Page 1

HP LaserJet 8000, 8000 N, 8000 DN

English

and HP Mopier 240 Printers

Service Manual Supplement

for Paper-handling Accessories

(C4781A, C4782A, C4785A)

Page 2

HP LaserJet 8000, 8000 N,

8000 DN, and HP Mopier 240

Printers Service Manual Supplement

for Paper-handling Accessories

HP 2000-sheet Input Tray

(C4781A)

HP Multibin Mailbox

(C4785A)

HP Duplex Unit (C4782A)

Page 3

© Copyright

Hewlett-Packard

Company 1998

All Rights Reserved.

Reproduction, adaptation,

or translation without

prior written permission

is prohibited, except as

allowed under the

copyright laws.

Publication number

C4085-91023

First edition, March 1998

Warranty

The information

contained in this

document is subject to

change without notice.

Hewlett-Packard makes

no warranty of any kind

with respect to this

information.

HEWLETT-PACKARD

SPECIFICALLY

DISCLAIMS THE

IMPLIED WARRANTY

OF

MERCHANTABILITY

AND FITNESS FOR A

PARTICULAR

PURPOSE.

Hewlett-Packard shall not

be liable for any direct,

indirect, incidental,

consequential, or other

damage alleged in

connection with the

furnishing or use of this

information.

WARNING

Electrical Shock Hazard

To avoid electrical shock,

use only supplied power

cords and connect only to

properly grounded

(3-hole) wall outlets.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714

Page 4

Conventions

This publication uses the following conventions:

The names of major printer parts and assemblies are Capitalized.

Color is used to emphasize important items.

Bold is used for emphasis.

Italic refers to a related document, is used for emphasis, or is used for

supporting text.

Note

Caution

WARNING!

Notes contain important information.

Caution messages appear before procedures that, if not observed, could

result in loss of data or damage to equipment.

Warning messages alert the reader to a specific procedure or practice

that, if not followed correctly, could cause personal injury.

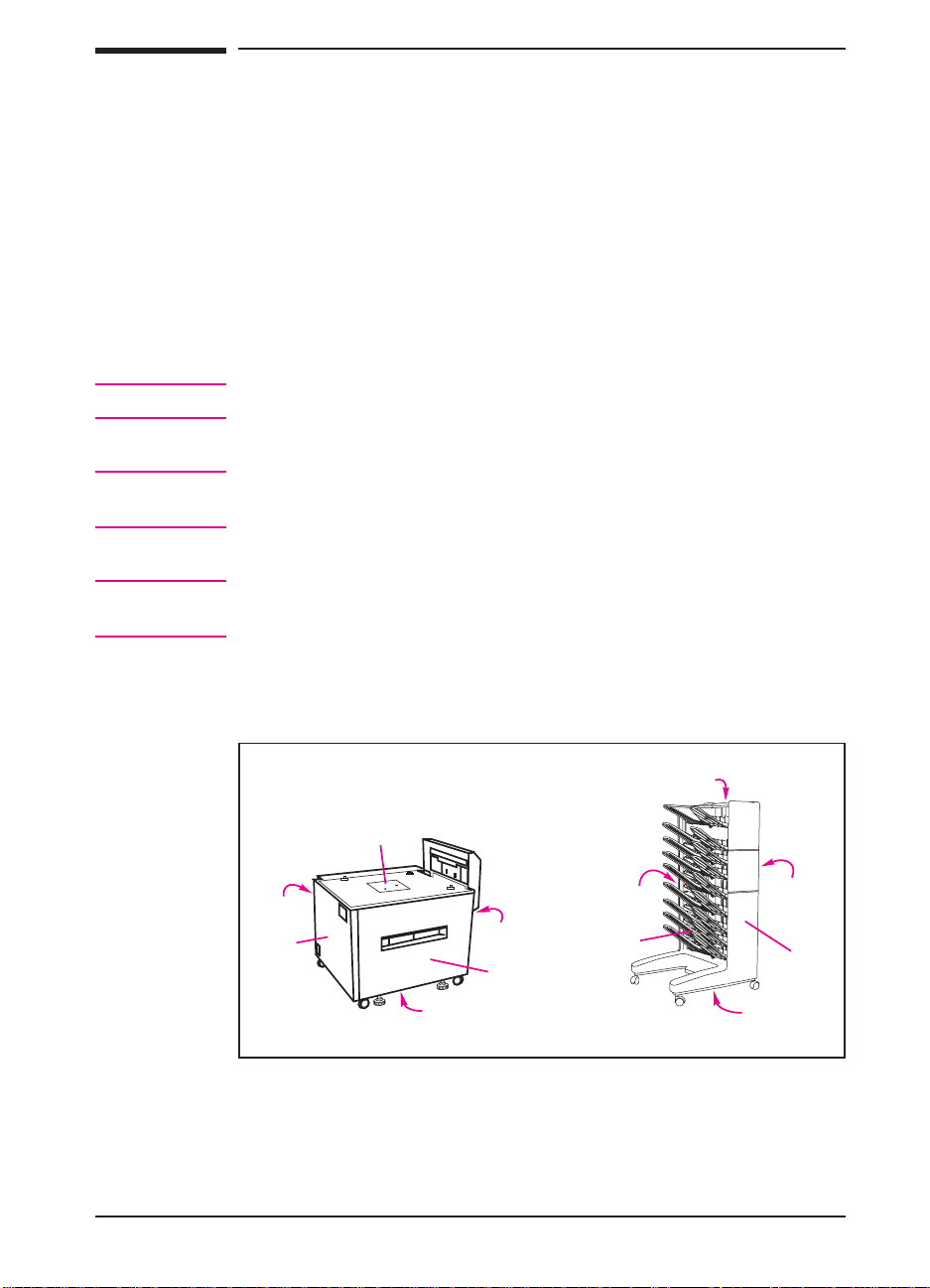

The illustration below shows the orientation of the paper-handling

accessories as they are referred to in this publication.

Top

Top

Back

Left

Right

Front

Back

Left

Right

Front

Bottom

Bottom

iii

Page 5

Contents

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

New Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . x

1 Theory of Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2000-sheet Input Tray Theory of Operation . . . . . . . . . . . . . 1-2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Pickup and Feed System . . . . . . . . . . . . . . . . . . . . . . 1-2

Lifter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Sensors, Switches, Clutches, and Motors . . . . . . . . . . . . . 1-5

Switches Functionality . . . . . . . . . . . . . . . . . . . . . . . 1-7

Multibin Mailbox Theory of Operation . . . . . . . . . . . . . . . 1-8

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Configuring the Operating Modes . . . . . . . . . . . . . . . . . 1-9

Sensors, Switches, Motors, and Controller PCA . . . . . . . . . 1-10

Receiving Paper . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Delivering Paper . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Power-on Sequence . . . . . . . . . . . . . . . . . . . . . . . . 1-14

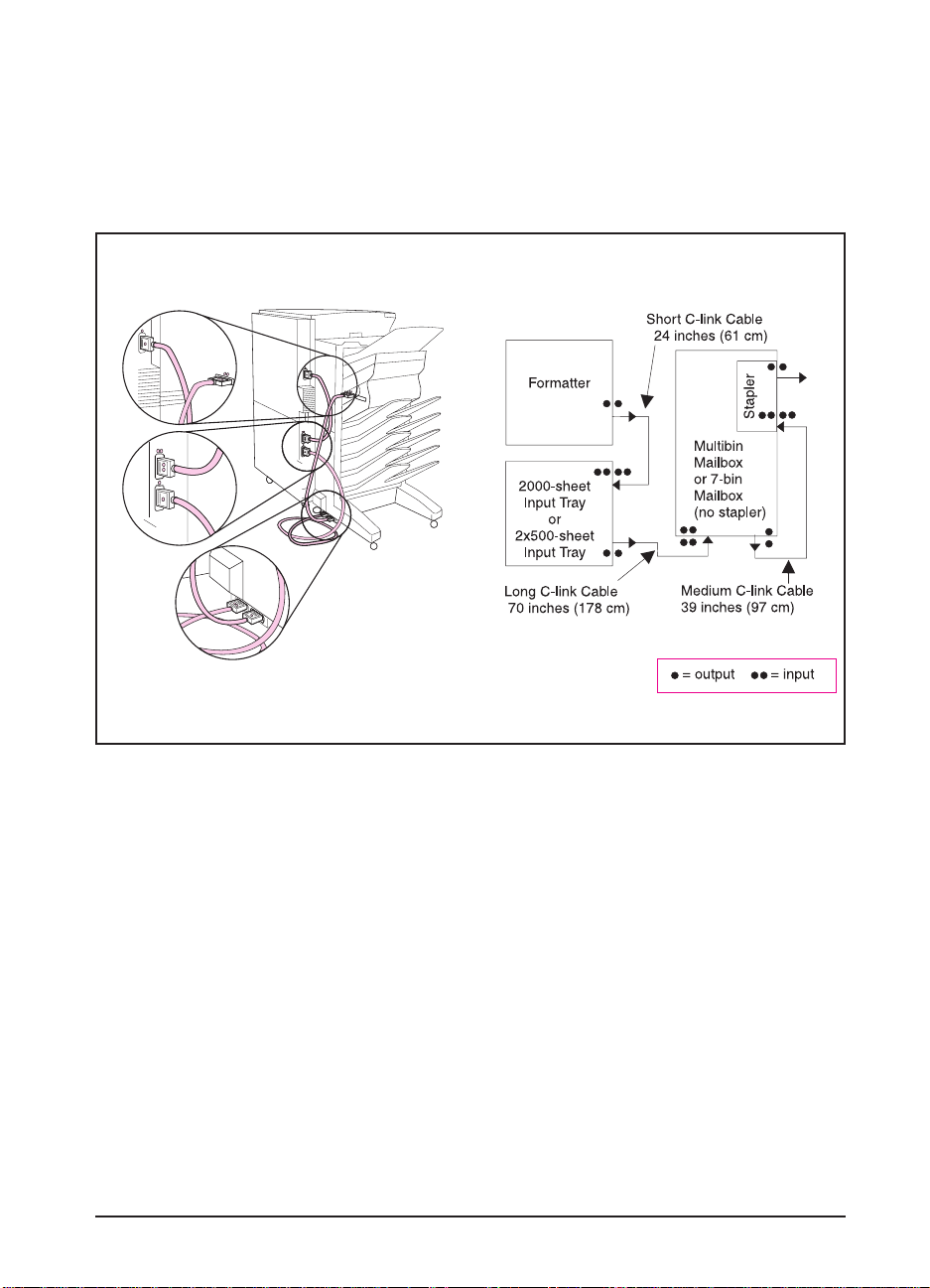

Communication Link (C-link) Cables . . . . . . . . . . . . . . . 1-15

Duplexer Theory of Operation . . . . . . . . . . . . . . . . . . . . 1-16

2 Removal and Replacement

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2000-sheet Input Tray Removal and Replacement . . . . . . . . . . 2-3

2000-sheet Input Tray Orientation . . . . . . . . . . . . . . . . . 2-3

2000-sheet Input Tray Front Cover . . . . . . . . . . . . . . . . 2-4

2000-sheet Input Tray Back Cover . . . . . . . . . . . . . . . . 2-5

2000-sheet Input Tray Left Cover . . . . . . . . . . . . . . . . . 2-6

2000-sheet Input Tray Right Cover . . . . . . . . . . . . . . . . 2-7

2000-sheet Input Tray Main Drive Assembly . . . . . . . . . . . 2-8

2000-sheet Input Tray Paper Tray . . . . . . . . . . . . . . . . . 2-9

2000-sheet Input Tray Main Cable Harness . . . . . . . . . . . . 2-10

2000-sheet Input Tray Controller PCA . . . . . . . . . . . . . . 2-11

2000-sheet Input Tray Front LED PCA Assembly . . . . . . . . 2-12

2000-sheet Input TrayPickup Assembly . . . . . . . . . . . . . 2-13

2000-sheet Input Tray Power Supply . . . . . . . . . . . . . . . 2-15

2000-sheet Input Tray Pickup, Feed, and Separation Rollers . . . 2-16

iv

Page 6

2000-sheet Input Tray Paper Quantity Switch Assembly . . . . 2-18

2000-sheet Input Tray Paper Size Switch Assembly . . . . . . 2-18

2000-sheet Input Tray VTU . . . . . . . . . . . . . . . . . . . 2-20

2000-sheet Input Tray Tension Springs . . . . . . . . . . . . . 2-21

2000-sheet Input Tray Locating Pins . . . . . . . . . . . . . . 2-22

2000-sheet Input Tray Outriggers (Stabilizing Feet) . . . . . . 2-23

2000-sheet Input Tray Casters . . . . . . . . . . . . . . . . . . 2-24

2000-sheet Input Tray Adjustable Foot . . . . . . . . . . . . . 2-25

Multibin Mailbox Removal and Replacement . . . . . . . . . . . 2-26

Multibin Mailbox Orientation . . . . . . . . . . . . . . . . . . 2-26

Multibin Mailbox Front and Back Covers . . . . . . . . . . . . 2-27

Multibin Mailbox Top Cover . . . . . . . . . . . . . . . . . . . 2-28

Multibin Mailbox Power Supply . . . . . . . . . . . . . . . . . 2-29

Multibin Mailbox Paper Bins and Blind Cover . . . . . . . . . 2-30

Multibin Mailbox Flipper Assembly . . . . . . . . . . . . . . . 2-31

Multibin Mailbox Delivery Head Motor . . . . . . . . . . . . . 2-34

Multibin Mailbox Transport Belt Motor . . . . . . . . . . . . . 2-35

Multibin Mailbox Input Paper Guide . . . . . . . . . . . . . . 2-36

Multibin Mailbox Metal Tape and Housing Assembly . . . . . 2-38

Multibin Mailbox Controller PCA . . . . . . . . . . . . . . . . 2-40

Multibin Mailbox Anticurl Strings . . . . . . . . . . . . . . . . 2-42

Multibin Mailbox Delivery Head Assembly . . . . . . . . . . . 2-44

Multibin Mailbox Interlock Switch . . . . . . . . . . . . . . . 2-47

Multibin Mailbox Diagnostic LED PCA . . . . . . . . . . . . 2-48

Multibin Mailbox User Status LED PCA . . . . . . . . . . . . 2-50

Multibin Mailbox Adjustable and Fixed Casters . . . . . . . . 2-52

Multibin Mailbox Attachment Assembly . . . . . . . . . . . . 2-53

3 Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Troubleshooting Approach . . . . . . . . . . . . . . . . . . . . . . 3-2

