Page 1

LASERJET ENTERPRISE 700

Troubleshooting Manual

2

3

M712

Page 2

Page 3

HP LaserJet Enterprise 700 M712

Troubleshooting Manual

Page 4

Copyright and License

© 2013 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CF235-90963

2, 01/2013

Edition

demark Cr

Tra

®

Adobe

, Adobe Photoshop®, Acrobat®, and

PostScript

edits

®

are trademarks of Adobe

Systems Incorporated.

Apple and the Apple logo are trademarks of

Apple Computer, Inc., registered in the U.S.

and other countries. iPod is a trademark of

Apple Computer, Inc. iPod is for legal or

rightholder-authorized copying only. Don't

steal music.

Microsoft®, Windows®, Windows® XP,

and Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

®

is a registered trademark of The

UNIX

Open Group.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging

the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal

injury, catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Theory of operation .......................................................................................................... 1

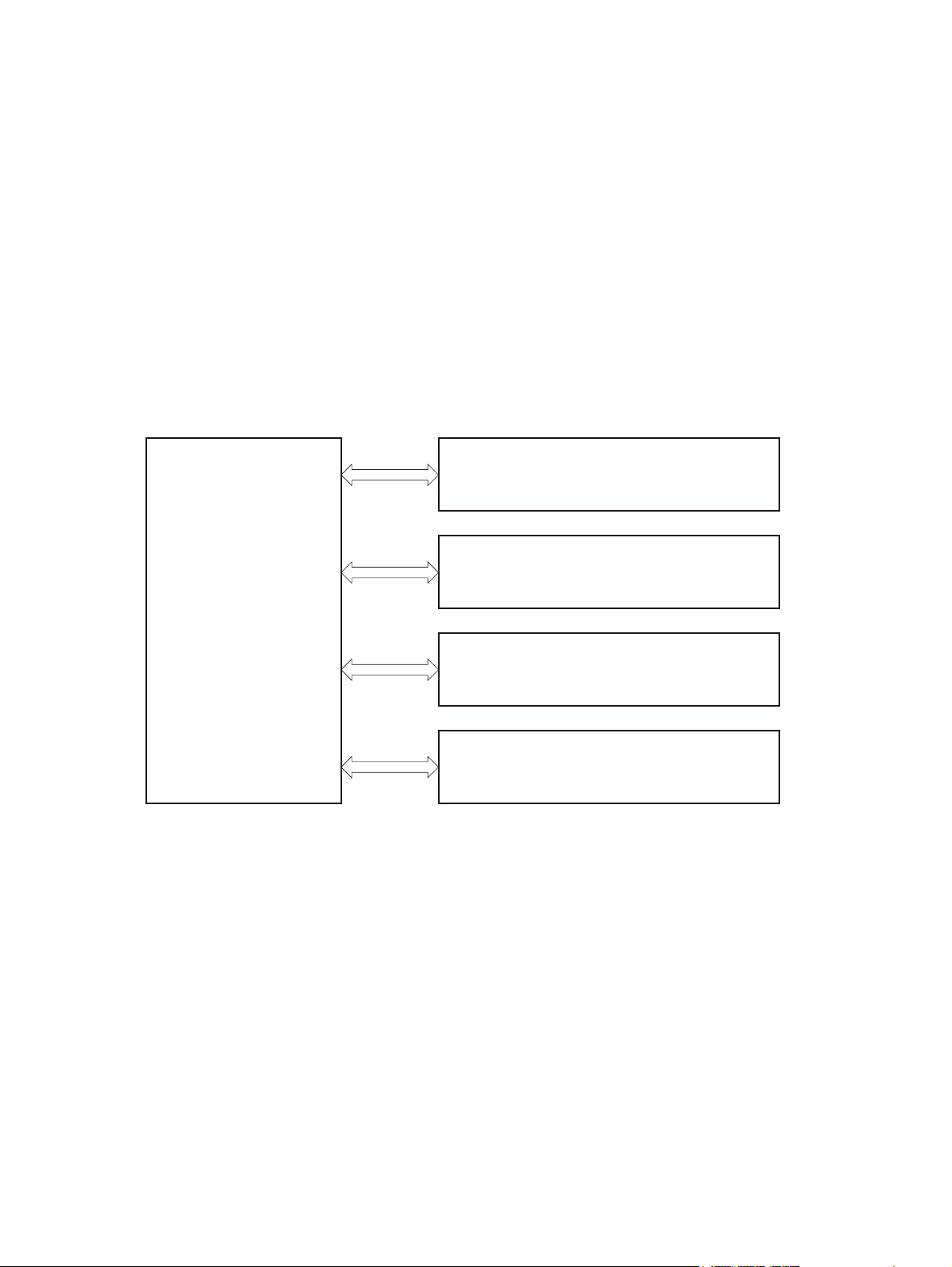

Basic operation ........................................................................................................................ 2

Function structure ...................................................................................................... 2

Operation sequence .................................................................................................. 2

