Page 1

hp LaserJet 1000 series

service

Page 2

Page 3

hp LaserJet 1000 series printer

service

Page 4

Copyright Information

© 2001 Hewlett-Packard

Company

All Rights Reserved.

Reproduction, adaptations, or

translation without prior written

permission is prohibited except

as allowed under copyright

laws.

Part number Q1342-90901

First edition, August 2001

Printed in USA

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to thi s informatio n .

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

NOTICE TO U.S.

GOVERNMENT USERS:

RESTRICTED RIGHTS

COMMERCIAL COMPUTER

SOFTWARE: “Use, duplication,

or disclosure by the

Government is subject to

restrictions as set forth in

subparagraph (c) (1)(ii) of the

Rights in Technical Data Clause

at DFARS 52.227-7013.”

Trademark Credits

Microsoft, Windows, and MSDOS are U.S. registered

trademarks of Microsoft

Corporation.

TrueType is a U.S. trademark of

Apple Computer, Inc.

All other products mentioned

herein might be trademarks of

their respective companies.

Safety Information

WARNING!

Potentia l Shock Hazard

Always follow basic safety

precautions when using this

product to reduce risk of injury

from fire or electric shock.

1 Read and understand all

instructions in the user

guide.

2 Observe all warnings and

instructions marked on the

product.

3 Use only a grounded

electrical outlet when

connecting the

HP LaserJet 1000 printer

to a power source. If you

don’t know whether the

outlet is grounded, check

with a qualified electrician.

4 Do not touch the contacts

on the end of any of the

sockets on the

HP LaserJet 1000 printer.

Replace damaged cords

immediately.

5 Unplug this product from

wall outlets before

cleaning.

6 Do not install or use this

product near water or

when you are wet.

7 Install the product securely

on a stable surface.

8 Install the product in a

protected location where

no one can step on or trip

over the power cord and

the power cord will not be

damaged.

9 If the product does not

operate normally, see the

online user guide.

10 Refer all servicing

questions to qualified

personnel.

Information regarding FCC

Class B, Parts 15 and 68

requirements can be found in

the user guide.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Contents

Figures

Tables

1 Product information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Printer features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Specification tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Overview of printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Front and side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Back and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Warranty statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Extended warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Toner cartridge information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Refilled toner cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Recycling of toner cartridges . . . . . . . . . . . . . . . . . . . . . . . . .10

2 Removal and replace ment

Removal and replacement strategy. . . . . . . . . . . . . . . . . . . . . . . .13

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Before performing service. . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Parts removal order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

External assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Media tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Cable pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Left side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ECU PCB fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Output sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Right side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Q1342-90910 iii

Page 6

Top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Connector PCB Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .30

LED status panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Front cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Toner cartridge door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Front guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Transfer roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Laser/scanner assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Fuser assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Output rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Face-down delivery assembly . . . . . . . . . . . . . . . . . . . . . .46

Face-up roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Right plate assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Pickup assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Pickup roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Paper lift plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Left plate assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Bottom assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

ECU pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Paper-feed assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

3 Troubleshooting

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

LED status lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Additional error messages . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Checking the toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . .71

To redistribute toner in the cartridge. . . . . . . . . . . . . . . . . .71

Solving image-quality problems . . . . . . . . . . . . . . . . . . . . . . .72

Solving print image-quality problems . . . . . . . . . . . . . . . . .72

Solving paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Functional checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Printing an engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Half self-test functional check . . . . . . . . . . . . . . . . . . . . . . . .81

To perform a half self-test check . . . . . . . . . . . . . . . . . . . .81

To perform other checks. . . . . . . . . . . . . . . . . . . . . . . . . . .81

Drum rotation functional check . . . . . . . . . . . . . . . . . . . . . . .82

Heating-element check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

High-voltage power supply check . . . . . . . . . . . . . . . . . . . . .84

To check the toner cartridge connection points . . . . . . . . .84

To check the high-voltage connector assembly . . . . . . . . .85

Paper-path check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

To override SW301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

iv Chapter - Contents Q1342-90910

Page 7

Repetitive image defect ruler . . . . . . . . . . . . . . . . . . . . . . . .87

Location of ECU Connectors . . . . . . . . . . . . . . . . . . . . . . . . .88

Location of printer connectors. . . . . . . . . . . . . . . . . . . . . . . . .89

4 Parts and diagrams

Ordering parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Related documentation and software . . . . . . . . . . . . . . . . . . .92

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

How to use the parts lists and diagrams . . . . . . . . . . . . . . . . . . . .94

Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Media tray and cable pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Internal components (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . .98

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Internal components (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . .100

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Electrical components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . .104

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . .106

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Fuser assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Index

Q1342-90910 v

Page 8

vi Chapter - Contents Q1342-90910

Page 9

Figures

Figure 1. Model and serial number label . . . . . . . . . . . . . . . . . . .3

Figure 2. Front and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 3. Back and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 4. Remove the toner cartridge. . . . . . . . . . . . . . . . . . . . .15

Figure 5. Remove the media tray . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 6. Remove the cable pod . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 7. Remove the left side cover . . . . . . . . . . . . . . . . . . . . .18

Figure 8. Open the straight-through output door . . . . . . . . . . . .19

Figure 9. Remove the back cover. . . . . . . . . . . . . . . . . . . . . . . .20

Figure 10. Remove the ECU PCB fuse . . . . . . . . . . . . . . . . . . . .21

Figure 11. Remove the output sensor . . . . . . . . . . . . . . . . . . . . .22

Figure 12. Remove the motor (fuser removed for clarity). . . . . . .23

Figure 13. Remove the right side cover mounting screw . . . . . . .24

Figure 14. Release the right side cover tab . . . . . . . . . . . . . . . . .25

Figure 15. Remove the right side cover . . . . . . . . . . . . . . . . . . . .26

Figure 16. Disconnect the solenoid wire harness. . . . . . . . . . . . .27

Figure 17. Remove the solenoid. . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 18. Remove the top cover . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 19. Remove the connector assembly . . . . . . . . . . . . . . . .30

Figure 20. Remove the LED status panel. . . . . . . . . . . . . . . . . . .31

Figure 21. Remove the front cover mounting screws. . . . . . . . . .32

Figure 22. Remove the front cover. . . . . . . . . . . . . . . . . . . . . . . .33

Figure 23. Release the toner cartridge door connecting links . . .34

Figure 24. Remove the toner cartridge door. . . . . . . . . . . . . . . . .35

Figure 25. Remove the front guide assembly. . . . . . . . . . . . . . . .36

Figure 26. Release the front guide assembly tabs (right side) . . .37

Figure 27. Release the front guide assembly tabs (left side) . . . .38

Figure 28. Remove the transfer roller. . . . . . . . . . . . . . . . . . . . . .39

Figure 29. Disconnect the laser/scanner harnessing . . . . . . . . . .40

Figure 30. Remove the laser/scanner . . . . . . . . . . . . . . . . . . . . .41

Figure 31. Remove the right fuser bracket . . . . . . . . . . . . . . . . . .42

Figure 32. Remove the left fuser bracket . . . . . . . . . . . . . . . . . . .43

Figure 33. Remove the fuser mounting screws . . . . . . . . . . . . . .44

Figure 34. Remove the fuser assembly . . . . . . . . . . . . . . . . . . . .45

Figure 35. Remove the output rollers . . . . . . . . . . . . . . . . . . . . . .46

Figure 36. Remove the face-up rollers . . . . . . . . . . . . . . . . . . . . .47

Figure 37. Remove the gear-clutch assembly . . . . . . . . . . . . . . .48

Q1342-90910 xi

Page 10

Figure 38. Remove the right plate assembly mounting screws . .49

Figure 39. Remove the pickup assembly mounting screw . . . . . .50

Figure 40. Remove the top pickup assembly mounting screws . .51

Figure 41. Remove the metal shield. . . . . . . . . . . . . . . . . . . . . . .52