Print the Event Log . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Display the Event Log . . . . . . . . . . . . . . . . . . . . . . . 3-2

Interpret the Event Log . . . . . . . . . . . . . . . . . . . . . . . 3-3

Print a Configuration Page . . . . . . . . . . . . . . . . . . . . . 3-3

C-link Communication Cables . . . . . . . . . . . . . . . . . . . 3-6

Paper Path Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Messages Structure . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

2000-sheet Input Tray Standalone Diagnostics . . . . . . . . . . . 3-10

2000-sheet Input Tray Motor Test . . . . . . . . . . . . . . . . 3-10

2000-sheet Input Tray Standalone Running Test . . . . . . . . 3-11

2000-sheet Input Tray Sensor Test . . . . . . . . . . . . . . . . 3-11

2000-sheet Input Tray LED Status Interpretation . . . . . . . . 3-12

Multibin Mailbox Standalone Diagnostics . . . . . . . . . . . . . 3-13

Multibin Mailbox LEDs Description . . . . . . . . . . . . . . 3-13

Multibin Mailbox Standalone Diagnostic Test . . . . . . . . . . 3-14

v

Page 7

Power-on Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Multibin Mailbox Paper Path Test . . . . . . . . . . . . . . . . . 3-15

Multibin Mailbox LEDs Status Interpretation . . . . . . . . . . . 3-15

General Troubleshooting Information . . . . . . . . . . . . . . . . 3-19

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

4 Parts

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2000-sheet Input Tray Components . . . . . . . . . . . . . . . . . 4-3

Multibin Mailbox Components . . . . . . . . . . . . . . . . . . . . 4-7

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

vi

Page 8

List of Figures

Figure 1-1 2000-sheet Input Tray Paper Path . . . . . . . . . . 1-4

Figure 1-2 2000-sheet Input Tray Sensors, Switches, Clutches,

and Motors . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-3 Multibin Mailbox Sensors, Switches, Motors, and

Controller PCA . . . . . . . . . . . . . . . . . . . . 1-11

Figure 1-4 Multibin Mailbox Paper Path . . . . . . . . . . . . . 1-13

Figure 1-5 C-link Cables, Supported Daisy-chain Connections . 1-15

Figure 1-6 Duplexer Location . . . . . . . . . . . . . . . . . . 1-16

Figure 2-1 Phillips versus Posidriv Screwdrivers . . . . . . . . 2-2

Figure 2-2 2000-sheet Input Tray Orientation . . . . . . . . . . 2-3

Figure 2-3 2000-sheet Input Tray Front Cover . . . . . . . . . . 2-4

Figure 2-4 2000-sheet Input Tray Back Cover . . . . . . . . . . 2-5

Figure 2-5 2000-sheet Input Tray Left Cover . . . . . . . . . . 2-6

Figure 2-6 2000-sheet Input Tray Right Cover . . . . . . . . . 2-7

Figure 2-7 2000-sheet Input Tray Main Drive Assembly . . . . 2-8

Figure 2-8 2000-sheet Input Tray Paper Tray . . . . . . . . . . 2-9

Figure 2-9 2000-sheet Input Tray Main Cable Harness . . . . . 2-10

Figure 2-10 2000-sheet Input Tray Controller PCA . . . . . . . . 2-11

Figure 2-11 2000-sheet Input Tray Front LED PCA . . . . . . . 2-12

Figure 2-12 2000-sheet Input TrayPickup Assembly . . . . . . . 2-13

Figure 2-13 2000-sheet Input Tray Pickup Assembly

Photosensors . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-14 2000-sheet Input Tray Power Supply . . . . . . . . . 2-15

Figure 2-15 2000-sheet Input Tray Rollers: Pickup, Feed, and

Separation . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-16 2000-sheet Input Tray Paper Size and Paper

Quantity Switch Assemblies (1 of 2) . . . . . . . . . 2-19

Figure 2-17 2000-sheet Input Tray Paper Size and Paper

Quantity Switch Assemblies (2 of 2) . . . . . . . . . 2-19

Figure 2-18 2000-sheet Input Tray Vertical Transfer Unit (VTU) 2-20

Figure 2-19 2000-sheet Input Tray Tension Springs . . . . . . . 2-21

Figure 2-20 2000-sheet Input Tray Locating Pins . . . . . . . . . 2-22

Figure 2-21 2000-sheet Input Tray Outriggers . . . . . . . . . . 2-23

Figure 2-22 2000-sheet Input Tray Casters . . . . . . . . . . . . 2-24

Figure 2-23 2000-sheet Input TrayAdjustable Foot . . . . . . . . 2-25

Figure 2-24 Multibin Mailbox Orientation . . . . . . . . . . . . 2-26

Figure 2-25 Multibin Mailbox Covers (Front and Back) . . . . . 2-27

Figure 2-26 Multibin Mailbox Top Cover . . . . . . . . . . . . . 2-28

Figure 2-27 Multibin Mailbox Power Supply . . . . . . . . . . . 2-29

Figure 2-28 Multibin Mailbox Paper Bins and Blind Cover . . . 2-30

Figure 2-29 Multibin Mailbox Flipper Assembly (1 of 3) . . . . 2-32

Figure 2-30 Multibin Mailbox Flipper Assembly (2 of 3) . . . . 2-32

vii

Page 9

Figure 2-31 Multibin Mailbox Flipper Assembly (3 of 3) . . . . 2-33

Figure 2-32 Multibin Mailbox Delivery Head Motor . . . . . . . 2-34

Figure 2-33 Multibin Mailbox Transport Belt Motor . . . . . . . 2-35

Figure 2-34 Multibin Mailbox Input Paper Guide (1 of 2) . . . . 2-36

Figure 2-35 Multibin Mailbox Input Paper Guide (2 of 2) . . . . 2-37

Figure 2-36 Multibin Mailbox Metal Tape and Housing

Assembly (1 of 2) . . . . . . . . . . . . . . . . . . 2-39

Figure 2-37 Multibin Mailbox Metal Tape and Housing

Assembly (2 of 2) . . . . . . . . . . . . . . . . . . 2-39

Figure 2-38 Multibin Mailbox Controller PCA (1 of 2) . . . . . 2-40

Figure 2-39 Multibin Mailbox Controller PCA (2 of 2) . . . . . 2-41

Figure 2-40 Multibin Mailbox Anticurl Strings (1 of 2) . . . . . 2-42

Figure 2-41 Multibin Mailbox Anticurl Strings (2 of 2) . . . . . 2-43

Figure 2-42 Multibin Mailbox Delivery Head Assembly

(1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Figure 2-43 Multibin Mailbox Delivery Head Assembly

(2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Figure 2-44 Multibin Mailbox Delivery Head Assembly

(3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Figure 2-45 Multibin Mailbox Delivery Head Assembly

(4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Figure 2-46 Multibin Mailbox Interlock Switch . . . . . . . . . 2-47

Figure 2-47 Multibin Mailbox Diagnostic LED PCA (1 of 2) . . 2-48

Figure 2-48 Multibin Mailbox Diagnostic LED PCA (2 of 2) . . 2-49

Figure 2-49 Multibin Mailbox User Status LED PCA (1 of 2) . . 2-50

Figure 2-50 Multibin Mailbox User Status LED PCA (2 of 2) . . 2-51

Figure 2-51 Multibin Mailbox Adjustable and Fixed Casters . . 2-52

Figure 2-52 Multibin Mailbox Attachment Assembly . . . . . . 2-53

Figure 3-1 Sample Configuration Page . . . . . . . . . . . . . 3-4

Figure 3-2 Sample Menu Page . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3 C-link Cables, Supported Daisy-chain Connections . 3-6

Figure 3-4 Paper Path Test Source and Output Selection . . . . 3-8

Figure 3-5 Multibin Mailbox LEDs Description . . . . . . . . 3-13

Figure 3-6 Multibin Mailbox Power Supply Test Mode Switch 3-14

Figure 3-7 2000-sheet Input Tray Controller PCA Inputs . . . . 3-20

Figure 3-8 2000-sheet Input Tray Controller PCA Outputs . . . 3-21

Figure 3-9 2000-sheet Input Tray Main Wiring Diagram . . . . 3-22

Figure 3-10 Multibin Mailbox Main Wiring Diagram . . . . . . 3-23

Figure 4-1 2000-sheet Input Tray (C4781A) Components

(1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2 2000-sheet Input Tray (C4781A) Components

(2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3 Multibin Mailbox (C4785A) Components (1 of 3) . 4-6

Figure 4-4 Multibin Mailbox (C4785A) Components (2 of 3) . 4-8

Figure 4-5 Multibin Mailbox (C4785A) Components (3 of 3) . 4-10

viii

Page 10

List of Tables

Table 1-1 2000-sheet Input Tray Sensors, Switches, Clutches,

and Motors . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-2 2000-sheet Input Tray Paper Quantity Switches . . . . 1-7

Table 1-3 2000-sheet Input Tray Paper Size Switches . . . . . . 1-7

Table 1-4 Multibin Mailbox Sensors, Switches, Motors, and

Controller PCA . . . . . . . . . . . . . . . . . . . . . 1-10

Table 3-1 DIP Switch Settings . . . . . . . . . . . . . . . . . . 3-10

Table 3-2 2000-sheet Input Tray LED Status Interpretation . . . 3-12

Table 3-3 Multibin Mailbox LED Status Interpretation . . . . . 3-15

Table 4-1 2000-sheet Input Tray (C4781A) Components

(1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 4-2 2000-sheet Input Tray (C4781A) Components

(2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 4-3 Multibin Mailbox (C4785A) Components (1 of 3) . . 4-7

Table 4-4 Multibin Mailbox (C4785A) Components (2 of 3) . . 4-9

Table 4-5 Multibin Mailbox (C4785A) Components (3 of 3) . . 4-11

Table 4-6 Duplexer . . . . . . . . . . . . . . . . . . . . . . . . 4-11

ix

Page 11

New Product Features

2000-sheet Input Tray

• variable speed

• standalone self-test diagnostics

• diagnostic LEDs

• user status LED

• new parts kits and field-replaceable units (FRUs)

Multibin Mailbox

• variable speed

• standalone self-test diagnostics

• diagnostic LEDs

• user status LED

• factory cable routing and preinstallation

• new parts kits and field-replaceable units (FRUs)

• new power supply

• adjustable casters

• new latching mechanism

Duplexer

• variable speed

• new FRU status

x

Page 12

Theory of Operation

Overview

The following information provides the theory of operation for the

following paper-handling accessories and parts:

• Paper-handling Controller

• HP 2000-sheet Input Tray

• HP Multibin Mailbox (MBM)

• Duplexer

The information in this manual supplements the information in the

HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240 Printers

Service Manual (part no. C4085-91017). Use this supplement with the

HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240 Printers

Service Manual.

1

Theory of Operation 1-1

Page 13

2000-sheet Input Tray Theory of Operation

Features

The HP 2000-sheet Input Tray now supports variable engine input

speeds, ranging from 6 to 32 ppm. The 2000-sheet Input Tray also

automatically senses paper size.

Pickup and Feed System

When the 2000-sheet Input Tray is loaded with paper and the paper tray

is closed, the paper stack moves into position under the Pickup, Feed,

and Separation Rollers. This operation is detected by the PS34 sensor in

the 2000-sheet Input Tray’s Pickup Assembly. The presence of paper in

the paper tray is detected by the PS33 sensor. The paper level is detected

by switches SW601 and SW602 in the Paper Quantity Switch Assembly.

The paper size is detected by switches SW701 through SW704 in the

Paper Size Switch Assembly.

When the Paper-handling Controller on the printer sends an input

command to the Controller PCA on the 2000-sheet Input Tray, the Paper

Deck Driver runs the Pickup Motor to rotate the Pickup, Feed, and

Separation Rollers. As the Pickup Roller turns, the paper feeds into the

Vertical Transfer Unit (VTU) and passes through the PS31 and PS32

sensors.

If the paper fails to reach the PS31 and PS32 sensors in the VTU within

the allotted time, the Controller PCA on the 2000-sheet Input Tray

assumes that a paper jam has occurred. The 2000-sheet Input Tray stops

the operation and reports the paper jam to the Paper-handling Controller

on the printer. A paper jam message appears on the printer control panel

display.

Hardware malfunctions are also displayed on the printer control panel.

1-2 Theory of Operation

Page 14

Lifter Operation

The lifter plate in the 2000-sheet Input Tray’s paper tray is held by two

wires that are wound on four pulleys by the Lifter Motor. When the

paper tray is open, the pulley gears disengage from the motor gears, and

the Lifter lowers by its own weight. The presence or absence of the tray

is detected by switches SW701 through SW704 on the unit’s Paper/Tray

Size Switch Assembly.

After the paper tray is closed, the Lifter Motor lifts the paper stack into

position; this action is detected by the PS34 sensor. The PS34 sensor

also maintains the height of the paper stack. As paper is picked up by the

rollers, the number of sheets decreases. Once the paper stack decreases

to a certain level, the PS34 sensor registers a low condition. Then the

Paper Deck Driver turns on the Lifter Motor again and lifts the paper

stack until the PS34 sensor registers sufficient paper in the tray.

Power Supply

The 2000-sheet Input Tray has an internal Power Supply that activates

when the printer’s power switch is turned on. The Paper-handling

Controller on the printer sends a power-on signal to the Power Supply

on the 2000-sheet Input Tray through the Controller PCA on the

2000-sheet Input Tray. When the signal is high, the Power Supply

provides both +24V and +5V to the Paper Deck Driver.The +24V drives

the motors, clutches, and solenoids for the lifter, feed, and pickup

systems. The +5V drives the sensors and PCA electronics.