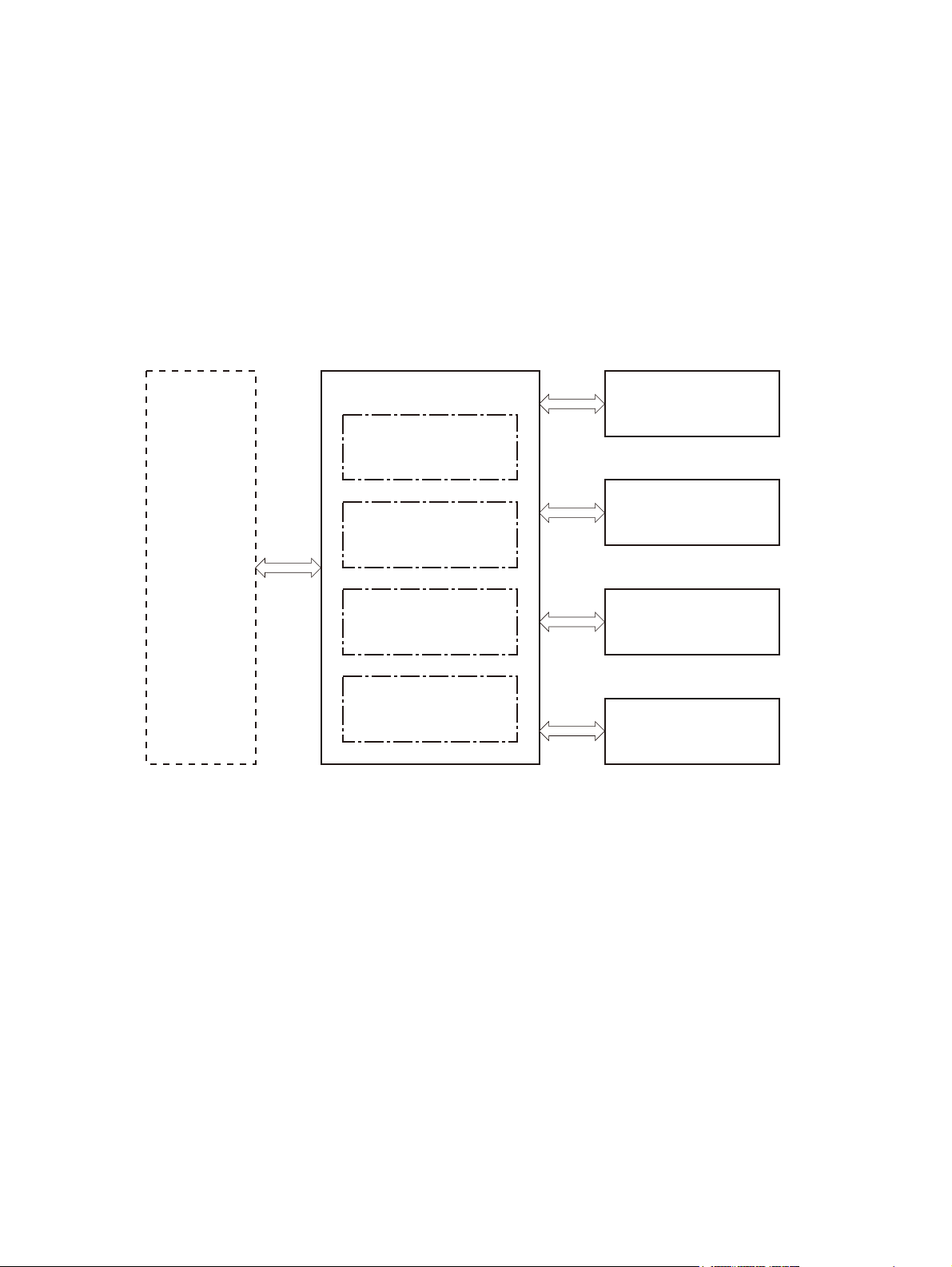

Engine control system ............................................................................................................... 4

DC controller PCA ..................................................................................................... 5

Motor control ............................................................................................. 6

Motor locations ........................................................................... 7

Failure detection ......................................................................... 7

Fan control ................................................................................................ 8

Fan locations .............................................................................. 9

Failure detection ......................................................................... 9

Low-voltage power-supply PCA ................................................................................. 10

Over-current/over-voltage/overload protection ............................................ 11

Safety interruption .................................................................................... 11

Power supply voltage detection .................................................................. 11

Sleep mode ............................................................................................. 12

Power supply illumination control ............................................................... 12

High-voltage power-supply PCA ................................................................................ 13

Fuser control ........................................................................................................... 15

Fuser temperature control .......................................................................... 17

Fuser heater protective function .................................................................. 17

Fuser failure detection ............................................................................... 18

Pressure roller cleaning ............................................................................. 19

Laser scanner system .............................................................................................................. 20

Laser scanner failure detection .................................................................................. 21

Laser scanner safety function .................................................................................... 21

Image-formation system ........................................................................................................... 22

Image-formation process .......................................................................................... 23

Latent-image formation block ..................................................................... 24

Step 1: primary charging ........................................................... 24

Step 2: laser-beam exposure ....................................................... 25

ENWW v

Page 8

Development block ................................................................................... 25

Step 3: developing .................................................................... 25

Transfer block .......................................................................................... 26

Step 4: image transfer ............................................................... 26

Step 5: separation from the drum ................................................ 26

Fuser block .............................................................................................. 27

Step 6: fusing ........................................................................... 27

Drum-cleaning block ................................................................................. 27

Step 7: drum cleaning ............................................................... 27

Toner cartridge ....................................................................................................... 27

Other image-formation functions ............................................................................... 29

Drum discharge ....................................................................................... 29

Transfer roller cleaning ............................................................................. 29

Environment change control ....................................................................... 30

Pickup, feed, and delivery system ............................................................................................. 31

Pickup and feed block ............................................................................................. 34

Cassette pickup ........................................................................................ 35

Cassette media-size detection and cassette-presence detection ....................... 35

Cassette lift operation ............................................................................... 36

Lift-up operation ........................................................................ 36

Lift-down operation .................................................................... 36

Cassette media-presence detection ............................................................. 37

Cassette multiple-feed prevention ................................................................ 37

MP tray pickup ........................................................................................ 39

MP tray media-presence detection .............................................................. 39

MP tray multiple-feed prevention ................................................................ 40

Feed-speed control ................................................................................... 40

Skew-feed prevention ................................................................................ 42

Media-length detection ............................................................................. 43

Fuse and delivery block ........................................................................................... 44

Loop control ............................................................................................ 44

Output bin media-full detection .................................................................. 46

Jam detection ......................................................................................................... 47

No pick jam 1 ......................................................................................... 47

Feed stay jam 1 ....................................................................................... 48

Fuser output delay jam 1 ........................................................................... 48