Figure 42. Remove the pickup roller assembly . . . . . . . . . . . . . .53

Figure 43. Remove the paper lift plate assembly. . . . . . . . . . . . .54

Figure 44. Remove the left plate assembly . . . . . . . . . . . . . . . . .55

Figure 45. Disconnect the ECU wire harnesses. . . . . . . . . . . . . .56

Figure 46. Remove the ECU mounting screws . . . . . . . . . . . . . .57

Figure 47. Remove the ECU pan . . . . . . . . . . . . . . . . . . . . . . . . .58

Figure 48. Remove the ECU PCB from the pan. . . . . . . . . . . . . .59

Figure 49. Remove wire harnesses . . . . . . . . . . . . . . . . . . . . . . .60

Figure 50. Remove the paper-feed assembly . . . . . . . . . . . . . . .61

Figure 51. Release the paper-feed roller . . . . . . . . . . . . . . . . . . .62

Figure 52. LED status lights location . . . . . . . . . . . . . . . . . . . . . .67

Figure 53. Engine-test button. . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Figure 54. Connectors for the heating element check . . . . . . . . .83

Figure 55. High-voltage connection points (right side) . . . . . . . . .84

Figure 56. High-voltage connection points (left side) . . . . . . . . . .84

Figure 57. High-voltage connector assembly (right side) . . . . . . .85

Figure 58. High-voltage connector assembly (left side) . . . . . . . .85

Figure 59. Override SW301 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Figure 60. Repetitive image defect ruler. . . . . . . . . . . . . . . . . . . .87

Figure 61. HP LaserJet 1000 ECU PCB. . . . . . . . . . . . . . . . . . . .88

Figure 62. Printer connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Figure 63. Media tray and cable pod . . . . . . . . . . . . . . . . . . . . . .95

Figure 64. HP LaserJet 1000 covers . . . . . . . . . . . . . . . . . . . . . .96

Figure 65. Internal components (1 of 2) . . . . . . . . . . . . . . . . . . . .98

Figure 66. Internal componentsm (2 of 2) . . . . . . . . . . . . . . . . .100

Figure 67. Electrical components . . . . . . . . . . . . . . . . . . . . . . . .102

Figure 68. Paper pickup assembly (1 of 2). . . . . . . . . . . . . . . . .104

Figure 69. Paper pickup assembly (2 of 2). . . . . . . . . . . . . . . . .106

Figure 70. Fuser assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

xii Chapter - Figures Q1342-90910

Page 11

Tables

Table 1. HP LaserJet 1000 Series printer features . . . . . . . . . . .2

Table 2. Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . .4

Table 3. Environmental specifications . . . . . . . . . . . . . . . . . . . .4

Table 4. Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Table 5. Print operating acoustical emissions specifications . . . .5

Table 6. Skew specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table 7. Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . .64

Table 8. LED status lights legend . . . . . . . . . . . . . . . . . . . . . . .67

Table 9. Status lights messages . . . . . . . . . . . . . . . . . . . . . . . .68

Table 10. Error messages (no LED status panel pattern) . . . . . .70

Table 11. Solving print image-quality problems . . . . . . . . . . . . . .72

Table 12. Solving paper-feed problems. . . . . . . . . . . . . . . . . . . .77

Table 13. Engine test troubleshooting . . . . . . . . . . . . . . . . . . . . .80

Table 14. ECU connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Table 15. Printer connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Table 16. Technical support websites . . . . . . . . . . . . . . . . . . . . .92

Table 17. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Table 18. Common fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Table 19. Printer tray and cover. . . . . . . . . . . . . . . . . . . . . . . . . .95

Table 20. Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Table 21. Internal components (1 of 2) . . . . . . . . . . . . . . . . . . . .99

Table 22. Internal components (2 of 2) . . . . . . . . . . . . . . . . . . .101

Table 23. Electrical components . . . . . . . . . . . . . . . . . . . . . . . .103

Table 24. Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . .105

Table 25. Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . .107

Table 26. Fuser assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Table 27. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . .110

Table 28. Numerical parts list. . . . . . . . . . . . . . . . . . . . . . . . . . .112

Q1342-90910 xiii

Page 12

xiv Chapter - Tables Q1342-90910

Page 13

1Product information

Chapter contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Printer features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Overview of printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Front and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Back and side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warranty statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Extended warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Toner cartridge information . . . . . . . . . . . . . . . . . . . . . . . . . .10

Refilled toner cartridges . . . . . . . . . . . . . . . . . . . . . . . .10

Recycling of toner cartridges . . . . . . . . . . . . . . . . . . . . 10

Q1342-90910 Chapter contents 1

Page 14

Introduction

This manual contains the necessary information to service the HP

LaserJet 1000 Series printer. Service topics include printer features,

product specifications, location of model and serial numbers,

warranty information, toner cartridge information, part removal

procedures, troubleshooting procedures, and an illustrated parts

chapter.

Hint See the HP LaserJet 1000 Series printer user guide for information

about printer installation, use, and operation.

Printer features

Table 1. HP LaserJet 1000 Series printer features

Speed z 10 pages per minute (ppm) letter-size media

Resolution

Connectivity

Media handling

Toner

Duty cycle

Memory

Microsoft

®

operating

systems supported

PCL printer language

z 600 dot-per-inch (dpi) printing

z 1.1 universal serial bus (USB) port

z External cable pod (formatter)

z The HP LaserJet 1000 Series printer is

designed for use only with an IBM-compatible

computer

z 250-sheet input tray

z 125-sheet output bin

z 2500 page toner cartridge life

z 1000 page-per-month average

z 1 MB SDRAM

z Windows

z Windows

z Windows

z Windows

z Enhanced PCL 5e (with MS-DOS

®

98

2000

Millennium Edition (Me)

XP

®

emulation)

2 Chapter 1 - Product information Q1342-90910

Page 15

Product specifications

Identification

The model number and serial numbers are listed on an identification

label located on the bottom of the printer. The serial number contains

information about the country of origin and the revision level,

production code, and production number of the printer. The label also

identifies power rating and regu la tor y inf ormati on.

Figure 1. Model and serial number label

Q1342-90910 Product specifications 3

Page 16

Specification tables

Table 2. Physical specifications

Category Specification

Height 253 mm (10 inches)

Depth 486 mm (19.1 inches)

Width 415 mm (16.3 inches)

Weight (toner

cartridge installed)

Table 3. Environmental specifications

Category Specification

Operating

environment (printer

plugged into an ac

outlet)

Printer storage

environment (printer

not plugged into an

ac outlet)

Toner cartridge

storage environment

(printer not plugged

into an ac outlet)

7.3 kg (16.1 lb)

z Temperature: 15° to 32.5° C (59° to 90.5° F)

z Humidity: 10 to 80 percent relative humidity

(no condensation)

z Temperature: -20° to 60° C (-4° to 140° F)

z Humidity: 10 to 90 percent relative humidity

(no condensation)

z Temperature: -20° to 40° C (-4° to 104° F)

z Humidity: 10 to 90 percent relative humidity

(no condensation)

Table 4. Power specifications

Category Specification

Power

requirements

z 110 Vac (± 12 percent), 60 (± 3) Hz; 127 Vac

(± 12 percent), 60 (± 3) Hz

-Or-

z 220 Vac (± 12 percent), 50/60 (± 3) Hz

z 240 Vac (± 12 percent), 50 (± 3) Hz

WARNING! Power sources are not

interchangeable.

CAUTION To prevent damage to the

printer, always connect it to a

surge-protected power source.

