HP Scitex FB500, FB700 service manual

HP Scitex FB500 /

FB700

Service Manual

*CQ114-90048*

Document part number: CQ114-90035, Rev. B

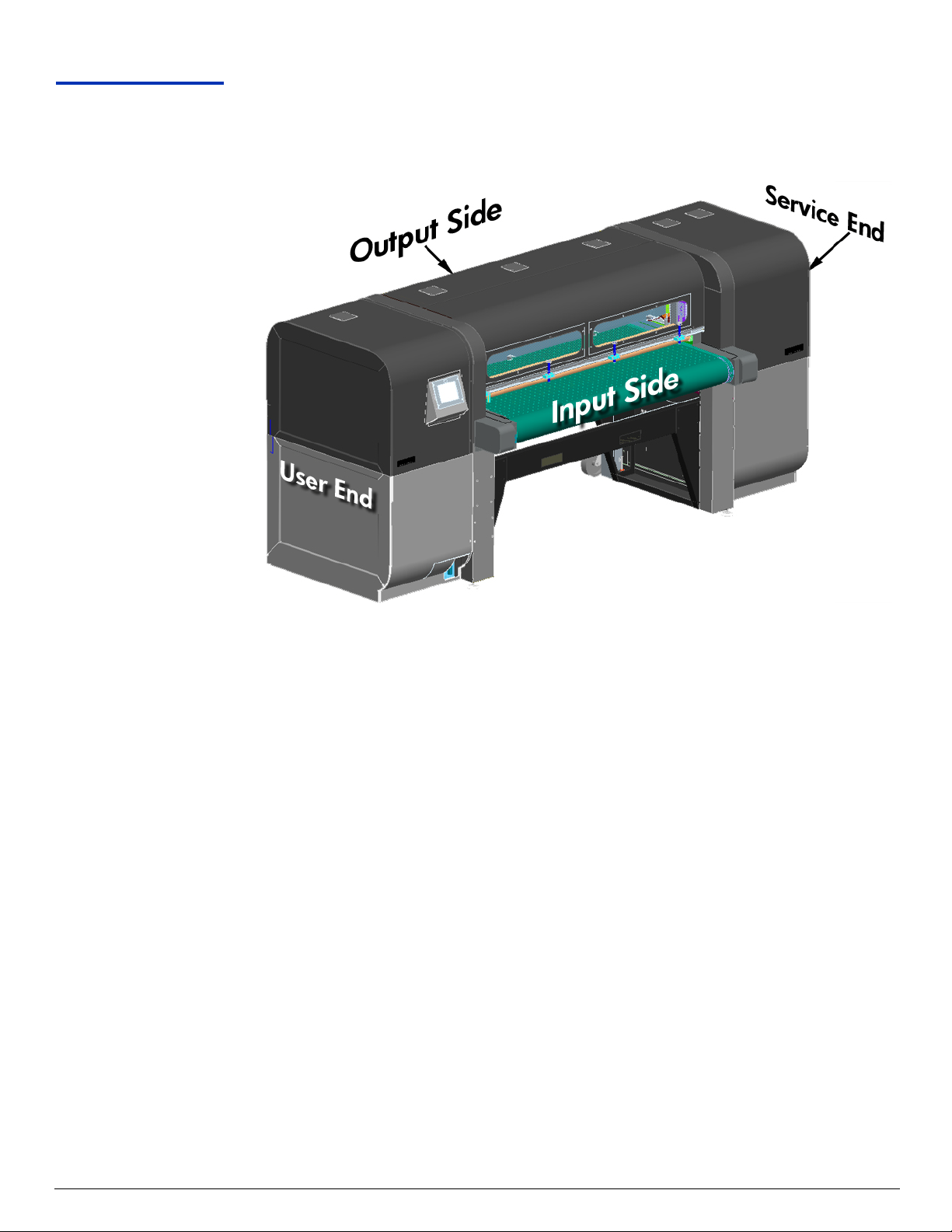

Table of Contents Printer orientation ................................................................................................12

Required tools ......................................................................................................13

