Page 1

6HUYLFH0DQXDO

7URXEOHVKRRWLQJ5HYLVLRQ

+3/DVHU-HW6L&$

+3/DVHU-HW6L0;&$

+3/DVHU-HW6L0RSLHU

&$&$

Page 2

&RS\ULJKW

+HZOHWW3DFNDUG&RPSDQ\

$OO5LJKWV5HVHUYHG

5HSURGXFWLRQDGDSWDWLRQRU

WUDQVODWLRQZLWKRXWSULRU

ZULWWHQSHUPLVVLRQLV

SURKLELWHGH[FHSWDV

DOORZHGXQGHUWKHFRS\ULJKW

ODZV

3XEOLFDWLRQQXPEHU

F

3ULQWHGLQ86$

:DUUDQW\

7KHLQIRUPDWLRQFRQWDLQHG

LQWKLVGRFXPHQWLVVXEMHFW

WRFKDQJHZLWKRXWQRWLFH

+HZOHWW3DFNDUGPDNHVQR

ZDUUDQW\RIDQ\NLQGZLWK

UHJDUGWRWKLVPDWHULDO

LQFOXGLQJEXWQRWOLPLWHGWR

WKHLPSOLHGZDUUDQWLHVRU

PHUFKDQWDELOLW\DQGILWQHVV

IRUDSDUWLFXODUSXUSRVH

+HZOHWW3DFNDUGVKDOOQRW

EHOLDEOHIRUHUURUVFRQWDLQHG

KHUHLQRUIRULQFLGHQWDORU

FRQVHTXHQWLDOGDPDJHGLQ

FRQQHFWLRQZLWKWKH

IXUQLVKLQJSHUIRUPDQFHRU

XVHRIWKLVPDWHULDO

:$51,1*

(OHFWULFDO6KRFN+D]DUG

7RDYRLGHOHFWULFDOVKRFN

XVHRQO\VXSSOLHGSRZHU

FRUGVDQGFRQQHFWRQO\WR

SURSHUO\JURXQGHGKROH

ZDOORXWOHWV

+HZOHWW3DFNDUG&RPSDQ\

&KLQGHQ%RXOHYDUG

%RLVH,GDKR

Page 3

Troubleshooting

Chapter Contents

Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Engine Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Display and Evaluate the Error Log . . . . . . . . . . . . . . . . . . . . 7-9

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Configuration Page Illustration and Key . . . . . . . . . . . . . . . . . 7-12

Menu Page Illustration and Key . . . . . . . . . . . . . . . . . . . . . . 7-13

Communications Link (C-Link) Cables . . . . . . . . . . . . . . . . . . 7-14

Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Check the Toner Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Faulty Image Examples . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Print and Evaluate the Error Log . . . . . . . . . . . . . . . . . . . . . 7-17

Error Log Interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Verify Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Verify Host System Operation . . . . . . . . . . . . . . . . . . . . . . . 7-20

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Paper Path Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Customer Print Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Control Panel Messages and Errors . . . . . . . . . . . . . . . . . . . . 7-23

Error Log Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

General Paper Path Troubleshooting . . . . . . . . . . . . . . . . . . . 7-36

Image Quality Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-63

Image System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 7-73

General Troubleshooting Information . . . . . . . . . . . . . . . . . . . 7-76

Miscellaneous Problems and Solutions . . . . . . . . . . . . . . . . . . 7-76

Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-81

Reference Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-82

7

Troubleshooting 7-1

Page 4

7-2 Troubleshooting

Page 5

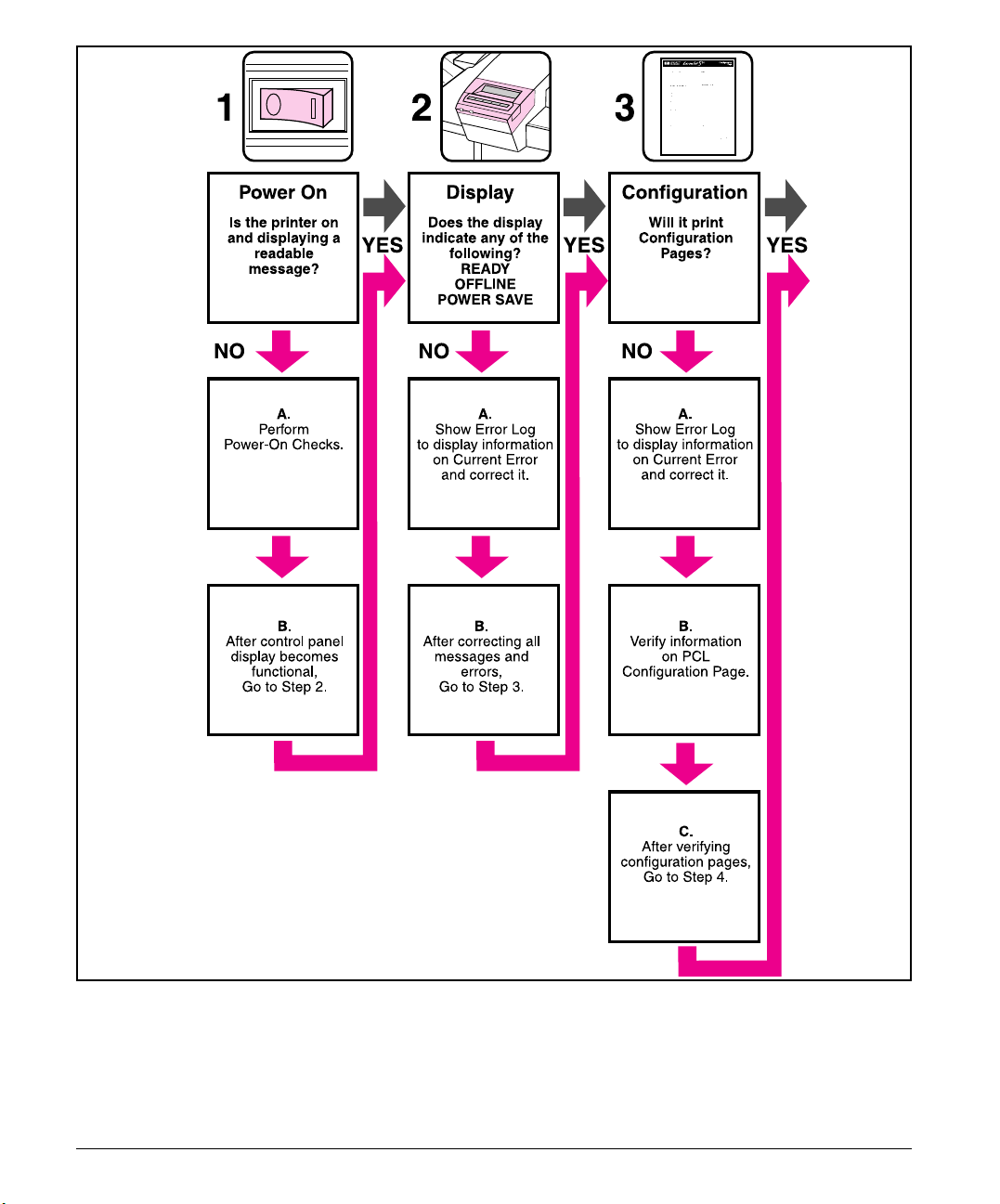

Troubleshooting Process

The troubleshooting process is a systematic approach that addresses the

major problems first and then other problems as you identify the causes for

printer malfunctions and errors. The Troubleshooting Process, Figure 7-1,

on the following two pages, illustrates the major steps for troubleshooting

the printing system. Each heading depicts a major troubleshooting step. A

YES answer to the questions allows you to proceed to the next major step.

A NO answer indicates that additional testing is needed. Proceed to the

referenced location and follow the directions for that area. After completing

the additional testing, proceed to the next major step.

The following list describes the basic questions for the customer and the

corresponding troubleshooting step to help you quickly define the problem(s).

7

Troubleshooting

Display

Page 7-9

Configuration

Page 7-10

Image Quality

Page 7-15

Error Log

Page 7-17

Communication

Page 7-19

Verification

Page 7-21

Does the display panel indicate Ready, Offline or PowerSave?

Contains the procedures for correcting control panel messages and displaying

and correcting error log codes.

Will the printer print configuration pages successfully?

Contains the procedures for printing the configuration pages, and evaluating

and correcting system configuration.

Does the print quality meet customer expectations?

Contains the image quality comparison tables, cleaning procedures, toner

cartridge checks, and High-voltage Power Supply chec ks.

Are there recurring problems in the error log?

Contains information about printing the error log and evaluating the error

history.

Can the customer print from the host system successfully?

Describes how to determine if the printer is communicating properly with the

host system.

Will the printer print from all sources to all destinations, and have all of

the errors in the errorlog been addressed?

Contains procedures for verifying the overall printer system operation.

Reference

Page 7-23

Contains detailed reference material such as the complete error code list,

system schematics, a list of miscellaneous problems and solutions, and a list of

all system sensors and their functions.

Troubleshooting 7-3

Page 6

Figure 7-1 HP LaserJet 5Si / 5Si MX / 5Si Mopier Troubleshooting Process

7-4 Troubleshooting

Page 7

7

Troubleshooting

Figure 7-2 HP LaserJet 5Si / 5Si MX / 5Si Mopier Troubleshooting Process

Troubleshooting 7-5

Page 8

Power-On

Overview

It is important to have the printer’s Control Panel functional as soon as

possible in the troubleshooting process so that the printer’s diagnostics can

assist in locating printer errors.

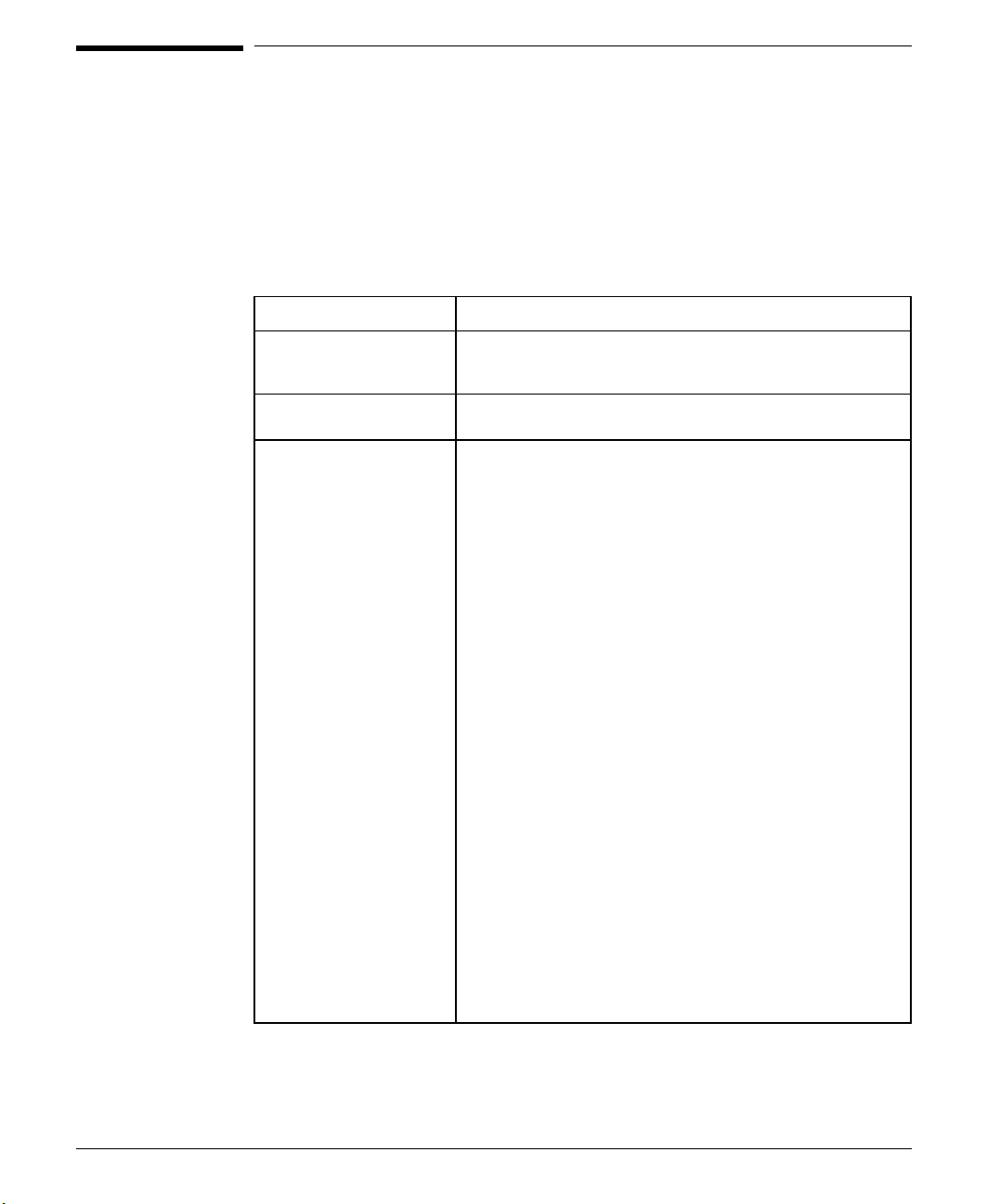

Problem Action

1. Is AC power available at

the printer’s power

receptacle?