4 Chapter 1 - Product information Q1342-90910

Page 17

Table 4. Power specifications (continued)

Category Specification

Power consumption

(in continuous copy

mode)

Power consumption

(idle)

Power consumption

(off)

Minimum

recommended circuit

capacity

285 W

7 W

0 W

4.5 A at 115 V

2.3 A at 230 V

Table 5. Print operating acoustical emissions specifications

Category Specification

Sound power level,

(1 bel = 10 decibels)

L

WAd

Sound pressure level,

(operator position)

L

pAm

Sound pressure level,

L

(bystander position)

pAm

6.1 dB(A)

56 dB(A)

48 dB(A)

Table 6. Skew specifications

Category Specification

Print skew—left 0.8 percent (2 mm on medi a 250 mm in le ngth) for

cut-sheet me dia

1.5 percent (3.3 mm on media 220 mm in length)

for cut-sheet media

0.87 percent (1.65 mm on m edia19 0 mm in w idth)

for cut-sheet media

Print skew—right 1.5 percent (3.3 mm on media 220 mm in width)

for envelopes, pos tcards, A5, and cu t-sh eet me dia

Cut-sheet leading

edge skew

Q1342-90910 Product specifications 5

0.87 percent (1.6 mm on media 190 mm in width)

Page 18

Overview of printer

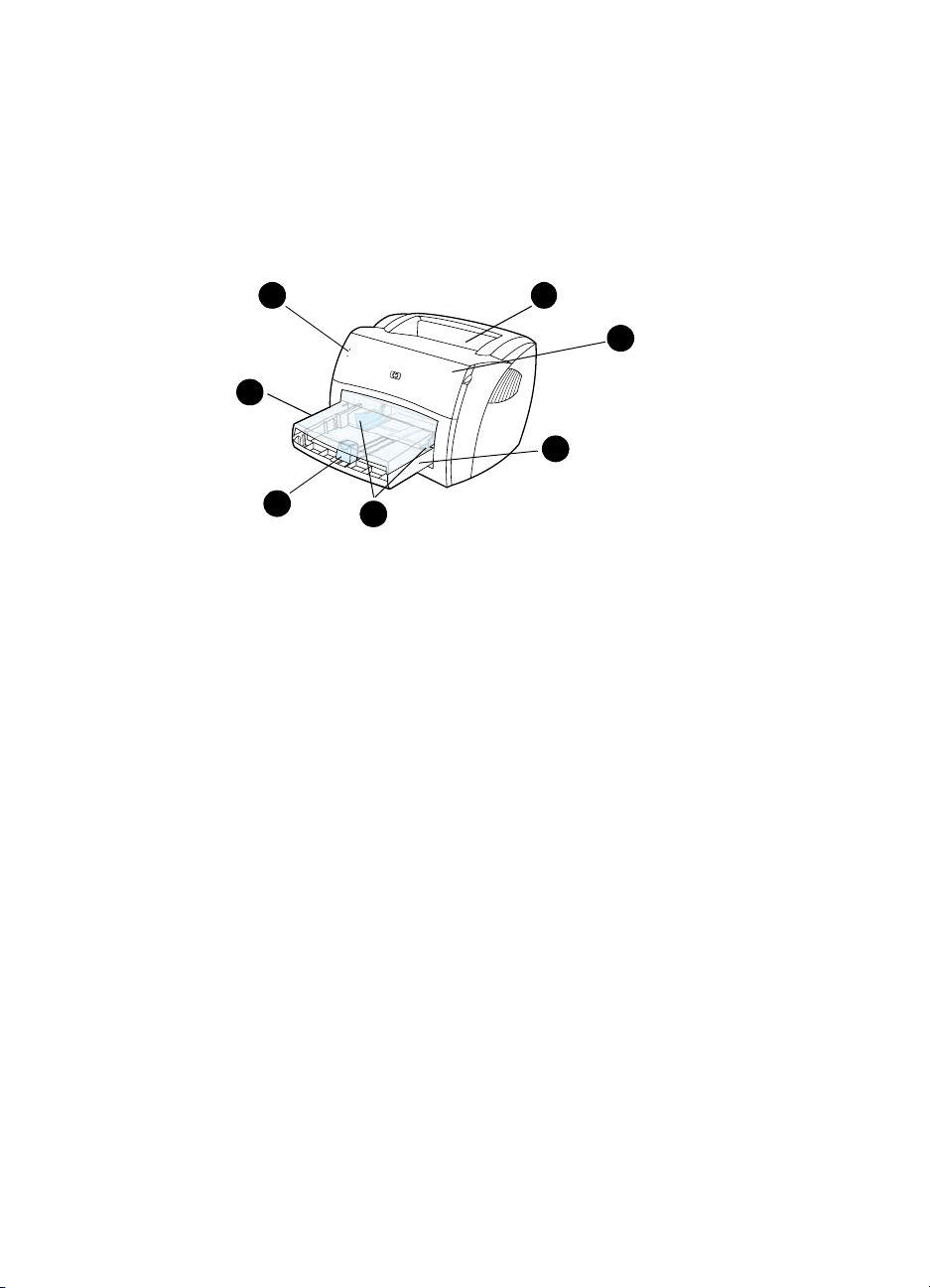

Front and side view

1

7

6

Figure 2. Front and side view

1 LED status lights

2 Output bin

3 Toner cartridge door

4 Input tray

5 Sliding side media guides

6 Long media support for the input tray

7 Input tray cover

5

2

3

4

6 Chapter 1 - Product information Q1342-90910

Page 19

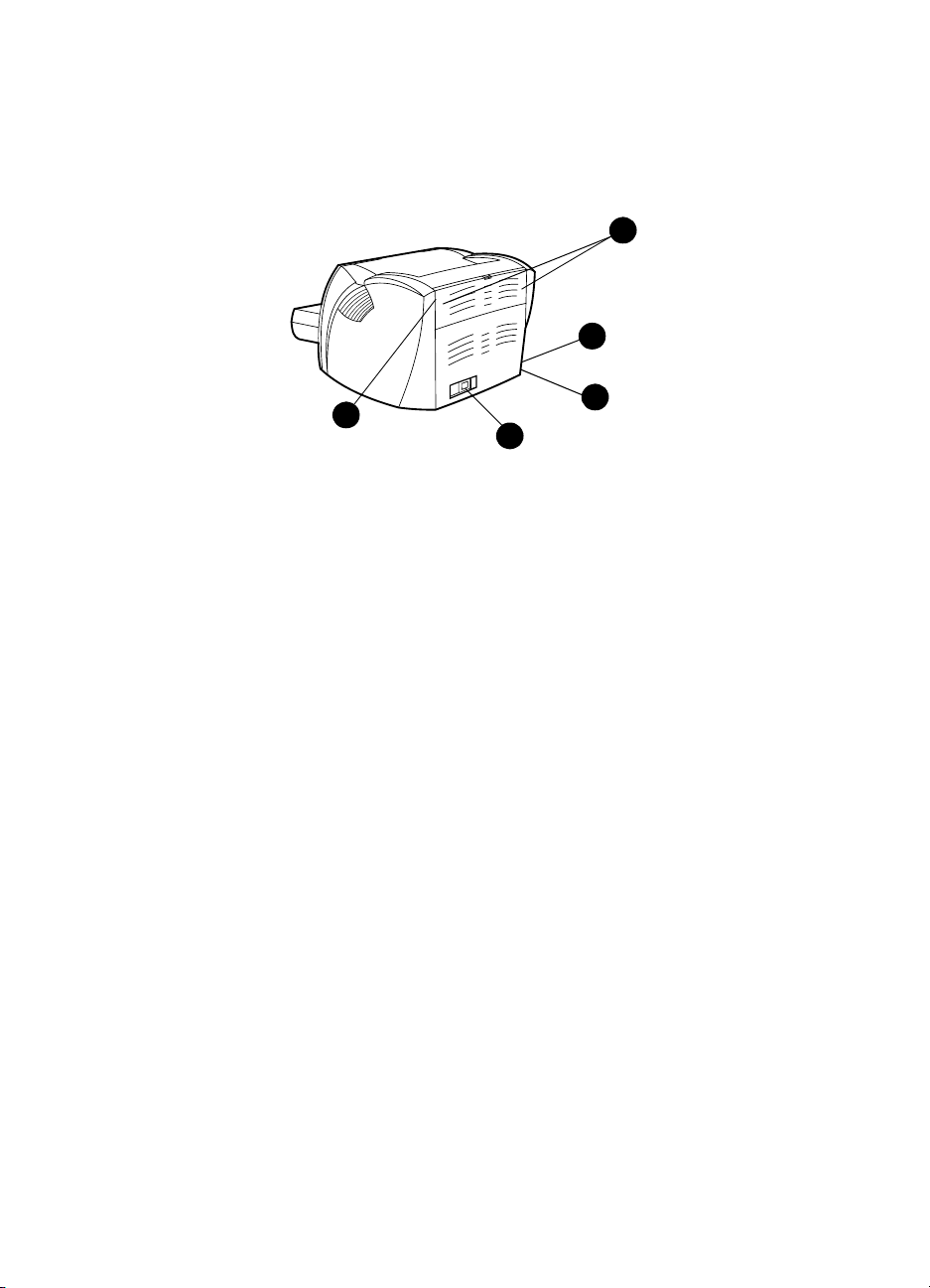

Back and side view

8

9

12

Figure 3. Back and side view

8 Media jam release levers

9 Port for the USB cable pod

10 Engine test button

11 Power receptacle

12 Straight-through output door

10

11

Q1342-90910 Overview of printer 7

Page 20

Warranty statement

DURATION OF WARRANTY: One year from date of purchase

1 HP warrants to you, the end-user customer, that HP hardware, accessories, and

supplies, will be free from defects in materials and workmanship after the date of