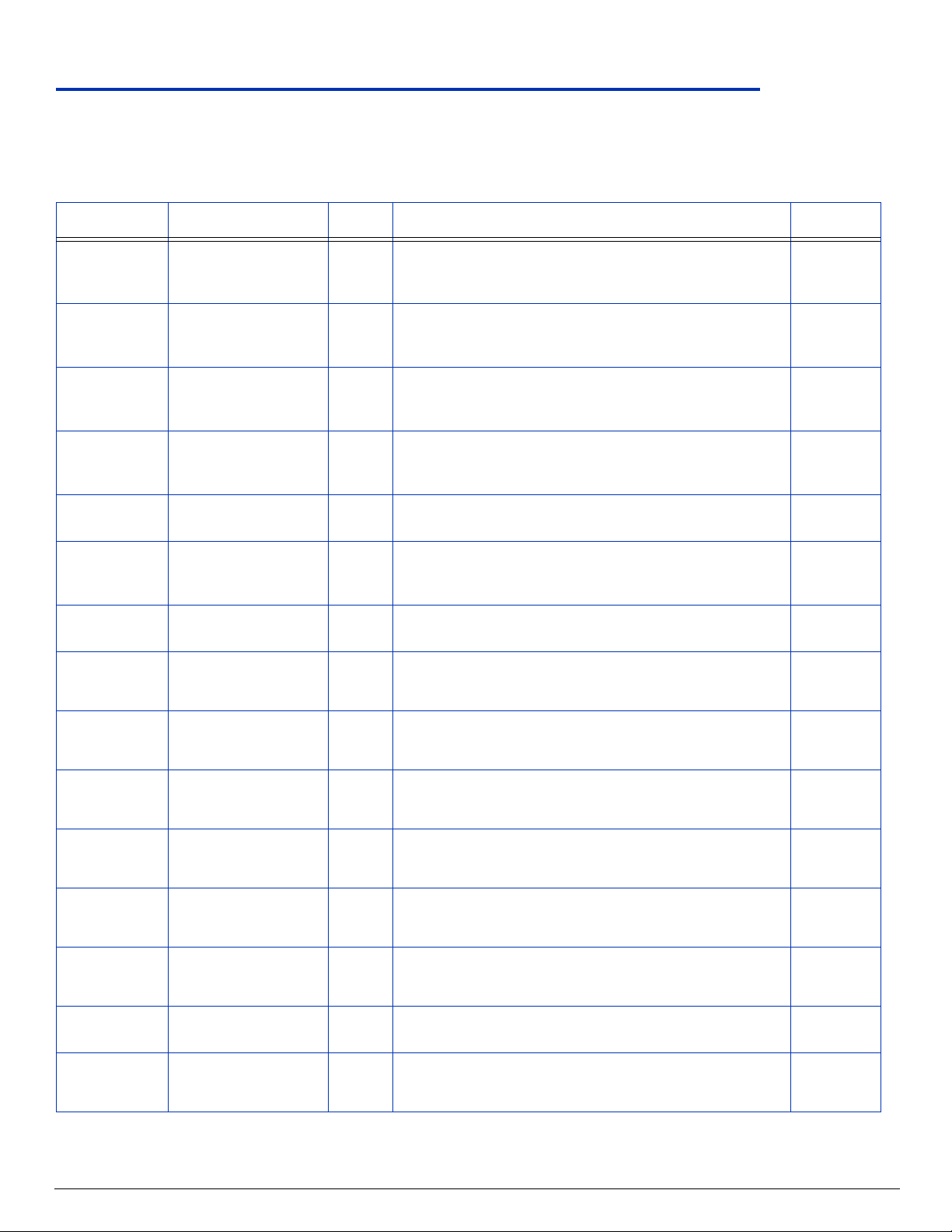

Parts List for Field Replaceable Modules.................................................. 14

Exploded Views...................................................................................... 31

Exploded views: Off-head supply assemblies .......................................................31

OHS part numbers .......................................................................................................................... 31

Ink pumps, Exploded view ............................................................................................................... 32

Vacuum pump assembly exploded view............................................................................................. 33

Vacuum reservoir, Exploded view ..................................................................................................... 34

Ink homogenizer, Exploded view ...................................................................................................... 35

Exploded views: Carriage assemblies ...................................................................36

Trolley assembly (upper and lower) exploded view ............................................................................. 36

Carriage assembly, exploded views.................................................................................................. 37

Carriage assembly brackets, exploded view.......................................................................................37

Carriage pen plate, exploded view................................................................................................... 38

Carriage reservoirs, exploded views ................................................................................................. 39

Printhead interface plate’s alignment pin, exploded view ..................................................................... 39

Carriage back plate, exploded view ................................................................................................. 40

Carriage side attachments, exploded views........................................................................................ 41

Exploded views: Carriage-drive assemblies ..........................................................48

Exploded views: Service station assemblies ..........................................................49

Exploded views: Track assemblies ........................................................................52

Track attachment at carriage ............................................................................................................ 52

Exploded views: Media-drive assemblies..............................................................54

Media-drive assemblies exploded views ............................................................................................ 54

Media-drive assemblies part numbers ................................................................................................ 57

Exploded views: Media-drive actuator assemblies ................................................58

Media-drive actuator assemblies exploded views ................................................................................ 58

Theory of operation and component identification................................... 65

Off-Head Supply Assemblies ................................................................................65

About the OHS (off-head supply)....................................................................................................... 65

About the vacuum assembly ............................................................................................................. 65

Vacuum assembly diagram .............................................................................................................. 66

Vacuum assembly air flow diagram................................................................................................... 67

About the vacuum pump .................................................................................................................. 68

About the vacuum regulator ............................................................................................................. 68

About the vacuum air-inlet filter......................................................................................................... 68

About the vacuum accumulator ......................................................................................................... 68

About the vacuum restrictor .............................................................................................................. 69

About the vacuum sensor ................................................................................................................. 69

About the vacuum assembly power supply ......................................................................................... 69

About the pressure pump ................................................................................................................. 70