Theory of Operation 1-3

Page 15

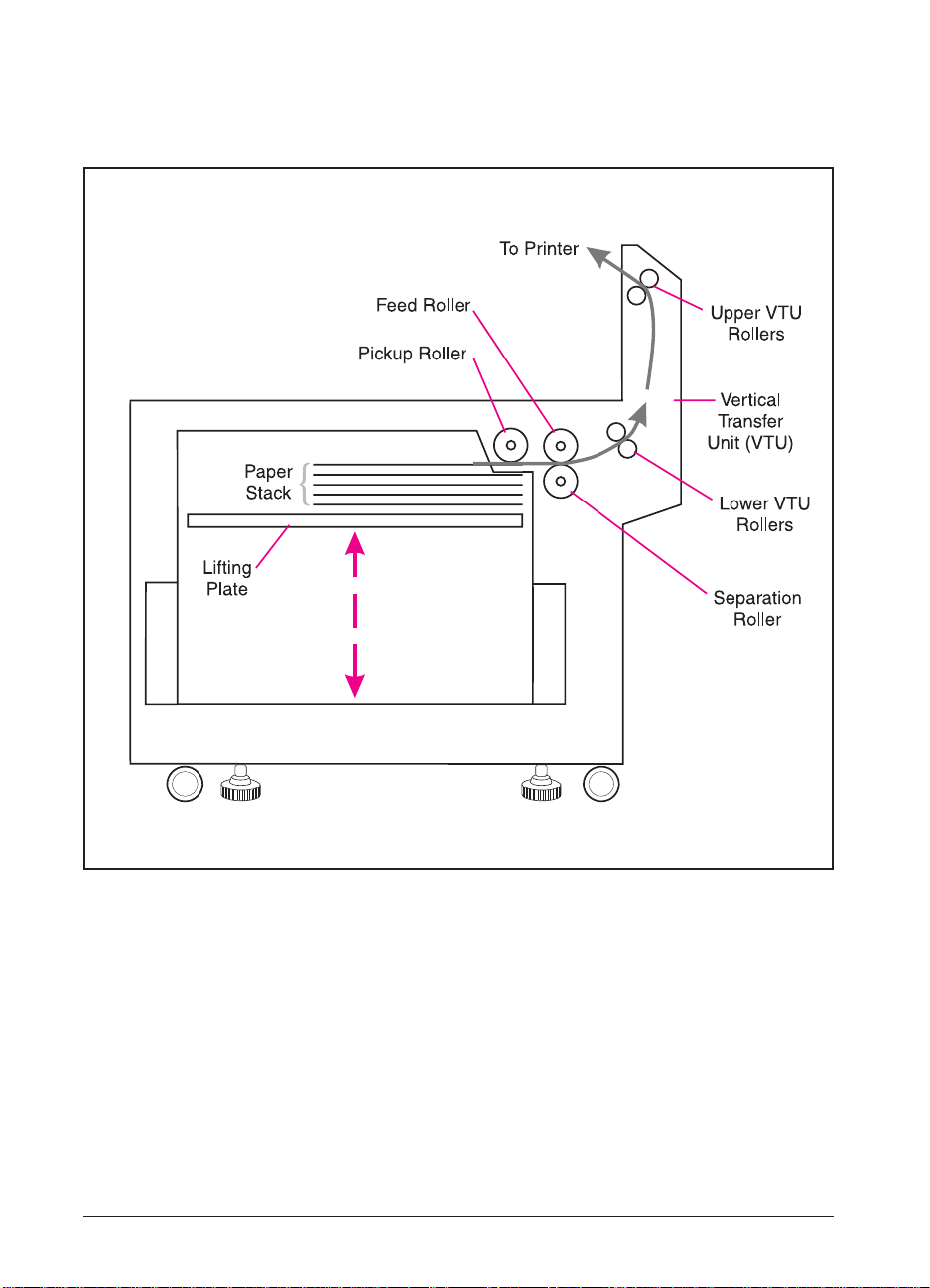

Paper Path

Figure 1-1 illustrates the paper path components in the 2000-sheet Input

Tray.

Figure 1-1 2000-sheet Input Tray Paper Path

1-4 Theory of Operation

Page 16

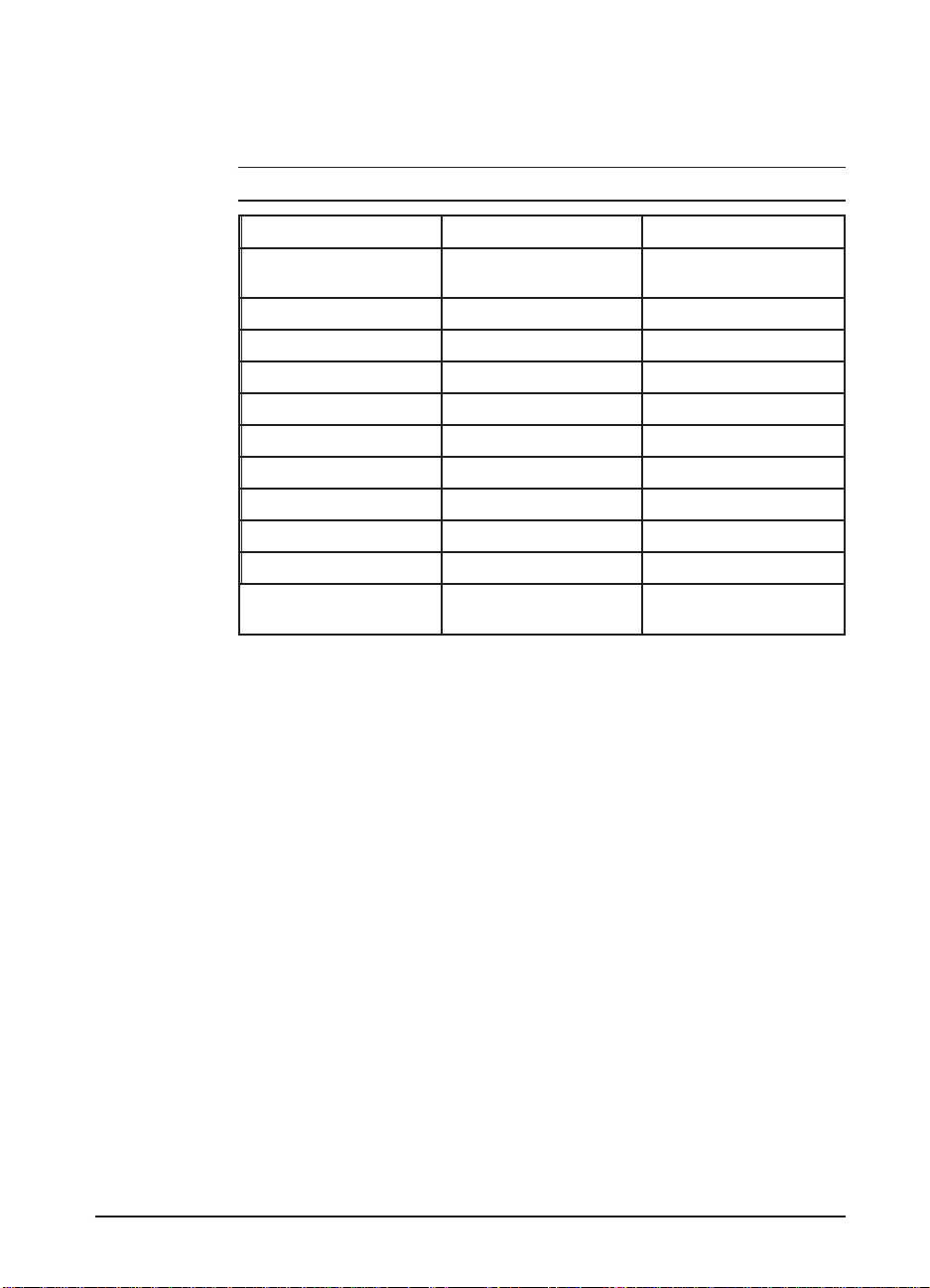

Sensors, Switches, Clutches, and Motors

Table 1-1 and Figure 1-2, on the next page describe and illustrate the

sensors, switches, clutches, and motors on the 2000-sheet Input Tray.

Table 1-1 2000-sheet Input Tray Sensors, Switches, Clutches, and Motors

Control Device Description Location

CL31 VerticalTransfer Unit (VTU)

Clutch

CL32 Main Drive Clutch VTU

MT31 Main Motor PaperDeck Drive Assembly

PS31 Paper Entry Sensor VTU

PS32 Paper Exit Sensor VTU

PS33 Paper Tray Empty Sensor PaperPickup Assembly

PS34 Paper Tray Raised Sensor PaperPickup Assembly

PS35 VTU Closed Sensor PaperPickup Assembly

SW601-SW602 Paper Quantity Switches Lower Chassis

SW701-SW704 Paper SizeSwitches Lower Chassis

PowerSupply Switch Normal/Diagnostic Mode

Switch

VerticalTransfer Unit (VTU)

PowerSupply

Theory of Operation 1-5

Page 17

Figure 1-2 2000-sheet Input Tray Sensors, Switches, Clutches, and Motors

1-6 Theory of Operation

Page 18

Switches Functionality

Tables 1-2 and 1-3 show the paper quantity and paper size switches on

the 2000-sheet Input Tray.

Paper Quantity Switches

Table 1-2 2000-sheet Input Tray Paper QuantitySwitches

SW601 SW602 Remaining Paper

Off Off 100%

On Off 75%

On On 50%

Off On 25%

Paper Size Switches

Table 1-3 2000-sheet Input Tray Paper Size Switches

Paper Size SW701 SW702 SW703 SW704

Ledger (portrait) Off On Off Off

A3 (portrait) On On Off Off

B4 (portrait) Off Off On Off

Legal (portrait) Off On On Off

Letter (landscape) Off On Off On

A4 (landscape) On On Off On

Theory of Operation 1-7

Page 19

Multibin Mailbox Theory of Operation

Features

The Multibin Mailbox (MBM) is an output unit designed for variable

speeds, ranging from 6 to 32 ppm. The Multibin Mailbox holds up to

2,100 sheets distributed in eight 250-sheet standard output bins and one

100-sheet left output bin. The Multibin Mailbox also features four

intelligent and configurable operating modes.

Operating Modes

Mailbox Mode

In Mailbox Mode, the network administrator can address each bin as an

output destination with a name assigned to it. The printer sends a print

job to the selected bin. If the assigned bin is full, the printer either stops

printing or sends subsequent pages to the overflow bin, which is also

defined by the network administrator.

Job Separator Mode

In Job Separator Mode, each print job is placed in a separate bin. All

Multibin Mailbox bins are used for this purpose, starting with the first

standard output bin (at the top). If a Multibin Mailbox bin is full, the

printer automatically sends the job to the next available bin. If there are

more jobs than bins, the extra jobs will start again at the top standard

output bin.

This process is seen by the printer software as one logical bin.

Virtual Stacker Mode

In Virtual Stacker Mode, printed sheets are stacked face down in the bins

from the lowest bin to the top bin, regardless of where a print job begins

or ends. All printed sheets are sent to the bottom bin until it is full;

subsequent sheets are sent to the next upward bin until it is full. This

mode of operation takes advantage of the total capacity of the Multibin

Mailbox bins.

In this mode, the software sees the Multibin Mailbox as one logical bin.

When the Multibin Mailbox is full, the printer stops sending paper until

all the bins are emptied.

1-8 Theory of Operation

Page 20

Collator Mode

Each mopy (copy) of a single job is sent to a different bin (next bin

down). This mode separates mopies automatically.

In Collator Mode, the device automatically separates mopies. Each

mopy is delivered in consecutive bins, starting with the top standard

output bin. In this case, one job contains several mopies.

Configuring the Operating Modes

The network administrator chooses the mode of operation through an

HP network configuration utility, such as the HP JetAdmin utility or the

HP LaserJet utility for the Macintosh. Additionally,on all workstations

that print to the printer, the printer driver might need to be set up to

reflect the chosen operating mode.

Bidirectional environment: The printer automatically selects the mode

established by the network administrator.

Unidirectional environment: The mode of operation can be changed in

the driver. The method for changing the mode varies with the driver and

type of operating system. For additional information, see the online help

for the printer software.