2. Is the printer’s ON/OFF

switch set to ON?

3. Are the printer’s fans on?

Ensure that the printer is not

in PowerSave mode

(See Figure 7-3 to locate

the fans.)

Verify.

Push the switch to the ON position.

Note: Fan operation is significant since all fans are controlled by

the printer’s DC Controller PCA. Operational fans indicate:

1. AC power is present in the printer.

2. DC power supply is functional (both 24vdc and 5vdc are

being generated).

3. DC Controller PCA ’s micro-processor is functional.

NO

YES

If the fans are NOT working, turn off the printer and remove the

printer’s Formatter PCA. Disconnect all the printer’s paper handling

options. Then turn on the printer and check the fans again.

If the fans are still not working, perform the following steps:

1. Verify that all f ans are connec ted to the DC Control ler

PCA according to Figure 7-32

2. Replace the low-voltage DC power supply.

3. Replace the DC Controller PCA.

If the fans are working but the printer’s Control Panel is blank, print

an engine test. See the section titled “Engine Test.”

If the engine test was successful, perform the following

steps:

1. Reseat or replace the cable from the Control Panel which is

connected to J203 of the DC Controller PCA (see Figure 7-34).

2. Replace the printer’s Formatter PCA.

3. Replace the Control Panel assembly.

If the engine test was not successful, replace the DC

Controller PCA.

7-6 Troubleshooting

Page 9

Figure 7-3

7

Troubleshooting

Note

Fan Location and Airflow

When the printer is in PowerSave mode, the fans are off.

Fan Number Fan Name

1 Laser/Scanner fan Exhaust air flows from the back of the printer,

2 Low-voltage Power Supply Lower right-hand corner of the printer.

3 Formatter (intake) Intake fan directly above the input power

4 Face-down Delivery Unit Directly above the center of the fusing

Fan Location

on the left-hand side of the fusing assembly.

receptacle.

assembly.

Troubleshooting 7-7

Page 10

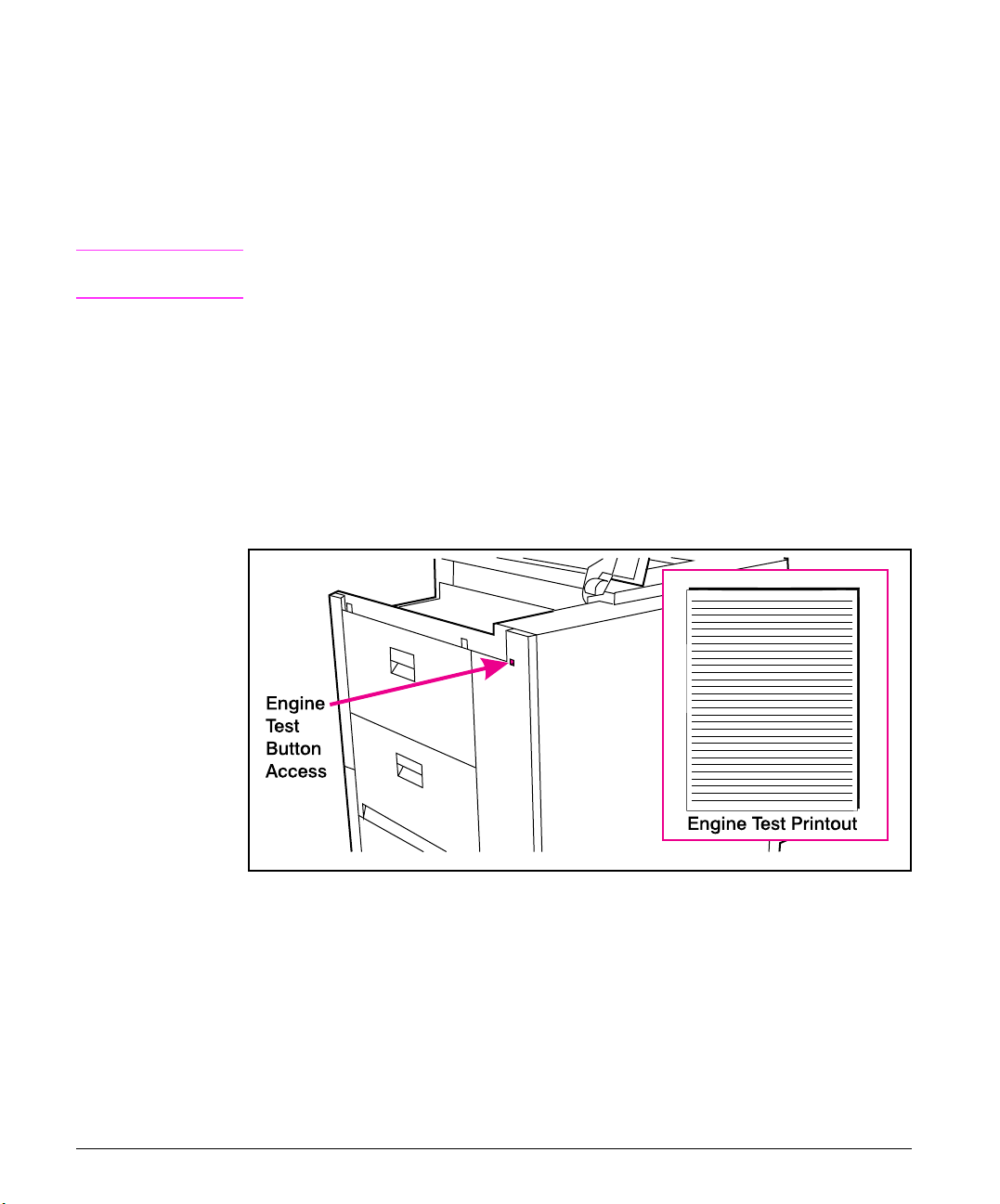

Engine Test

The engine test verifies that the print engine is functioning correctly. The

Formatter PCA is completely bypassed during an engine test. This test is

very useful for isolating printer problems. The engine test prints a full page

of horizontal lines across the entire printable area, and is also useful for

checking and adjusting registration. The engine test prints from Tray 3

only, and can be activated with the Formatter PCA removed.

Note

Figure 7-4

Tray 3 must be installed and loaded with paper to perform an engine test.

Also, ensure that the EP toner cartridge is installed in the printer.

Engine Test Button Location

The engine test button is located on the DC Controller PCA. It is accessible

through a hole at the right rear of the printer.

Printing an Engine Test

To print an engine test, use a non-metallic object to press the engine test

button (see Figure 7-4). A single test page will print.

7-8 Troubleshooting

Engine Test Button

Page 11

Display

Overview

Use the printer’s Control Panel to access the error log to troubleshoot the

printer. With the printer’s test menu, you can access the printer’s error log

to display more information about the current error. The error log retains

the printer’s last 50 error messages.

Note

Refer to the section titled “Reference” for more information about correcting

printer error log messages.

The error log codes and the error on the display panel do not always

correspond. The numbers in the display panel message may not be the same

in the error log. Ensure that you refer to the correct number in the

"Reference" section.

Display and Evaluate the Error Log

If the printer cannot print or move any paper, follow these steps to display

the error log:

1 Press [Menu] until TEST MENU appears.

2 Press [Item] until SHOW ERROR LOG appears.

3 Press [Select] to show the error log.

4 Press + to scroll through the error log.

5 Write down the error messages. For example:

50 13.59.11 52700

EXTERNAL INPUT DEVIC

Error Log on Display Panel

13.11 PAPER JAM

Display Panel Message

7

Troubleshooting

50 = Error Number

13.59.11 = Error Log Code

52700 = Page Count

6 Check the error log for specific error trends in the last 10,000 printed pages.

7 Ask the customer for any observed error trends.

8 Record any specific error trends.

9 Refer to the error log table in the "Reference" section and follow the

recommended action.

10 If the display panel indicates any messages other than Ready, Offline or

PowerSave, restart at step 1. If not, go to the next section.