Fuser output stay jam 1 ............................................................................. 48

Output delay jam 1 .................................................................................. 48

Output delay jam 2 .................................................................................. 48

Output stay jam 1 .................................................................................... 48

Residual paper jam 1 ............................................................................... 49

vi ENWW

Page 9

Fuser wrap jam 1 ..................................................................................... 49

Door open jam 1 ..................................................................................... 49

Multiple-feed jam 1 .................................................................................. 49

Automatic delivery .................................................................................................. 49

500-sheet paper feeder (Tray 4) .............................................................................................. 50

500-sheet paper feeder motor control ........................................................................ 51

500-sheet paper feeder failure detection ..................................................... 51

500-sheet paper feeder pickup and feed operation ..................................................... 52

500-sheet paper feeder cassette pickup ...................................................... 53

500-sheet paper feeder cassette media-size detection and cassette-presence

detection ................................................................................................. 53

500-sheet paper feeder lift-up operation ..................................................... 54

500-sheet paper feeder cassette media-presence detection ............................ 55

500-sheet paper feeder cassette multiple-feed prevention .............................. 55

500-sheet paper feeder jam detection ....................................................................... 56

No pick jam 2 ......................................................................................... 56

Residual paper jam 1 ............................................................................... 56

Door open jam 1 ..................................................................................... 57

500-sheet paper feeder automatic delivery ................................................................. 57

1x500 and 3x500 paper feeder and stand .............................................................................. 58

Paper deck motor control ......................................................................................... 61

Paper deck failure detection ...................................................................... 61

Paper deck pickup-and-feed operation ....................................................................... 61

Paper deck cassette media-size detection and cassette-presence detection ....... 63

Paper deck lift-up operation ....................................................................... 64

Paper deck cassette media-presence detection ............................................. 65

Paper deck jam detection ......................................................................................... 65

No pick jam 2 ......................................................................................... 65

No pick jam 3 (3x500-sheet paper deck only) ............................................. 66

Residual paper jam 1 ............................................................................... 66

Door open jam 1 ..................................................................................... 66

Paper deck automatic delivery .................................................................................. 66

3,500-sheet high-capacity input (HCI) feeder ............................................................................. 67

HCI motor control .................................................................................................... 69

HCI failure detection ................................................................................. 69

HCI pickup-and-feed operation ................................................................................. 70

HCI cassette media-size detection and cassette-presence detection ................. 71

HCI lift-up operation ................................................................................. 72

HCI cassette media-presence detection ....................................................... 72

HCI jam detection ................................................................................................... 74

No pick jam 2 ......................................................................................... 74

ENWW vii

Page 10

No pick jam 3 ......................................................................................... 74

Residual paper jam 1 ............................................................................... 75

Door open jam 1 ..................................................................................... 75

HCI automatic delivery ............................................................................................ 75

Duplexer ............................................................................................................................... 76

Duplexer motor control ............................................................................................ 77

Duplexer motor failure detection ................................................................. 77

Duplexer fan control ................................................................................................ 78

Duplexer fan failure detection .................................................................... 78

Duplexer reverse and feed operation ......................................................................... 78

Duplexer reverse and feed operation sequence ............................................ 79

Side misregistration detection .................................................................... 80

Side misregistration failure detection ............................................ 82

Duplexer jam detection ............................................................................................ 82

Fuser output stay jam 2 ............................................................................. 82

Reverse jam 1 .......................................................................................... 83

Duplex re-pickup jam 1 ............................................................................. 83

Duplex re-pickup jam 2 ............................................................................. 83

Duplex re-pickup jam 3 ............................................................................. 83

Residual paper jam 1 ............................................................................... 83

Duplexer automatic delivery ..................................................................................... 83

2 Solve problems ............................................................................................................... 85

Solve problems checklist ......................................................................................................... 86

Menu map ............................................................................................................................ 88

Preboot menu options ............................................................................................................. 89

Current settings pages ............................................................................................................ 97

Troubleshooting process .......................................................................................................... 98

Determine the problem source ................................................................................... 98

Troubleshooting flowchart ......................................................................... 98

Power subsystem ..................................................................................................... 99

Power-on checks ...................................................................................... 99

Power-on troubleshooting overview .............................................. 99

Tools for troubleshooting ....................................................................................................... 101

Individual component diagnostics ............................................................................ 101

LED diagnostics ...................................................................................... 101

Understand lights on the formatter ............................................. 101

Engine diagnostics ................................................................................. 104

Engine-test button .................................................................... 104

Paper path test ....................................................................................... 106

Paper path sensor tests ........................................................................... 106

viii ENWW

Page 11

Manual sensor tests ................................................................................ 108

Cartridge door switch (SW3) .................................................... 110

Left door switch (SW1) ............................................................. 111

Right door sensor (SR8) ............................................................ 112

Cartridge install sensor (SR1) .................................................... 113

Top (top-of-page) sensor (SR9) .................................................. 114

Fuser loop sensor (SR6) ............................................................ 115

Fuser output sensor (SR12) ....................................................... 116

Duplex switchback sensor (SR1) ................................................ 117

Duplexer refeed sensor (SR2) .................................................... 118

Tray 4 feed sensor (SR1) .......................................................... 119

Output sensor (SR3) ................................................................. 120

Tray/bin manual sensor tests ................................................................... 121

Main product trays .................................................................. 123

Optional 500-sheet paper tray (Tray 4) ...................................... 131

1x500 and 3x500 paper deck trays ......................................... 136

HCI trays ................................................................................ 138

Print/stop test ........................................................................................ 144

Component tests ..................................................................................... 145

Control-panel tests ................................................................... 145

Half self-test ............................................................................ 145

Drum rotation test check ........................................................... 146

Component test (special-mode test) ............................................ 146

Diagrams ............................................................................................................. 148

Block diagrams ...................................................................................... 148

Location of connectors ............................................................................ 153

DC controller connections ......................................................... 153