Theory of Operation 1-9

Page 21

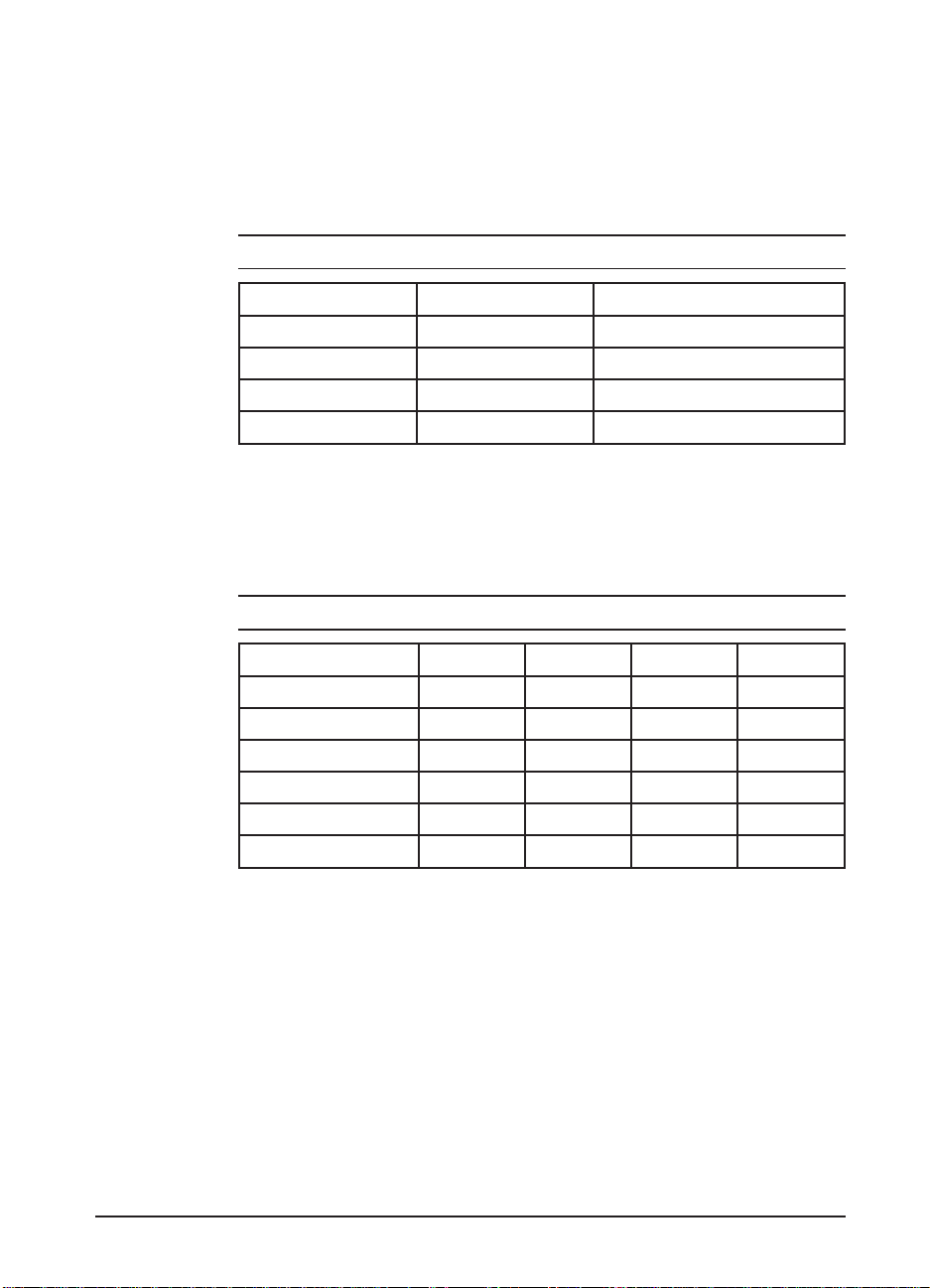

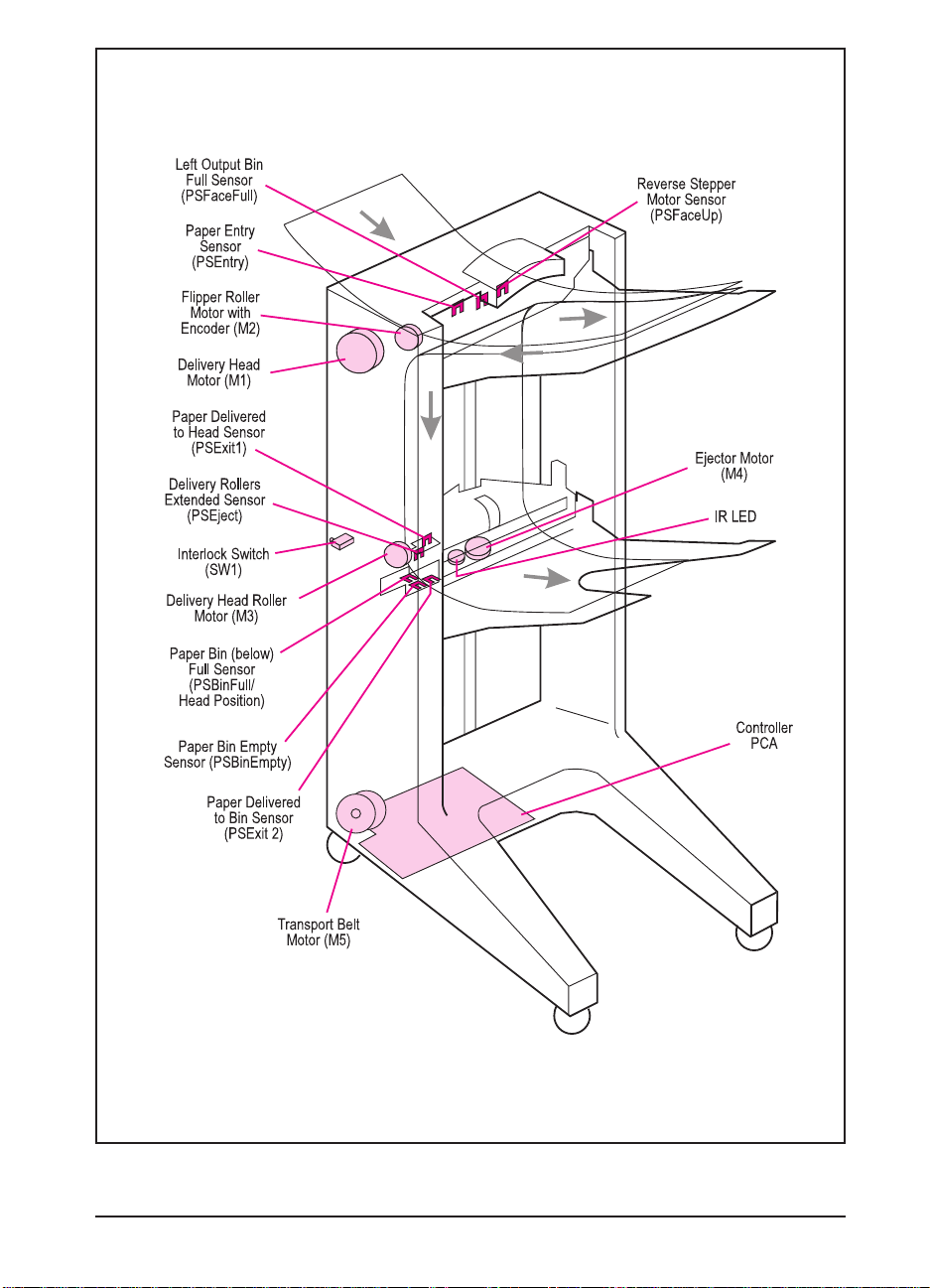

Sensors, Switches, Motors, and Controller PCA

Table 1-4 and Figure 1-3 on the next page illustrate and describe the

Multibin Mailbox sensors, switches, motors, and Controller PCA.

Table 1-4 Multibin Mailbox Sensors, Switches, Motors,and Controller PCA

Control Device Description Location

M1 Delivery Head Motor Upper-back Side

M2 Flipper Roller Motor with

M3 Delivery Head Roller Motor Delivery Head Assembly

M4 Ejector Motor Under Delivery Head Assembly

M5 Transport Belt Motor Lower-back Side

PSBinEmpty PaperBin Empty Sensor Delivery HeadAssembly

PSBinFull/Head

Position

PSEject Delivery Rollers Extended

PSEntry Paper Entry Sensor Flipper Assembly (top, center)

PSExit1 Paper Deliveredto Head

PSExit2 Paper Deliveredto Bin Sensor Delivery Head Assembly

PSFaceUp Reverse Stepper Motor Sensor Flipper Assembly (top, center)

PSFaceFull Left Output Bin Full Sensor Flipper Assembly (top, center)

SW1 Interlock Switch Middle-back Side

IR LED Infrared Light-emitting Diode

Encoder

PaperBin (below)Full Sensor Delivery Head Assembly

Sensor

Sensor

(forStapler Assembly)

Flipper Assembly (upper back)

(upper back)

(upper back)

(upper back)

Delivery Head Assembly

(upper back)

Delivery Head Assembly

(upper back)

(upper back)

Delivery Head Assembly (left, center)

1-10 Theory of Operation

Page 22

Figure 1-3 Multibin Mailbox Sensors, Switches, Motors, and Controller PCA

Theory of Operation 1-11

Page 23

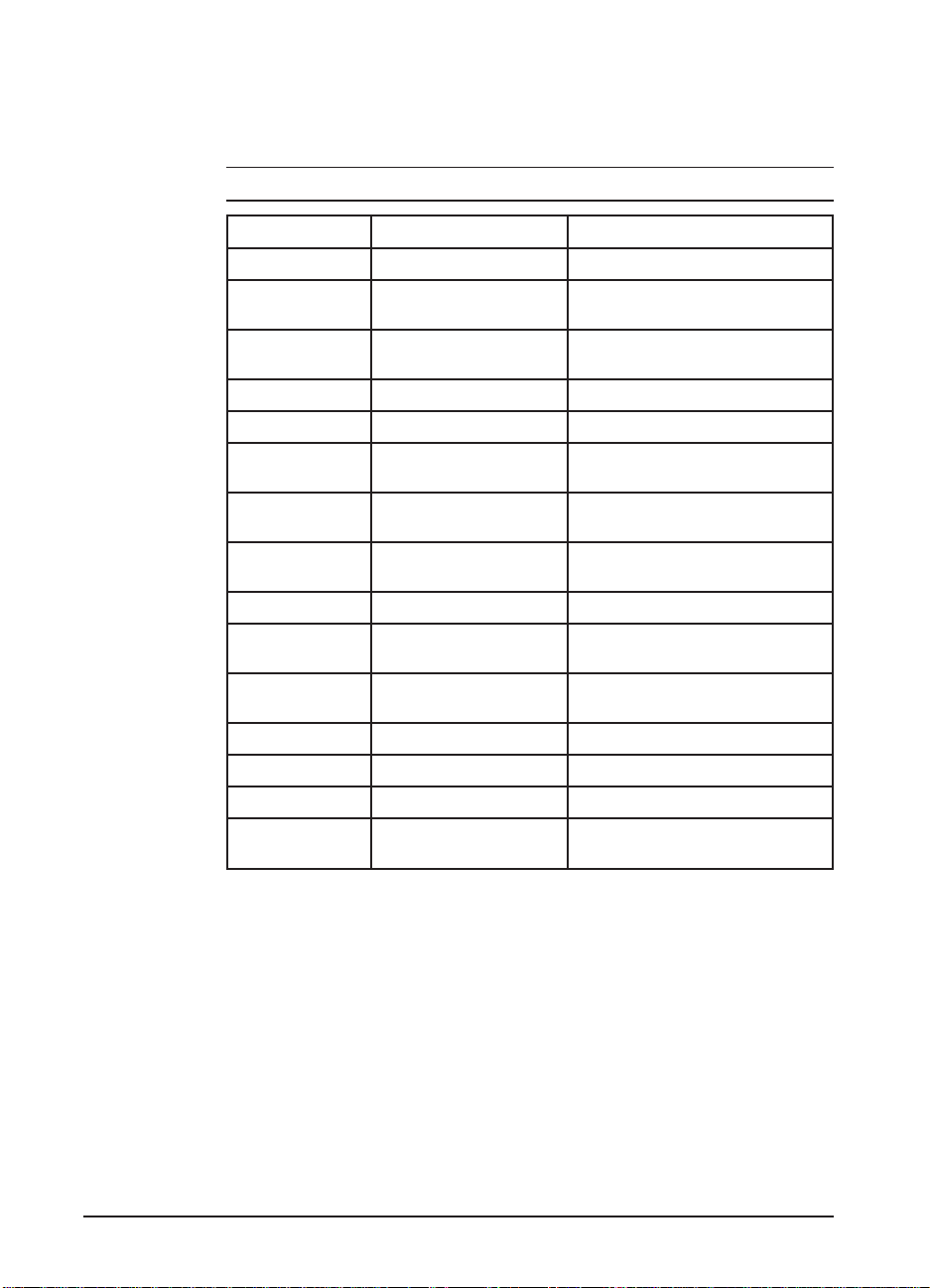

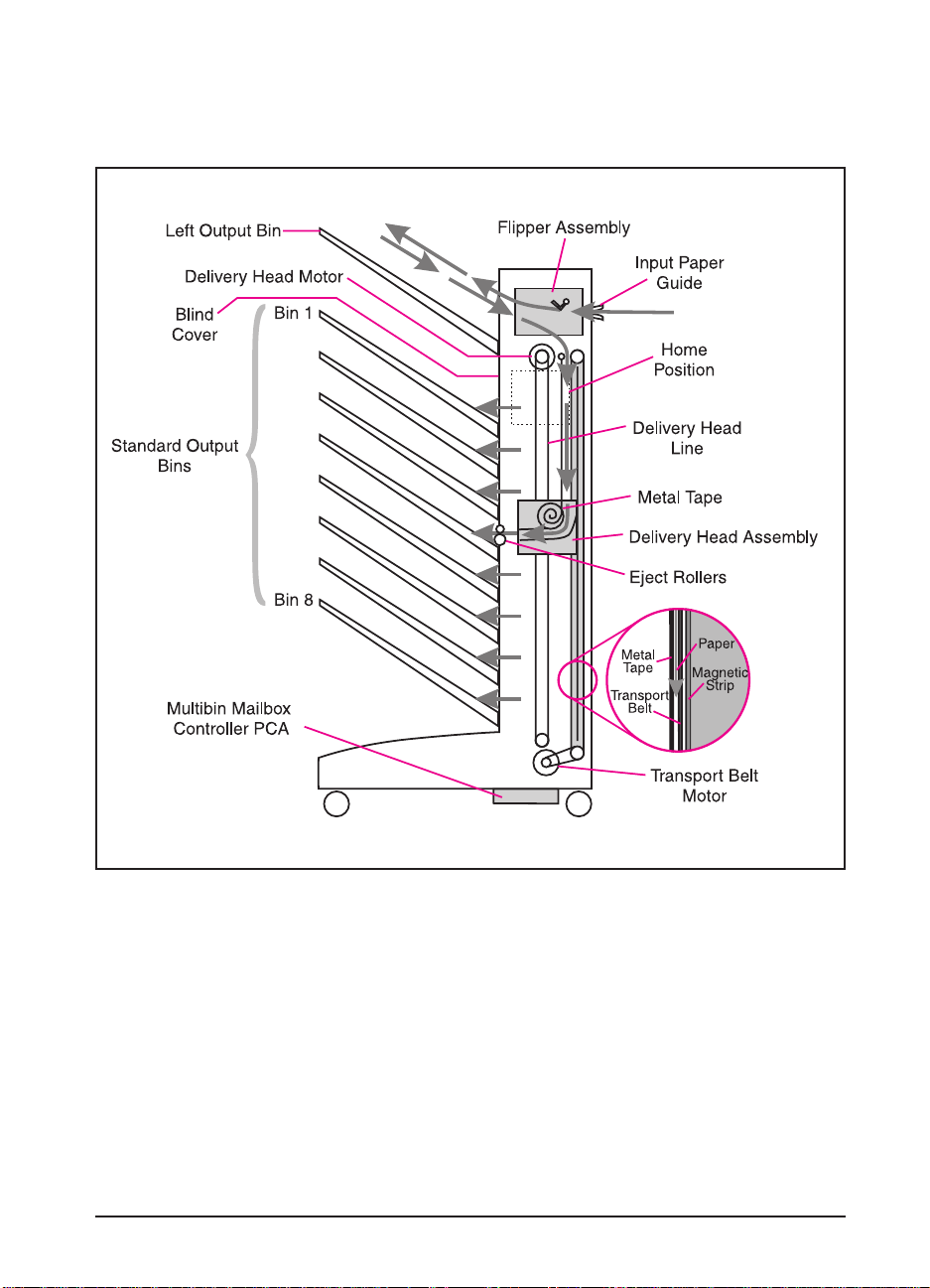

Receiving Paper

The printer delivers paper to the Multibin Mailbox through the left

output delivery slot (Input Paper Guide) at a rate of 107 mm per second.

