M

, of a quartz crystal with coated (or composite) and uncoated

q-Fc

, as follows:

f

1,2

and Lostis3 that the change in

[1]

where M

is the mass of the uncoated quartz crystal. Simple substitutions lead to

q

the equation that was used with the first “frequency measurement” instruments:

[2]

IPN 074-547-P1B

where the film thickness, T

, is proportional (through K) to the frequency change,

f

DF, and inversely proportional to the density of the film, d

2

N

atdq/Fq

; where dq (= 2.649 gm/cm3) is the density of single crystal quartz and Nat

. The constant, K =

f

(=166100 Hz cm) is the frequency constant of AT cut quartz. A crystal with a

starting frequency of 6.0 MHz will display a reduction of its frequency by 2.27 Hz

when 1 angstrom of Aluminum (density of 2.77 gm/cm

3

) is added to its surface. In

this manner the thickness of a rigid adlayer is inferred from the precise

measurement of the crystal’s frequency shift. The quantitative knowledge of this

1.G. Z. Sauerbrey, Phys. Verhand .8, 193 (1957)

2.G. Z. Sauerbrey, Z. Phys. 155

3.P. Lostis, Rev. Opt. 38

,206 (1959)

,1 (1959)

6 - 1

Page 56

Q-pod Operating Manual

effect provides a means of determining how much material is being deposited on a

substrate in a vacuum system, a measurement that was not convenient or practical

prior to this understanding.

6.1.1 Monitor Crystals

No matter how sophisticated the electronics surrounding it, the essential device of

the deposition monitor is the quartz crystal. The quartz crystal shown in Figure 6-1

has a frequency response spectrum that is schematically shown in Figure 6-2. The

ordinate represents the magnitude of response, or current flow of the crystal, at the

specified frequency.

Figure 6-1 Quartz Resonator

The lowest frequency response is primarily a “thickness shear” mode that is called

the fundamental. The characteristic movement of the thickness shear mode is for

displacement to take place parallel to the major monitor crystal faces. In other

words, the faces are displacement antinodes as shown in Figure 6-3. The

responses located slightly higher in frequency are called anharmonics; they are a

combination of the thickness shear and thickness twist modes. The response at

about three times the frequency of the fundamental is called the third

quasiharmonic. There are also a series of anharmonics slightly higher in frequency

associated with the quasiharmonic.

The monitor crystal design depicted in Figure 6-1 is the result of several significant

improvements from the square crystals with fully electroded plane parallel faces

that were first used. The first improvement was to use circular crystals. This

increased symmetry greatly reduced the number of allowed vibrational modes. The

second set of improvements was to contour one face of the crystal and to reduce

the size of the exciting electrode. These improvements have the effect of trapping

the acoustic energy. Reducing the electrode diameter limits the excitation to the

central area. Contouring dissipates the energy of the traveling acoustic wave

before it reaches the edge of the crystal. Energy is not reflected back to the center

where it can interfere with other newly launched waves, essentially making a small