purchase, for the period specified above. The customer is responsible for

maintaining proof of date of purchase. If HP receives notice of such defects during

the warranty period, HP will, at its option, either repair or replace products which

prove to be defective. Any replacement products may be either new or like-new,

provided that it has functionality at least equal to that of the product being

replaced.

2 HP warrants to you that HP software will not fail to execute its programming

instructions after the date of purchase, for the period specified above, due to

defects in material and workmanship when properly installed and used. If HP

receives notice of such defects during the warranty period, HP will replace

software media which does not execute its programming instructions due to such

defects.

3 HP does not warrant that the operation of HP products will be uninterrupted or

error free. If HP is unable, within a reasonable time, to repair or replace any

product to a condition as warranted, you will be entitled to a refund of the

purchase price upon prompt return of the product.

4 HP products may contain remanufactured parts equivalent to a new in

performance or may have been subject to incidental use.

5 Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not supplied

by HP, (c) unauthorized modification or misuse, (d) operation outside of the

published environmental specifications for the product, or (d) improper site

preparation or maintenance.

6 HP MAKES NO OTHER EXPRESS WARRANTY OR CONDITION WHETHER

WRITTEN OR ORAL. TO THE EXTENT ALLOWED BY LOCAL LAW, ANY

IMPLIED WARRANTY OR CONDITION OR MERCHANTABILITY,

SATISFACTORY QUALITY, OR FITNESS FOR A PARTICULAR PURPOSE IS

LIMITED TO THE DURATION OF THE EXPRESS WARRANTY SET FORTH

ABOVE. Some countries, states or provinces do not allow limitations on the

duration of an implied warranty, so the above limitation or exclusion might not

apply to you. This warranty gives you specific legal rights and you might also have

other rights that vary from country to country, state to state, or province to

province.

8 Chapter 1 - Product information Q1342-90910

Page 21

7 TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS

WARRANTY STATEMENT ARE YOUR SOLE AND EXCLUSIVE REMEDIES.

EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL HP OR ITS SUPPLIERS

BE LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR OTHER

DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE. Some

countries, states or provinces do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not apply to

you.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND; THE

WARRANTY TERMS CONTAINED IN THIS STATEMENT, EXCEPT TO THE

EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, RESTRICT OR

MODIFY AND ARE IN ADDITION TO THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

Extended warranty

HP SupportPack provides coverage for the HP hardware product and

all HP-supplied internal components. The hardware maintenance

warranty covers a three-year period from the date of the HP product

purchase. The customer must purchase the HP SupportPack

(document number is 9036) within 180 days of the HP product

purchase. Customers can contact the nearest HP-authorized dealer

about this service.

Q1342-90910 Warranty statement 9

Page 22

Toner cartridge information

The toner cartridge is designed to simplify replacement of the major

consumable parts. The toner cartridge contains the printing

mechanism and a supply of toner.

At five percent page coverage, a toner cartridge prints approximately

2500 pages. However, a toner cartridge should print more pages if it

regularly prints pages with less coverage, such as short memos. The

cartridge might print fewer pages if heavy or bold print is used.

For best results, always use a toner cartridge before the expiration

date stamped on the toner cartridge box.

Refilled toner cartridges

Although Hewlett-Packard does not prohibit the use of refilled toner

cartridges during the warranty period or while the printer is under a

maintenance contract, it is not recommended for the following

reasons:

z Repairs resulting from the use of refilled toner cartridges are not

covered under Hewlett-Packard warranty or maintenance

contracts.

z Hewlett-Packard has no control or process to ensure that a

refilled toner cartridge functions at the high level of reliability of a

new HP LaserJet toner cartridge. Hewlett-Packard also cannot

predict the long-term reliability effect on the printer from using

different toner formulations found in refilled cartridges.

z The print quality of HP LaserJet toner cartridges influences the

customer’s percepti on of the printer . Hewl ett-P ack ar d has no

control over the actual print quality of a refilled toner cartridge.

Recycling of toner cartridges

In order to reduce waste, Hewlett-Packard offers a recycling program.

Cartridge components that do not wear out are recycled. Plastics and

other materials are recycled. Hewlett-Packard pays the shipping

costs from the user to the recycling plant (within the United States).

To join this recycling effort, follow the instructions inside the toner

cartridge box.

10 Chapter 1 - Product information Q1342-90910

Page 23

Removal and

2

replacement

Chapter contents

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Before performing service . . . . . . . . . . . . . . . . . . . . . .13

Toner cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Parts removal order . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Toner cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Left side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ECU PCB fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Connector PCB Assembly . . . . . . . . . . . . . . . . . . . . . . 30

Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Toner cartridge door. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Front guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Transfer roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Laser/scanner assembly. . . . . . . . . . . . . . . . . . . . . . . .40

Output rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Face-up roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Right plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Right plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Right plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Q1342-90910 Chapter contents 11

Page 24

Pickup assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pickup roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Paper lift plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Left plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Bottom assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

ECU pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Paper-feed assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

12 Chapter 2 - Removal and replacement Q1342-90910

Page 25

Removal and replacement strategy

This chapter documents the removal and replacement of field

replaceable units (FRUs) only. Replacement is generally the reverse

of removal. Occasionally, notes and hints are included to provide

directions for difficult or critical replacement procedures.

WARNING! Unplug the power cord from the power source before servicing the

printer. Failure to follow this warning can result in personal injury or

damage to the printer. Certain functional checks during troubleshooting

require power supplied to the printer. However, power should be

disconnected when removing assemblies.

Never operate the printer with the laser/scanner assembly exposed.

The reflected beam, although invisible, can damage your eyes. When

servicing the printer, replace the top cover before operating the printer.

CAUTION The printer contains electrostatic discharge (ESD) sensitive

components. Always perform service work at an ESD-protected

workstation. If an ESD-protected workstation is not available,

discharge body static and ground the printer chassis before servicing

the printer.

Required tools

z #2 Phillips screwdriver with magnetic tip

z Small flat-blade screwdriver

z Needle-nose pliers

z penlight (optional)

Note Use of a Posidrive screwdriver damages screw-heads on the printer.

Use a #2 Phillips screwdriver.

Hint To install a self-tapping screw, first turn it counterclockwise to align it

with the existing thread pattern, then carefully turn it clockwise to

tighten. Do not overtighten.

Before performing service

z Unplug the power cable and remove all media from the printer.

z Place the printer on an ESD mat or discharge body static and

ground the printer chassis.

z Remove the toner cartridge and media tray. See “Toner

cartridge” on page 15 and “Media tray” on page 16.