About the pressure sensor ................................................................................................................ 70

About the ink pumps........................................................................................................................ 71

About the ink-pump check valve........................................................................................................ 72

About the permanent ink filters ......................................................................................................... 72

About the ink.................................................................................................................................. 73

About the tubes............................................................................................................................... 73

About the ink boxes ........................................................................................................................ 73

About the profilers .......................................................................................................................... 74

About the white ink option ............................................................................................................... 74

About the ink homogenizer (shaker) .................................................................................................. 75

About the ink-box filters ................................................................................................................... 75

About the OHS controller................................................................................................................. 76

Carriage...............................................................................................................76

Wiring diagram for FB500 Carriage Assembly .................................................................................. 77

Wiring diagram for FB700 Carriage Assembly .................................................................................. 78

About the carriage head height ........................................................................................................ 79

About the lamps.............................................................................................................................. 79

About the lamp bulbs ...................................................................................................................... 80

About the camera ........................................................................................................................... 80

About the air manifold..................................................................................................................... 81

About the carriage ink filters............................................................................................................. 81

About the printhead reservoirs .......................................................................................................... 82

About the thermistors ....................................................................................................................... 83

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 1 of 510

About the vacuum tubes................................................................................................................... 84

About the vacuum tubes, split ........................................................................................................... 84

About the printheads ....................................................................................................................... 85

About the printhead interface plate ................................................................................................... 86

About printhead serial numbers ........................................................................................................ 87

About printhead y-axis and x-axis positioning..................................................................................... 87

About printhead saber angle............................................................................................................ 87

About carriage (gross) saber angle ................................................................................................... 87

About the carriage headboard ......................................................................................................... 87

About the carriage headboard lights ................................................................................................. 88

About the encoder reader ................................................................................................................ 89

About the carriage home sensor ....................................................................................................... 89

About the carriage trolley assembly................................................................................................... 90

About the upper carriage trolley assembly ......................................................................................... 90

About the lower carriage trolley assembly.......................................................................................... 90

Service station ......................................................................................................91

About the service station .................................................................................................................. 91

About ink purges ............................................................................................................................ 91

About the Shop-Vac ........................................................................................................................ 91

About the float Sensor ..................................................................................................................... 92

About the service station wipers........................................................................................................ 93

About the wiper-carriage home sensor............................................................................................... 93

About the gap sensor ...................................................................................................................... 94

About the service station access sensor .............................................................................................. 94

About the service station actuator (up-down motor)..............................................................................94

About the service station encoder...................................................................................................... 94

About the service station encoder reader ........................................................................................... 95

About the waste-ink jug.................................................................................................................... 96

Carriage-drive......................................................................................................97

About the carriage-drive assembly .................................................................................................... 97

About the carriage-drive smooth pulley .............................................................................................. 97

About the carriage-drive shaft........................................................................................................... 97

About the carriage-drive timing belt................................................................................................... 97

About the carriage-drive motor ......................................................................................................... 98

About the Carriage Idler .................................................................................................................. 98

About the carriage-drive belt ............................................................................................................ 98

About the carriage-drive belt length and tension ................................................................................. 99

About the rail strips ......................................................................................................................... 99

About the carriage encoder strip..................................................................................................... 100

Track assemblies ................................................................................................101

About the track assembly ............................................................................................................... 101

About the ink tubes ....................................................................................................................... 101

About the LVDS cable.................................................................................................................... 102

About the headboard power cables ................................................................................................ 102

About the H-block clamp................................................................................................................ 102

Media drive........................................................................................................104

About the media-drive motor .......................................................................................................... 104

About the media-drive motor coupling ............................................................................................. 104

About the media-drive motor encoder .............................................................................................. 105

About the high-resolution encoder ring............................................................................................. 105

About the high-resolution belt encoder reader................................................................................... 105

About the media-drive belt ............................................................................................................. 108

About the media-drive roller ........................................................................................................... 108

About the idler roller ..................................................................................................................... 109

About the adjustment bearing block assembly .................................................................................. 109

About the vacuum trays ................................................................................................................. 110

About the airflow plate .................................................................................................................. 111

About the ionizer .......................................................................................................................... 111

About the N-up pins ...................................................................................................................... 111

About the actuator motors .............................................................................................................. 112

About the media alignment bar ...................................................................................................... 113

About the input roller..................................................................................................................... 113

About the output roller ................................................................................................................... 114

About the media thickness sensor.................................................................................................... 114

About the media detection sensor ................................................................................................... 114

Roll-to-roll ............................................................................................ 115

About the roll-to-roll assembly ...........................................................................115

Lift and press foam rollers .............................................................................................................. 115

About the supply assemblies........................................................................................................... 115

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 2 of 510

Mid-spool support for heavy media rolls .......................................................................................... 116

About the takeup assemblies .......................................................................................................... 117

About the limit switches ................................................................................................................. 118

Electronics ..........................................................................................................119

Wiring diagram for the FB500 printer ............................................................................................. 119

Wiring diagram for FB500 main electronics..................................................................................... 120