Troubleshooting 7-9

Page 12

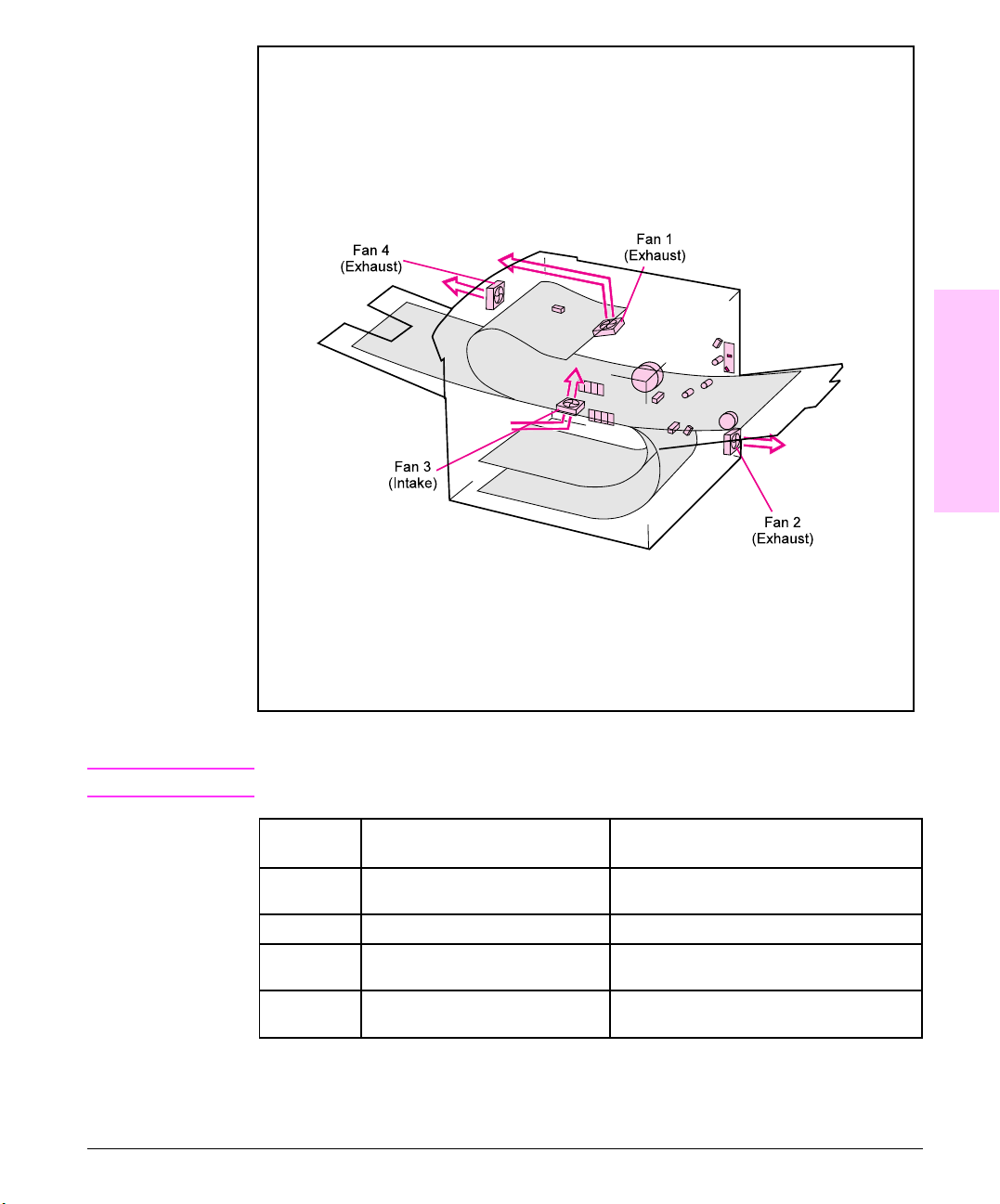

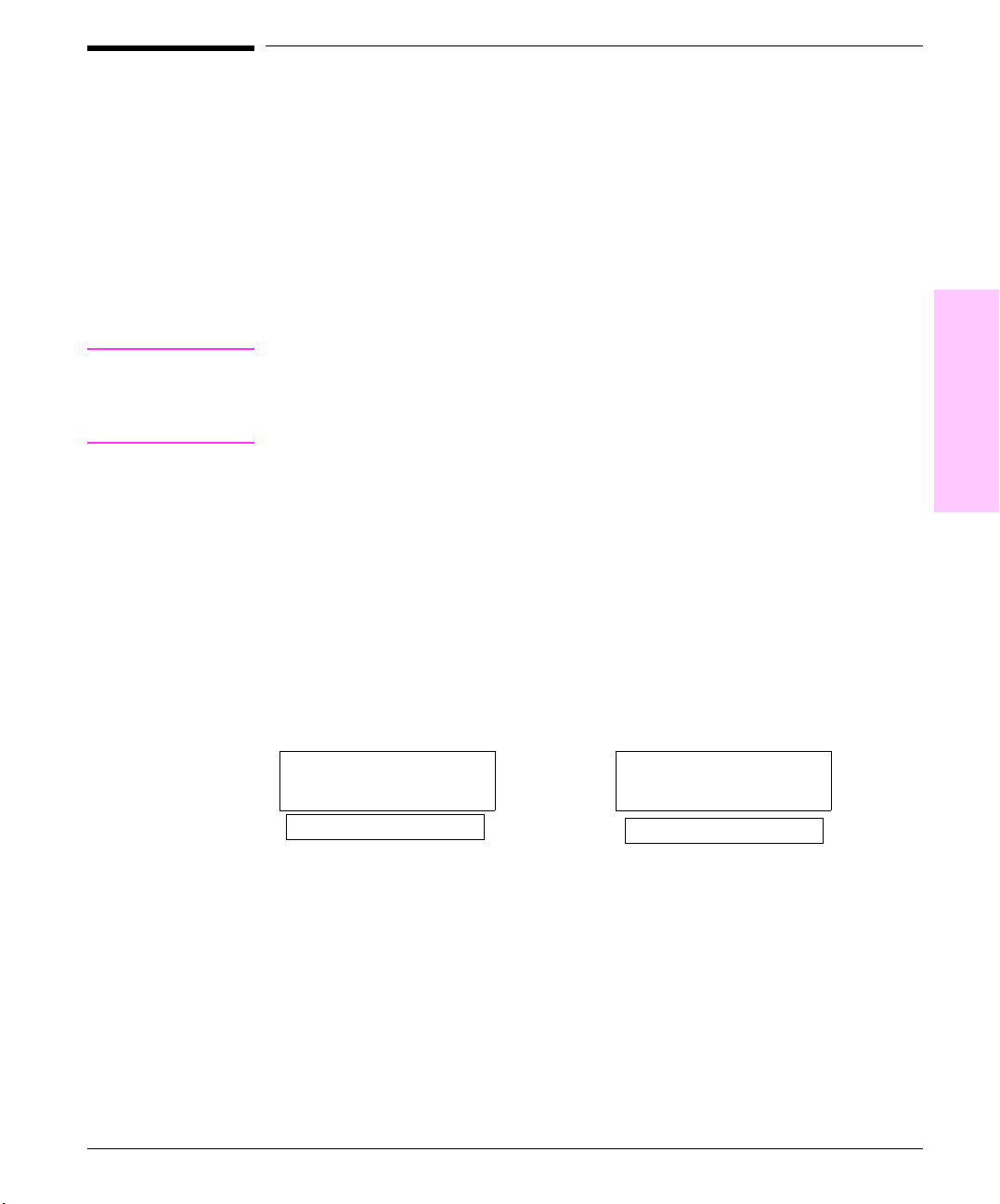

Configuration

Use the configuration pages to verify the proper installation of accessories,

options, and personalities. When you print the configuration pages, the

printer checks its internal controller and I/O interface, then prints two

pages. One shows the overall printer configuration, and the one shows the

current menu settings. Refer to Figure 7-5 for information about

interpreting the configuration page. If any of the installed devices are not

shown on the configuration pages, verify that the C-Link cabling is correctly

connected and functional, and that DC power is available to the paper

handling devices (Figure 7-7). Check and reseat suspect cable connections.

If any of the cables are replaced, you must cycle the power to have the

printer recognize the device again.

To print a PCL configuration page:

1 Press [Menu] until TEST MENU appears.

2 Press [Item] until PCL CONFIGURATION PAGE appears.

3 Press [Select] to print the configuration pages.

Verify that any installed options are present on the

configuration pages.

Under Installed Personalities, look for options such as:

• Postscript (C2765A)

• 420 MB Disk (C2965A)

• SIMM types RAM or ROM and sizes.

7-10 Troubleshooting

Verify that the options which are physically installed in your printer are

reflected in the PCL configuration page. If an installed device is not shown

on the PCL configuration page, check the following table.

Page 13

Device Action if installed and not detected

Duplex Unit Power-off, reseat or replace duplex unit and power-on.

Envelope Feeder Power-off, reseat or replace envelope feeder and power-on.

Device 1

2000 Sheet Input Unit

Device 2

Multi-Bin Mailbox

Device 3

Stapler Module

Verify C-Link cables are installed correctly, see Figure 7-7.

Remove all C-Link connections and visually inspect for connector

damage on the cable pins and connector ends.

Try using a different cable to connect the problem device directly to

the External Paper Handling Controller. All C-Link cables are wired

the same, but are different lengths.

If a device is not recognized, replace device controller or defective

C-link cable.

Device 1

2000 Sheet Input Unit

Device 2

Multi-Bin Mailbox

Verify AC power is present in the 2000 Sheet Input Unit.

Note: The tray will not lift if C-link cable is not connected properly to

External Paper Handling Controller.

Verify that the external DC power supply is receiving power.

Verify that the external DC power supply output is connected to the

Multi-Bin Mailbox controller.

Note: The Multi-Bin Mailbo x wi ll not appear on the PCL

configuration page without the C-Link cables properly installed or

external power applied.

Replace external DC power supply.

Replace Multi-Bin Mailbox controller.

After verifying that the PCL configuration pages accurately reflect the

installed devices, proceed to the section titled “Image Quality.”

7

Troubleshooting

Troubleshooting 7-11

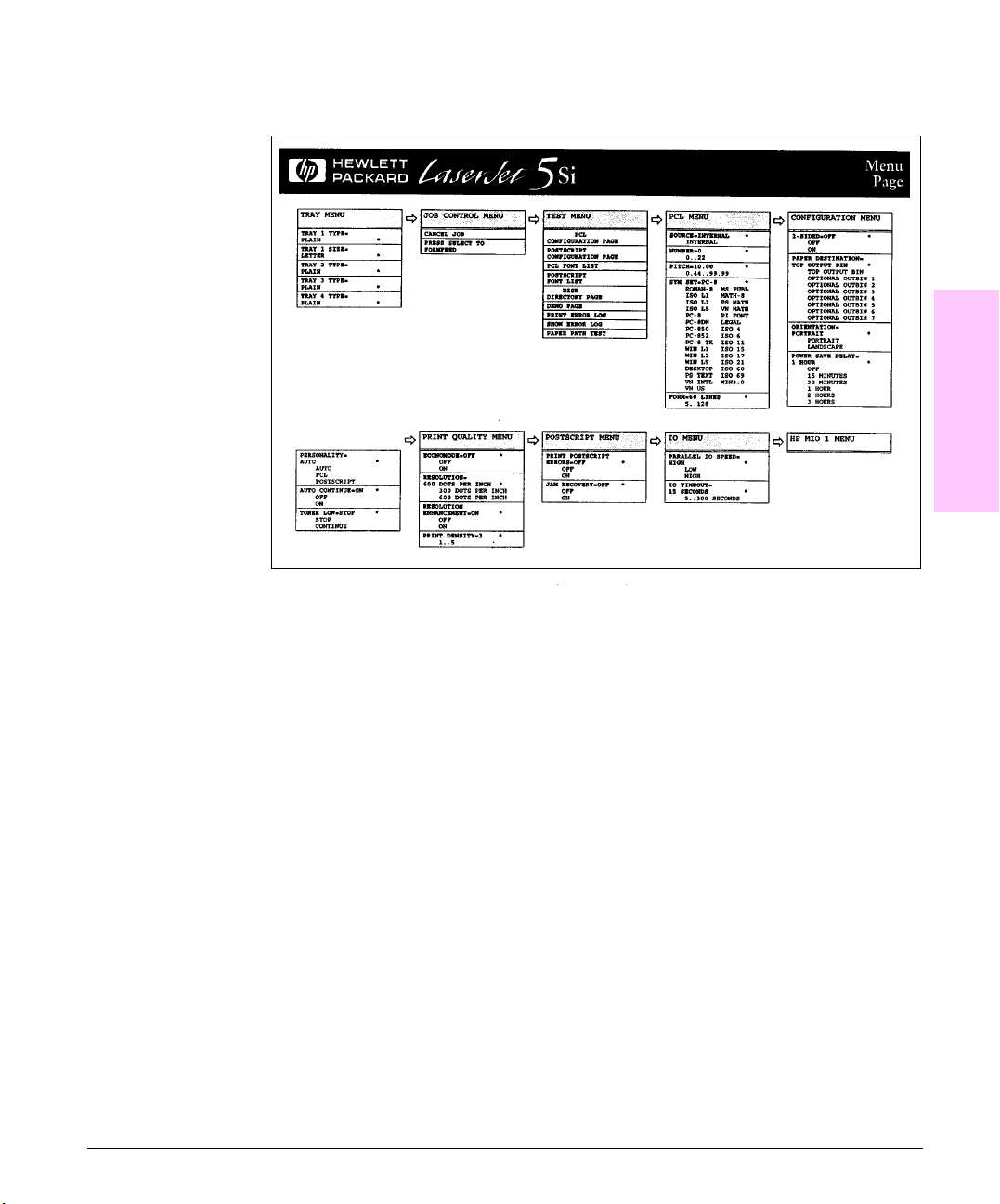

Page 14

Figure 7-5

Configuration Page Illustration and Key

The default S/N is

AAXXYY99999. To set

the correct S/N, refer to the

SERVICE MODE procedure

in Chapter 3 of this manual.

Formatter and firmware’s

datecode and version

number.

The three most recent

error log messages

display here.

The MIO Block shows

network communication.

See Figure 7-9.

Check the

installed

memory to see

if it corresponds

with what is

physically

installed in the

printer.

All the paper handling

devices that are

physically present

should be listed in this

section. Verify that

each device is

connected according

to Figure 7-6.

When configured

correctly:

7-12 Troubleshooting

Device 1=2000 sheet

Device 2=Mailbox

Device 3=Stapler

Configuration Page Example

Page 15

Figure 7-6

Menu Page Example

7

Troubleshooting

Menu Page Example

Troubleshooting 7-13

Page 16

Figure 7-7

Communications Link (C-Link) Cables

Note

Communications Link (C-Link)Cables, Supported Daisy Chain Connections

All C-Link cables have a single dot molded into the device output connector

cable end, and two dots molded into the device input connector cable end.

The devices may not be recognized by the External Paper Handling

Controller if the cables are not connected exactly as shown in Figure 7-7.

It is important that the C-Link cables are installed in the supported daisy

chain configuration as shown in Figure 7-7. This is so that the devices are

recognized and correctly reported on the error log.

Example: In the error log message "13.12.03", the last two digits ".03"

indicate that Device 3 has failed in the supported configuration:

Device 1 = 2000 Sheet Input Tray

Device 2 = Multi-Bin Mailbox

Device 3 = Stapler Module

It is possible, but not recommended, to attach the C-Link cables in other

configurations. This will rearrange the supported device numbering. Keep

in mind this configuration when evaluating the error log.

7-14 Troubleshooting

Page 17

Image Quality

When you are working with customers, obtain a print sample before you

begin troubleshooting their printer. Ask the customer to explain the quality

they expect from the printer. The print sample will also help clarify the

customer’s explanation.

Problem Action

1. Do you have a print

sample?

2. Does the problem repeat

on the page?

3. Is the toner cartridge full

and is it manufactured by HP.

4. Is the printer clean? Perform the cleaning procedure described in Chapter 4 of this

5. Is the customer using

print media that meets all

HP paper specification

standards?

6. Is the print sample similar

to those in the Print Quality

Tables in the “Reference.”

section?

7. Is the problem on the

drum or transfer roller?

Obtain a print sample from the customer.

Use the Repetitive Defect Ruler in the "Reference Section."

Check the toner cartridge using the check list on next page.

manual.

For more information about HP’s paper specification standards, see

Chapter 1 of this manual and the

Specification Guide.

Compare and perform the actions recommended in the Print

Quality Tables.

Perf orm the "Half Self Test" in the "Reference Section" to determine

where the defect is.

HP LaserJet Family Paper

7

Troubleshooting

If the defect is on the drum, replace the Toner cartridge High

Voltage Supply.

If it is not on the drum, replace the transfer roller.

Troubleshooting 7-15

Page 18

Check the Toner Cartridge

Image formation defects are often the result of toner cartridge problems. If

there is any doubt, always replace the toner cartridge before troubleshooting

image defects.

Use the following check list to ensure that the toner cartridge is still

operable.

• Ensure that the toner cartridge has toner.

Full toner cartridge weight = 3000 grams (106 oz)

Empty weight = 2300 grams (80.5 oz)

• Check the expiration date of the toner cartridge (stamped on the cartridge

box).

• Check the toner cartridge to see if it has been disassembled or refilled.

• Ensure that the toner cartridge is seated properly in the printer cavity.

• Inspect the cartridge for leaking toner through worn seals. (If the drum has

been manually rotated it may have caused internal damage and toner spills

may result.)

Note

Toner Cartridges are rated for 15,000 images at 5% coverage. It is possible

to wear out the gears and the cartridge seals before TONER LOW is displayed if

the 15,000 image expectancy is exceeded.

• Check the surface of the photosensitive drum in the cartridge to see if it has

been damaged or scratched. Touching the drum will contaminate the

photosensitive surface and may cause spotting and defects during printing.