Paper arrival is sensed by the PSEntry sensor, which activates the

Flipper Roller Motor (M2), causing the paper to move through the

Multibin Mailbox transport and delivery system. See Figure 1-4.

Delivering Paper

The Delivery Head Assembly on the Multibin Mailbox moves or stays in

the indicated bin according to the commands coming from the

Paper-handling Controller on the printer. If paper is designated for the

left output bin, the Multibin Mailbox feeds it through the Flipper

Assembly. If paper is designated for one of the standard output bins, the

Multibin Mailbox feeds it through the Flipper Assembly until the

trailing edge is sensed by the PSFaceUp sensor. Then the Flipper Roller

Motor (M2) reverses and feeds the paper down between the Transport

Belt and the Metal Tape until it reaches the Delivery Head Assembly.

1-12 Theory of Operation

Page 24

Paper Path

Figure 1-4 illustrates the components of the Multibin Mailbox paper

path.

Figure 1-4 Multibin Mailbox Paper Path

Theory of Operation 1-13

Page 25

Power-on Sequence

During the power-on sequence, the Delivery Head Assembly moves first

to the top “home” position at the left output bin. From that position the

delivery head moves down, scanning to determine if all the Multibin

Mailbox bins are installed, if they contain paper, and if they are full.

Then the Delivery Head proceeds upward again to the home position

and remains there for about 7 seconds. Finally, the Delivery Head

Assembly moves to the bottom bin, where it waits for the next command

from the Paper-handling Controller.

Note

If one of the bins has been removed or is not seated correctly, the

Delivery Head Assembly will not complete the scan and will send an

error message to the printer control panel.

1-14 Theory of Operation

Page 26

Communication Link (C-link) Cables

Communication with the Multibin Mailbox is handled through the

Paper-handling Controller on the printer. The information coming from

the Paper-handling Controller is carried by the C-link cables that

connect the Paper-handling Controller PCA to all the devices that

support the C-link protocol.

Figure 1-5 C-link Cables, Supported Daisy-chain Connections

Theory of Operation 1-15

Page 27

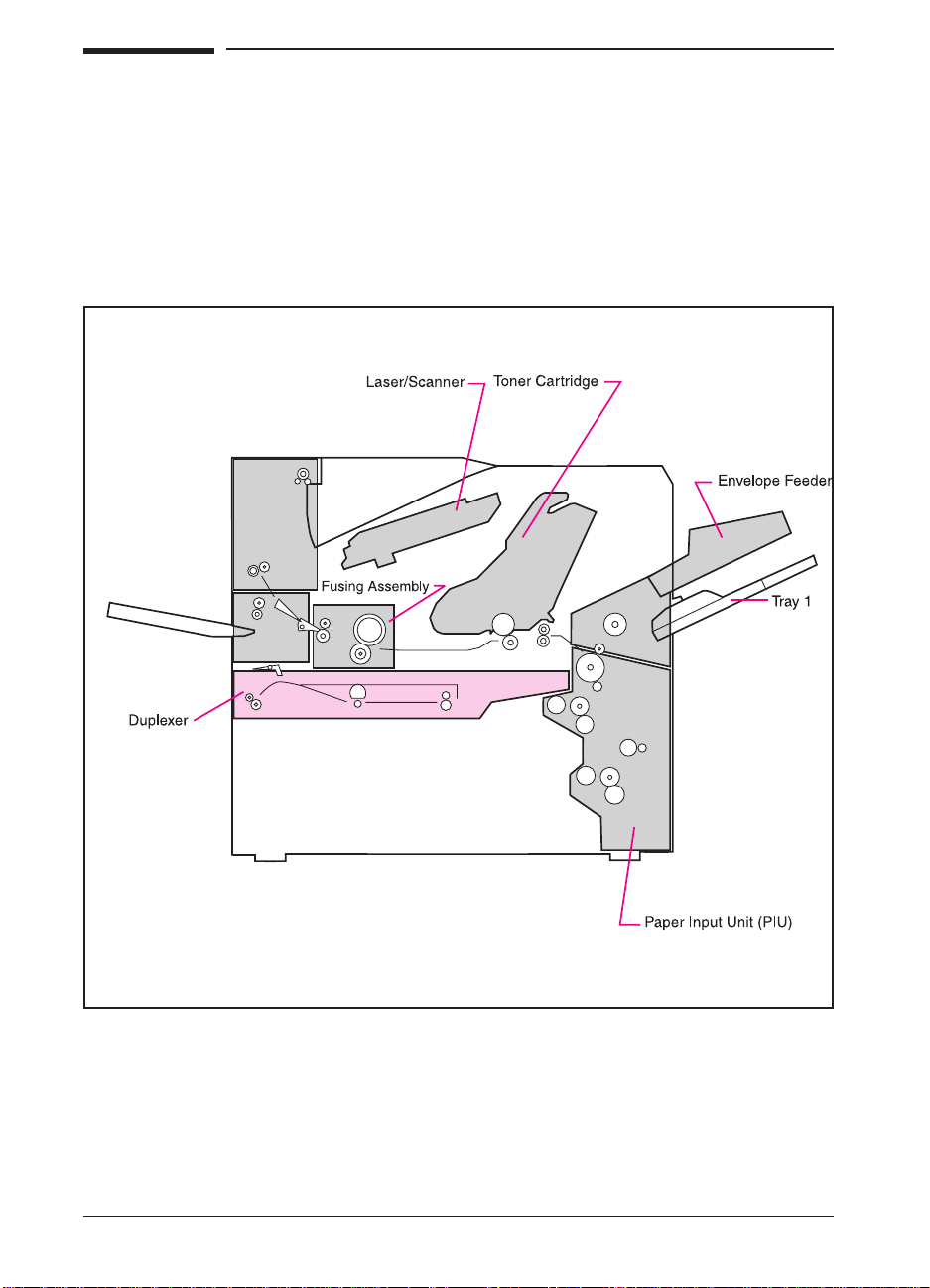

Duplexer Theory of Operation

The Duplexer installs inside the printer, below the Fusing Assembly. The

back side of the paper is printed first. Then the paper is turned over and

fed back through the paper path for front-sided printing. The new

Duplexer supports variable engine input speeds.

The Envelope Feeder installs on the right side of the printer above

Tray 1.

Figure 1-6 Duplexer Location

1-16 Theory of Operation

Page 28

Removal and Replacement

OverviewOverview

This chapter provides removal and replacement information for the

following HP paper-handling accessories:

• HP 2000-sheet Input Tray

• Multibin Mailbox (MBM)

The removal and replacement information presented in this chapter

supplements the information in the HP LaserJet 8000, 8000 N,

8000 DN, and HP Mopier 240 Printers Service Manual. Use this

supplement with the HP LaserJet 8000, 8000 N, 8000 DN, and

HP Mopier 240 Printers Service Manual.

2

WARNING!

Caution

Electrical Shock Hazard

To avoid electrical shock, use only supplied power cords and connect

only to properly grounded (3-hole) wall outlets.

The printer and accessories contain parts that are sensitive to

electrostatic discharge (ESD). Always service printers at an

ESD-protected workstation. Watch for the ESD reminder symbol on

illustrations.

Removal and Replacement 2-1

Page 29

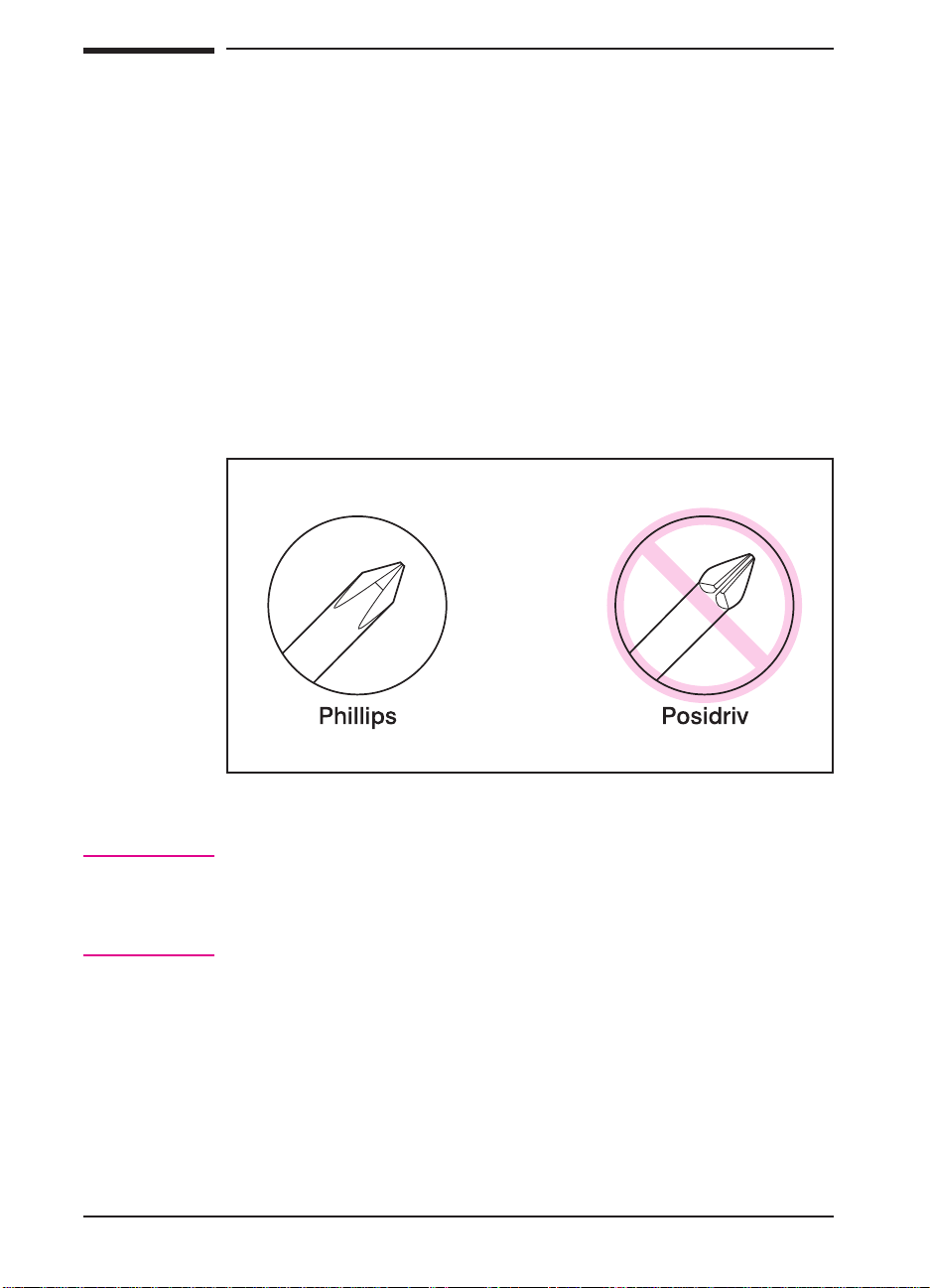

Figure 2-1

Required Tools

• #2 Phillips screwdriver (6-inch [152 mm] shaft)

• Small flat-blade screwdriver

• Small needle-nose pliers

• T-10, T-15, and T-20 Torx driver (6-inch shaft) for the Multibin Mailbox

All components in the 2000-sheet Input Tray use Phillips-head screws

that require a #2 Phillips screwdriver. Make sure that you have a Phillips

screwdriver and not a Posidriv screwdriver. Figure 2-1 shows the

difference between a Phillips and a Posidriv screwdriver. Note that the

Phillips tip has more beveled surfaces.

Phillips versus Posidriv Screwdrivers

Caution

2-2 Removal and Replacement

To install a self-tapping screw, first turn it counterclockwise to align it

with the existing thread pattern. Then carefully turn it clockwise to

tighten it. Do not over-tighten it. If a self-tapping screw hole becomes

stripped, either repair the screw hole or replace the affected assembly.

Page 30

2000-sheet Input Tray Removal and

Replacement

WARNING!

Note Reinstallation is generally the reverse of the removal process. Carefully

For the procedures in this section, the printer and all accessories must be

unplugged. Before attempting to service the 2000-sheet Input Tray,

unplug the power cord from the power source; otherwise, severe injury

may result.

The printer and accessories may have sharp edges that could cause

injury.

follow any additional instructions provided under “To Reinstall.”

2000-sheet Input Tray Orientation

Figure 2-2 shows the orientation of the 2000-sheet Input Tray as it is

referred to in this section.

Top

Back

Left

Figure 2-2 2000-sheet Input Tray Orientation

Right

Front

Bottom

Removal and Replacement 2-3

Page 31

Figure 2-3

2000-sheet Input Tray Front Cover

1 Open the paper tray on the 2000-sheet Input Tray to the stops (Figure

2-3).

2 Remove the Paper Limit Back Plate from the paper tray (callout 1).

3 Remove the 4 screws in the front of the tray: 3 screws at the top of the

tray and 1 screw on the front-right side of the tray (callout 2).

4 Using a flat-blade screwdriver, release the plastic retaining tabs at the

left- and right-front sides of the tray (callout 3).

5 Carefully lift up on the Front Cover, and then pull it out to release the

plastic retaining tabs that secure the bottom of the Front Cover to the

tray chassis (callout 4).

To Reinstall:

1 Replace all the plastic retaining tabs properly (callout 4).

2 Reinstall the front adjustable plate, and configure it properly (callout 1).

3 Reinstall the cassette-size labels.

2000-sheet Input Tray Front Cover

2-4 Removal and Replacement

Page 32

Figure 2-4

2000-sheet Input Tray Back Cover

1 Make sure that the power cord for the 2000-sheet Input Tray is

unplugged from the power source.

2 Remove the 4 screws that secure the Back Cover of the 2000-sheet Input

Tray to the chassis: 1 screw on each corner (Figure 2-4, callout 1).

3 Pull the Back Cover out from the chassis.

To Reinstall:

1 Insert the tab on the lower-left corner into its alignment slot.

2000-sheet Input Tray Back Cover

Removal and Replacement 2-5

Page 33

Figure 2-5

2000-sheet Input Tray Left Cover

1 Unplug the power cord and the C-link interface cables from the

2000-sheet Input Tray.

2 Remove the 2 screws that are located at the top of the 2000-sheet Input

Tray’s Left Cover: 1 screw near each corner (Figure 2-5, callout 1).