Wiring diagram for the FB700 printer ............................................................................................. 121

Wiring diagram for FB700 main electronics..................................................................................... 122

About the main electronics box....................................................................................................... 123

Electronics box components identified ............................................................................................. 123

About the motor control board........................................................................................................ 124

About the 38v/24v power supply ................................................................................................... 125

About the AC power distribution board ........................................................................................... 125

About the AC filter ........................................................................................................................ 125

About the AC relay ....................................................................................................................... 126

About the ATX power supply .......................................................................................................... 126

About the hard disk....................................................................................................................... 126

About the motherboard.................................................................................................................. 126

About the UV power supply............................................................................................................ 126

About the I/O board..................................................................................................................... 128

About the main power cable ..........................................................................................................129

Uninterrupted power supply ........................................................................................................... 130

Cable Pinouts .....................................................................................................131

Troubleshooting printer components ..................................................... 142

Troubleshooting carriage-drive assemblies .........................................................142

Carriage motion failures ................................................................................................................ 142

Troubleshooting carriage motion failures.......................................................................................... 142

Troubleshooting the carriage-drive smooth pulley .............................................................................. 144

Troubleshooting the carriage-drive shaft........................................................................................... 144

Troubleshooting the carriage-drive timing belt................................................................................... 144

Troubleshooting the carriage-drive motor ......................................................................................... 144

Troubleshooting the carriage-drive belt ............................................................................................ 145

Troubleshooting the rail strips ......................................................................................................... 145

Troubleshooting the carriage encoder strip....................................................................................... 145

Troubleshooting Carriage Assemblies .................................................................146

Troubleshooting carriage head height ............................................................................................. 146

Troubleshooting the lamps.............................................................................................................. 146

Troubleshooting the camera ........................................................................................................... 146

Troubleshooting the air manifold..................................................................................................... 146

Troubleshooting the carriage ink filters............................................................................................. 147

Troubleshooting printhead reservoirs ............................................................................................... 147

Troubleshooting thermistors ............................................................................................................ 147

Troubleshooting the vacuum tube .................................................................................................... 147

Troubleshooting split vacuum tubes.................................................................................................. 147

Troubleshooting printheads ............................................................................................................ 147

Troubleshooting the printhead interface plate ................................................................................... 148

Troubleshooting the carriage headboard ......................................................................................... 148

Troubleshooting the carriage encoder reader ................................................................................... 148

Troubleshooting the home sensor .................................................................................................... 149

Troubleshooting the upper trolley .................................................................................................... 149

Troubleshooting the lower trolley..................................................................................................... 149

Troubleshooting the OHS assemblies ..................................................................150

Troubleshooting the vacuum assembly ............................................................................................. 150

Troubleshooting the vacuum pump .................................................................................................. 150

Troubleshooting the vacuum regulator.............................................................................................. 150

Troubleshooting the vacuum accumulator ......................................................................................... 150

Troubleshooting the vacuum restrictor ..............................................................................................151

Troubleshooting the vacuum sensor ................................................................................................. 151

Troubleshooting vacuum power supply ............................................................................................ 151

Troubleshooting the pressure pump ................................................................................................. 151

Troubleshooting the ink pumps........................................................................................................ 151

Troubleshooting the ink-line check valve ........................................................................................... 151

Troubleshooting profilers................................................................................................................ 152

Troubleshooting the ink shaker........................................................................................................ 152

Troubleshooting ink-box filters......................................................................................................... 152

Troubleshooting the OHS controller ................................................................................................. 152

Troubleshooting maintenance system .................................................................153

Troubleshooting the service station .................................................................................................. 153

Troubleshooting the printhead wipers .............................................................................................. 153

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 3 of 510

Troubleshooting the service station encoder and encoder reader......................................................... 153

Troubleshooting the waste ink jug ................................................................................................... 154

Troubleshooting the track assemblies ................................................................ 155

Troubleshooting the track assembly ................................................................................................. 155

Troubleshooting the LVDS cable and LVDS error ............................................................................... 155

Detecting a damaged LVDS chip..................................................................................................... 156

Troubleshooting error: Failed to Program FPGA ................................................................................157

Troubleshooting the media-drive assemblies.......................................................159

Troubleshooting the media-drive motor coupling ............................................................................... 159

Troubleshooting the media-drive motor encoder ................................................................................ 159

Troubleshooting the high-resolution media-drive encoder.................................................................... 159

Troubleshooting the media-drive belt ............................................................................................... 160

Troubleshooting the ionizer ............................................................................................................ 160

Troubleshooting the media alignment bar......................................................................................... 160

Troubleshooting the rail actuator motor ............................................................................................ 160

Troubleshooting the media thickness sensor ...................................................................................... 160

Troubleshooting the media detection sensor...................................................................................... 160

Troubleshooting the supply spool .................................................................................................... 161

Troubleshooting the electronic assemblies...........................................................162

Troubleshooting the motor control board .......................................................................................... 162

Troubleshooting the I/O board ....................................................................................................... 162

Troubleshooting the 38/24v power supply....................................................................................... 162