• White areas on the page may indicate that the drum has been exposed to

light for too long. If white areas appear, stop the printer and wait a few

minutes. This should eliminate most defective images. If not, the toner

cartridge may be placed in a dark environment for several days, which may

restore some life to the drum.

Faulty Image Examples

The “Reference” section contains Image troubleshooting and sample image

defects and their possible causes. Since there are many variables in the

printing process, it is possible to encounter image defects that are not shown

in the examples. If you find a defect that is not depicted, record the probable

cause along with the printing environment conditions and save a copy of the

defect for future reference.

7-16 Troubleshooting

Page 19

Error Log

Use the error log to diagnose and troubleshoot printer errors and

intermittent failures.

Print and Evaluate the Error Log

The printer’s internal error log stores the last 50 errors and can be printed

at any time. To print the error log:

• Press [Menu] until TEST MENU appears.

• Press [Item] Until PRINT ERROR LOG appears

• Press [Select] to print the error log.

After printing the error log:

• Check the error log for specific error trends in the last 10,000 printed

pages.

• Ask the customer for any observed error trends.

• Record any specific error trends.

• Refer to the error log table in the “Reference” section of this chapter to

interpret error log codes.

7

Troubleshooting

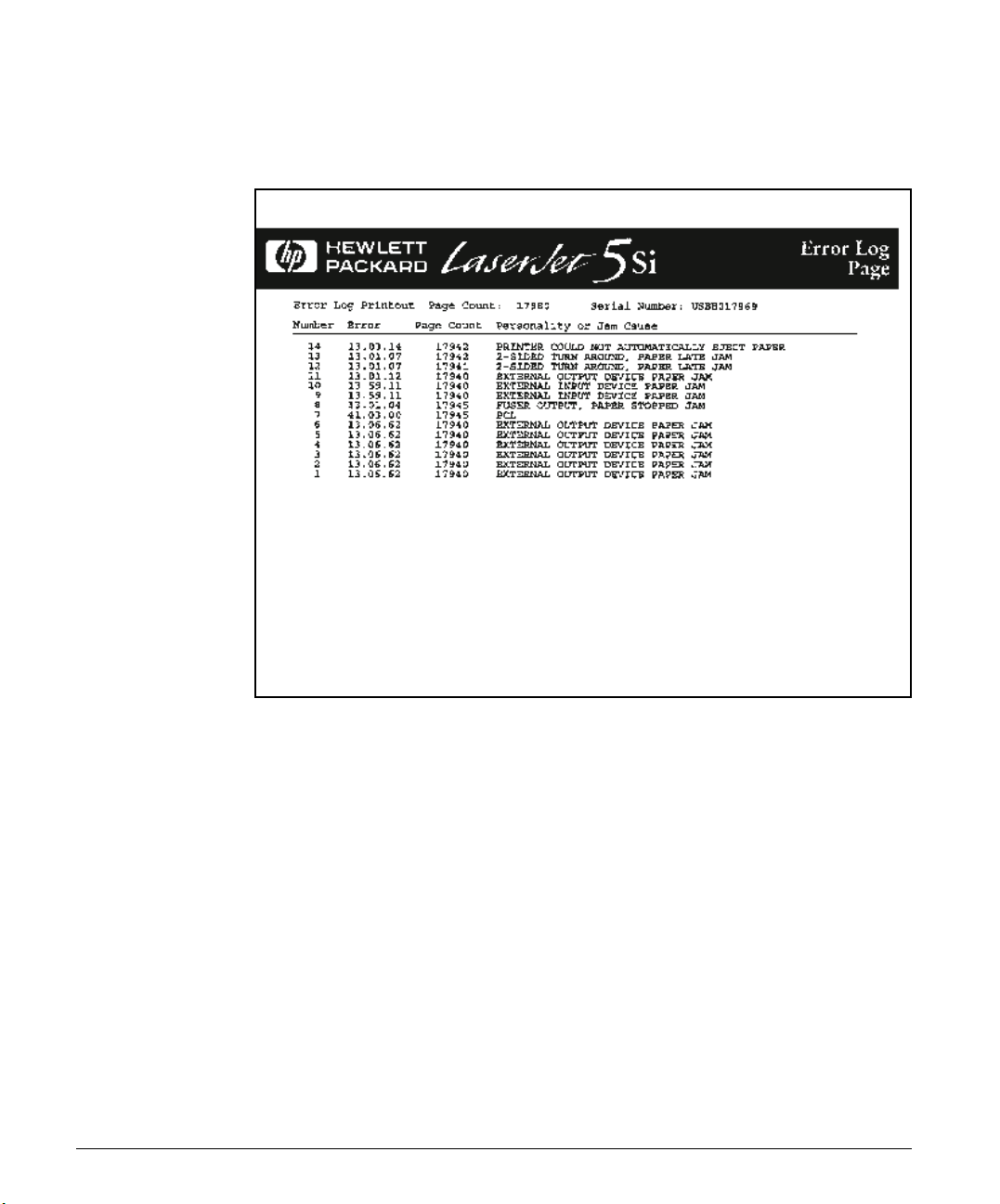

Error Log Interpretation

The error log is the key tool in troubleshooting printer problems. Figure 7-8

shows a typical error log. The error log shows the current page count at the

top center of the page, with the printer’s serial number directly to the right

of the page count. The left column is the error sequence number, with the

error listed at the top (the highest sequence number is the most recent error

logged). The next column is the page count at the time of the error, and the

last column is the Personality (PCL or PostScript) column or the Jam Cause

at the time of the error.

The error log records all errors in a different format than the Control Panel

Display. For example, should a 50.1 FUSER ERROR / CYCLE POWER be

displayed on the Control Panel Display, the error log will record a 50.02.01

error, with the 02 signifying that 2 sensors were blocked. Likewise, when a

13.1 through 13.9 are displayed on the Control Panel, the error log will

record a 13.0x.01 through 13.0x.09, where x = the number of sensors blocked

in the printer.

When an error is detected in an Optional Paper Handling Device, a 13.11,

13.12 or 66.xx.yy will be posted to the Control Panel.

Troubleshooting 7-17

Page 20

Figure 7-8

Whenever a 13.xx appears on the Control Panel, a good practice is to clear

all the paper from the printer, take the printer offline, and print the error

log. If you cannot print the error log, you can still display it on the display

panel. Write the error next to the last error logged. The last error is the

error at the top of the error log printout with the highest number in the

leftmost column.

7-18 Troubleshooting

Error Log Page

To interpret the error log:

• Each individual entry in the log is called an "ERROR," with all errors

occurring at the same page count an "EVENT." Read the Recommended

Action for each error comprising an event to gain a clear picture of what

took place during that event. Events usually conclude with a timeout or

no response from device (Error 66.nn.nn in printer logs) which requires a

power cycle of the print engine.

• It is assumed that any Paper Handling Devices are connected as shown

in the C-Link Cable Diagram (Figure 7-7). The errors will be logged with

different device numbers if any non-standard cabling is installed.

• Use the error log table in the “Reference” section of this chapter to

associate errors in the error log with the Control Panel error message.

Follow the Recommended Action listed in the table for each error or

event.

Page 21

Communication

Ask the customer to run a print job from the host system. If the print job is

successful, proceed to the following step, “Verification.”

Verify Communication

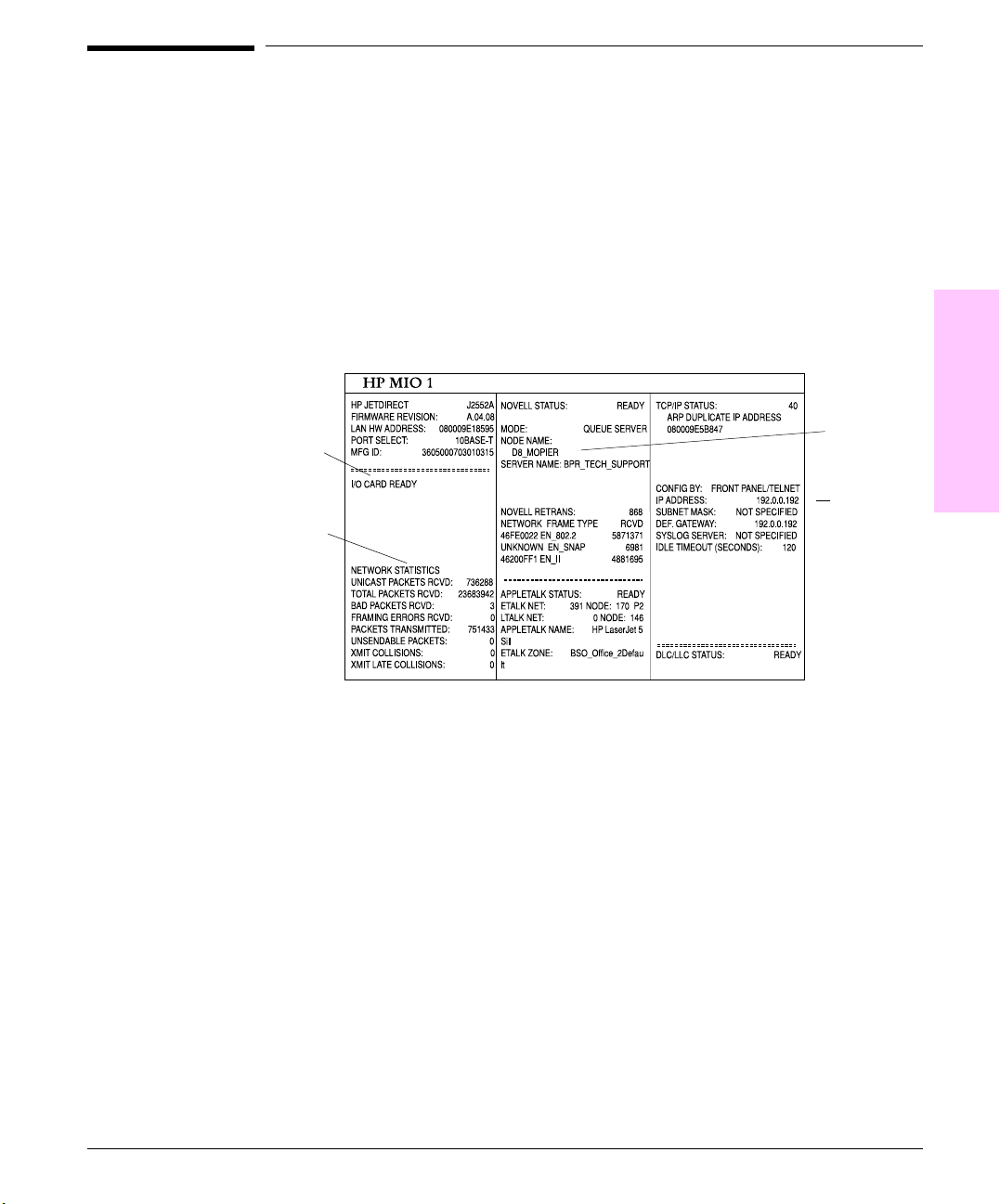

Figure 7-9

Print the PCL configuration page and study the HP MIO block. The MIO

block will appear on the bottom portion of the configuration page. An

example of a properly operating MIO block appears in Figure 7-9.

Node Name

I/OCard

Ready

IP Address

Network

Statistics

MIO block on Configuration Page

• If the MIO Jet Direct Card has successfully powered up and completed its

internal diagnostics, the "I/O CARD READY" message will appear. If

communication is lost, an "I/O NOT READY" message appears followed by a

two digit error code. Consult the HP JetDirect Network Interface

Configuration Guide for further details and recommended action.

7

Troubleshooting

• The "Network Statistics" column indicate that the network activity has been

occurring. Bad packets, framing errors, un-sendable packets and collisions

should be minimal. If a high percentage (greater than one percent) of these

occur, contact the network administrator. All of the statistics are set to zero

when the printer is powered-off.

• The "Novell Status" block should state the Novell printer server name to

which the printer is connected. If the node name reads "NPIxxxxxx"

(xxxxxx=last six digits of the MIO’s LAN address), the MIO card has not

been configured for a Novell server. This could indicate that the card is

Troubleshooting 7-19

Page 22

operating under a IPX protocol other than Novell. Consult with the

network administrator if the Node Name is not present.

• In the TCP/IP protocol block, the default IP address is "192.0.0.192." It is

acceptable to operate the printer with this default address. The error

message, "ARP DUPLICATE IP ADDRESS" may appear in this block. This

is also an acceptable error code if the TCP/IP protocol is not being used.

Please check with the network administrator to determine the correct IP

Address for the printer.

Verify Host System Operation

Try to print to another known working printer or move the failing printer to

a known working location. Verify that the correct driver is installed and

operating properly. Check with HP Service and Support in the User’s

Manual to obtain the latest Windows and PostScript drivers.

Note

To display the printer driver version:

In the printer driver, select the Print Quality tab and click on About to

display the printer driver revision level.

Verify Network and Server Operation

• Try to print the job to the printer’s parallel port.

• Try to print from the host system through the network to another printer.