Q1342-90910 Removal and replacement strategy 13

Page 26

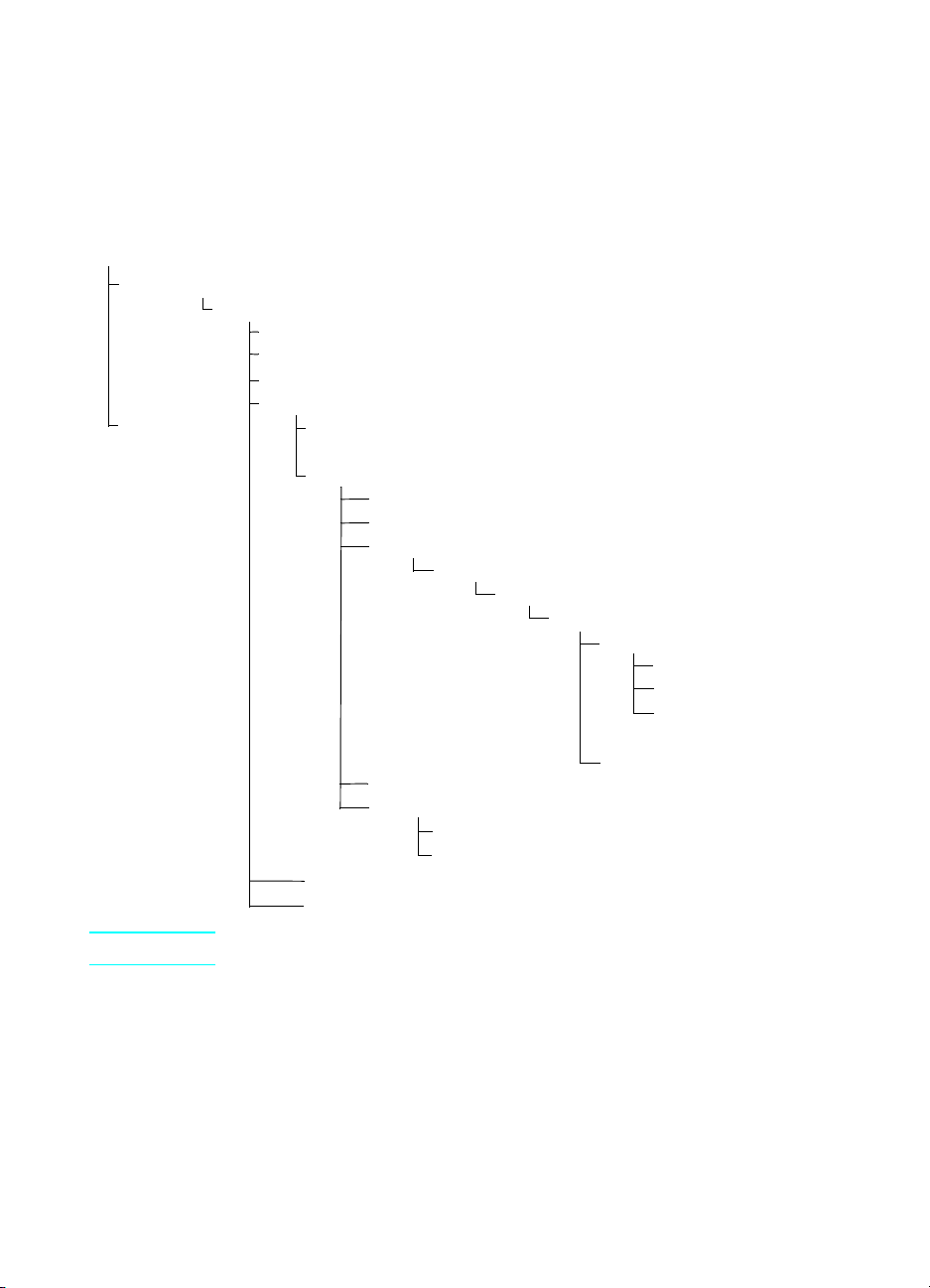

Parts removal order

Use the following diagram to determine the order in which parts must

be removed.

Toner

cartridge

Media tray

Cable pod

Left side cover

Back cover

ECU PCB fuse

Output sensor

Motor

Right cover

Transfer roller Solenoid

Top Cover

LED status panel

Connector PCB

Front cover

Toner cartridge door

Front guide

Fuser assembly (see note)

Right plate assembly

Pickup assembly

Pickup roller

Paper lift

Left plate assembly

Laser/scanner assembly

Fuser assembly

Face-down roller

Face-up roller

ECU pan

Paper feed assembly

Note The fuser assembly is intentionally listed twice.

14 Chapter 2 - Removal and replacement Q1342-90910

Page 27

Toner cartridge

CAUTION To prevent damage, do not expose the toner cartridge to light. Cover

it with a piece of paper.

Note You will feel resistance when you open the toner cartridge door.

1 Open the toner cartridge door.

2 Remove the toner cartridge.

Figure 4. Remove the toner cartridge

Q1342-90910 Removal and replacement strategy 15

Page 28

External assemblies

Media tray

1 Lift off the media tray cover (callout 1).

2 Slightly tilt up the media tray and pull it away from the printer.

11

Figure 5. Remove the media tray

16 Chapter 2 - Removal and replacement Q1342-90910

Page 29

Cable pod

1 Turn the two pod thumbscrews counterclockwise until they turn

freely.

2 Grasp the pod, and gently pull it away from the printer.

Figure 6. Remove the cable pod

Hint For easier installation, start tightening the top thumbscrew (do not fully

tighten) and then tighten the bottom thumbscrew when replacing the

cable pod. Make sure to fully tighten both thumbscrews.

Q1342-90910 External assemblies 17

Page 30

Left side cover

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

2 Open the toner cartridge door.

3 Remove the single left-cover retaining screw (callout 1).

4 Pull out on the rear of the cover and rotate it away from the

printer.

11

Figure 7. Remove the left side cover

Hint It might be necessary to release the left side cover-locking tab found

under the printer.

Hint The left-side retaining screw is slightly longer than similar screws used

in the printer. Keep this screw separated from other screws while

servicing the printer to avoid misplacing it.

18 Chapter 2 - Removal and replacement Q1342-90910

Page 31

Back cover

1 Remove the following assemblies:

z Toner cartridge, media tray, cable pod, and left side cover. See

“Toner cartridge” on page 15 through “Left side cover” on

page 18.

2 Open the straight-through output door (callout 1).

3 Remove the single screw (callout 2) from the back of the printer.

2

2

2

1

Figure 8. Open the straight-through output door

Q1342-90910 External assemblies 19

Page 32

4 Release the two locking tabs (not shown). The left tab is located

under the printer and the right tab is located on the right side of

the printer, near the cable pod port.

5 Press down and hold the two green jam-release levers (callout 3)

and pull the cover off of the printer.

13

Figure 9. Remove the back cover

CAUTION When replacing the back cover, verify that the bottom left retainer tab

(under the printer) is inside the printer chassis. This tab can be broken

if not properly inserted into the printer chassis.

20 Chapter 2 - Removal and replacement Q1342-90910

Page 33

ECU PCB fuse

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side and back covers. See “Left side cover” on page 18

through “Back cover” on page 19.

2 Grasp the ECU PCB fuse (callout 1) and pull it out of the

mounting clips.

11

Figure 10. Remove the ECU PCB fuse

WARNING! To protect against the risk of fire, always replace the ECU PCB fuse

with the same type and rating fuse. Fuse type and rating is printed on

the ECU PCB next to the fuse.

Note Purchase this fuse at a local hardware store or from an electrical

component supplier.

Q1342-90910 External assemblies 21

Page 34

Output sensor

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side and back covers. See “Left side cover” on page 18

through “Back cover” on page 19.

2 Disconnect the output sensor (callout 1) wire harness (at the ECU

end). Unlace the harness from the harness lance points.

3 Remove the single output sensor mounting screw and remove

the sensor.

11

Figure 11. Remove the output sensor

22 Chapter 2 - Removal and replacement Q1342-90910

Page 35

Motor

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side and back covers. See “Left side cover” on page 18

through “Back cover” on page 19.

Hint Removing the fuser is not necessary, but doing so will make replacing

the motor easier. See “Fuser assembly” on page 42.

2 Disconnect the motor cable connector (callout 1) on the side of

the motor.

3 Remove the two screws (callout 2) from the motor and lift the

motor out of the printer.

2

2

2

1

Figure 12. Remove the motor (fuser removed for clarity)

Note When replacing the motor, verify that the connector (callout 1) is

located toward the front of the printer.