Printer’s Service Menus......................................................................... 163

TOOLS > USER CLEANING AND MAINTENANCE....................................................163

Menu: Maintenance reminders ....................................................................................................... 163

Menu: Replace UV lamp bulb or bulbs............................................................................................. 163

Menu: Clean rail encoder strip ....................................................................................................... 163

Menu: Clean ionizer needles.......................................................................................................... 163

Menu: Clean and lube rail strips ..................................................................................................... 163

Menu: Clean print head orifice plates.............................................................................................. 163

Menu: Clean/lube service station rails............................................................................................. 163

Menu: Clean service station wiper .................................................................................................. 163

Menu: Clean carriage wheels......................................................................................................... 164

Menu: Vacuum bottom of carriage .................................................................................................. 164

Menu: Clean carriage home sensor................................................................................................. 164

Menu: Replace UV lamp filters........................................................................................................ 164

Menu: Clean electronics box filters.................................................................................................. 164

Menu: Replace service station wiper................................................................................................ 164

Menu: Drain waste from service station............................................................................................ 164

Menu: Clean media thickness sensor roller....................................................................................... 164

TOOLS > USER DIAGNOSTICS ..............................................................................165

Menu: Carriage motion ................................................................................................................. 165

Menu: Rail motion......................................................................................................................... 165

Menu: Calibration......................................................................................................................... 165

Menu: Verify H2H Y Alignment....................................................................................................... 165

Menu: Print quality ........................................................................................................................ 165

Menu: Service station .................................................................................................................... 165

Vacuum pressure .......................................................................................................................... 165

Menu: Hard drive ......................................................................................................................... 165

Menu: LVDS ................................................................................................................................. 165

Menu: Print diagnostic plot............................................................................................................. 165

Menu: Print jet statistics.................................................................................................................. 166

Menu: Warnings and actions list .................................................................................................... 166

Menu: Error history ....................................................................................................................... 166

Menu: Log error history.................................................................................................................. 166

Menu: Log system info ................................................................................................................... 166

TOOLS > SERVICE PRINTER > DEVICE TESTS...........................................................167

Menu: Device test wizard............................................................................................................... 167

Menu: Vacuum fan test .................................................................................................................. 167

Menu: Media thickness sensor test .................................................................................................. 167

Menu: Rail-height motor test ........................................................................................................... 168

Menu: Roller, alignment bar, sensor and switch test .......................................................................... 168

Menu: Carriage home sensor test.................................................................................................... 168

Menu: Profiler test ......................................................................................................................... 168

Menu: Service station tests ............................................................................................................. 169

Menu: Cabinet fans test ................................................................................................................. 169

Menu: Carriage cooling fan test ..................................................................................................... 169

Menu: Ionizer relay test ................................................................................................................. 170

Menu: UV lamp test....................................................................................................................... 170

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 4 of 510

Menu: Media motion velocity test.................................................................................................... 170

Menu: Test media drive control system............................................................................................. 171

TOOLS > SERVICE PRINTER > DEVICE TESTS > IMAGE SENSOR TESTS......................172

Menu: Visually examine LEDs ......................................................................................................... 172

Menu: Whitepoint......................................................................................................................... 172

Menu: Take picture of white paper.................................................................................................. 172

Menu: Take raw picture of dots ...................................................................................................... 173

Menu: Take enhanced picture of dots .............................................................................................. 173

TOOLS > SERVICE PRINTER > DEVICE TESTS...........................................................174

Menu: Open loop actuator test ....................................................................................................... 174

Menu: Open loop service station test............................................................................................... 174

Menu: Pod test.............................................................................................................................. 174

Menu: Hard drive file system check ................................................................................................. 174

TOOLS > SERVICE PRINTER > PRINT TESTS ............................................................175

Menu: Print prime bars .................................................................................................................. 175

Menu: Print test............................................................................................................................. 175

Menu: Belt & rail parallel test ......................................................................................................... 175

Menu: Media feed accuracy test, one.............................................................................................. 175

Menu: Media feed accuracy test, all ............................................................................................... 176

Menu: Horizontal dot accuracy....................................................................................................... 176

Menu: Vertical dot accuracy........................................................................................................... 176

Menu: Print test page..................................................................................................................... 176

Menu: Print faux 662 .................................................................................................................... 176

Menu: Comb banding ramps.......................................................................................................... 176

TOOLS > SERVICE PRINTER > INK SYSTEM TESTS...................................................176

Menu: Air valves........................................................................................................................... 176

Menu: Prime ink pumps ................................................................................................................. 176

Menu: Ink pumps .......................................................................................................................... 177

Menu: Ink / air thermistors............................................................................................................. 177

Menu: Pressure pump .................................................................................................................... 177

Menu: Vacuum pump .................................................................................................................... 177

Menu: Turn ON / OFF white ink shaker .......................................................................................... 178

Menu: Initial ink fill........................................................................................................................ 178

Menu: Prep for shipping ................................................................................................................ 178

Menu: Disable on-head system ....................................................................................................... 178