Contact the network administrator for assistance.

7-20 Troubleshooting

Page 23

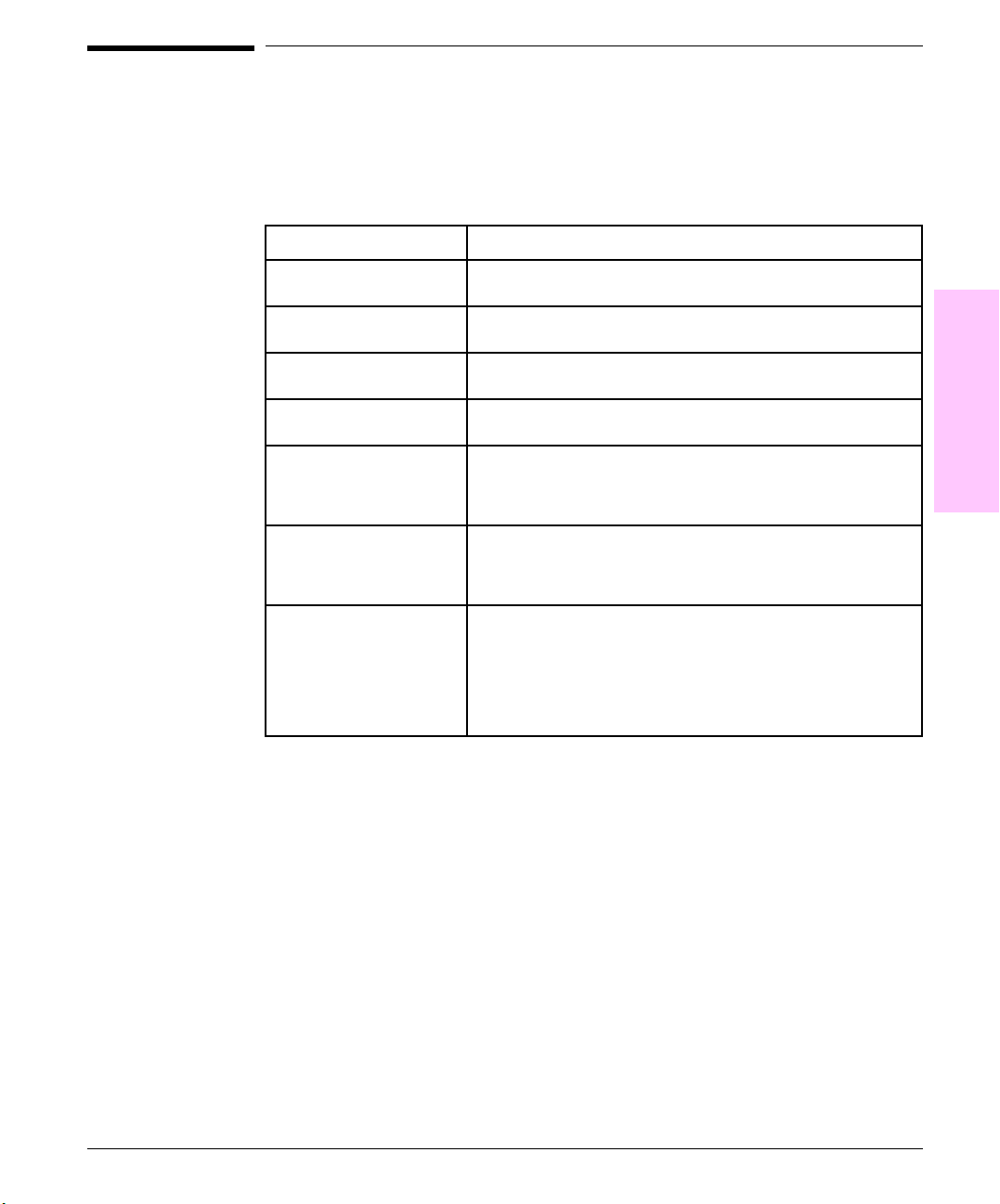

Verification

Paper Path Test

Using the error trend information from Step 5 (Error Log), you may verify a

specific printer paper path with the paper path test. You must first set the

desired paper destination in the configuration menu and then select the

paper path test. The paper path test menu will allow you to select the

desired paper source and number.

Note

In order to perform the paper path test, the printer must be configured to

mailbox mode. If the printer is not in mailbox mode, ask the JetAdmin

administrator to change the configuration to mailbox mode to complete this

test.

To perform a paper path test:

Set Destination and Duplex first:

• Press [Menu] until CONFIGURATION MENU appears.

• Press [Item] until PAPER DESTINATION appears.

• Press [+] to cycle selections until the desired paper destination appears.

• Press [Select] to select the desired destination for the Paper Path Test.

• To set duplex, press [Menu] until CONFIGURATION MENU appears.

• Press [Item] until 2 SIDED = XX appears.

• Press + to select duplex or single side.

Set Source and number of pages last:

• Press [Menu] until TEST MENU appears.

• Press [Item] until PAPER PATH TEST appears.

• Press [Select].

• Press [+] to cycle selections until the desired paper source appears.

• Press [Select].

• Press [+] to cycle selections until the desired number of images appears.

You can choose 1, 10, 50, 100 or 500 copies.

• Press [Select] to perform the Paper Path Test.

7

Troubleshooting

Troubleshooting 7-21

Page 24

Figure 7-10

Note

7-22 Troubleshooting

Paper Path Test Source and Output Selection

Customer Print Job

Ask the customer to send a print job from the problem source(s) to the

problem destination(s). Try to recreate the paper jam errors by having the

customer do typical print jobs and the type of print job that has been

causing the paper jams.

When verifying print jobs, ensure that all of the settings are selected as

desired. Keep in mind that application settings take priority over Driver

settings, which take priority over the the printer control panel settings. If a

single setting is not present in the application, but is set in the driver, that

will override the front panel settings.

JetAdmin does have capabilities to override paper types and sizes and

certain conditions.

Page 25

Reference

Control Panel Messages and Errors

Printer messages displayed on the control panel provide five categories of

information. Each message category is assigned a priority. If more than one

condition occurs at the same time, the highest priority message is displayed.

When it has been cleared, the next priority message will be displayed, and

so on. The displayed messages and their priorities are:

Note

• Catastrophic System Messages

• Service Messages

• Error Messages

• Attendance Required Messages

• Device Status Messages

Error, Service, and Catastrophic System messages are preceded by a

number designation. Device Status and Attendance Required messages

(except for paper jam messages) do not have a number designation.

The Error Log Table is organized by the display panel messages. All of the

alphabetical messages are listed first, followed by numeric display panel

messages. The error log codes (the second column) are in no order. They

are merely listed with the associated display panel message.

7

Troubleshooting

Troubleshooting 7-23

Page 26

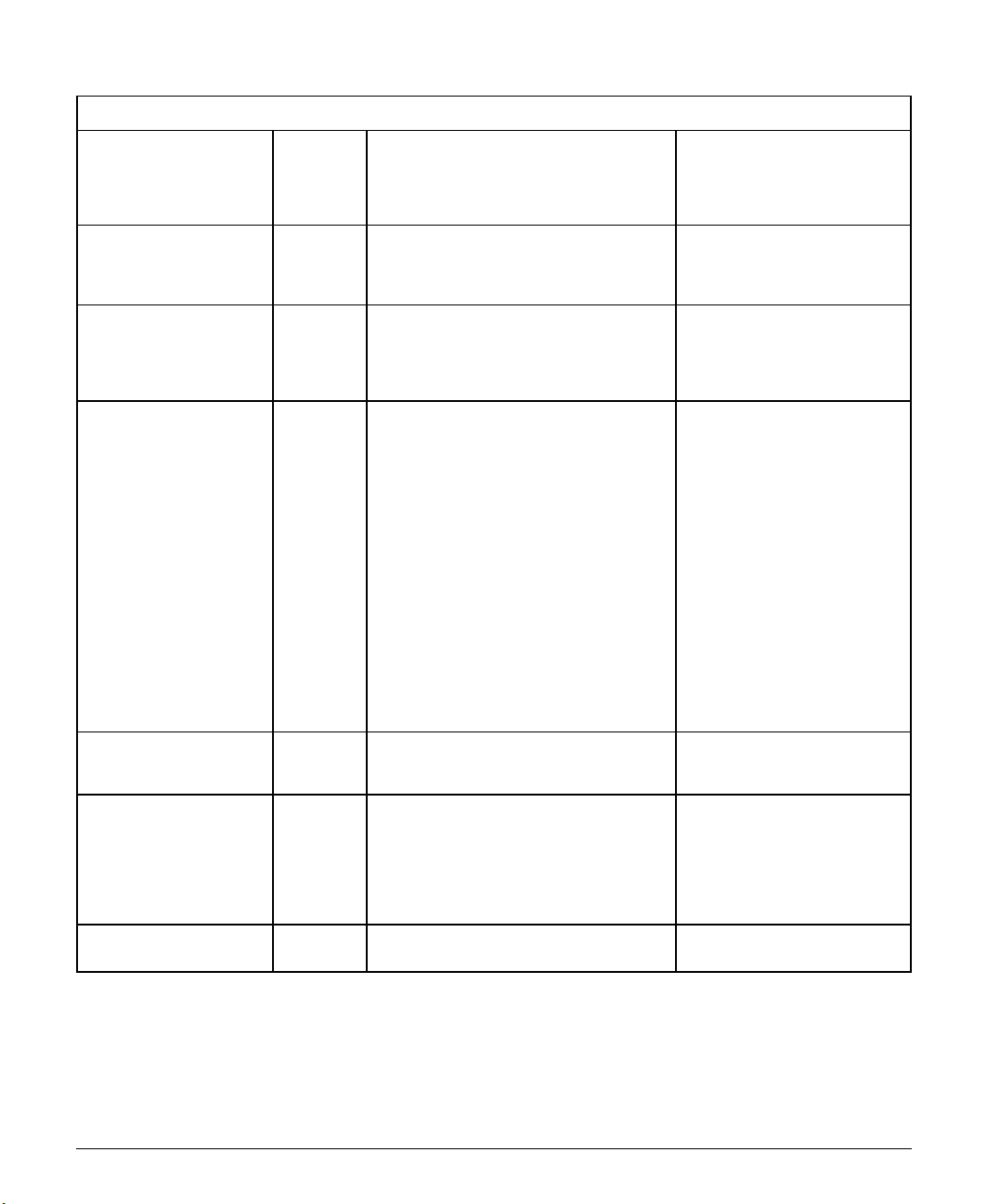

Error Log Table

Message Error

Description Recommended

Log

Category/

Message

ACCESS DENIED Status After an attempt to select a locked-out

CANCELING JOB Status The printer is canceling the currently active

CLEAR JAMMED STAPLE Attendance

CLEARING PAPER FROM

THE PRINTER

CLOSE PRINTER COVER Attendance

COPIES XX OF Y Status This message indicates the progress of the

Required

13.10.03

Status The printer is attempting to remove unusable

Required

function, this message displays for

approximately 2 seconds.

job.

Staples are jammed in the stapler. To clear the jam, open the Stapler

paper. This may oc cur after you clear a paper

jam.

One of the printer’s doors or its cover is not

latched or seated properly. Interlock switches

are connected to each door and the cover.

For the Top Cover and Fuser Door, close

SW1. The Ri ght Paper Path Door enables

photosensor PS3 on the Pickup PCA of the

Paper Input Unit (PIU).

current job.

Action

The JetAdmin Administrator

controls the control panel lockout

feature. Request from the

administrator to unlock function.

No action required. If message

displays for over 5 minutes, cycle

power. An extremely large print

job with detailed graphics may

take up to five minutes to cancel.

Top Cover Assembly by pressing

the green tab with your thumb

and pulling the green circular tab

with your forefinger (refer to

Figure 7-11). Remove loose or

damaged staples from the stapler .

Push the circular tab to snap it

back into place. Close the Top

Cover Assembly.

NOTE: If any staples are

removed while clearing a staple

jam, up to 12 documents may not

be stapled when printing resumes

because the stapler must reload.

Check the Staple Cartridge.

Replace it as required. Replace

the Stapler Top Cover. Replace

the entire stapler as required.

No action required.

Ensure the following are closed:

Top Cover, Rear Fuser Access

Door, and Right Paper Path

Access Door (below Tray 1).

No action required.