Q1342-90910 External assemblies 23

Page 36

Right side cover

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side and back covers. See “Left side cover” on page 18

through “Back cover” on page 19.

2 Open the toner cartridge door.

3 Remove one screw (callout 1) on the back of the printer.

11

Figure 13. Remove the right side cover mounting screw

24 Chapter 2 - Removal and replacement Q1342-90910

Page 37

4 Lift the right side of the printer and release the tab (callout 2) on

the bottom of the cover.

2

2

Figure 14. Release the right side cover tab

Q1342-90910 External assemblies 25

Page 38

5 While continuing to press the release tab, grasp the top of the

cover and rotate it away from the printer.

Figure 15. Remove the right side cover

26 Chapter 2 - Removal and replacement Q1342-90910

Page 39

Solenoid

1 Remove the following assemblies:

z Toner cartridge, media tray and formatter pod. See “Toner

cartridge” on page 15 through “Cable pod” on page 17.

z Left side, back, and right side covers. See “Left side cover” on

page 18 through “Right side cover” on page 24.

2 Unplug the brown solenoid wire connector (callout 1) from the

ECU and carefully unwind the solenoid harness from the harness

lance points (callout 2).

222

1

Figure 16. Disconnect the solenoid wire harness

Q1342-90910 External assemblies 27

Page 40

3 Remove the screw (callout 3) on the solenoid.

4 Gently thread the solenoid cable through the hole (callout 4) in

the right side plate.

5 Lift the solenoid off of the printer.

2

3

2

4

Figure 17. Remove the solenoid

28 Chapter 2 - Removal and replacement Q1342-90910

Page 41

Top cover

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17

z Left side, back, and right side covers. See “Left side cover” on

page 18 through “Right side cover” on page 24.

2 Open the toner cartridge door.

3 Loosen, but do not remove, the two screws (callout 1) on the

back of the printer.

4 Remove the two screws (callout 2) on the top of the printer.

5 Lift the cover off of the printer.

2

2

2

1

Figure 18. Remove the top cover

Q1342-90910 External assemblies 29

Page 42

Connector PCB Assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

2 Open the toner cartridge door.

3 Disconnect the laser scanner ribbon cable (at the laser/scanner

end), laser scanner wire harness, LED status panel wire harness,

and ECU ribbon cable.

4 Remove the three connector PCB assembly mounting screws

(callout 1), and remove the assembly.

11

Figure 19. Remove the connector assembly

30 Chapter 2 - Removal and replacement Q1342-90910

Page 43

LED status panel

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

2 Open the toner cartridge door.

3 Disconnect the status panel cable (callout 1) from the connector

assembly. Unlace the harness from the harness clip.

4 Remove two screws (callout 2) from the top of the control panel

assembly.

5 Lift and remove the panel assembly.

2

2

3

3

11

Figure 20. Remove the LED status panel

Hint When replacing the LED status panel assembly, verify that the locator

tab (callout 3) is correctly positioned in the provided hole.

Q1342-90910 External assemblies 31

Page 44

Front cover

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

2 Close the toner cartridge door.

3 Loosen two screws (one shown in callout 1), one on each side of

the cover.

2

1

Figure 21. Remove the front cover mounting screws

32 Chapter 2 - Removal and replacement Q1342-90910

Page 45

4 Pull forward on the top of the front cover to release the three front

cover tabs (callout 2).

5 Slightly raise the front of the printer and rotate the top of the cover

toward you to release the tabs on the bottom of the front cover.

Remove the front cover.

12

Figure 22. Remove the front cover

Q1342-90910 External assemblies 33

Page 46

Toner cartridge door

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Front cover. See “Front cover” on page 32.

2 Open the toner cartridge door.

3 Press the two small tabs (callout 1) on the inside of the right

connecting link to release it.

4 Repeat on the left side.

21

Figure 23. Release the toner cartridge door connecting links

34 Chapter 2 - Removal and replacement Q1342-90910

Page 47

5 Unhook the right side toner cartridge door hinge and slide the

toner cartridge door toward the left to remove it.

22

Figure 24. Remove the toner cartridge door

CAUTION When the cartridge door is replaced, the hinge must be behind the door

stop (callout 2). The door will not close if the door is installed with the

hinge in front of or on top of the door stop.

Hint After the toner cartridge door is removed, it is easy to remove the two

connecting links.

Q1342-90910 External assemblies 35

Page 48

Front guide

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Front cover and toner cartridge door. See “Front cover” on

page 32 through “Toner cartridge door” on page 34.

2 Remove the two front guide mounting screws (callout 1).

11

Figure 25. Remove the front guide assembly

36 Chapter 2 - Removal and replacement Q1342-90910

Page 49

3 Release the two right side front guide tabs (callout 2).

12

Figure 26. Release the front guide assembly tabs (right side)

Q1342-90910 External assemblies 37

Page 50

4 Release the two front guide tabs on the left side (callout 3).

5 Remove the front guide assembly.

13

Figure 27. Release the front guide assembly tabs (left side)

38 Chapter 2 - Removal and replacement Q1342-90910

Page 51

Internal assemblies

Transfer roller

1 Remove the following assemblies:

z Toner cartridge and media tray. See “Toner cartridge” on page 15

through “Media tray” on page 16.

2 Use needle-nose pliers to gently squeeze the two small tabs on

the transfer roller.

3 Lift the transfer roller up, slide it to the right, and lift it out of the

printer.

CAUTION Skin oils can damage the transfer roller sponge. Do not touch the black

transfer roller sponge.

Figure 28. Remove the transfer roller

Hint Do not misplace the small grounding spring that is underneath the right

side of the transfer roller.

Q1342-90910 Internal assemblies 39

Page 52

Laser/scanner assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

CAUTION Never operate the printer with the laser/scanner assembly exposed.

The reflected beam, although invisible, can damage your eyes. When

servicing the printer, replace the top cover before operating the printer.

2 Disconnect the ribbon cable from its socket (callout 1) on the

laser/scanner.

3 Disconnect the wire harness cable connector (callout 2) from the

connector assembly and unlace the harness from the cable

lance.

1

1

2

2

Figure 29. Disconnect the laser/scanner harnessing

40 Chapter 2 - Removal and replacement Q1342-90910

Page 53

4 Release the two shutter-retaining tabs (callout 3) and remove the

shutter and shutter spring.

CAUTION Use care when releasing the shutter-retaining tabs. The tabs are plastic

and can be broken. Only bend the tabs enough to release the shutter

lever.

5 Remove the four screws (callout 4) that fasten the scanner to the

printer chassis and remove the laser/scanner.

3443

Figure 30. Remove the laser/scanner

CAUTION When replacing the laser/scanner, verify that it is fully seated on the

printer chassis. The laser/scanner can be damaged when the mounting

screws are tightened if it is not fully seated.

Hint Insert the spring into the hole on the laser/scanner before you snap the

shutter lever back into place.

Q1342-90910 Internal assemblies 41

Page 54

Fuser assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

2 Remove two screws (callout 1) from the right fuser bracket.

3 Remove a third screw (callout 2) from behind the large gear on

the right fuser plate. Rotate the gear counter clockwise to align a

hole in the gear with the screw-head.

4 Remove the bracket.

2

1

2

2

Figure 31. Remove the right fuser bracket

42 Chapter 2 - Removal and replacement Q1342-90910

Page 55

5 Remove three screws (callout 3) from the left fuser bracket.

6 Remove the bracket.

13

Figure 32. Remove the left fuser bracket

Q1342-90910 Internal assemblies 43

Page 56

7 Remove two screws (one shown in callout 4), one from each side

of the printer (right side shown).

14

Figure 33. Remove the fuser mounting screws

44 Chapter 2 - Removal and replacement Q1342-90910

Page 57

8 Unplug the fuser cable connector (callout 5) by pressing and

releasing the clip on the back of the connector.

9 Unplug four smaller cable connectors (callout 6) from the ECU

and remove the harnesses from the fuser harness lance points.

10 Unplug the spade connector (callout 7).

11 Slightly spread the chassis to release the fuser locator pins and

then lift the fuser assembly out of the printer.