TOOLS > SERVICE PRINTER > SERVICE CALIBRATIONS ...........................................179

Menu: Calibration wizard.............................................................................................................. 179

TOOLS > SERVICE PRINTER > SERVICE CALIBRATIONS > INDIVIDUAL CALIBRATIONS180

Menu: LCD touchscreen calibration ................................................................................................. 180

Menu: Head height calibration ....................................................................................................... 180

Menu: Media thickness sensor calibration ........................................................................................ 180

Menu: Service station calibration .................................................................................................... 181

Menu: Input roller home calibration................................................................................................. 181

Menu: Output roller home calibration .............................................................................................. 182

Menu: Alignment bar home calibration............................................................................................ 182

Menu: UV lamps shutter calibration................................................................................................. 182

Menu: Image sensor height & position ............................................................................................. 183

Menu: Printhead Y calibration ........................................................................................................ 183

Menu: Media feed calibration ........................................................................................................ 184

Menu: Manual bidi calibration ....................................................................................................... 184

Menu: Auto head X calibration ....................................................................................................... 185

Menu: Pin & alignment bar position ................................................................................................ 185

Menu: Media sensor position calibration ......................................................................................... 185

Menu: Media alignment bar alignment ............................................................................................ 185

TOOLS > SERVICE PRINTER > SERVICE CALIBRATIONS ...........................................186

Menu: Invalidate calibration........................................................................................................... 186

TOOLS > SERVICE PRINTER > RESET HOME POSITIONS..........................................187

Menu: Reset carriage home position................................................................................................ 187

Menu: Reset rail home position ....................................................................................................... 187

Menu: Home service station ........................................................................................................... 187

Menu: Home UV shutters................................................................................................................ 187

Menu: Home input roller ................................................................................................................ 188

Menu: Home output roller .............................................................................................................. 188

Menu: Home alignment bar............................................................................................................ 188

TOOLS > SERVICE PRINTER ..................................................................................189

Menu: Measure media width.......................................................................................................... 189

Menu: Replace printhead............................................................................................................... 189

Menu: Fill replaced printhead......................................................................................................... 189

Menu: Set head vacuum ................................................................................................................ 189

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 5 of 510

Menu: Reset image sensor.............................................................................................................. 190

Menu: Prep for shipping ................................................................................................................ 190

Menu: Install shipping restraint ....................................................................................................... 190

Menu: Set clock ............................................................................................................................ 190

Menu: Raise rail, bar, and rollers.................................................................................................... 191

Menu: Restore hard drive to defaults ............................................................................................... 191

Menu: Support roll fed: yes ............................................................................................................ 191

Menu: Roll fed media control: method a .......................................................................................... 191

Menu: Configure warming attns...................................................................................................... 191

Menu: Carriage control ................................................................................................................. 191

Menu: Show autoH2H Y calibration................................................................................................ 192

Menu: UV current sense method...................................................................................................... 192

Menu: Auto printhead service......................................................................................................... 192

Error codes, warnings and actions......................................................................193

Menu: ERRORS............................................................................................................................. 193

Menu: ACTIONS .......................................................................................................................... 194

Menu: WARNINGS ...................................................................................................................... 195

Cleaning and Maintenance.................................................................... 196

Schedule of tasks normally completed by printer’s operator ...............................196

Schedule of cleaning and maintenance performed by service provider................197

Replacing UV lamp filters ............................................................................................................... 199

Cleaning the printheads................................................................................................................. 199

Clean the electronics box fan filters ................................................................................................. 202

Clean and grease the service station wiper slide rails ........................................................................ 203

Replace the service station wipers ................................................................................................... 205

Clean service station wiper ............................................................................................................ 206

Clean and oil rail carriage-wheel strips............................................................................................ 206

Clean the rail encoder strip ............................................................................................................ 208

Clean carriage wheels................................................................................................................... 208

Clean bottom of carriage............................................................................................................... 210

Clean ionizer tips with brush .......................................................................................................... 211

Service station empty / close.......................................................................................................... 212

Waste-ink jug’s open and closed positions ....................................................................................... 212

Clean media thickness sensor roller................................................................................................. 213

Clean the carriage home sensor ..................................................................................................... 213

Cleaning the high-resolution encoder hub ........................................................................................ 214

Replacement of field replaceable modules (FRMs) ................................. 216

Managing Power Off Scenarios ..........................................................................216

Enclosures ..........................................................................................................217

Remove the user-end and service-end enclosures ............................................................................... 217

Installing the user and service-end enclosure..................................................................................... 217

Removing the output-side, user-end belt enclosure.............................................................................. 218

Removing the input-side, user-end belt enclosure ............................................................................... 218

Removing the light-blocking tray...................................................................................................... 218

Installing the light-blocking tray ....................................................................................................... 219

Disconnecting the OHS Cabinet...................................................................................................... 219

Removing the output-side top door .................................................................................................. 220

Installing the output-side top door.................................................................................................... 222

Removing a fan from the output-side door ........................................................................................ 222

Installing a fan in the output-door .................................................................................................... 223