7-24 Troubleshooting

Page 27

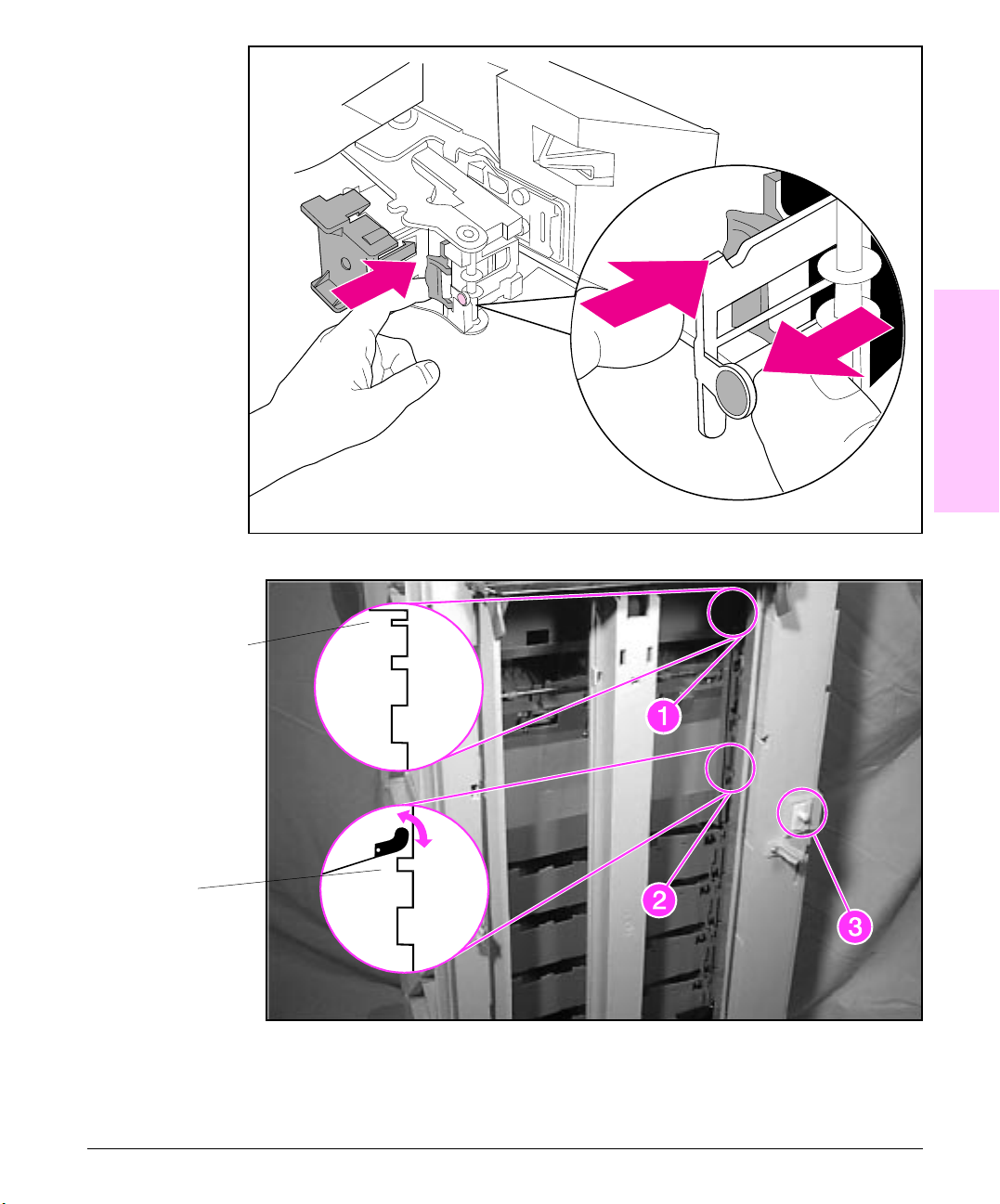

Figure 7-11

Figure 7-12

7

Troubleshooting

Clearing Staple Jams

"Home" position gap.

When the output bin

is full, the flag blocks

the gap.

Scanbar and MBM Interlock Switch (SW1).

1 and 2 - Scanbar gaps. 3 - Multi-Bin Mailbox Interlock Switch

Troubleshooting 7-25

Page 28

Message Error

Description Recommended

Log

Category/

Message

ENGINE TEST Status This message displays after the engine test

FORMFEEDING

(The [On Line] LED flashes.)

HP MIO 1 INITIALIZING Status This message displays while the upper HP

HP MIO 2 INITIALIZING Status This message displays while the lower HP

HP MIO 1 NOT READY Status The upper MIO card is not ready. One of two

Status A form feed is in process. No action required. When the

button is pressed and indicates that the

engine test is in process. If the test fails, an

error or attendance message displays.

MIO card initializes. The printer supports I/O

switching and remains online, but the

channel is not active during initialization.

NOTE: Since older MIO cards cannot

remove the message, the printer will remove

the message after a 5-minute timeout.

MIO card initializes. The printer supports I/O

switching and remains online, but the

channel is not active during initialization.

NOTE: Since older MIO cards cannot

remove the message, the printer will remove

the message after a 5-minute timeout.

situations may occur. First, the parallel port

and the lower MIO card may continue to

operate nominally. If the upper MIO card is

operating correctly and communicating with

the network, this message will disappear

after approximately one minute. No action is

required. Second, if the upper MIO card is

unable to communicate with the network, this

message will display for five minutes and

then disappear. In this case, the printer is not

communicating with the network, even

though the message is no longer displayed.

Action

No action required. Refer to the

Power On section for more

information about performing an

engine test.

paper reaches the destination

output bin, the [Ready] message

displays and the [On Line] LED

returns to a steady state.

No action required. If the

message displays after five

minutes, a problem may exist in

the network card, the network

configuration, or with the host. For

more information about the MIO

card, refer to your network

documentation.

No action required. If the

message displays after five

minutes, a problem may exist in

the network card, the network

configuration, or with the host. For

more information about the MIO

card, refer to your network

documentation.

The problem may be a bad MIO

card, bad cable or connection on

the network, or a network

problem. For more information

about the MIO card, refer to your

network documentation. Verify

that the product numbers for the

MIO card is supported by printer.

7-26 Troubleshooting

Page 29

Figure 7-13

7

Troubleshooting

High-voltage Power Supply contacts

1. Primary Charging Roller Connector

2. Toner Registration/Toner Sensor

3. Developing Roller Bias Connector

4. Drum Ground Connector

Troubleshooting 7-27

Page 30

Message Error

Description Recommended

Log

Category/

Message

HP MIO 2 NOT READY Status The lower MIO card is not ready. One of two

INPUT DEVICE FEED

PATH OPEN

INPUT OPERATION

CONDITION xx.1y

Attendance

Required

Attendance

Required

situations may occur. First, the parallel port

and the upper MIO card may continue to

operate nominally. If the lower MIO card is

operating correctly and communicating with

the network, this message will disappear

after approximately one minute. No action is

required. Second, if the lower MIO card is

unable to communicate with the network, this

message will display for five minutes and

then disappear. In this case, the printer is not

communicating with the network, even

though the message is no longer displayed.

An external input device such as the

2000-Sheet Input Tray (Tray 4) is disrupting

the paper path. The opening and clos ing of

the Tray 4 Vertical Transfer Door should

cause this message to be displayed (the

closed door "blocks" PS35).

An external input device has a condition that

needs to be corrected before printing can

continue.

See error log 13.17.11 -13.59.11

Action

The problem may be a bad MIO

card, bad cable or connection on

the network, or a network

problem. For more information

about the MIO card, refer to your

network documentation. Verify

that the product numbers for the

MIO card is supported by printer.

Check feed path, covers and

doors on external input device(s).

Check PS35 on the vertical

transfer assembly.

Check the indicated input device

and correct the error condition.

Cycle power and print PCL

configuration pages to verify all

devices are shown in printout.

See Figure 7-5.

INPUT TRAY = ALL TRAYS Status The printer will pull paper from all available

INSTALL TONER

CARTRIDGE

INTERNAL TEST Status The printer is executing a non-printing self

Attendance

Required

paper trays.

The toner cartridge is missing or installed

incorrectly. The print engine detects the

presence of the toner cartridge by reading

the voltage at the Toner Registration/Toner

Sensor on the High-voltage Power Supply.

For sensor location on the power supply, refer

to Figure 7-13. The contact can be ac ces s ed

from the right-hand side wall of the toner

cartridge cavity in the printer.

test.

7-28 Troubleshooting

No action required.

Ensure the toner cartridge is

seated properly, or install a new

toner cartridge, ensuring it is

seated properly. If the error

persists: Check functionality of

the toner cartridge and

High-voltage Power Supply

contacts (refer to Figure 7-13).

Replace the toner cartridge.

Replace the High-voltage Power

Supply.

No action required. If this

message displays for over three

minutes, first cycle power. If this

persists, verify that the Formatter

connections are secure. Then

remove all optional SIMMs and

MIO(s).

Page 31

Message Error

Log

Description Recommended

Action

Category/

Message

LOAD TRAY X or LOAD

ENV FEEDER

type> <paper size>

MANUAL FEED TRAY 1

<media type> <paper size>

MOPY XX OF Y from Tray n Status This message indicates the progress of the

OFFLINE Status The printer is offline and cannot receive data. Press [Online] .

OUT OF STAPLES Attendance

OUTPUT DEVICE

DELIVERY PATH OPEN

<media

Attendance

Required

Attendance

Required

Required

Attendance

Required

The printer received a request for a media

type and size that is not currently installed in

the printer.

The printer received a request for a media

type and size manually fed from Tray 1.

current job.

The staple cartridge is empty. Staples are

detected by a photosensor and flag located

beneath the staple cartridge access slot.

Inserting a cartridge with staples pushes

down this flag.

One of the printer’s interlock switches is not

set properly. Thi s mes sage di spl ays for one of

two reasons:

1. An external output device, such as the

Multi-Bin Mailbox, is disrupting the paper

path. Switch SW1, the interlock switch, is not

depressed (callout 3, Figure 7-12).

2. The stapler’s top cover is open. Two

interlock switches detect whether the

stapler’s top cover is closed (refer to Figure

5-21).

Load the indicated tray with the

correct media, or override the

media type and size through the

printer’s Control Panel for that

print job.

Note: If paper is loaded when the

printer is in POWER SAVE, it may

not be recognized. Open and

close the affected source when

printer is in READY mode.

Load the correct media in Tray 1.

If the correct media is already

loaded, press [Online] so the

printer will use that media.

Note: If paper is loaded when the

printer is in POWER SAVE, it may

not be recognized. Open and

close the affected source when

printer is in READY mode.

No action required.

Replace the staple cartridge.

NOTE: The stapler will retain

some staples; do not remove

them. Remove the cartridge.

Verify that the flag beneath the

staple cartridge slot moves freely.

If it is damaged, replace the

stapler’s top cover. Replace the

Stapler Assembly.

Ensure the mailbox is installed

tightly against the printer

(especially at the top of the

mailbox). Carpeting and/or

uneven flooring may cause the

top of the mailbox to move away

from the printer, which causes

this error to occur. Verify that

Switch SW1 is working properly

(callout 3, Figure 7-12).

Close the stapler’ s top cover. The

printer will reset. Verify that the

switches in the stapling unit are

correctly wired and functional.

Perform continuity checks with

the switches.

7

Troubleshooting

Troubleshooting 7-29

Page 32

Message Error

Description Recommended

Log

Category/

Message

OUTPUT OPERATION

CONDITION x.yy

PAPER DESTINATION =

ALL BINS

PERFORM USER

MAINTENANCE

PRESS SELECT TO

CANCEL JOB

PRINTING

CONFIGURATION PAGE

PRINTING DEMO PAGE Status This message displays while the printer

PRINTING DISK

DIRECTORY

PRINTING ERROR LOG Status This message displays while the printer

PRINTING FONT LIST Status This message displays while the printer

PRINTING PAPER PATH

TEST

PROCESSING JOB FROM

ENV FEEDER

Attendance

Required

Status The printer will output paper to all available

Status The printer requires a formal maintenance

Status This message displays to confirm that you

Status This message displays while the printer

Status This message displays while the printer

Status This message displays during a paper path

Status The printer is processing data from the active

An external output device has a condition

that needs to be corrected before printing

can resume.

x = output device

0 = Paper Handling Controller

2 = Multi-Bin Mailbox

3 = Stapler

yy = condition code

For the Multi-Bin Mailbox: 01 = Face-Up bin

not installed.

bins.

procedure.

canceled the currently active job.

prints the configuration pages.

prints a demo page.

prints an optional disk accessory directory.

prints the error log.

prints a font list.

test. This test can print 1, 10, 50, 100, or 500

pages.

I/O channel. Some data is printed and some

data cannot be printed, such as downloading

fonts or macros. The media source is the

Envelope Feeder.

Action

Cycle power and print PCL

configuration pages to verify all

devices are shown in printout.

See Figure 7-5.

Check the indicated output device

and correct its condition. Check

C-Link Cables for proper

connection. For the Multi-Bin

Mailbox/Mailbox with Stapler,

ensure that the Face-Up Bin is

properly installed.

No action required.

Perform the required

maintenance in accordance with

chapter 4. Access the

Configuration Menu, and select

SERVICE MESSAGE=OFF.

Press [Select] to cancel a print

job. This may take up to 5 minutes

to cancel the print job. Press any

other key to continue.

No action required.

No action required.

No action required.

No action required.

No action required.

No action required. To stop the

test, access the JOB CONTROL

menu, and select CANCEL JOB.

No action required.