Plug/jack locations ................................................................................. 155

Locations of major components ................................................................ 156

General timing charts ............................................................................. 171

Circuit diagrams .................................................................................... 172

Internal test pages ................................................................................................. 174

Clean the paper path ............................................................................. 174

Set up an auto cleaning page ................................................... 174

Print a configuration page ....................................................................... 175

Configuration page ................................................................. 175

HP embedded Jetdirect page .................................................... 176

Finding important information on the configuration pages ............ 177

Control panel menus .............................................................................................. 178

Administration menu ............................................................................... 178

Reports menu .......................................................................... 178

ENWW ix

Page 12

General Settings menu ............................................................. 179

General Print Settings menu ...................................................... 185

Default Print Options menu ....................................................... 188

Display Settings menu .............................................................. 189

Manage Supplies menu ........................................................... 191

Manage Trays menu ................................................................ 192

Network Settings menu ............................................................ 194

Troubleshooting menu .............................................................. 208

Device Maintenance menu ...................................................................... 210

Backup/Restore menu .............................................................. 210

Calibration/Cleaning menu ...................................................... 211

USB Firmware Upgrade menu ................................................... 212

Service menu .......................................................................... 212

Interpret control-panel messages ............................................................................. 213

Control-panel message types ................................................................... 213

Control-panel messages .......................................................................... 213

11.00.YY Internal clock error To continue, touch “OK” ................ 213

20.00.00 Insufficient memory: <Device> To continue, touch “OK” 213

21.00.00 Page too complex To continue, touch “OK” ................. 214

33.WX.YZ Used board/disk installed ........................................ 214

40.00.01 USB I/O buffer overflow To continue, touch “OK” ........ 214

40.00.02 Embedded I/O buffer overflow To continue, touch “OK” 214

40.00.03 EIO <X> buffer overflow To continue, touch “OK” ........ 214

40.00.04 EIO <X> bad transmission To continue, touch “OK” ..... 215

40.00.05 Embedded I/O bad transmission To continue, touch

“OK” ..................................................................................... 215

41.03.YZ Unexpected size in Tray <X> ..................................... 215

41.03.YZ Unexpected size in Tray <X> To use another tray, touch

"Options" ............................................................................... 216

41.05.YZ Unexpected type in Tray <X> ..................................... 216

41.05.YZ Unexpected type in Tray <X> To use another tray,

touch "Options" ...................................................................... 217

41.WX.YZ Error To use another tray, touch "Options" ................. 218

47.FC.YZ Printer calibration failed To continue, touch “OK” ......... 220

47.WX.YZ Printer calibration failed ........................................... 221

49.XX.YY Error To continue turn off then on ................................ 221

50.WX.YZ Fuser error To continue turn off then on ...................... 221

51.00.YY Error To continue turn off then on ................................ 225

52.00.00 Error To continue turn off then on ............................... 225

52.00.20 Error To continue turn off then on ............................... 226

52.<XX>.00 Error To continue turn off then on ............................ 226

x ENWW

Page 13

54.XX.YY Error ....................................................................... 226

55.XX.YY DC controller error To continue turn off then on ............ 227

56.00.YY Error To continue turn off then on ................................ 227

57.00.0X Error ....................................................................... 228

58.00.04 Error To continue turn off then on ............................... 228

59.00.00 Error To continue turn off then on ............................... 228

59.00.20 Error To continue turn off then on ............................... 229

59.00.30 Error To continue turn off then on ............................... 229

59.00.40 Error To continue turn off then on ............................... 229

59.05.50 Error To continue turn off then on ............................... 229

59.05.60 Error To continue turn off then on ............................... 230

60.00.0Y Tray <Y> lifting error ................................................ 230

62.00.00 No system To continue turn off then on ........................ 230

69.11.YY Error To continue, touch “OK” .................................... 231

70.00.00 Error To continue turn off then on ............................... 231

81.WX.YZ Embedded JetDirect Error To continue turn off then on . . 231

81.YY.YY EIO Error To continue turn off then on ......................... 232

98.00.0X Corrupt data in X volume ........................................... 232

<Binname> full Remove all paper from bin ................................. 232

Bad optional tray connection .................................................... 233

Black Cartridge low ................................................................. 233

Black Cartridge very low .......................................................... 233

Black Cartridge very low To continue, touch “OK” ...................... 233

Card slot device failure To clear touch “Clear” ........................... 234

Card slot file operation failed To clear touch “Clear” ................... 234

Card slot file system is full To clear touch “Clear” ........................ 234

Card slot is write protected To clear touch “Clear” ...................... 234

Card slot not initialized To clear touch “Clear” ........................... 234

Cartridge ship mode ................................................................ 235

Chosen personality not available To continue, touch “OK” ........... 235

Cleaning disk <X>% complete Do not power off ......................... 235

Close left door ........................................................................ 235

Close top cover ....................................................................... 236

Data received ......................................................................... 236

Disk full Delete stored jobs ........................................................ 236

Disk low Delete stored jobs ....................................................... 236

EIO <X> disk not functional ...................................................... 237

EIO <X> disk spinning up ......................................................... 237

EIO device failure To clear touch “Clear” ................................... 237

EIO file operation failed To clear touch “Clear” .......................... 237

EIO file system is full To clear touch “Clear” ............................... 237

ENWW xi

Page 14

EIO is write protected To clear touch “Clear” .............................. 238

EIO not initialized To clear touch “Clear” ................................... 238

Event log is empty ................................................................... 238

Fuser Kit Low .......................................................................... 238

Fuser Kit very low .................................................................... 238

Fuser Kit very low To continue, touch “OK” ................................ 239

Incompatible <supply> ............................................................. 239

Incompatible supplies .............................................................. 239

Initializing... ........................................................................... 240

Install Black Cartridge .............................................................. 240

Install Fuser Unit ...................................................................... 240

Install supplies ........................................................................ 240