Carriage FRM Assemblies ...................................................................................224

Carriage assembly cover ............................................................................................................... 224

Removing printheads ..................................................................................................................... 224

Releasing the service station latch ................................................................................................... 225

Installing Printheads....................................................................................................................... 226

Install the flex cables ..................................................................................................................... 229

Post printhead-replacement calibrations ........................................................................................... 230

Removing the carriage headboard .................................................................................................. 230

Disconnecting the carriage pressure sensor tube ............................................................................... 230

Removing the headboard (with mounting plate) ................................................................................ 231

Installing the carriage headboard (with mounting plate)..................................................................... 231

Headboard cable connection chart ................................................................................................. 232

Removing the carriage camera board.............................................................................................. 233

Installing the carriage camera board ............................................................................................... 234

Removing a thermistor set .............................................................................................................. 235

Power off printer and unplug power cords ....................................................................................... 235

Removing the printhead reservoir cover ........................................................................................... 235

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 6 of 510

Clamp vacuum tubes to service printhead components....................................................................... 236

Installing a thermistor set................................................................................................................ 237

Removing the carriage air manifold................................................................................................. 238

Removing the pressure and vacuum tube.......................................................................................... 239

Installing the carriage air manifold .................................................................................................. 240

Removing the carriage encoder reader ............................................................................................ 240

Installing the carriage encoder reader ............................................................................................. 242

Removing the carriage from the rail................................................................................................. 242

Disconnecting the lamp power cables.............................................................................................. 243

Disconnecting the ink tube from the ink reservoir............................................................................... 243

Remove the trolley attachment bracket ............................................................................................. 244

Installing the carriage on the rail..................................................................................................... 244

Reconnecting tubes using tube joiner (tube mender)........................................................................... 245

Removing the upper trolley plate ..................................................................................................... 246

Installing the upper trolley plate ...................................................................................................... 248

Removing the home sensor ............................................................................................................. 249

Installing the home sensor .............................................................................................................. 249

Removing the home sensor flag....................................................................................................... 250

Installing the home sensor flag........................................................................................................ 250

Carriage Lamp Assemblies..................................................................................251

Remove the user-end lamp cover ..................................................................................................... 251

Installing the user-end lamp cover.................................................................................................... 252

Remove the service-end lamp cover ................................................................................................. 252

Install the service-end lamp cover .................................................................................................... 252

Removing the UV Lamp Bulb........................................................................................................... 253

Installing the UV Lamp Bulb ............................................................................................................ 254

Removing the Lamp Glass .............................................................................................................. 255

Installing the lamp glass................................................................................................................. 256

Removing the lamp fan assembly .................................................................................................... 256

Installing the lamp fan ................................................................................................................... 257

Removing a single lamp fan ........................................................................................................... 257

Installing a single lamp fan............................................................................................................. 258

Carriage-drive assemblies ..................................................................................259

Releasing the carriage-drive belt tension .......................................................................................... 259

Removing the carriage-drive idler.................................................................................................... 259

Installing the carriage-drive idler ..................................................................................................... 259

Removing the carriage-drive belt..................................................................................................... 260

Installing the carriage-drive belt ...................................................................................................... 260

Remove the carriage-drive motor..................................................................................................... 261

Remove the carriage-drive timing belt .............................................................................................. 262

Install the carriage-drive motor........................................................................................................ 262

Remove the carriage-drive shaft ...................................................................................................... 262

Remove the carriage-drive assembly housing .................................................................................... 263

Remove the rail encoder strip .............................................................................264

Installing the rail encoder strip ........................................................................................................ 264

Removing rail wheel strips.............................................................................................................. 266

Installing a rail wheel strip ............................................................................................................. 267

Media-drive media-drive assemblies ..................................................................270

Removing the high-resolution encoder.............................................................................................. 270

Installing the high-resolution encoder ............................................................................................... 273

Set the high-resolution encoder’s readhead spacing .......................................................................... 274

Aligning the high-resolution encoder................................................................................................ 275

Turning off AGC (Automatic Gain Control)....................................................................................... 276

Align readhead with AGC turned off............................................................................................... 277

High-resolution encoder incremental signal calibration....................................................................... 278

Activate high-resolution encoder calibration mode............................................................................. 279

Set the reference mark for the high-resolution encoder ....................................................................... 279

Turning AGC on for the high-resolution encoder interface .................................................................. 279

Removing the media-drive motor ..................................................................................................... 280

Loosening the media-drive belt tension............................................................................................. 280

Removing the media-drive motor ..................................................................................................... 283

Installing the media-drive motor ...................................................................................................... 284

Torque conversion......................................................................................................................... 287

Tensioning the media-drive belt....................................................................................................... 288

Removing the media-drive motor’s encoder ...................................................................................... 288

Installing the media-drive motor’s encoder........................................................................................ 290

Remove an input roller actuator assembly......................................................................................... 291

Install an input actuator assembly.................................................................................................... 293

Calibrate the input roller assembly .................................................................................................. 293

Remove an alignment bar actuator assembly .................................................................................... 294