7-30 Troubleshooting

Page 33

Message Error

Description Recommended

Log

Category/

Message

PROCESSING JOB FROM

TRAY x

READY Status This is the default message. The printer is

REMOVE PAPER FROM

TOP OUTPUT BIN or

REMOVE PAPER FROM

OPTIONAL OUTPUT BIN n

RESTORING FACTORY

SETTINGS

SELECT LANGUAGE Status This message displays after pressing and

SERVICE MODE Status This message displays after accessing the

SKIP DISK LOAD Status This message displays for approximately one

STAPLER ALIGN ERROR Attendance

Status The printer is processing data from the active

Attendance

Required

Status This message displays during a COLD

Required

I/O channel. Some data is printed and some

data cannot be printed, such as downloading

fonts or macros. The media source is the

indicated tray.

x = tray number

1 = Tray 1

2 = Tray 2

3 = Tray 3

4 = 2000-Sheet Input Unit

ready to use.

The destination output bin is full and the

printer will not send anymore pages to that

bin.

RESET. All printing environment parameters,

personality and device defaults return to their

factory default settings. When it is completed,

the printer displays [On Line] or [Ready].

holding [Select] while powering on the

printer.

Service Mode.

second after powering on the printer while

pressing and holding [Menu]. Indicates that

the disk-based system execution is disab l ed.

The printer continues its normal initialization

process.

The paper is misaligned in the stapler and

cannot be stapled.

Action

If an incorrect tray is displayed,

check the tray selected and the

type settings. If printer does not

respond after pressing the control

panel keys, cycle power to clear

the error.

Note: If paper is loaded when the

printer is in POWER SAVE, it may

not be recognized. Open and

close the affected source when

printer is in READY mode.

No action required.

Remove the paper from the

indicated output bin. For a

mailbox with a stapler: Check the

bin full actuator at the bottom of

the stapler housing. Replace as

required. Check the stapling bed

and cables. Replace as required.

The stapling bed includes cables .

Replace the entire stapler.

No action required.

Press [ + ] to scroll through the

available languages. Press

[Select] to activate the displayed

language.

To display the Service Mode

menus, press [Item]. Press

[Online] to exit the Service

Mode. For more information

about the Service Mode, refer to

Chapter 3.

To reset the printer, cycle power,

and do not press and hold

[Menu].

Remove the paper from the

stapler and resend the job. Check

for paper in the actuator near the

stapler bed. Replace the stapler.

7

Troubleshooting

Troubleshooting 7-31

Page 34

Message Error

Description Recommended

Log

Category/

Message

STAPLER LIMIT REACHED Attendance

Required

TONER LOW Attendance

Required

TRAY n EMPTY Status The paper tray is empty. Paper is sensed in

The stapler has reached its maximum of 20

sheets to be stapled.

The toner cartridge is running out of toner.

NOTE: Check the Configuration Menu. If

TONER LOW=CONT, the printer will continue

printing; but if TONER LOW=STOP displays,

the printer will stop printing and go off line.

the tray by triangular-shaped, black plastic

flags and photosensors. If paper is not in a

tray, the flags will rotate through an access in

the paper tray. When paper is present, the

flags are blocked from rotating through this

access.

Action

Remove the 20 sheets from the

bin. The printer will automatically

continue and staple the remaining

pages separately.

Shake the toner cartridge or

replace it. If TONER LOW

remains displayed and no other

conditions are present, printing

will automatically continue, but

the print quality will gradually

degrade. If the message persists:

check the contact points on the

left end of the toner cartridge and

inside the toner cartridge cavity

(refer to Figure 7-13 ) and replace

the toner cartridge. Replace the

High V ol tage PCA.

The printer will still function. Load

paper, if desired. If the message

is intermittent or persists with

paper in the tray: Ensure the

black triangular-shaped paper out

flag is not stuck in the down

position by rough media. Do this

before opening the tray. To check

this flag without opening Tray 2,

remove the Duplexer if it is

present. Open the Front Access

Door (refer to Figure 1-2). This

provides you with a clear view of

the Tray 2 paper out sensor flag

(refer to Figure 7-14 ).To check

this flag without opening Tray 3,

use a flashlight to observe the

paper out flag. If either paper flag

is damaged, replace the paper

flag or replace the paper input

unit. If the printer is using Tray 2

or 3 and the message is

accompanied by a clicking noise

every few seconds, replace the

Paper Input Assembly.

7-32 Troubleshooting

Page 35

Figure 7-14

Figure 7-15

7

Troubleshooting

Tray 2 (1) and Tray 3 (2) Paper Out Flags

Vertical Transfer Door Closed Sensor (PS35)

1. PS35 Vertical Transfer Door Switch

2. Drive Gear

3. Vertical Transfer Door Registration Sensor Flag PS31

4. Vertical Transfer Door Paper Jam Sensor Flag PS32

Troubleshooting 7-33

Page 36

Message Error

Log

Description Recommended

Action

Category/

Message

TRAY 4 EMPTY Status Tray 4 is empty or not lifting. Under normal

operating conditions, when Tray 4 is closed

the paper stack lifts until the paper is directly

beneath Tray 4’s feed rol lers. P hotos ens or

flag PS34, the paper surface photosensor,

determines when the paper stack is lifted to

its feed position. Mechanically, Tray 4 lifts

when the tray is closed. When closed, a

drive gear on Tray 4 engages with the drive

mechanism located on the back-side of the

2000-Sheet Input Unit. A pilot locating pin

and bushing are present to ensure that the

gear from Tray 4 and the drive motor gear

assembly engage properly. Once engaged,

the rotating gears use a cable lift mechanism

to lift Tray 4’s paper stack.

Tray 4 is not lifting and/or makes abnormal

noises.

Tray 4 is partially lifting or not lifting at all

because paper loaded on the left side of the

tray is blocking upward movement.

Microswitch SW31 is defective or

disconnected (callout 2, Figure 7-23).

TRAY n OPEN Status The indicated paper tray is open. The printer will still function. Close

WARMING UP Status The Fuser is warming up and the printer is

not ready. It may be necessary to display the

error log to determine if more information is

available to assist you in troubleshooting.

V erify the 2000-Sheet Input Tray

is present under the Paper

Handling Options of the PCL

configuration pages. To w atch

Tray 4 lift, Open the transfer door.

Open and close Tray 4. With the

transfer door open, defeat the

transfer door closed photosensor

(PS35) by pushing in on the

sensor flag (callout 1, Figure

7-15). See if Tray 4 is lifting. The

white drive gear on the right-hand

side of the transfer door should

be rotating. If it is not rotating,

verify the cable connections

between Main Motor (M1), the

Tray 4 Controller PCA, and the

Tray 4 Power Supply (refer to

Figure 6-58, callout 1 and Figure

6-56, callout 1). Verify the lift

cables are not broken (refer to

Figure 7-24). Replace the

2000-Sheet Input Unit if the lift

cables are broken. Tray 4 is not

seated into the gear when lifting.

Check the white bushing on Tray

4, which is located on a steel

locating pin. If the bushing is

cracked or broken, replace the

bushing, and replace the gear

assembly. Remove any paper

from the left side of Tray 4.

Replace the paper surface

sensing switch (SW31) located at

the center top of the 2000-Sheet

Input Unit (callout 2, Figure 7-23).

the tray if desired.

Wait until the printer signals ready

to accept data. The us er may

access the menus before the

printer goes online. If this

message remains displayed,

separate all accessories from the

printer. Cycle power and recheck

messages. If no error, replace

accessories one at a time.

Recycle power. If message

persists, replace the F ormatter .

Replace the DC Controller.

Replace the Power Supply.

7-34 Troubleshooting

Page 37

Figure 7-16

7

Troubleshooting

PS31 Tray 4, Transfer Door Registration Photsensor

PS32 Tray 4, Transfer Door Paper Jam Photosensor

PS2 Paper Input Unit Paper Jam Photosensor

PS1 Registration Assembly Photosensor

PS1403 Fusing Exit Photosensor

PS1402 Face Down Delivery Paper Jam Photosensor.

PS Entry Flipper Assembly of Multi-Bin Mailbox

Sensor Flag Locations Along the Paper Path

Troubleshooting 7-35

Page 38

General Paper Path Troubleshooting

Paper jams occur in the printer when paper does not either reach or clear a

photosensor along the printer’s paper path in a specific amount of time. If a

paper jam occurs, a "13.xx PAPER JAM" message is displayed on the printer’s

Control Panel. The following lists general questions you should ask and

topics you should explore prior to troubleshooting:

General Paper Path Troubleshooting Questions

Problem Action

What is the frequency of the

paper jams (e.g. continuous,

one jam per 100 pages, one

jam per 1000 pages, etc. . .)?

Do paper jams only occur

when the paper is fed from a

particular paper input source

(e.g., Tray 1, T r a y 2, Tray 3,

Tray 4 or Envelope Feeder)?

Do jams only occur when

paper is output to a specific

output bin (e.g., face-down

output bin, face-up bin,

mailbox bin, duplex

operation, stapler)?

Do paper jams occur with a

specific type of media?

Where does the leading

edge of the first sheet of

paper in the printer’s paper

path stop when a jam

occurs? Are any sheets of

paper physically damaged or

torn?

Is the customer loading the

paper trays correctly?

Is the customer overfilling

the paper trays?

Are the paper tray guides

set correctly?

Does the printer need

cleaning?

When was the User

Maintenance performed on

the printer?

Verify with customer. Print or Show Error Log to determine paper

jam history. See the Display and Error Log Sections of this Chapter

and evaluate error log.

See Verification Section of this chapter and use Paper Path Test to

isolate problem.

See Verification Section of this chapter and use Paper Path Test to

isolate problem.

Try known good media. See the HP LaserJet Printer Family Paper

Specifications Guide. Note that the guide is bundled with the

Service Manual.

Attempt to duplicate. See Verification Section of this chapter and

use Paper Path Test. Inspect the paper path and all paper path

mechanical assemblies prior to the leading paper jam.

Observe customer loading paper. Do not fan paper. Refer to proper

paper handling procedures in the Paper Specification Guide.

Ensure paper is NOT over the maximum fill marks in the paper

trays. Observe customer loading paper in trays.

Ensure Tray 2 and 3 left-side paper fence is set correctly at both the

front and rear of the tray; and that the front fence is locked into the

correct position. For Tray 4 ensure all adjustments are set correc tl y:

front, back, and side at the top and bottom of the tray.

Inspect paper path and paper path rollers. Refer to cleaning

procedures in Chapter 4.

Determine from PCL Configuration Page the number of pages

since the last maintenance (refer to Figure 7-5). The User

Maintenance Kit should be installed every 350,000 images by the

customer.

7-36 Troubleshooting

Page 39

Message Error

13.0 PAPER JAM CLEAR

PRINTER

13.x PAPER JAM CLEAR n

PAGES

< OR >

13.xx PAPER JAM CLEAR

n PAGES

Log

Category/

Message

Attendance

Required

Attendance

Required

Description Recommended

Paper is jammed somewhere in the paper

path, or a sensor flag may be stuck, causing

a false paper jam warning. The jam was

detected immediately after a power cycle.

See Figure 7-13 for sensor flag locations.

Paper is jammed in the specified Paper

Handling Device. Troubleshoot the Error Log

message (either Show or Print the Error Log).

n = number of pages inside the print

mechanism

x = cause of Jam

(e.g., "12.3 PAPER JAM" would indicate

a jam in the Fuser Assembly)

Action

Refer to the General Paper Path

Troubleshooting.

Remove jammed paper (see

Clearing Paper Jams in the

User’s Manual).

Troubleshooting Hints

Refer to the General Paper Path

Troubleshooting.

Verify movement is not hindered

in any of the Paper Jam sensor

flags (see Figure 7-13).

PS31 (in the Transfer Door)

PS32 (in the Transfer Door)

PS2 (at the paper input slot)

PS1 (at the Registration

Assembly)

PS1403 (Fusing Exit)

PS1402 (Face Down

Delivery)

PSEntry (Flipper Assembly

of Multi-Bin MailBox)

7

Troubleshooting

Use the Paper Path Test to isolate

the specific paper path if possible

(e.g., Tray 1, T r a y 2, Tray 3, Tray 4

or the Duplex paper path).

To view the Tray 3 paper path,

remove Tray 2 and view pickup

rollers through the tray 2 cavity.

To view the Tray 2 paper path,

remove the duplex option if

installed, and view the Tray 2

pickup rollers through the Front

Duplex P aper Jam access door.

For Tray 1, view pickup roller at

Tray 1. For Tray 4, override the

Transfer Door interlock (PS35,

refer to Figure 7-12) and watch

the pickup roller as paper is being

fed.

The Duplex paper path can be

viewed by removing Tray 3 and

opening the Front Duplex Paper

Jam access door.

Troubleshooting 7-37

Page 40

Message Error

13.x PAPER JAM

(Continued)

Log

Category/

Message

Description Recommended

Action

Printer Engine Specific Paper Jams

13.0

13.1

13.2

13.3

13.4

13.5

13.6

13.0n.00

13.0n.0

113.0n.02

13.0n.03

13.0n.04

13.0n.05

13.0n.06

0 = Non Specific paper jam.