Internal disk device failure To clear touch “Clear” ....................... 240

Internal disk file operation failed To clear touch “Clear” ............... 241

Internal disk file system is full To clear touch “Clear” .................... 241

Internal disk is write protected To clear touch “Clear” .................. 241

Internal disk not found ............................................................. 241

Internal disk not functional ........................................................ 241

Internal disk not initialized To clear touch “Clear” ....................... 242

Internal disk spinning up .......................................................... 242

Load Tray 1 [Type] [Size] ......................................................... 242

Load Tray 1 [Type] [Size] To continue, touch “OK” ...................... 242

Load Tray <X>: [Size] .............................................................. 242

Load Tray <X>: [Size] To continue, touch “OK” .......................... 243

Load Tray <X>: [Size] To use another tray, touch "Options" ......... 243

Load Tray <X>: [Type], [Size] ................................................... 243

Load Tray <X>: [Type], [Size] To use another tray, touch

"Options" ............................................................................... 244

Manually feed output stack Then touch "OK" to print second sides 244

Manually feed: [Size] .............................................................. 245

Manually feed: [Size] To continue, touch “OK” ........................... 245

Manually feed: [Size] To use another tray, touch "Options" .......... 245

Manually feed: [Type], [Size] To continue, touch “OK” ................ 246

Manually feed: [Type], [Size] To use another tray, touch

"Options" ............................................................................... 246

No job to cancel ..................................................................... 246

Output Bin full ......................................................................... 246

Paperless mode ....................................................................... 247

Printing Engine Test... .............................................................. 247

Printing stopped To continue, touch “OK” ................................... 247

RAM Disk device failure To clear touch “Clear” .......................... 247

xii ENWW

Page 15

RAM Disk file operation failed To clear touch “Clear” .................. 247

RAM Disk file system is full To clear touch “Clear” ....................... 248

RAM Disk is write protected To clear touch “Clear” ..................... 248

RAM Disk not initialized To clear touch “Clear” .......................... 248

Remove cartridge lock ............................................................. 248

Remove the toner cartridge ....................................................... 248

Replace Black Cartridge ........................................................... 249

Replace Fuser Kit ..................................................................... 249

Replace supplies ..................................................................... 249

ROM disk device failed To clear touch “Clear” ........................... 250

ROM disk file operation failed To clear touch “Clear” .................. 250

ROM disk file system is full To clear touch “Clear” ....................... 250

ROM disk is write protected To clear touch “Clear” ..................... 250

ROM disk not initialized To clear touch “Clear” .......................... 250

Size mismatch in Tray <X> ....................................................... 251

Standard bin full Remove all paper from bin ............................... 251

Supplies low ........................................................................... 251

Supplies very low To continue, touch “OK” ................................. 251

Supply memory warning .......................................................... 252

Tray <X> empty: [Size] ............................................................ 252

Tray <X> empty: [Type], [Size] ................................................. 252

Tray <X> open ........................................................................ 252

Tray <X> overfilled Remove excess paper .................................. 253

Tray <X> overfilled To use another tray, touch "Options" ............. 253

Type mismatch Tray <X> .......................................................... 253

Unable to cancel firmware update job ....................................... 254

Unable to install the firmware ................................................... 254

Unsupported drive installed ...................................................... 254

Unsupported supply in use ........................................................ 254

Unsupported supply installed .................................................... 255

Unsupported supply installed To continue, touch “OK” ................. 255

Unsupported tray configuration ................................................. 255

Unsupported USB accessory detected Remove USB accessory ....... 255

Upgrade complete To continue turn off then on ........................... 256

USB accessory needs too much power Remove USB and turn off

then on .................................................................................. 256

USB accessory not functional .................................................... 256

USB hubs are not fully supported Some operations may not work

properly ................................................................................. 256

USB is write protected To clear touch “Clear” ............................. 256

USB not initialized To clear touch “Clear” .................................. 257

ENWW xiii

Page 16

USB storage accessory removed Clearing any associated data ..... 257

USB storage device failure To clear touch “Clear” ....................... 257

USB storage file operation failed To clear touch “Clear” .............. 257

USB storage file system is full To clear touch “Clear” ................... 257

Used supply in use .................................................................. 257

Used supply installed To continue, touch “OK” ............................ 258

Event log messages ............................................................................................... 259

Print or view an event log ........................................................................ 260

Clear an event log .................................................................................. 260

Event log message table .......................................................................... 260

Clear jams .......................................................................................................................... 263

Jam locations ........................................................................................................ 263

Auto-navigation for clearing jams ............................................................................ 263

Clear jams in the output-bin area ............................................................................ 264

Clear jams in Tray 1 .............................................................................................. 264

Clear jams in Tray 2 or Tray 3 ................................................................................ 265

Clear jams in the 500-sheet trays ............................................................................ 267

Clear jams in the 3,500-sheet high-capacity tray ....................................................... 268

Clear jams from the toner-cartridge area .................................................................. 271

Clear jams in the fuser ........................................................................................... 274

Clear jams from the duplexer .................................................................................. 276

Solve paper-handling problems .............................................................................................. 277

The product picks up multiple sheets of paper ........................................................... 277

The product does not pick up paper ........................................................................ 277

Use manual print modes ....................................................................................................... 278

Print quality troubleshooting tools ........................................................................................... 280

Repetitive defects measurements .............................................................................. 280

Solve image-quality problems ................................................................................................ 281

Image defect examples .......................................................................................... 281

Clean the product ................................................................................................................ 289

Print a cleaning page ............................................................................................ 289

Solve performance problems ................................................................................................. 290

Solve connectivity problems ................................................................................................... 291

Solve USB connection problems .............................................................................. 291

Solve wired network problems ................................................................................ 291

The product has a poor physical connection. ............................................. 291

The computer is using the incorrect IP address for the product ...................... 291

The computer is unable to communicate with the product ............................ 292

The product is using incorrect link and duplex settings for the network .......... 292

New software programs might be causing compatibility problems ................ 292