3 Remove the Left Cover from the unit:

a Pull out on the top of the Left Cover, and then lift up on the Left

Cover’s right side to clear the retaining tabs that are along the Left

Cover’s bottom edge (callout 2).

b Pull out on the Left Cover’s lower-left corner to release the plastic

retainer tab that secures that corner of the cover to the chassis

(callout 3).

To Reinstall:

1 Replace the left side of the Left Cover first (callout 3).

2 Tilt the right side of the Left Cover down and toward the chassis to place

the lower retaining tabs over the chassis rail (callout 2).

2000-sheet Input Tray Left Cover

2-6 Removal and Replacement

Page 34

Figure 2-6

2000-sheet Input Tray Right Cover

1 Remove the Vertical Transfer Unit (VTU) from the 2000-sheet Input

Tray (see Figure 2-18).

2 Remove the 2 screws that are located near the middle of the 2000-sheet

Input Tray’s Right Cover: 1 screw on each side (Figure 2-6, callout 1).

3 Using a flat-blade screwdriver, release the plastic retaining tab that

secures the Right Cover’s upper-left corner to the chassis (callout 2).

4 To remove the Right Cover, carefully pull out on the top of the cover

while lifting it upward to clear the retaining tabs that are along the

cover’s bottom edge.

To Reinstall:

1 Place the retaining tabs that are along the Right Cover’s bottom edge

over the chassis rail.

2 Reinstall the VTU (see Figure 2-18).

2000-sheet Input Tray Right Cover

Removal and Replacement 2-7

Page 35

Figure 2-7

2000-sheet Input Tray Main Drive Assembly

1 Remove the Back Cover from the 2000-sheet Input Tray (see Figure

2-4).

2 Locate the cable that runs from the Main Drive Assembly on the

2000-sheet Input Tray to the unit’s Controller PCA. Disconnect the

cable from the J206 connector on the Controller PCA (Figure 2-7,

callout 1).

3 Release the cable from the 2 cable clips that hold the cable to the chassis

(callout 2).

4 Remove the 2 screws that connect the Main Drive Assembly to the

chassis: 1 screw on top of the Main Drive Assembly and 1 screw on the

bottom (callout 3).

5 Pull the Main Drive Assembly away from the chassis.

6 Inspect the Paper Deck Drive Bushing on the Main Drive Assembly. If

the bushing is damaged, it can be replaced without replacing the whole

drive assembly.

To Reinstall:

1 Reroute the cable through the cable clips (callout 2) and reconnect the

cable to the J206 connector on the Controller PCA (callout 1).

2000-sheet Input Tray Main Drive Assembly

2-8 Removal and Replacement

Page 36

Figure 2-8

2000-sheet Input Tray Paper Tray

1 Open the paper tray on the 2000-sheet Input Tray and remove any

unused paper.

2 Remove the Vertical Transfer Unit (VTU) from the 2000-sheet Input

Tray (see Figure 2-18).

3 Remove the Left and Right Covers from the 2000-sheet Input Tray (see

Figure 2-5 and Figure 2-6).

4 Remove the 2 screws and metal retaining tabs from the sides of the

unit’s chassis: 1 screw and retaining tab on each side of the chassis

(Figure 2-8, callout 1).

5 Slide the paper tray straight out of the chassis while carefully supporting

the rear of the paper tray.

To Reinstall:

1 Make sure that the retaining tabs are tightly secured to the unit’s chassis

(callout 1).

2 After replacing the tray, print a test page. If the print is too close to the

paper’s edge, adjust the tray. (For instructions, see the HP LaserJet

8000, 8000 N, 8000 DN, and HP Mopier 240 Printers Service Manual.)

2000-sheet Input Tray Paper Tray

Removal and Replacement 2-9

Page 37

Figure 2-9

2000-sheet Input Tray Main Cable Harness

1 Remove the Back Cover from the 2000-sheet Input Tray (see Figure

2-4).

2 Locate and disconnect the 6 cable connectors that connect the Main

Cable Harness to the Controller PCA on the 2000-sheet Input Tray

(Figure 2-9, callout 1).

3 Locate and disconnect the 5 cable connectors that connect the Main

Cable Harness to the unit’s chassis (callout 2).

4 Release the cable harness from the 4 cable clips that hold the harness to

the unit’s chassis (callout 3).

To Reinstall:

1 Properly replace all 11 cable harness connectors (callouts 1 and 2).

2 Reattach the harness to the 4 cable clips that hold the harness to the

unit’s chassis (callout 3).

2000-sheet Input Tray Main Cable Harness

2-10 Removal and Replacement

Page 38

Figure 2-10

2000-sheet Input Tray Controller PCA

1 Remove the Back and Left Covers from the 2000-sheet Input Tray (see

Figure 2-4 and Figure 2-5).

2 Disconnect the 11 cables from the Controller PCA on the 2000-sheet

Input Tray (Figure 2-10, callout 1).

3 Remove the 4 hex screws that secure the 2 C-link cable connectors to

the metal base (callout 2).

4 Remove the 2 screws that secure the right side of the Controller PCA to

the metal base (callout 3).

5 Release the 2 plastic retaining posts that secure the left side of the

Controller PCA to the metal base (callout 4), and then pull the

Controller PCA out from the unit’s chassis.

To Reinstall:

1 Seat the Controller PCA firmly onto the plastic retaining posts that

secure the left side of the Controller PCA to the metal plate on the

chassis (callout 4).

2 Properly reconnect all 11 cables to the Controller PCA (callout 1).

3 Make sure that the DIP switches on the Controller PCA are in the

normal setting (off) (callout 5). (See Table 3-1.)

2000-sheet Input Tray Controller PCA

Removal and Replacement 2-11

Page 39

Figure 2-11

2000-sheet Input Tray Front LED PCA Assembly

1 Open the paper tray on the 2000-sheet Input Tray halfway to the stops.

2 On the upper-left corner of the front of the unit’s chassis, locate and

remove the 1 screw that secures the LED PCA Assembly to the chassis

(Figure 2-11, callout 1).

3 Reach behind the LED PCA Assembly and pull it away from the chassis.

4 To remove the LED PCA from the cable connector, release the 3 plastic

retaining tabs that secure the LED PCA to the connector (Figure 2-11,

callout 2).

5 Pull the LED PCA from the connector.

To Reinstall:

1 Reconnect the LED PCA to the connector (callout 2).

2000-sheet Input Tray Front LED PCA

2-12 Removal and Replacement

Page 40

Figure 2-12

2000-sheet Input TrayPickup Assembly

1 Remove the Vertical Transfer Unit (VTU) from the 2000-sheet Input

Tray (see Figure 2-18).

2 Remove the Right Cover from the 2000-sheet Input Tray (see Figure

2-6).

3 Open the paper tray on the 2000-sheet Input Tray to the stops.

4 Disconnect the 3 cables that are located at the bottom-right side of the

Pickup Assembly (Figure 2-12, callout 1).

5 Remove the 5 screws that secure the Pickup Assembly to the unit’s

chassis: 3 screws along the top, and 1 screw on each side (callout 2).

6 Slide the Pickup Assembly straight out of the chassis.

To Reinstall:

1 Make sure that the paper tray is open to easily slide the Pickup

Assembly into the chassis.

2 Make sure that the Pickup Assembly is seated properly in the locating

slots (callout 3).

3 Reconnect the 3 cables that are located at the bottom-right side of the

Pickup Assembly (callout 1).

2000-sheet Input Tray Pickup Assembly

Removal and Replacement 2-13

Page 41

Figure 2-13

There are three photosensors on the Pickup Assembly:

• one to sense that the Transfer Assembly is closed (Figure 2-13,

callout 1).

• one to sense that the tray has raised the paper to the proper height

(callout 2).

• one to sense that the tray is empty (callout 3).

To remove a photosensor:

1 Remove the Pickup Assembly (see Figure 2-12).

2 Unplug the connector from the sensor.

3 Release the side-oriented retaining tabs and rotate the sensor to free the

end-oriented retaining tabs on the opposite end.

2000-sheet Input Tray Pickup Assembly Photosensors

2-14 Removal and Replacement

Page 42

Figure 2-14

2000-sheet Input Tray Power Supply

1 Remove the Back and Left Covers from the 2000-sheet Input Tray (see

Figure 2-4 and Figure 2-5).

2 Locate the cable that runs from the Controller PCA on the 2000-sheet

Input Tray to the unit’s Power Supply (Figure 2-14, callout 1).

Disconnect the cable from the Power Supply by pushing on the retaining

tab that is located behind the cable connector (callout 2).

3 Remove the 2 screws that secure the Power Supply to the chassis

(callout 3).

4 Lift the Power Supply upward to clear the locating tabs underneath, and

then slide the Power Supply to the left to free it from the chassis

(callout 4).

To Reinstall:

1 Carefully align the locating tabs so that they are positioned correctly.

2 Reconnect the cable that runs from the Power Supply to the Controller

PCA on the 2000-sheet Input Tray (callout 1). The cable connector is

seated properly when it clicks.

2000-sheet Input Tray Power Supply

Removal and Replacement 2-15

Page 43

2000-sheet Input Tray Pickup, Feed, and

Separation Rollers

Three rollers in the 2000-sheet Input Tray pick up paper and feed it to

the printer:

• The Pickup Roller is the upper-forward roller (Figure 2-15, callout 1).

• The Feed Roller is the upper-rear roller (callout 2).

• The Separation Roller is the lower roller (callout 3).

Note The Feed and Separation Rollers in the 2000-sheet Input Tray are

interchangeable with each other and with the Feed and Separation

Rollers in trays 2 and 3 on the printer. Additionally, the Pickup Roller in

the 2000-sheet Input Tray is interchangeable with the Pickup Rollers in

trays 2 and 3 on the printer.

The Feed and Separation Rollers have protruding retaining tabs that

secure the rollers to their respective shafts. The retaining tab on the

Pickup Roller is recessed.

Note

The Feed and Separation Rollers must be replaced every 350,000

images. The two rollers are included in the following HP LaserJet 8000,

8000 N, and 8000 DN maintenance kit: C3971B (110V), C3972B

(220V). The kit contains all the necessary parts for the required user

maintenance procedure.

To Remove the Feed and Separation Rollers

1 Open the Vertical Transfer Unit (VTU) on the 2000-sheet Input Tray.

2 Locate the rollers inside the tray cavity. To remove a roller, pinch the

retainer tabs together and slide the roller off the shaft. Remove the Feed

Roller (upper-rear roller) first. Then remove the Separation Roller

(lower roller).

To Remove the Pickup Roller

1 Open the paper tray on the 2000-sheet Input Tray to the stops.

2 Remove the Left Cover from the 2000-sheet Input Tray (see Figure 2-5).

3 Locate the Pickup Roller inside the tray cavity.

4 Pinch the recessed retainer tab on the roller, and slide the roller off the

shaft.

2-16 Removal and Replacement

Page 44

To Reinstall:

1 If all three rollers were removed, reinstall the Pickup Roller first

(callout 1).

2 When reinstalling the Feed and Separation Rollers, install the Separation

Roller (lower roller) first (callout 3). Then install the Feed Roller

(upper-rear roller) (callout 2).

3 When installing a roller, listen for a click. It signals that the roller is

secured onto the shaft.

Note

Figure 2-15

Avoid letting the rollers fall into the tray cavity.

2000-sheet Input Tray Rollers: Pickup, Feed, and Separation

Removal and Replacement 2-17

Page 45

2000-sheet Input Tray Paper Quantity Switch

Assembly

1 Remove the Back Cover from the 2000-sheet Input Tray (see Figure

2-4).

2 Locate the cable that runs from the Paper Quantity Switch Assembly on

the 2000-sheet Input Tray to the unit’s Controller PCA. Disconnect the

cable from the Controller PCA (J205 connector), and then free the cable

from the cable clips that secure it to the chassis (Figure 2-16, callout 1).

3 Remove the 1 screw (callout 2) and the metal retaining spring (callout 3)

that hold the switch assembly in place.

4 Pull the switch assembly out of its cavity (Figure 2-17, callout 1).

To Reinstall:

1 When reinstalling the metal retaining spring that holds the switch

assembly in place (Figure 2-16, callout 2), seat the retaining spring onto

the locating pins that are on the chassis.

2 Reconnect the switch assembly’s cable to the J205 connector on the

Controller PCA (Figure 2-16, callout 1).

2000-sheet Input Tray Paper Size Switch

Assembly

1 Remove the Back Cover from the 2000-sheet Input Tray (see Figure

2-4).

2 Locate the cable that runs from the Paper Size Switch Assembly on the

2000-sheet Input Tray to the unit’s Controller PCA. Disconnect the

cable from the Controller PCA (J204 connector) (Figure 2-16, callout 4).

3 Remove the 1 screw (callout 5) and the metal retaining spring (callout 6)

that hold the switch assembly in place.

4 Pull the switch assembly out of its cavity (Figure 2-17, callout 2).

To Reinstall:

1 When reinstalling the metal retaining spring that holds the switch

assembly in place (Figure 2-16, callout 5), seat the retaining spring onto

the locating pins on the chassis.

2 Reconnect the switch assembly’s cable to the J204 connector on the

Controller PCA (Figure 2-16, callout 4).

2-18 Removal and Replacement

Page 46

Figure 2-16

Figure 2-17

2000-sheet Input Tray Paper Size and Paper Quantity Switch

Assemblies (1 of 2)

2000-sheet Input Tray Paper Size and Paper Quantity Switch

Assemblies (2 of 2)

Removal and Replacement 2-19

Page 47

2000-sheet Input Tray VTU

1 Open the Vertical Transfer Unit (VTU) on the 2000-sheet Input Tray.

2 Rotate the 2 plastic cams on the VTU hinges toward the 2000-sheet

Input Tray to the secure position (Figure 2-18, callout 1).

WARNING!

WARNING!

Figure 2-18

Do not release the plastic cams from the secure position while the VTU

is off. The springs on the cams are very strong and may cause injury.

3 Locate the 2 cables that run from the VTU to the chassis at the right

side’s upper-back corner (Figure 2-18, callout 2) and disconnect the 2

cables from the chassis.

4 Remove the 2 screws that secure the VTU to the chassis: 1 screw near

each end of the VTU (Figure 2-18, callout 3).

5 Lift the VTU straight up to clear the metal locating tabs on the chassis.

To Reinstall:

Release the plastic cams only after tightening the screws that secure the

VTU to the chassis.

1 Before tightening the screws, make sure that the metal locating tabs are

in place.