1 = PAPER FEED 1 PAPER LATE JAM

(Paper late arriving at PS2)

2 = PAPER FEED 2 PAPER LATE JAM

(Paper late arriving at PS1 )

3 = FUSER OUTPUT PAPER LATE JAM

(Paper late arriving at PS1403)

4 = FUSER OUTPUT PAPER STOPPED

JAM

5 = FACE DOWN OUTPUT PAPER LATE

JAM

6 = FACE DOWN OUTPUT PAPER

STOPPED JAM

PS2 is located in the Paper

Pickup Unit (refer to Figure 7-16).

Inspect paper path. Verify flag

movement by manually inserting

sheet of paper into slot beneath

right side paper path access door

and listening for flag movement.

PS1 is the Registration

photosensor (refer to Figure

7-15). Remove the toner

cartridge and lift up on green

lever to access sens or fl ag. Verify

flag movement.

PS1403 is located in the Fusing

Assembly (refer to Figure 7-16).

Remove Toner Cartridge and the

Fuser Access Door and inspect

paper path. Verify photosensor

flag in the Fusing Assembly

moves freely.

PS1402, the face-down delivery

photosensor is located on the

Face-Down Delivery assembly

(refer to Figure 7-15). Inspect

Diverter Drive Assembly, located

on the access door to the Fusing

Assembly and the Face Down

Delivery Assembly. Verify paper

path from the Fusing Assembly to

the top Face Down Bin is clear

and all sensor flags move freely.

7-38 Troubleshooting

Page 41

Message Error

13.x PAPER JAM

(Continued)

13.7

13.8

13.9

13.9n

13.10

13.x PAPER JAM

(Continued)

13.11 13.17.11

13.x PAPER JAM

(Continued)

13.12 13.01.12

Log

Category/

Message

13.0n.07

13.0n.08

13.0n.09

13.0n.10

through

13.59.11

through

13.08.82

Description Recommended

Duplex Module Paper Jams

7 = 2-SIDED TURNAROUND PAPER LATE

JAM

8 = 2-SIDED TURNAROUND PAPER

STOPPED JAM

9 = 2-SIDED PATH PAPER LATE JAM

10 = 2-SIDED PATH PAPER STOPPED

JAM

2000 Sheet Input T ra y P aper Jams

11 = 2000 Sheet High Capacity Input

related Paper Jam messages. Several of

these message are further explained

later in this reference table.

Multi-Bin MailBox Paper Jams

12 = Multi-Bin MailBox / MailBox with Stapler

Paper Jam.

Action

Paper Jam message 13.7 through

13.10 involve paper jams related

to the Duplex Module. Paper is

diverted into the Duplex module

after leaving the Fusing Assembly.

The paper is then "turned around

and re-fed into printer’s paper

path (refer to Figure 7-16). To

view a duplex print operation,

remove Tray 3 and initiate a

duplex print job from the printer’s

Control Panel; you should be able

to observe the trailing edge of the

paper being turned around in the

Tray 3 paper cavity. For duplex

print problems, first re-seat the

module. If problems persist,

replace the complete Duplex

Assembly. The Fusing Assembly

and Diverter Assembly may also

cause duplex printing problems .

Verify their operation.

This group of errors is related to

the first device on in the C-Link

daisy chain (see Figure 7-7); in

the supported configuration this

should be the 2000 Sheet High

Capacity Tray . The known

individual error log messages are

documented in this Reference

Table in numerical order; refer to

the error log column of this table.

This group of errors are related to

the second device on in the

C-Link daisy chain (see Figure

7-6); in the supported

configuration this should be the

Multi-Bin MailBox. The known

individual error log messages are

documened in this Reference

Table in numerical order, refer to

the error log column of this table.

7

Troubleshooting

Troubleshooting 7-39

Page 42

Message Error

13.x PAPER JAM

(Continued)

Log

Category/

Message

13.10.03

through

13.13.03

Description Recommended

Stapler Assembly Errors

Action

This group of errors are related to

the third device on in the C-Link

daisy chain (see Figure 7-6); in

the supported configuration this

should be the Staple Assembly .

The known individual error log

messages are documened in this

Reference Table in numerical

order, refer to the errorlog column

of this table.

13.13

13.14

13.11 PAPER JAM Error

Message

13.17.11

13 = FUSER ACCORDION JAM

14 = PRINTER COULD NOT AUTO EJECT

PAPER

A paper jam occurred at the Vertical Transfer

Assembly entrance. Paper did not reach

entry sensor (PS31) on time. If the feed

rollers are not working properly, the paper will

not advance or it will arrive at sensor PS32

late (see Figure 7-14).

Fusing Assembly related paper

jams. Inspect paper path before

and after the Fusing Assembly.

Inspect entire paper path for

paper or debris (refer to Figure

7-16).

Verify that PS31 and PS32

sensor flags are not blocked and

that the sensors are free of dust

and debris. Using the Paper Path

Test, initiate a print job using Tray

4 as the paper input source.

Open the Transfer Door, then

override PS35 (refer to Figure

7-15). Ensure the feed rollers are

advancing paper. If the rollers do

not rotate, verify that the following

Tray 4 connectors are secure:

Main Drive Assembly (callout 1 in

Figure 6-56), Pickup Assembly

(callouts 2 and 3 in Figure 6-59),

Controller PCA (callout 1 in

Figure 6-58), Power Supply

(callout 1 in Figure 6-61). If the

problem persists, replace the Tray

4 Pickup Assembly. If the rollers

drop down and rotate but do not

advance the paper, replace the

feed rollers.

7-40 Troubleshooting

NOTE: The customer replaces

the feed rollers during 350K User

Maintenance. Replace the Paper

Pickup Assembly.

Page 43

Message Error

Category/

Message

13.11 PAPER JAM Error

Message

13.27.11

13.11 PAPER JAM Error

Message

13.33.11

13.11 PAPER JAM Error

Message

13.43.11

13.11 PAPER JAM Error

Message

13.49.11

Log

Description Recommended

A paper jam occurred at the Vertical Transfer

Assembly. Paper did not reach exit sensor

(PS32) on time (see Figure 7-14).

A paper jam occurred at the Vertical Transfer

Assembly entrance. Paper stays in PS31

longer than expected (see Figure 7-15).

A paper jam occurred at the Vertical Transfer

Assembly exit. Paper stays in PS32 longer

than expected (see Figure 7-15).

A paper jam occurred at the Vertical Transfer

Assembly entrance while powering on the

printer or after opening the V e rtical Transfer

Assembly. Paper in PS31 at power-on. See

Figure 7-15.

Action

See all recommendations listed

for Error Log Message 13.17.11,

and follow these steps: Check the

brass washer on outboard side of

V e rtical Transfer Door registration

clutch is present and that the

registration clutch does not move

more than 2mm from side-to-side.

Clean PS32 and the V e rtical

Transfer Assembly rollers.

Replace the Vertical Transfer

Assembly.

See all recommendations listed

for Error Log Message 13.27.11.

See all recommendations listed

for Error Log Message 13.27.11.

See all recommendations listed

for Error Log Message 13.27.11.

7

Troubleshooting

Troubleshooting 7-41

Page 44

Figure 7-17

Figure 7-18

Flipper Assembly and Paper Sensor Flags (Multi-Bin Mailbox)

1. PS Face Up 2. PS Face Up Full 3. PS Entry Sensor

7-42 Troubleshooting

Paper Sensor Exit

1. PSExit1 - Detects paper entering head assembly.

2. PSExit2 - Detects paper exiting head assembly.

Page 45

Message Error

Category/

Message

13.11 PAPER JAM Error

Message

13.59.11

13.12 PAPER JAM Error

Message

13.01.12

13.12 PAPER JAM Error

Message

13.02.22

Log

Description Recommended

A paper jam occurred at Vertical Transfer

Assembly exit or after opening the Vertical

Transfer Assembly. Paper in PS32 (see

Figure 7-14) at power-on (flush routine not

implemented at power-on). If Error Log

Message 13.59.1y is followed by 66.00.19 or

66.00.20 in the printer’s error log, this means

the printer was printing a long job and a

time-out occurred.

A paper jam occurred at the Flipper

Assembly’s input (refer to Figure 7-17). The

flipper assembly is located in the upper

portion of the Multi-Bin Mailbox; the assembly

receives paper from the printer via the Input

Paper Guide and directs paper into either the

face-up bin or into the transport belt of the

mailbox. PSEntry detects paper entering the

Flipper Assembly.

NOTE: Power off the printer. Position the

mailbox away from the print engine. Hold

down the mailbox interlock (refer to Figure

7-12, callout 3). Then po w er on the printer.

The mailbox goes through its normal

power-on sequence (the head assembly in

the mailbox moves to the bottom-most

position on the mailbox, then travels up to its

home position). Any fault condition in the

mailbox prevents it from going through its

normal power-on, full down and up

sequence.

A paper jam occurred at the Face-Up Bin

(output of the Flipper Assembly). The Flipper

Assembly, located in the upper portion of the

Multi-Bin Mailbox, receives paper from the

printer via the Input Paper Assembly (refer to

Figure 7-20). The assembly directs paper to

either the Face-Up Bin or to the mailbox’s

transport belt. PSFaceUp sensor flag detects

paper as the paper moves from the Flipper

Assembly into the Face-Up Bin (refer to

Figure 7-17).

Action

See all recommendations listed

for Error Log Message 13.27.11,

and follow these steps: Cycle

power to clear the error. Replace

vertical transfer door assembly.

Clear the paper jam:

Ensure the Multi-Bin Mailbox is

seated adjacent to the printer,

and the mailbox input paper guide

fits snugly into the print engine.

Both devices should sit on level,

sturdy surfaces. Check the

PSEntry photosensor flag by

opening the paper access flap at

the rear of the flipper assembly

(refer to Figure 7-17). Slide a

piece of paper through the paper

input slot. While sliding the paper

through the slot, see if the black

page width flag moves up and

down easily. If the flag’s

movement is hindered, remove

the obstruction or replace the

mailbox assembly.

Under normal operating

conditions, if you were to hold this

flag up, to its top-most position,

and then power-on the printer, the

printer displays 13.12 PAPER

JAM (Error Log Message

13.01.12).

Clear the paper jam by verifying

that the sensor flag is free moving

(refer to Figure 7-17). Remove

any obstructions. Replace the

Multi-Bin Mailbox if it is broken or

interferes with the flag’s

movement.

Under normal operating

conditions, if you were to hold this

flag up, to its top-most position,

and then power-on the printer, the

printer displays 13.12 PAPER

JAM (Error Log Message

13.02.22).

7

Troubleshooting

Troubleshooting 7-43

Page 46

Figure 7-19

Figure 7-20

Mailbox Motor and Encoder Disk (callout 1)

7-44 Troubleshooting

Stapler Unit

1. Offset Pusher 2. Exit Flap

3. Registration Pusher 4. Slider Arms

Page 47

Message Error

Category/

Message

13.12 PAPER JAM Error

Message

13.03.32

13.12 PAPER JAM Error

Message

13.04.42

13.04.52

13.12 PAPER JAM Error

Message

13.06.62

Log

Description Recommended

A paper jam occurred along the Transport

Belt. When the paper’s final destination is

either the stapler or one of the mailboxes,

paper moves from the Flipper Assembly to

the Transport Belt. Magnetic attraction holds

the paper between the transport belt and a

magnetic strip affixed to the moving head

assembly. See Figure 7-22.

A paper jam occurred in the delivery head.

The delivery head receives paper as it moves

down the Transport Belt. The delivery head

delivers paper to either the designated

mailbox slot or to the stapling assembly. The

PSExit 1 photosensor flag detects paper as it

enters the delivery head (refer to Figure

7-18). Once paper is sensed, the eject motor

rotates and moves paper to the bin. The

PSExit 2 photosensor flag detects the

paper’s trailing edge as it moves from the

head assembly into the designated bin (refer

to Figure 7-18).

A paper jam occurred on the delivery head

(while scanning for bins). During power-on,

the Multi-Bin Mailbox and the delivery head

travels the length of the mailbox verifying that

all bins (and the stapler) are installed. This is

performed when the PS Bin Full/Head

Position photosensor, located in the delivery

head assembly, reads a "scan bar". The scan

bar is formed by plastic protrusions located

on the rear surface of each bin and the

stapling assembly (refer to Figure 7-12).

When all the bins are in place, one

continuous scan bar is formed.

Action

Clear the paper jam by following

these steps: Inspect the Metallic

Tape; remove any obstructions

that may be in its path. Remove

the left side cover of the MailBox.

Verify that the Encoder Disc is

securely mounted to the

Transport Motor shaft and the

Encoder photosensor is

positioned correctly to read the

segmented encoder disc (see

Figure 7-19). If the error persists,

replace the Multi-Bin MailBox.

Clear the paper jam:

Inspect the delivery head from

the output side of the mailbox. (It

may be necessary to remove the

stapling assembly and/or some of

the mailbox slots. Refer to Figure

7-18.) Verify that PSExit 1 and

PSExit 2 sensor flags can move

freely. The PSExit1 flag should

rotate towards the output bins,

and the PSExit 2 flag should

move up and down. Remove any

obstructions. If flag moves

normally, but the error still