The computer or workstation might be set up incorrectly .............................. 292

xiv ENWW

Page 17

The product is disabled, or other network settings are incorrect .................... 292

Service mode functions ......................................................................................................... 293

Service menu ........................................................................................................ 293

Product resets ....................................................................................................... 294

Restore factory-set defaults ....................................................................... 294

Restore the service ID .............................................................................. 294

Product cold reset ................................................................................... 295

Format Disk and Partial Clean functions ................................................................... 296

Active and repository firmware locations ................................................... 296

Partial Clean ......................................................................................... 296

Execute a 3 Partial Clean ......................................................... 297

Format Disk ........................................................................................... 297

Execute a 2 Format Disk ........................................................... 298

Product firmware upgrades ................................................................................................... 299

Determine the installed revision of firmware .............................................................. 299

Perform a firmware upgrade ................................................................................... 299

Embedded Web Server ........................................................................... 299

USB storage device (Preboot menu) .......................................................... 300

USB storage device (control-panel menu) ................................................... 302

Appendix A Service and support ..................................................................................... 303

Hewlett-Packard limited warranty statement ............................................................................. 304

HP's Premium Protection Warranty: LaserJet toner cartridge limited warranty statement ................. 306

HP policy on non-HP supplies ................................................................................................ 307

HP anticounterfeit Web site ................................................................................................... 308

Data stored on the toner cartridge .......................................................................................... 309

End User License Agreement .................................................................................................. 310

OpenSSL ............................................................................................................................. 313

Customer self-repair warranty service ..................................................................................... 314

Customer support ................................................................................................................. 315

Appendix B Product specifications ................................................................................... 317

Physical specifications .......................................................................................................... 318

Power consumption, electrical specifications, and acoustic emissions .......................................... 318

Environmental specifications .................................................................................................. 318

Appendix C Regulatory information ................................................................................. 319

FCC regulations ................................................................................................................... 320

Environmental product stewardship program ........................................................................... 321

Protecting the environment ...................................................................................... 321

ENWW xv

Page 18

Ozone production ................................................................................................. 321

Power consumption ............................................................................................... 321

Toner consumption ................................................................................................ 321

Paper use ............................................................................................................. 321

Plastics ................................................................................................................. 321

HP LaserJet print supplies ....................................................................................... 322

Return and recycling instructions ............................................................................. 322

United States and Puerto Rico .................................................................. 322

Multiple returns (more than one cartridge) .................................. 322

Single returns .......................................................................... 322

Shipping ................................................................................ 322

Non-U.S. returns .................................................................................... 323

Paper .................................................................................................................. 323

Material restrictions ............................................................................................... 323

Disposal of waste equipment by users ...................................................................... 324

Electronic hardware recycling ................................................................................. 324

Chemical substances ............................................................................................. 324

Material Safety Data Sheet (MSDS) ......................................................................... 324

For more information ............................................................................................. 324

Declaration of conformity ...................................................................................................... 326

Safety statements ................................................................................................................. 328

Laser safety .......................................................................................................... 328

Canadian DOC regulations .................................................................................... 328

VCCI statement (Japan) .......................................................................................... 328

Power cord instructions .......................................................................................... 328

Power cord statement (Japan) ................................................................................. 328

EMC statement (China) .......................................................................................... 329

EMC statement (Korea) .......................................................................................... 329

EMI statement (Taiwan) .......................................................................................... 329

Laser statement for Finland ..................................................................................... 329

GS statement (Germany) ........................................................................................ 331

Substances Table (China) ....................................................................................... 331

Restriction on Hazardous Substances statement (Turkey) ............................................. 331

Restriction on Hazardous Substances statement (Ukraine) ........................................... 331

Index ............................................................................................................................... 333

xvi ENWW

Page 19

List of tables

Table 1-1 Operation sequence ............................................................................................................... 3

Table 1-2 Motor locations ...................................................................................................................... 7

Table 1-3 Fan locations ......................................................................................................................... 9

Table 1-4 Low voltage power supply DC power specifications .................................................................. 10

Table 1-5 Pickup, feed, and delivery system sensors and switches ............................................................. 32

Table 1-6 Pickup, feed, and delivery system solenoid and motors ............................................................. 33

Table 1-7 Media switch combinations ................................................................................................... 36

Table 1-8 500-sheet paper feeder electrical components ......................................................................... 51

Table 1-9 500-sheet paper feeder motors .............................................................................................. 51

Table 1-10 500-sheet paper feeder pickup and feed components ............................................................. 52

Table 1-11 500-sheet paper feeder media switch combinations ................................................................ 54

Table 1-12 Paper deck electrical components ......................................................................................... 59

Table 1-13 Paper deck motors .............................................................................................................. 61

Table 1-14 Paper deck pickup-and-feed operation components ................................................................ 62

Table 1-15 Paper deck media switch combinations ................................................................................. 63

Table 1-16 HCI electrical components ................................................................................................... 68

Table 1-17 HCI motors ........................................................................................................................ 69

Table 1-18 HCI pickup-and-feed operation components ........................................................................... 70

Table 1-19 Duplexer electrical components ............................................................................................ 77

Table 1-20 Duplexer motor .................................................................................................................. 77

Table 1-21 Duplexer fan ...................................................................................................................... 78

Table 1-22 Duplexer reverse and feed components ................................................................................. 79

Table 2-1 Preboot menu options (1 of 6) ................................................................................................ 90

Table 2-2 Preboot menu options (2 of 6) ................................................................................................ 92

Table 2-3 Preboot menu options (3 of 6) ................................................................................................ 93

Table 2-4 Preboot menu options (4 of 6) ................................................................................................ 94

Table 2-5 Preboot menu options (5 of 6) ................................................................................................ 94

Table 2-6 Preboot menu options (6 of 6) ................................................................................................ 95

Table 2-7 Tr

Table 2-8 Heartbeat LED, product initialization ..................................................................................... 102