2 Reconnect the cables that run from the VTU to the chassis at the right

side’s upper-back corner (callout 2).

2000-sheet Input Tray Vertical Transfer Unit (VTU)

2-20 Removal and Replacement

Page 48

Figure 2-19

2000-sheet Input Tray Tension Springs

1 Remove the Left Cover of the 2000-sheet Input Tray (see Figure 2-5).

2 Open the paper tray on the 2000-sheet Input Tray all the way to the

stops.

3 Inside the tray cavity, locate and remove the 2 springs on the tray

runners: 1 spring on left runner (left side of the chassis) and 1 spring on

the right runner (right side of the chassis) (Figure 2-19).

2000-sheet Input Tray Tension Springs

Removal and Replacement 2-21

Page 49

Figure 2-20

2000-sheet Input Tray Locating Pins

1 Remove the printer from the 2000-sheet Input Tray. (For instructions,

see the HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240

Printers Service Manual.)

2 Locate the 3 Locating Pins on the top of the 2000-sheet Input Tray

(Figure 2-20, callout 1), and remove the 2 screws on each Locating Pin.

3 Remove the Locating Pins by lifting them straight up.

2000-sheet Input Tray Locating Pins

2-22 Removal and Replacement

Page 50

Figure 2-21

2000-sheet Input Tray Outriggers (Stabilizing

Feet)

1 Remove the printer from the 2000-sheet Input Tray. (For instructions,

see the HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240

Printers Service Manual.)

2 Tip the 2000-sheet Input Tray onto its left side.

3 Locate the Outriggers on the bottom of the unit: 2 on the front side and 1

on the right side (callout 1).

4 Remove an Outrigger by sliding the entire foot assembly (Outrigger and

metal bar) out of its metal channel while pushing the end of the foot

assembly toward the chassis (callout 2).

To Reinstall:

1 Reinstall the protective cover (end cap) onto each foot assembly.

2000-sheet Input Tray Outriggers

Removal and Replacement 2-23

Page 51

Figure 2-22

2000-sheet Input Tray Casters

1 Remove the printer from the 2000-sheet Input Tray. (For instructions,

see the HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240

Printers Service Manual.)

2 Tip the 2000-sheet Input Tray onto its left side.

3 Locate the 4 Casters, 1 on each corner of the chassis (Figure 2-22,

callout 1).

4 Remove a Caster by removing the 2 screws that hold the Caster to the

chassis (callout 2).

To Reinstall:

1 Tighten the screws securely when reinstalling each caster (callout 2).

2000-sheet Input Tray Casters

2-24 Removal and Replacement

Page 52

Figure 2-23

2000-sheet Input Tray Adjustable Foot

1 Remove the printer from the 2000-sheet Input Tray. (For instructions,

see the HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240

Printers Service Manual.)

2 Tip the 2000-sheet Input Tray onto its left side.

3 Locate the Adjustable Foot (Figure 2-23, callout 1), and remove the 2

screws that secure the Adjustable Foot to the chassis (callout 2).

2000-sheet Input Tray Adjustable Foot

Removal and Replacement 2-25

Page 53

Multibin Mailbox Removal and

Replacement

WARNING!

Note

For the procedures in this section, the printer and all accessories must be

unplugged. Before attempting to service a Multibin Mailbox, unplug the

power cord from the power source; otherwise, severe injury may result.

This printer and accessories may have sharp edges that could cause

injury.

Reinstallation is generally the reverse of the removal process. Carefully

follow any additional instructions provided under “To Reinstall.”

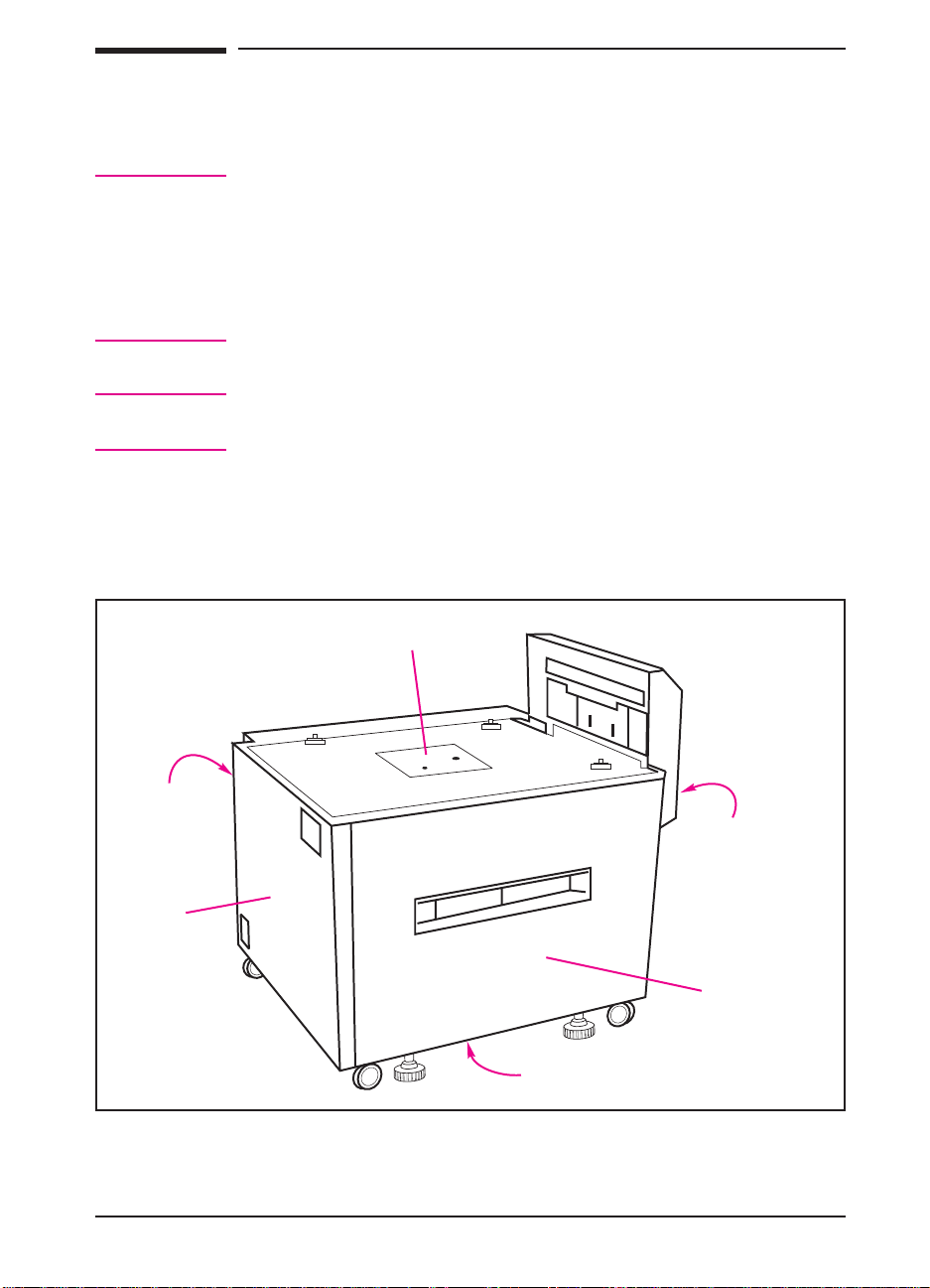

Multibin Mailbox Orientation

Figure 2-24 shows the orientation of the Multibin Mailbox as it is

referred to in this section.

Top

Back

Left

Figure 2-24 Multibin Mailbox Orientation

2-26 Removal and Replacement

Right

Front

Bottom

Page 54

Multibin Mailbox Front and Back Covers

Note

WARNING!

Figure 2-25

The procedures for removing the Front and Back Covers are the same.

However, before removing the Back Cover, disconnect the Power

Supply cable that connects the Multibin Mailbox Power Supply to the

Multibin Mailbox Controller PCA.

Unplug the power cord from the Multibin Mailbox Power Supply, and

then unplug the Multibin Mailbox Power Supply cable from the

Multibin Mailbox Controller PCA.

1 Remove the Multibin Mailbox from the printer. (For instructions, see the

HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240 Printers

Service Manual.)

2 For each cover, using a small flat-blade screwdriver, release the 3

retaining tabs that secure the cover to the right side of the Multibin

Mailbox frame (callout 1), and rotate the cover outward to release it

from the frame.

To Reinstall:

1 Insert the retaining tabs that secure each cover to the left side of the

Multibin Mailbox frame, and then snap the opposite edge of each cover

into position.

Multibin Mailbox Covers (Front and Back)

Removal and Replacement 2-27

Page 55

Figure 2-26

Multibin Mailbox Top Cover

1 Remove the Front and Back Covers from the Multibin Mailbox (see

Figure 2-25).

2 Locate the User Status LED PCA at the upper-front side of the Multibin

Mailbox frame (Figure 2-26, callout 1), and disconnect the cable from

the LED PCA.

3 Remove the LED PCA by removing the 1 screw that secures the LED

PCA to the Multibin Mailbox frame (callout 2).

4 Remove the 2 screws closest to the upper-right side of the Multibin

Mailbox: 1 screw on the front and back sides of the Multibin Mailbox

frame (callout 3).

5 Pull and lift the Top Cover from the Multibin Mailbox frame.

To Reinstall:

1 After reinstalling the Top Cover, reattach the User Status LED PCA

(callout 1), and then reconnect the cable to the LED PCA.

Multibin Mailbox Top Cover

2-28 Removal and Replacement

Page 56

Figure 2-27

Multibin Mailbox Power Supply

1 Locate the cable that runs from the Multibin Mailbox Power Supply

down to the Multibin Mailbox Controller PCA, and disconnect the cable

from the Controller PCA (Figure 2-27, callout 1).

2 Remove the Power Supply from the Back Cover of the Multibin

Mailbox by pressing the plastic retaining tabs that are on each side of

the Power Supply (callout 2).

To Reinstall:

1 Align the Power Supply with the mounting holes that are on the Back

Cover so that the retaining tabs on the Power Supply (callout 2) fit into

their respective slots.

2 Reconnect the Power Supply Cable to the Multibin Mailbox Controller

PCA (callout 1).

Multibin Mailbox Power Supply

Removal and Replacement 2-29

Page 57

Figure 2-28

Multibin Mailbox Paper Bins and Blind Cover

The procedure for removing a paper bin and the Blind Cover is the

same. Each bin rests in its labeled slot.

1 Remove the Left Output Bin first. Lift up on the outer edge of the bin to

clear the retaining notch in the frame, and then pull the bin away from

the Multibin Mailbox frame (callout 1).

2 Remove the Blind Cover.

3 Remove each Standard Output Bin, starting at the top and working down

in sequence.

To Reinstall:

1 Slide a bin into its designated slot, and then lower the bin into the

retaining notch in the frame.

2 Replace the paper bins, beginning with the bottom Standard Output Bin

and continuing upward in order.

3 Place the Blind Cover between Standard Output Bin 1 and the Left

Output Bin.

Multibin Mailbox Paper Bins and Blind Cover

2-30 Removal and Replacement

Page 58

Multibin Mailbox Flipper Assembly

1 Remove all the paper bins and the Blind Cover from the Multibin

Mailbox (see Figure 2-28).

2 Remove the Front, Back, and Top Covers from the Multibin Mailbox

(see Figure 2-25 and Figure 2-26).

3 Remove the 2 screws closest to the upper-left side of the Multibin

Mailbox: 1 screw on the front and back sides of the Multibin Mailbox

frame (Figure 2-29, callouts 1).

4 Hold down the Jam Access Door while unplugging the ground wire that

runs from the Input Paper Guide to the Flipper Motor (Figure 2-30,

callout 2).

5 Unplug the Flipper Assembly’s 3 cables from the connectors that are

located on the Multibin Mailbox unit’s back side (Figure 2-29, callout 3).

6 Using a flat-blade screwdriver, release the plastic retaining tab that

secures the Flipper Assembly to the top of the Multibin Mailbox frame

(Figure 2-31, callout 4).

7 Hold down the Jam Access Door, and pull out the Flipper Assembly

(Figure 2-31, callout 5).

To Reinstall:

1 Hold down the Jam Access Door to reconnect the ground wire to the

Flipper Motor (Figure 2-30, callout 2).

2 Route the Flipper Assembly’s 3 cables through the back side of the

Multibin Mailbox frame and reconnect the 3 cables to the connectors

(Figure 2-29, callout 3).

Caution Do not over-tighten the screws that secure the Flipper Assembly to the

Multibin Mailbox frame. The nuts in the Flipper Assembly could rotate

in their slots.

Removal and Replacement 2-31

Page 59

Figure 2-29

Figure 2-30

Multibin Mailbox Flipper Assembly (1 of 3)

Multibin Mailbox Flipper Assembly (2 of 3)

2-32 Removal and Replacement

Page 60

Figure 2-31

Multibin Mailbox Flipper Assembly (3 of 3)

Removal and Replacement 2-33

Page 61

Figure 2-32

Multibin Mailbox Delivery Head Motor

1 Remove the Back Cover from the Multibin Mailbox (see Figure 2-25).

2 Locate the cable that runs from the Delivery Head Motor down to the

Multibin Mailbox Controller PCA, and disconnect the cable from the

connector in the middle of the Multibin Mailbox frame (Figure 2-32,

callout 1).

3 Remove the 2 screws that secure the Delivery Head Motor to the

Multibin Mailbox frame (callout 2).

4 Pull the Delivery Head Motor away from the Multibin Mailbox frame.

To Reinstall:

1 Position the motor in the Multibin Mailbox frame so that the cable

grommets face down.

2 Reconnect the motor’s cable to the connector in the middle of the frame

(callout 1).

Multibin Mailbox Delivery Head Motor

2-34 Removal and Replacement

Page 62

Multibin Mailbox Transport Belt Motor

1 Remove the Back Cover from the Multibin Mailbox (see Figure 2-25).

2 Remove all the paper bins and the Blind Cover from the Multibin

Mailbox (see Figure 2-28).

3 Release the Controller PCA Assembly from the bottom of the Multibin

Mailbox frame (see Figure 2-38, steps 1 through 7).

4 Locate the cable that runs from the Transport Belt Motor to the Multibin

Mailbox Controller PCA, and disconnect the cable from the J8

connector on the Controller PCA (Figure 2-33, callout 1).

5 Remove the 2 screws (and washers) that secure the Transport Belt Motor

to the Multibin Mailbox frame (callout 2).