2

5

2

7

2

6

Figure 34. Remove the fuser assembly

Q1342-90910 Internal assemblies 45

Page 58

Output rollers

Face-down delivery assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Fuser assembly. See “Fuser assembly” on page 42.

2 Remove two screws (callout 1) and lift the face-down delivery

assembly away from the fuser assembly.

11

Figure 35. Remove the output rollers

46 Chapter 2 - Removal and replacement Q1342-90910

Page 59

Face-up roller

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Fuser assembly. See “Fuser assembly” on page 42.

2 Turn the fuser assembly over and remove the gear (callout 1)

from the face-up roller

3 Release the tab (callout 2) on the face-up roller bushing and

rotate the bushing forward until the pin releases. Remove the

bushing.

4 Slide the face-up roller toward the gear end until the roller clears

the roller retainer (opposite the gear end), and lift it out of the

fuser assembly.

2221

Figure 36. Remove the face-up rollers

Note When replacing the face-up roller bushing, verify that the locking pin is

seated correctly to prevent the roller from slipping out of t he roller

retainer.

Q1342-90910 Internal assemblies 47

Page 60

Right plate assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Unlace the solenoid wire harness. See “Solenoid” on page 27.

z Front cover, toner cartridge door, and front guide. See “Front

cover” on page 32 through “Front guide” on page 36.

z Fuser assembly. See “Fuser assembly” on page 42.

2 Lift the small white tab to release the clutch, and slide the clutch

to the left (toward the pickup roller).

Hint Keep the two halves of the clutch gear together to avoid losing the

internal clutch spring.

Figure 37. Remove the gear-clutch assembly

48 Chapter 2 - Removal and replacement Q1342-90910

Page 61

3 Remove seven mounting screws (callout 2). if the motor is

installed, disconnect the motor wire harness.

4 Apply slight pressure and pull the right plate assembly off of the

printer.

22

Figure 38. Remove the right plate assembly mounting screws

Q1342-90910 Internal assemblies 49

Page 62

Pickup assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Front cover, toner cartridge door, and front guide. See “Front

cover” on page 32 through “Front guide” on page 36.

z Fuser assembly. See “Fuser assembly” on page 42.

z Right plate assembly. See “Right plate assembly” on page 48.

2 Remove the side pickup assembly mounting screw (callout 1).

11

Figure 39. Remove the pickup assembly mounting screw

50 Chapter 2 - Removal and replacement Q1342-90910

Page 63

3 Remove the two top mounting screws (callout 2).

2

2

Figure 40. Remove the top pickup assembly mounting screws

Q1342-90910 Internal assemblies 51

Page 64

4 Lift the metal shield (callout 3) straight up and remove it from the

printer.

23

Figure 41. Remove the metal shield

52 Chapter 2 - Removal and replacement Q1342-90910

Page 65

Pickup roller assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Front cover, toner cartridge door, and front guide. See “Front

cover” on page 32 through “Front guide” on page 36.

z Fuser assembly. See “Fuser assembly” on page 42.

z Right plate assembly, and pickup assembly. See “Right plate

assembly” on page 48 through “Pickup assembly” on page 50.

2 Release the locking tab on the right side pickup roller cam

(callout 1) and slide the cam to the left about one inch.

3 Slide the roller shaft toward the right until the left end releases.

4 Carefully pull the left end of the shaft toward you until it clears the

left side of the chassis. Remove the pickup roller assembly.

21

Figure 42. Remove the pickup roller assembly

Q1342-90910 Internal assemblies 53

Page 66

Paper lift plate assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Front cover, toner cartridge door, and front guide. See “Front

cover” on page 32 through “Front guide” on page 36.

z Fuser assembly. See “Fuser assembly” on page 42.

z Right plate assembly and pickup assembly. See “Right plate

assembly” on page 48 through “Pickup assembly” on page 50.

2 Grasp the large plastic tabs (callout 1) on each side of the paper

lift plate and rotate it forward.

CAUTION To avoid damaging them, do not pull on the paper guides.

3 Lift the paper lift plate up and out of the bushings (callout 2).

21

2

3

2

2

Figure 43. Remove the paper lift plate assembly

Hint When replacing the paper lift plate, verify that the lift plate springs

(callout 3) are fully seated onto the circular spring positioning

pedestals.

54 Chapter 2 - Removal and replacement Q1342-90910

Page 67

Left plate assembly

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, right side, and top covers. See “Left side cover”

on page 18 throu gh “Top cover” on page 29.

z Front cover, toner cartridge door, and front guide. See “Front

cover” on page 32 through “Front guide” on page 36.

z Fuser assembly. See “Fuser assembly” on page 42.

2 Disconnect the laser/scanner ribbon cable (at the laser/scanner

end). Disconnect the laser/scanner wire harness and the ECU

ribbon cable from the connector PCB. Remove the laser/scanner

harness from the wire clip.

3 Remove the eight mounting screws (callout 1) and lift the left

plate assembly off of the printer.

11

Figure 44. Remove the left plate assembly

Q1342-90910 Internal assemblies 55

Page 68

Bottom assemblies

ECU pan

1 Remove the following assemblies:

z Toner cartridge, media tray, and cable pod. See “Toner cartridge”

on page 15 throu gh “Cable pod” on page 17.

z Left side, back, and right side covers. See “Left side cover” on

page 18 through “Right side cover” on page 24.

2 Unplug the three spade connectors (callout 1).

3 Disconnect the motor cable connector (callout 2).

4 Unplug the fuser cable connector (callout 3) by pressing and

releasing the clip on the back of the connector.

5 Unplug the remaining four wire harness connectors (callout 4)

from the ECU.

2

1

2

2

2

3

2

4

Figure 45. Disconnect the ECU wire harnesses

56 Chapter 2 - Removal and replacement Q1342-90910

Page 69

6 Unplug the ribbon cable from the ECU to the connector assembly

PCB (callout 5).

7 Remove two screws (callout 6) on each side of the printer (left

side shown).

216

5

Figure 46. Remove the ECU mounting screws

Q1342-90910 Bottom assemblies 57

Page 70

8 Gently pull the two sides of the printer away from the ECU pan to

release the ECU pan.

9 Slide the ECU pan out and away from the printer.

Figure 47. Remove the ECU pan

58 Chapter 2 - Removal and replacement Q1342-90910

Page 71

10 Remove the motor wire harness from the wire clip (callout 7).

11 Remove the three ECU PCB mounting screws (callout 8).

12 Remove the two power cord receptacle plate mounting

screws (callout 9).

13 Lift the ECU PCB off of the ECU pan.

7

7

128

9

Figure 48. Remove the ECU PCB from the pan

Note The ECU board is replaced as a single unit. Only soldered cables ship

with the replacement board. If other cables are damaged during

removal, you will have to order replacements.

Q1342-90910 Bottom assemblies 59

Page 72

Paper-feed assembly

1 Remove the following assemblies:

z Toner cartridge, media tray and formatter pod. See “Toner

cartridge” on page 15 through “Cable pod” on page 17.

z Left side, back, and right side covers. See “Left side cover” on

page 18 through “Right side cover” on page 24.

z Right plate assembly. See “Right plate assembly” on page 48.

z ECU pan. See “ECU pan” on page 56.

Note Do not remove the gear shield instead of the right plate assembly. The

gear shield retains some of the gears. Removing the gear shield can

cause loose gears and springs to be misplaced.

2 Unwind the optic paper sensor and solenoid cables from the

cable guides (callout 1) on the paper-feed mechanism.

3 If necessary, remove one screw (callout 2) from the paper sensor

PCB assembly and remove the sensor PCB.

4 Remove the two mounting screws (callout 3) from the paper-feed

mechanism.

2

2

3

3

2

1

Figure 49. Remove wire harnesses

60 Chapter 2 - Removal and replacement Q1342-90910

Page 73

5 Apply slight pressure to disengage the paper-feed assembly

bushings from the roller shaft (callout 4). Lift the paper-feed

assembly up and out of the printer.