Table 2-9 Paper-path sensors .............................................................................................................. 107

Table 2-10 Manual sensor tests .......................................................................................................... 108

oubleshooting flowchart ...................................................................................................... 98

ENWW xvii

Page 20

Table 2-11 Tray/bin manual sensor test ............................................................................................... 121

Table 2-12 Component tests ............................................................................................................... 146

Table 2-13 Product cross section ......................................................................................................... 148

Table 2-14 Optional paper feeder (Tray 4) cross section ....................................................................... 149

Table 2-15 1x500-sheet paper deck cross section ................................................................................. 150

Table 2-16 3x500-sheet paper deck cross section ................................................................................. 151

Table 2-17 3,500-sheet HCI cross section ............................................................................................ 152

Table 2-18 DC controller connections .................................................................................................. 153

Table 2-19 Plug/jack locations ........................................................................................................... 155

Table 2-20 External component locations ............................................................................................. 156

Table 2-21 Major component locations (1 of 3) .................................................................................... 157

Table 2-22 Major component locations (2 of 3) .................................................................................... 158

Table 2-23 Major component locations (3 of 3) .................................................................................... 158

Table 2-24 PCA locations .................................................................................................................. 159

Table 2-25 Motor locations ................................................................................................................ 160

Table 2-26 Fan locations ................................................................................................................... 160

Table 2-27 Roller locations ................................................................................................................. 161

Table 2-28 500-sheet feeder external component locations .................................................................... 162

Table 2-29 500-sheet feeder internal component locations ..................................................................... 163

Table 2-30 1x500 paper deck external component locations ................................................................. 164

Table 2-31 1x500 paper deck internal component locations .................................................................. 165

Table 2-32 3x500 paper deck external component locations ................................................................. 166

Table 2-33 3x500 paper deck internal component locations .................................................................. 167

Table 2-34 HCI external component locations ...................................................................................... 168

Table 2-35 HCI internal component locations (1 of 2) ........................................................................... 169

Table 2-36 HCI internal component locations (2 of 2) ........................................................................... 170

Table 2-37 Important information on the configuration pages ................................................................. 177

Table 2-38 Reports menu ................................................................................................................ 178

Table 2-39 General Settings menu ................................................................................................. 179

Table 2-40 General Print Settings me

Table 2-41 Default Print Options menu .......................................................................................... 188

Table 2-42 Display Settings menu .................................................................................................. 190

Table 2-43 Manage Supplies menu ................................................................................................ 191

Table 2-44 Manage Trays menu ..................................................................................................... 193

Table 2-45 Network Settings menu ................................................................................................ 195

Table 2-46 Jetdirect Menu ............................................................................................................. 195

Table 2-47 Troubleshooting menu .................................................................................................. 208

Table 2-48 Backup/Restore menu .................................................................................................. 211

Table 2-49 Calibration/Cleaning menu .......................................................................................... 211

Table 2-50 Print modes under the Adjust Paper Types sub menu ....................................................... 278

Table 2-51 MP modes under the Optimize submenu ........................................................................... 279

nu ........................................................................................ 186

xviii ENWW

Page 21

Table 2-52 Image defect examples ..................................................................................................... 281

Table 2-53 Solve performance problems .............................................................................................. 290

Table B-1 Product dimensions and weights ........................................................................................... 318

Table B-2 Product dimensions with all doors and trays fully opened ........................................................ 318

Table B-3 Operating-environment specifications .................................................................................... 318

ENWW xix

Page 22

xx ENWW

Page 23

List of figures

Figure 1-1 Function structure ................................................................................................................... 2

Figure 1-2 Engine control system ............................................................................................................. 4

Figure 1-3 DC controller PCA ................................................................................................................. 5

Figure 1-4 Motor locations ..................................................................................................................... 7

Figure 1-5 Fan locations ........................................................................................................................ 9

Figure 1-6 Low-voltage power-supply PCA ............................................................................................. 10

Figure 1-7 High-voltage power-supply PCA ............................................................................................ 13

Figure 1-8 Fuser components ................................................................................................................ 15

Figure 1-9 Fuser control system ............................................................................................................. 16

Figure 1-10 Laser scanner system .......................................................................................................... 20

Figure 1-11 Image-formation system ...................................................................................................... 22

Figure 1-12 Image-formation components .............................................................................................. 23

Figure 1-13 Image-formation process .................................................................................................... 24

Figure 1-14 Primary charging ............................................................................................................... 24

Figure 1-15 Laser-beam exposure ......................................................................................................... 25

Figure 1-16 Developing ....................................................................................................................... 25

Figure 1-17 Image transfer ................................................................................................................... 26

Figure 1-18 Separation from the drum ................................................................................................... 26

Figure 1-19 Fusing .............................................................................................................................. 27

Figure 1-20 Drum cleaning .................................................................................................................. 27

Figure 1-21 Toner cartridge components ................................................................................................ 28

Figure 1-22 Drum discharge ................................................................................................................. 29

Figure 1-23 Transfer roller cleaning ...................................................................................................... 30

Figure 1-24 Pickup, feed, and delivery system ........................................................................................ 31

Figure 1-25 Pickup, feed, and delivery system sensors and switches .......................................................... 32

Figure 1-26 Pickup, feed, and delivery-system solenoid and motors ........................................................... 33

Figure 1-27 Pickup and feed block ........................................................................................................ 34

Figure 1-28 Ca

Figure 1-29 Cassette lift operation ........................................................................................................ 37

Figure 1-30 Cassette multiple feed prevention ........................................................................................ 38

Figure 1-31 MP tray pickup .................................................................................................................. 39

Figure 1-32 MP tray multiple-feed prevention .......................................................................................... 40

ssette pickup mechanism ................................................................................................ 35

ENWW xxi

Page 24

Figure 1-33 Skew-feed prevention ......................................................................................................... 42

Figure 1-34 Fuse and delivery block ...................................................................................................... 44