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 7 of 510

Install an alignment bar actuator assembly ....................................................................................... 295

Calibrate the alignment bar............................................................................................................ 295

Replace an output-roller actuator assembly ....................................................................................... 296

Remove the output roller................................................................................................................. 296

Install an output-roller actuator assembly .......................................................................................... 297

Calibrate the output-roller............................................................................................................... 297

Rail exploded views ...................................................................................................................... 297

Remove a rail actuator................................................................................................................... 298

Install a rail actuator assembly........................................................................................................ 301

Removing the optional foot switch......................................................................302

Installing the replacement foot switch............................................................................................... 302

Media-drive fan arrays ......................................................................................303

Fan array exploded views.............................................................................................................. 303

Removing the output-side vacuum fan array...................................................................................... 304

Installing the output-side vacuum fan array .......................................................................................305

Removing the middle vacuum fan array ........................................................................................... 305

Installing the middle vacuum fan array............................................................................................. 306

Removing the input-side fan array ................................................................................................... 307

Installing the input-side fan array..................................................................................................... 308

Replacing a fan-array fan .............................................................................................................. 309

Media-drive belt, Removal.............................................................................................................. 311

Installing the media-drive belt ......................................................................................................... 318

Center the media rollers................................................................................................................. 320

Center the driver roller................................................................................................................... 320

Begin idler roller centering ............................................................................................................. 321

Checking media-drive belt tension................................................................................................... 321

Belt tension specification ................................................................................................................ 323

Make sure media rollers are parallel ............................................................................................... 324

Check belt tracking ....................................................................................................................... 324

Measure roller tracking with a dial indicator .................................................................................... 325

Move the belt using the velocity test................................................................................................. 325

Lap the belt .................................................................................................................................. 326

Media Sensors....................................................................................................327

Remove the media thickness sensor ................................................................................................. 327

Install the media thickness sensor .................................................................................................... 327

Calibrate the Media Thickness Sensor ............................................................................................. 328

Remove the media detection sensor................................................................................................. 328

Install the media detection sensor .................................................................................................... 328

Roll-to-roll assemblies ........................................................................................329

Fasteners for roll-to-roll assemblies................................................................................................... 329

Optional roll-to-roll box contents...................................................................................................... 330

Installation of optional roll-to-roll kit ..................................................................331

Required tools .............................................................................................................................. 331

Configure printer for roll-to-roll........................................................................................................ 331

Level the printer ............................................................................................................................ 331

Install the roll-to-roll supply arms...................................................................................................... 332

Roll-to-roll alignment tool configurations ............................................................334

Assemble tool for supply and/or takeup spools................................................................................. 334

Roll-to-roll alignment tool configurations for supply and/or takeup....................................................... 335

Roll-to-roll alignment tool configuration for foam rollers ...................................................................... 335

Roll-to-roll alignment tool configurations for foam roller tool configuration............................................. 335

Align the roll-to-roll supply spool........................................................................336

Align the service-end supply spool position....................................................................................... 337

Tighten the supply arm turnbuckle bolts............................................................................................ 341

Align the foam roller racks ............................................................................................................. 342

Center the foam rollers between the foam roller collars ...................................................................... 345

Roll-to-roll Takeup..............................................................................................348

Remove the output roller................................................................................................................. 348

Set the takeup roller position .......................................................................................................... 348

Tighten the takeup arm’s turnbuckle bolts ......................................................................................... 350

Install the roll-to-roll moveable dancer bar ........................................................................................ 352

Install the fixed bar into the dancer rack .......................................................................................... 354

Takeup motor power ..................................................................................................................... 355

Verify movement of dancer bar....................................................................................................... 356

Verify takeup motor turn-off trigger point .......................................................................................... 356

Verify takeup motor’s turn-on trigger point........................................................................................ 357

Adjusting takeup switch positions.................................................................................................... 358

Install the output roller.................................................................................................................... 359

Loading roll-to-roll media ...................................................................................360

Part No. CQ114-90035 Rev B HP Scitex FB500 / FB700 Service Manual Page 8 of 510

Media loading overview................................................................................................................ 360

Prepare the printer ........................................................................................................................ 361

Center the media on the supply spool.............................................................................................. 361

Initiate LOAD MEDIA from printer’s menu......................................................................................... 363

Mid-spool support for heavy media rolls .......................................................................................... 366

Electronic assembly FRMs ...................................................................................367

Removing the fan’s air filter ............................................................................................................ 367

Installing the fan filter cover............................................................................................................ 367

Removing the electronics box covers................................................................................................ 368

Installing the electronics box covers................................................................................................. 368

Removing the motor control board .................................................................................................. 368

Installing the motor control board.................................................................................................... 370

Removing the FB 500 ebox UV power output cables ......................................................................... 370

Installing the FB 500 ebox UV power output cables........................................................................... 372

Removing the ebox ionizer power-out cable ..................................................................................... 372

Installing the ebox ionizer power-out cable....................................................................................... 374

Removing the ebox ShopVac power-out cable .................................................................................. 374