2

4

2

6

2

5

Figure 50. Remove the paper-feed assembly

Hint When replacing the paper feed assembly, insert the two tabs

(callout 5) on the paper-feed assembly into the provided recesses

(callout 6) near the roller. Insert the bottom of the sensor flag into the

hole in front of the paper-feed roller shaft and verify that the sensor flag

moves freely.

Q1342-90910 Bottom assemblies 61

Page 74

6 Use needle-nose pliers to push the two tabs away from the end of

the paper-feed roller shaft.

7 Pull the paper-feed roller shaft away from the gear end and

remove it.

Figure 51. Release the paper-feed roller

62 Chapter 2 - Removal and replacement Q1342-90910

Page 75

3

Troubleshooting

Chapter contents

Basic troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

LED status lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Checking the toner cartridge . . . . . . . . . . . . . . . . . . . .71

Solving image-quality problems . . . . . . . . . . . . . . . . . . 72

Solving paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . .77

Functional checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Half self-test functional check. . . . . . . . . . . . . . . . . . . .81

Drum rotation functional check. . . . . . . . . . . . . . . . . . . 82

Heating-element check. . . . . . . . . . . . . . . . . . . . . . . . .83

High-voltage power supply check. . . . . . . . . . . . . . . . . 84

Paper-path check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Troubleshooting tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Repetitive image defect ruler . . . . . . . . . . . . . . . . . . . . 87

Location of ECU Connectors . . . . . . . . . . . . . . . . . . . . 88

Q1342-90910 Chapter contents 63

Page 76

Basic troubleshooting

Table 7. Basic troubleshooting

# Verification steps Pos sib le problems Sol ution s

Does the printer turn

1

on successfully?

When the product is

connected to a grounded

power source, the printer

motor should

continuously rotate for

about six seconds.

Power is not being

supplied to the printer.

There are open wire

harness connectors.

There are pinched or

frayed wire harness

wires.

The motor or ECU has

failed.

1. Verify that the product is plugged in.

2. Verify that the power cable is functional

and the cable is plugged into the correct

power source (110 V or 220 V ac).

3. Verify that FU102 (the ECU PCB fuse)

on the ECU is not open.

4. Verify that the fuser levers are in the up

position.

5. Verify that the printer door is closed.

6. Verify that the motor connector is seated

into the ECU.

7. Verify that the motor is correctly mounted

on the printer chassis.

8. Check for and replace pinched or frayed

wire harness wires.

9. Replace the motor.

10. Replace the ECU.

Do engine tests

2

print?

Print an engine test. (See

page 79.)The engine test

should print without

paper-feed problems or

print-quality problems.

The printed page is filled

with evenly spaced

horizontal lines

(approximately 1 mm

apart).

The engine test button is

pressed, but nothing

happens.

The motor rotates on and

off (about 1 second), and

then stops (no paper

feed).

The motor rotates on, off,

on, off in short cycles,

and then stops (no paper

feed).

The engine-test was successful.

1. The toner cartridge is missing or the

toner cartridge door is open. Install a toner

cartridge and/or close the door.

2. A faulty toner-cartridge-to-ECU

connection exists. Verify that all connectors

to the ECU are firmly seated and contacts

are clean.

3. A faulty connector-PCB-to-ECU

connection exists. Replace the connector

assembly.

1. Verify that the laser/scanner connectors

are fully seated.

2. Replace the laser/scanner.

1. Verify that the fuser wire connectors are

fully seated.

2. Replace the fuser.

64 Chapter 3 - Troubleshooting Q1342-90910

Page 77

Table 7. Basic troubleshooting (continued)

# Verification steps Pos sib le problems Sol ution s

Do engine tests

2

print? (continued)

The printer attempts to

pick up paper three times

and then the motor stops

(no paper feed).

The printer attempts to

pick up paper three

times, and the paper

feeds but comes out

blank.

The printer attempts to

pick up paper three times

and the laser/scanner

emits a high-pitched

whine, but the motor

does not turn.

The printed page is filled

with evenly spaced

horizontal lines, but the

toner can be easily

smeared.

The engine-test page

begins to print, but the

page stops just after

tripping the output sensor

flag.

1. The media tray is empty. Place media in

the tray.

2. The printer is dirty. Clean the printer.

3. Replace the pickup roller.

4. Replace the paper pickup assembly

1. the paper-feed assembly connections

are faulty. Verify that the all paper-feed

assembly connectors to the ECU are firmly

seated.

2. Replace the paper-feed assembly.

1. Verify that the motor connector is firmly

seated.

2. Replace the motor

1. Make sure that the media meets

specifications detailed in the Print Media

Guide for the HP LaserJet printer family.

2. A faulty fuser assembly power

connection exists. Verify that the fuser

power connectors are firmly seated.

3. Replace the fuser.

1. Verify that the output sensor (on the back

of the fuser) connector is firmly seated at

the ECU end.

2. Replace the output sensor

Hint When you attempt to troubleshoot engine-test page problems, it

might be necessary to unplug the printer from the power source

(power off), and then plug it back into the power source (power on)

before printing a subsequent engine-test page. Verify that the printer

was successfully turned on (see verification step 1).

3 The printer motor

rotates for about six

seconds and stops, but

the LED status R

light does not illuminate.

When the printer is

successfully turned on, the

green Ready status light is

illuminated and the printer is

ready to process a job.

EADY

Wire harness connectors

are open.

Harness wires are

pinched or frayed. The

cable pod, connector

assembly, or LED status

panel has failed.

1. Verify that the LED status panel

connector to the connector assembly is

firmly seated.

2. Verify that the connector-assembly-toECU flat ribbon cable is firmly seated (at

the connector assembly end).

3. Replace the cable pod

4. Replace the connector PCB assembly

5. Replace the LED status light panel.

Note The LED lights will not operate if the cable pod is not connected to

the printer.

Q1342-90910 Basic troubleshooting 65

Page 78

Table 7. Basic troubleshooting (continued)

# Verification steps Pos sib le problems Sol ution s

Is the software

4

installed correctly?

The software is not

installed, or an error

occurred during software

installation.

Uninstall and then reinstall the product

software. Make sure you use the correct

installation procedure and the correct port

setting.

Does the product

5

print from the

computer?

Connect the cable pod to

the printer and the USB

cable to the computer.

Use a word-processing

application to send a print

job to the printer.

Is the printed image

6

of poor quality?

Does the media jam

7

in the printer paper

path?

The cable is not

connected correctly.

An incorrect printer driver

is selected.

Other devices are

connected to the USB

port.

A USB port driver

problem exists.

The cable pod has failed. Replace the cable pod.

Various print image-

quality problems.

Various printer paperpath problems.

Reconnect the cable.

Select the correct printer driver.

Disconnect the other devices and try again

to print.

1. Reset the computer BIOS USB settings.

See the computer user guide for

instructions.

2. Try a different USB port.

1. Make sure that the media meets

specifications detailed in the Print Media

Guide for the HP LaserJet printer family.

2. Identify the image quality problem. See

“Solving image-quality problems” on

page 72.

Isolate the printer paper-path problem. See

“Paper-path check” on page 86.

66 Chapter 3 - Troubleshooting Q1342-90910

Page 79

Errors

LED status lights

The status lights give the user information about the status of the

printer. Until the cable pod initializes the firmware, only the ready and

fatal-error light patterns can appear. If the cable pod is not connected

when the printer power is turned on, the motor rotates (for about 6

seconds) but the status lights remain off (the firmware is not

initialized). If the cable pod is connected while printer power is on, the

printer turns off and then on, the motor rotates (for about 6 seconds)

and the cable pod initializes the firmware.

Ready

light

(green)

Attention

light

(amber)

Figure 52. LED status lights location

Table 8. LED status lights legend

Light symbol Meaning of symbol

Light off

Light on

Light blinking

Q1342-90910 Errors 67

Page 80

Table 9. Status lights messages

Message Possible causes Solutions

The Ready and Attention lights are not

illuminated.

The Ready and Attention lights blink.

The cable pod is initializing the firmware

or the unit is printing a cleaning page.

1. Verify that the power cord is

connected to the printer and the power is

turned on.

2. The cable pod is not connected or has

failed. Verify that the cable pod is