Figure 1-35 Loop control ...................................................................................................................... 45

Figure 1-36 Output bin media-full detection ............................................................................................ 46

Figure 1-37 Product engine jam detection sensors and switches ................................................................ 47

Figure 1-38 500-sheet paper feeder paper path ..................................................................................... 50

Figure 1-39 500-sheet paper feeder signal flow ..................................................................................... 50

Figure 1-40 500-sheet paper feeder motor locations ............................................................................... 51

Figure 1-41 500-sheet paper feeder pickup and feed components ............................................................ 52

Figure 1-42 500-sheet paper feeder pickup and feed cassette pickup ....................................................... 53

Figure 1-43 500-sheet paper feeder lift-up operation ............................................................................... 54

Figure 1-44 500-sheet paper feeder multiple-feed prevention ................................................................... 56

Figure 1-45 500-sheet paper feeder cassette jam detection sensor ............................................................ 56

Figure 1-46 Paper deck paper path ...................................................................................................... 58

Figure 1-47 Paper deck signal flow ....................................................................................................... 59

Figure 1-48 Paper deck motors ............................................................................................................. 61

Figure 1-49 Paper deck pickup and feed components ............................................................................. 62

Figure 1-50 Paper deck lift-up operation ................................................................................................ 64

Figure 1-51 Paper deck jam detection sensors ........................................................................................ 65

Figure 1-52 HCI paper path ................................................................................................................. 67

Figure 1-53 HCI signal flow ................................................................................................................. 68

Figure 1-54 HCI motors ....................................................................................................................... 69

Figure 1-55 HCI pickup-and-feed operation ............................................................................................ 70

Figure 1-56 HCI lift-up operation .......................................................................................................... 72

Figure 1-57 HCI jam detection sensors .................................................................................................. 74

Figure 1-58 Duplexer paper path .......................................................................................................... 76

Figure 1-59 Duplexer signal flow .......................................................................................................... 76

Figure 1-60 Duplexer motor ................................................................................................................. 77

Figure 1-61 Duplexer fan ..................................................................................................................... 78

Figure 1-62 Dup

Figure 1-63 Duplexer side misregistration detection ................................................................................ 81

Figure 1-64 Duplexer jam detection sensors ........................................................................................... 82

Figure 2-1 Locating the engine-test-page switch ..................................................................................... 105

Figure 2-2 Test the cartridge door switch ............................................................................................. 110

Figure 2-3 Test the left door switch ...................................................................................................... 111

Figure 2-4 Test the top sensor ............................................................................................................. 114

Figure 2-5 Fuser loop sensor .............................................................................................................. 115

Figure 2-6 Fuser output sensor ............................................................................................................ 116

Figure 2-7 Duplex switchback sensor ................................................................................................... 117

Figure 2-8 Duplexer refeed sensor ...................................................................................................... 118

Figure 2-9 Tray 4 feed sensor ............................................................................................................. 119

lexer reverse and feed operation ................................................................................... 79

xxii ENWW

Page 25

Figure 2-10 Output sensor ................................................................................................................. 120

Figure 2-11 Tray 1 paper sensor ........................................................................................................ 123

Figure 2-12 Tray 2 paper sensor ........................................................................................................ 124

Figure 2-13 Tray 2 paper surface sensor ............................................................................................. 125

Figure 2-14 Tray 2 paper size switches ............................................................................................... 126

Figure 2-15 Tray 3 paper sensor ........................................................................................................ 127

Figure 2-16 Tray 3 paper surface sensor ............................................................................................. 128

Figure 2-17 Tray 3 paper size switches ............................................................................................... 129

Figure 2-18 Output bin full sensor ....................................................................................................... 130

Figure 2-19 Tray 4 paper sensor ........................................................................................................ 131

Figure 2-20 Tray 4 paper surface sensor ............................................................................................. 132

Figure 2-21 Tray 4 paper size switches ............................................................................................... 133

Figure 2-22 Tray 4 feed sensor ........................................................................................................... 134

Figure 2-23 Lower right door sensor .................................................................................................... 135

Figure 2-24 Test the Tray 4 door switch ............................................................................................... 136

Figure 2-25 Tray 4 paper sensor ........................................................................................................ 138

Figure 2-26 Tray 4 paper surface sensor ............................................................................................. 139

Figure 2-27 Tray 4 paper size sensor .................................................................................................. 139

Figure 2-28 Tray 4 paper feed sensor ................................................................................................. 140

Figure 2-29 Tray 4 door open sensor .................................................................................................. 141

Figure 2-30 Tray 5 paper sensor ........................................................................................................ 141

Figure 2-31 Tray paper surface sensor ................................................................................................ 142

Figure 2-32 Tray 5 paper size sensor .................................................................................................. 143

Figure 2-33 Tray 5 feed sensor ........................................................................................................... 143

Figure 2-34 HCI exit sensor ................................................................................................................ 144

Figure 2-35 Product cross section ........................................................................................................ 148

Figure 2-36 Optional paper feeder (Tray 4) cross section ...................................................................... 149

Figure 2-37 1x500-sheet paper deck cross section ................................................................................ 150

Figure 2-38 3x500-sheet paper deck cross section ................................................................................ 151

Figure 2-39 3,500-sheet HCI cros

Figure 2-40 DC controller connections ................................................................................................. 153

Figure 2-41 External component locations ............................................................................................ 156

Figure 2-42 Major component locations (1 of 3) ................................................................................... 157

Figure 2-43 Major component locations (2 of 3) ................................................................................... 158

Figure 2-44 Major component locations (3 of 3) ................................................................................... 158

Figure 2-45 PCA locations ................................................................................................................. 159

Figure 2-46 Motor locations ............................................................................................................... 160

Figure 2-47 Fan locations .................................................................................................................. 160

Figure 2-48 Roller locations ............................................................................................................... 161

Figure 2-49 500-sheet feeder external component locations ................................................................... 162