Caution

Figure 2-33

When pulling out the motor, be careful to not damage the internal drive

belt.

6 Gently pull out the motor.

To Reinstall:

1 Reroute the cable on the Transport Belt Motor behind the flat cable, and

connect it to the J8 connector on the Multibin Mailbox Controller PCA

(callout 1).

2 Reinstall the Multibin Mailbox Controller PCA Assembly (see Figure

2-38).

3 Replace the internal drive belt onto the Transport Belt Motor’s gear

before replacing and tightening the screws that secure the motor to the

frame.

Multibin Mailbox Transport Belt Motor

Removal and Replacement 2-35

Page 63

Figure 2-34

Multibin Mailbox Input Paper Guide

1 Remove the Multibin Mailbox from the printer. (For instructions, see the

HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240 Printers

Service Manual.)

2 Remove the Left Output Bin and the Blind Cover from the Multibin

Mailbox (see Figure 2-28).

3 Hold down the Jam Access Door while unplugging the ground wire that

runs from the Input Paper Guide to the Flipper Motor (Figure 2-34,

callout 1).

4 Use a flat-blade screwdriver to release the retaining tabs that secure the

Input Paper Guide to the upper-right side of the Multibin Mailbox

(Figure 2-35, callout 2).

5 Pull the Input Paper Guide free of the frame (callout 3) while routing the

ground wire that connects to the end of the paper guide through the

wire’s access hole (callout 4).

To Reinstall:

1 Reroute the ground wire through its access hole (Figure 2-35, callout 4).

2 Reconnect the ground wire to the Flipper Motor (Figure 2-34, callout 1).

3 Replace the Left Output Bin and the Blind Cover (see Figure 2-28).

Multibin Mailbox Input Paper Guide (1 of 2)

2-36 Removal and Replacement

Page 64

Figure 2-35

Multibin Mailbox Input Paper Guide (2 of 2)

Removal and Replacement 2-37

Page 65

Multibin Mailbox Metal Tape and Housing

Assembly

1 Remove all the paper bins and the Blind Cover from the Multibin

Mailbox (see Figure 2-28).

WARNING!

The Metal Tape’s sharp edges can cause serious injury. When rewinding

the Metal Tape into its housing, hold the tape securely and rewind it

slowly.

2 With the Delivery Head Assembly at the top of the Multibin Mailbox,

hold the Metal Tape near the end, and push and release the retainer tab

that secures the end of the tape to the top of the Multibin Mailbox frame

(Figure 2-36, callout 1). Then let the tape slowly rewind into its housing.

3 Remove the 1 screw that secures the Static Brush to the Delivery Head

Assembly (callout 2), and then move the Static Brush out of the way.

4 Lower the Delivery Head Assembly halfway to the stops.

5 Using a flat-blade screwdriver, release the plastic retaining tabs located

on each side of the tape housing (Figure 2-37, callout 3).

6 Gently pull on the Delivery Head Assembly to remove the end of the

tape from behind the rollers that hold the tape in its track (callout 4).

Then pull the tape housing toward you to remove it.

To Reinstall:

1 Thread the end of the Metal Tape behind the rollers (callout 4), and then

pull the end of the tape to the top of the Multibin Mailbox and reinsert it

into place (Figure 2-36, callout 1).

2 Use the guide pins to reinstall the tape housing (Figure 2-37, callout 3).

When the housing is correctly positioned, it will click into place.

3 Reinstall the static brush (Figure 2-36, callout 1).

2-38 Removal and Replacement

Page 66

Figure 2-36

Figure 2-37

Multibin Mailbox Metal Tape and Housing Assembly (1 of 2)

Multibin Mailbox Metal Tape and Housing Assembly (2 of 2)

Removal and Replacement 2-39

Page 67

Multibin Mailbox Controller PCA

1 Remove the Multibin Mailbox from the printer. (For instructions, see the

HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240 Printers

Service Manual.)

2 Locate the power cable that runs from the Multibin Mailbox Power

Supply down to the Multibin Mailbox Controller PCA, and disconnect

the cable from the Controller PCA (Figure 2-38, callout 1).

3 Disconnect the C-link cable from the Multibin Mailbox Controller PCA

(callout 2).

4 Remove all paper bins and the Blind Cover from the Multibin Mailbox

(see Figure 2-28).

5 Carefully lay the Multibin Mailbox onto its front side.

6 Loosen the 1 grounding screw and the 2 self-tapping screws that secure

the Controller PCA to the bottom-right side of the Multibin Mailbox

frame (callout 3).

7 Remove the 2 self-tapping screws that secure the Controller PCA to the

bottom-left side of the Multibin Mailbox frame (callout 4).

8 Open the metal box to reveal the Controller PCA.

9 Disconnect the 8 cables from the Controller PCA (Figure 2-39,

callout 5).

To Reinstall:

1 Reconnect the 8 cables to the connectors on the Multibin Mailbox

Controller PCA (callout 5).

Figure 2-38

Multibin Mailbox Controller PCA (1 of 2)

2-40 Removal and Replacement

Page 68

Figure 2-39

Multibin Mailbox Controller PCA (2 of 2)

Removal and Replacement 2-41

Page 69

Figure 2-40

Multibin Mailbox Anticurl Strings

1 Remove the Back Cover, all the paper bins, and the Blind Cover from

the Multibin Mailbox (see Figure 2-25 and Figure 2-28).

2 At the lower-left side of the Multibin Mailbox frame, locate the Tension

Springs on the Anticurl Strings, and remove the 2 screws that secure the

springs to the frame (Figure 2-40, callout 1).

3 Remove the Anticurl Strings from the lower pulleys (callout 2).

4 Remove the Delivery Head Assembly from the Multibin Mailbox frame

(see Figure 2-42).

5 Release the upper ends of the Anticurl Strings from the Jam Access

Door by pushing the retaining tabs that secure the strings to the Jam

Access Door (Figure 2-41, callout 3).

To Reinstall:

1 Reverse the procedure given above.

Multibin Mailbox Anticurl Strings (1 of 2)

2-42 Removal and Replacement

Page 70

Figure 2-41

Multibin Mailbox Anticurl Strings (2 of 2)

Removal and Replacement 2-43

Page 71

Multibin Mailbox Delivery Head Assembly

1 Remove the Back Cover from the Multibin Mailbox (see Figure 2-25).

2 Remove all the paper bins and the Blind Cover from the Multibin

Mailbox (see Figure 2-28).

WARNING!

The Metal Tape’s sharp edges can cause serious injury. When rewinding

the Metal Tape into its housing, hold the tape securely and rewind it

slowly.

3 With the Delivery Head Assembly at the top of the Multibin Mailbox,

hold the Metal Tape near the end, and release the retainer tab that

secures the end of the tape to the top of the Multibin Mailbox frame

(Figure 2-42, callout 1). Then let the tape slowly rewind into its housing.

4 At the lower-left side of the Multibin Mailbox frame, locate the Tension

Springs on the Anticurl Strings, and remove the 2 screws that secure the

springs to the frame (Figure 2-43, callout 2).

5 Remove the Anticurl Strings from the lower pulleys (callout 3).

6 On the back side of the Multibin Mailbox, release the flat ribbon cable

from the cable clip that secures the cable to the Multibin Mailbox frame

(Figure 2-44, callout 4), and gently disconnect the flat ribbon cable from

the Delivery Head Assembly (callout 5).

7 Raise the Delivery Head Assembly to the top of the Multibin Mailbox

frame.

8 Hold up the Delivery Head Assembly,and remove the 2 screws that

secure it to the elevator mounts: 1 screw on each end of the assembly

(Figure 2-42, callout 6). The screw that secures the back end is captive.

9 Rotate the Delivery Head Assembly clockwise while guiding the back

end out of its access opening (see Figure 2-45).

10 Release the Anticurl Strings from the pulleys on each end of the

Delivery Head Assembly (Figure 2-45, callout 7).

To Reinstall:

1 Replace the Anticurl Strings into the pulleys on the ends of the Delivery

Head Assembly.

2 Reinstall the Delivery Head Assembly onto its elevator mounts and

secure it with the screws. Make sure that the locating pins are in place.

3 Replace the Tension Springs on the Anticurl Strings at the bottom of the

frame with the T-10 Torx screws (Figure 2-43, callout 2).

4 Snap the Anticurl Strings into the pulleys at the bottom of the frame

(Figure 2-43, callout 3).

5 Reconnect the flat ribbon cable to the Delivery Head Assembly, and

secure the cable to the frame with the cable clip (Figure 2-44, callouts 4

and 5).

6 Make sure that the Delivery Head Assembly moves up and down freely.

2-44 Removal and Replacement

Page 72

Figure 2-42

Figure 2-43

Multibin Mailbox Delivery Head Assembly (1 of 4)

Multibin Mailbox Delivery Head Assembly (2 of 4)

Removal and Replacement 2-45

Page 73

Figure 2-44

Figure 2-45

Multibin Mailbox Delivery Head Assembly (3 of 4)

Multibin Mailbox Delivery Head Assembly (4 of 4)

2-46 Removal and Replacement

Page 74

Multibin Mailbox Interlock Switch

1 Remove the Back Cover from the Multibin Mailbox (see Figure 2-25).

Caution Before removing the wires from the Multibin Mailbox Interlock Switch,

note the location of each wire. Replacing the wires incorrectly can

damage the Interlock Switch.

2 Inside the back side of the Multibin Mailbox frame, disconnect the 2

wires from the Interlock Switch (Figure 2-46, callout 1).

3 Remove the Interlock Switch by pressing together the 2 retaining tabs

that hold the switch in place (callout 2).

To Reinstall:

1 Reconnect the wires in the correct positions (callout 1).

Figure 2-46

Multibin Mailbox Interlock Switch

Removal and Replacement 2-47

Page 75

Figure 2-47

Multibin Mailbox Diagnostic LED PCA

1 Locate the Diagnostic LED that is on the back side of the Multibin

Mailbox (Figure 2-47, callout 1).

2 Remove the Back Cover from the Multibin Mailbox (see Figure 2-25).

3 Disconnect the 2 flat cables from the Diagnostic LED PCA (Figure

2-48, callout 2).

4 Remove the 1 screw that secures the Diagnostic LED PCA to the

Multibin Mailbox frame (callout 3).

5 Pull the Diagnostic LED PCA away from the Multibin Mailbox frame.

Multibin Mailbox Diagnostic LED PCA (1 of 2)

2-48 Removal and Replacement

Page 76

Figure 2-48

Multibin Mailbox Diagnostic LED PCA (2 of 2)

Removal and Replacement 2-49

Page 77

Figure 2-49

Multibin Mailbox User Status LED PCA

1 Locate the User Status LED PCA that is on the upper-front side of the

Multibin Mailbox (Figure 2-49, callout 1).

2 Remove the Front Cover from the Multibin Mailbox (see Figure 2-25).

3 Disconnect the cable from the User Status LED PCA (Figure 2-50,

callout 2).

4 Remove the 1 screw that secures the LED PCA to the Multibin Mailbox

frame (callout 3).

5 Pull the LED PCA away from the Multibin Mailbox frame.

Multibin Mailbox User Status LED PCA (1 of 2)

2-50 Removal and Replacement

Page 78

Figure 2-50

Multibin Mailbox User Status LED PCA (2 of 2)

Removal and Replacement 2-51

Page 79

Multibin Mailbox Adjustable and Fixed Casters

Note

Figure 2-51

The procedures for removing the Adjustable and Fixed Casters are the

same.

1 Remove the Multibin Mailbox from the printer. (For instructions, see the

HP LaserJet 8000, 8000 N, 8000 DN, and HP Mopier 240 Printers

Service Manual.)

2 Carefully lay the Multibin Mailbox onto its front side.

3 Remove the 1 screw that secures the caster to the Multibin Mailbox

frame (Figure 2-51, callout 1).

4 Remove the Caster.

Multibin Mailbox Adjustable and Fixed Casters

2-52 Removal and Replacement

Page 80

Figure 2-52

Multibin Mailbox Attachment Assembly

1 Disconnect the power cable and the C-link cable from the Multibin

Mailbox Controller PCA (see Figure 2-38, callouts 1 and 2).

2 Release the Controller PCA from the Multibin Mailbox frame, but leave

the wire cables connected to the Controller PCA (see Figure 2-39).

3 Set the Controller PCA on top of the Multibin Mailbox unit (Figure

2-52, callout 1).

4 Remove the E-clip (callout 2).

5 Release the pivot pin that holds the Attachment Assembly’s rod to the

Multibin Mailbox frame.

6 Remove the attachment assembly.

To Reinstall:

1 Replace the E-clip.

2 Reconnect the C-link cable and the power cable to the Controller PCA.

Multibin Mailbox Attachment Assembly

Removal and Replacement 2-53

Page 81

2-54 Removal and Replacement

Page 82

Troubleshooting

Overview

This chapter provides additional troubleshooting information for the

2000-sheet Input Tray,Multibin Mailbox (MBM), and Duplexer. Use

this information with the HP LaserJet 8000, 8000 N, and 8000 DN

Printers Service Manual.

3

Troubleshooting 3-1

Page 83

Troubleshooting Approach

This section provides a systematic approach to identifying the causes of

malfunctions and errors on the paper-handling accessories that attach to

the printer.

As a first step, confirm that the printer is turned on and is displaying a

readable message on the control panel display. It must indicate READY,

OFFLINE,orPOWERSAVE ON for a normal operating condition.

Otherwise, an error message will be displayed and logged in the Event

Log. With the printer’s test menu, you can access the Event Log to

display more specific information about the current error. The Event

Log can be printed or displayed.

Print the Event Log

The printer’s internal Event Log stores the most recent errors and can be

printed at any time. To print the Event Log:

1

Press [Menu] until INFORMATION MENU appears.

2

Press [Item] until PRINT EVENT LOG appears.

3 Press [Select] to print the Event Log.

Display the Event Log

If the printer cannot print or move any paper, follow these steps to

display the Event Log:

1

Press [Menu] until INFORMATION MENU appears.

2

Press [Item] until SHOW EVENT LOG appears.

3 Press [Select] to show the Event Log.

4 Press [+] or [-] to scroll through the Event Log.

5 Write down the error messages. For example:

6 Check the Event Log for specific error trends in the last 10,000 printed

pages.

7 Ask the customer for any observed error trends. (For example, do paper

jams tend to occur in a specific area of the printer?)